Pump for supplying high-pressure fuel

A high-pressure fuel and supply pump technology, which is applied to fuel injection pumps, fuel injection devices, liquid fuel engines, etc., can solve the problems of gnawing or wear of sliding parts, which cannot be guaranteed, and achieve the effect of reducing gnawing or wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

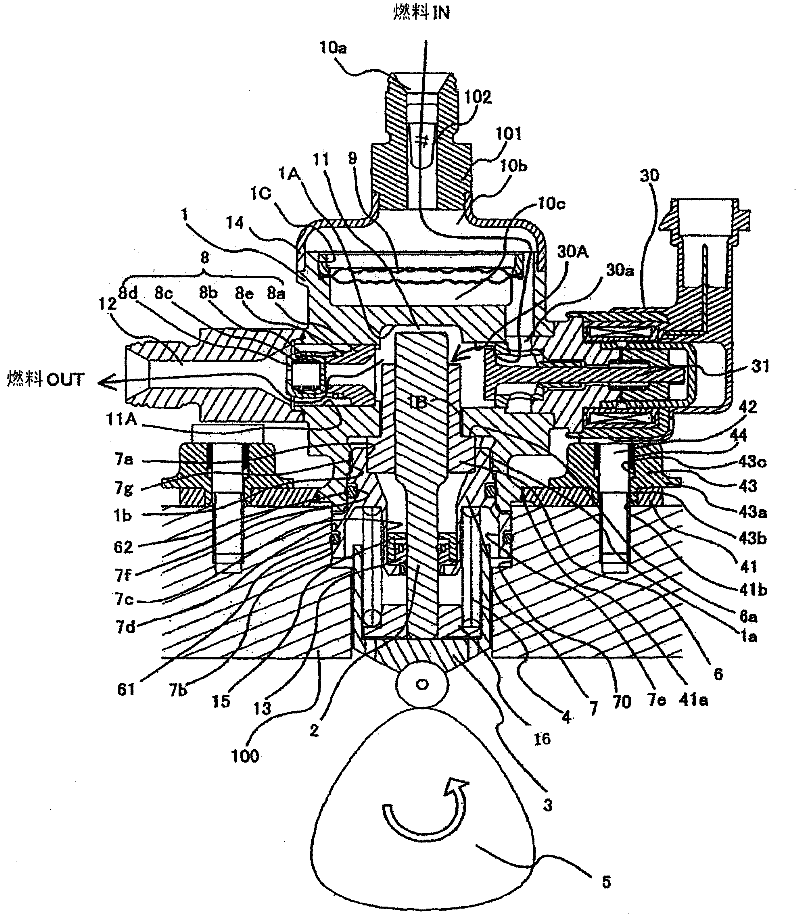

[0049] pass Figure 1 to Figure 12 Examples of the present invention will be described.

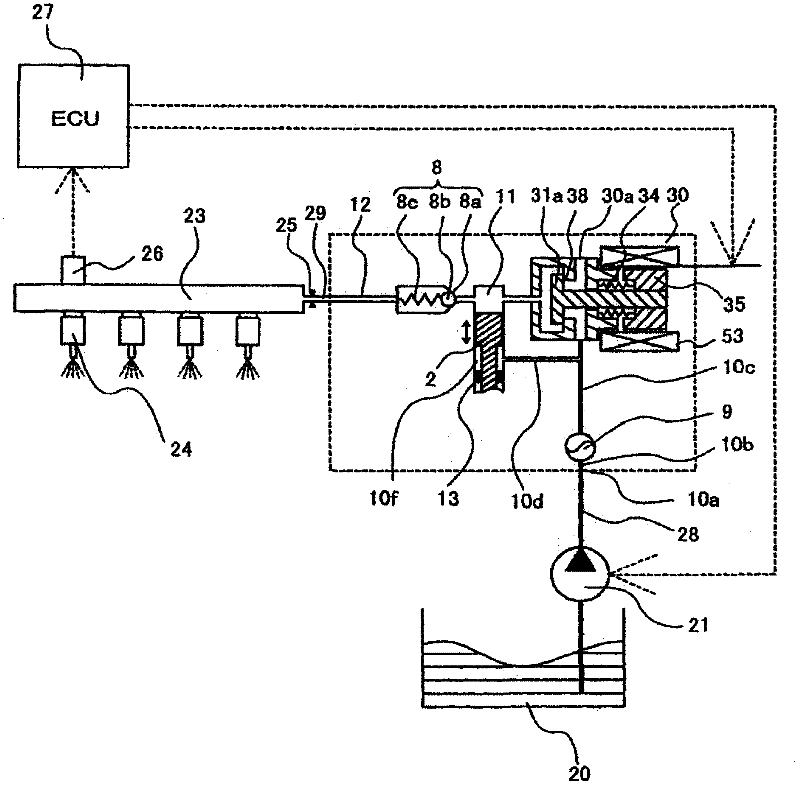

[0050] exist figure 1 In , the part enclosed by the dotted line represents the pump casing 1 of the high-pressure pump, and the mechanism and components shown in the dotted line represent the case of being integrated into the pump casing 1 of the high-pressure pump.

[0051] The fuel in the fuel tank 20 is pumped by the feed pump 21 based on a signal from the engine control unit 27 (hereinafter referred to as ECU), pressurized to an appropriate feed pressure, and delivered to the suction port 10a of the high-pressure fuel supply pump through the suction pipe 28 .

[0052] After passing through the suction port 10a, the fuel passes through the filter 102 fixed in the suction joint 101, then passes through the suction flow path 10b, the metal diaphragm dampers 9, 10c, and reaches the suction of the electromagnetically driven valve mechanism 30 constituting the capacity variable mechanism....

