Patents

Literature

55results about How to "Increased dimensional tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

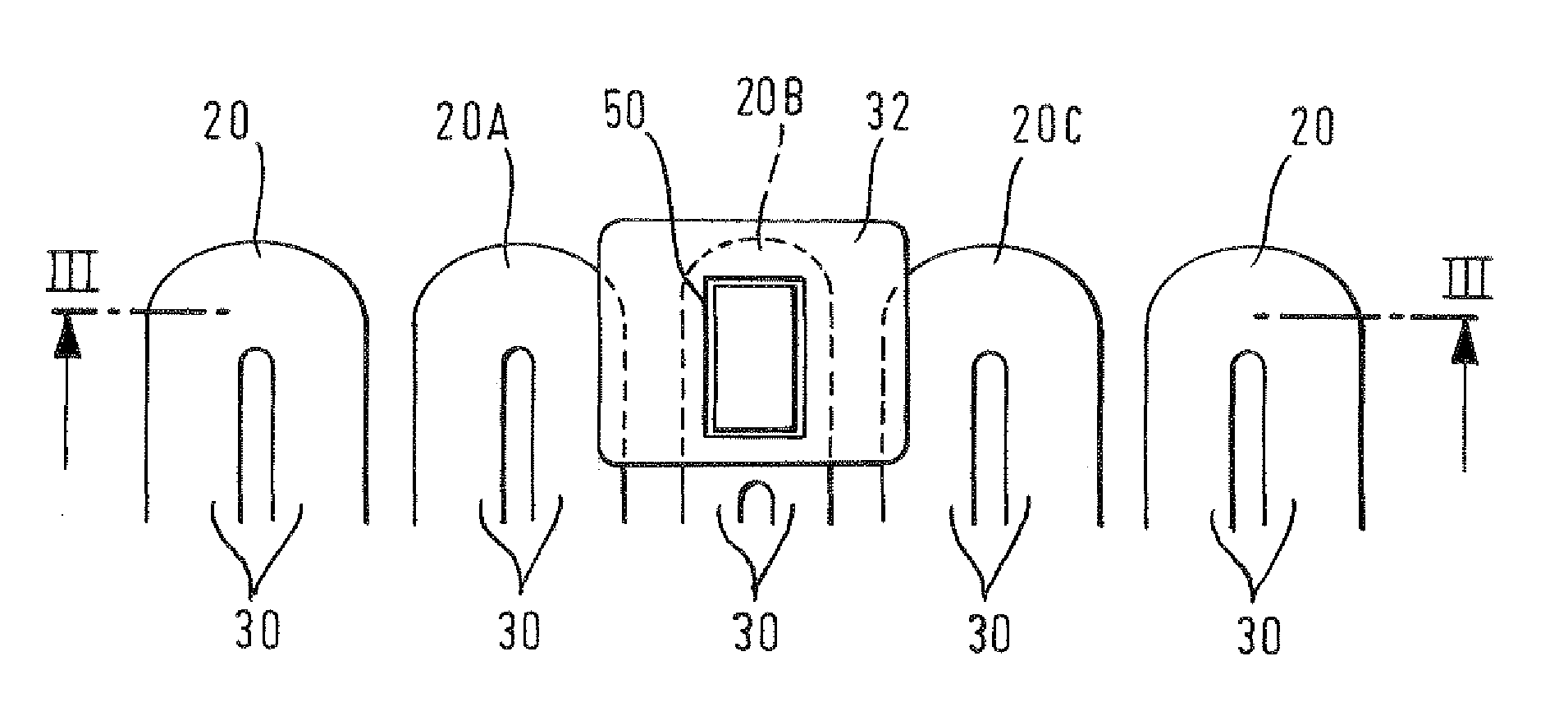

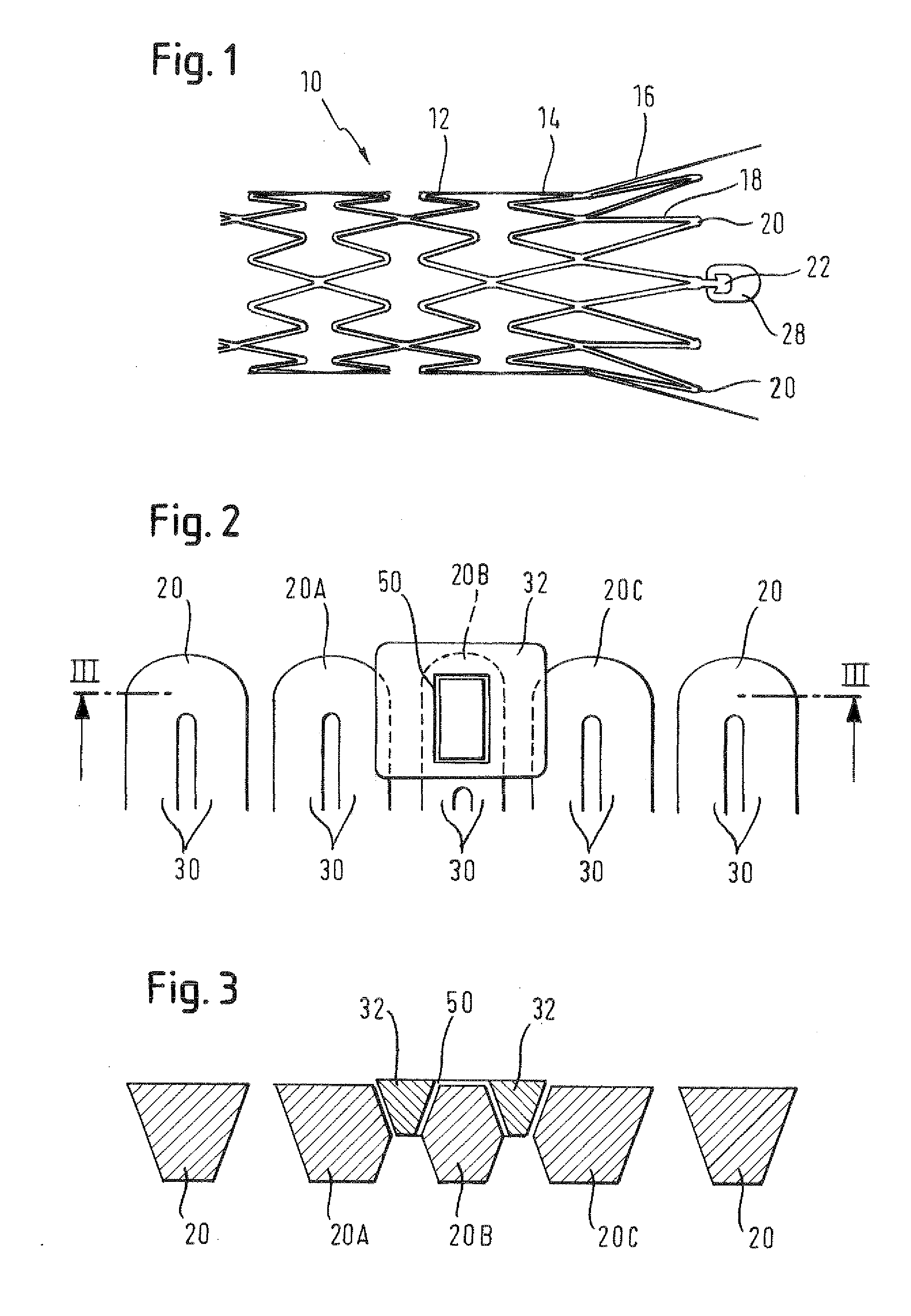

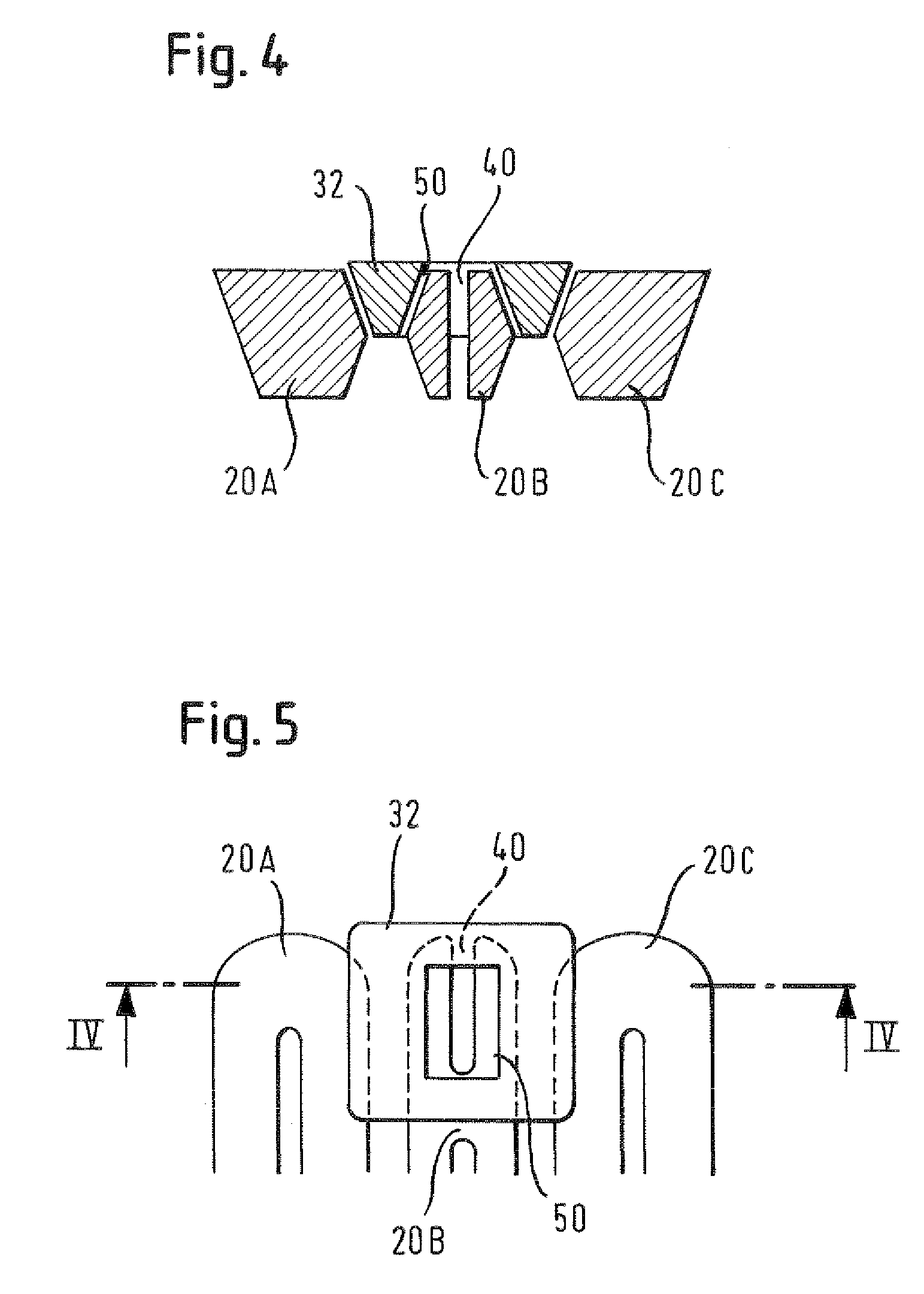

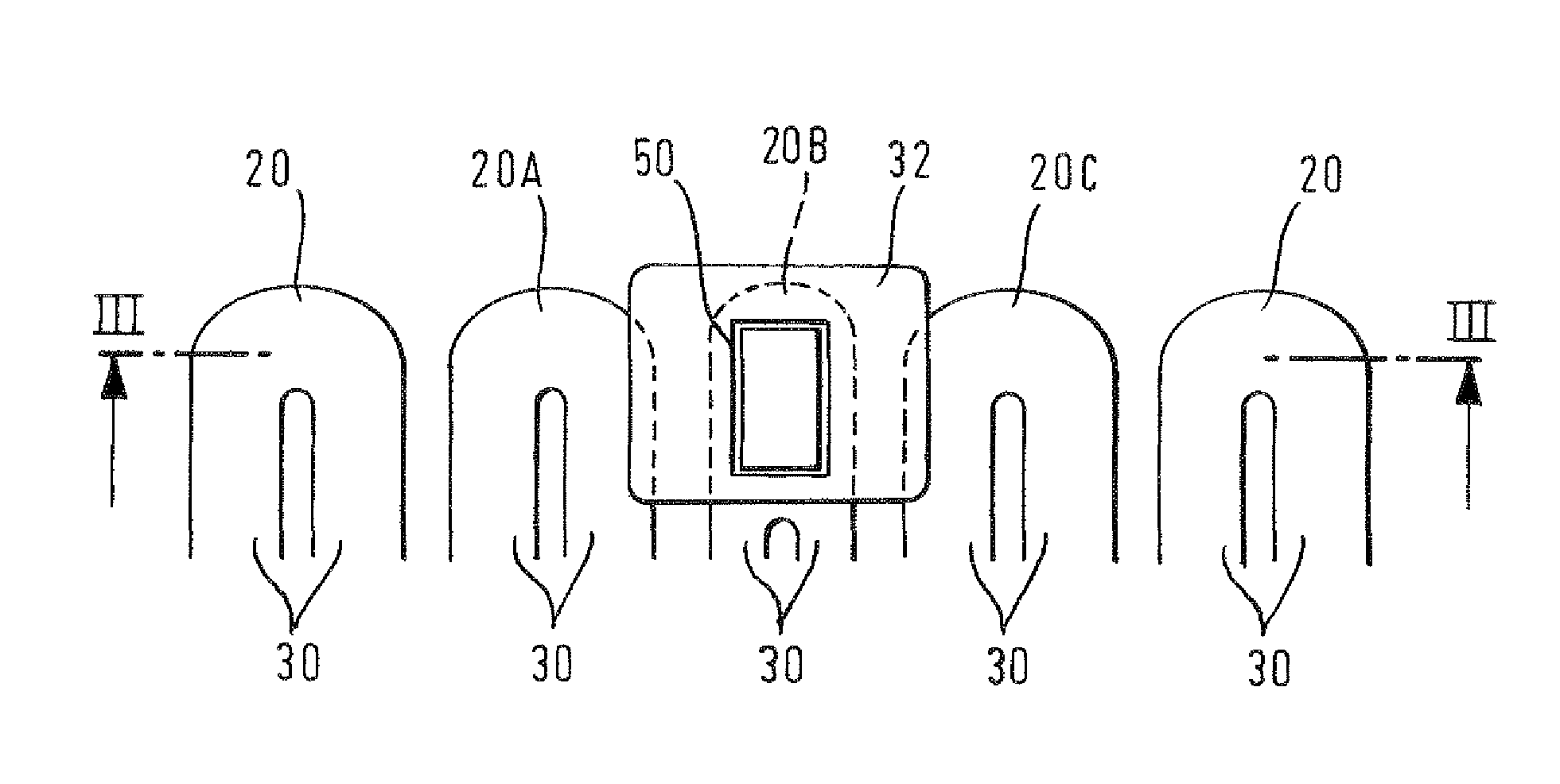

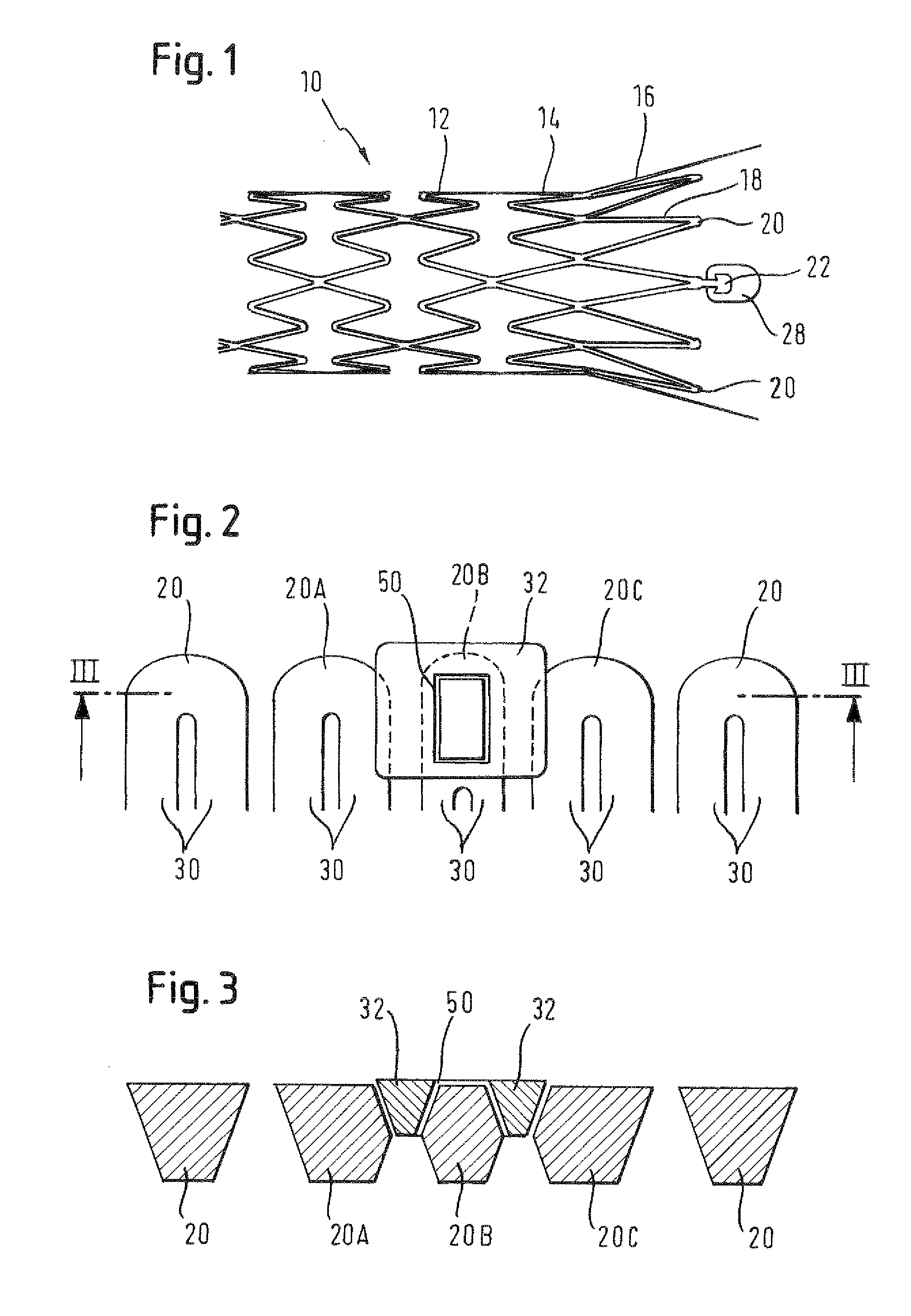

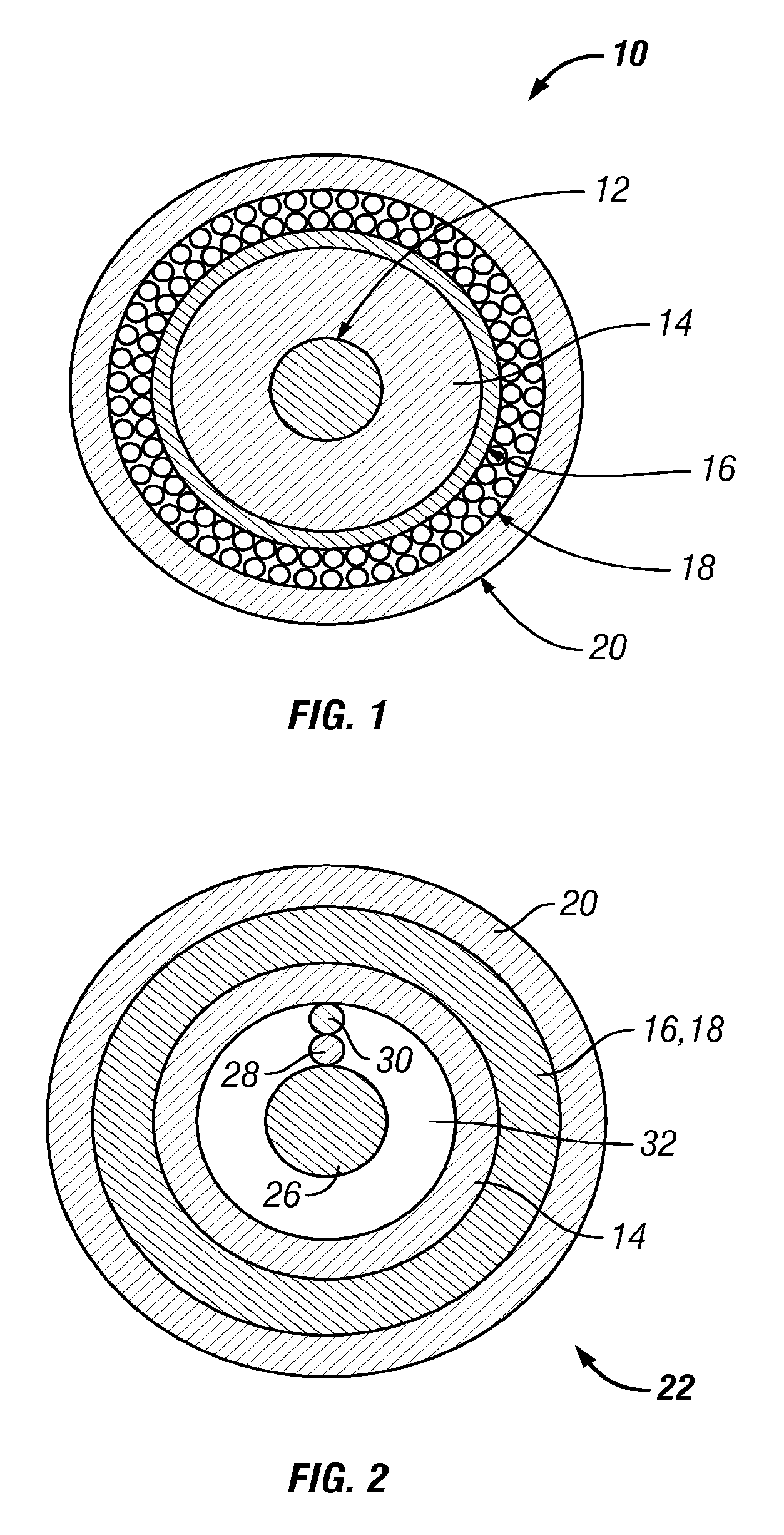

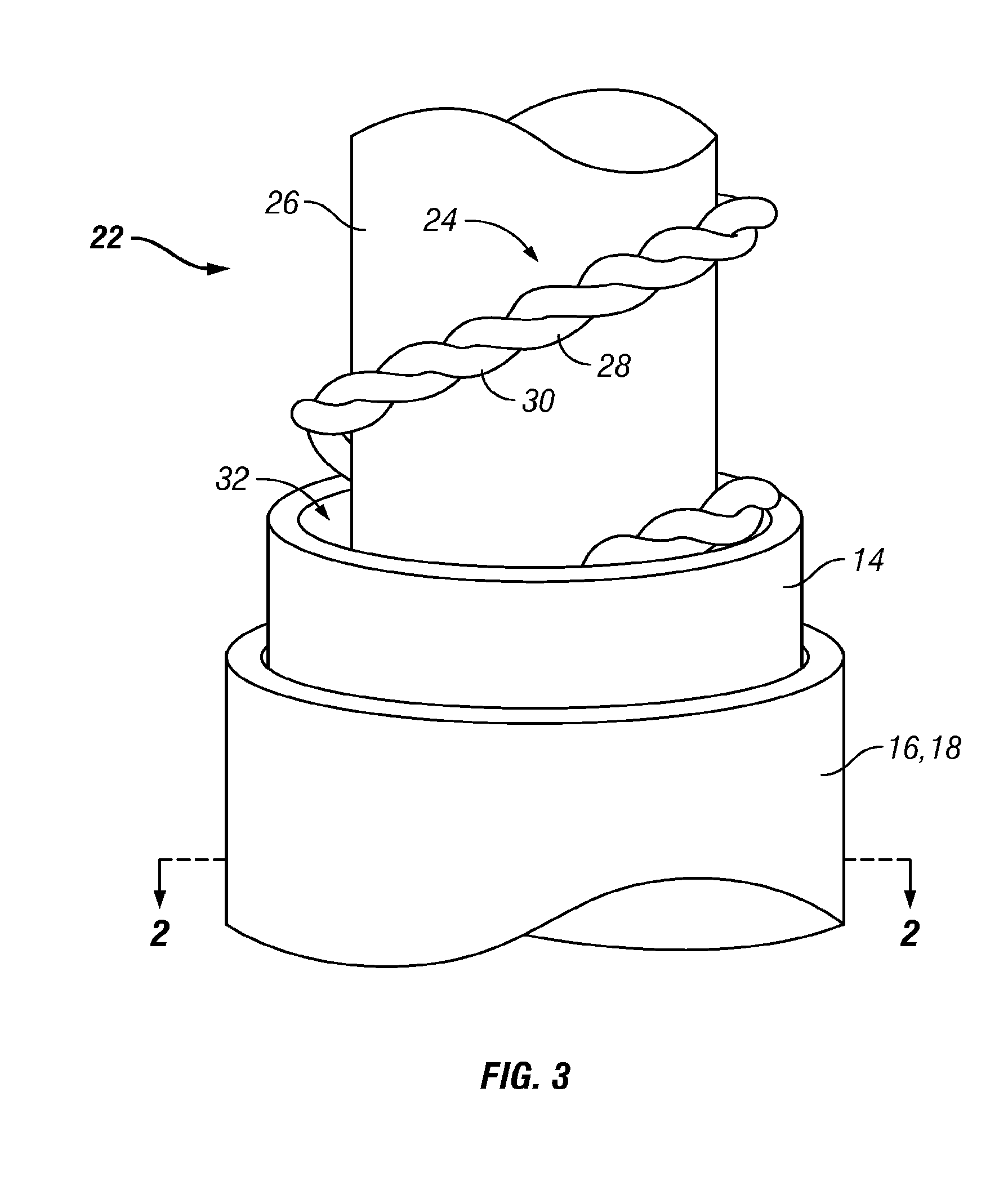

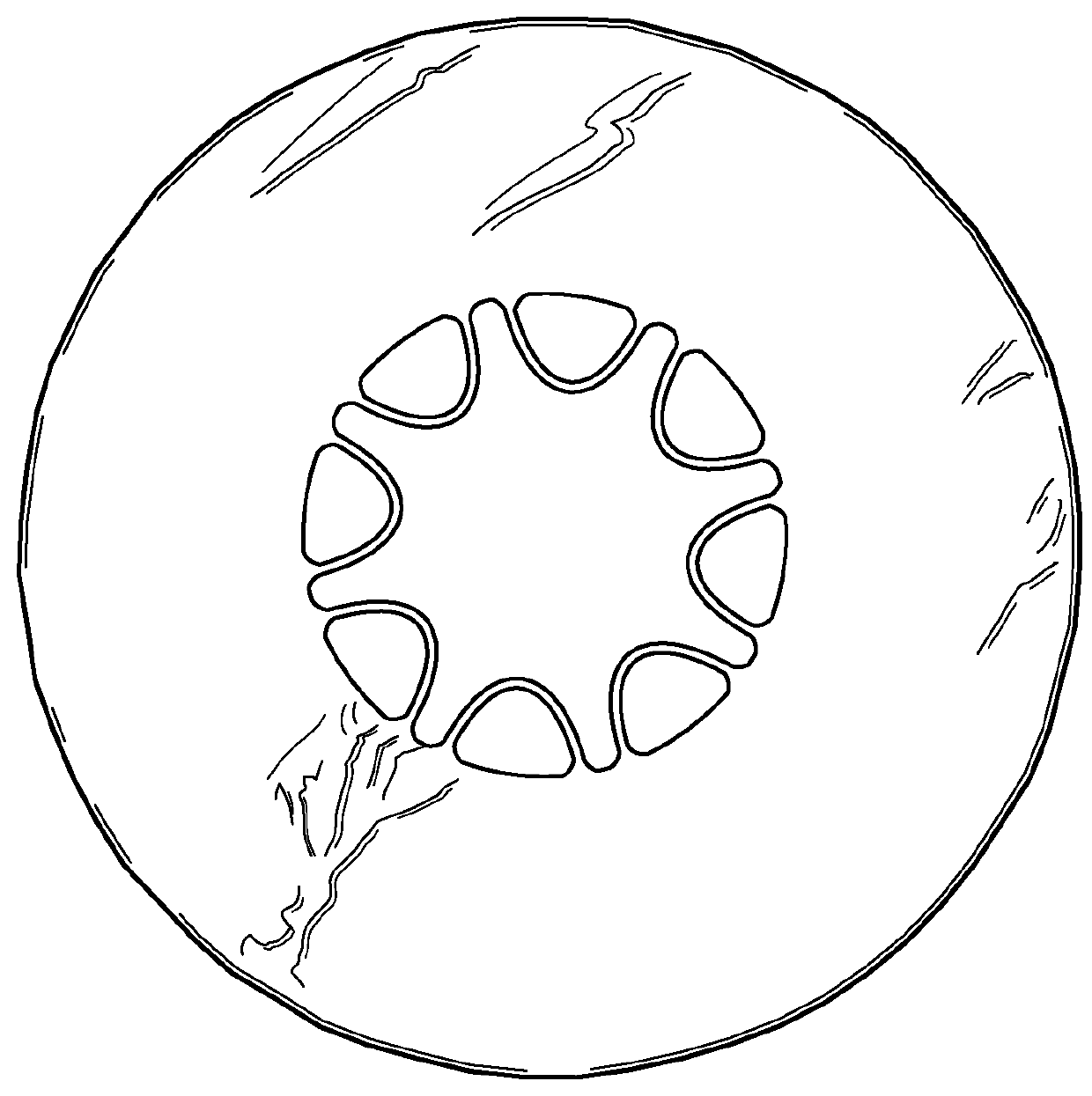

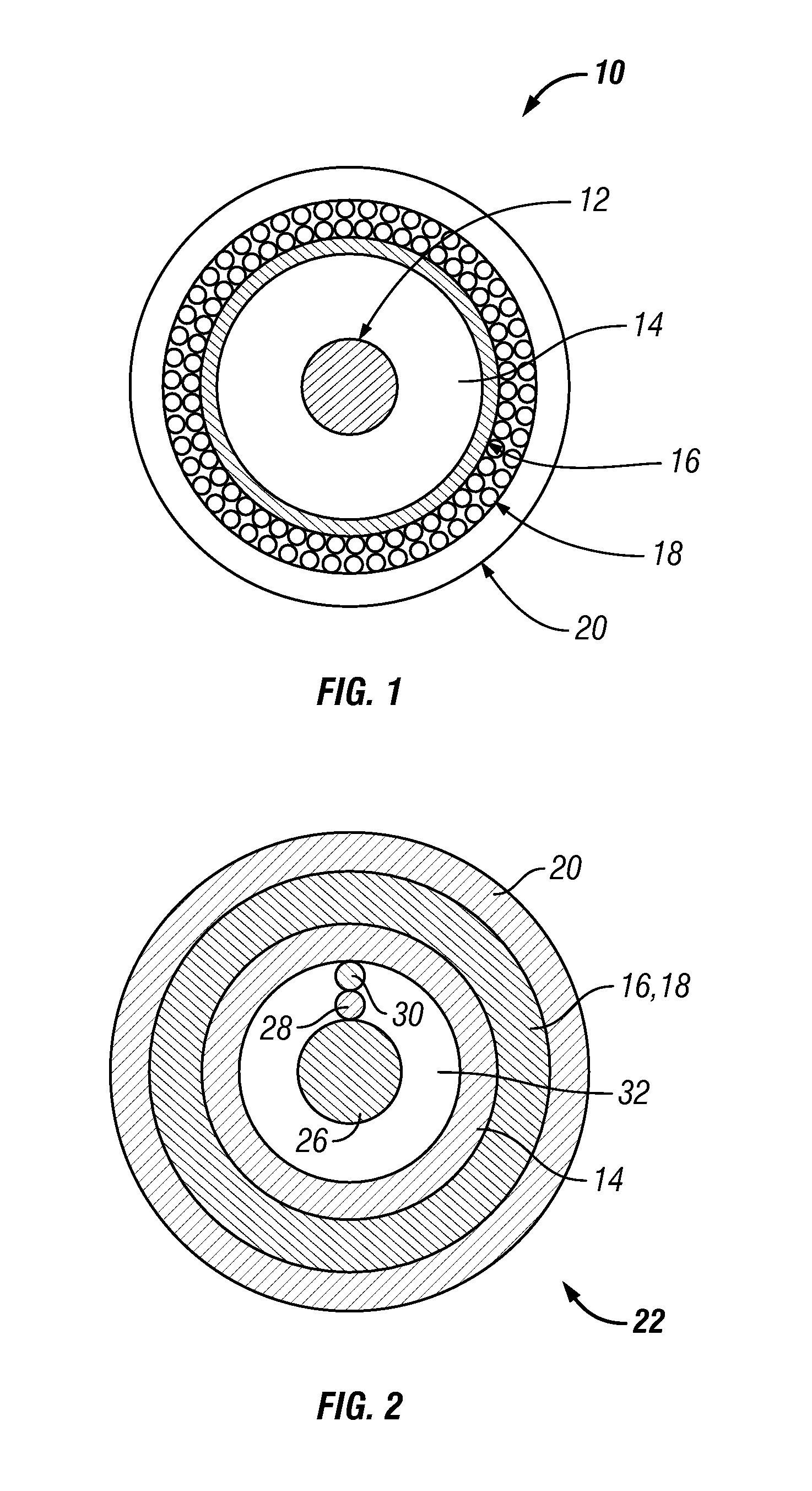

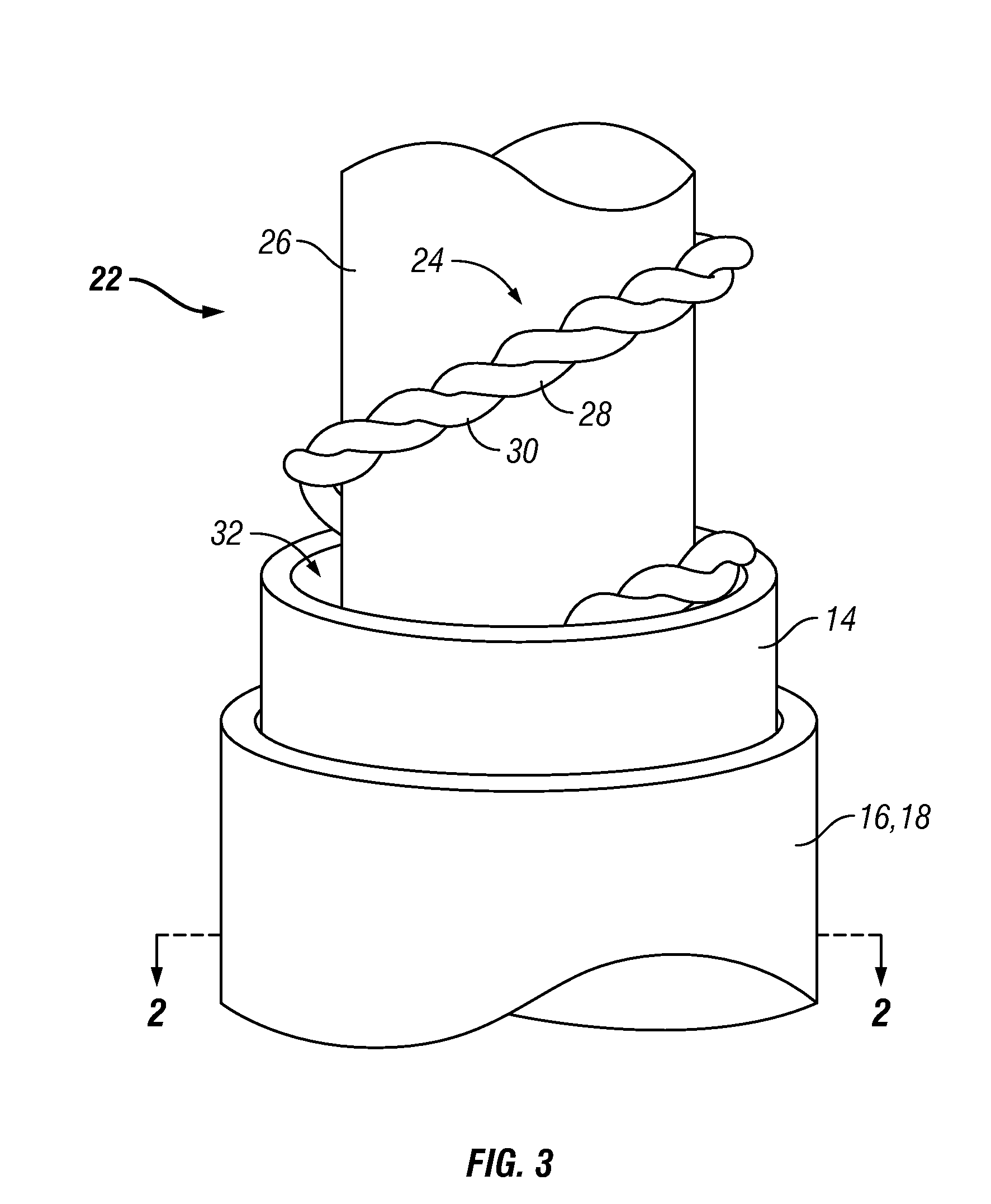

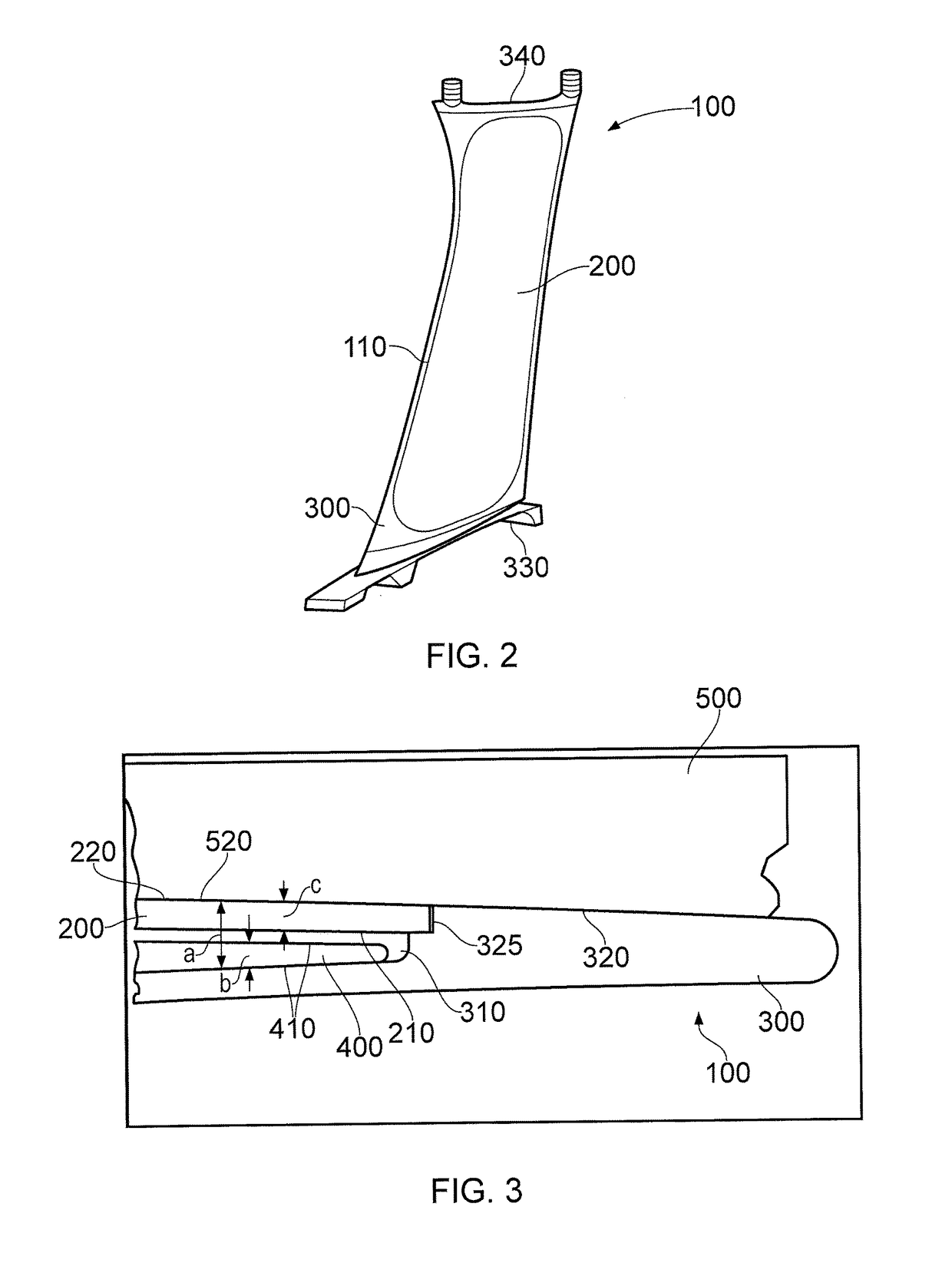

Stenting Ring with Marker

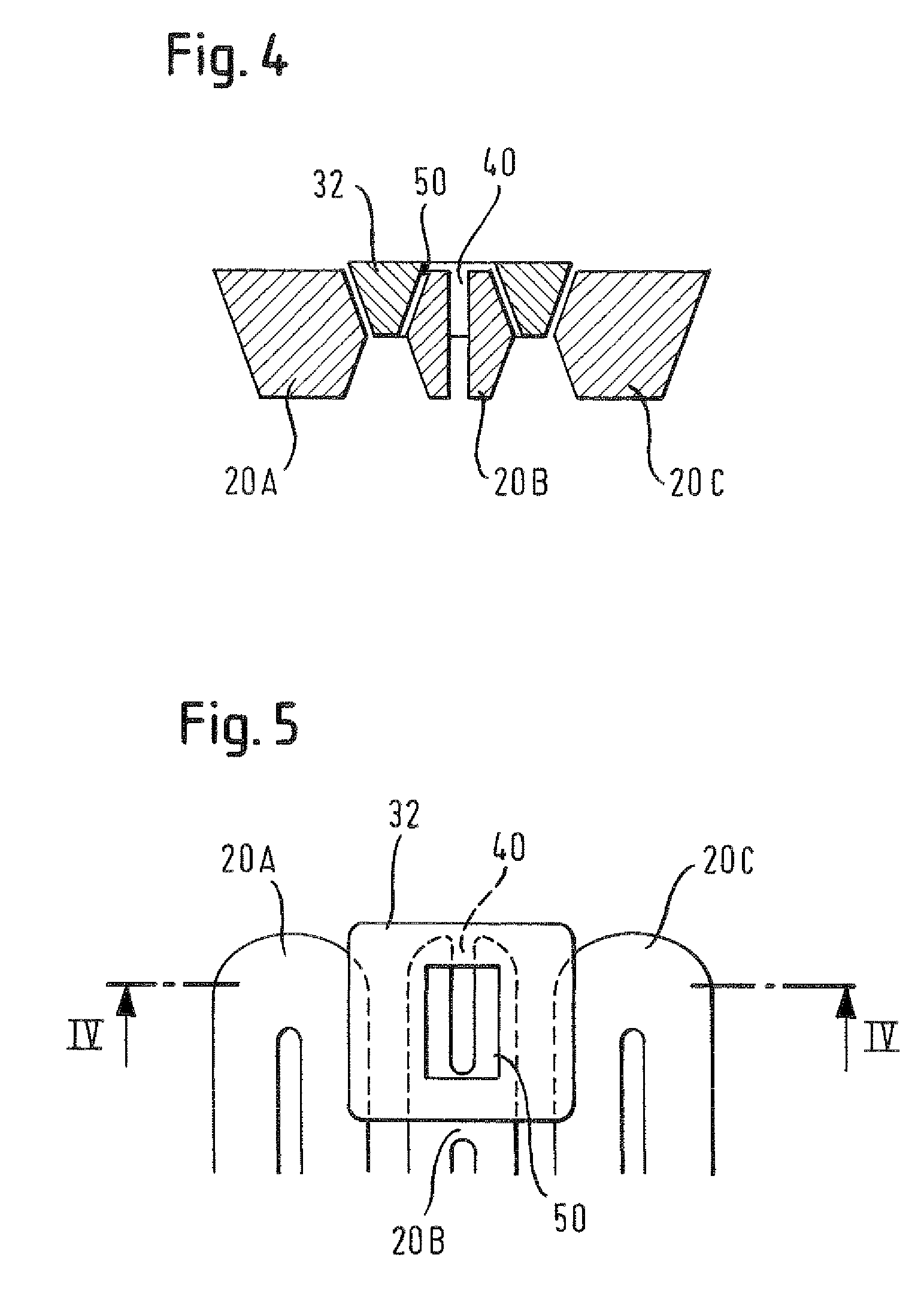

A stenting ring made of a tube or rolled-up sheet that has a characteristic wall thickness. The ring defines a lumen and is equipped with at least one marker made of a material different from that of the ring. The ring is expansible from a radially compact disposition with a relatively small circumference to a radially expanded disposition with a relatively large circumference. The ring exhibits in the compact disposition a serpentine arrangement of succeeding struts lying in alternate opposite directions to the longitudinal axis of the lumen. The marker has a thickness in the radial direction of the ring that is less than the characteristic wall thickness, and has a width that extends circumferentially around an arc of the ring. The marker is attached to the ring at a zone located