Patents

Literature

1151results about "Pump parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

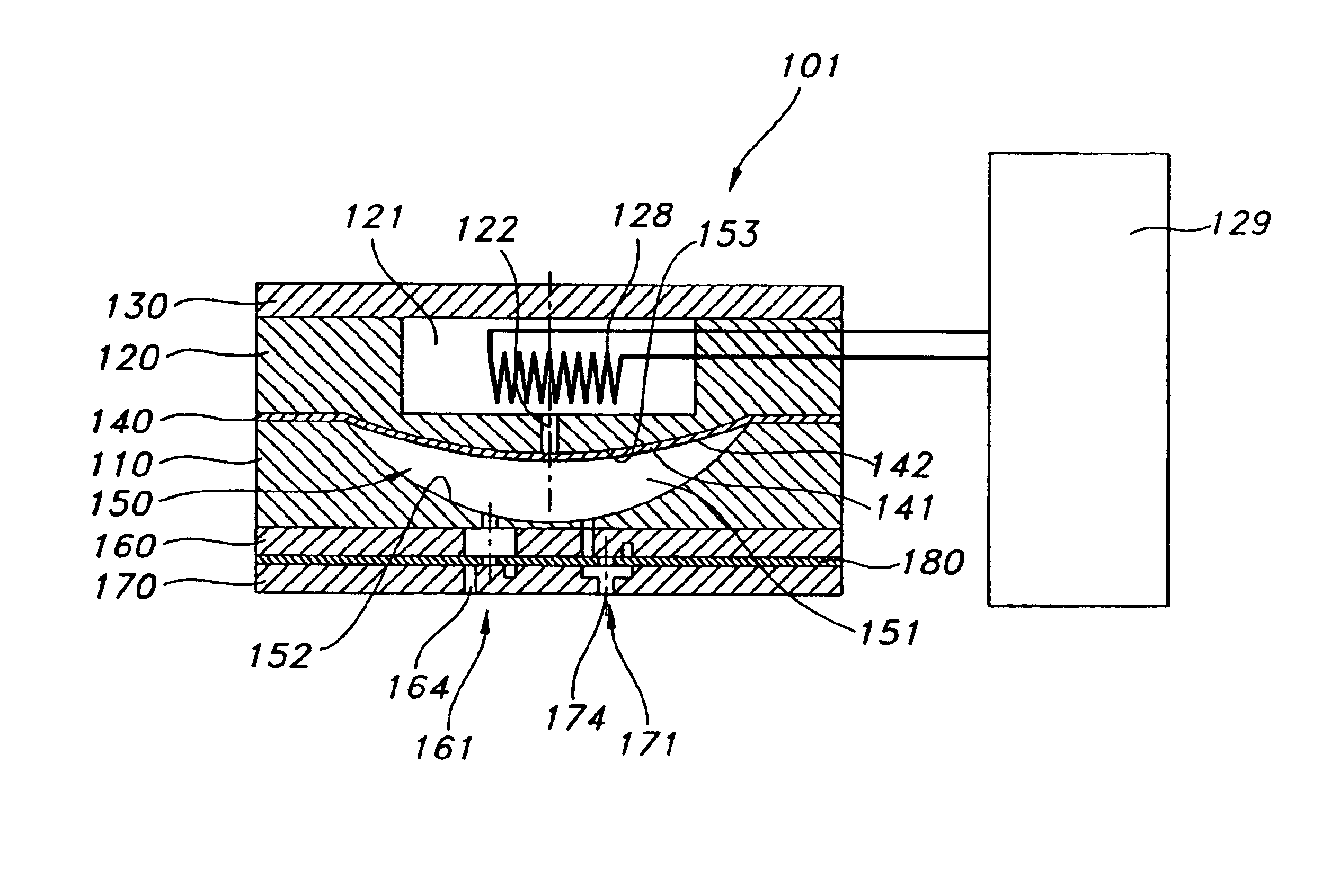

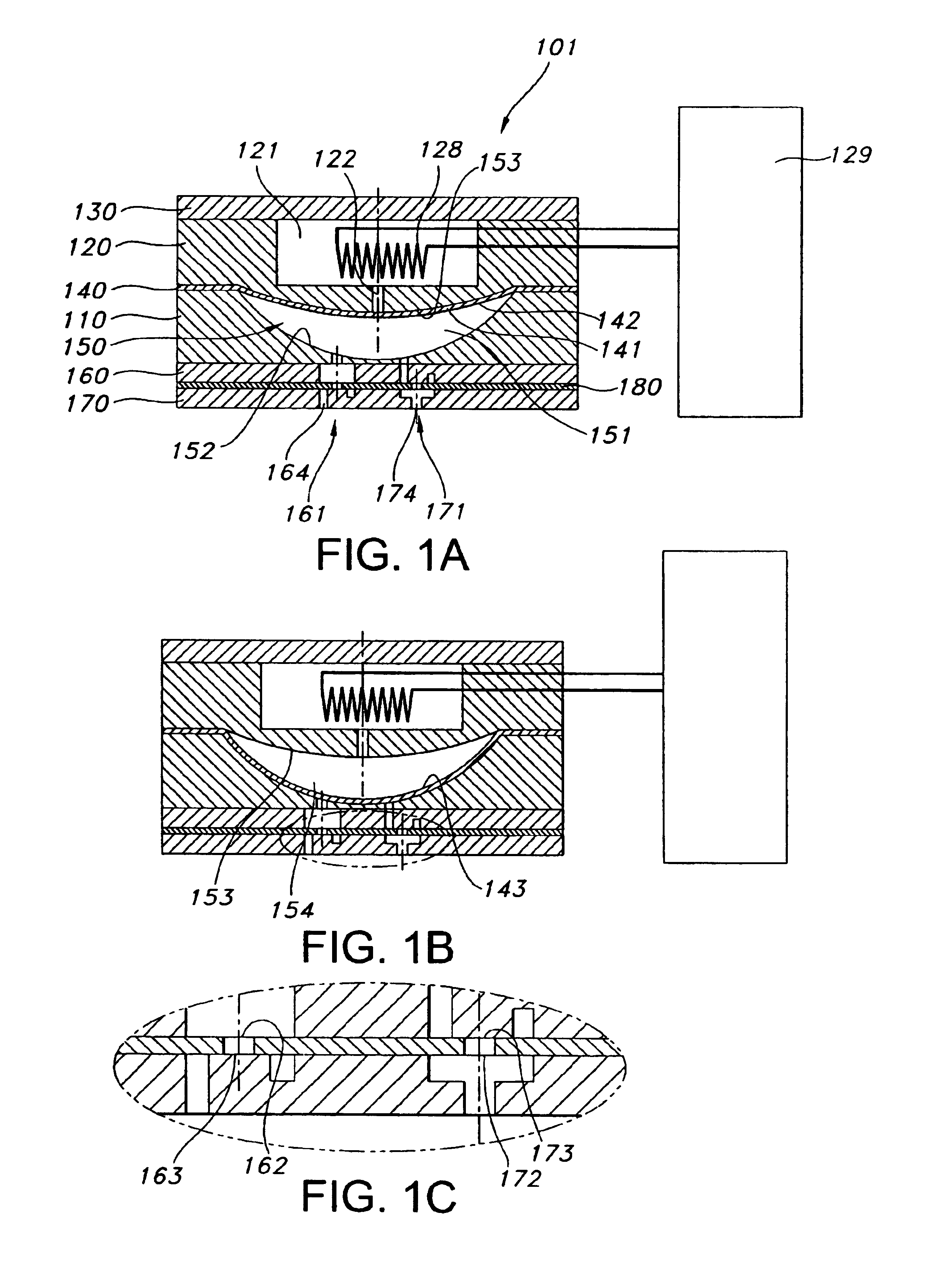

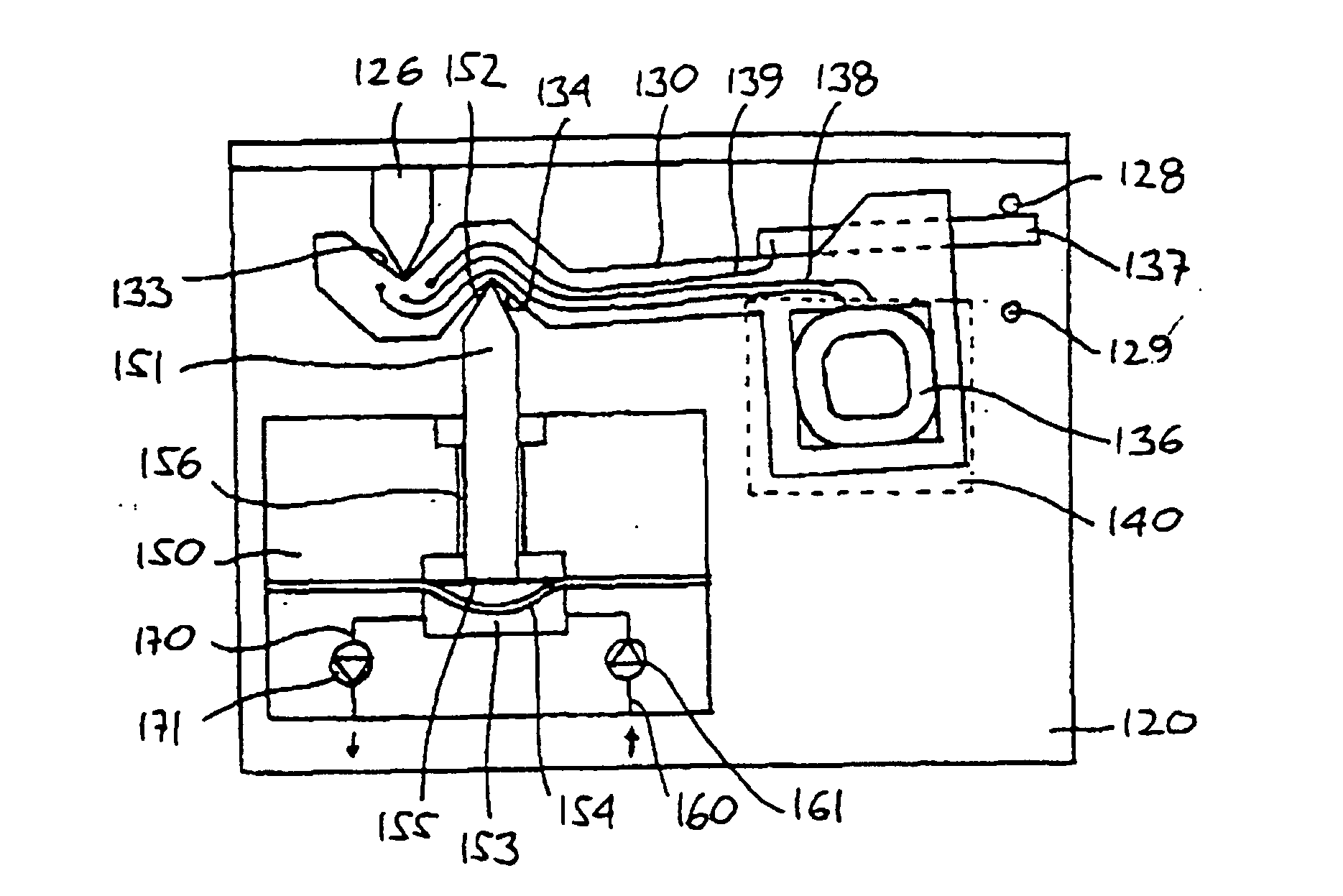

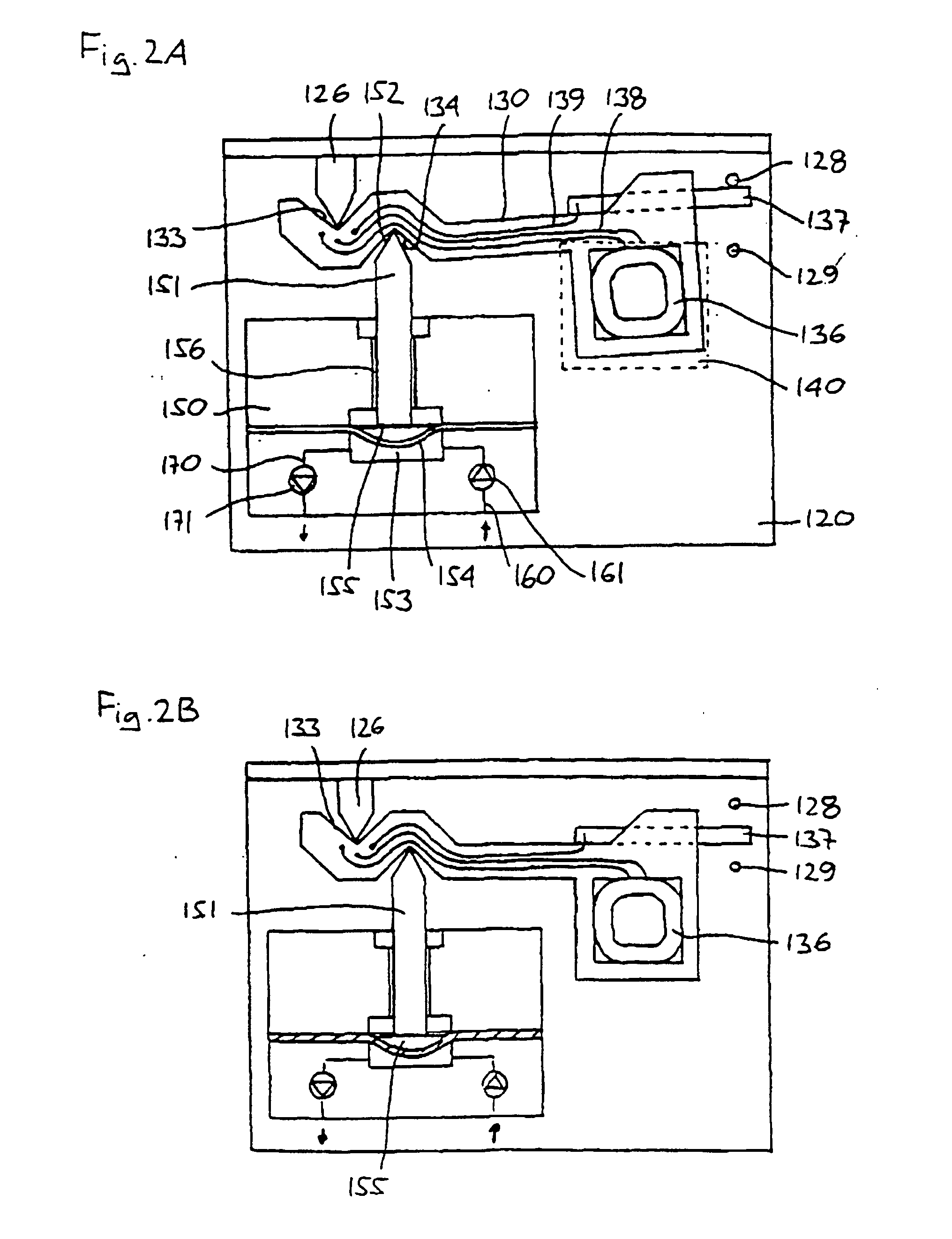

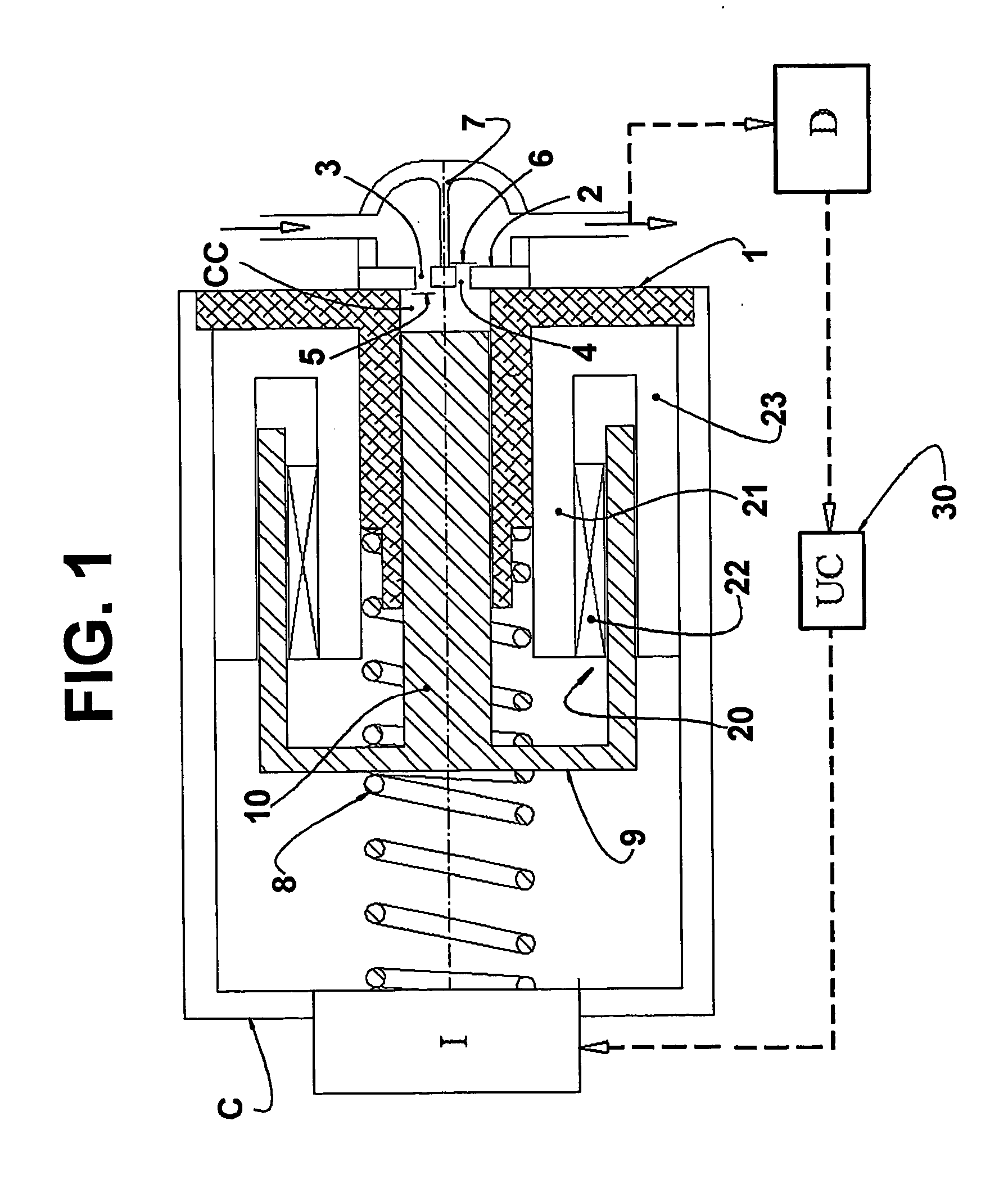

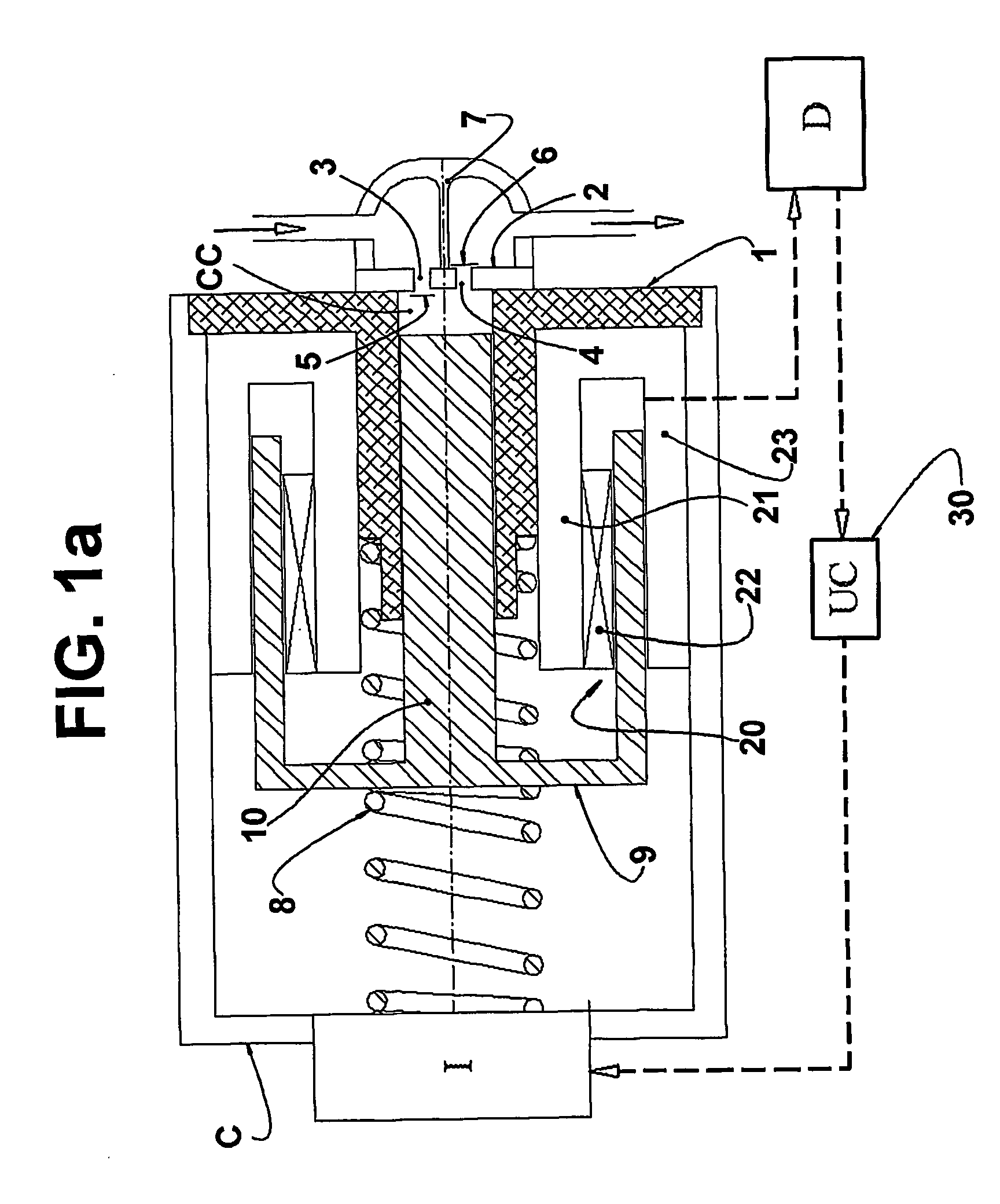

Membrane pump with stretchable pump membrane

InactiveUS6948918B2Stiff systemImprove accuracyValve arrangementsPositive displacement pump componentsPump chamberInlet valve

The invention relates to membrane pumps for delivering liquids. More specifically, a pump is provided having a pump housing with a pump cavity formed between first and second wall portions thereof, and an pump membrane pump membrane having first and second membrane surfaces arranged within the pump cavity, whereby a pump chamber is provided between the first wall portion and the first membrane surface, and an actuation chamber is provided between the second wall and the second membrane surface. Inlet means comprising an inlet valve in fluid communication with the pump chamber, and outlet means comprising an outlet valve in fluid communication with the pump chamber are provided. The pump membrane has a maximum volume position, and a drained volume position in which the first membrane surface in a stretched state abuts the first wall. To drive the membrane, actuating means for periodically shifting the pump membrane between the maximum volume position and the drained volume position is provided, thereby, in a situation of use, providing a flow of fluid.

