Cell-biological scaffold complex and 3D printing forming method thereof

A bio-scaffold and 3D printing technology, applied in prosthetics, medical science, additive processing, etc., can solve the problems of difficult adhesion of cells, large pore size, and inability to form pores, so as to improve the loss of cell suspension, mechanical The effect of good performance and controllable shape profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

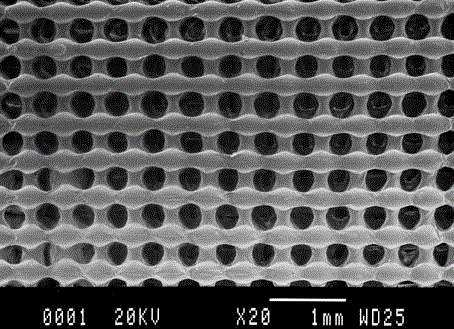

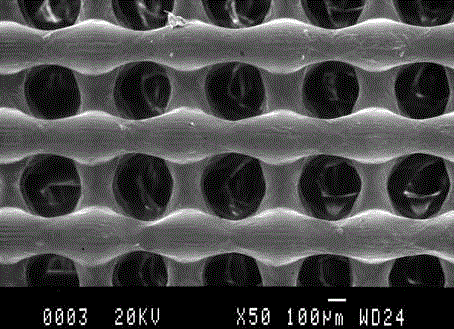

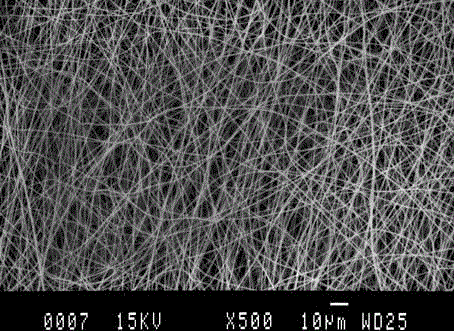

Image

Examples

Embodiment 1

[0040] 1, the preparation of PCL-nHA composite material, the mass ratio of described PCL and nHA is 4:1:

[0041] Weigh 4g of polycaprolactone PCL and add it to 36g of dichloromethane solution, stir on a magnetic stirrer until fully dissolved, add 1g of nHA hydroxyapatite powder, stir on a magnetic stirrer until the solution is uniform, vacuumize and degas , placed in a fume hood until the organic solvent is completely volatilized, and set aside.

[0042] 2 Preparation of collagen-chitosan electrospinning solution:

[0043] Chitosan and collagen were dissolved in deionized water successively at a mass ratio of 1:2 to prepare an electrospinning solution with a mass fraction of 8%.

[0044] 3 Preparation of bone cell suspension:

[0045] Transfer the culture flask containing osteoblasts to the ultra-clean workbench, remove the old culture medium, add trypsin to digest for 1 minute, remove the trypsin, add DMEM / F12 cell culture medium containing 20% serum to terminate the dig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com