Patents

Literature

104results about How to "Sufficient flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

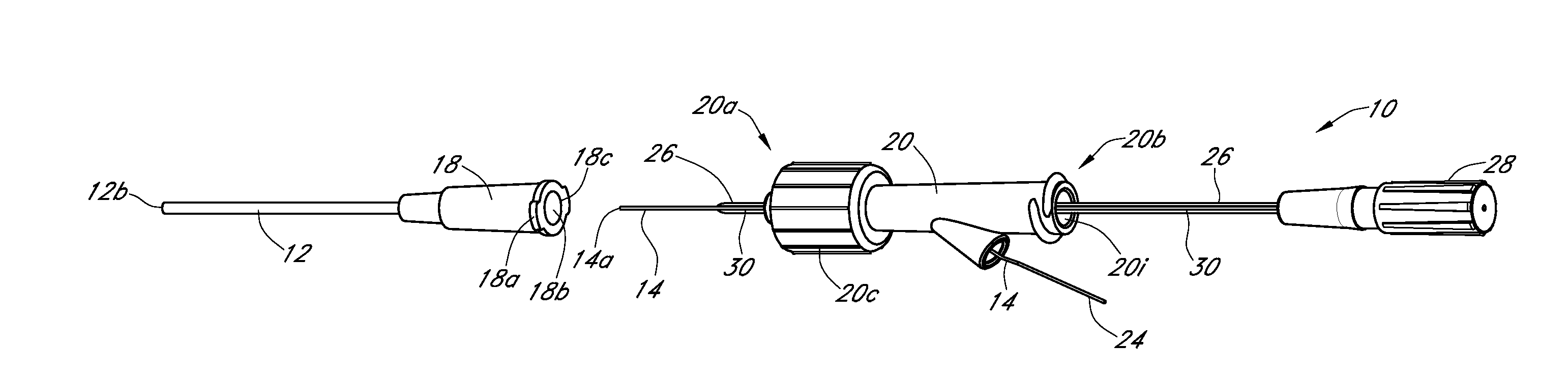

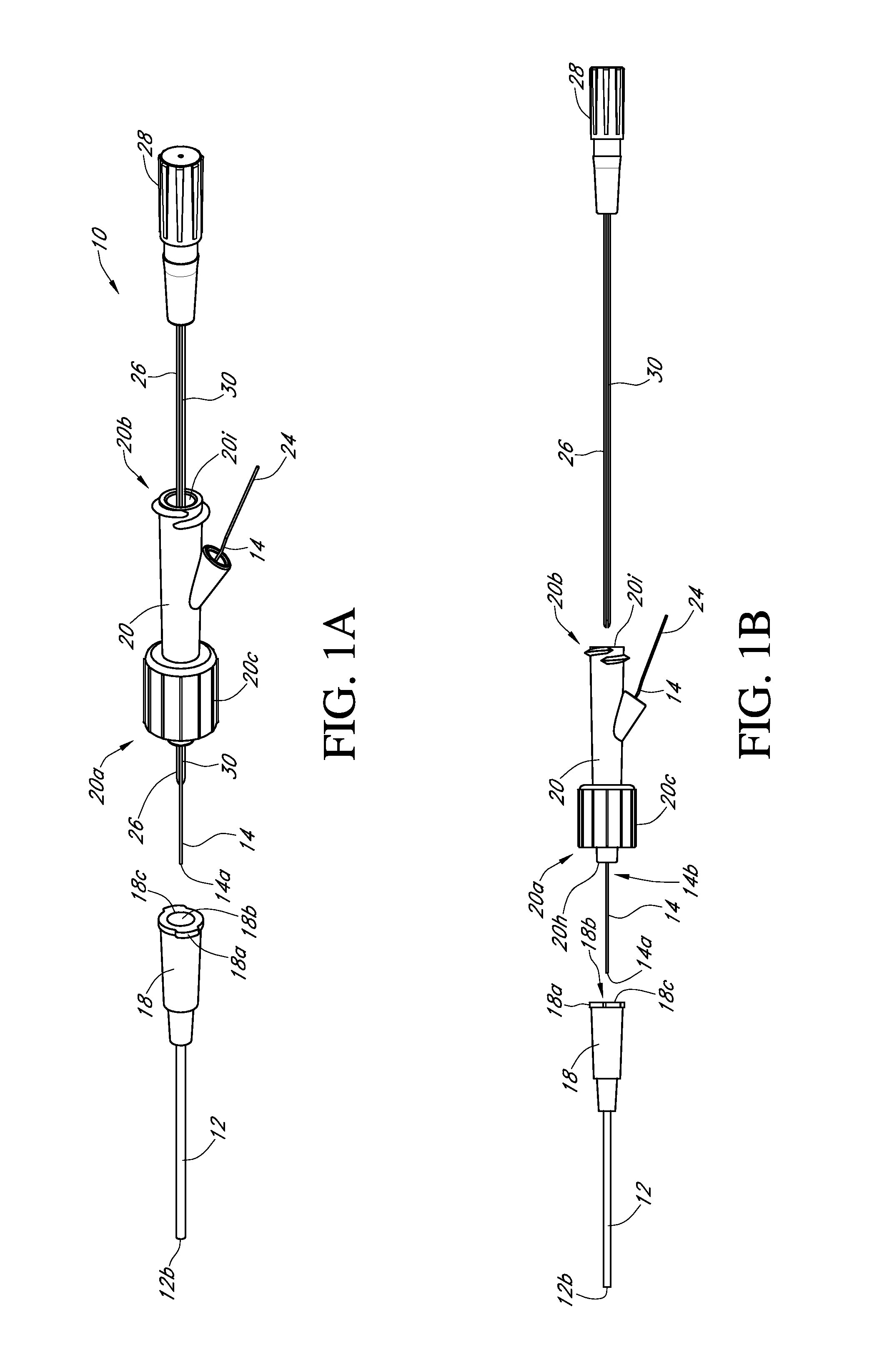

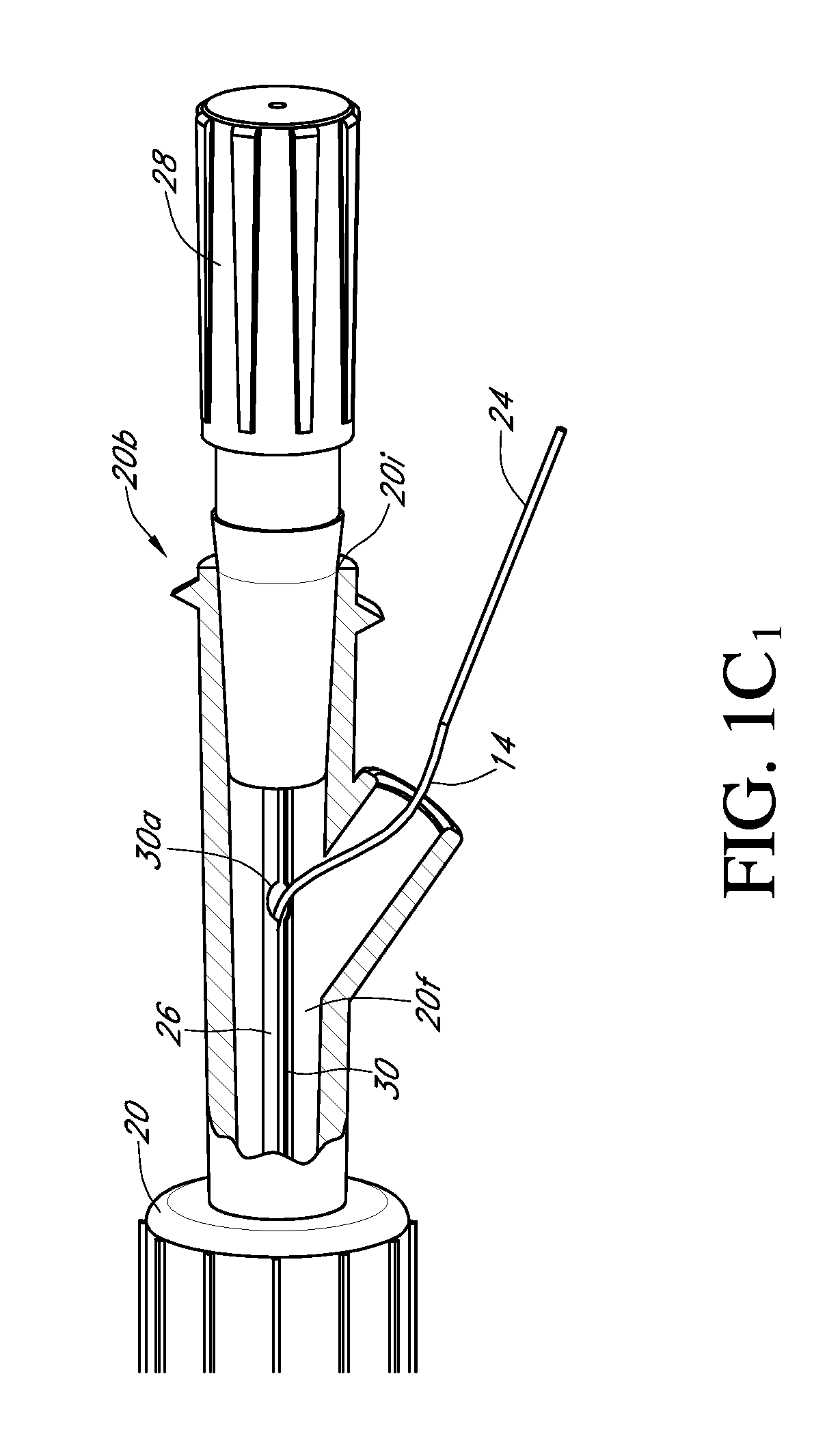

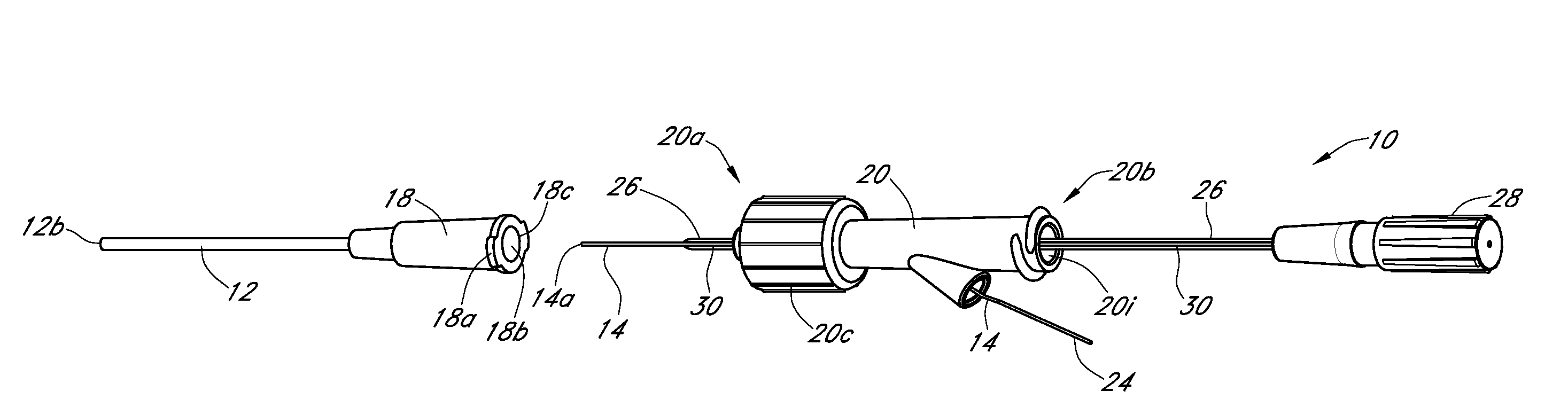

Analyte sensor

InactiveUS20090242399A1Sufficient flow rateReduce the amount requiredImmobilised enzymesBioreactor/fermenter combinationsEngineeringSensor system

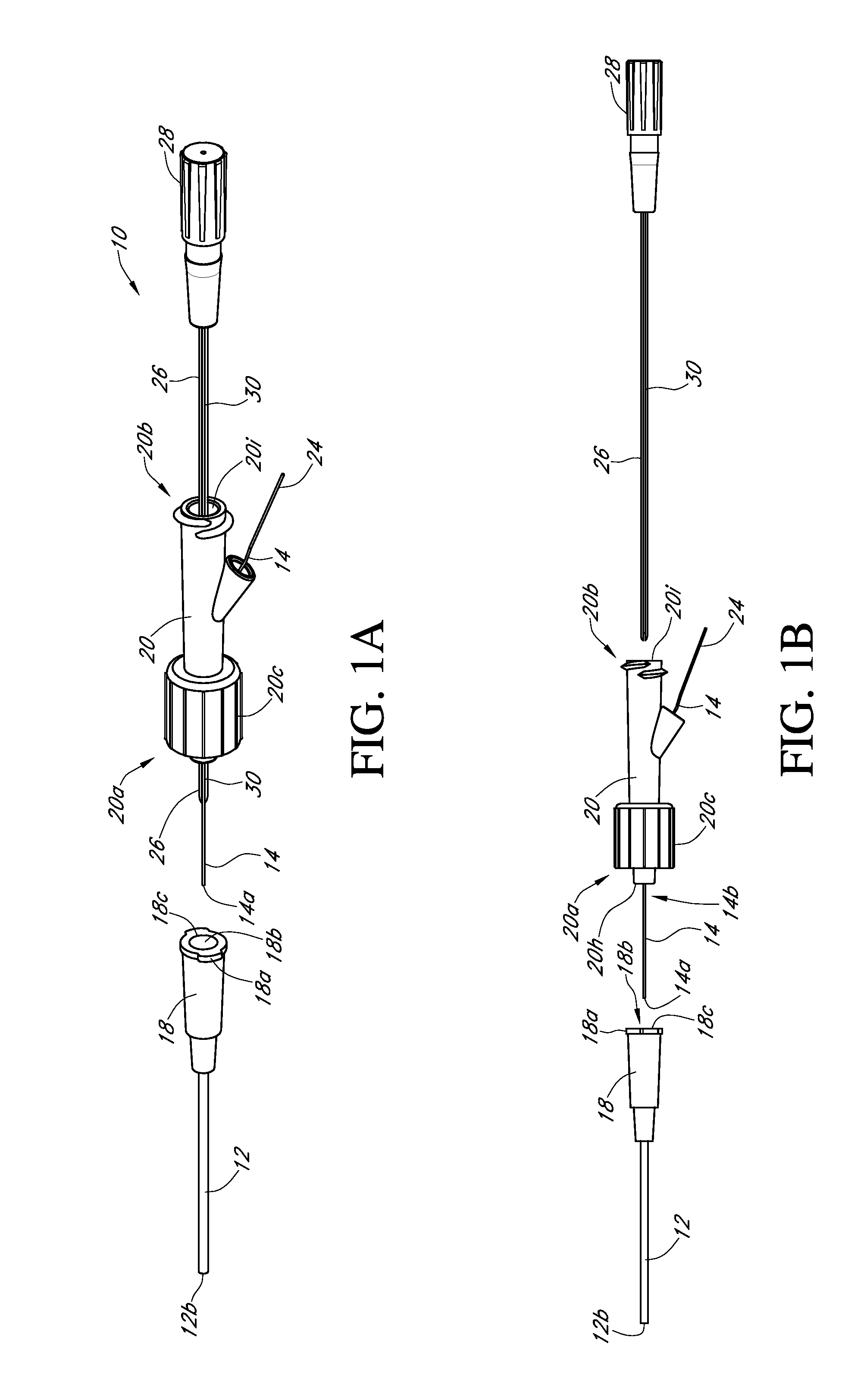

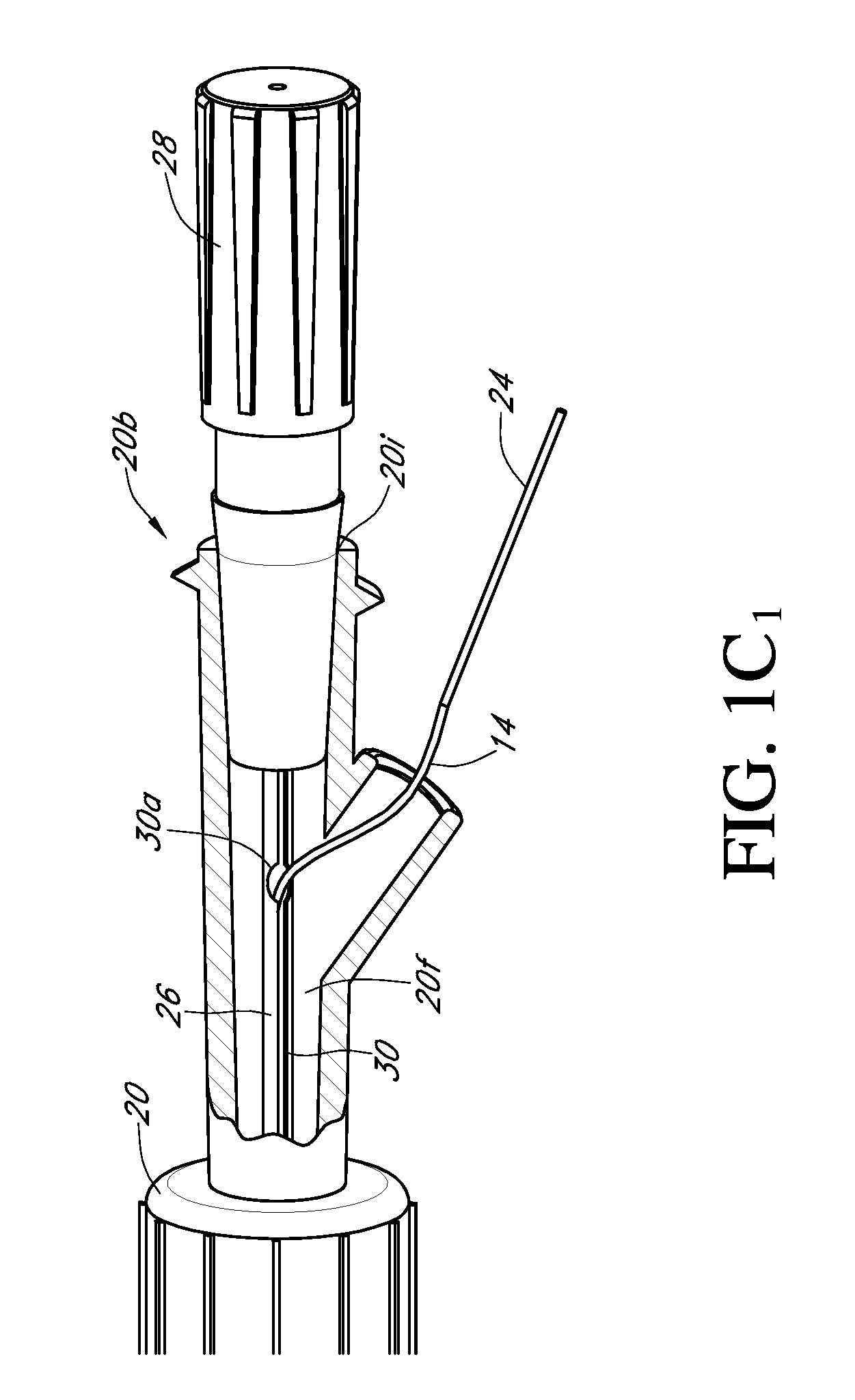

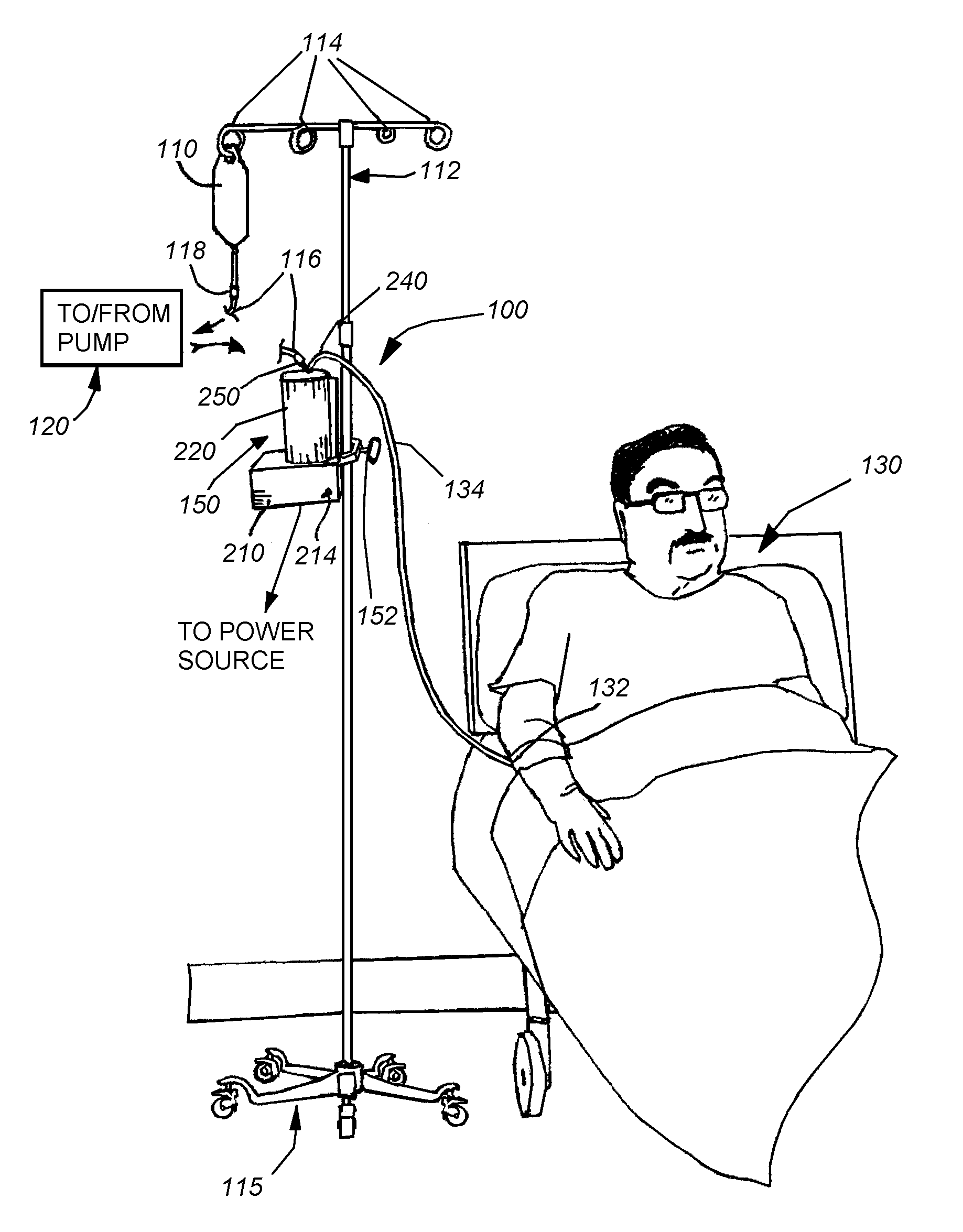

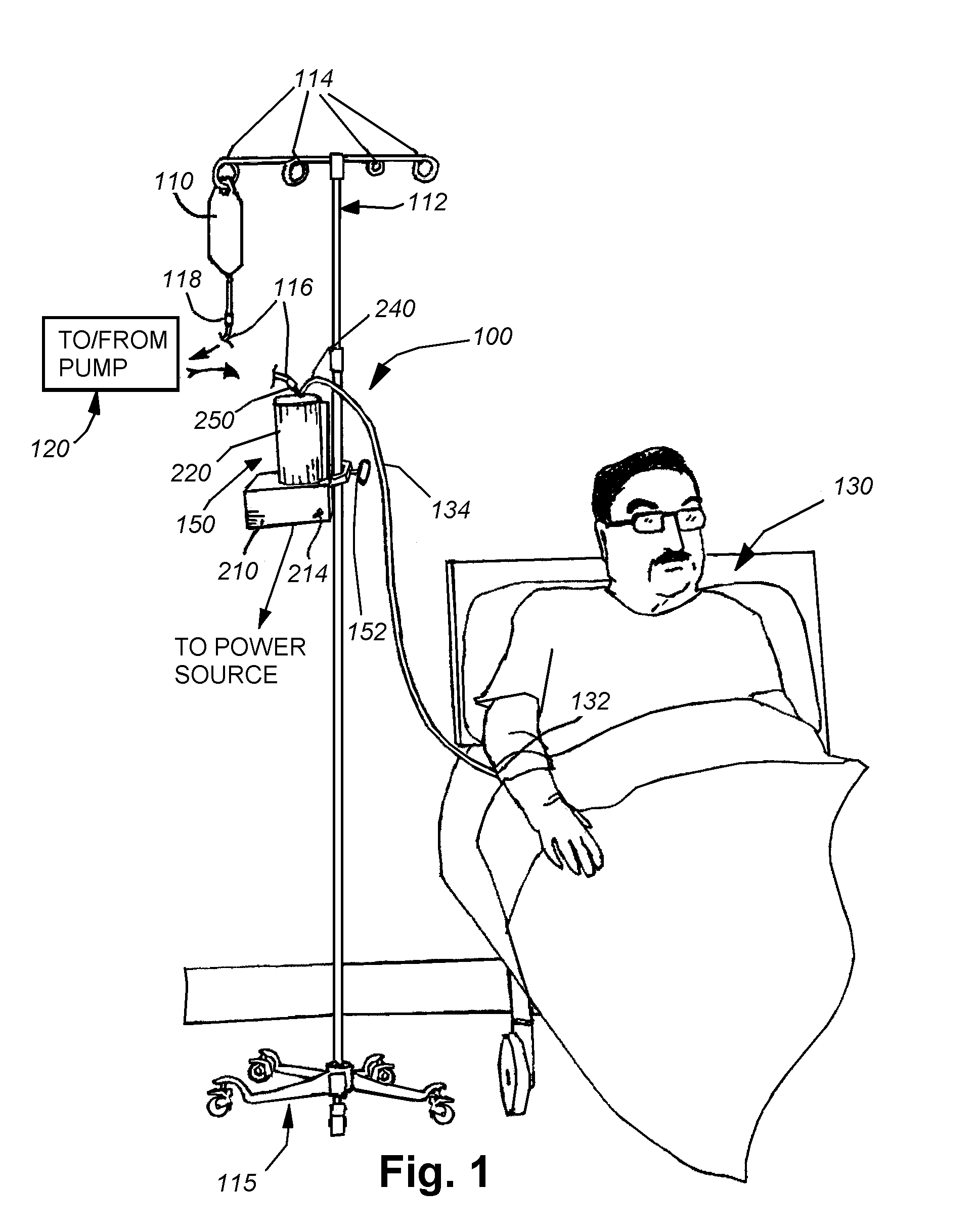

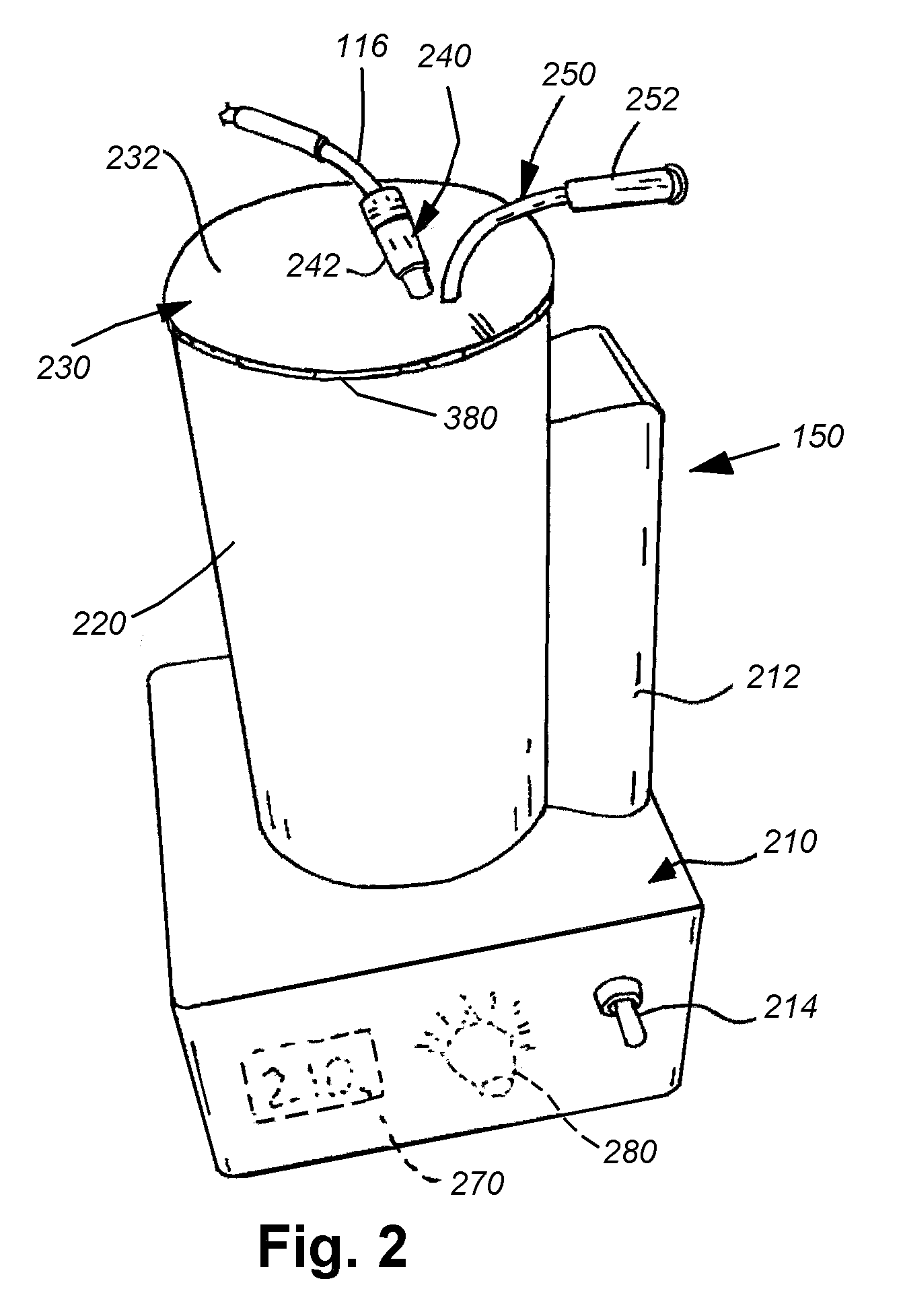

Systems and methods of use for continuous analyte measurement of a host's vascular system are provided. In some embodiments, a continuous glucose measurement system includes a vascular access device, a sensor and sensor electronics, the system being configured for insertion into communication with a host's circulatory system.

Owner:DEXCOM

Analyte sensor

InactiveUS20080197024A1Sufficient flow rateReduce the amount requiredImmobilised enzymesDrug and medicationsVascular Access DevicesAnalyte

Systems and methods of use for continuous analyte measurement of a host's vascular system are provided. In some embodiments, a continuous glucose measurement system includes a vascular access device, a sensor and sensor electronics, the system being configured for insertion into communication with a host's circulatory system.

Owner:DEXCOM

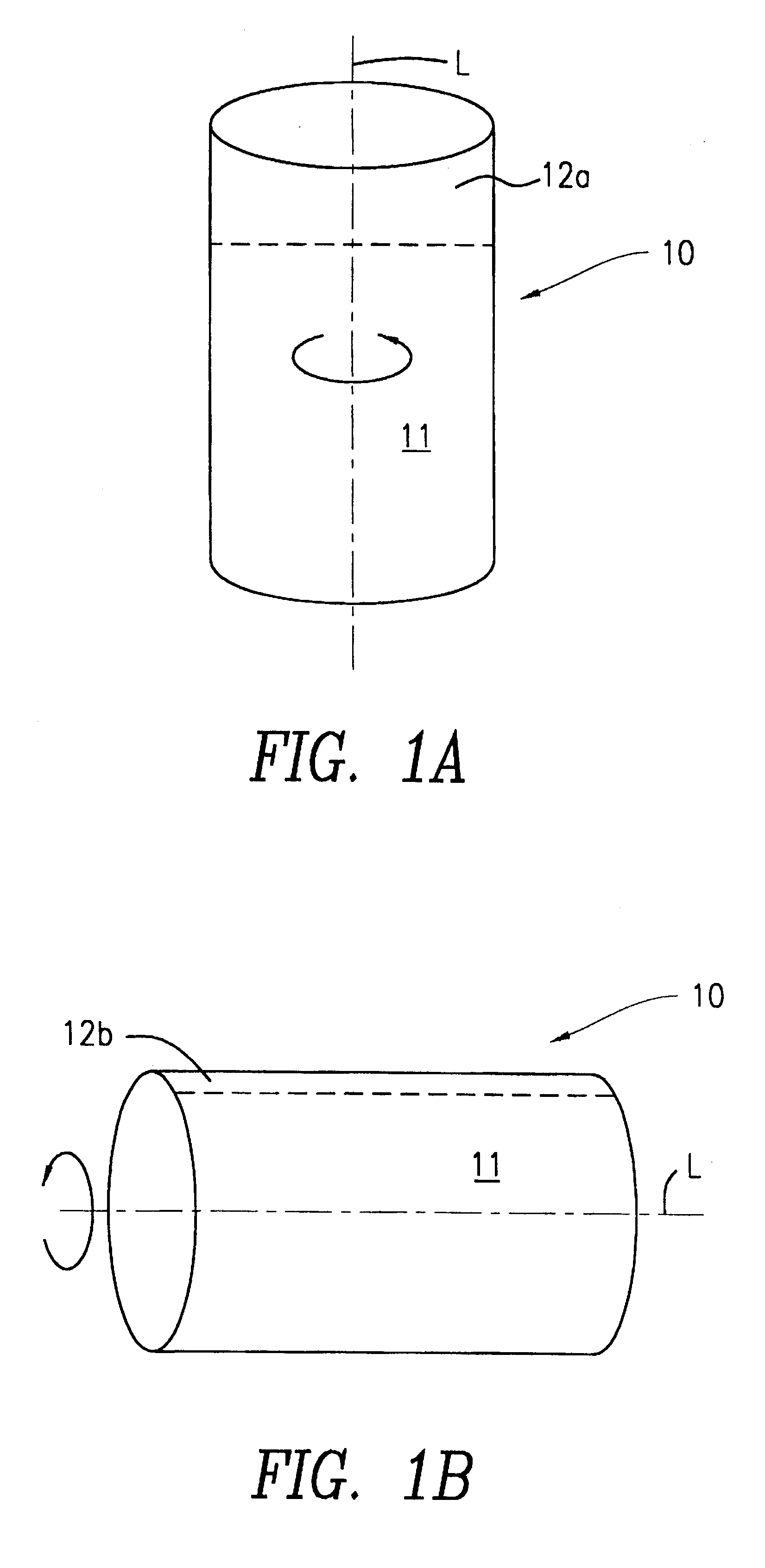

Method of expanding tobacco using steam

ActiveUS7556047B2Increasing filling powerImprove filling capacityTobacco preparationTobacco treatmentEngineeringTobacco use