Owner:NOVO NORDISK AS

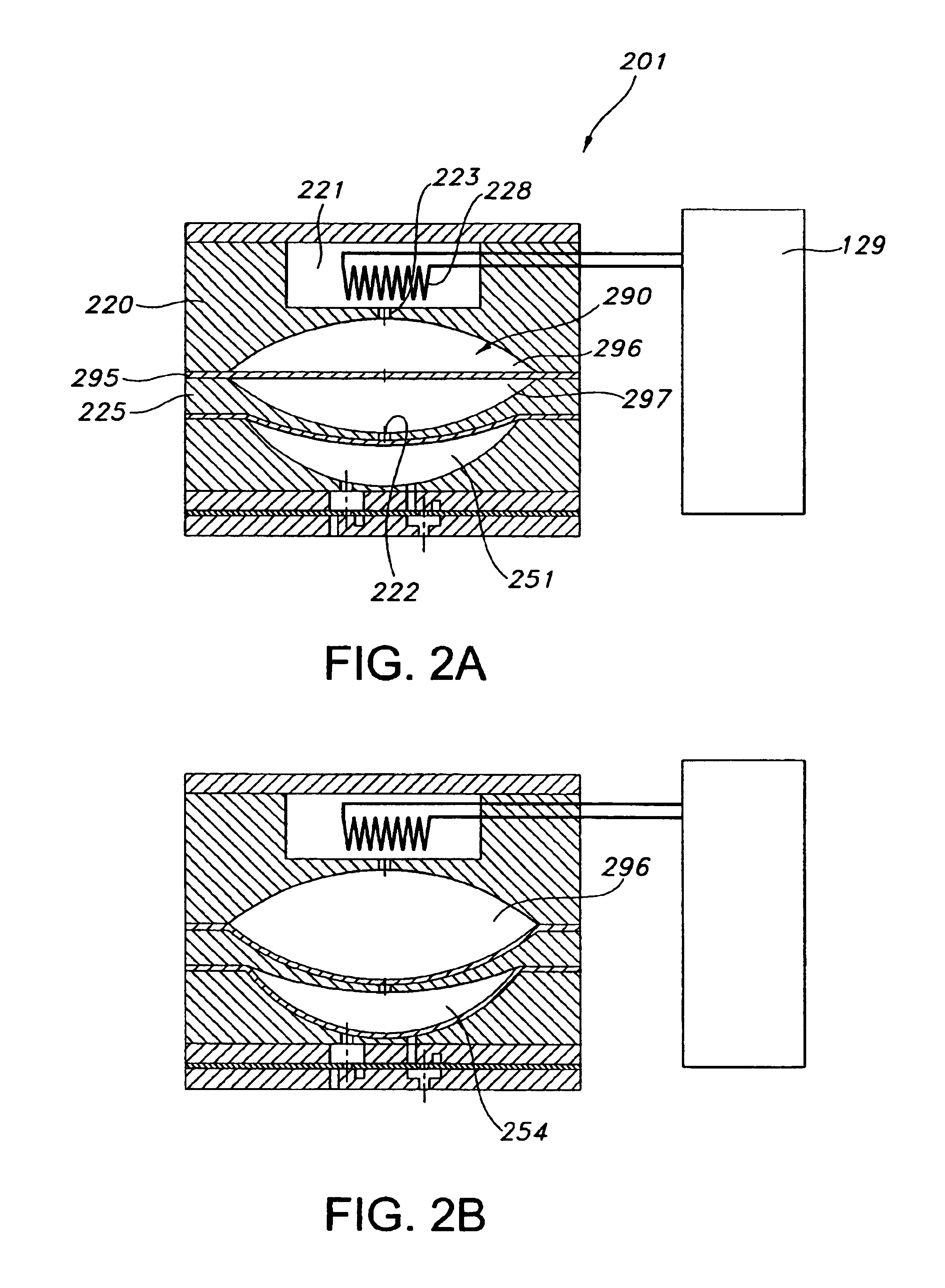

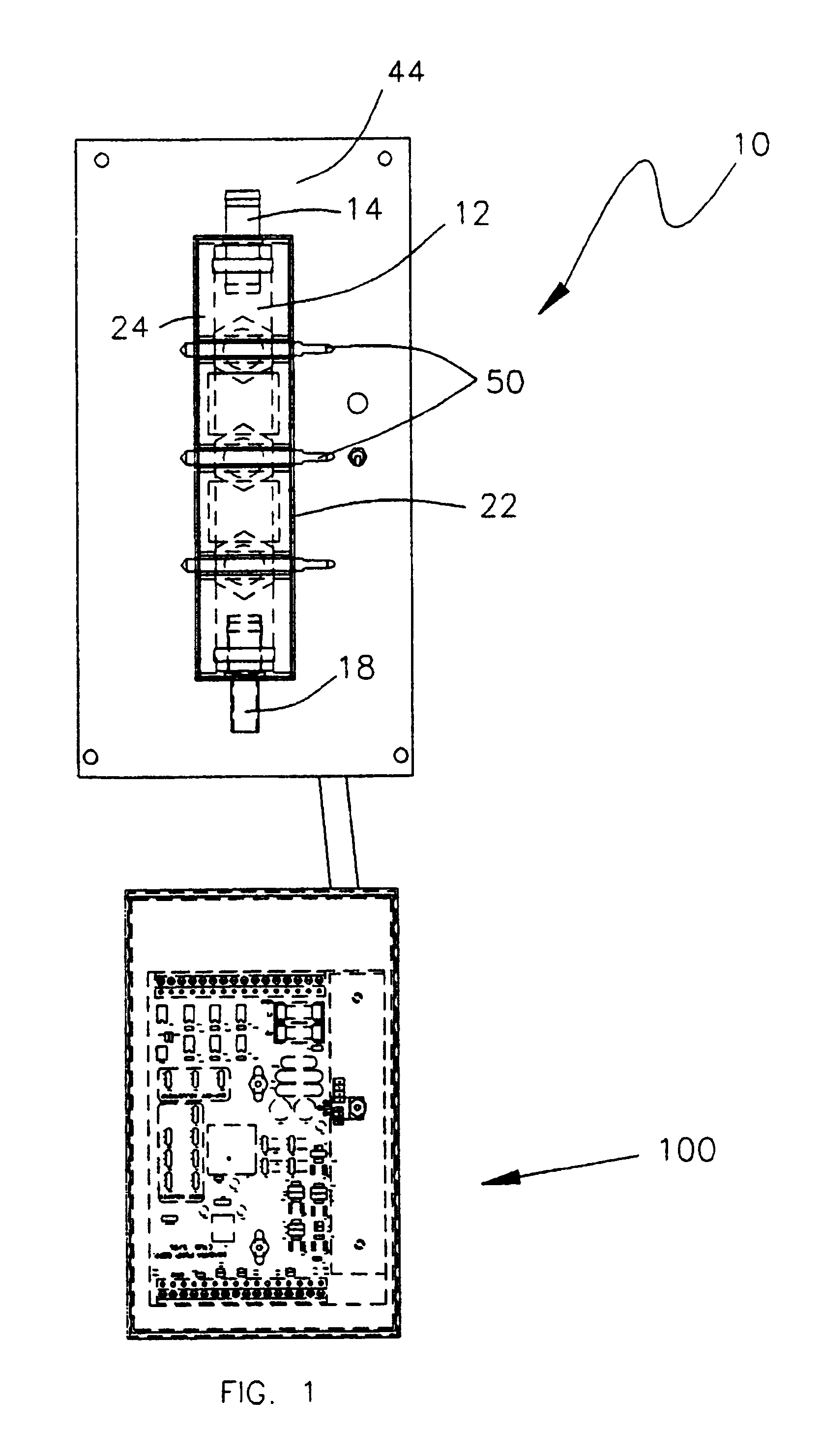

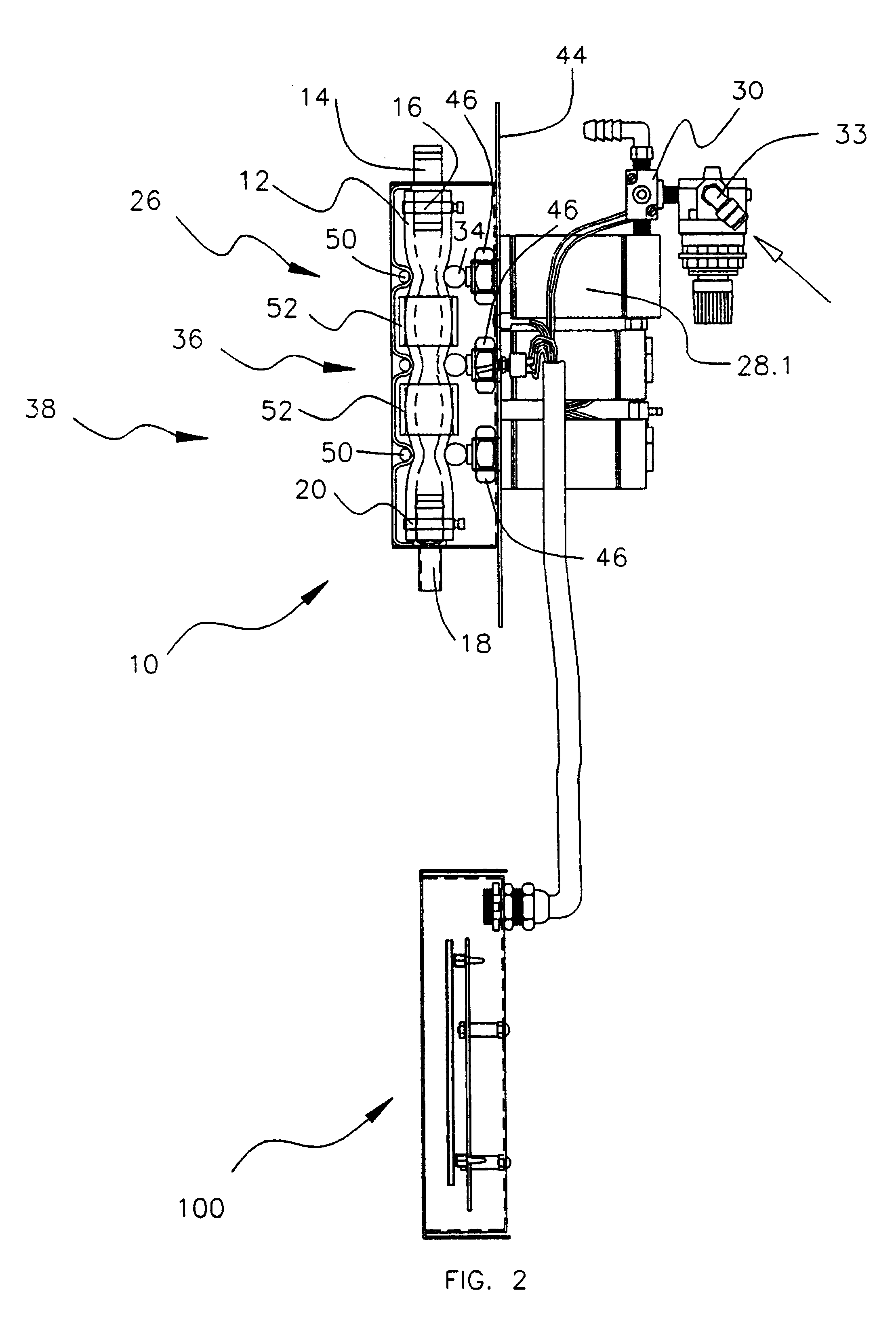

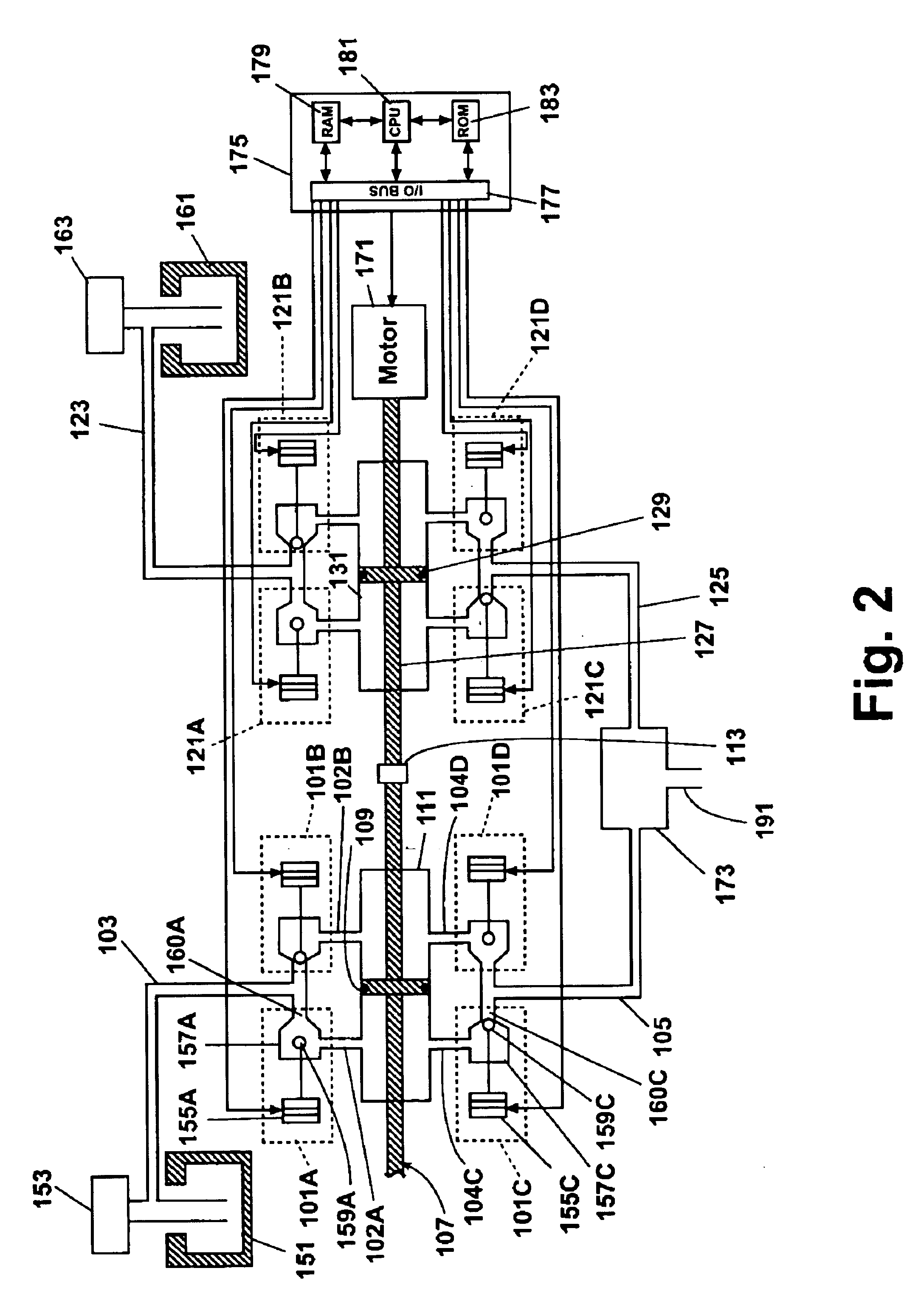

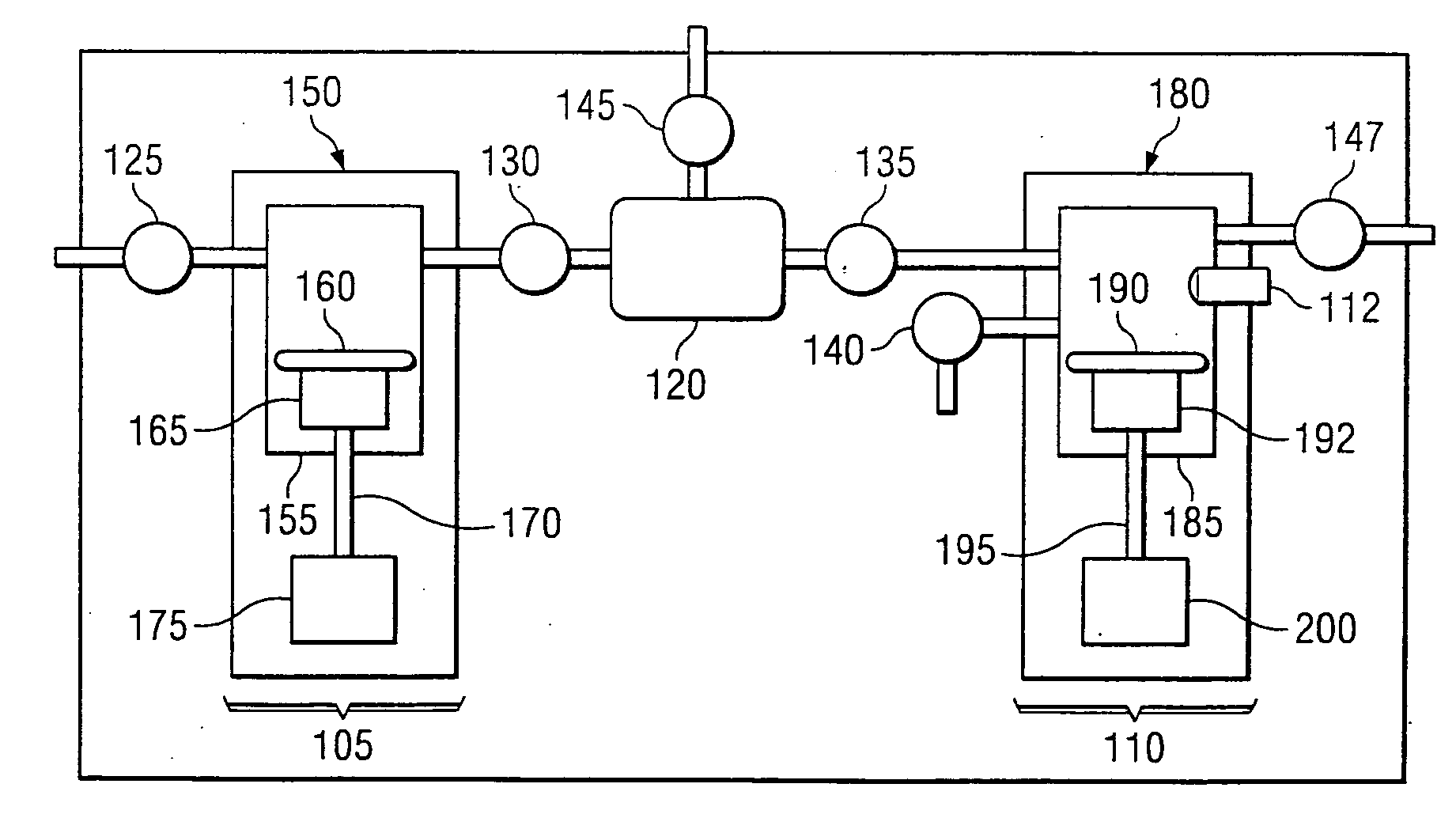

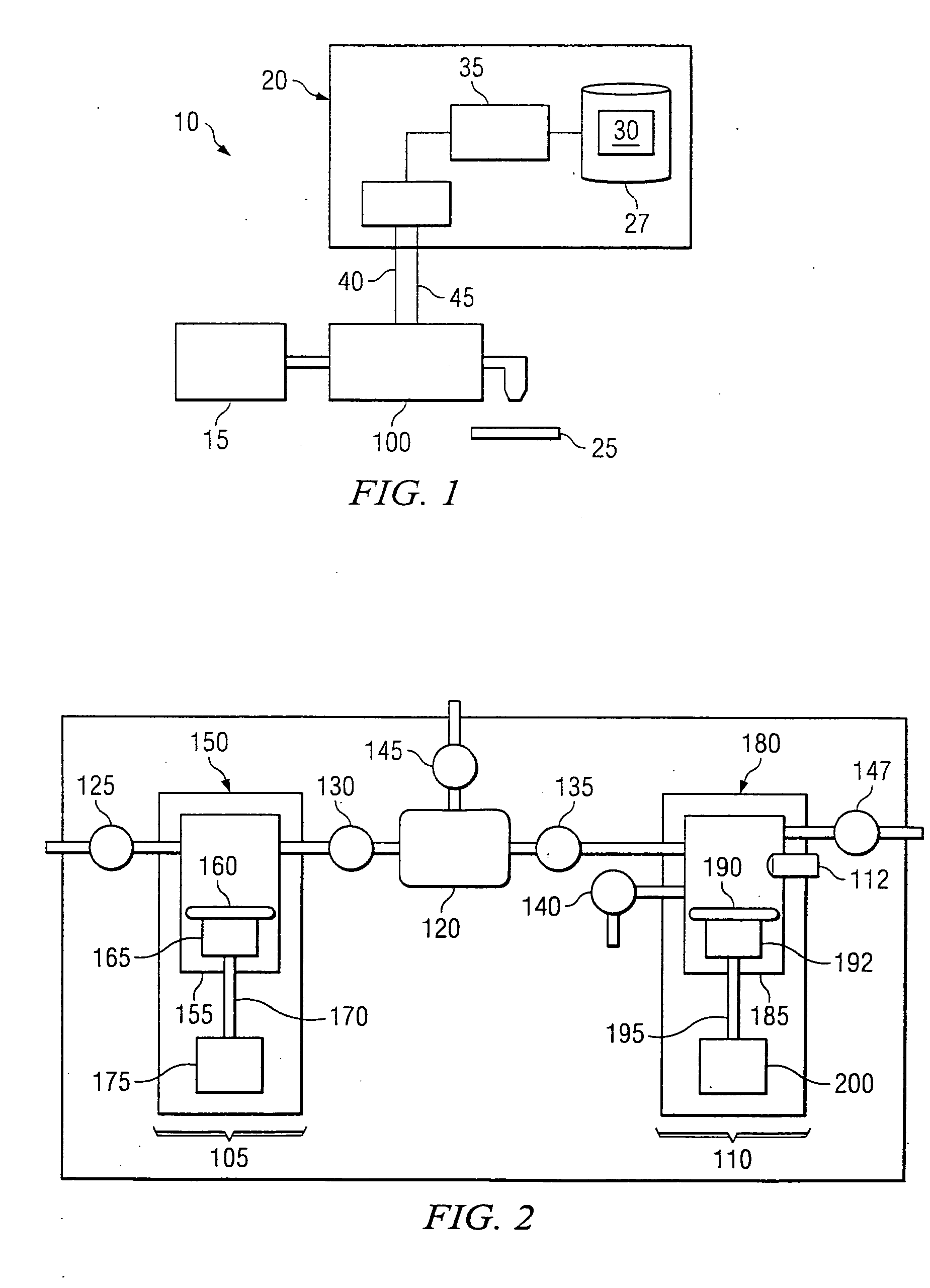

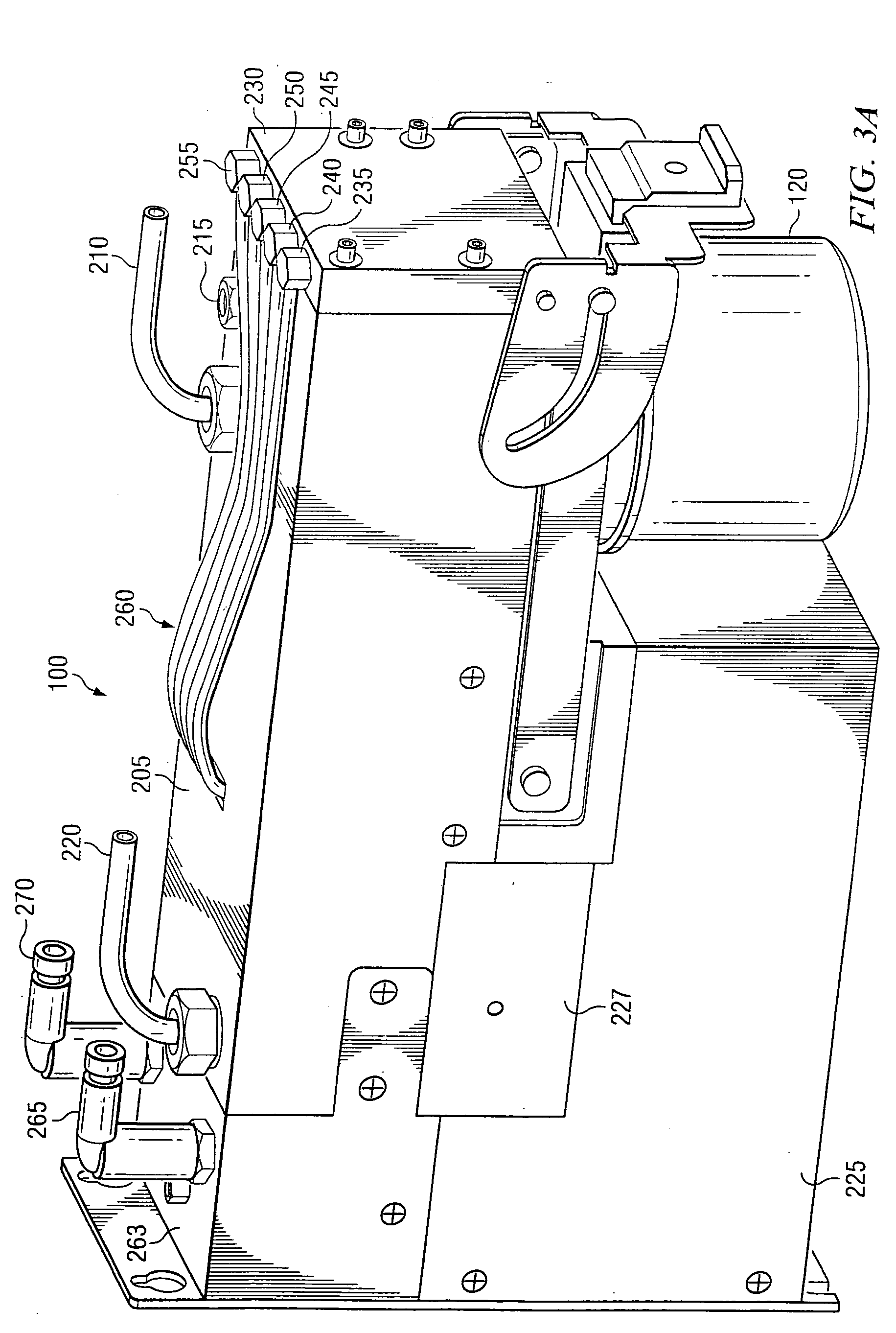

Linear peristaltic pump

InactiveUS6213739B1High liquid pumping pressureExtends useful pump tube lifeFluid parameterFlexible member pumpsPeristaltic pumpActuator

A liquid pumping apparatus for pumping liquids, more specifically a linear peristaltic pump apparatus. The apparatus consists of a high durometer compressible elastomeric liquid flow tube (12), an infeed valve assembly (26), an outfeed valve assembly (38), an extensible and retractable actuator anvil (34) having a round surface which engages the flow tube (12) at all times, an opposed anvil (24.1) having a round surface in engagement with the flow tube at all times, the flow tube being held between the anvils (34, 24.1) in a slightly compressed state when the anvil (34) is retracted, and a control assembly (100) for causing the movable anvil to be sequentially extended and retracted to cause flow within the flow tube (12) from the infeed valve assembly (26) to the outfeed valve assembly (38). With this apparatus the lumen of the flow tube (12) to the sides of the anvils is not completely reduced to zero volume during displacement compression whereby gas embolisms do not erupt or explode when discharged. Two principal embodiments are disclosed, one having infeed and outfeed check valves which oclude the flow tube, and the other having check valves.

Owner:NIAGARA PUMP CORP

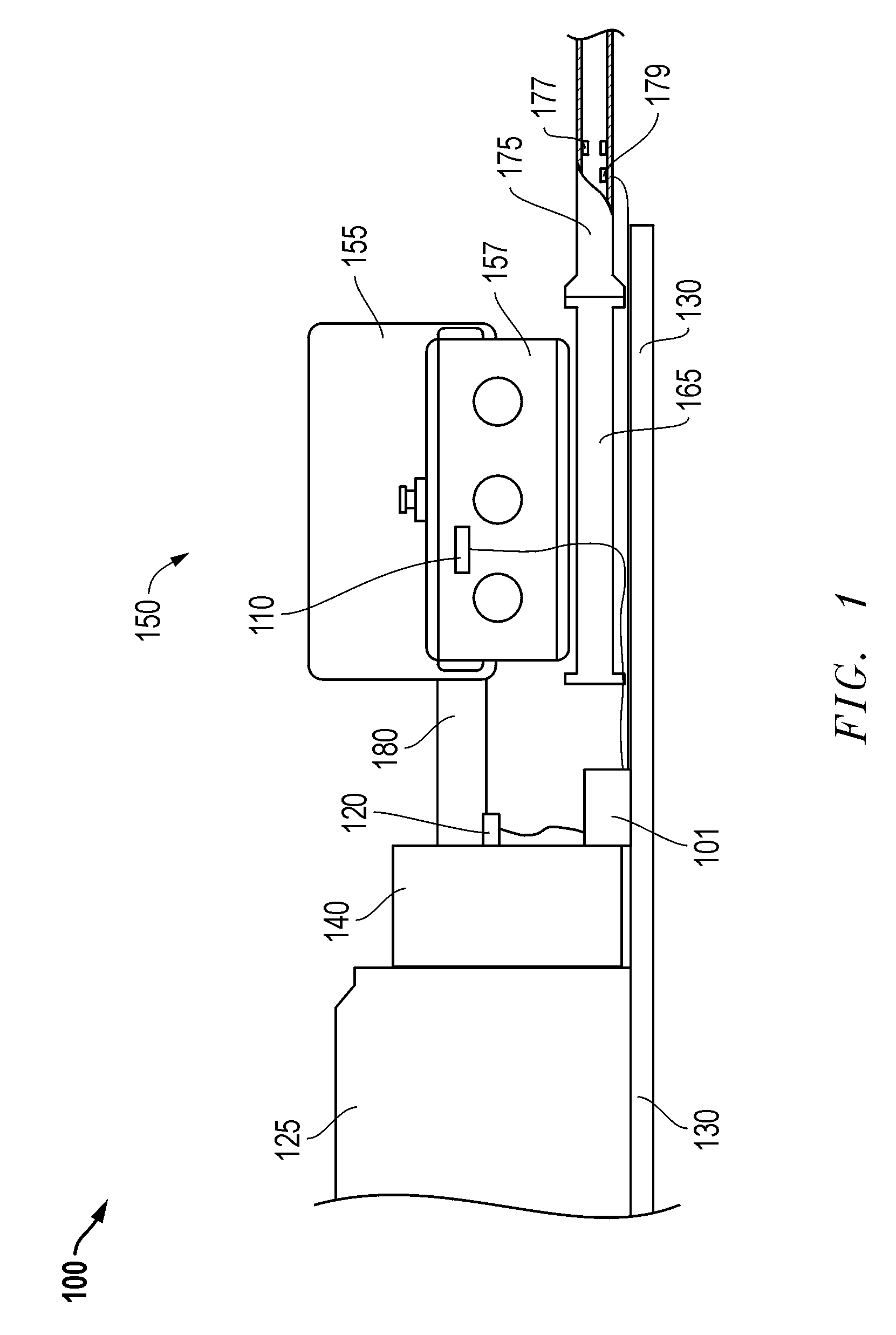

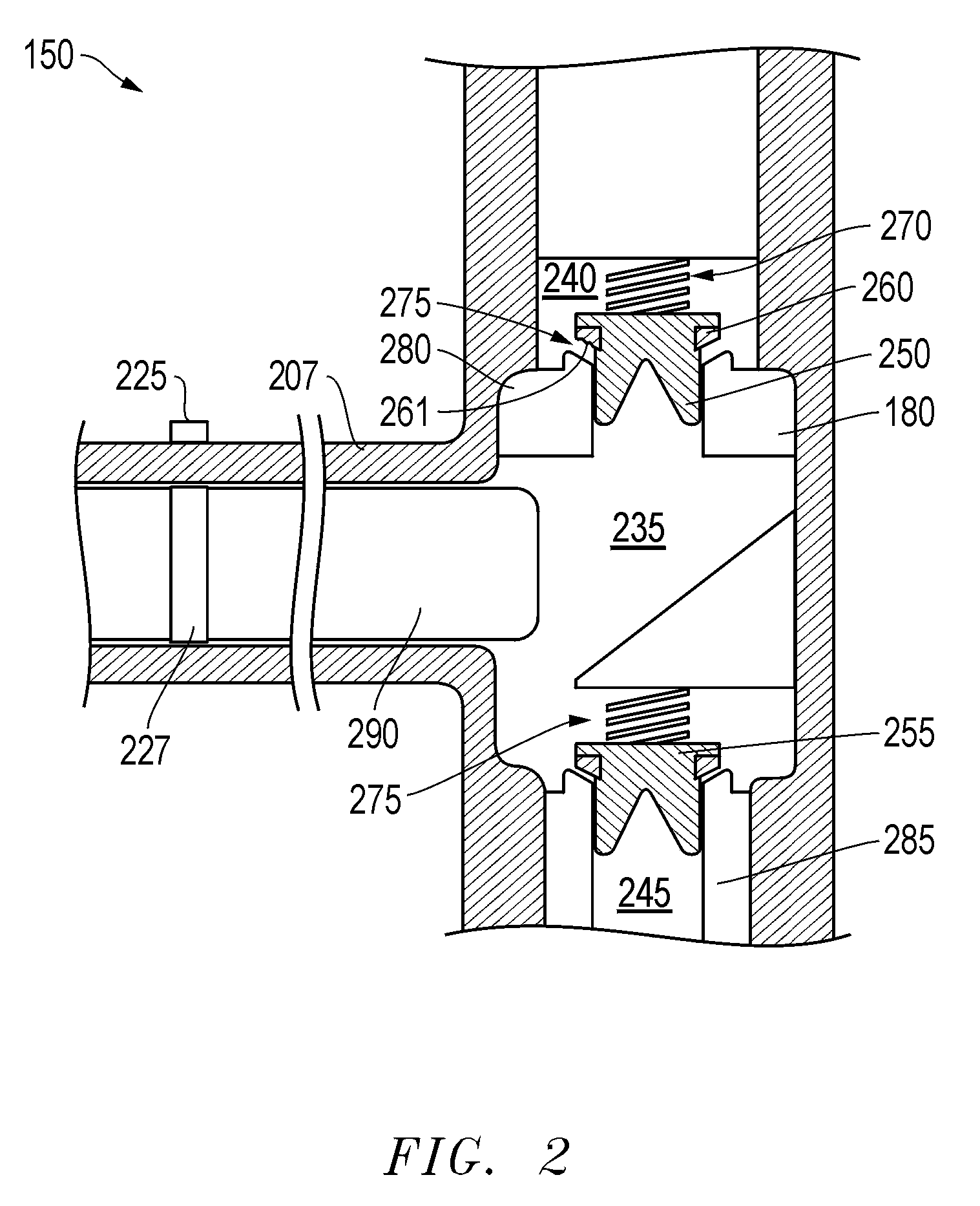

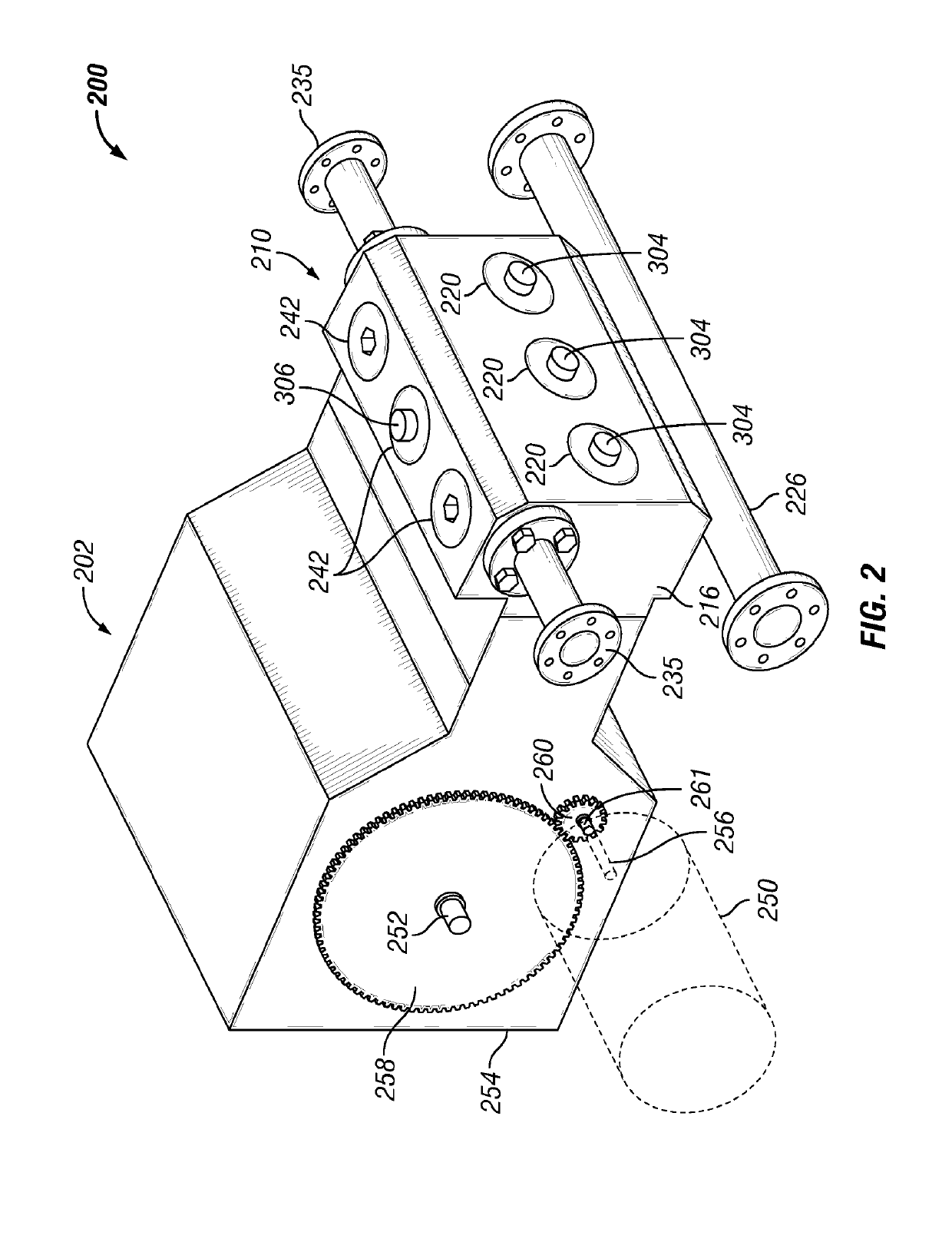

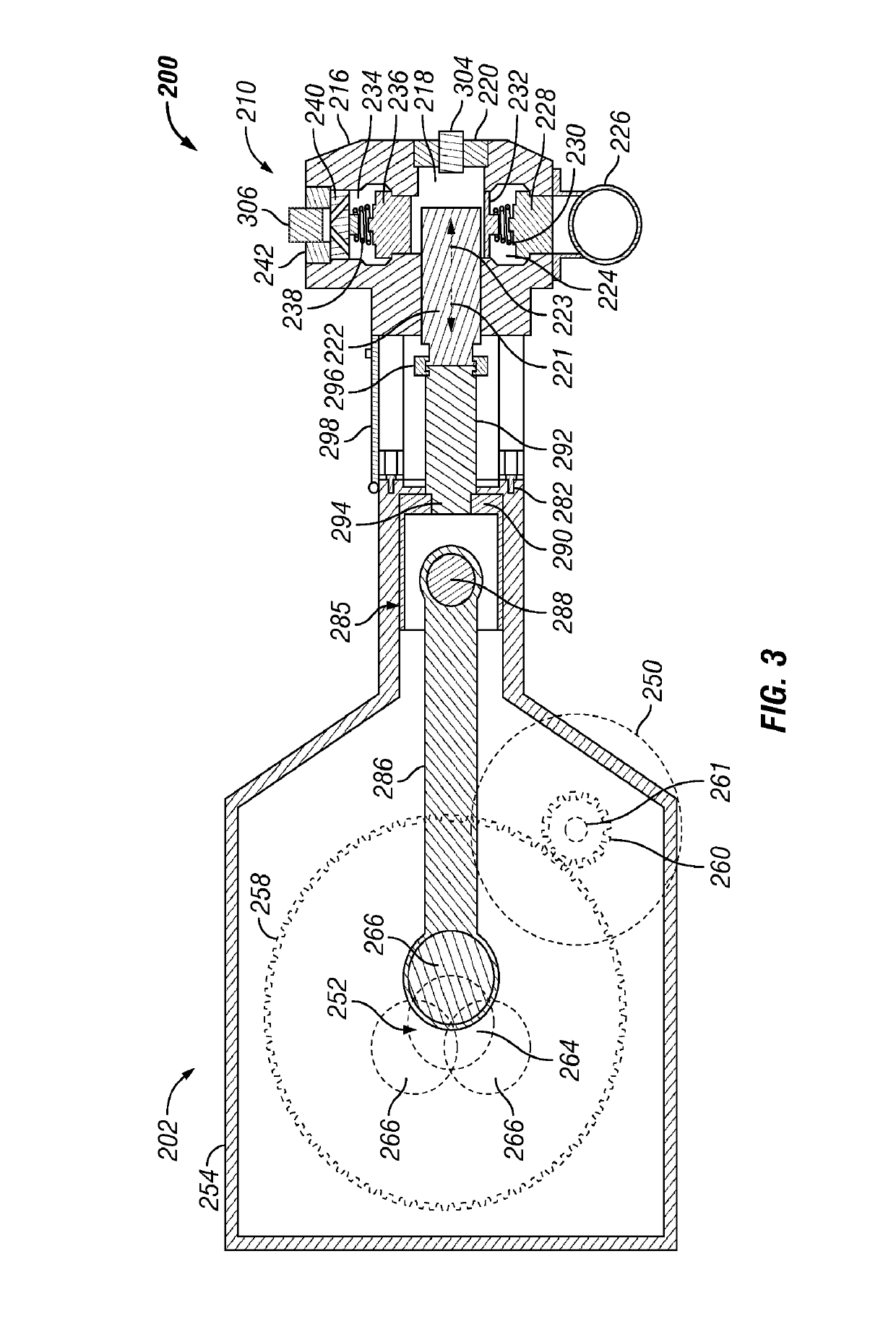

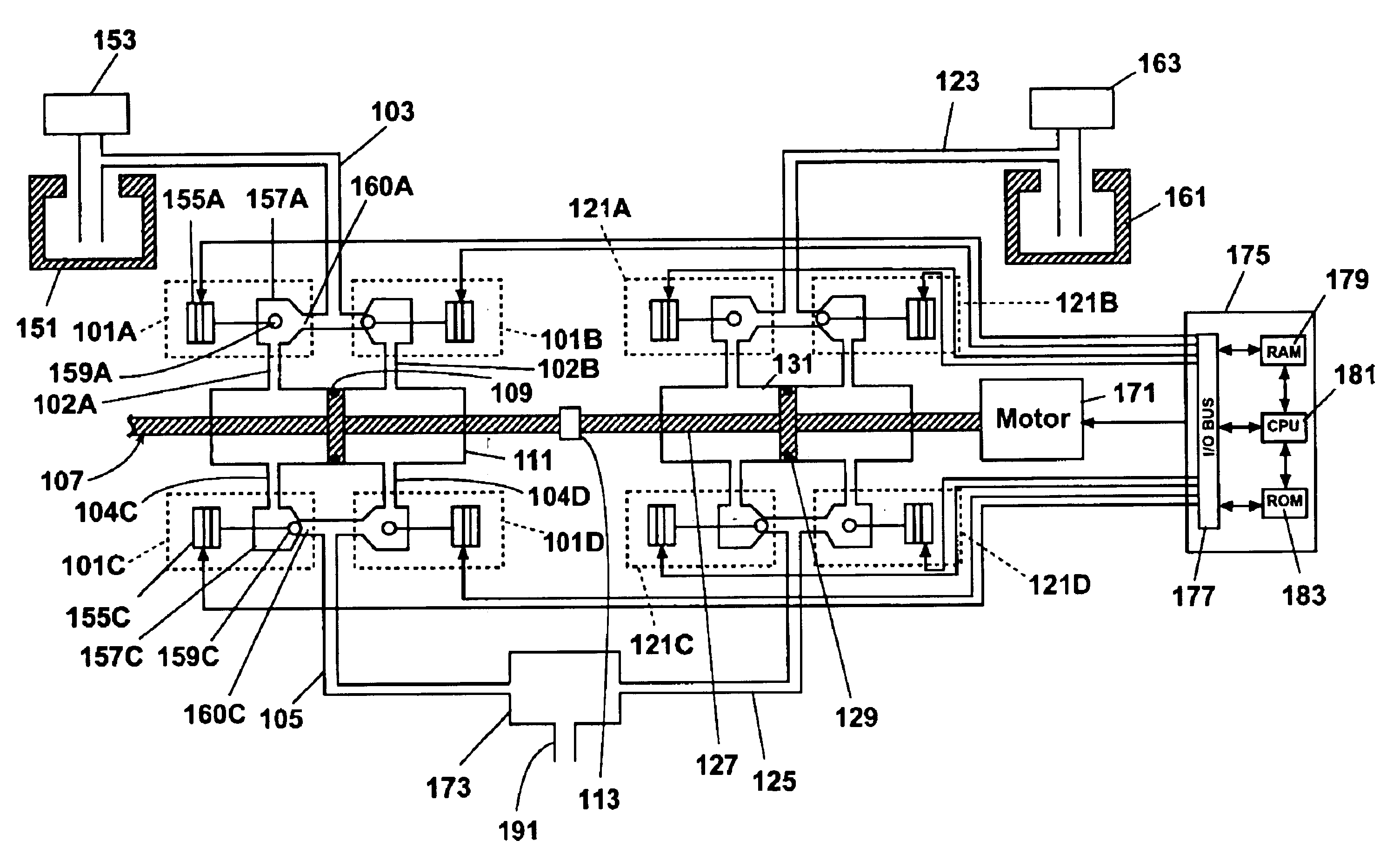

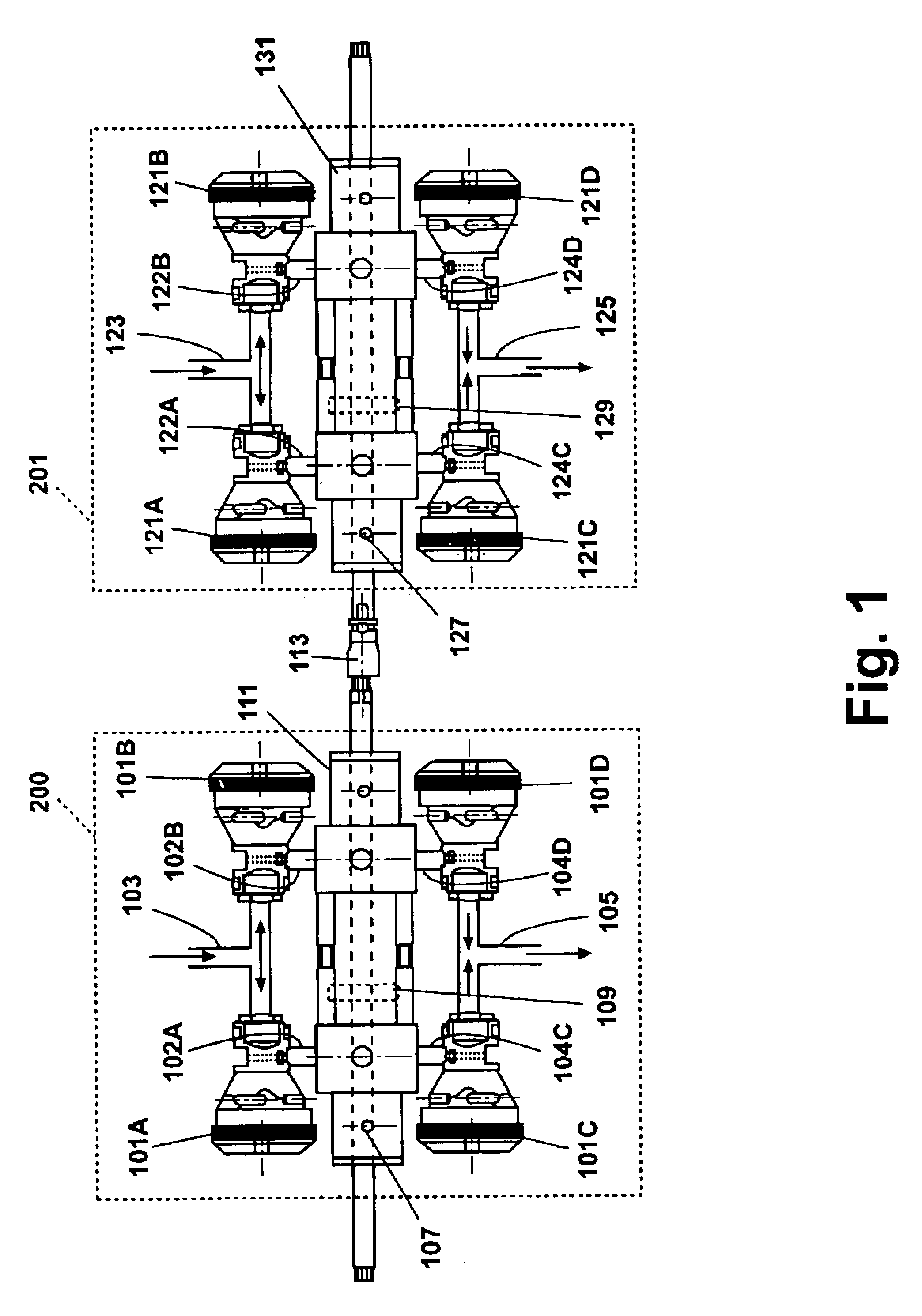

Reducing fluid pressure spikes in a pumping system

A pumping system including a plurality of pumps each having a pump fluid outlet, a drive shaft, a prime mover, and fluid displacing members operatively coupled with the drive shaft. A common fluid conduit may be fluidly coupled with each pump fluid outlet. A control system of the pumping system includes position sensors operable to generate information relating to phase and / or speed of each pump, pressure sensors operable to generate information relating to fluid pressure spikes, and a controller in communication with the position and pressure sensors. The controller is operable to cause the prime movers to adjust the phasing of the pumps with respect to each other, based on the information relating to fluid pressure spikes, and synchronize the speed of the pumps.

Owner:LIBERTY OILFIELD SERVICES LLC

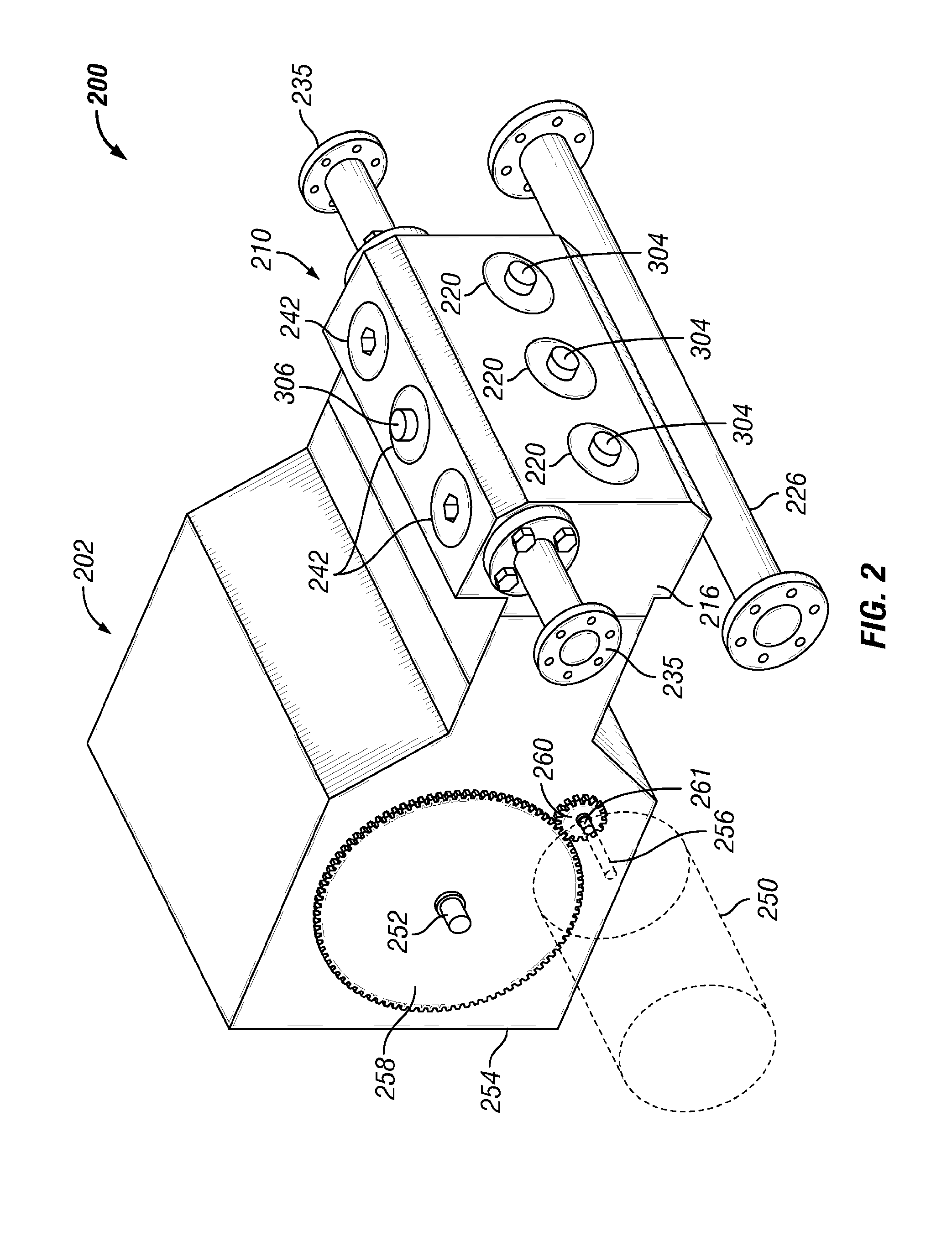

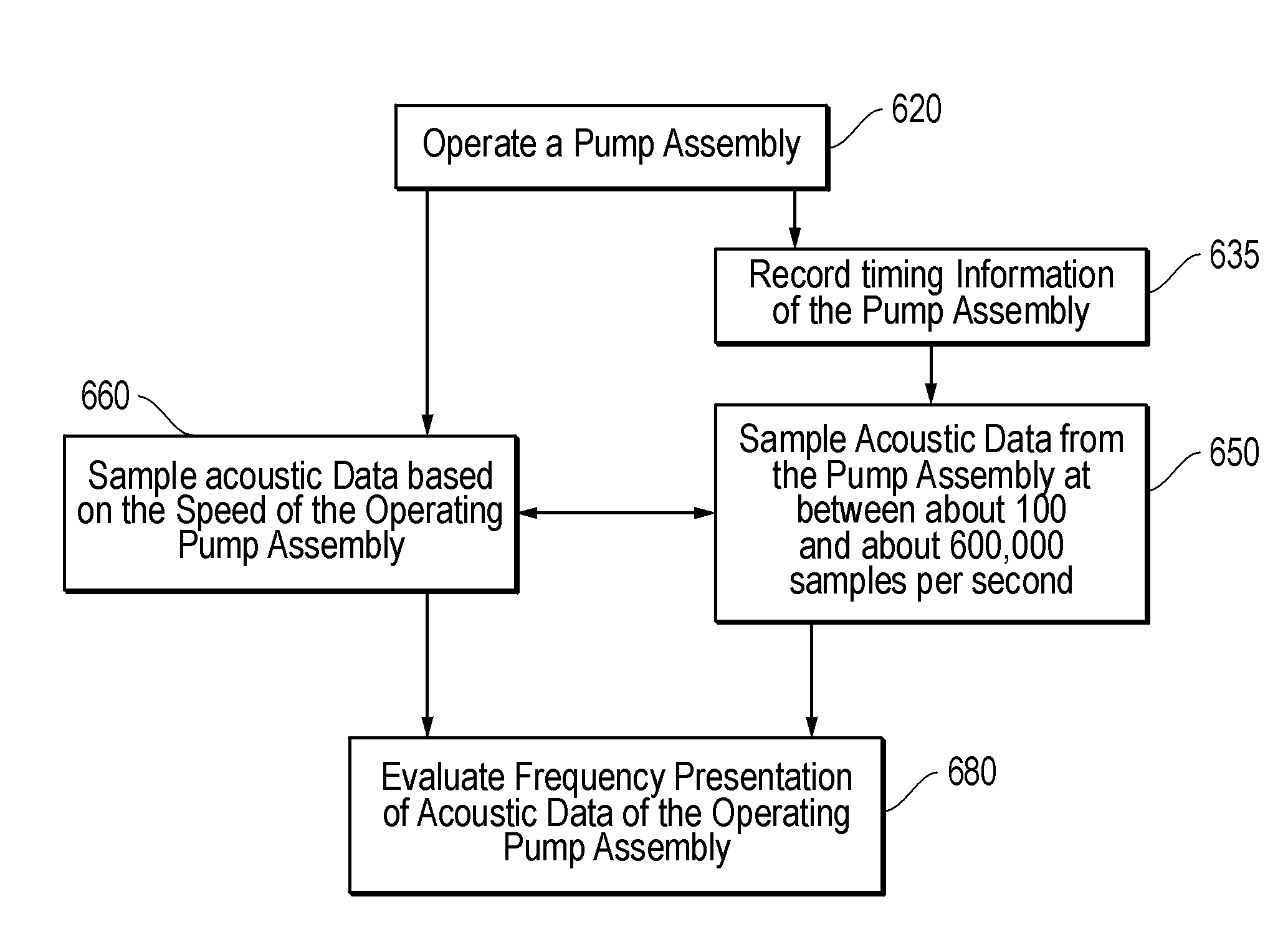

Pump integrity monitoring

InactiveUS20080006089A1Vibration measurement in solidsDetection of fluid at leakage pointImage resolutionComputer science

A method of monitoring integrity of a pump. The method may include recording timing information of the pump during operation while simultaneously sampling acoustic data with a high speed equidistant acquisition mechanism or at a rate based on the speed of the pump in operation. The acquisition of acoustic data is followed by evaluation thereof. Such techniques may improve resolution of acquired data while substantially increasing processor capacity for evaluation. A pump integrity monitor for carrying out such techniques is also described.

Owner:SCHLUMBERGER TECH CORP

Reducing fluid pressure spikes in a pumping system

A pumping system including a plurality of pumps each having a pump fluid outlet, a drive shaft, a prime mover, and fluid displacing members operatively coupled with the drive shaft. A common fluid conduit may be fluidly coupled with each pump fluid outlet. A control system of the pumping system includes position sensors operable to generate information relating to phase and / or speed of each pump, pressure sensors operable to generate information relating to fluid pressure spikes, and a controller in communication with the position and pressure sensors. The controller is operable to cause the prime movers to adjust the phasing of the pumps with respect to each other, based on the information relating to fluid pressure spikes, and synchronize the speed of the pumps.

