Patents

Literature

229results about "Wear reducing fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

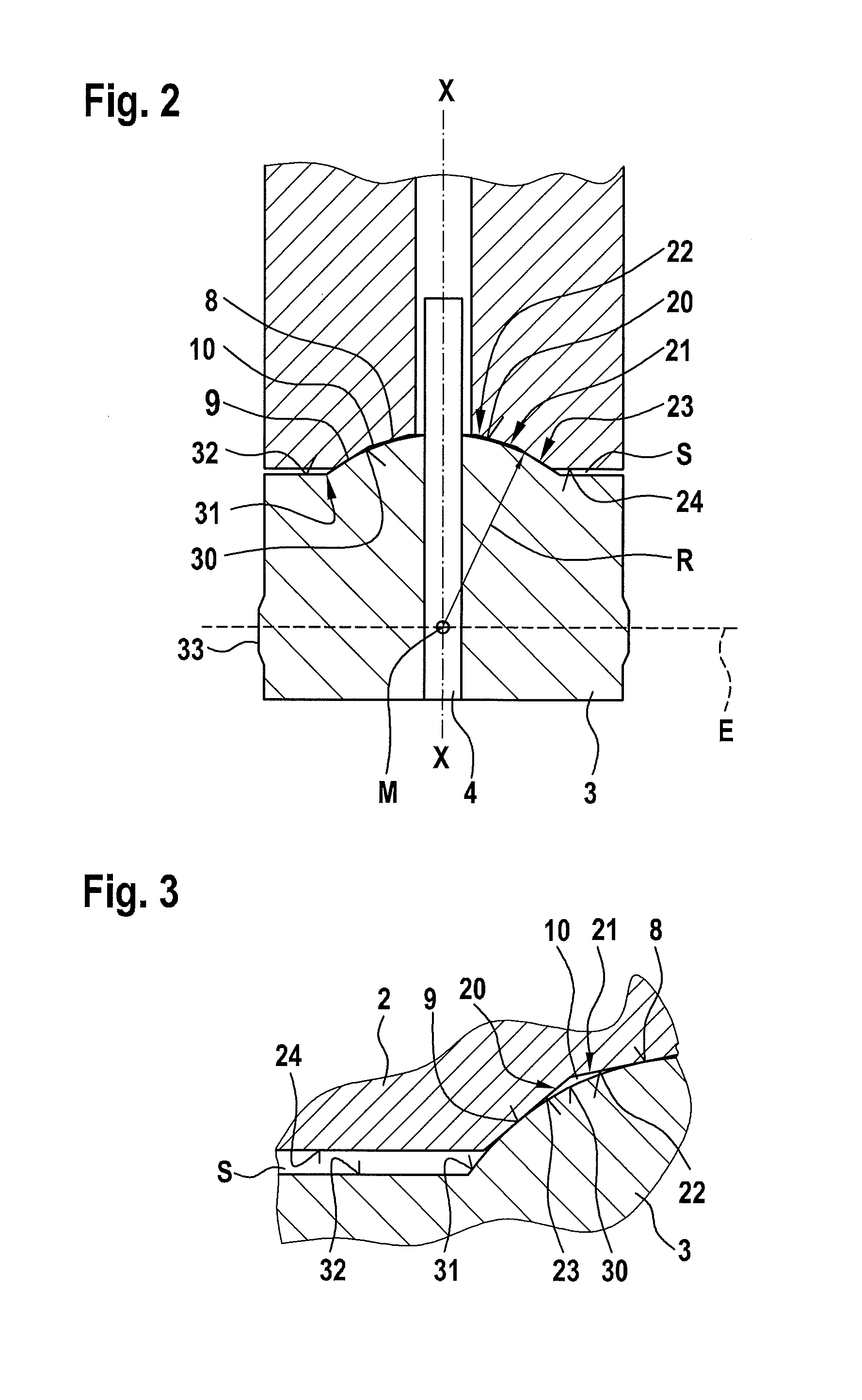

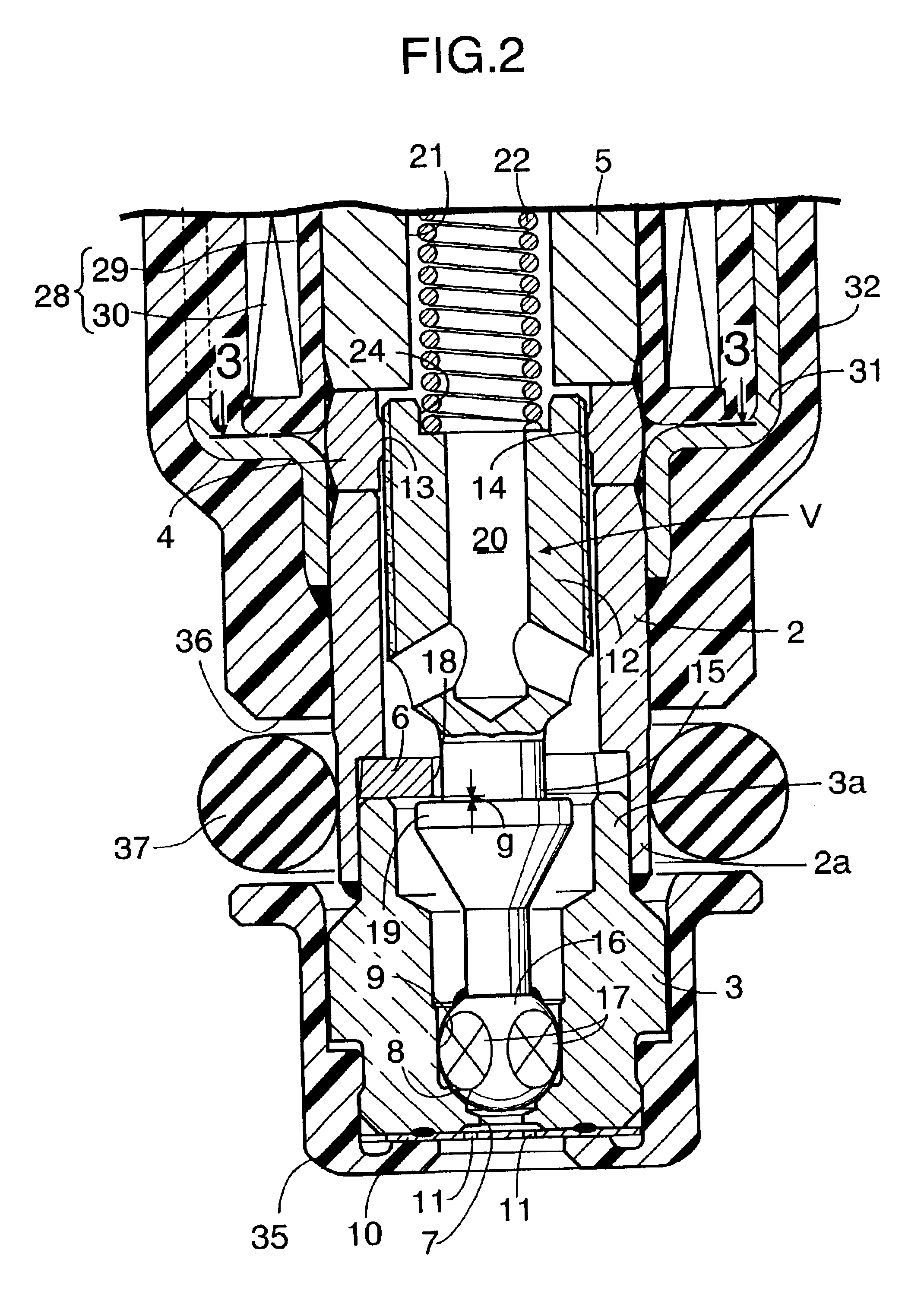

Fuel injection system having pre-injection and main injection

InactiveUS6302080B1Improve permeabilityIncrease the angleElectrical controlInternal combustion piston enginesTop dead centerEngineering

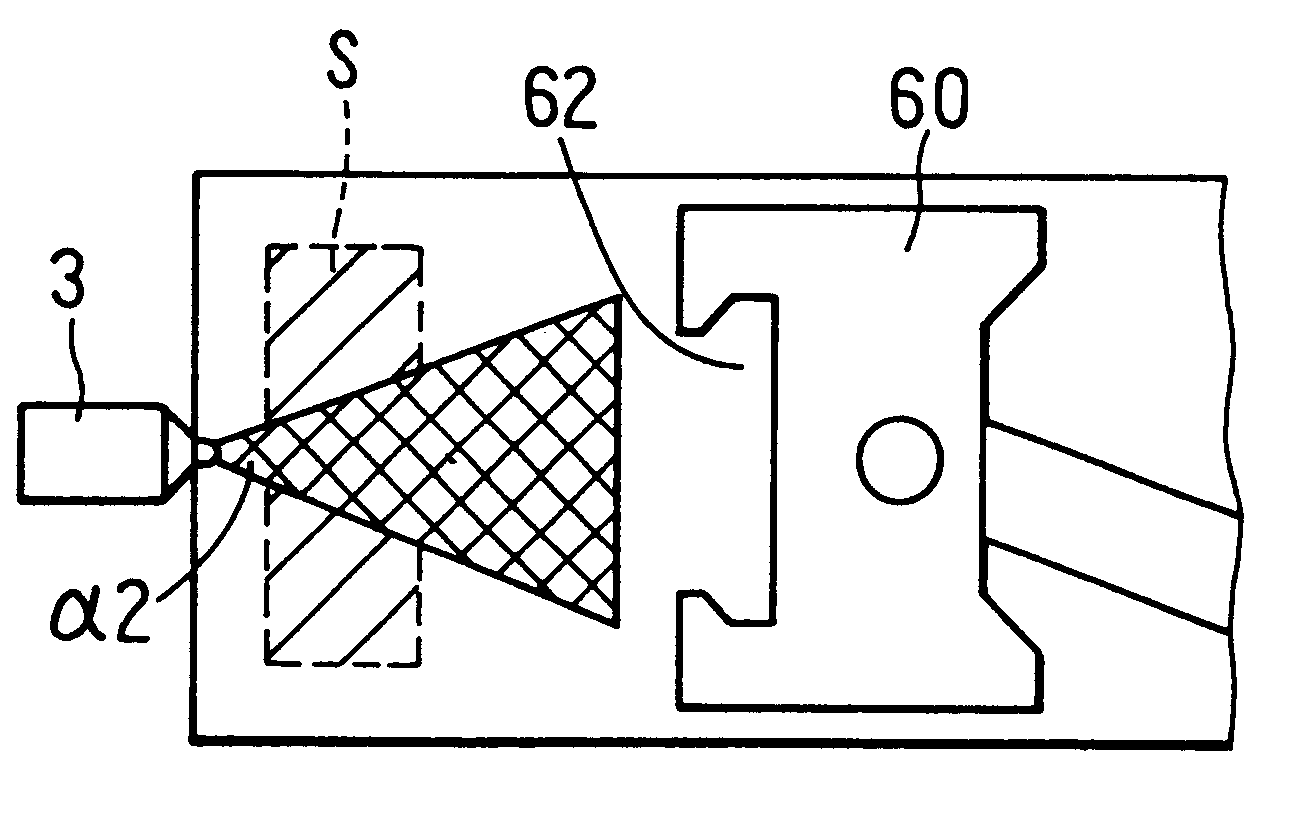

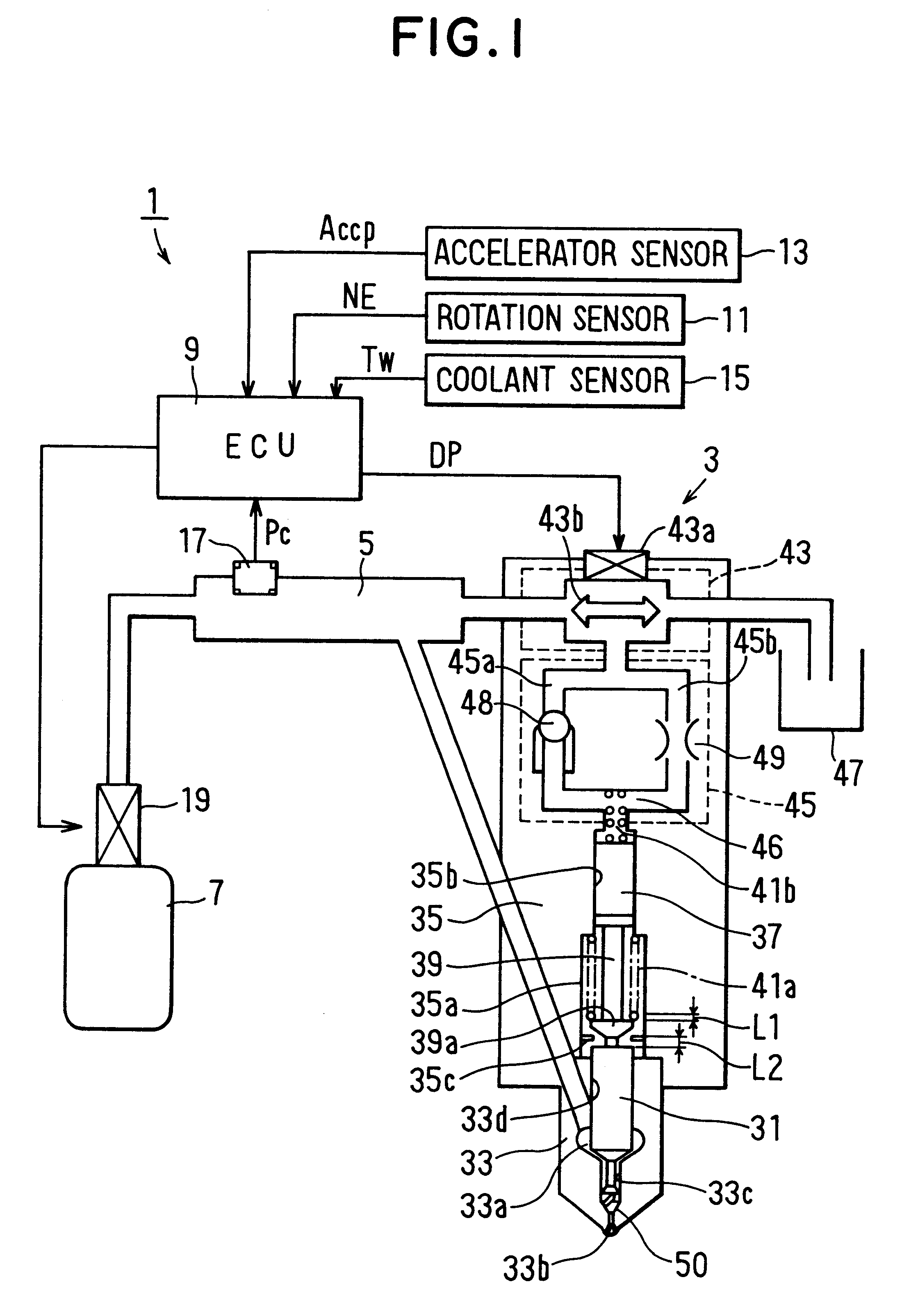

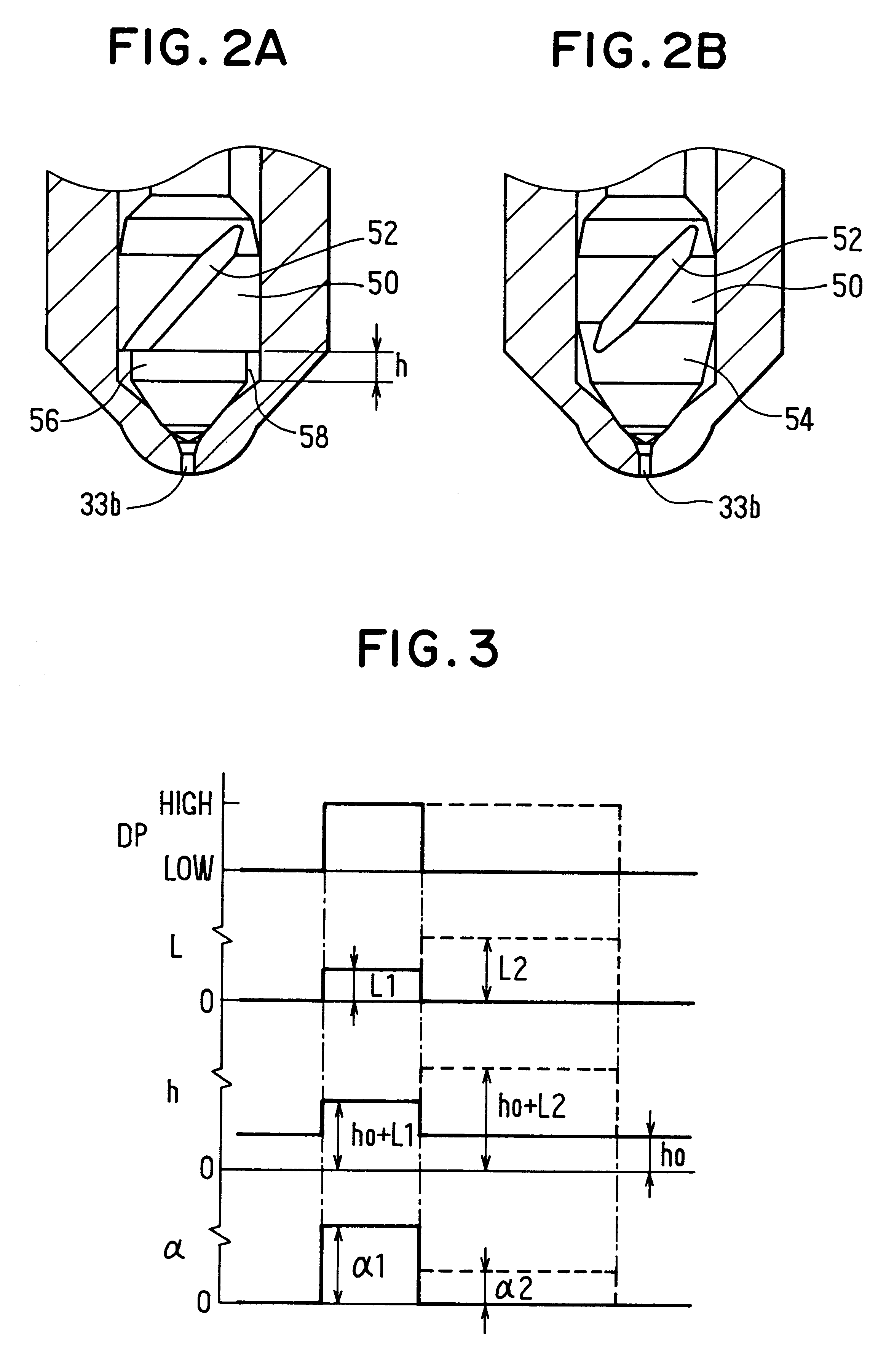

The angle of fuel spray at the time of pre-injection is set to a wider angle of spray and the angle of fuel spray at the time of main injection is set to a narrower angle of spray. The pre-injection timing is set so that when fuel spray after the pre-injection is diffused in a cylinder and stratified, the stratified fuel spray is ignited by a rise in the pressure in the cylinder in association with movement of a piston from the bottom dead center to the top dead center. The main injection timing is set so that when the spray stratified by the pre-injection is burned, the fuel spray injected by the main injection passes through the combustion zone while being ignited in the combustion zone, reaches a combustion chamber of the piston, and is burned in the combustion chamber.

Owner:DENSO CORP

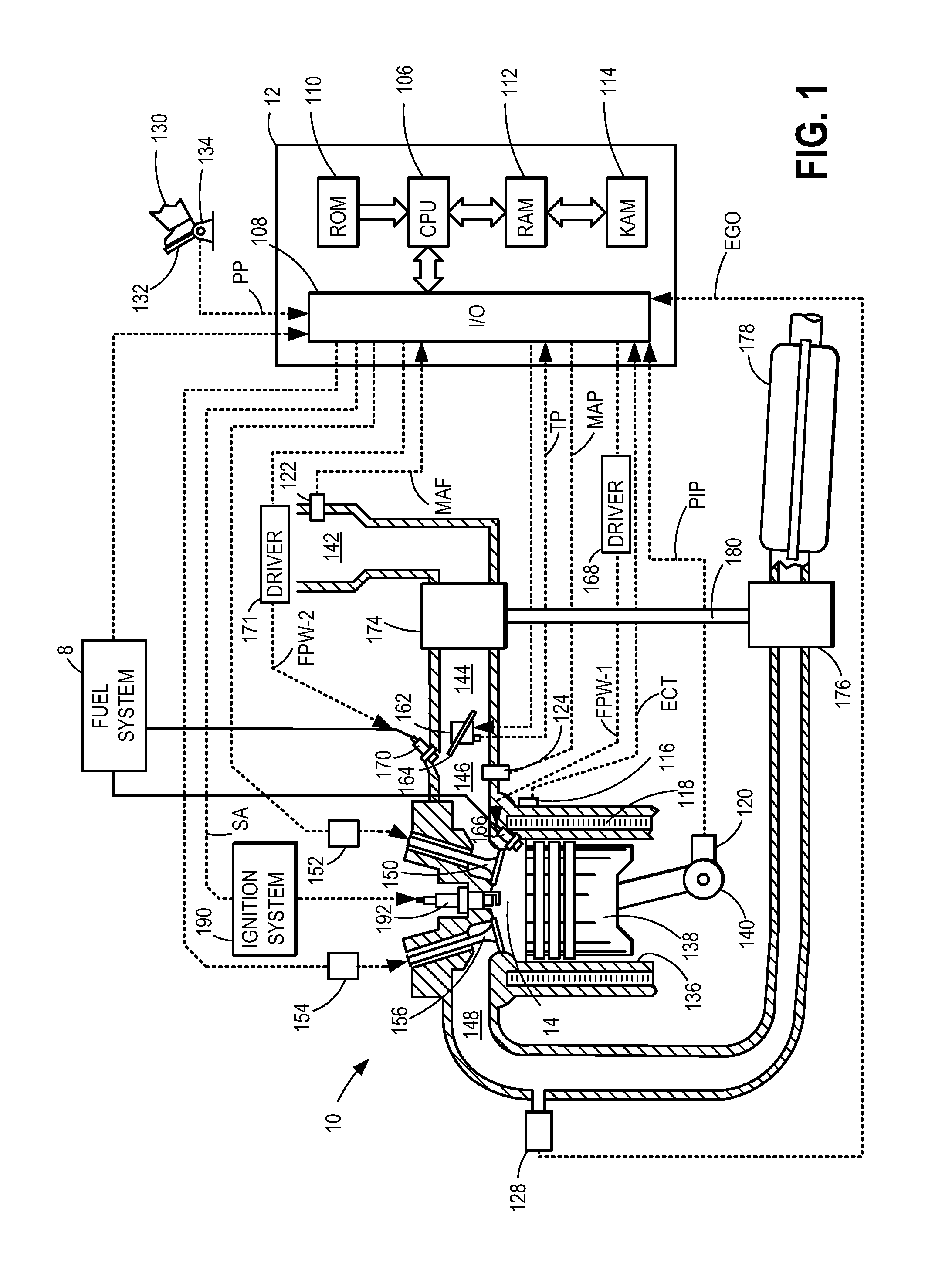

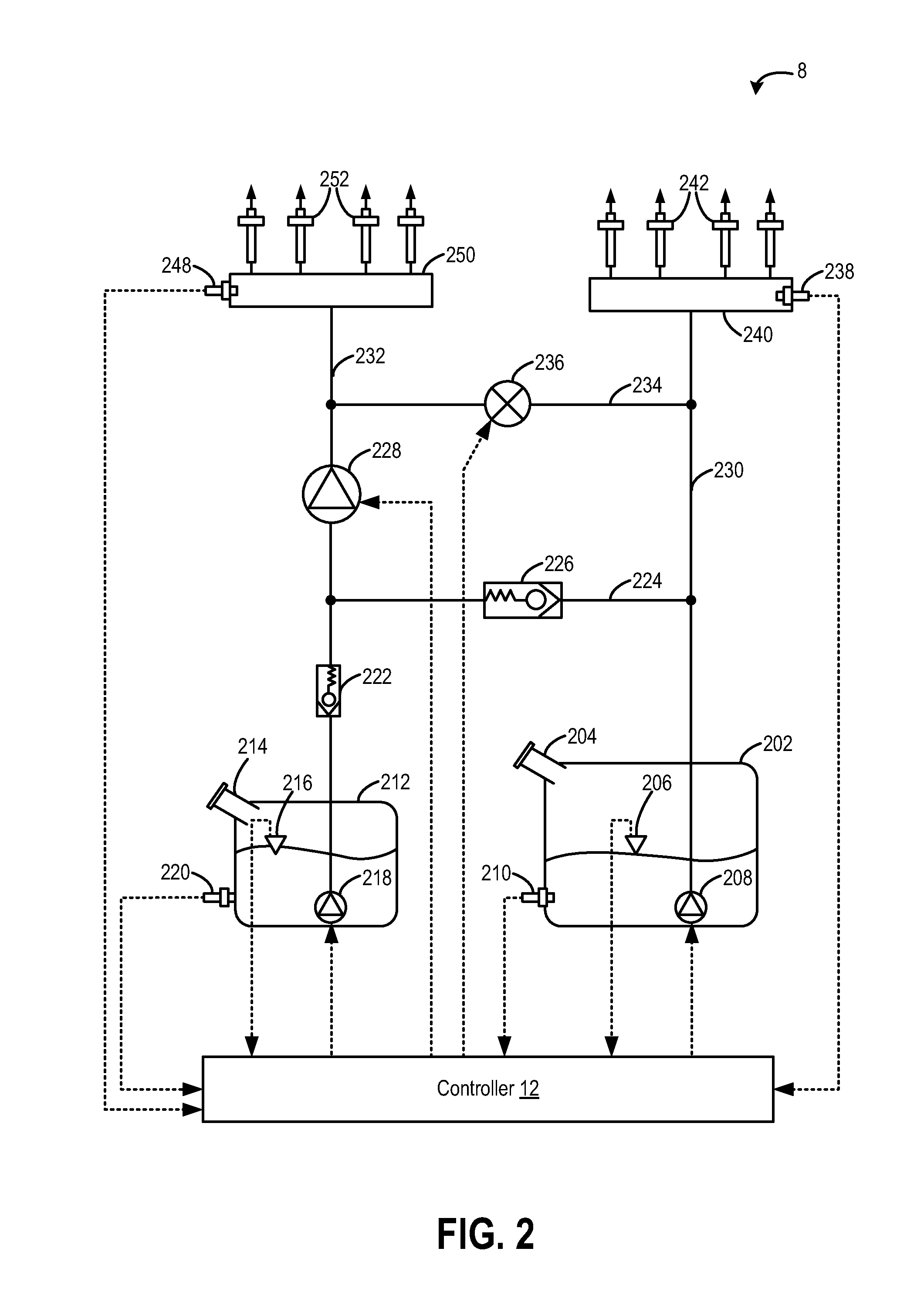

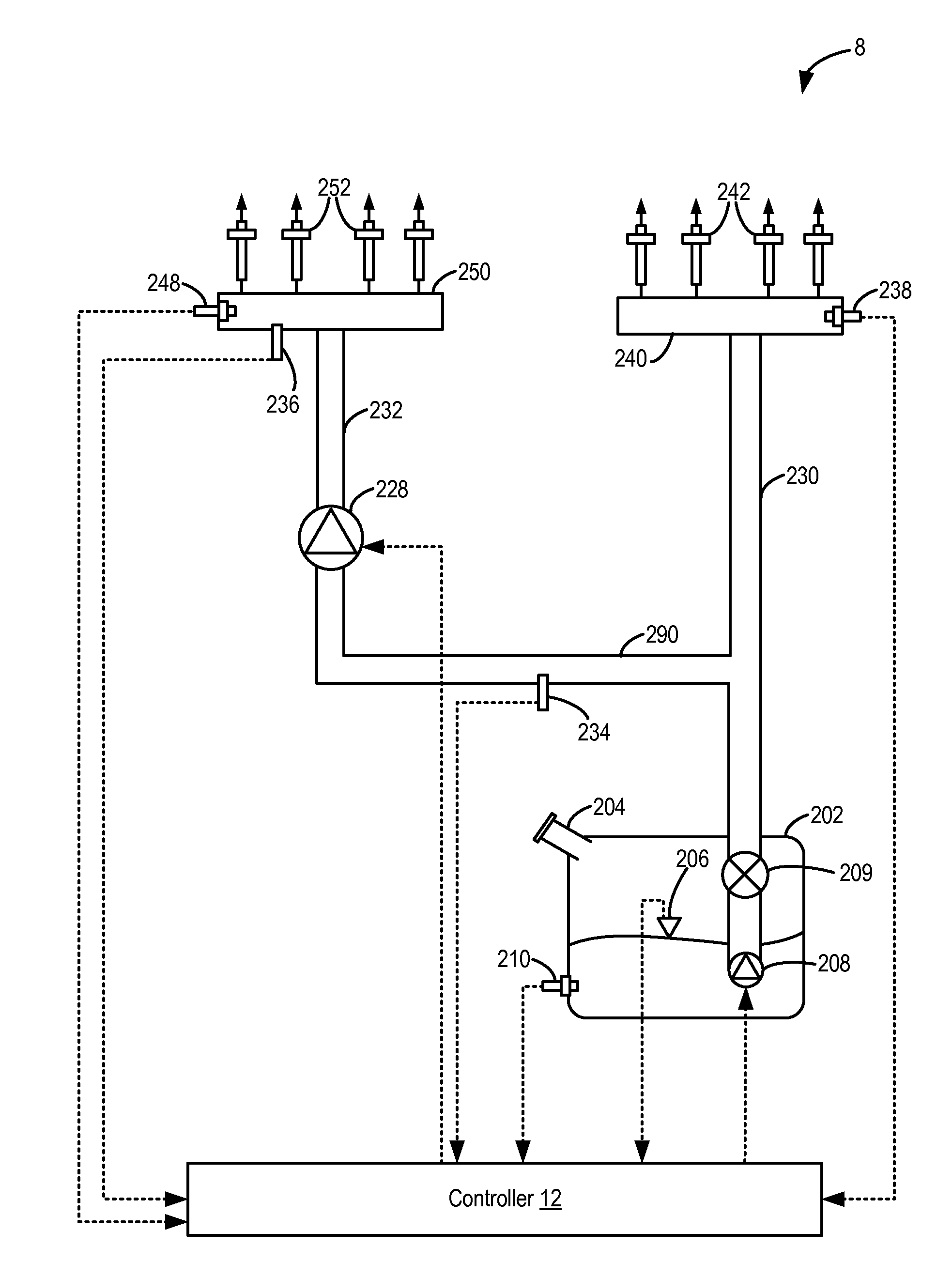

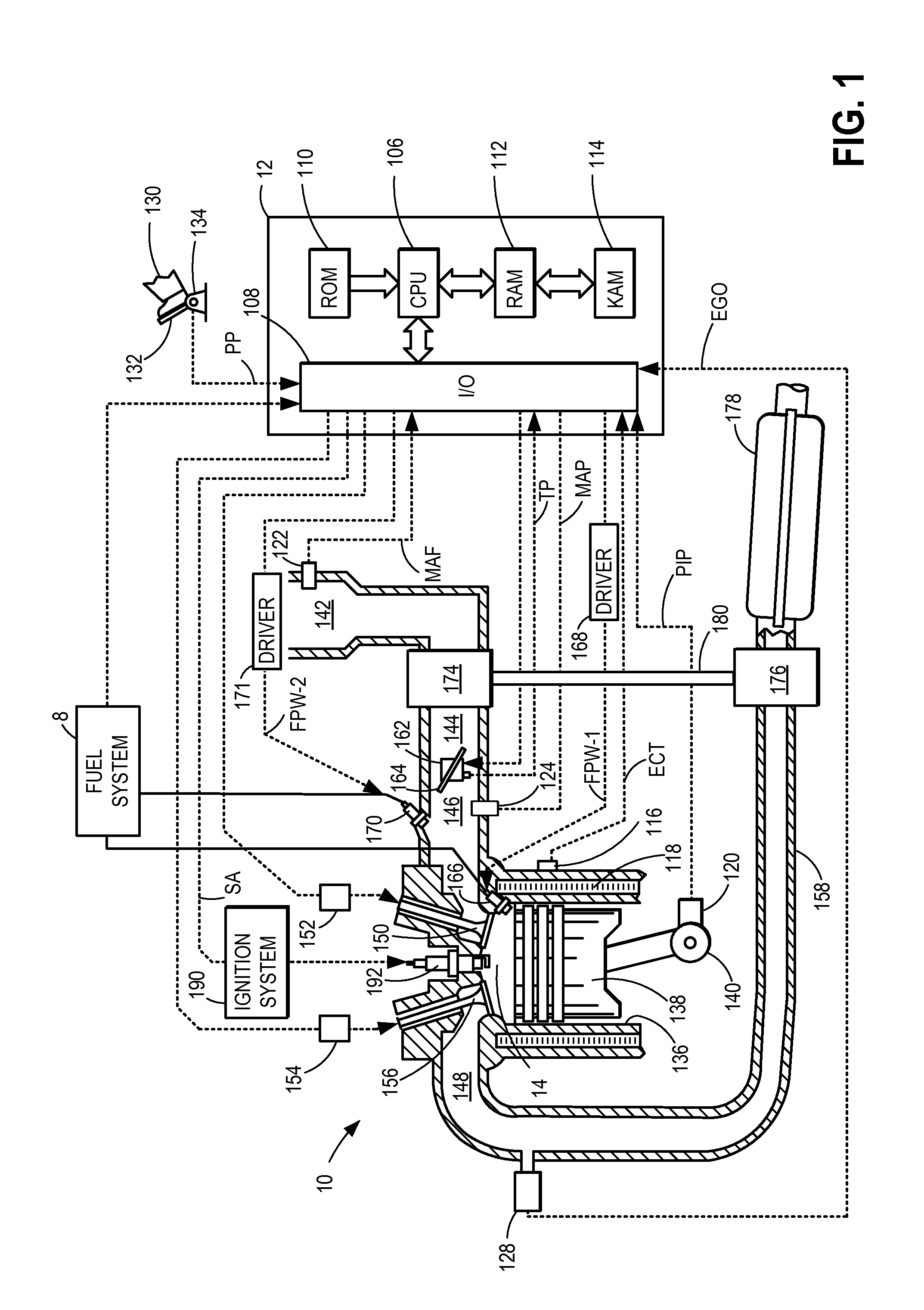

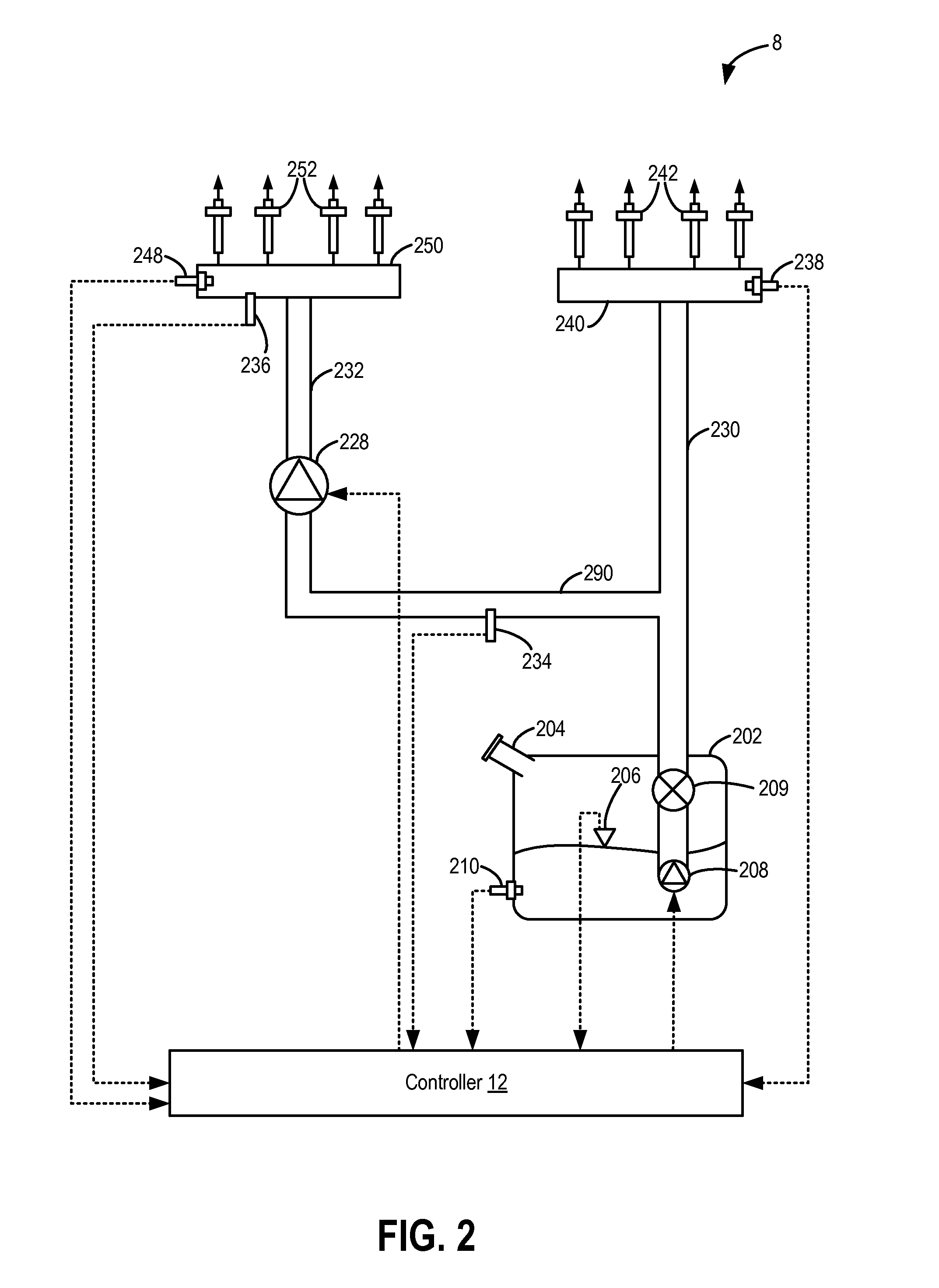

Direct injection fuel pump

ActiveUS20140224209A1Reduce degradation rateImprove fuel pump lubricationElectrical controlWear reducing fuel injectionLubricationFuel pump