at a point intermediate in the extent of said arc. The marker overlaps with a respective one of said struts, at each end of its circumferential arc, when the ring is in the compact disposition, the respective struts moving away from each other, and from the marker, when the ring expands towards said radially expanded disposition.

Owner:CR BARD INC

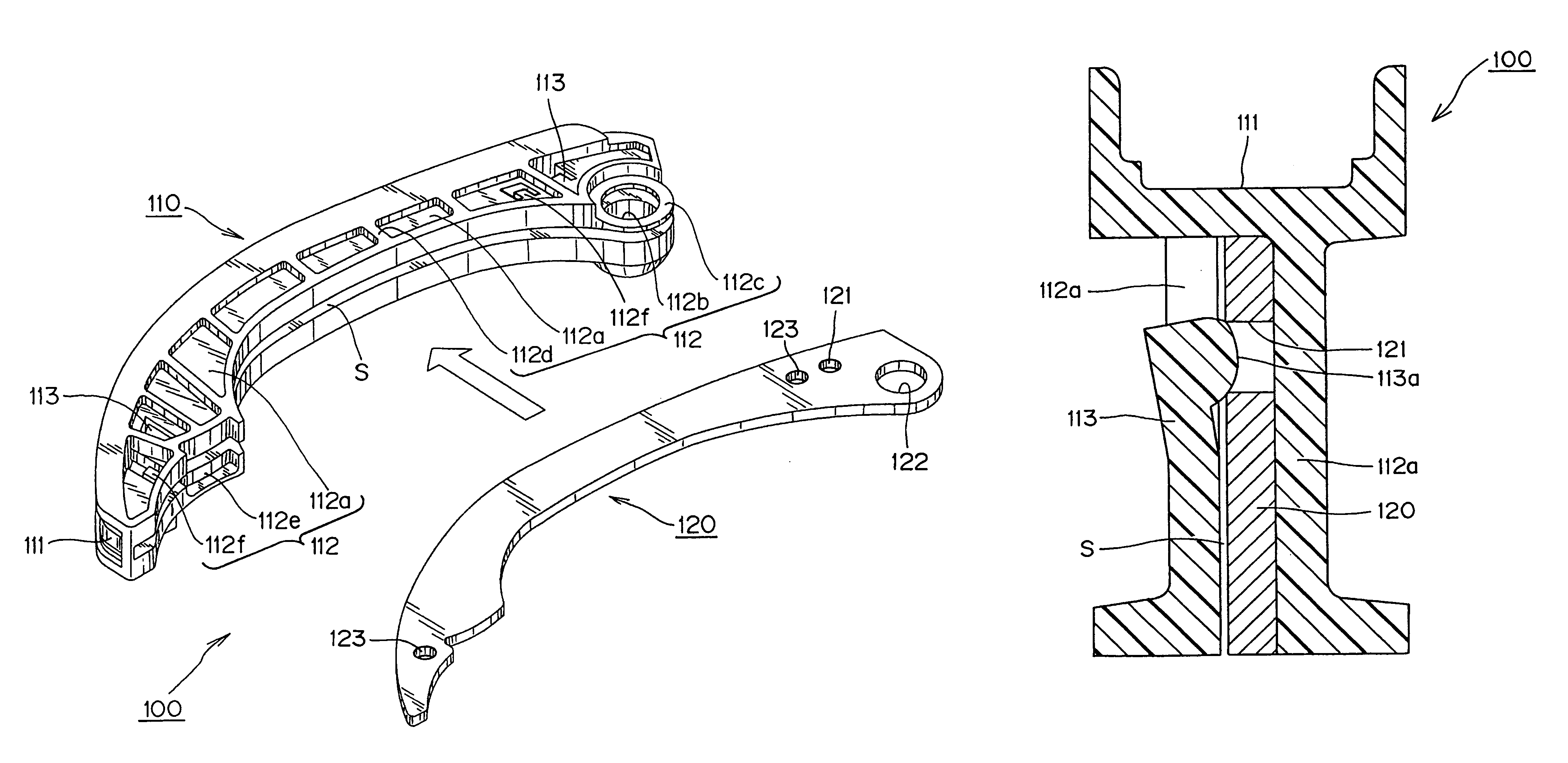

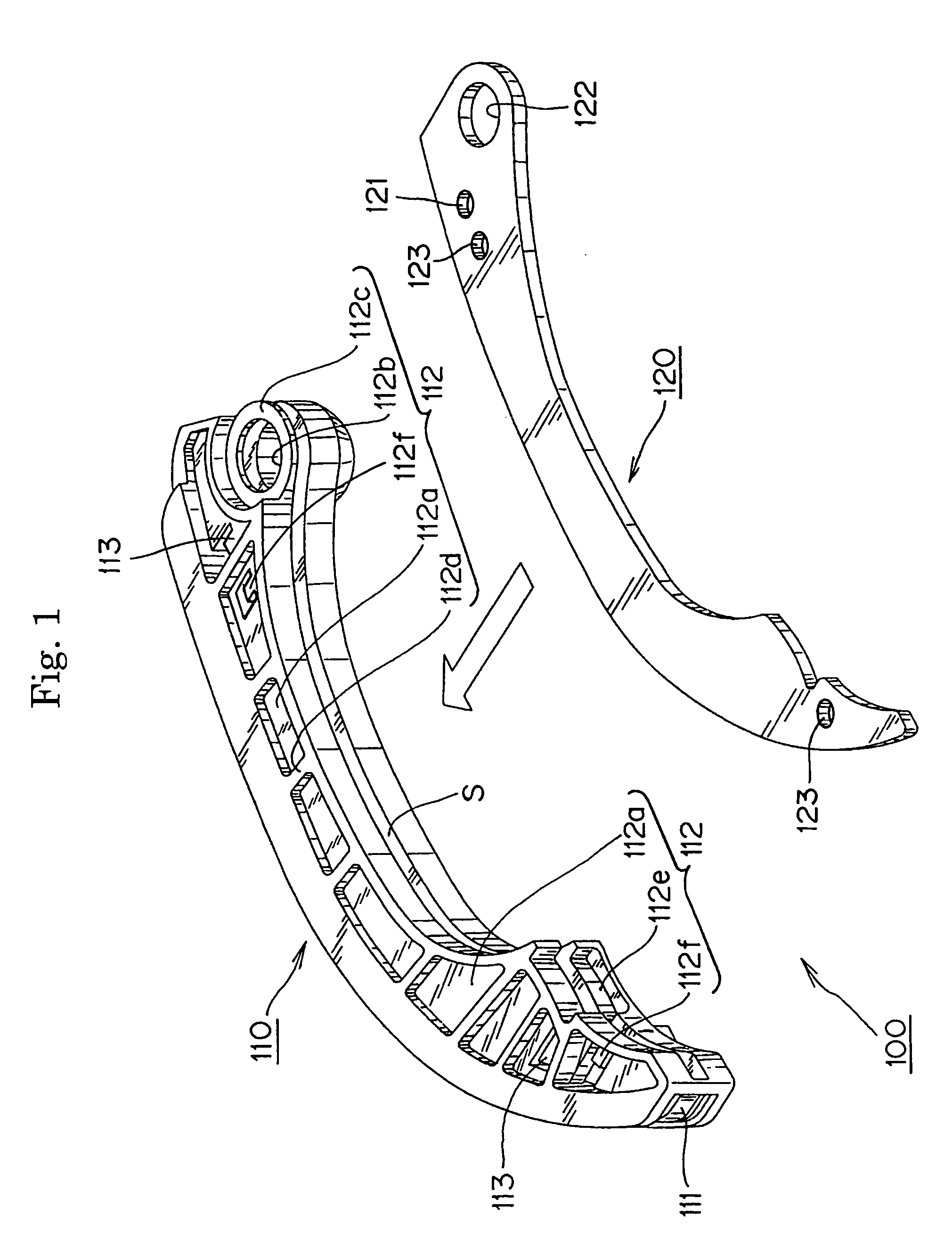

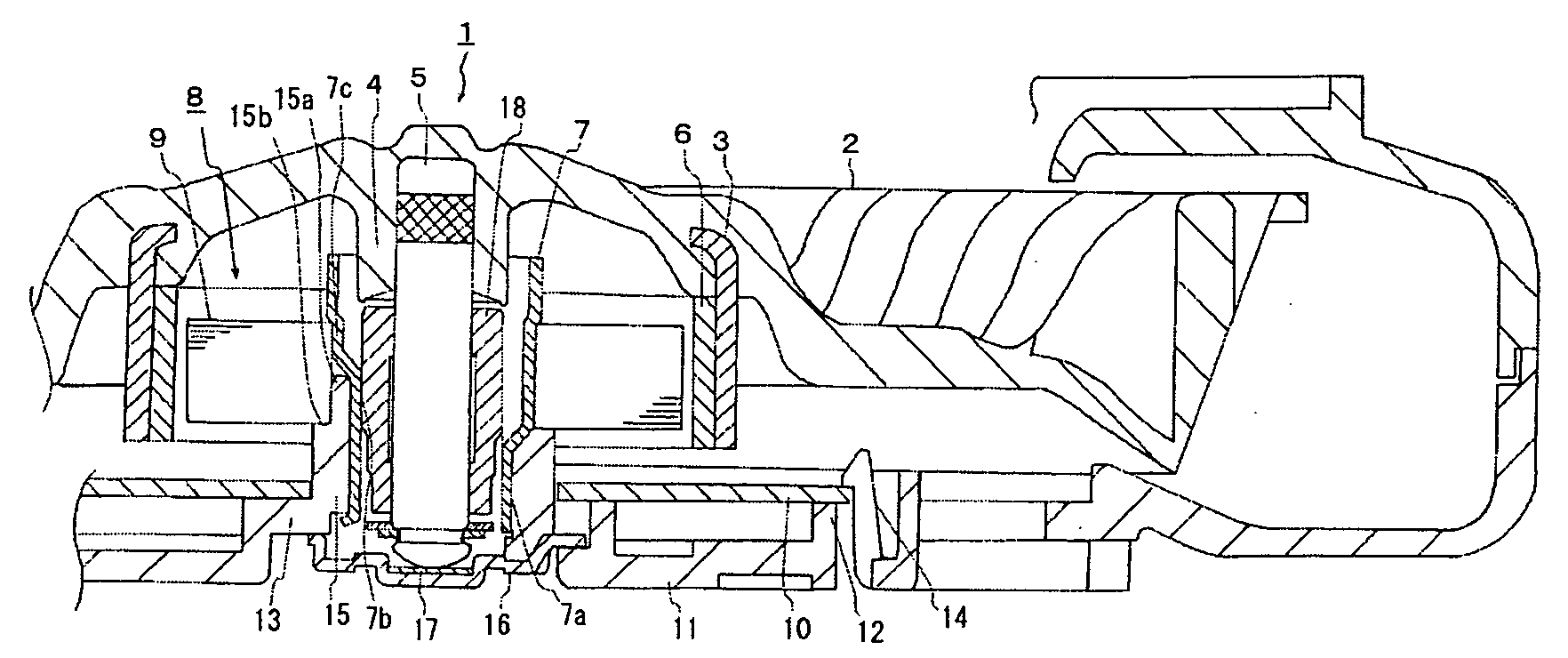

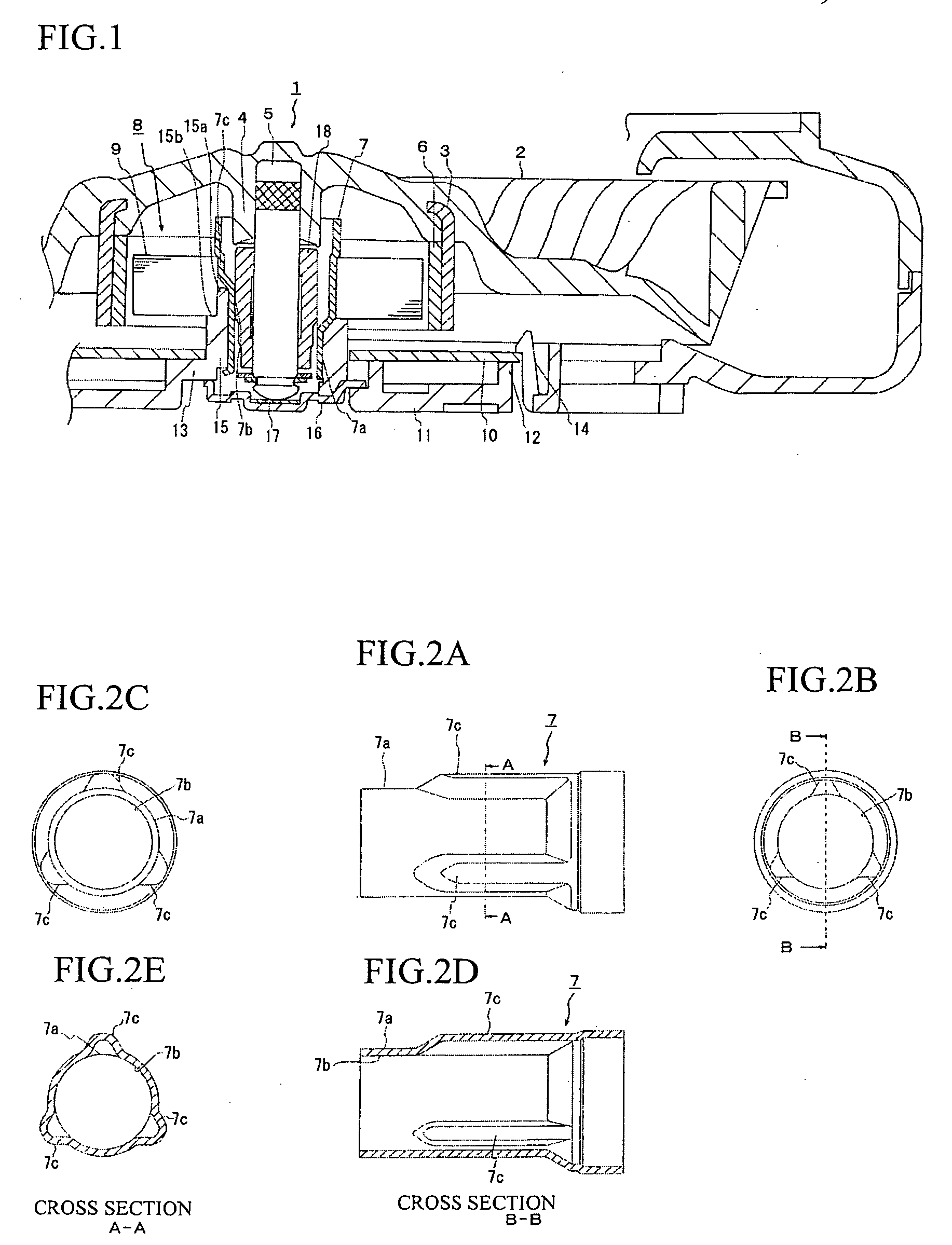

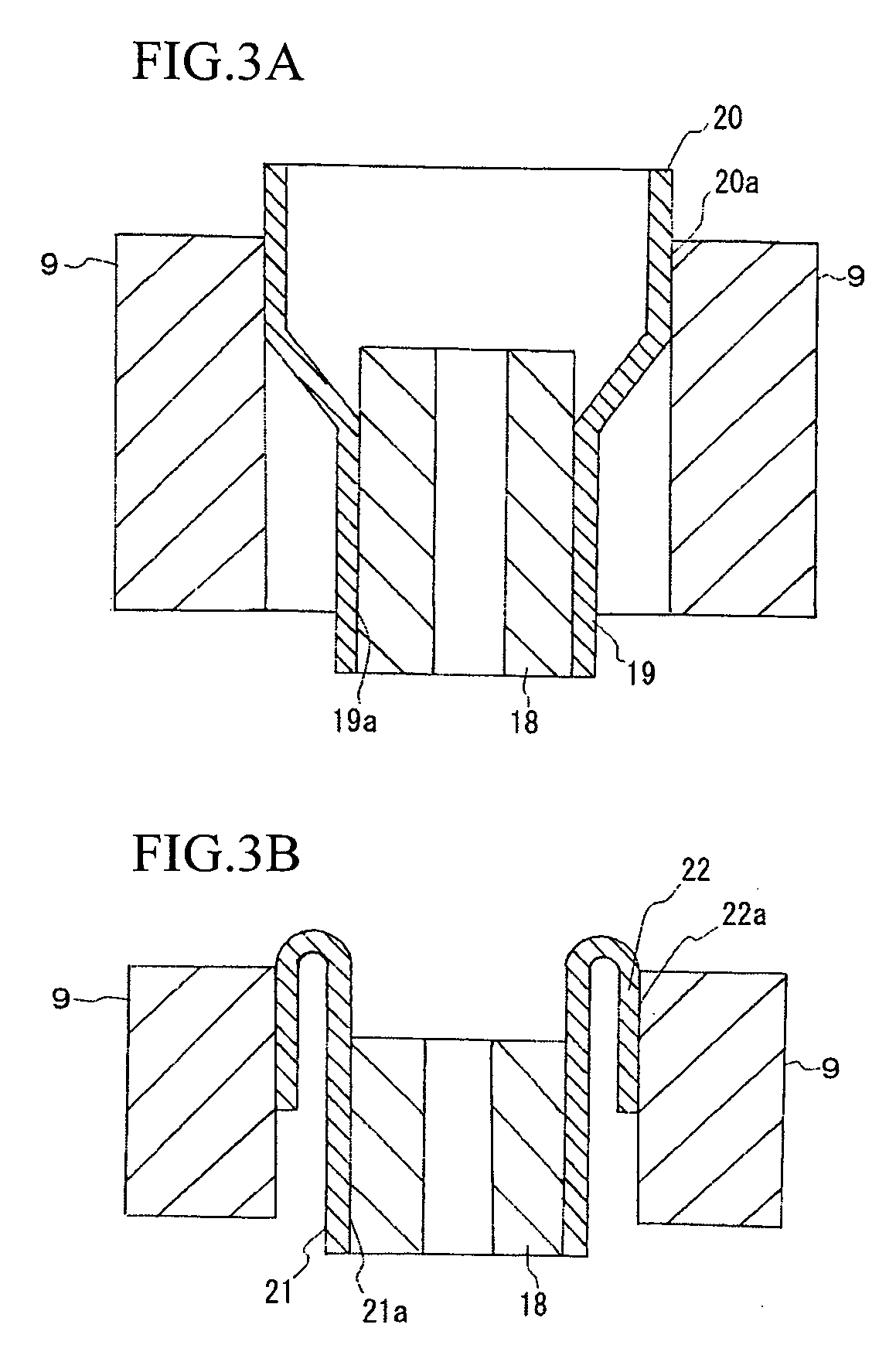

Synthetic resin guide

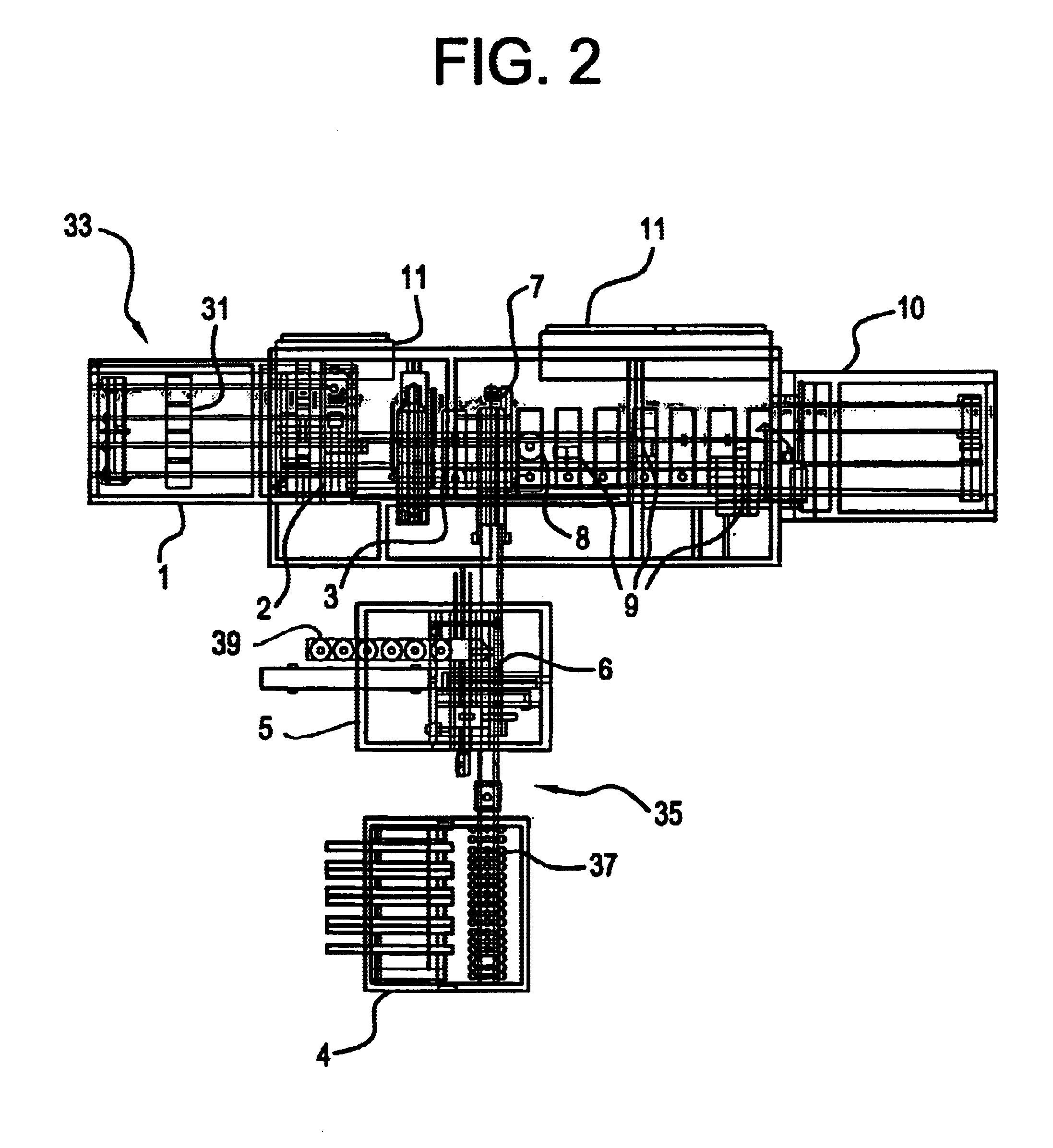

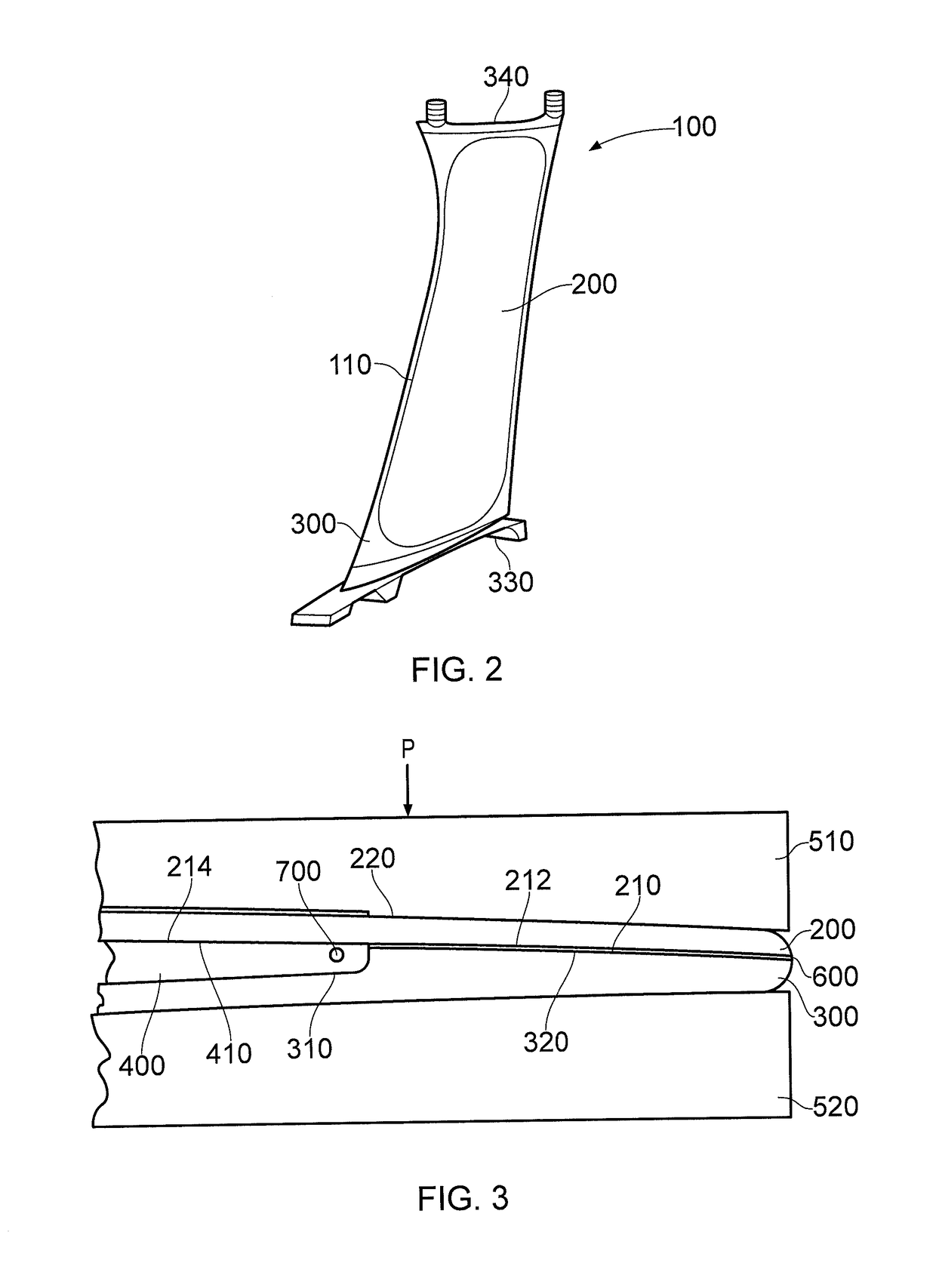

InactiveUS20050277506A1Lower requirementIncreased dimensional tolerancesGearingEngineeringSynthetic resin

A synthetic resin guide for a transmission device comprises an integrally molded, synthetic resin guide body having a shoe with a front surface for sliding contact with a chain, and a support on its back surface, the support having a longitudinal slot, formed between two opposed walls, for receiving a reinforcing plate. Both the guide body and the plate having mounting holes that are coaxial when the plate is incorporated into the guide body. A pressing member, integrally formed on one of the walls of the guide body, includes an eccentric head which uniformly presses against opposite parts of the edge of an opening of a positioning hole in the reinforcing plate.