Owner:R J REYNOLDS TOBACCO COMPANY

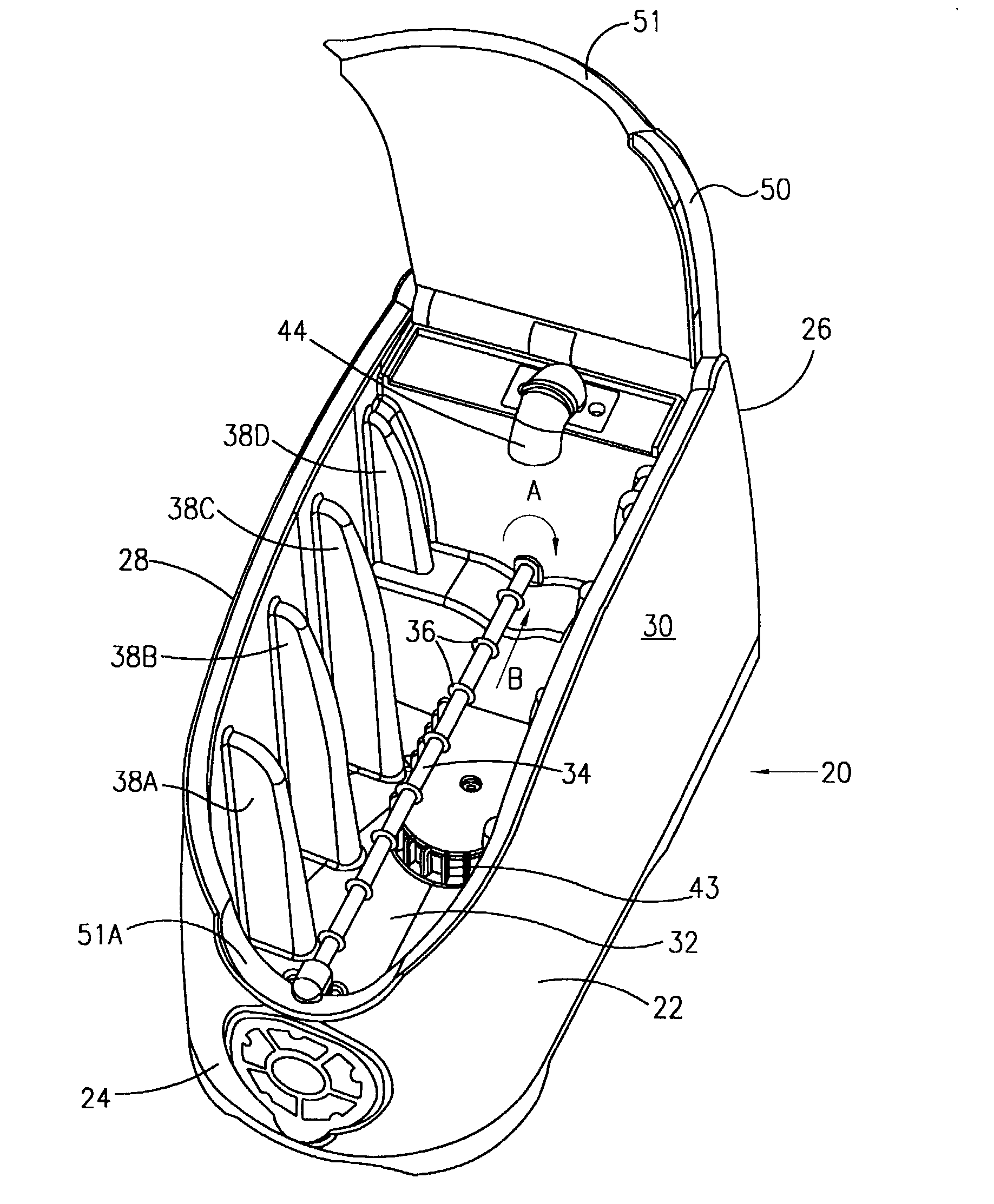

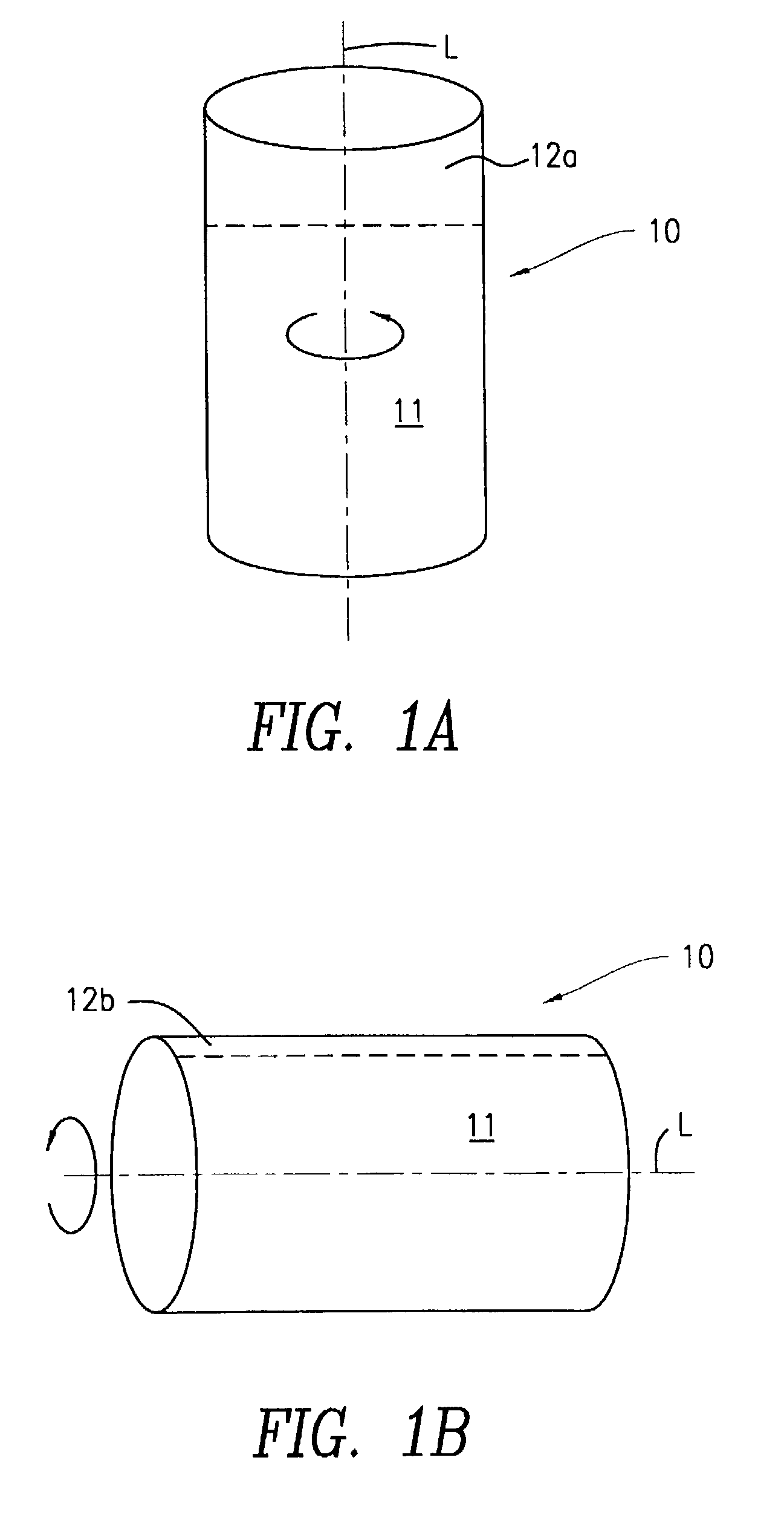

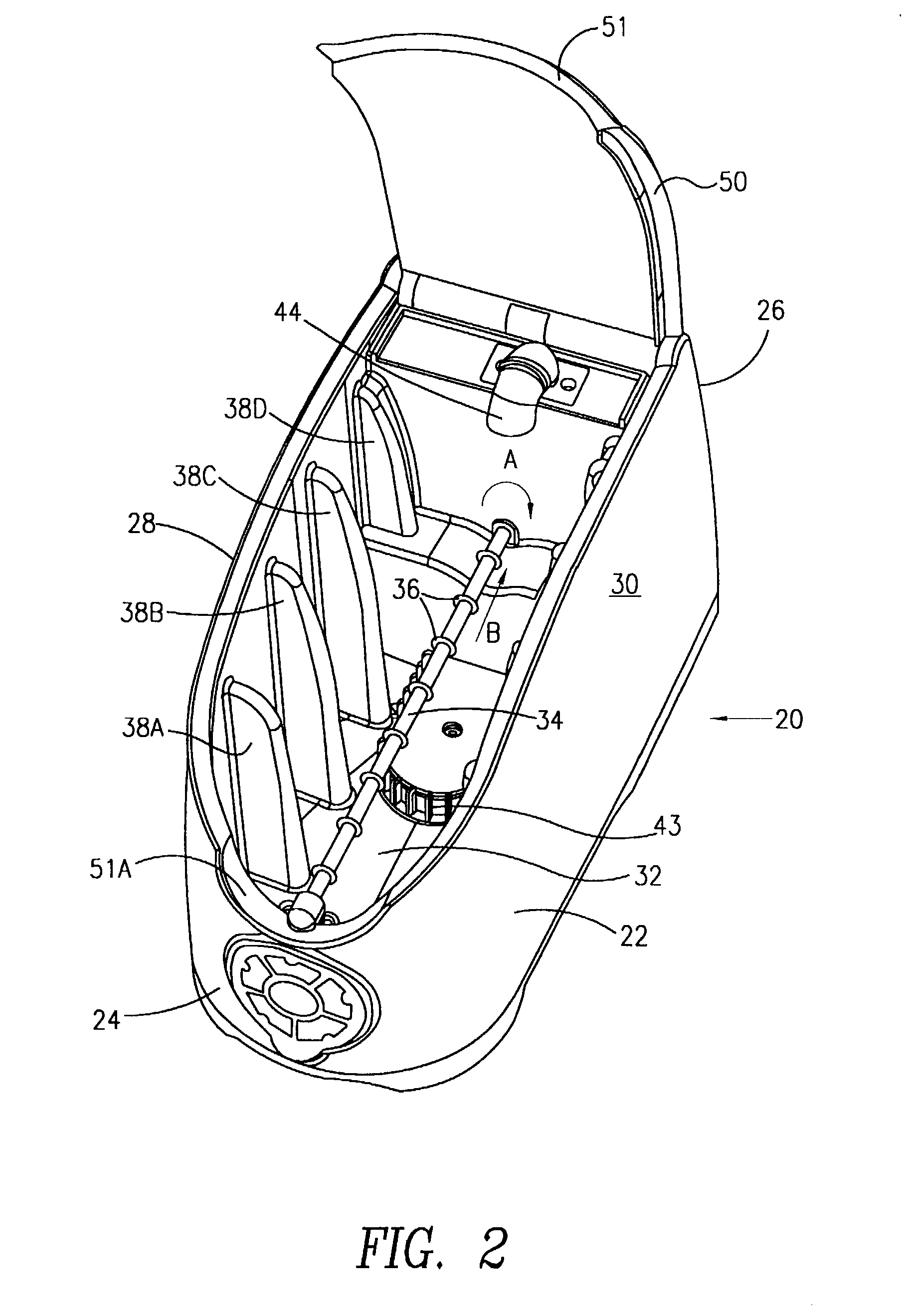

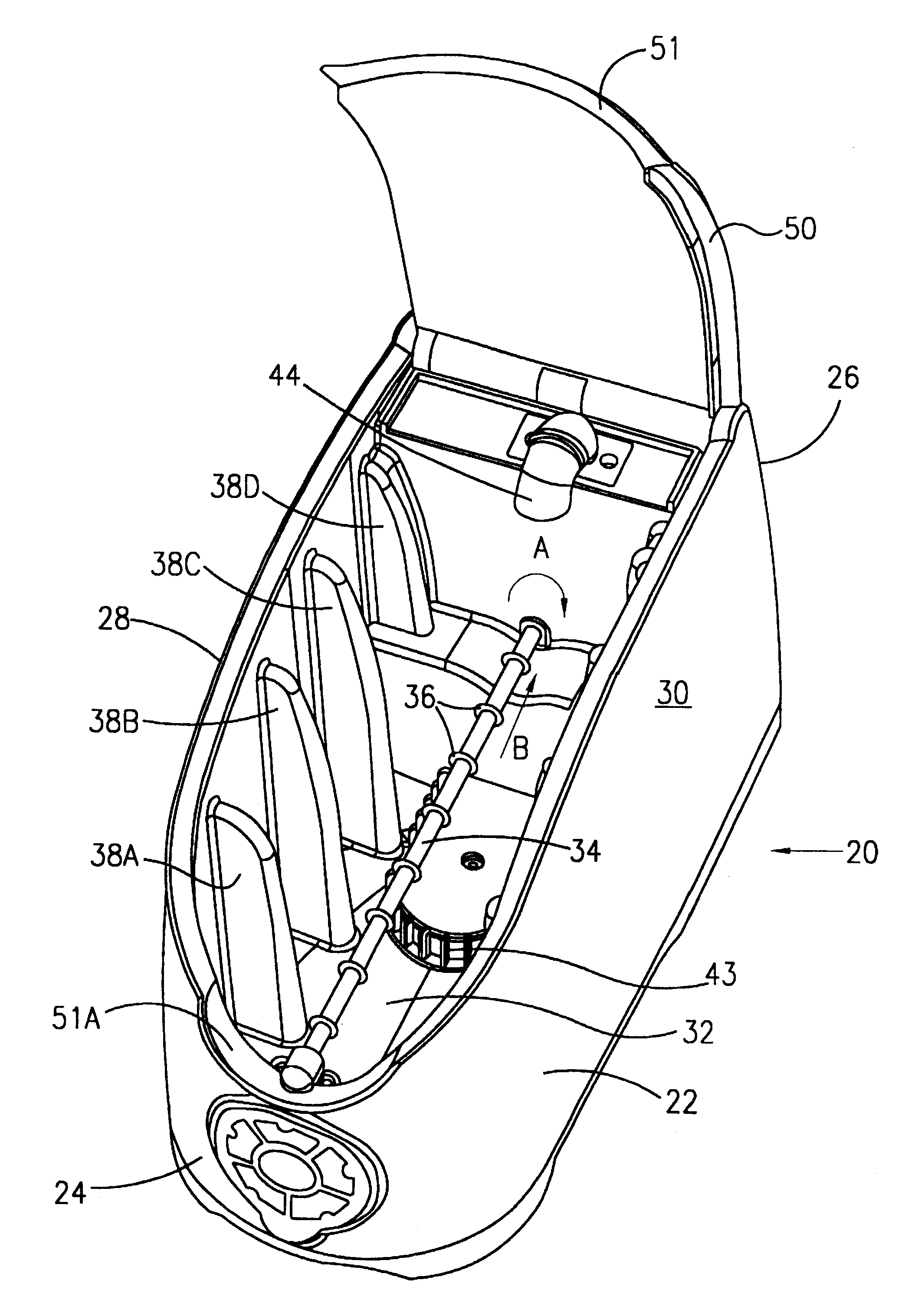

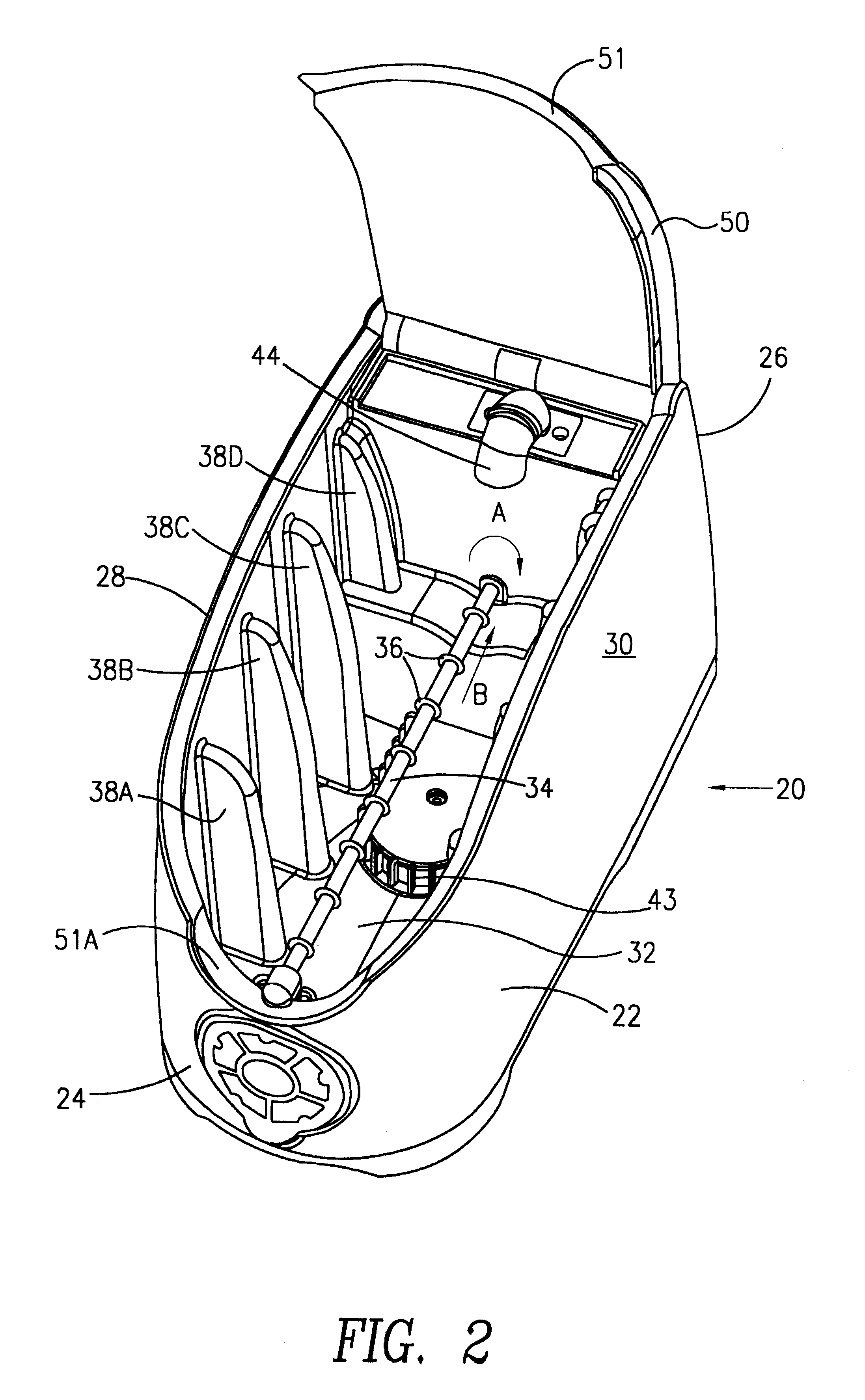

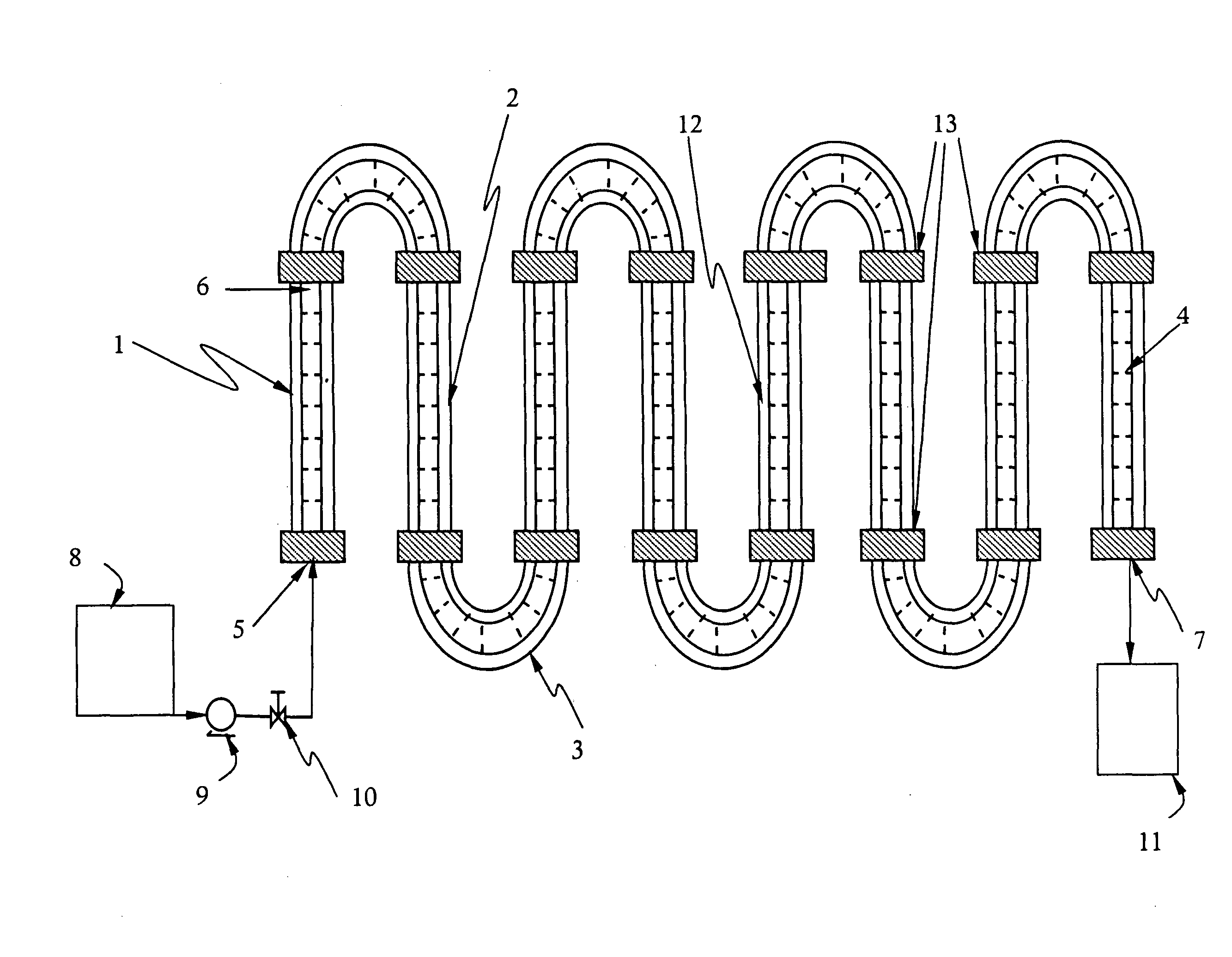

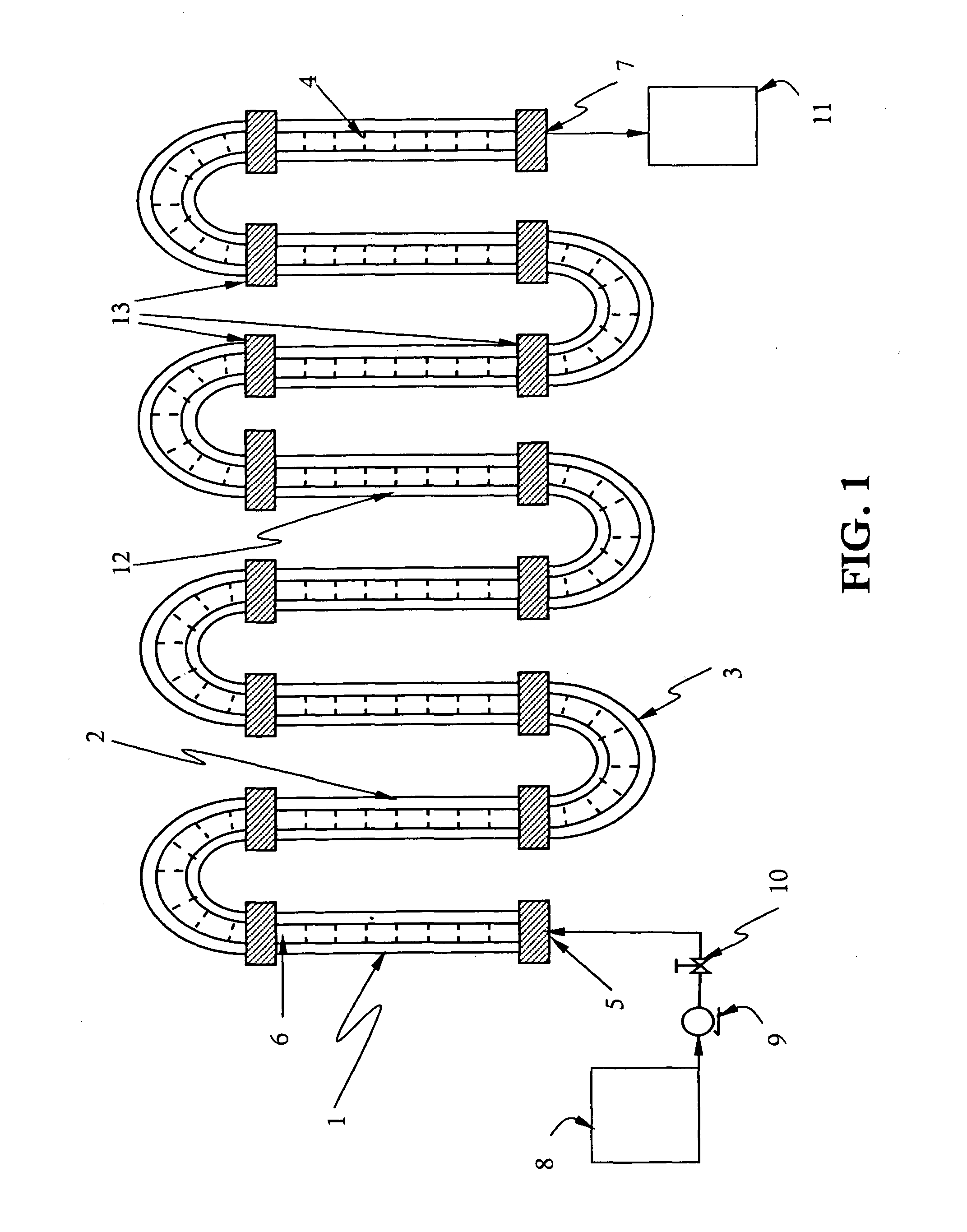

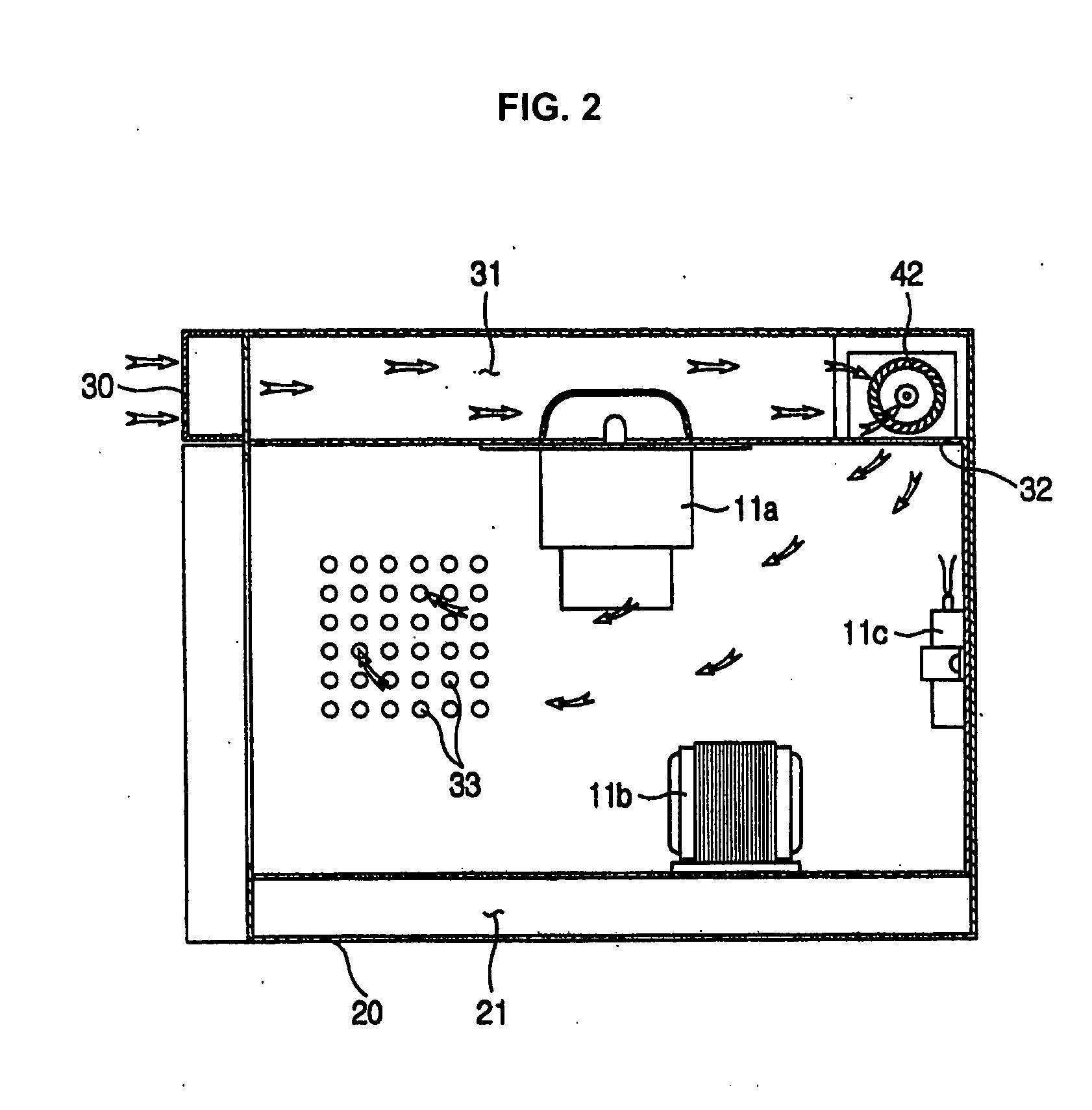

Rapid fluid cooling and heating device and method

InactiveUS20020124576A1Increase surface areaGreat frictional contactFrozen sweetsContainer filling methodsIce creamElectrical and Electronics engineering

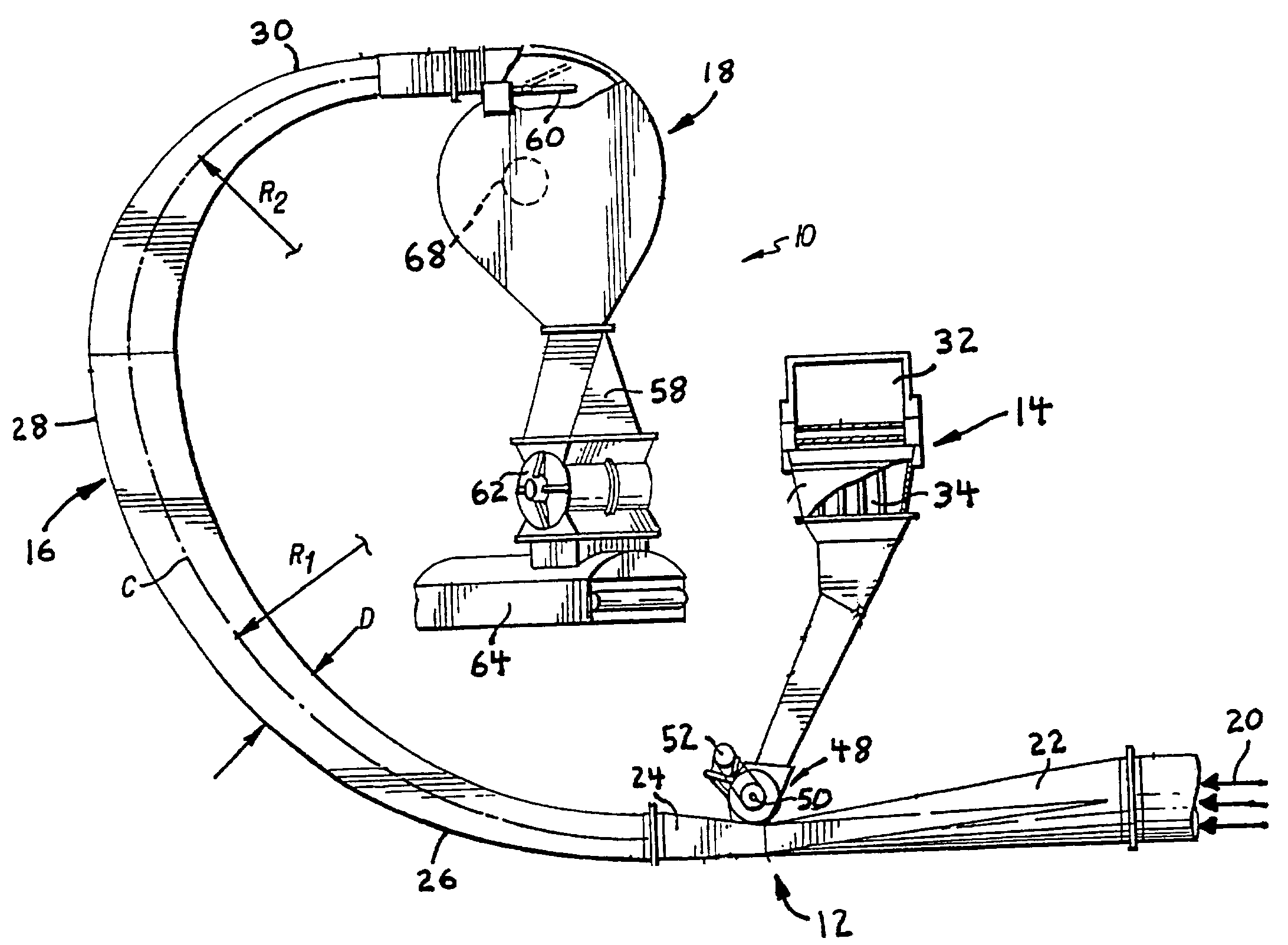

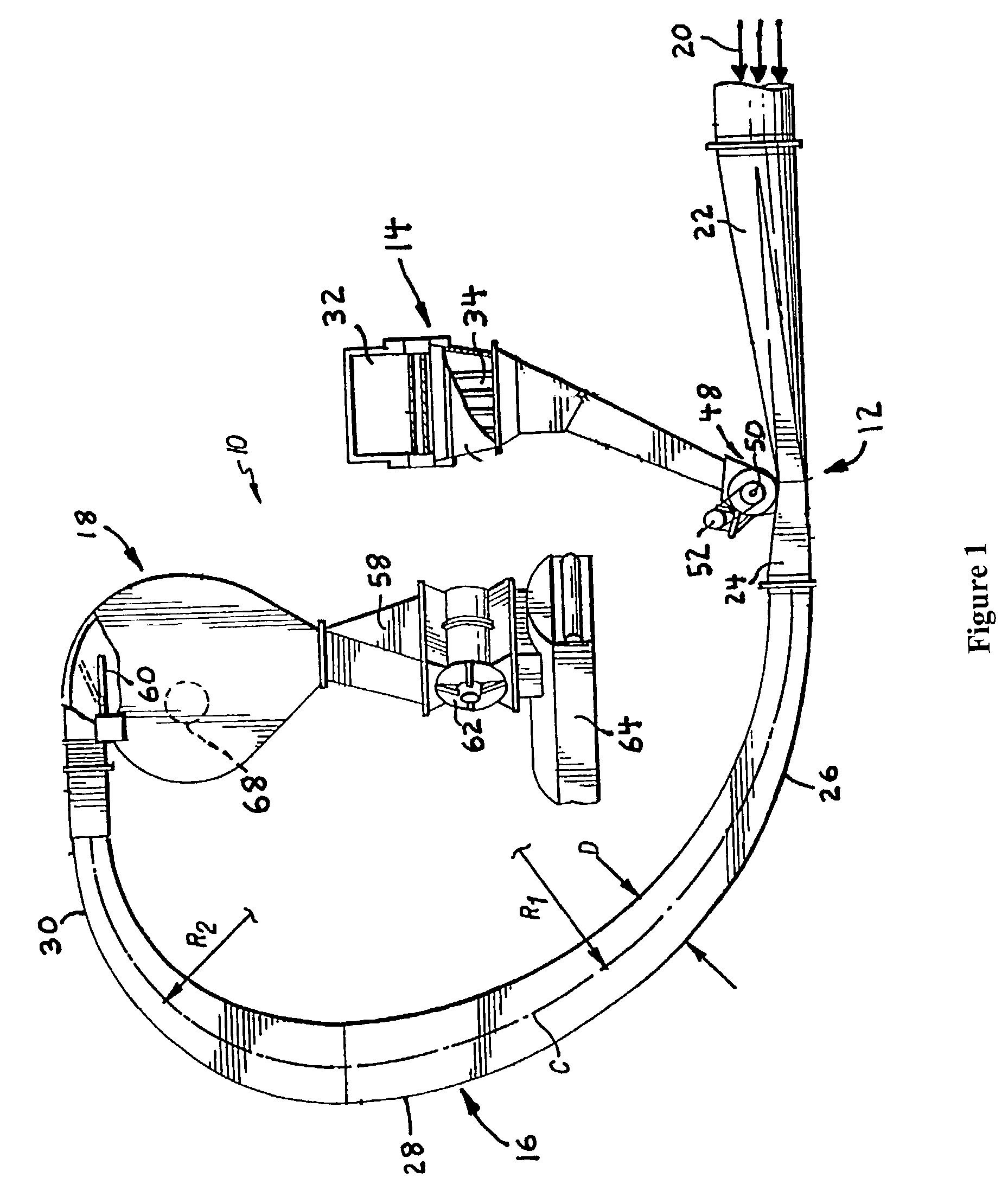

A method and device for rapidly changing at least one of the temperature and the state of a liquid in a container is provided. The container is rapidly rotated about its longitudinal axis. A source of a thin film of a medium having a different temperature than the liquid in the container is provided to thermally affect the container while rotating the container. The container is positioned at an angle to the horizontal of less than 45°, and the position of the container with respect to the thin film source is controlled by angling the axis of the container skewed from the axis of the rotating mechanism. The device can be used to cool liquids such as beverages, warm liquids such as infant formula, and / or make ice cream.

Owner:THE COOPER UNION FOR THE ADVANCEMENT OF SCI & ART

Rapid fluid cooling and heating device and method

InactiveUS6662574B2Rapid coolingIncrease surface areaFrozen sweetsDomestic refrigeratorsIce CreamsThin membrane

A method and device for rapidly changing at least one of the temperature and the state of a liquid in a container is provided. The container is rapidly rotated about its longitudinal axis. A source of a thin film of a medium having a different temperature than the liquid in the container is provided to thermally affect the container while rotating the container. The container is positioned at an angle to the horizontal of less than 45°, and the position of the container with respect to the thin film source is controlled by angling the axis of the container skewed from the axis of the rotating mechanism. The device can be used to cool liquids such as beverages, warm liquids such as infant formula, and / or make ice cream.

Owner:THE COOPER UNION FOR THE ADVANCEMENT OF SCI & ART

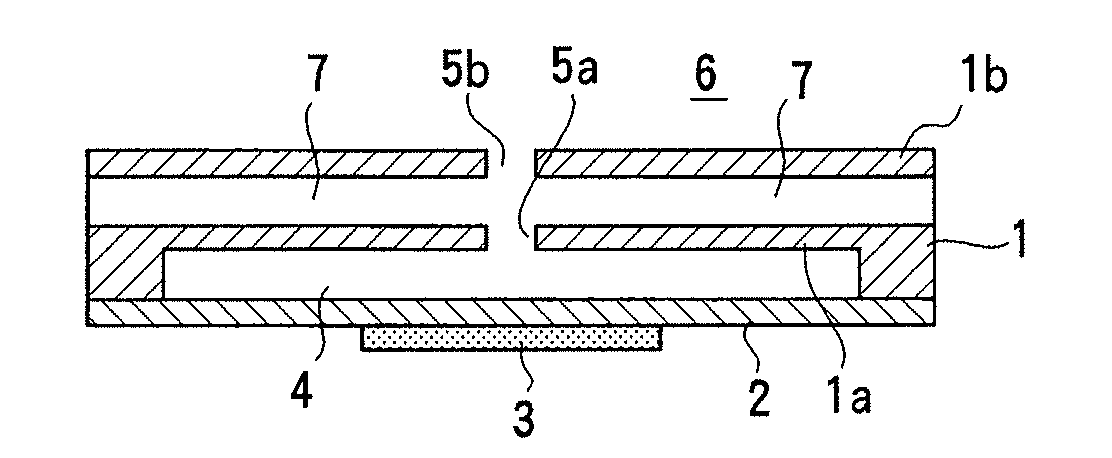

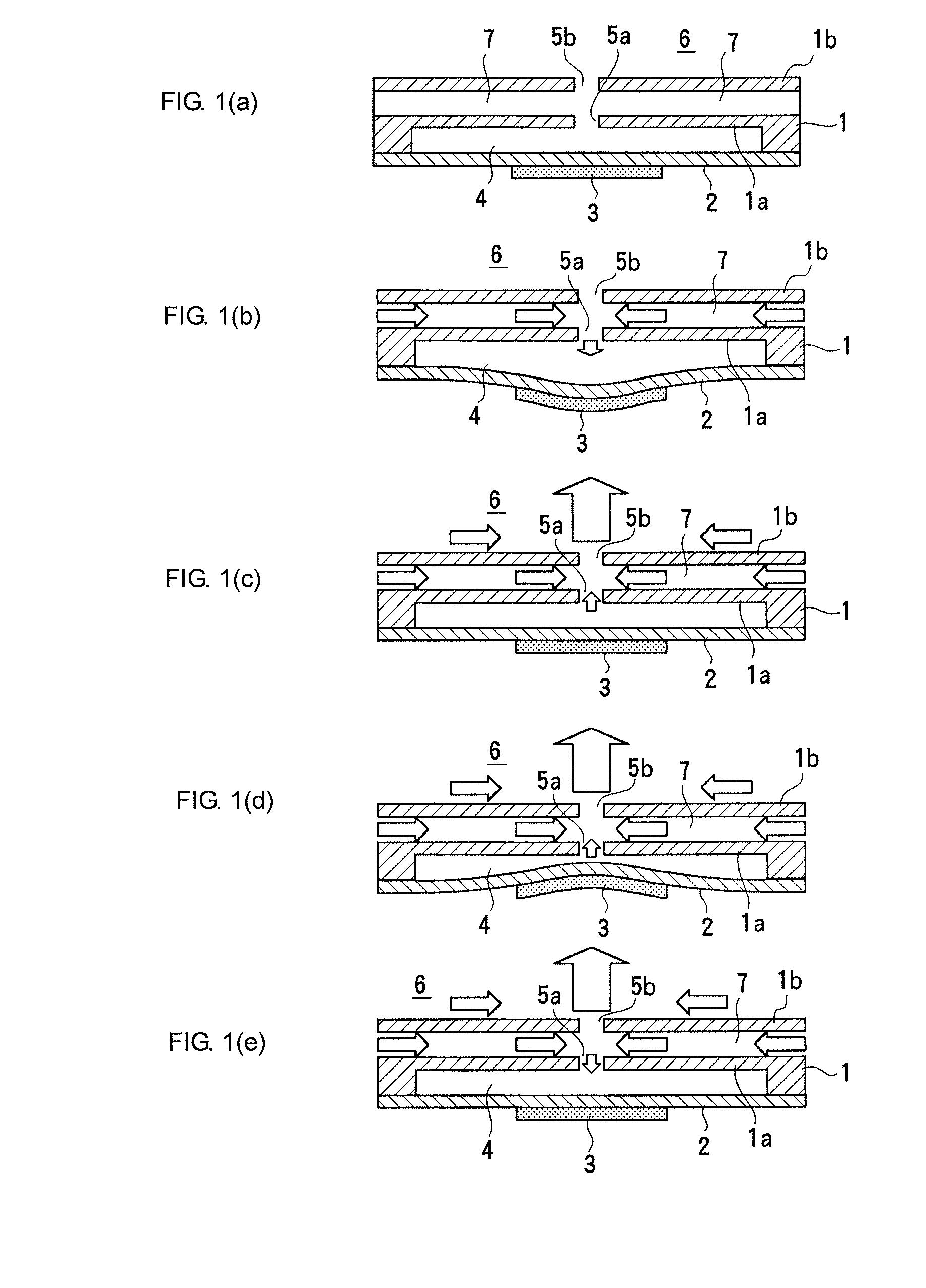

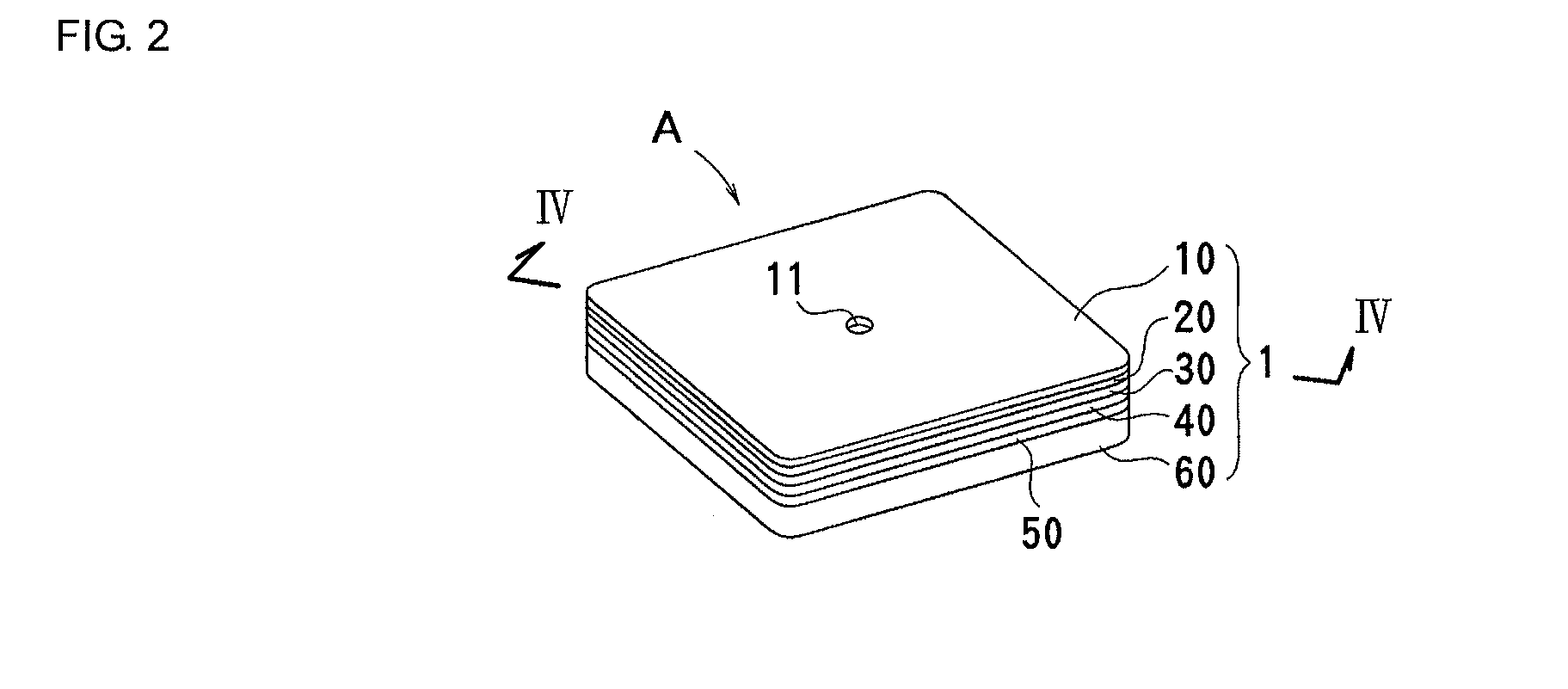

Piezoelectric micro-blower

InactiveUS20090232682A1Efficiently conveyedSufficient flow ratePositive displacement pump componentsFlexible member pumpsElectricityEngineering

A piezoelectric micro-blower capable of efficiently conveying compressive fluid without use of a check valve and ensuring a sufficient flow rate. The micro-blower has a blower body with a first wall and a second wall. Openings are formed in the respective walls and face a center of a diaphragm. An inflow path allowing the openings to communicate with the outside is formed between the walls. By applying a voltage to a piezoelectric element to cause the diaphragm to vibrate, a part of the first wall close to the first opening vibrates. Thus, gas can be drawn from the inflow path and discharged from the opening in the second wall.