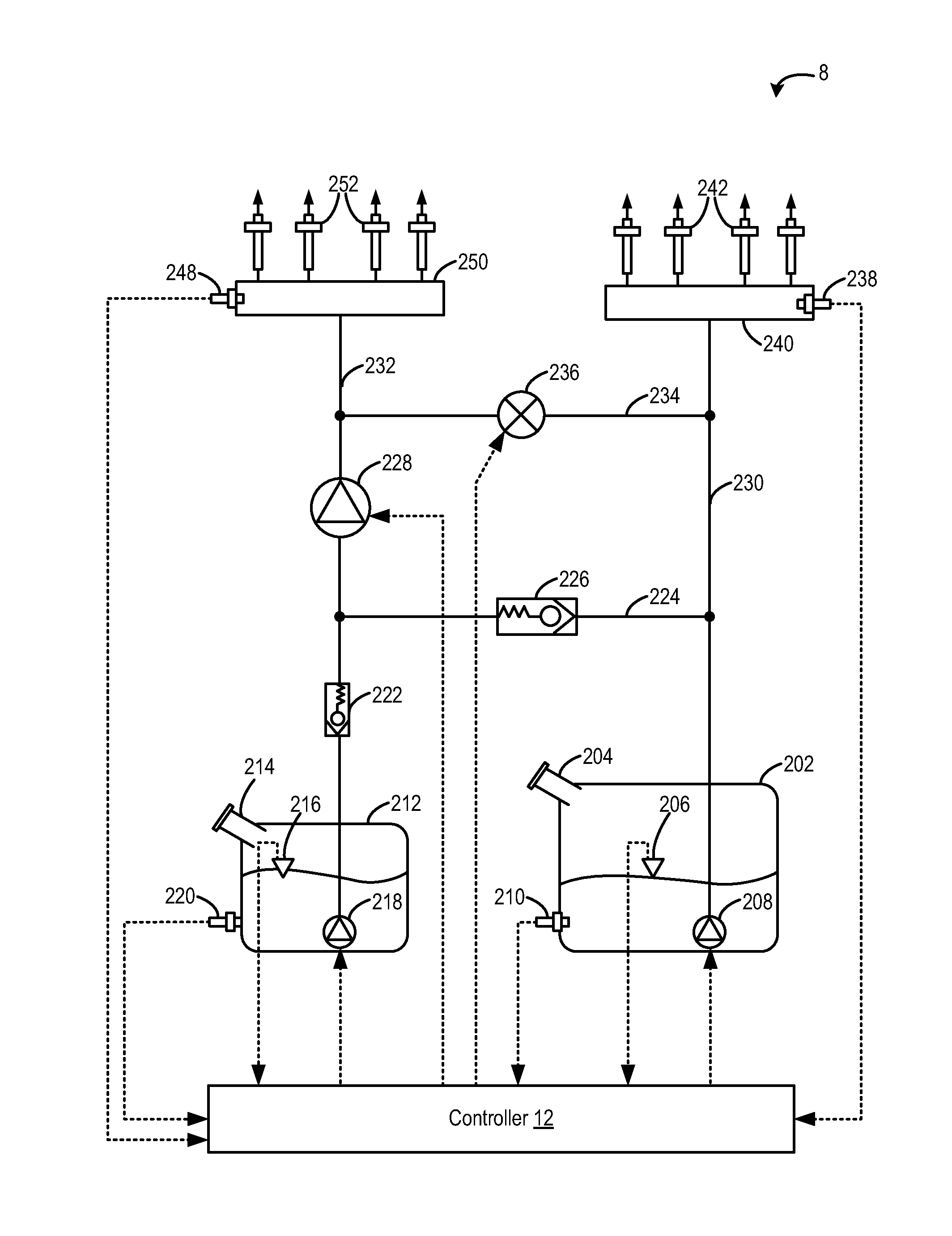

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

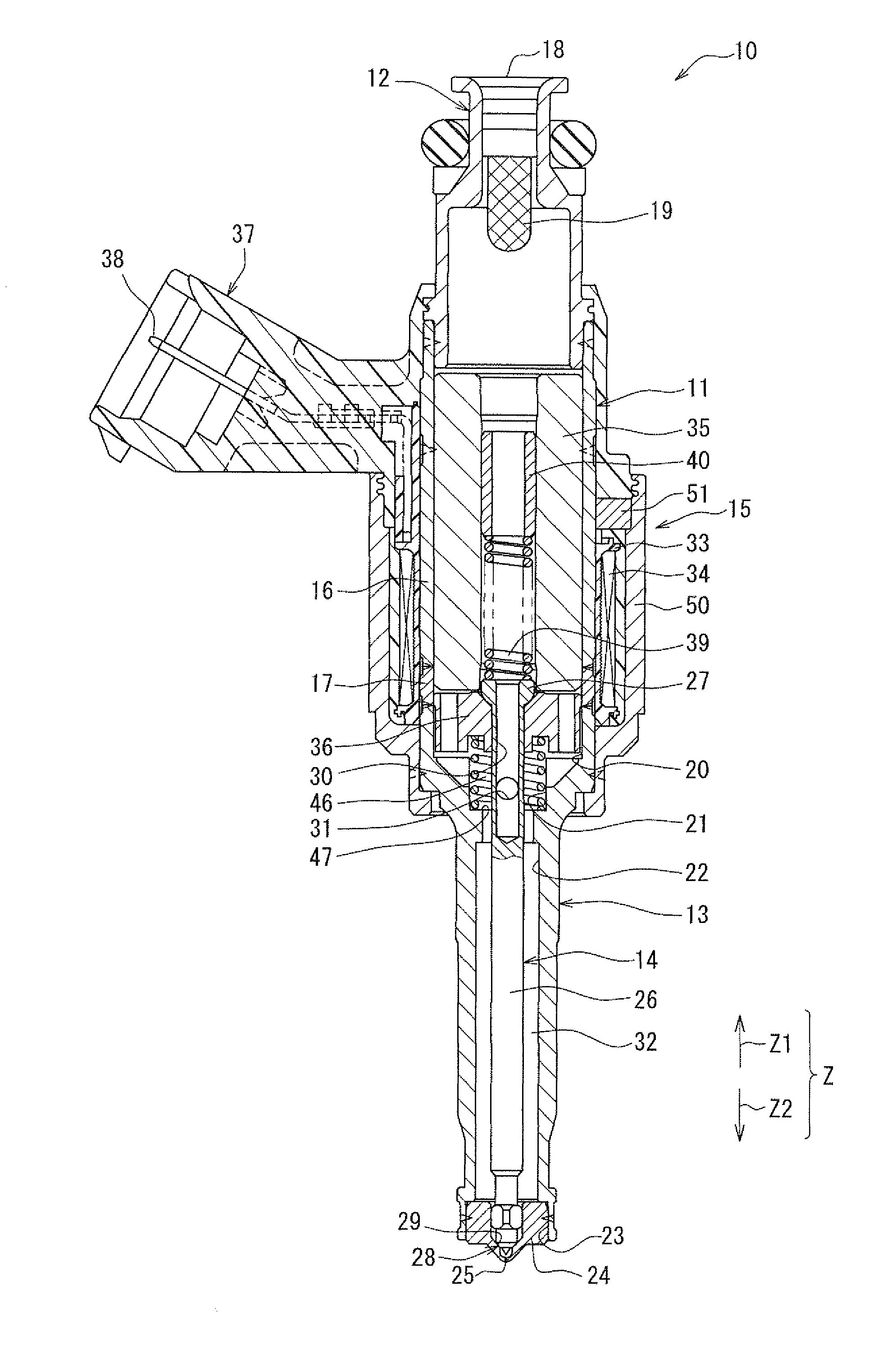

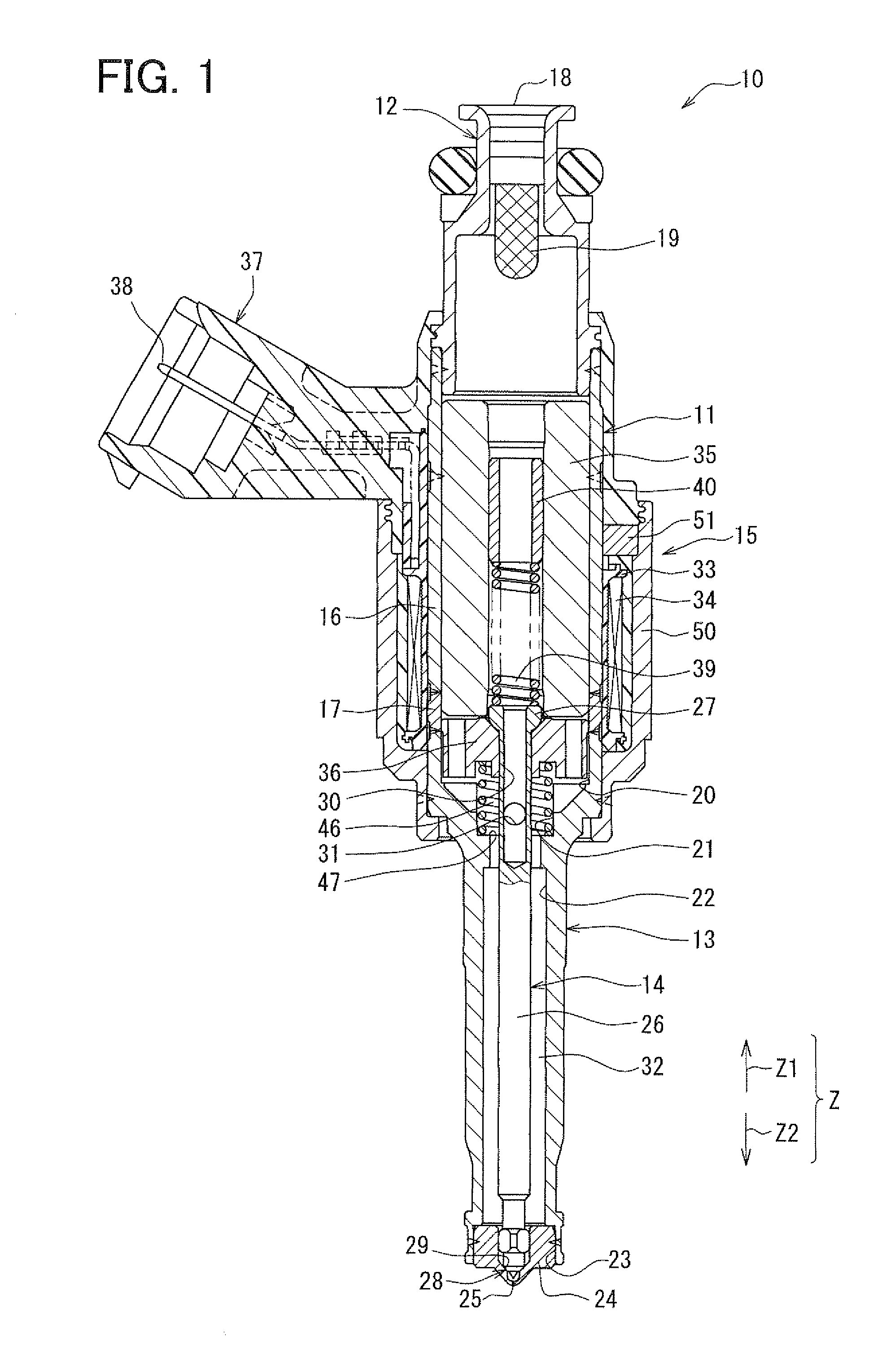

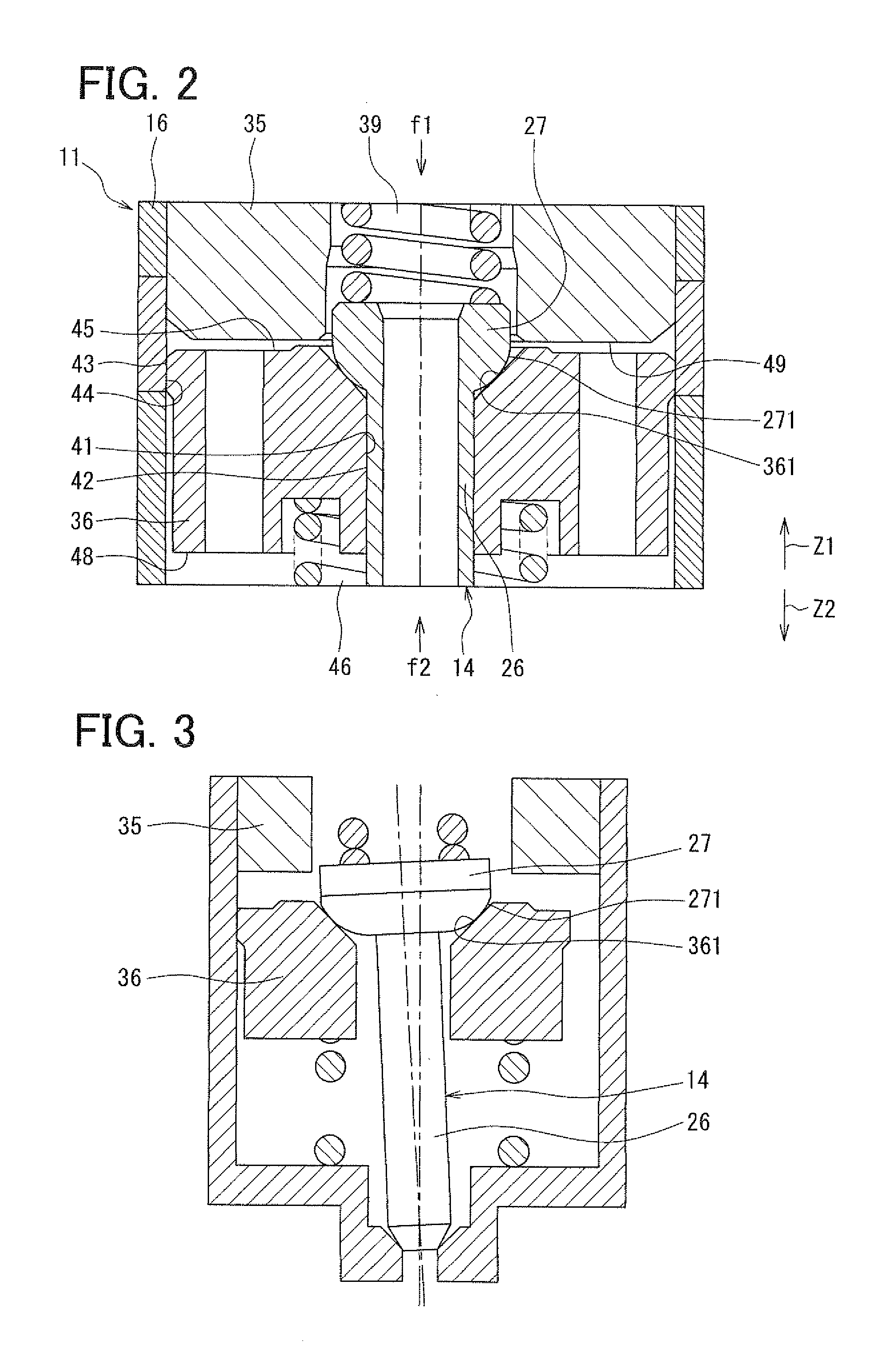

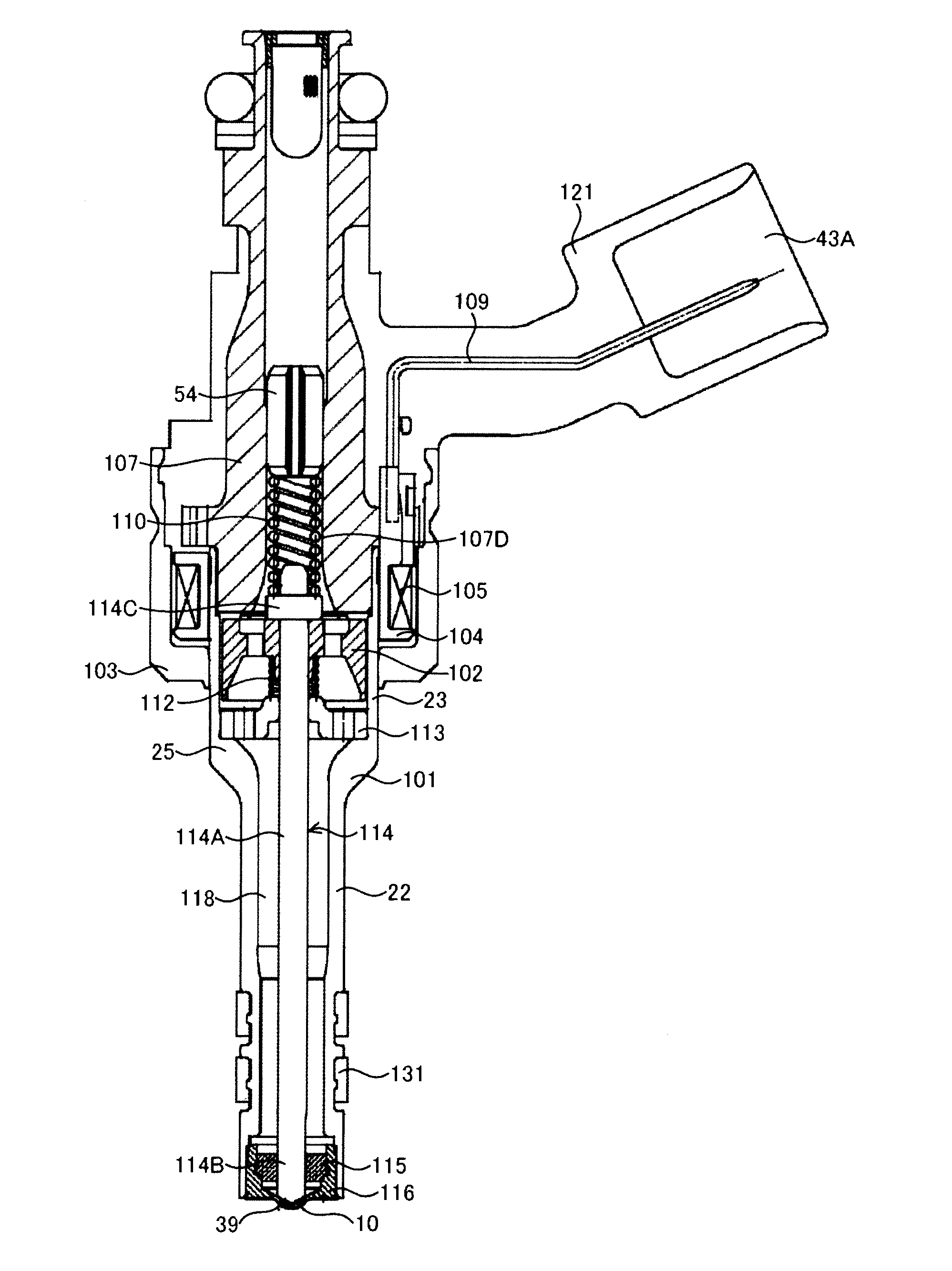

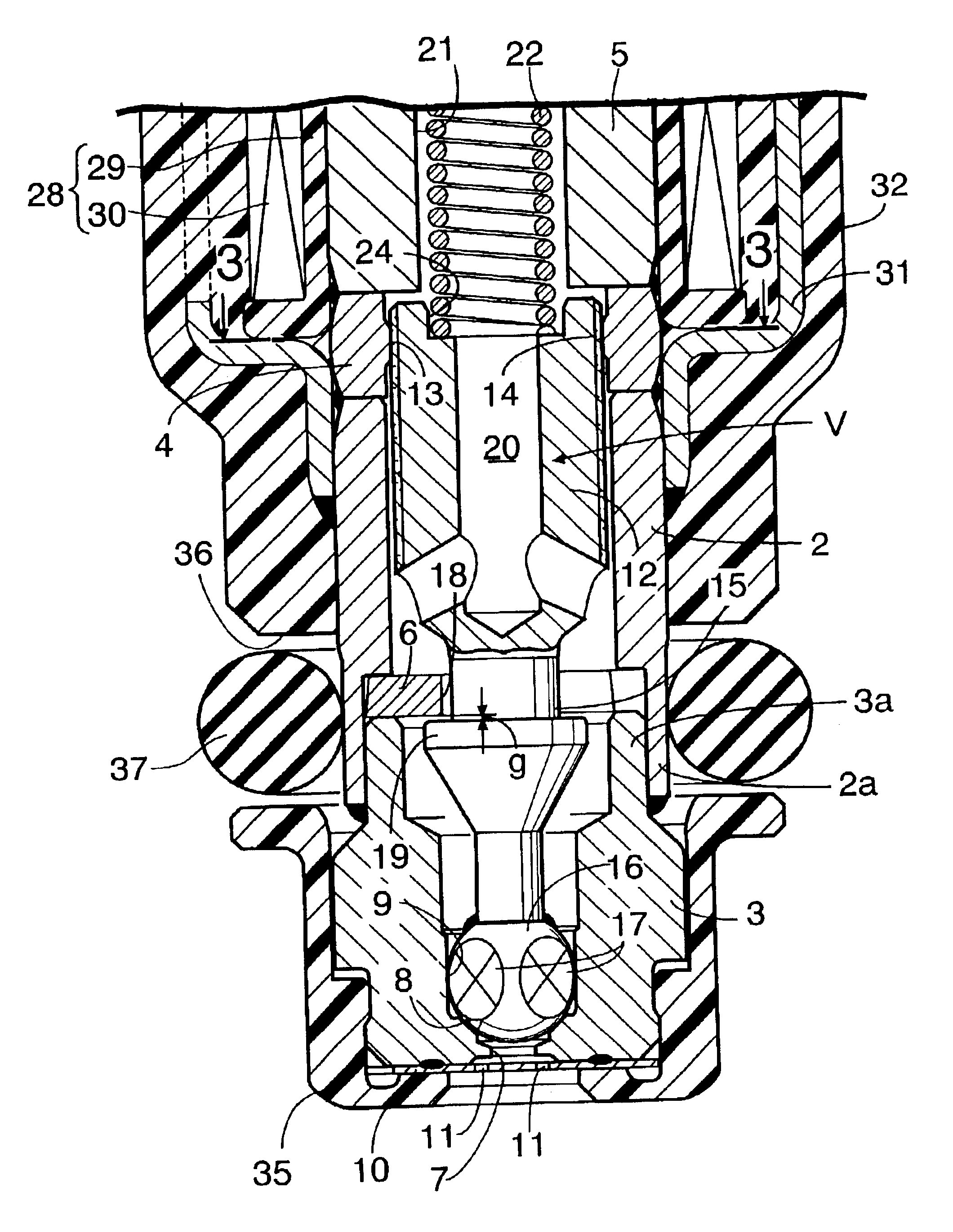

Injector

An injector includes a housing, a fixed core, a movable core, a valve member, and a resilient member pressing the valve member toward a nozzle hole. An inner peripheral surface of the housing axially guides an outer peripheral surface of the movable core. The inner peripheral surface and the outer peripheral surface define an outer clearance therebetween. The valve member includes a shaft-shaped portion and a stopper portion, which contacts the movable core and has a stopper inclined surface. An outer peripheral surface of the shaft-shaped portion and an inner peripheral surface of an insertion hole of the movable core define an inner clearance therebetween. The stopper inclined surface inclines radially inward of the shaft-shaped portion axially toward the nozzle hole. An axial clearance is formed between the stopper inclined surface and the movable core radially outward of a contact portion between the stopper inclined surface and the movable core.

Owner:DENSO CORP

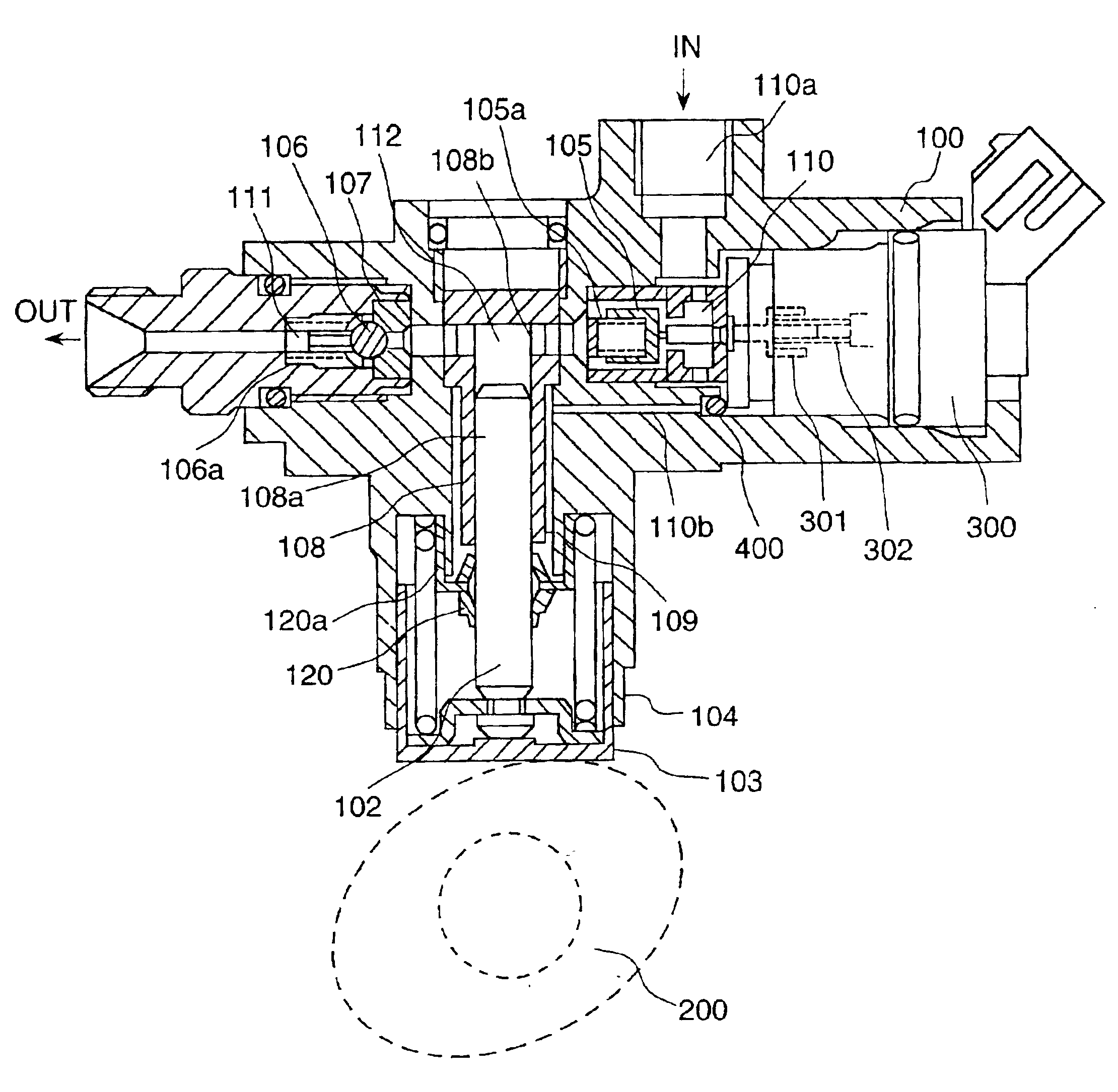

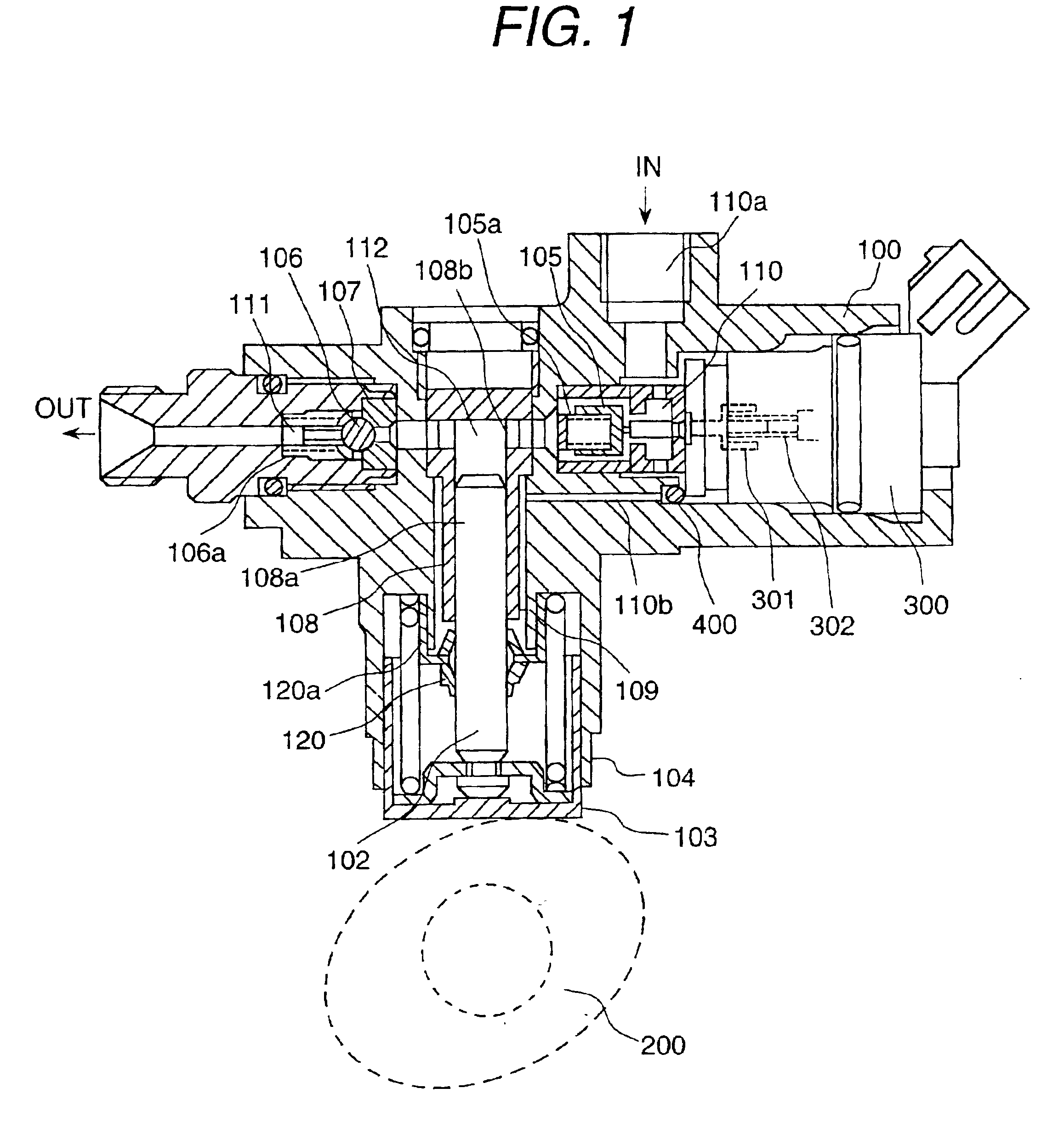

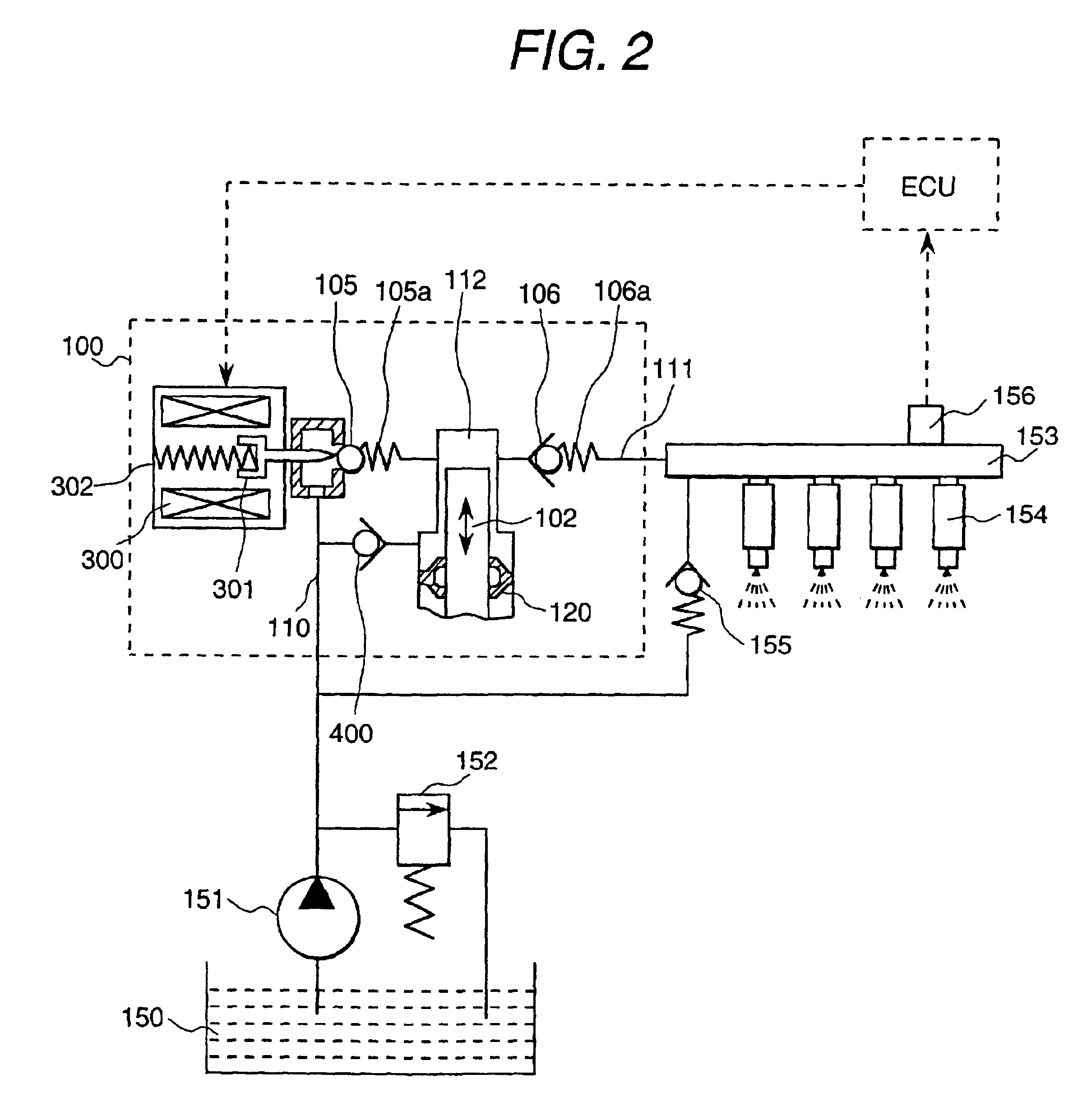

Fuel pump and direct fuel injection engine

InactiveUS6860255B2Improve wear resistanceHigh hardnessPositive displacement pump componentsWear reducing fuel injectionInjectorCorrosion resistant

A fuel pump, of which sliding mechanism parts in its fuel chamber have good wear resistance under a severe environment, and a direct fuel injection engine using the fuel pump are provided.In a fuel pump for pressurizing and delivering fuel to a fuel injector of a vehicle engine, at least one of sliding surfaces of a slant plate, a slipper and a plunger sliding in a lubricating oil and at least one of sliding surfaces of sliding members of a plunger and a cylinder contacting with and sliding on each other through the fuel are formed of a hardened layer composed of any one of a nitrided layer, a carburization quenched layer and a carbonitrided layer, or coated with a high corrosion resistant and hard metal compound layer over the hardened layer.

Owner:HITACHI LTD

Fuel injection valve

ActiveUS20050035222A1Ensure durabilityReduce coefficient of frictionNon-fuel substance addition to fuelWear reducing fuel injectionSurface roughnessHardness

A fuel injection valve for an automotive internal combustion engine comprises a needle valve and an opposite member which are in slidable contact with each other in presence of fuel. A hard carbon thin film is coated on at least one of the sliding sections of the base materials of the needle valve and the opposite member. The hard carbon thin film has a surface hardness ranging from 1500 to 4500 kg / mm2 in Knoop hardness, a film thickness ranging from 0.3 to 2.0 μm, and a surface roughness (Ry) (μm) which satisfies a relationship represented by the following formula (A):Ry<(0.75−Hk / 8000)×h+0.0875 (A)where h is the thickness (μm) of the hard carbon thin film; Hk is the surface hardness in Knoop hardness (kg / mm2) of the hard carbon thin film.

Owner:NISSAN MOTOR CO LTD

Dual fuel injector for a common rail system

InactiveUS20120187218A1Internal combustion piston enginesWear reducing fuel injectionCommon railEngineering

A dual fuel common rail fuel injector includes a first and second control valve assembly and a first and second check needle. The dual fuel injector is capable of selectively injecting two different fuels such as diesel and liquid natural gas. The first and second control valve assemblies operate using a single fuel, such as diesel, as the control medium. The dual fuel common rail injector further includes a hydraulic lock assembly.

Owner:CATERPILLAR INC

Dual fuel injector for a common rail system

InactiveUS8459576B2Internal combustion piston enginesWear reducing fuel injectionCommon railControl valves

A dual fuel common rail fuel injector includes a first and second control valve assembly and a first and second check needle. The dual fuel injector is capable of selectively injecting two different fuels such as diesel and liquid natural gas. The first and second control valve assemblies operate using a single fuel, such as diesel, as the control medium. The dual fuel common rail injector further includes a hydraulic lock assembly.

Owner:CATERPILLAR INC

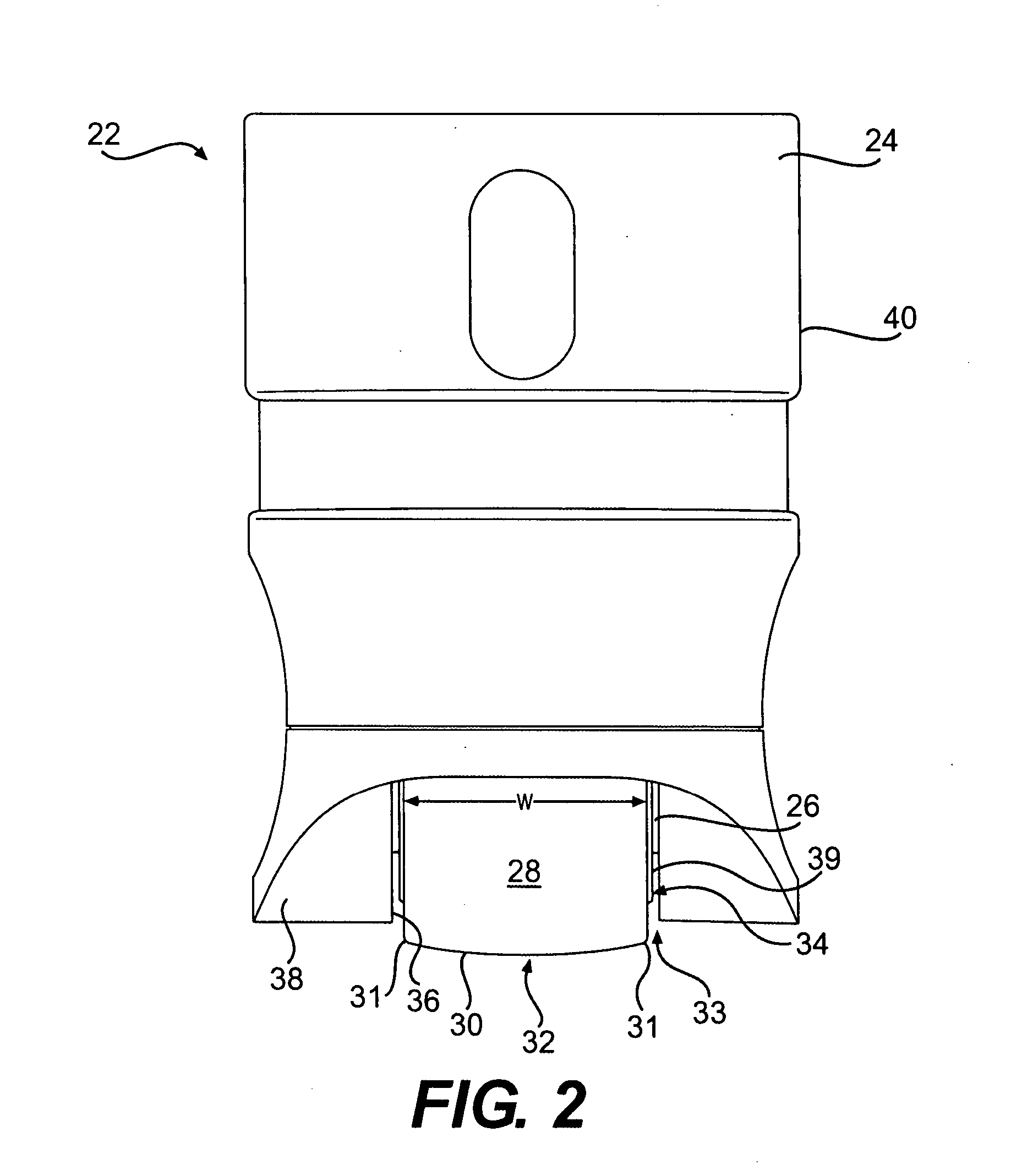

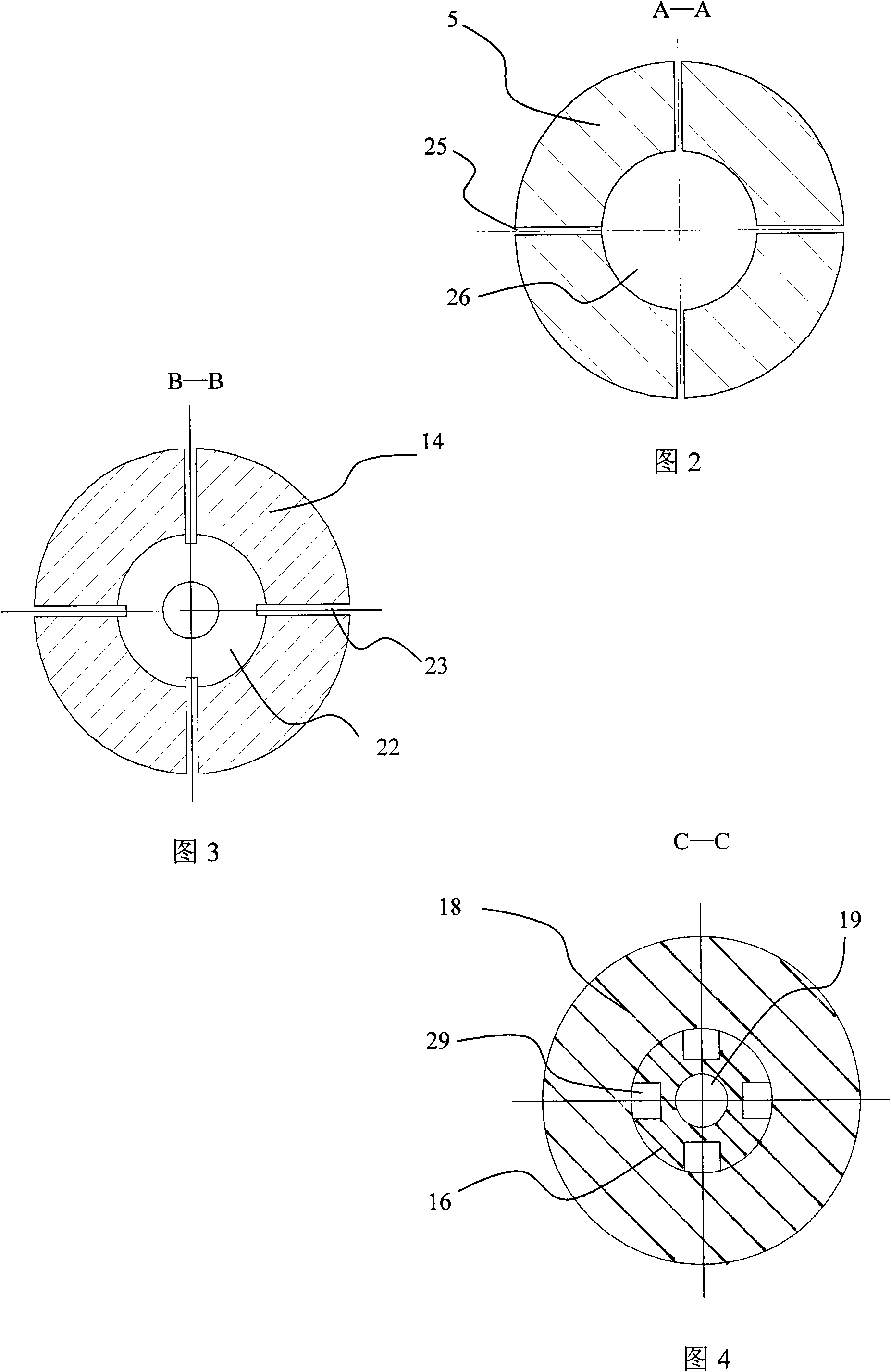

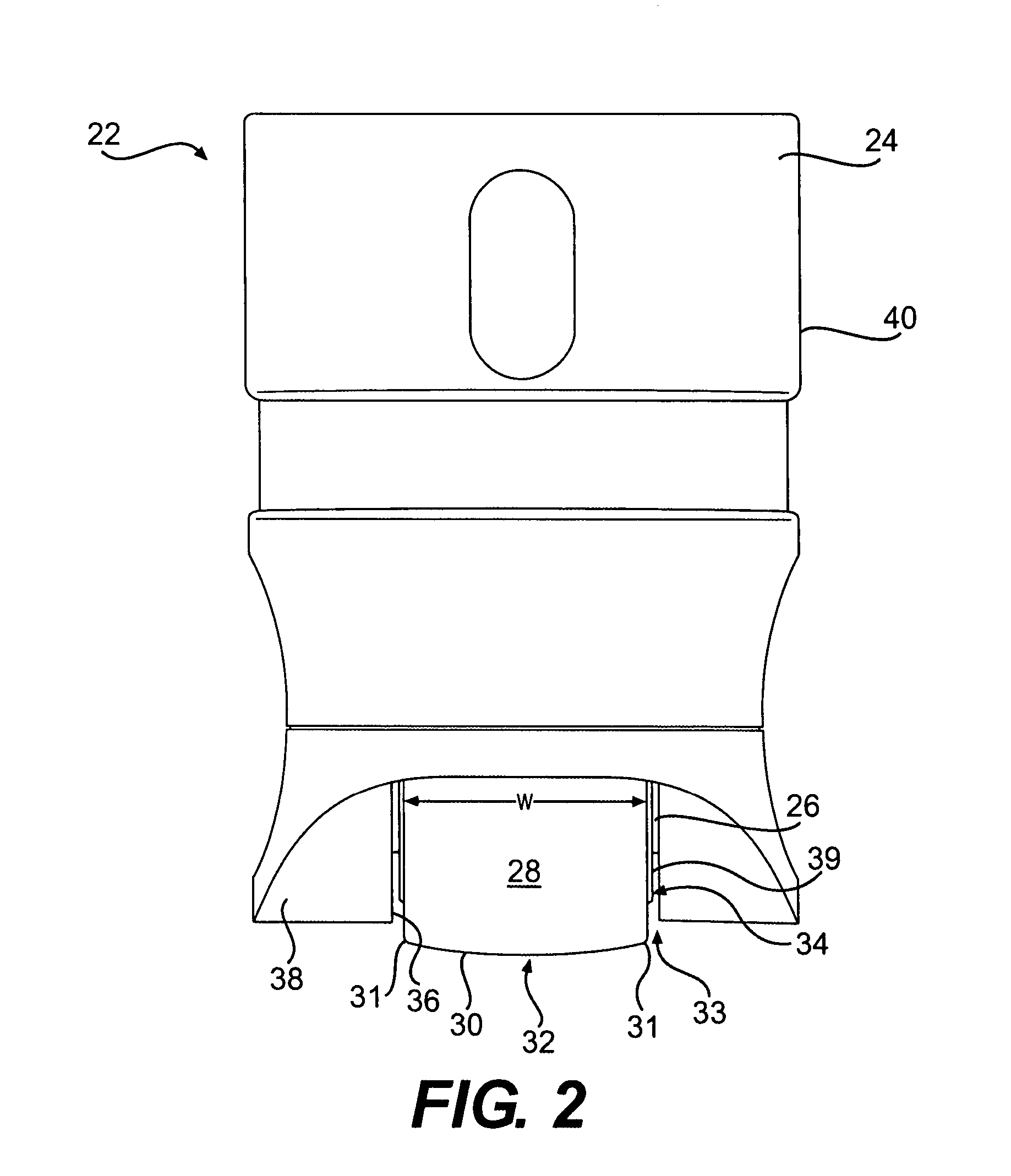

Tappet assembly

In one aspect, the present disclosure is directed to a tappet assembly for a machine. The assembly may include a tappet body, a pin fixedly mounted in the tappet body, and a substantially cylindrical roller mounted about the pin. The roller may have a substantially cylindrical outer surface with a circumferential dimension and a width dimension, the width dimension being defined by two lateral edges. The roller may be configured to provide rolling contact between the outer surface of the roller and a cam lobe. The outer surface of the roller may be crowned such that at maximum operational loading conditions of the machine a footprint of contact pressure from the cam lobe is spread substantially the full width of outer cylindrical surface of the roller.