Owner:TSUBAKIMOTO CHAIN CO

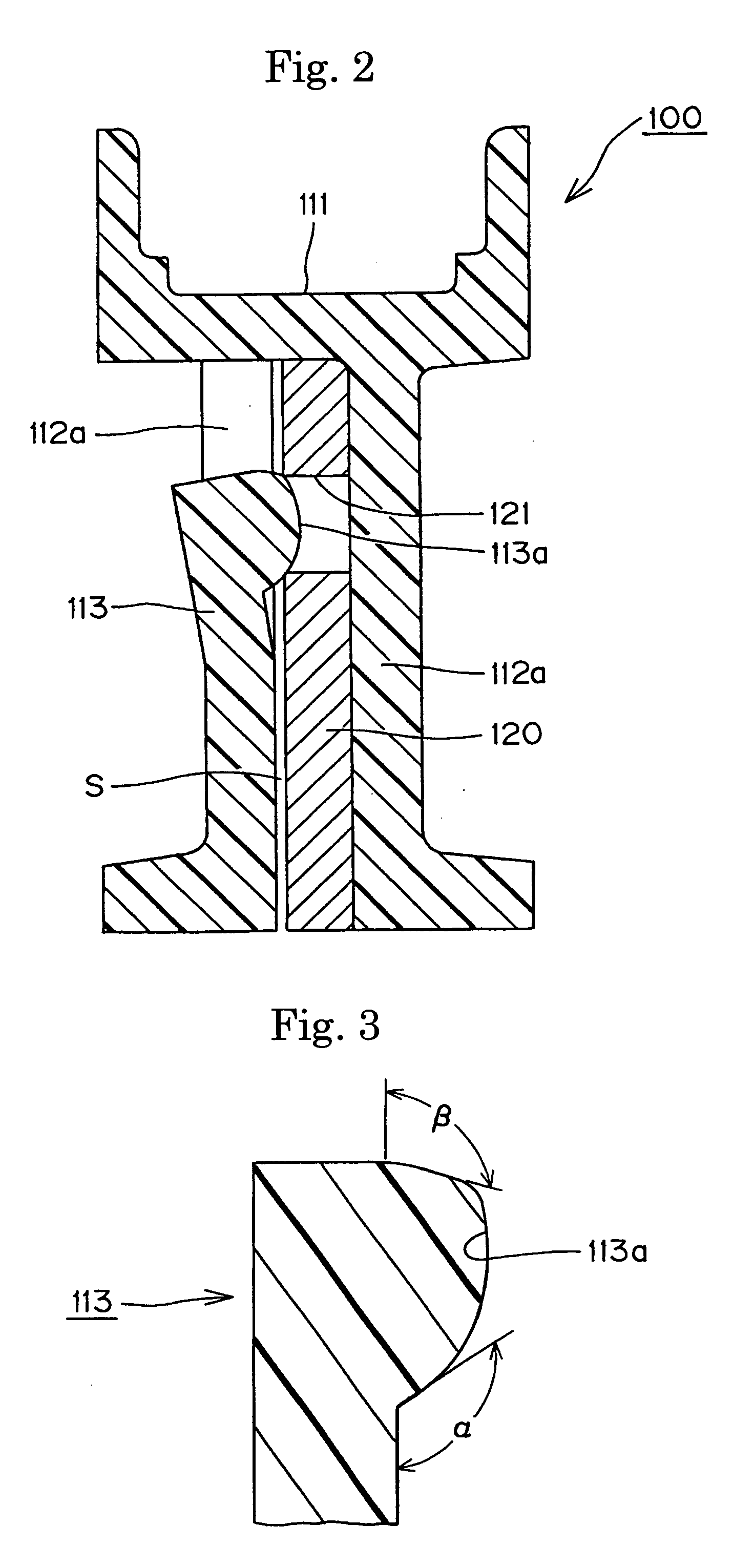

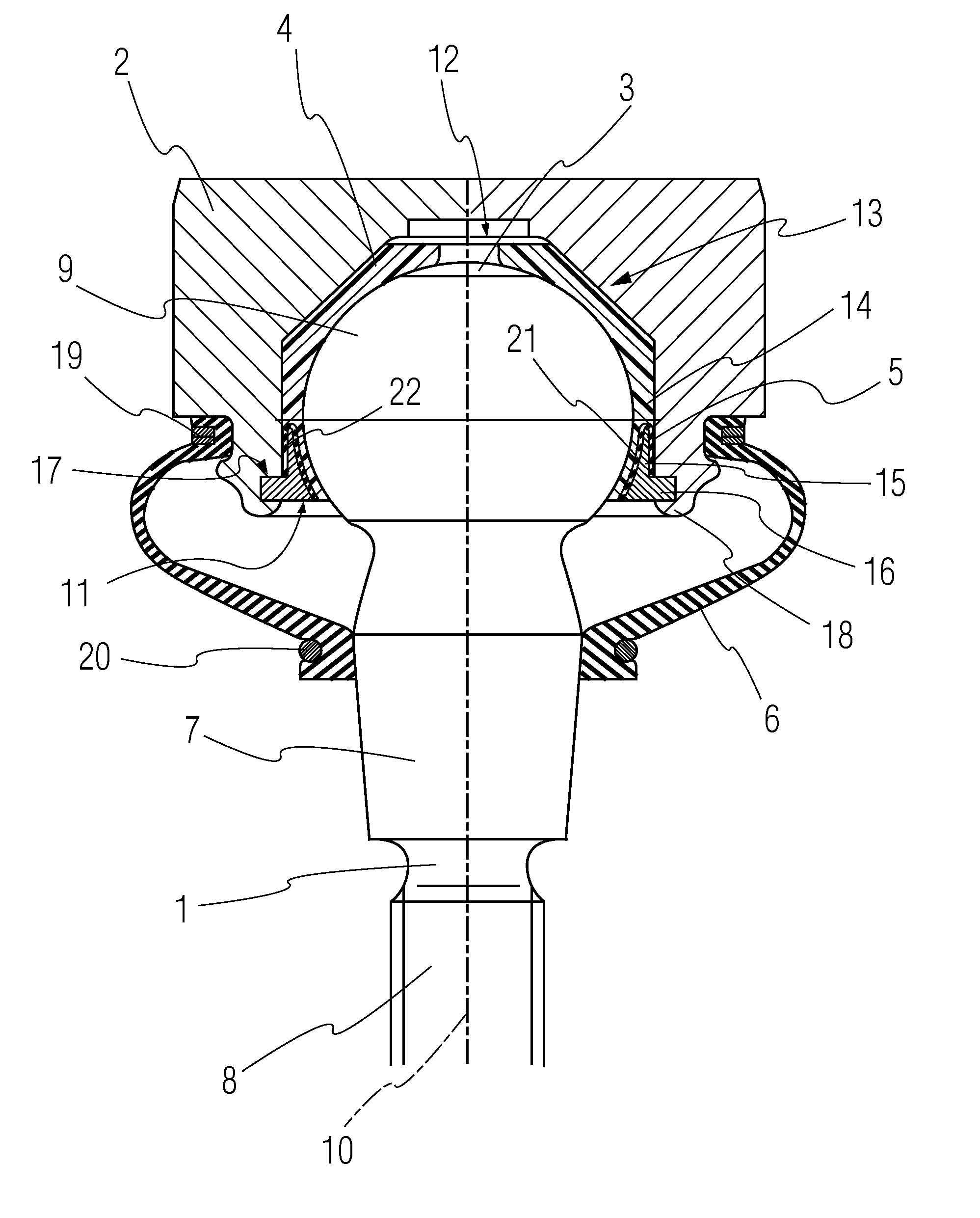

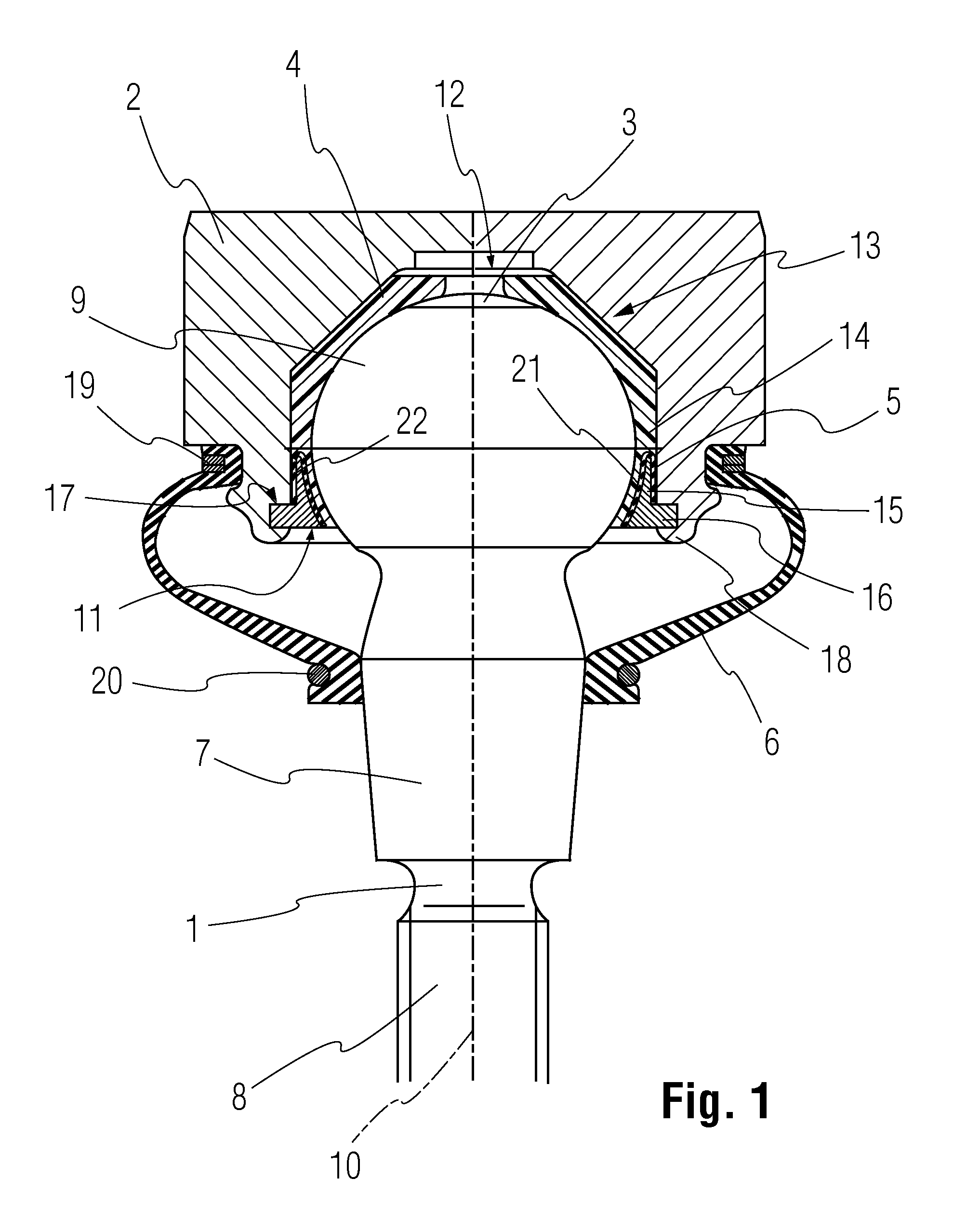

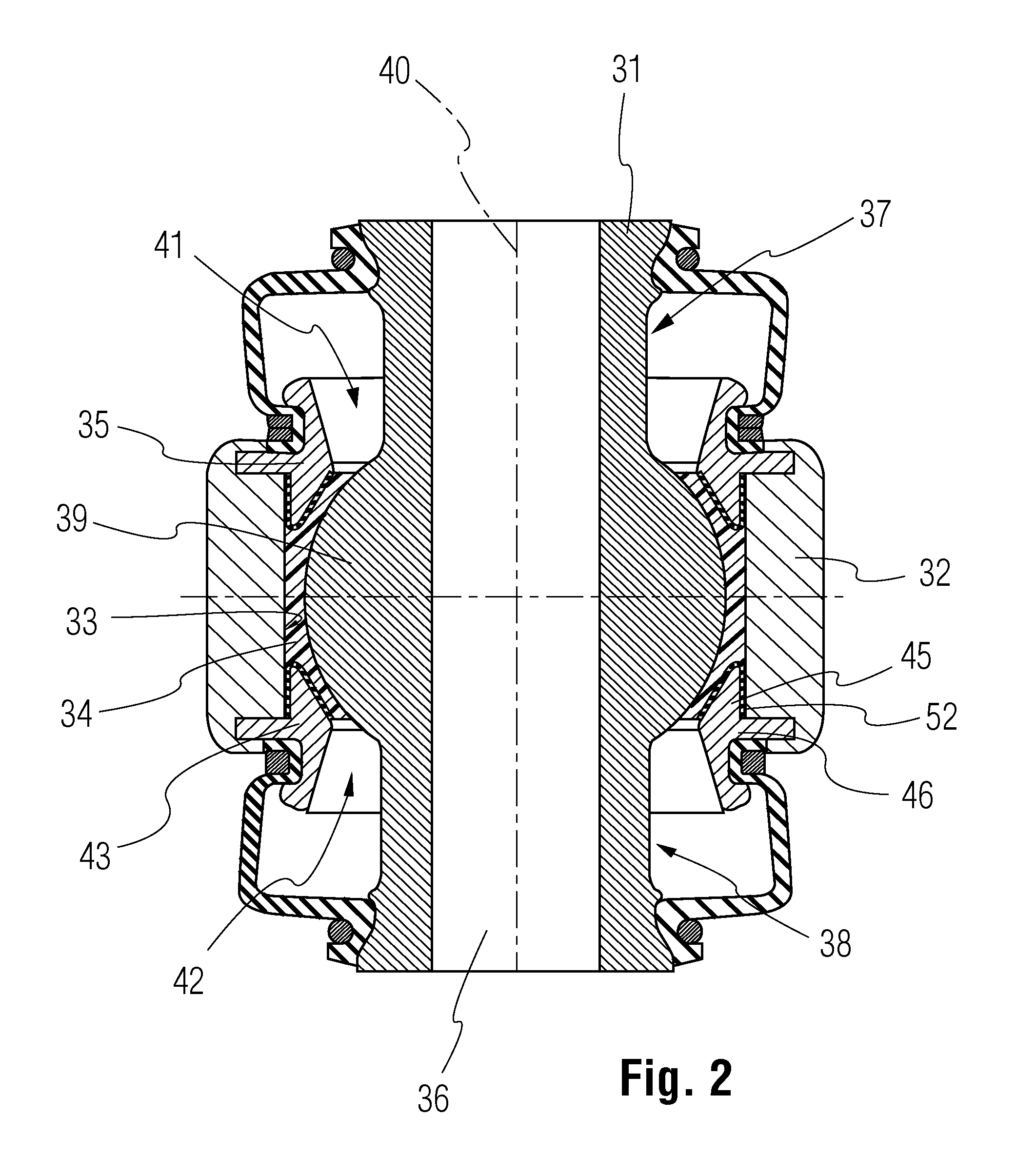

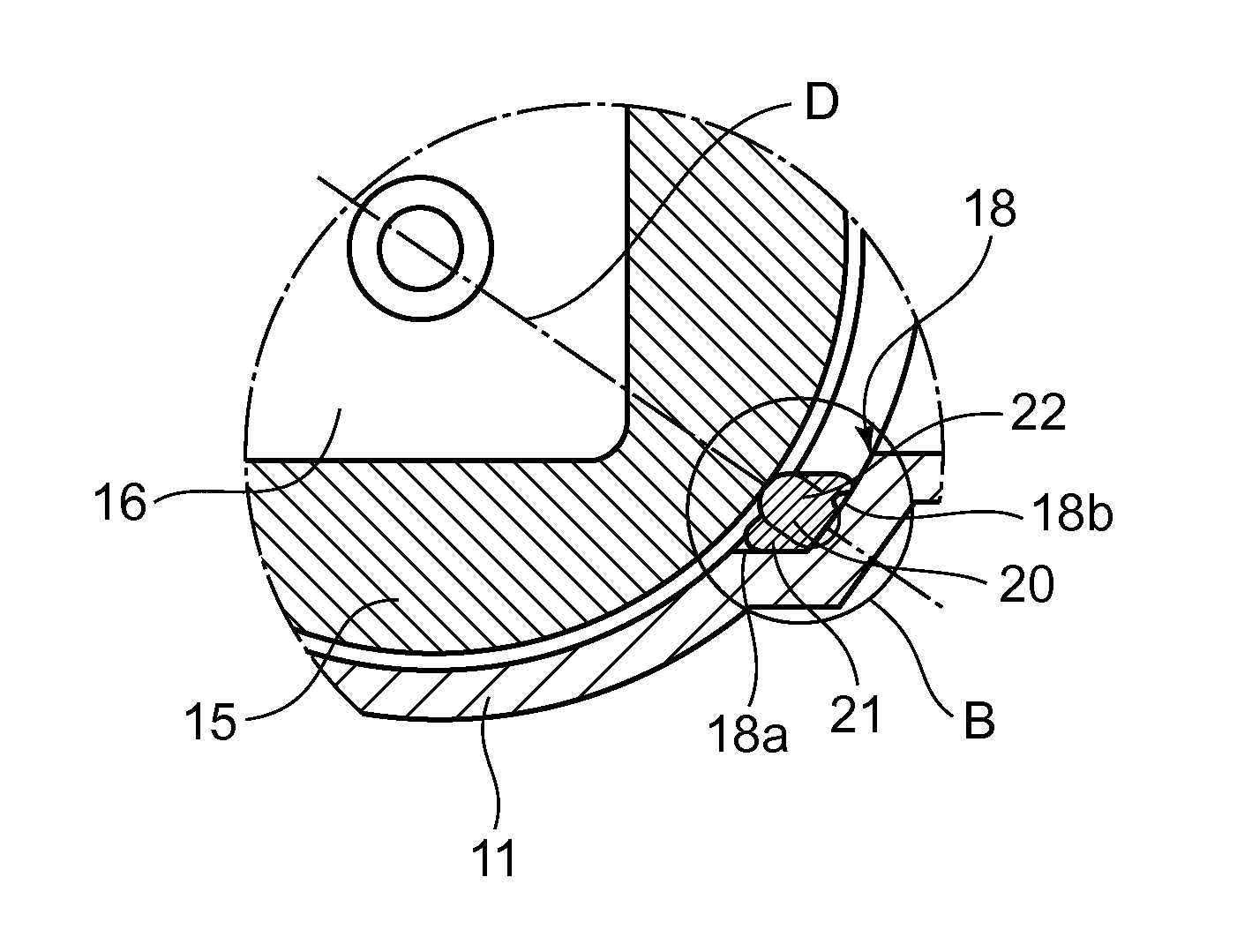

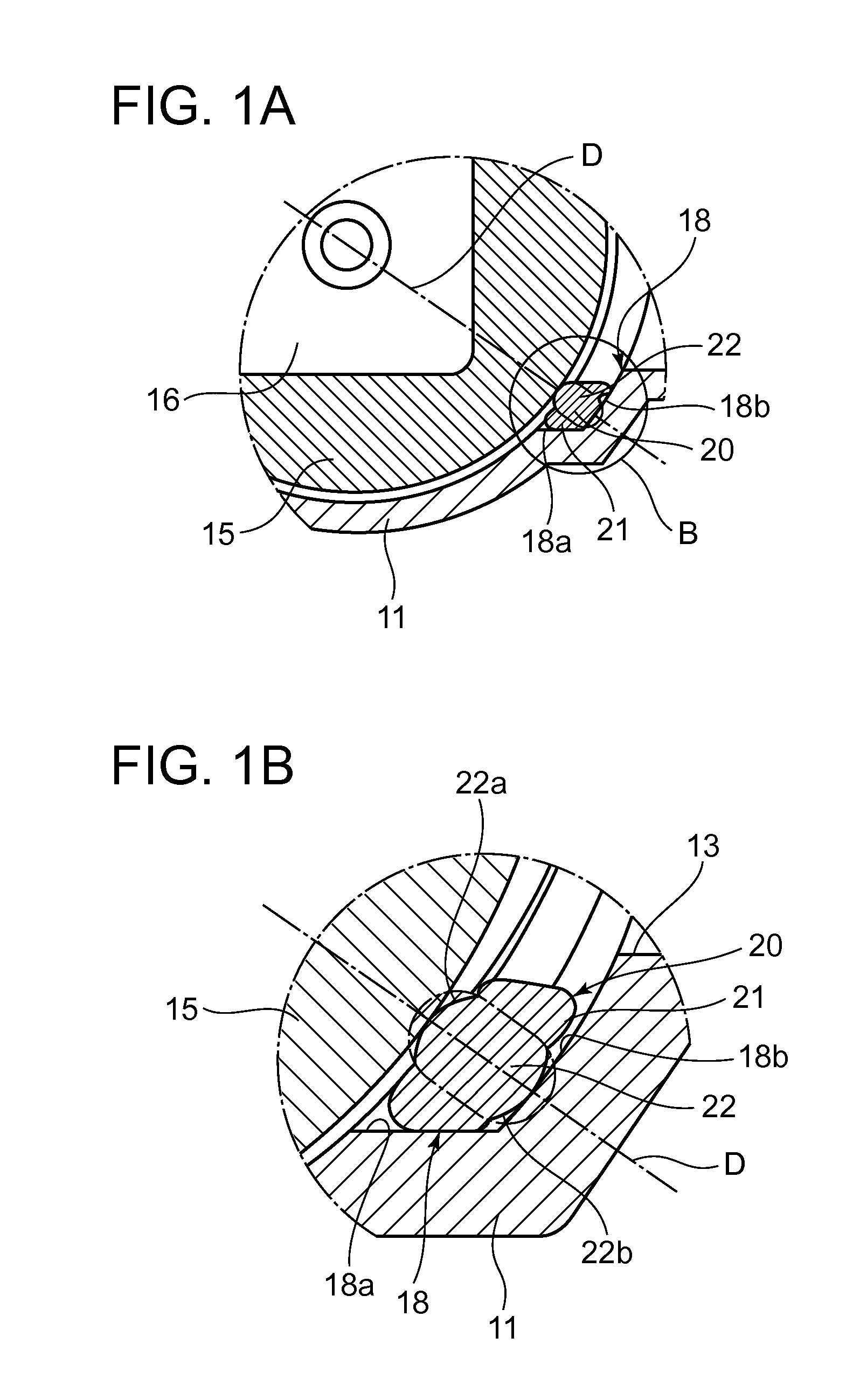

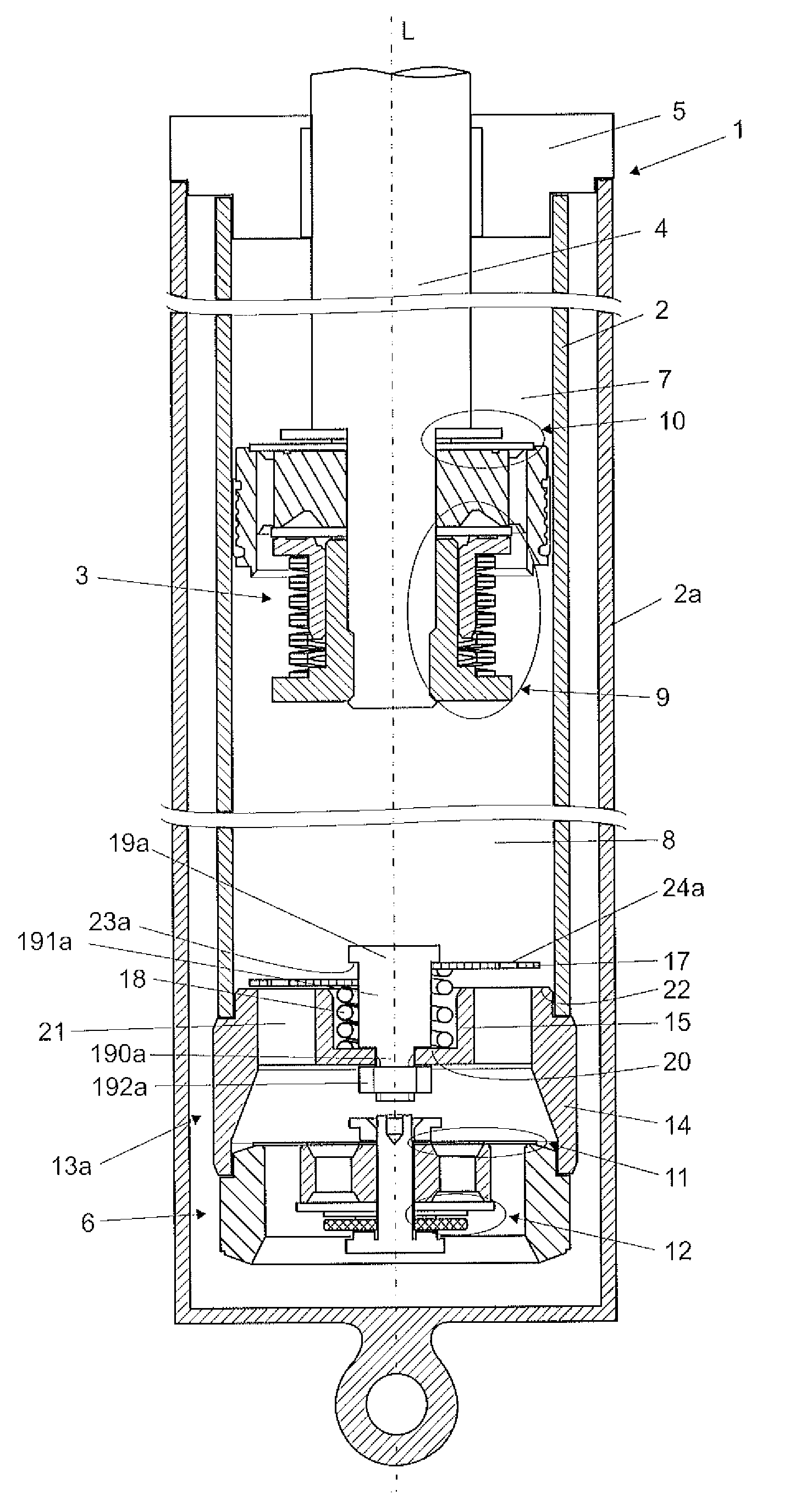

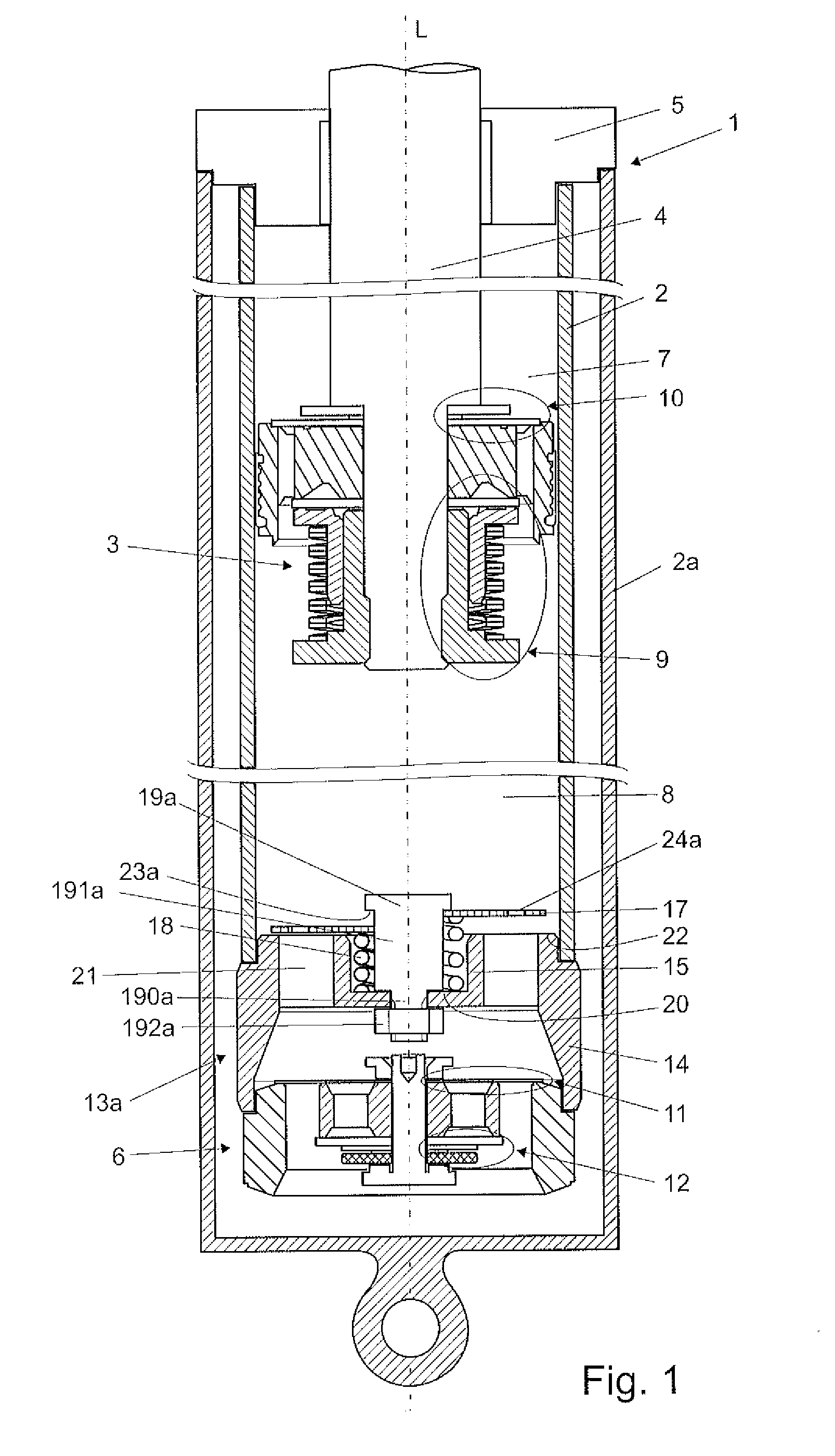

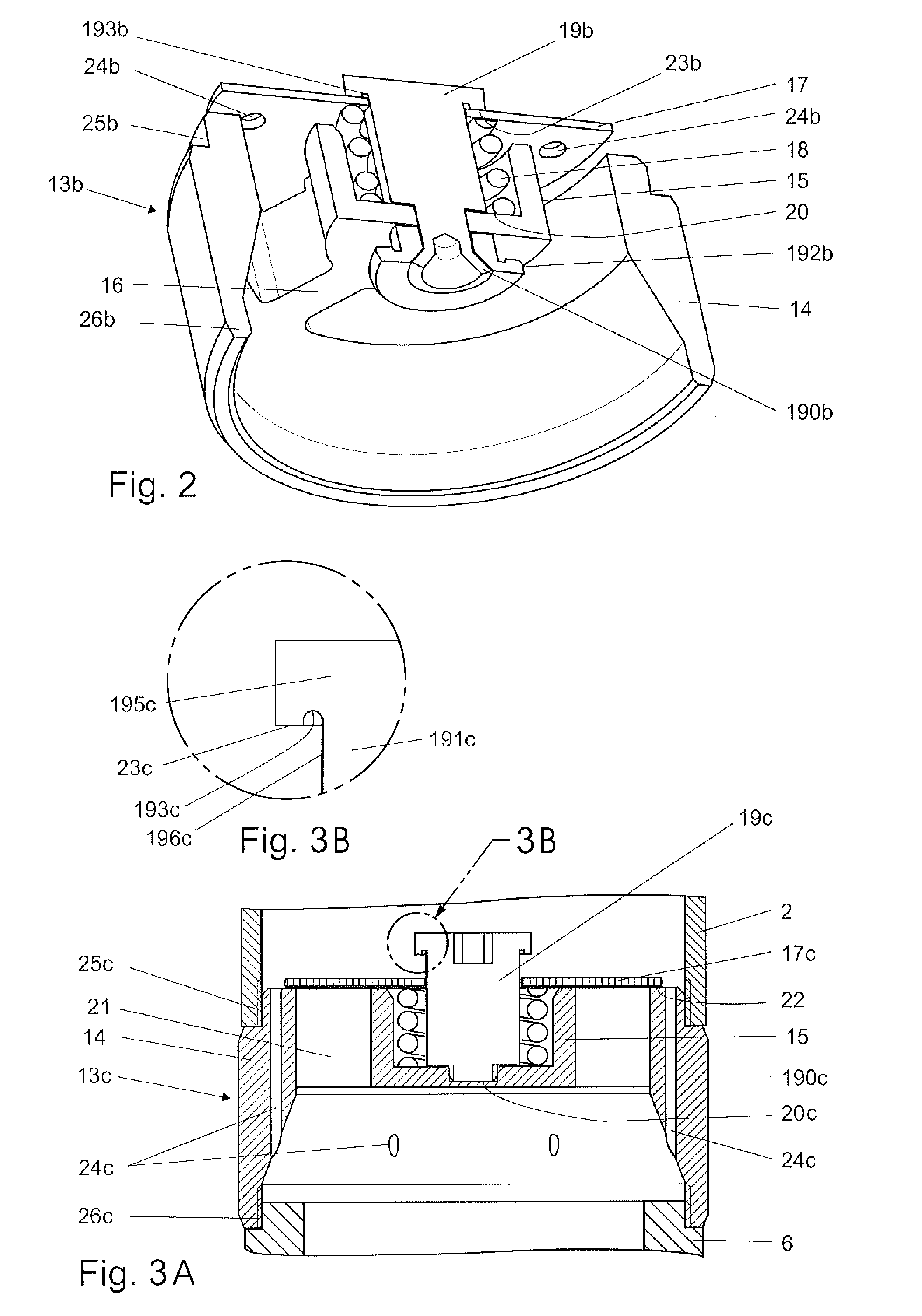

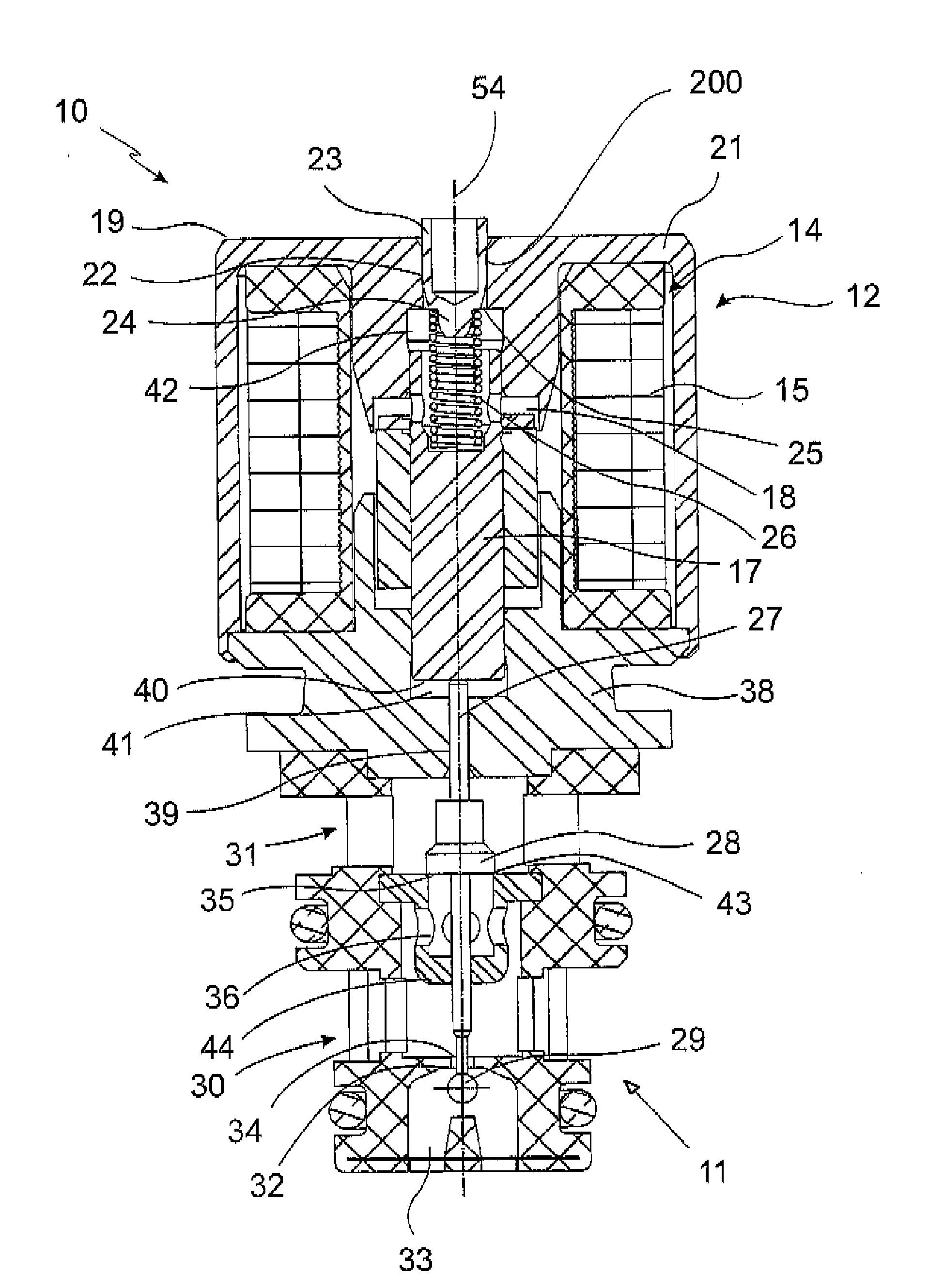

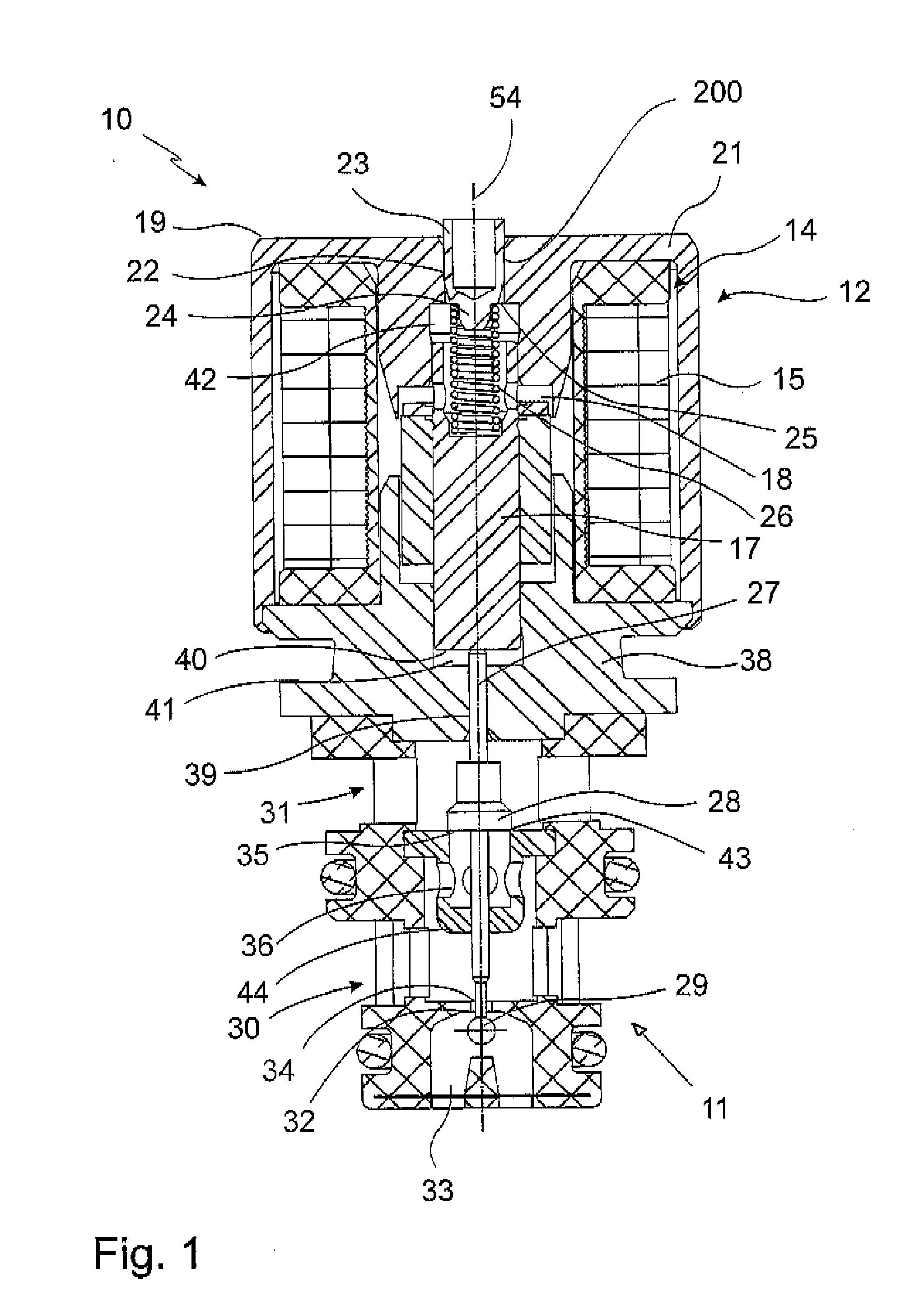

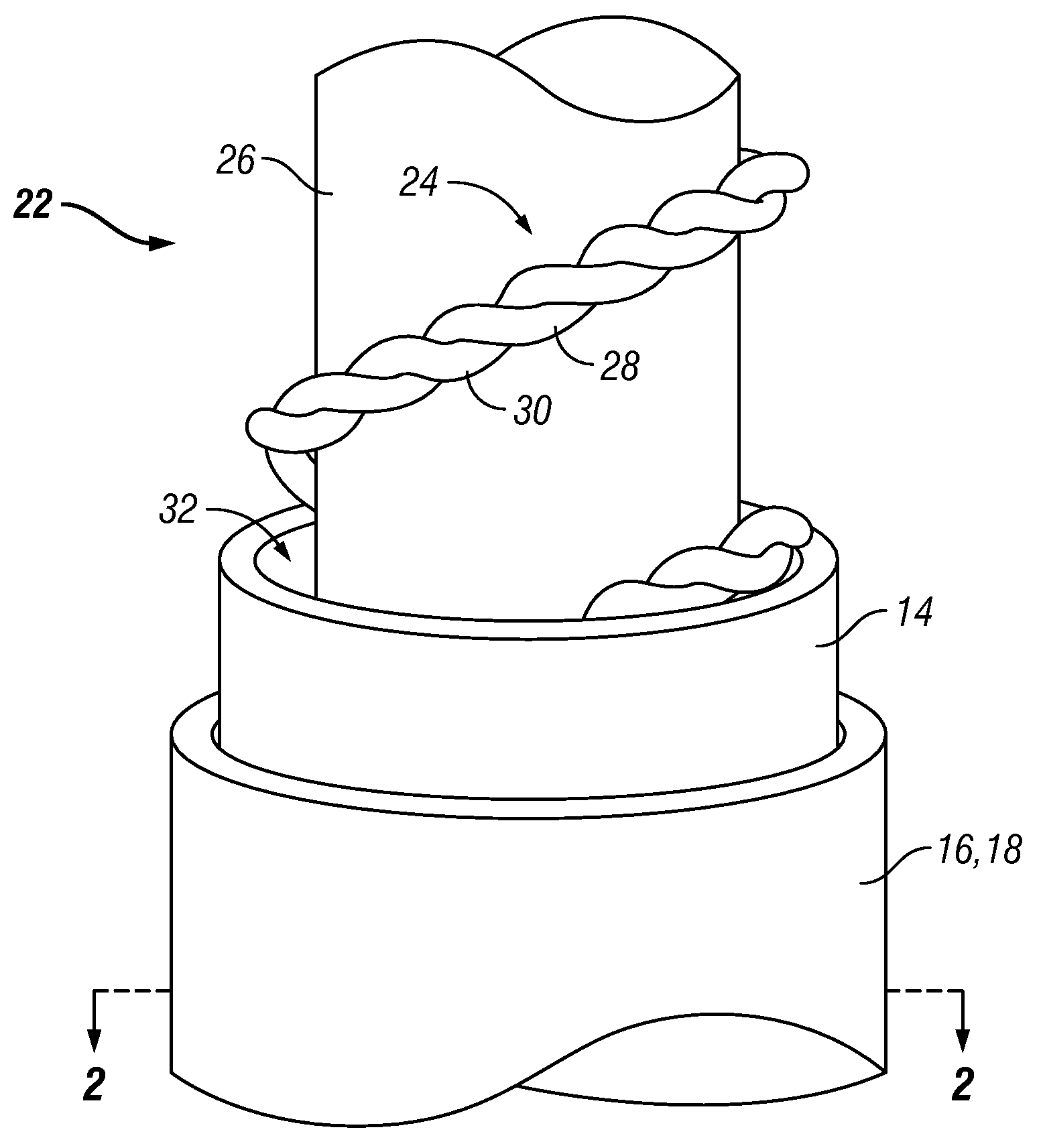

Ball-and-socket joint

InactiveUS7357591B2Increased dimensional tolerancesImprove toleranceCouplings for rigid shaftsPivotal connectionsManufacturing cost reductionEngineering

A ball-and-socket joint has a pivot pin accommodated rotatably and tiltably with a spherical joint area in a bearing shell. The bearing shell is in turn arranged in the recess of a joint housing. A closing ring fixes the bearing shell in the joint housing in the axial longitudinal direction of the pivot pin by at least one surface pair. Corresponding to a first solution variant, an intermediate element made of an elastic material may be arranged between the corresponding contact surfaces of the surface pair on the bearing shell and the closing ring. As an alternative an insert element may be arranged between the outer contour of the bearing shell and the bottom area of the recess, wherein at least one intermediate element made of an elastic material is arranged between the outer surface of the insert element and the corresponding inner surface of the recess. The requirement imposed on the dimensional accuracy of the ball-and-socket joint components can be substantially reduced due to these solution variants, which contributes to a reduction of the manufacturing costs.