Owner:MURATA MFG CO LTD

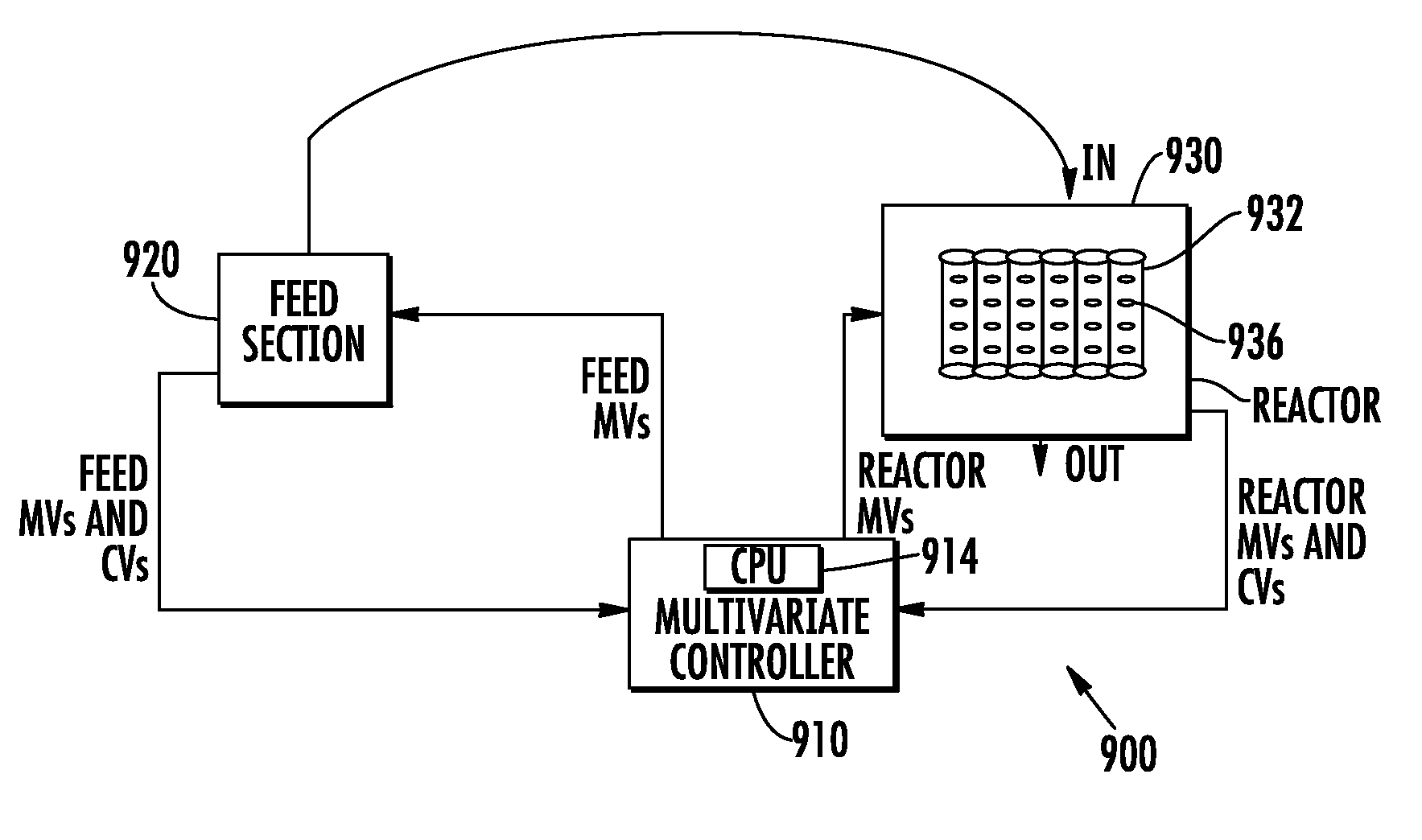

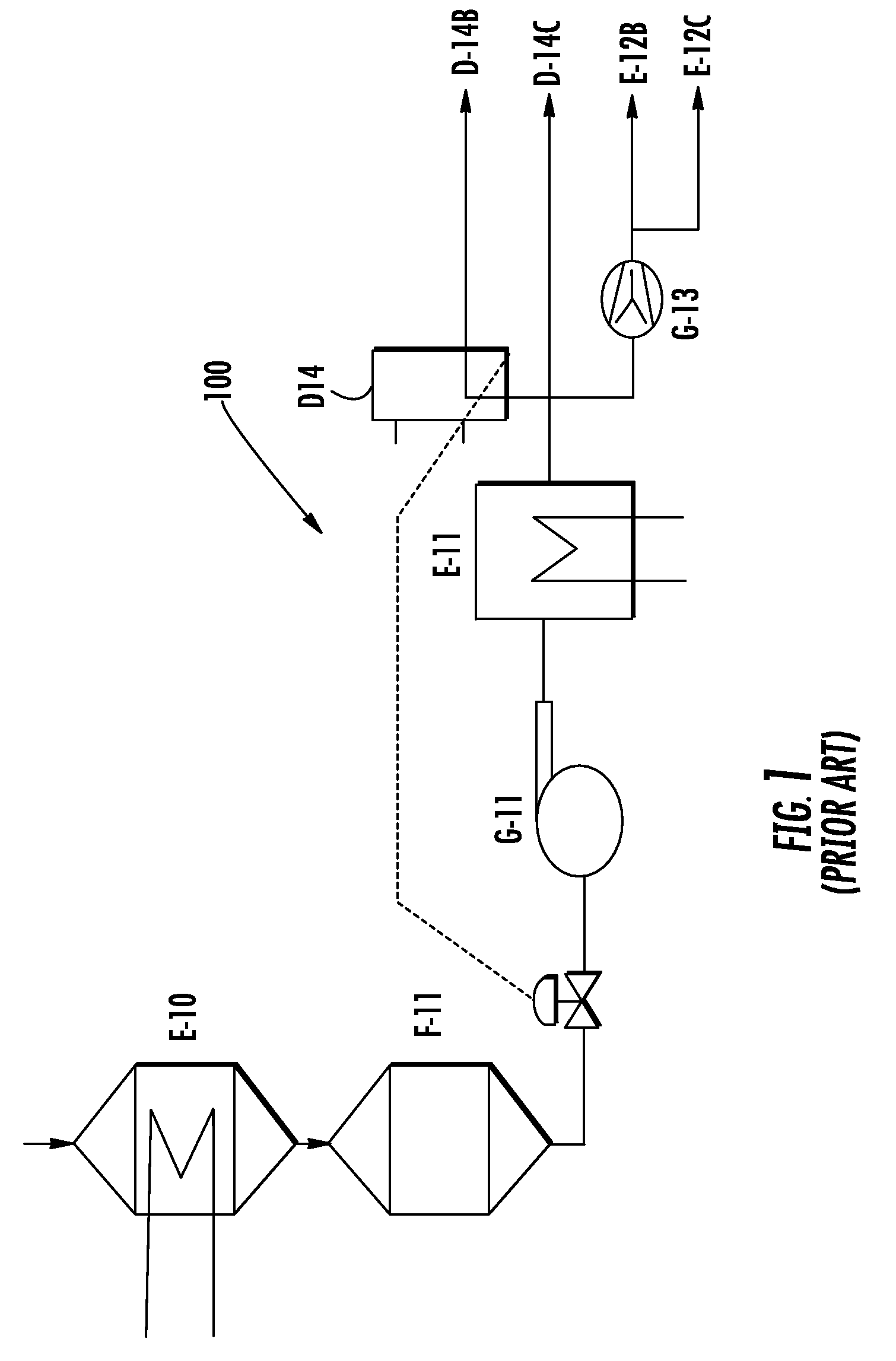

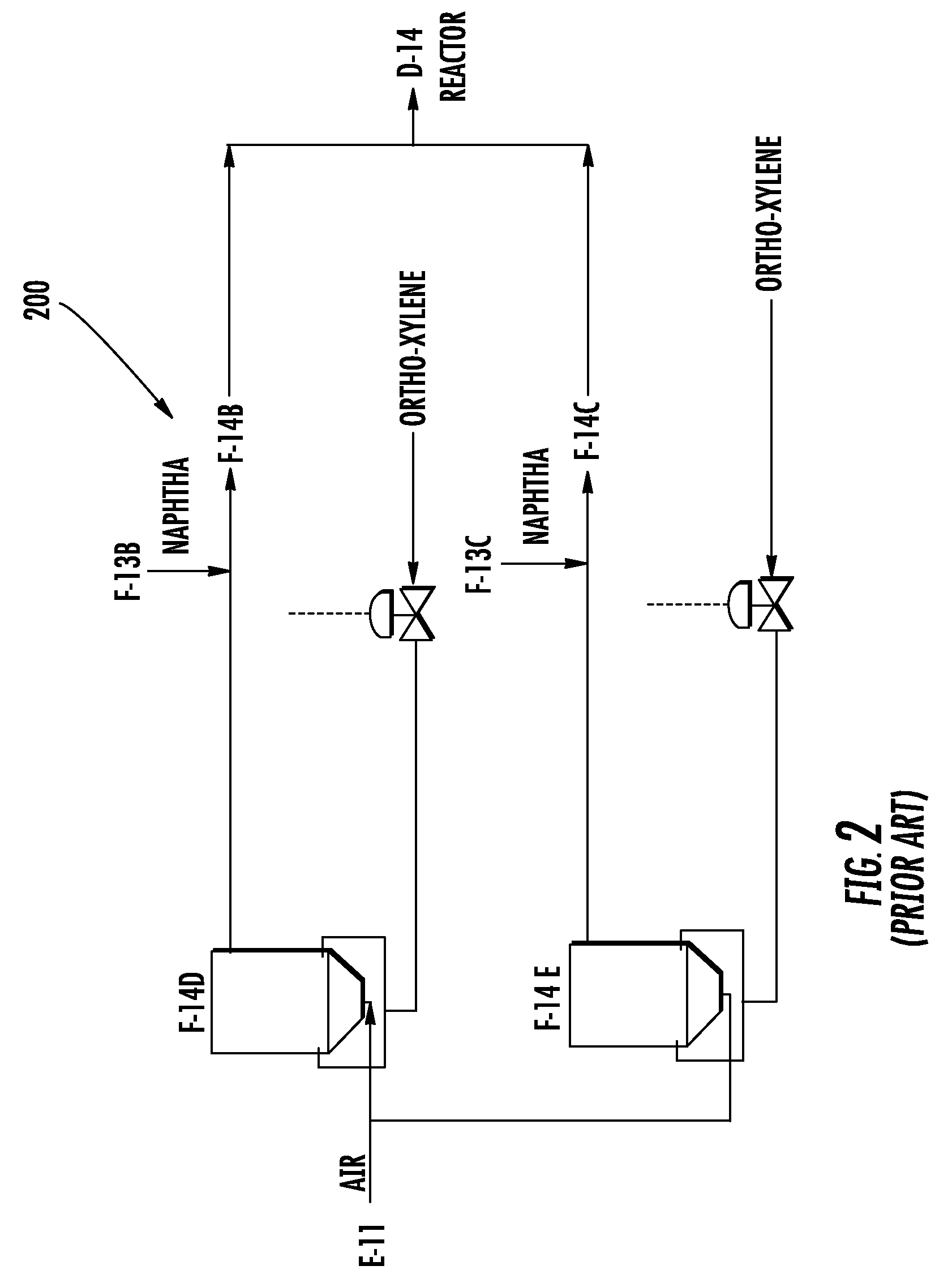

Multivariable process controller and methodology for controlling catalyzed chemical reaction to form phthalic anhydride and other functionalized aromatics

InactiveUS8060258B2Increase productivityMinimizing flow rateSampled-variable control systemsGaseous chemical processesChemical reactionChemical reactor

A multivariable method and process controller is for controlling a catalyzed chemical reaction to form phthalic anhydride (PA), produced by a production unit including a chemical reactor having a plurality of pipes connected in parallel having inner surfaces affixed with at least one solid catalyst. The reactor implements a process for forming PA by receiving flows of reagents including at least one oxidizable substituted aromatic and an oxygen including source gas at one or more inlets of the reactor. A dynamic multivariable model for the process represents the effects of moving a plurality of manipulated variables (MVs) including a flow of the oxygen including source gas and a flow or temperature of the oxidizable substituted aromatic on controlled variables (CVs) including a temperature at a plurality of positions along a length of the pipes. During the process, a first parameter related to performance of the catalyst in producing PA and a second parameter including a temperature at one or more of the plurality of positions in measured. Using the dynamic model, the temperature in the plurality of positions along the length of the reactor are automatically adjusting based on at least the first measured parameter, which permits the temperature profile to be adjusted to compensate for ageing of the catalyst to improve production efficiency.

Owner:HONEYWELL INT INC

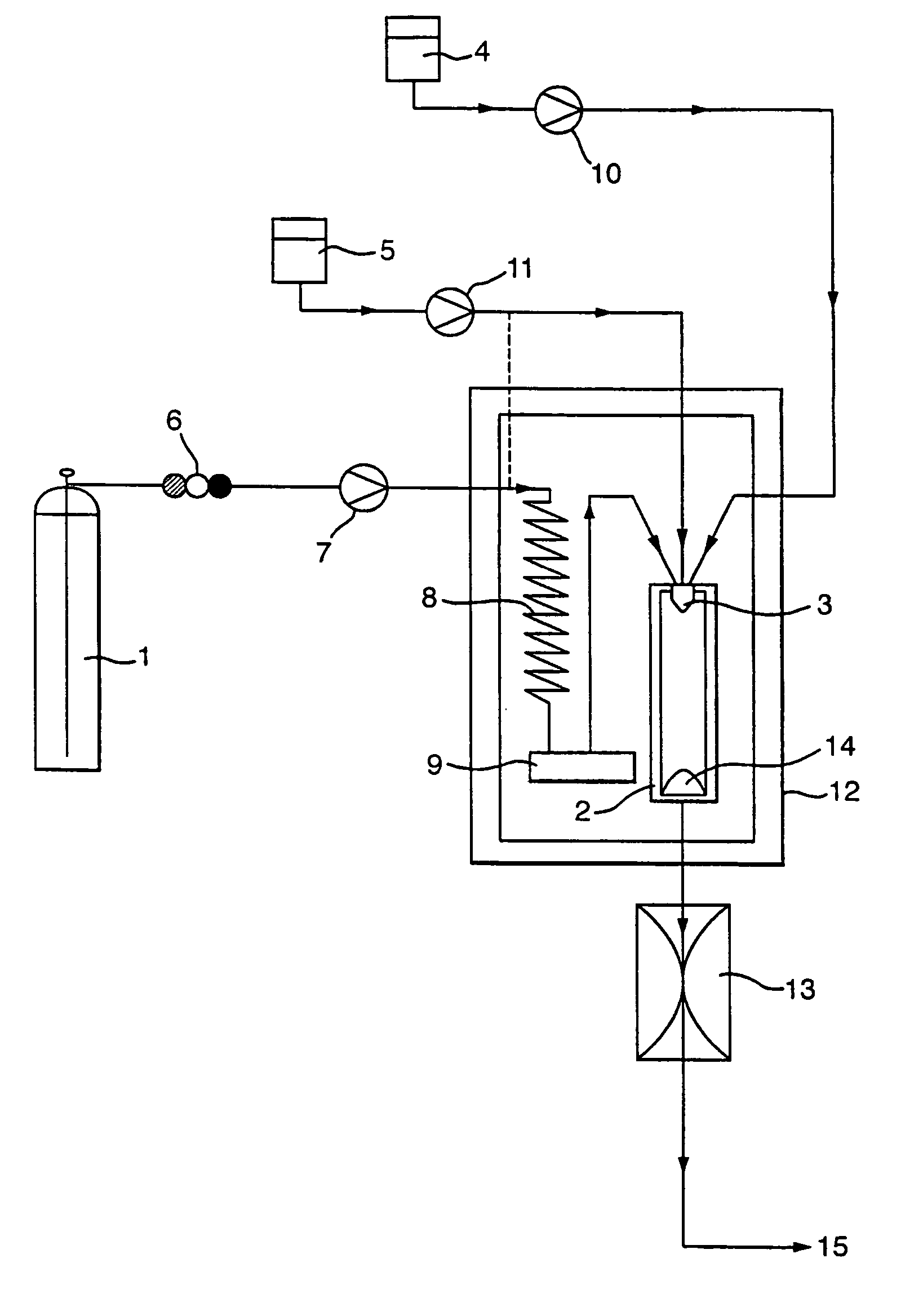

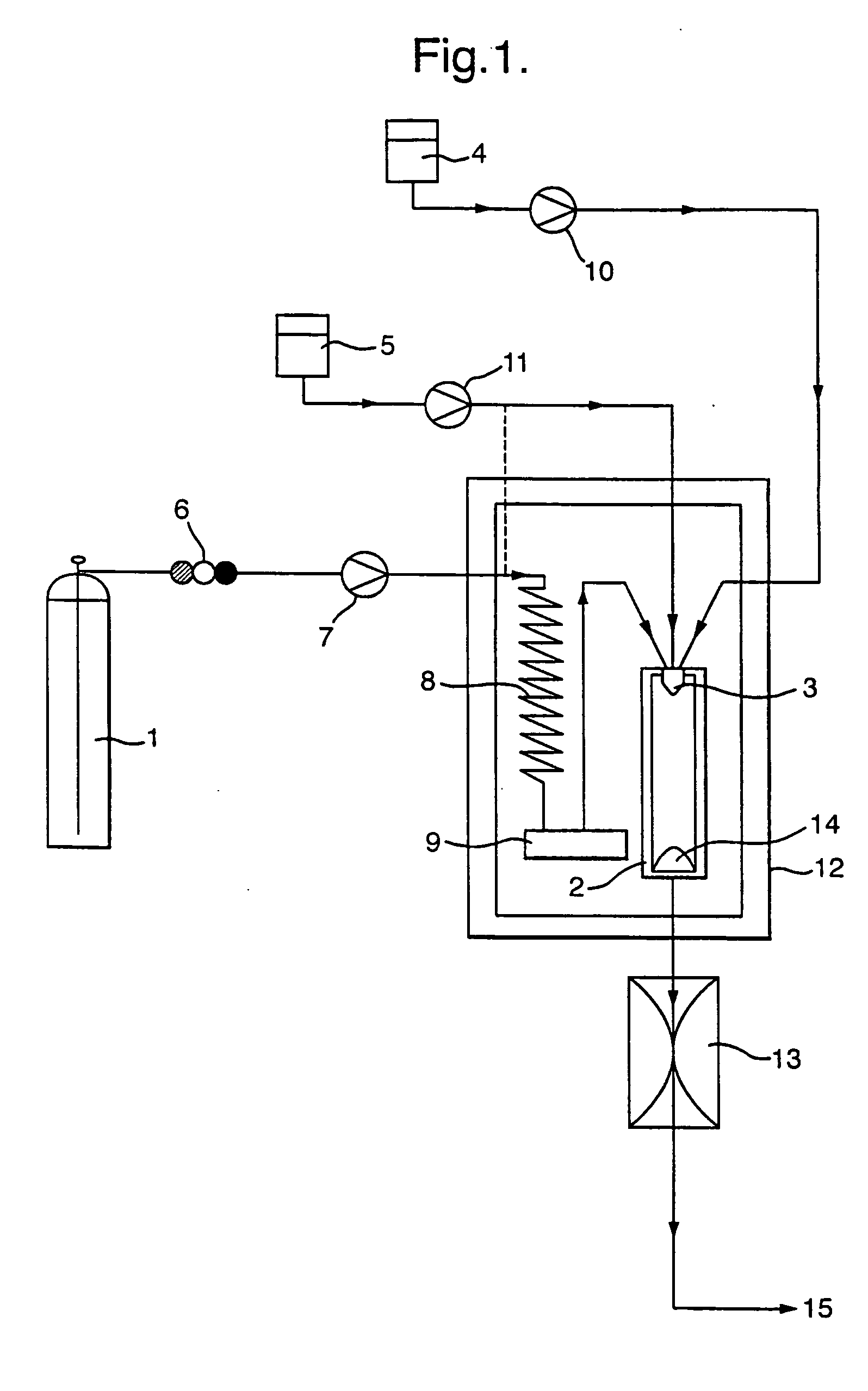

Method of particle formation

InactiveUS20050206023A1Characteristic is differentSufficient flow ratePressurized chemical processPeptide/protein ingredientsAnti solventTemperature and pressure

The invention provides a method for forming particles of a target substance, comprising (a) co-introducing into a particle formation vessel, under controlled temperature and pressure, a supercritical or near-critical anti-solvent fluid; a “target solution or suspension” of the target in a first vehicle; and a second vehicle which is soluble in the anti-solvent fluid; and (b) using the anti-solvent to disperse the target solution / suspension and the second vehicle, and to extract the vehicles, substantially simultaneously and substantially immediately on introduction of the fluids into the particle formation vessel, wherein the second vehicle is immiscible with the first, and wherein contact between the target solution / suspension and the second vehicle occurs a sufficiently short period of time before their dispersion by the anti-solvent, and with sufficient physical mixing, as to allow only insignificant, if any, phase separation to occur between the two vehicles between their contact with one another and their dispersion.

