Method for making rock bedding structure model based on 3D printing technology

A 3D printing and structural model technology, applied in the field of 3D printing, can solve the problems of high cost and long model production cycle, and achieve the effect of ensuring representativeness, reducing time and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings of the present invention.

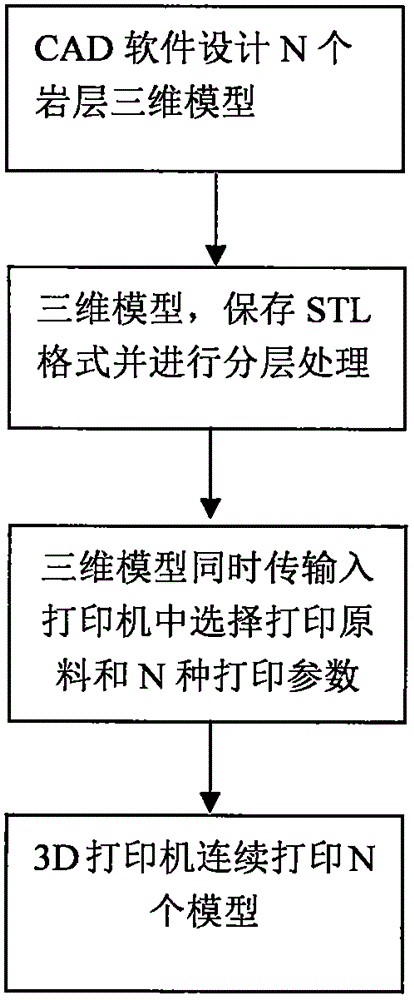

[0021] see figure 1 As shown, a method for making a rock bedding structure model based on 3D printing technology comprises the following steps when using the present invention:

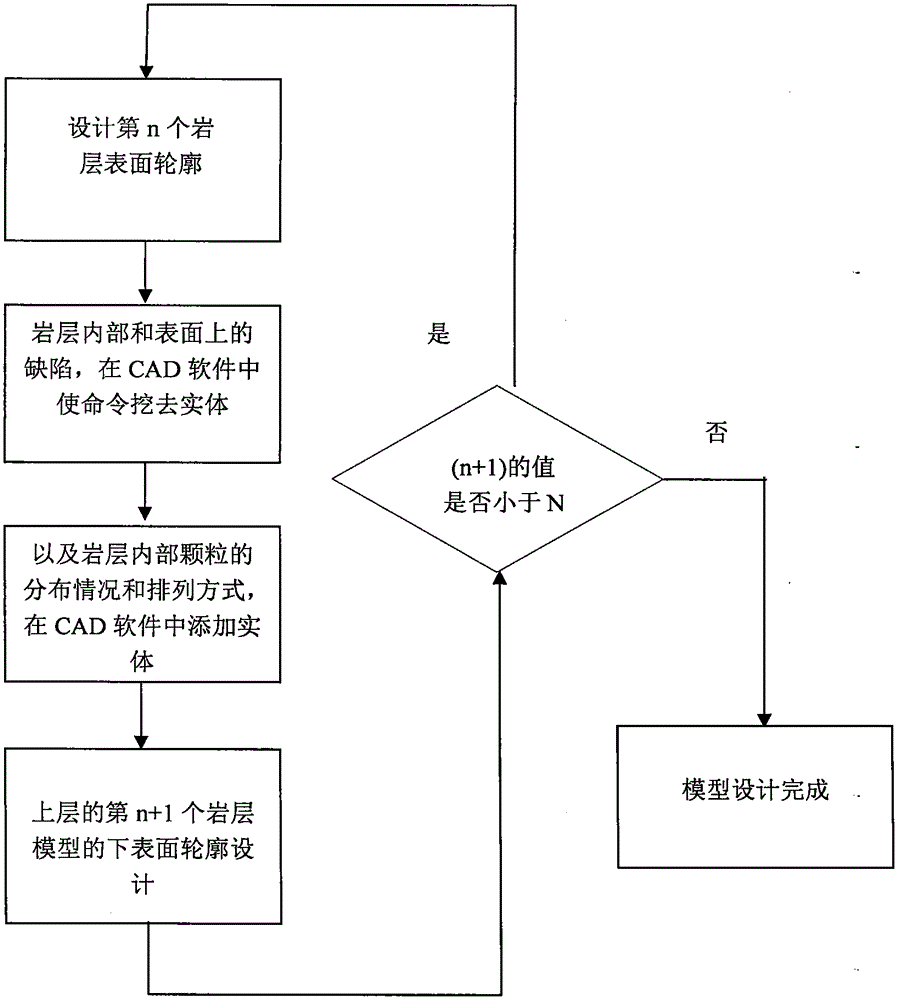

[0022] Step 1): Use CAD software to design 5 three-dimensional models of rock formations to represent adjacent rock formations of the same nature. When designing the rock formation model, the cross-sectional shape of the rock formation, various defects such as pores and cracks inside and on the surface of the rock formation, as well as the representative particles inside the rock formation, the distribution and arrangement of the particles are designed according to the needs of follow-up research. When using CAD software to design 5 3D models of rock formations, the lower surface of the lowest rock formation model is horizontal, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com