Lubricant injector for large slow-running two-stroke engine and production method

A syringe and two-stroke technology, applied in the field of syringes, can solve problems such as increased wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

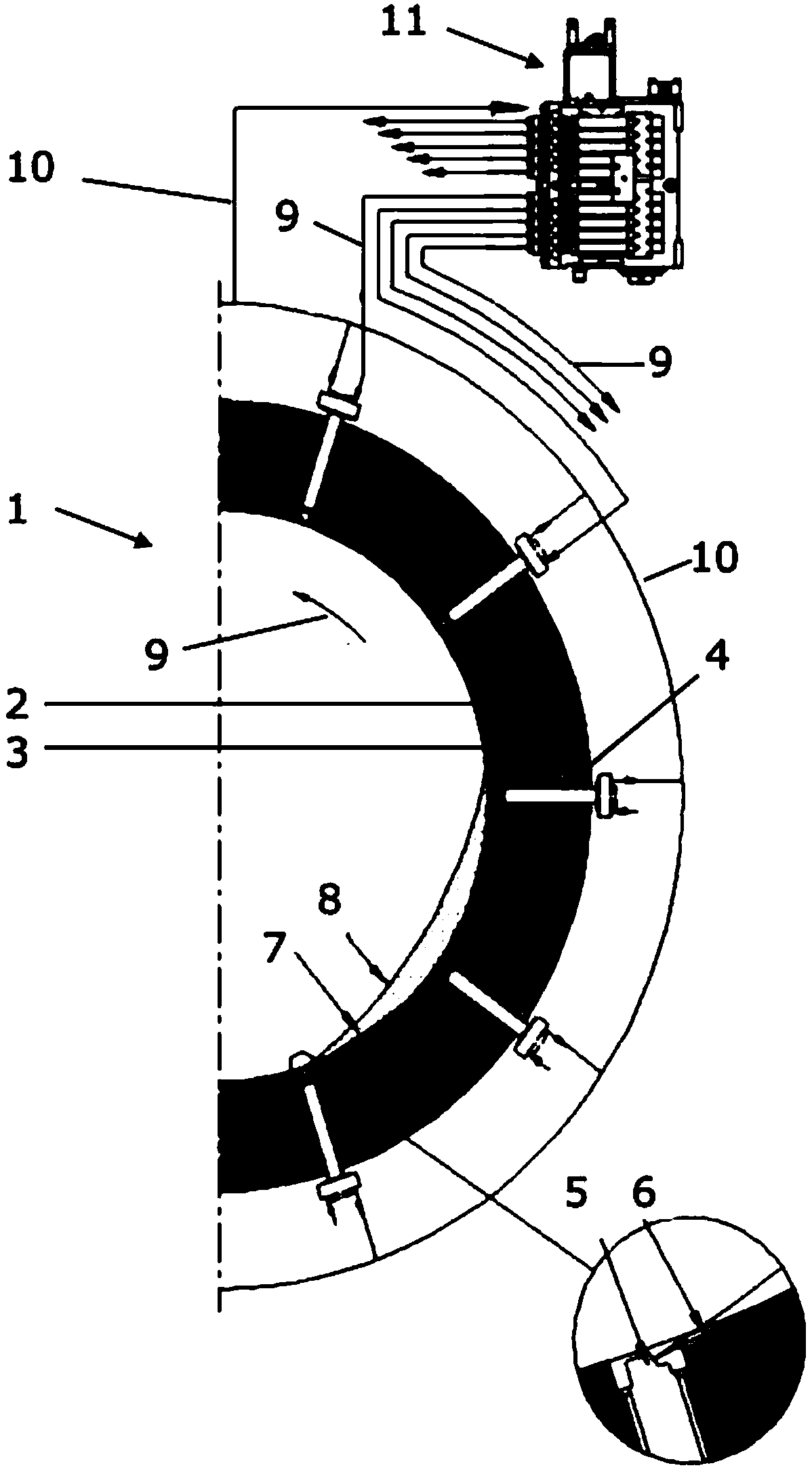

[0031] figure 1 Shown is one half of a cylinder of a large low-speed two-stroke engine, such as a marine diesel engine. The cylinder comprises a cylinder liner 2 arranged inside a cylinder wall 3 . Inside the cylinder wall 3, there are a plurality of lubricating oil injectors 4 distributed along a circle, and the angular distance between adjacent injectors is equal. The injector 4 receives lubricating oil from the lubricating pump and control system 11 through the lubricating supply line 9 . Some lubricating oil is returned to the pump through the lubricating return line 10 . A lubrication pump and control system 11 supplies pressurized lubrication oil to the injector 4 in precisely timed pulses synchronized with the movement of the pistons in the engine 1 . For this synchronization, the lubrication pump and control system 11 includes a computer that monitors the actual state and motion parameters of the engine, including the speed, load and position of the crankshaft, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com