Owner:NEKTAR THERAPEUTICS INC

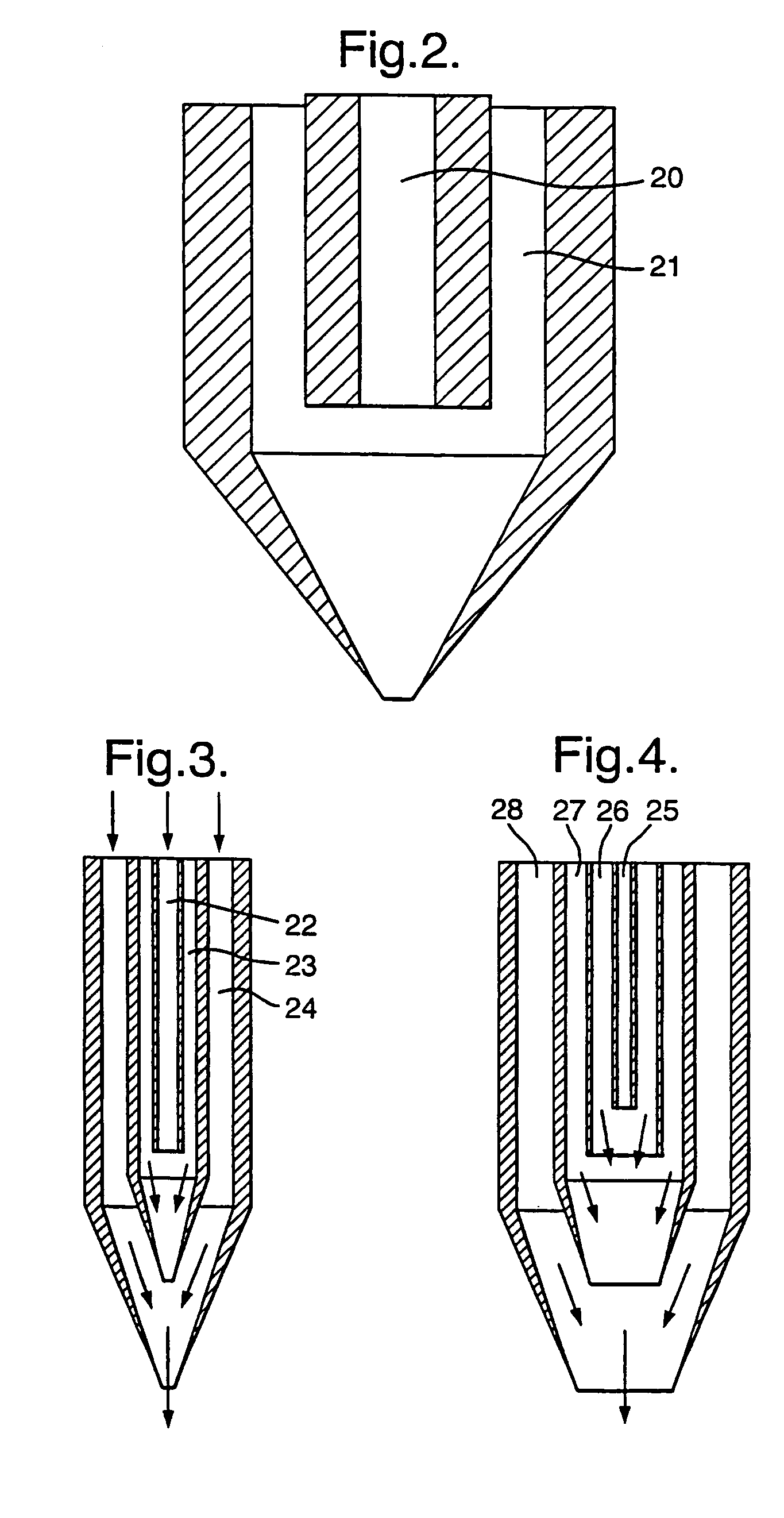

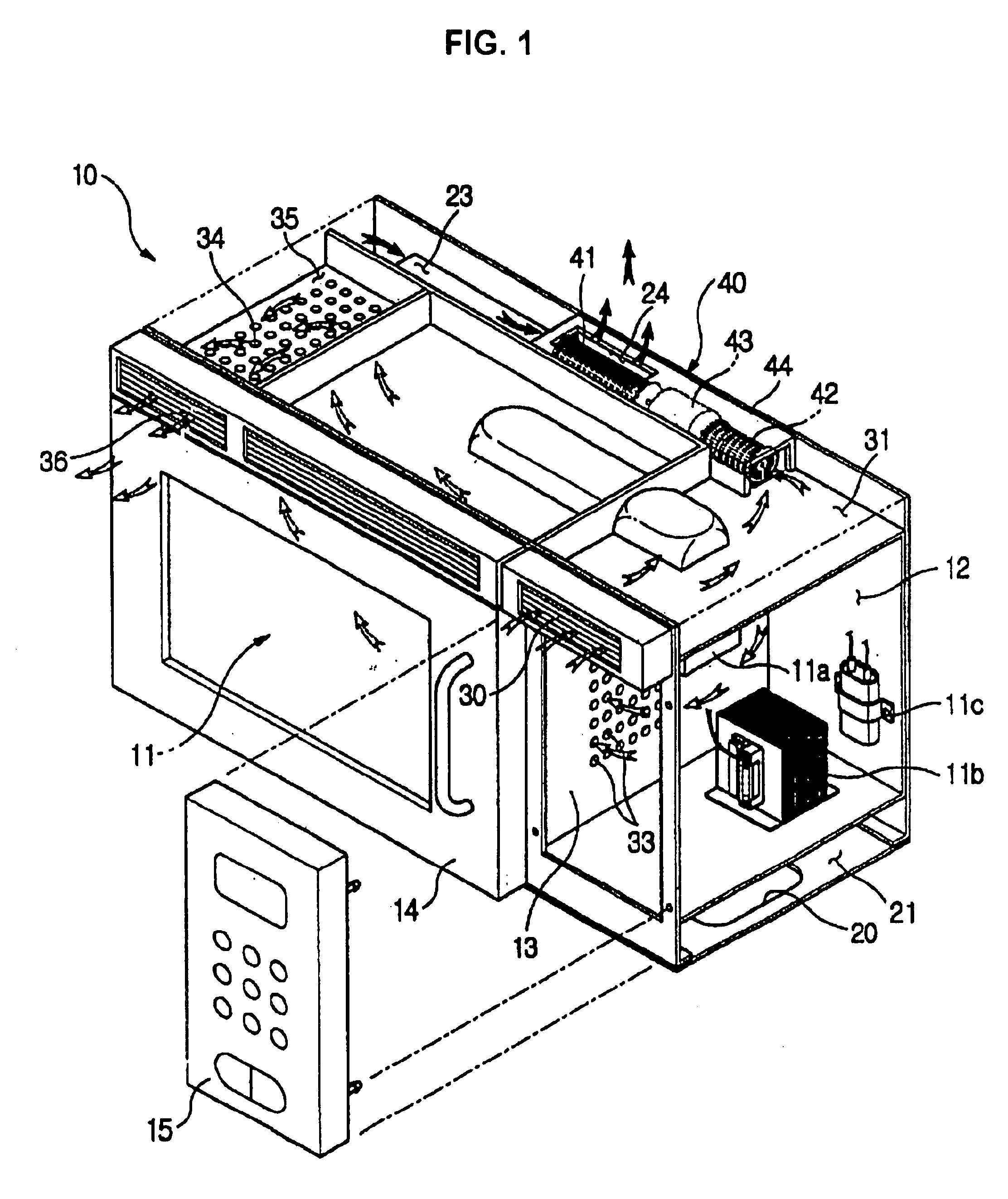

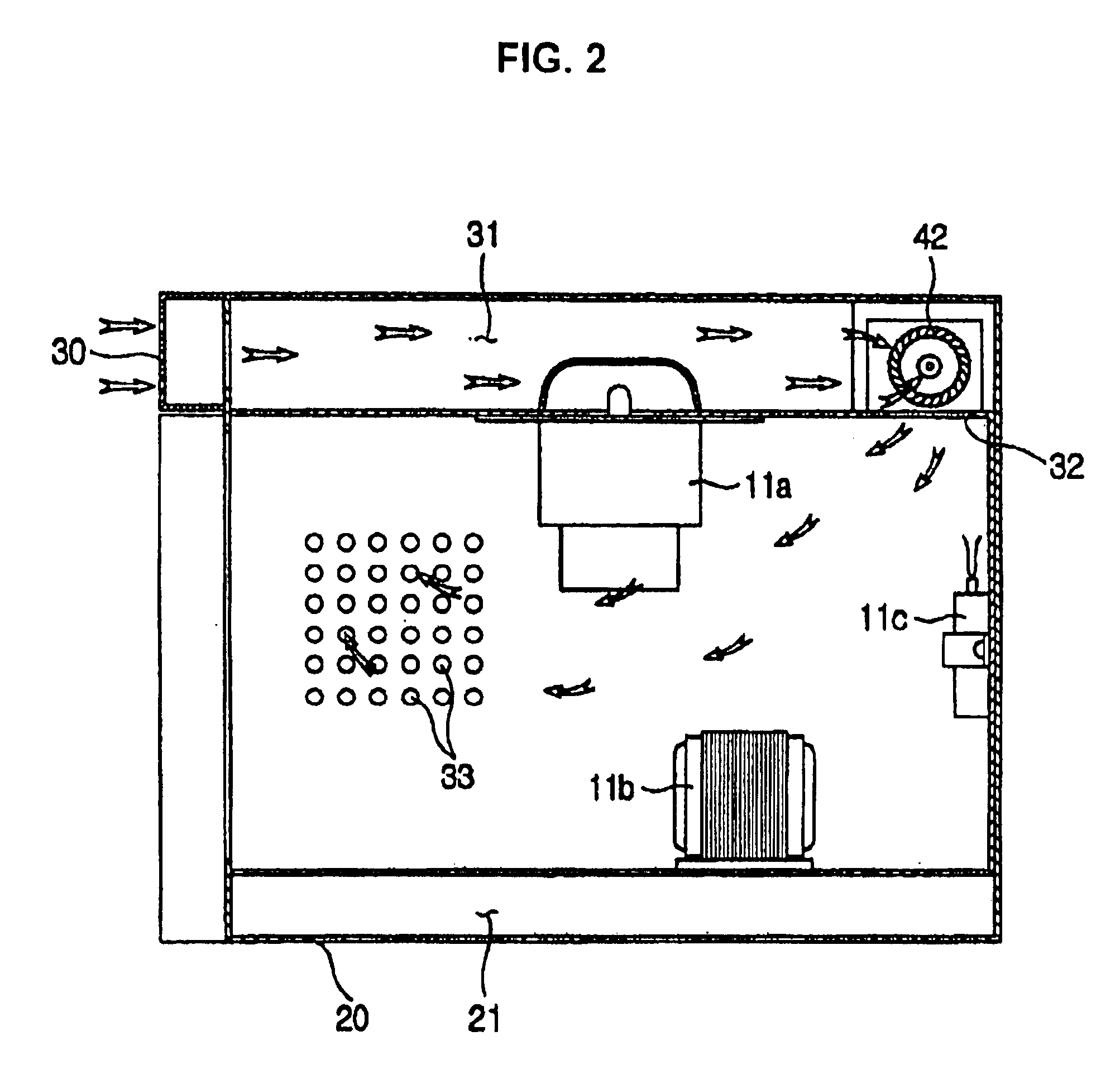

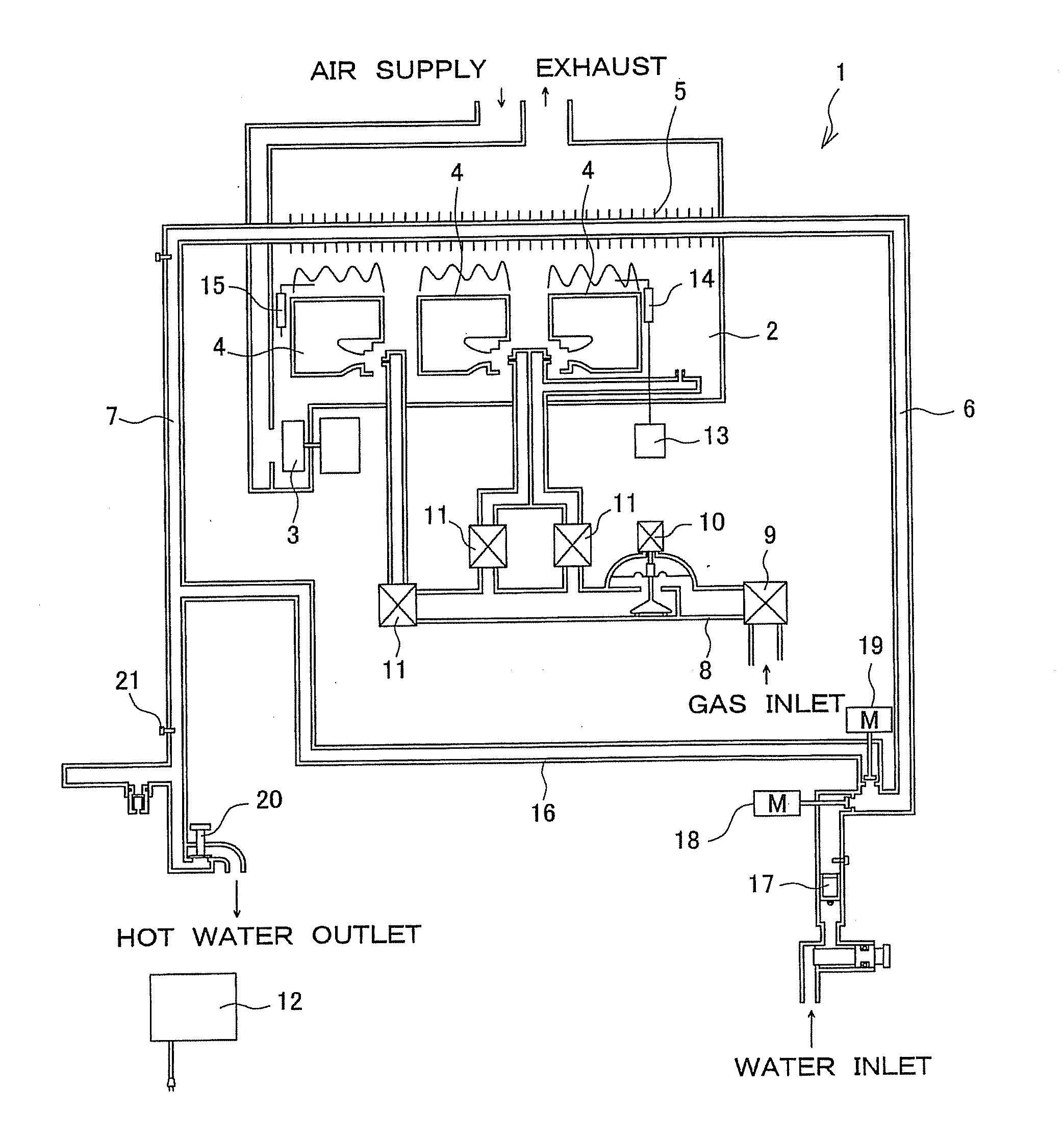

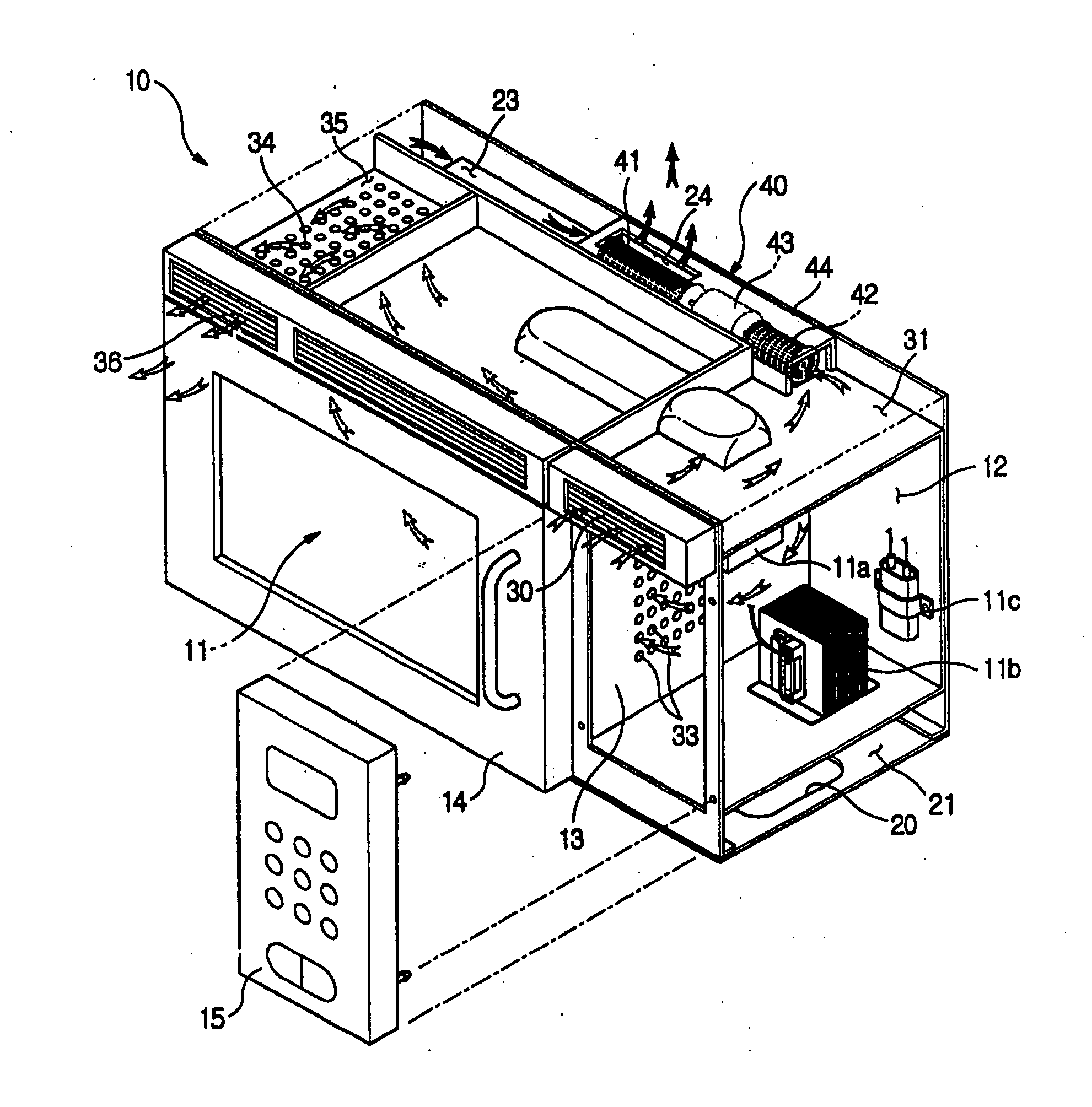

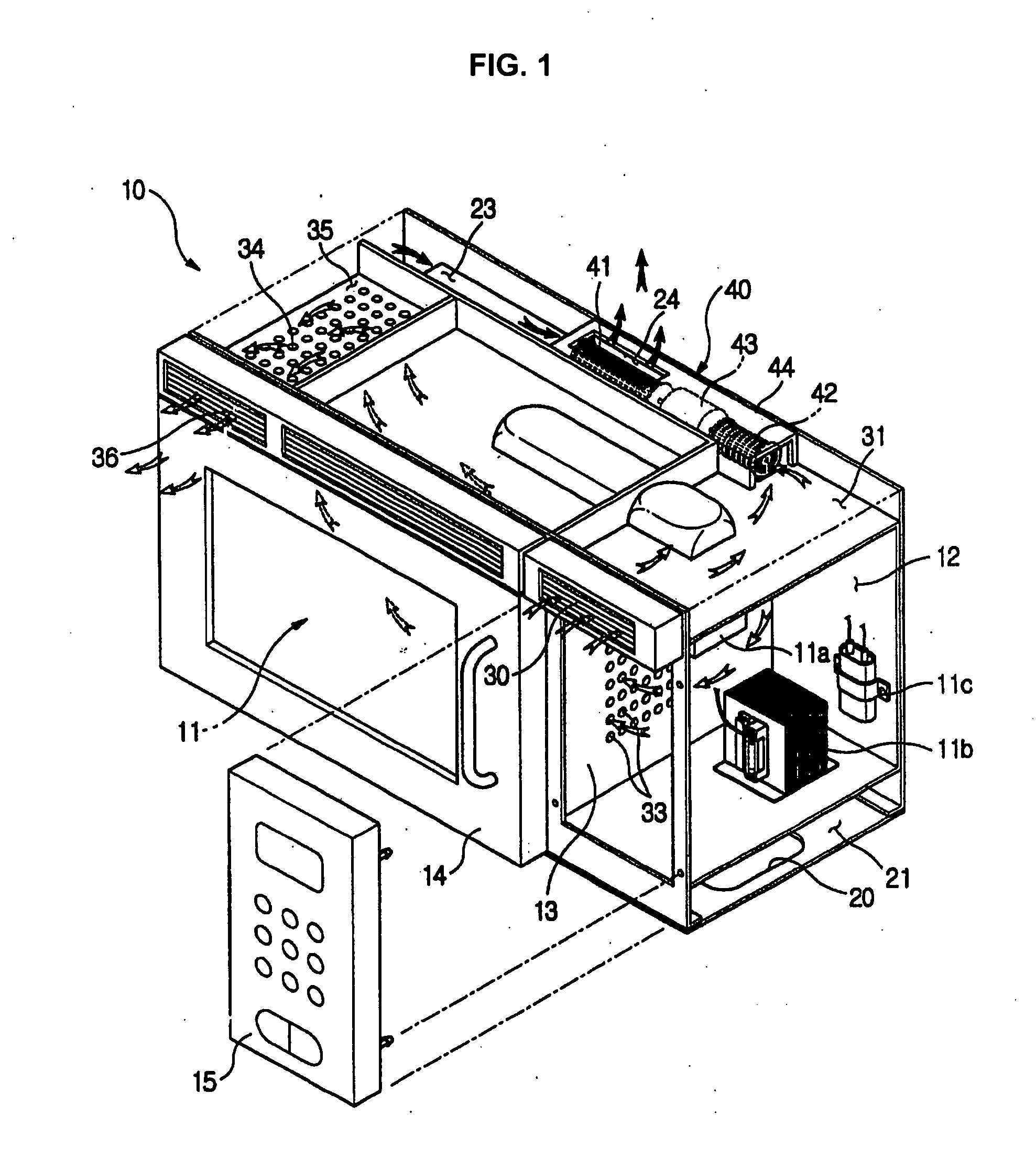

Exhaust and ventilation system for mountable type microwave oven

InactiveUS6864472B2Reduce in quantityImprove of manufactureDomestic stoves or rangesLighting and heating apparatusSuction forceMicrowave oven

A mountable type microwave oven including a blower fan assembly installed at a rear-upper portion of a cabinet to cool a machine room and ventilate a cooking chamber. The microwave oven includes a cabinet mounted on a wall of a cooking space, or under a storage cabinet, and having a cooking chamber to cook food therein and a machine room to house a plurality of electrical components, which are isolated from each other, an exhaust path to exhaust contaminated air generated from a cooking appliance installed below the wall-mounted microwave oven, a cooling-ventilation path to cool the machine room and to ventilate the cooking chamber, and a blower fan assembly including a drive motor having a pair of shafts to generate a rotating force, an exhaust fan joined to one shaft of the drive motor to generate a suction force and a propulsive force to cause the contaminated air to flow along the exhaust path, and a cooling-ventilation fan joined to the other shaft of the drive motor to generate suction and propulsive forces to cause air to flow along the cooling-ventilation path. Since the cooling-ventilation fan performs cooling of the machine room and ventilation of the cooking chamber, there is no need to provide an additional blower fan. Thus, the number of components of the microwave oven is reduced, thereby reducing production costs and improving productivity.

Owner:SAMSUNG ELECTRONICS CO LTD

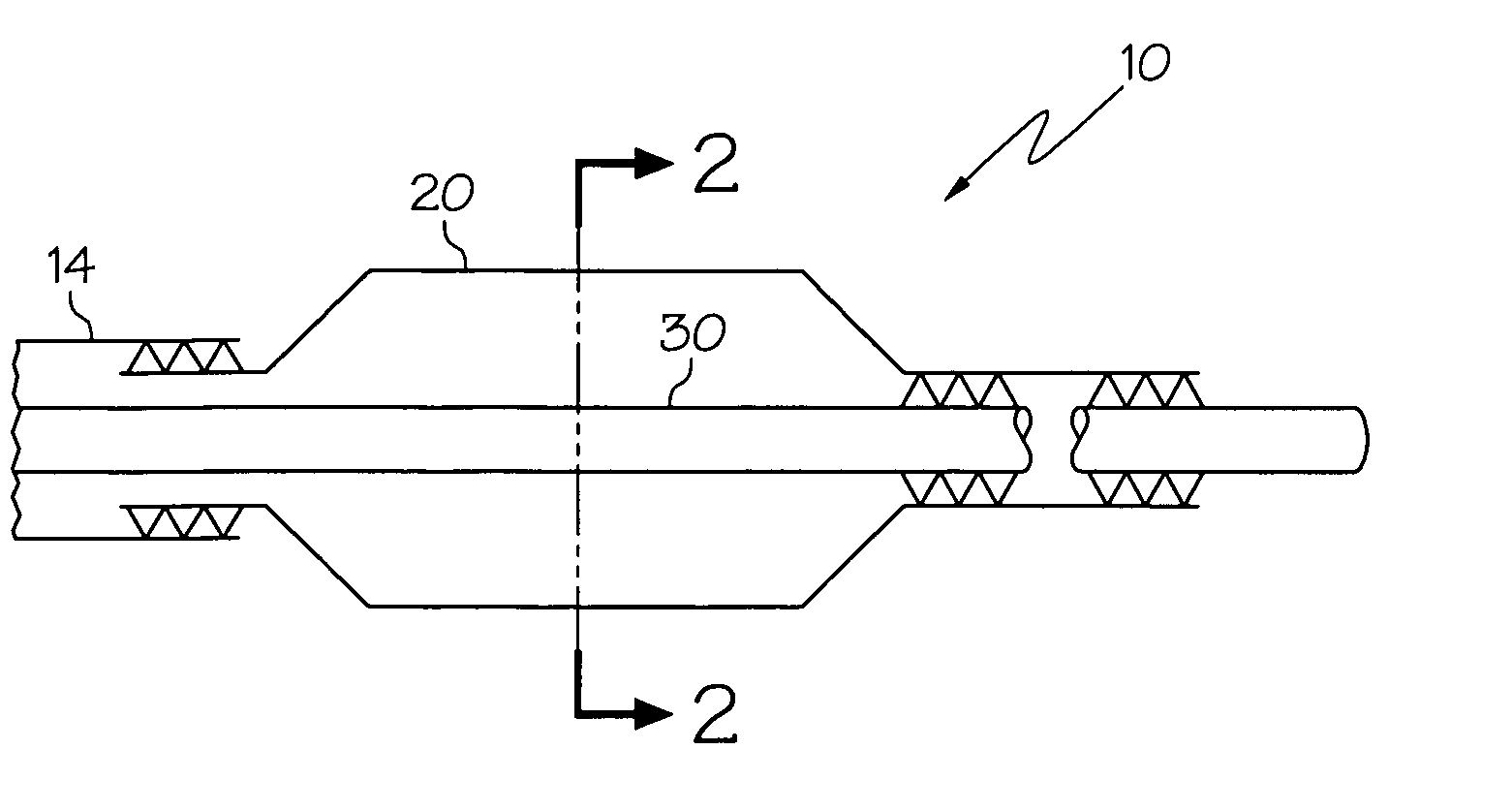

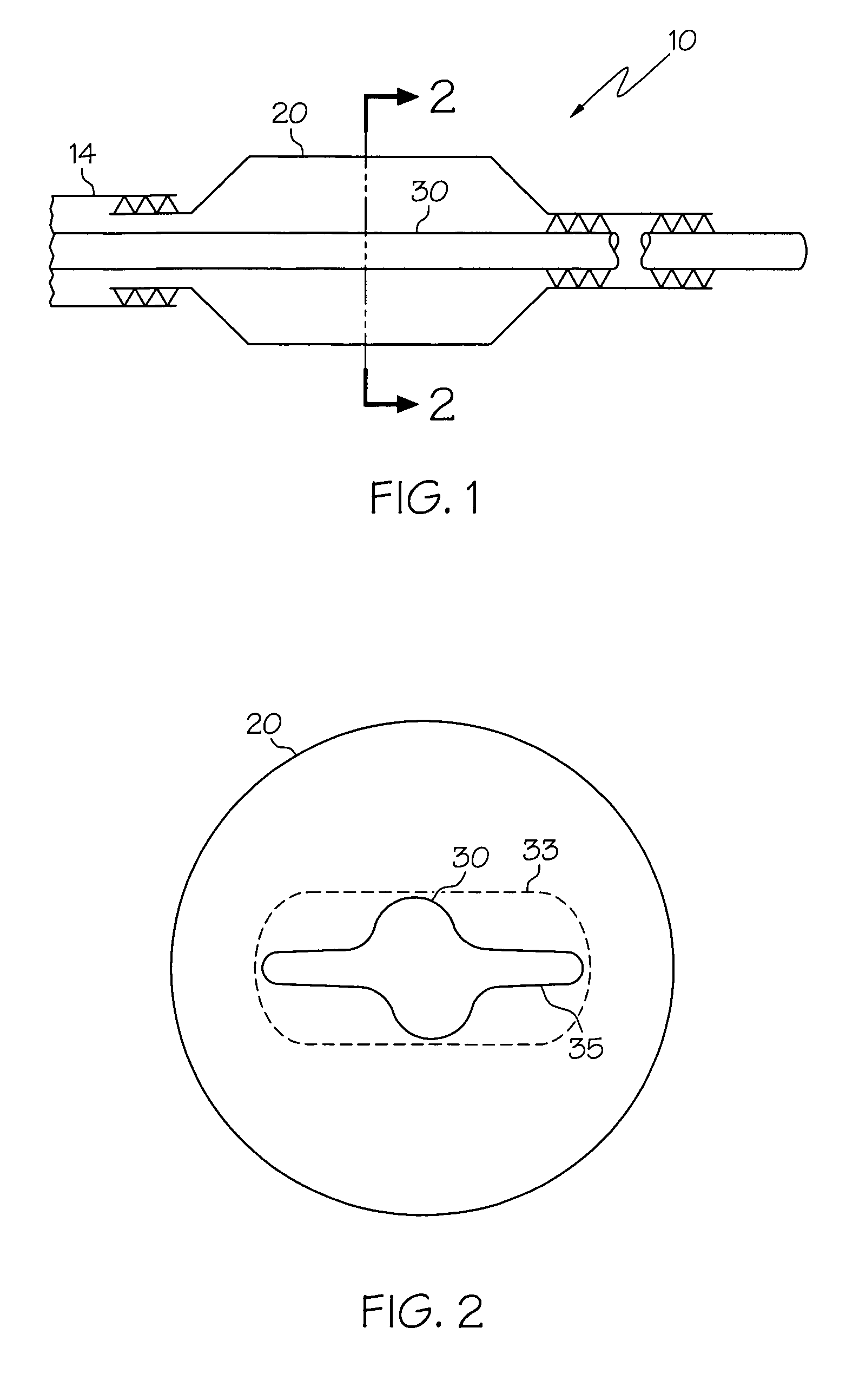

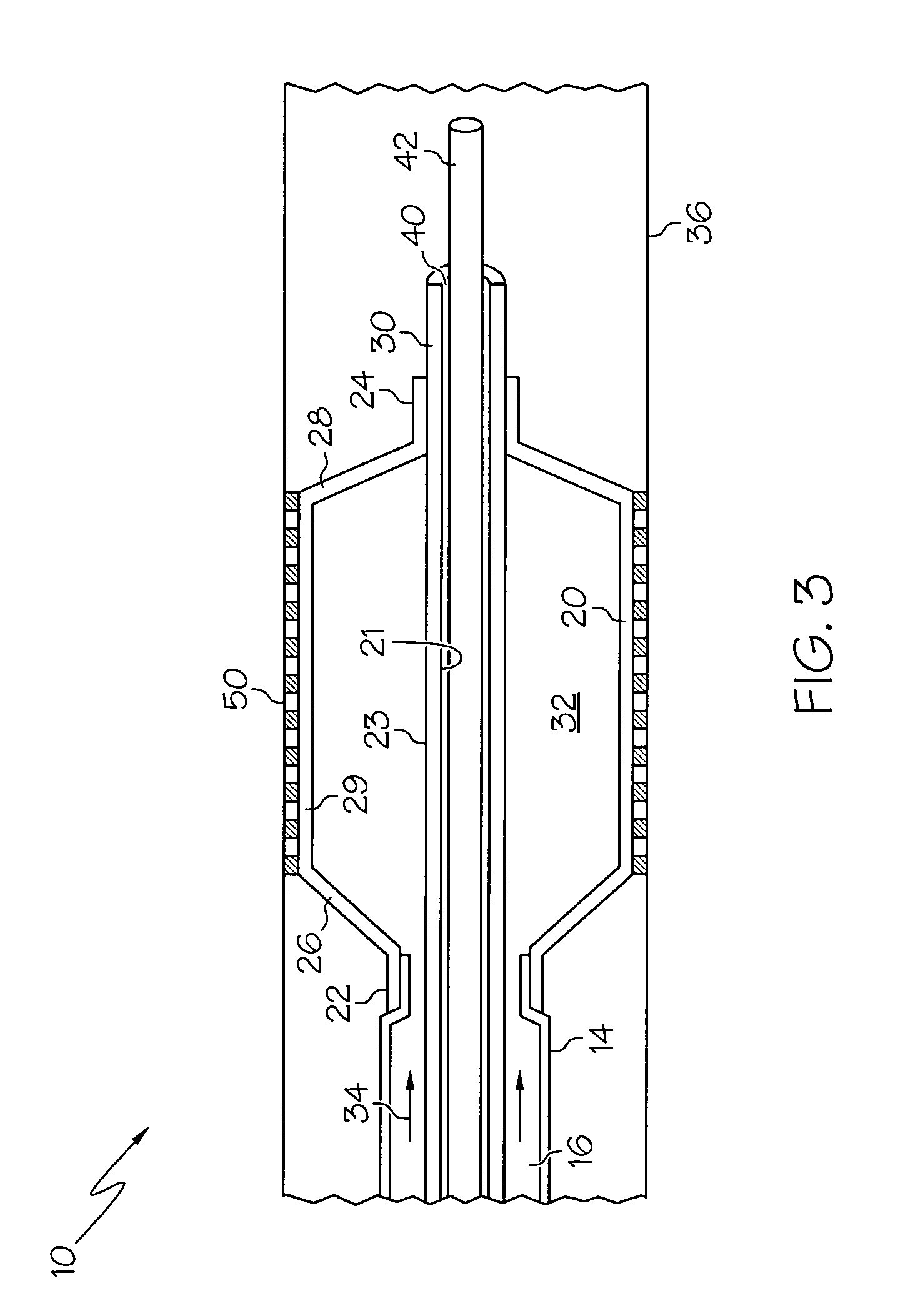

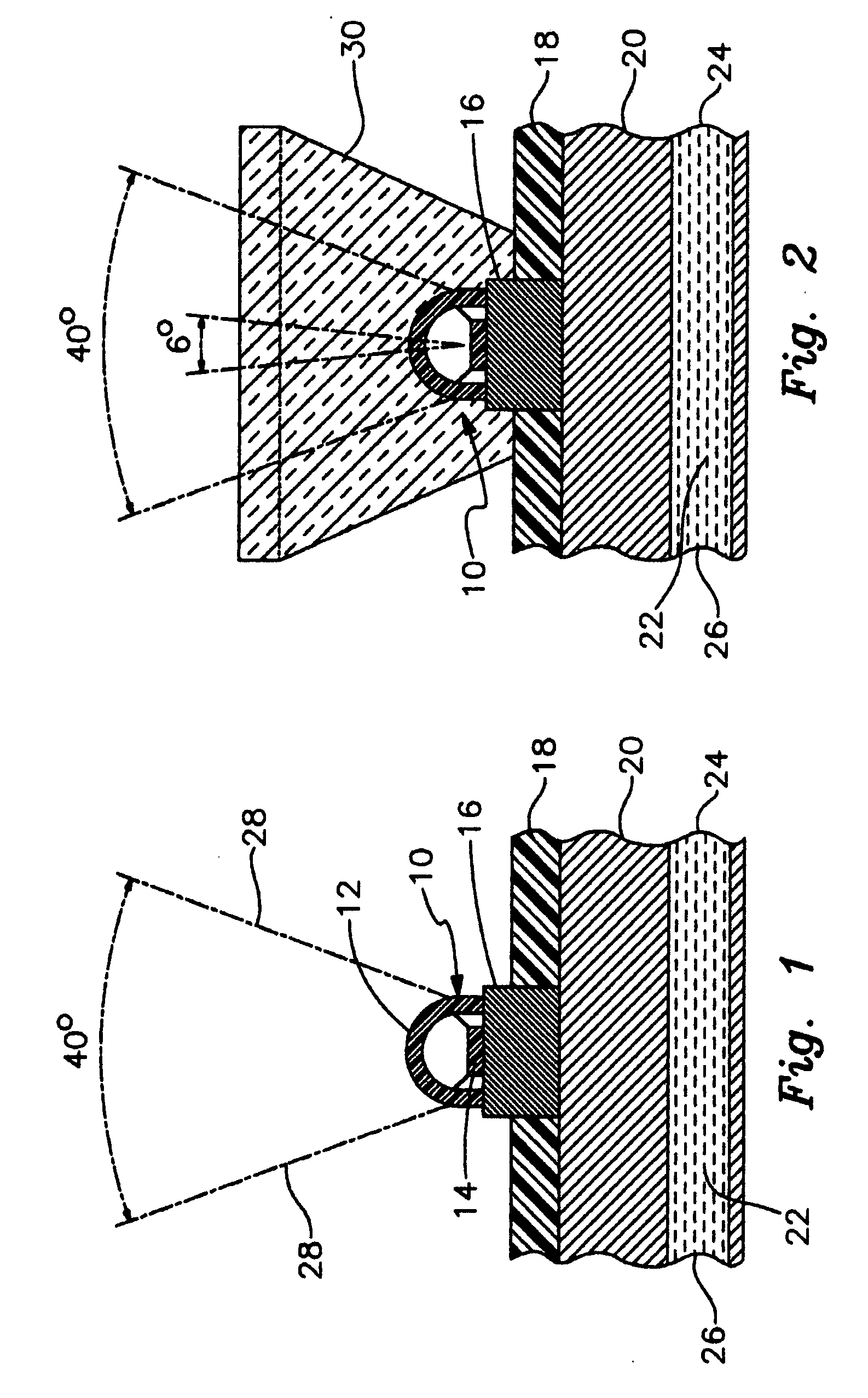

Balloon catheter with expandable wire lumen

A catheter comprises an outer shaft and an inner shaft defining a balloon inflation lumen for transport of an inflation fluid therethrough. The expandable balloon has a proximal waist portion and a distal waist portion with a body portion there between. The balloon is engaged to a distal region of the outer shaft and defines an exterior and an interior where the interior is in fluid communication with the balloon inflation lumen. The inner shaft has an inner shaft wall defining a guidewire lumen for passage of a guidewire. A distal portion of the inner shaft is expandable from an unexpanded state to an expanded state such that in the expanded state the guidewire lumen has a greater cross-sectional area than in the unexpanded state.

Owner:BOSTON SCI SCIMED INC

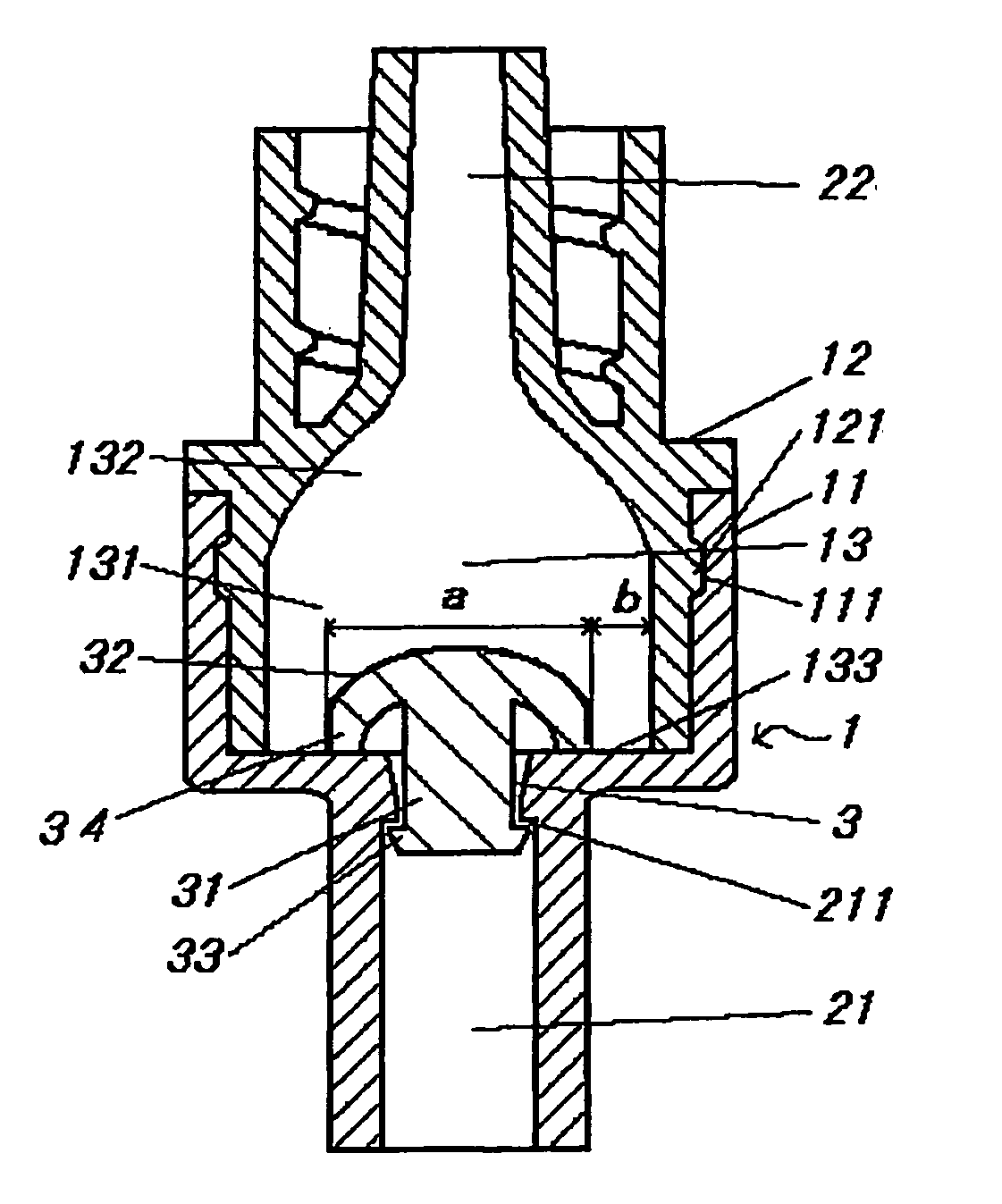

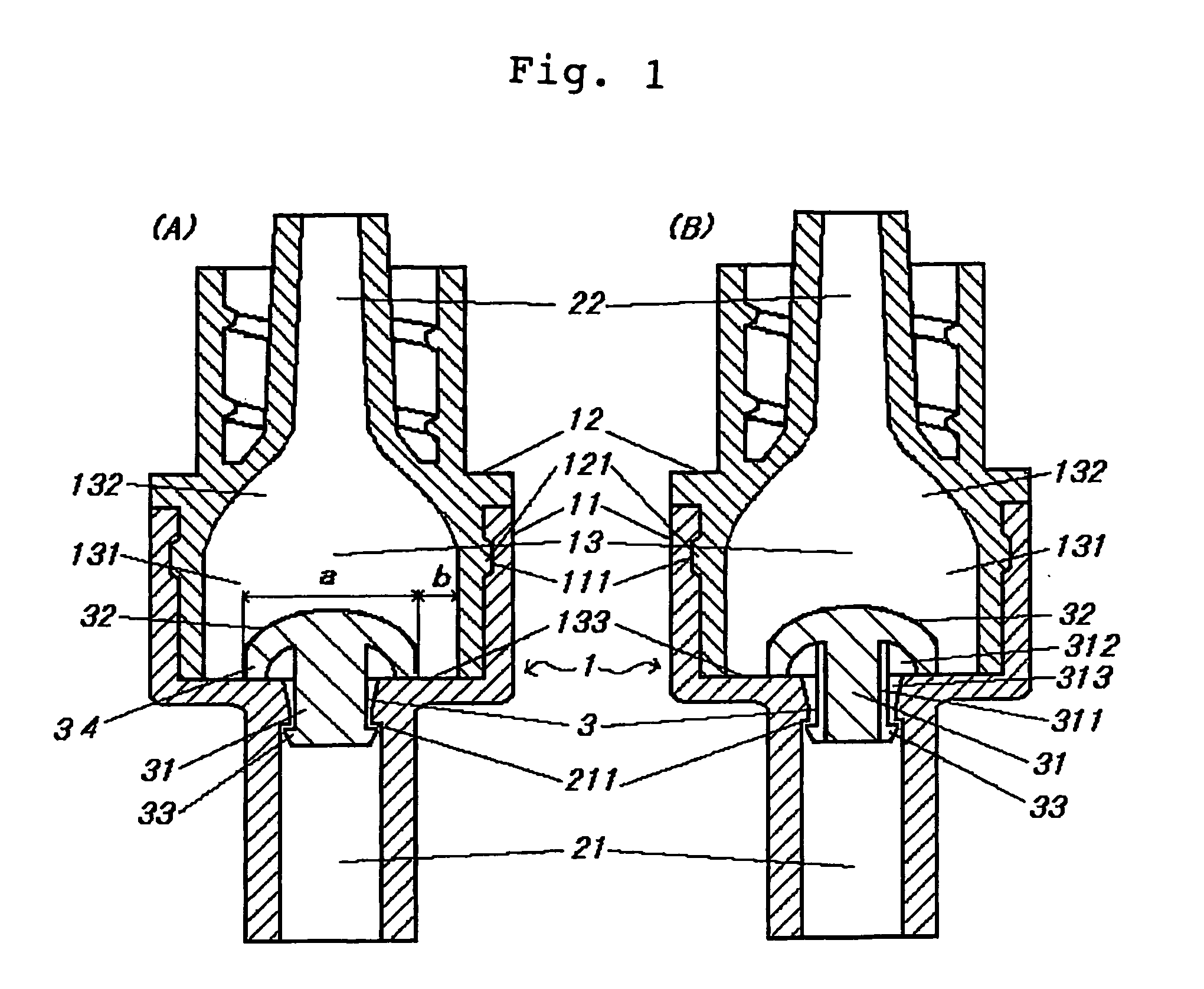

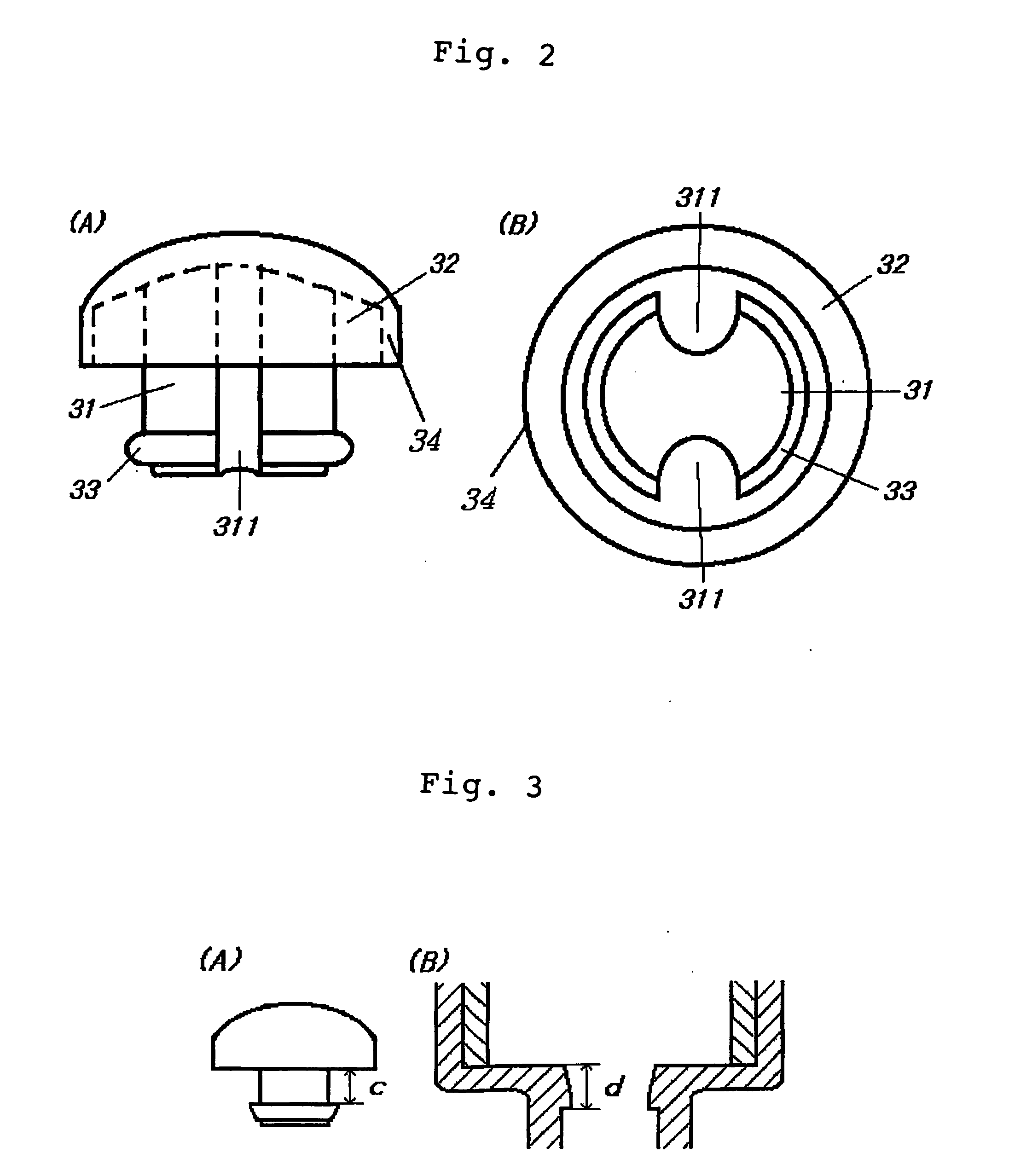

Fluid control device

InactiveUS20060155248A1Sufficient flow rateAccurate measurementMedical devicesCatheterFluid controlBlood pressure

A fluid control device is characterized in that the device is structured of a hollow first fluid path (21) and second fluid path (22), a housing portion (1) formed between the first fluid path and the second fluid path and having a hollow portion with a cross-sectional area larger than cross-sectional areas of both fluid paths, and a valve member (3) that has a main body (31) and a projection portion (32) that are installed in an opening portion where the first fluid path is connected to the hollow portion and that is formed of an elastic material. The fluid control device enables the circulation of liquid when the pressure of liquid flowing from the first fluid path toward the second fluid path is more than a predetermined level. The fluid control device enables accurate and safe measurement of pressure including blood pressure, and, when flushing operation of an infusion circuit etc. is finished, the device enables speedy lowering of pressure to a value that accurately reflects blood pressure of a patient and enables obtaining of a necessary flow rate in a region where pressure is relatively low.

Owner:JMS CO LTD

Inline intravenous fluid sterilizer

ActiveUS8747764B1Preventing formation of bubbles during useSufficient flow rateScattering properties measurementsSolid sorbent liquid separationEngineeringCatheter

An inline intravenous (IV) fluid sterilization system can be located within directly upstream of the patient's access point, downstream of any breach points, so as to ensure fluid sterility. The chamber space between the walls is accessed by a fluid inlet port and a fluid outlet port between which the fluid flows. The inlet port is connected to a conduit / tubing from the fluid source and the outlet port is interconnected with a conduit / tubing that is free of breach points and interconnects to the patient access point. The inner wall allows for transmission of UV light into the fluid space. The walls define a space therebetween that is relatively small radially, allowing for a sufficient flow rate, but providing a large surface area and small fluid depth for exposure to the UV light. The UV light is provided by an elongated lamp within a cavity of the inner wall.