Owner:ZF LEMFOERDER METALLWAREN AG

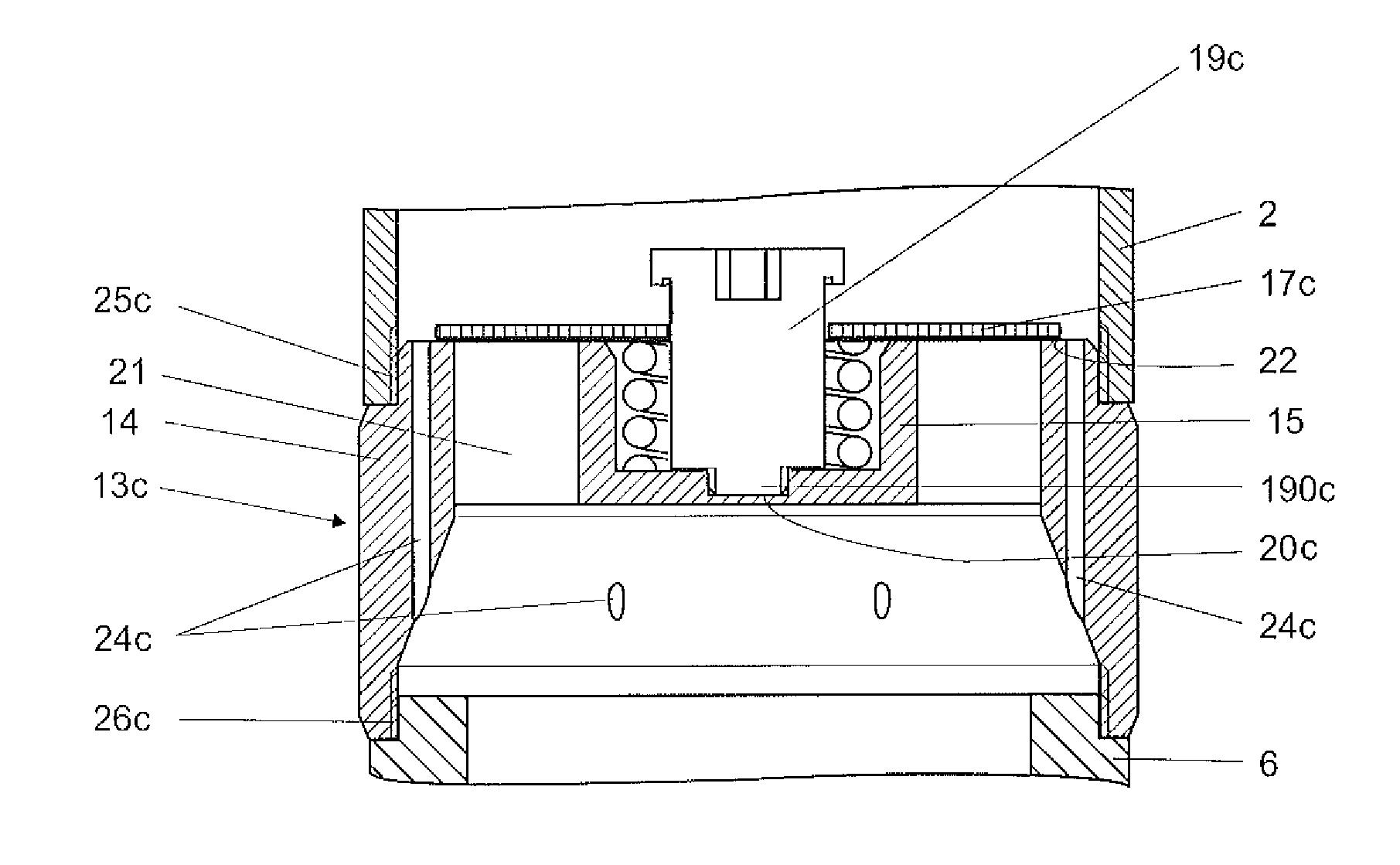

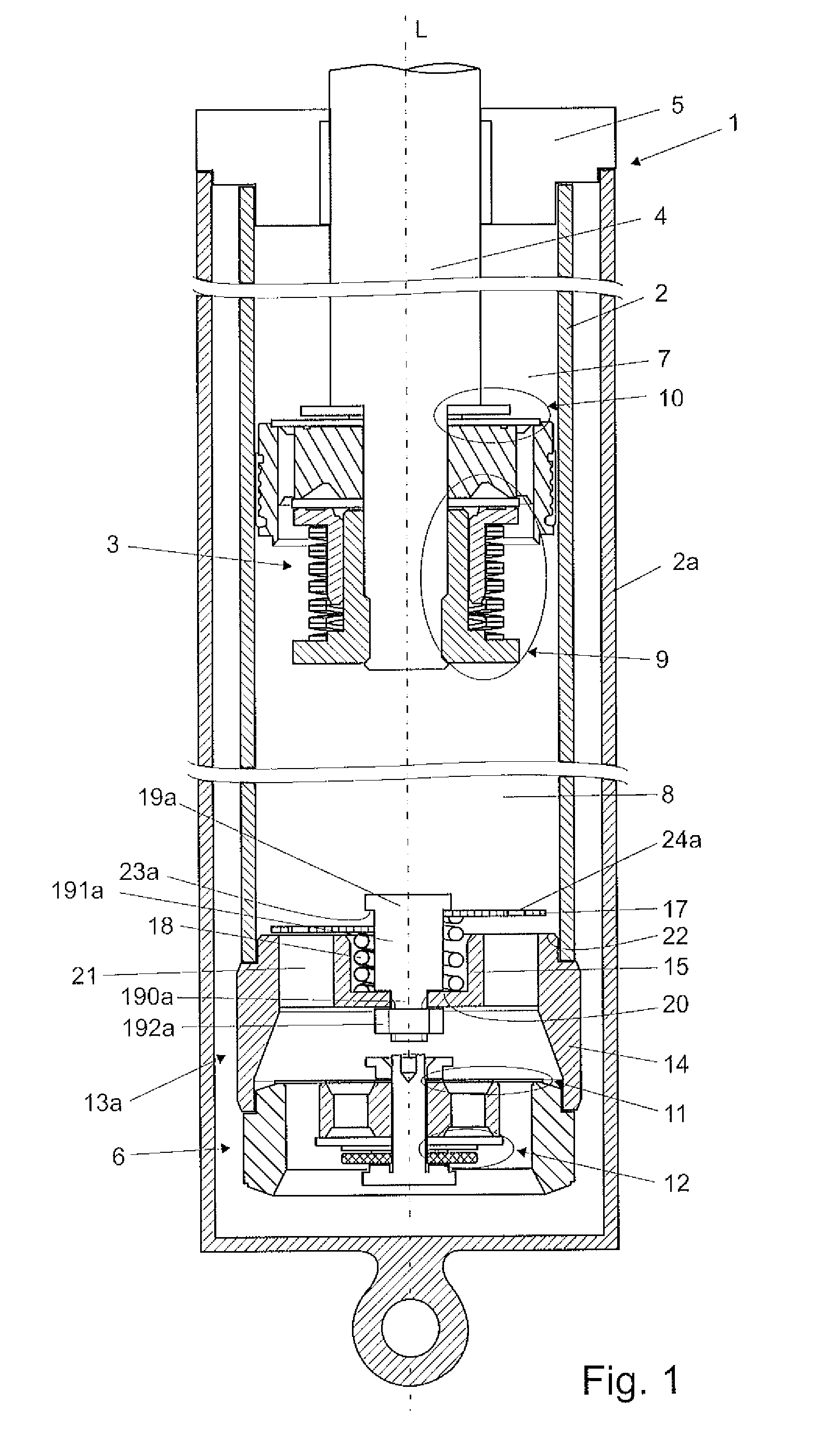

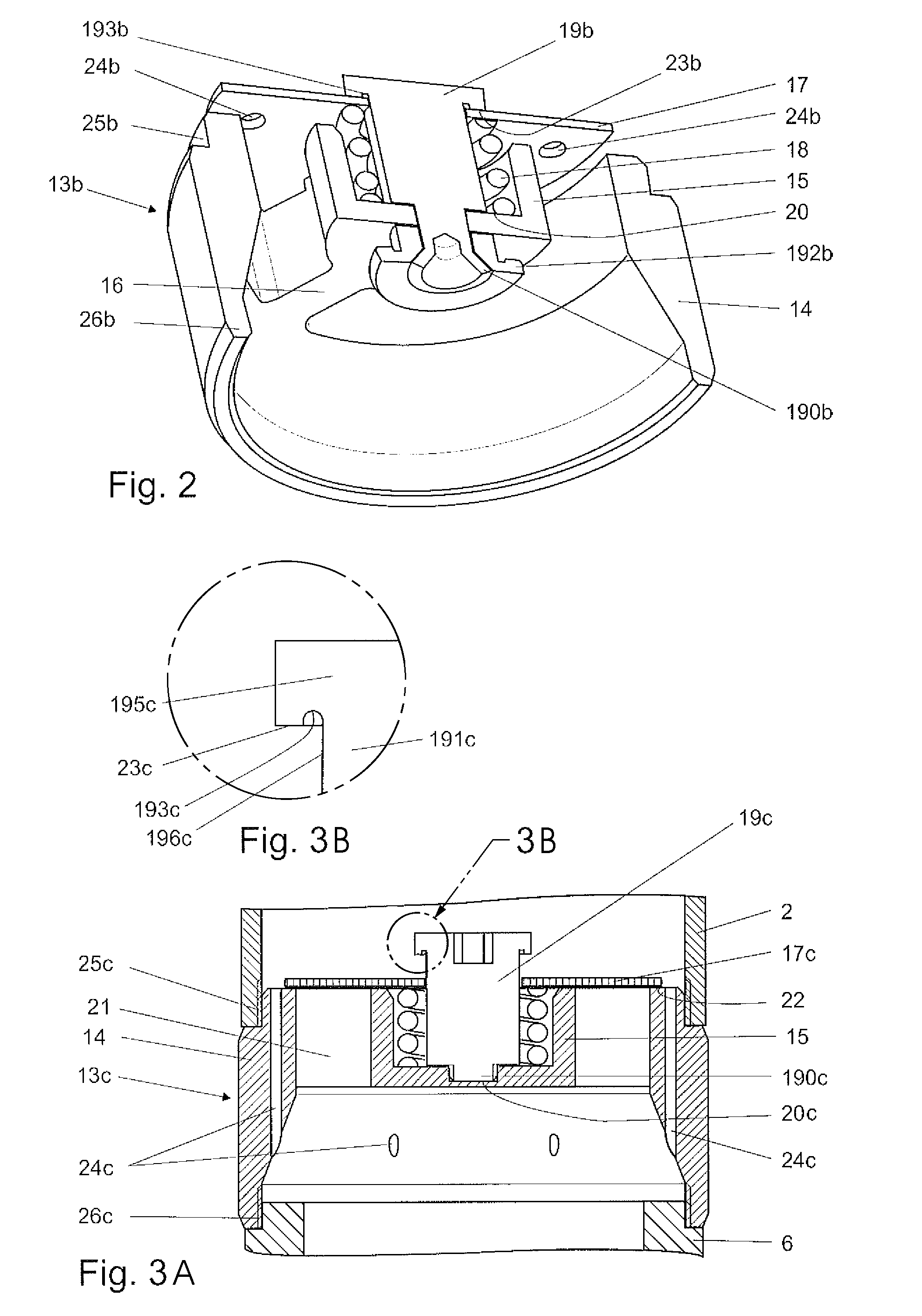

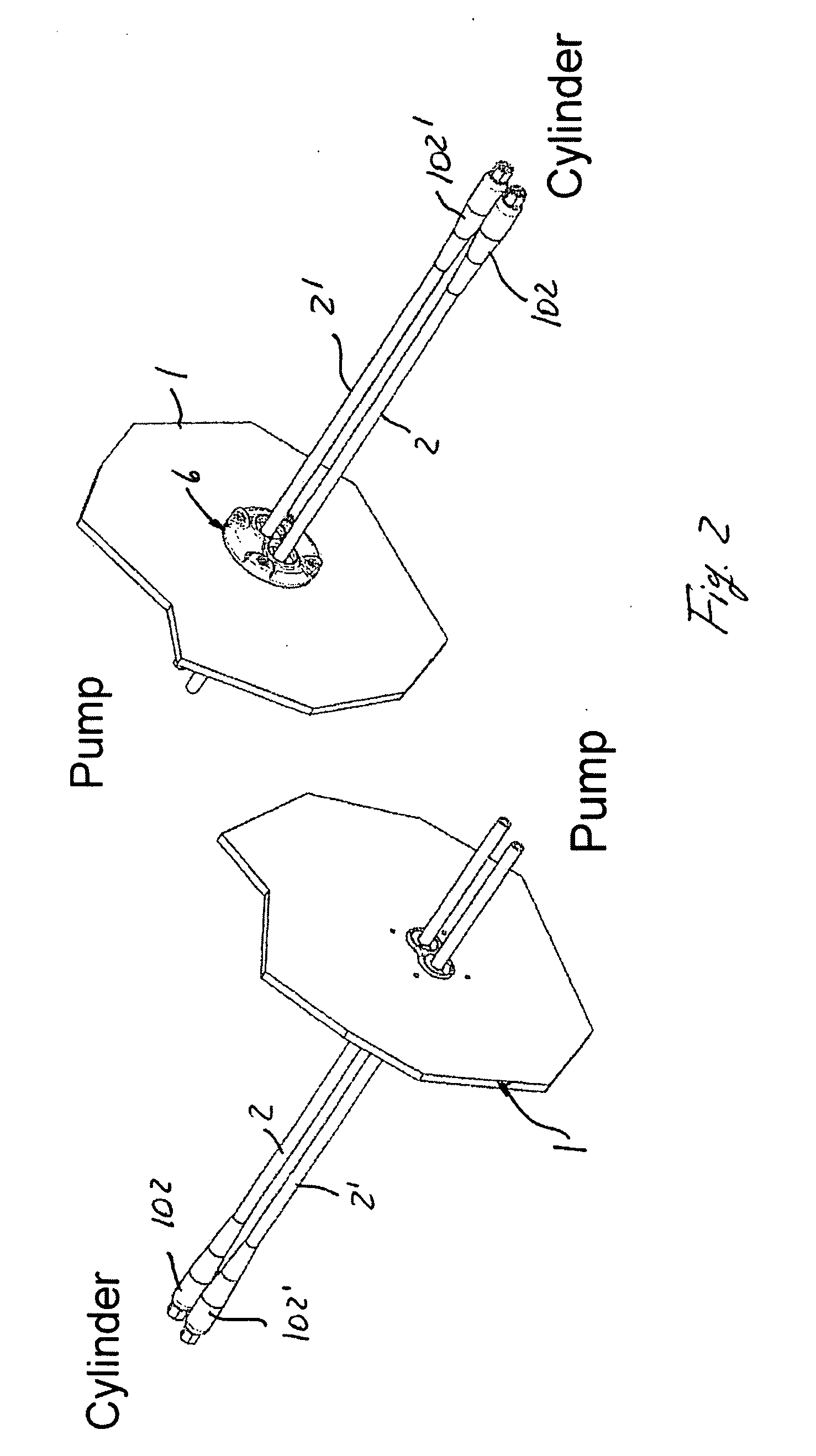

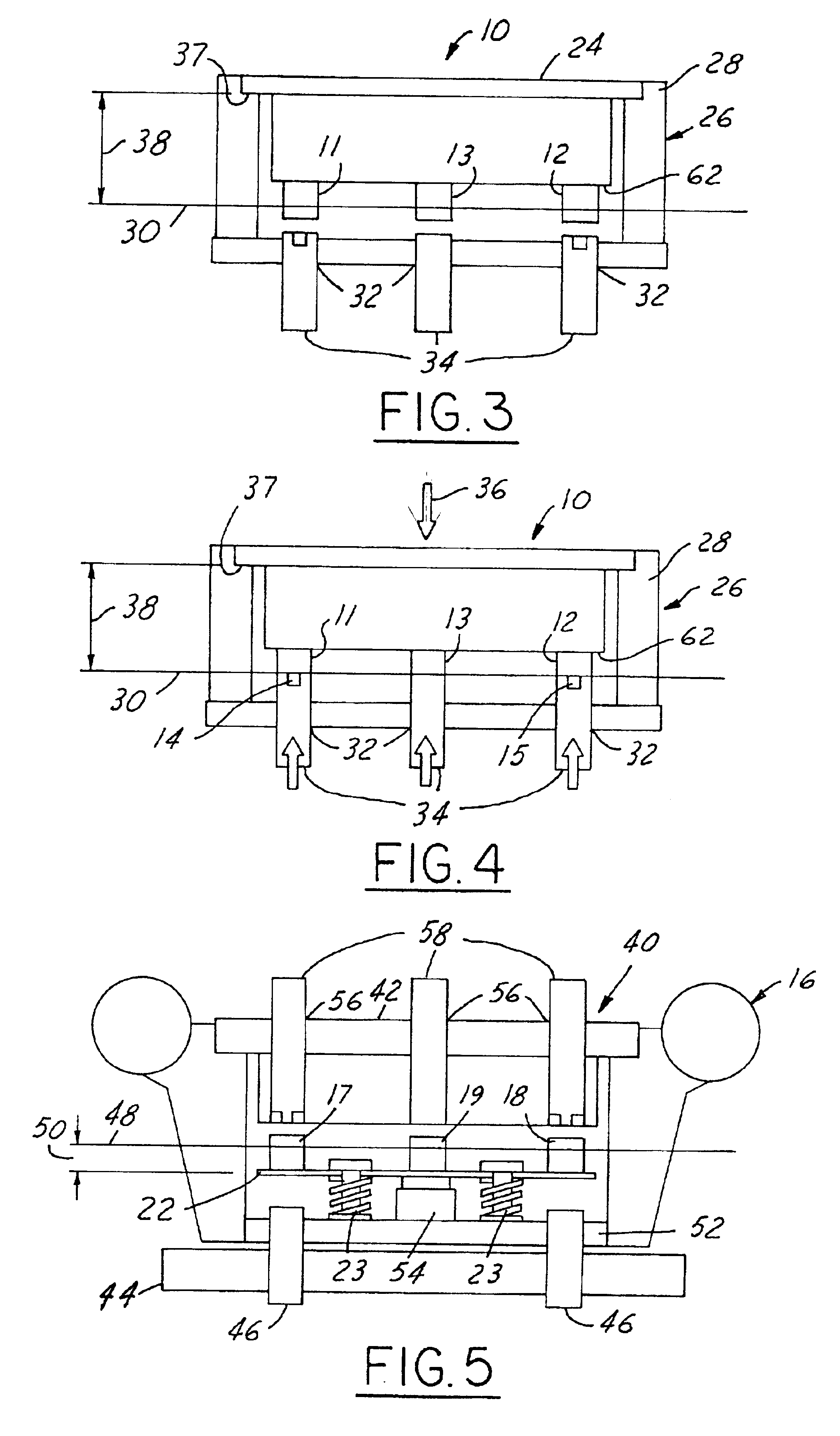

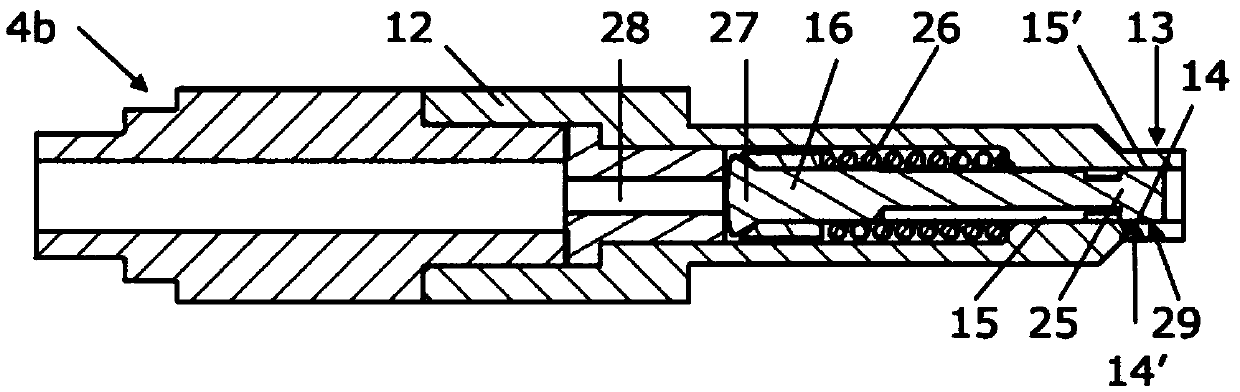

Hydraulic damper with compensation chamber

InactiveUS8132654B2Reduce the amount of solutionLow costSpringsShock absorbersWorking fluidComputer module

The invention relates to a hydraulic damper, in particular for the suspension system of a motor vehicle, comprising a tube filled with working fluid; a piston assembly slidably positioned inside the tube; a fluid compensation chamber located outside of the tube, and a base valve assembly at the end of the tube for controlling the flow of working fluid between the tube and the compensation chamber. A compression valve module added between the piston assembly and the base valve assembly allows the damping to increase during extremely fast compression strokes without modification of the other damper components, affecting neither tuning options nor performance in a normal operating range of piston velocities.

Owner:BWI CO LTD SA

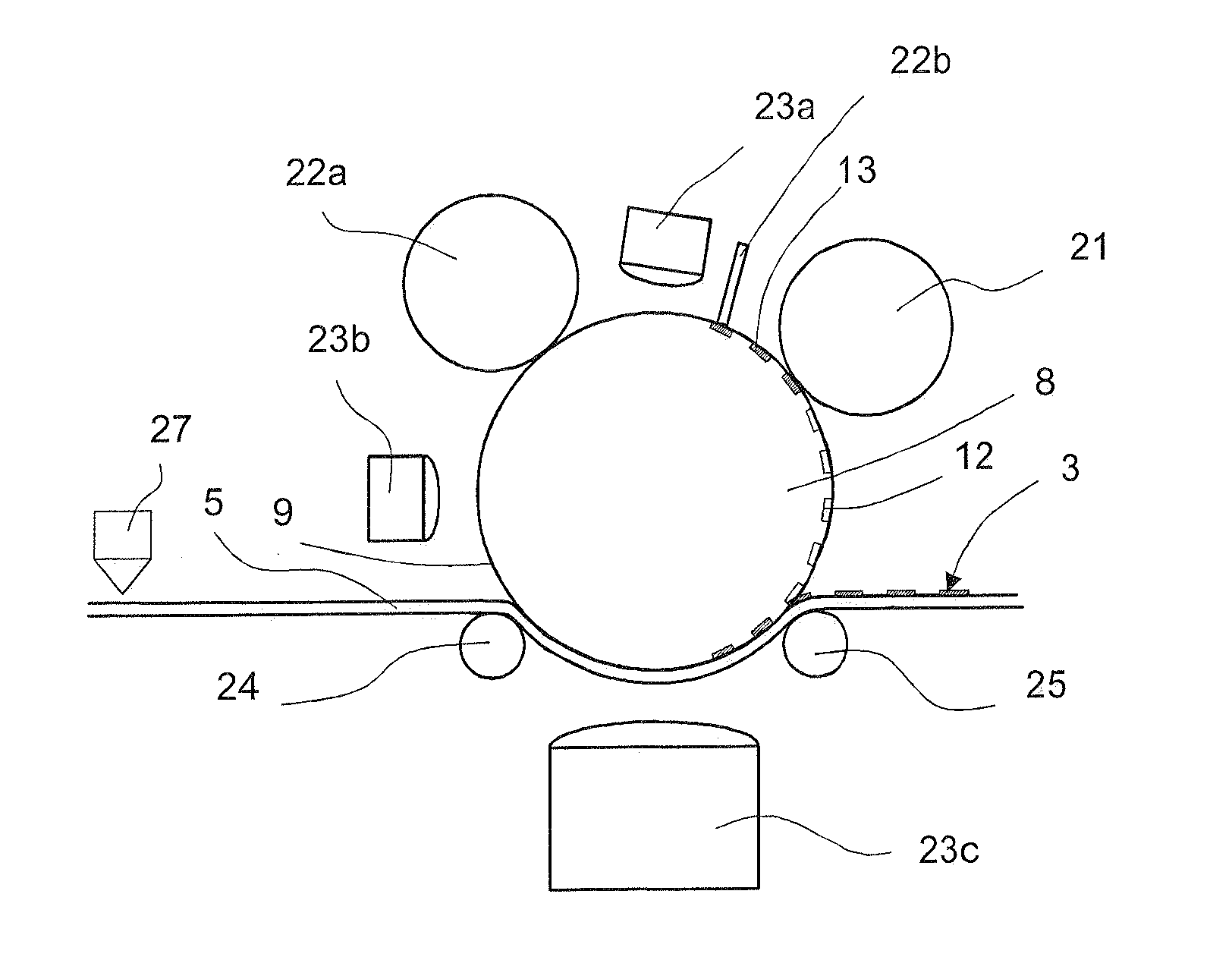

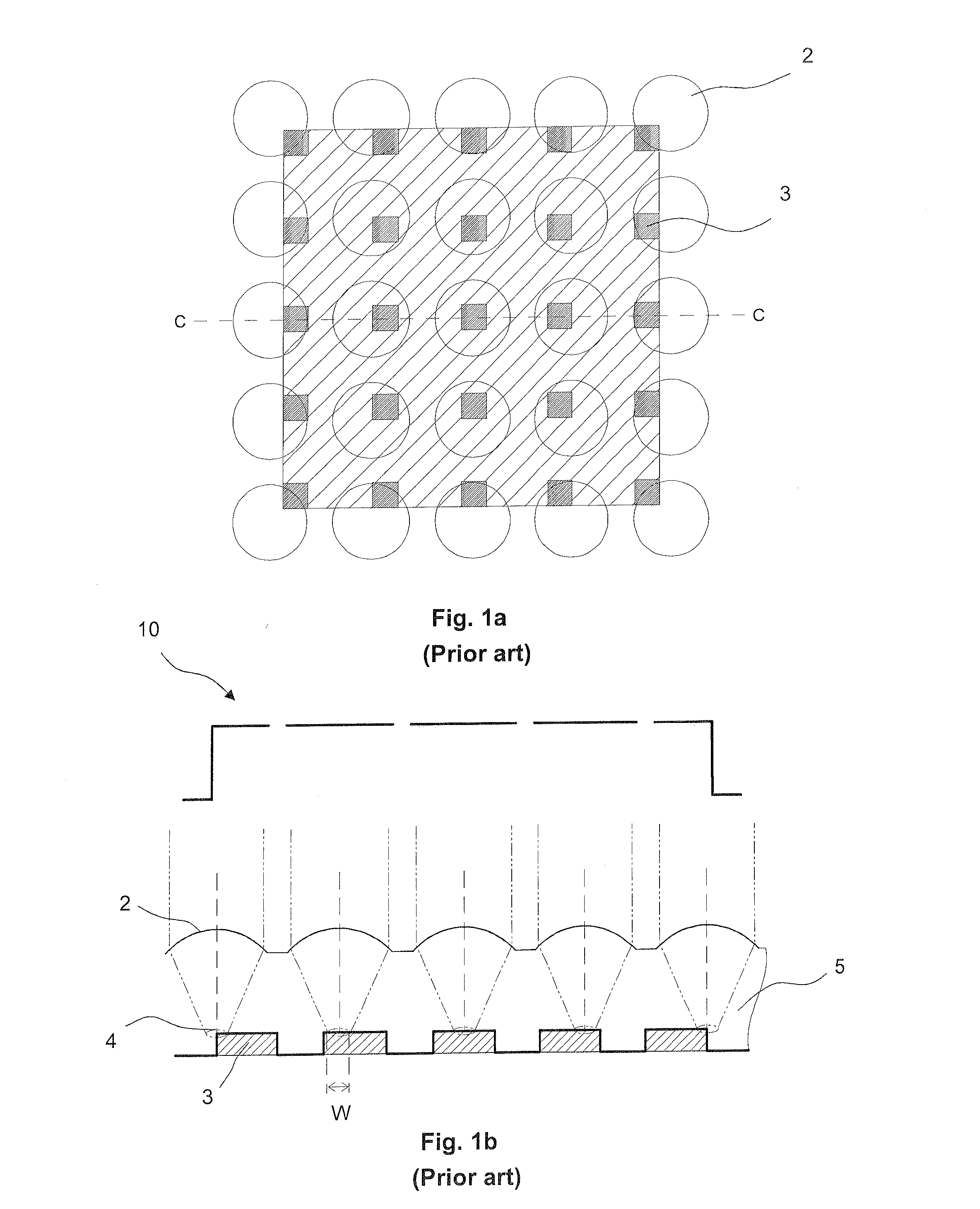

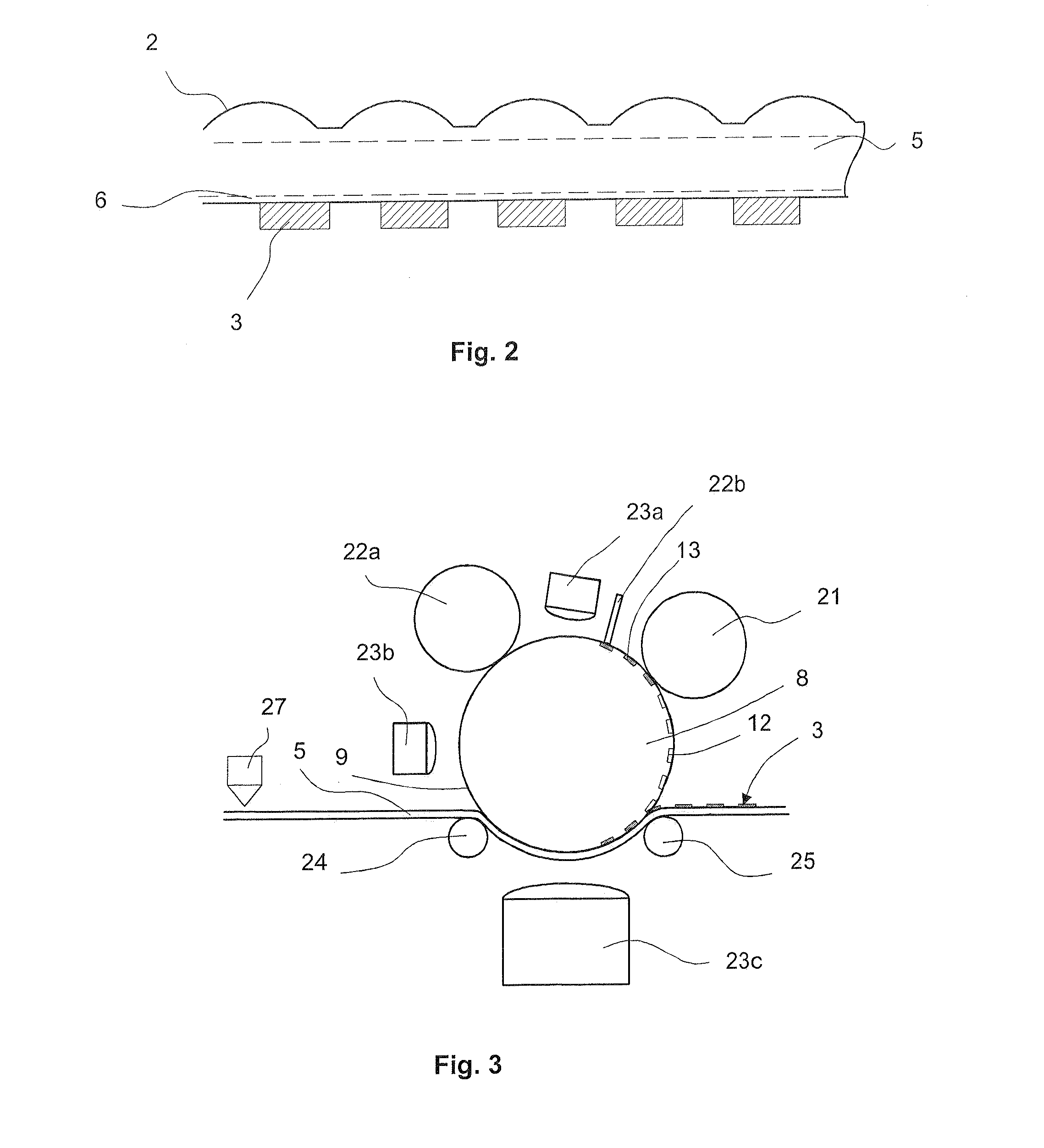

Method for printing product features on a substrate sheet

ActiveUS20120321793A1Increased dimensional tolerancesLess artefactRotary intaglio printing pressPattern printingEngineeringImage object