Owner:CATERPILLAR INC

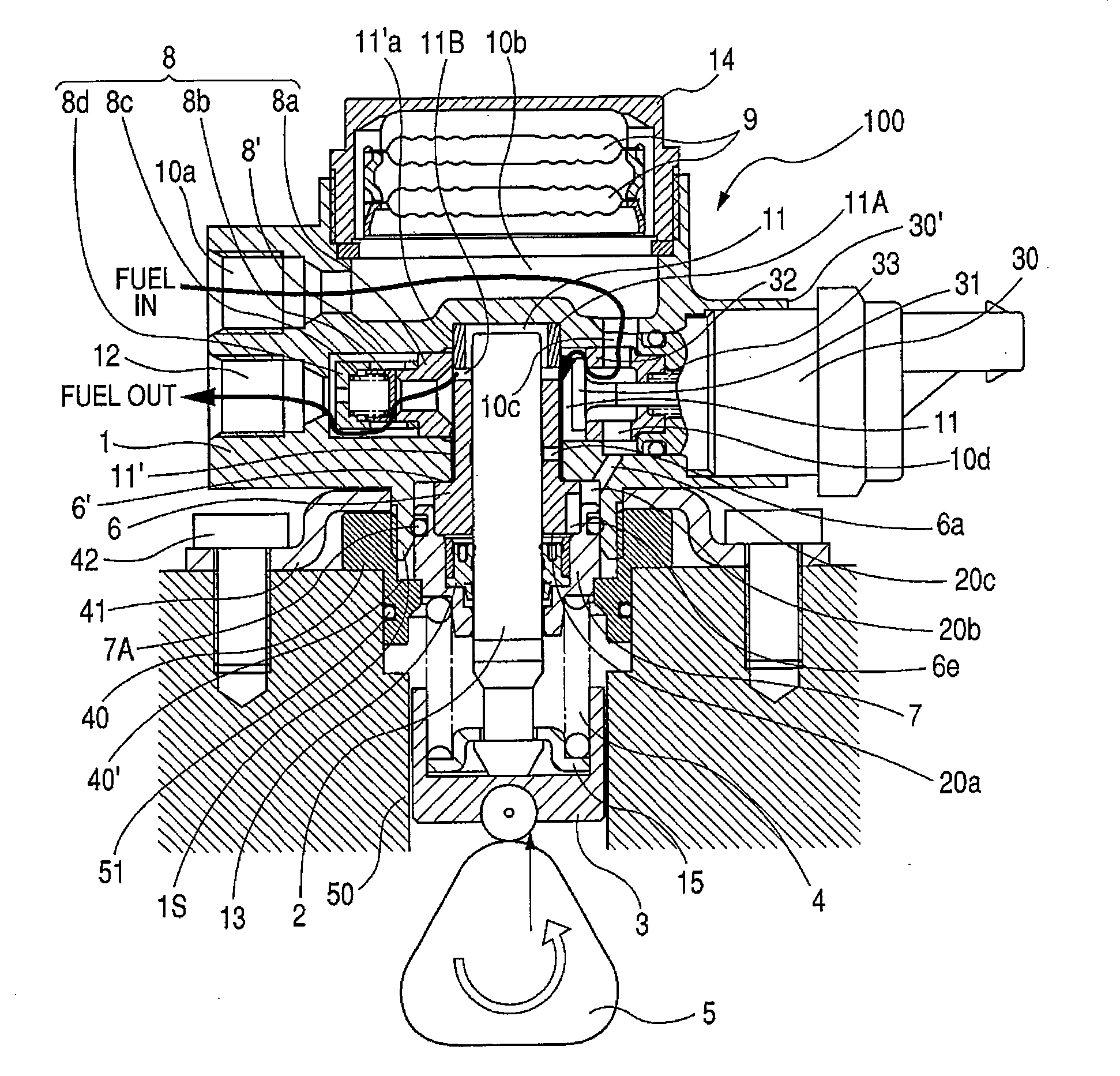

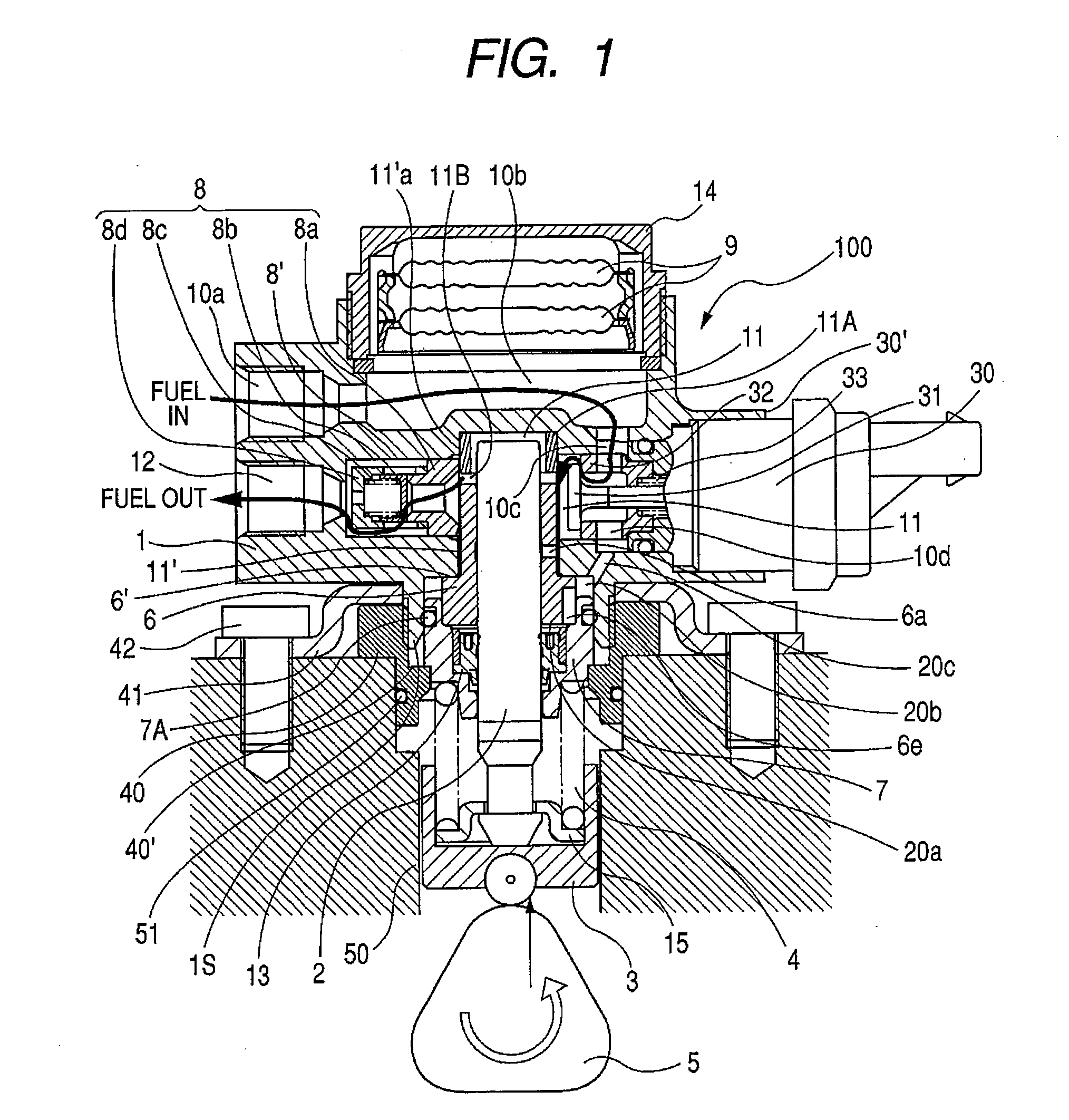

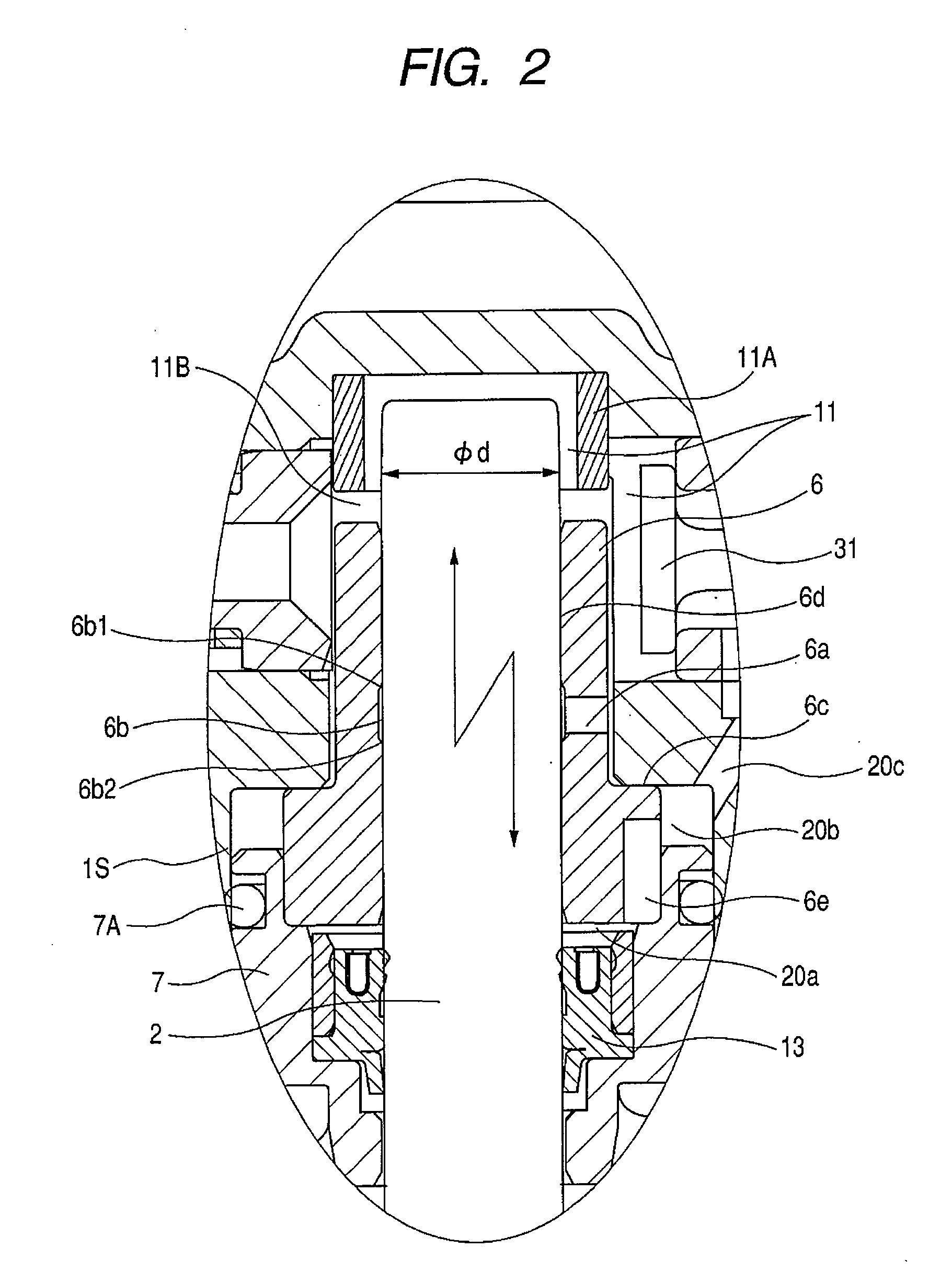

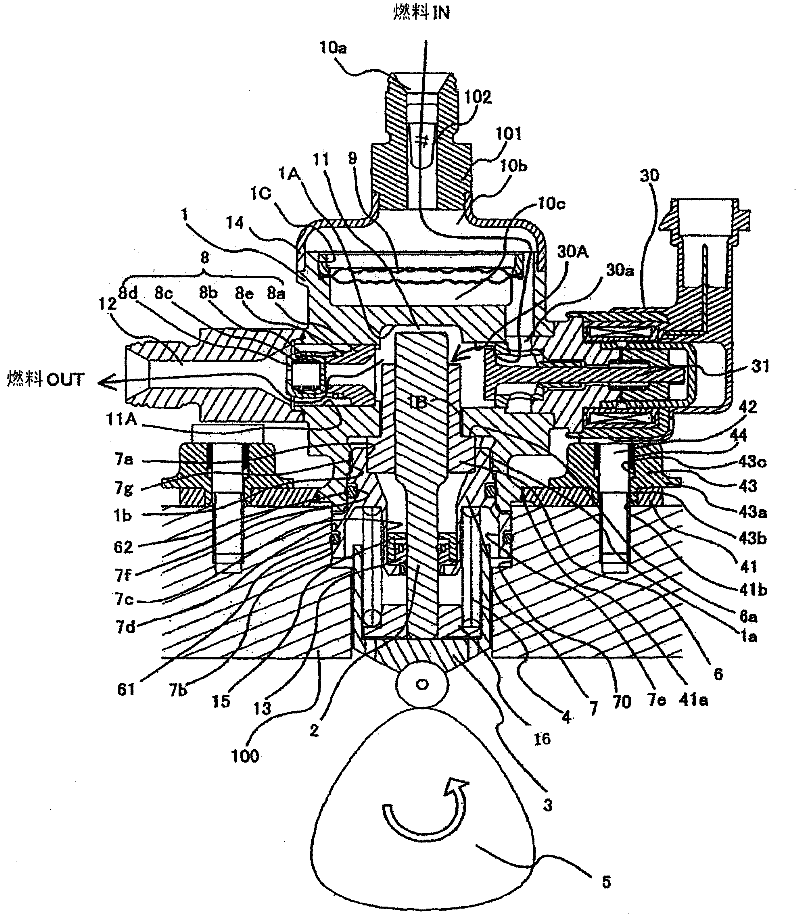

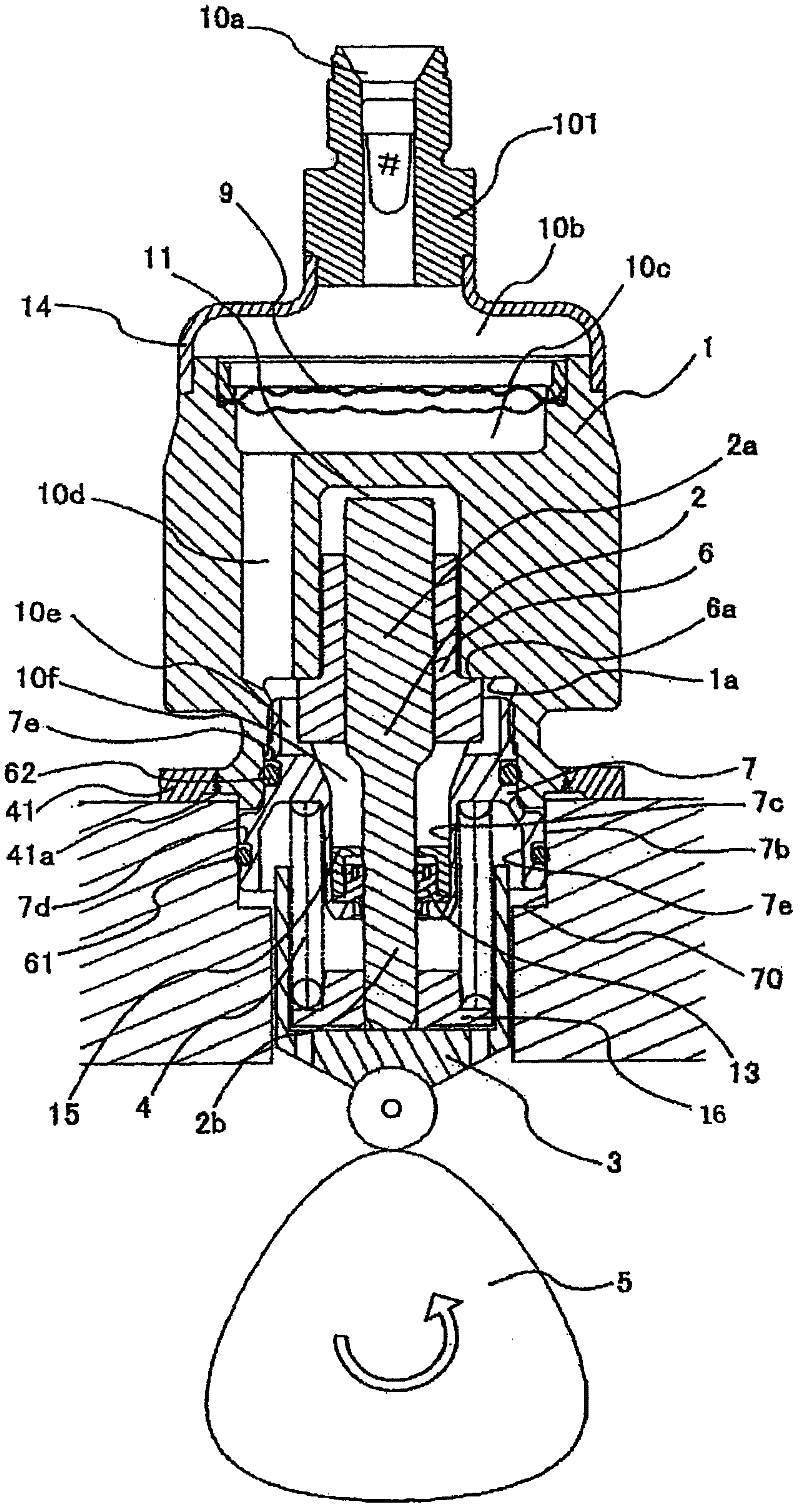

High-Pressure Fuel Pump

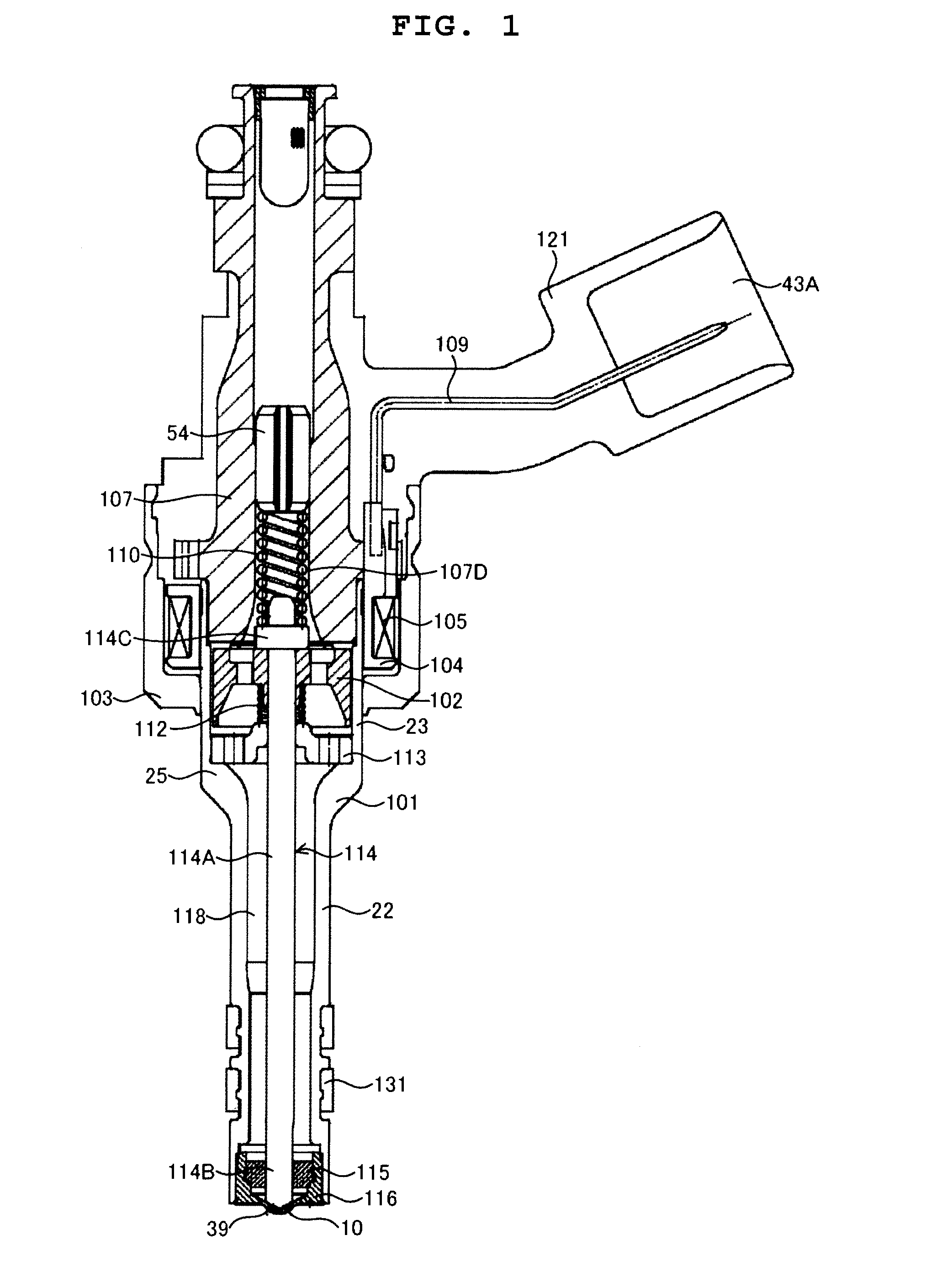

ActiveUS20080019853A1Improve the lubrication effectImprove toughnessPositive displacement pump componentsWear reducing fuel injectionReciprocating motionInlet valve

A high-pressure fuel pump is comprises of: a plunger which slidably fits to a cylinder and reciprocates for pressurizing and discharging a fuel taken in a pressurizing chamber; an inlet valve device for taking in a fuel into the pressurizing chamber; an outlet valve device for discharging the pressurized fuel from the pressurizing chamber; and a communicating pass which comprises a hole or a groove formed in the cylinder, and communicates between a pressurized fuel area and a gap between the cylinder and the plunger.

Owner:HITACHI ASTEMO LTD

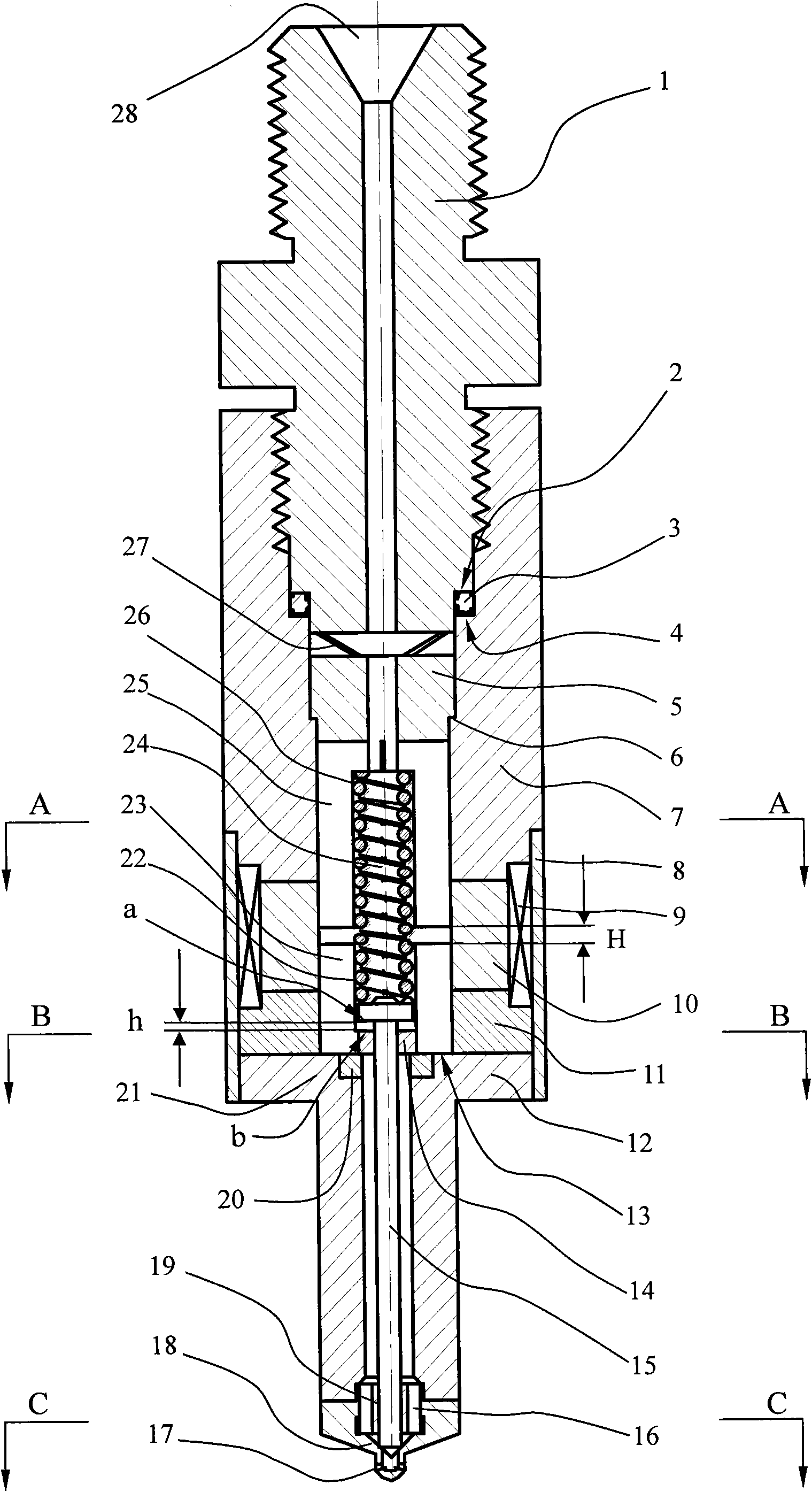

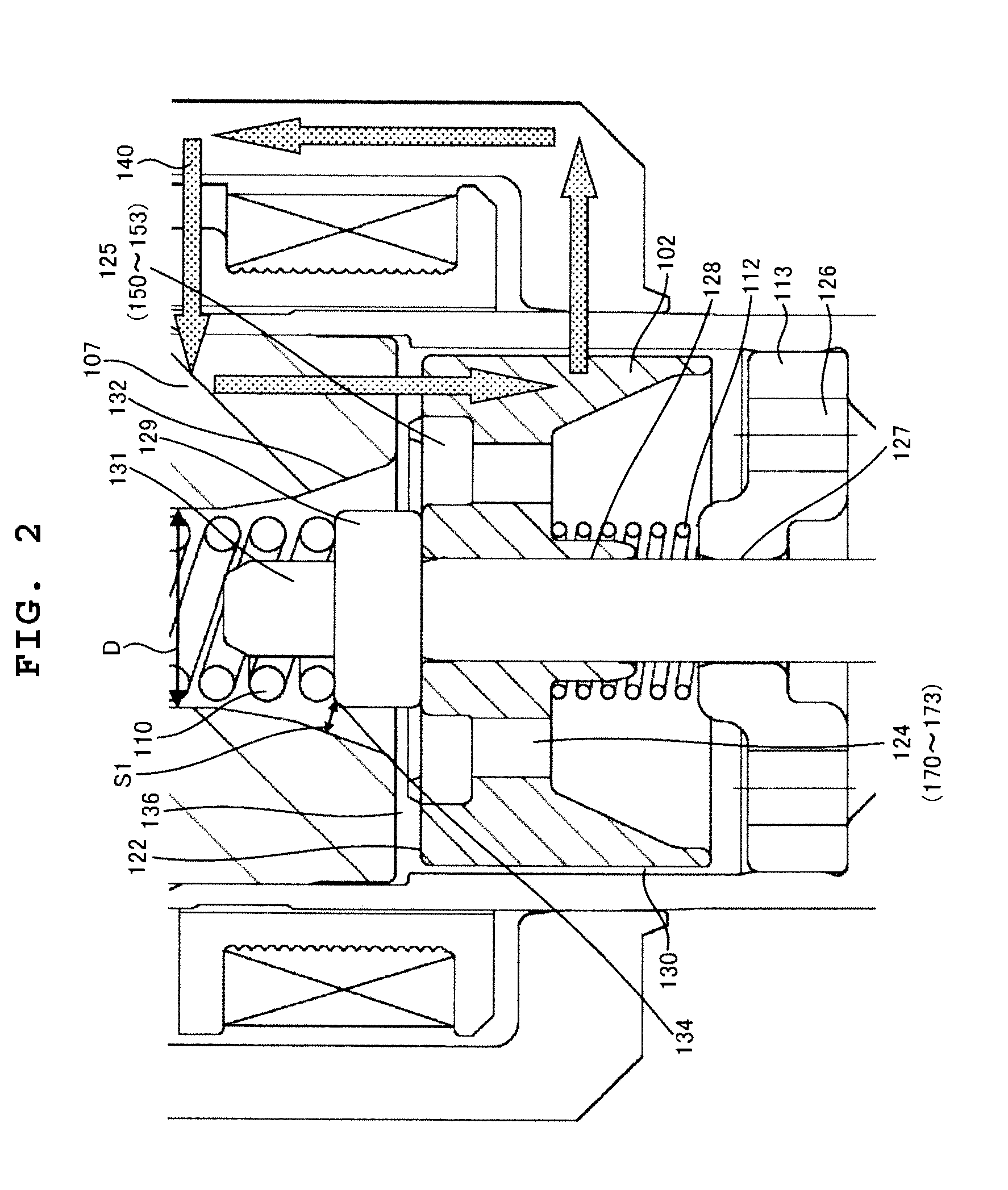

Common rail electronic control jet apparatus

ActiveCN101539084AReduce control linksImprove energy utilizationWear reducing fuel injectionMagnetic flux influencing fuel injectionCommon railEngineering

The invention relates to a common rail electronic control jet apparatus, belonging to technology of an electronic control fuel injection system. The controller comprises an oil inlet joint, an oil inlet, an electromagnet device, a nozzle body, a needle valve, a valve seat and a jet orifice; wherein, the electromagnet device includes a static iron core, a moving iron core and a coil, and a working clearance H exists between the static iron core and the moving iron core along the axial direction; the moving iron core is movably connected with the needle valve along the axial direction; the controller also comprises a compression spring acting on the needle valve, a force application mechanism acting on the moving iron core and a blocking mechanism used for providing axial anti-thrust when the moving iron core resets. The common rail electronic control jet apparatus has the advantages of low manufacturing cost, good reliability and low drive energy.

Owner:浙江朗杰电子有限公司

Tappet assembly

In one aspect, the present disclosure is directed to a tappet assembly for a machine. The assembly may include a tappet body, a pin fixedly mounted in the tappet body, and a substantially cylindrical roller mounted about the pin. The roller may have a substantially cylindrical outer surface with a circumferential dimension and a width dimension, the width dimension being defined by two lateral edges. The roller may be configured to provide rolling contact between the outer surface of the roller and a cam lobe. The outer surface of the roller may be crowned such that at maximum operational loading conditions of the machine a footprint of contact pressure from the cam lobe is spread substantially the full width of outer cylindrical surface of the roller.