Owner:LIBERTY OILFIELD SERVICES LLC

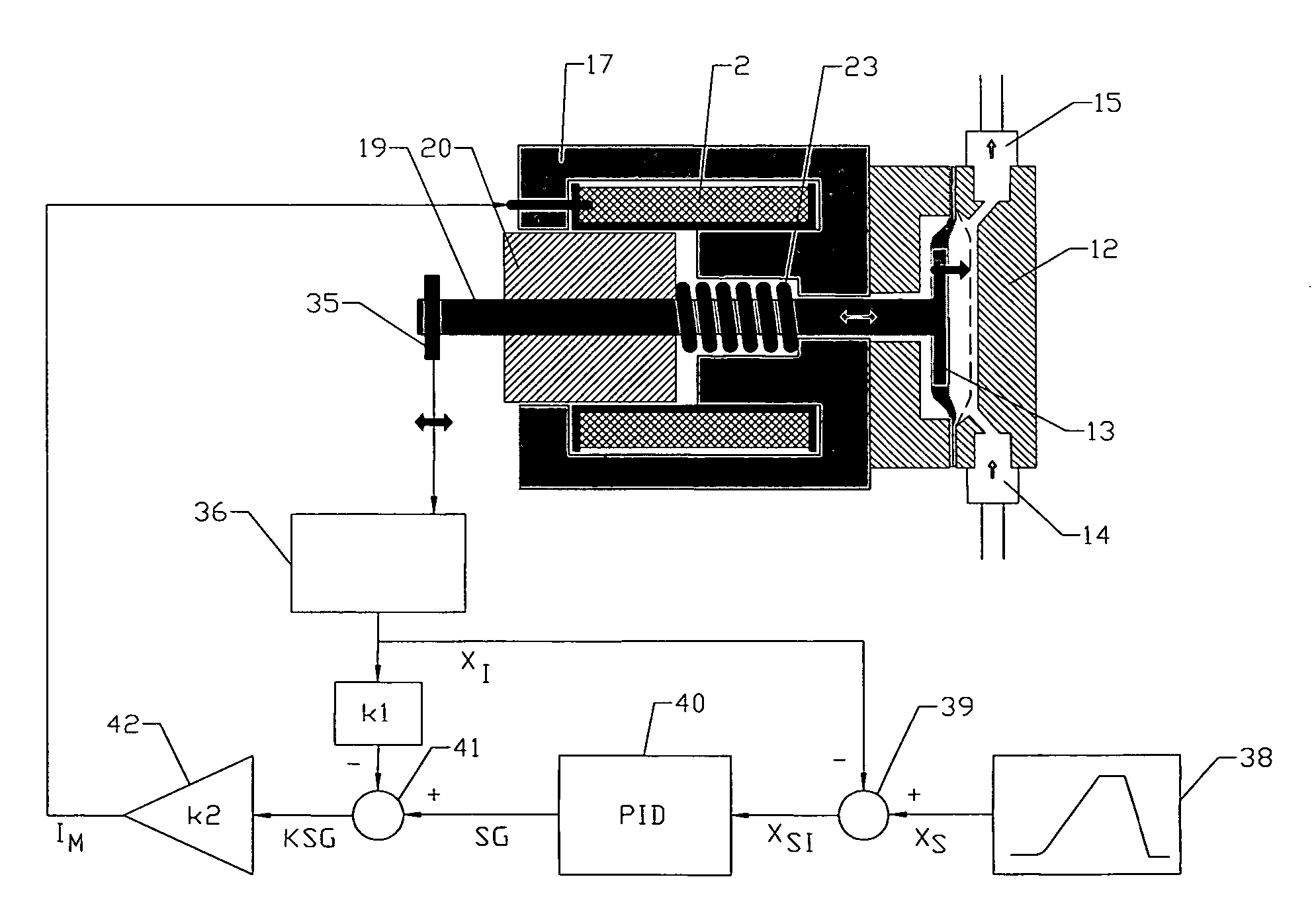

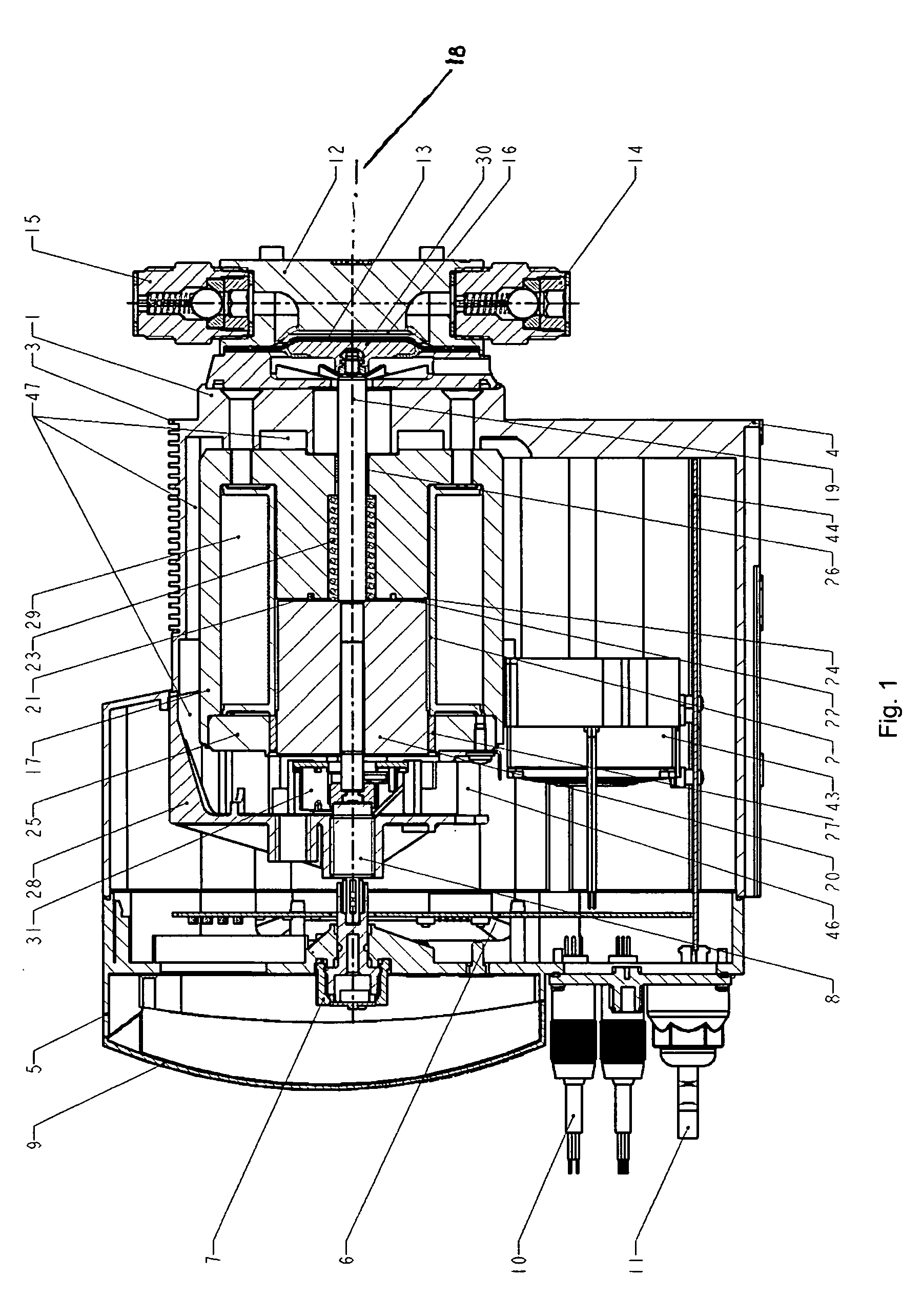

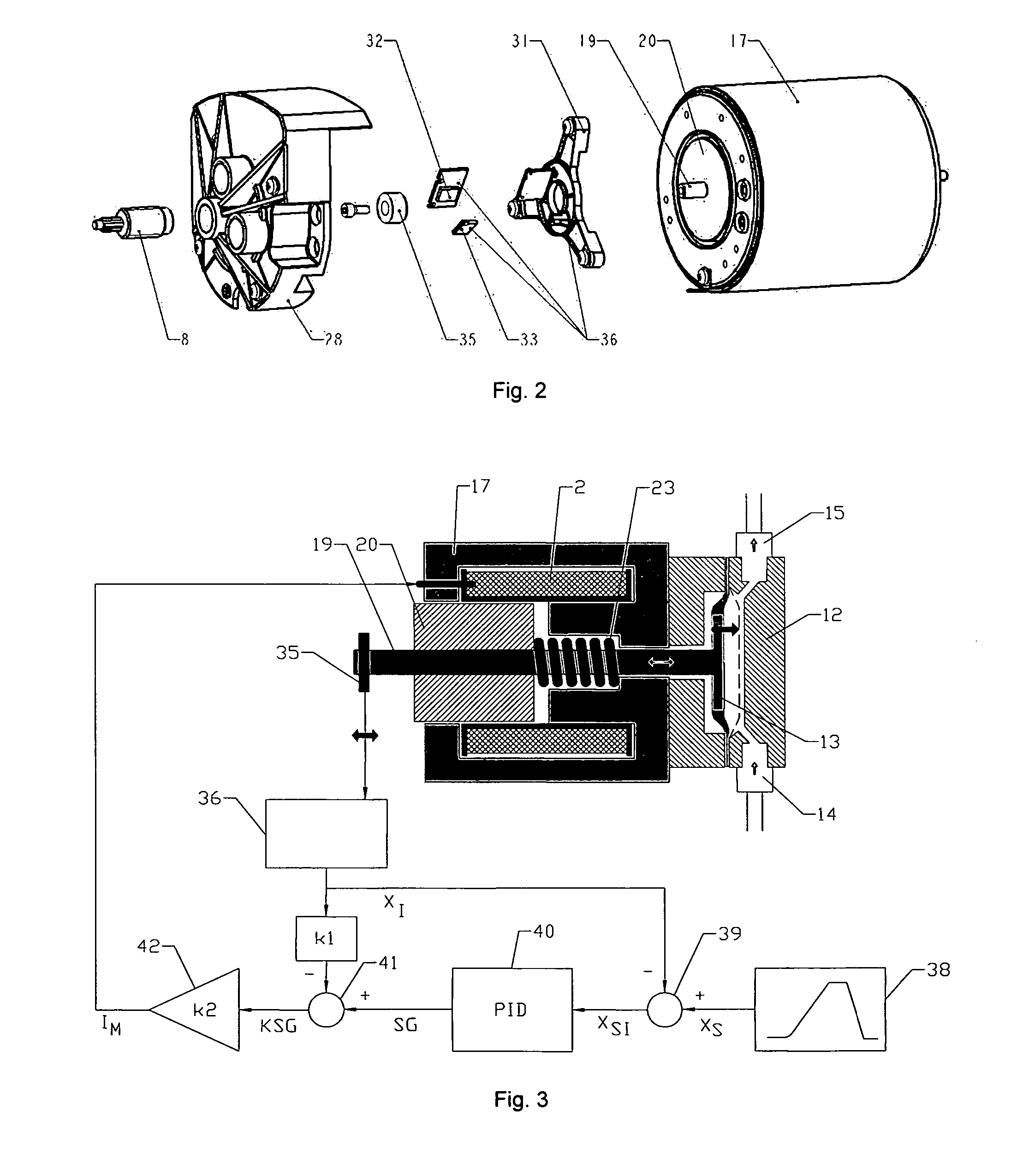

Magnetic drive metering pump

ActiveUS20070040454A1Motor/generator/converter stoppersDC motor speed/torque controlMagnetic tension forceInlet valve

A magnetic drive metering pump in which a movable thrust member fixed to a connecting rod is axially movable in a longitudinal axis in a magnet shroud anchored in a pump housing so that the thrust member with the connecting rod, on electrically driving (actuating) the magnetizing coil, is drawn into the magnet shroud against the force of a recuperating spring, reducing an air gap between the thrust member and an inner face of magnetic shroud, into a bore in the magnet shroud and after deactivating the magnet the thrust member is returned to the starting position by the recuperating spring so that the thrust member and an elastic displacement member actuated thereby on carries out an oscillating motion continued activation and deactivation of the magnetizing coil, which diaphragm cooperates alternately with an outlet and an inlet valve to produce a pump stroke (pressure stroke) and a priming stroke in a metering head arranged in the longitudinal axis. In such a magnetic drive metering pump, a reference element is associated with the module constituted by the thrust member and connecting rod, the position of which reference element is detected by a positional sensor, wherein the positional sensor provides an actual signal which is in a fixed relationship to the position of the reference element, and in that the motion of the unit formed by the thrust member and the connecting rod is influenced as regards control accuracy via a control circuit so that it follows a predetermined nominal profile.

Owner:PROMINENT

Actuator system comprising detector means

The invention provides an actuator system comprising an actuator member having first and second positions. The system further comprises actuating means for moving the actuator member between the first and second positions and detection means for detecting the first respectively the second position and supplying time signals indicative thereof. A controller determines on the basis of supplied time signals the time lapsed when the actuator member is moved between the first and second positions in a given direction, the controller comprising information representing at least one defined time range, each time range being associated with movement of the actuator member in a given direction between the first and second positions and a given actuation force, the controller being adapted to compare the determined time lapsed with the defined time range(s) and perform an action corresponding to the time range associated with the determined time lapsed.

Owner:TDK CORPARATION +1

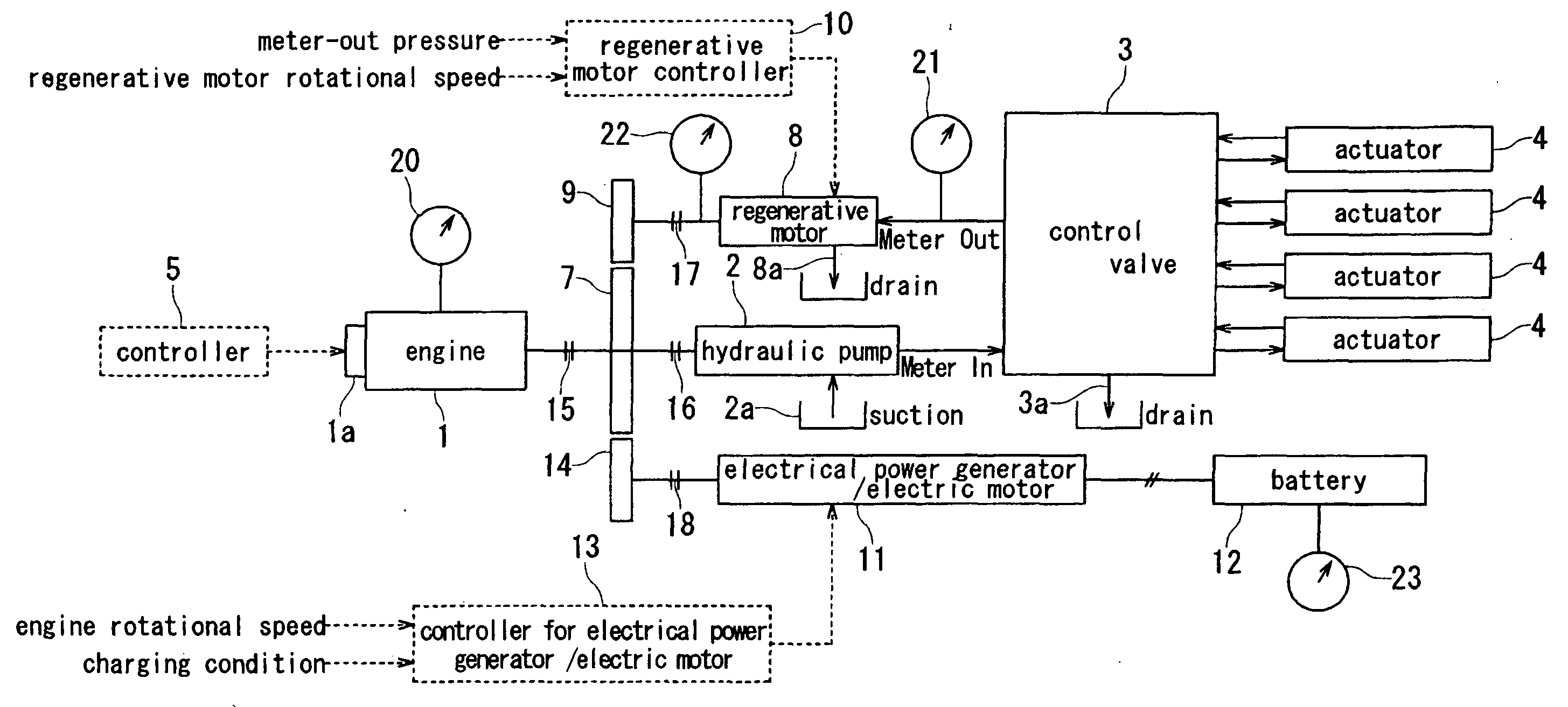

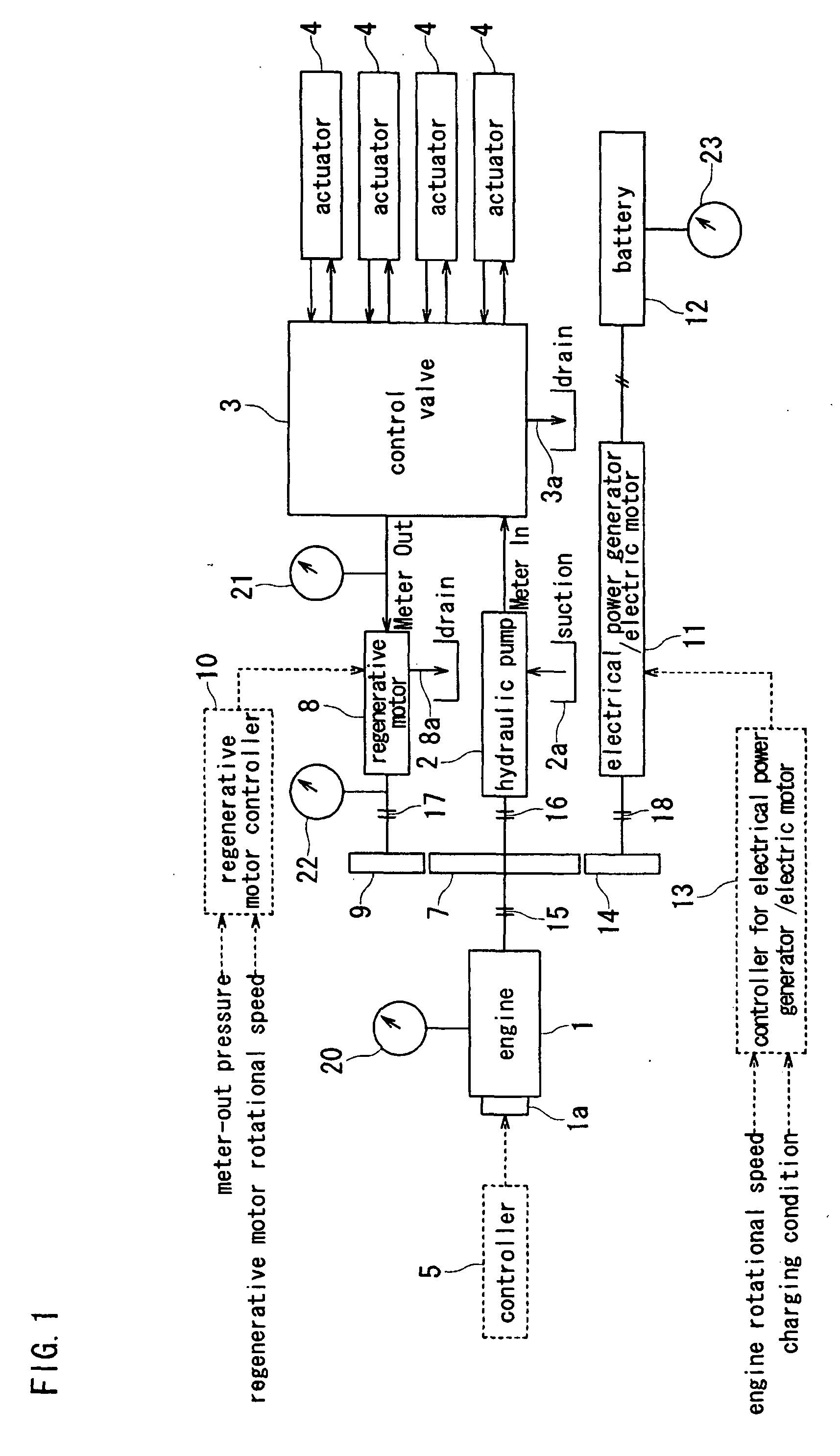

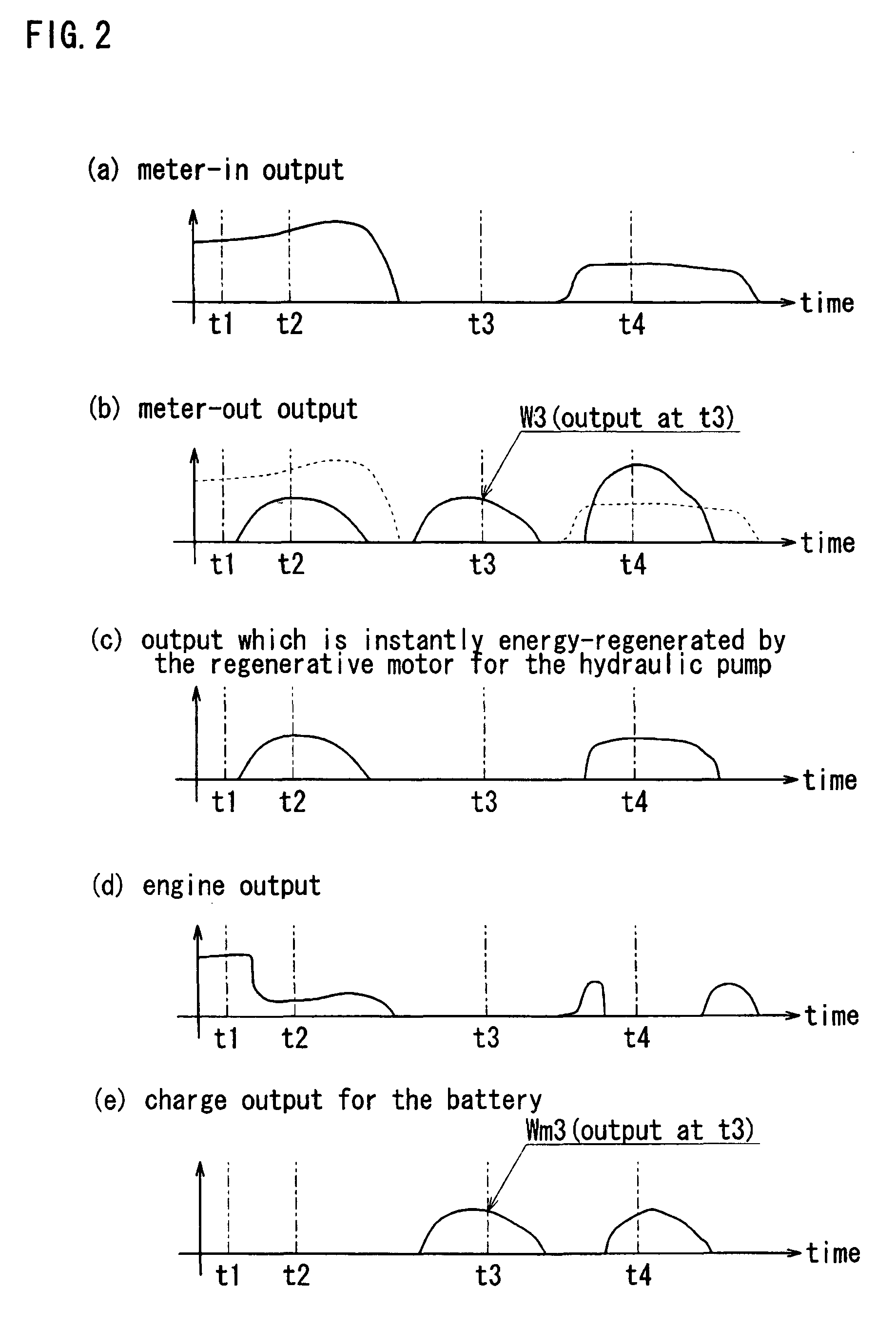

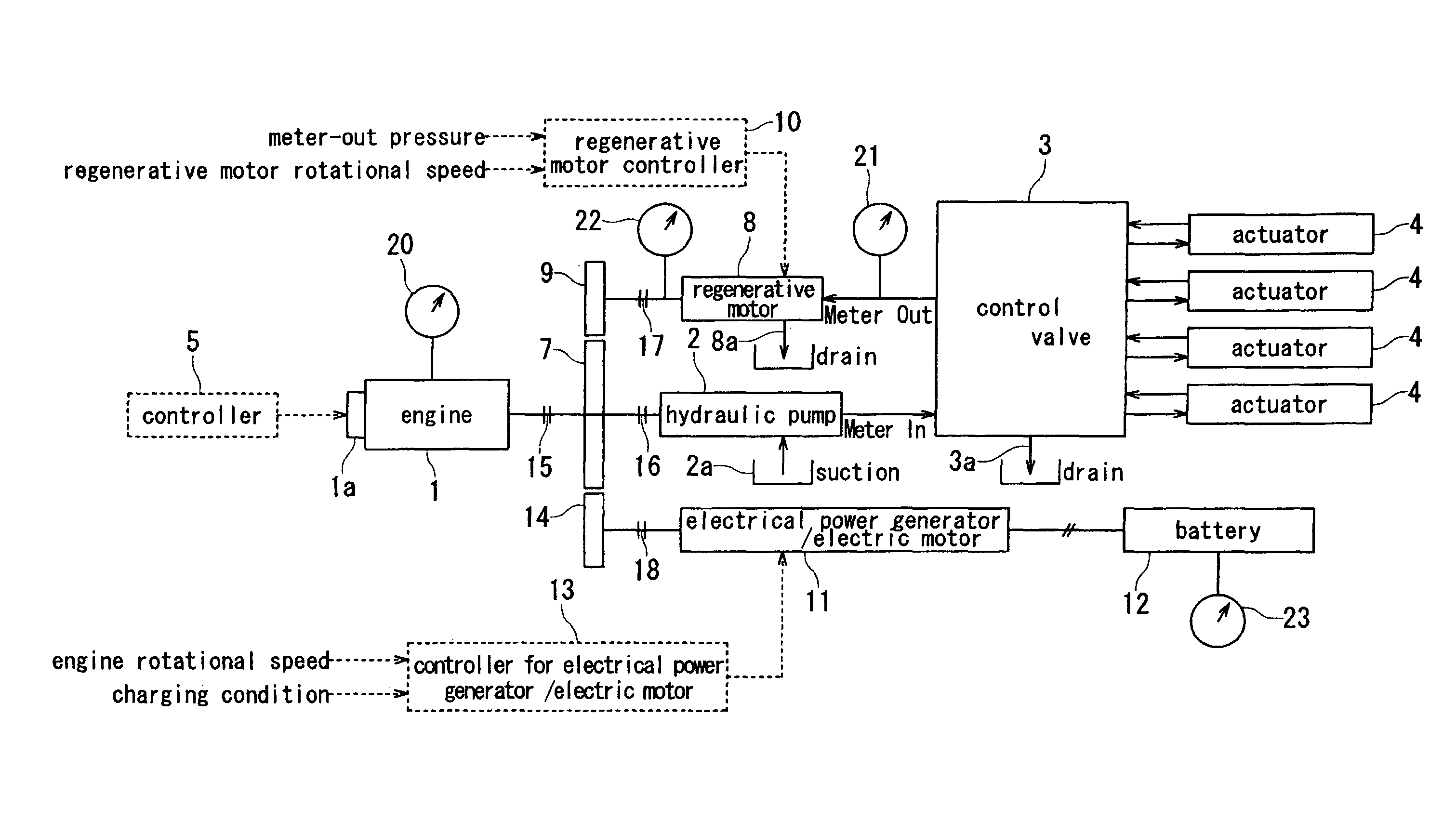

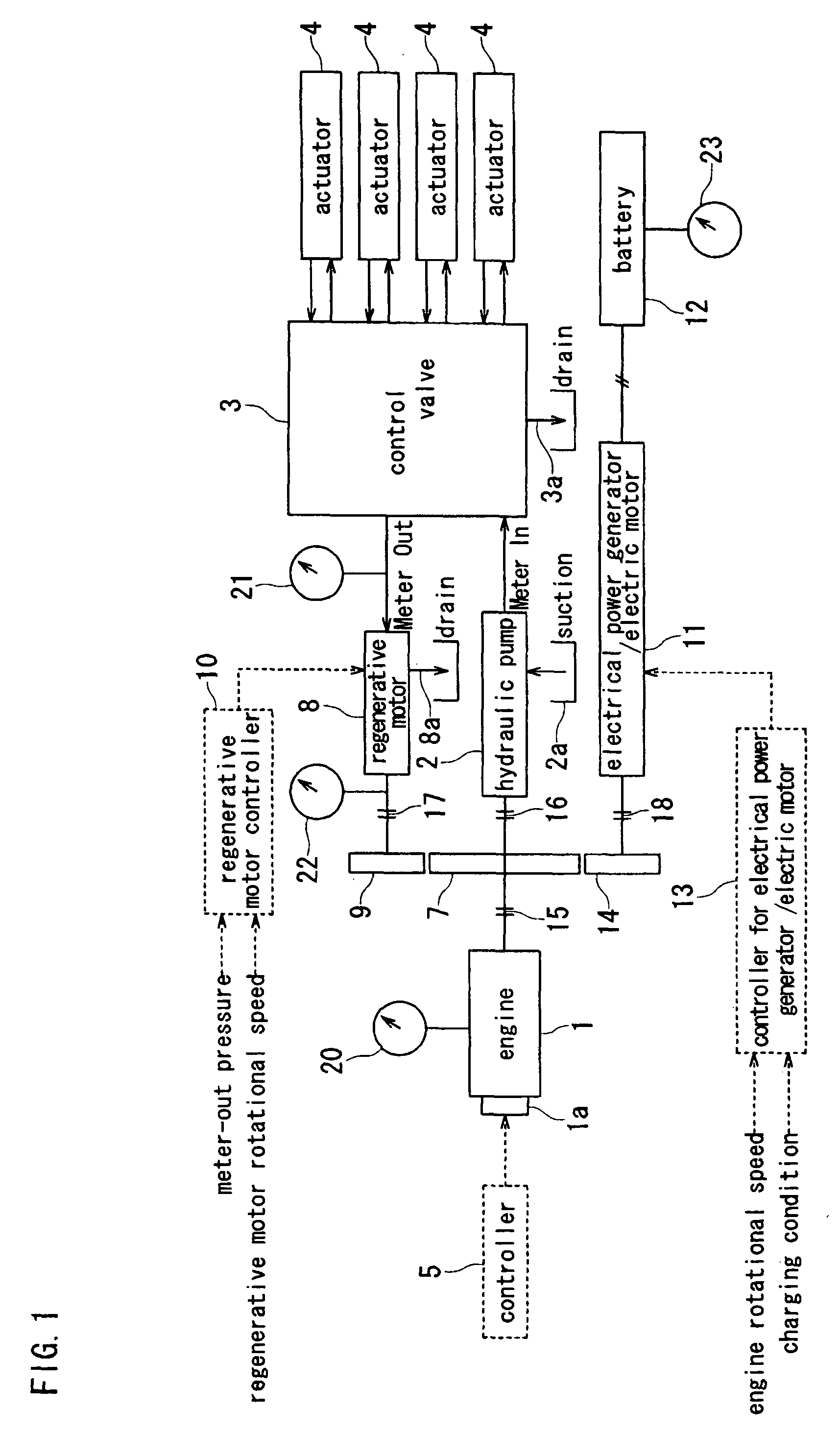

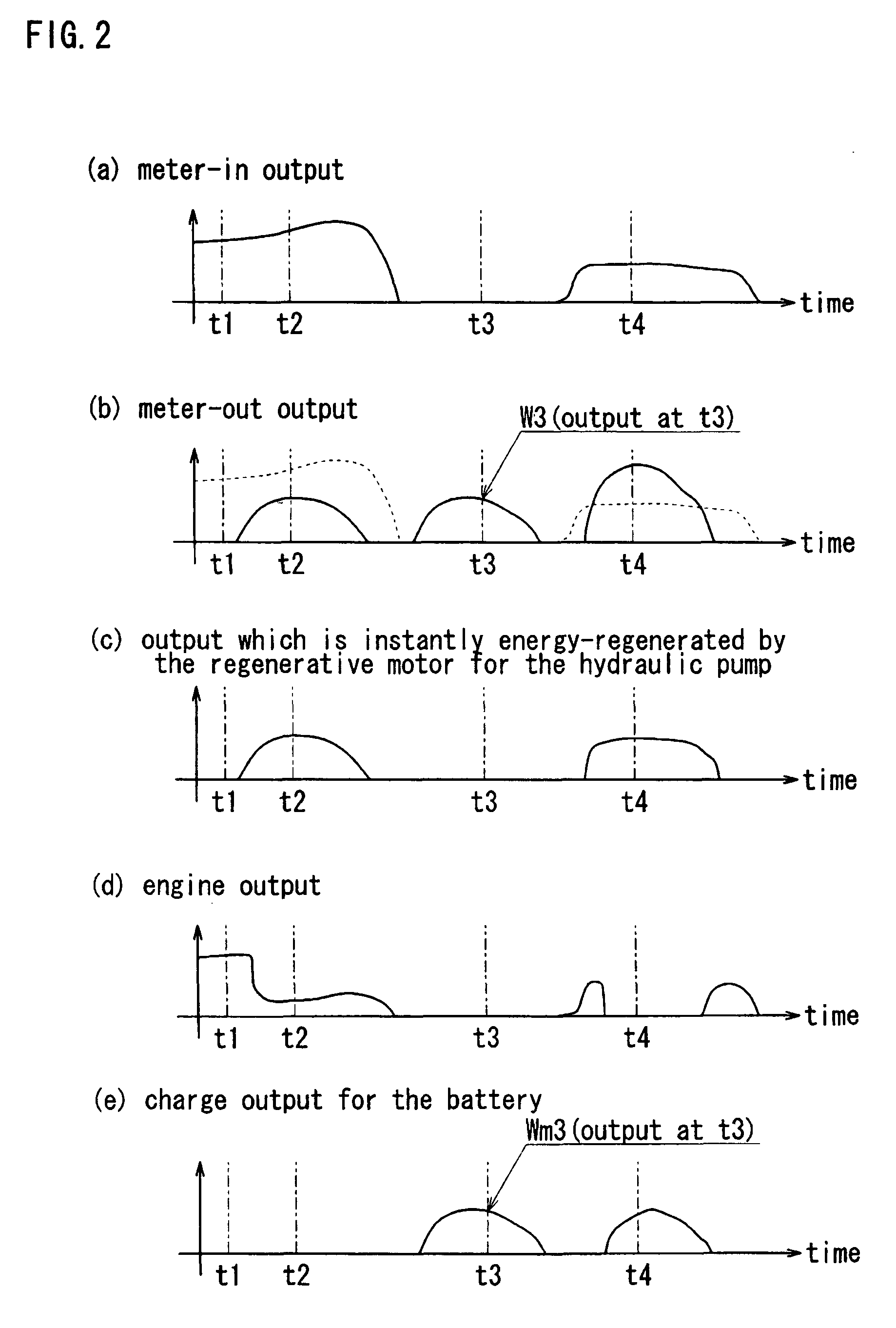

Construction machine

ActiveUS20050036894A1High electrical power generation efficiencyEfficient energy regenerationFluid couplingsMotor parameterElectricityHydraulic pump

In order to provide a construction machine by which energy regeneration can be performed reliably and battery and electrical power generator can be miniaturized, a construction machine has an engine, a hydraulic pump driven by the engine, and an actuator driven by discharge oil from the hydraulic pump, and a regenerative motor which rotates by return oil from the actuator is connected to the rotation shaft of the hydraulic pump. The hydraulic pump is driven by the engine and the regenerative motor when drive torque necessary in the hydraulic pump is larger than output torque generated by operation of the regenerative motor. Meanwhile, the hydraulic pump is driven by the regenerative motor when the drive torque of the hydraulic pump is smaller than output torque of the regenerative motor, and an electrical power generator connected to the rotation shaft of the hydraulic pump is operated to generate electricity by excess torque which has not been energy-regenerated in the hydraulic pump so that this generated electrical power is charged in a battery.