Owner:ROLLING OPTIKS AB

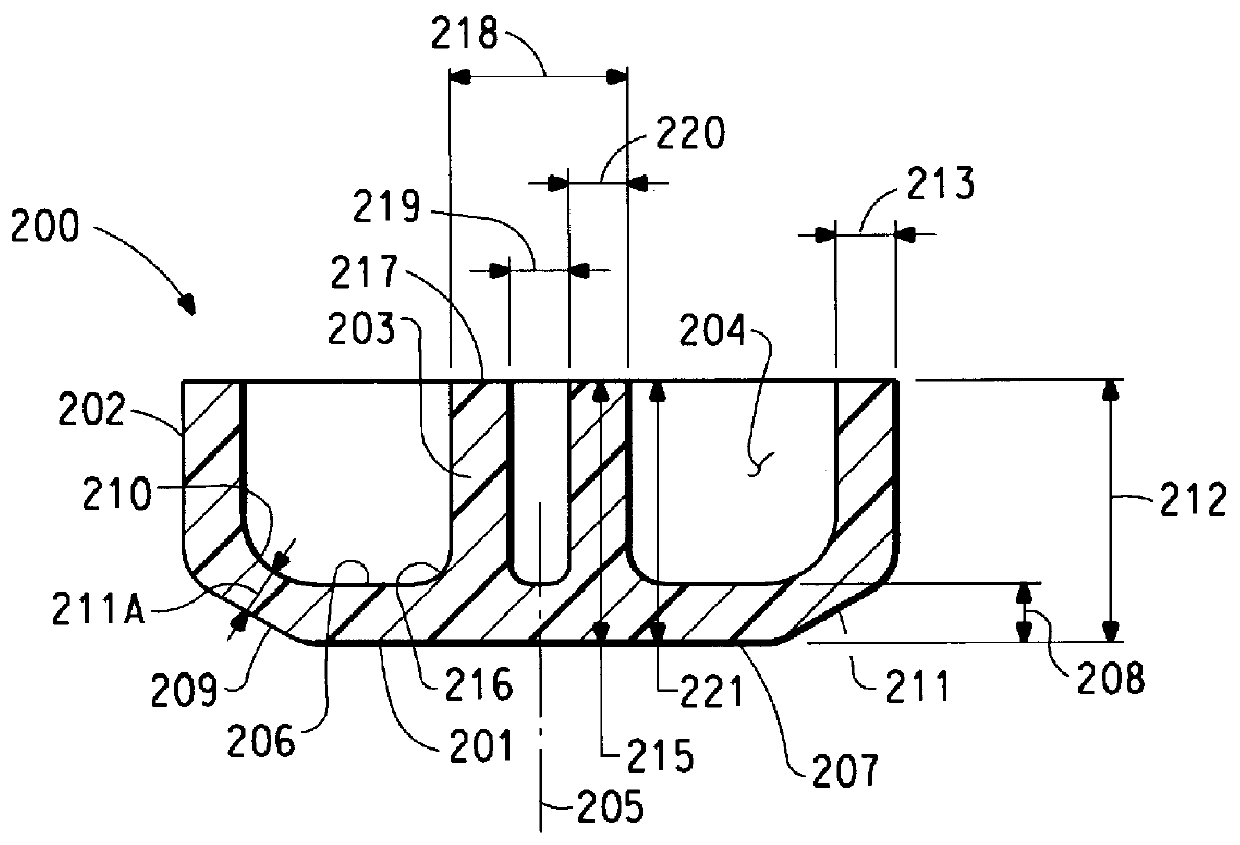

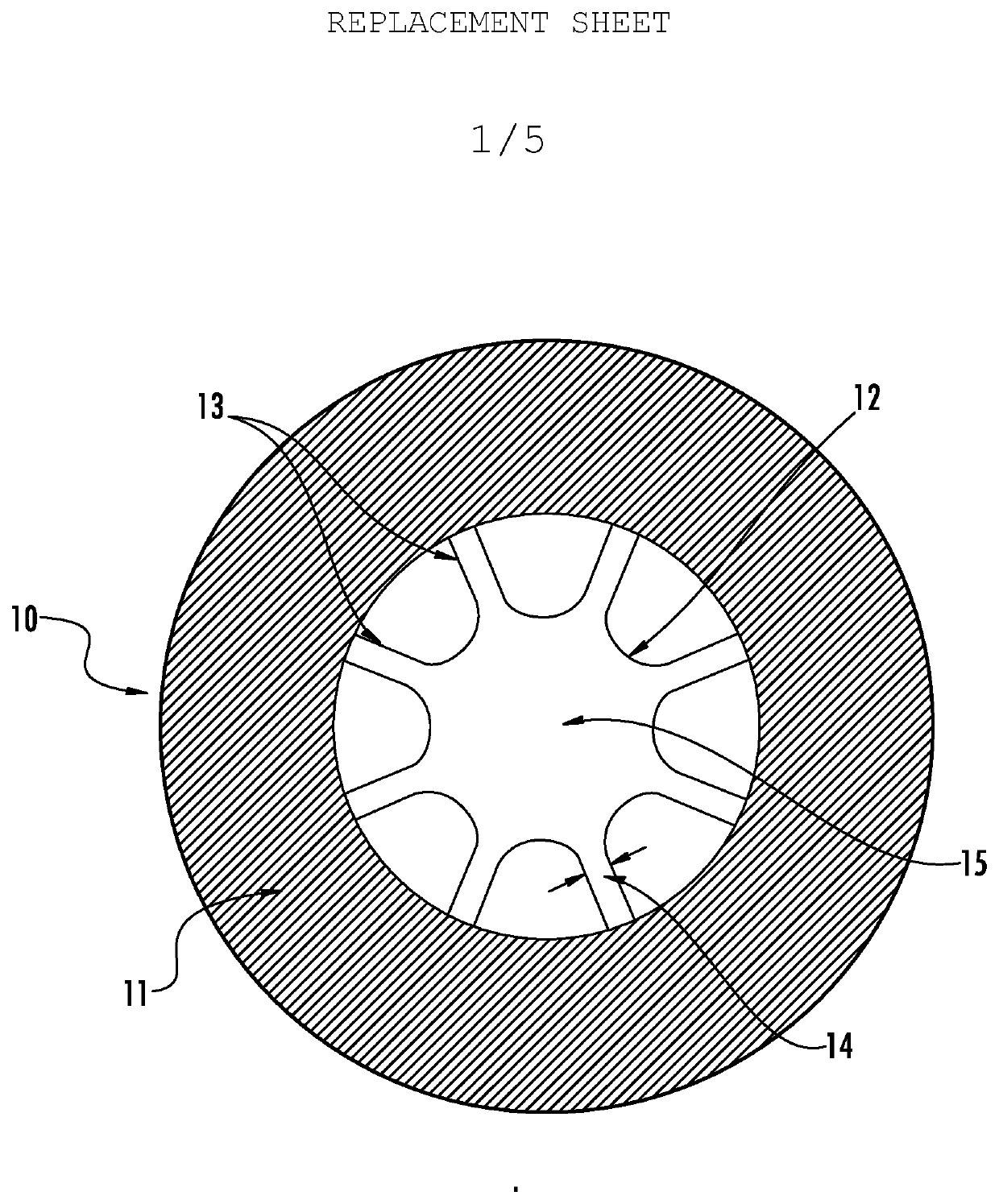

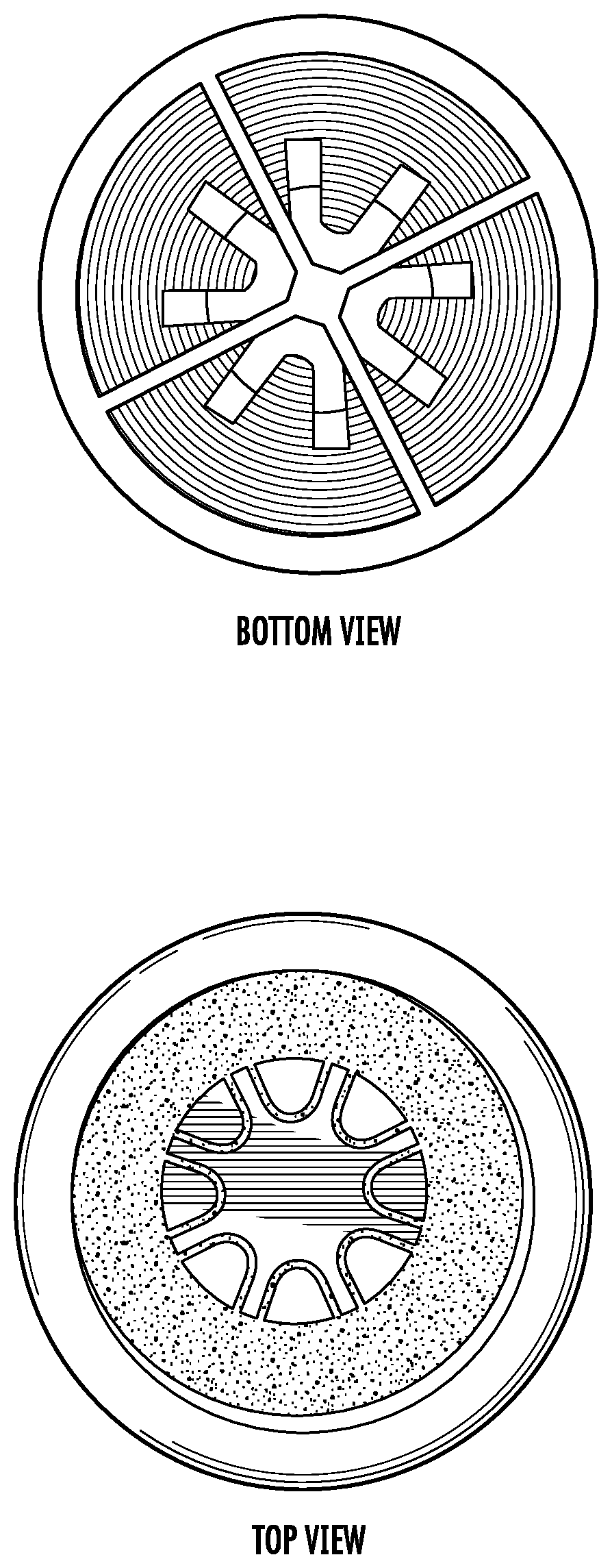

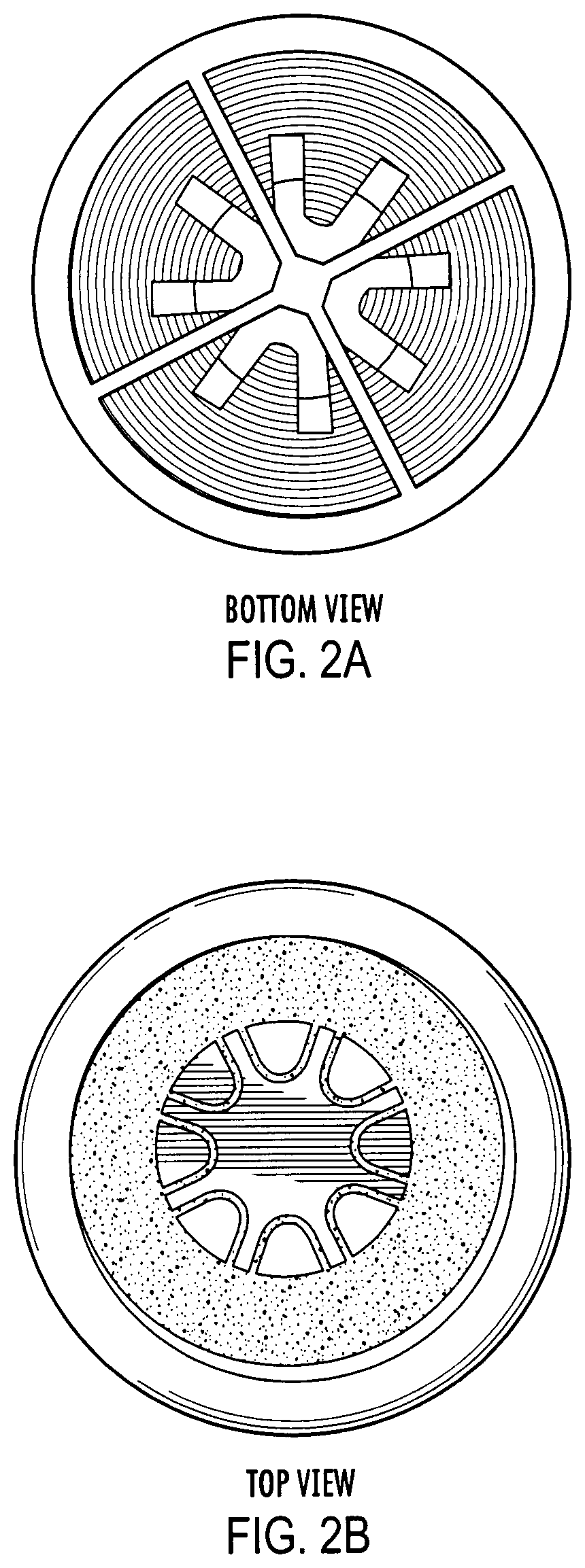

Uniform cross-section and ribbed thermoplastic compressor valve

InactiveUS6024126AReduce partIncreased dimensional tolerancesPositive displacement pump componentsCheck valvesEngineeringMechanical engineering

A uniform cross-section and ribbed thermoplastic compressor valve which can be used as a discharge valve for a compressor and has internal rib structure and uniform wall thickness. The valve member can be made of high-performance polymeric resin such as polyimide. The valve member comprises a base member, an annular wall member, a central member protruding from the base member, and a plurality of internal wall members. The internal wall members provide the internal rib structure which strengthens the valve member and allows for light-weight construction. Preferably, there are six internal wall members and the central member has a cavity.

Owner:EI DU PONT DE NEMOURS & CO

Stenting ring with marker

A stenting ring made of a tube or rolled-up sheet that has a characteristic wall thickness. The ring defines a lumen and is equipped with at least one marker made of a material different from that of the ring. The ring is expansible from a radially compact disposition with a relatively small circumference to a radially expanded disposition with a relatively large circumference. The ring exhibits in the compact disposition a serpentine arrangement of succeeding struts lying in alternate opposite directions to the longitudinal axis of the lumen. The marker has a thickness in the radial direction of the ring that is less than the characteristic wall thickness, and has a width that extends circumferentially around an arc of the ring. The marker is attached to the ring at a zone located at a point intermediate in the extent of said arc. The marker overlaps with a respective one of said struts, at each end of its circumferential arc, when the ring is in the compact disposition, the respective struts moving away from each other, and from the marker, when the ring expands towards said radially expanded disposition.

Owner:CR BARD INC

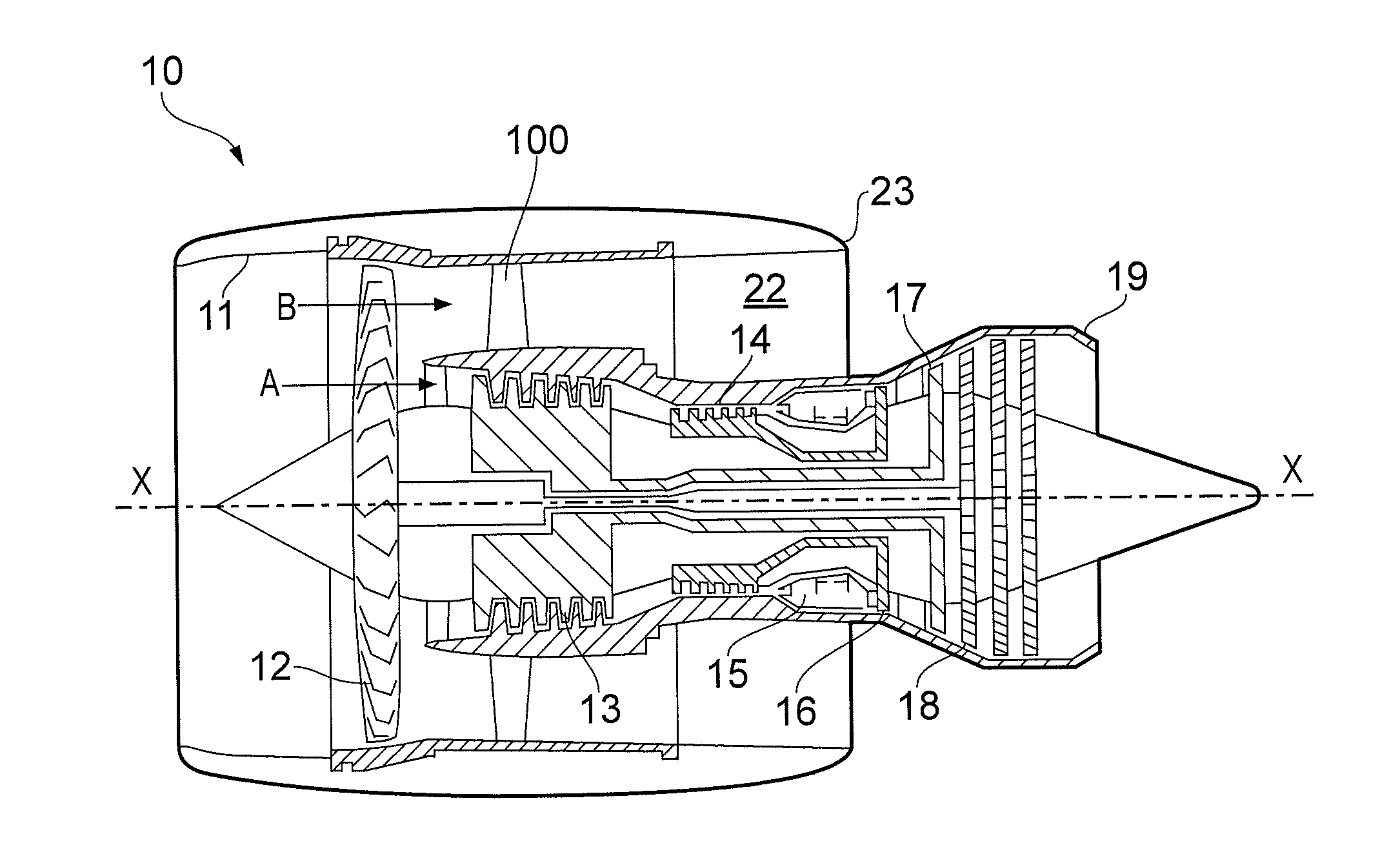

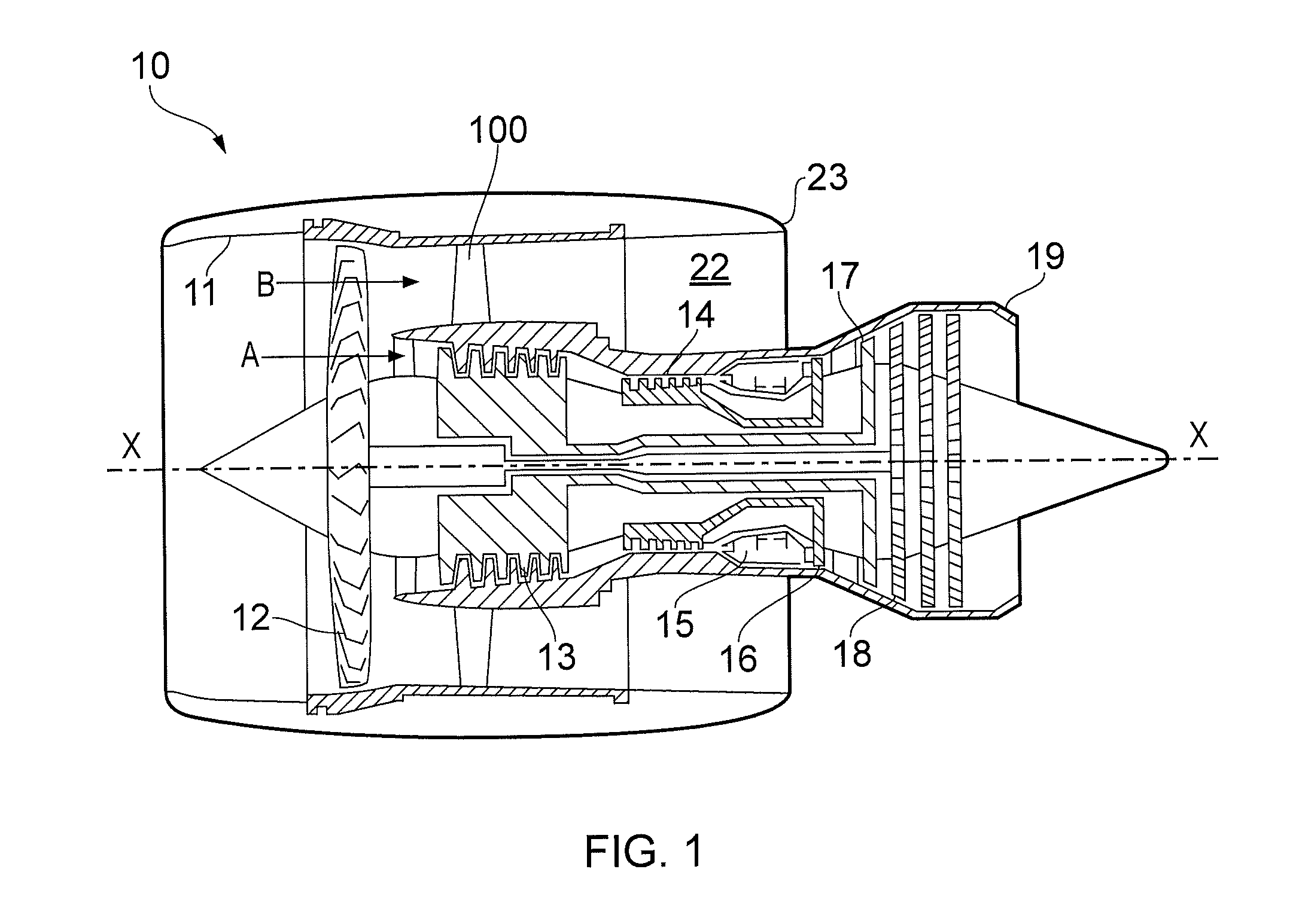

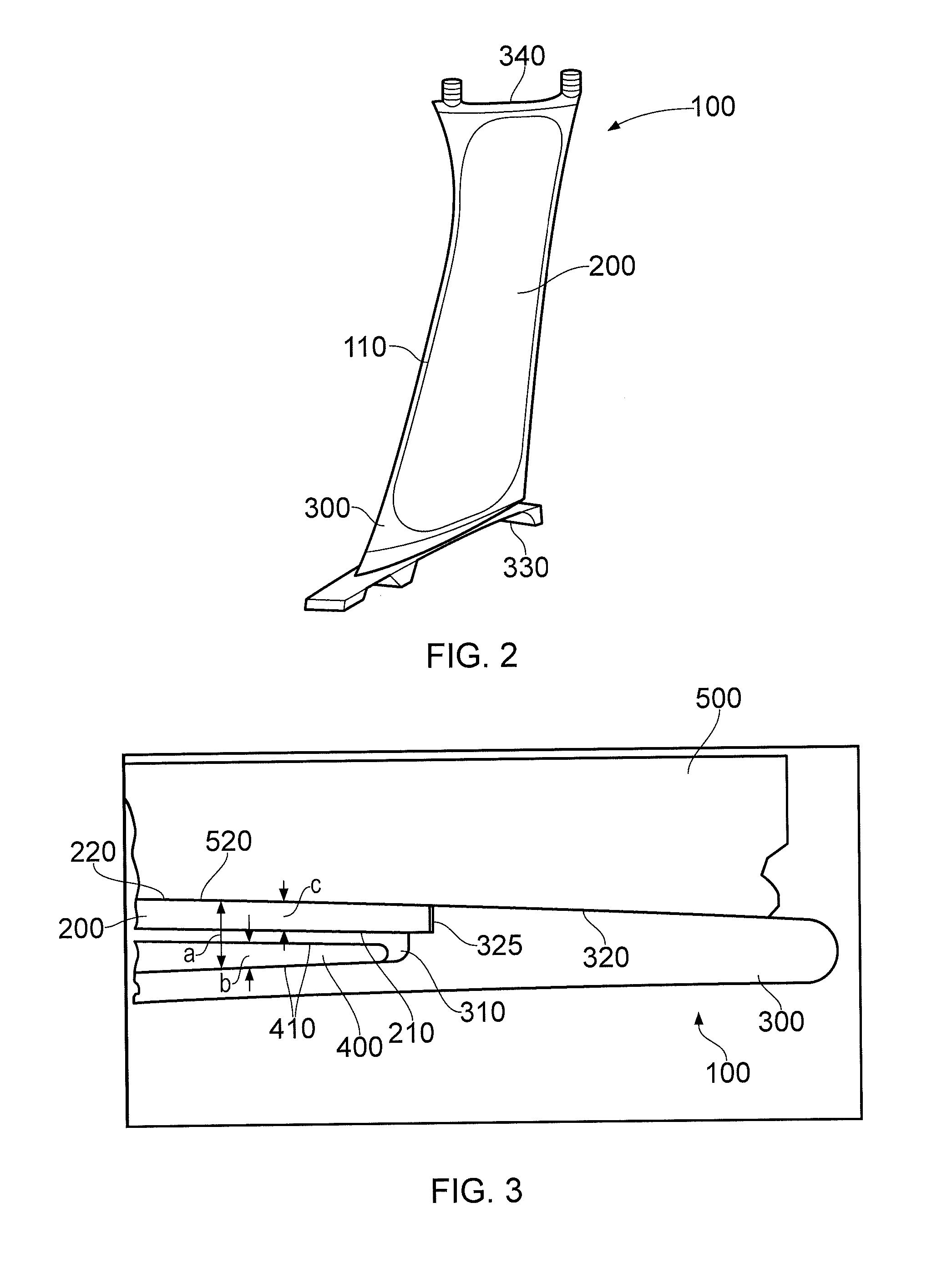

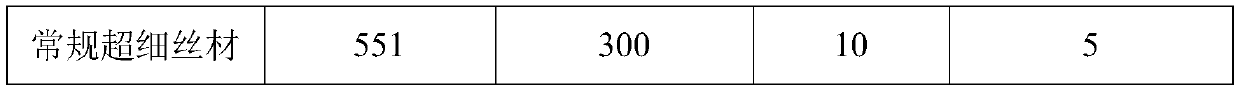

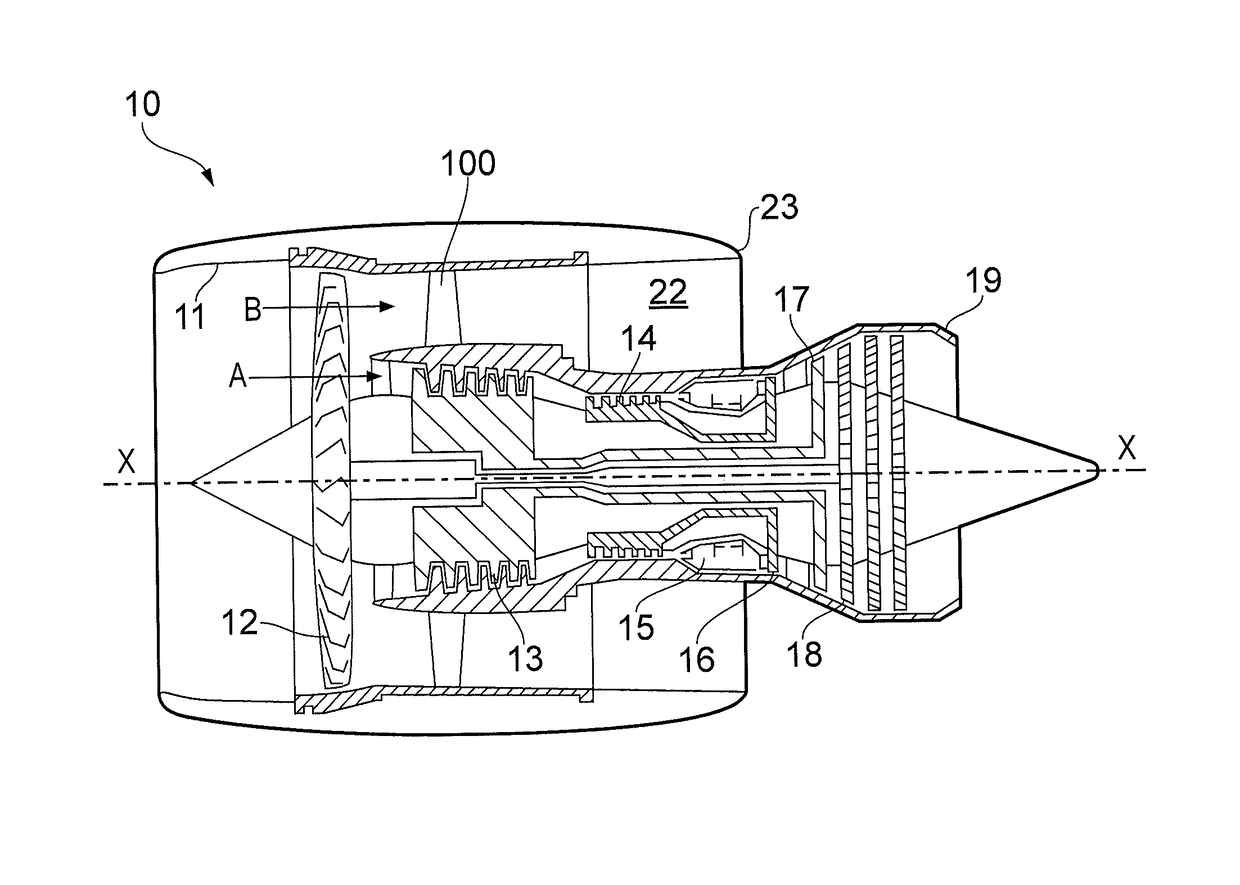

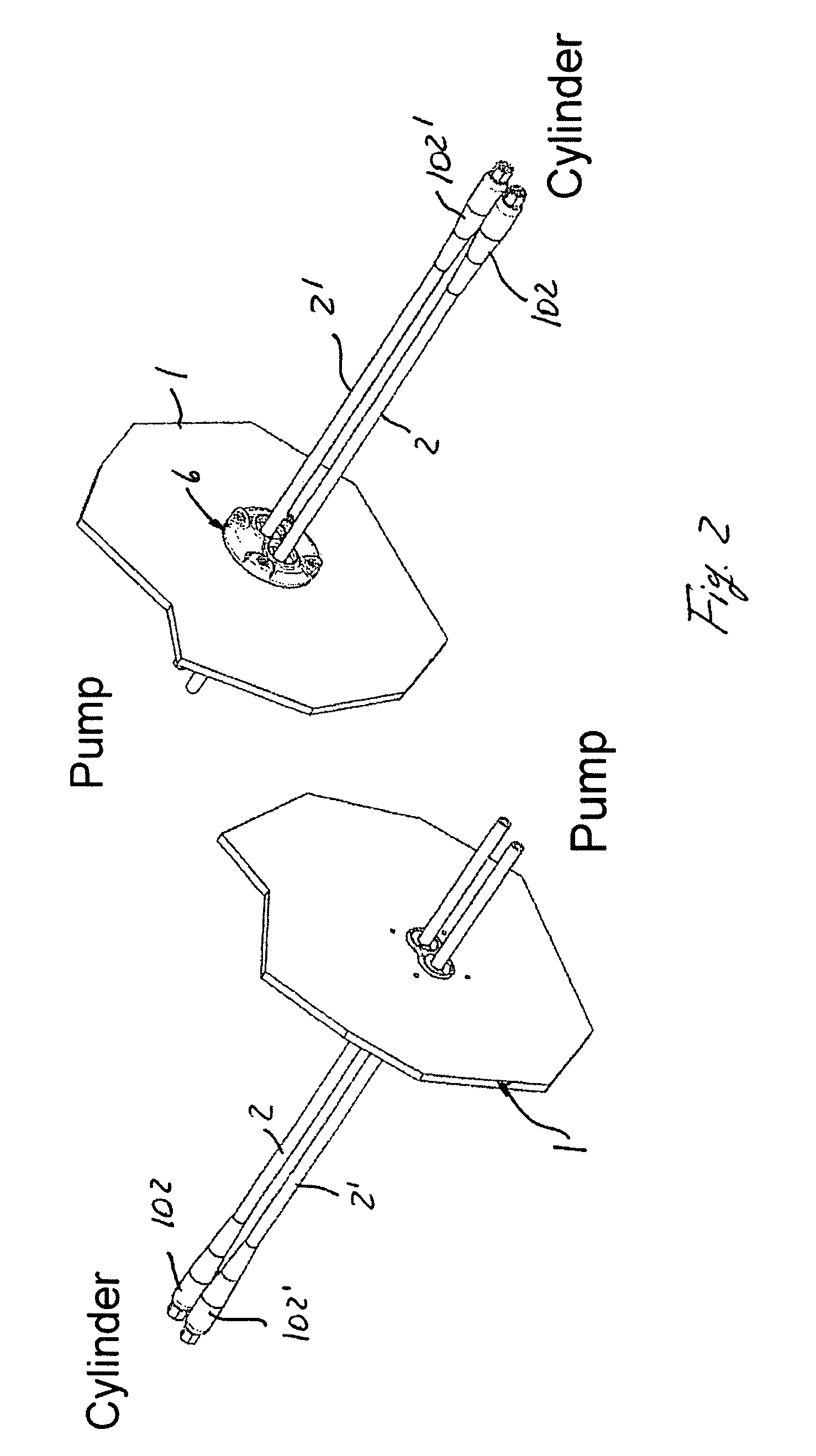

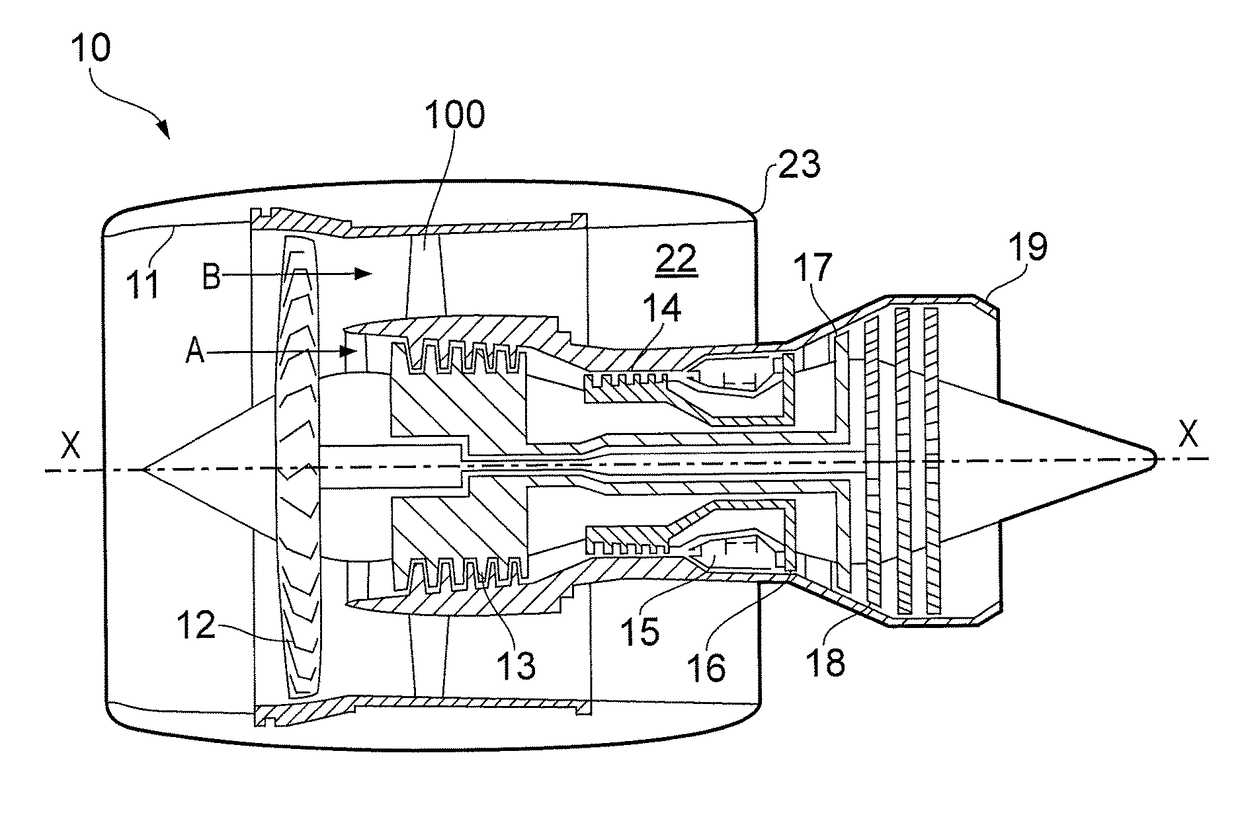

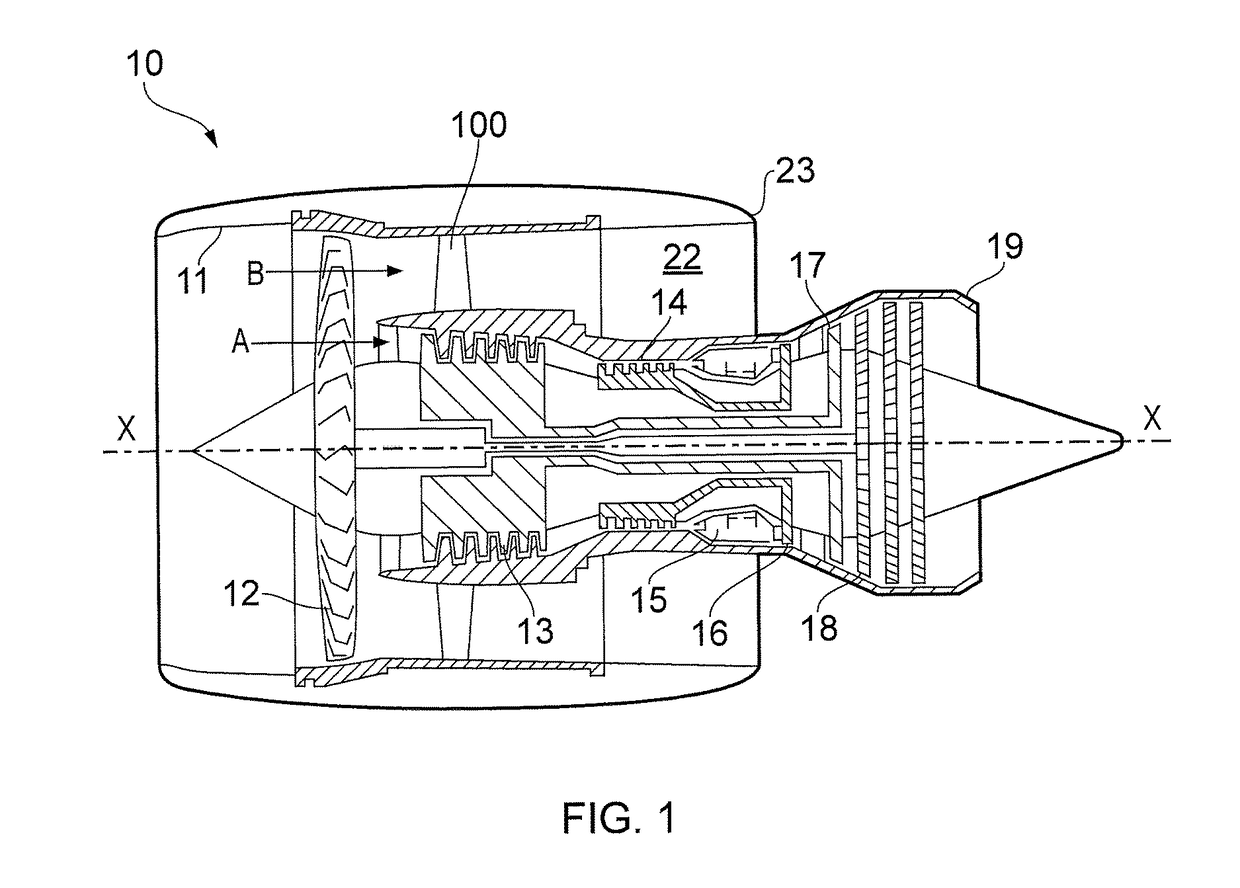

Manufacture of filled aerofoil

ActiveUS20150125308A1Increased dimensional tolerancesReduce material wasteBlade accessoriesMetal-working apparatusEngineeringTurbine

A method of manufacturing a filled aerofoil component (100) for a gas turbine engine (10) comprises using a capping panel (200) to cover a pocket (310) in a pocketed aerofoil body (300). During manufacture, a pre-formed filler insert (400) is provided to support the capping panel (200) in the correct position. This ensures that the outer surface of the capping panel (200) is located as accurately as possible. This means that the capping panel (200) can be made to be as thin as possible, which in turn reduces weight and material wastage. The pre-formed filler insert (400) provides a lightweight core for the finished aerofoil component in use.