Owner:CATERPILLAR INC

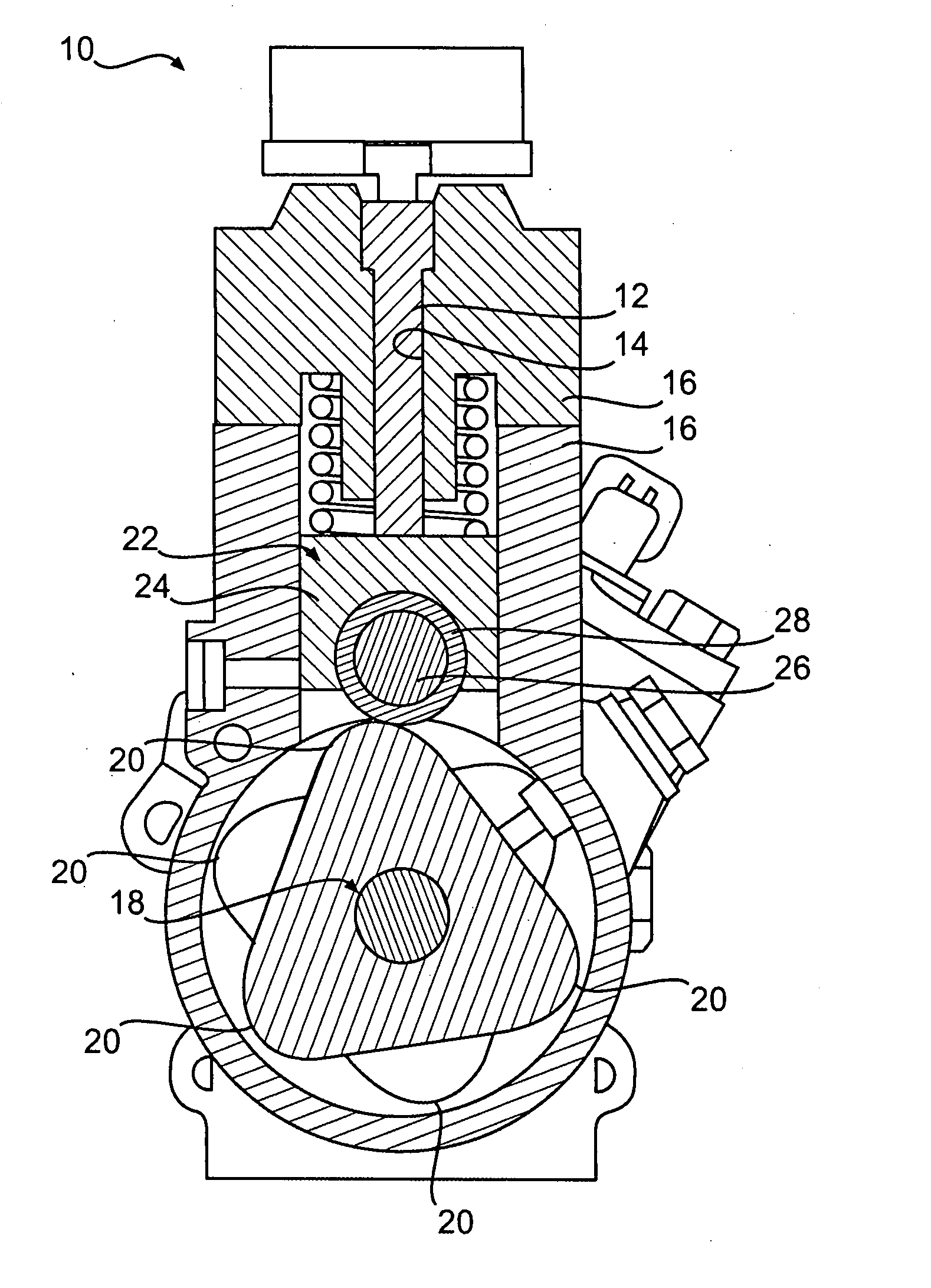

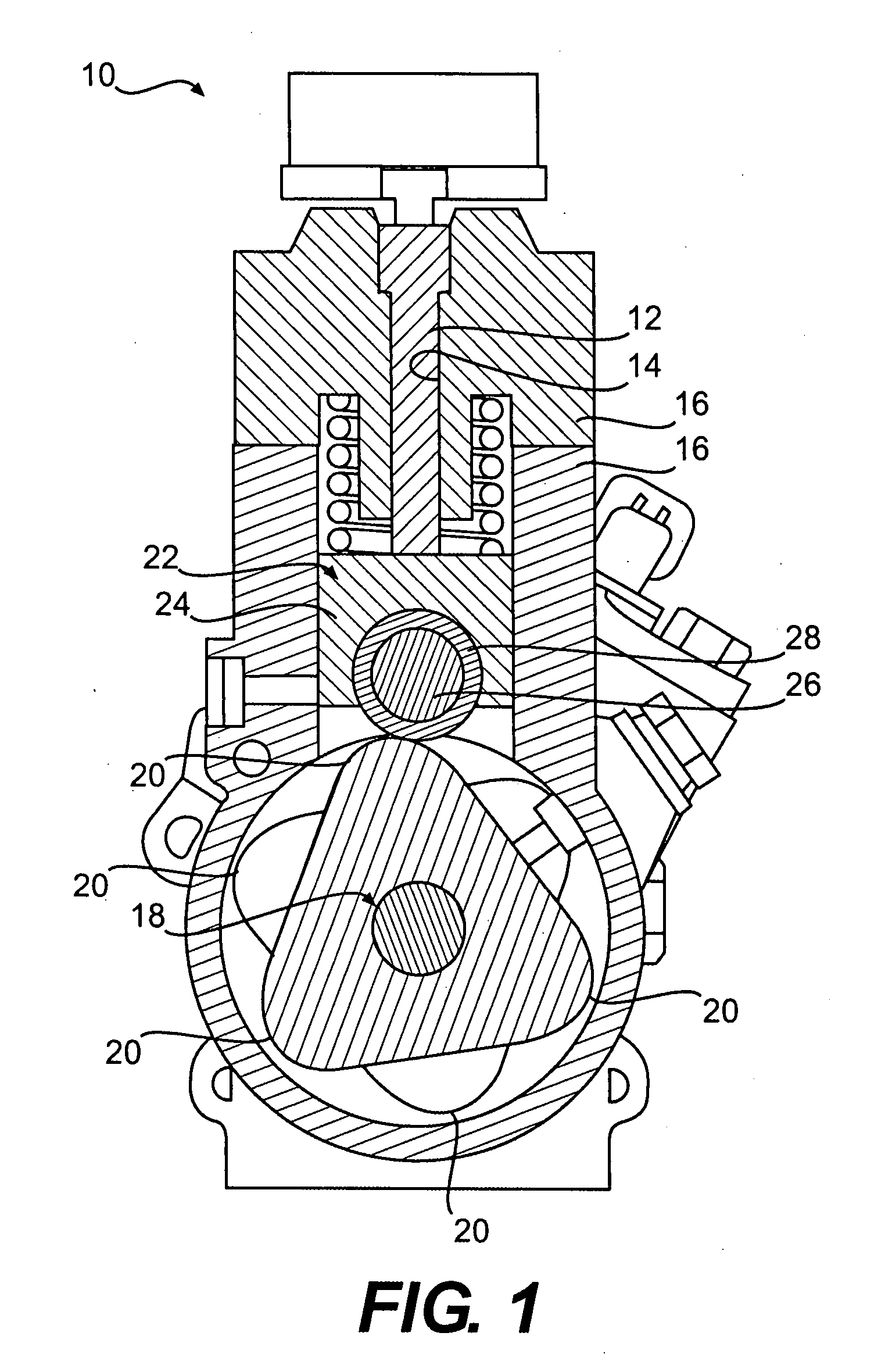

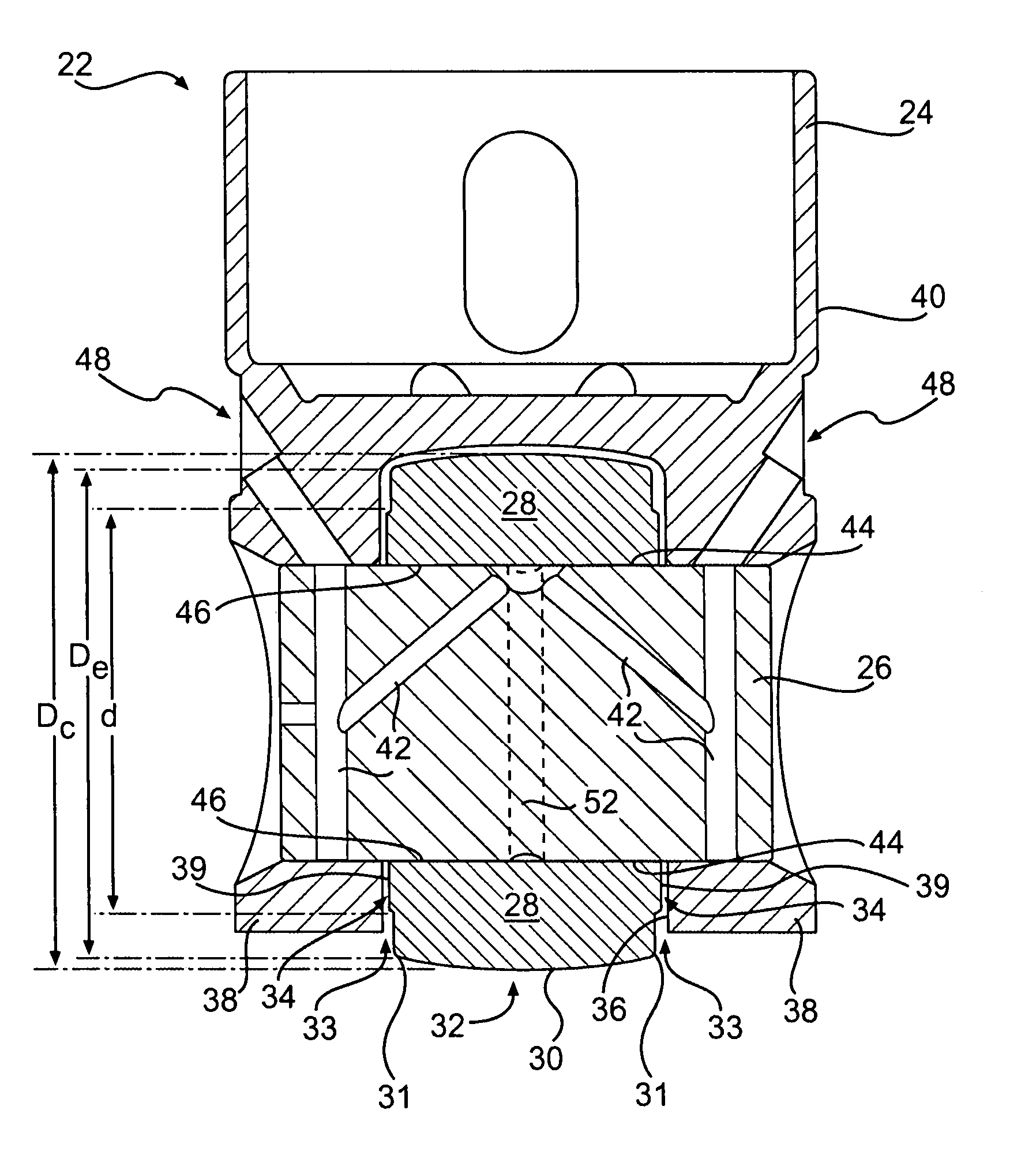

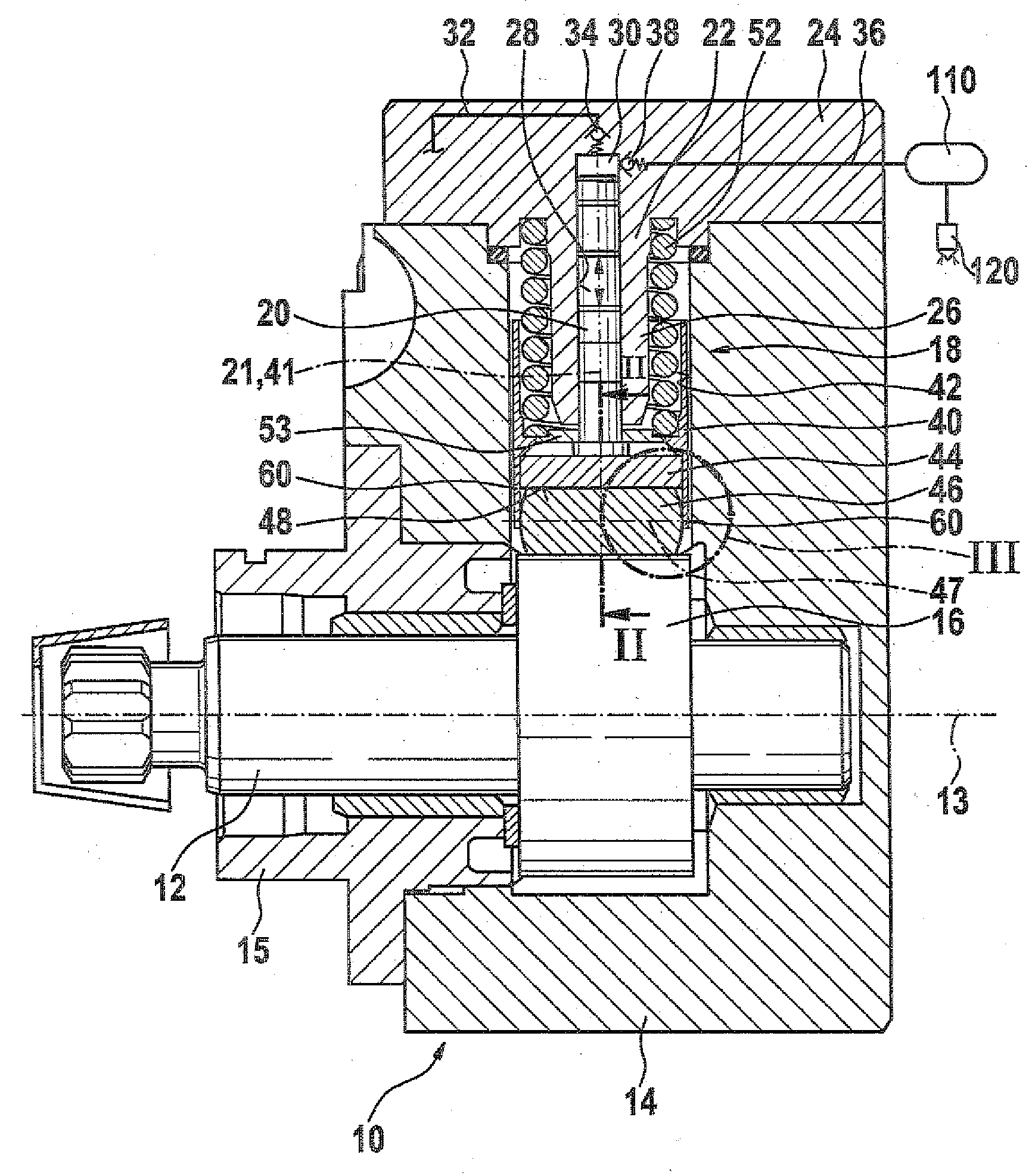

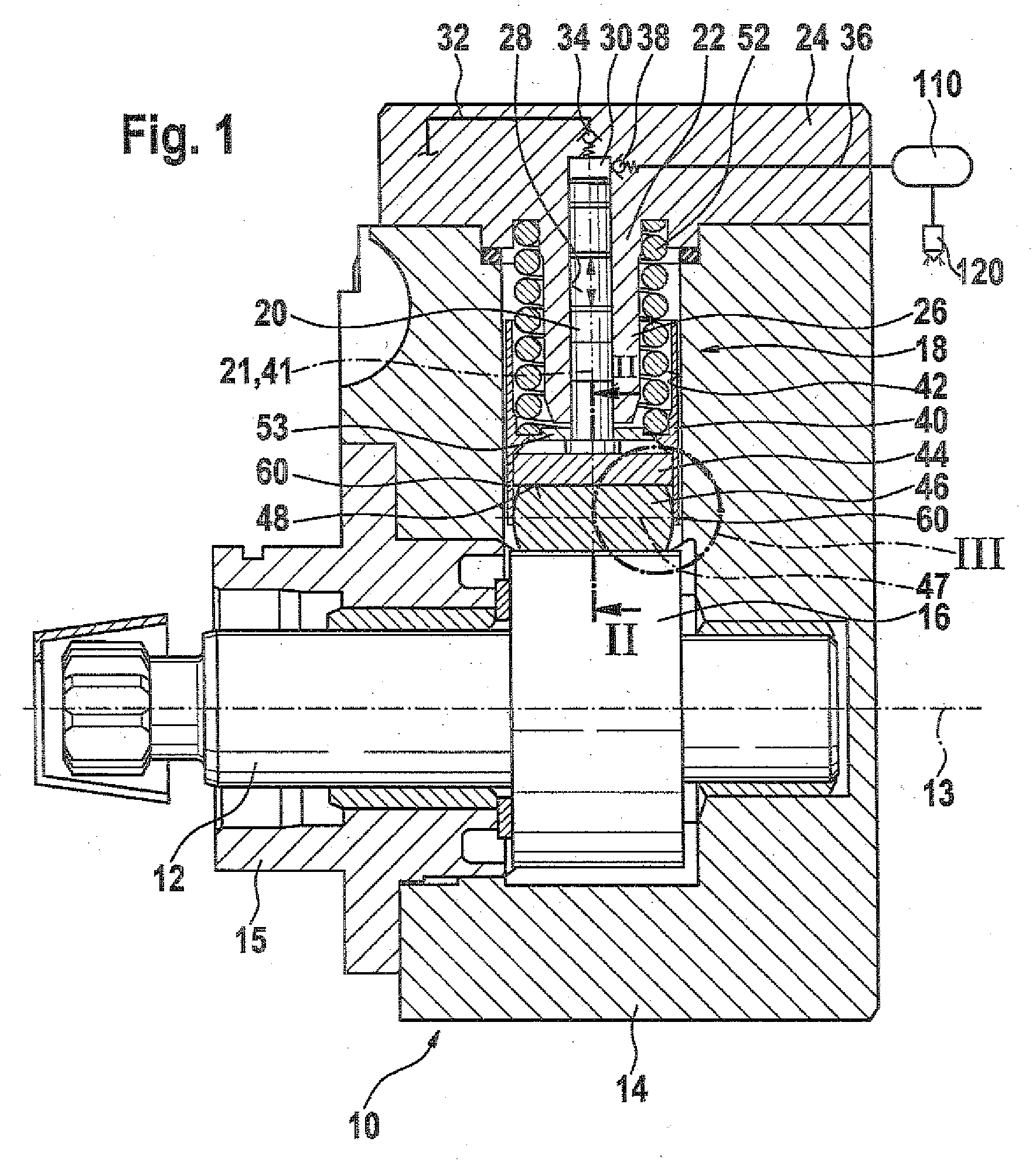

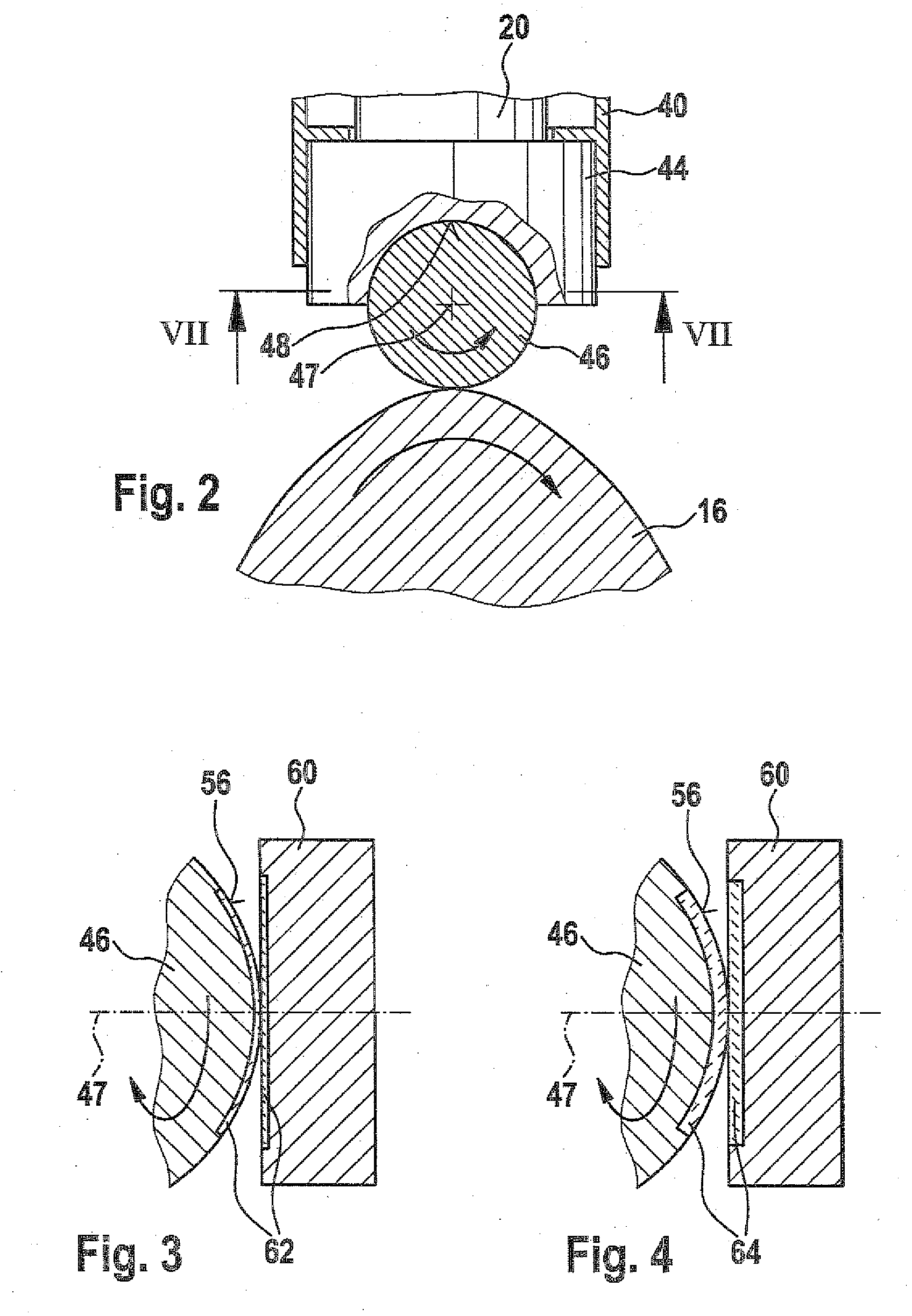

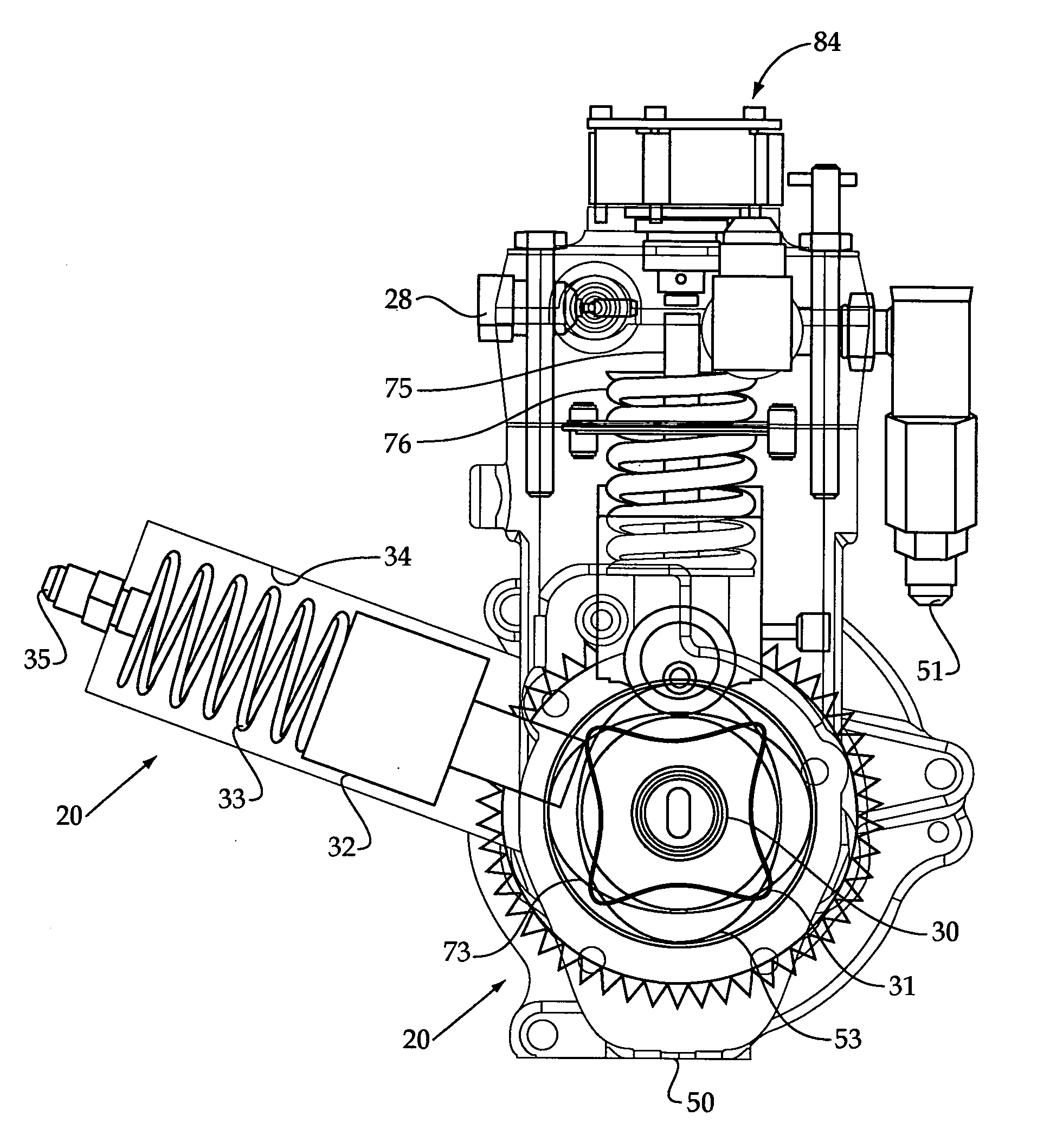

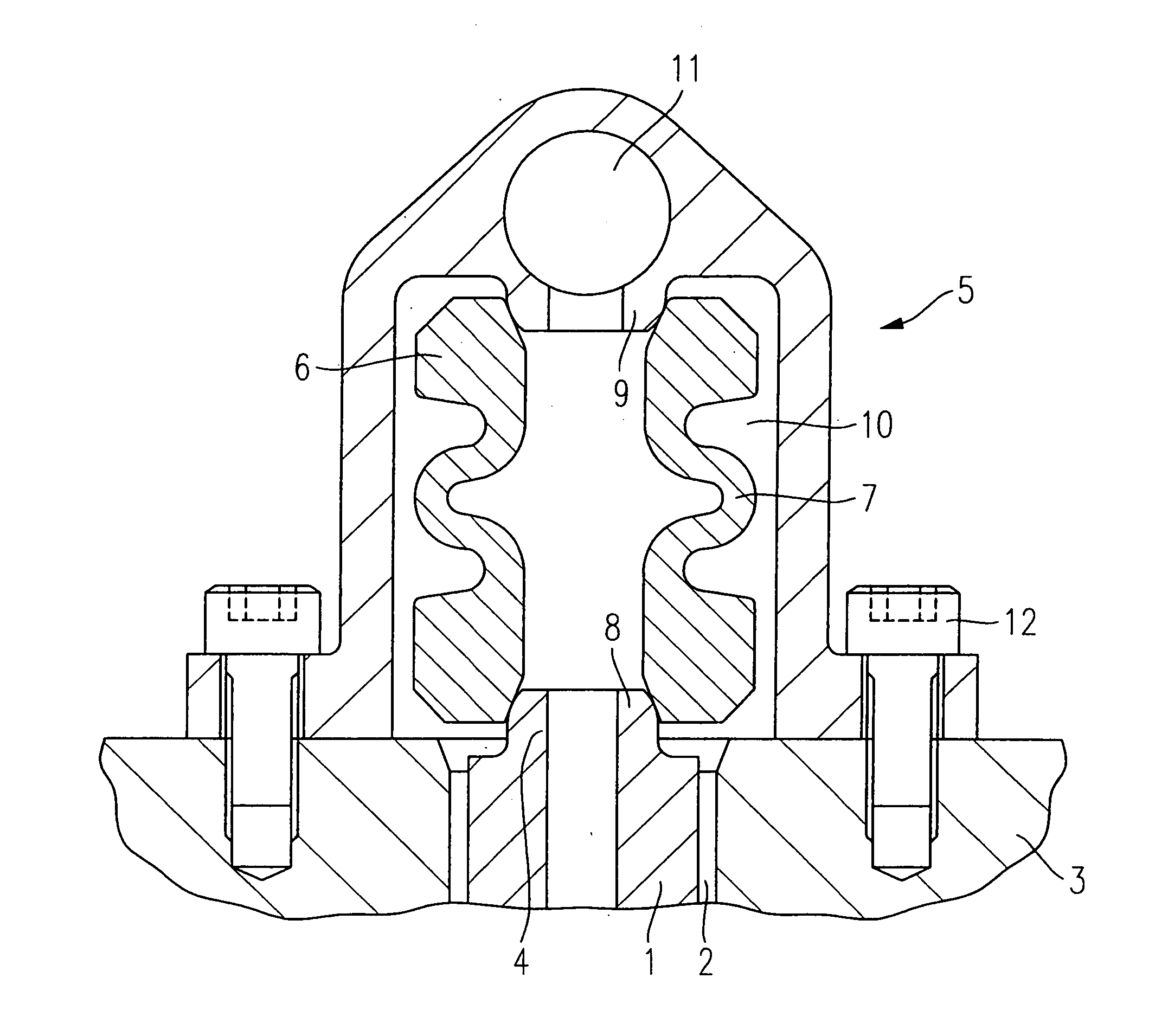

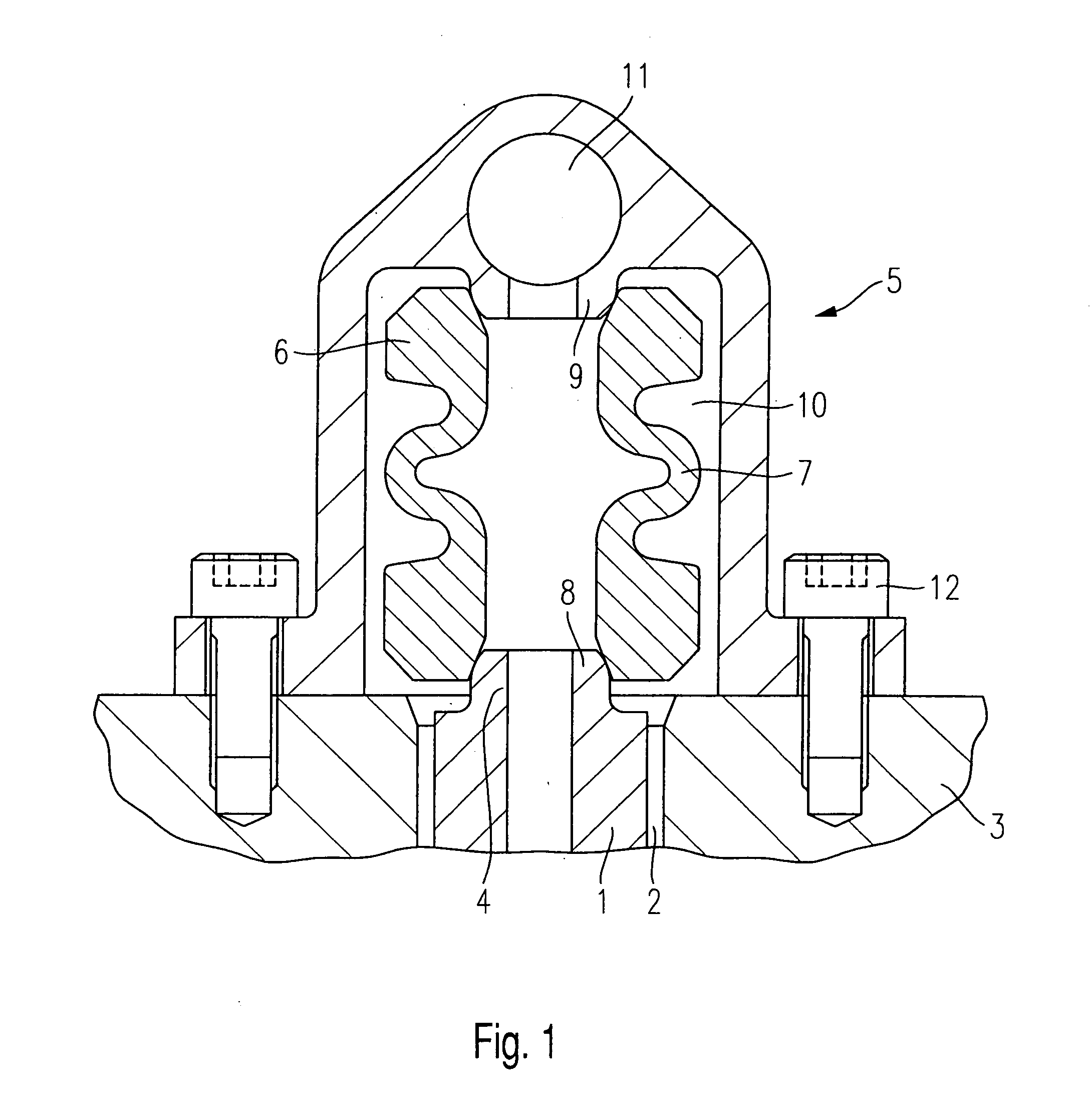

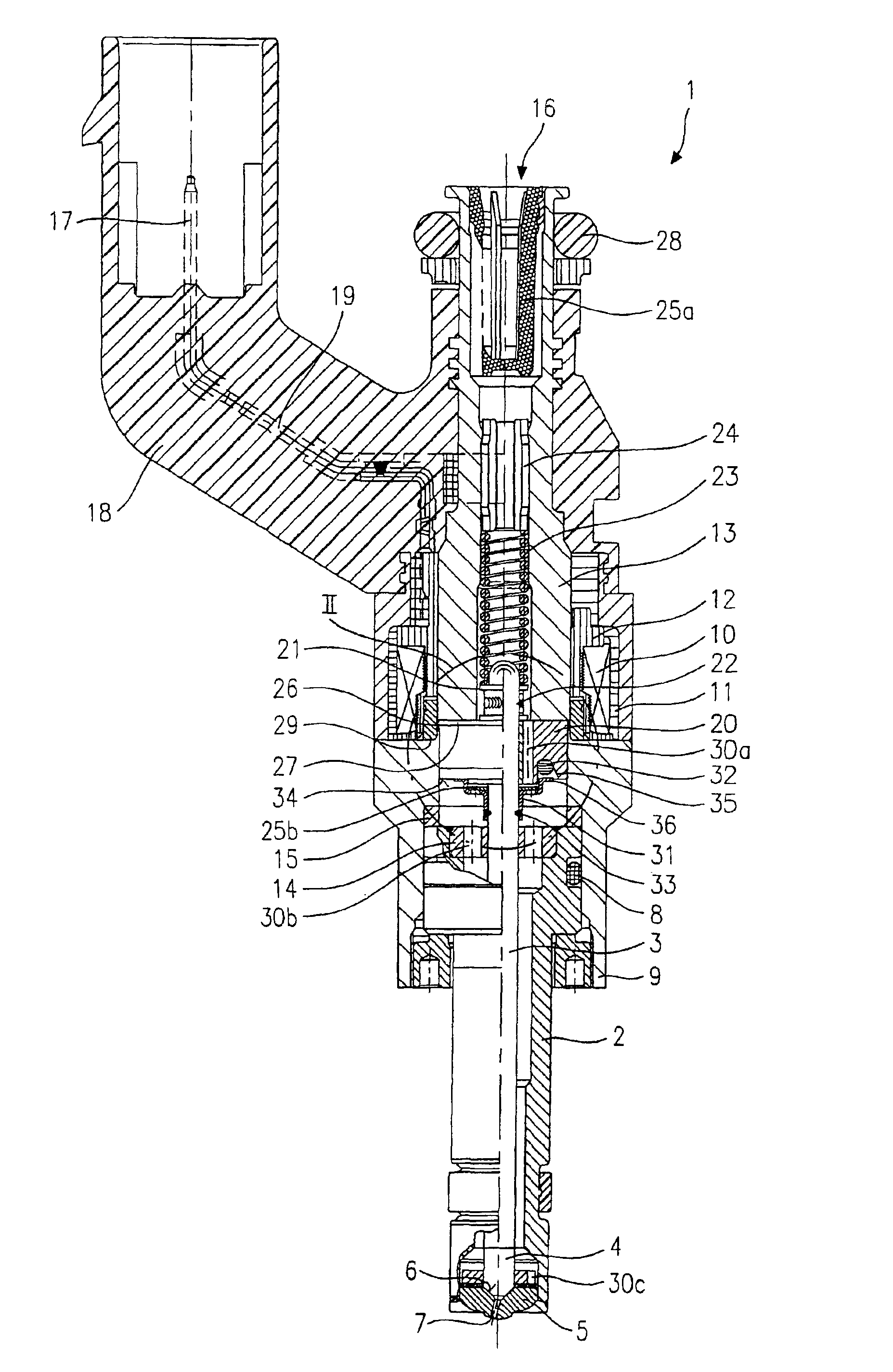

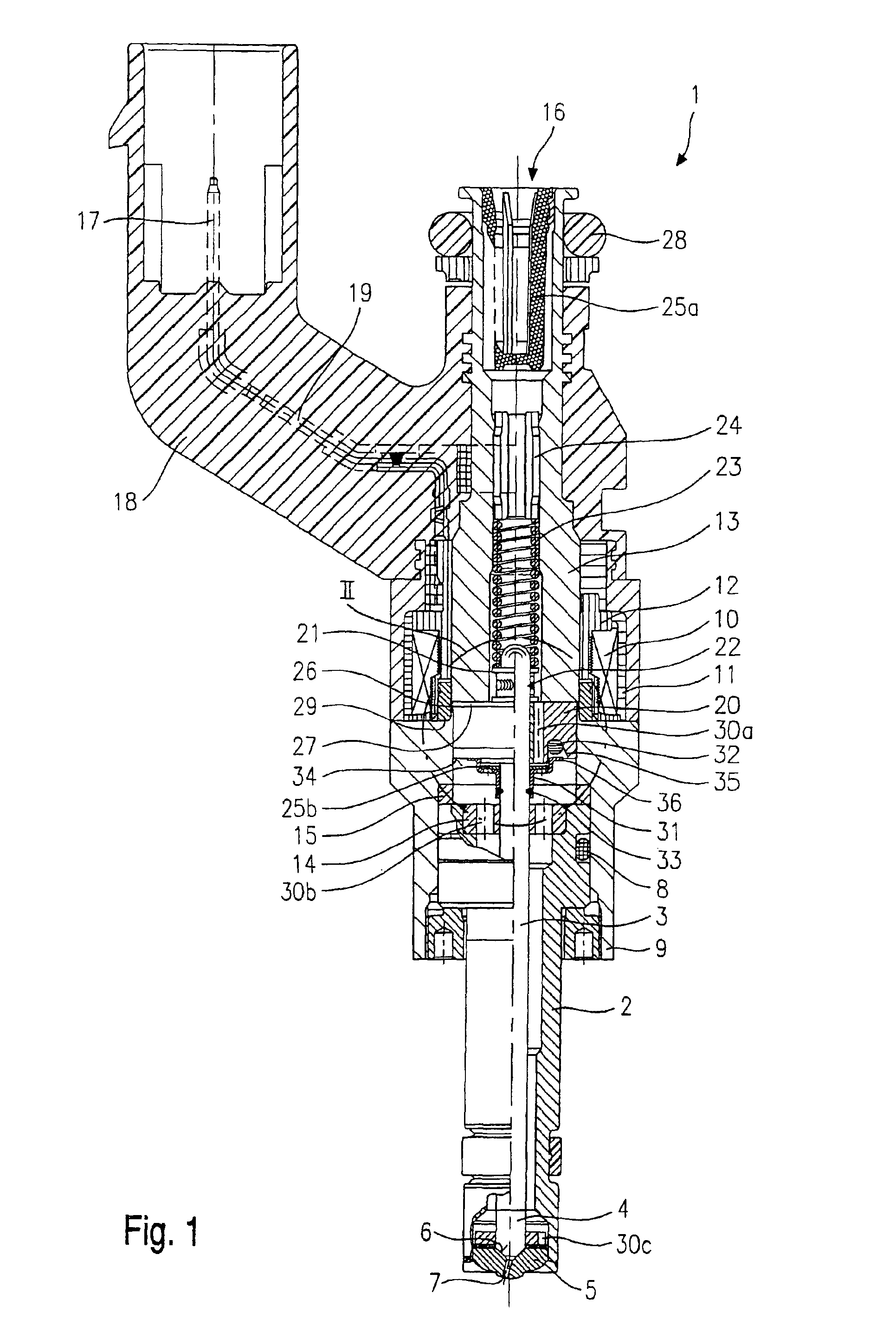

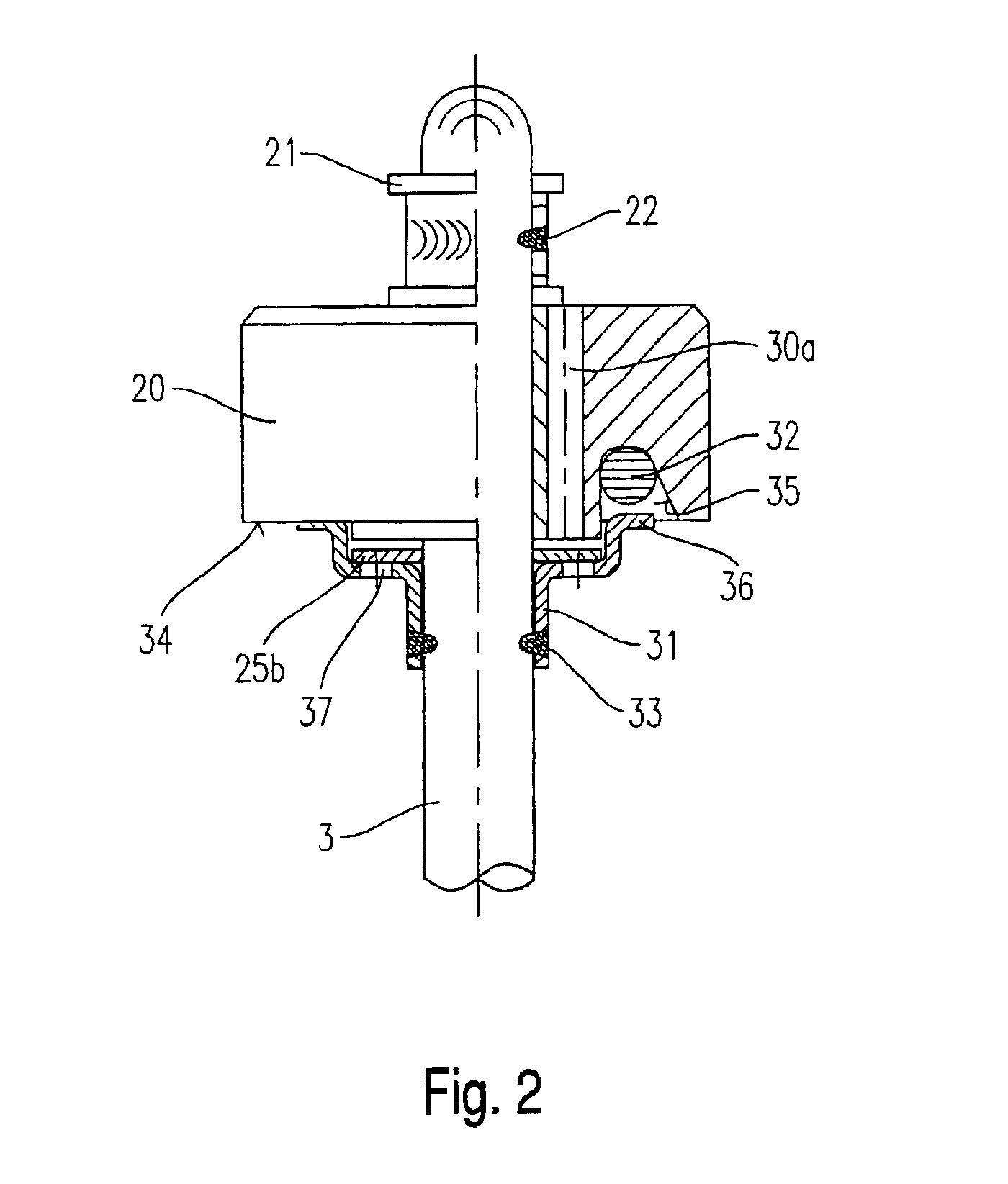

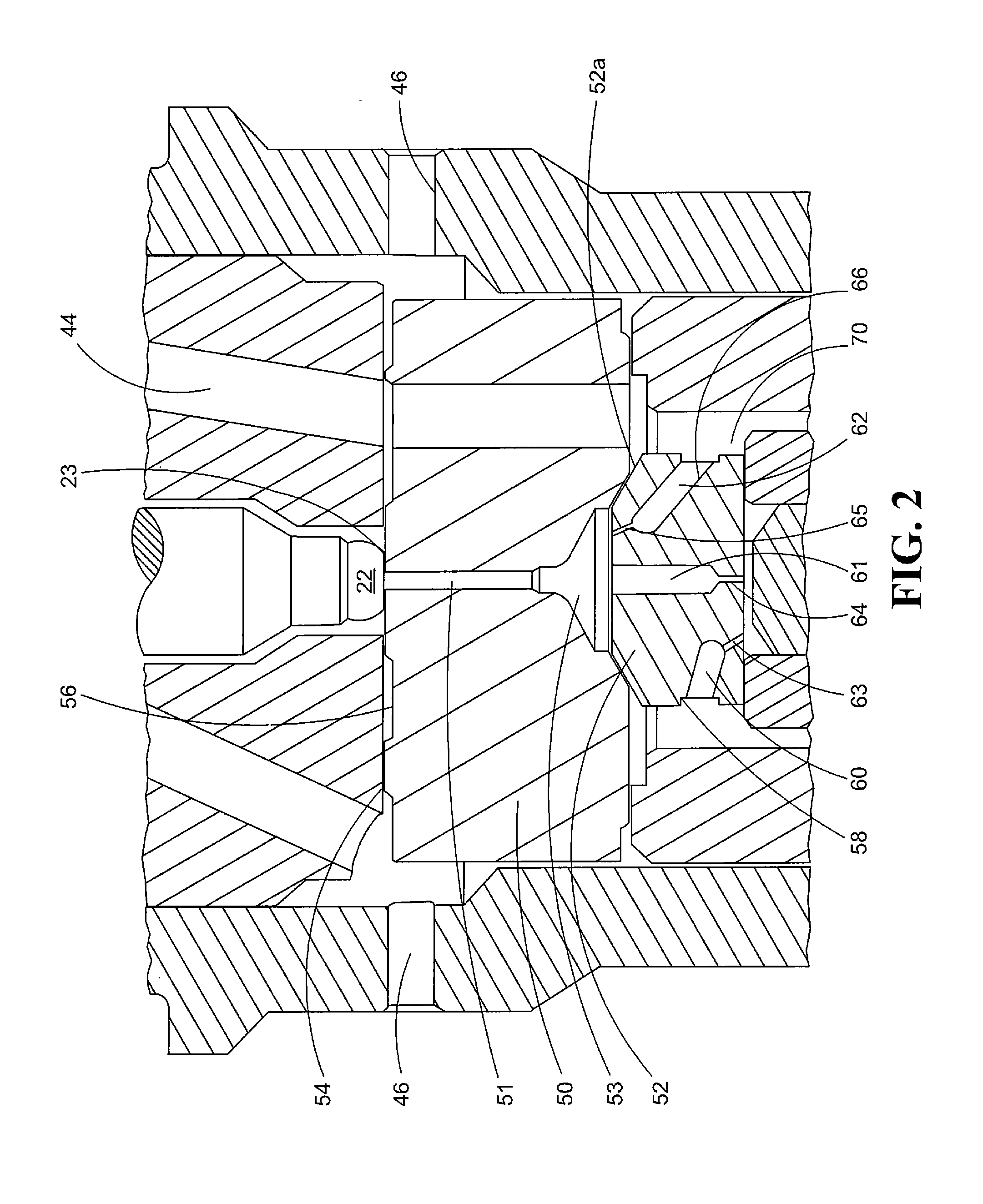

High Pressure Pump, in Particular for a Fuel Injection System Of an Internal Combustion Engine

The high pressure pump comprises a drive shaft (12) with at least one cam (16) or eccentric and at least one pump element (18) with a pump piston (20), driven in the reciprocating direction by the cam (16) or eccentric on the driveshaft (12) in a reciprocating motion. A support element (44) is arranged between the pump piston (20) and the cam (16) or eccentric on the driveshaft (12) and also a roller (46) running on the cam (16) or eccentric is mounted to rotate therein. A support (60) for the roller (46) in the direction of rotation is arranged adjacent to the same in the direction of the rotational axis (47) of the roller (46). The roller (46) and / or the support (60) comprises a surface with high wear resistance at least in the contact region between the roller (46) and the support (60).

Owner:ROBERT BOSCH GMBH

Cam Roller Pin With Transverse Grooves

ActiveUS20070277763A1Reducing localized contact pressureIncrease contactValve arrangementsYielding couplingContact pressureTransverse groove

A roller pin for carrying a cam roller in a tappet assembly is provided. The roller pin providing reduced run in time and reduced peak and localized contact pressure between the cam roller and roller pin. The roller pin comprises a substantially cylindrical shaft having a length, a first end and a second end. The length extends from the first end to the second end. The shaft includes a plurality of grooves axially spaced apart and extending in a direction being transverse to the length. The plurality of grooves located proximate the first and second ends and extending only partially the circumference of the shaft.