Owner:KOMATSU LTD

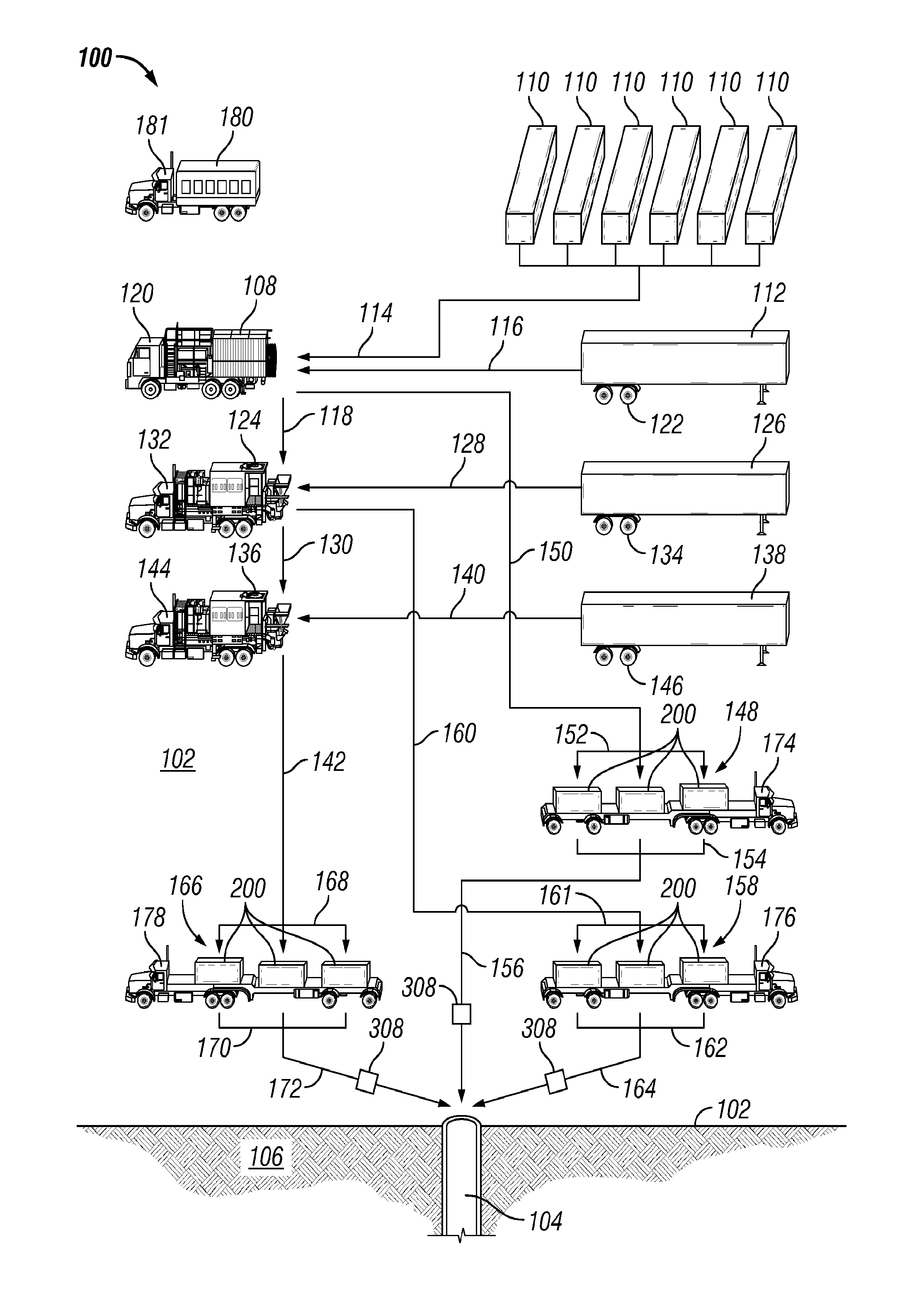

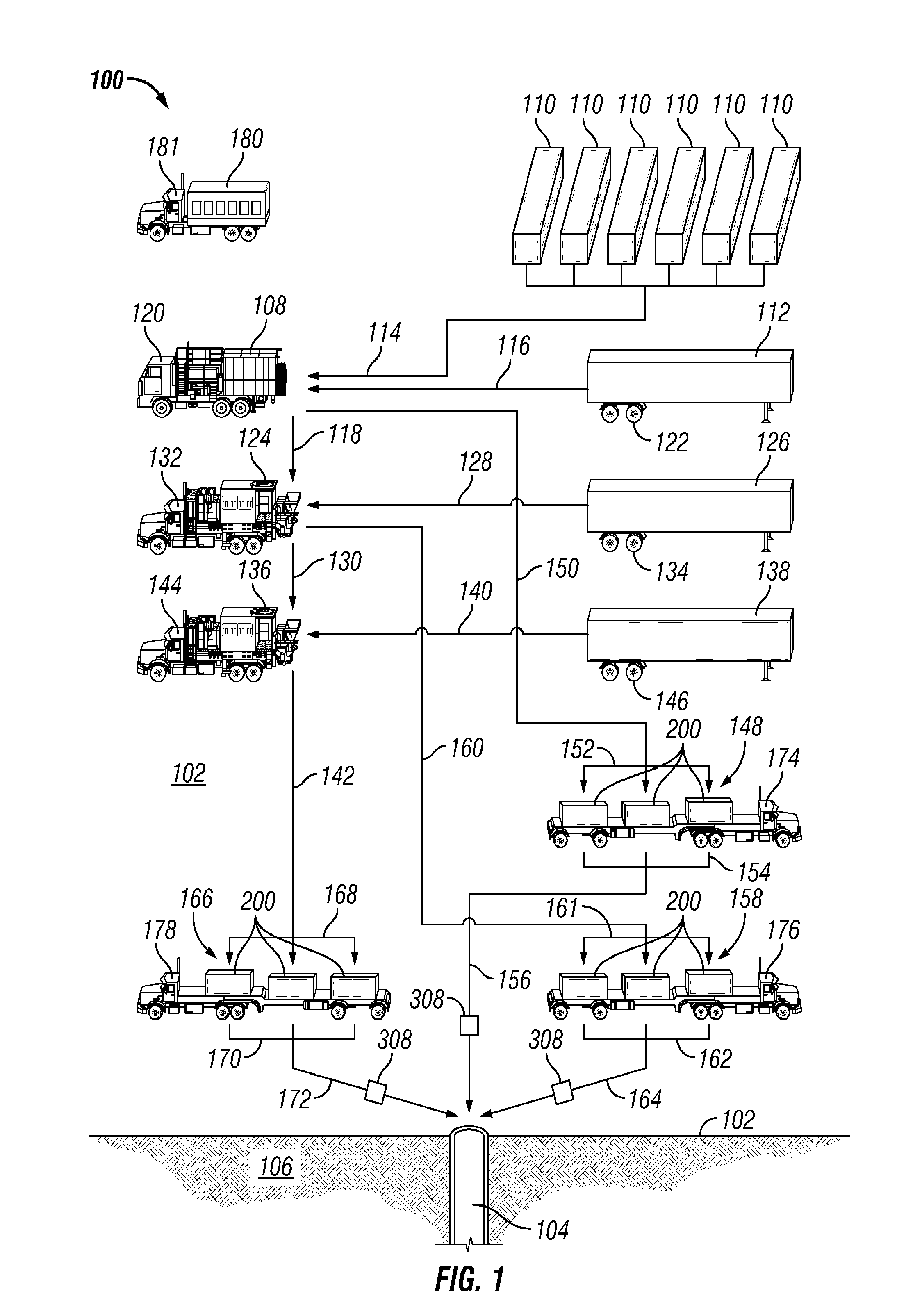

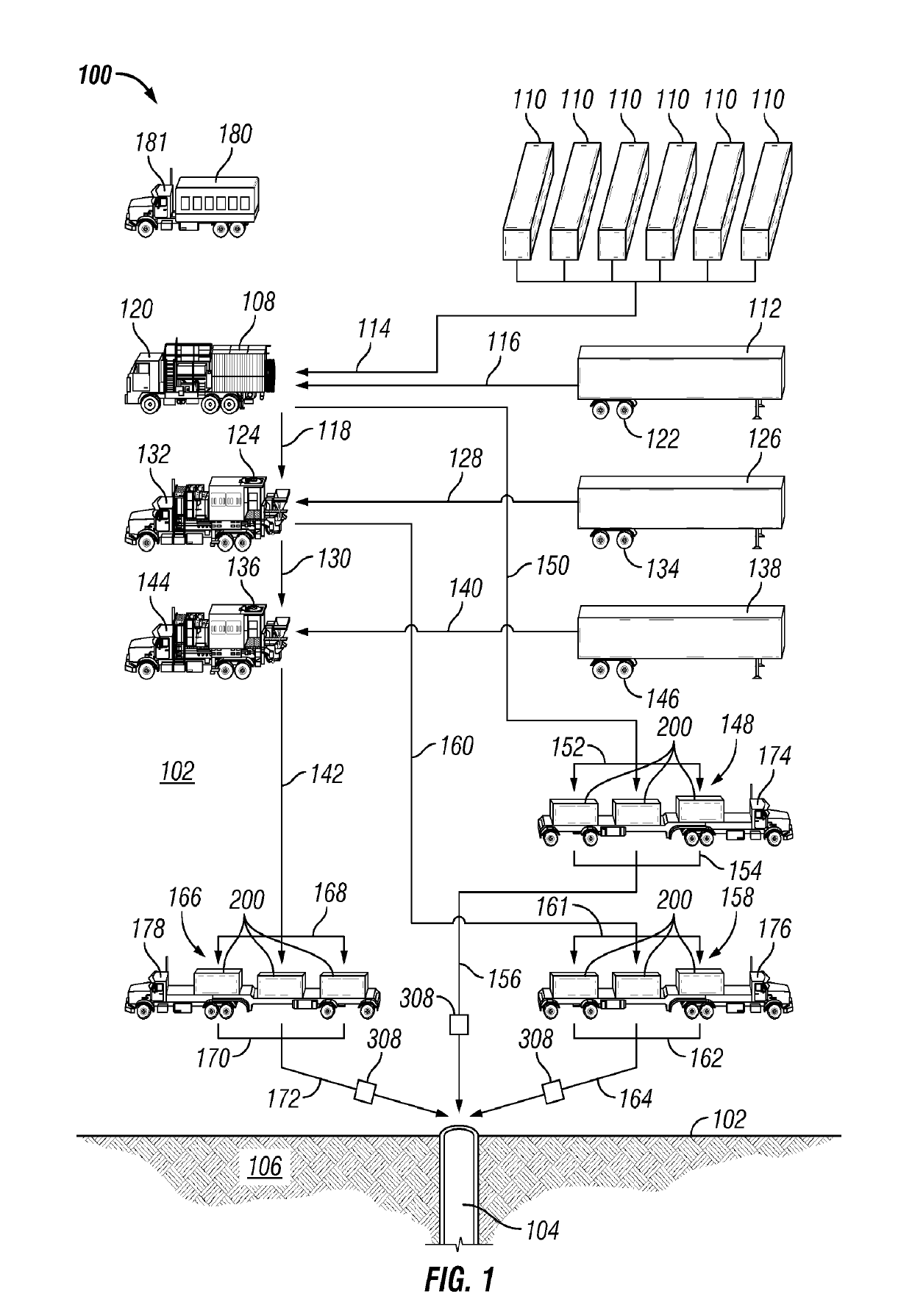

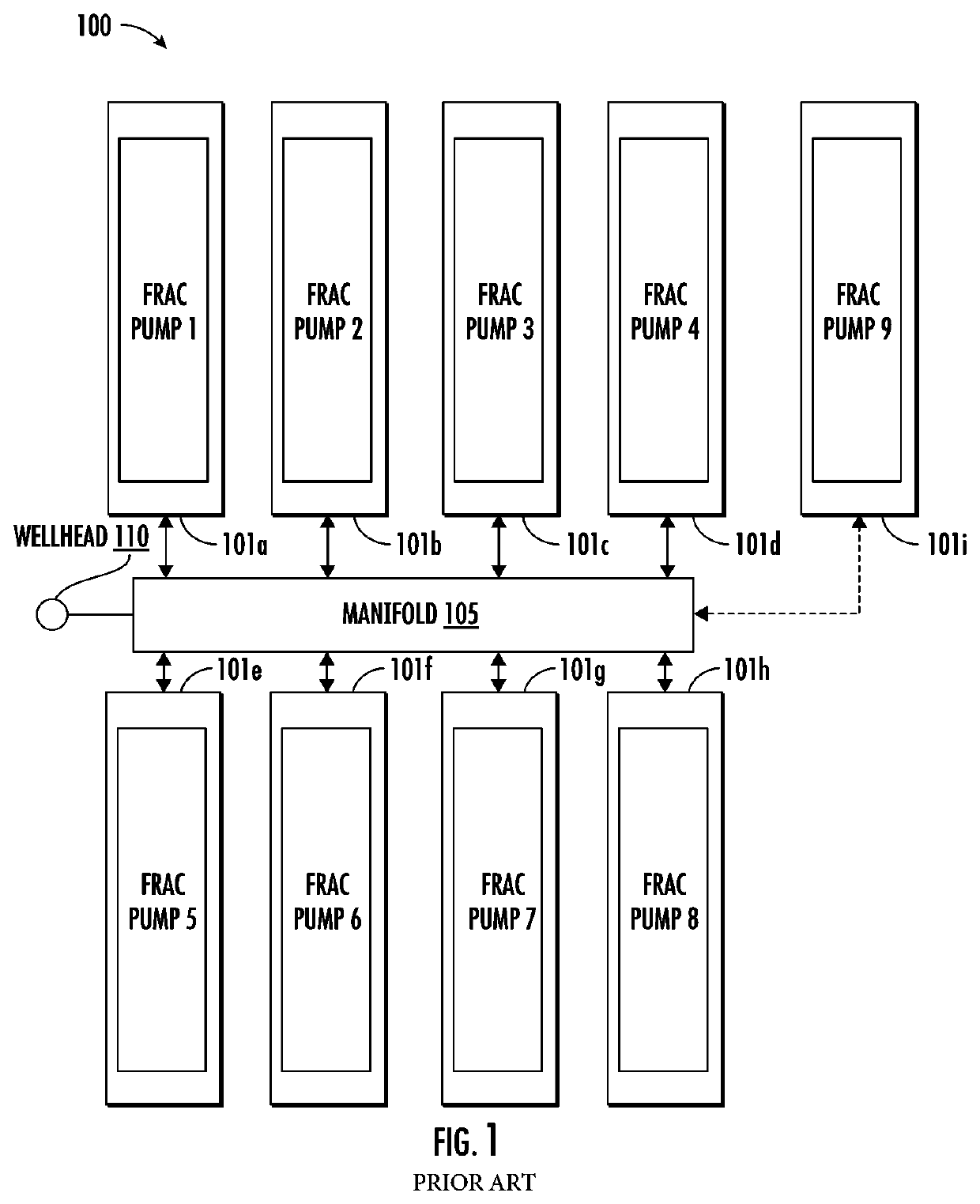

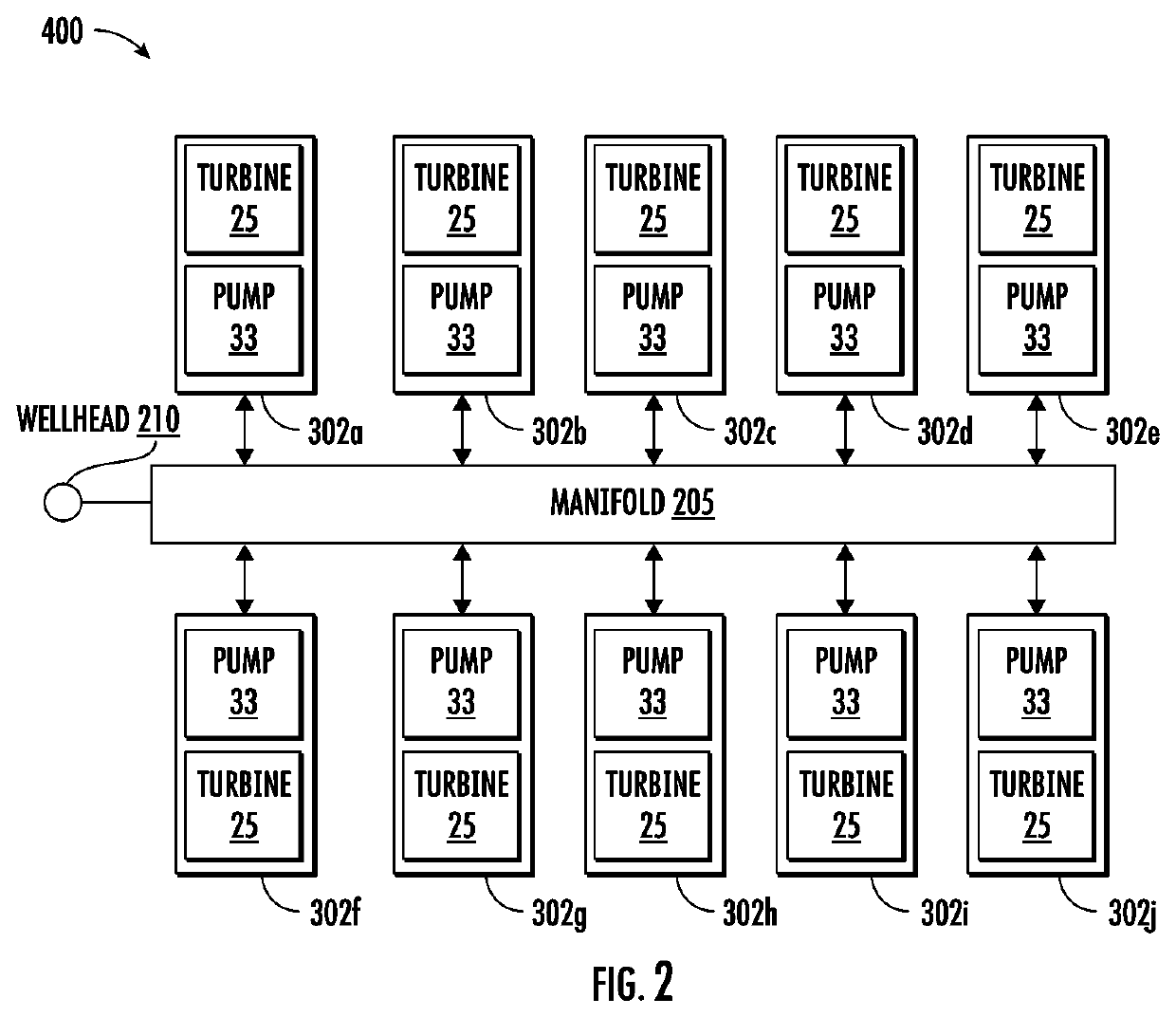

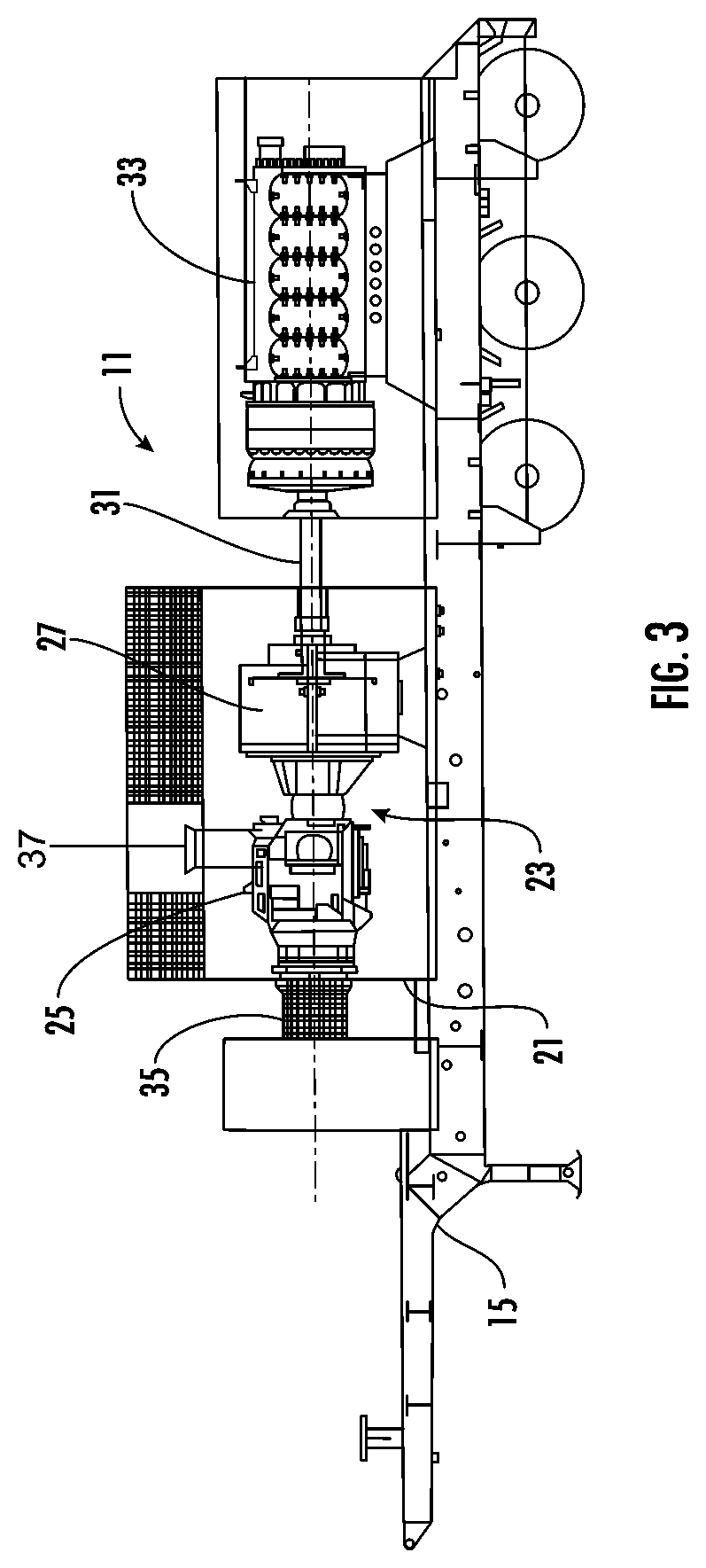

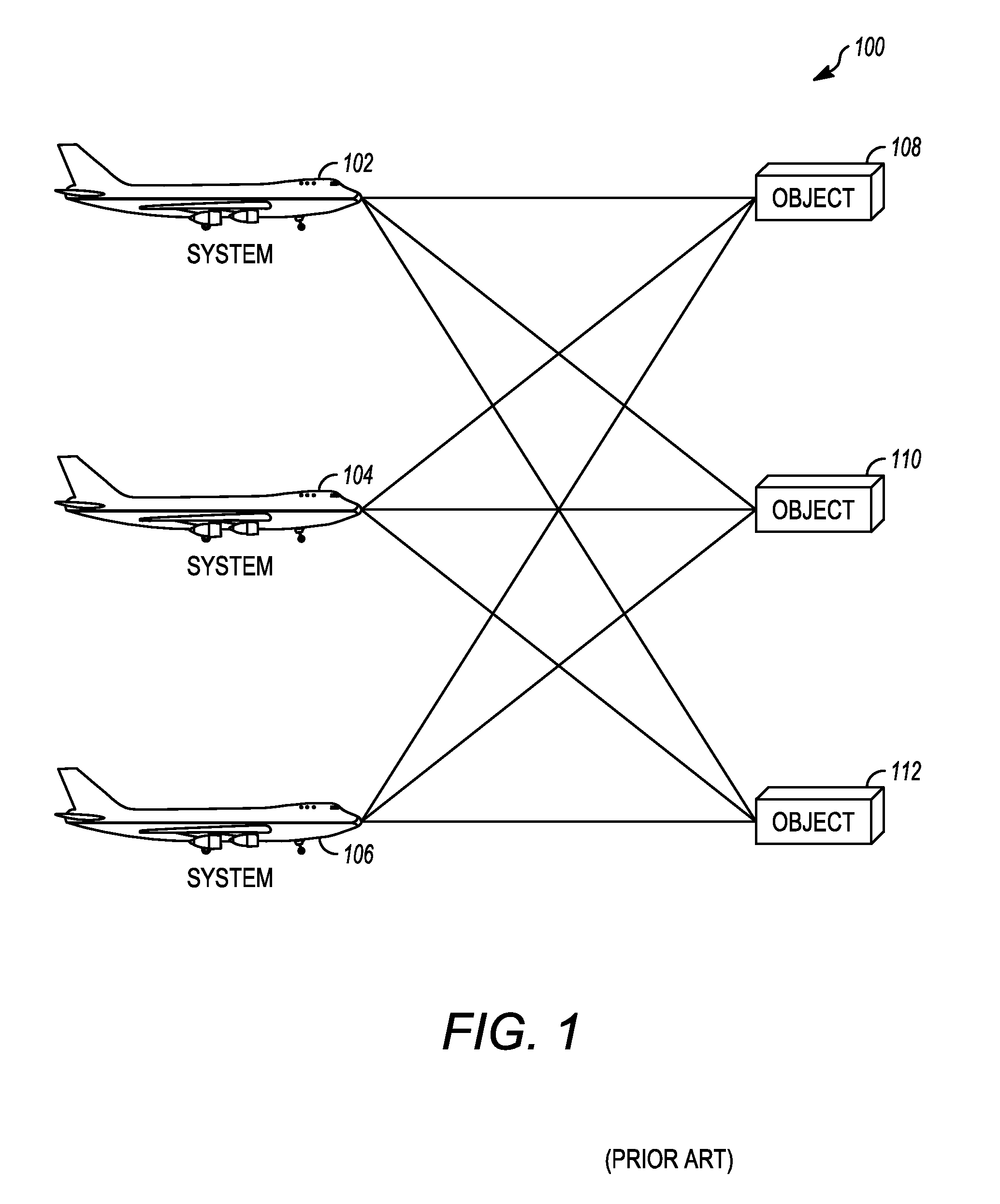

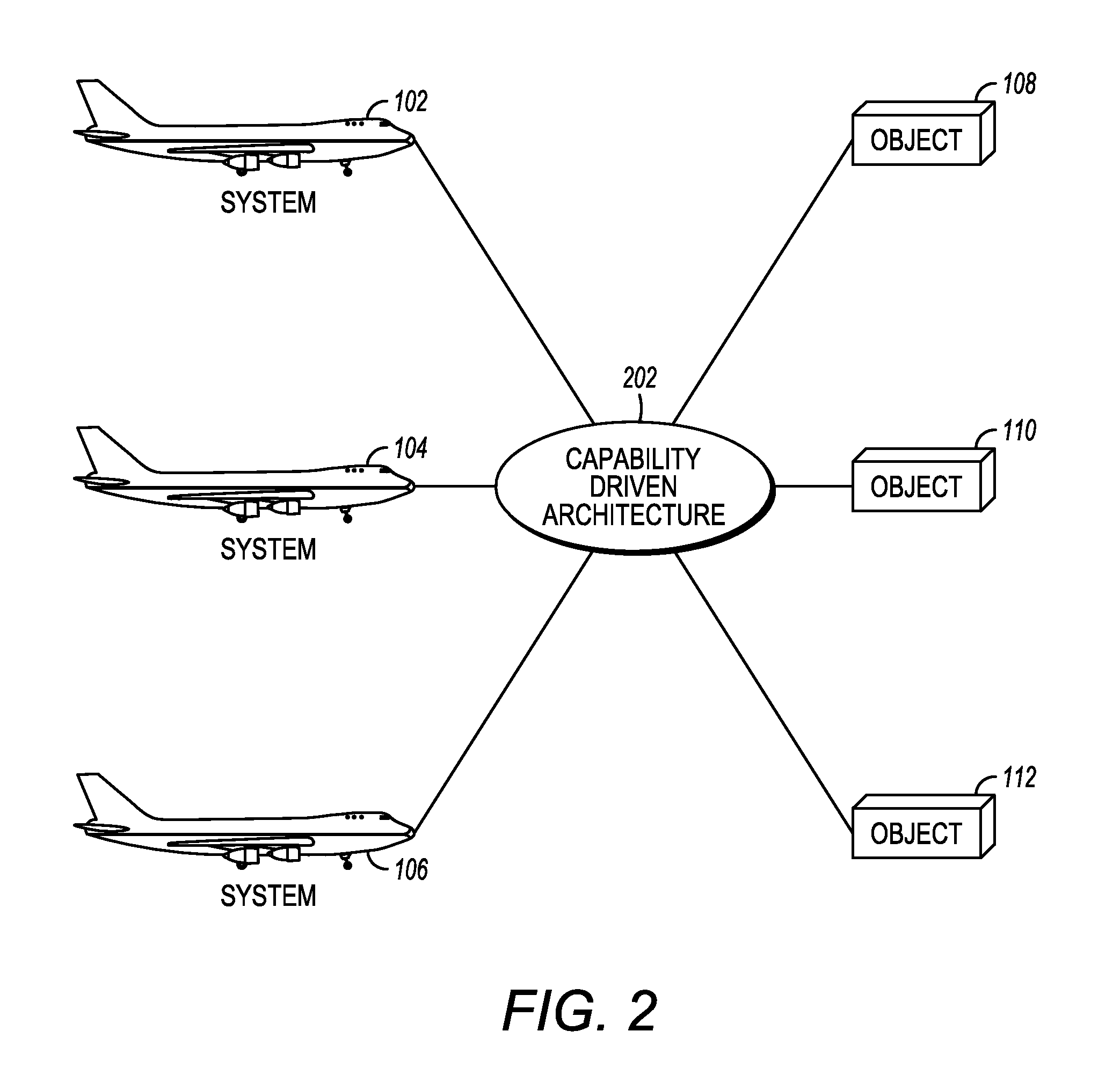

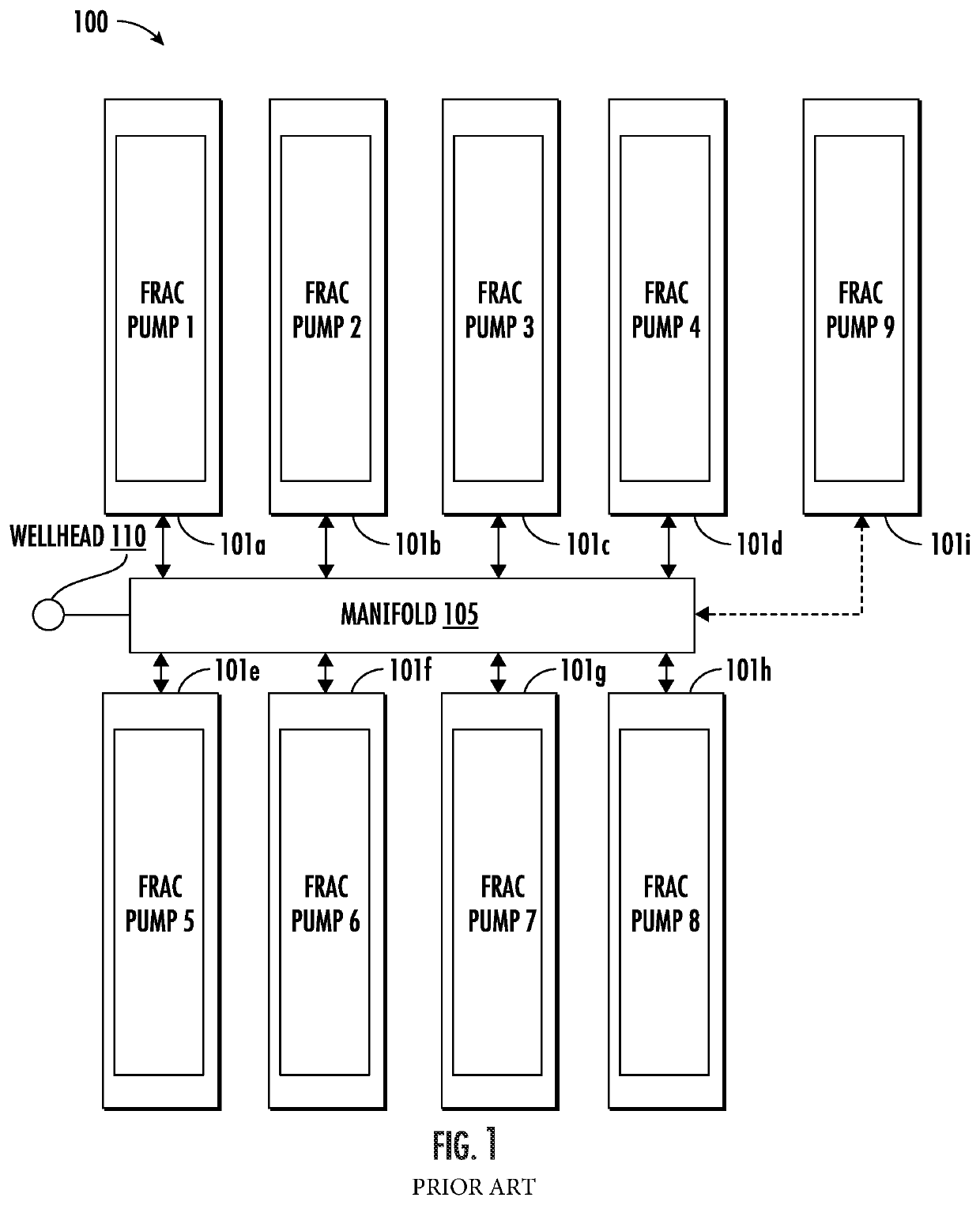

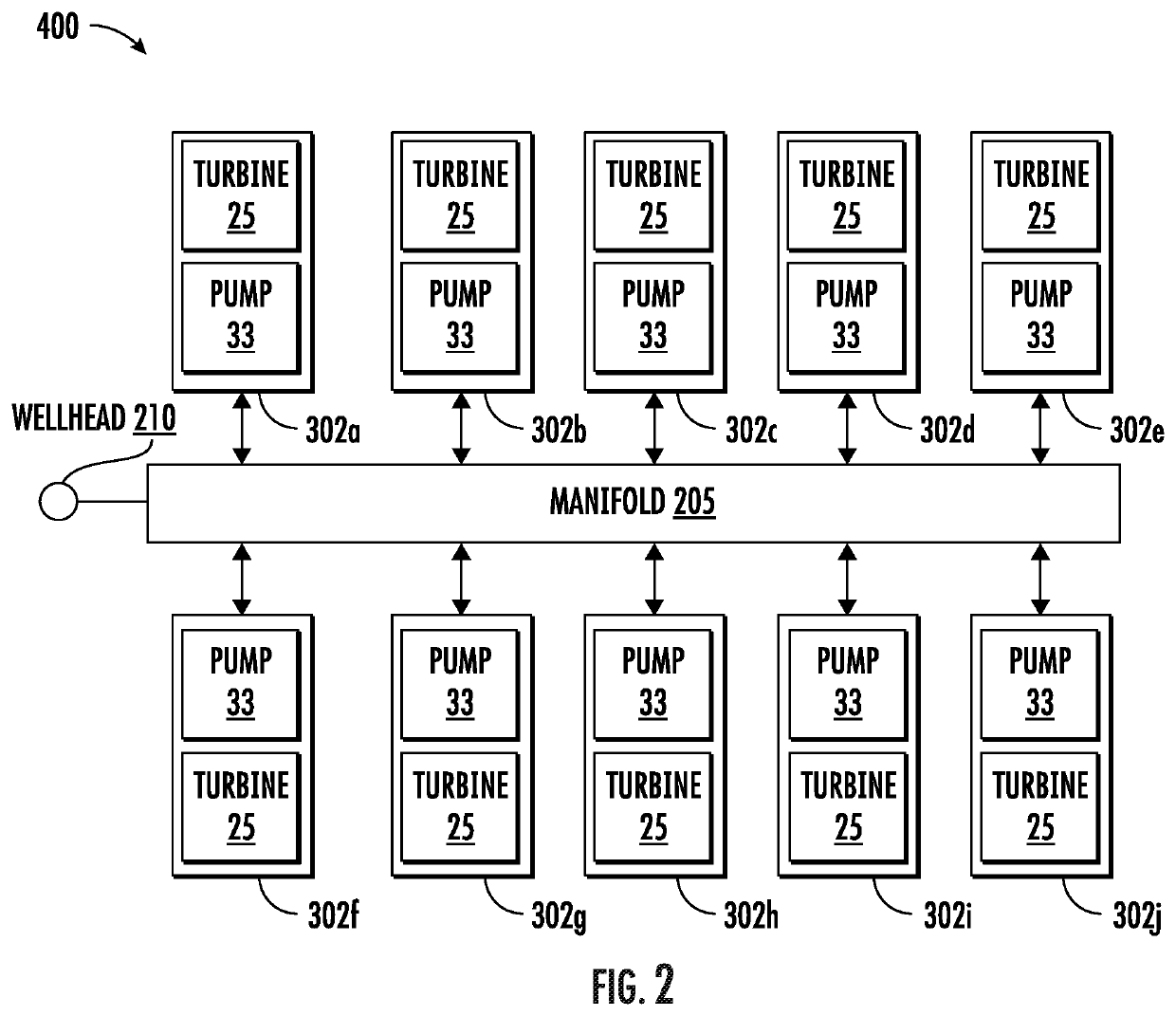

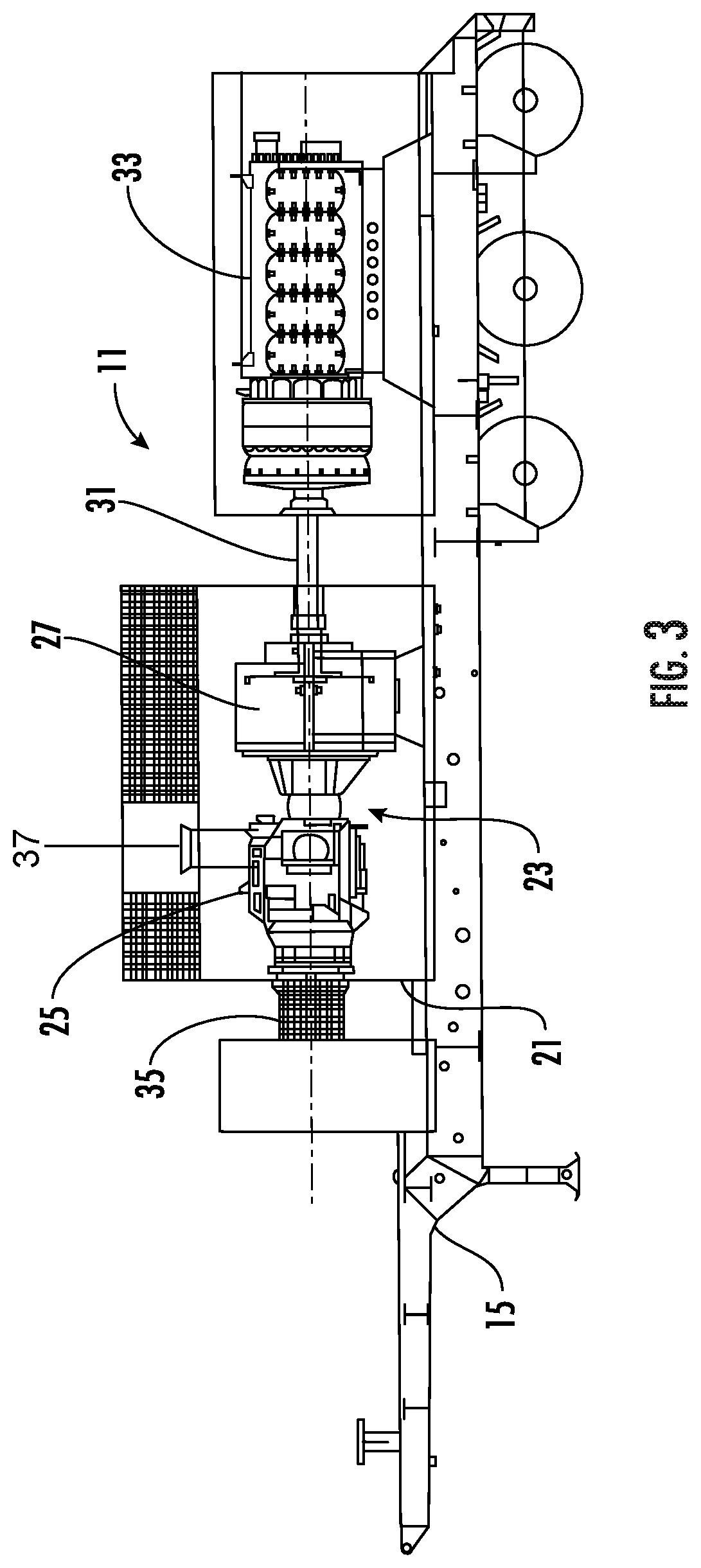

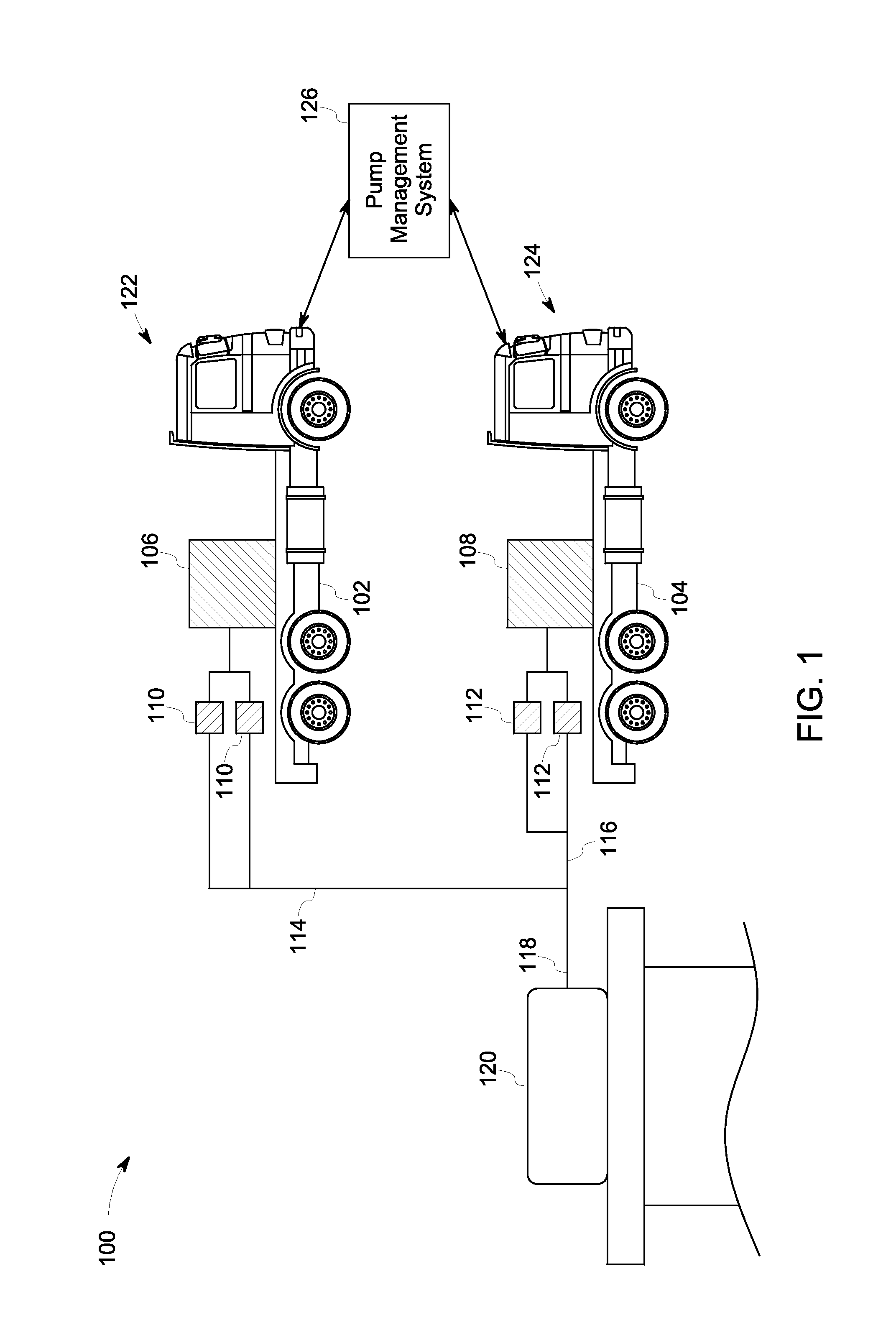

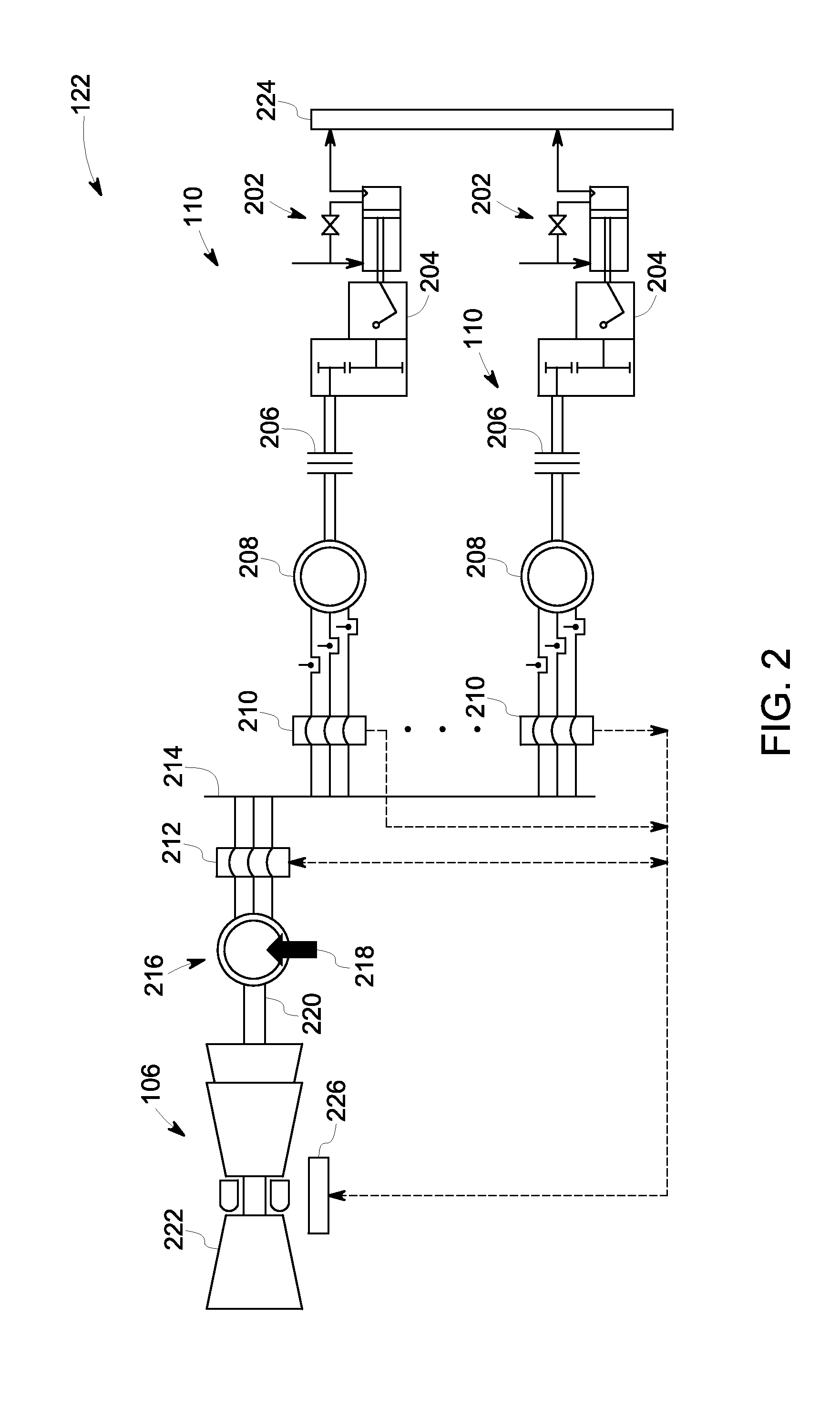

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

Multi-compatible digital engine controller

A digital engine controller compatible with multiple variants of gas turbine engine is programmed to receive identification of a variant of gas turbine engine coupled to the digital controller and thereafter to automatically determine and adjust inputs to the engine, according to the received identification of engine variant, to meet user-specified output.