Embodiment approach 1

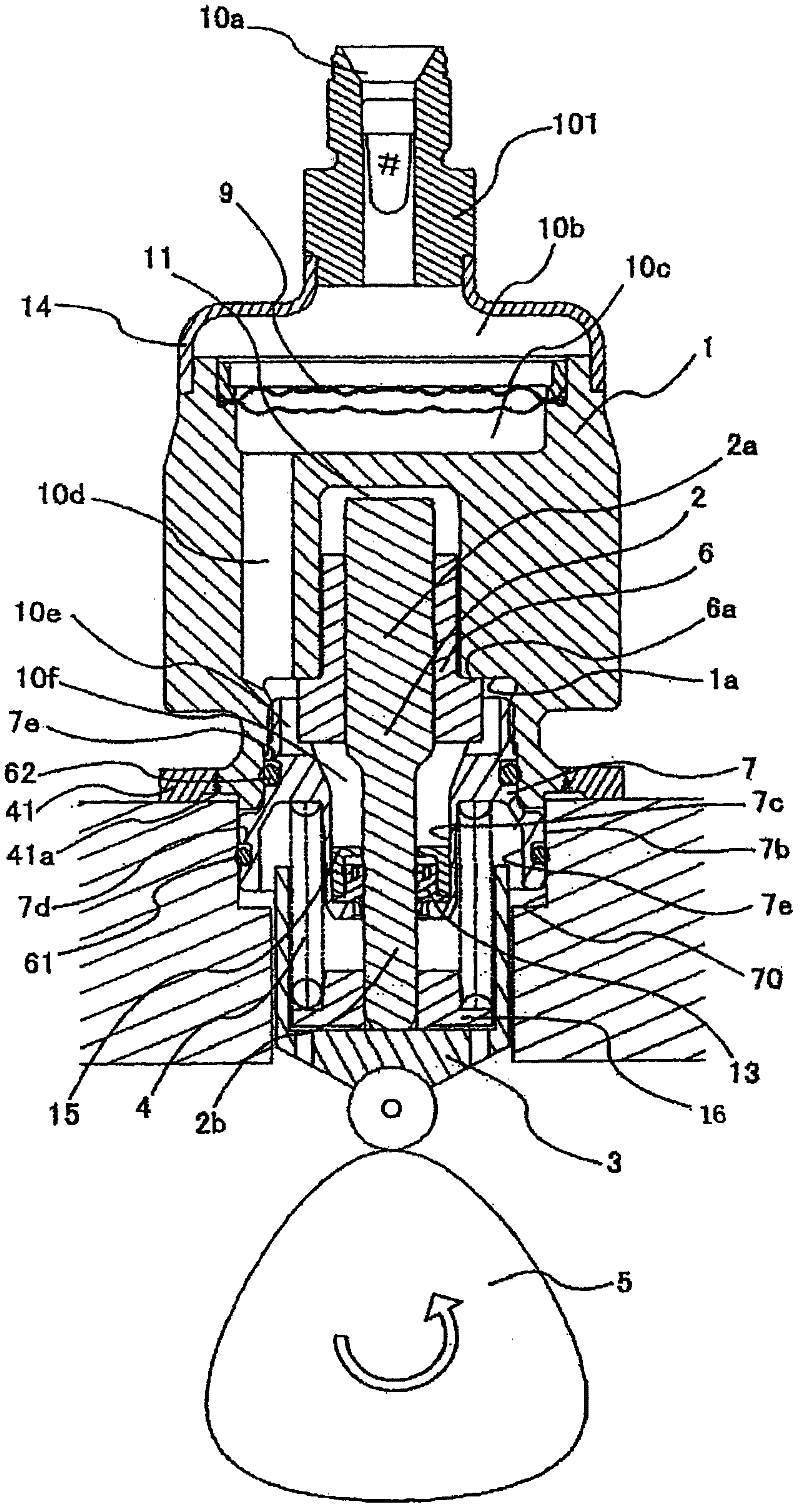

[0179] An electromagnetically driven valve mechanism having:

[0180] An outwardly opening valve member provided at the inlet of the fluid;

[0181] movable plunger operated by electromagnetic force;

[0182] fixing the working cylinder to the bracket of the pump housing;

[0183]A restricting member restricting the displacement of the plunger at a specific position;

[0184] a spring member biasing the movable plunger to a side opposite to the restricting member;

[0185] an electromagnetic drive mechanism that applies electromagnetic force to the movable plunger to apply force to the valve member and the movable plunger in a direction to close the fluid inlet;

[0186] The valve seat on which the valve member is tightly contacted and disengaged;

[0187] supporting the movable plunger as a reciprocating bearing member,

[0188] The valve seat and the bearing member are constituted as one part machined from the same member.

Embodiment approach 2

[0190] The electromagnetically driven valve mechanism according to Embodiment 1, wherein

[0191] fixing an anchor at the end of the movable plunger opposite the valve member,

[0192] the anchor is disposed facing said limiting member across a magnetic gap,

[0193] the restricting member constitutes a magnetic core portion of the electromagnetic drive mechanism,

[0194] A cover member made of a magnetic material that surrounds the anchor and the magnetic gap and seals the inside is fixed to the magnetic core portion of the restricting member,

[0195] An electromagnetic coil is mounted on the outer periphery of the cover member made of magnetic material,

[0196] A magnetic collar member is provided on its outer periphery, and the magnetic collar member cooperates with the anchor, the magnetic gap, the magnetic core portion, and the magnetic material cover member to form a magnetic path.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com