Owner:WOODWARD GOVERNOR CO

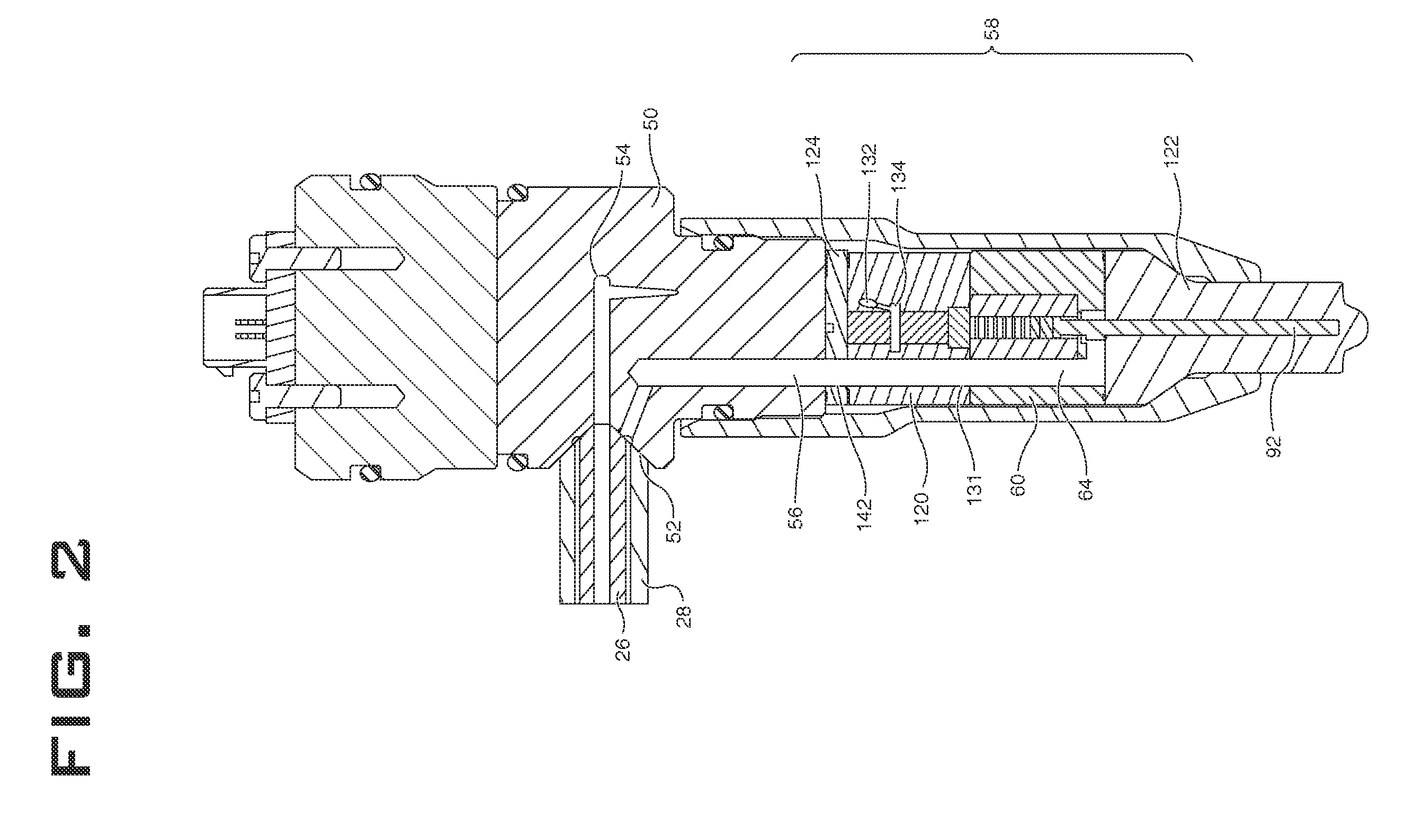

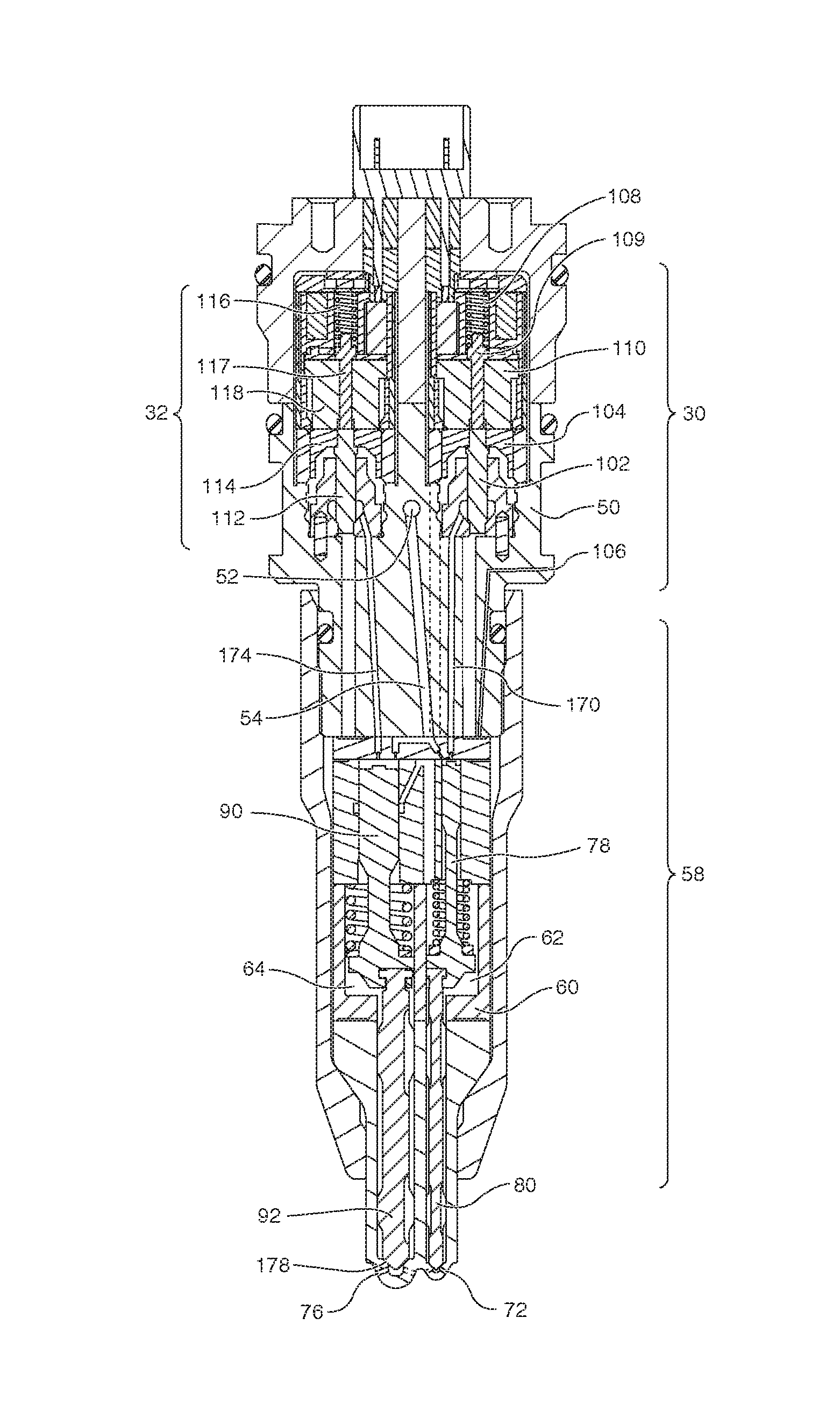

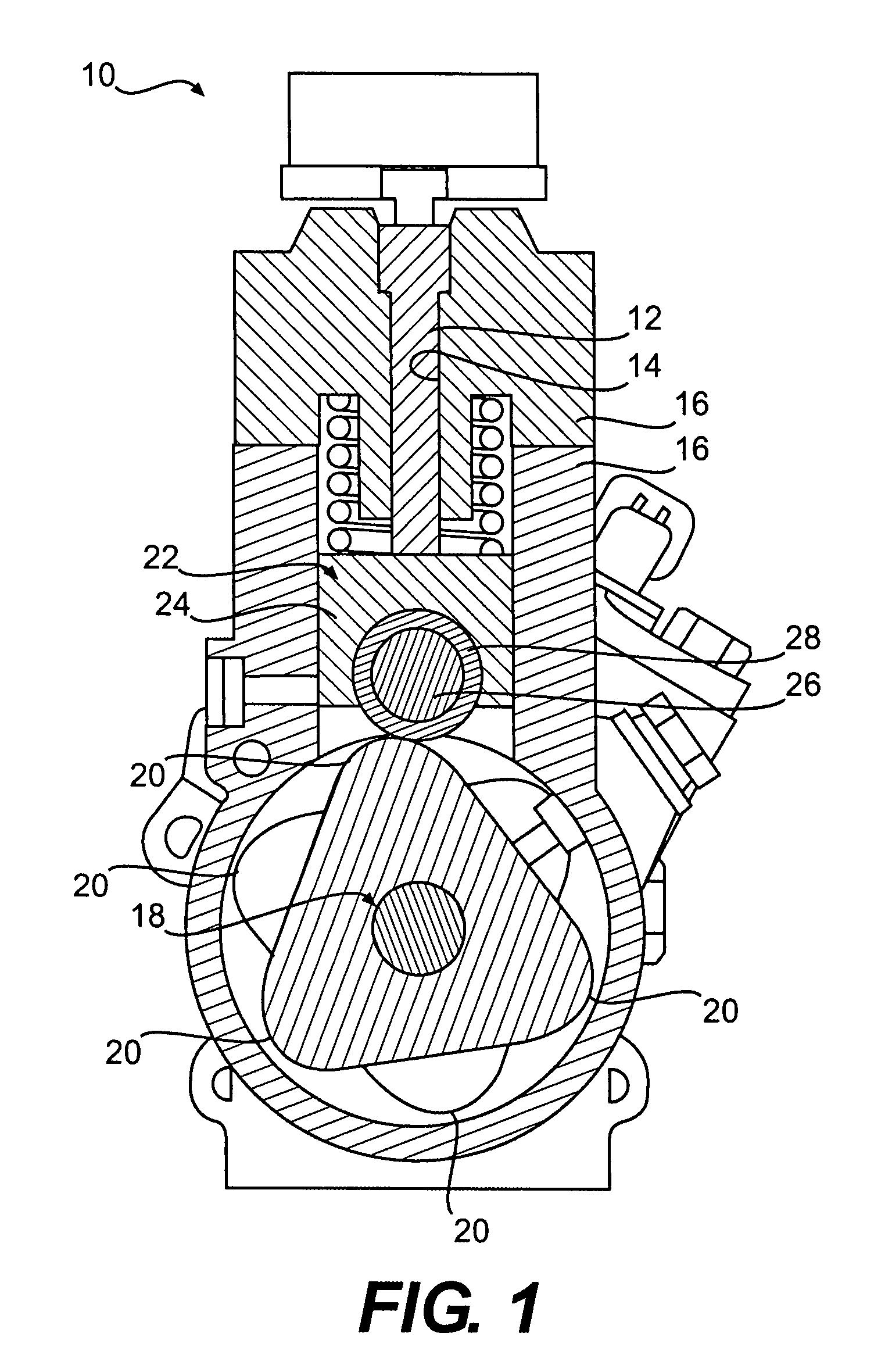

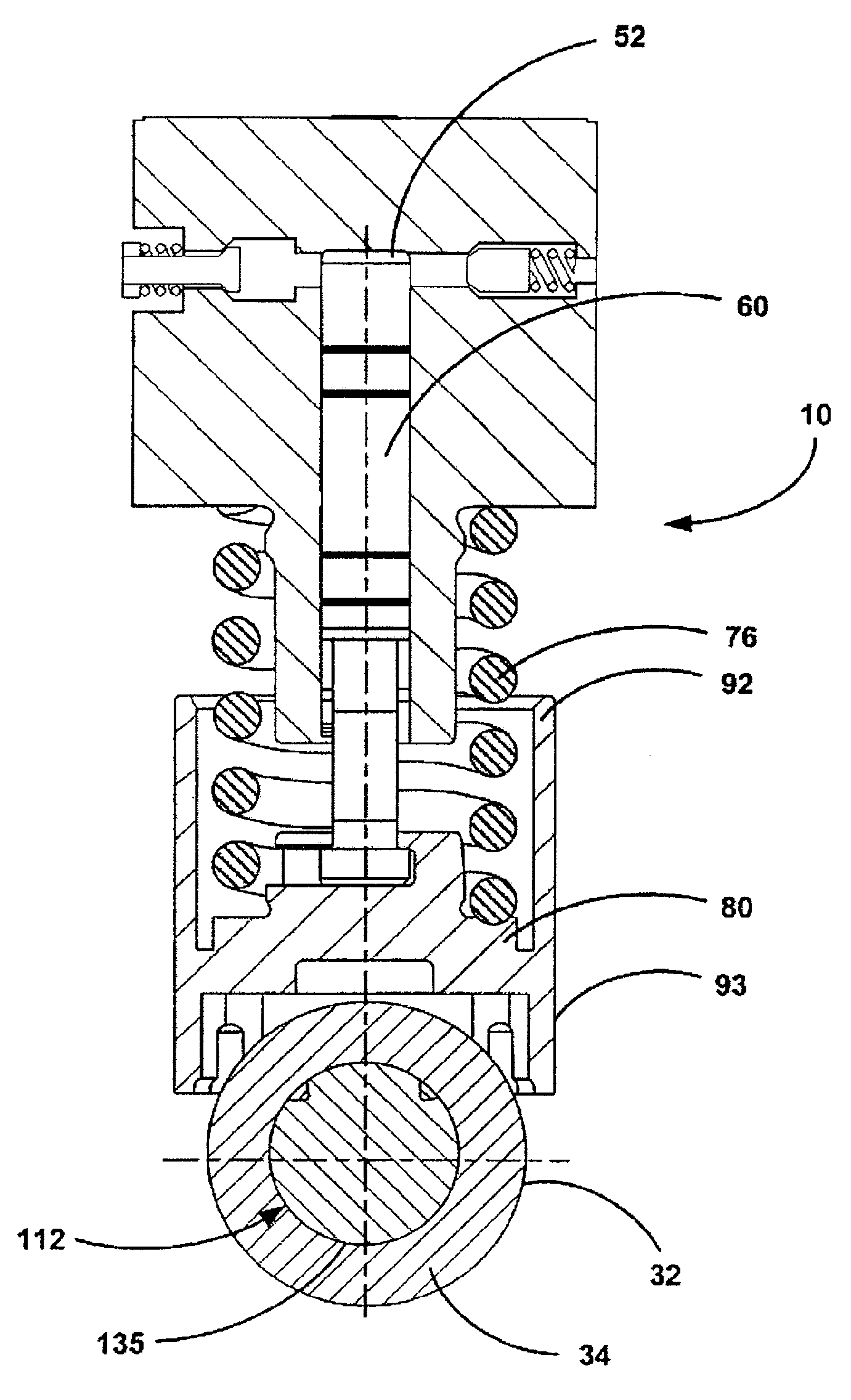

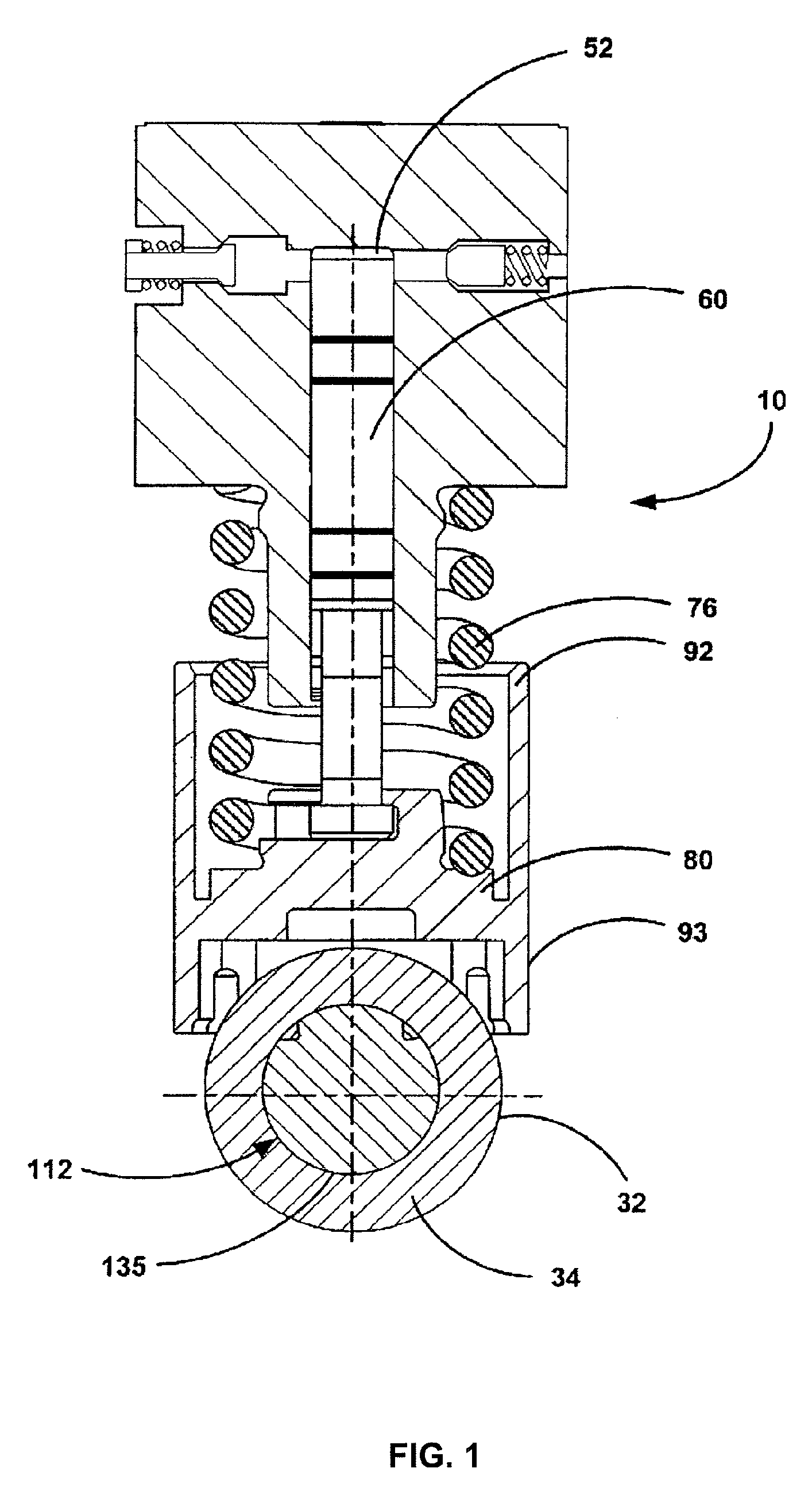

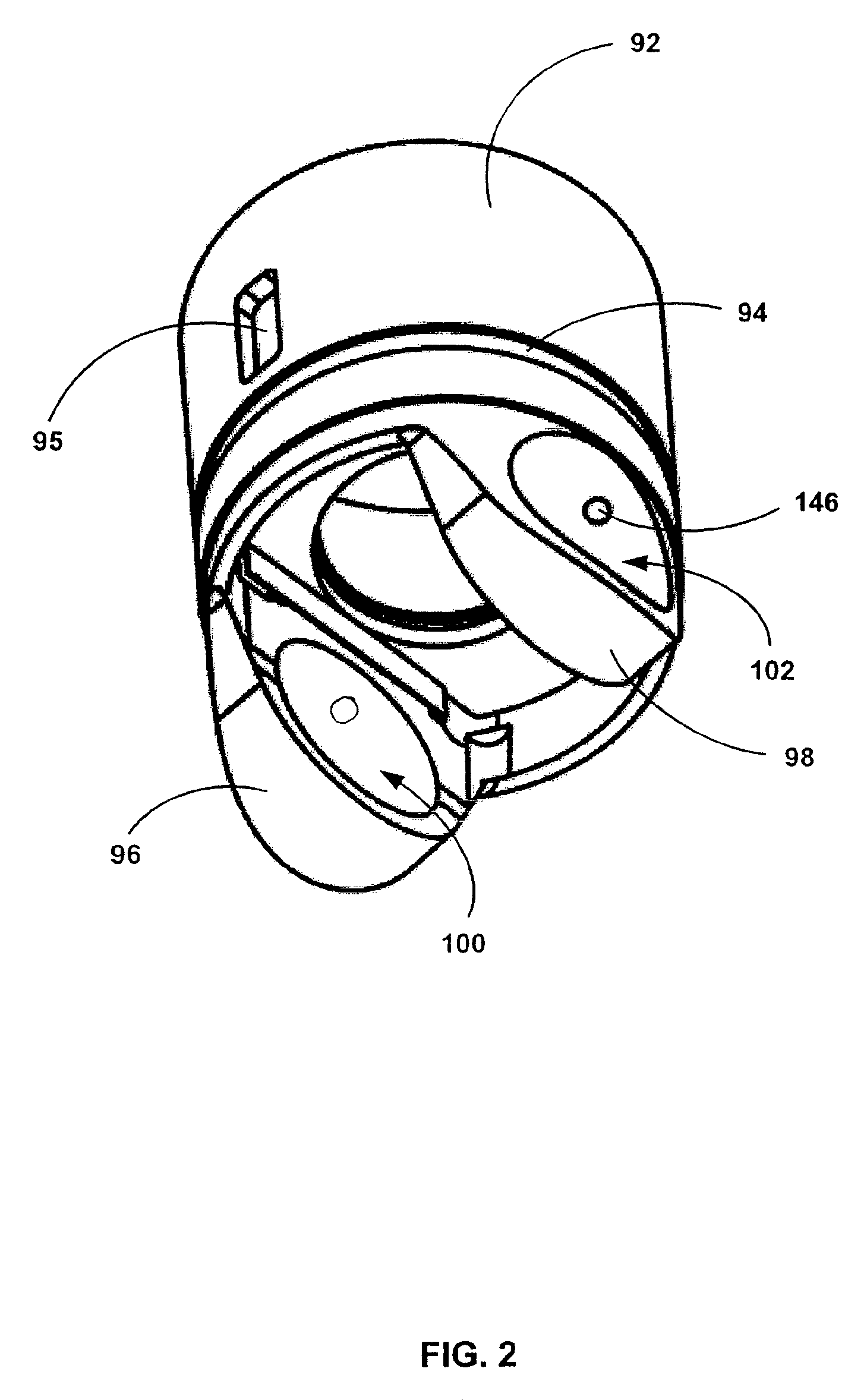

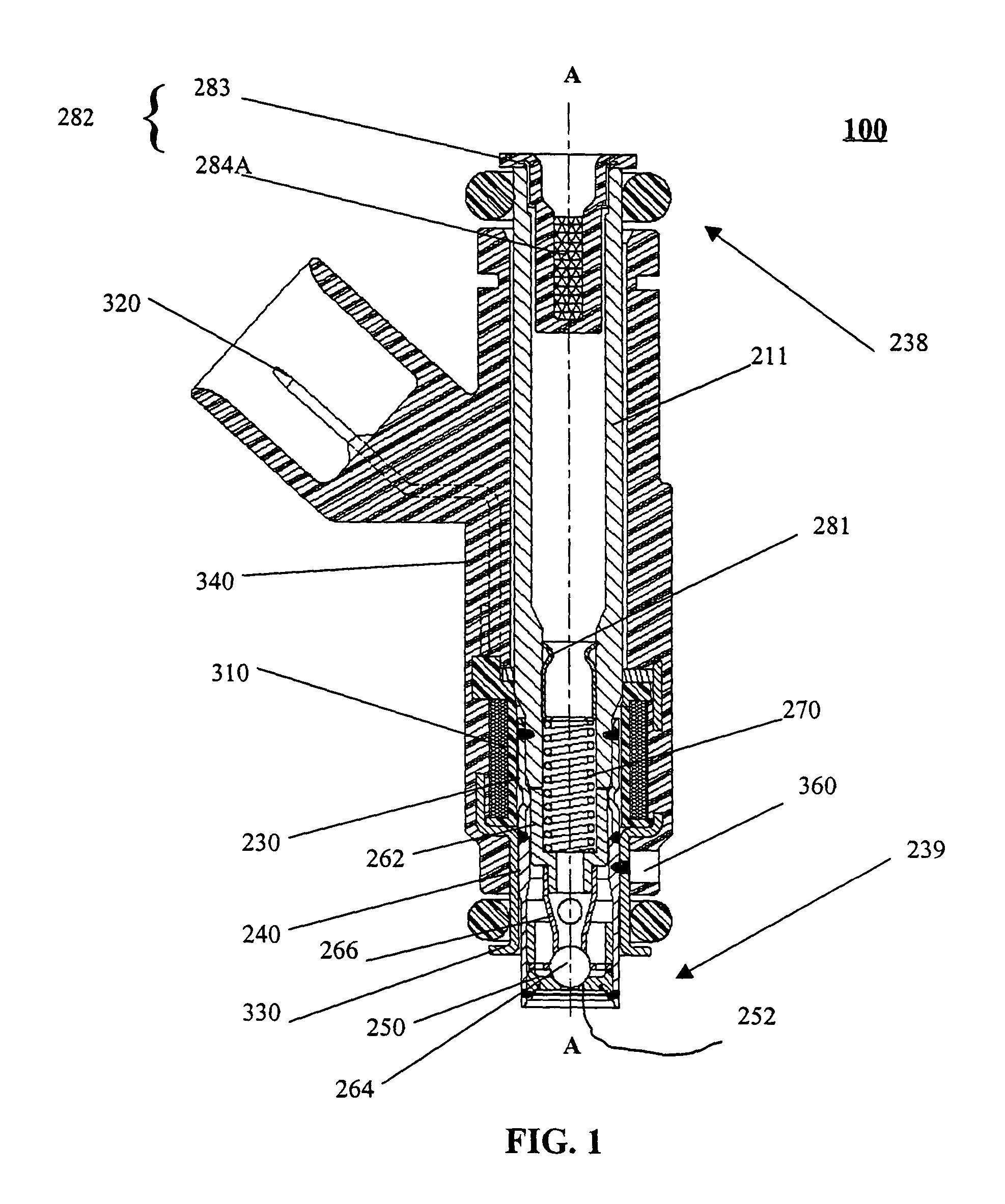

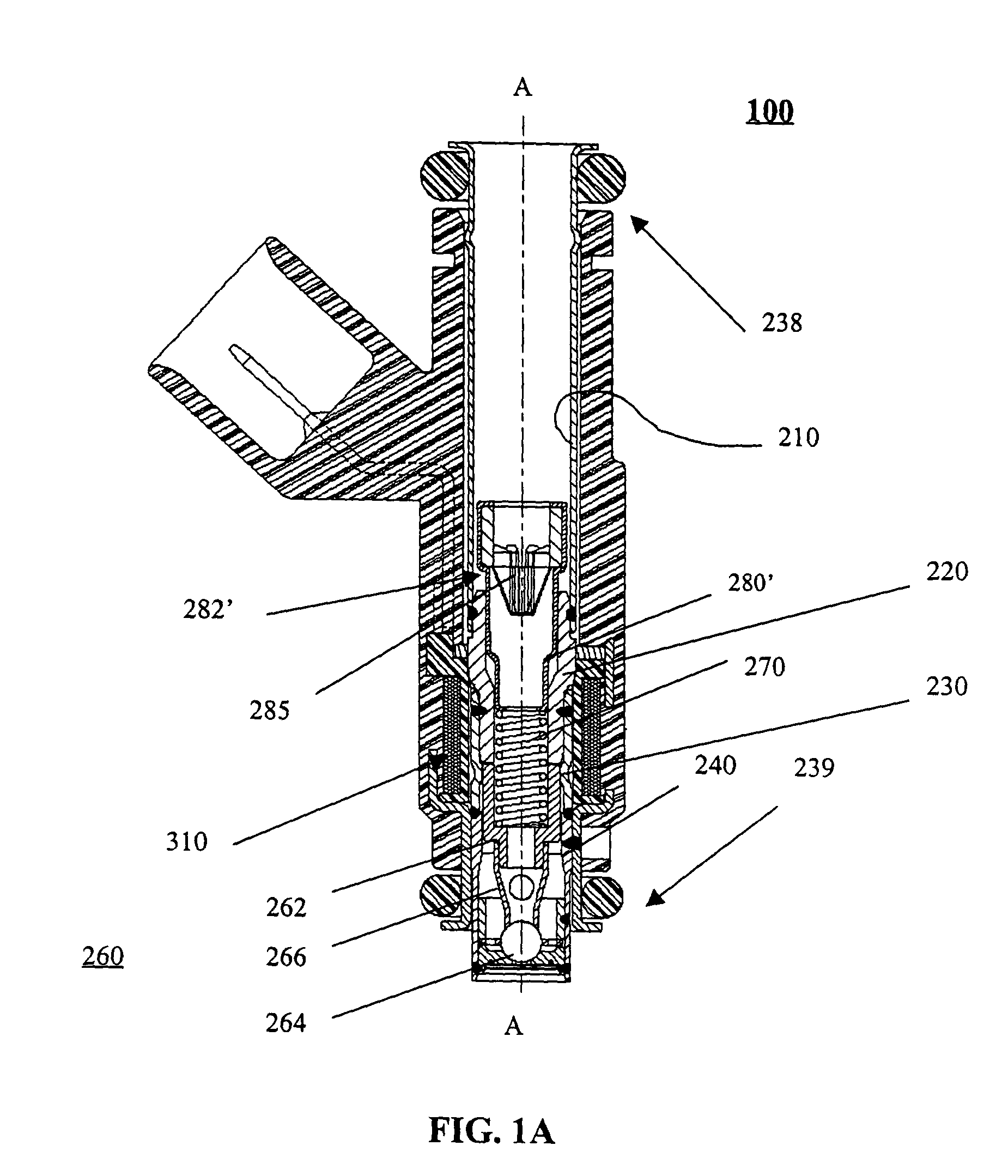

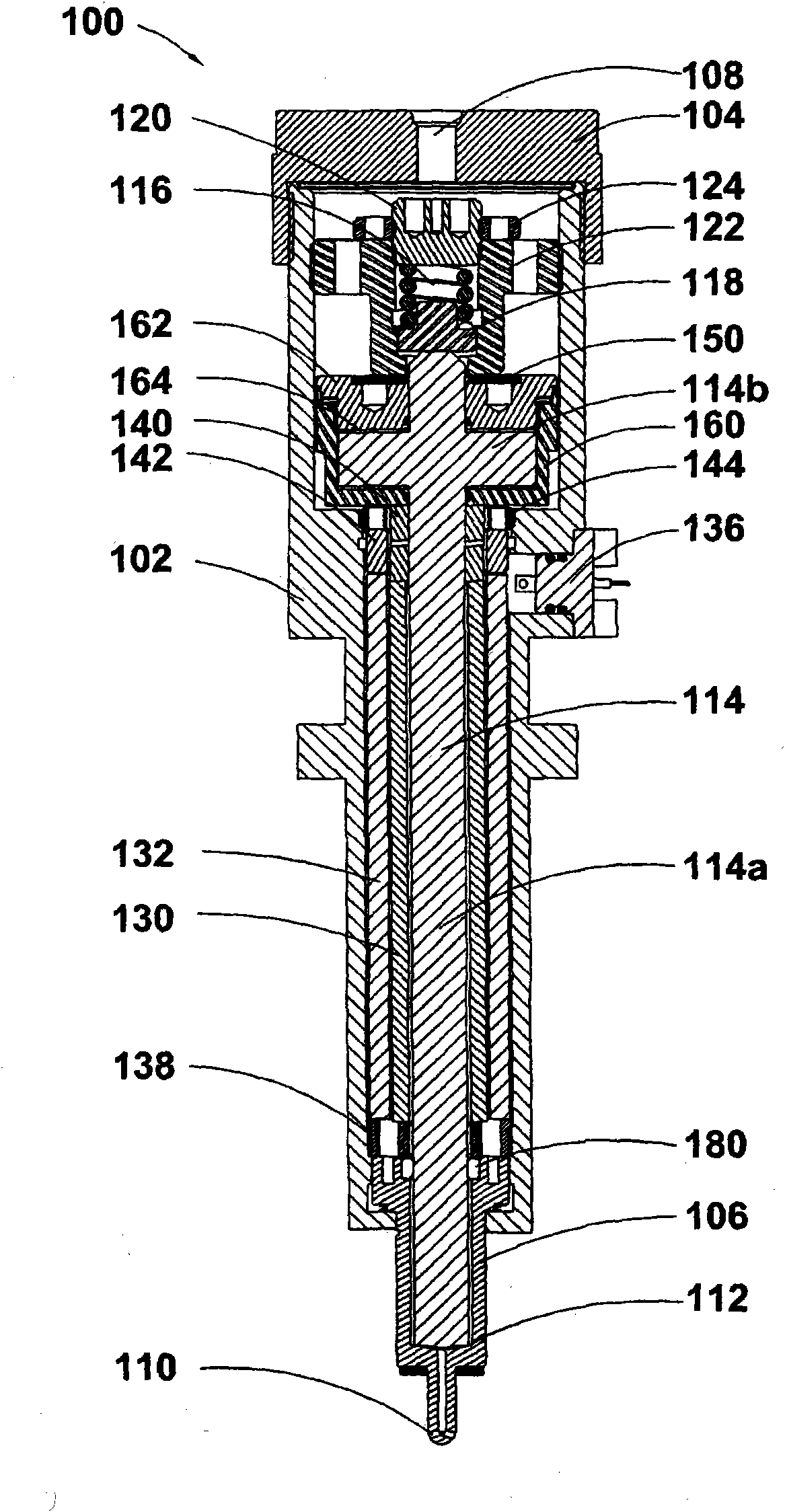

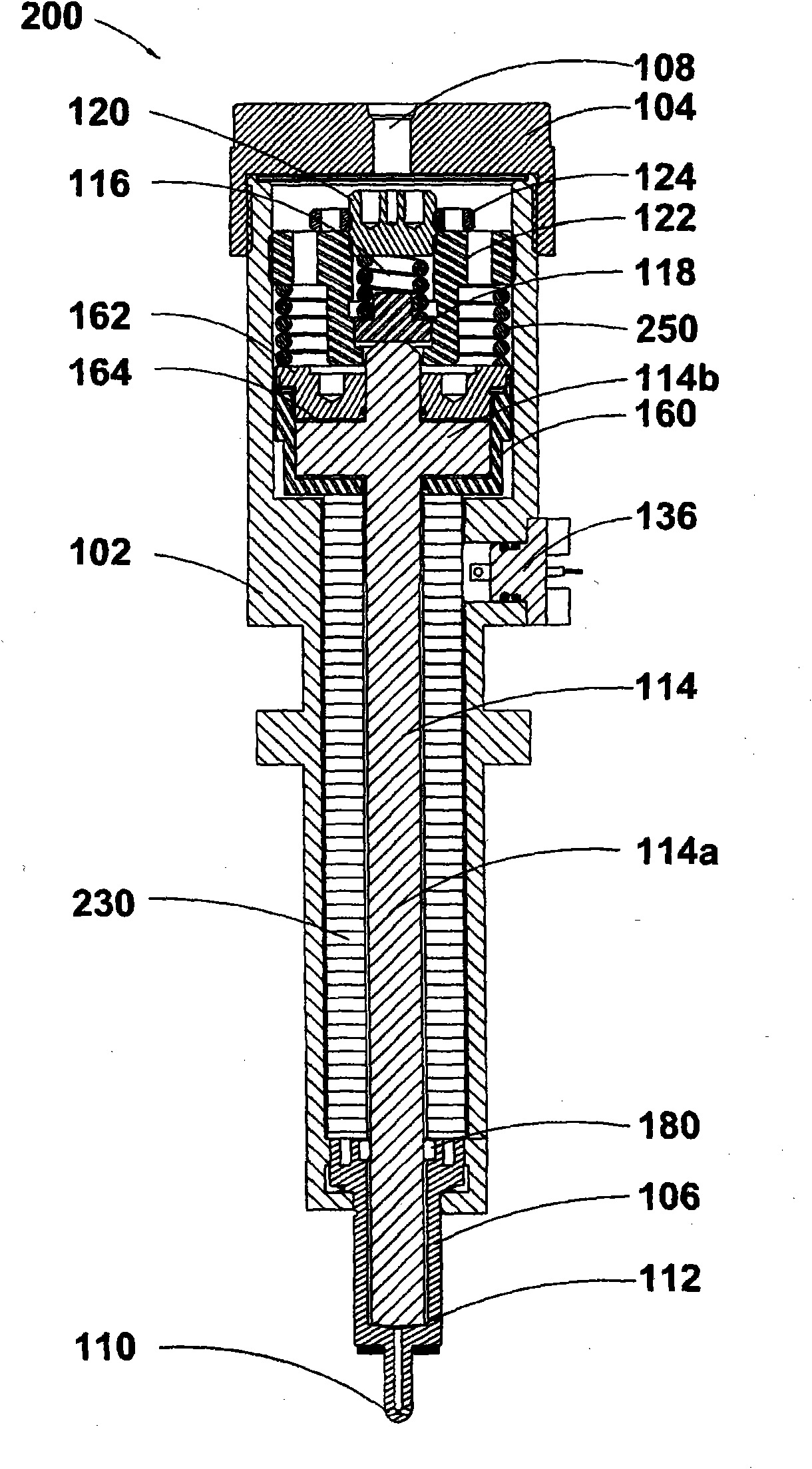

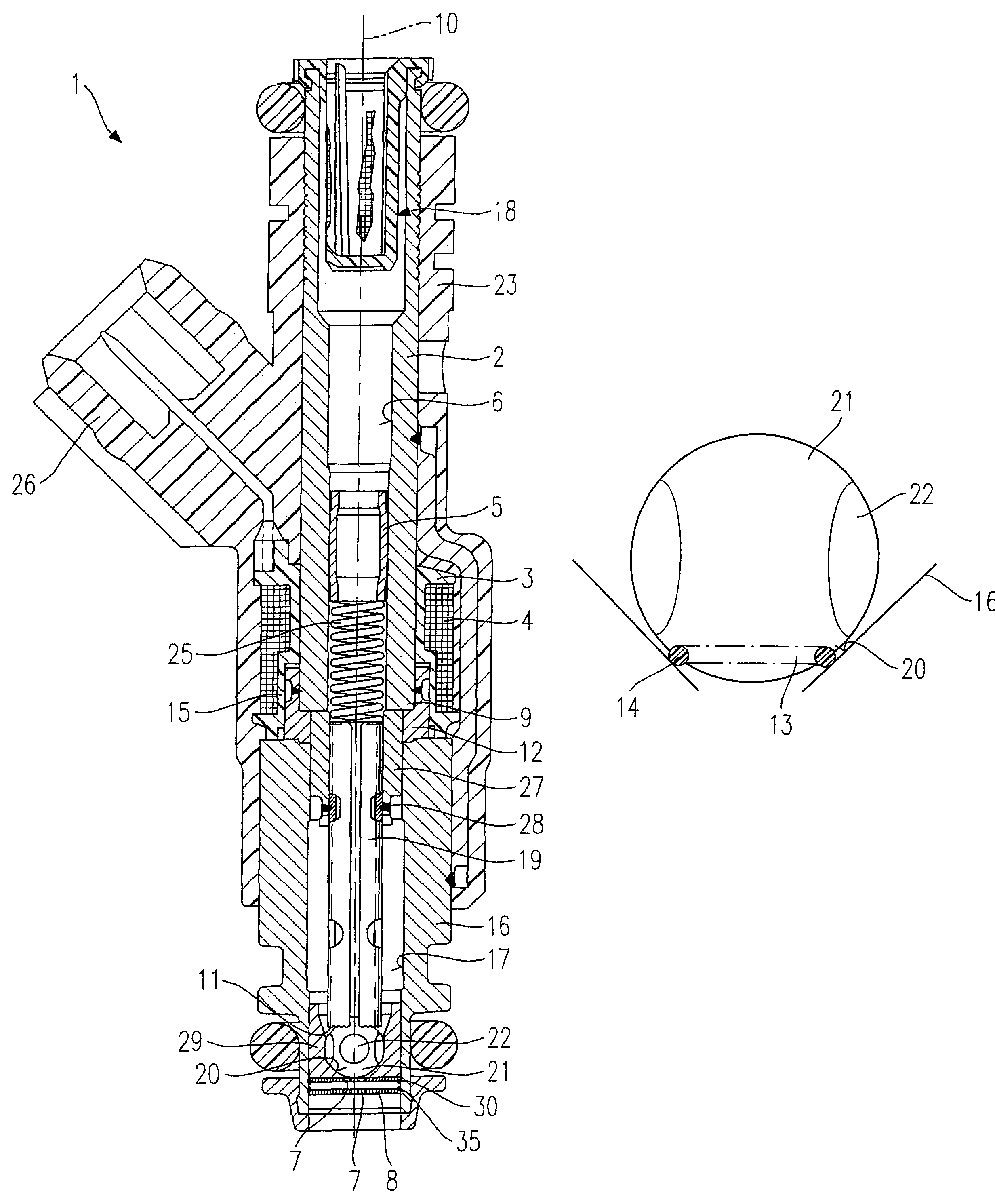

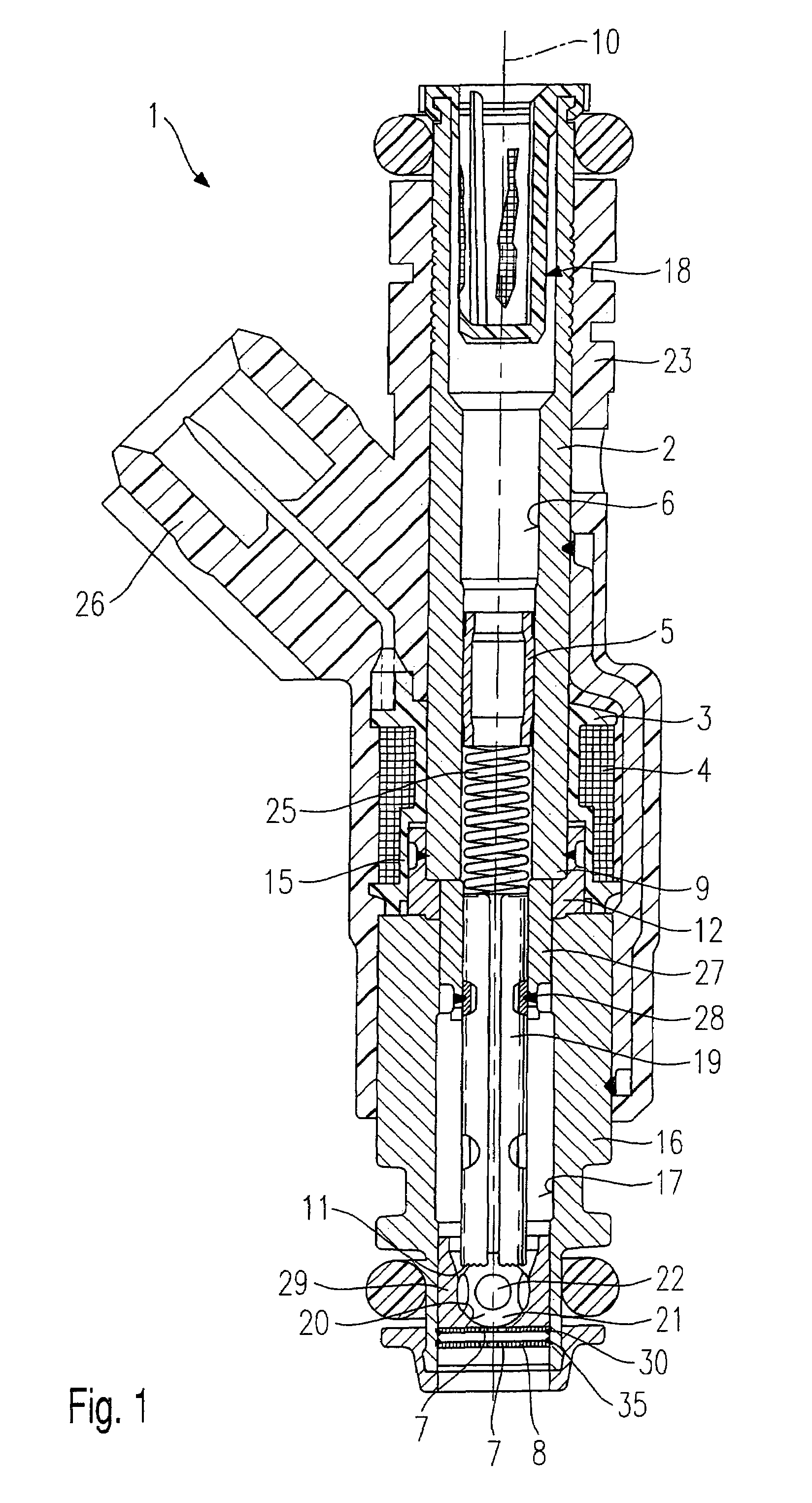

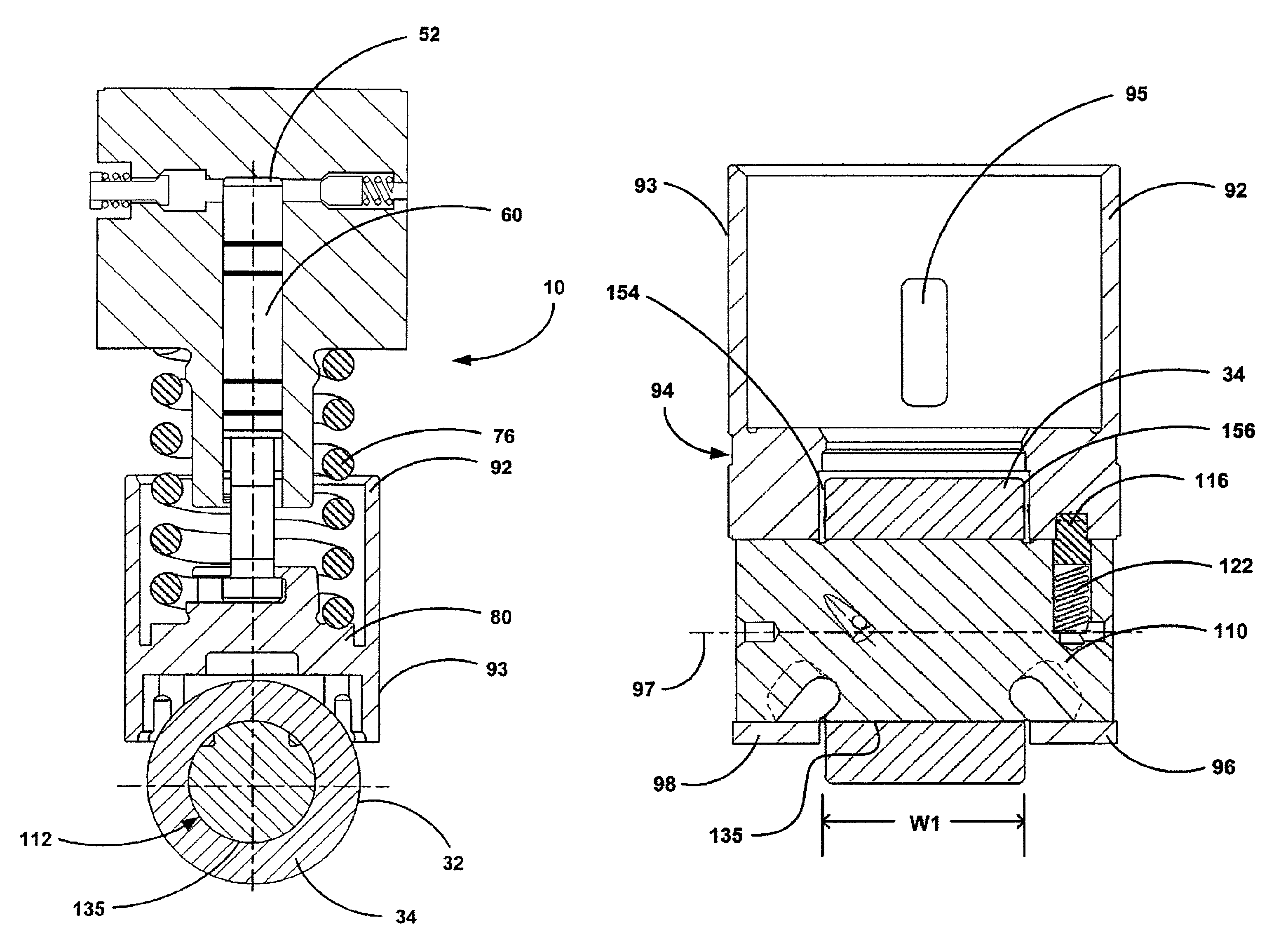

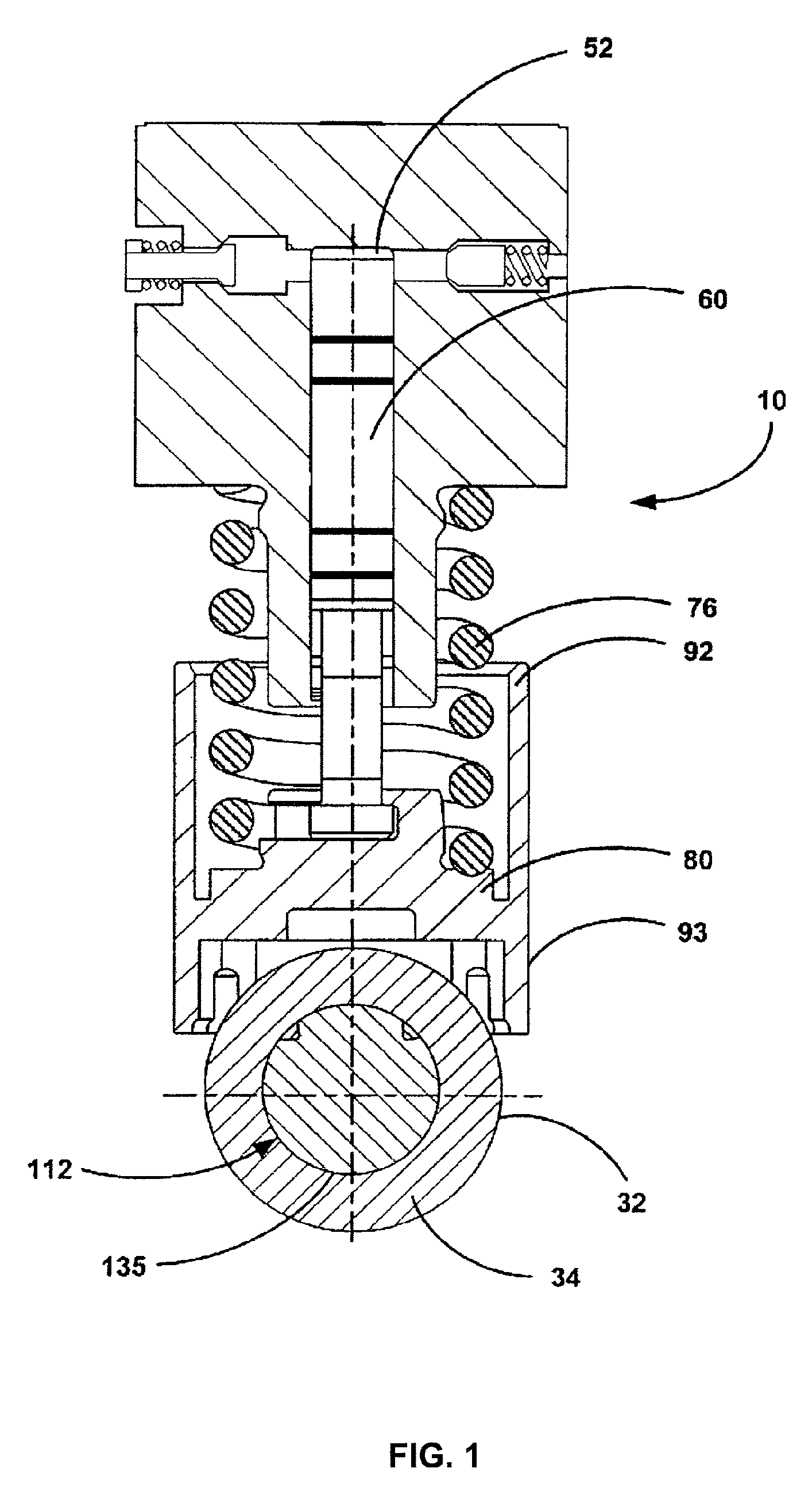

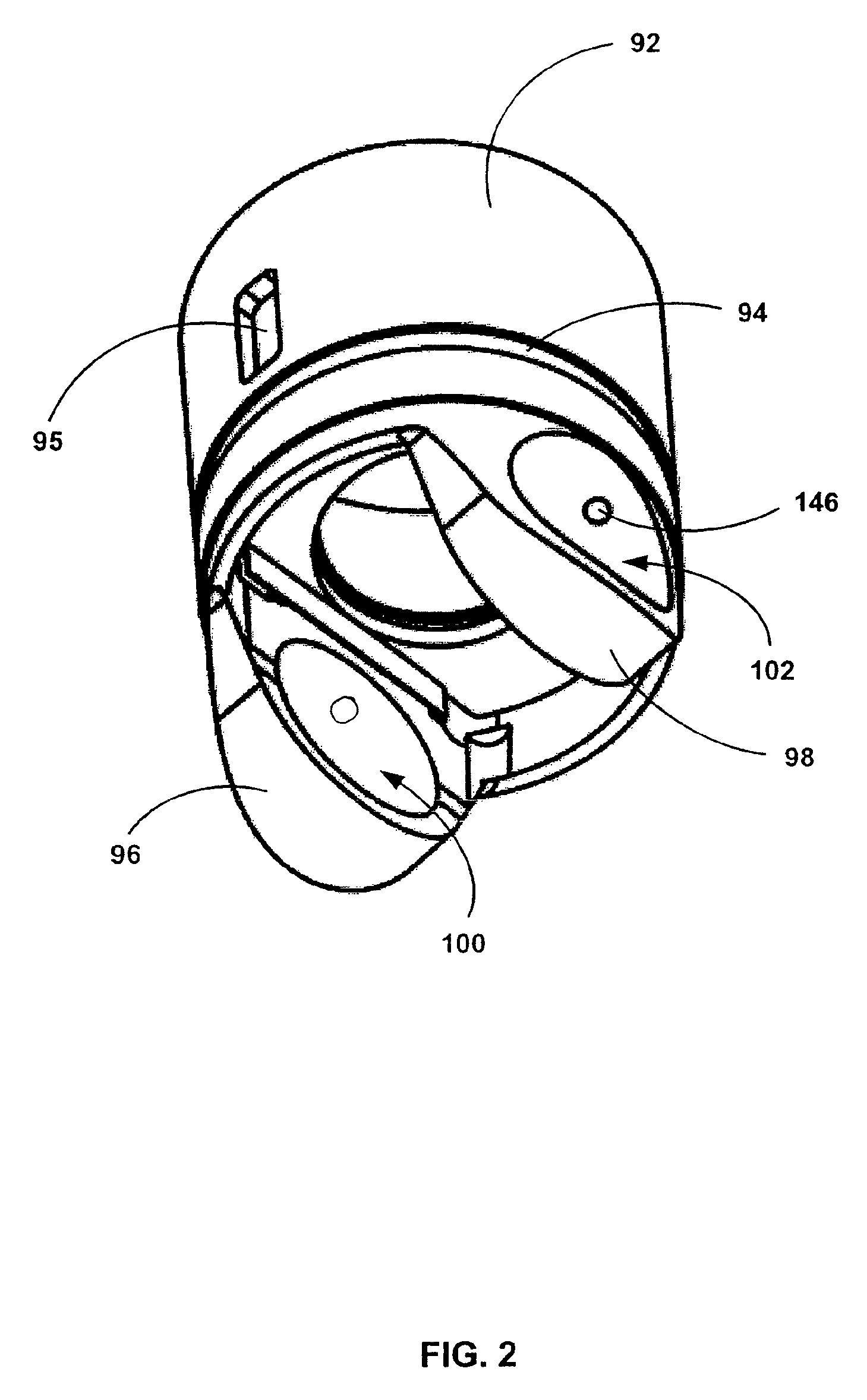

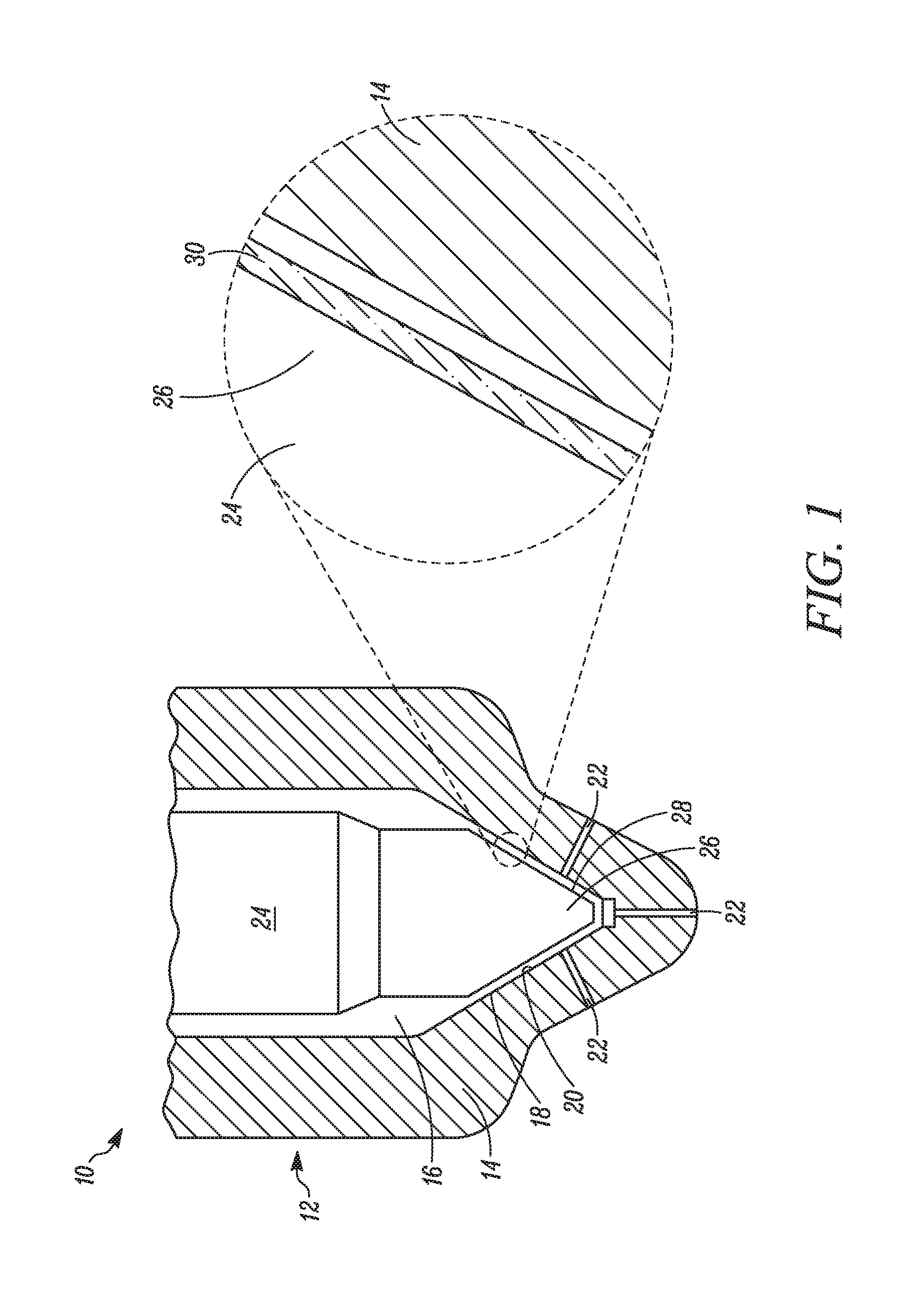

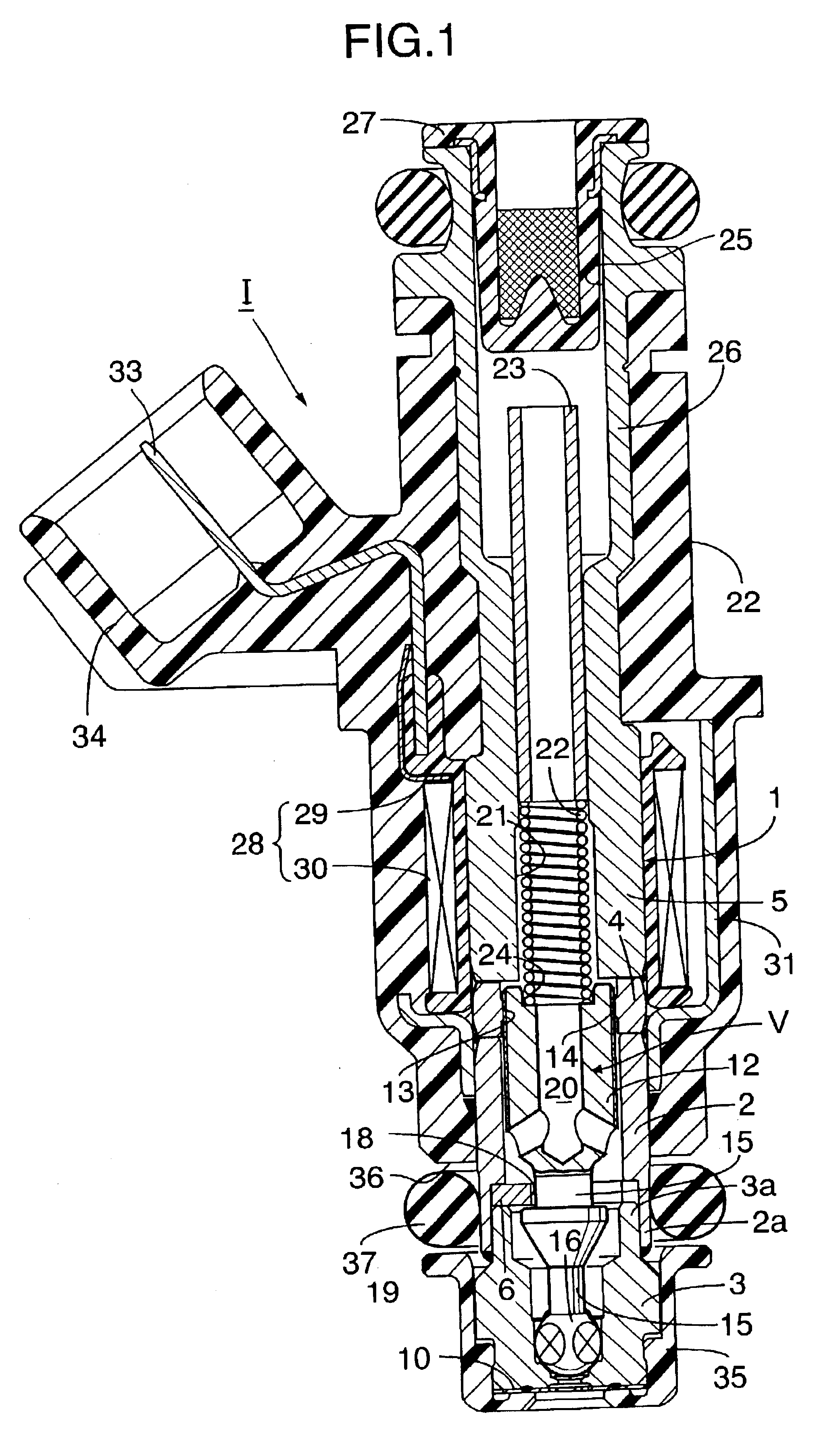

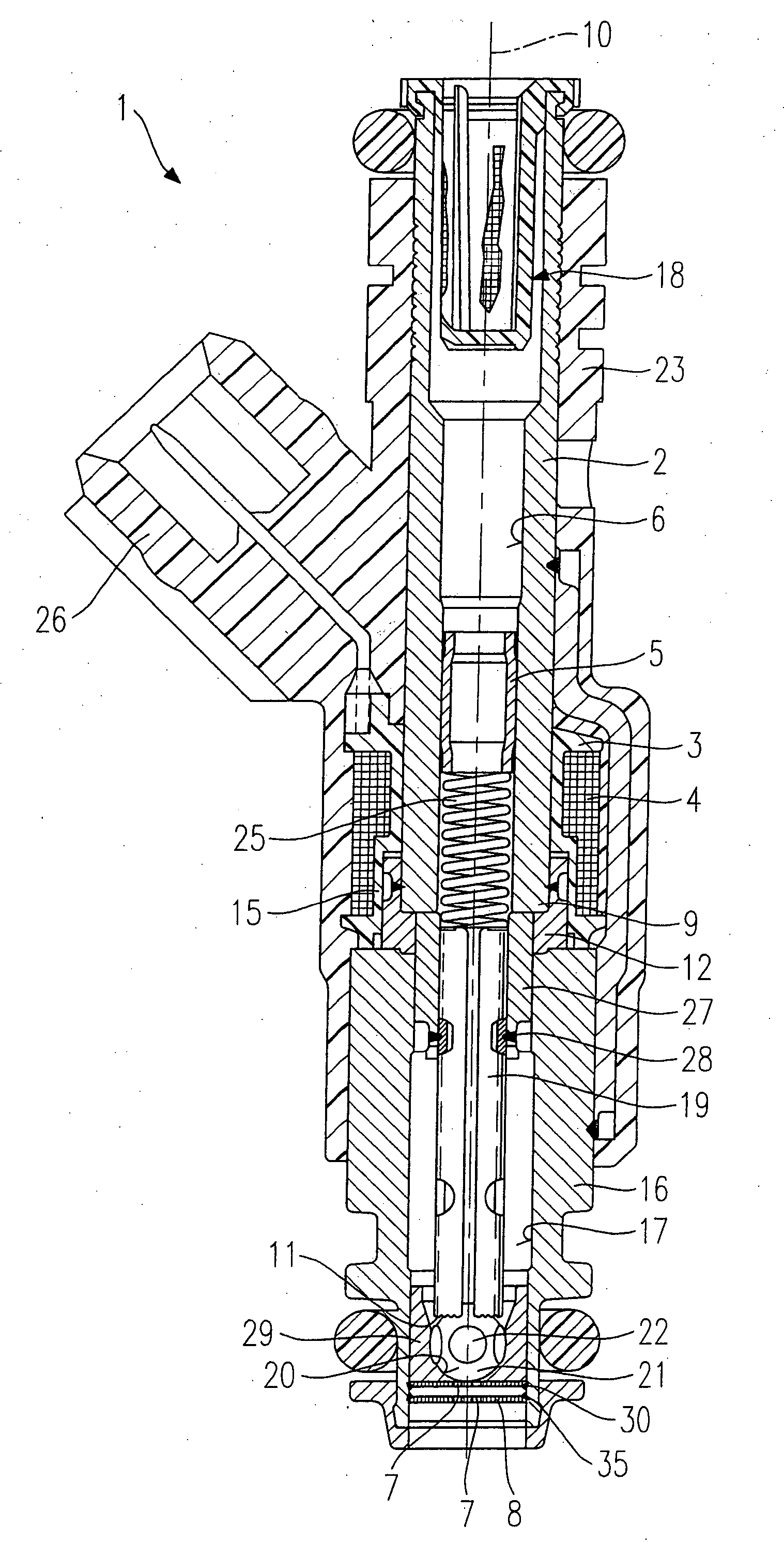

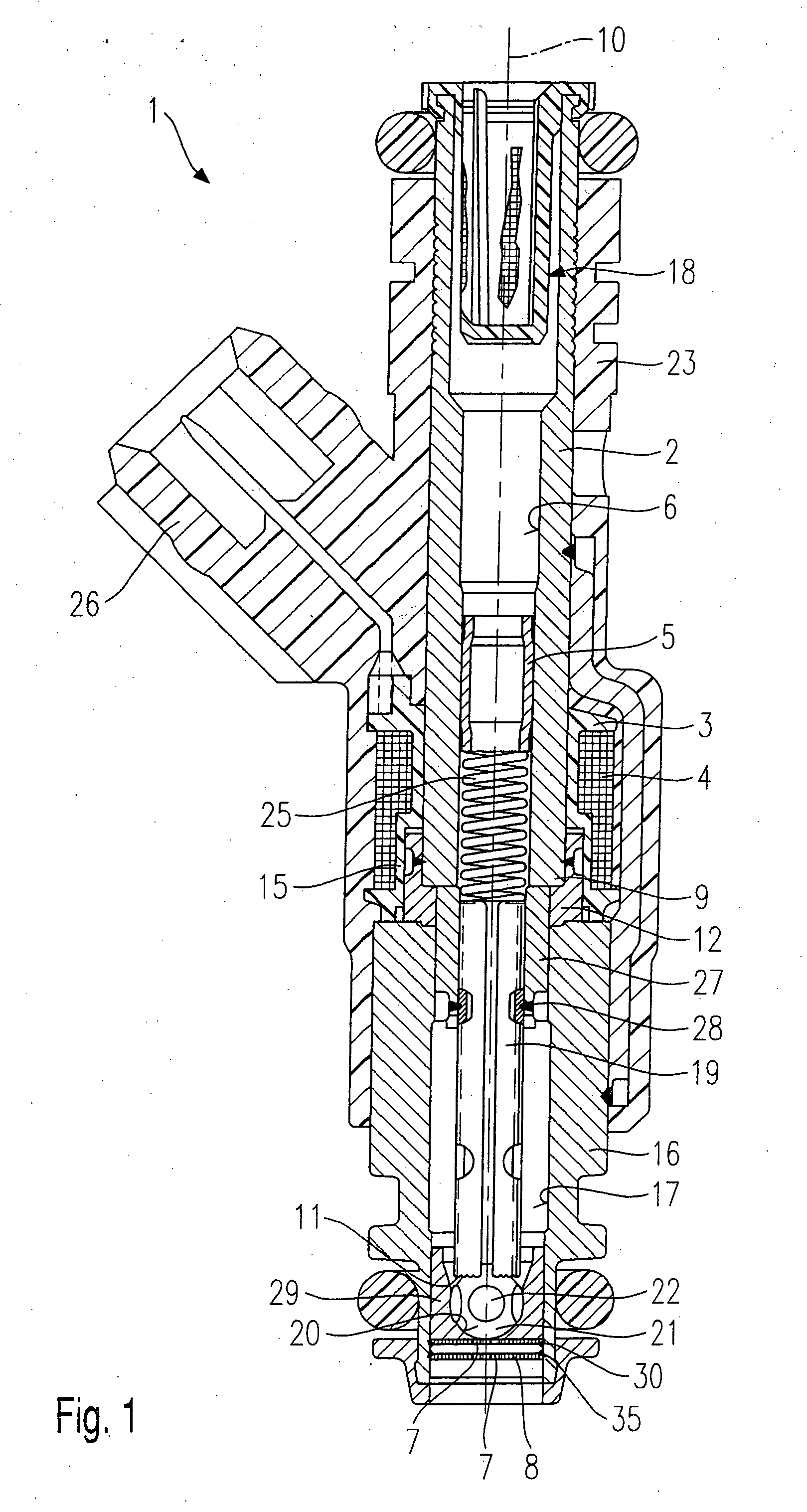

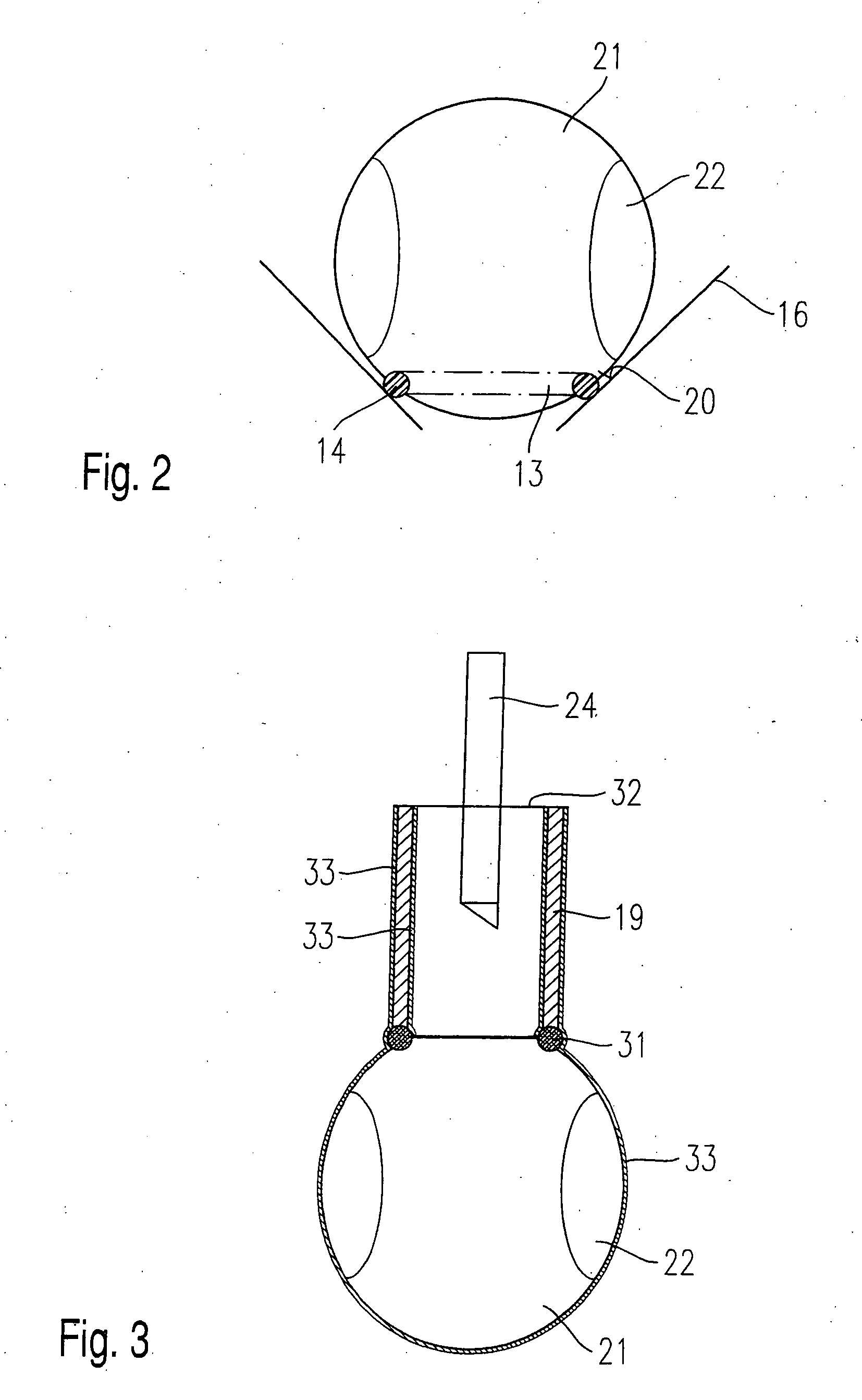

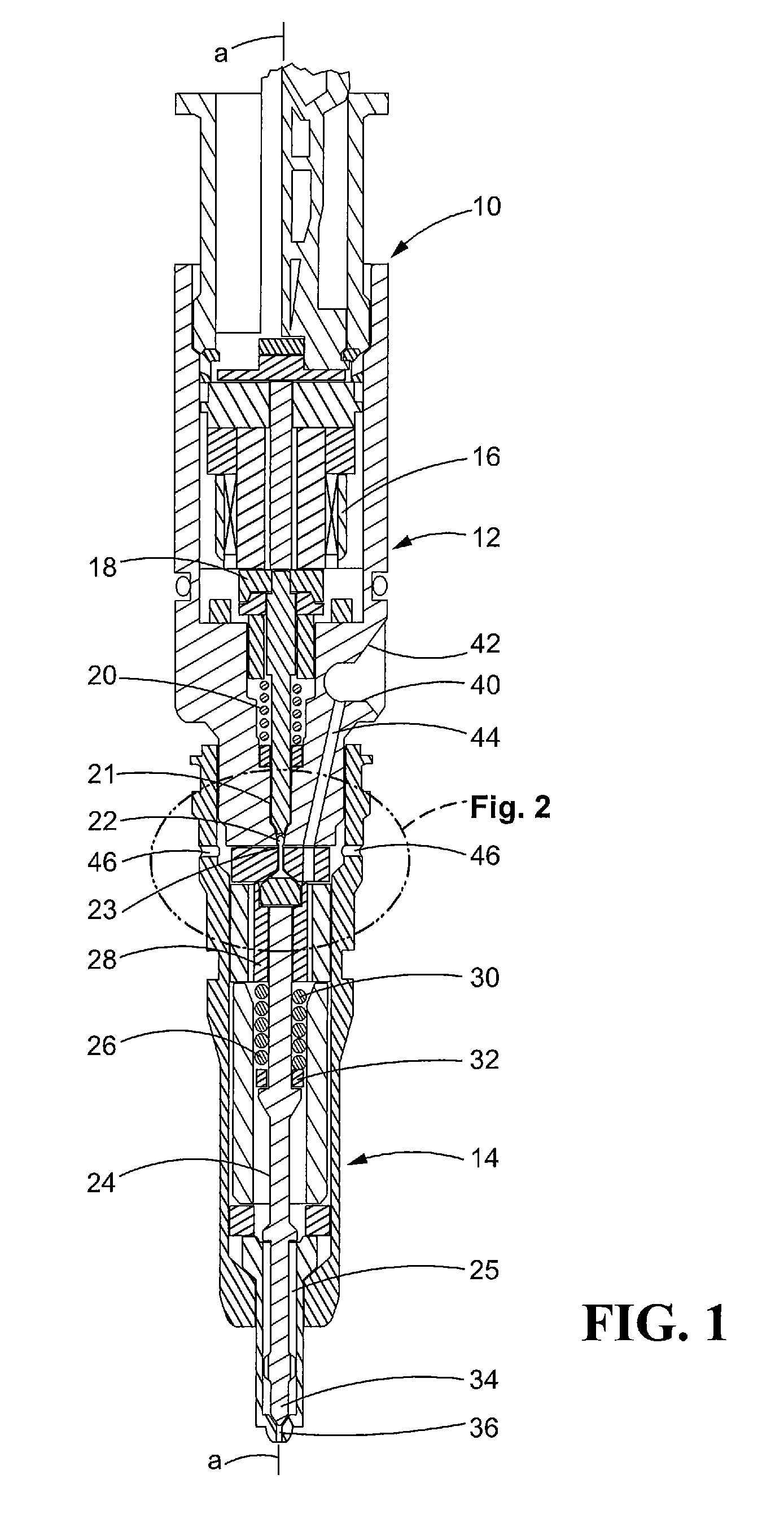

Modular fuel injector and method of assembling the modular fuel injector

InactiveUS7347383B2Wear reducing fuel injectionFuel-injection pumpsEngineeringInternal combustion engine

A fuel injector for use with an internal combustion engine. The fuel injector comprises a valve group subassembly and a coil group subassembly. The valve group subassembly includes a tube assembly having a longitudinal axis that extends between a first end and a second end; a seat that is secured at the second end of the tube assembly and that defines an opening; an armature assembly that is disposed within the tube assembly; a member that biases the armature assembly toward the seat; an adjusting tube that is disposed in the tube assembly and that engages the member for adjusting a biasing force of the member; a filter that is at least within the tube assembly; and a first attachment portion. The coil group subassembly includes a solenoid coil that is operable to displace the armature assembly with respect to the seat; and a second attachment portion that is fixedly connected to the first attachment portion.