Owner:ROLLS ROYCE PLC

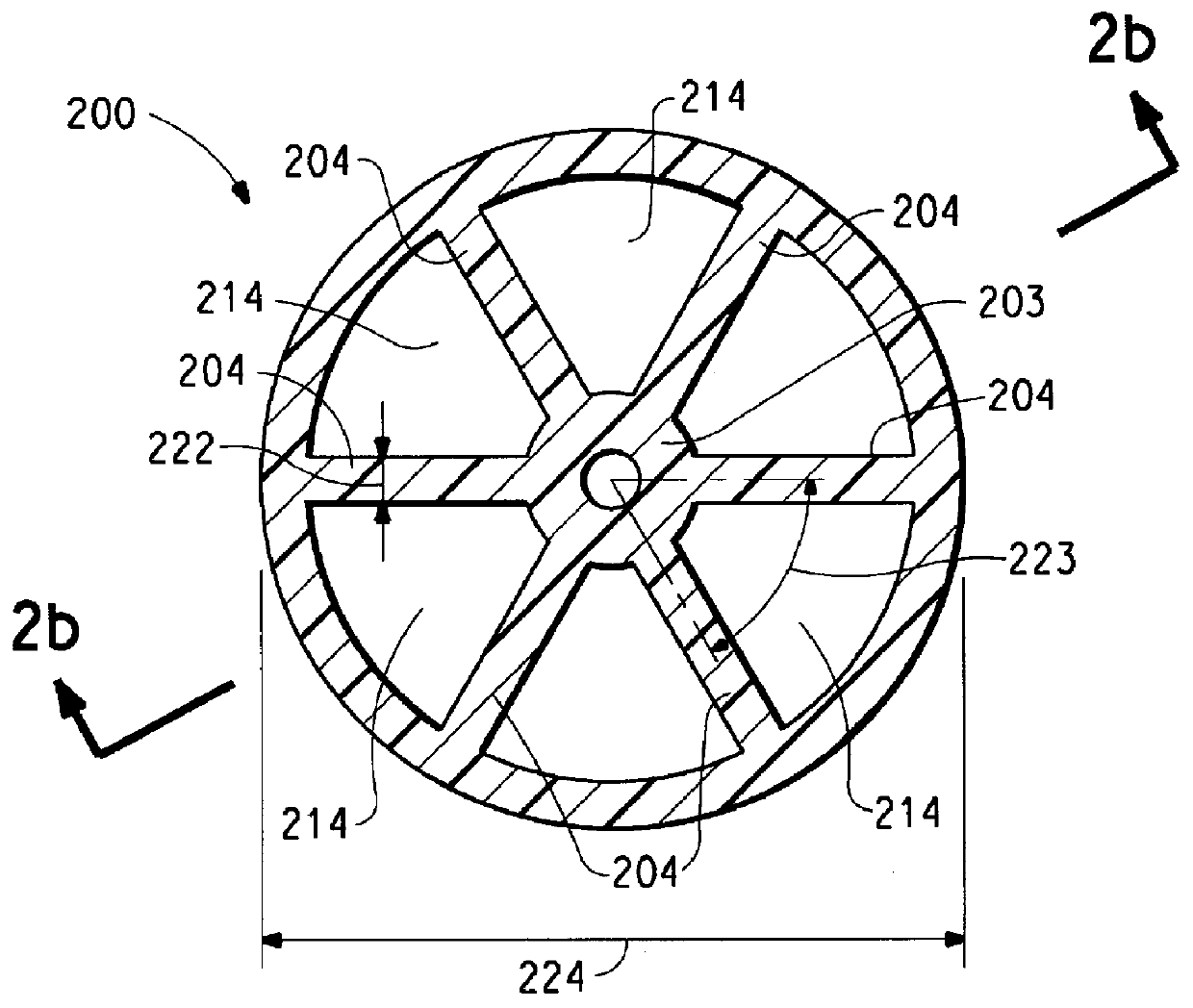

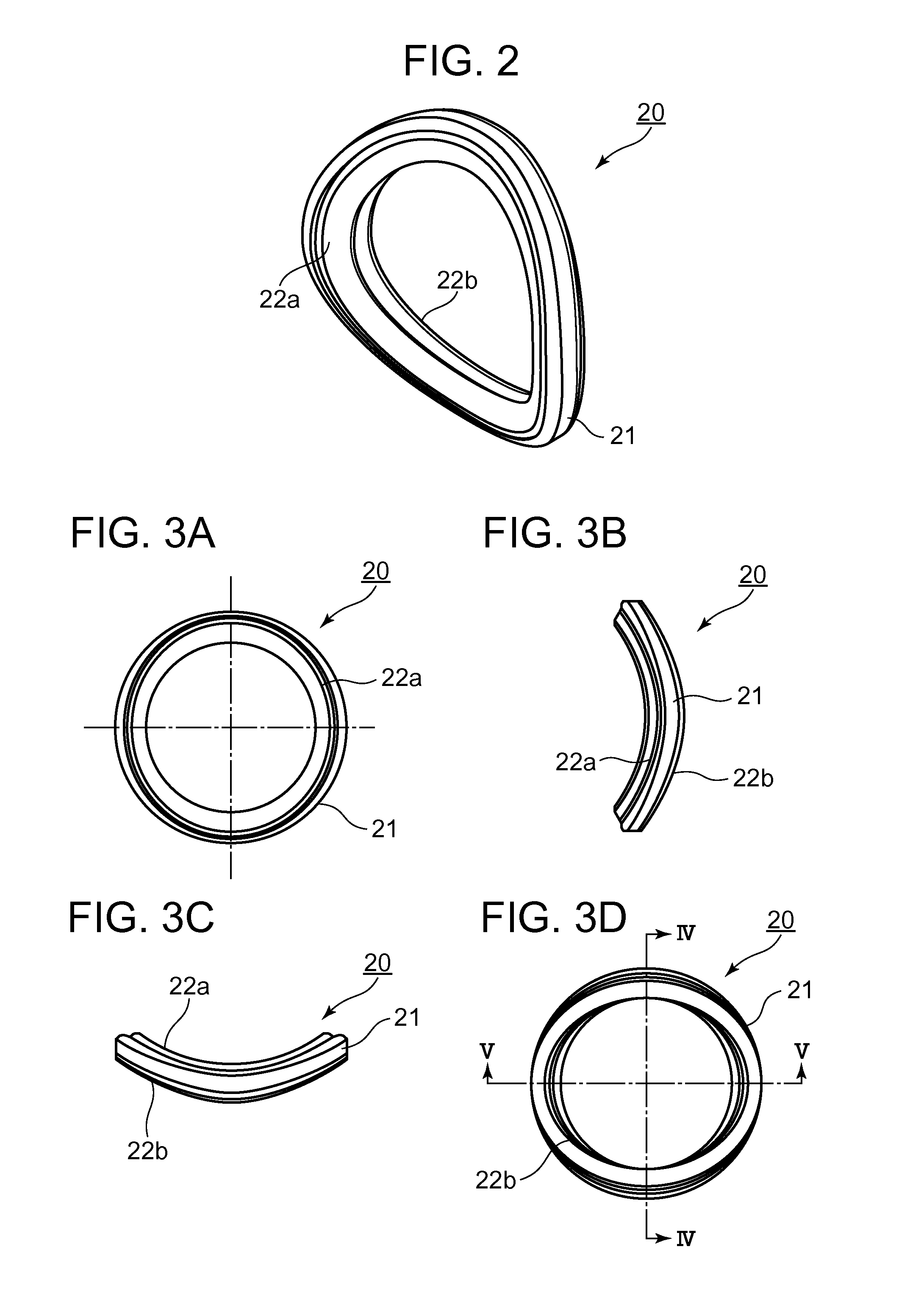

Rotary valve seal member and rotary valve using same

A rotary valve seal member that is held in sliding contact with a valve element that rotates, turns, or slides within a valve housing of a rotary valve and is capable of providing a secure seal as the valve element operates. The seal member has the structure of a three-dimensional ring having a cross-section composed of an oval portion, aligned with a normal line to the outside of the valve element and having a bulge at the end that protrudes and presses against the outer surface of the valve element, and a rectangular portion, into which the oval portion is integrated in a state in which the oval portion is aligned with the normal line to the outside of the valve element, that is retained within an annular groove with the outer side of the rectangular portion in contact with the wall of the annular groove.

Owner:NIPPON THERMOSTAT CO LTD

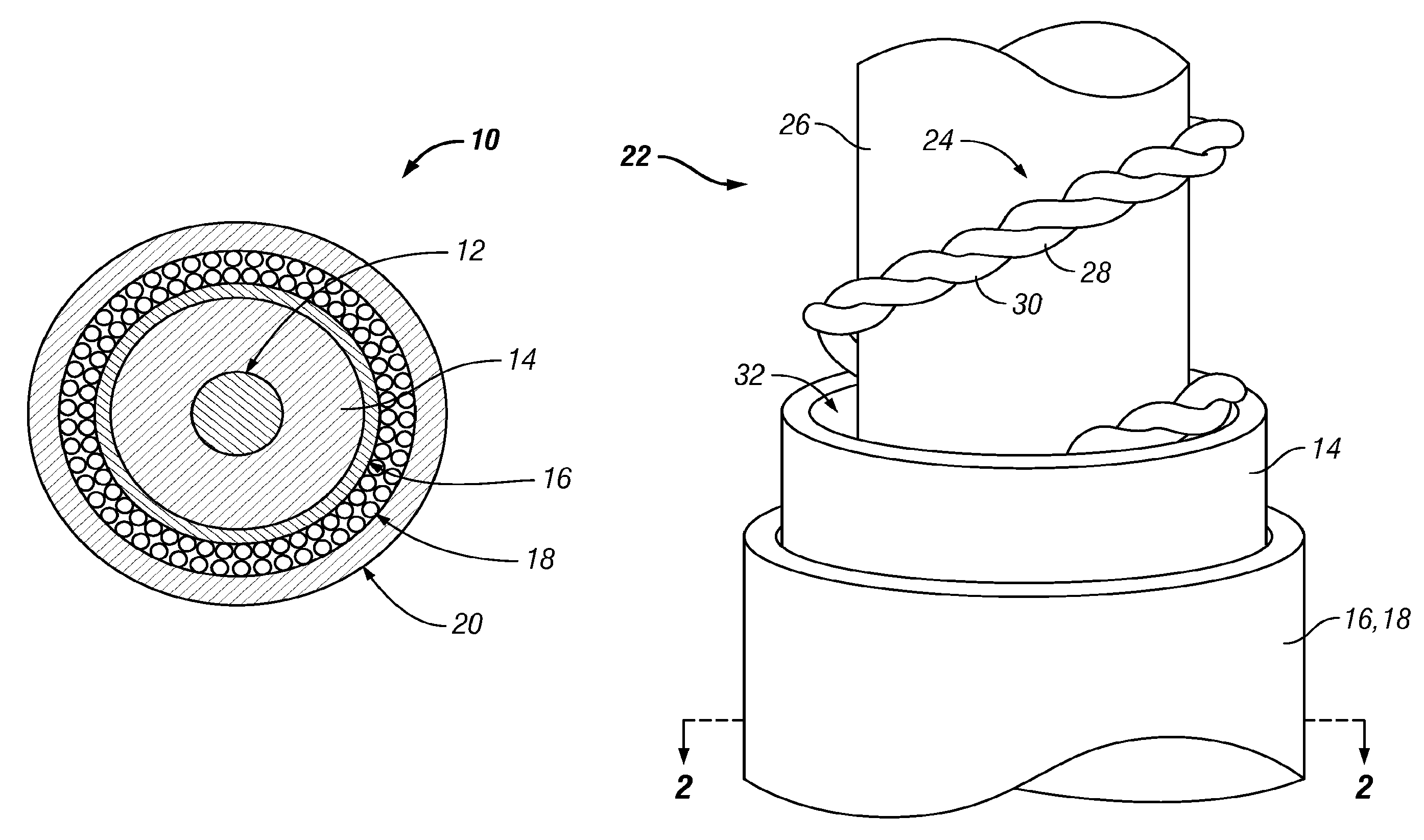

Ultra high-speed coaxial cable

ActiveUS7795536B2Low dissipation factorEasy to manufacturePlastic/resin/waxes insulatorsCable insulation constructionUltra high speedCoaxial cable

Owner:TEMP FLEX L L C

Outer rotor motor

ActiveUS20090115276A1Thin materialLow costMagnetic circuitSliding contact bearingsEngineeringMachining

An outer rotor motor has a bearing housing with reduced machining and material costs, can be assembled with high accuracy, and has favorable durability. A bearing is attached to an inner circumferential surface of a housing main body that has been formed in a cylindrical shape by plastic deformation caused by press molding a metal matrix. At least one protruding surface is formed by plastic deformation so as to protrude further outward than the housing main body, and the stator core is attached to the outer circumference-side of the at least one protruding surface.

Owner:SHINANO KENSHI

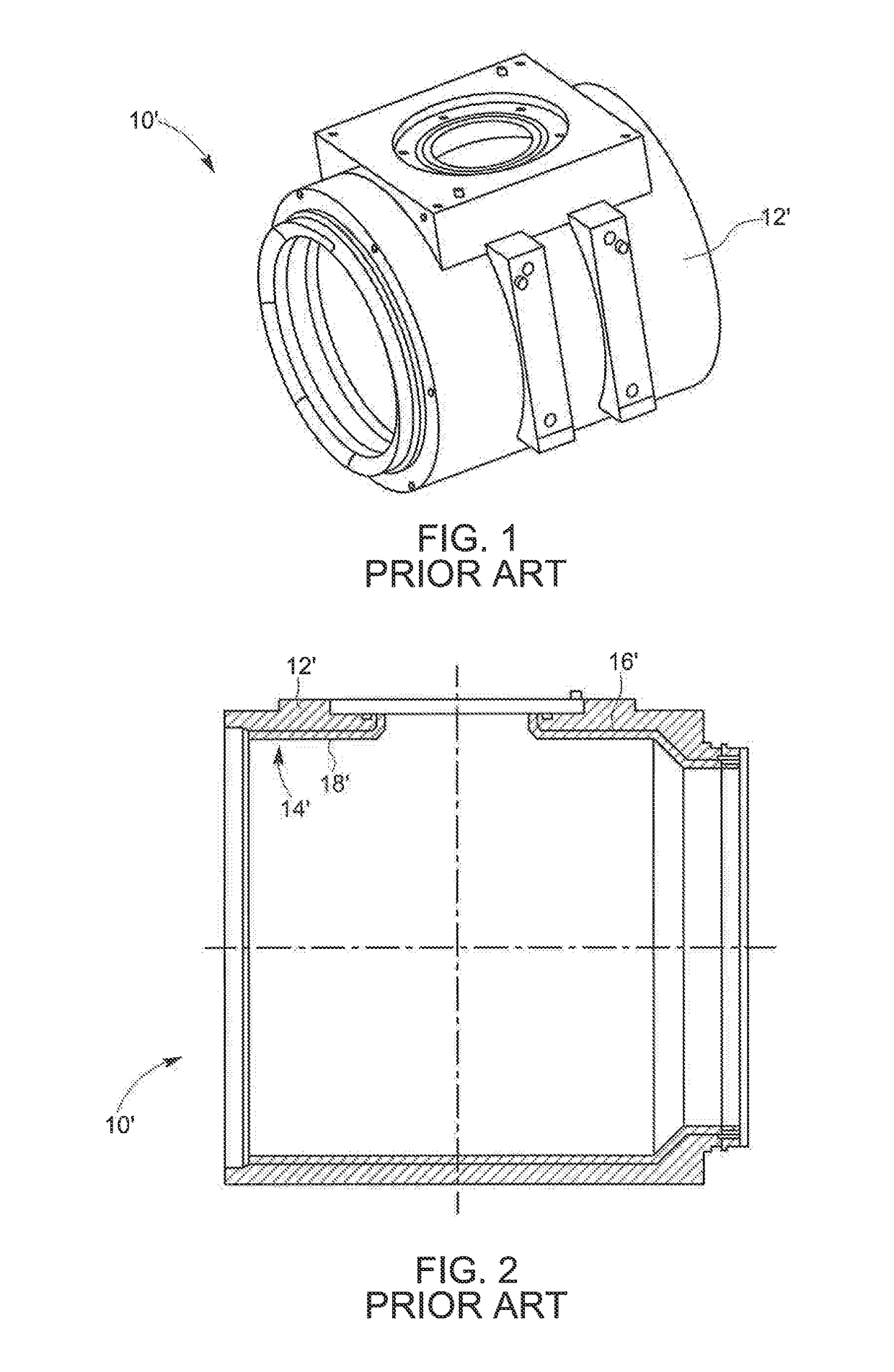

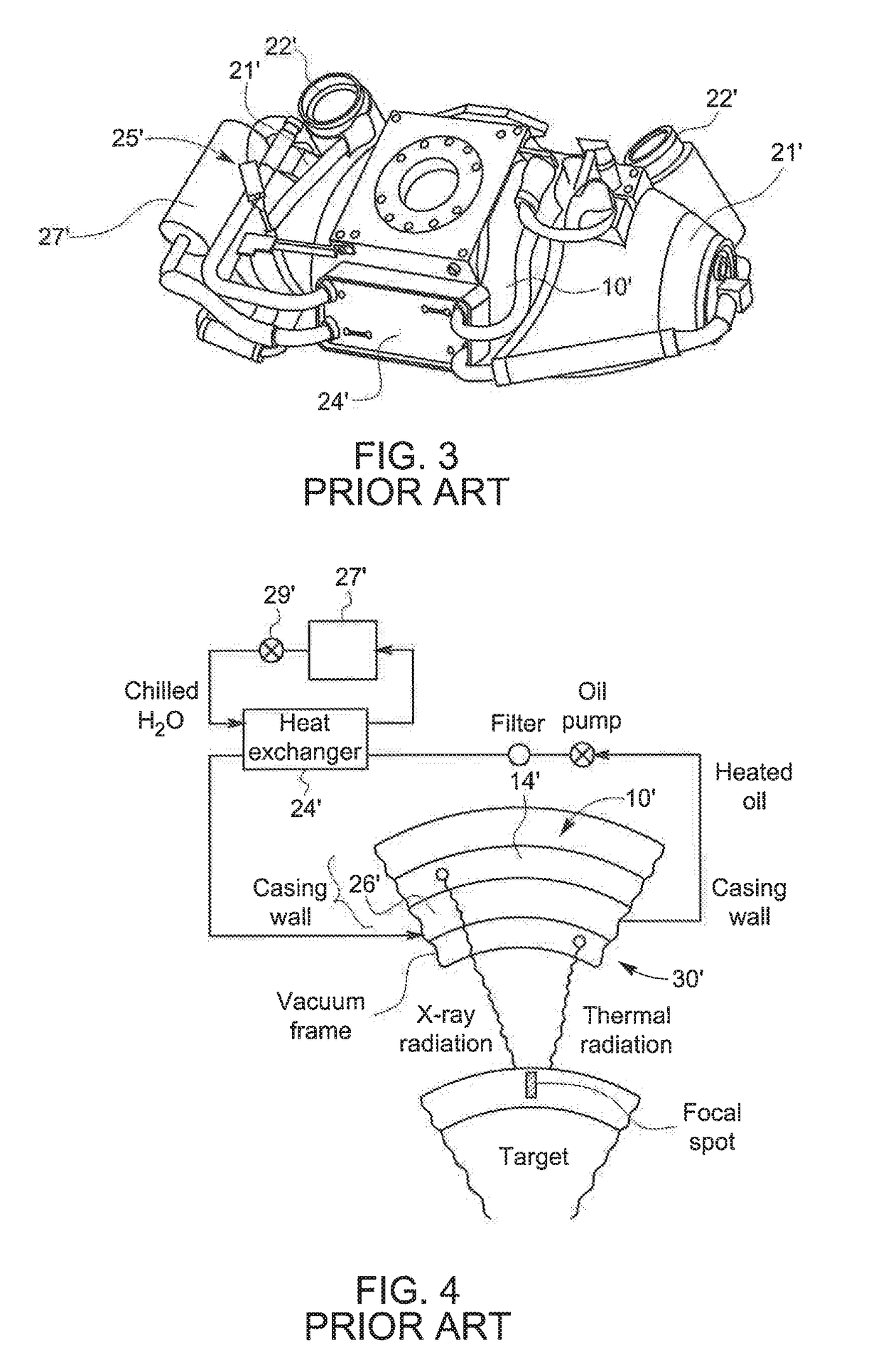

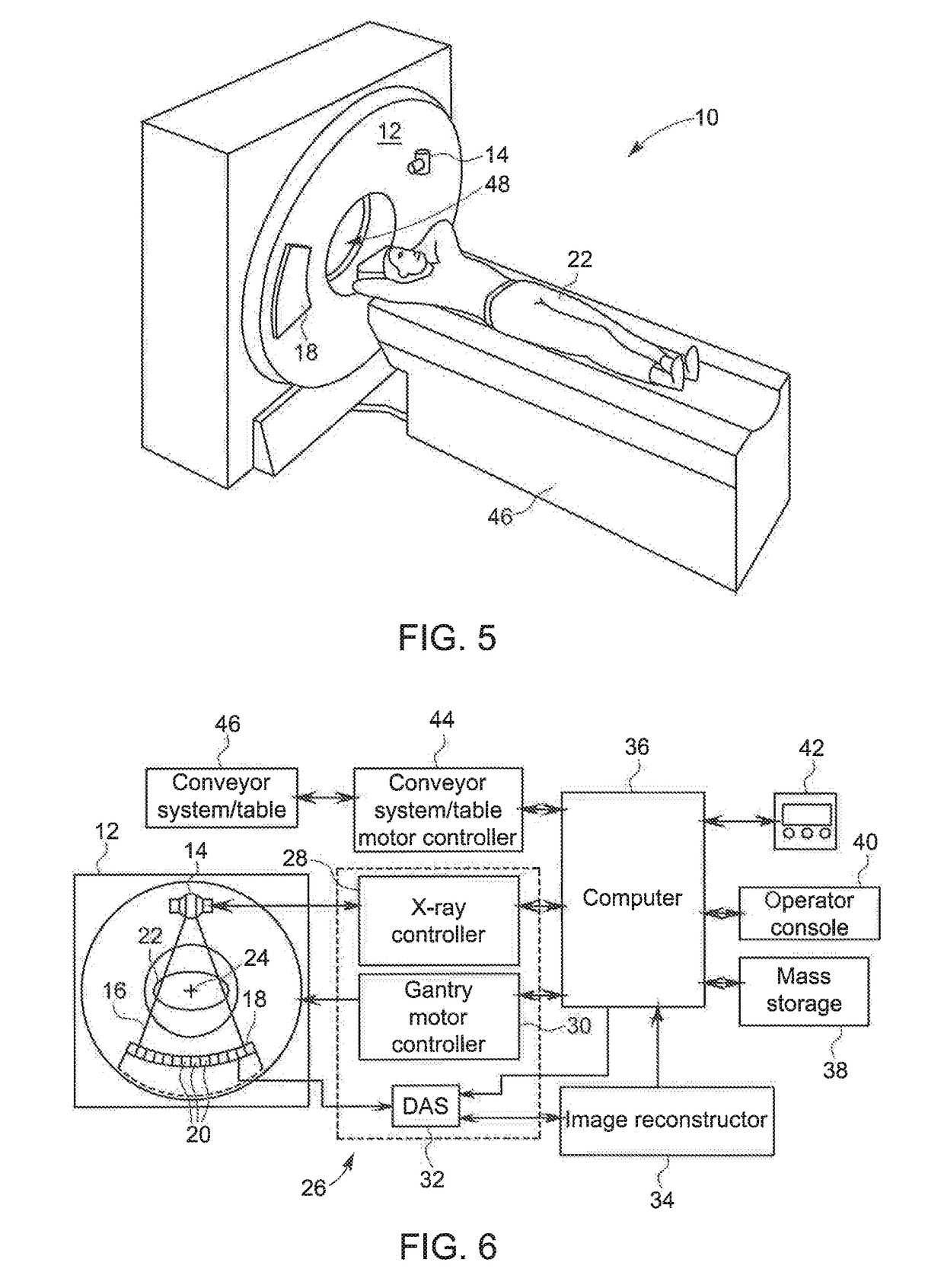

X-Ray Tube Casing

ActiveUS20180376574A1Reduce weightSmall sizeAdditive manufacturing apparatusX-ray tube electrodesFiller metalCooling fluid

An x-ray tube casing is provided which includes a central frame having internal passages to supply a cooling fluid directly to the casing without the need for an external dedicated heat exchanger. The cooling fluid flowing through the passages in the easing can thermally contact the dielectric coolant within the casing to cool the tube coolant during operation of the x-ray tube. The casing is formed in an additive manufacturing process to allow for tight tolerances with regard to the structure for the casing and the internal passages to reduce the size and weight of the casing. The casing can additionally be formed from a metal matrix including a metal with high x-ray attenuation and a filler metal. The metal matrix eliminates the need for a separate x-ray attenuation layer within the casing, further reducing the size, number of parts and assembly complexity of the casing.

Owner:GENERAL ELECTRIC CO

Hydraulic Damper With Compensation Chamber

InactiveUS20090321203A1Reduce the amount of solutionLow costSpringsShock absorbersMobile vehicleWorking fluid

The invention relates to a hydraulic damper, in particular for the suspension system of a motor vehicle, comprising a tube filled with working fluid; a piston assembly slidably positioned inside the tube; a fluid compensation chamber located outside of the tube, and a base valve assembly at the end of the tube for controlling the flow of working fluid between the tube and the compensation chamber. A compression valve module added between the piston assembly and the base valve assembly allows the damping to increase during extremely fast compression strokes without modification of the other damper components, affecting neither tuning options nor performance in a normal operating range of piston velocities.

Owner:BWI CO LTD SA

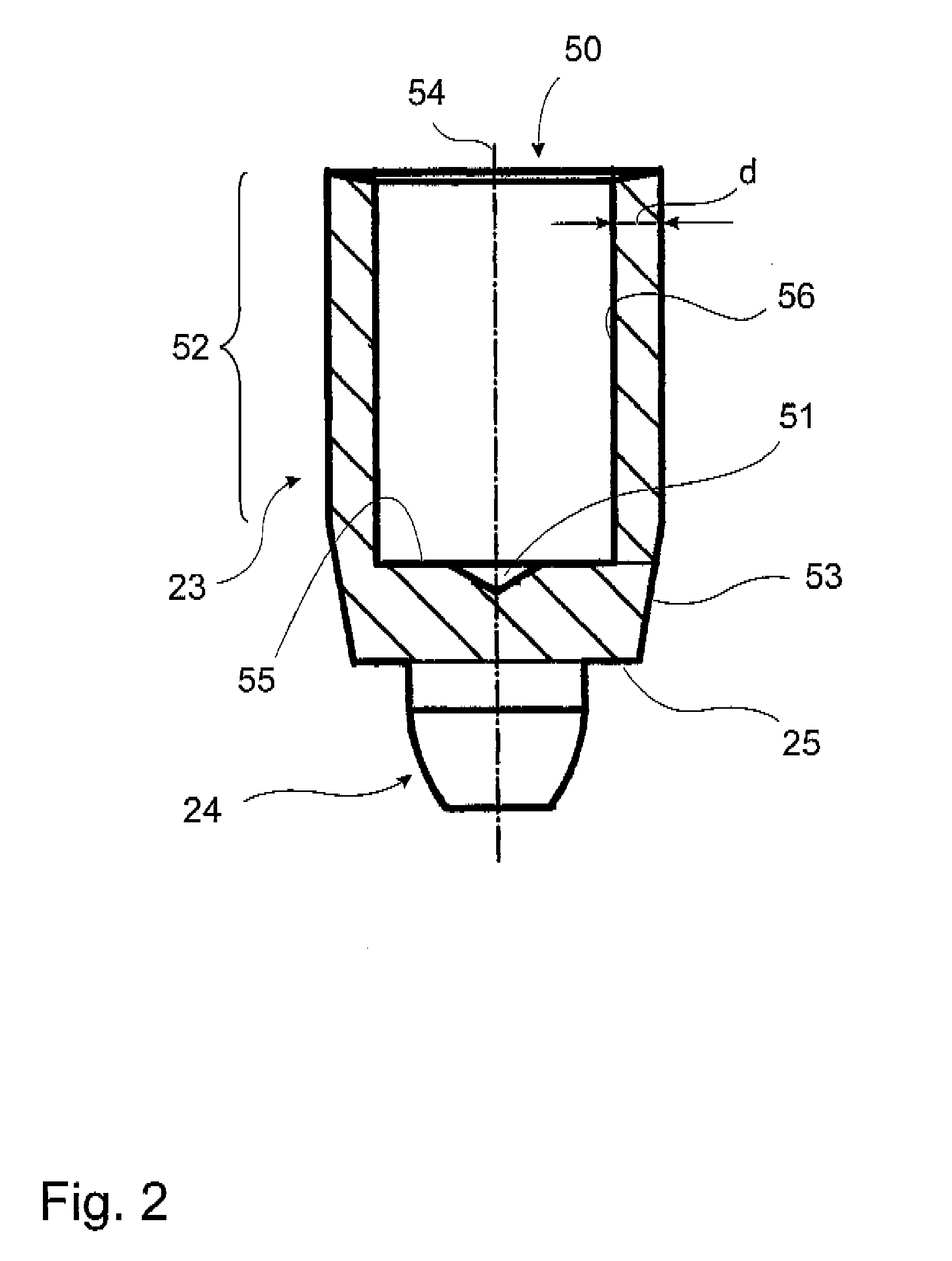

Electromagnet with adjusting screw

InactiveUS20130032742A1Adjustable effectIncreased dimensional tolerancesOperating means/releasing devices for valvesInductances/transformers/magnets manufacturePenetration depthElectromagnet

The invention refers to a solenoid with a coil that can be supplied with current, an armature supported movably in an armature housing that can be moved by a magnetic field resulting from supplying the coil with current, a magnetic yoke, an armature spring and an adjustment pin that can be inserted in the magnetic yoke, wherein the armature spring is supported, on the one hand, on the adjustment spring, and, on the other hand, on the armature, and the characteristic line of the solenoid can be adjusted through penetration depth of the adjustment pin in the magnetic yoke or the solenoid.