Owner:B B R MEDICAL INNOVATIONS

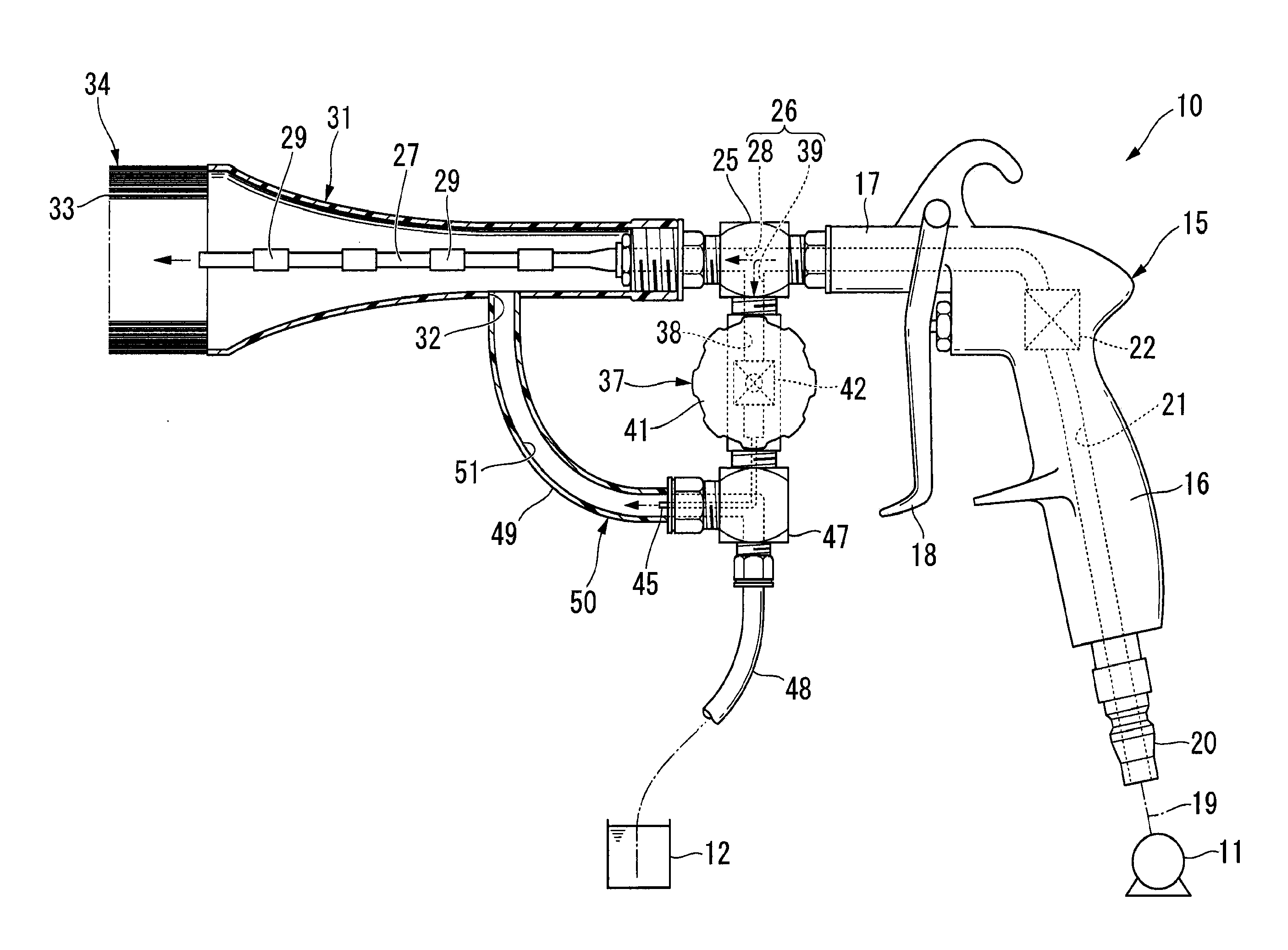

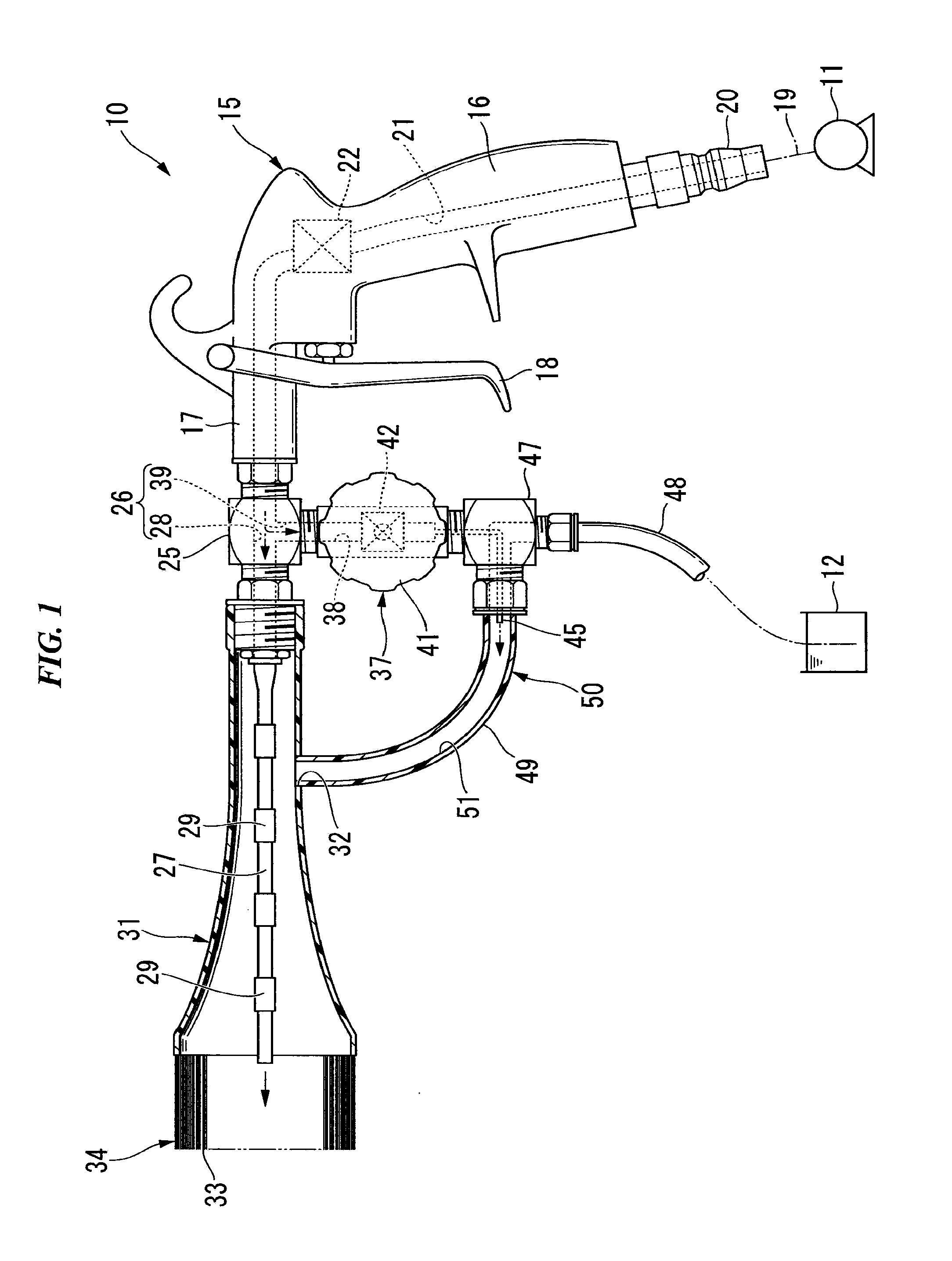

Fluid spraying gun

ActiveUS20100176219A1Sufficient amountSufficient flow rateMovable spraying apparatusSpray nozzlesPipe fittingEngineering

A fluid spraying gun of the present invention includes: a tube-shape guide, on which a brush extending forward is implanted; a nozzle, which is formed of a flexible pipe member with a front end thereof as a free end, and sprays one portion of gas, which is supplied from the flow separation portion and passes through the nozzle, toward the brush from the front end thereof, while the nozzle undergoes the gyrating motion guided by the tube-shape guide; an inner nozzle, which sprays gas which has passed through a flow rate adjustment portion from a tip portion thereof; and a liquid distribution pipe, which penetrates the tube-shape guide, links an inside of the tube-shape guide with a liquid supply source, has an intermediate portion into which the inner nozzle is inserted in a state where the inner nozzle is directed toward the tube-shape guide, and draws up liquid from the liquid supply source by a negative pressure arising from spraying of gas by the inner nozzle to cause spraying of liquid on the inside of the tube-shape guide. According to the present invention, it is possible to provide a fluid spraying gun in which a liquid with an adequate flow rate can be mixed with a gas, converted into minute drops and sprayed.

Owner:GA REW

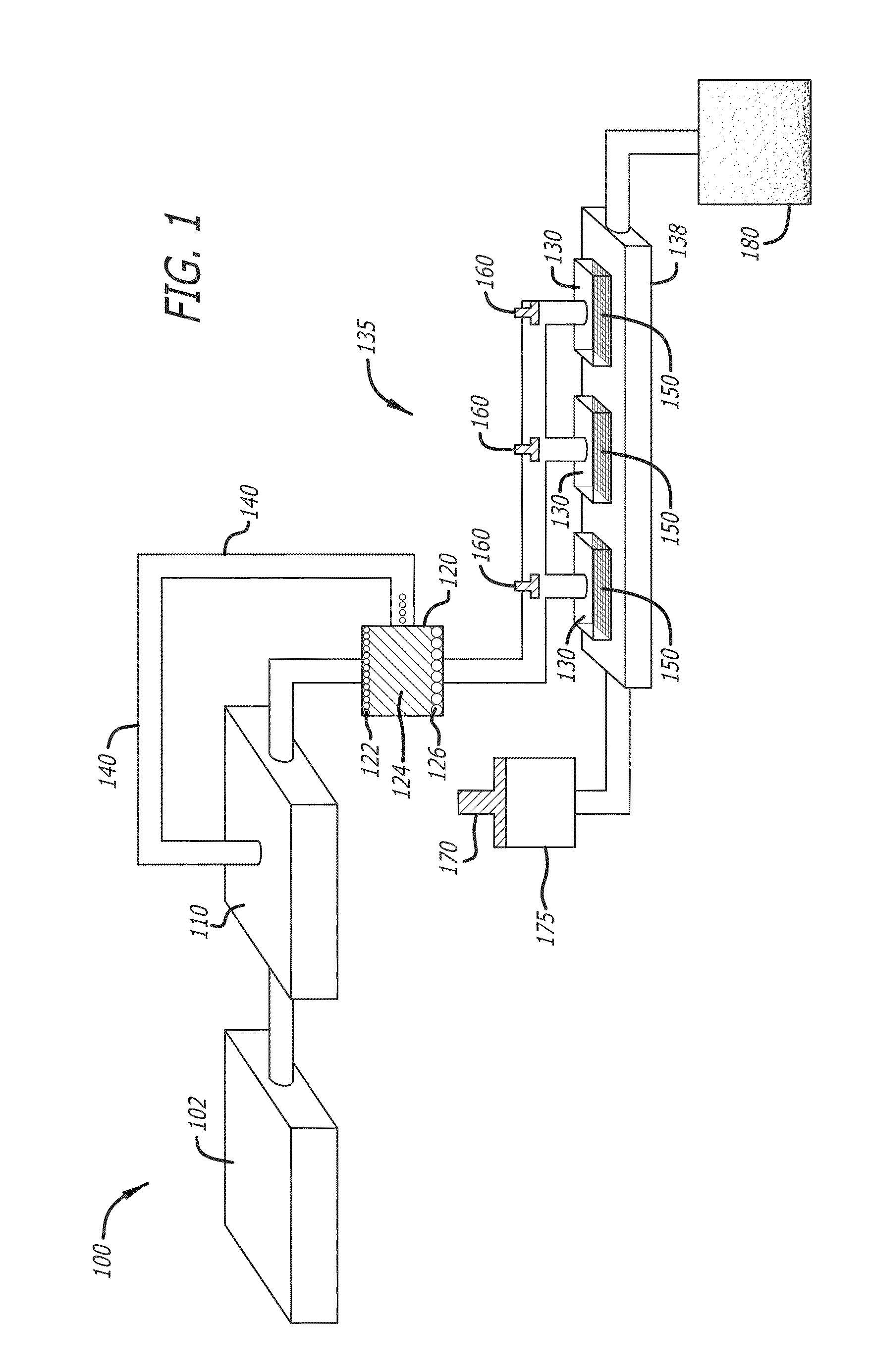

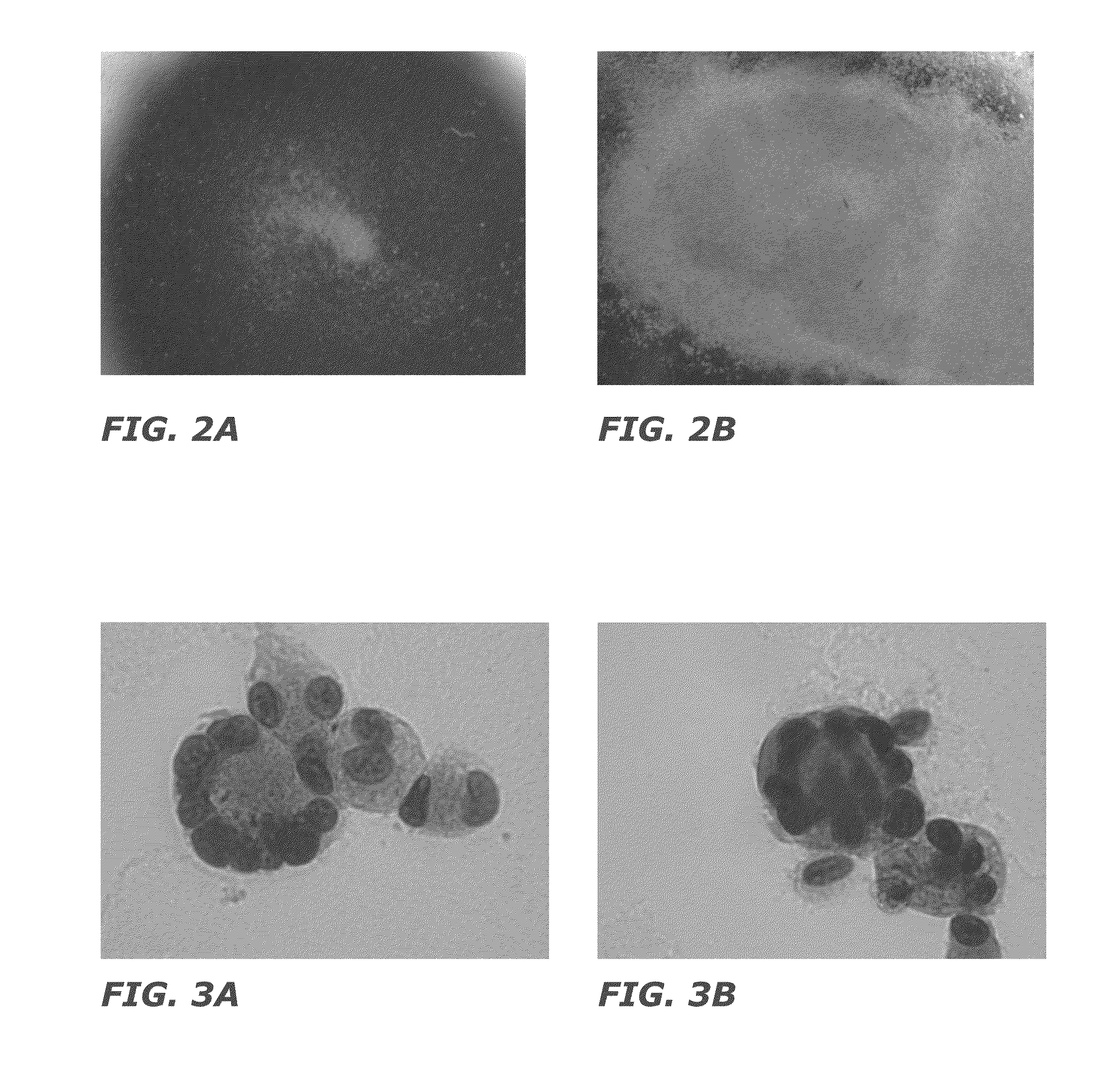

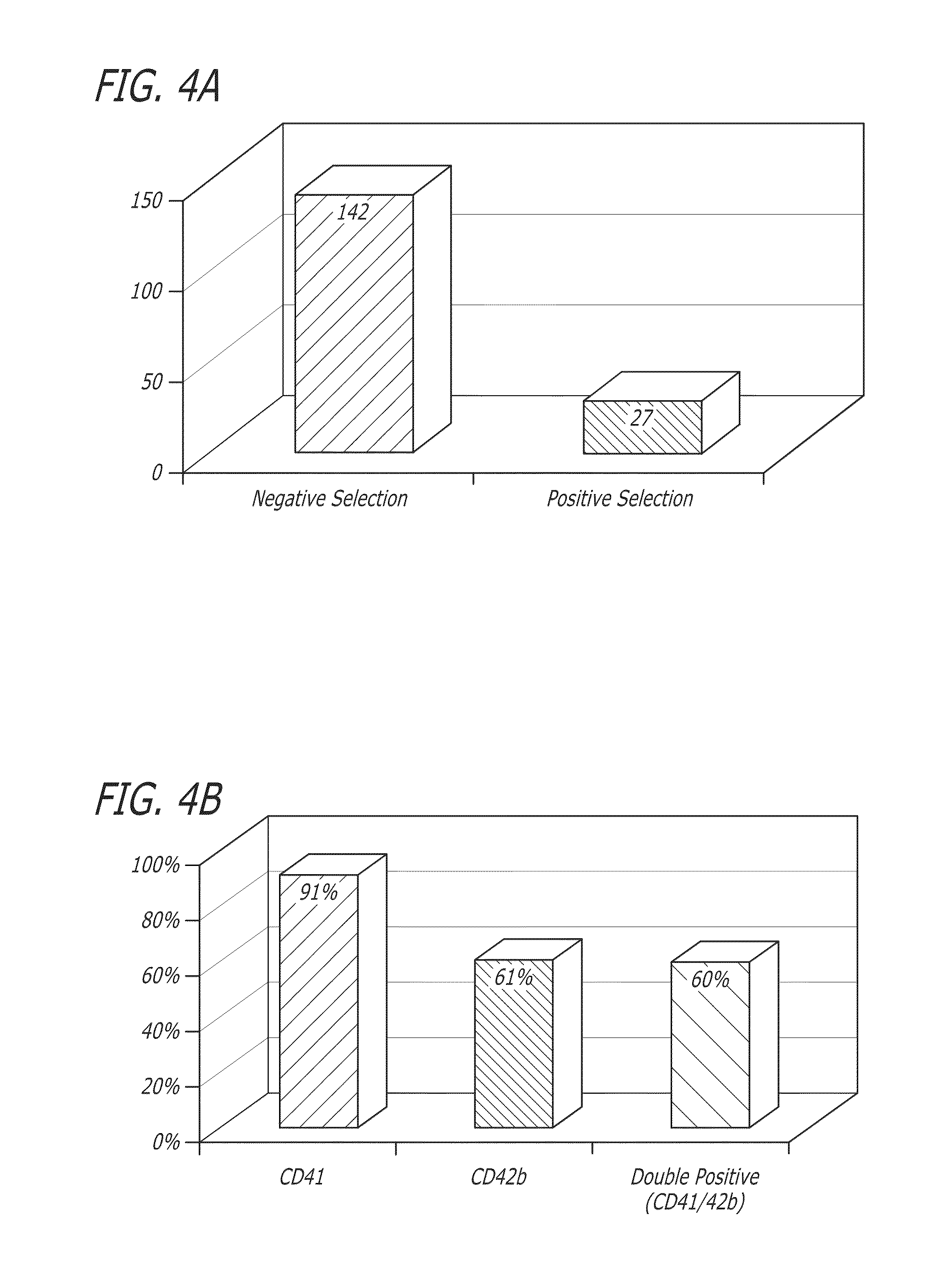

Megakaryocyte and Platelet Production from Stem Cells

ActiveUS20160002586A1Sufficient flow rateIncrease in platelet productionBioreactor/fermenter combinationsBiological substance pretreatmentsMegakaryocyteEx vivo

Methods for obtaining purified populations of megakaryocytes and platelets by ex vivo culture of stem cells are provided herein.

Owner:NEW YORK BLOOD CENT

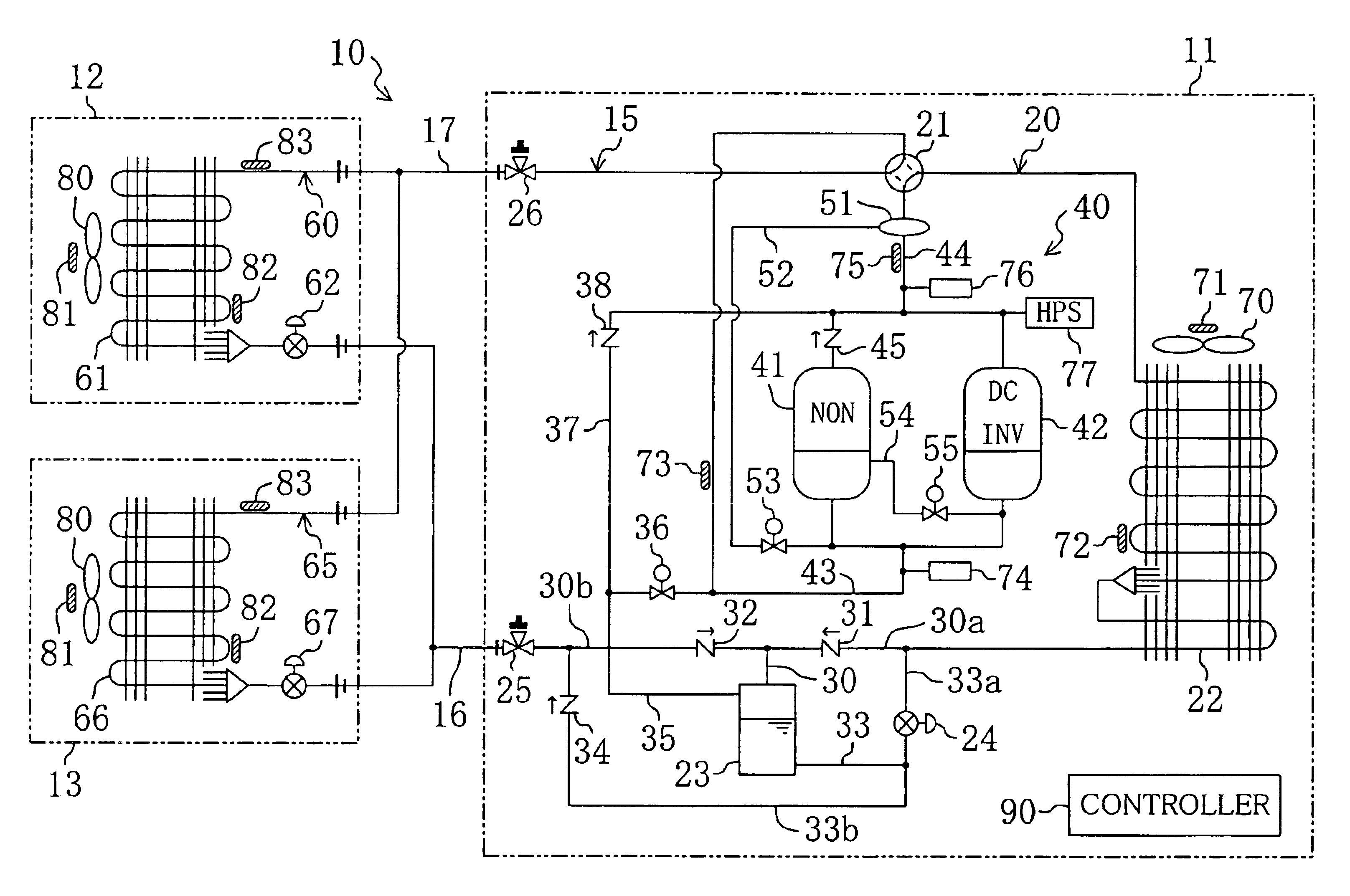

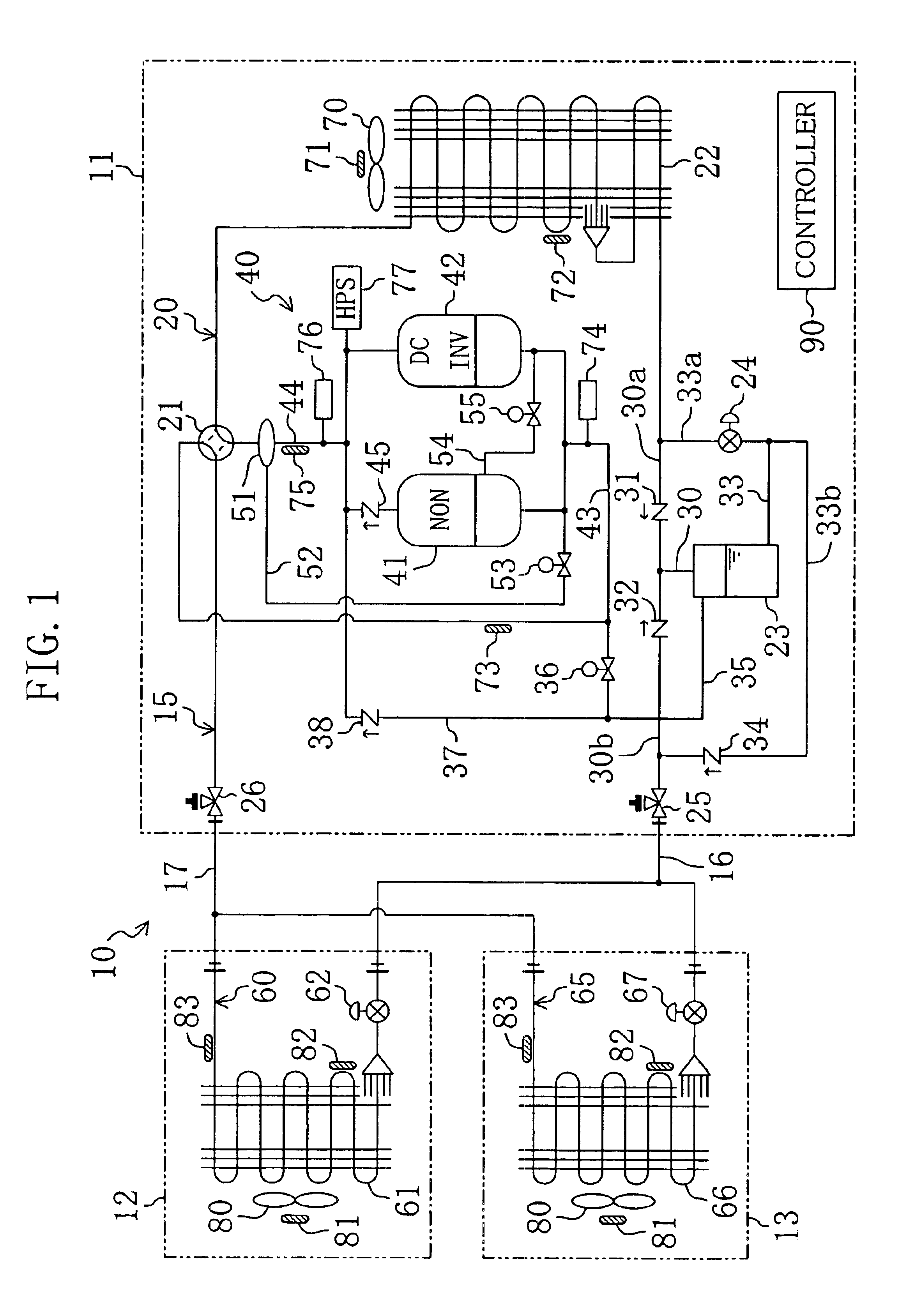

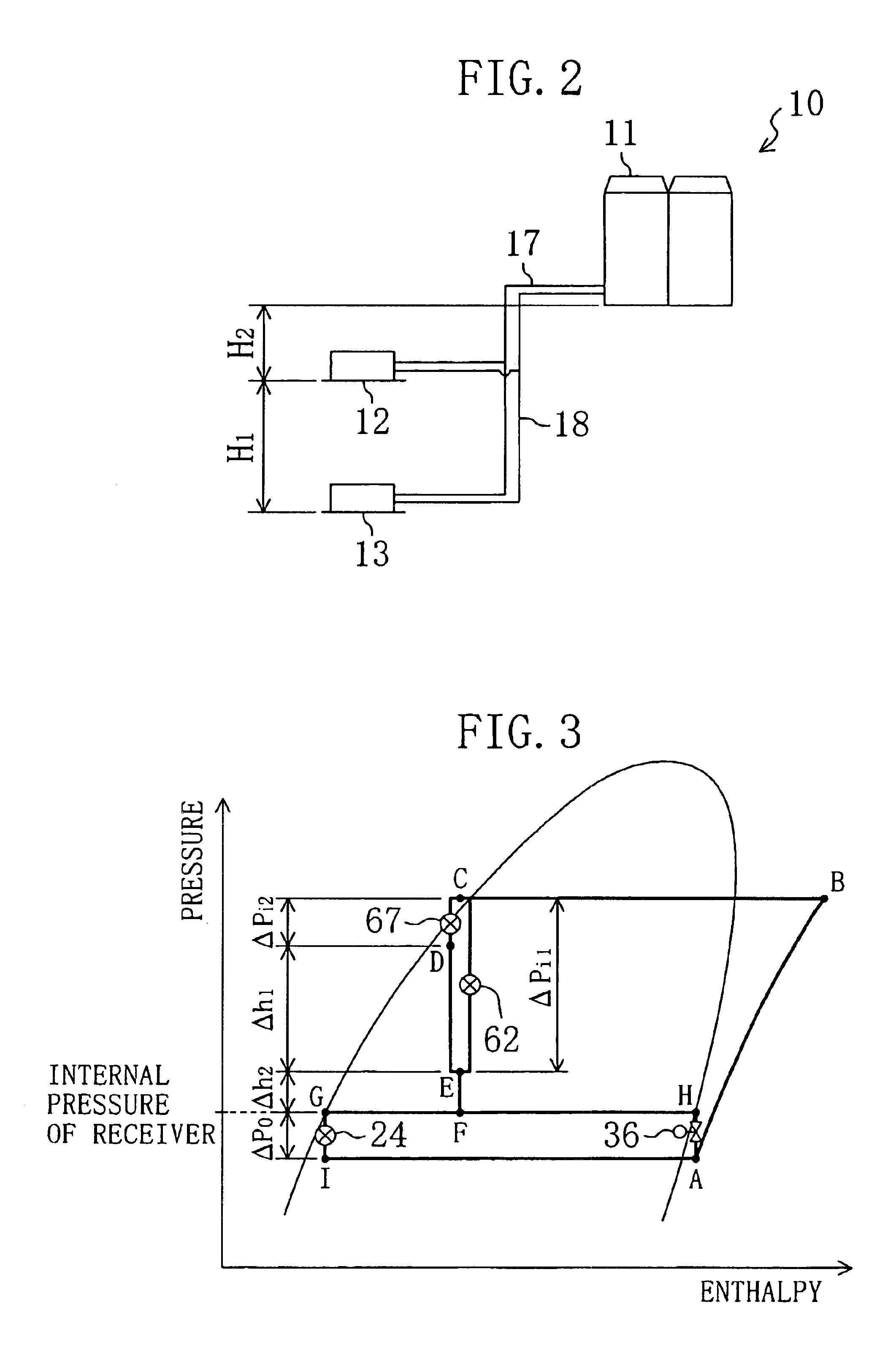

Heat pump apparatus

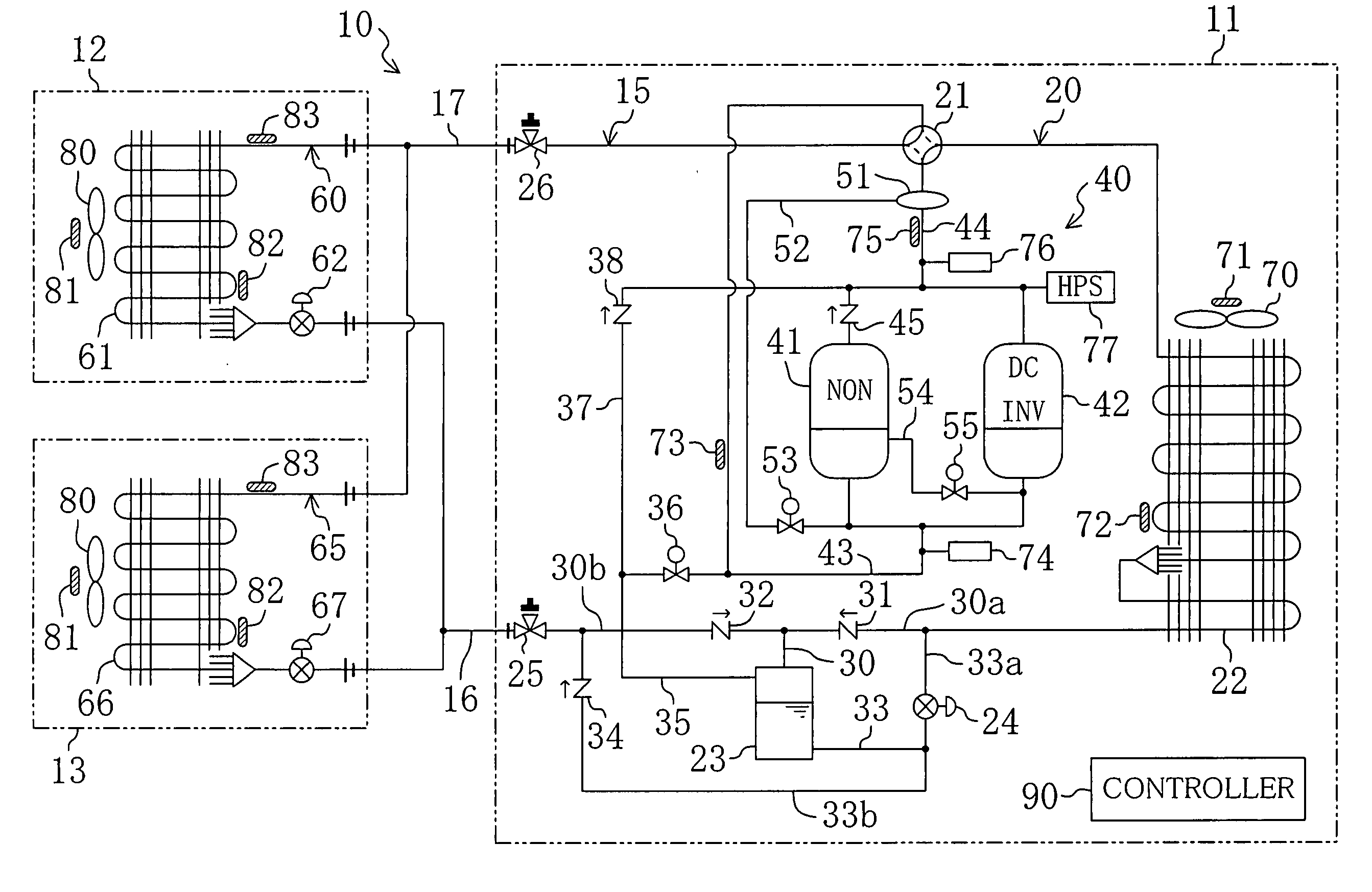

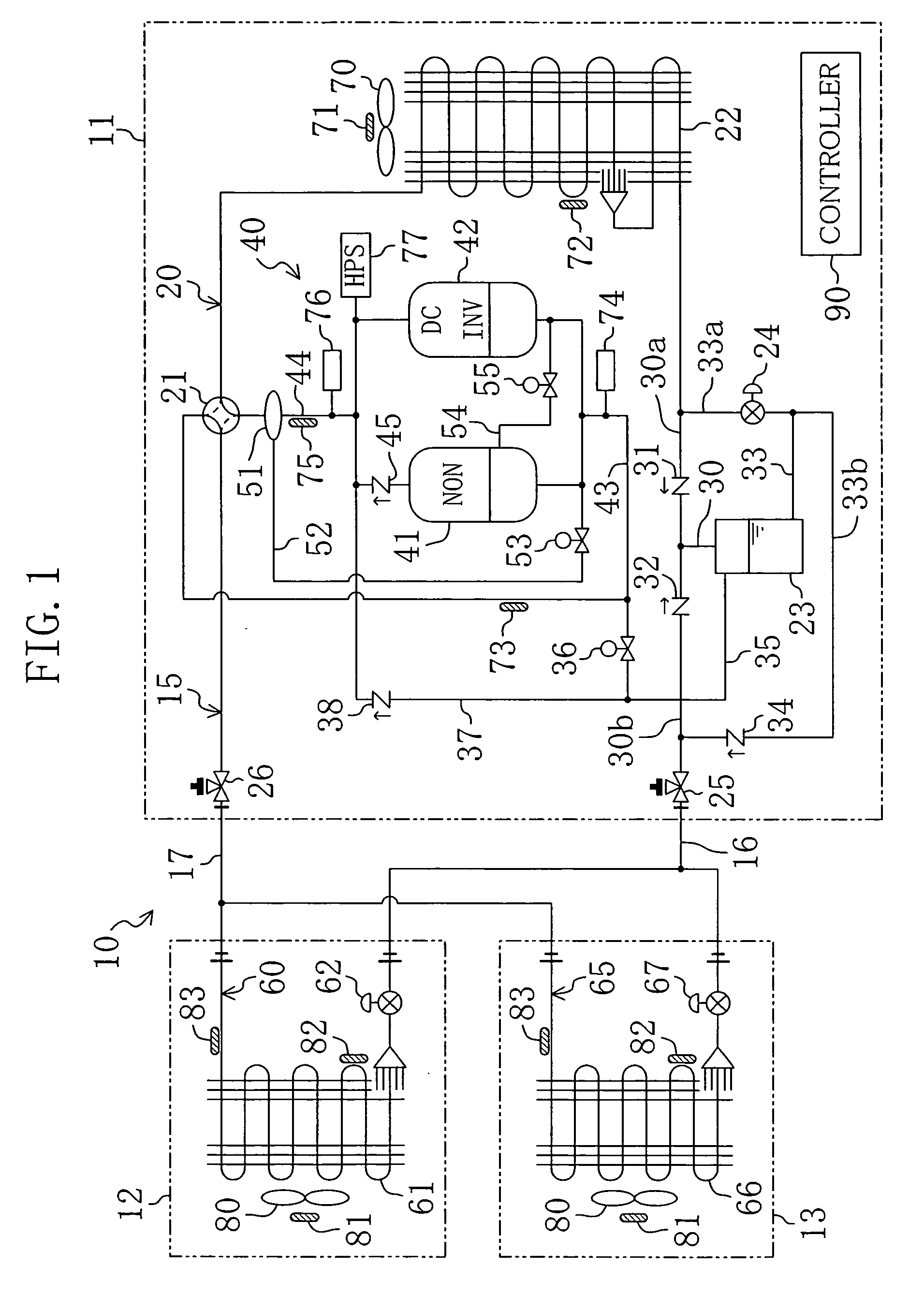

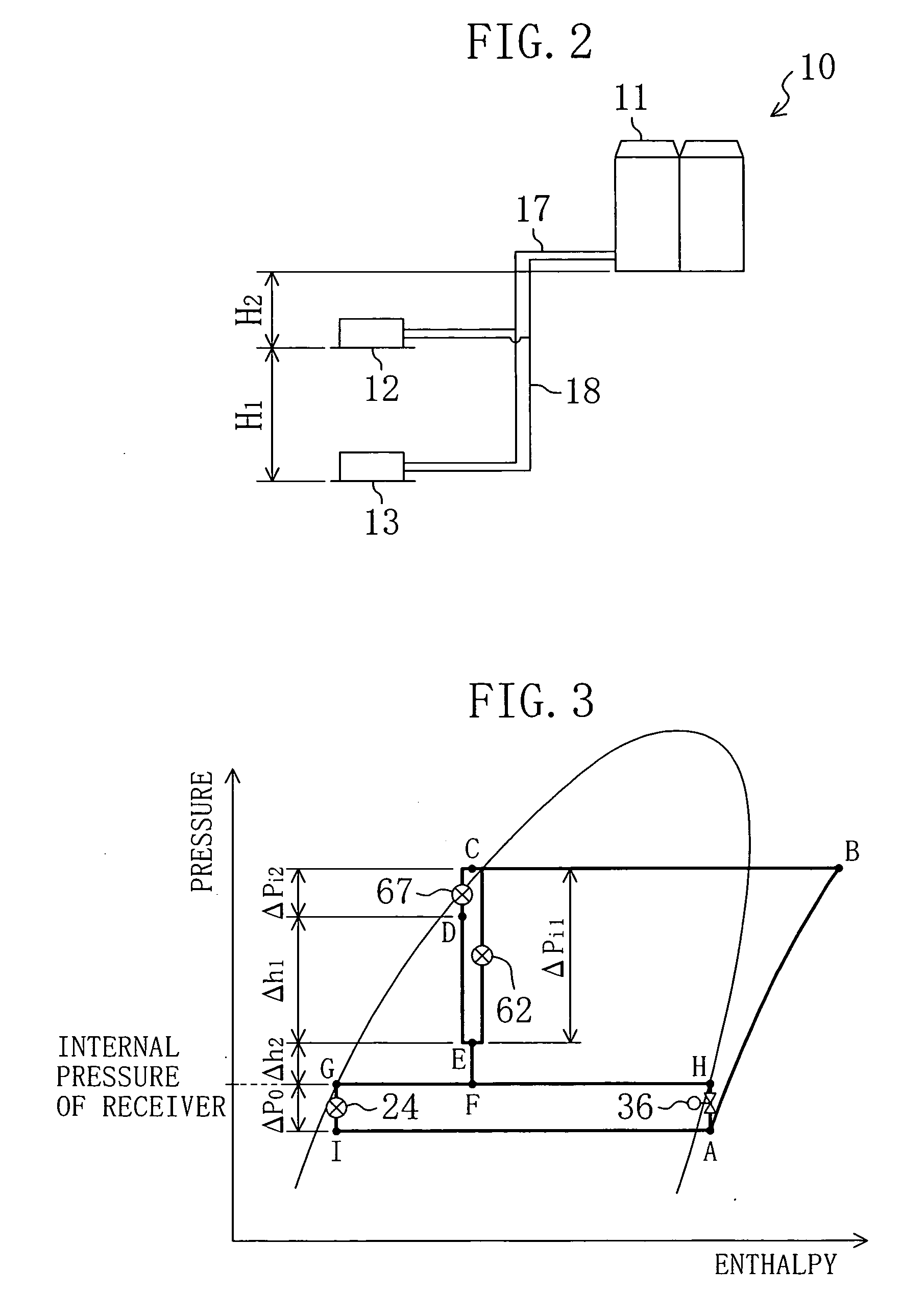

InactiveUS20040182101A1Reduce pressureAvoid loopsEfficient regulation technologiesCompression machines with reversible cycleSolenoid valveEngineering

Indoor circuits (60, 65) of indoor units (12, 13) are each connected in parallel to an outdoor circuit (20) of an outdoor unit (11). The outdoor circuit (20) has a gas vent pipe (35) by which a receiver (23) is brought into communication with suction sides of compressors (41, 42). During the heating operation in the heating mode of operation, a gas vent solenoid valve (36) is placed in the open state so that the receiver (23) decreases in pressure. This relaxes restrictions on the difference in installation height between each indoor unit of a multi type airconditioner having a plurality of indoor units.