Owner:TURBINE POWERED TECH LLC 51

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC

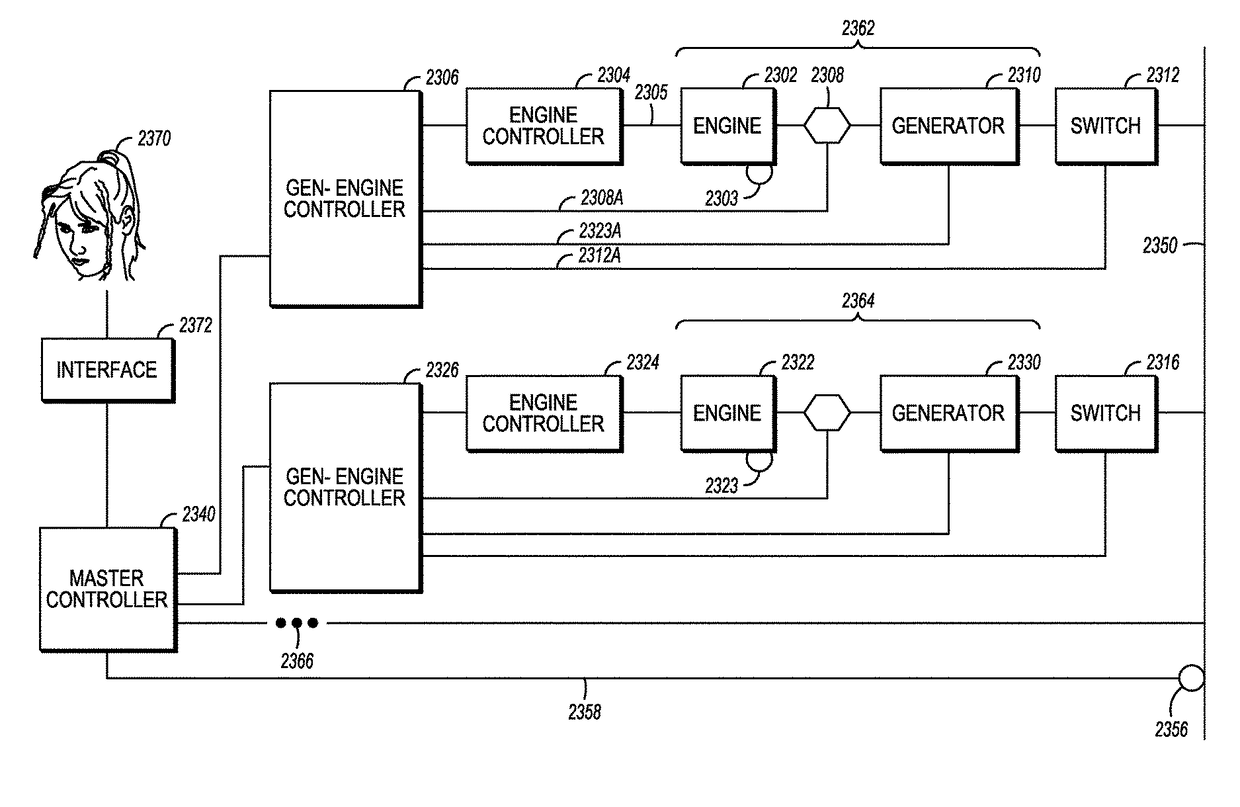

System and method for automatically controlling one or multiple turbogenerators

At least one controller manages a gas turbine engine driving a generator directly or indirectly coupled to the engine. The controller is programmed to automatically determine and adjust inputs to the gas turbine engine in order to cause the generator to produce a user-specified electrical output. Multiple sets of generator, engine, and controller may be used, in which case a master controller individually manages the other controllers to collectively provide the a user-specified electrical output.

Owner:TURBINE POWERED TECH LLC

Construction machine

InactiveUS7086226B2Reliable collectionReliable regenerationFluid couplingsMotor parameterElectricityEnergy regeneration

Owner:KOMATSU LTD

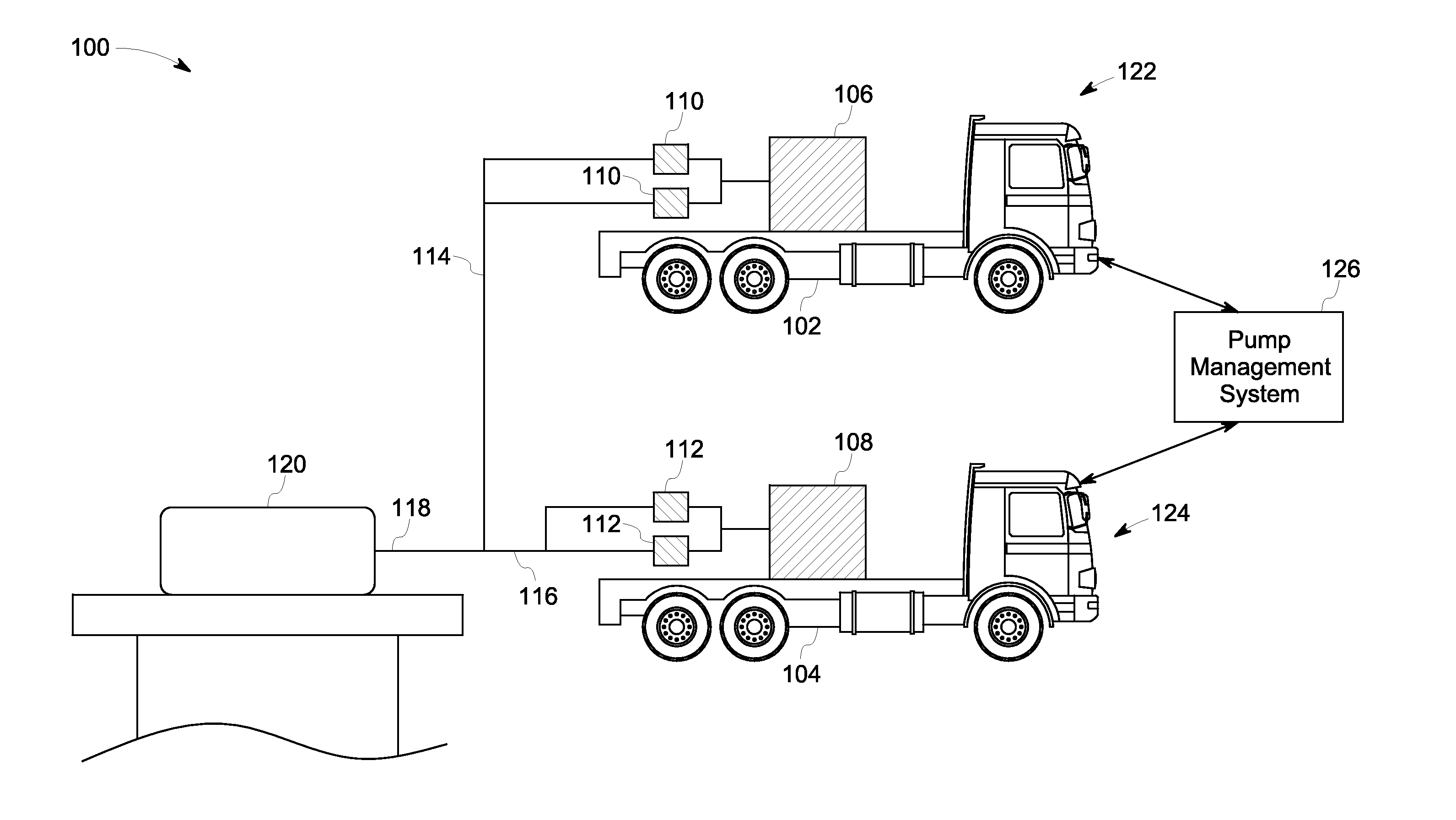

System and method for health management of pumping system

ActiveUS20160195082A1Guaranteed uptimeFluid parameterFlexible member pumpsSimulationManagement system

A method implemented by at least one processor includes receiving a plurality of operating parameters of a pumping system, wherein the pumping system has a plurality of pump-units powered by a generator-unit. The operating parameters include a pump-unit parameter and a generator-unit parameter. The method also includes receiving reference data of the pumping system, wherein the reference data includes measurements from the pumping system representative of performance of the plurality of pump-units. The method also includes determining one or more health parameters corresponding to one or more pump-units based on the plurality of operating parameters and the reference data. The method further includes modifying one or more input parameters of the generator-unit based on the one or more health parameters for continued operation of the pumping system.

Owner:HYDRIL USA DISTRIBUTION LLC

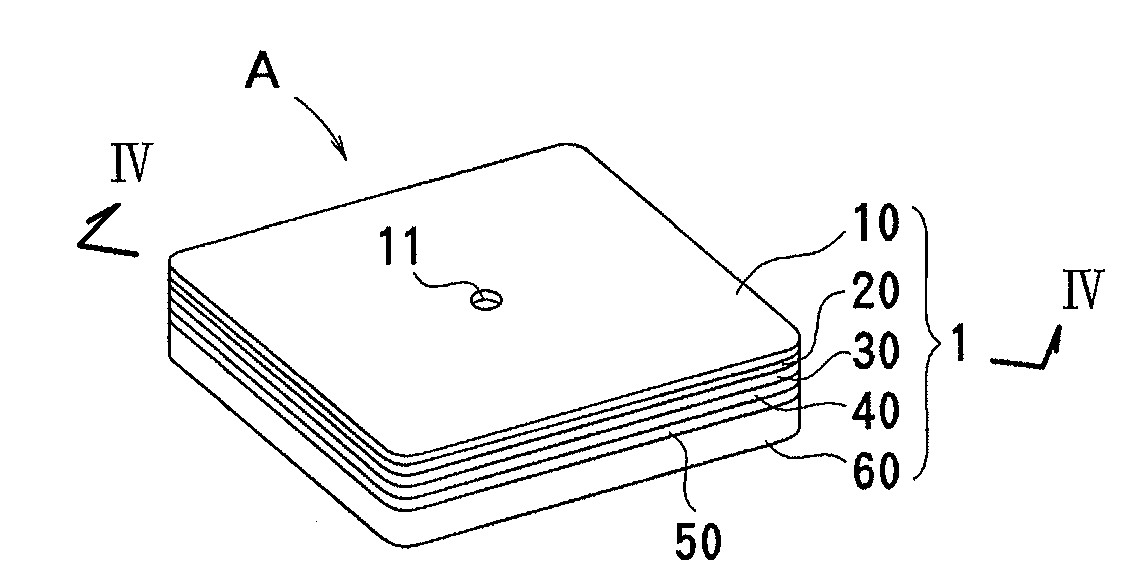

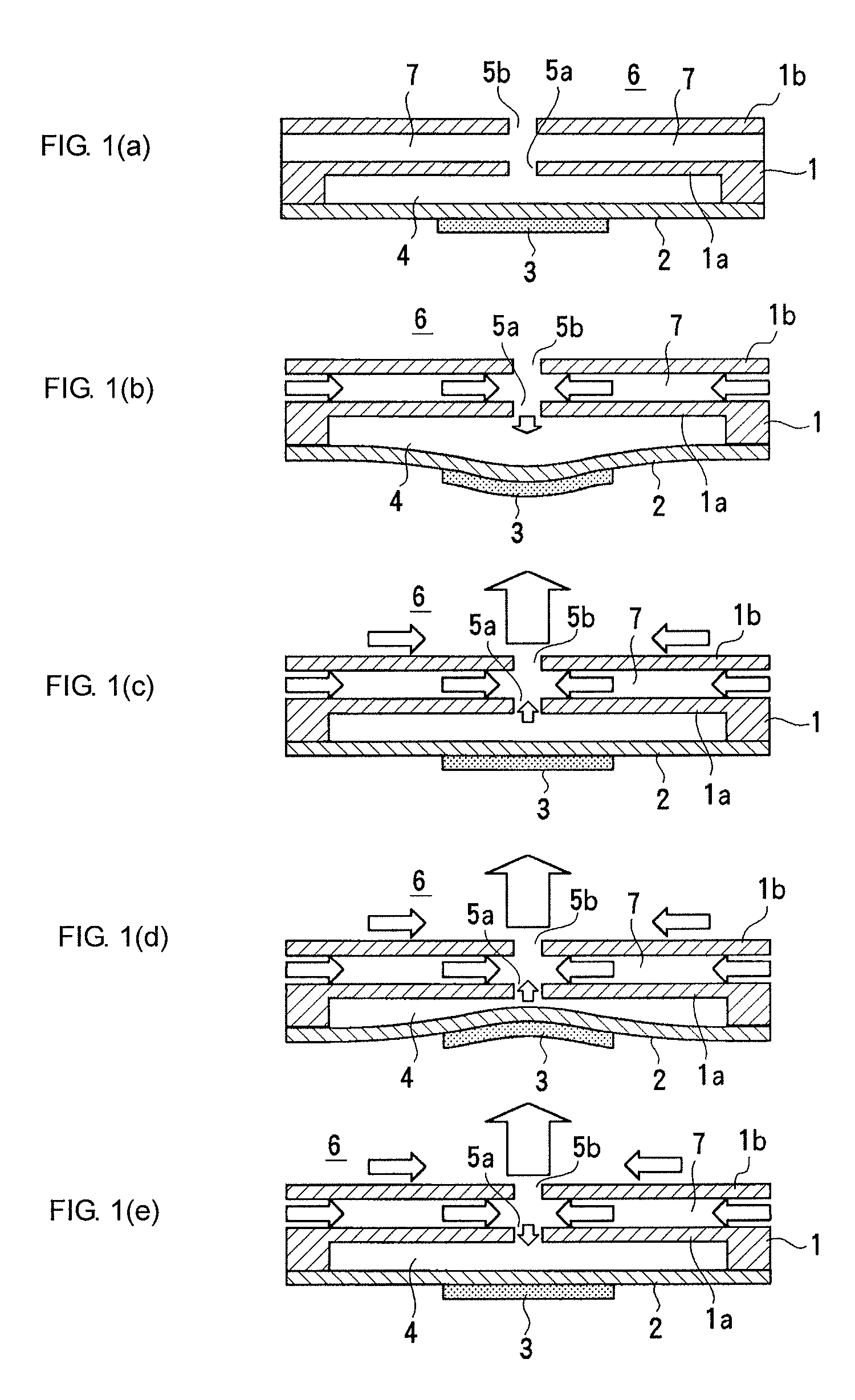

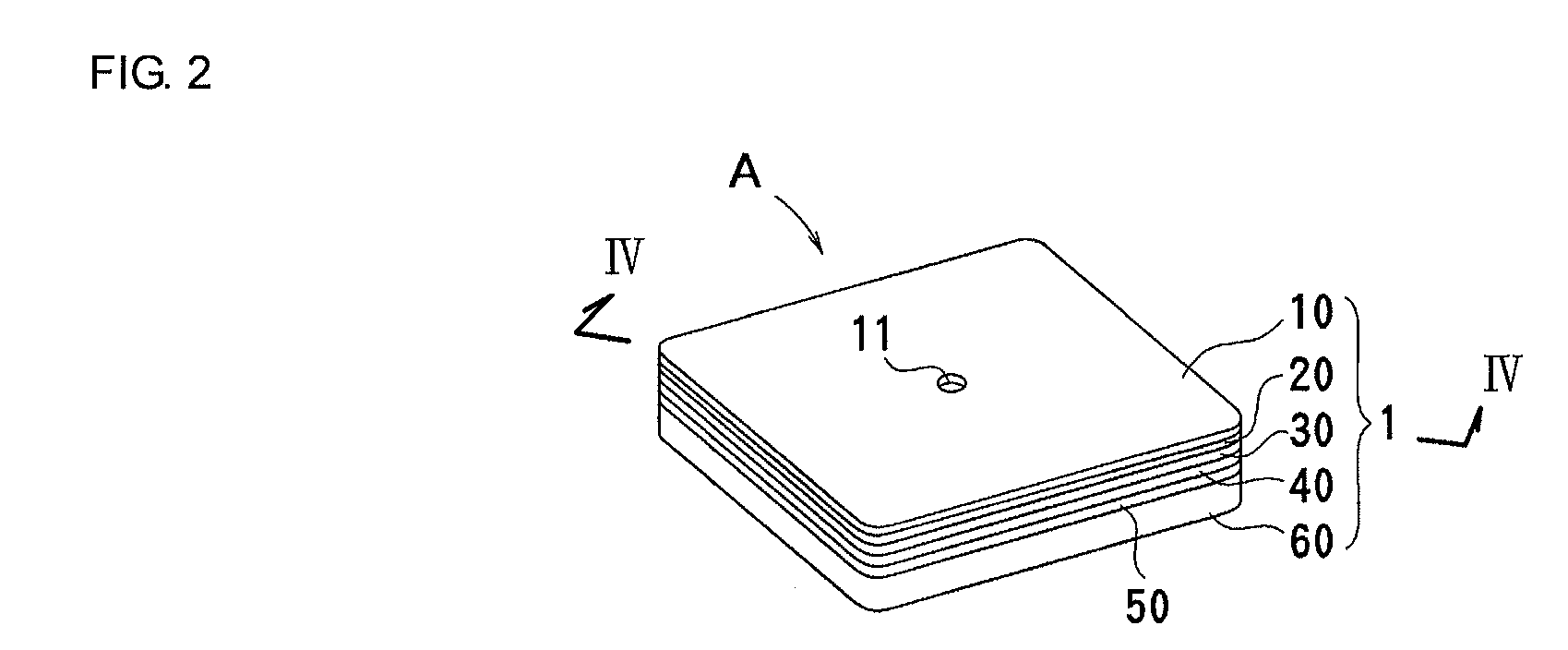

Piezoelectric micro-blower

ActiveUS20090232683A1Efficiently conveyedSufficient flow ratePositive displacement pump componentsFlexible member pumpsElectricityEngineering

A piezoelectric micro-blower capable of efficiently conveying compressive fluid without use of a check valve and ensuring a sufficient flow rate. The micro-blower has a blower body with a first wall and a second wall. Openings are formed in the respective walls and face a center of a diaphragm. An inflow path allowing the openings to communicate with the outside is formed between the walls. By applying a voltage to a piezoelectric element to cause the diaphragm to vibrate, a part of the first wall close to the first opening vibrates. Thus, gas can be drawn from the inflow path and discharged from the opening in the second wall.

Owner:MURATA MFG CO LTD

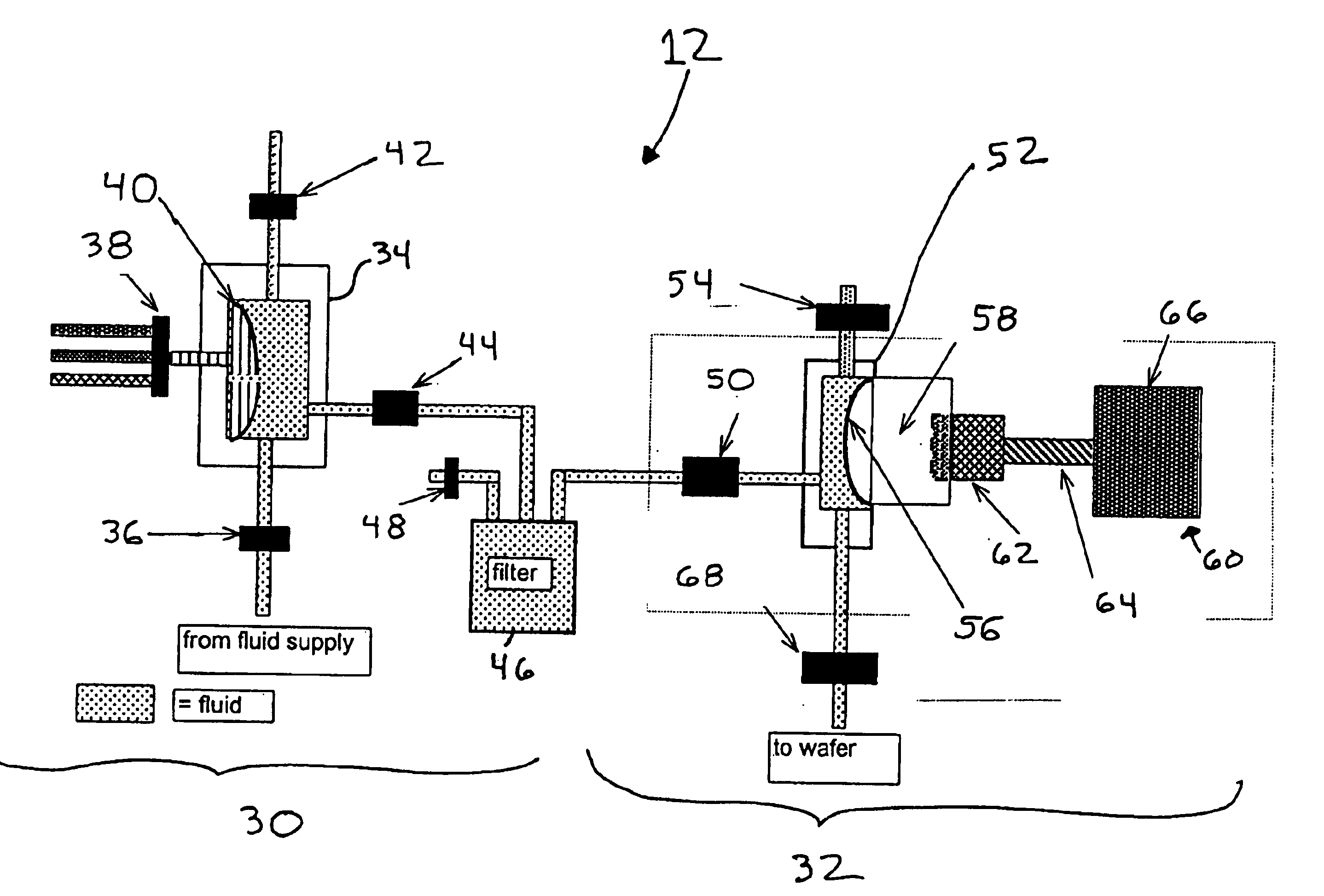

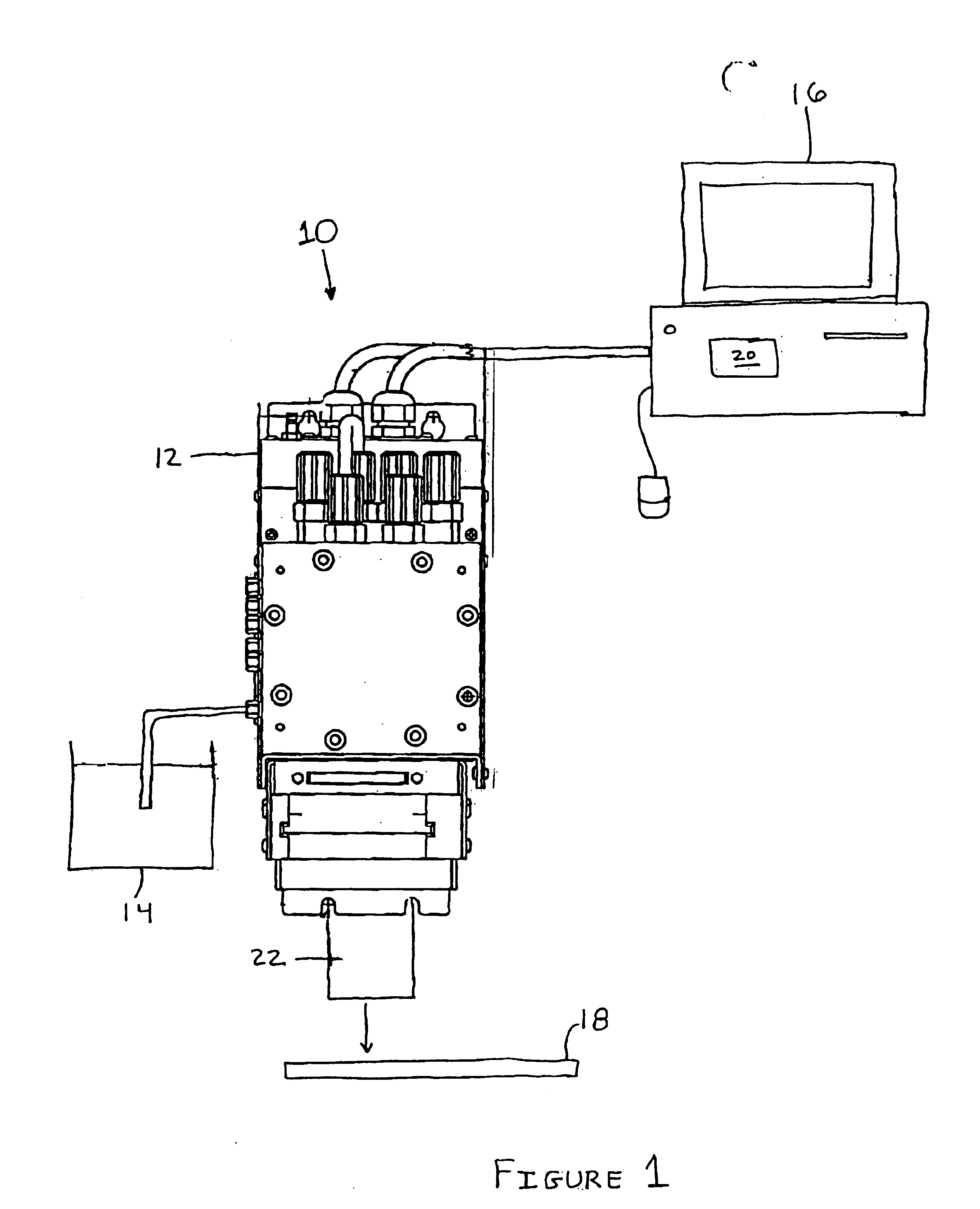

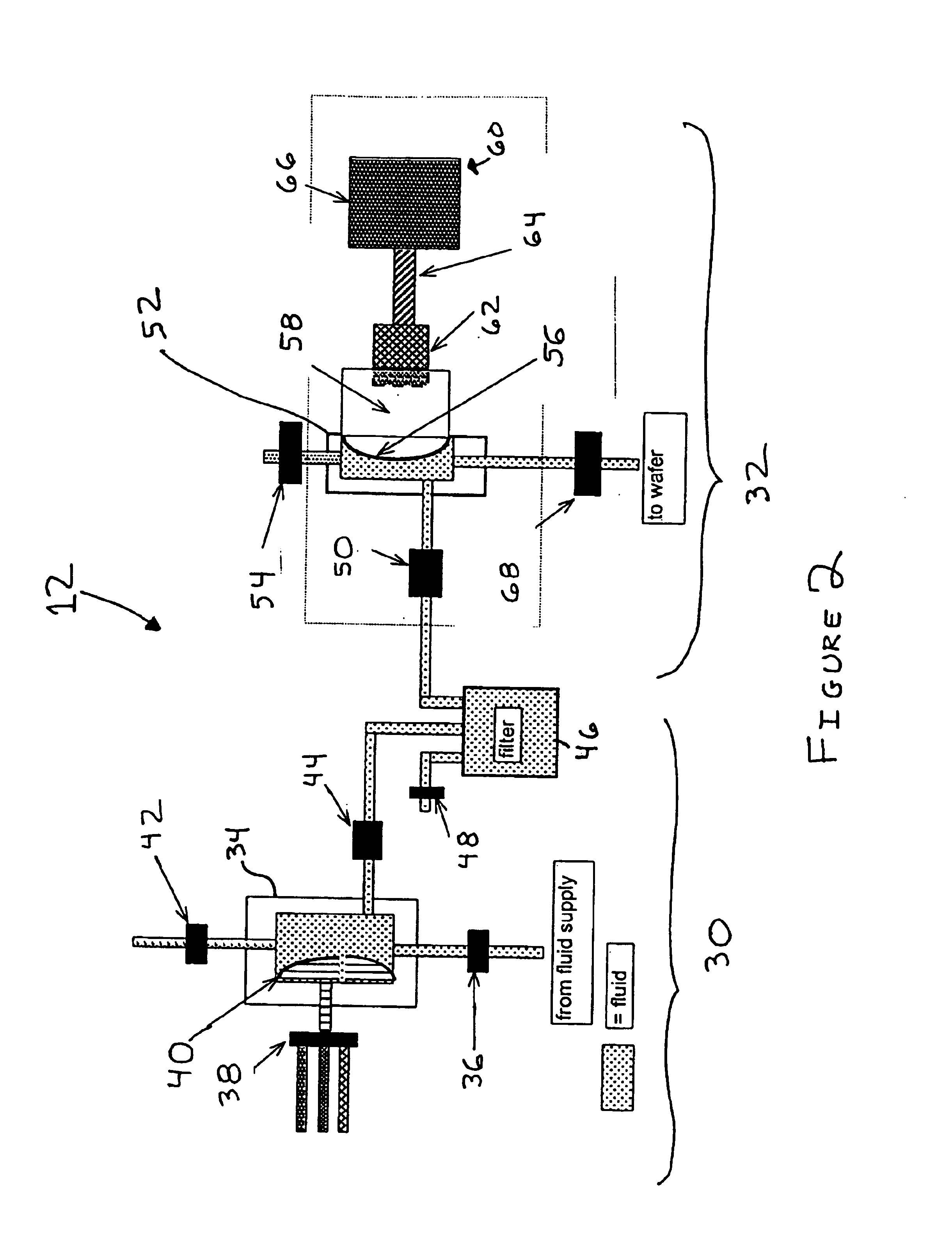

Pump controller for precision pumping apparatus

InactiveUS7029238B1Low dispensing rateEasy to controlFluid parameterFlexible member pumpsEngineeringViscosity