Owner:VITESCO TECH USA LLC

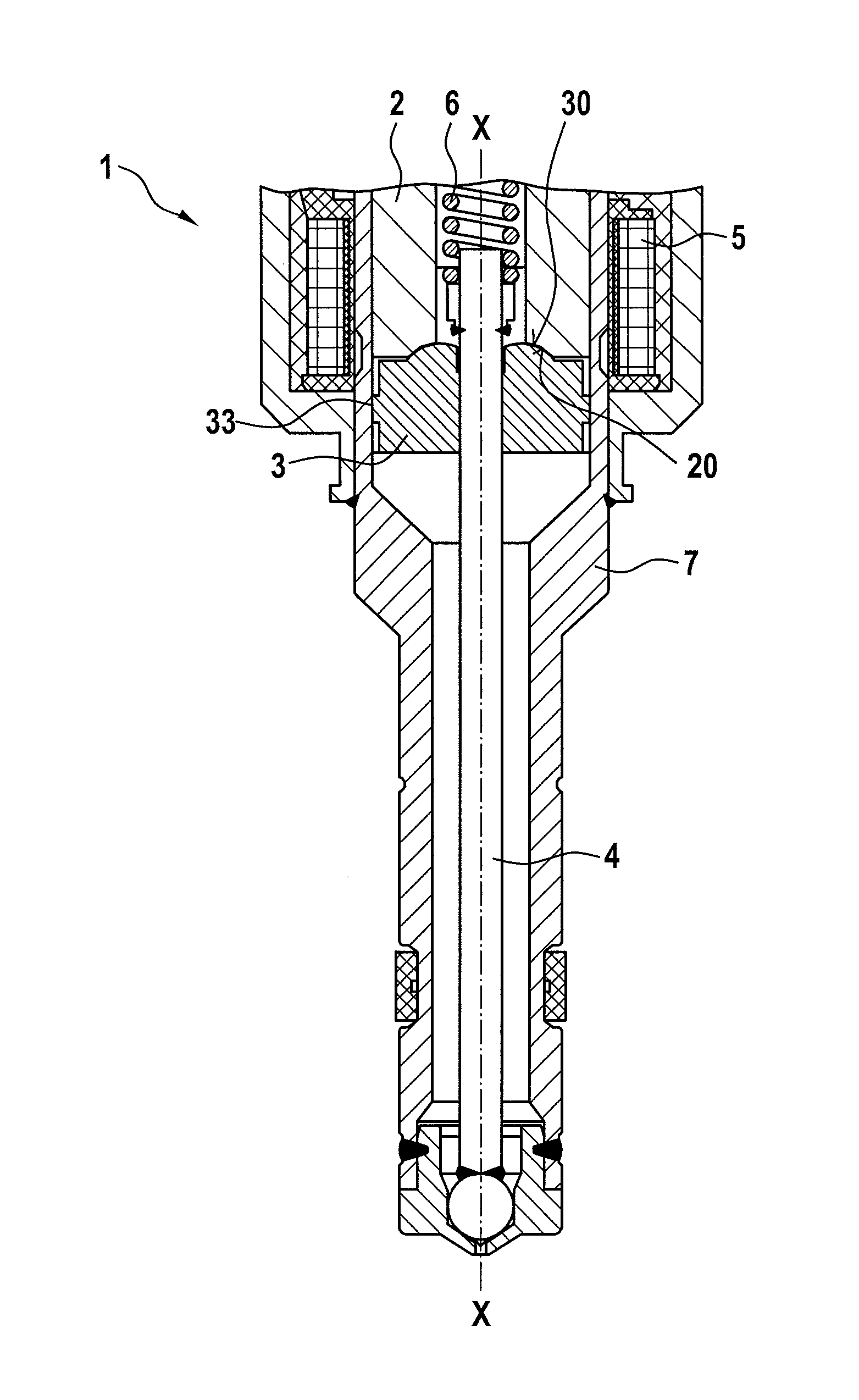

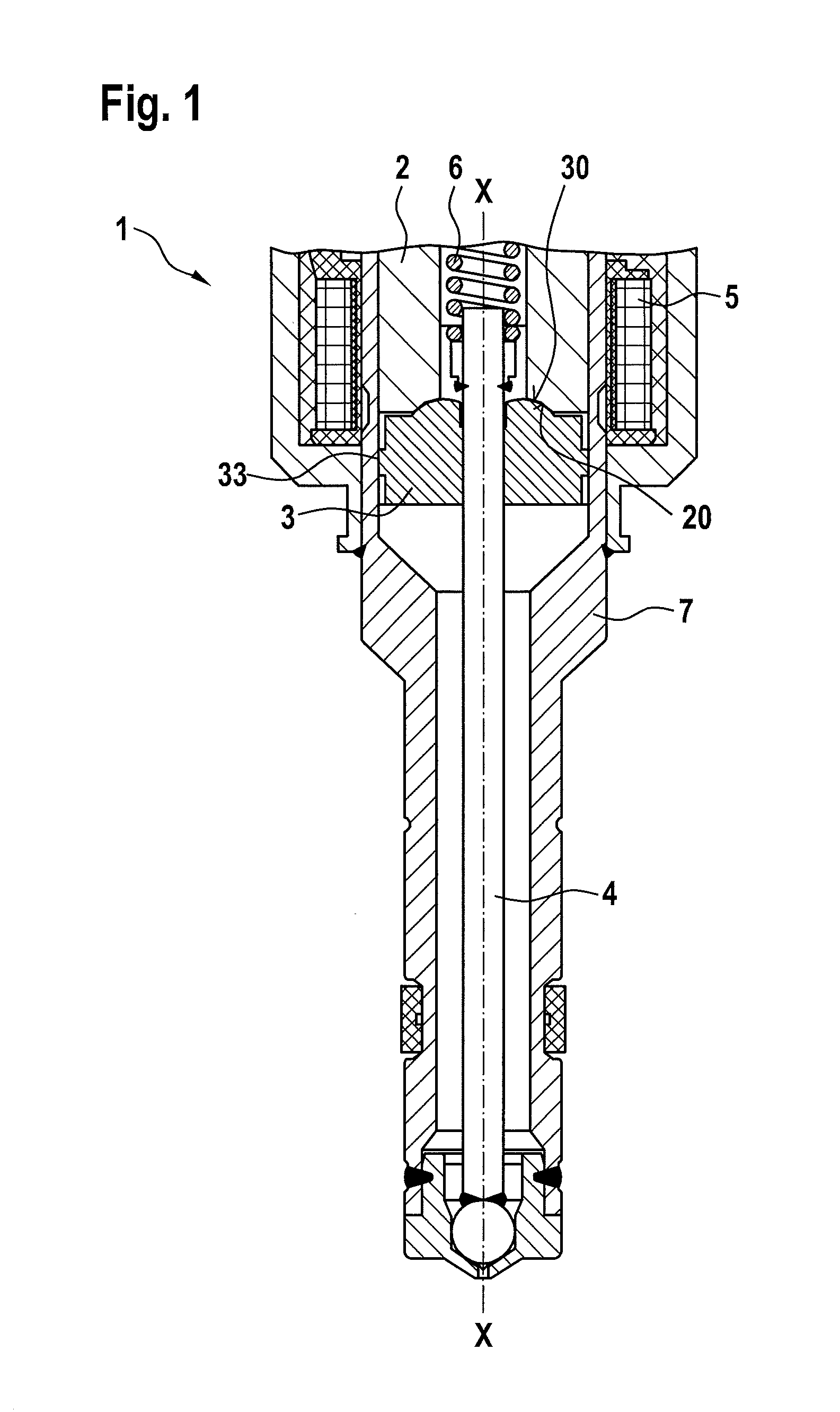

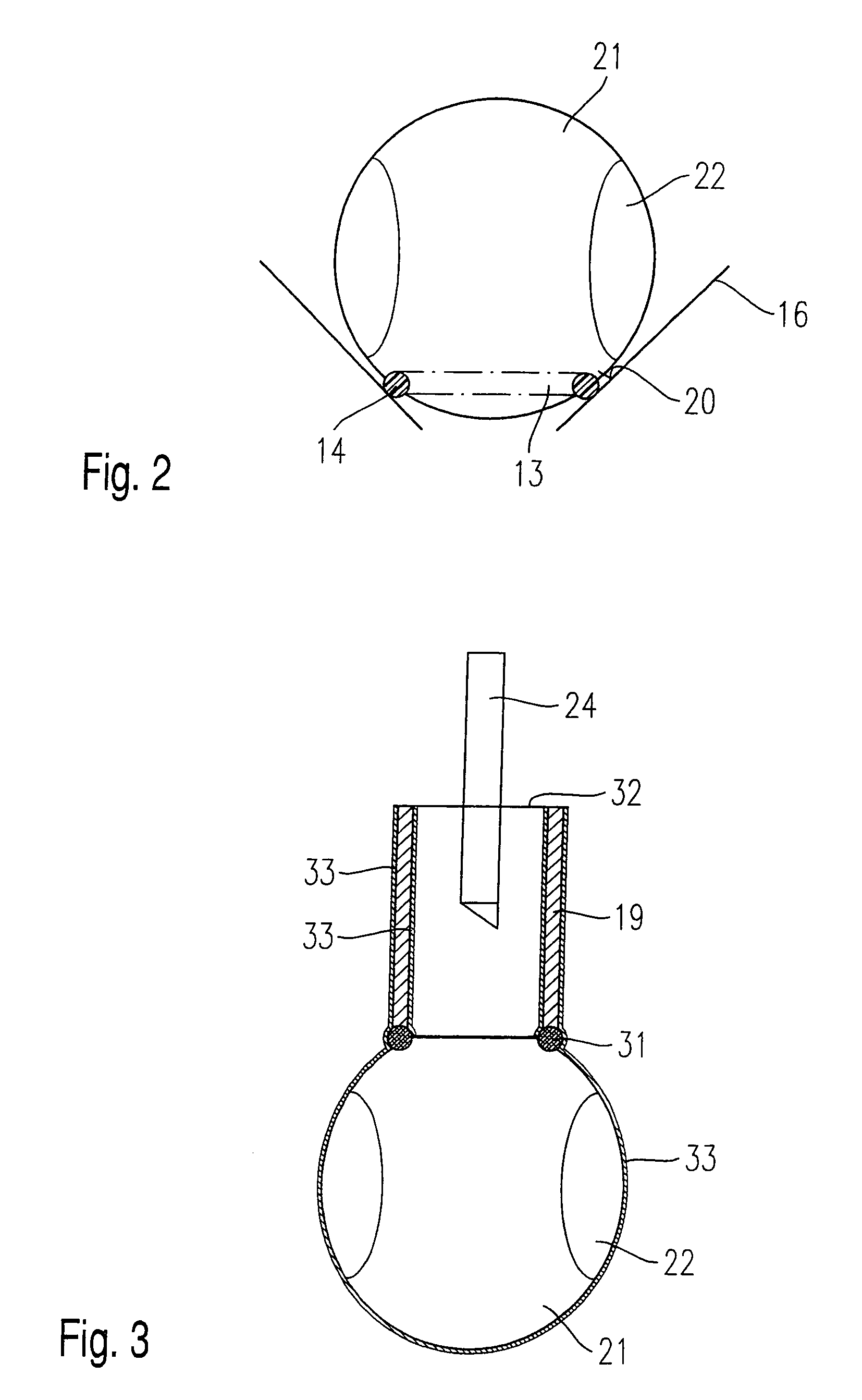

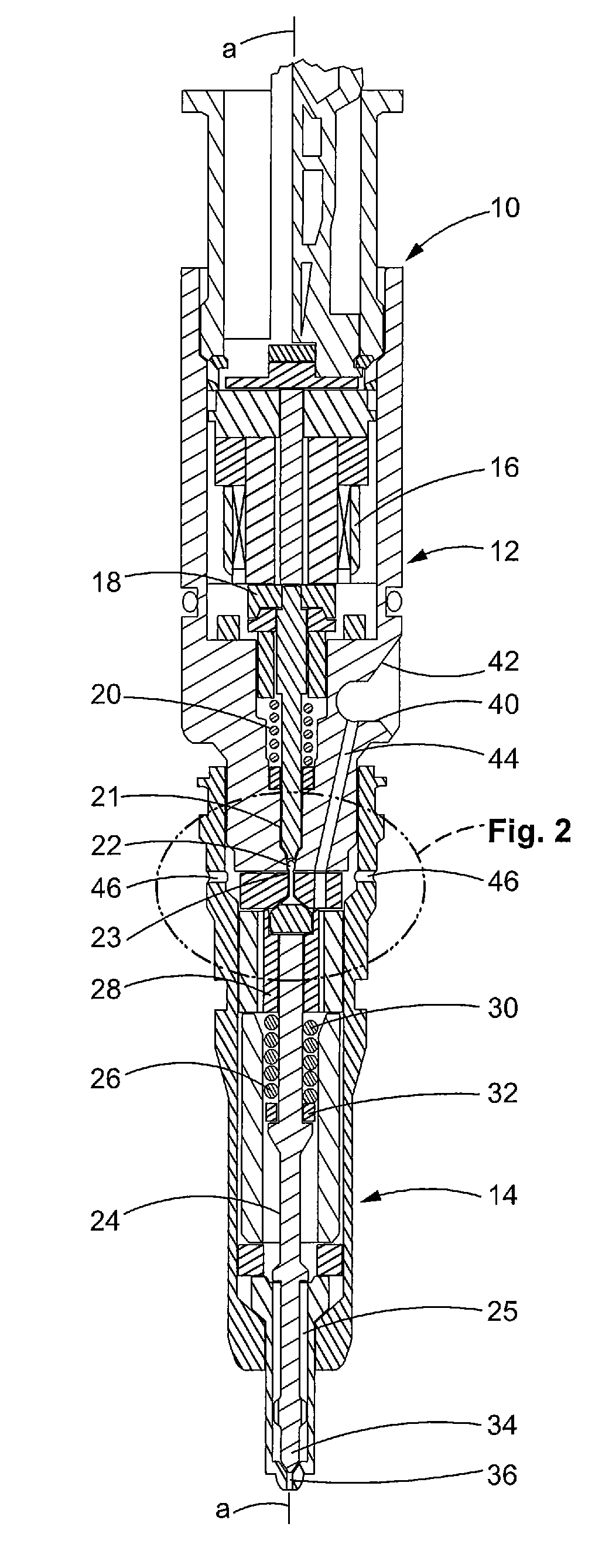

Electromagnetically actuatable valve

ActiveUS20140346382A1Reduce impactImprove wear characteristicsOperating means/releasing devices for valvesWear reducing fuel injectionContact lineElectrical and Electronics engineering

An electromagnetically actuatable valve is described, for controlling fluids, having an inner pole and a magnetic armature, the inner pole having a first end face oriented to the magnetic armature, and the magnetic armature having a second end face oriented to the inner pole, a first contact line and a second contact line being present between the first and second end face when the inner pole and the magnetic armature come into contact with one another, and a damping volume being present between the first and second contact line when the inner pole and the magnetic armature come into contact with one another.

Owner:ROBERT BOSCH GMBH

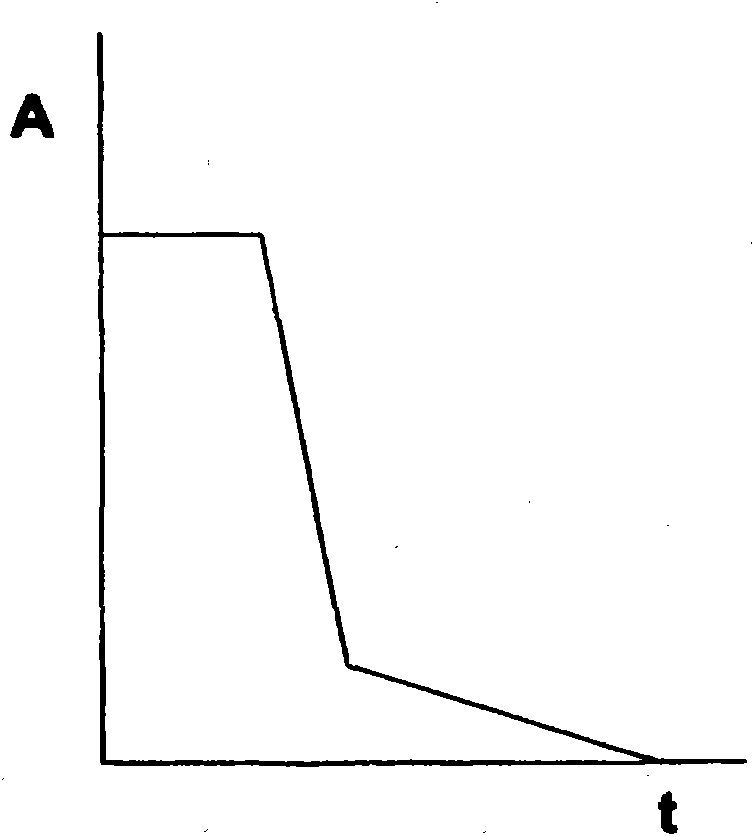

Directly actuated valve with a strain-type actuator and a method of operating same

ActiveCN101861487AReduce the amplitudeElectrical controlOperating means/releasing devices for valvesEngineeringActuator

Disclosed is a method of operating a directly actuated valve that comprises a strain-type actuator to actuate a valve member to travel between a closed position and an open position, the method comprising transmitting displacements from the strain-type actuator to the valve member, maintaining a compressive stress on the actuator that is greater than a predetermined minimum stress by applying a pre-load compressive stress and limiting to less than predetermined limits at least one of: (a) acceleration and deceleration of the valve member when moving between open positions and the closed position; and (b) velocity of said valve member immediately before contacting the valve seat. One of the preferred techniques for limiting the velocity of the valve member while also reducing the amount offluid that flows through the valve during the closing time, comprises changing the closing rate of the valve member so that the valve member travels most of the closing distance quickly during the beginning of a closing movement, and then slowing down the closing rate of the valve member in a second portion of the closing movement, so that the velocity of the valve member is less than a predetermined limit immediately before contacting the valve seat.

Owner:WESTPORT POWER

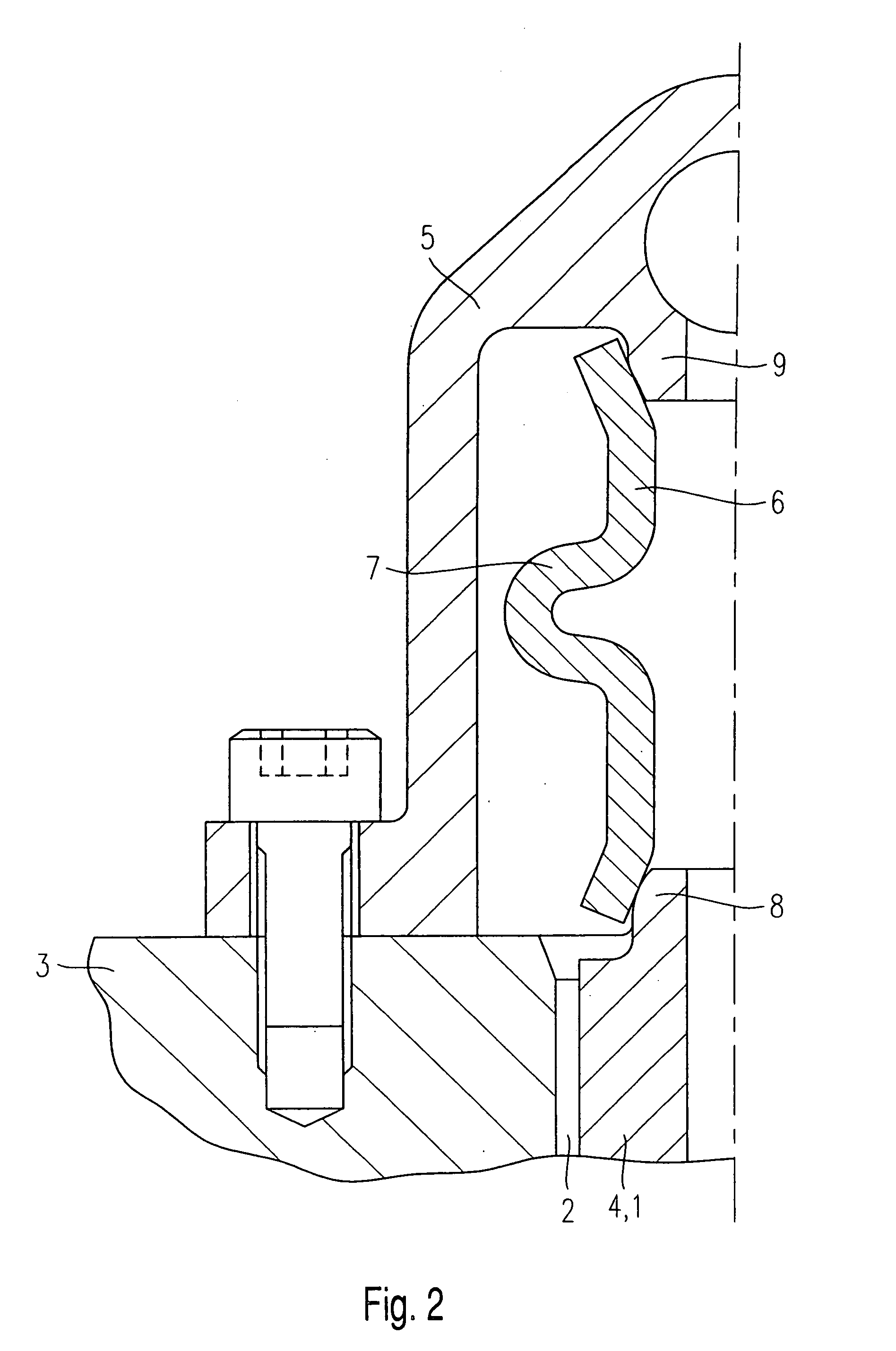

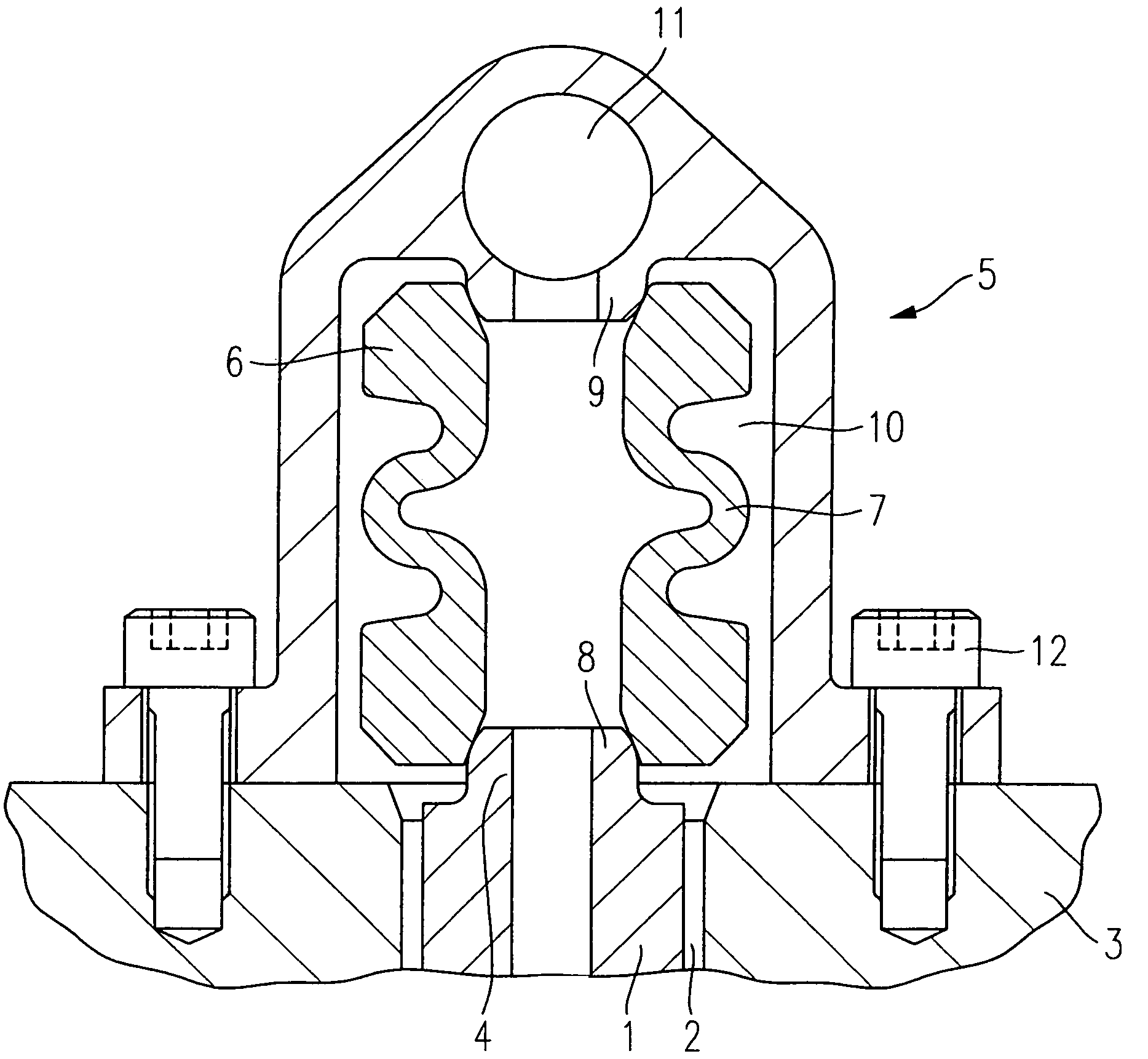

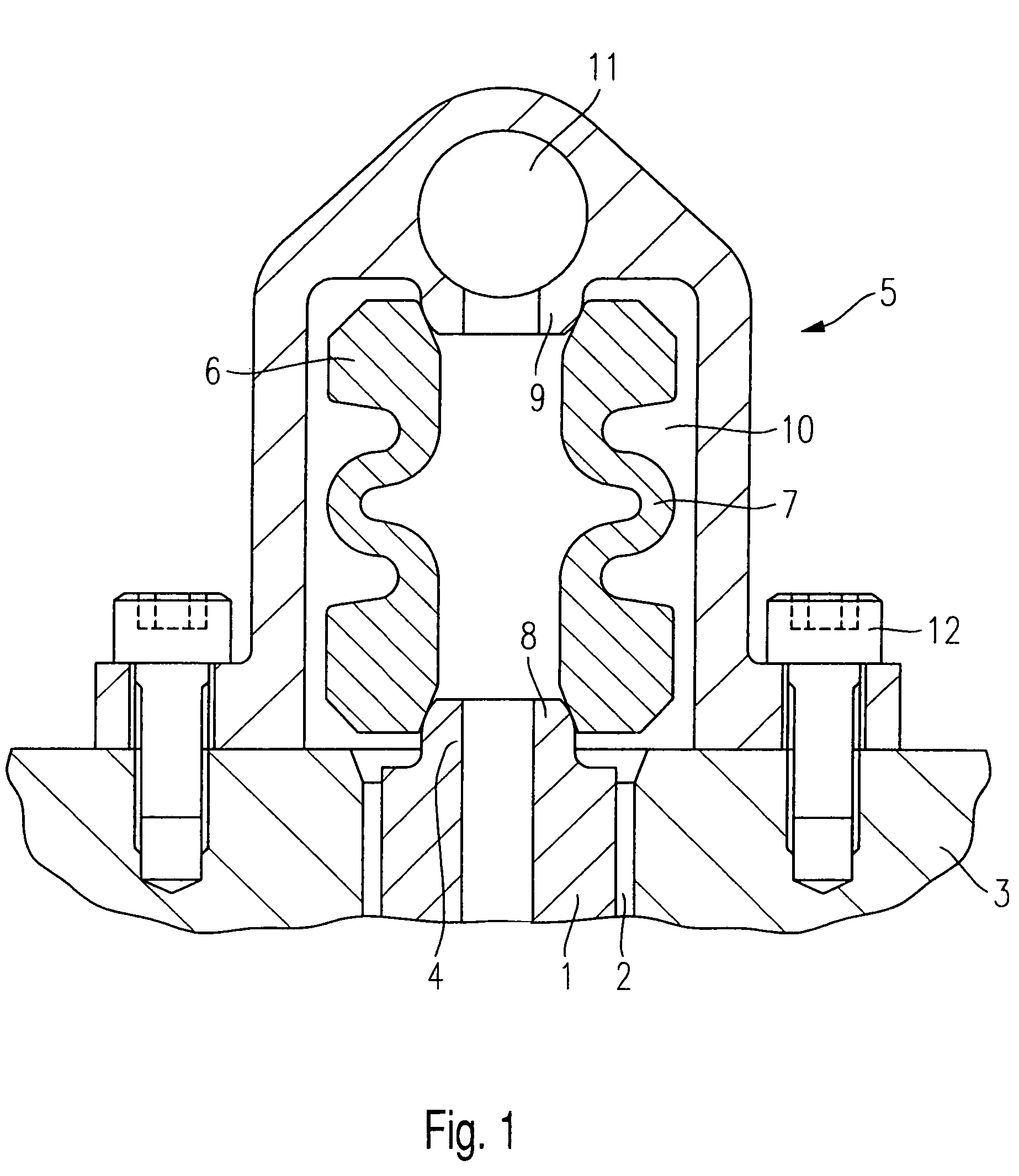

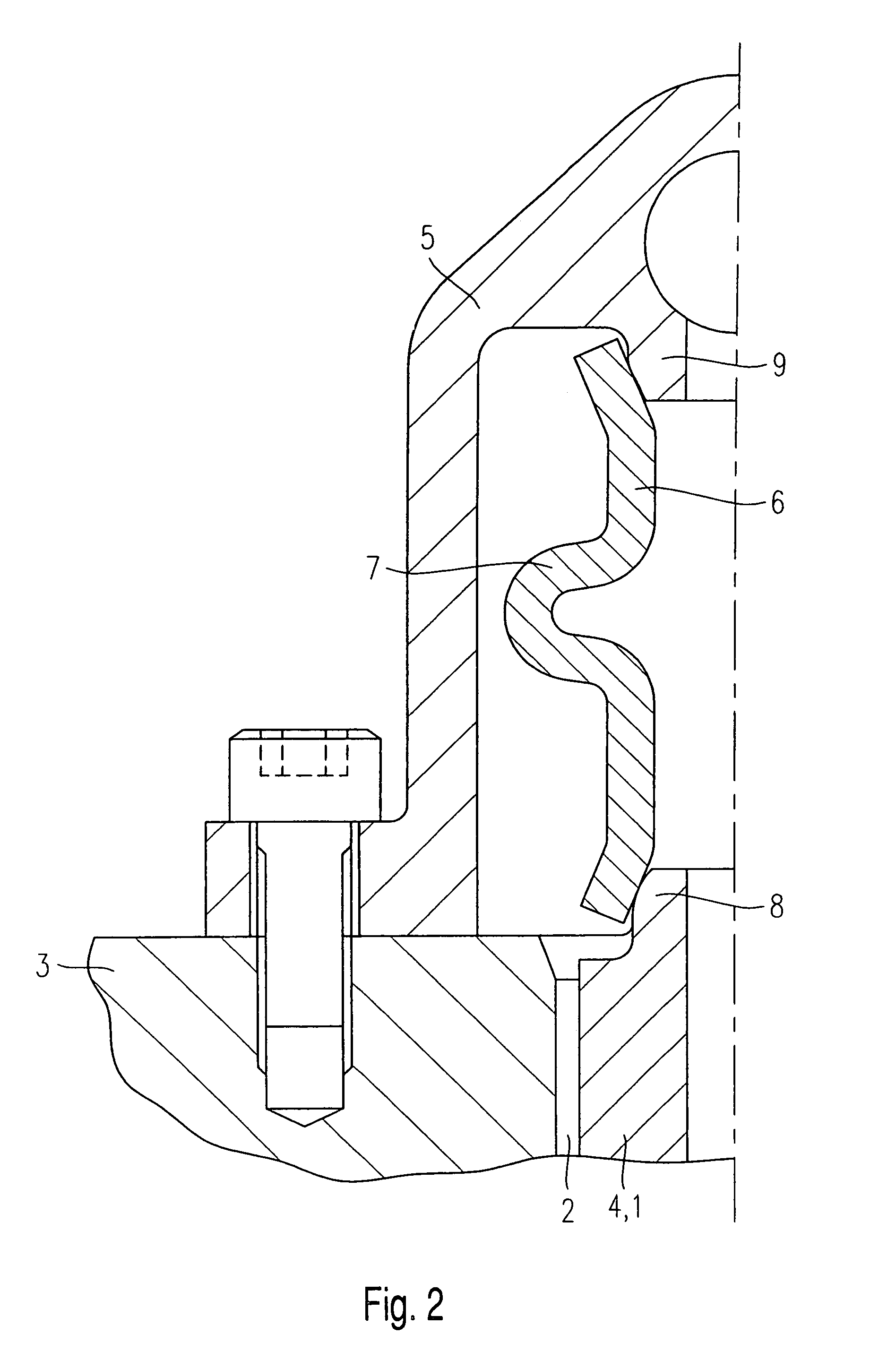

Pump for supplying high-pressure fuel

ActiveCN102197212AReduce nibblingReduce wearPositive displacement pump componentsWear reducing fuel injectionEngineeringInternal combustion engine

A pump for supplying high-pressure fuel, wherein, when the pump is mounted to an engine block of an internal combustion engine, a cylinder of the pump can be accurately positioned in a mounting hole formed in the engine block. A pump for supplying high-pressure fuel comprises a holder, the holder being provided with an outer circular tube surface section fitted in a pump mounting hole formed in an engine block of an internal combustion engine, and also with a circular tube fitting section fitted to the outer periphery of a cylinder of the pump. The holder is a single part formed by working the same member to form the outer circular tube surface section and the circular tube fitting section. The center axis of a piston plunger inserting hole formed in the cylinder can be easily made coaxial with the center axis of the mounting hole formed in the engine block of the internal combustion engine. Biting and wear between the cylinder and a piston plunger caused by side force applied by a drive mechanism to the plunger can be reduced.

Owner:HITACHI ASTEMO LTD

Injection valve with a corrosion-inhibiting, wear-resistant coating and method for the production thereof

InactiveUS7506826B2Efficient mannerImprove reliabilityWear reducing fuel injectionFuel-injection pumpsFuel cellsWear resistant

A fuel injector for injecting water, in particular into the gas flow of fuel cells, has a valve needle having joined to its spray-discharge end a valve-closure member, which cooperates with a valve-seat surface formed on a valve-closure member a sealing seat. A spray-discharge orifice is provided downstream from the sealing seat, at least a portion of the surfaces of the fuel injector that come into contact with water being coated by a corrosion-inhibiting and / or friction-reducing coating.

Owner:ROBERT BOSCH GMBH

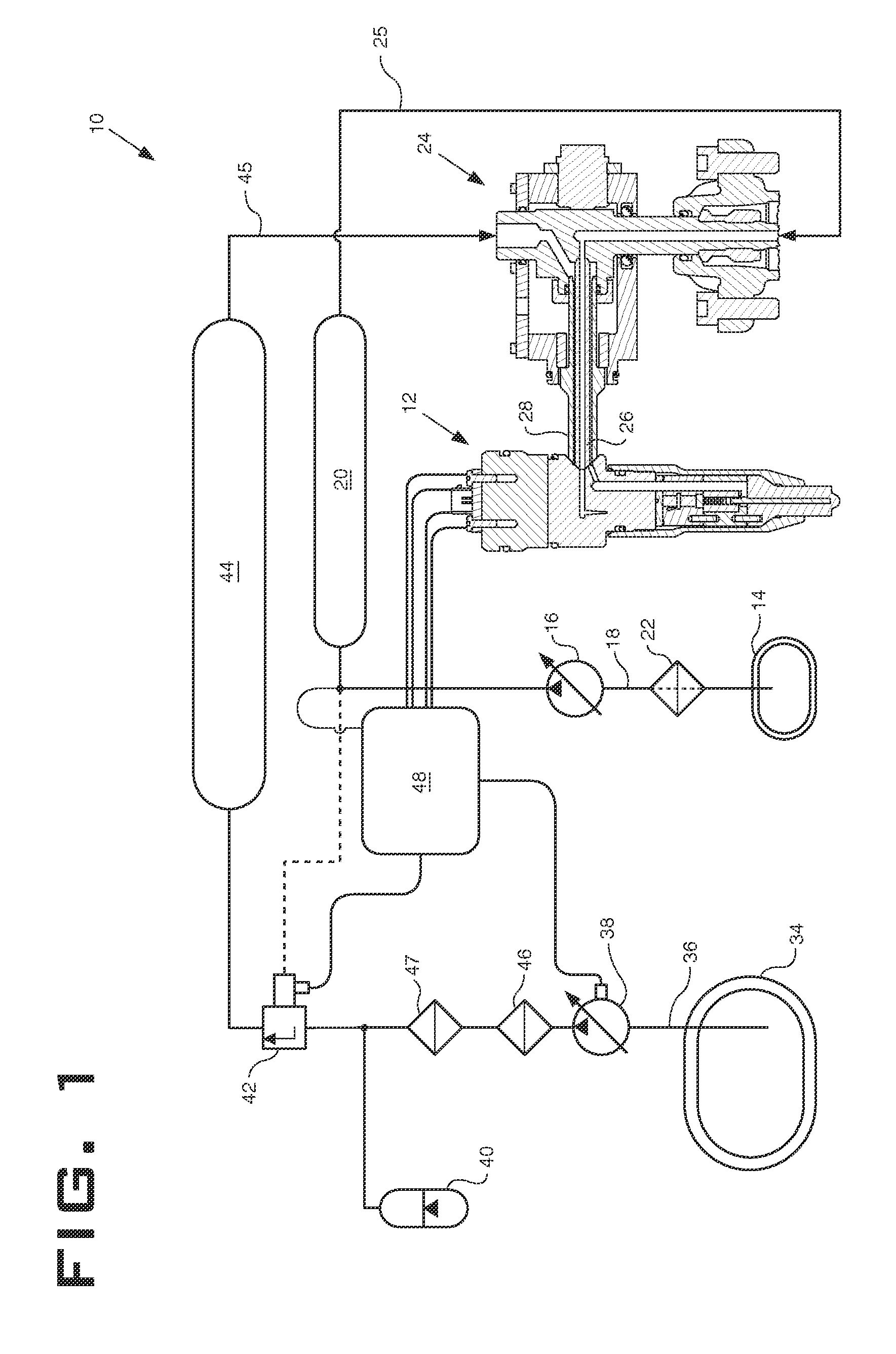

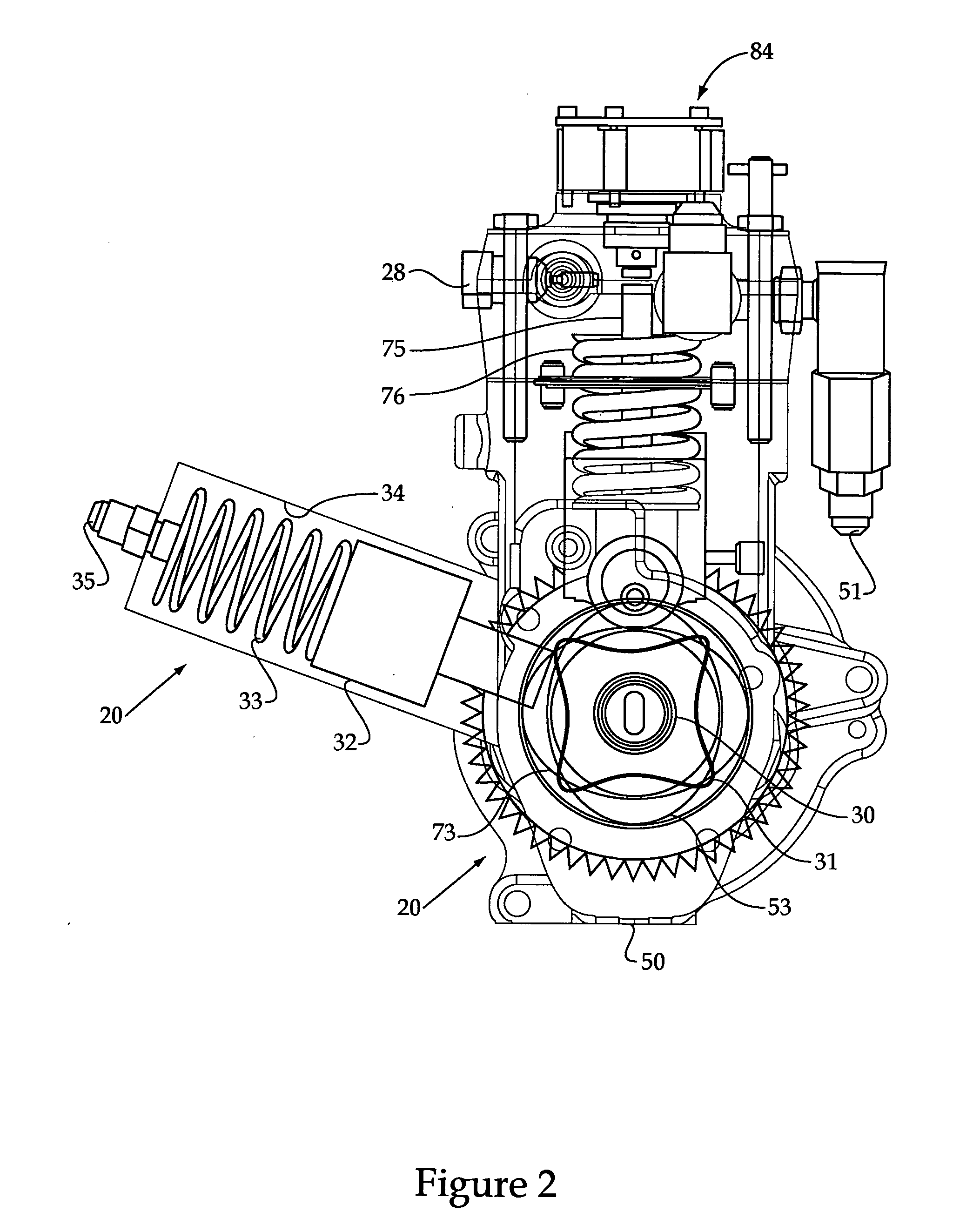

Pump with torque reversal avoidance feature and engine system using same

InactiveUS20080115770A1Positive torqueWear reducing fuel injectionPump parameterAfter treatmentCommon rail

A high pressure pump for a common rail fuel system avoids torque reversals in its cam shaft by applying a cyclic parasitic load. As the high pressure pump pistons transition from a pumping stroke to a retraction stroke, the cyclic parasitic loading device is loaded to avoid torque reversals in the cam shaft. The cyclic parasitic load device may include a medium pressure pump, such as for supplying medium pressure fuel to a particle trap regeneration device associated with the exhaust after treatment system.