Owner:DAIKIN IND LTD

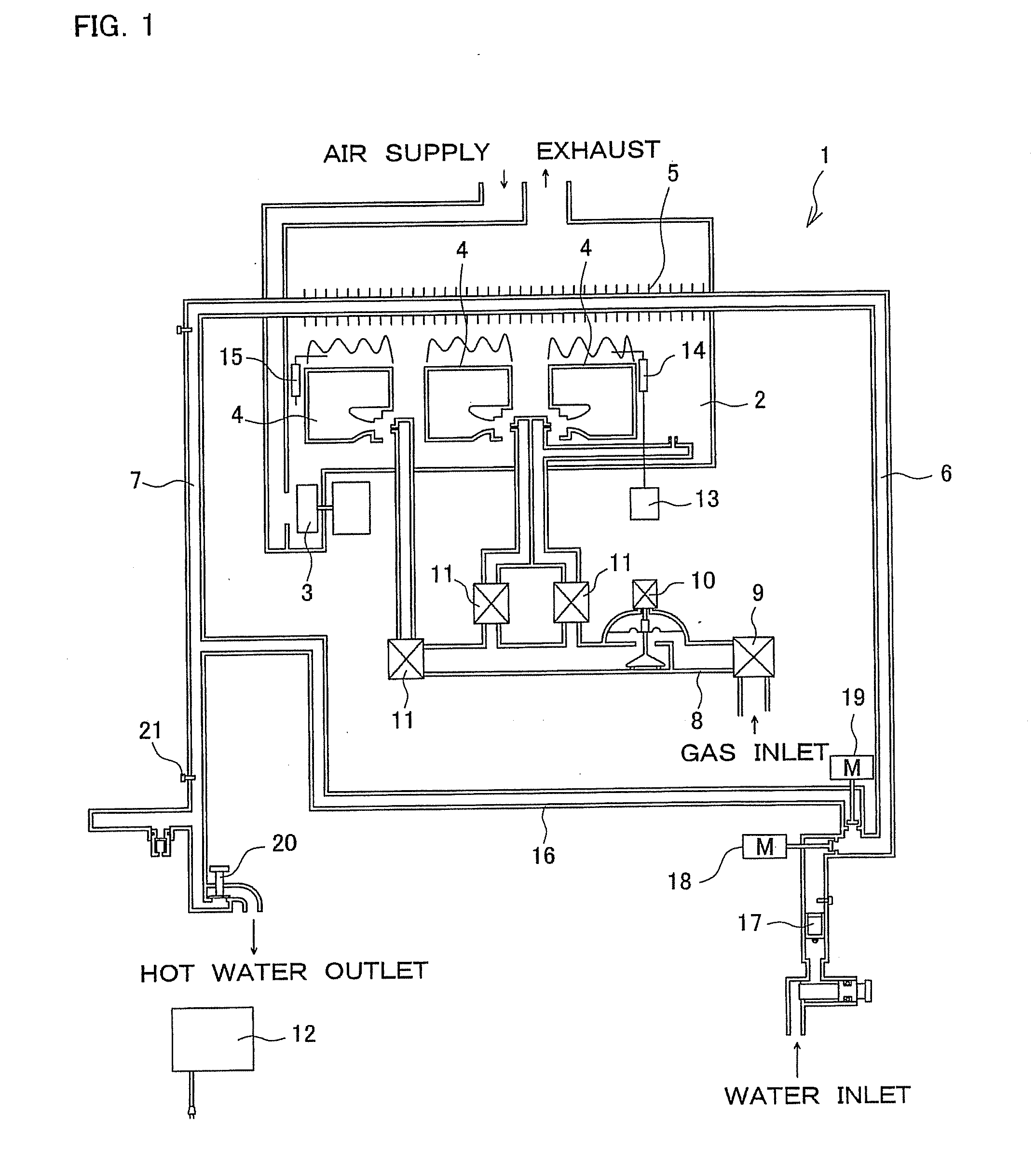

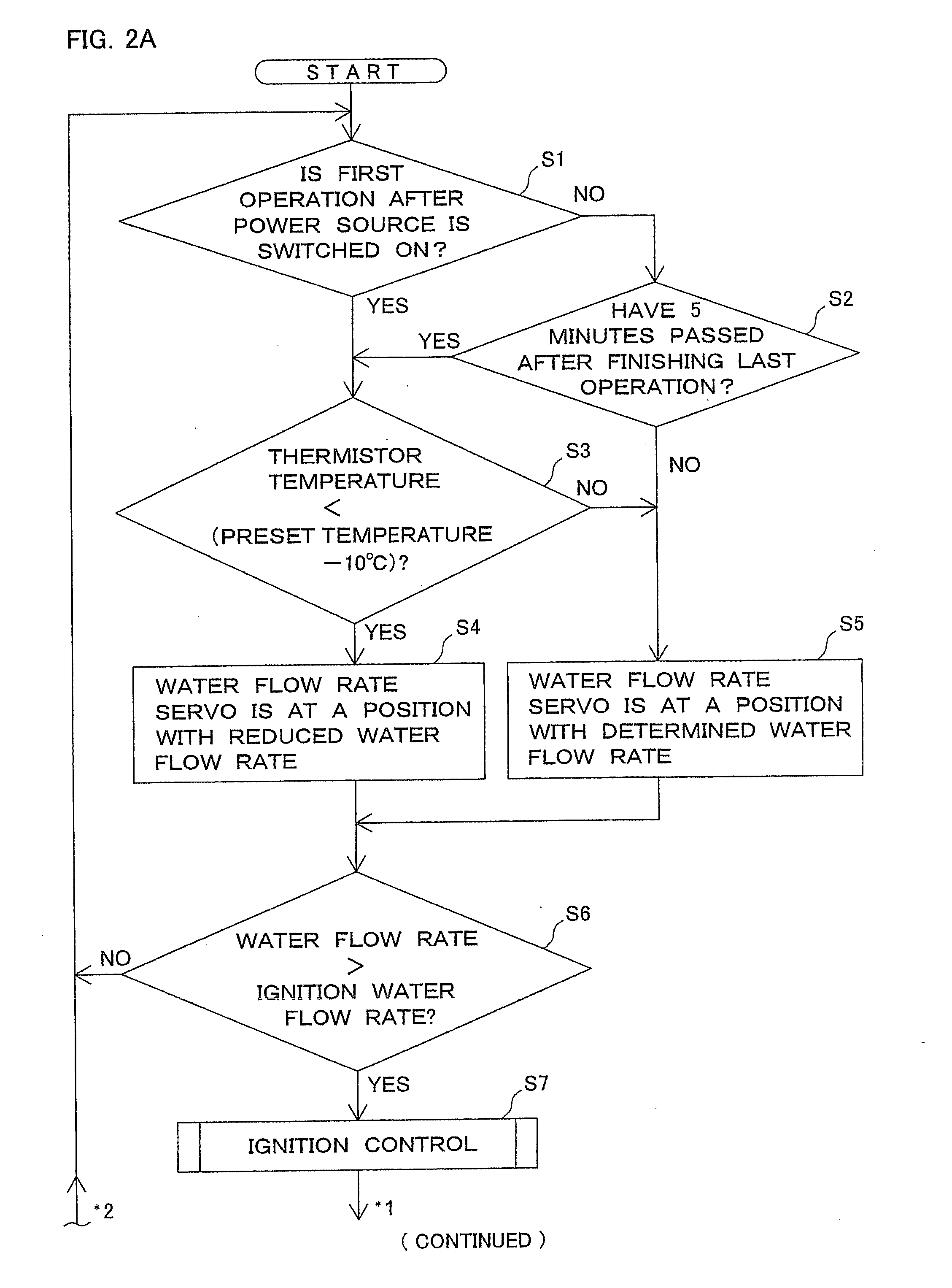

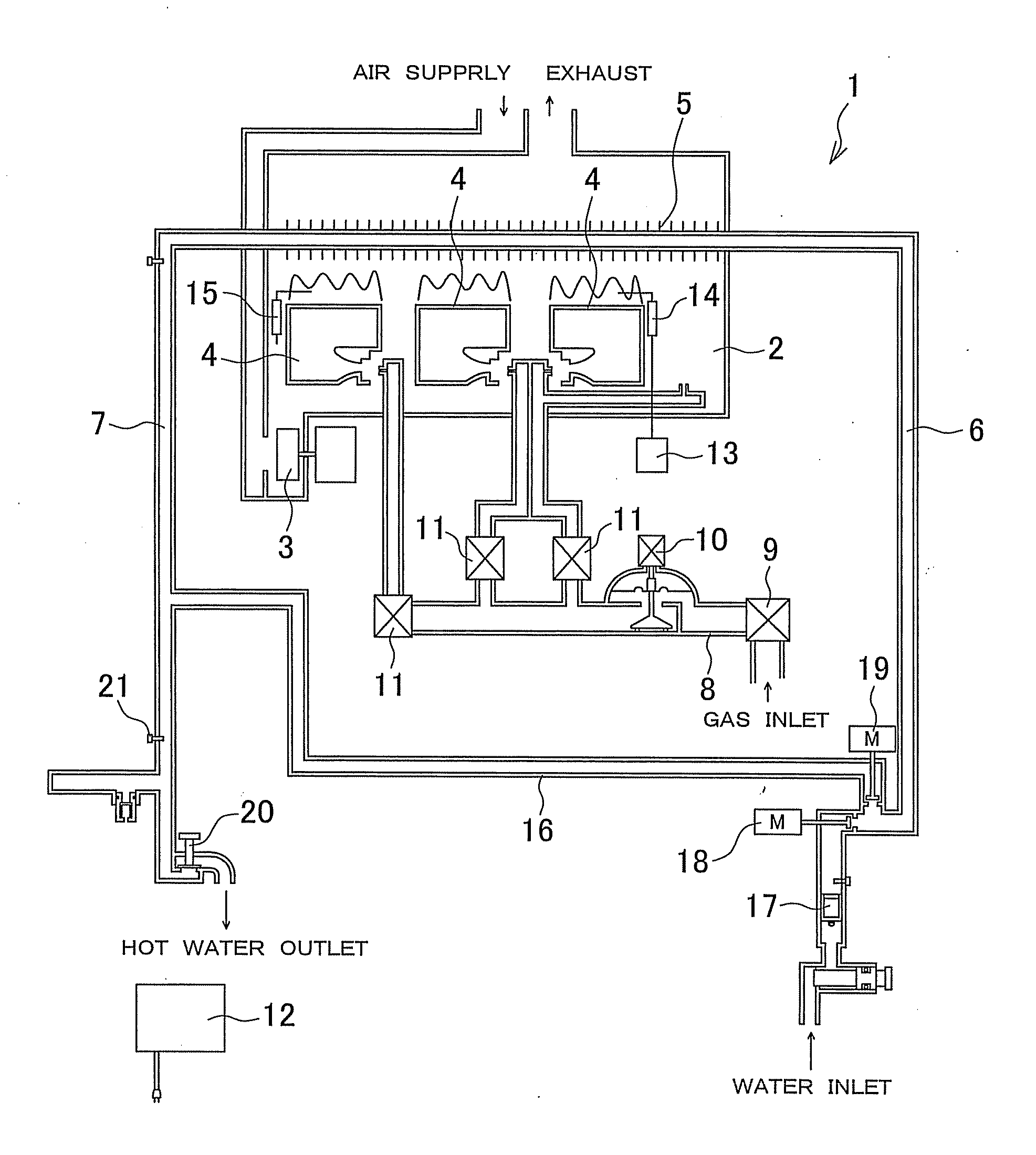

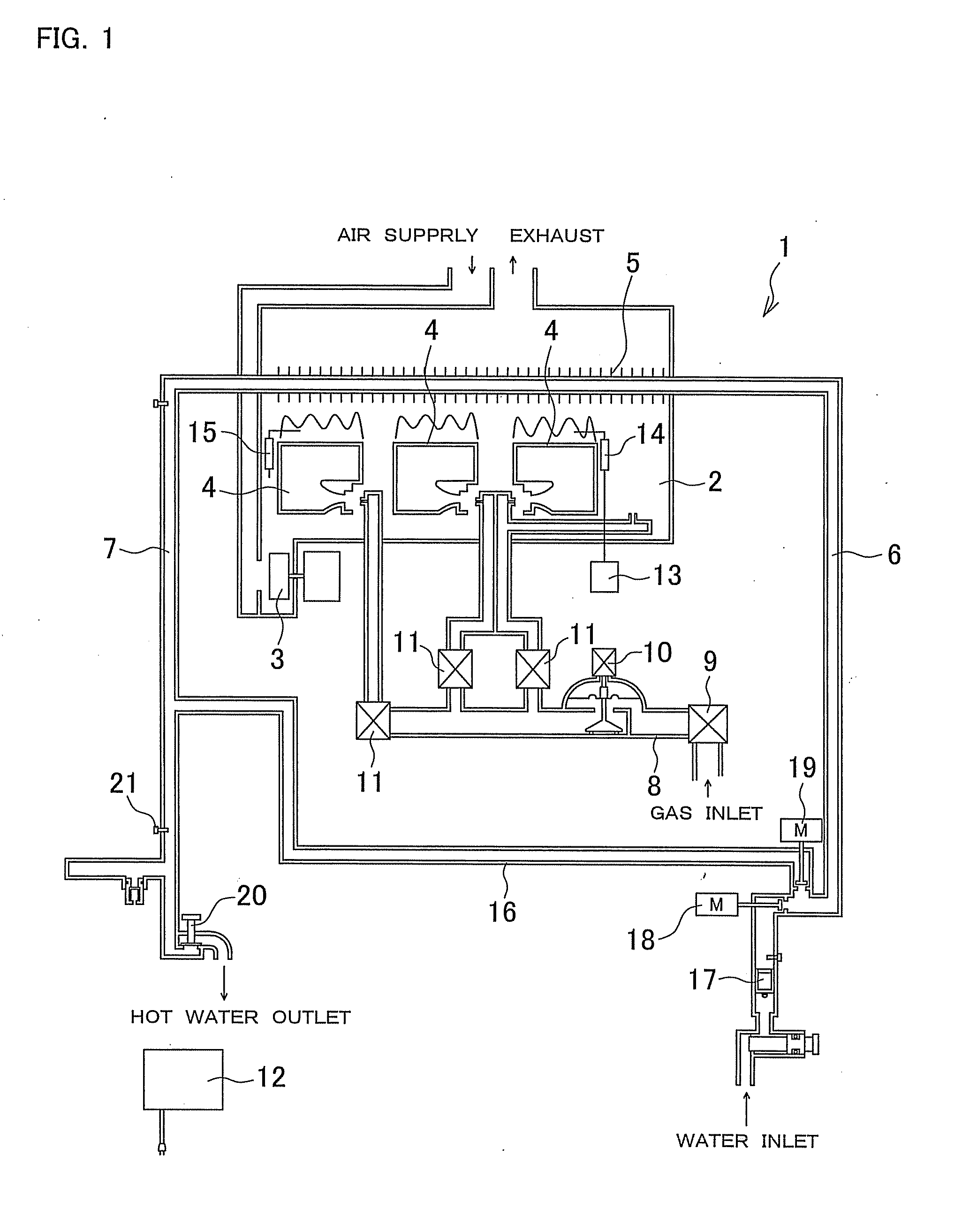

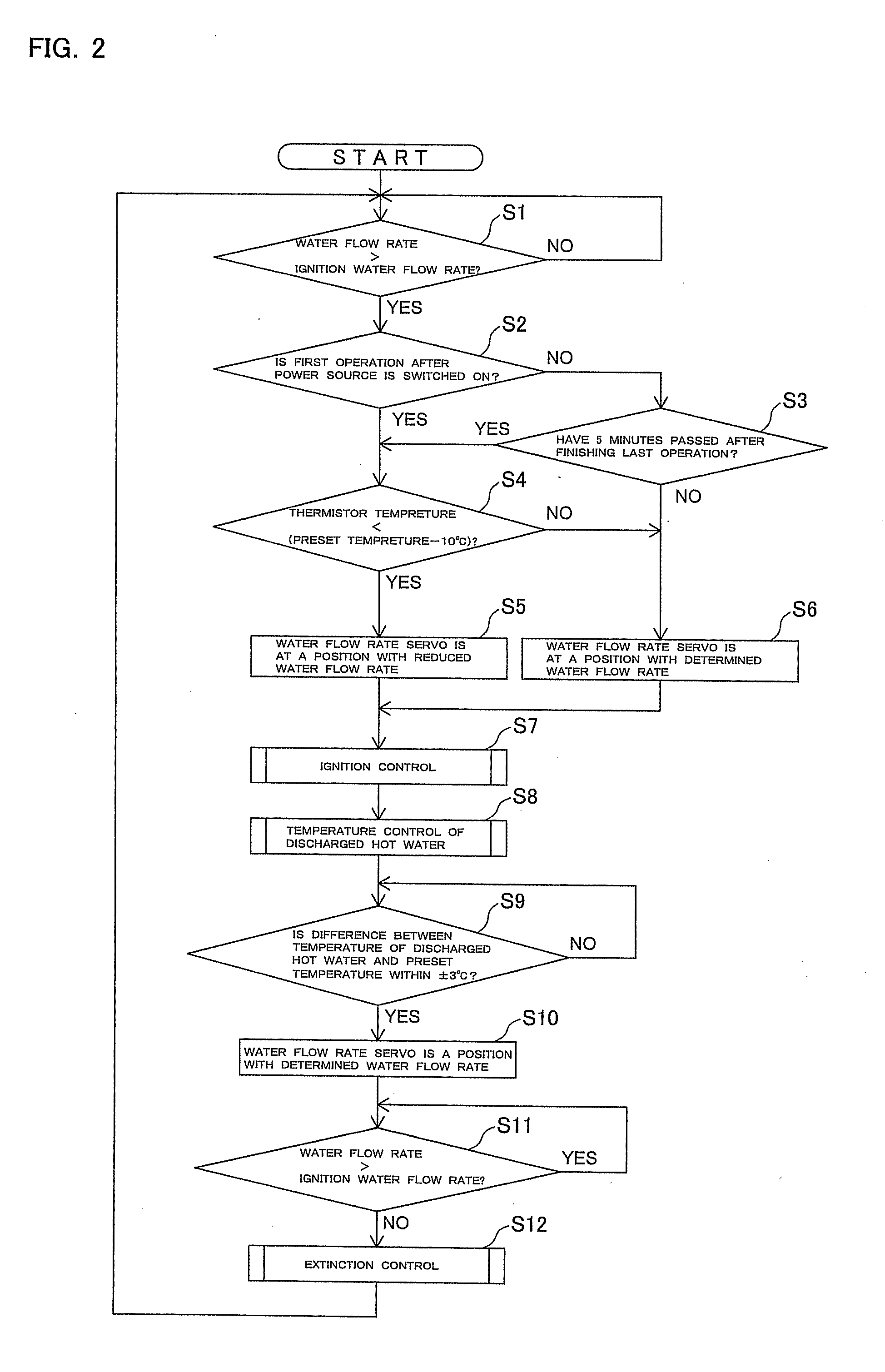

Water heater

ActiveUS20100116223A1Shorten the timeSave gasCentral heating componentsControl of fluid heatersElectrical resistance and conductanceTemperature control

In a non-operation state, a controller determines whether the first operation was made after a power source being switched on in S1, and determines whether 5 minutes has passed after finishing the last operation in S2. When the first operation was not made or 5 minutes have lapsed after the last operation, the controller determines whether a difference between a detected temperature acquired by a thermistor and a preset temperature is more than 10° C. in S3. When a temperature difference is more than 10° C., a water flow rate servo is made to stand by at a position with a flow rate of flowing water reduced to less than a determined flow rate by a predetermined amount in S4. When a hot water faucet is opened in this standing by state, a temperature control of discharged hot water at the time of starting of an operation (S8) is performed with the reduced flow rate of flowing water.

Owner:PALOMA IND LTD

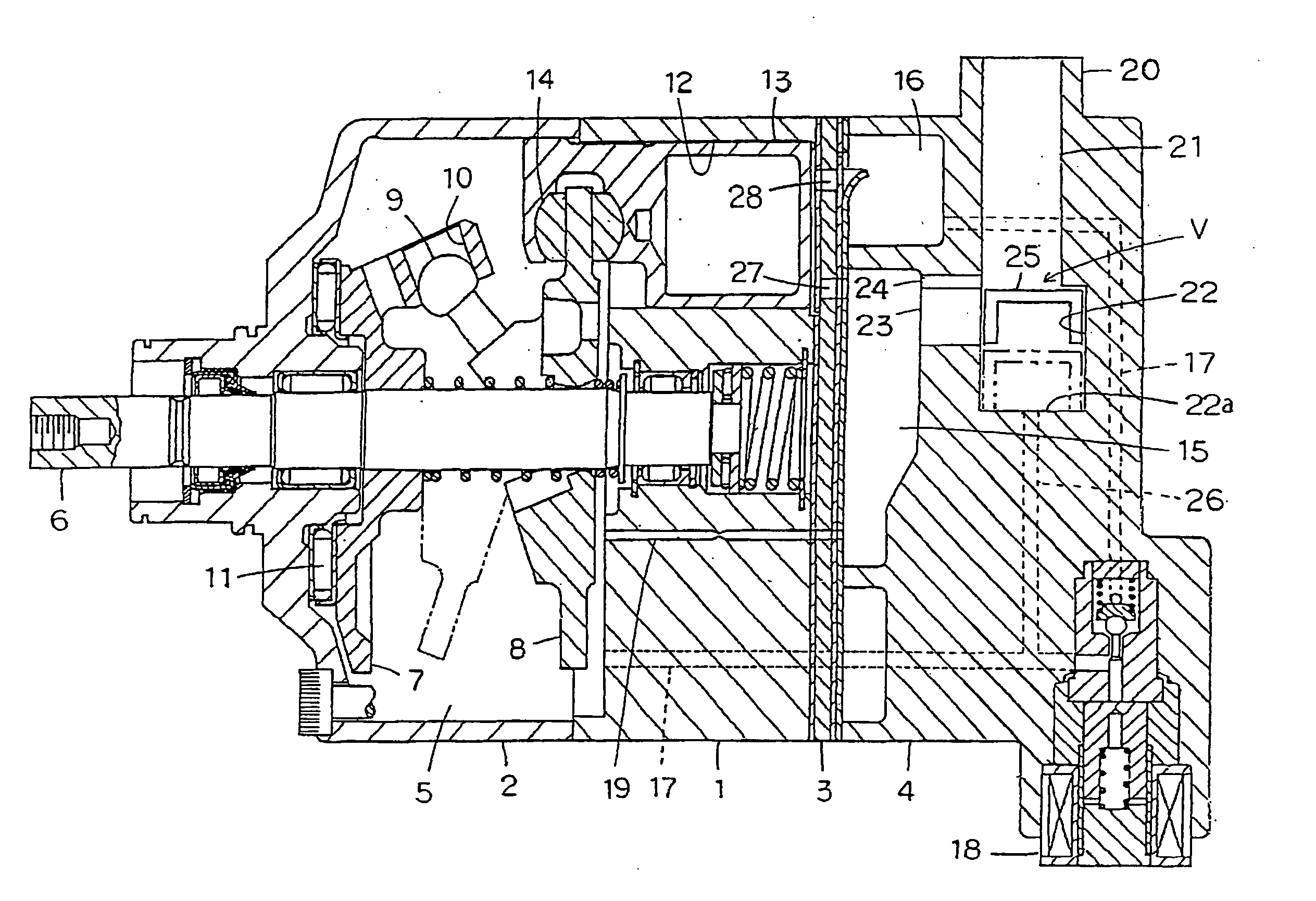

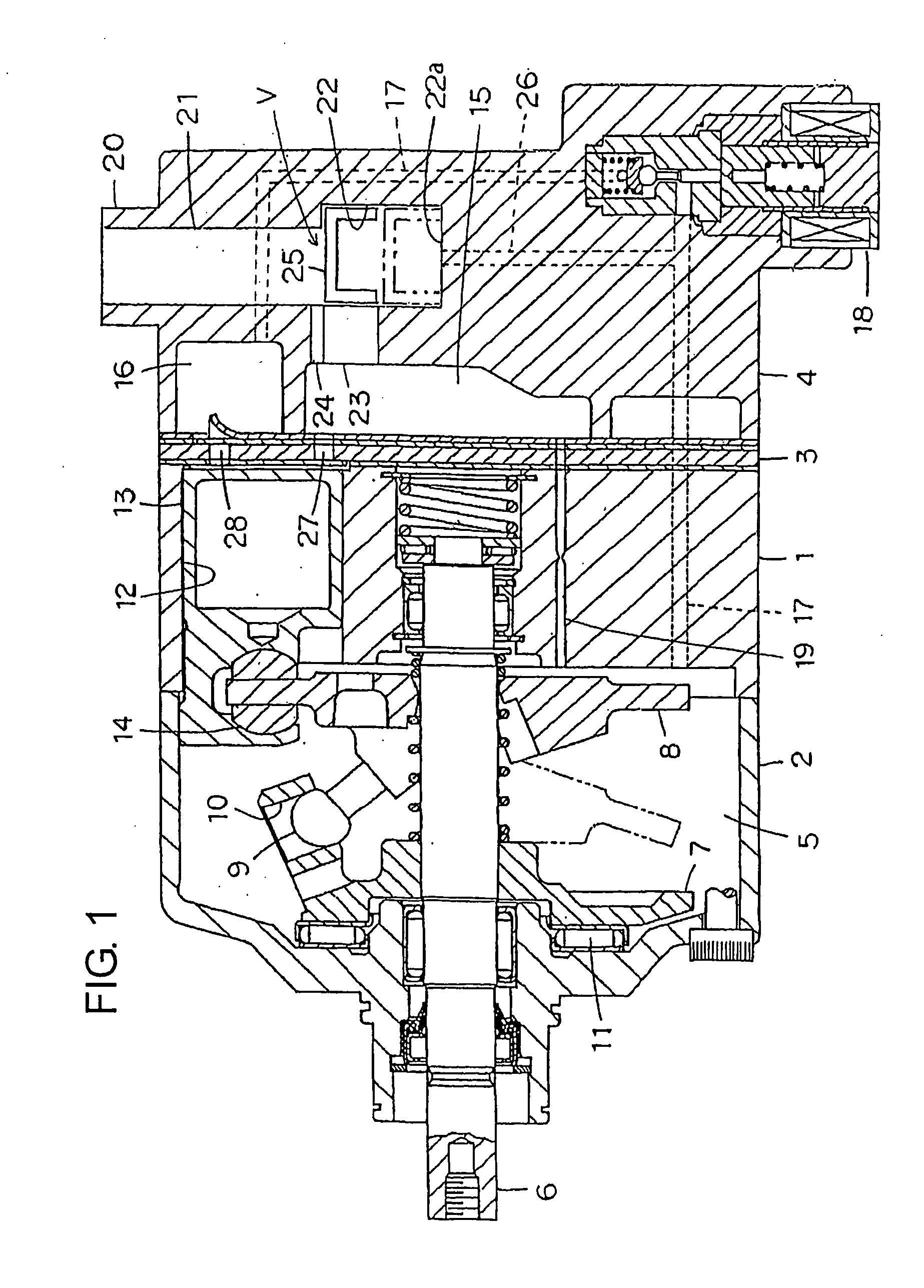

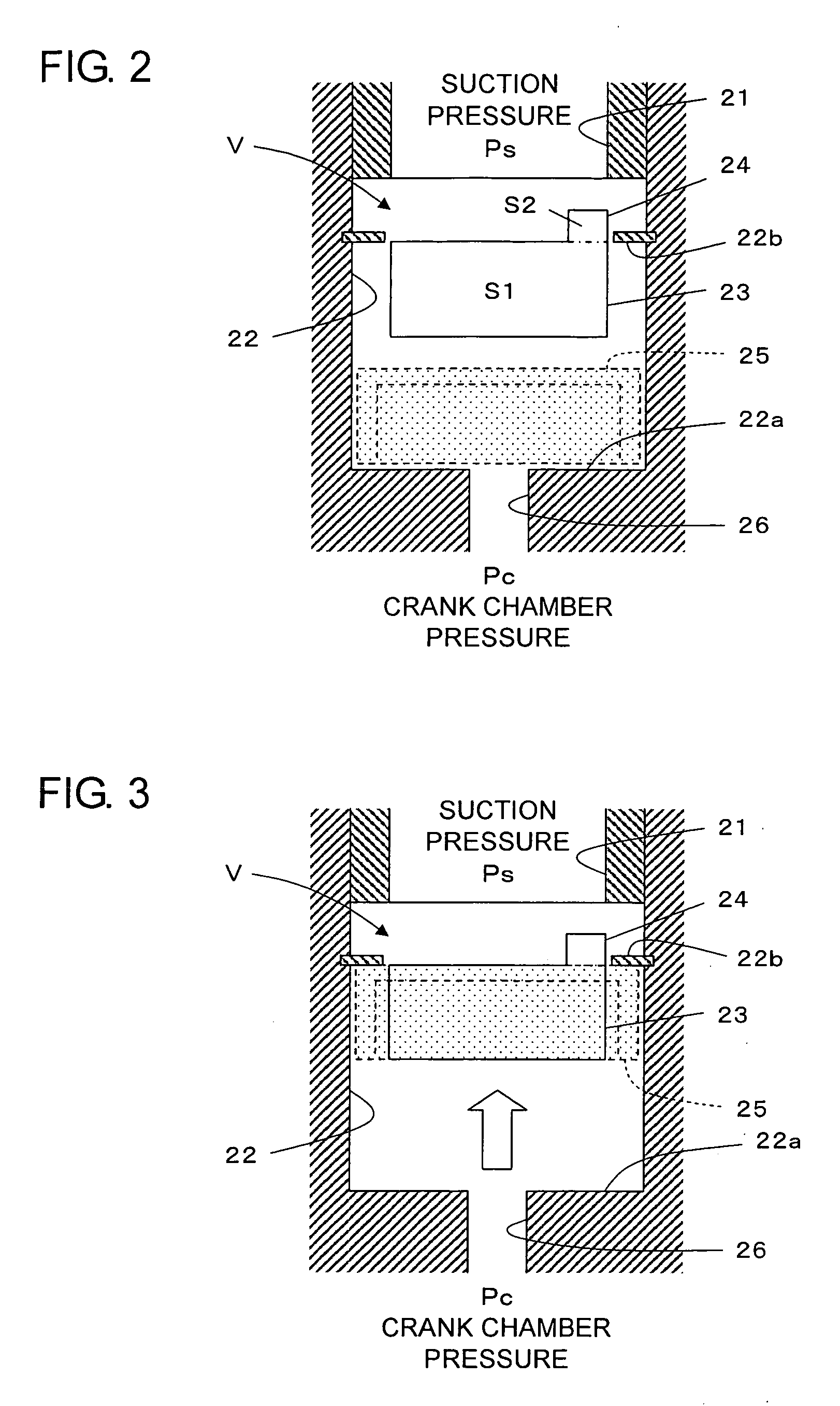

Variable displacement compressor

ActiveUS20050244279A1Achieving Reliability RequirementsSufficient flow ratePump controlMechanical energy handlingEngineeringDisplacement control

A variable displacement compressor in which variable control of displacement is effected through adjustment of a crank chamber pressure, includes: a suction port; a suction chamber; a suction passage establishing communication between the suction port and the suction chamber; and an opening control valve arranged in the suction passage and adapted to adjust the opening of the suction passage based on a pressure difference between a suction pressure in the suction port and the crank chamber pressure.

Owner:TOYOTA IND CORP

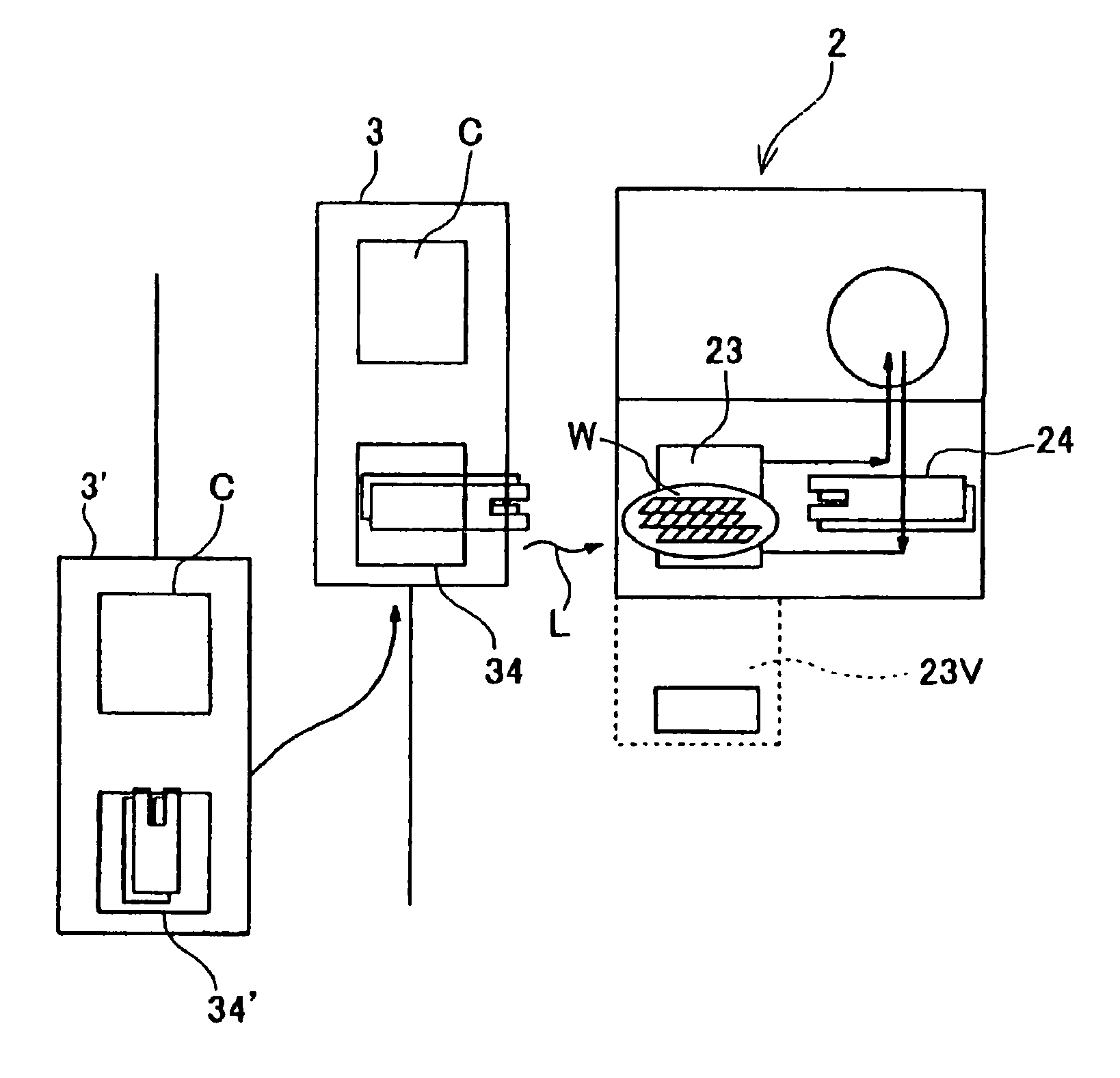

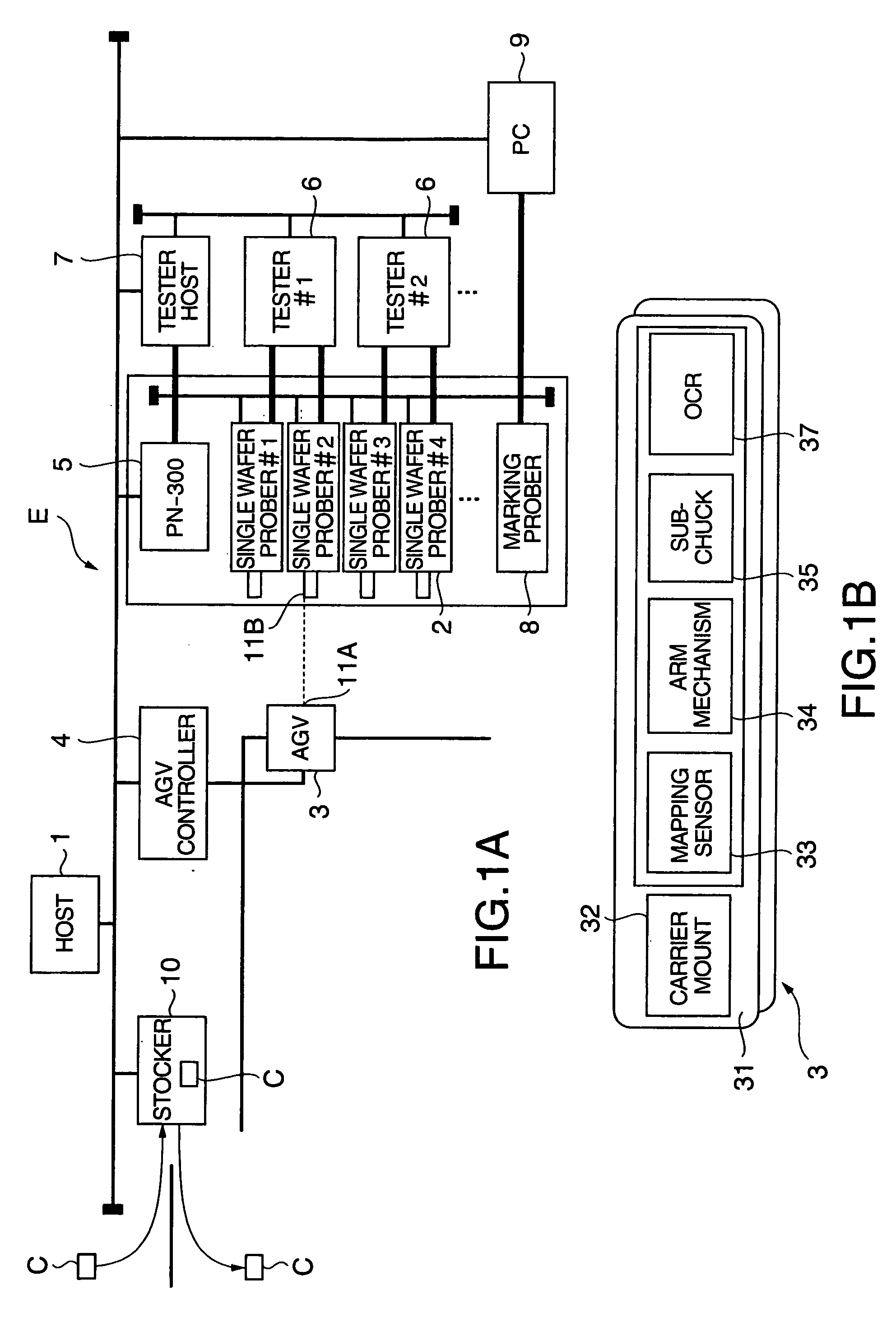

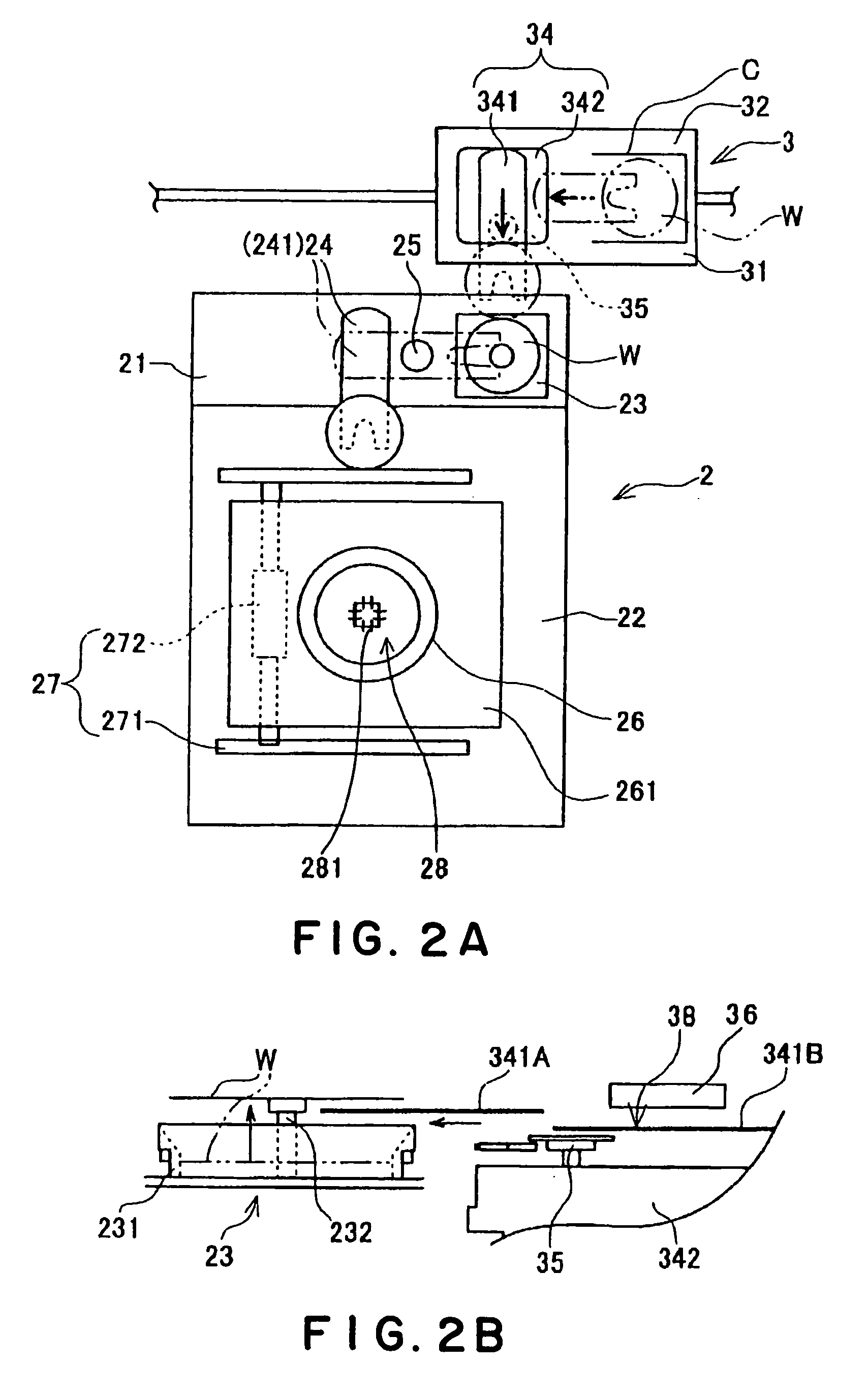

Conveyance system, conveyance method and vacuum holding apparatus for object to be processed, and centering method for water

InactiveUS20040046545A1Preventing footprintImprove throughputComputer controlElectrical measurement instrument detailsEngineeringSemiconductor

A conveyance system E for wafers W includes a host computer 1 for carrying out the management of the production of semiconductor devices, a plurality of probers 2 for inspecting the electric characteristics of the wafers W under the administration of the host computer 1, an AGV 3 for automatically transporting the wafers W in block of a carrier in order to deliver the wafers W one by one to these probers 2 according to respective demands and an AGV controller 4 for controlling the operation of the AGV 3 under the administration of the host computer 1.