Owner:ENTEGRIS INC

Overheat protection for fluid pump

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

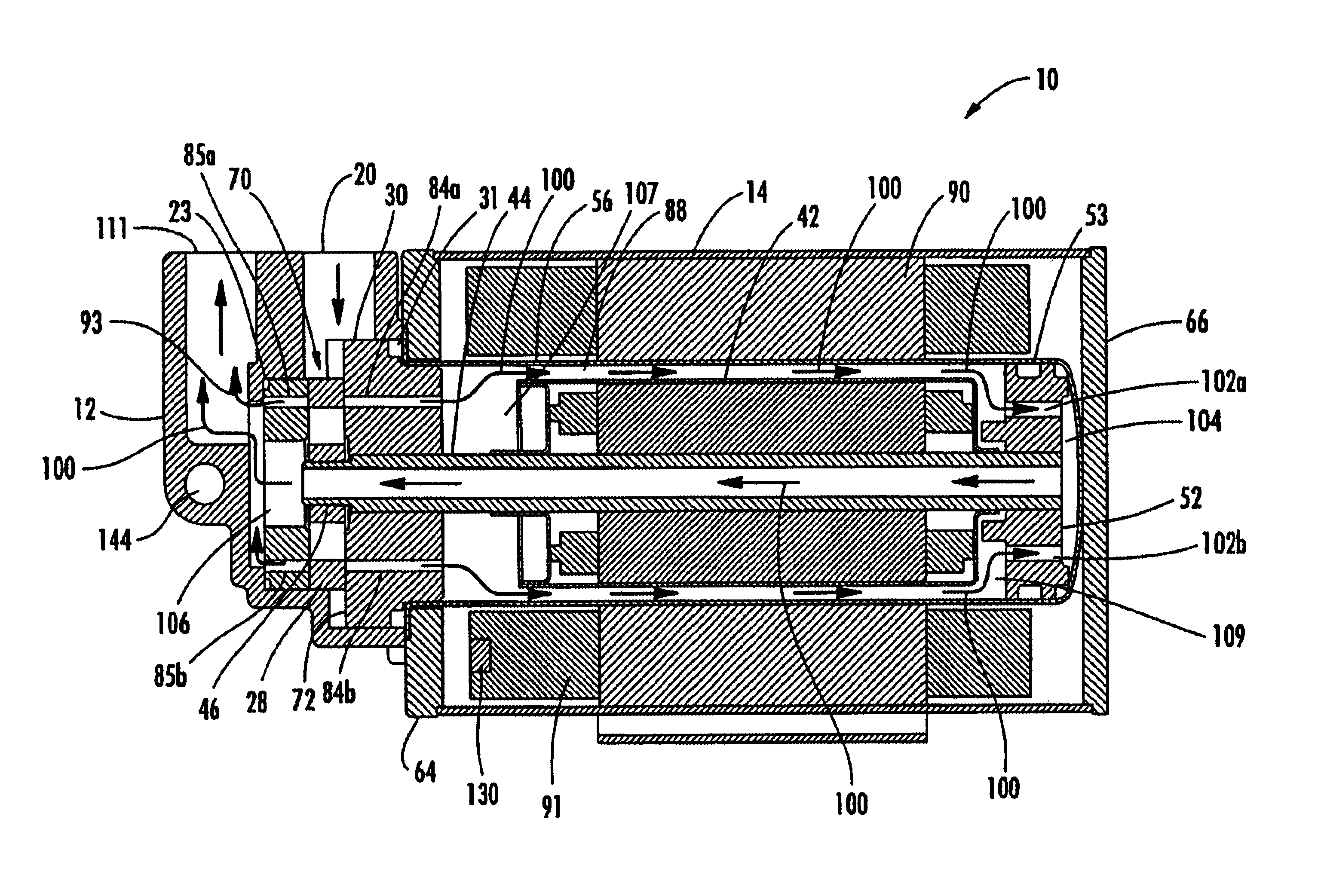

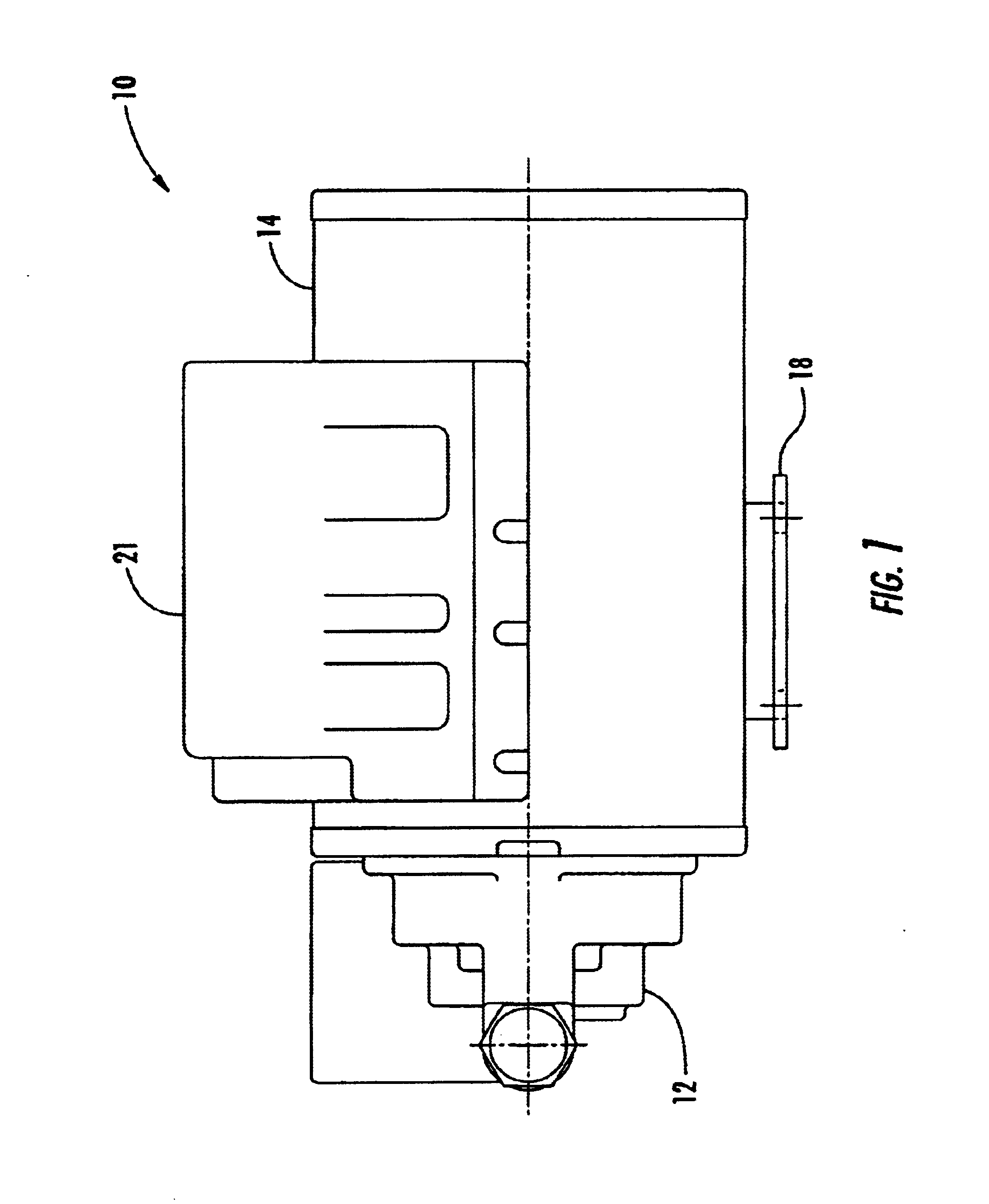

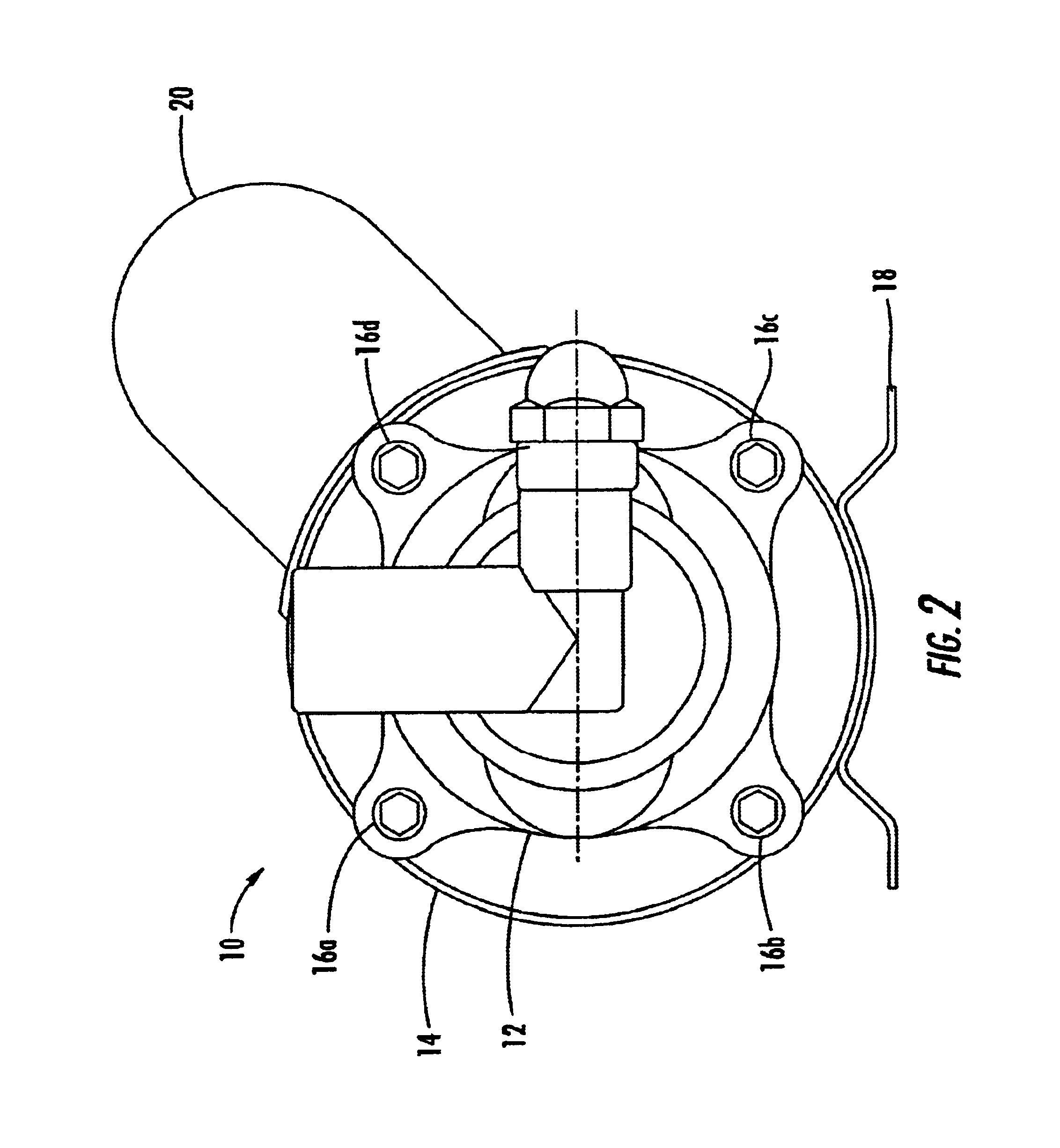

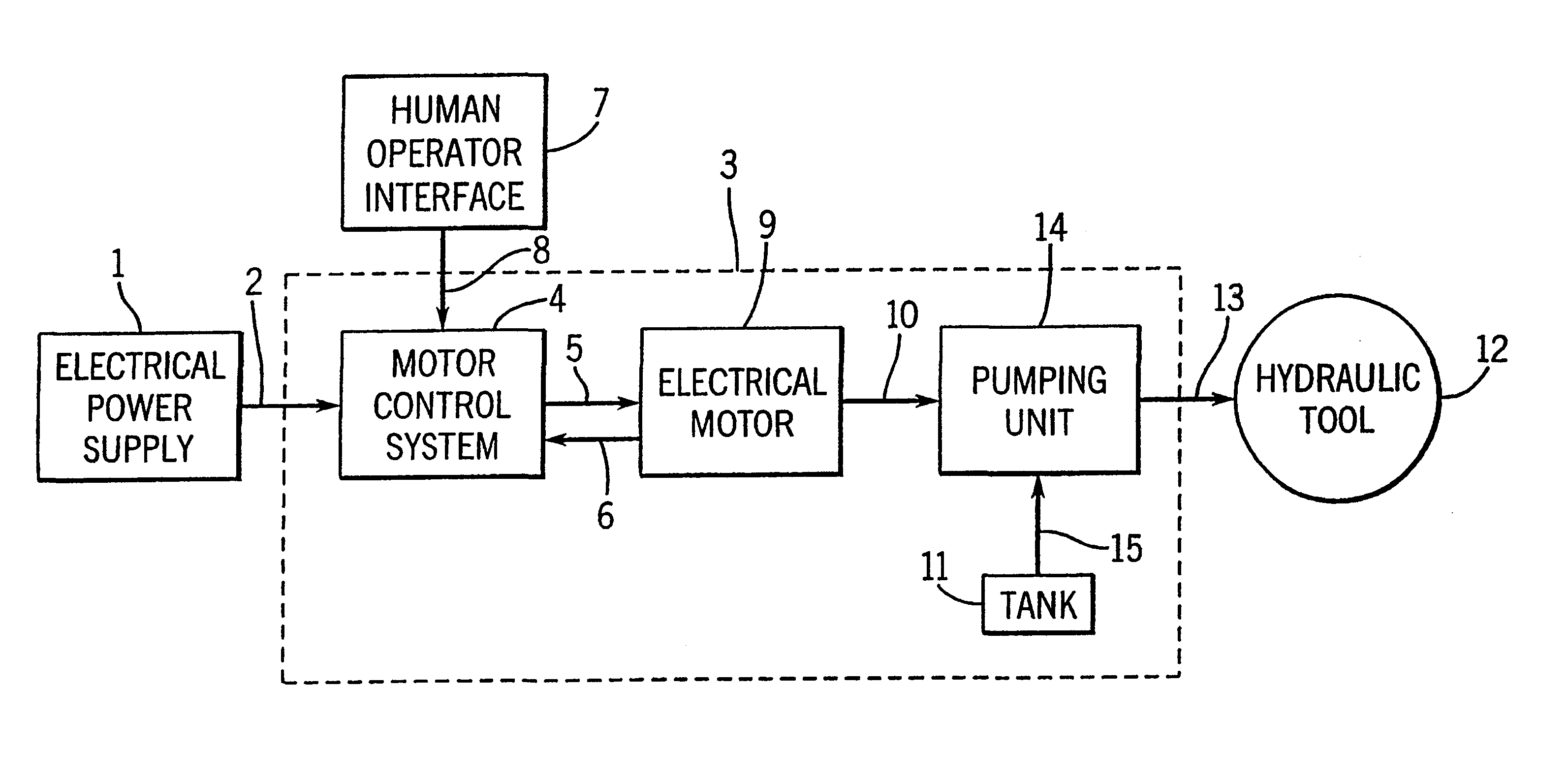

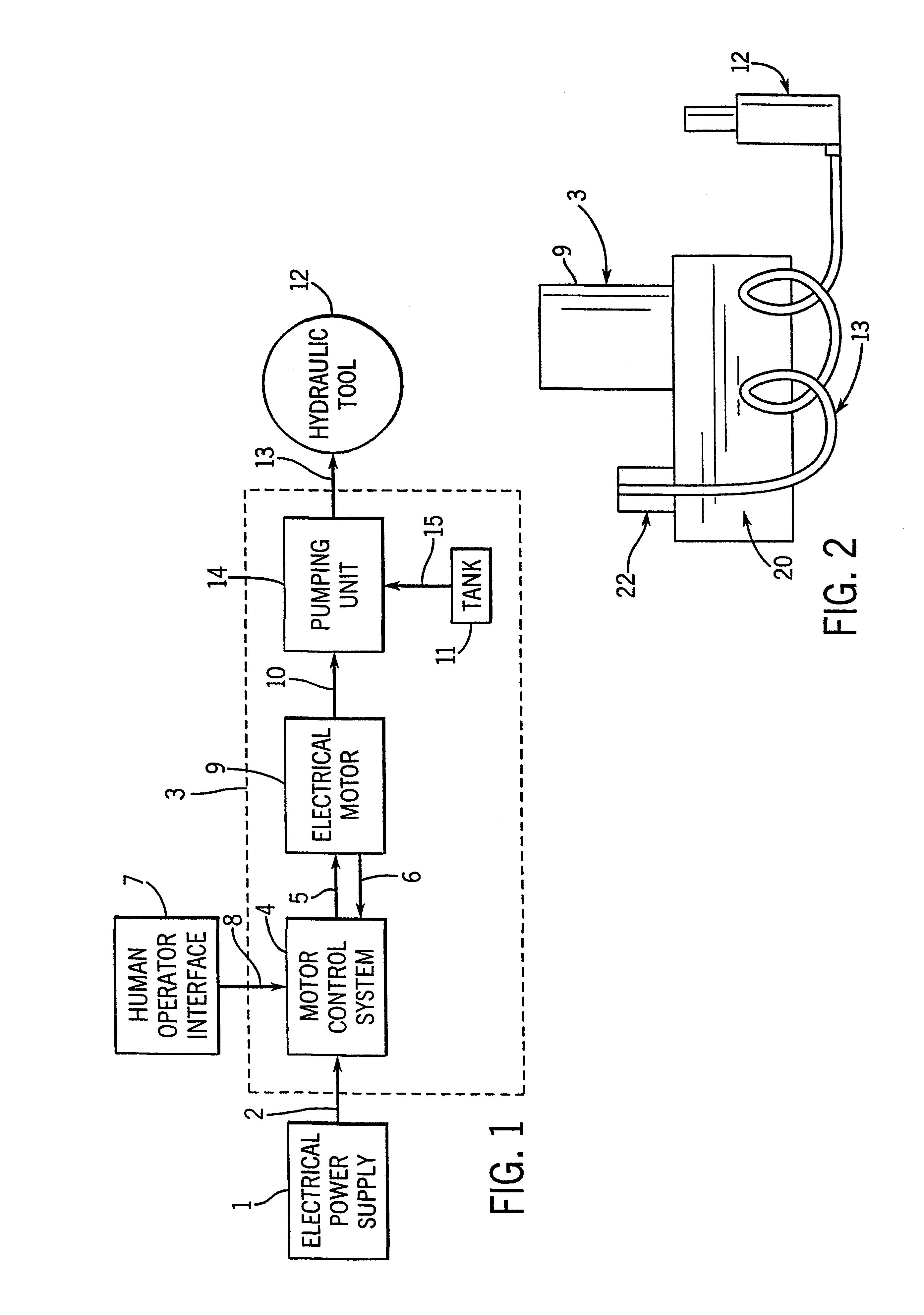

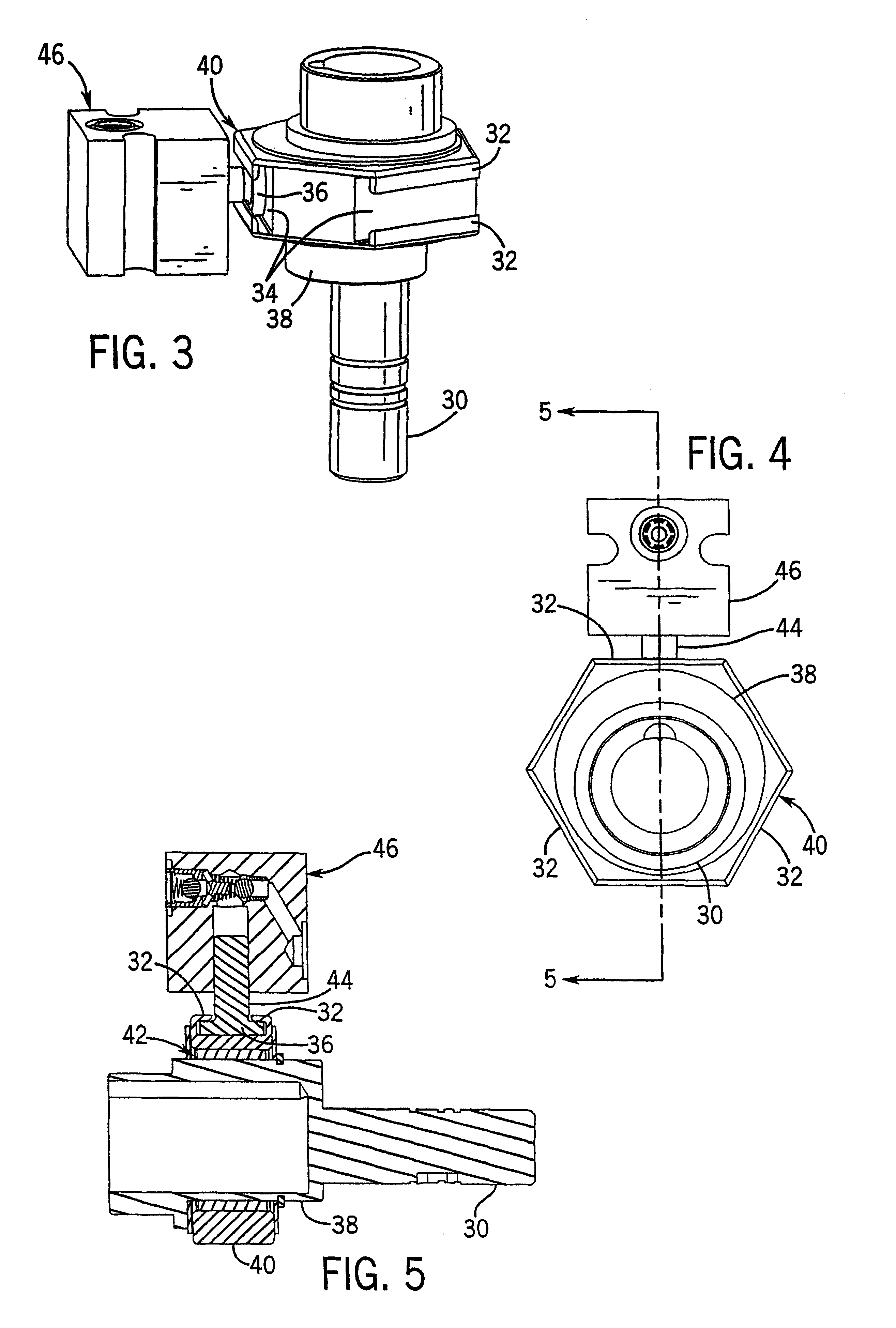

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

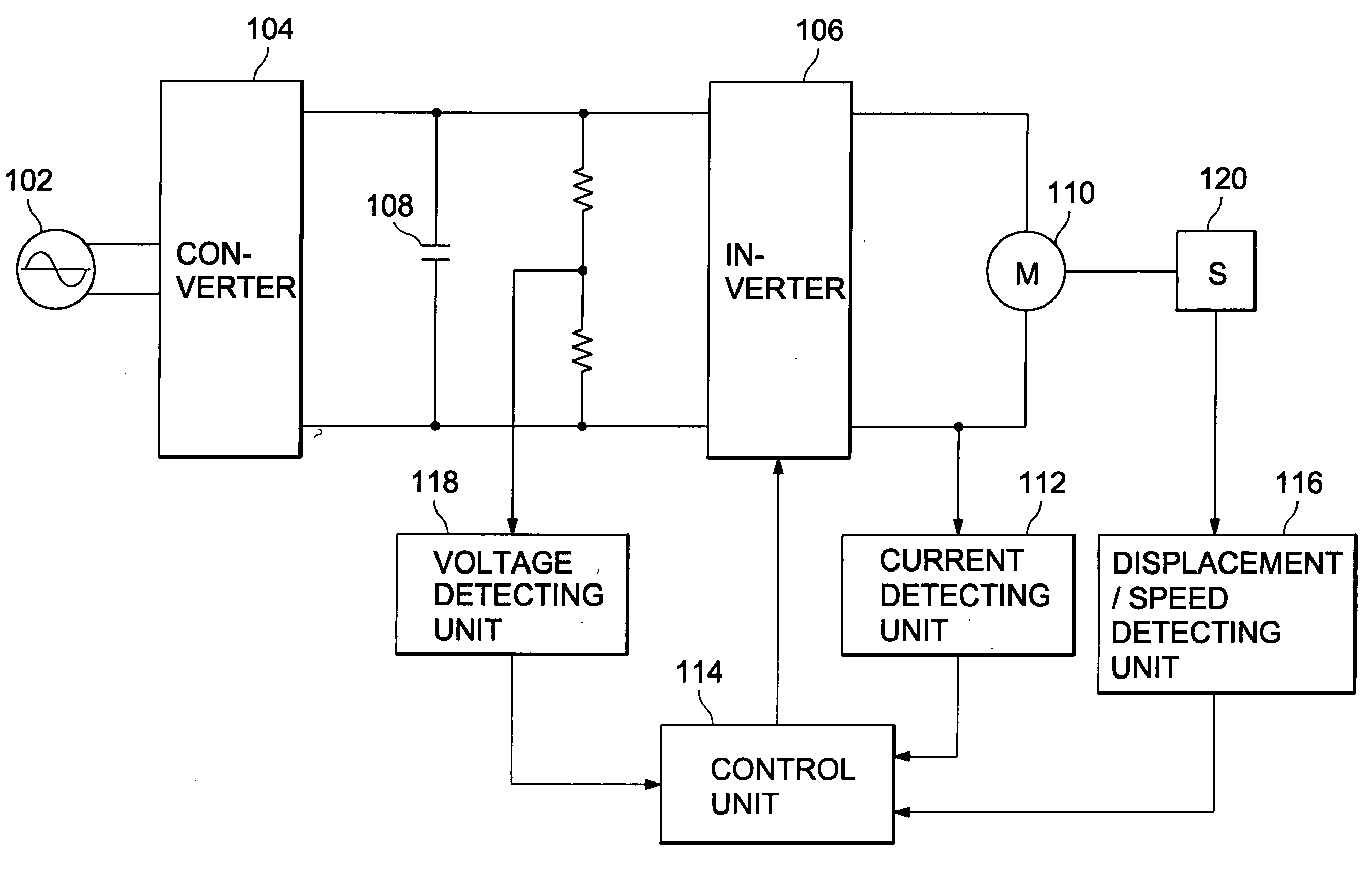

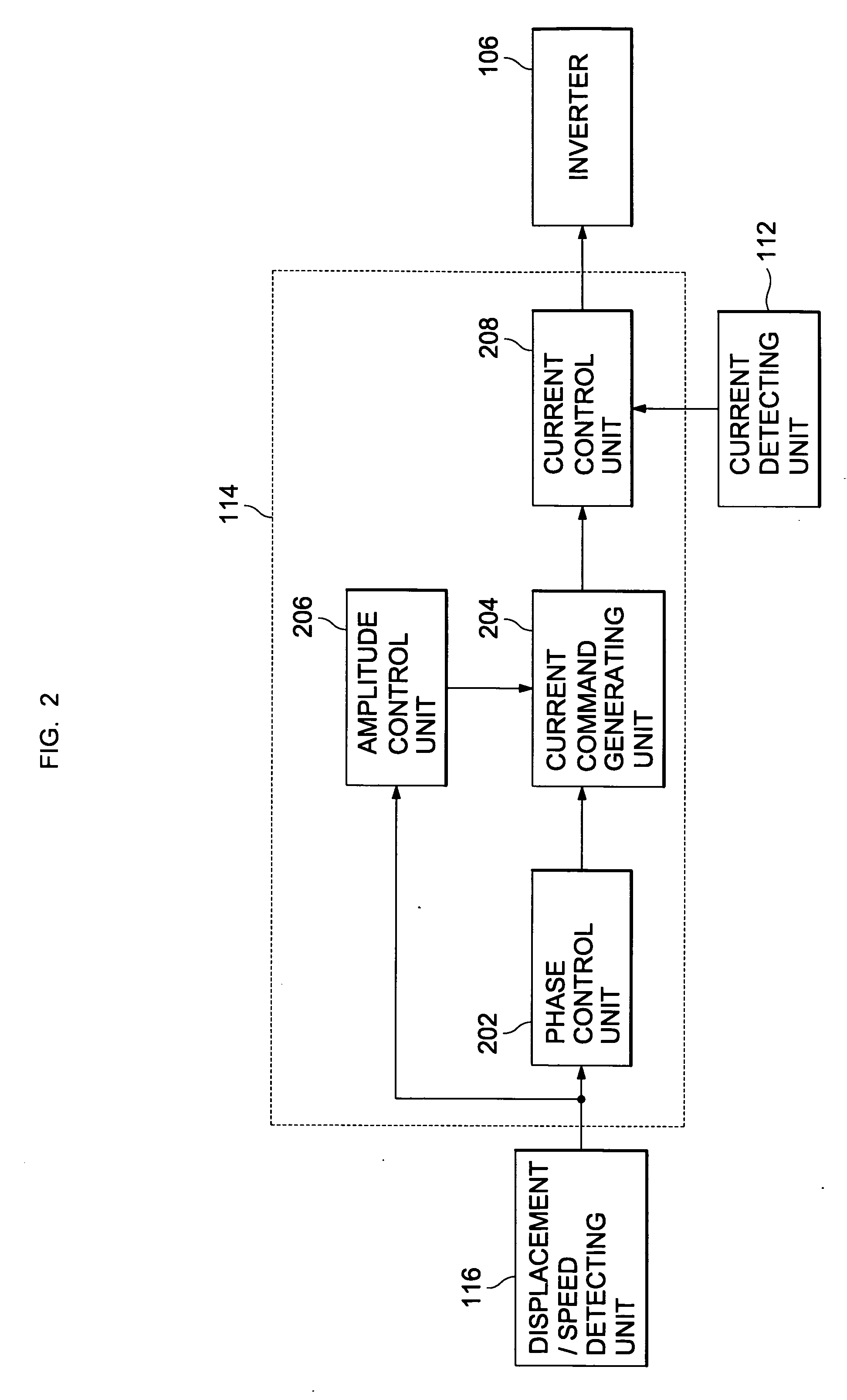

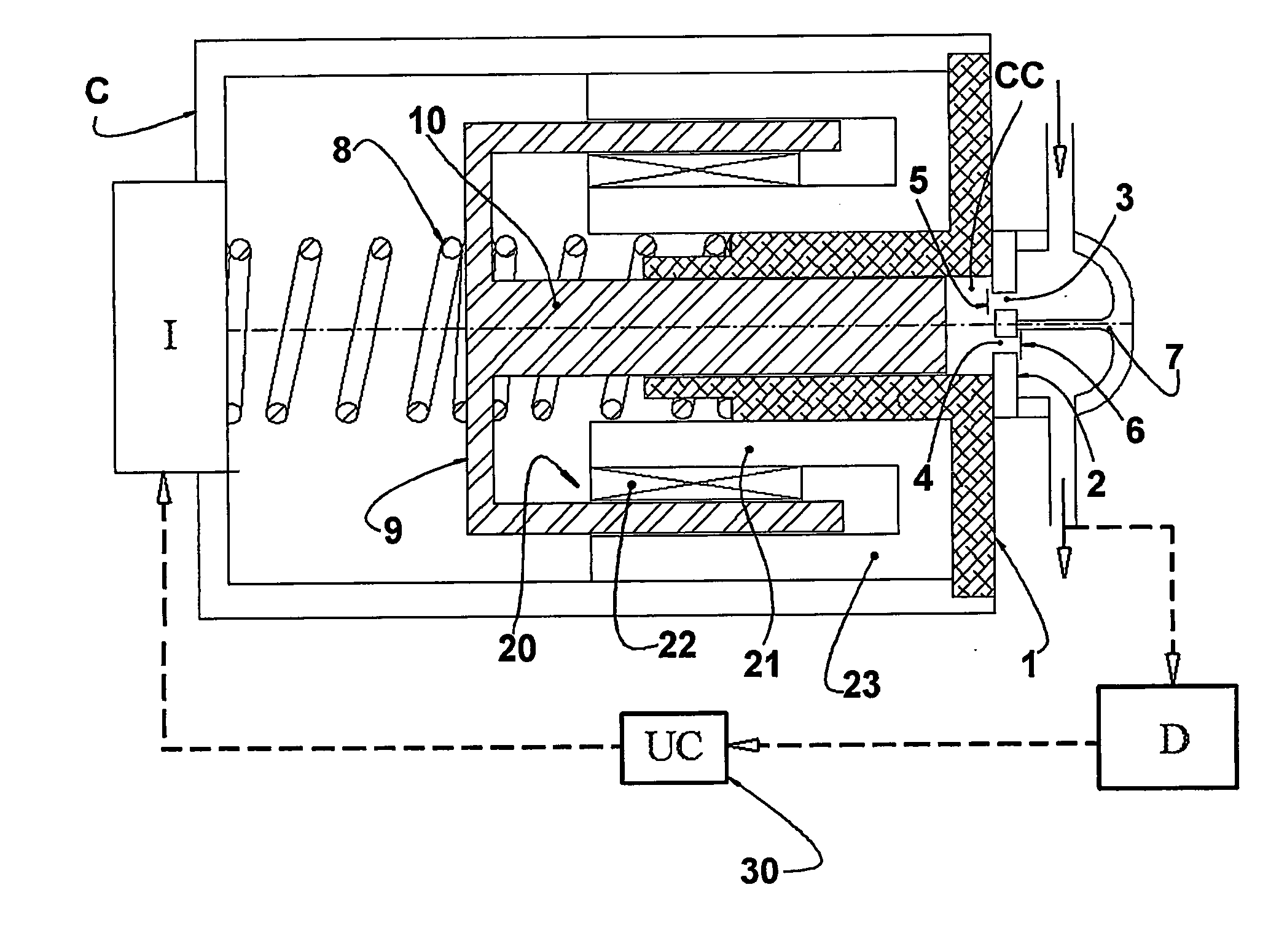

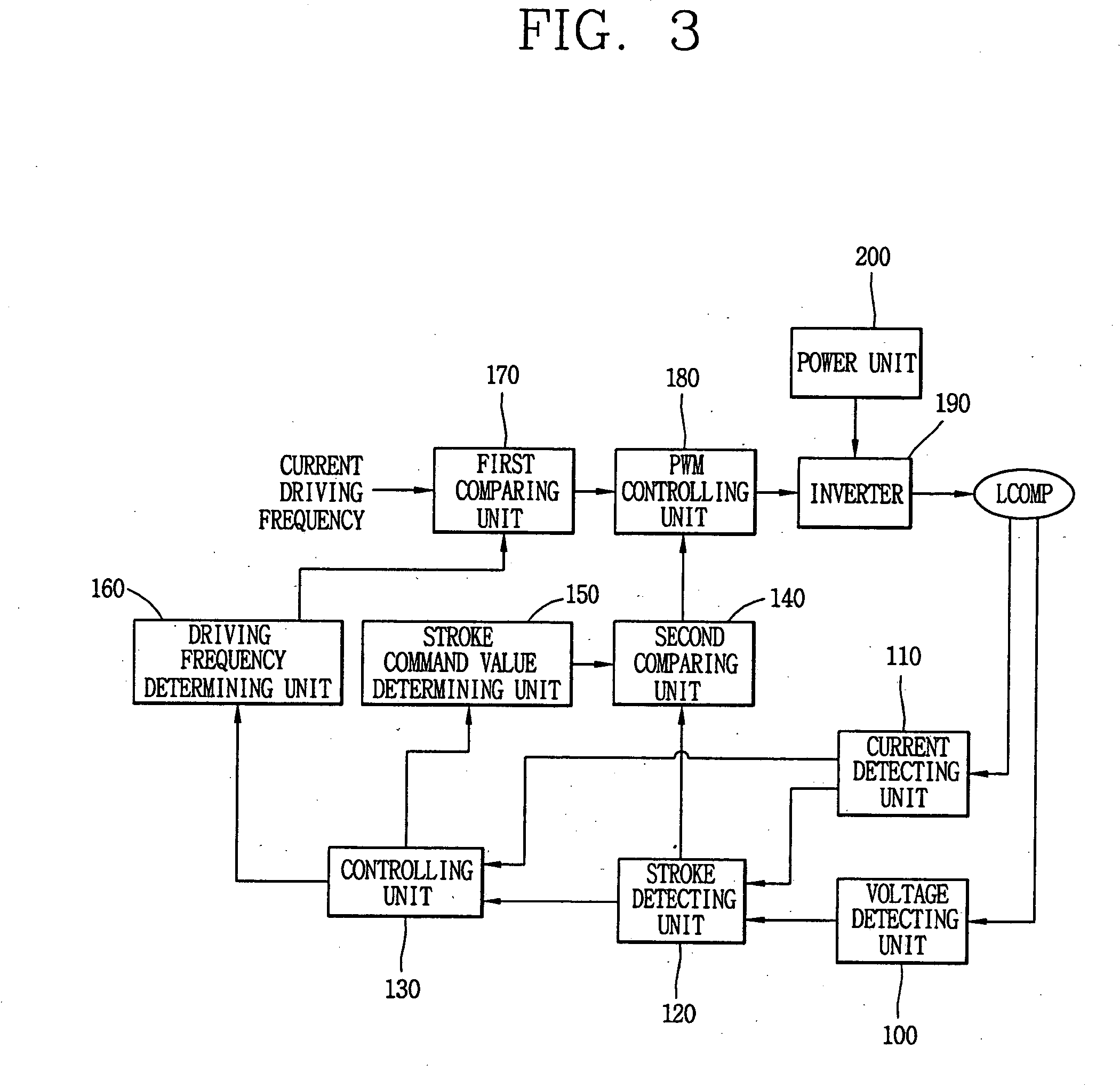

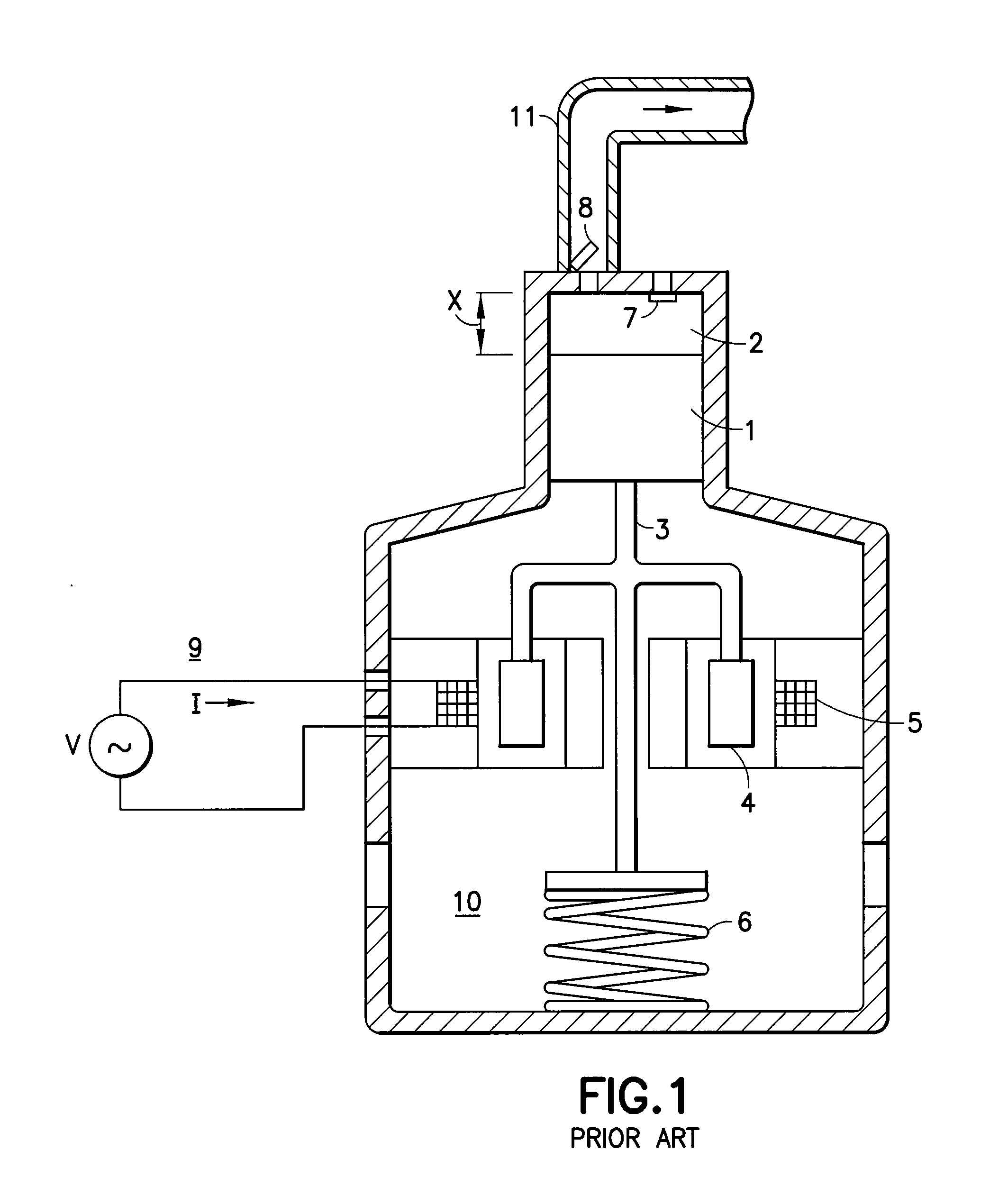

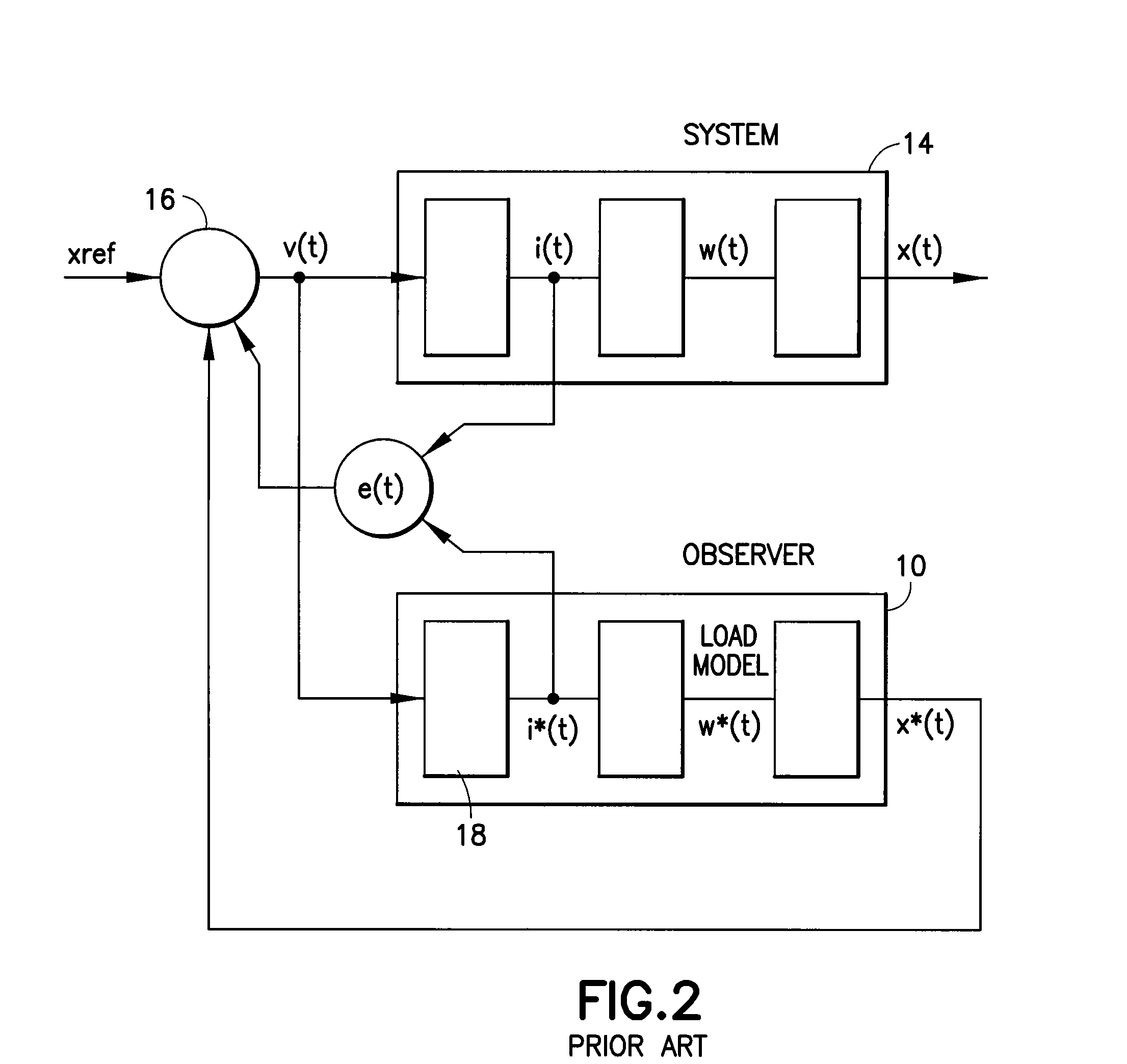

Linear compressor and apparatus to control the same

InactiveUS20050031470A1Most efficientDC motor speed/torque controlAC motor controlDriving currentResonance

A linear compressor and apparatus to control the linear compressor are provided which allows a frequency of a drive current supplied to a drive motor to synchronize with a resonance frequency varying according to a load fluctuation, in real time, thus obtaining a maximum efficiency of the linear compressor. The linear compressor includes a drive motor, a piston reciprocating by the drive motor and a control unit generating a reference current having a phase difference of 90° with respect to a displacement waveform of the piston and a frequency equal to the displacement waveform of the piston, and controls a drive current supplied to the drive motor to synchronize with a resonance frequency of the piston by synchronizing the drive current with the reference current.

Owner:SAMSUNG ELECTRONICS CO LTD

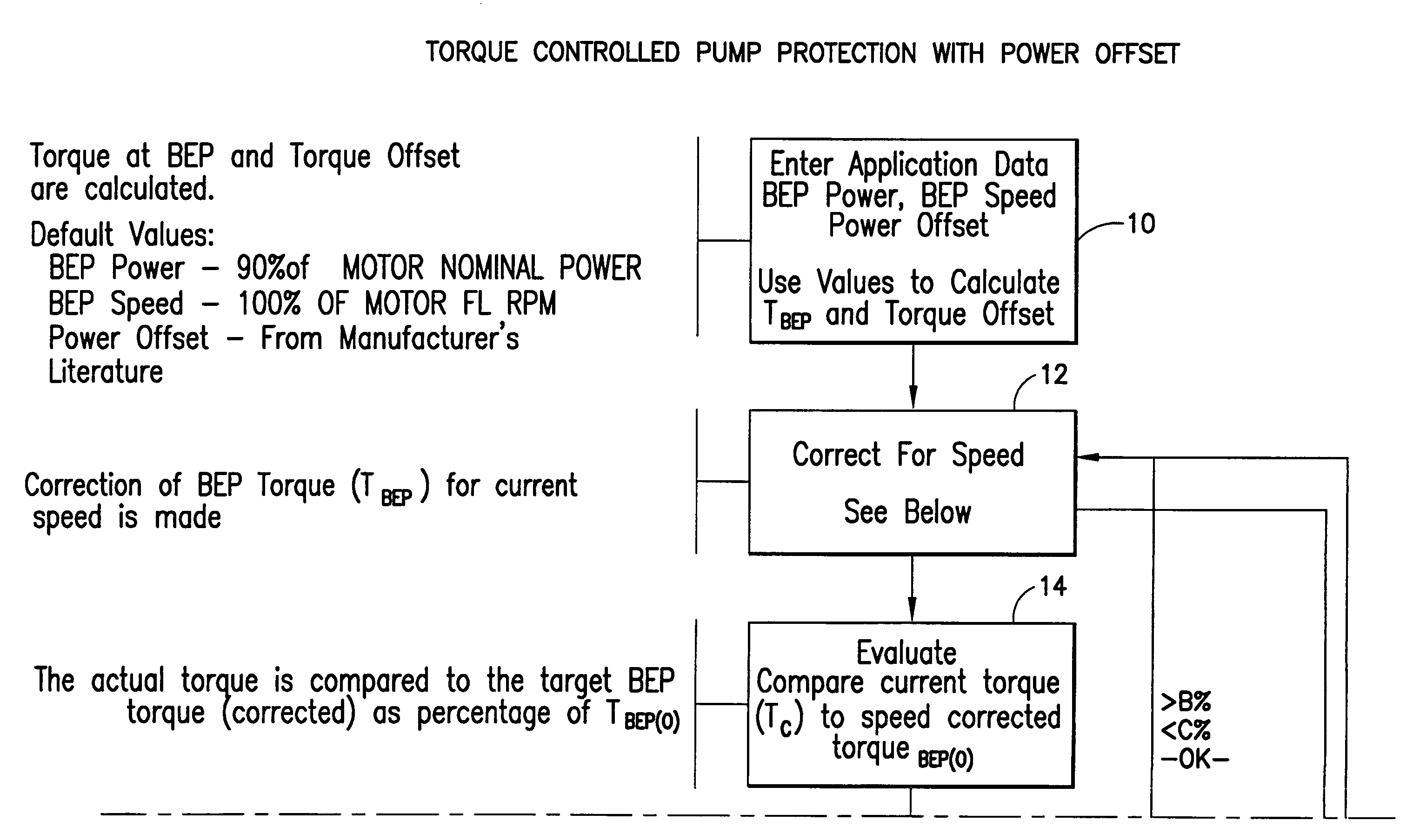

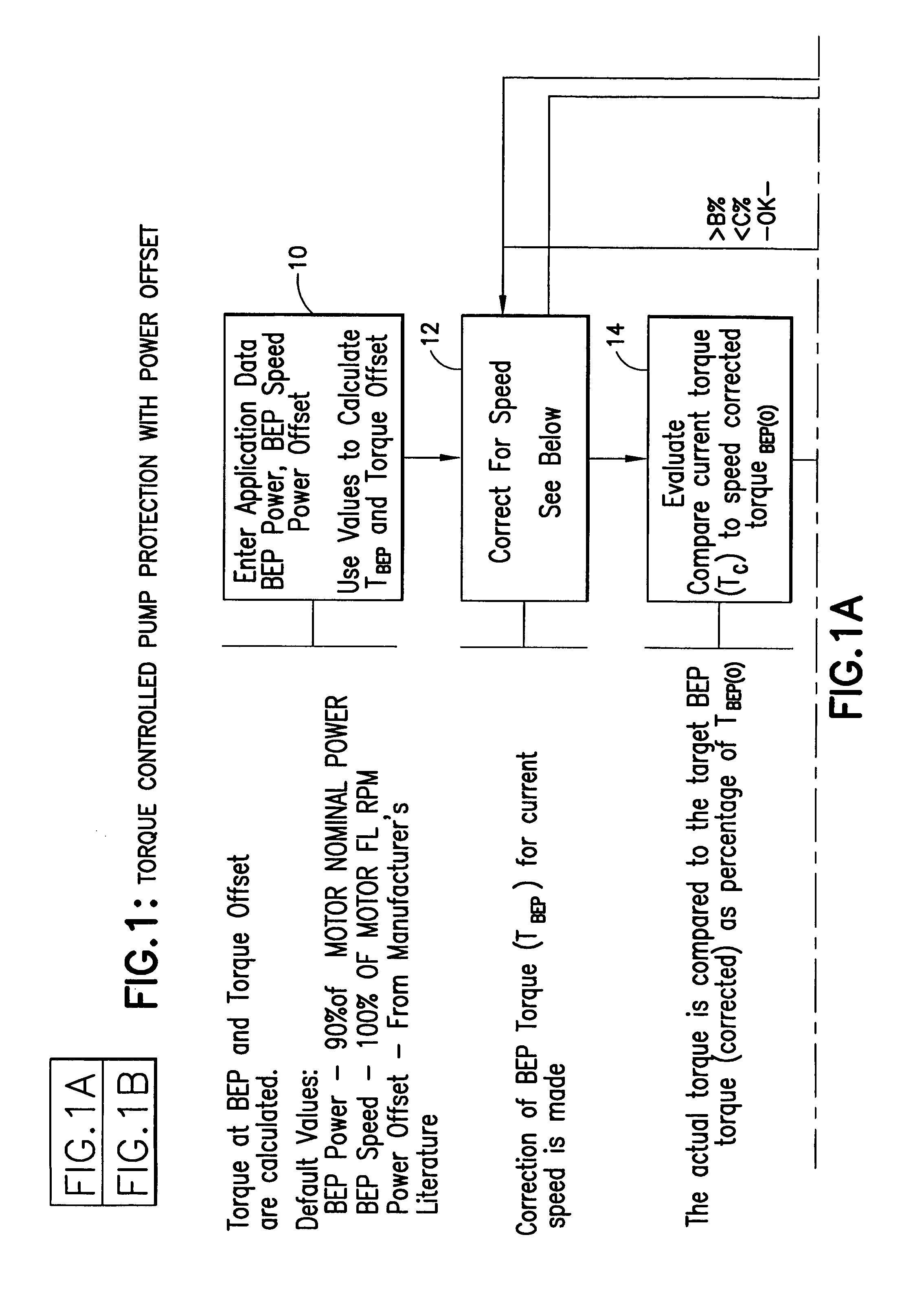

Torque controlled pump protection with mechanical loss compensation

ActiveUS7080508B2Eliminate needExtended speed rangeFluid couplingsFlexible member pumpsEngineeringControl theory

A method and apparatus are provided for controlling the operation of a pump, such as a centrifugal pump, featuring steps of either adjusting the operation of the pump, or issues a warning to a user of the pump of an undesirable operating condition, or both, based on a comparison of an actual torque value and a corrected torque value either alone or in combination with a further step of compensating the corrected torque value based on a mechanical power offset correction. The corrected torque value may include a Best Efficiency Point (BEP) torque value and may also be compensated for based on at least the current operating speed of the pump. The pump has a controller for performing the steps of the method. The controller can compensate the corrected torque value based on the square of the speed change of the pump. The comparison may include a ratio of the actual torque value to the corrected torque value.