Owner:CATERPILLAR INC

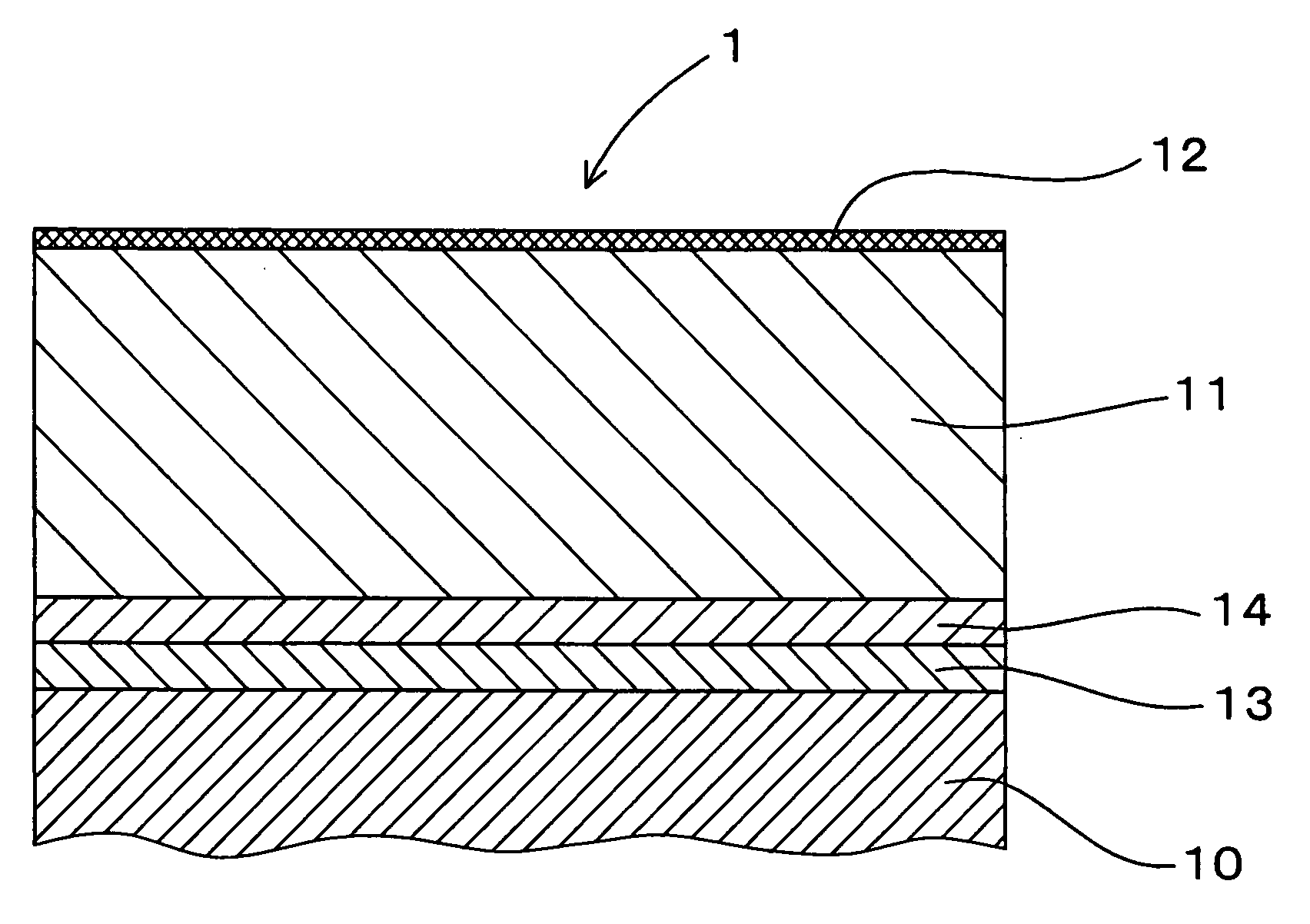

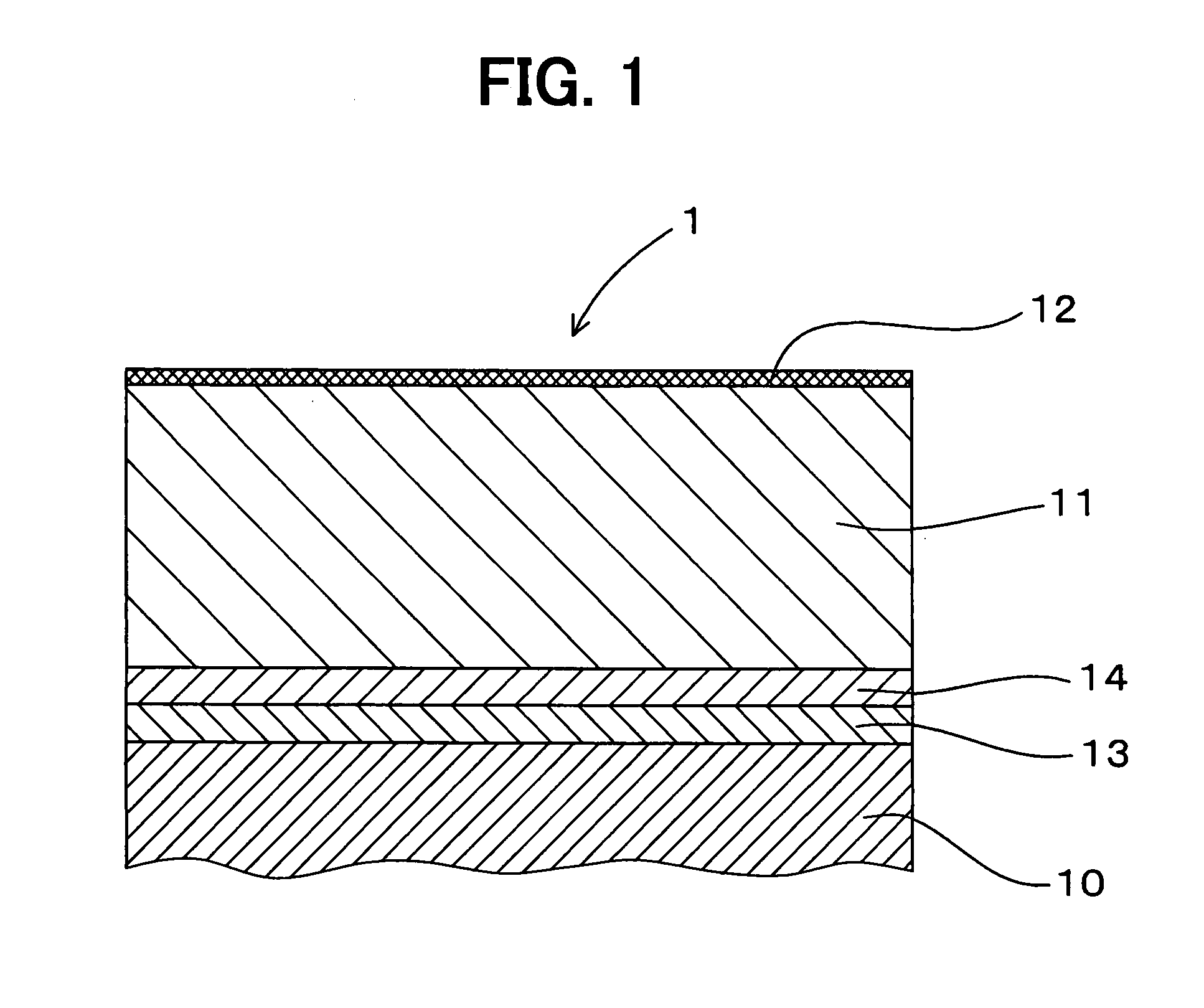

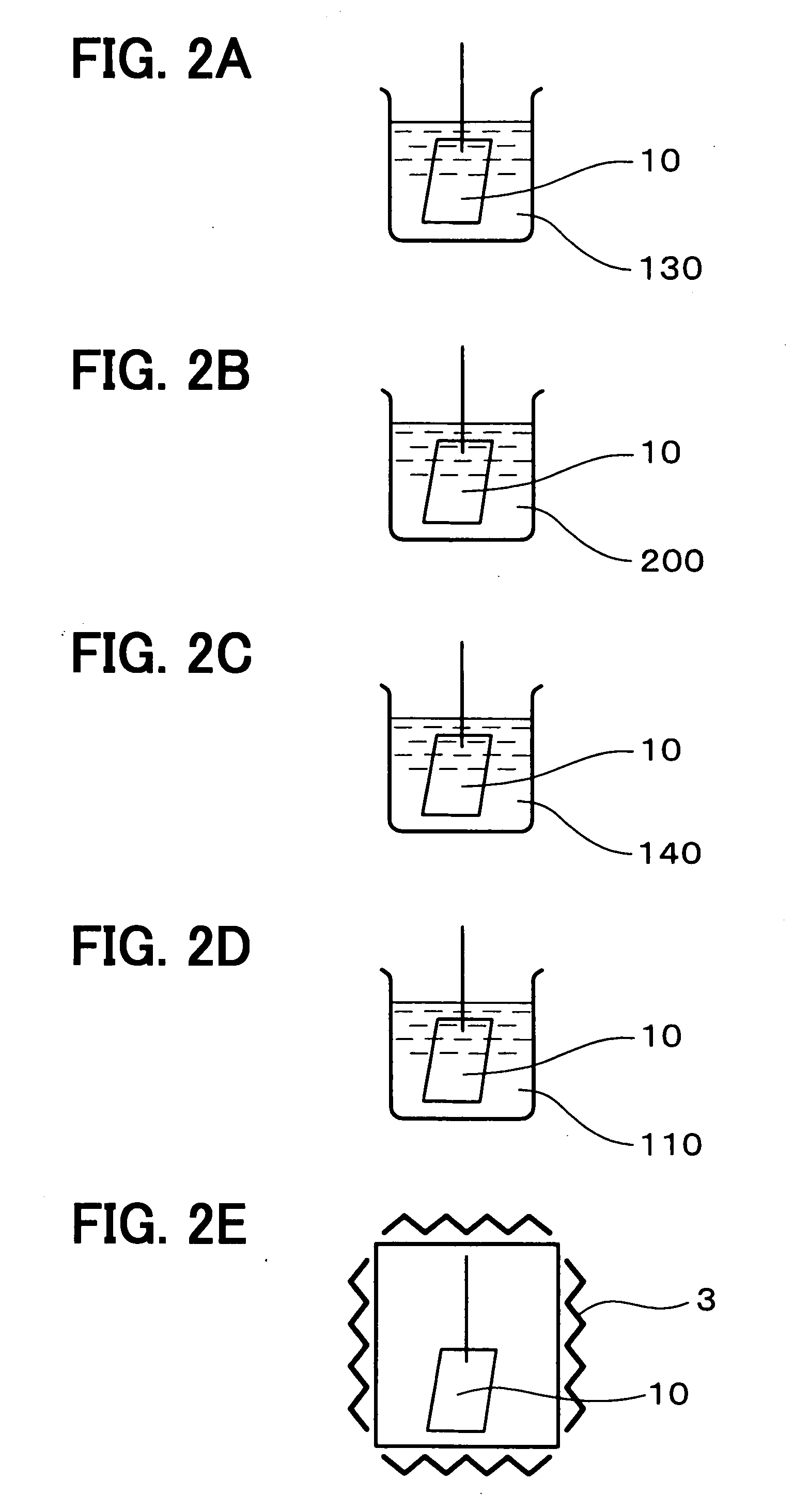

Coating structure and method for forming the same

InactiveUS20070264491A1Sufficient water-shedding propertyLarge surface roughnessWear reducing fuel injectionSynthetic resin layered productsFluorine containingMetal

A coating structure for a metal member includes a surface-smoothing layer formed on the metal member for smoothing a surface of the metal member, and a fluorine-based film formed on the surface-smoothing layer. The fluorine-based film can be formed by applying a fluorine-containing solution on the surface-smoothing layer, and by drying the fluorine-containing solution. The coating structure can be suitably used for a fuel injection nozzle.

Owner:DENSO CORP

Cam roller pin with transverse grooves

ActiveUS7878169B2Reducing localized contact pressureIncrease contactValve arrangementsYielding couplingContact pressureTransverse groove

A roller pin for carrying a cam roller in a tappet assembly is provided. The roller pin providing reduced run in time and reduced peak and localized contact pressure between the cam roller and roller pin. The roller pin comprises a substantially cylindrical shaft having a length, a first end and a second end. The length extends from the first end to the second end. The shaft includes a plurality of grooves axially spaced apart and extending in a direction being transverse to the length. The plurality of grooves located proximate the first and second ends and extending only partially the circumference of the shaft.

Owner:WOODWARD GOVERNOR CO

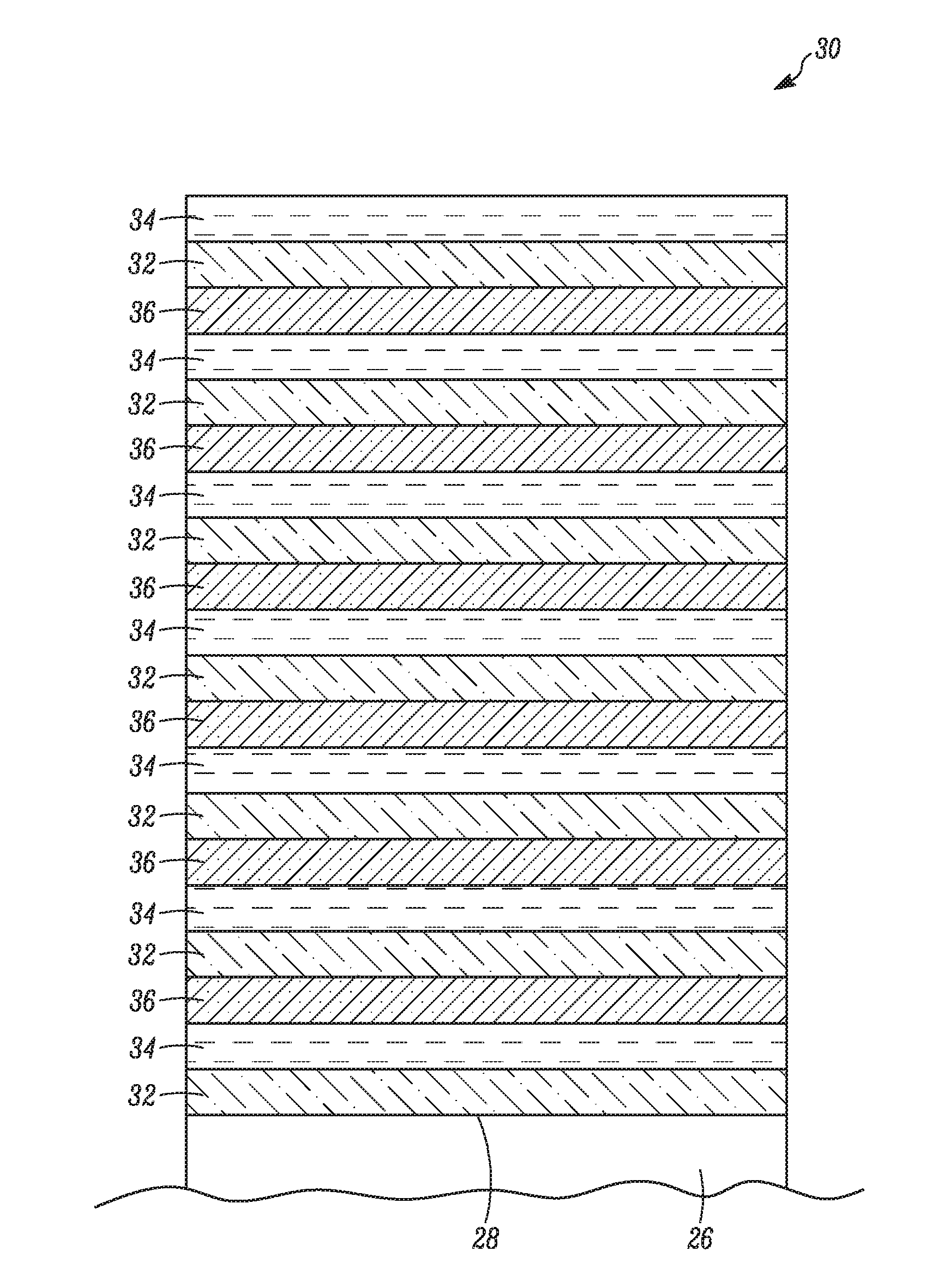

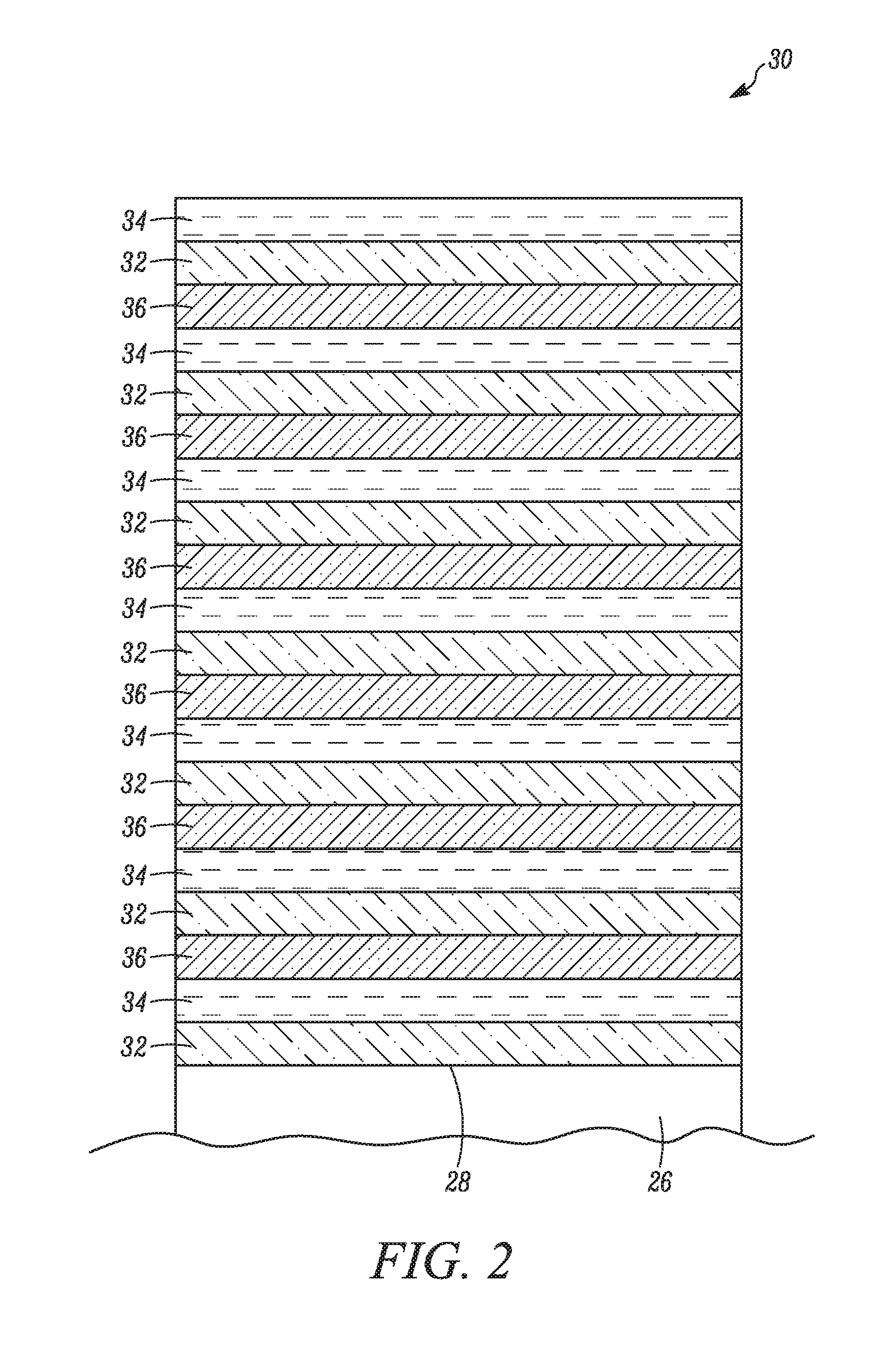

Multilayer coating for a component

InactiveUS20160230274A1Wear reducing fuel injectionCorrosion preventing fuel injectionDiamond-like carbonHardness

A multilayer coating for a metallic surface of a component is provided. The multilayer coating includes a first coating having a metal nitride. The first coating at least partially overlaps the metallic surface. The multilayer coating also includes a second coating having a metal. The second coating at least partially overlaps the first coating. The multilayer coating further includes a third coating having a Diamond Like Carbon (DLC) material. The third coating at least partially overlaps the second coating. The first coating, the second coating, and the third coating differ from one another with respect to at least one of hardness, elasticity, corrosion resistance, and lubricity. The multilayer coating includes at least ten overlapping layers having successive layers of the first coating, the second coating, and the third coating in repeating sequence.

Owner:CATERPILLAR INC

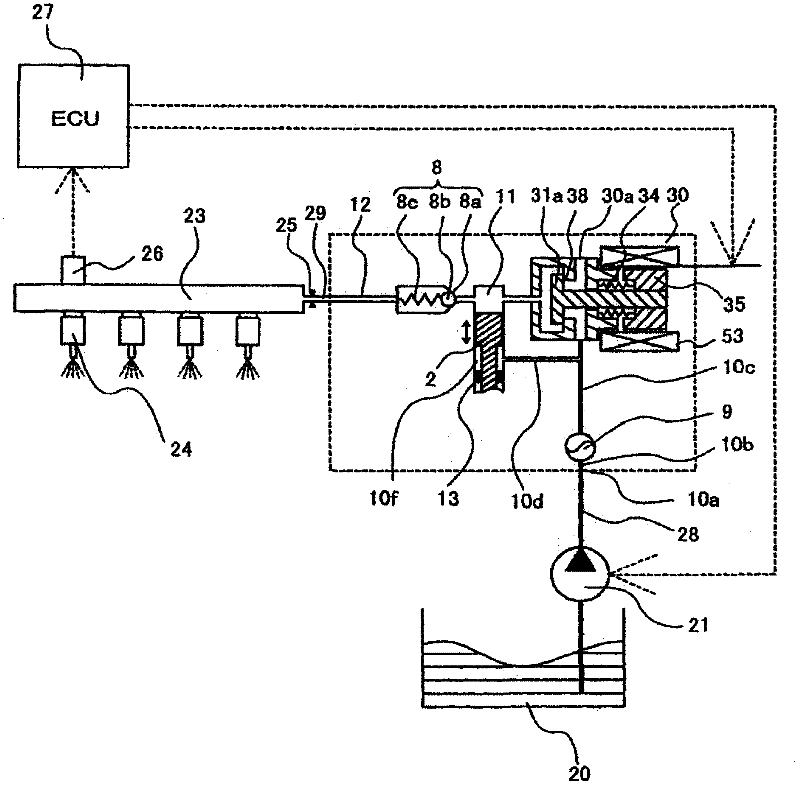

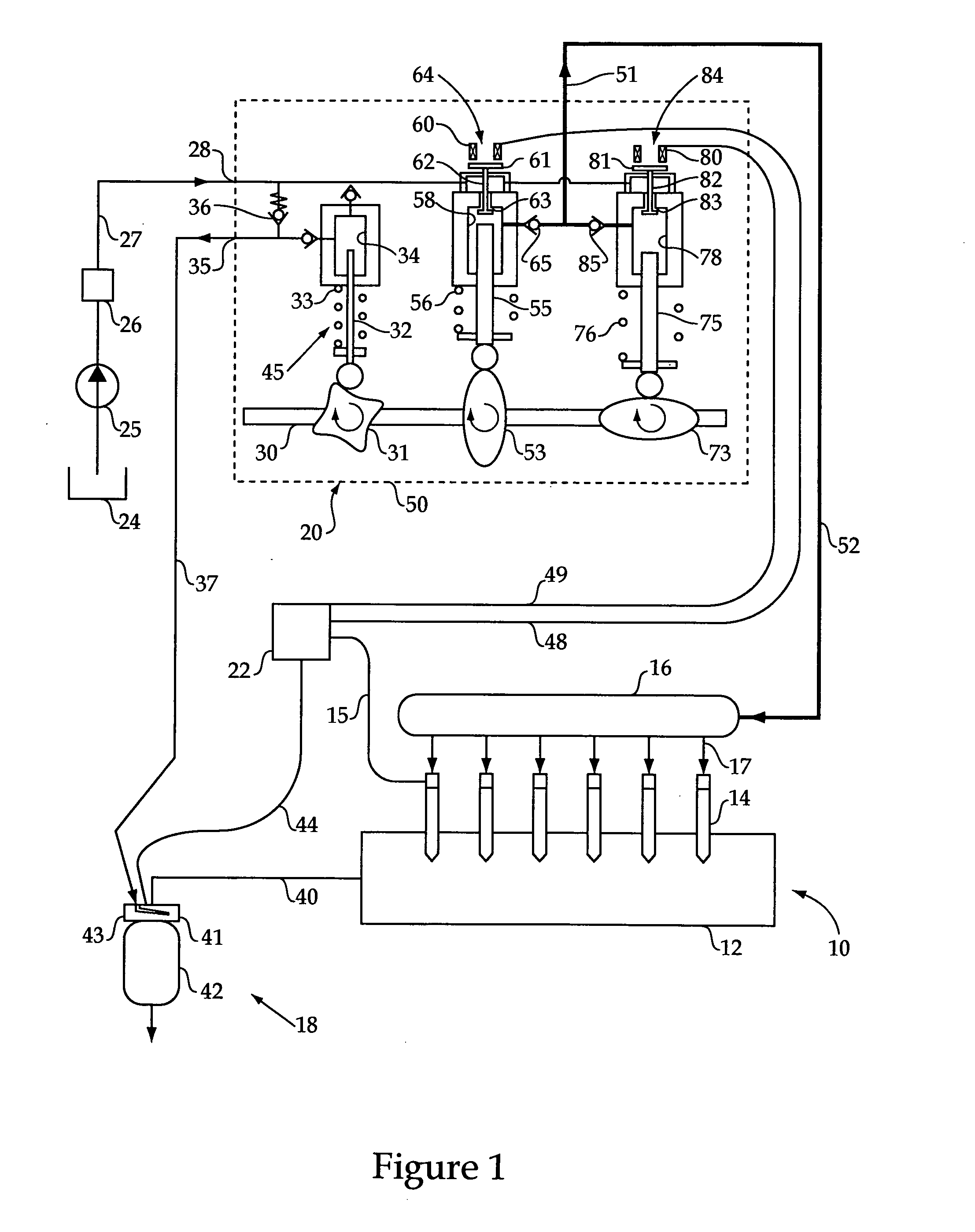

Fuel injection system

InactiveUS20060021601A1Simple wayEasy to assembleWear reducing fuel injectionLow pressure fuel injectionCombustion chamberCylinder head

A fuel injection system, in particular for direct injection of fuel into the combustion chamber of an internal combustion engine has a plurality of fuel injectors, whose injection ends, at least, are situated in receptacle bore holes of a cylinder head. The inlet side of the fuel injectors has a connecting piece, which engages with a supply line segment. Pressurized fuel is supplied to the fuel injector via the supply line segment. The connecting piece is sealed off from the supply line segment by a gasket. The gasket has a sleeve-shaped design and has a plastically deformable shaped area, which is plastically deformed during the assembly of the supply line segment with the connecting piece, and has elastic properties while in operation.

Owner:ROBERT BOSCH GMBH

Fuel injection system

InactiveUS7188611B2Easy to assembleElastic spring constantWear reducing fuel injectionLow pressure fuel injectionCombustion chamberCylinder head

Owner:ROBERT BOSCH GMBH

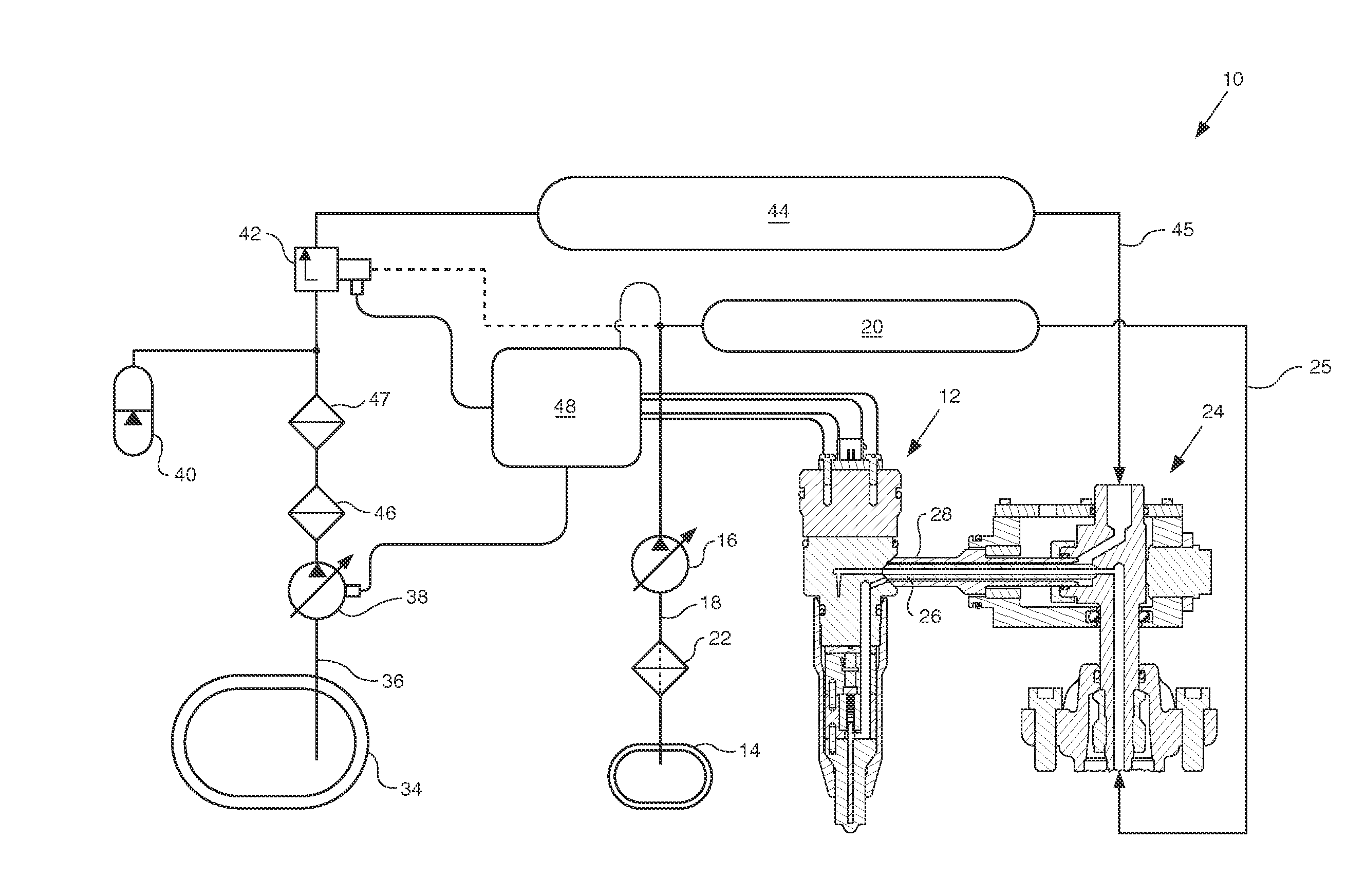

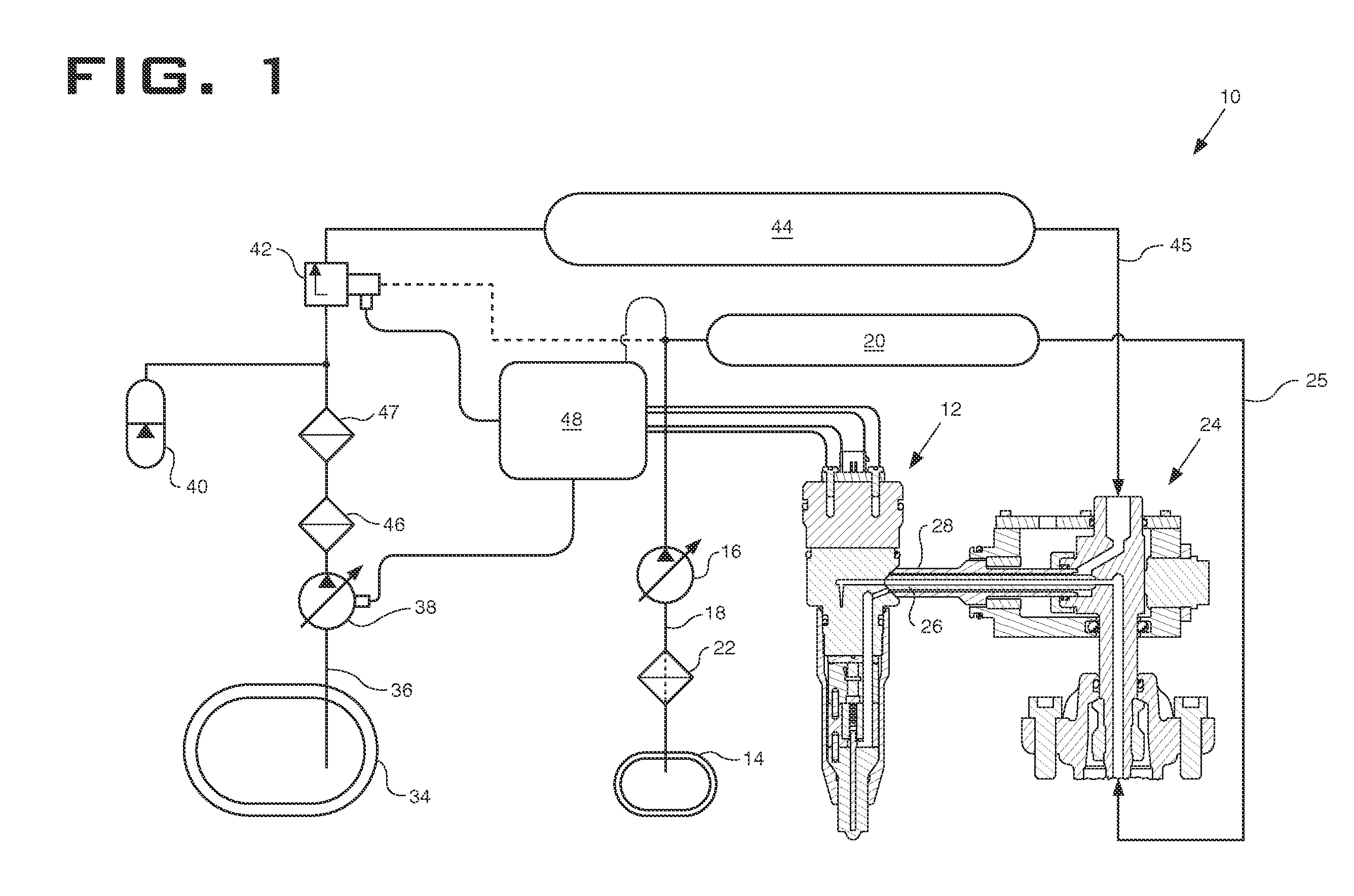

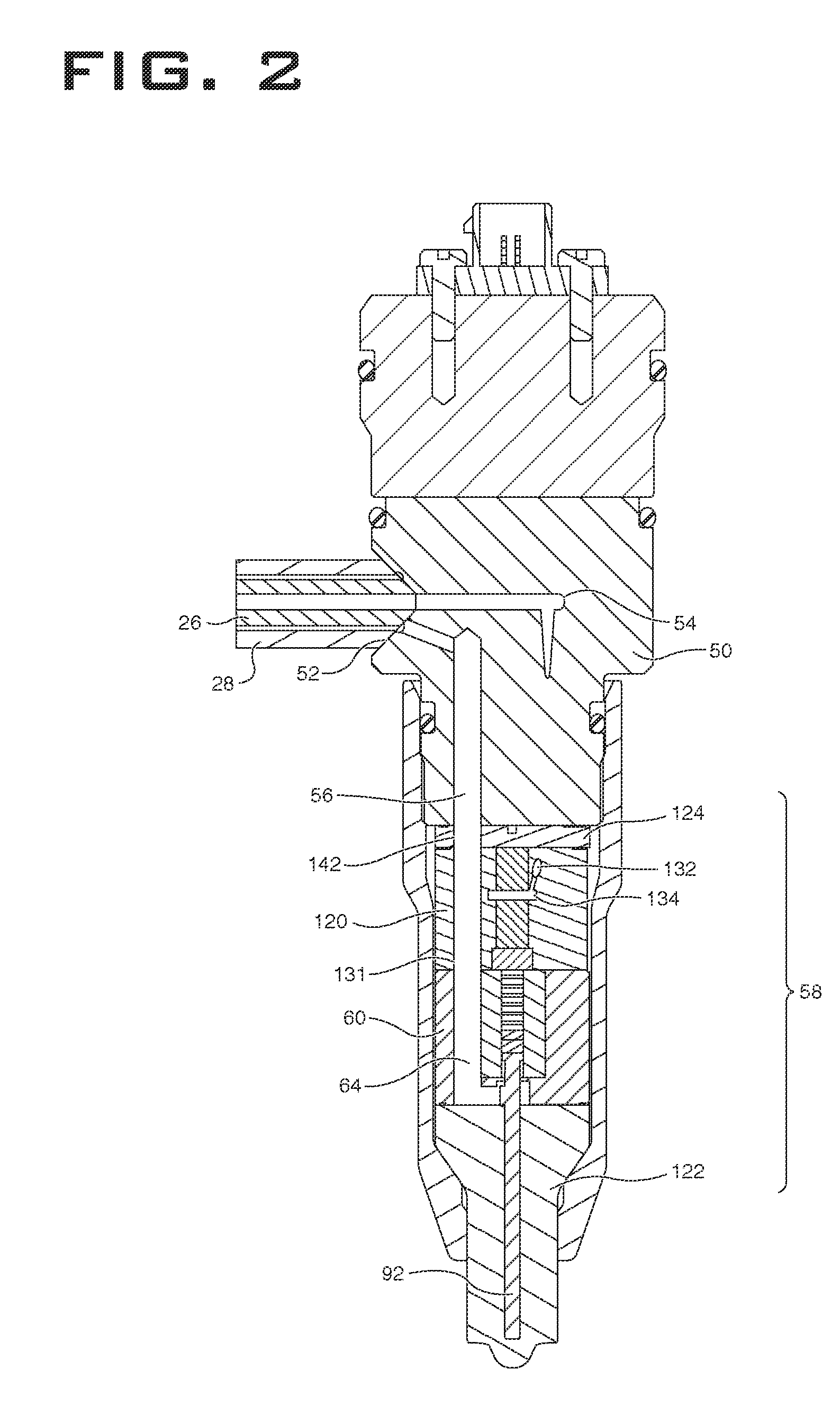

Direct injection fuel pump system

InactiveUS20160208757A1Improve engine performanceWell mixedWear reducing fuel injectionPositive displacement pump componentsEngineeringHigh pressure

Systems and methods are provided for operating a direct injection fuel pump. One example system comprises an accumulator positioned within a bore of the direct injection fuel pump in a coaxial manner wherein the accumulator is positioned downstream from a solenoid activated check valve. The accumulator may regulate pressure in a compression chamber of the direct injection fuel pump and a high pressure fuel rail when the direct injection fuel pump is operating in a default pressure mode.

Owner:FORD GLOBAL TECH LLC

Fuel injector

InactiveUS20130075501A1More responsiveImprove responsivenessWear reducing fuel injectionMagnetic flux influencing fuel injectionEngineeringMagnetic flux

Improving the injection fuel mass accuracy of fuel injector, it is necessary to make the fuel injector perform seat valve opening and closing operation quickly. When the shapes of a fixed core and an anchor are optimized to improve the responsiveness of a magnetic flux, it is necessary to ensure a sufficient fuel path area while preventing adhesion by making the adherence phenomenon rarely occur between an end face of the anchor and an end face of the fixed core. A through hole passes through an anchor forming an armature of an electromagnetic fuel injector from a face of the anchor where the anchor faces a fixed core to a back face where the through hole has a large-diameter portion and a small-diameter portion, and the large-diameter portion is located in an upstream part and is offset to the outer periphery with respect to the small-diameter portion.

Owner:HITACHI AUTOMOTIVE SYST LTD

Electromagnetic fuel injection valve

InactiveUS6851630B2Increase sliding resistanceExcellent in stabilization of opened and closed attitudeWear reducing fuel injectionSpray nozzlesDiamond-like carbonSurface roughness

An electromagnetic fuel injection valve includes a valve housing coupled to at one end thereof to a valve seat member; a stationary core coupled to the other end of the valve housing; and a valve assembly comprised of a movable core slidably accommodated in the valve housing, and a valve member connected to the movable core through a rod portion and adapted to cooperate with the valve seat. In the electromagnetic fuel injection valve, the valve housing is provided with a guide portion on which the valve assembly is axially slidably carried, and a high-hardness coating of diamond-like carbon including silicon is formed on an outer peripheral surface of the valve assembly contacting with the guide portion. The surface roughness Rmax of the high-hardness coating is set in a range of 0.05 to 0.2 μm. Thus, it is possible to achieve the stabilization of opened and closed attitudes of the valve assembly and the responsiveness of the valve assembly, thereby contributing an improvement in low fuel consumption in an engine.

Owner:KEIHIN CORP

Fuel injector

InactiveUS6994281B2Shorten the lengthImprove accuracyWear reducing fuel injectionSpray nozzlesCombustionEngineering

A fuel injector for fuel-injection systems of internal combustion engines includes a valve needle cooperating with a valve-seat surface to form a sealing seat, and an armature engaging with the valve needle, the armature being axially moveable at the valve needle and being damped, via a damping element, which is located in a recess in a downstream-side end face of the armature, with respect to a cup-shaped sleeve positioned downstream from the armature and joined to the valve needle in force-locking manner. Furthermore, the fuel injector includes a filter element, the filter element being positioned downstream from the armature in the cup-shaped sleeve.

Owner:ROBERT BOSCH GMBH

Injection valve with a corrosion-inhibiting, wear-resistant coating and method for the production thereof

InactiveUS20060202049A1Efficient mannerImprove reliabilityWear reducing fuel injectionFuel-injection pumpsFuel cellsWear resistant

Owner:ROBERT BOSCH GMBH

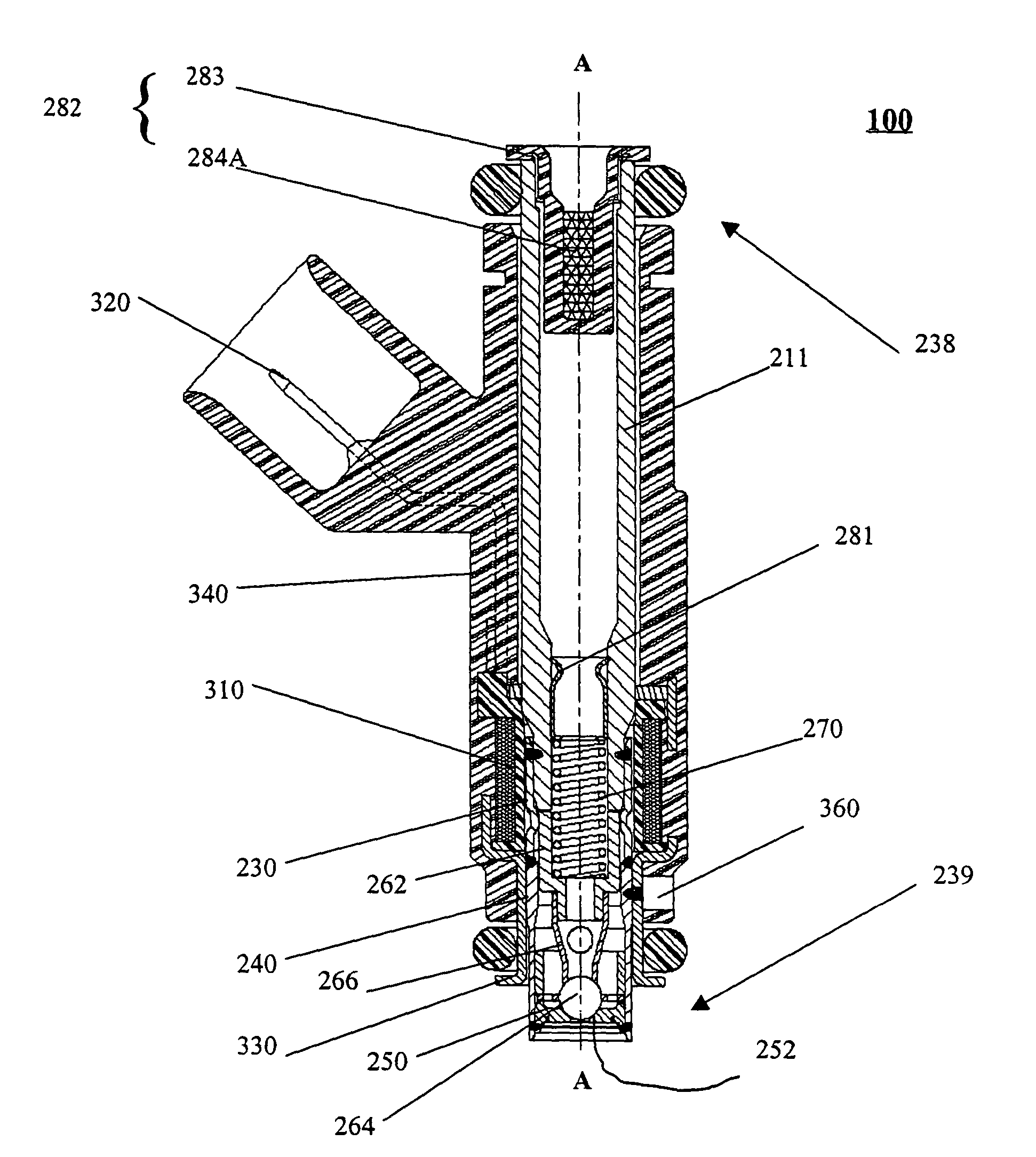

Injector Orifice Plate Filter

A hoop filter is adapted to protect a pressure control orifice plate in a common rail fuel injector from being plugged by contaminated fuel. Shaped in the form of a band, the filter is configured to engage the circumference of a pressure control orifice plate. For purposes of filtration, the orifice plate has a circumferential groove which intersects at least one internal orifice; the groove is externally covered by the body of the hoop filter. In one embodiment, the band-shaped hoop filter has small apertures adapted to filter out any particle having a size greater than 50 microns. In another disclosed embodiment, the hoop filter is a solid band-shaped edge filter without any apertures; instead the orifice plate periphery includes circumferentially spaced vertical grooves which interface with the bottom and top edges of the filter to restrict entry of contaminant particles.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com