Owner:TOKYO ELECTRON LTD

Water heater

ActiveUS20100116222A1Shorten the timeSave gasFuel supply regulationCentral heating componentsTemperature controlElectrical resistance and conductance

At a time of starting of an operation, a controller determines whether the first operation was made after a power source being switched on in S1, and determines whether 5 minutes have passed after the previous operation in S2. When the first operation was not made or 5 minutes have lapsed after the last operation, the controller determines whether a difference between a detected temperature acquired by a thermistor and a preset temperature is more than 10° C. in S3. When a temperature difference is more than 10° C., a water flow rate servo is set at a position where a flow rate of flowing water is reduced from a determined flow rate by a predetermined amount in S4, and the controller performs a temperature control of discharged hot water in S8.

Owner:PALOMA

Heat pump apparatus

InactiveUS6826924B2Reduce pressureAvoid loopsEfficient regulation technologiesCompression machines with reversible cycleSolenoid valveHeat pump

Indoor circuits (60, 65) of indoor units (12, 13) are each connected in parallel to an outdoor circuit (20) of an outdoor unit (11). The outdoor circuit (20) has a gas vent pipe (35) by which a receiver (23) is brought into communication with suction sides of compressors (41, 42). During the heating operation in the heating mode of operation, a gas vent solenoid valve (36) is placed in the open state so that the receiver (23) decreases in pressure. This relaxes restrictions on the difference in installation height between each indoor unit of a multi type airconditioner having a plurality of indoor units.

Owner:DAIKIN IND LTD

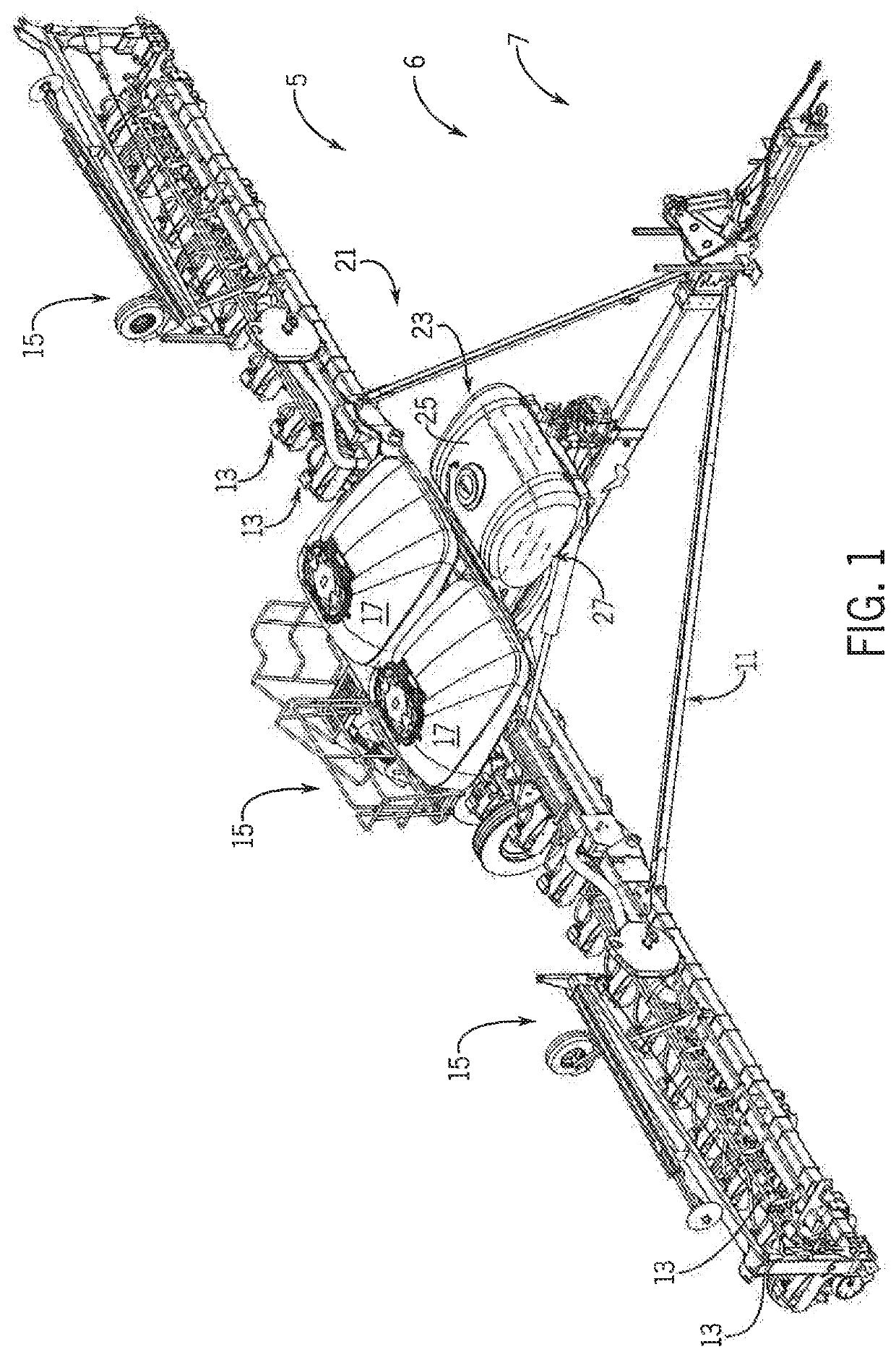

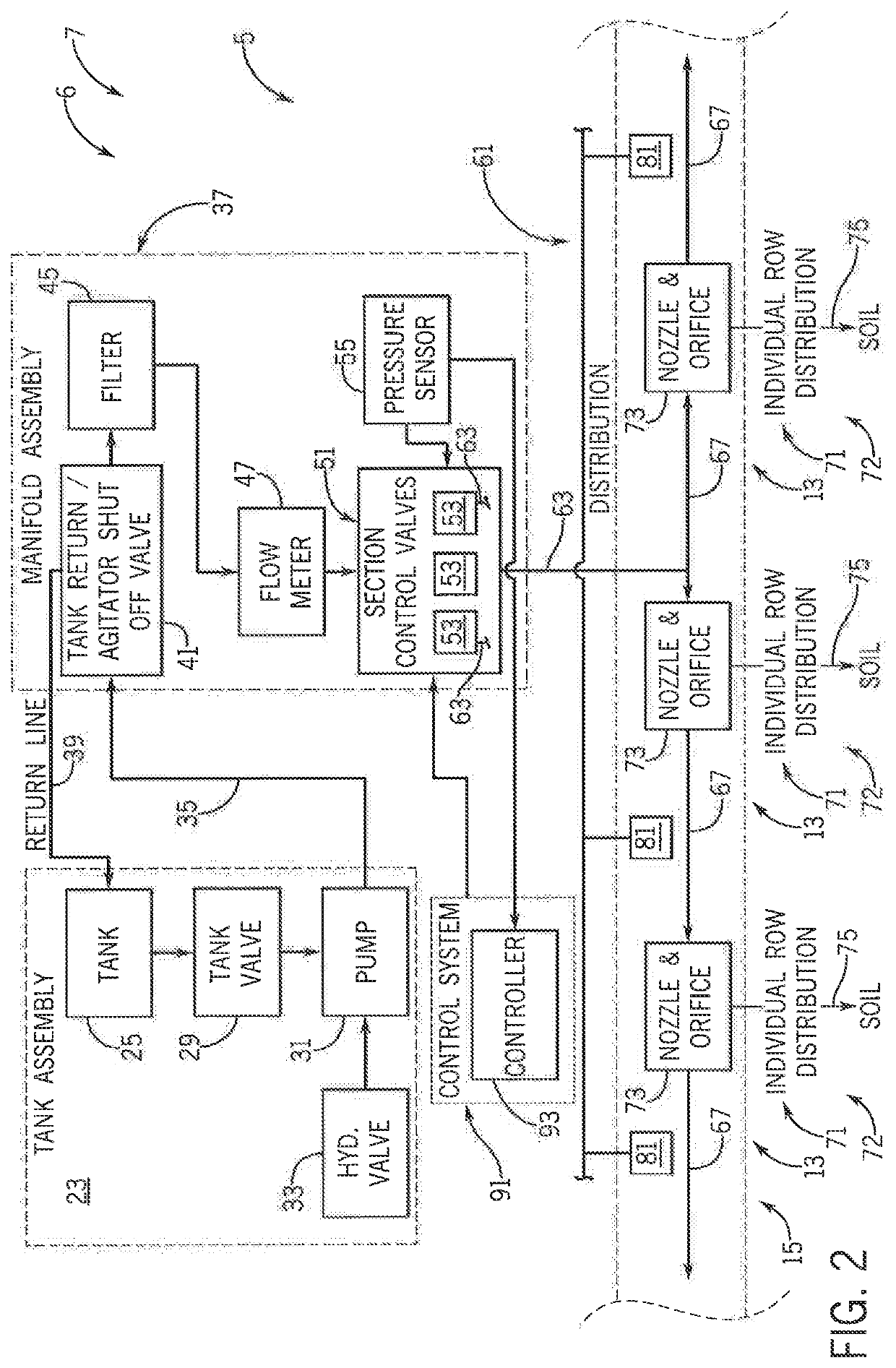

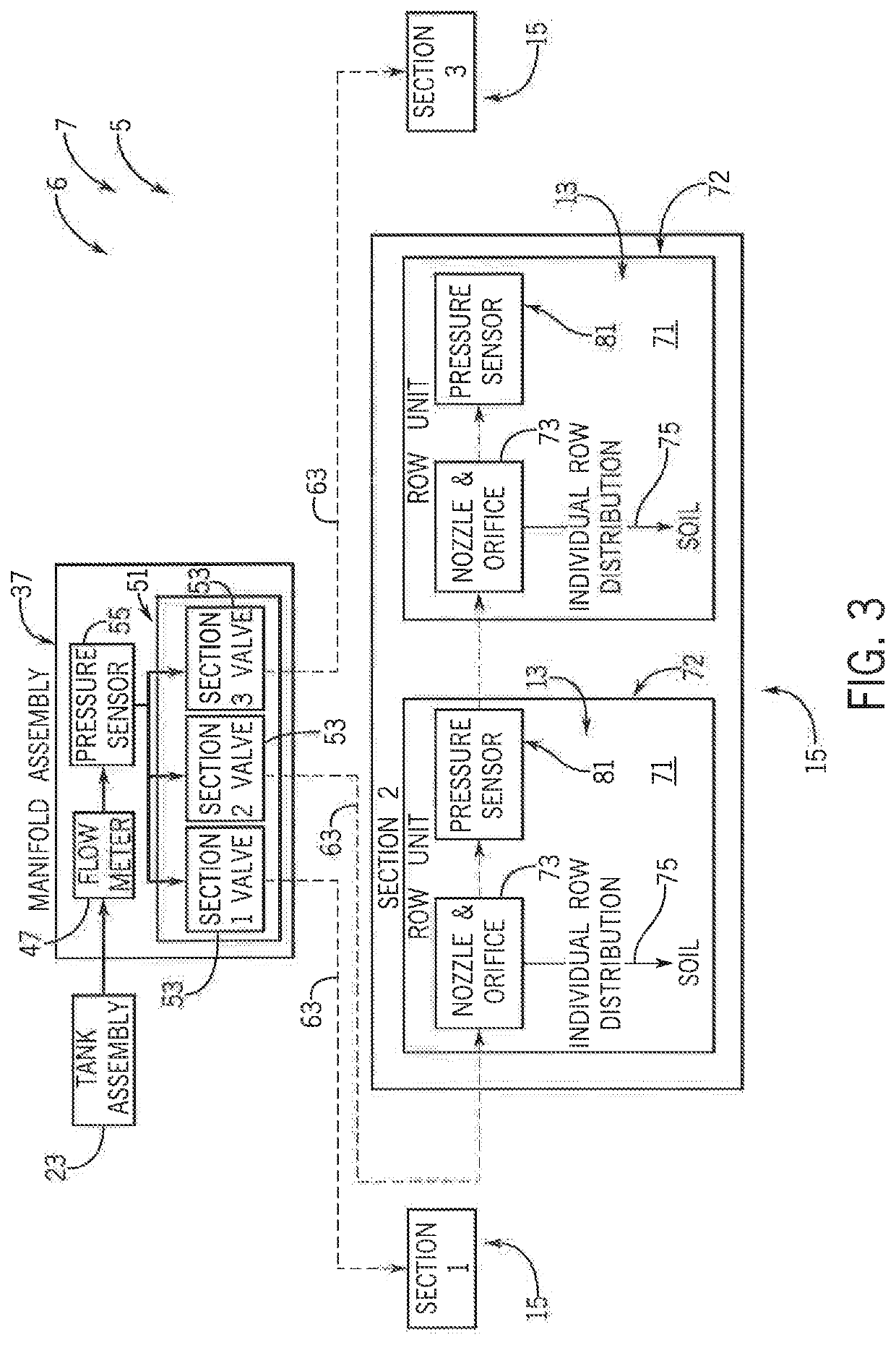

Flow Monitoring And Error Detection In A Mobile Liquid Agricultural Product Applicator

ActiveUS20200196520A1Sufficient flow rateAgricultural machinesLiquid fertiliser regulation systemsControl systemLiquid state

An error detection and flow rate monitoring system of a liquid fertilizer distribution system of an agricultural implement that can provide feedback to identify compromised flow states in the system and corresponding locations of potential blockage or component failure. The system may include pressure sensors that may be evaluated in pairs or otherwise analyzed comparatively to determine flow rate or other characteristics through nozzle assemblies. The pressure sensors may be mounted in the wet boom between the rows. A control system compares the pressure values before and after each row to determine the pressure drop across its nozzle assembly and may further use the pressure drop values to determine flow or application rates and corresponding errors in the pressure drop, flow rate, and application rate compared to their acceptable values and may provide feedback to identify a specific location(s) of potential blockage or flow-control component failure.

Owner:BLUE LEAF I P

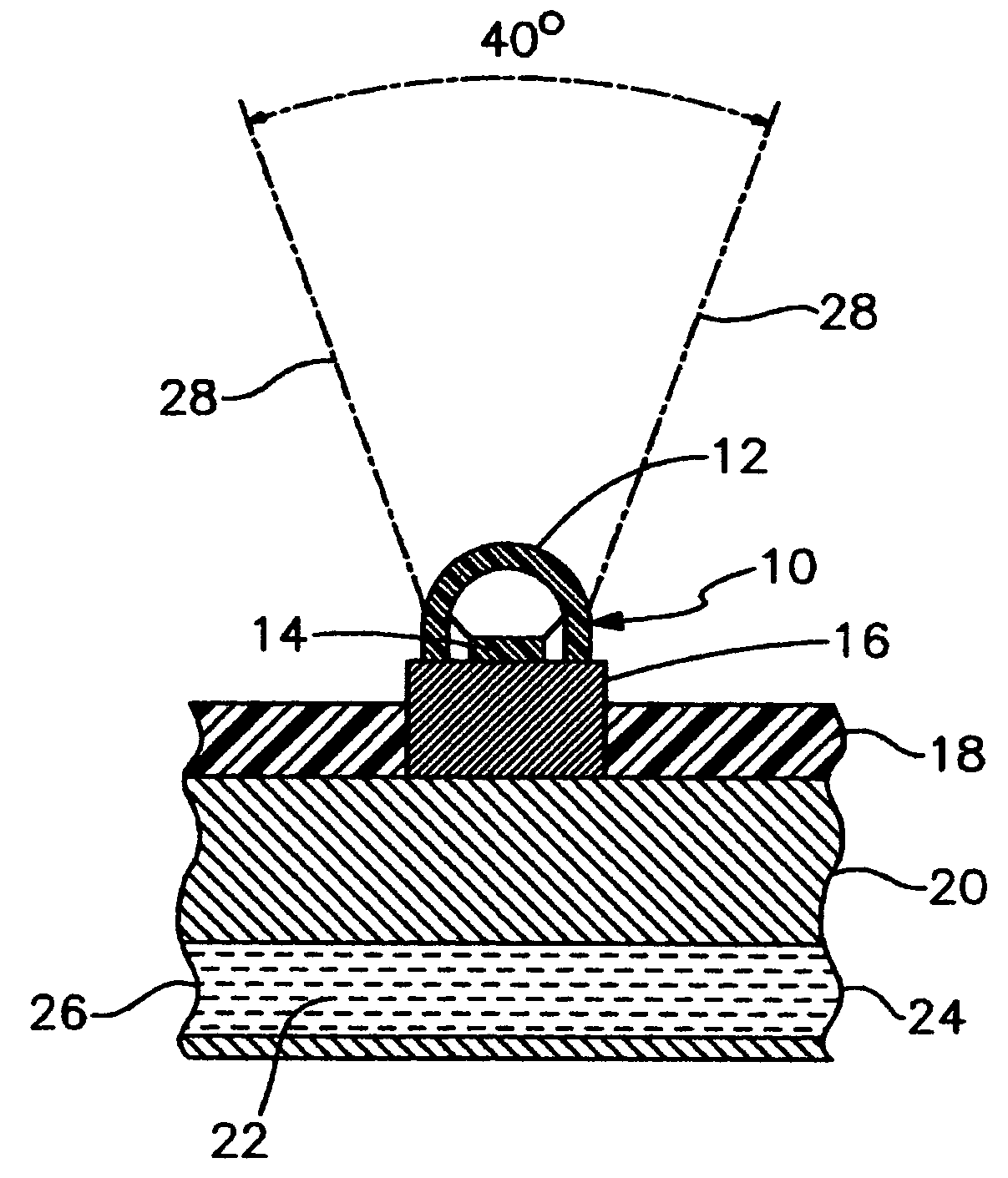

Mixing apparatus and process

ActiveUS20100124145A1Effective dispersionPromote uniform mixingFlow mixersTransportation and packagingEngineeringBiomedical engineering

Owner:NITECH SOLUTIONS LTD

LED cooling system

InactiveUS20080212332A1Easy to operateHigh strengthPoint-like light sourceLighting heating/cooling arrangementsElectricityEngineering

The invention relates to a LED cooling system that effects cooling of the LED's during use, and helps the LED's have a longer operating function, and uses less electricity for the LED's to operate. The use of cooling also provides a steadier light and has greater efficiency.

Owner:MEDINIS DAVID M

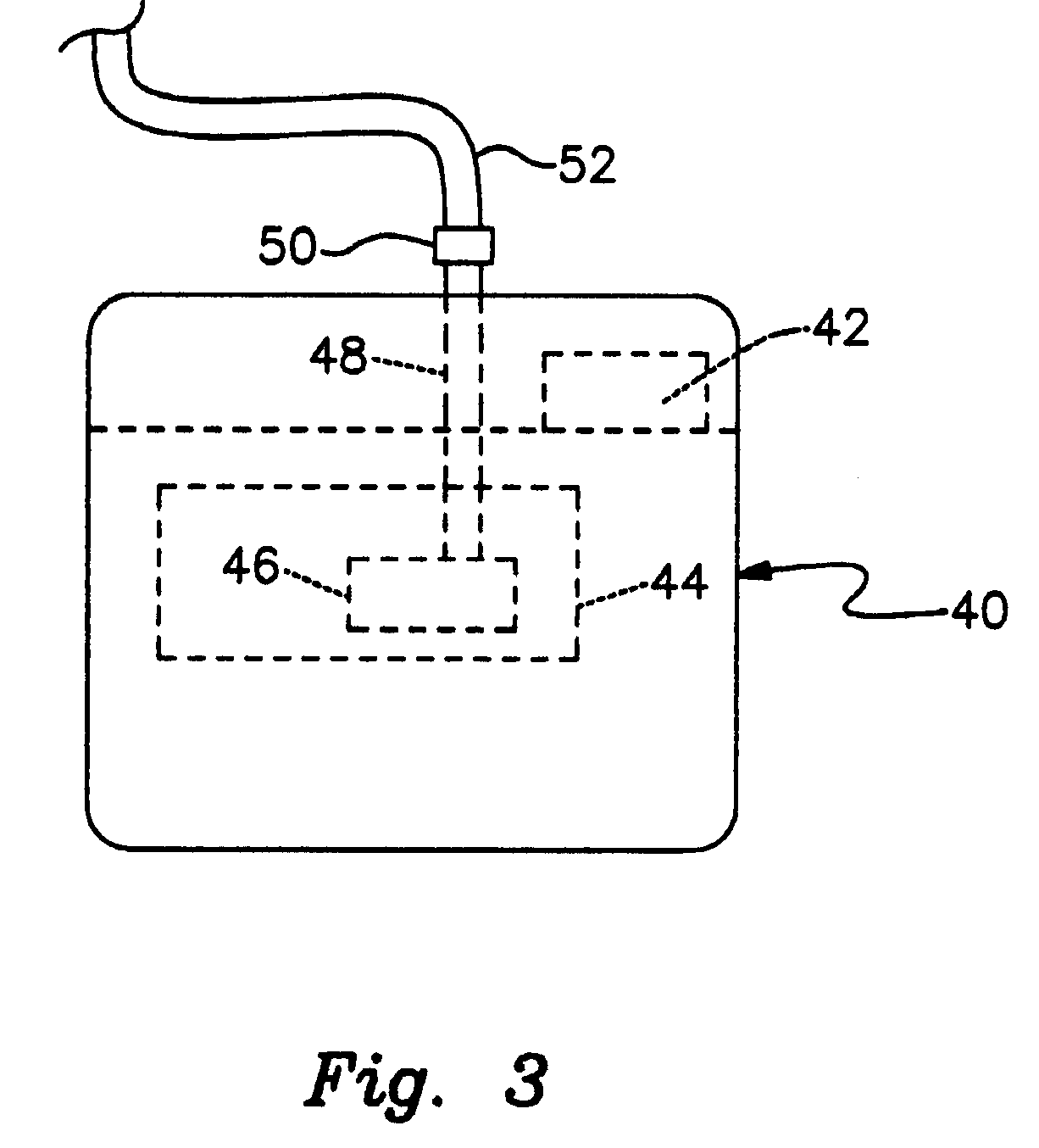

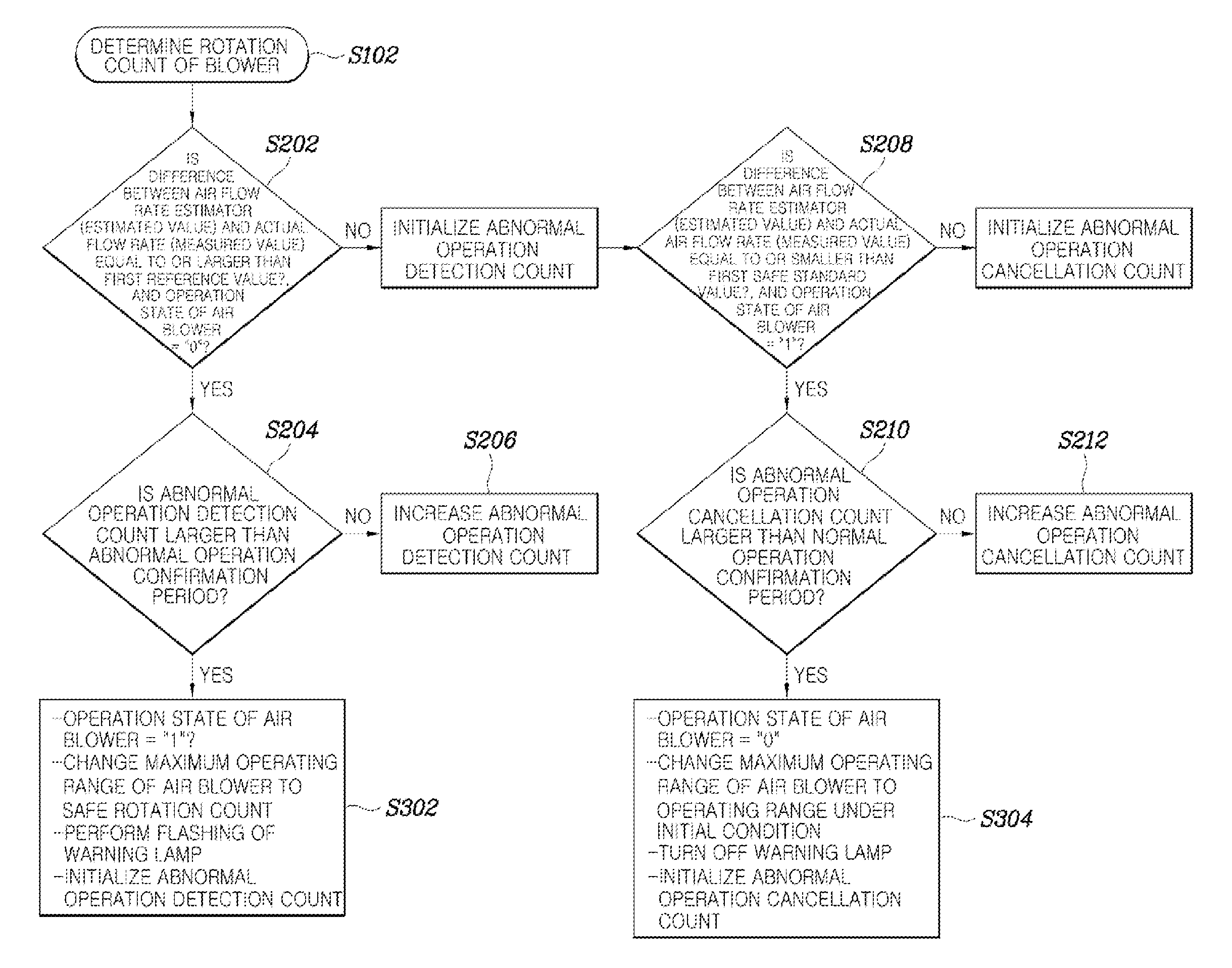

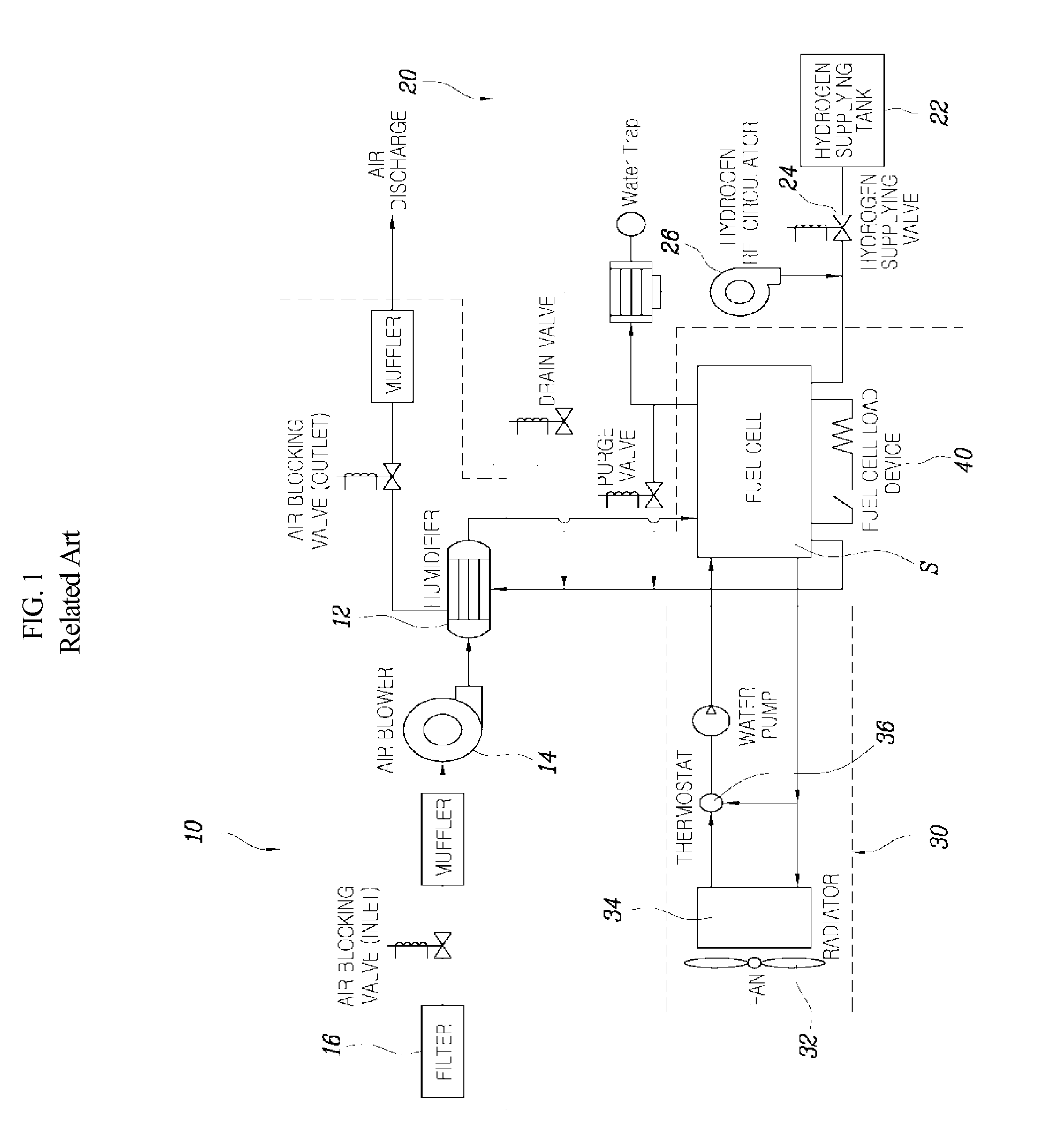

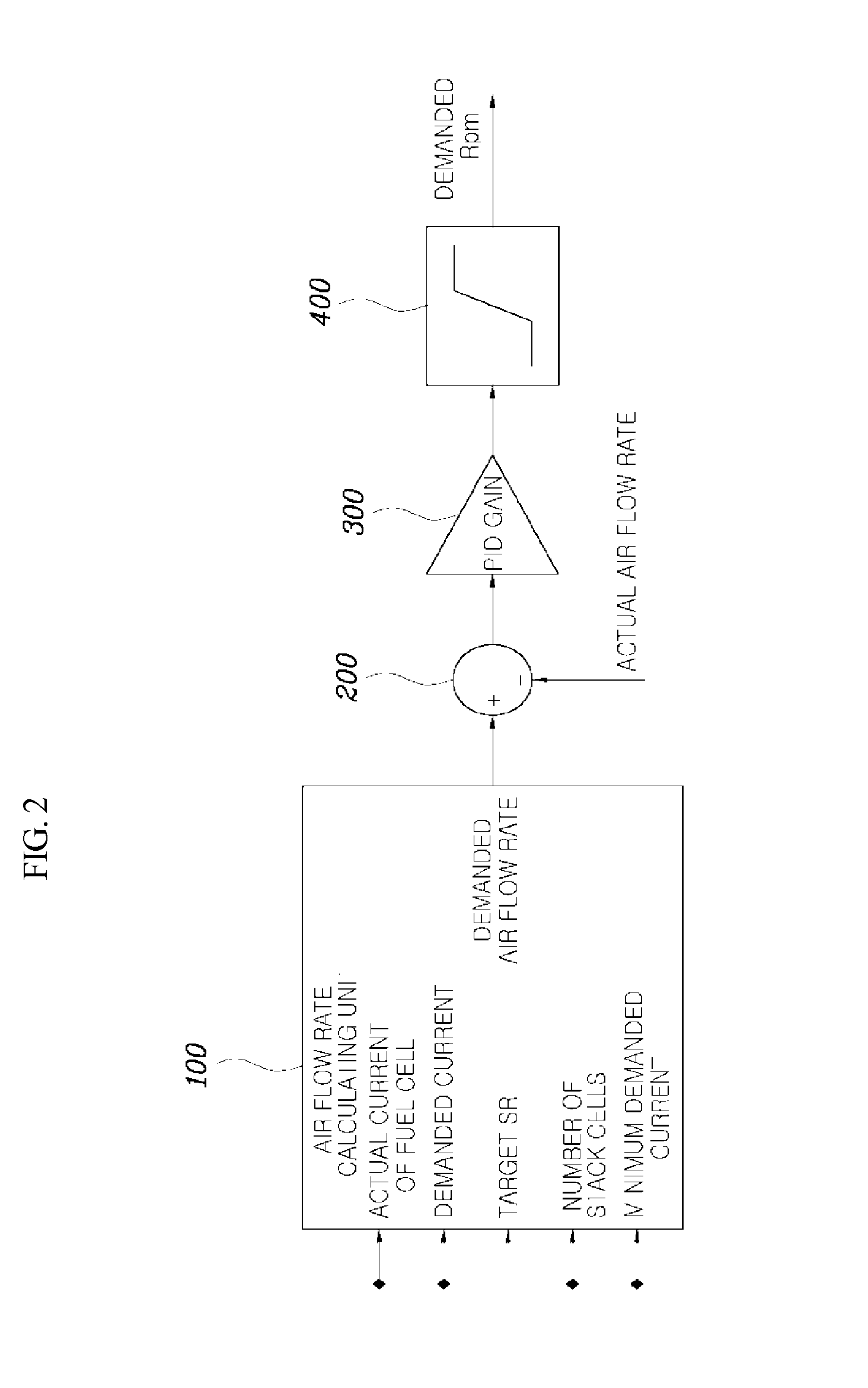

System and method of controlling air blower for fuel cell vehicle

ActiveUS20160006049A1Guaranteed uptimeSufficient flow rateFuel cell auxillariesPropulsion by batteries/cellsFuel cellsAir blower

A system and method of controlling an air blower for a fuel cell vehicle are provided. The method includes determining an operation amount of an air blower to secure a sufficient air flow rate under present operating conditions and obtaining information regarding clogging of an air channel or information regarding a back pressure using the operation amount of the air blower. In addition, a maximum operating range of the air blower is changed based on whether a present state is an air channel-clogged state or a back pressure-increased state.