Owner:ITT MFG ENTERPRISES LLC

Thermal Monitoring System and Method

InactiveUS20210306720A1Thermometer detailsThermometers using electric/magnetic elementsThermal monitoringProcess engineering

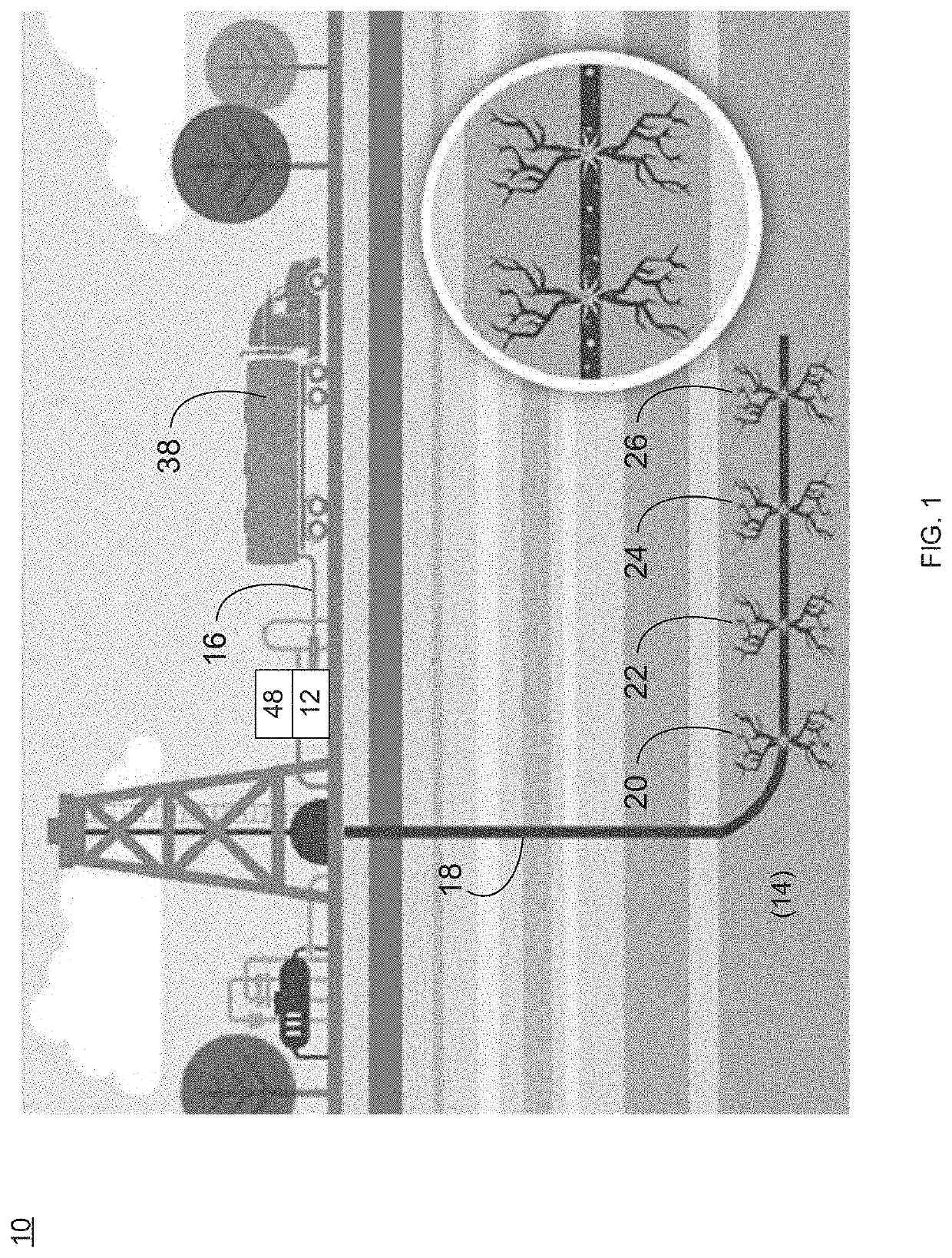

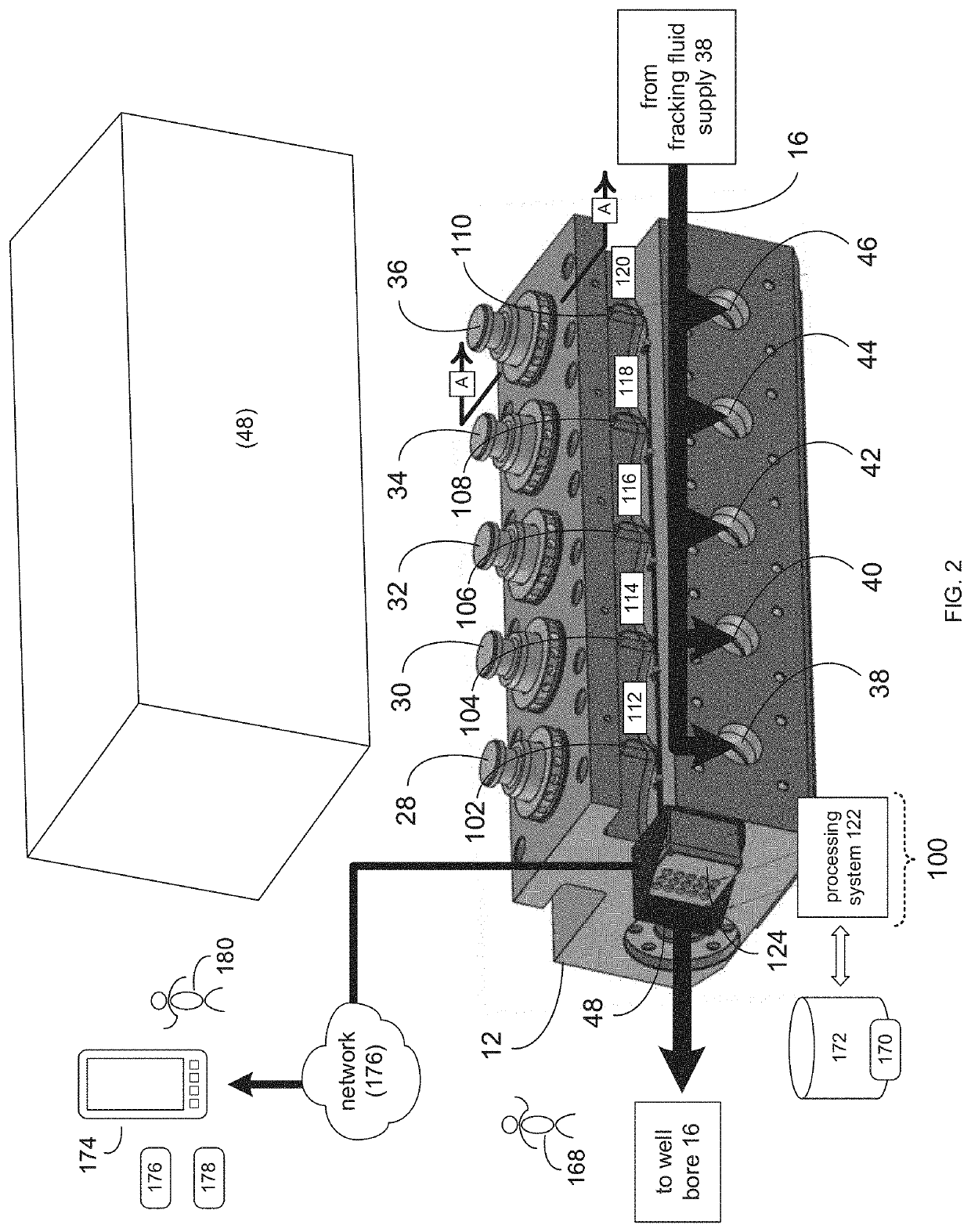

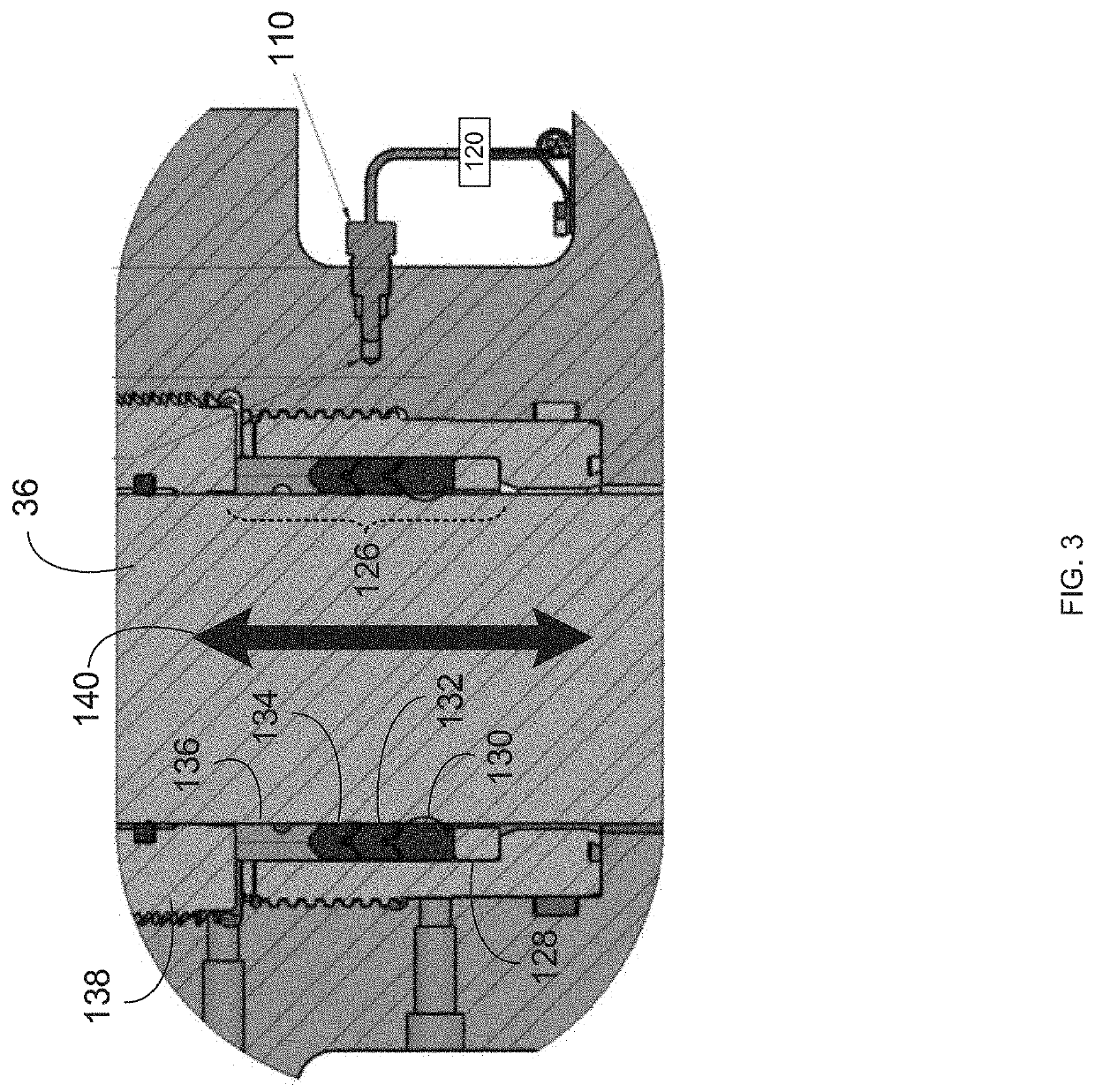

A thermal monitoring system includes: one or more thermal sensors configured to monitor the temperature of one or more portions of a fracking pump and generate one or more thermal indication signals; a processing system configured to receive the one or more thermal indication signals and associate the one or more thermal indication signals with one or more operating temperatures of the one or more portions of the fracking pump; and an indication system configured to provide a thermal condition indicator based, at least in part, upon the one or more operating temperatures of the one or more portions of the fracking pump.

Owner:SALT & LIGHT ENERGY EQUIP LLC

System for adjusting resonance frequencies in a linear compressor

InactiveUS20060110259A1Low costIncreased energy lossFluid parameterPositive displacement pump componentsReciprocating motionLinear compressor

A system for adjusting resonant frequencies in a linear compressor comprising, in the interior of a shell: a linear motor: a cylinder; a piston reciprocating inside the cylinder; and an actuating means operatively coupling the piston to the linear motor, said system comprising: a detecting means to detect a load imposed to the linear motor, in an operational condition of the latter related to the gas pressure in the discharge thereof; and a frequency adjusting means operatively associated with the detecting means and with the resonant assembly, in order to define, as a function of said operational condition, a frequency adjustment, by varying at least one of the values related to the mass of the resonant assembly and to the average stroke of the piston, to a value of the mechanical resonance frequency corresponding to the electrical supply frequency.

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

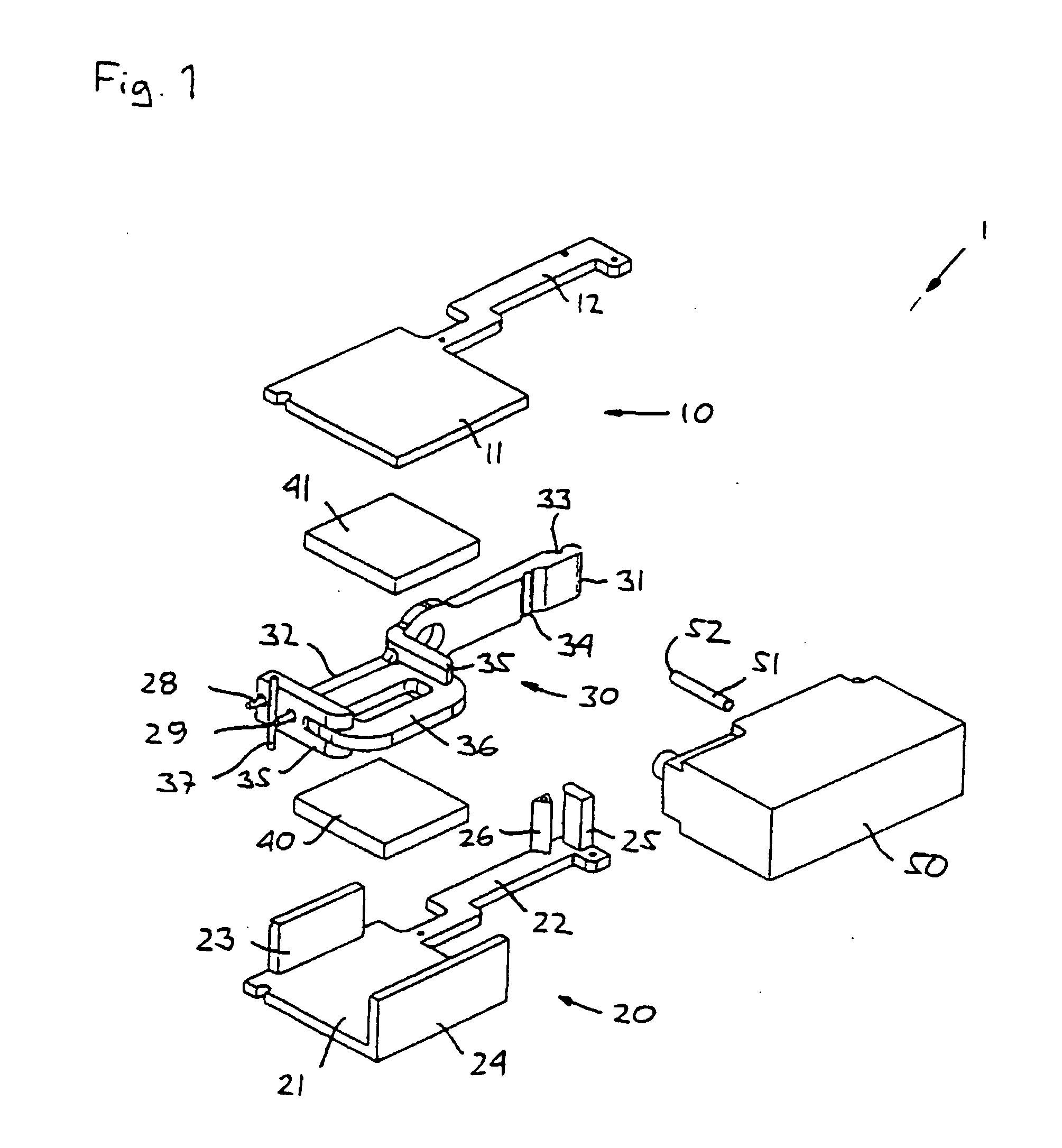

Metering system & methods

InactiveUS6840404B1Easy inflowEasy outflowMixer accessoriesLiquid transferring devicesControl flowEngineering

A metering system for controlling the flow of a fluid is disclosed. The metering system comprises a metering device, two input valves that actively control flow of fluid into the metering device, and two output valves that actively control flow of fluid from the metering device. The input and output valves are selectively opened and closed to cause metered amounts of fluid to be dispensed from the metering device through the output valves.

Owner:NORDSON CORP

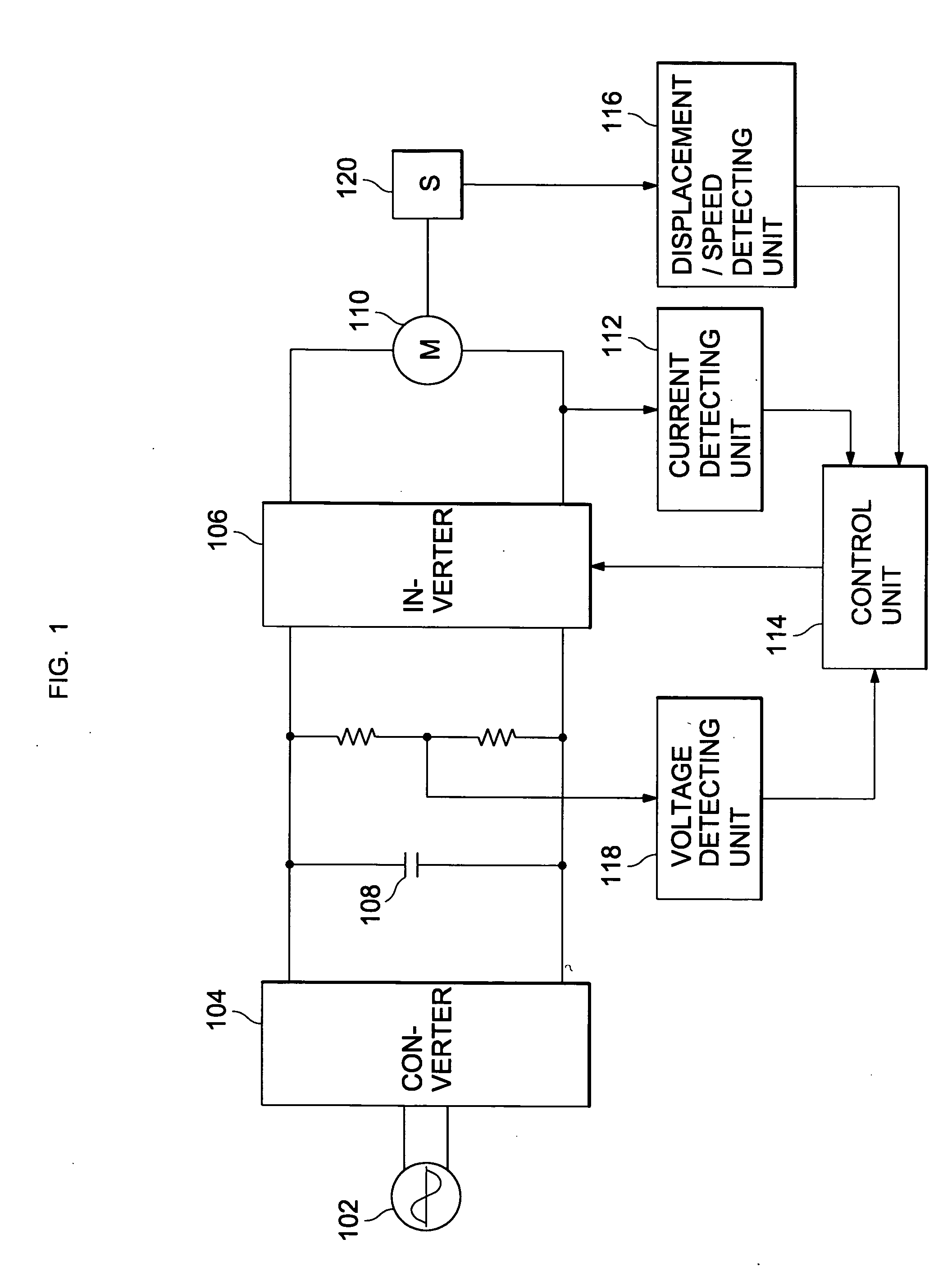

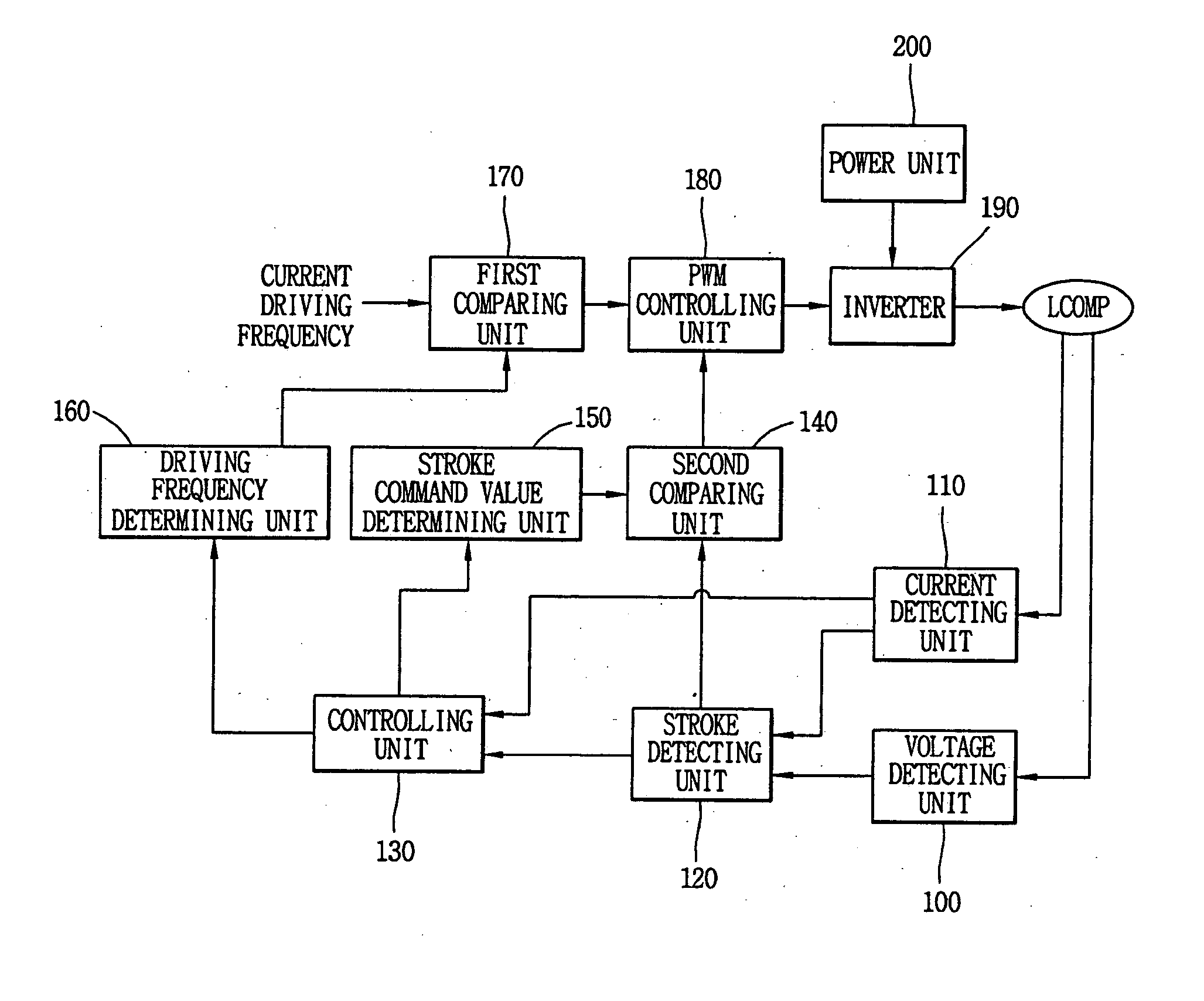

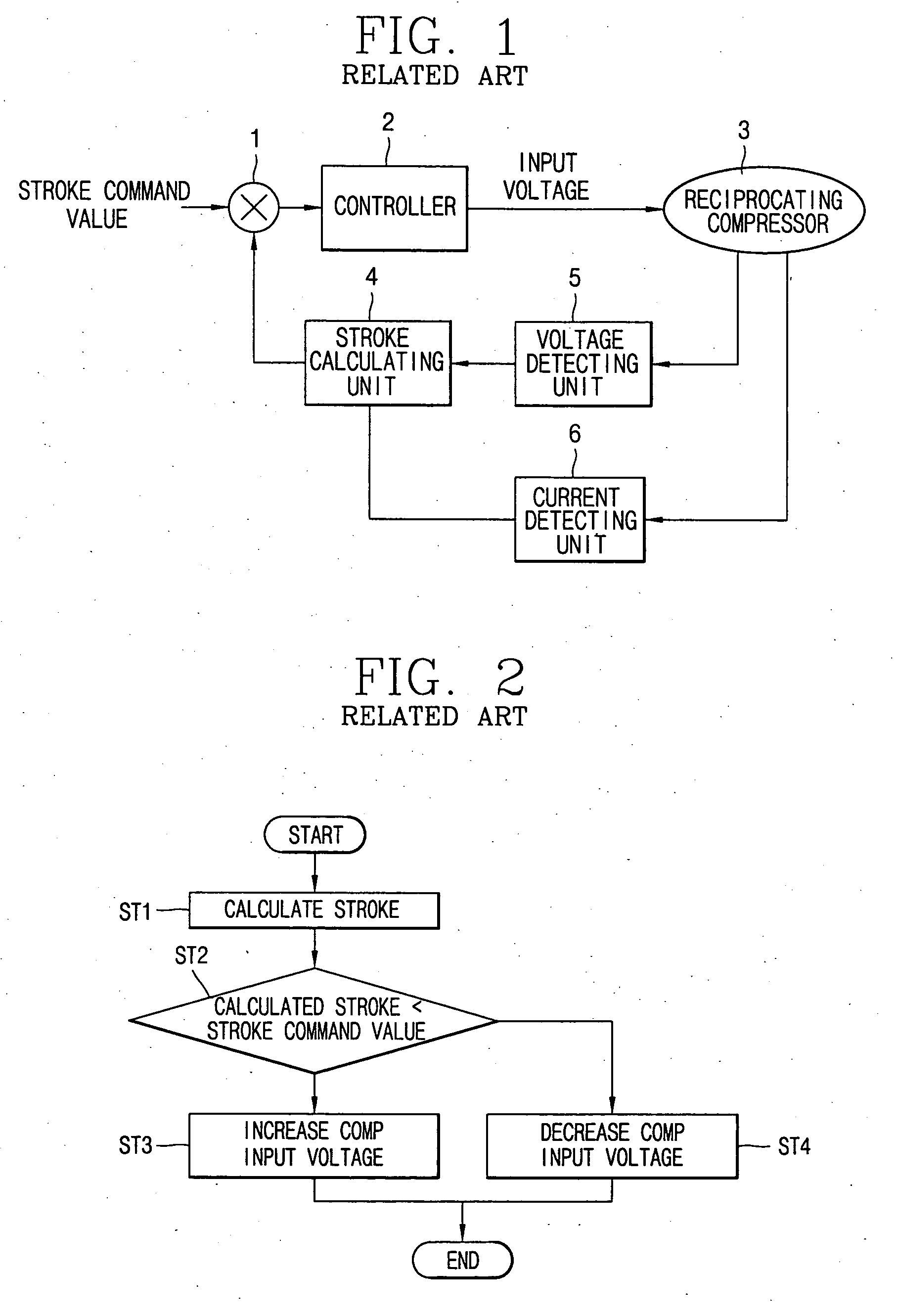

Apparatus for controlling driving of reciprocating compressor and method thereof

ActiveUS20060228224A1Improve efficiencyLow efficiencyMotor/generator/converter stoppersDC motor speed/torque controlControl signalPhase difference

Disclosed are an apparatus for controlling a driving of a reciprocating compressor capable of enhancing an efficiency by differently controlling a frequency and a stroke voltage according to a load size and capable of reducing consumption power, and a method thereof. The apparatus comprises a controlling unit for judging a load size by comparing a phase difference between a detected current and a stroke with a reference phase difference, and outputting a frequency control signal and a stroke control signal according to the judged load size.

Owner:LG ELECTRONICS INC

System and method for correcting for pressure variations using a motor

Owner:ENTEGRIS INC

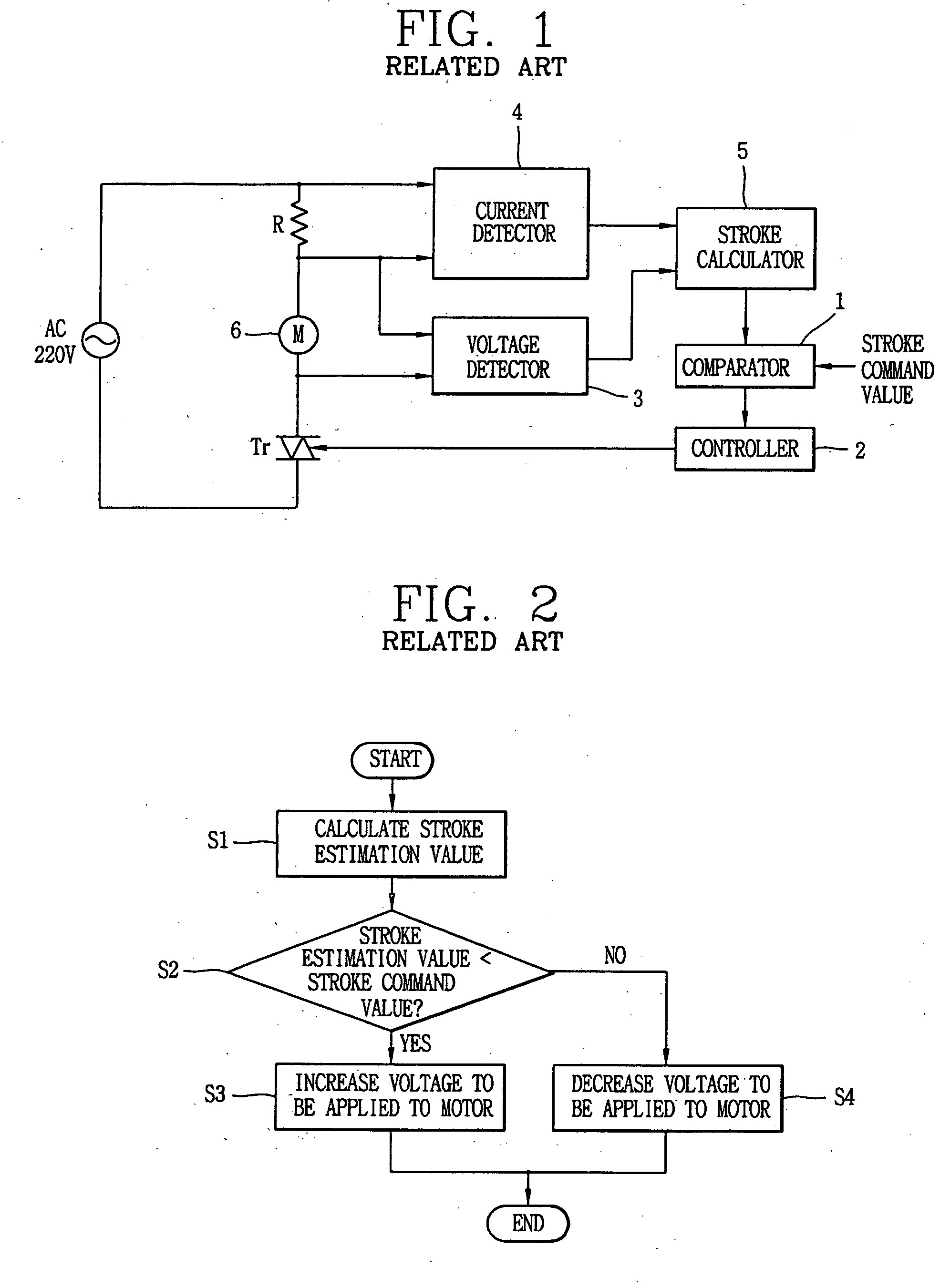

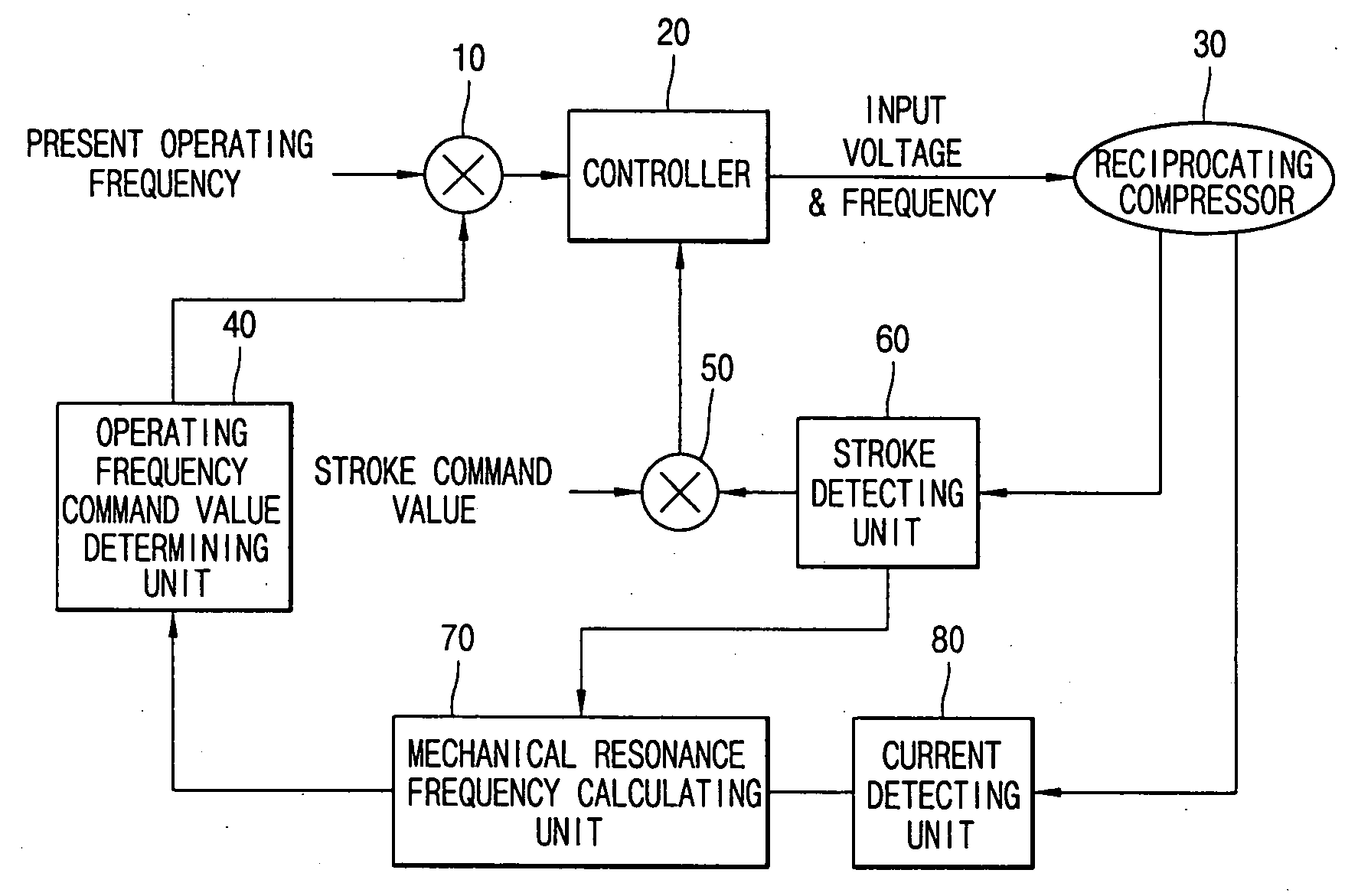

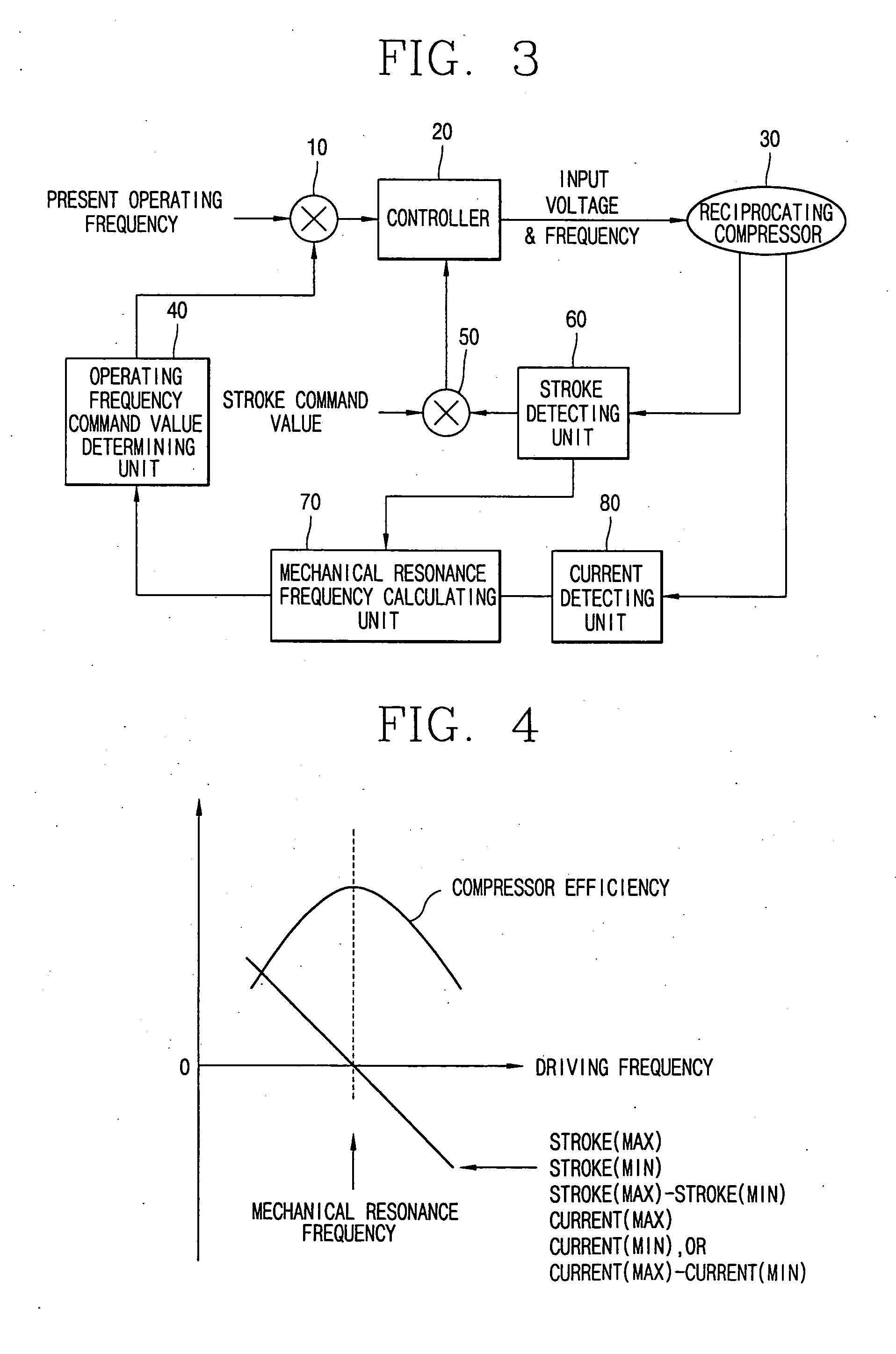

Apparatus and method for controlling operation of reciprocating compressor

ActiveUS20050111987A1Easy to operateAC motor controlDC motor speed/torque controlEngineeringMechanical resonance

The present invention relates to an apparatus and method for controlling operation of a reciprocating compressor. The operating efficiency of the compressor can be improved by performing the steps of: detecting a current and a stroke applied a compressor; a calculating a mechanical resonance frequency by using the detected current and stroke; and determining an operating frequency command value by adding or subtracting the present operating frequency so as to be within a predetermined range of the calculated mechanical resonance frequency and then driving the compressor by the operating frequency command value.