Owner:SVM SCHULTZ VERW

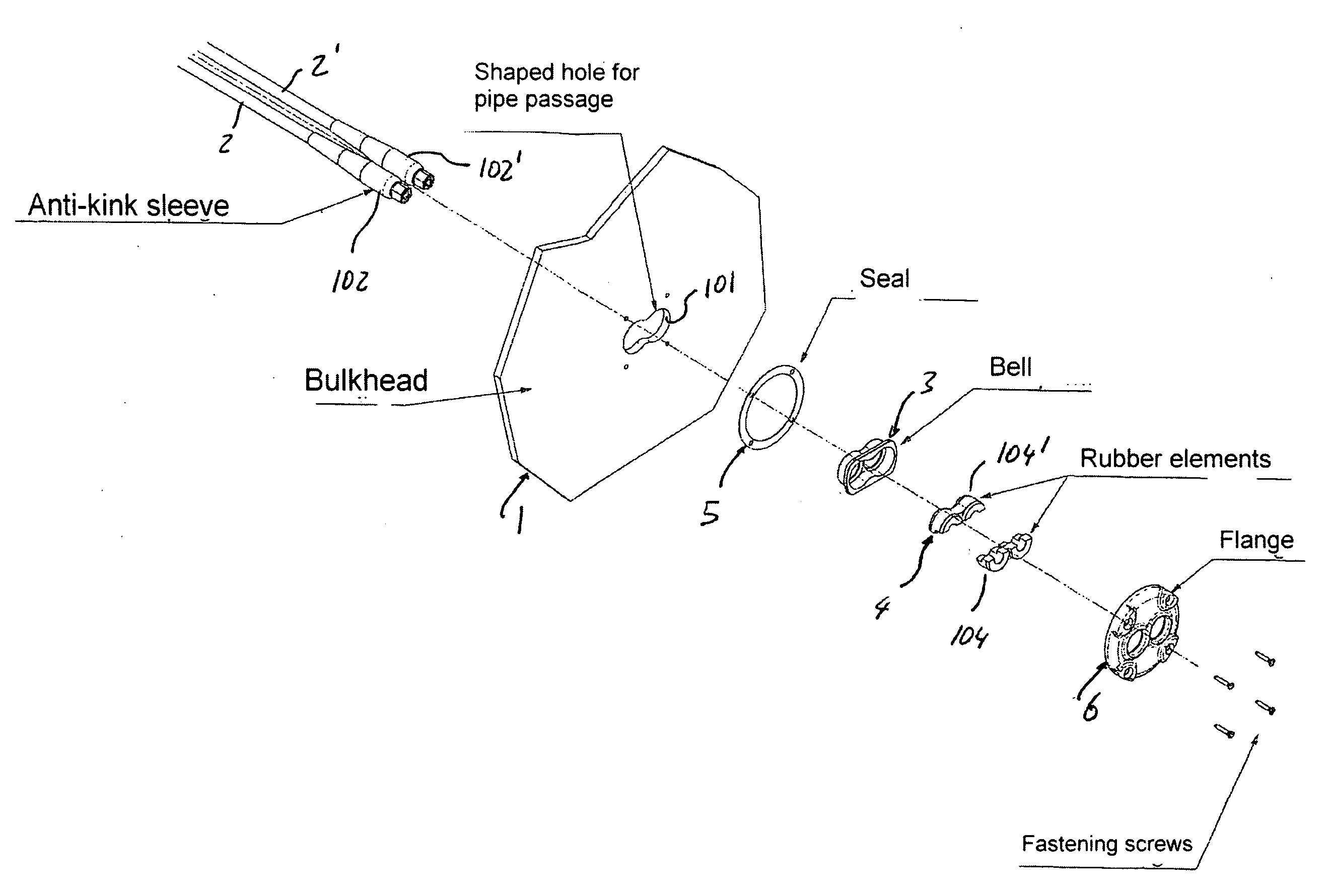

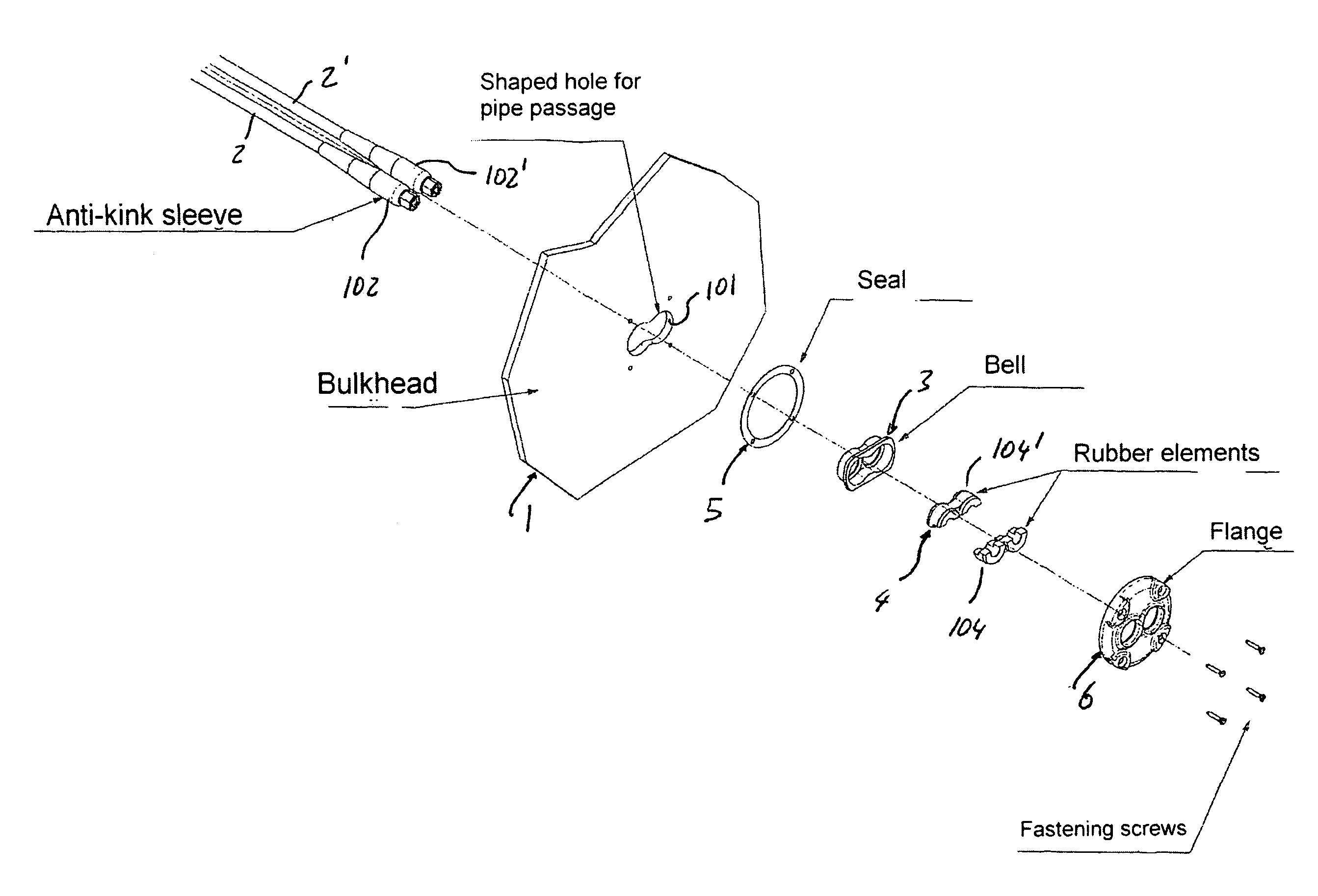

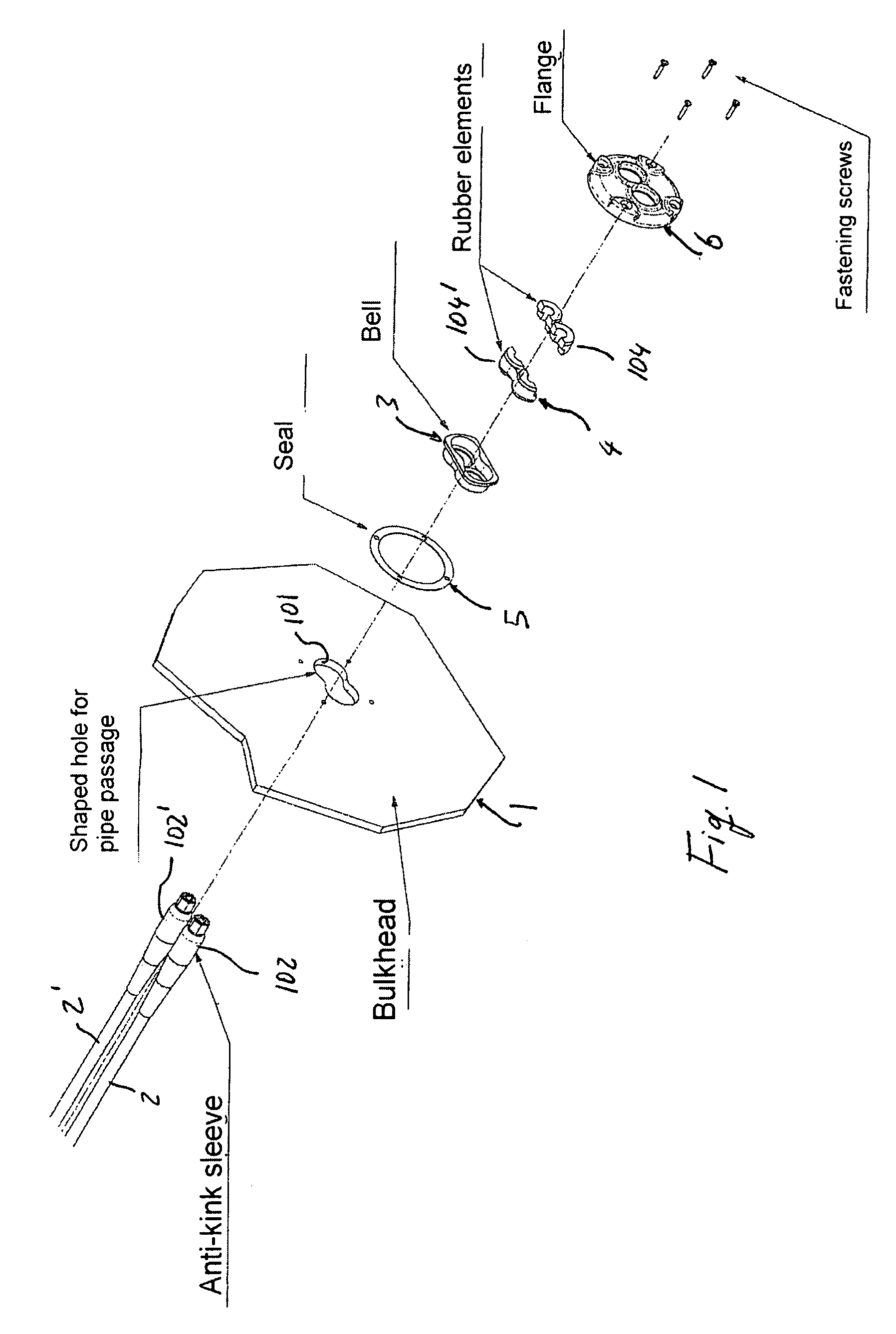

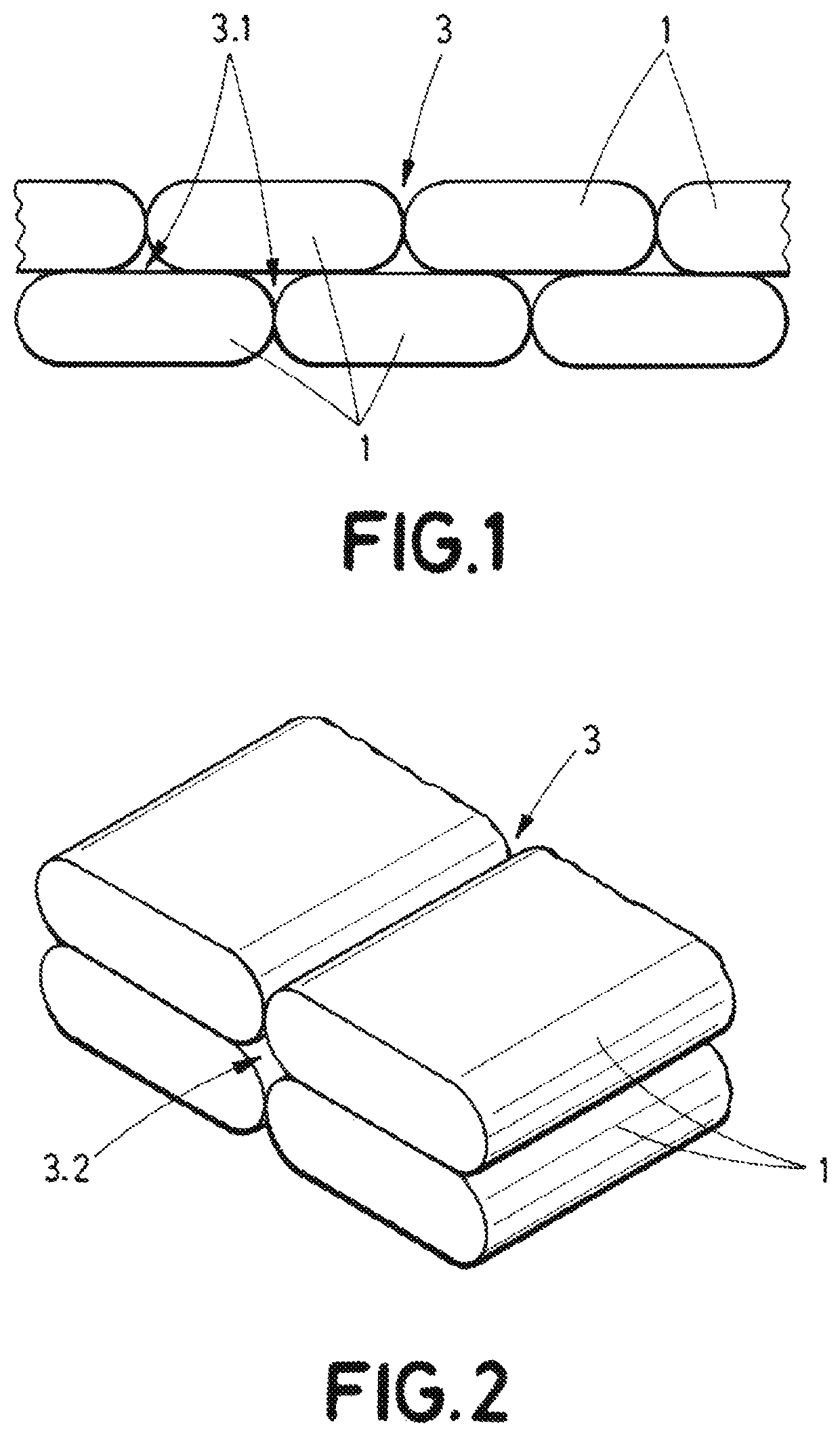

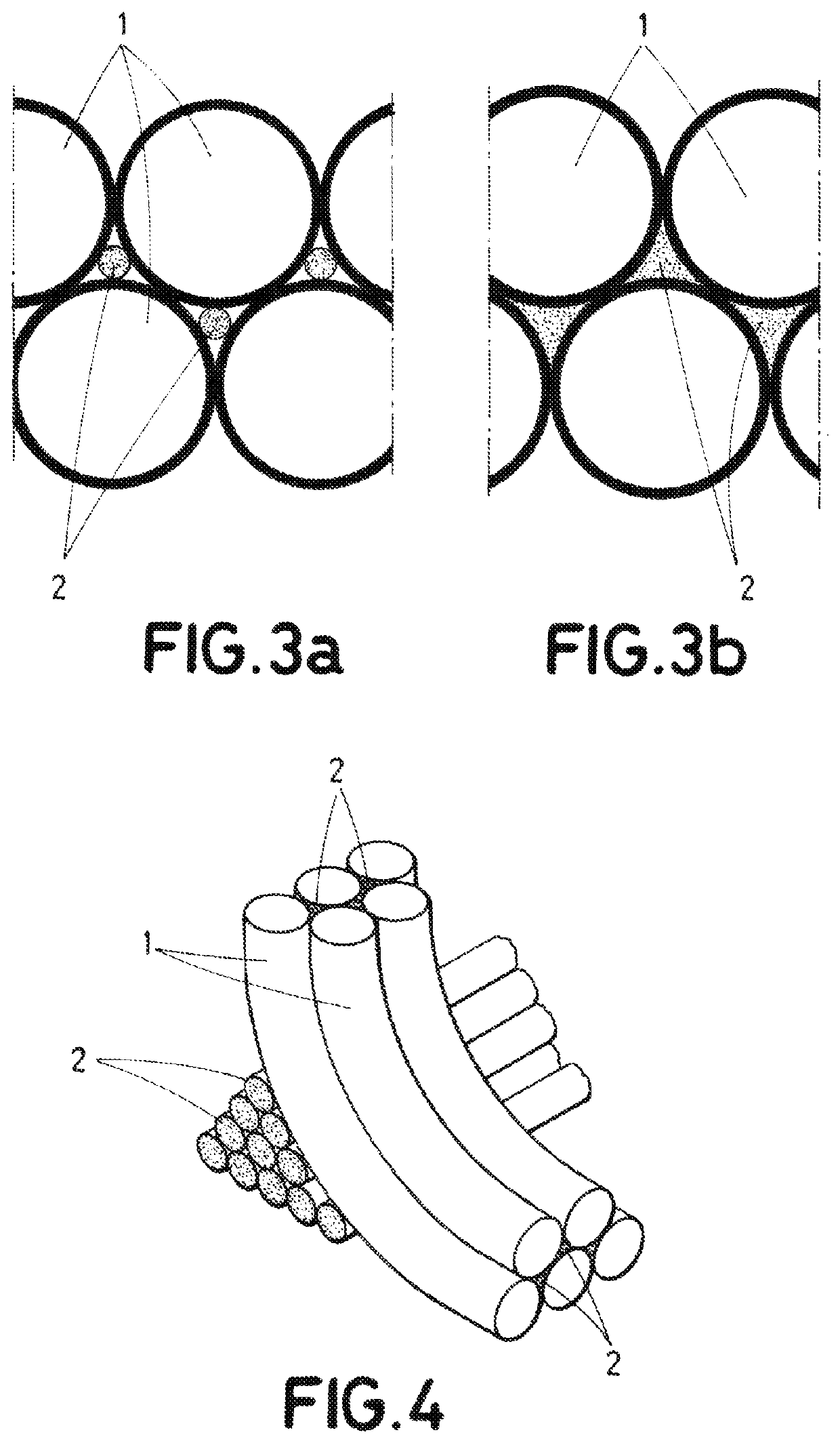

Guide element for the passage of pipes, cables or the like through a wall

InactiveUS20090179420A1Optimally adjusts locking force and elasticityDegradation in quality levelElectrical apparatusPropulsion power plantsEngineeringFlange

A guide element for passing one or more pipes, cables or the like through a wall includes an interposition element between the one or more pipes and the edge of the passage aperture, and an annular clamping flange on one or both sides of the wall. The flange is substantially concentric with the aperture and it is coupled to the wall along an annular perimetric strip surrounding the aperture. The interposition element is an elastic wedging and / or urging element between one or more pipes and the edge of the aperture, and the ring or flange clamps the interposition element in a wedged and / or urged condition.

Owner:ULTRAFLEX

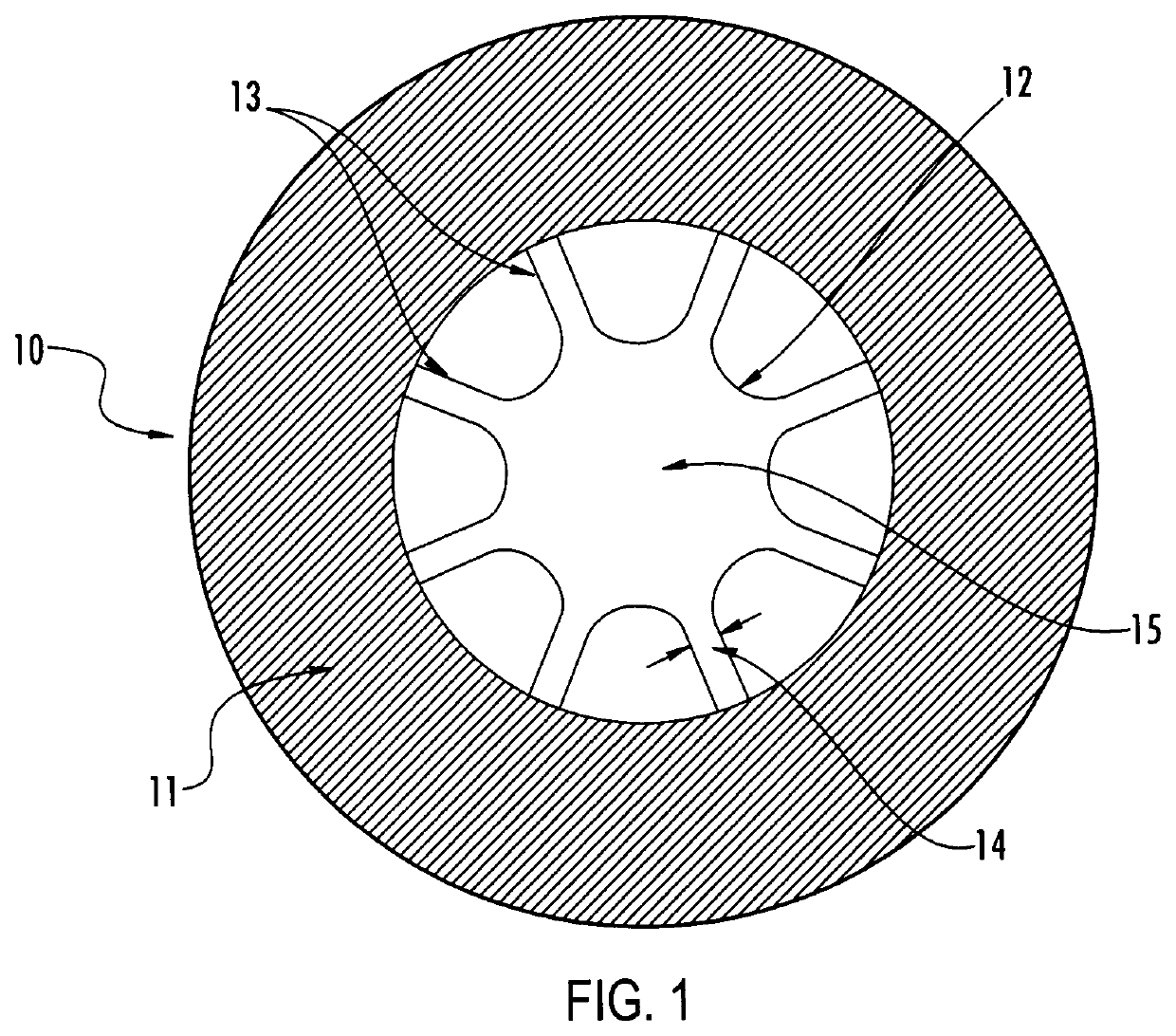

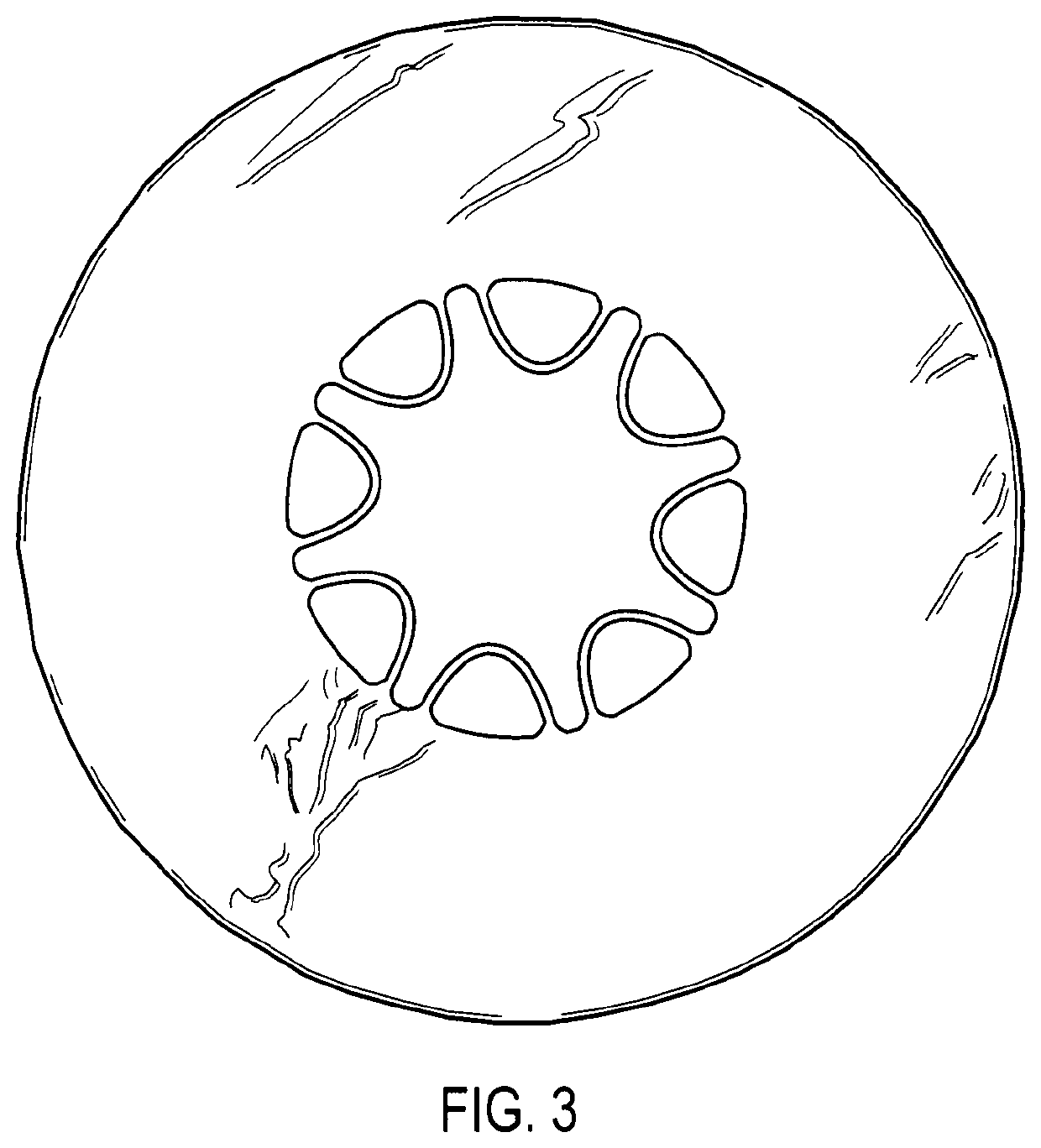

Hollow-core fiber with Anti-resonant arches and method of manufacturing thereof

ActiveUS20200326473A1Minimize fiber transmission lossEffectively in single mode operationGlass making apparatusCladded optical fibreFiberEngineering

A hollow-core fiber with a single layer of robust anti-resonant optical arches is disclosed, which is designed and made of infrared soft glass and allows the transmission of mid- to long-infrared wavelengths (1-15 microns). Each curved arch is solidly attached at two locations on the outer solid region surface and together the arches define the core diameter. The thickness and spacing between the arches are selected to minimize the fiber transmission loss <1 dB / m at wavelengths in the mid- to long-infrared where the infrared soft glass has high absorption >30 dB / m. A hollow-core preform with anti-resonant arches is made by extrusion of infrared soft glasses through a die specifically designed to produce the hollow-core fiber with anti-resonant arches.

Owner:IRFLEX CORP

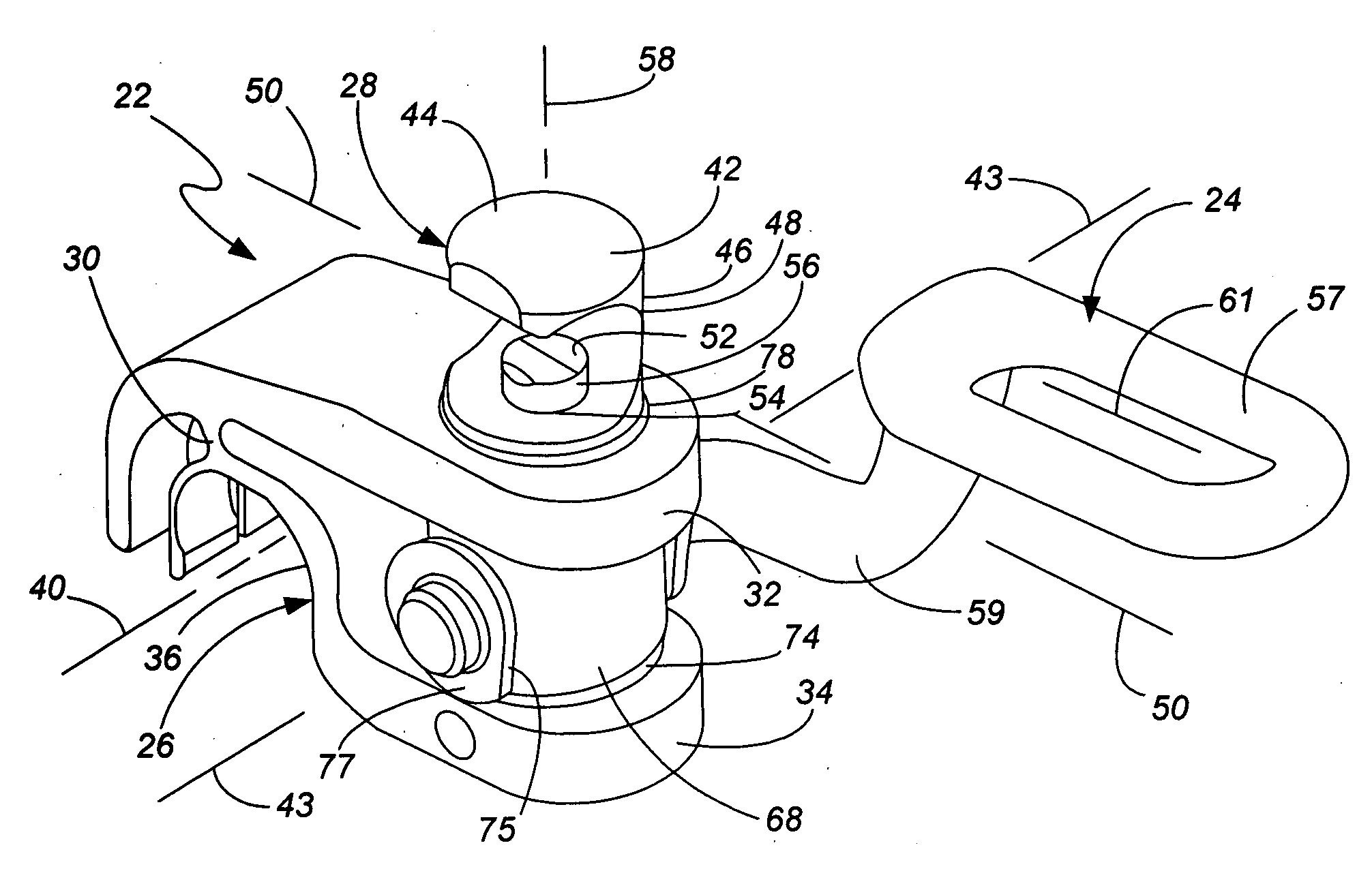

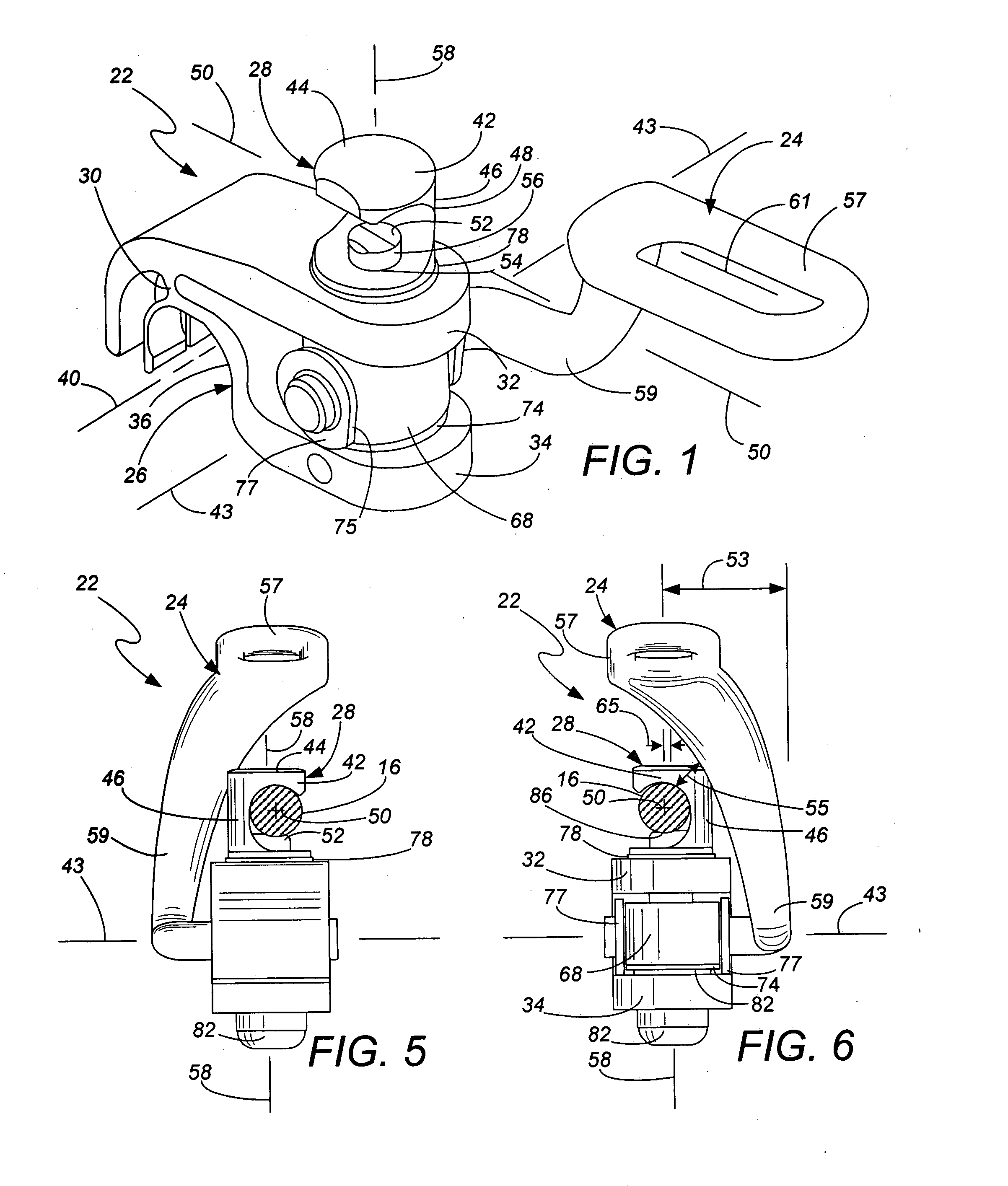

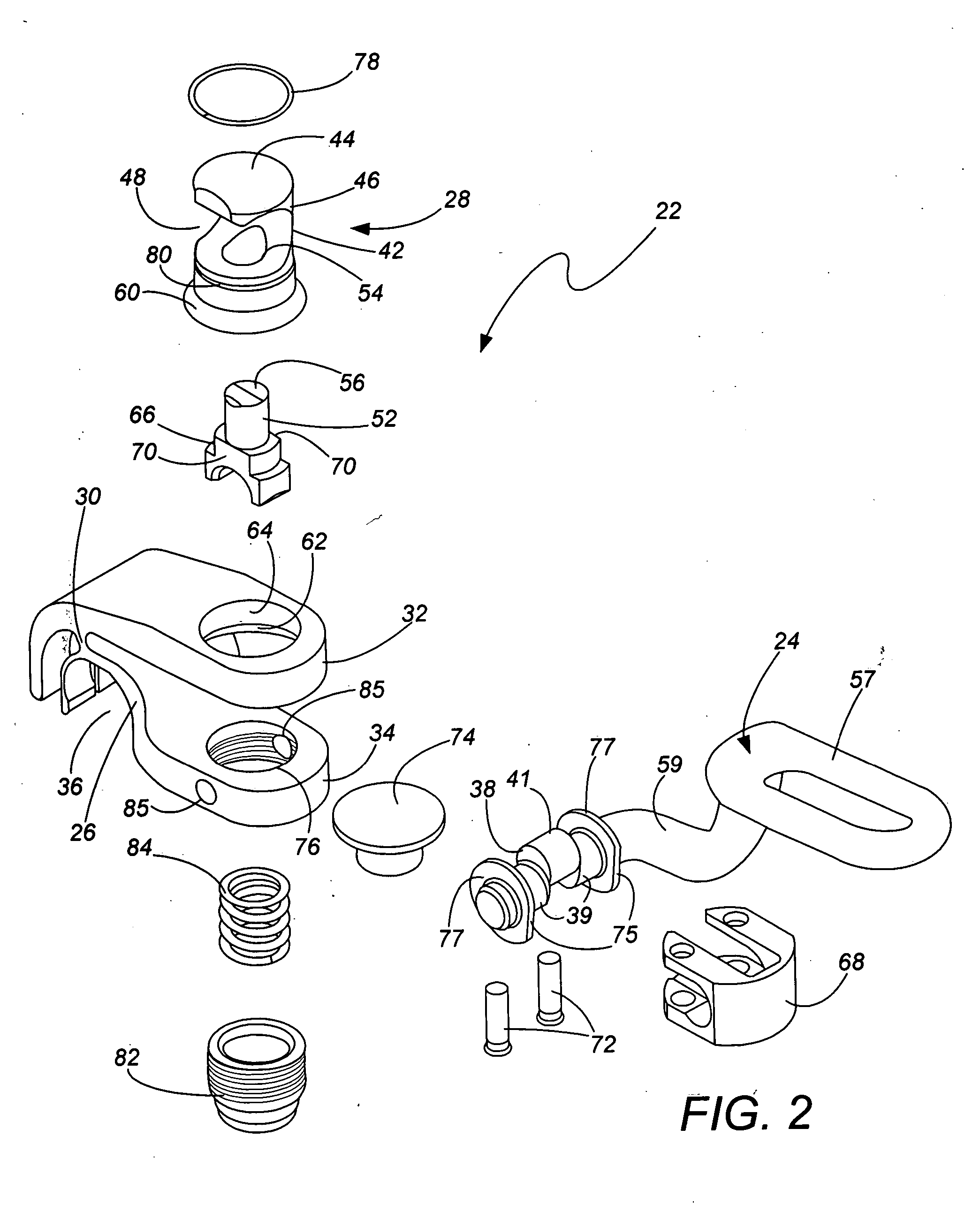

Method of making a surgical clamp

InactiveUS20070191686A1Avoiding non-uniform shrinkageUniform thicknessDiagnosticsSurgical instrument supportSurgical ClampsEngineering

A surgical clamp includes a support frame clamp member, a retraction shaft clamp member and a handle linked to the support frame clamp member and the retraction shaft clamp member for moving the clamp members between loosened and tightened positions. The handle includes a cam, and the handle / cam is unitarily formed by metal injection molding. The handle includes relatively uniform thickness throughout to better accept the shrinkage induced by the metal injection molding process. The base used for a bottom position of the cam is adjustable and spring loaded, to better support a wider range of manufacturing tolerances on the cam as well as the other components of the clamp without over stressing the metal injection molded handle during use. The handle includes a gripping portion with a planar portion inducing alignment of the clamping force as desired for best operation of the clamp.

Owner:MINNESOTA SCI

Ultra high-speed coaxial cable

ActiveUS20090183897A1Low dissipation factorEasy to manufactureCable insulation constructionInsulated cablesUltra high speedElectrical conductor

A cable for the ultra high-speed communication of high-frequency signals. The cable includes a longitudinal conductor and an insulator sheath at least partially covering the longitudinal conductor. The cable further includes an inner conductive sheath disposed about an outer periphery of the insulator sheath and an outer insulator jacket disposed about an outer periphery of the inner conductive sheath. The insulator sheath is manufactured from a high-purity fluorinated ethylene propylene.

Owner:TEMP FLEX L L C

Hot die forging and pressing process for sun wheel of automobile automatic gearbox

InactiveCN105268885AHigh precisionReduce cutting timeMetal-working apparatusWheelsEngineeringAutomotive transmission

The invention provides a hot die forging and pressing process for a sun wheel of an automobile automatic gearbox. The process includes the following steps of (1) blank making, (2) spheroidizing annealing, (3) carburizing, (4) quenching and tempering, (5) accurate grinding of inner holes, (6) counter bore grinding, (7) end face grinding, (8) accurate grinding of outer circles, (9) gear honing and (10) polishing and anti-rust oil coating. The hot die forging and pressing process is used for machining and molding the sun wheel of the automobile automatic gearbox, the obtained sun wheel is high in precision, the cutting time is short, the machining cost is low, environment friendliness is achieved, energy is saved, and the allowance for machining is little.

Owner:JIANGSU BAOJIE FORGING

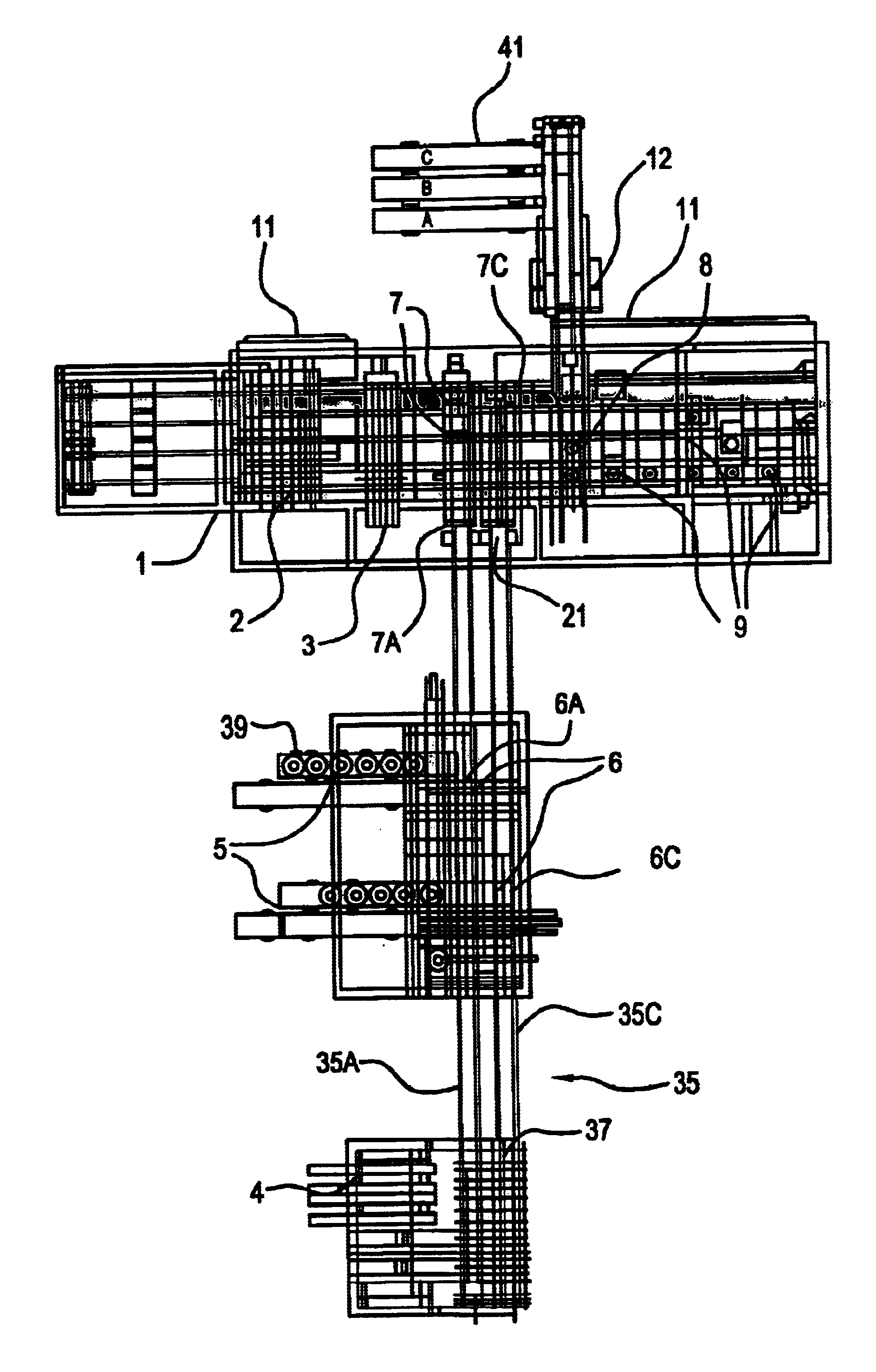

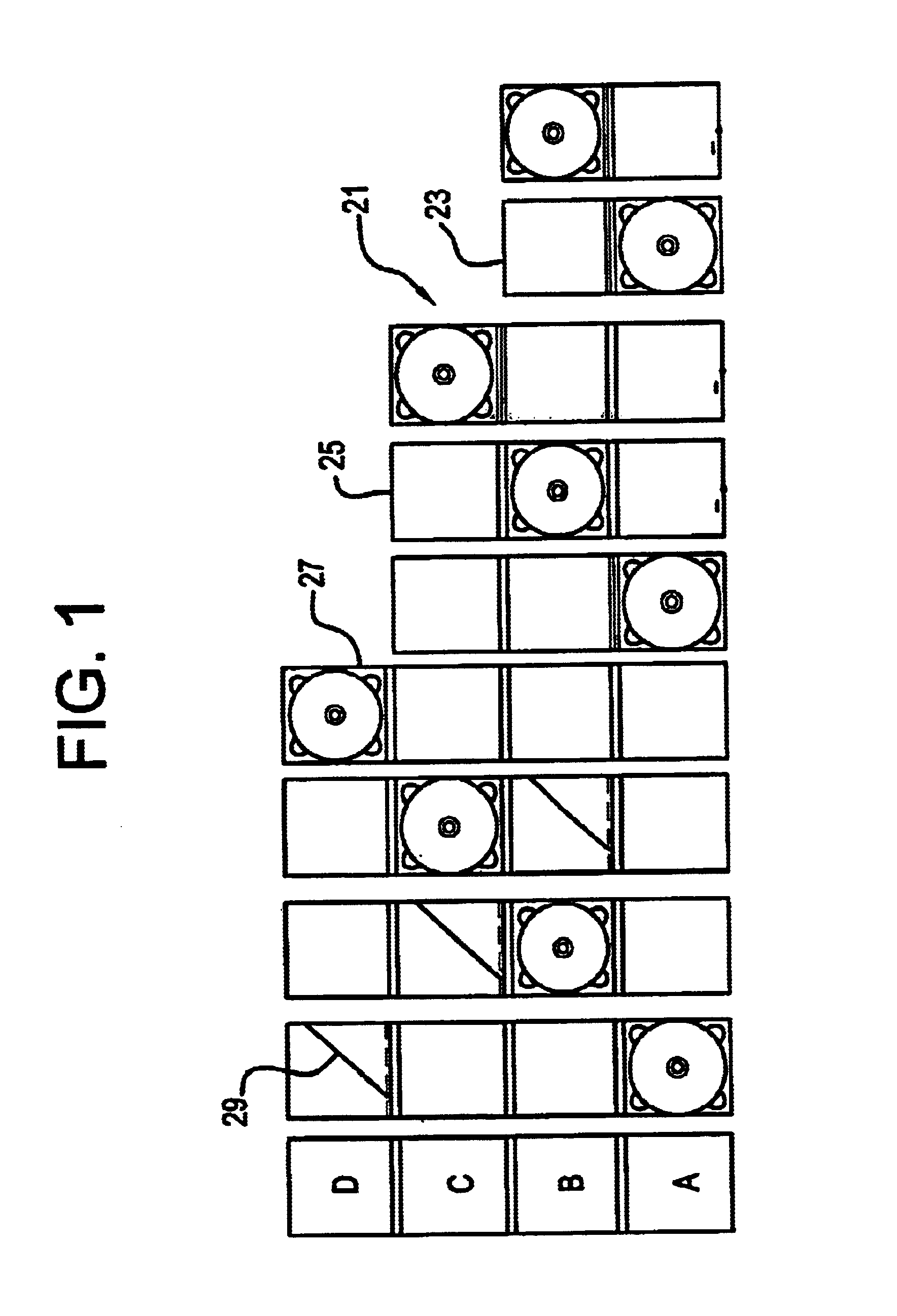

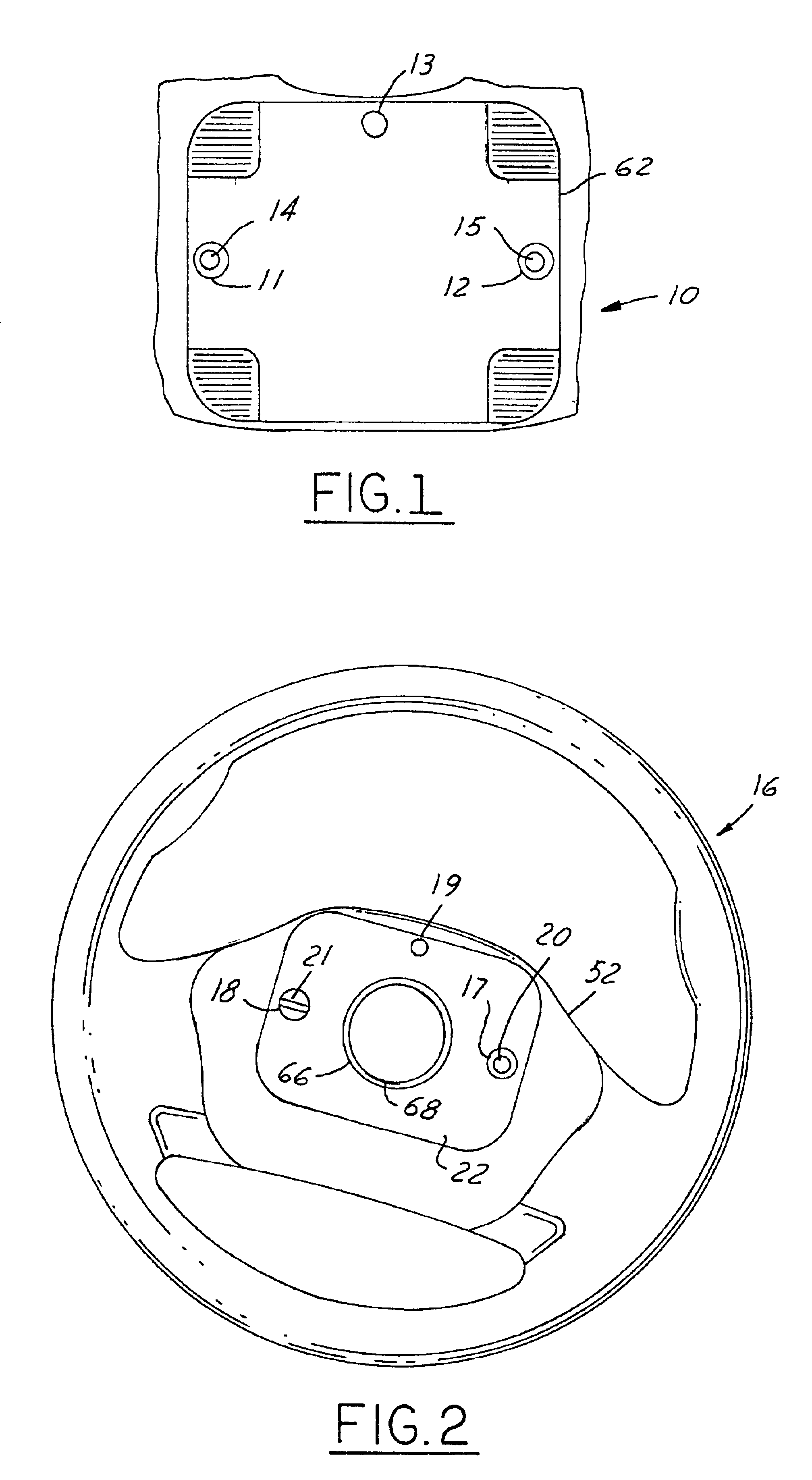

Disc packaging

InactiveUS6898923B2Quick changeIncreased dimensional tolerancesWrapper folding/bending apparatusMultiple wrapper applicationCardboardCircular disc

Creased paper board packages are unstacked, separated and conveyed. Discs are loaded into dimensionally controlled trays using relatively fine alignment, placement and assembly tolerances. Subsequently, the disc-loaded trays are assembled onto less dimensionally controlled tray-holding panels on creases paper boards using relatively less stringent tolerances. Booklets are inserted in pockets in panels adjacent the disc-holding panels, and the paper board packages are closed.