Owner:HYUNDAI MOTOR CO LTD +1

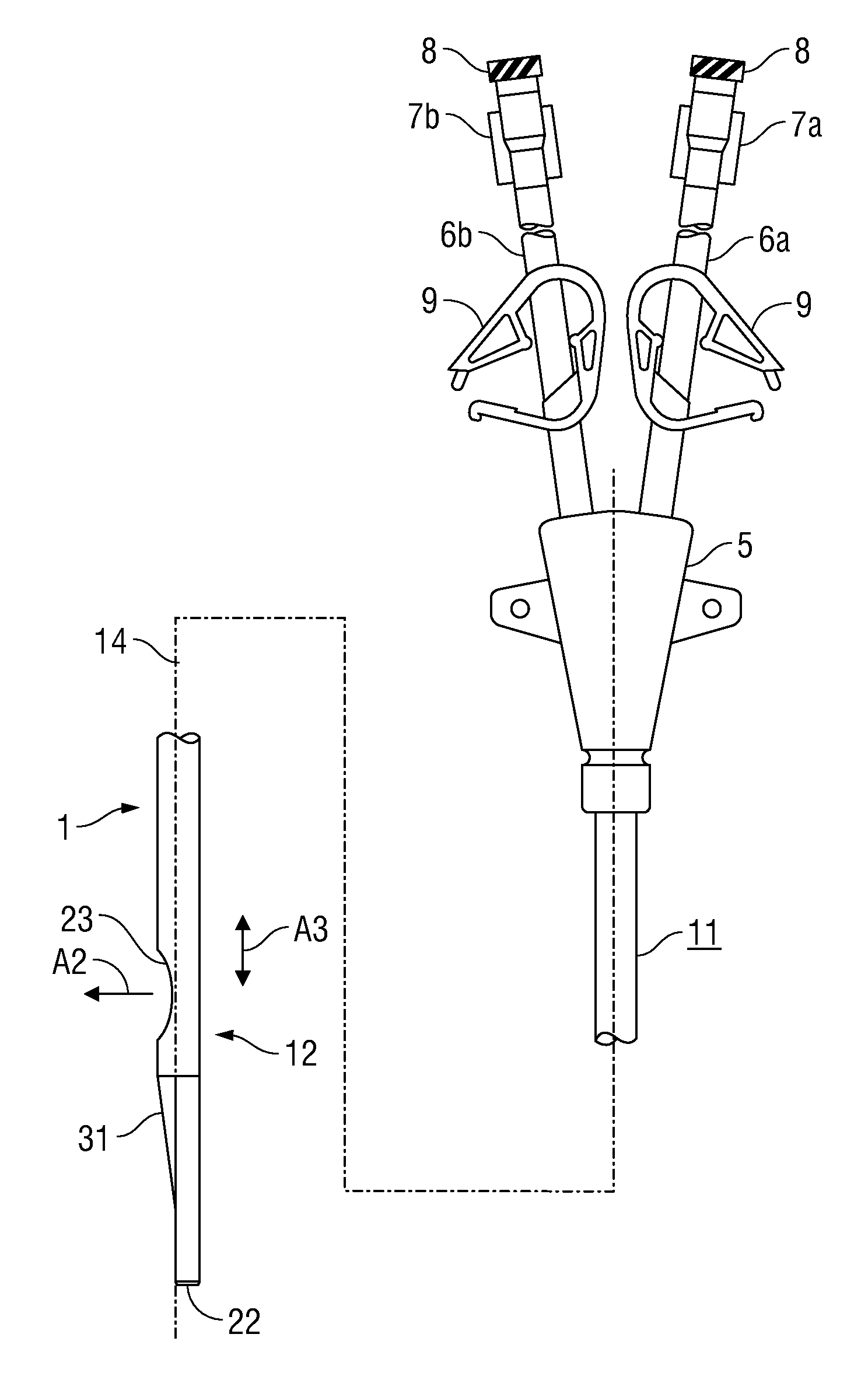

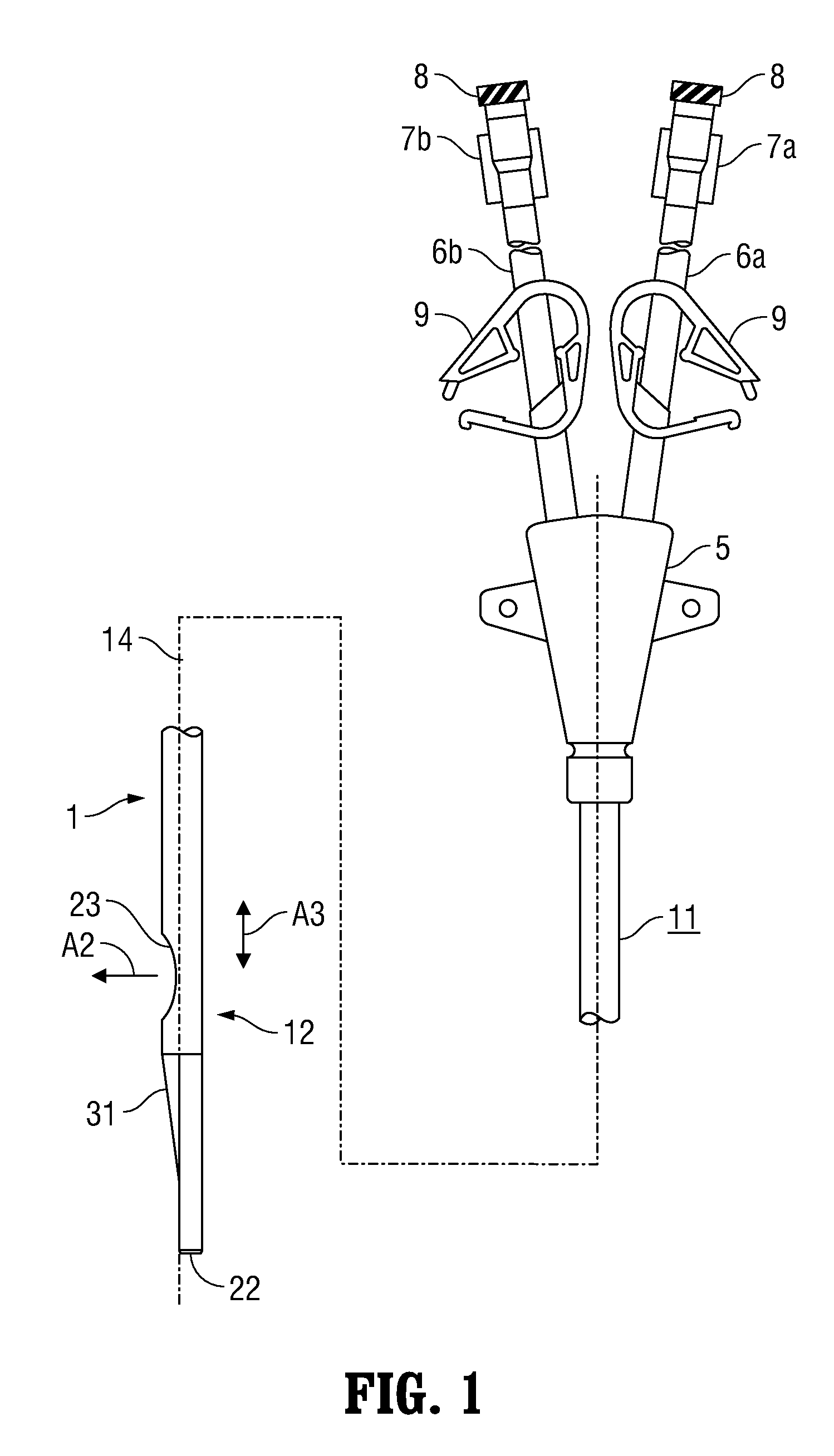

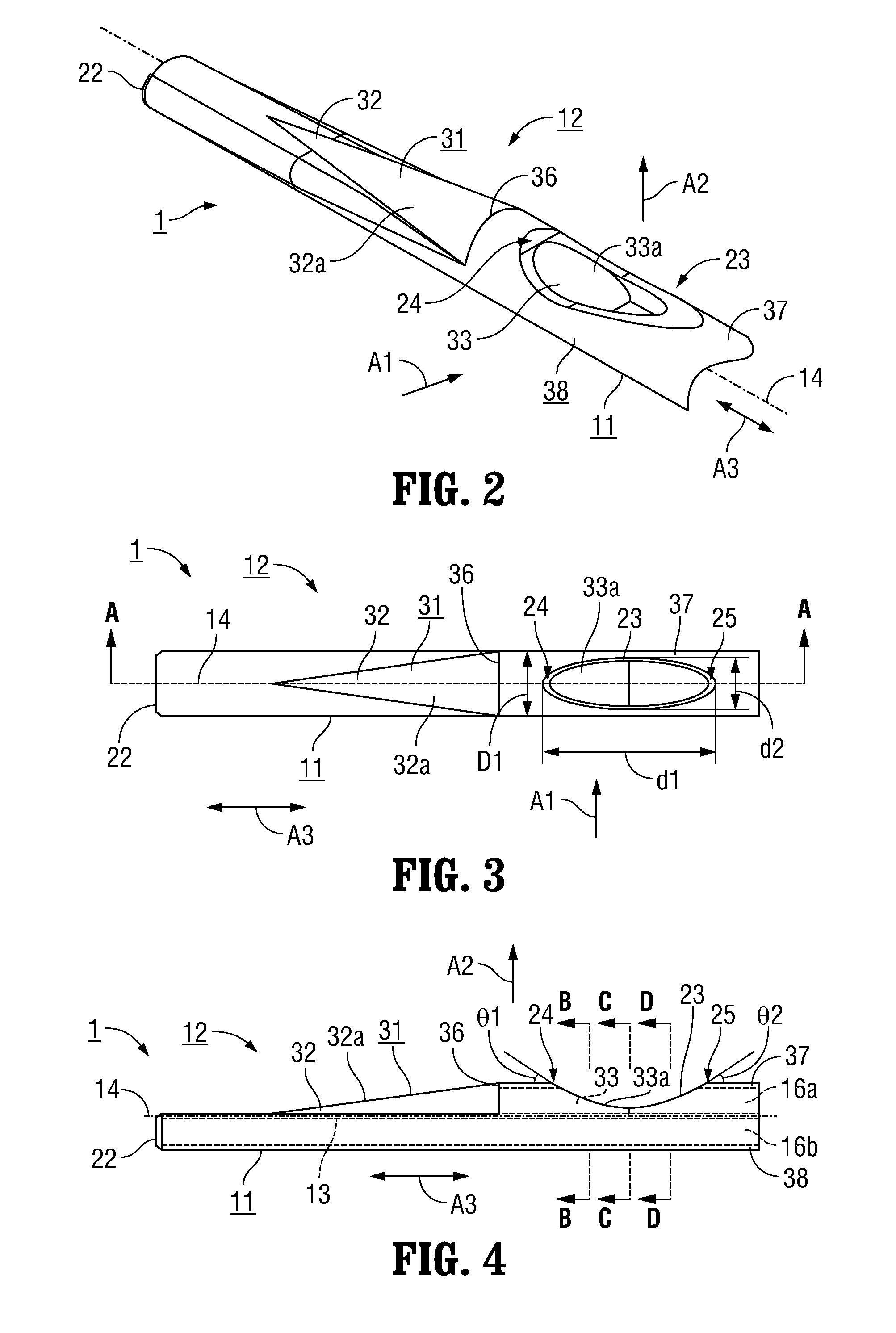

Dialysis catheter

InactiveUS20130053763A1Sufficient flow rateLittle resistanceMulti-lumen catheterDialysis systemsCatheters dialysisLong axis

A dialysis catheter is disclosed which comprises a catheter main body and a closure member. The catheter main body includes a first lumen which communicates with a tip-end hole and a second lumen which communicates with a side hole. The closure member has a shape in which a tip-end side of the closure member is inclined with a reduced diameter for closing off a tip-end opening. The side hole is a long hole extending in the catheter long-axis direction. The major axis of the side hole is at least 1.5 times the outer diameter of the catheter, and the minor axis is between 0.5 and 0.9 times the outer diameter. A base-end side of the closure member extends to the position of the side hole and seals the tip-end region thereof.

Owner:TYCO HEALTHCARE GRP LP

Mountable type microwave oven

ActiveUS20040262303A1Sufficient flow rateImprove cooling effectDomestic stoves or rangesLighting and heating apparatusProduction rateMicrowave oven

A mountable type microwave oven including a blower fan assembly installed at a rear-upper portion of a cabinet to cool a machine room and ventilate a cooking chamber. The microwave oven includes a cabinet mounted on a wall of a cooking space, or under a storage cabinet, and having a cooking chamber to cook food therein and a machine room to house a plurality of electrical components, which are isolated from each other, an exhaust path to exhaust contaminated air generated from a cooking appliance installed below the wall-mounted microwave oven, a cooling-ventilation path to cool the machine room and to ventilate the cooking chamber, and a blower fan assembly including a drive motor having a pair of shafts to generate a rotating force, an exhaust fan joined to one shaft of the drive motor to generate a suction force and a propulsive force to cause the contaminated air to flow along the exhaust path, and a cooling-ventilation fan joined to the other shaft of the drive motor to generate suction and propulsive forces to cause air to flow along the cooling-ventilation path. Since the cooling-ventilation fan performs cooling of the machine room and ventilation of the cooking chamber, there is no need to provide an additional blower fan. Thus, the number of components of the microwave oven is reduced, thereby reducing production costs and improving productivity.

Owner:SAMSUNG ELECTRONICS CO LTD

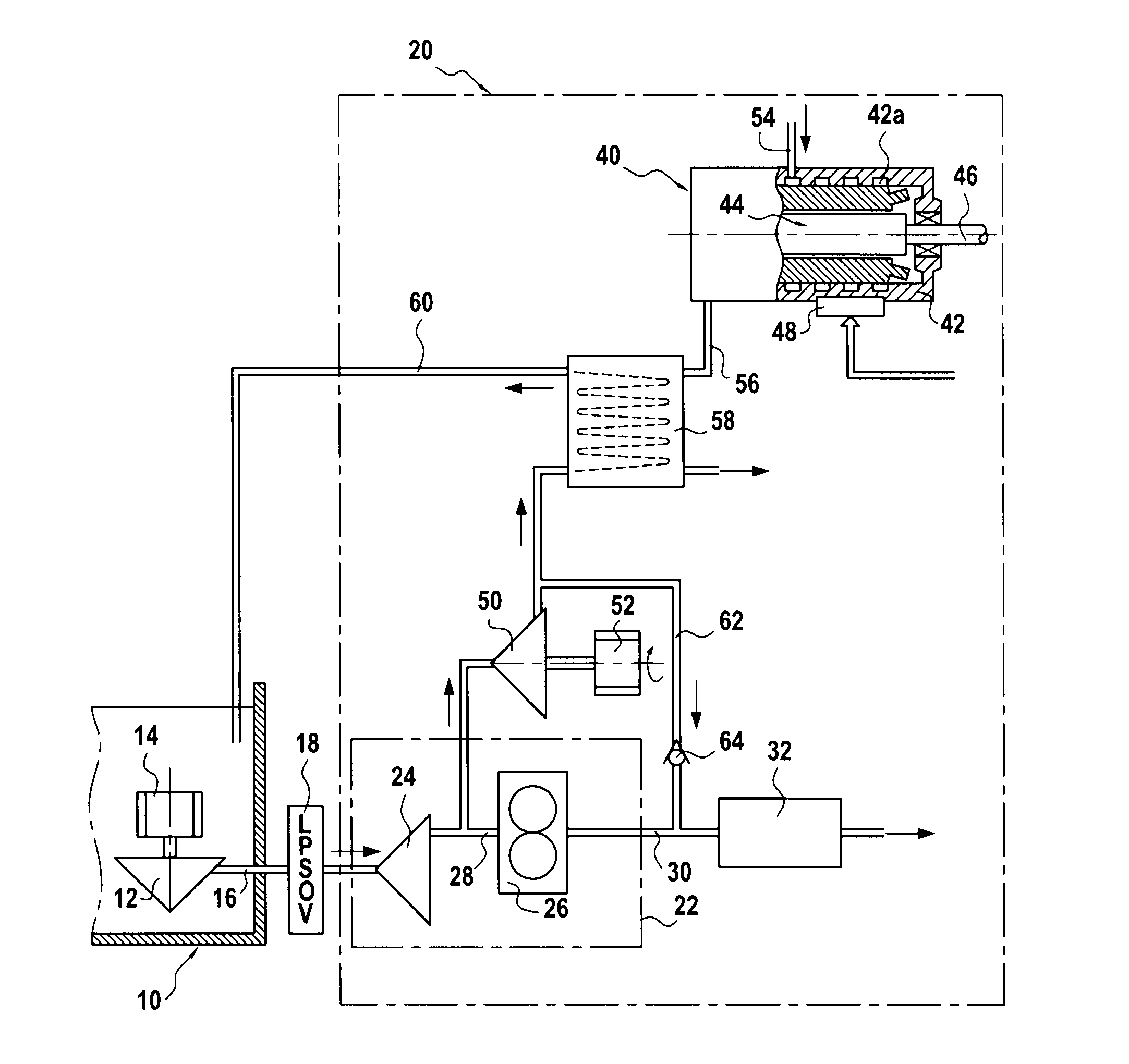

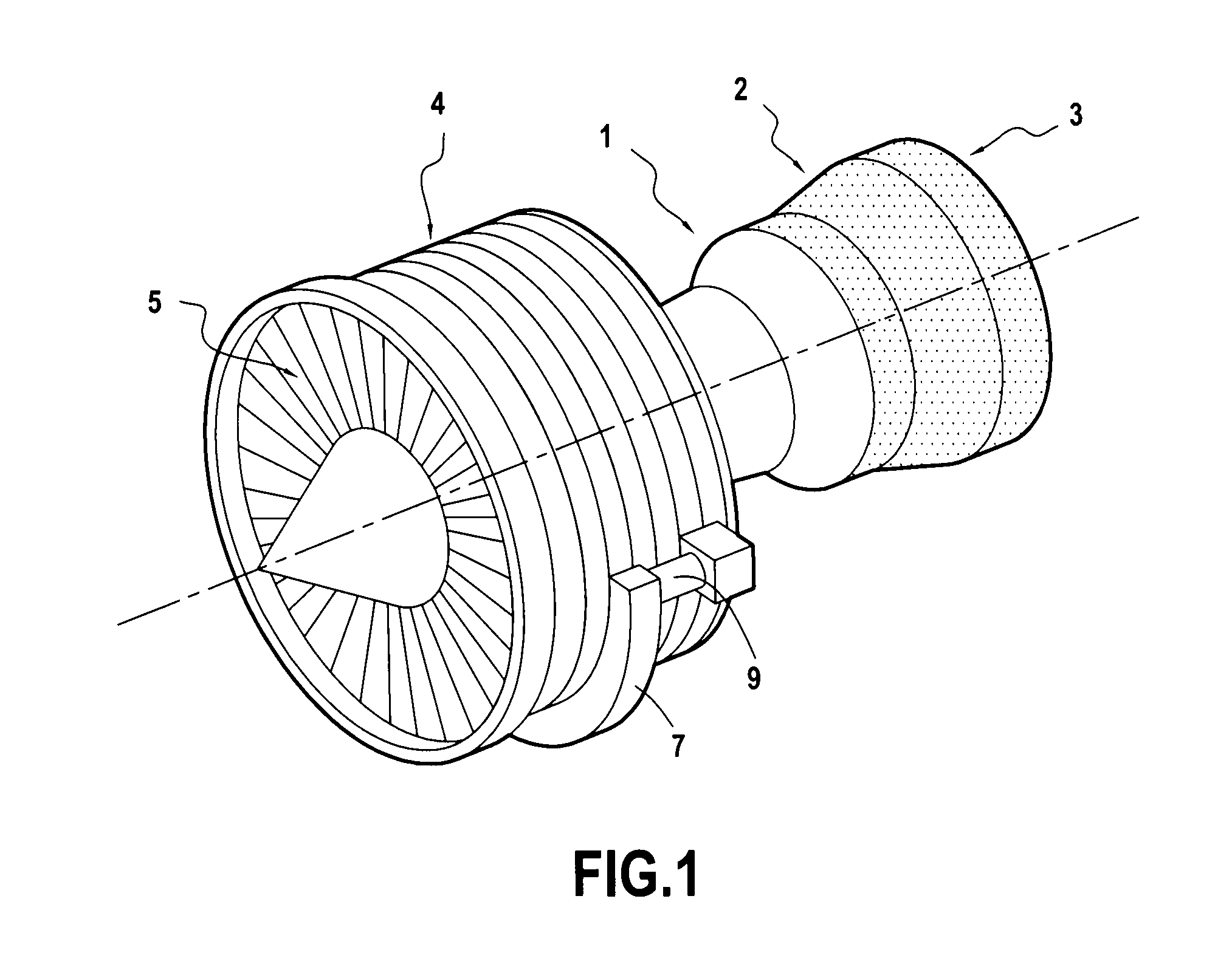

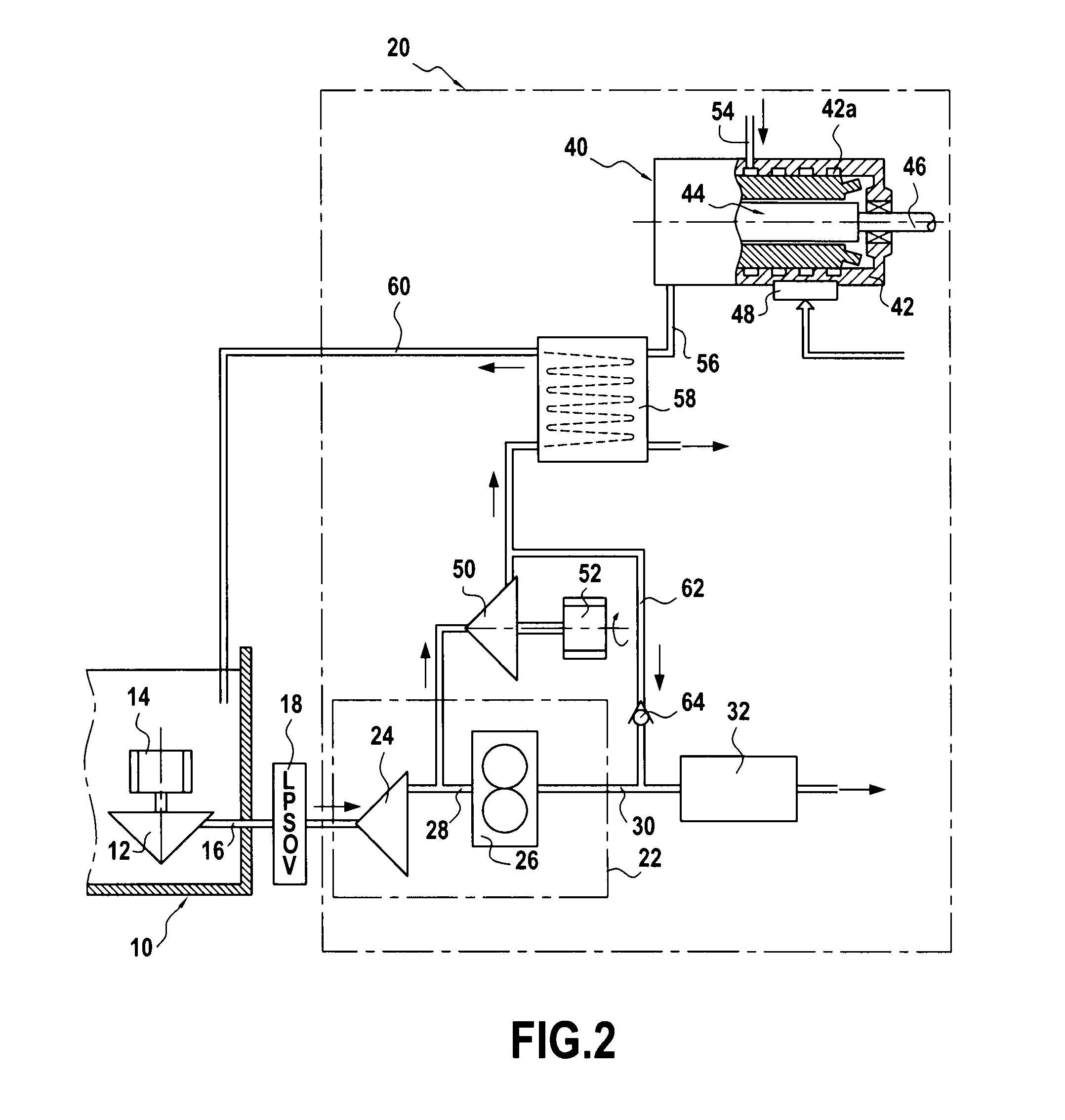

Aeronautical engine with cooling of an electric starting device

ActiveUS20110296846A1Reduce capacityReduce quality problemsTurbine/propulsion engine coolingTurbine/propulsion fuel deliveryAviationEngineering

An aeronautical engine including a fuel pumping device including a high pressure fuel pump including an inlet connected to a low pressure fuel conduit and an outlet connected to a main circuit for feeding high pressure fuel, an electric device starting the engine, and a device cooling the electric starting device connected to the pumping device to ensure cooling by circulation of fuel. The cooling device is supplied with fuel by a pump that includes an inlet connected to the pumping device, upstream from the high pressure pump, and that is driven by an electric motor independently of the high pressure pump.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Therma processing method for crankshaft of high-power engine

InactiveCN1540004ASufficient quenching hardnessEnough depthFurnace typesHeat treatment furnacesEngineeringCrankshaft

A technology for thermally treating the crankshaft of high-power engine includes such steps as heating to 830-850 deg.c, holding the temp for 2 hrs, quenching in the liquid at 20-55 deg.C for 6-8 min, tempering at 640-660 deg.C for 3 hrs, and air cooling. Its advantage is high comprehensive mechanical performance of treated crankshaft.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

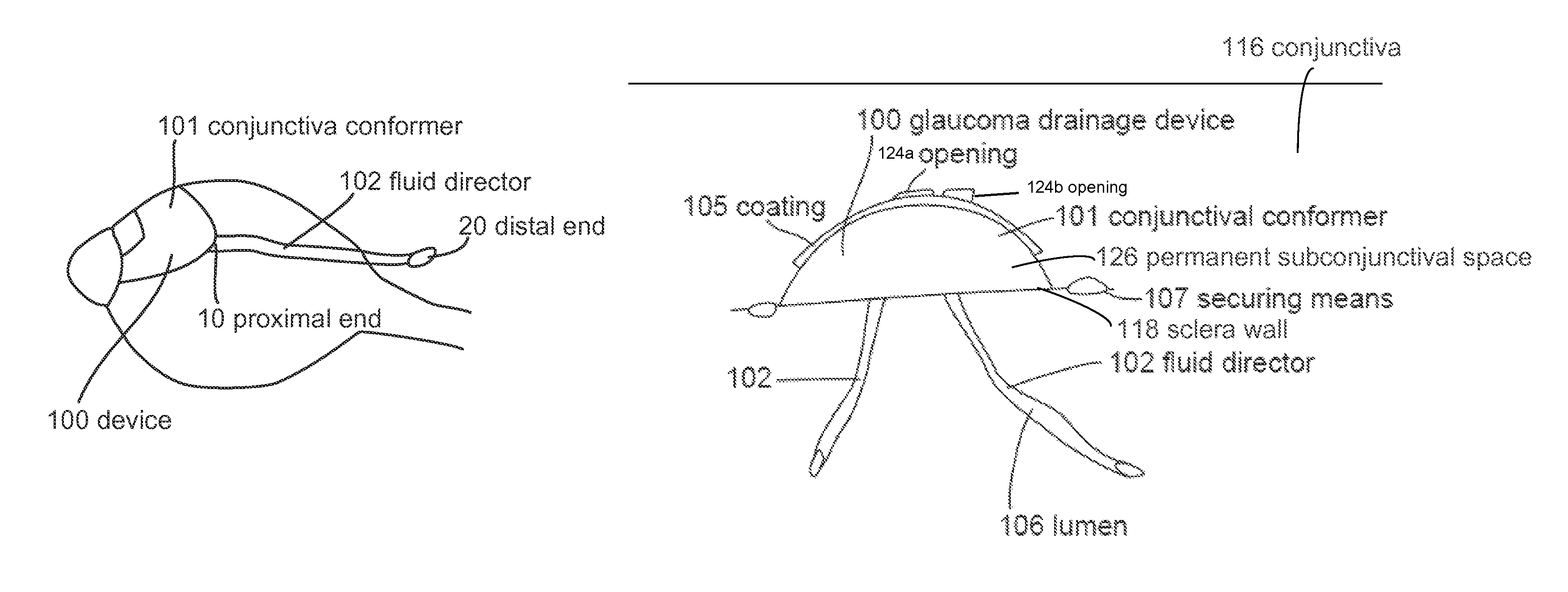

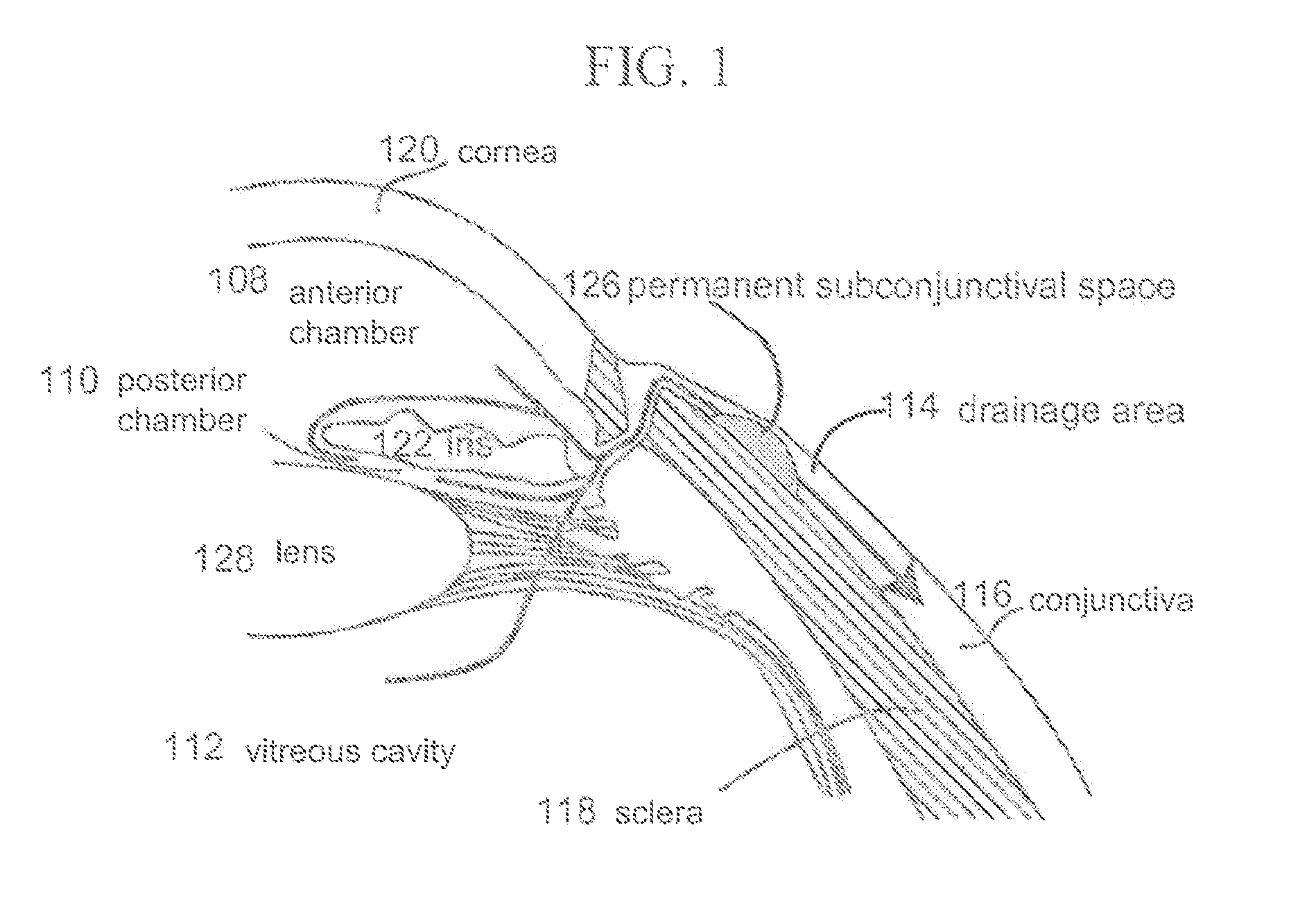

Subconjunctival conformer device and uses thereof

ActiveUS9370444B2Minimize infectionEnhance and direct flowEye surgeryIntravenous devicesConjunctivaElevated intraocular pressure

The present invention provides a device for use in an eye with elevated intraocular pressure or glaucoma, the device comprising a subconjunctival conformer shaped to conform to the eye wall and a fluid director that directs or facilitates the flow of intraocular fluid out of the eye and into the subconjunctival or retrobulbar space. The present invention also provides a method of lowering intraocular pressure using the device of the present invention.

Owner:CUNNINGHAM JR EMMETT T

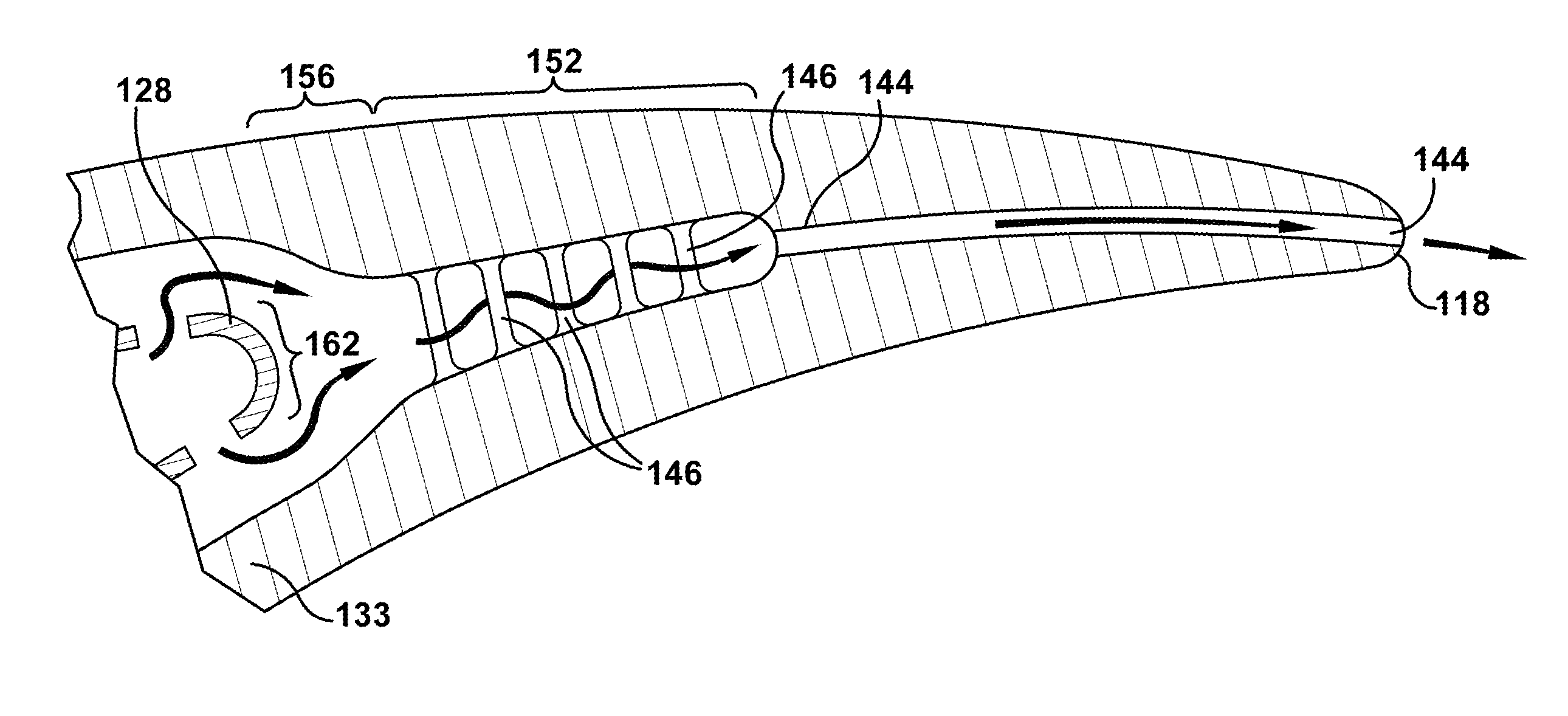

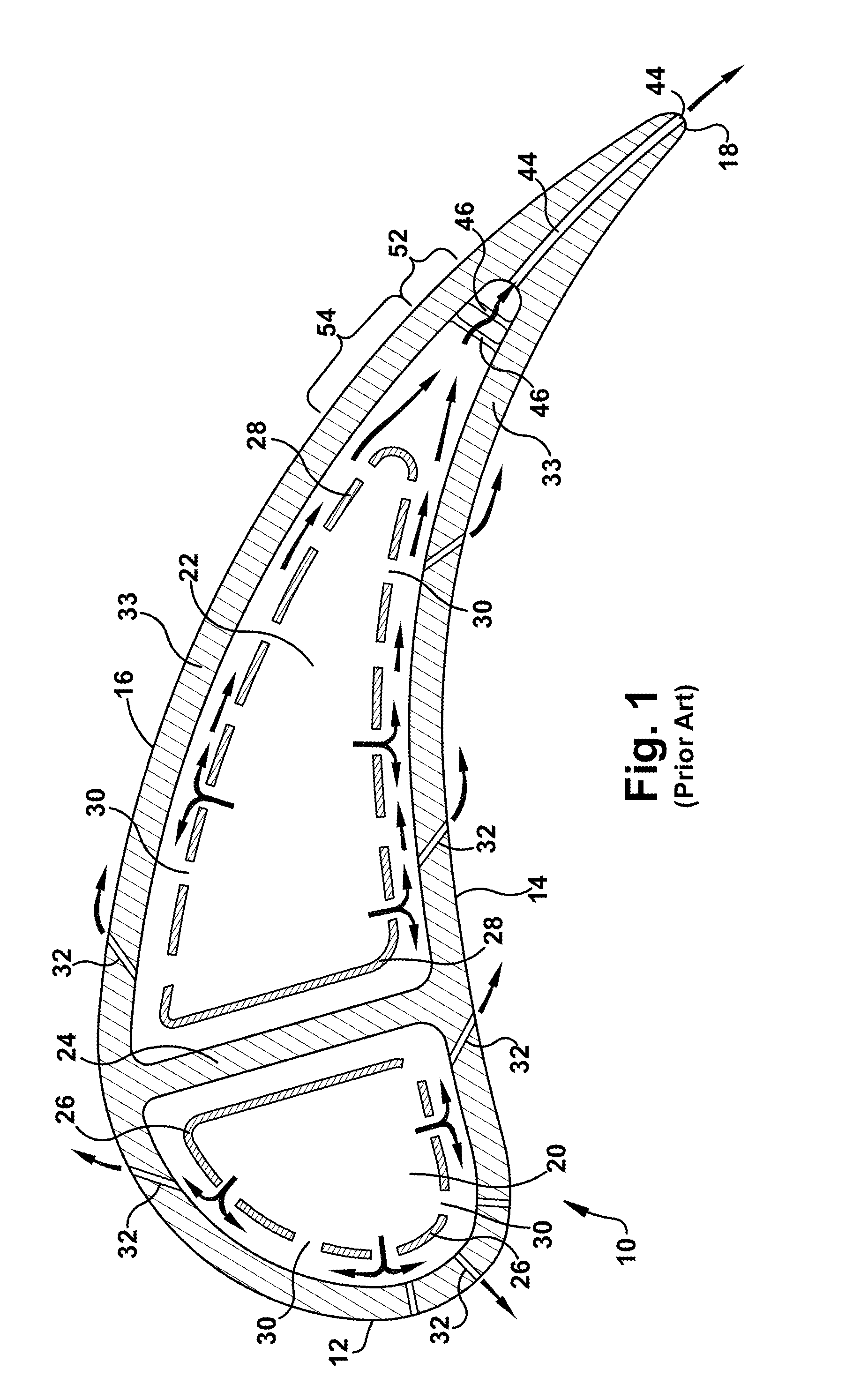

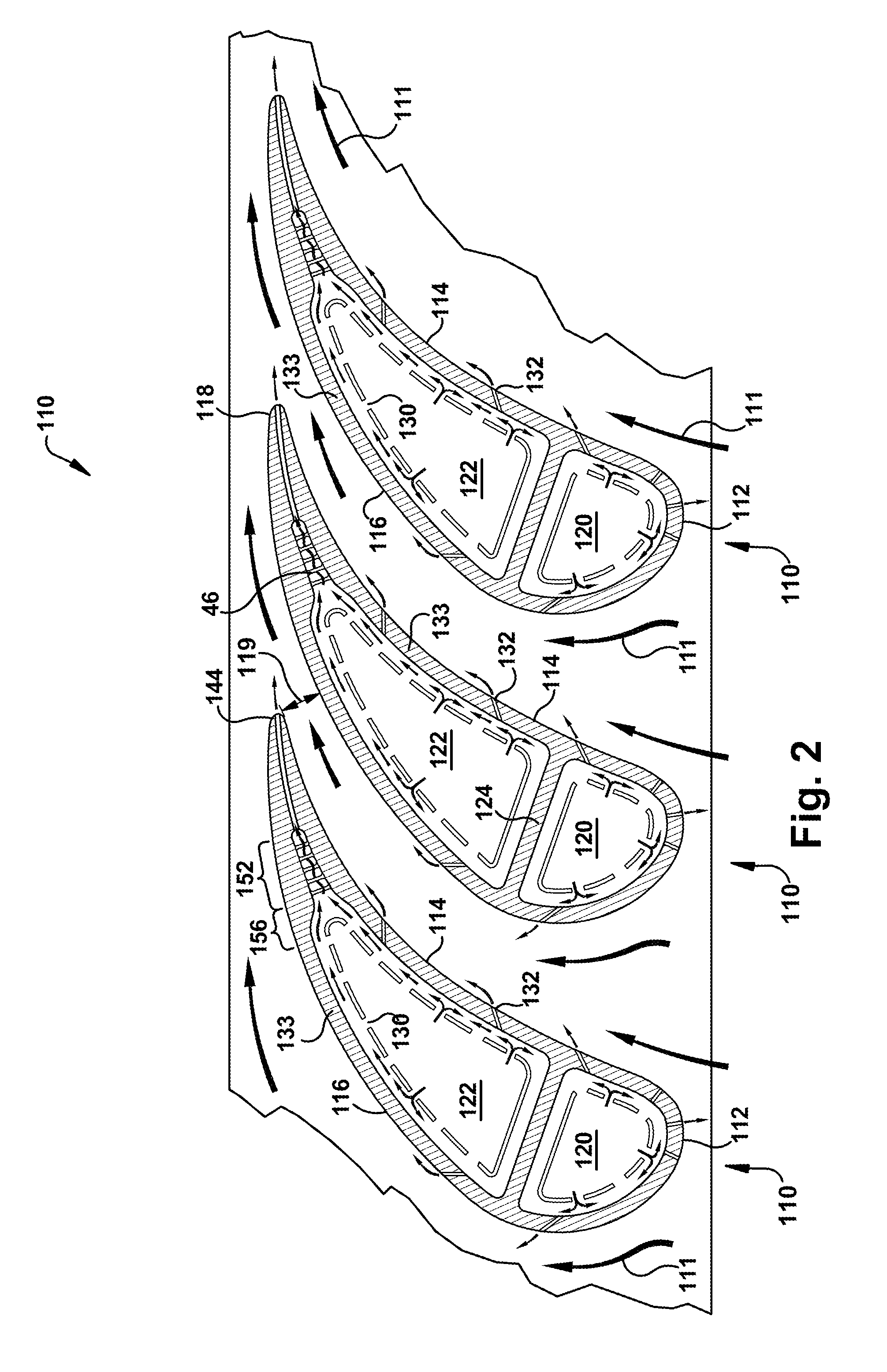

Turbine blade cooling circuits

ActiveUS20100166564A1Increase the areaLocalized hot spot is reducedPropellersRotary propellersLeading edgeTurbine blade

A turbine blade with a generally hollow airfoil having an outer wall that defines a chamber for receiving cooling air, the airfoil comprising a leading edge that resides in an upstream direction, a trailing edge that resides in a downstream direction, a convex suction side, a concave pressure side, and an insert disposed within the chamber that is configured to initially receive at least a portion of the cooling air entering the chamber and direct the cooling air through a plurality of insert apertures to cool the inner surface of the outer wall, the insert further comprising a configuration that generally conforms to the contour of the outer wall of the chamber but in spaced relation thereto, wherein the chamber and insert narrow as they extend toward the trailing edge, the insert eventually terminating and the chamber eventually terminating at a pin array section, wherein a first distance exists that comprises the generally axial distance between the position of downstream termination point of the insert and the position of an upstream beginning point of the pin array section, wherein the pin array section, at a downstream end, comprises a plurality of openings that define an inlet to a plurality of trailing edge cooling apertures, and wherein the chamber, the insert, and the pin array section are configured such that the first distance is approximately minimized.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com