Owner:LG ELECTRONICS INC

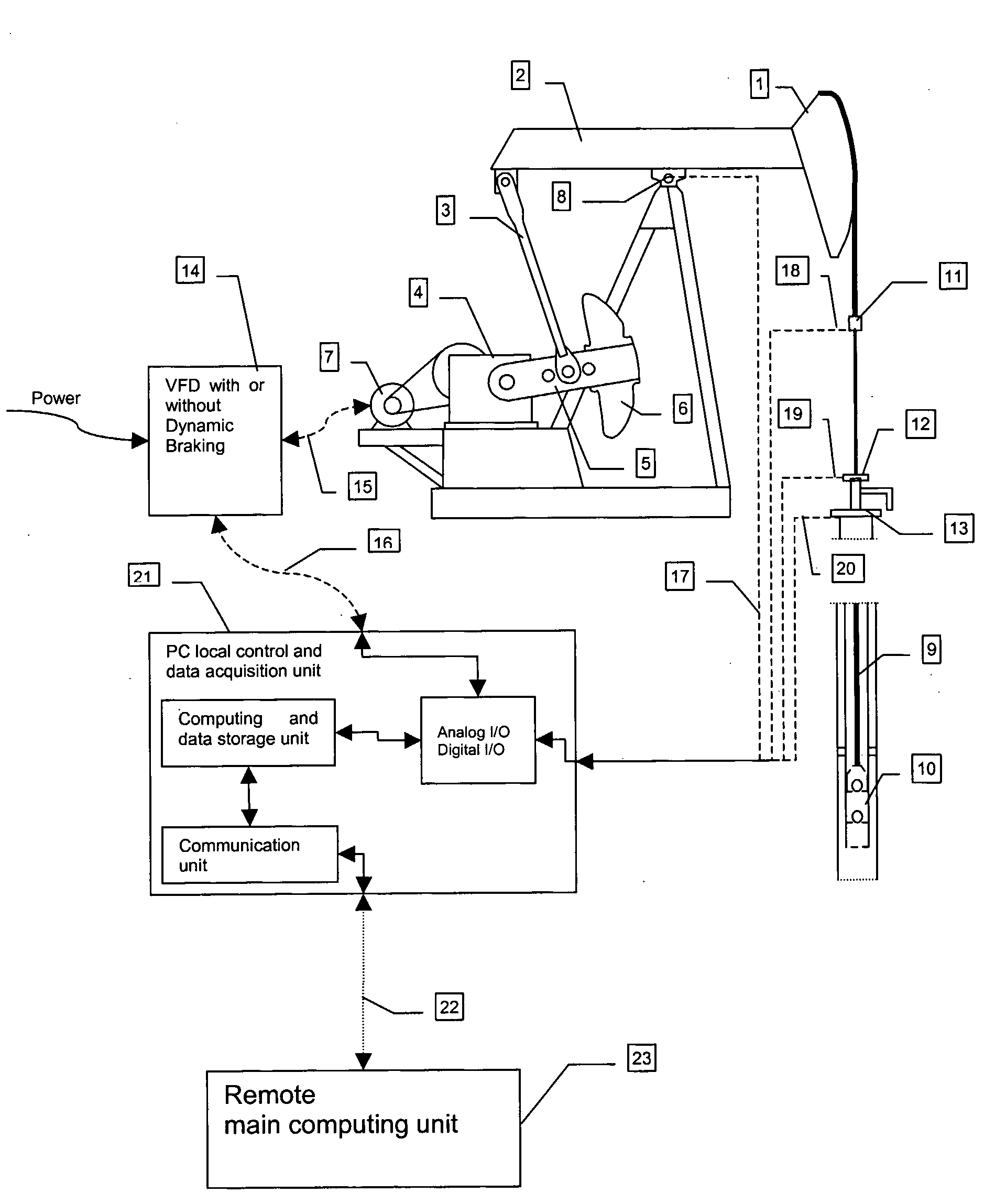

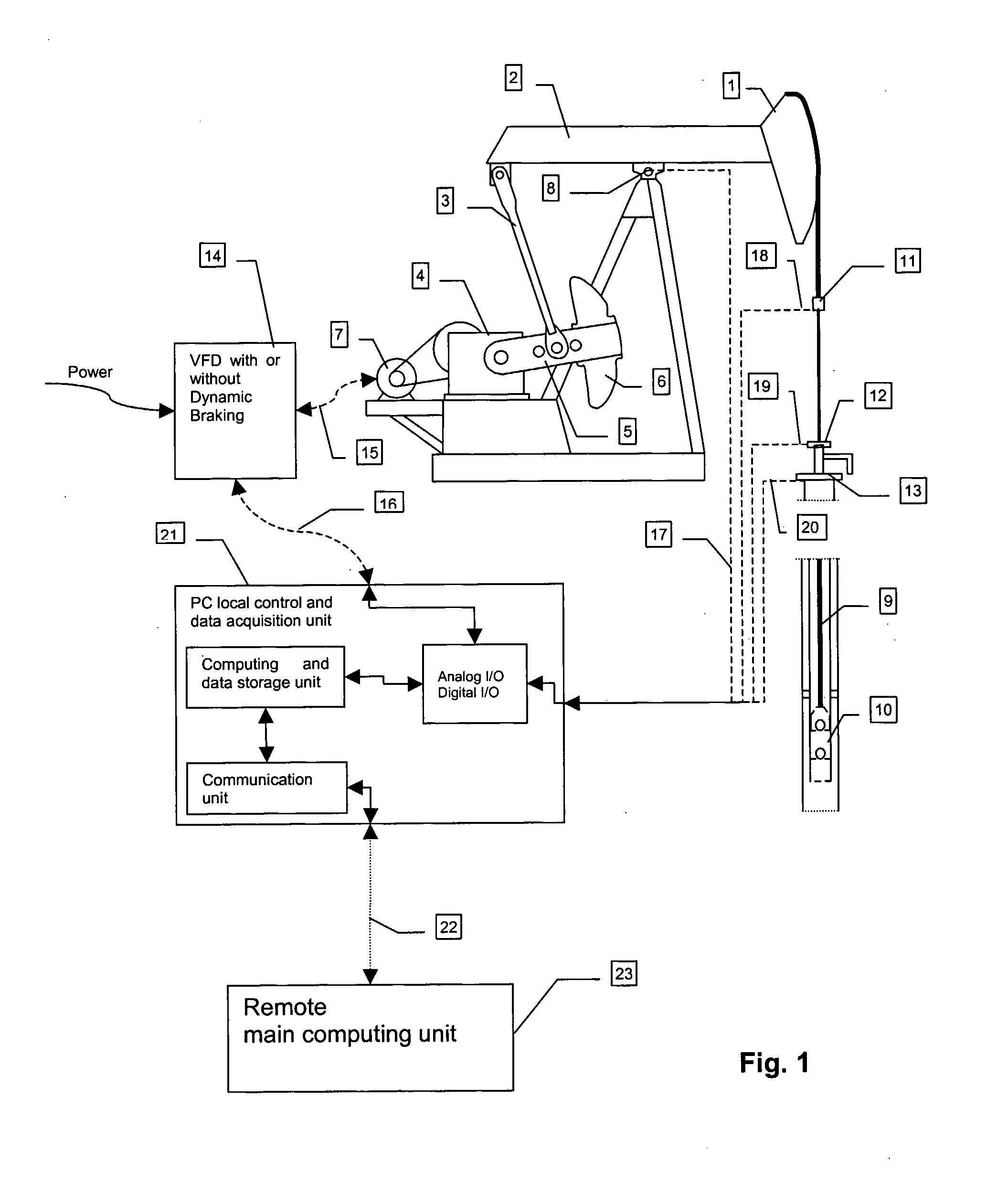

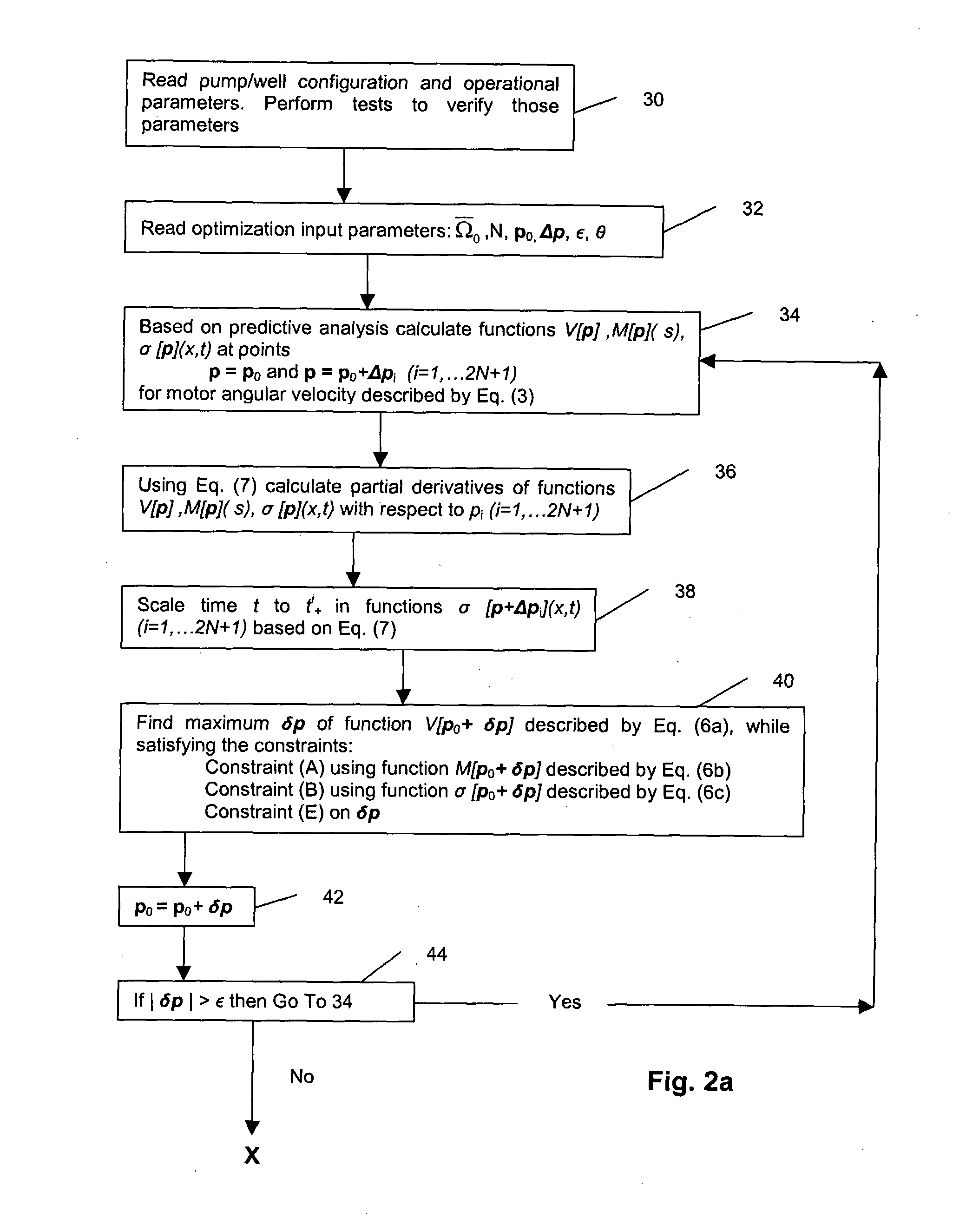

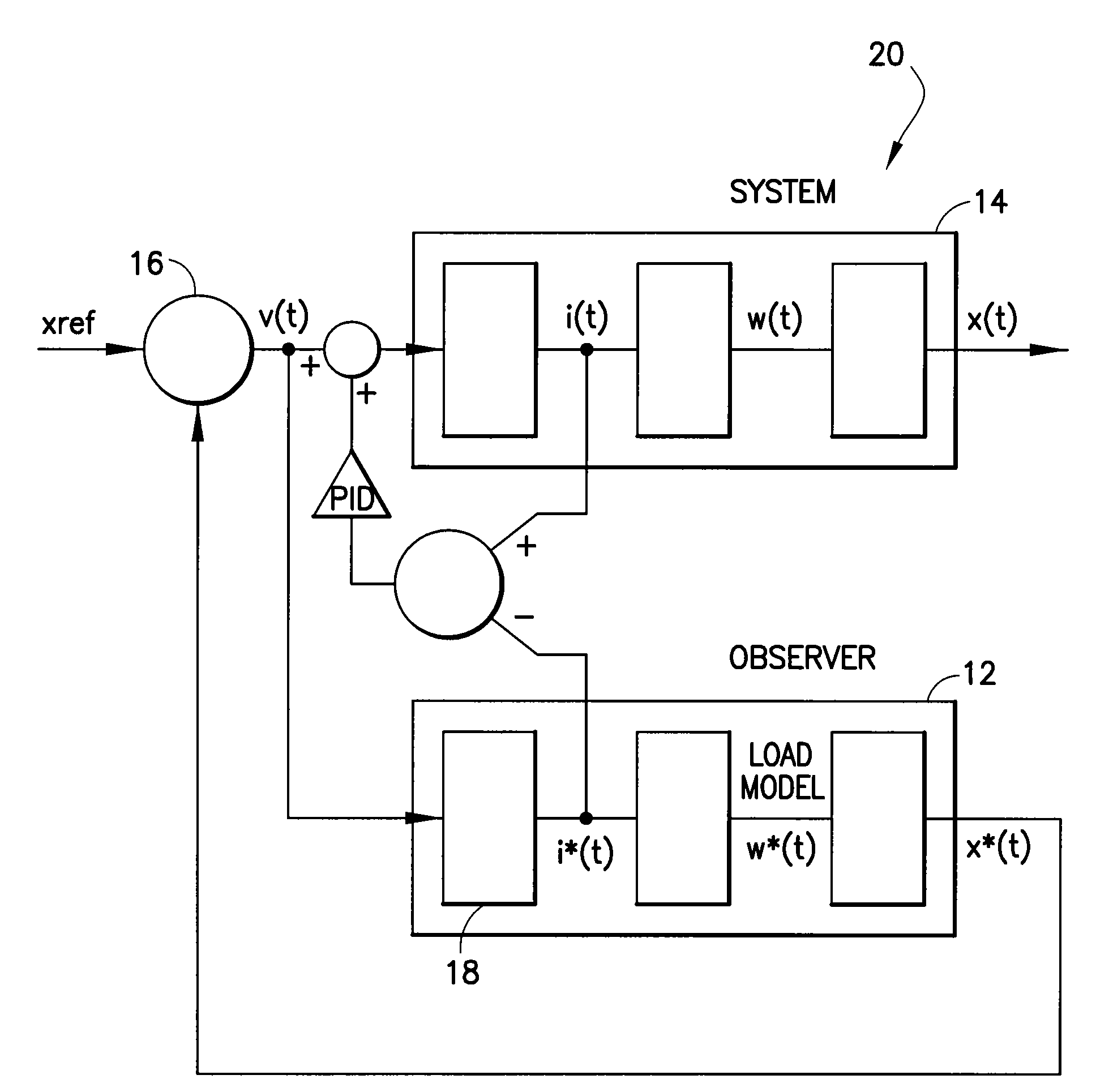

Method and System for Optimizing Downhole Fluid Production

InactiveUS20080240930A1Maximize oil productionReduce operating costsFluid parameterSurveyEngineeringUltimate tensile strength

A method and system for pumping unit with an elastic rod system is applied to maximize fluid production. The maximum stroke of the pump and the shortest cycle time are calculated based on all static and dynamic properties of downhole and surface components without a limitation to angular speed of the prime mover. Limitations of structural and fatigue strength are incorporated into the optimization calculation to ensure safe operation while maximizing pumped volume and minimizing energy consumption. Calculated optimal prime mover speed is applied to the sucker rod pump by means of beam pumping, long stroke or hydraulic pumping unit by controlling velocity, acceleration and torque of the electric prime mover or by controlling pressure and flow rate in hydraulically actuated sucker rod pumping system.

Owner:PUMPWELL SOLUTIONS

Sensor-less control method for linear compressors

ActiveUS20070196214A1Optimal control methodAllow optimizationDC motor speed/torque controlElectric motor speed/torque regulationTemperature controlPower flow

A method of protecting a cylinder of a compressor comprising a piston, a linear permanent magnet (PM) having a coil and a magnet, and a sensor-less control of the PM for moving the piston in and out of the cylinder. The method including the steps of receiving a reference position of the piston from a temperature control loop; deriving a compensation voltage and a load spring effect information from a current through the coil; providing a model input voltage to a model of a mechanical structure of the compressor for predicting position of the piston, the model input voltage comprising a first voltage derived from the reference position; a compressor input voltage comprising the first voltage and the compensation voltage; and using a position control loop to recognize when the maximum compression ratio is desired and controlling the piston to achieve maximum compression ratio without causing damage to the discharge valve.

Owner:INFINEON TECH AMERICAS CORP

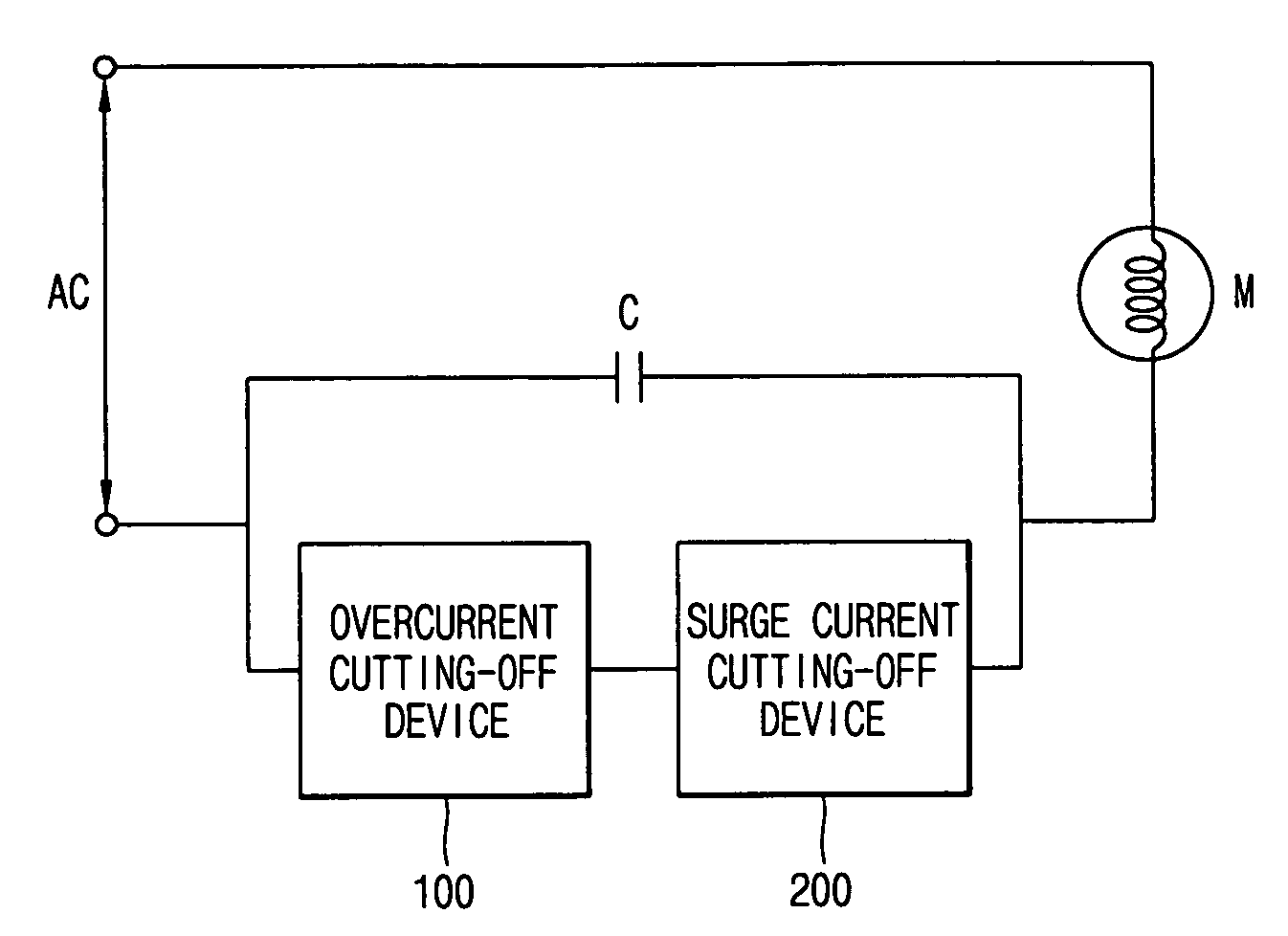

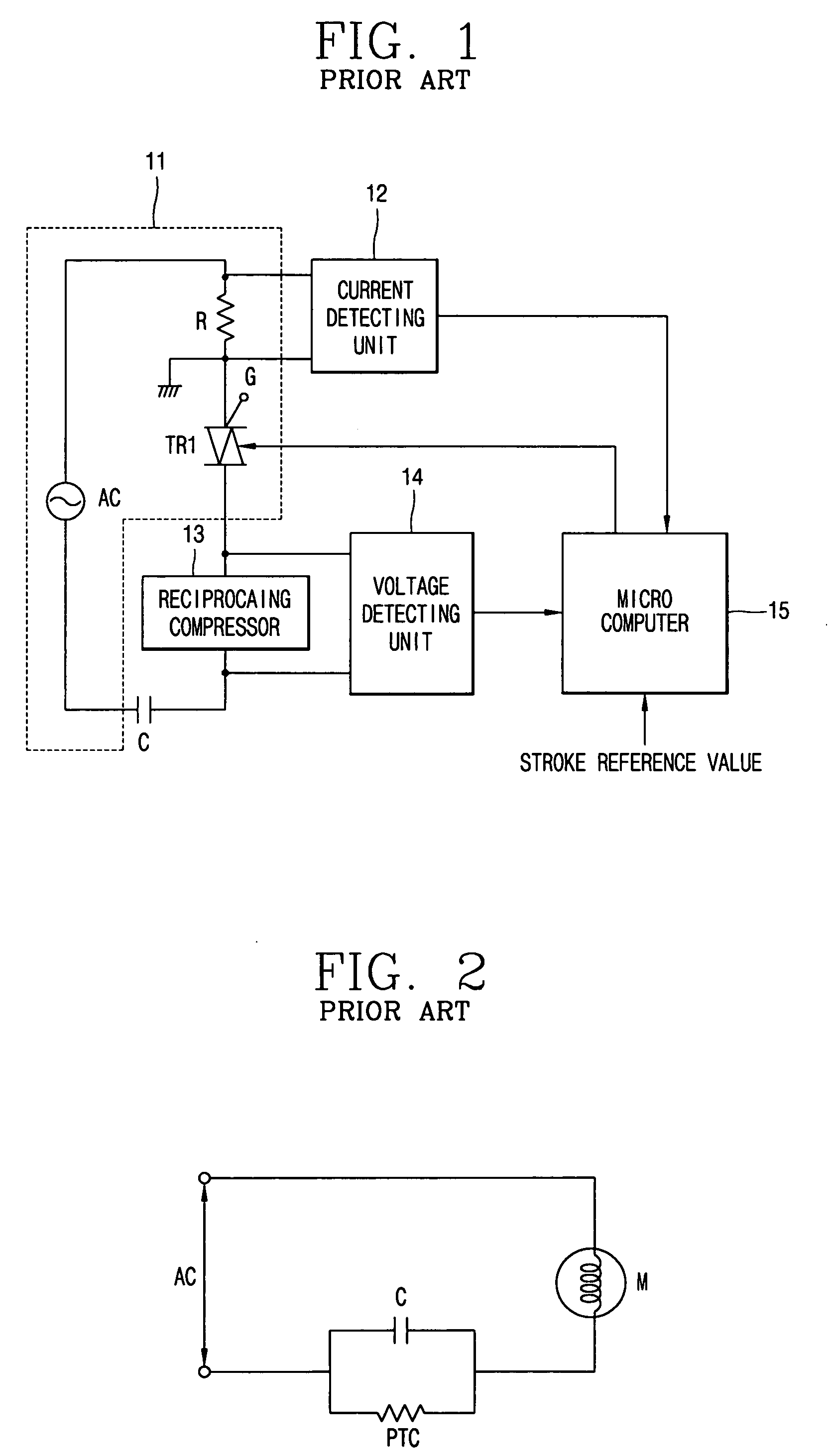

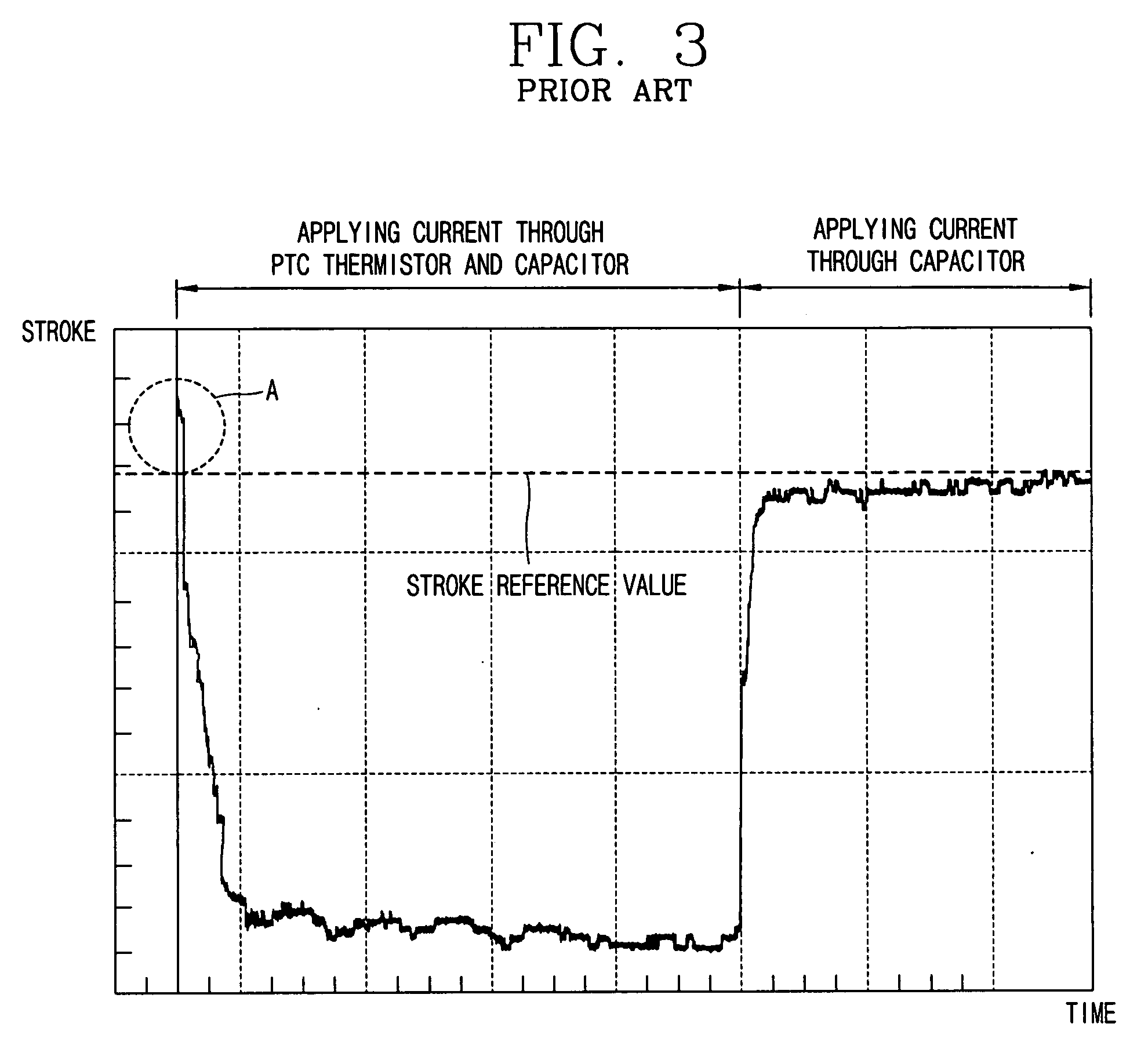

Apparatus for controlling operation of reciprocating compressor

InactiveUS20050053471A1Operation efficiency can be improvedTotal current dropSingle-phase induction motor startersDC motor speed/torque controlInductanceElectrical current

An apparatus for controlling an operation of a reciprocating compressor includes a inductance increasing device connected to a motor of the reciprocating compressor, so that a surge current generated when power is applied to the reciprocating compressor at an initial stage is reduced and thus an initial stroke of the reciprocating compressor is reduced. Accordingly, operational efficiency of the reciprocating compressor is improved.

Owner:LG ELECTRONICS INC

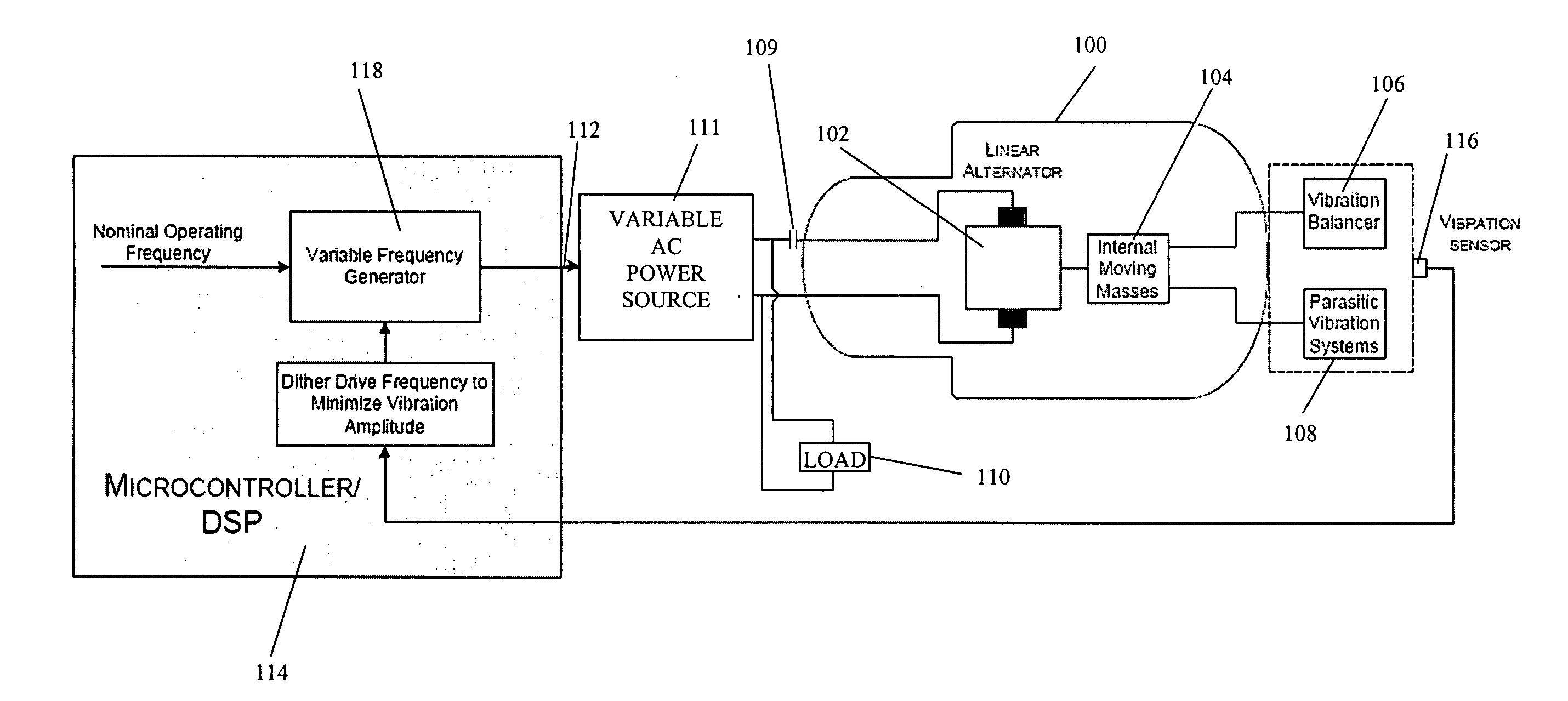

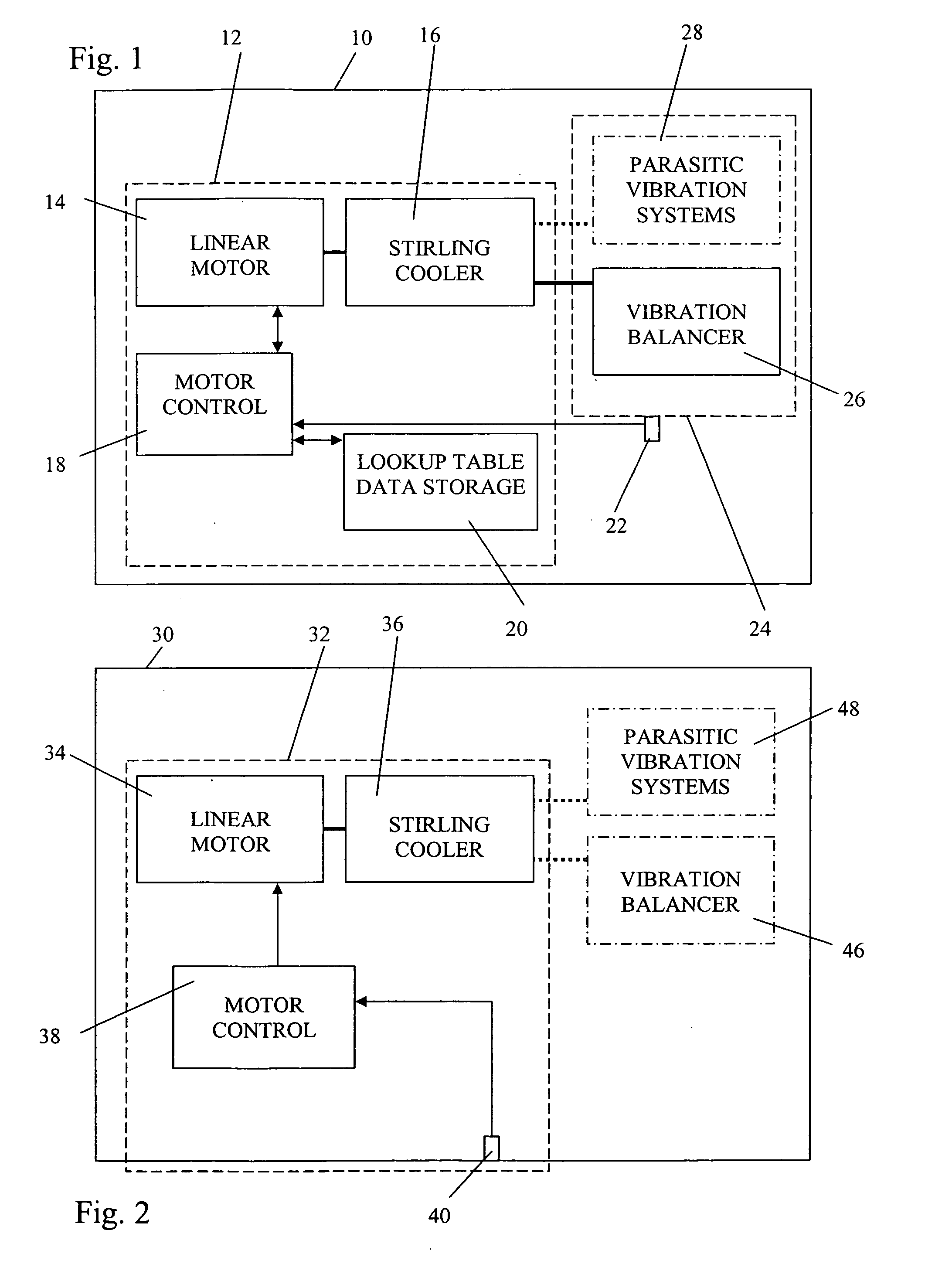

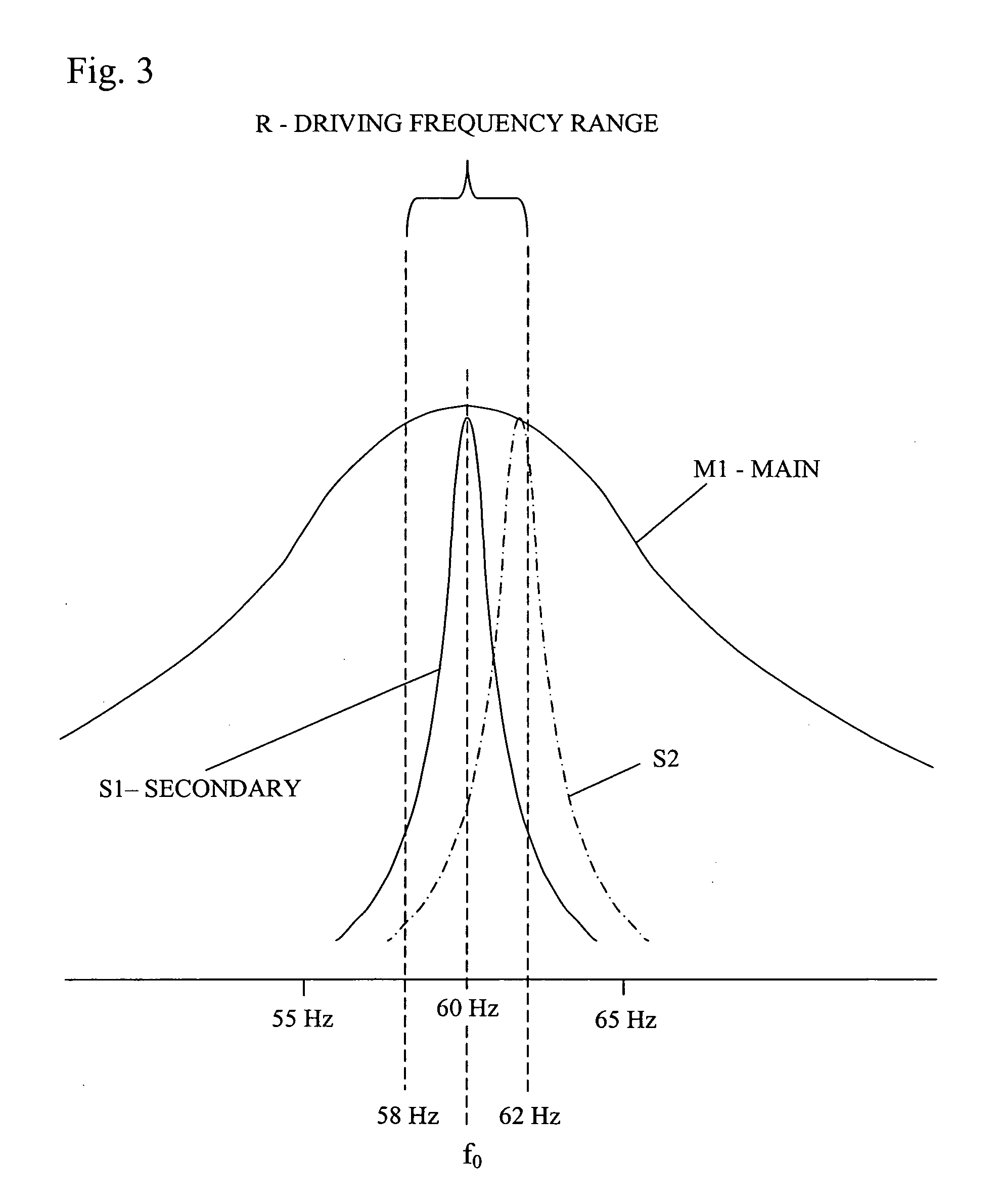

Vibration control of free piston machines through frequency adjustment

InactiveUS20070256428A1Minimizing amplitudeReduces and minimizes amplitudeAssociation with control/drive circuitsInertia force compensationVibration controlReciprocating motion

A method and apparatus for minimizing the amplitude of mechanical vibrations of a mechanical apparatus including a linear, freely reciprocating, prime mover coupled to and driving a reciprocating mass of a driven machine in reciprocation at a driving frequency. The coupled prime mover and driven machine have a spring applying a force upon the reciprocating mass to form a resonant main system having a main system resonant frequency of reciprocation. A driving frequency range over which the driven machine operates at an acceptable efficiency of operation is determined and stored. A parameter of the operation of the mechanical apparatus, such as the amplitude of vibrations or an operating temperature, is sensed and the prime mover is driven in response to the sensed parameter at a driving frequency that is offset from the main system resonant frequency of reciprocation, is within the driving frequency range of acceptable efficiency of operation and reduces or minimizes the amplitude of mechanical vibration of the mechanical apparatus under existing operating conditions.

Owner:SUNPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com