Owner:PTG

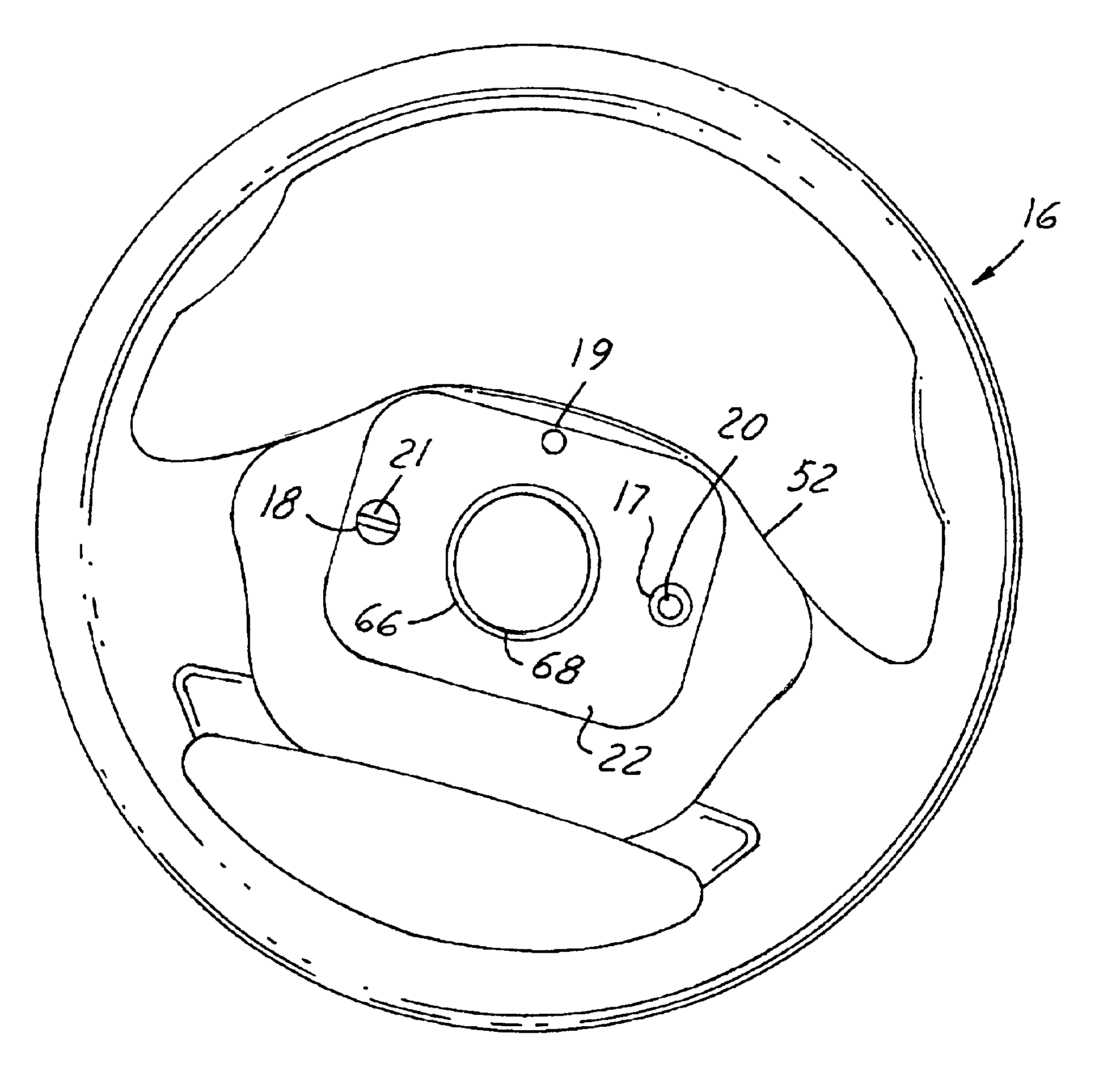

Method of preparing air bag module and vehicle support for final process positioning

InactiveUS6877770B2Reduces accumulation of dimensionalIncreased dimensional tolerancesAcoustic signal devicesPedestrian/occupant safety arrangementSteering wheelEngineering

A method of preparing an air bag module for final process positioning includes the step of providing an air bag module, the air bag module having unformed locating features for guiding the air bag module into a mountable position on a vehicle component. The method next includes the step of shaping the locating features to a predetermined size. The method may also include the step of providing a vehicle support, such as a steering wheel, with unformed locating features for guiding the air bag module into a mountable position on the vehicle support. The method may further include shaping the unformed locating features of the vehicle support to a predetermined size. The method ensures that the air bag module will consistently fit with the vehicle support and reduce an accumulation of dimensional tolerances in the components of the air bag module and vehicle support.

Owner:CENTOCO WHEEL CORP

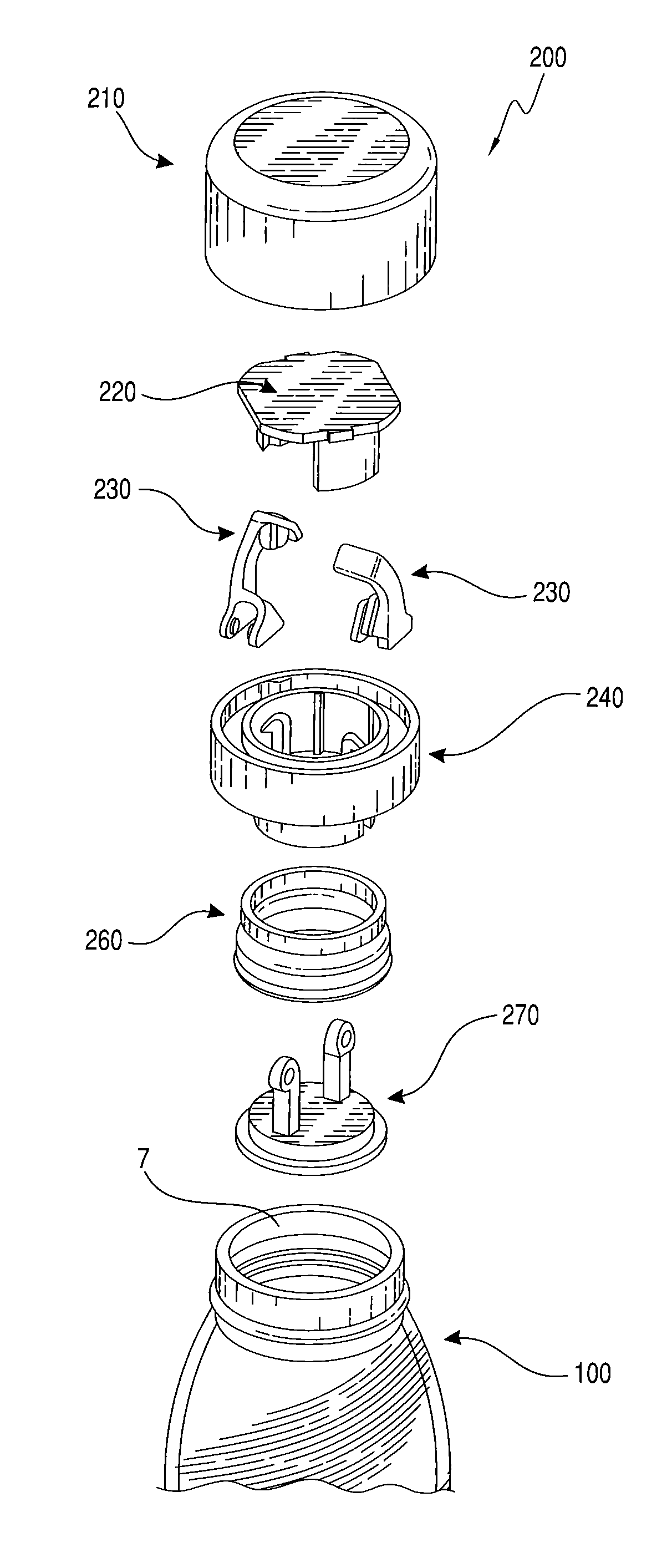

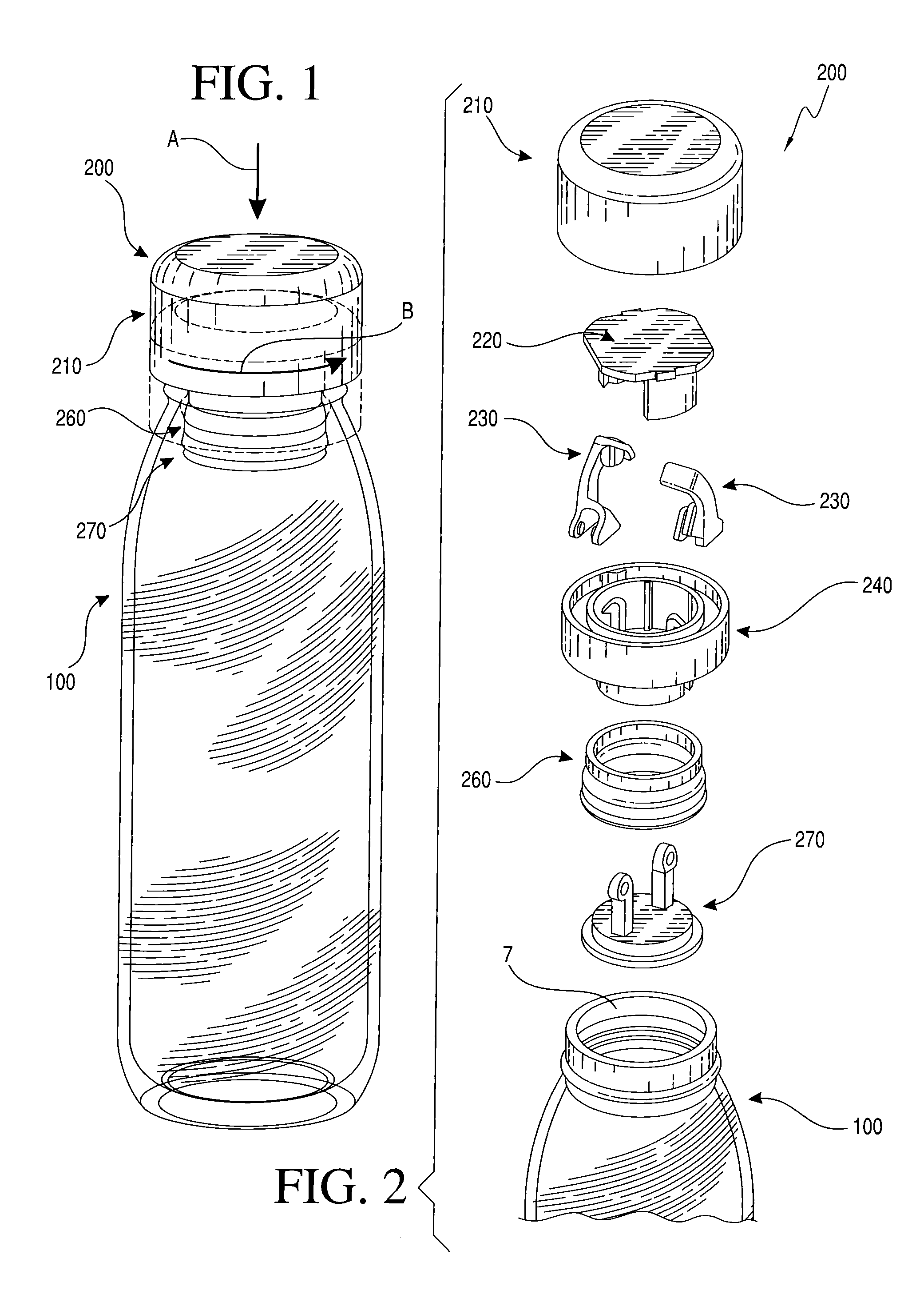

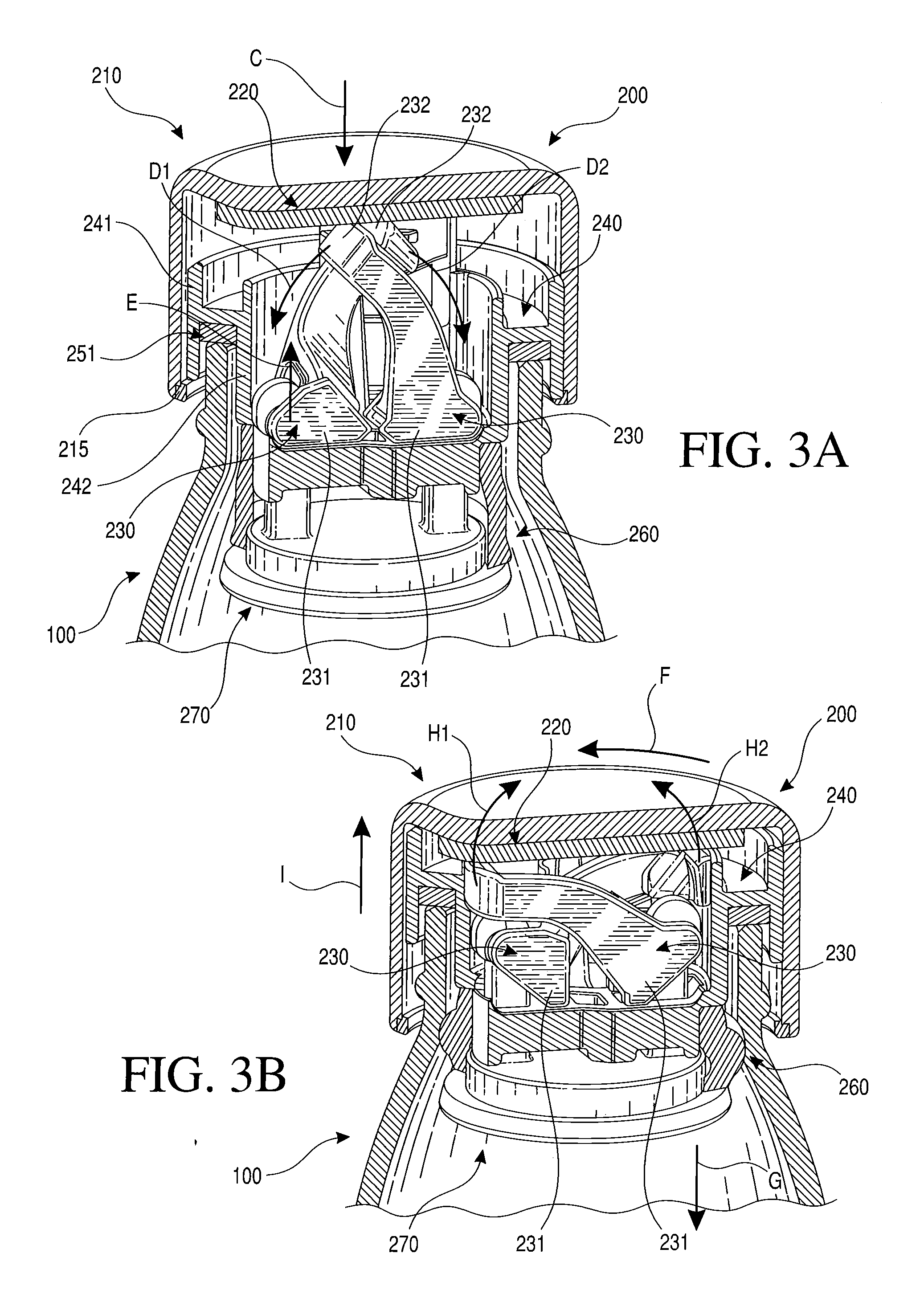

Push-On Twist-Off Bottle Closure

InactiveUS20150210445A1Increased dimensional tolerancesLess precisionCapsClosure capsEngineeringBottle neck

A closure system for a drinking bottle or other container is disclosed. The closure system comprises a bottle and a bottle closure. The bottle closure, in turn, comprises among its components a cap interface manipulated directly by the user's hand, a platform that translates vertically in relation to the cap interface, and a flexible annular stopper body directly manipulated by the platform. When the bottle closure is placed on the open bottle neck and the cap interface is pushed downward toward the bottom of the bottle, a lever-based mechanism forces opposite upward movement of the platform. The platform squeezes the stopper body, and at the end of the downward pushing motion, the system is locked in a static position. The squeezed stopper body forms a liquid-tight seal with the bottle, while holding potential energy via elastic deformation. From this sealed position, the cap interface may be radially twisted relative to the bottle, releasing the locked platform and the stopper's potential energy. As the stopper gains its original shape, simultaneously the liquid-tight seal is removed, the cap interface moves upward, and the platform moves downward. The loosened bottle closure may now be separated from the bottle.

Owner:MELINGER PROD

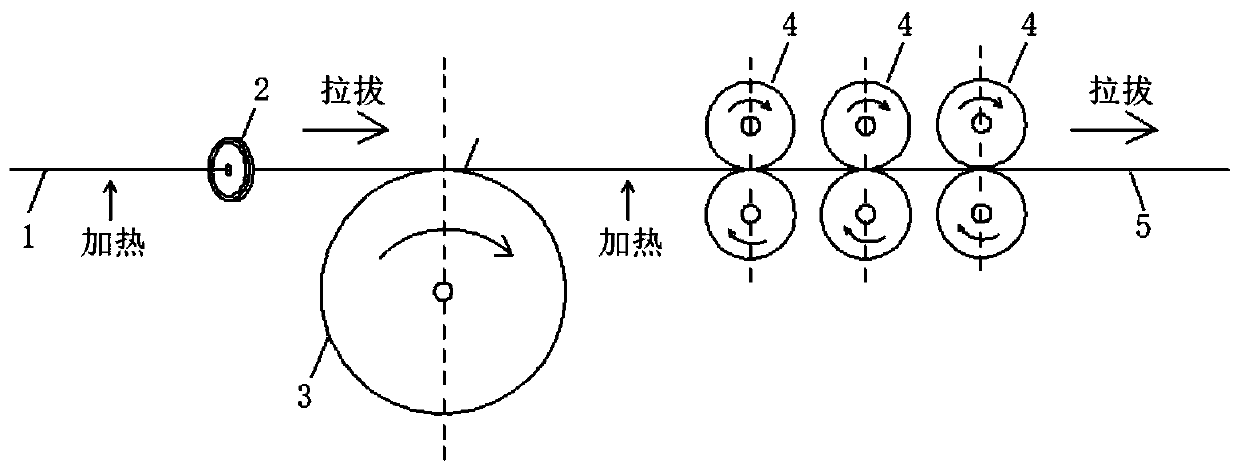

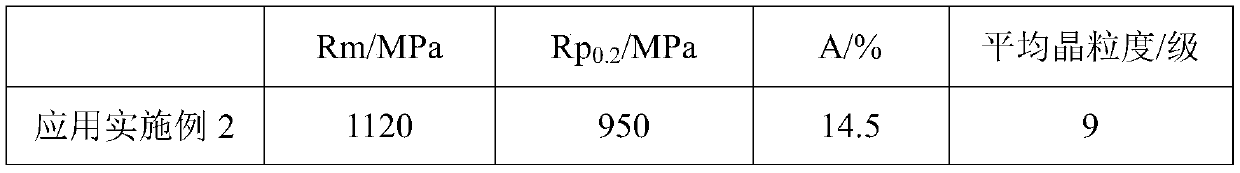

Continuous processing method of nickel-titanium shape memory alloy square thin wire material

ActiveCN111346931AFine continuous machining deformationFine production efficiencyWire straightening devicesExtrusion cleaning devicesSingle plateShape-memory alloy

The invention discloses a continuous processing method of a nickel-titanium shape memory alloy square thin wire material. The continuous processing method of the nickel-titanium shape memory alloy square thin wire material comprises the following steps of: step 1) performing surface treatment on a [Phi]3 mm nickel-titanium alloy thin round wire blank; step 2) performing square hot die drawing andhot roller drawing on the nickel-titanium alloy thin round wire blank after surface treatment in step 1) to obtain a nickel-titanium alloy square thin wire material; and step 3) performing square colddie drawing and online straightening heat treatment on the nickel-titanium alloy square thin wire material in step 2) to obtain the nickel-titanium shape memory alloy square thin wire material. The nickel-titanium shape memory alloy square thin wire material obtained by the invention has high strength, good dimensional tolerance and surface quality, large single plate heavy, and high production efficiency, which completely meets the requirements of the nickel-titanium shape memory alloy wire material for medical use, has high production efficiency, and is easy to realize large-scale production.

Owner:宝鸡华沃新材料有限公司

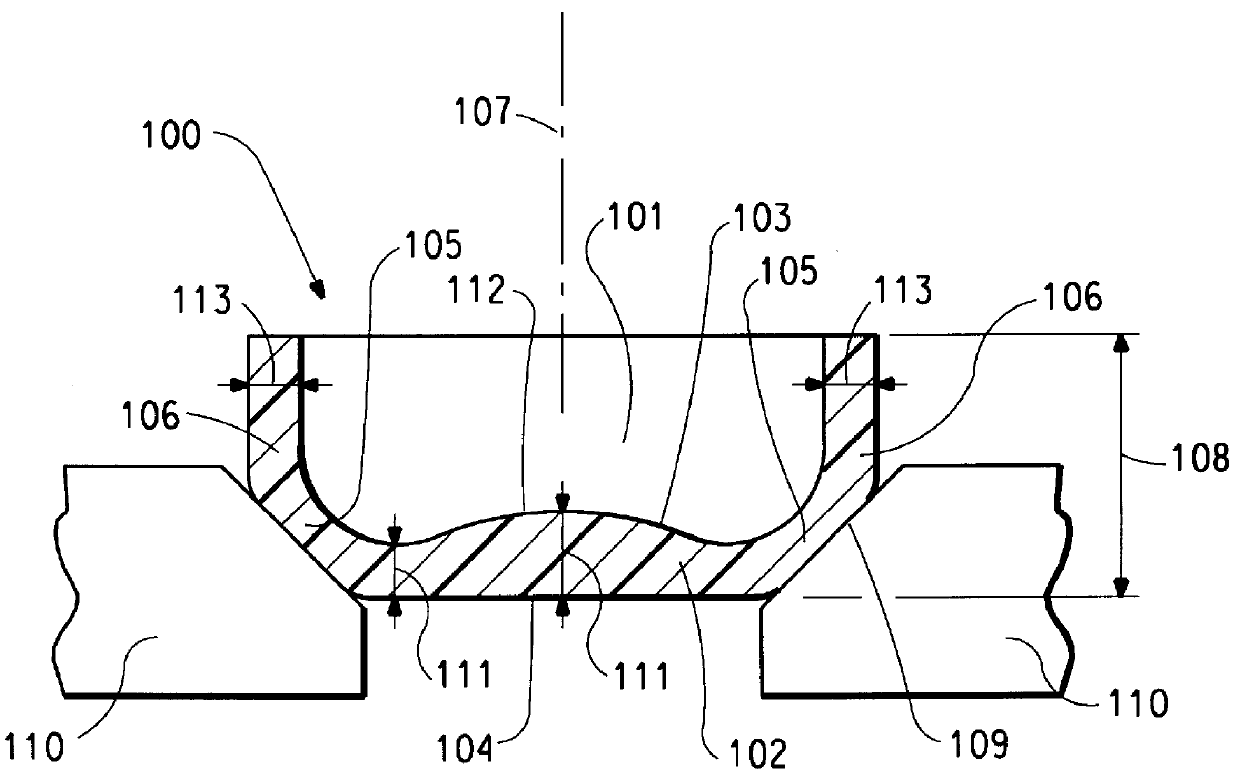

Manufacture of hollow aerofoil

ActiveUS9771807B2Reduce material wasteIncreased dimensional tolerancesTurbinesBlade accessoriesGas turbinesEngineering

Owner:ROLLS ROYCE PLC

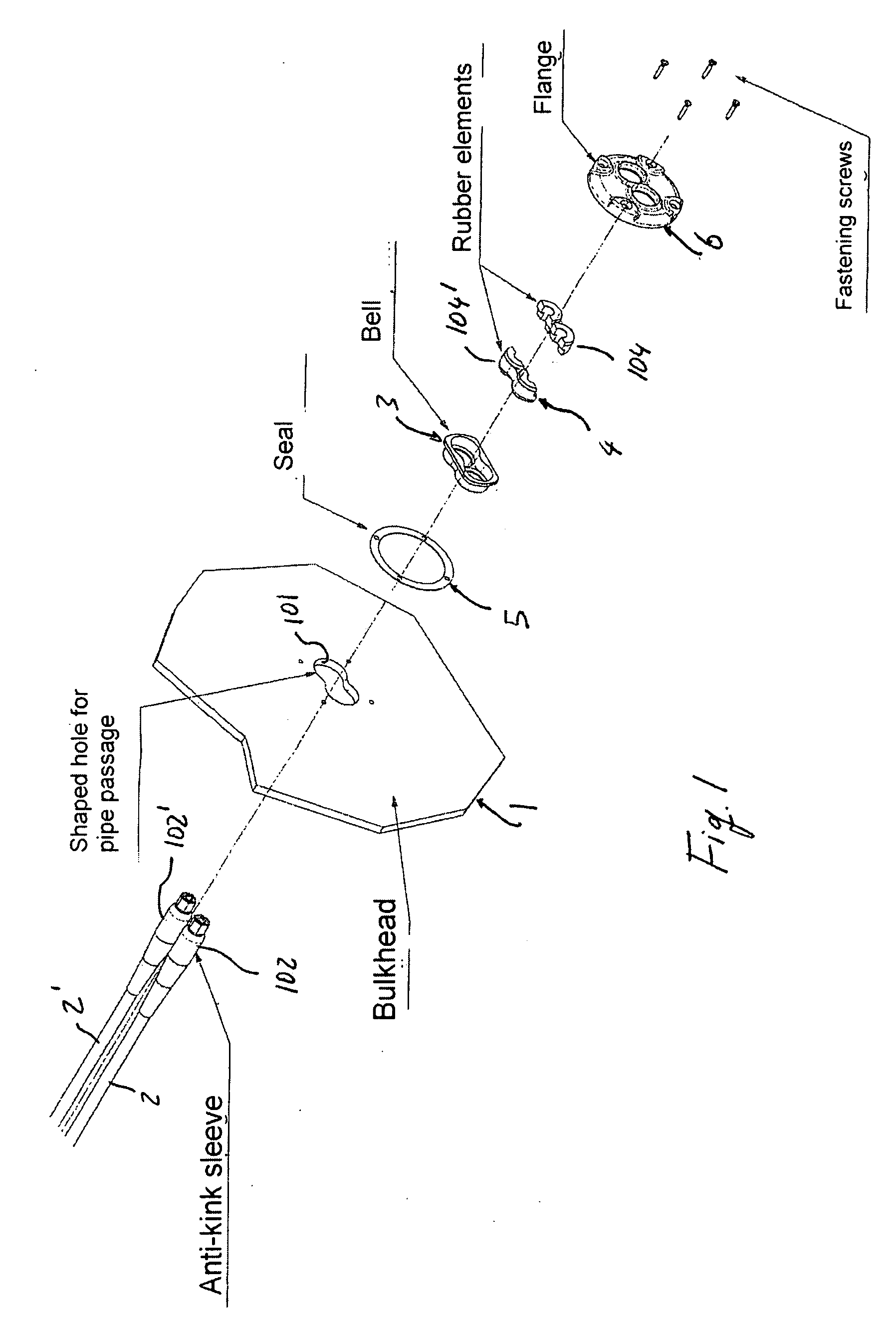

Guide element for the passage of pipes, cables or the like through a wall

InactiveUS7880090B2Eliminates variables related to the manual abilityGood repeatabilityPropulsion power plantsPipesEngineeringFlange

A guide element for passing one or more pipes, cables or the like through a wall includes an interposition element between the one or more pipes and the edge of the passage aperture, and an annular clamping flange on one or both sides of the wall. The flange is substantially concentric with the aperture and it is coupled to the wall along an annular perimetric strip surrounding the aperture. The interposition element is an elastic wedging and / or urging element between one or more pipes and the edge of the aperture, and the ring or flange clamps the interposition element in a wedged and / or urged condition.

Owner:ULTRAFLEX

Manufacture of filled aerofoil

ActiveUS9855628B2Reduce material wasteIncreased dimensional tolerancesBlade accessoriesEfficient propulsion technologiesEngineeringGas turbines

Owner:ROLLS ROYCE PLC

Hollow-core fiber with anti-resonant arches and method of manufacturing thereof

ActiveUS10816721B1Guaranteed uptimeUniform shapeGlass making apparatusCladded optical fibreFiberEngineering

A hollow-core fiber with a single layer of robust anti-resonant optical arches is disclosed, which is designed and made of infrared soft glass and allows the transmission of mid- to long-infrared wavelengths (1-15 microns). Each curved arch is solidly attached at two locations on the outer solid region surface and together the arches define the core diameter. The thickness and spacing between the arches are selected to minimize the fiber transmission loss <1 dB / m at wavelengths in the mid- to long-infrared where the infrared soft glass has high absorption >30 dB / m. A hollow-core preform with anti-resonant arches is made by extrusion of infrared soft glasses through a die specifically designed to produce the hollow-core fiber with anti-resonant arches.

Owner:IRFLEX CORP

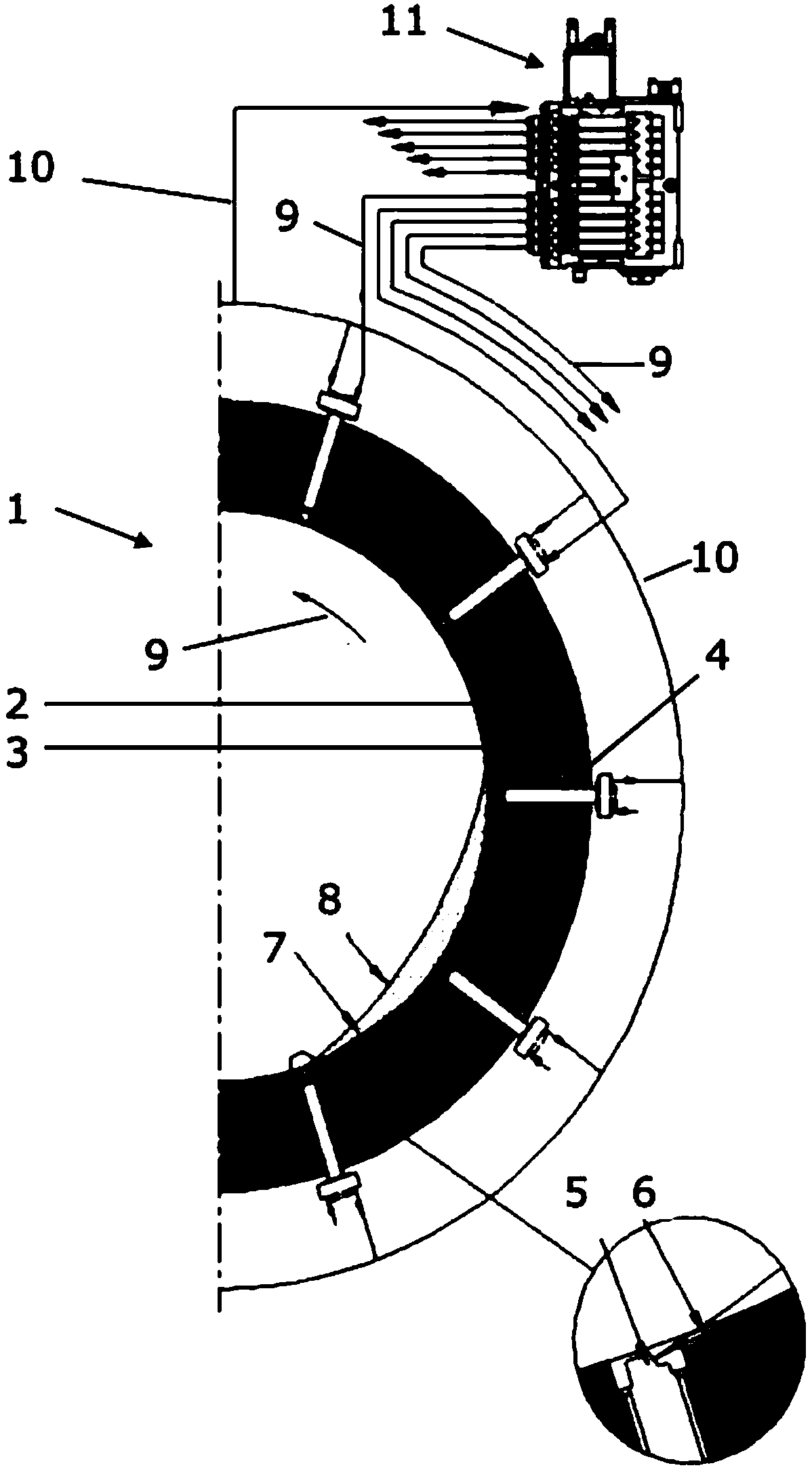

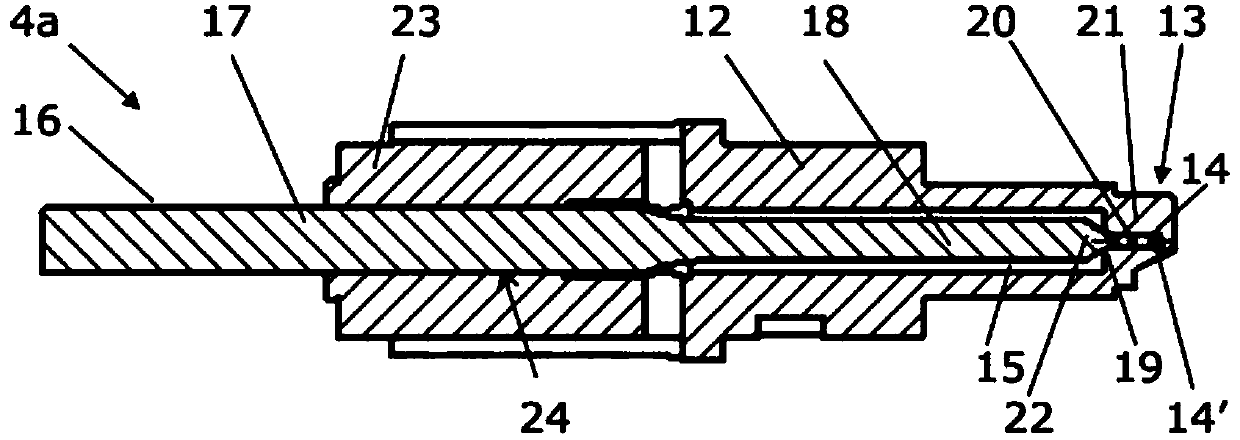

Lubricant injector for large slow-running two-stroke engine and production method

ActiveCN107873069AHigh hardnessIncreased dimensional tolerancesWear reducing fuel injectionMachines/enginesSlider bearingDieseling

Injectors for injection of lubrication oil into the cylinder of a large slow-running two-stroke engine, especially marine diesel engine, proved better uniform performance the when using hardened surfaces for the plain bearing in which the valve member slides. Also, hardened surfaces for valve seats at the nozzle was an improvement.

Owner:HANS JENSEN LUBRICATORS

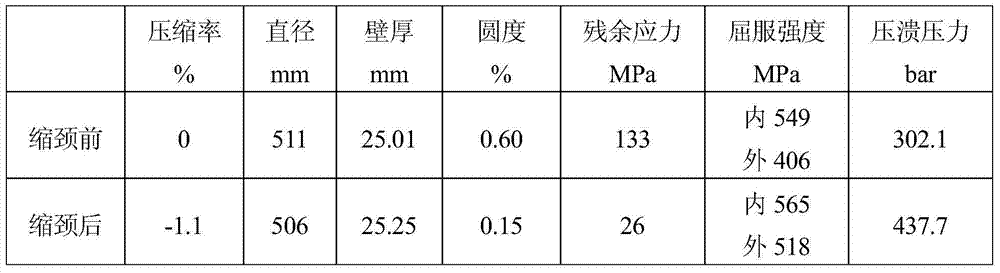

Reducing production method of deepwater submerged arc welding large-caliber steel pipes

ActiveCN104511720AIncreased dimensional tolerancesImprove straightnessArc welding apparatusThick wallUltimate tensile strength

The invention discloses a reducing production method of deepwater submerged arc welding large-caliber steel pipes. In order to overcome the defects of reduction of the compression strength and incapability of satisfying the bruising pressure performance requirements of deepwater pipelines in a traditional JCOE process for producing thick-wall steel pipes, the method comprises such process steps as edge milling, edge pre-bending, JCO molding, joint closing and prewelding, inner welding, outer welding, mechanical reducing, quality checking, water pressure test, quality checking and chamfering, wherein the mechanical reducing is to perform the annular compression for the whole lengths of the steel pipes by a steel pipe sizing press. The method has the following beneficial effects: the steel pipe sizing press is used for annularly compressing the full lengths of the steel pipes, so that the steel pipes are locally deformed, the diameters of the pipes are decreased, and the size tolerances of the steel pipes are improved; because of the mechanical reducing, the residual stress is reduced, the straightness of the steel pipes is improved, the cold molding process of the steel pipes is optimized, and the compression yield strength and the bruising pressure of the steel pipes are improved; and all technical parameters of the steel pipes accord with the deepwater pipeline requirements through strict technical control.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Method for manufacturing a part

InactiveUS20210299947A1Improve tightnessReduce water ingestion issue3D object support structuresManufacturing data aquisition/processingManufacturing technologyAdditive layer manufacturing

A method for manufacturing a part layer-upon-layer using Additive Manufacturing technology suitable for structural applications. The method includes selectively depositing at least a first type filament and a second type filament, wherein the second type filament differs from the first type filament at least in the cross-sectional dimension.

Owner:AIRBUS OPERATIONS SL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com