Patents

Literature

147results about How to "Improve filling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of expanding tobacco using steam

ActiveUS7556047B2Increasing filling powerImprove filling capacityTobacco preparationTobacco treatmentEngineeringTobacco use

Owner:R J REYNOLDS TOBACCO COMPANY

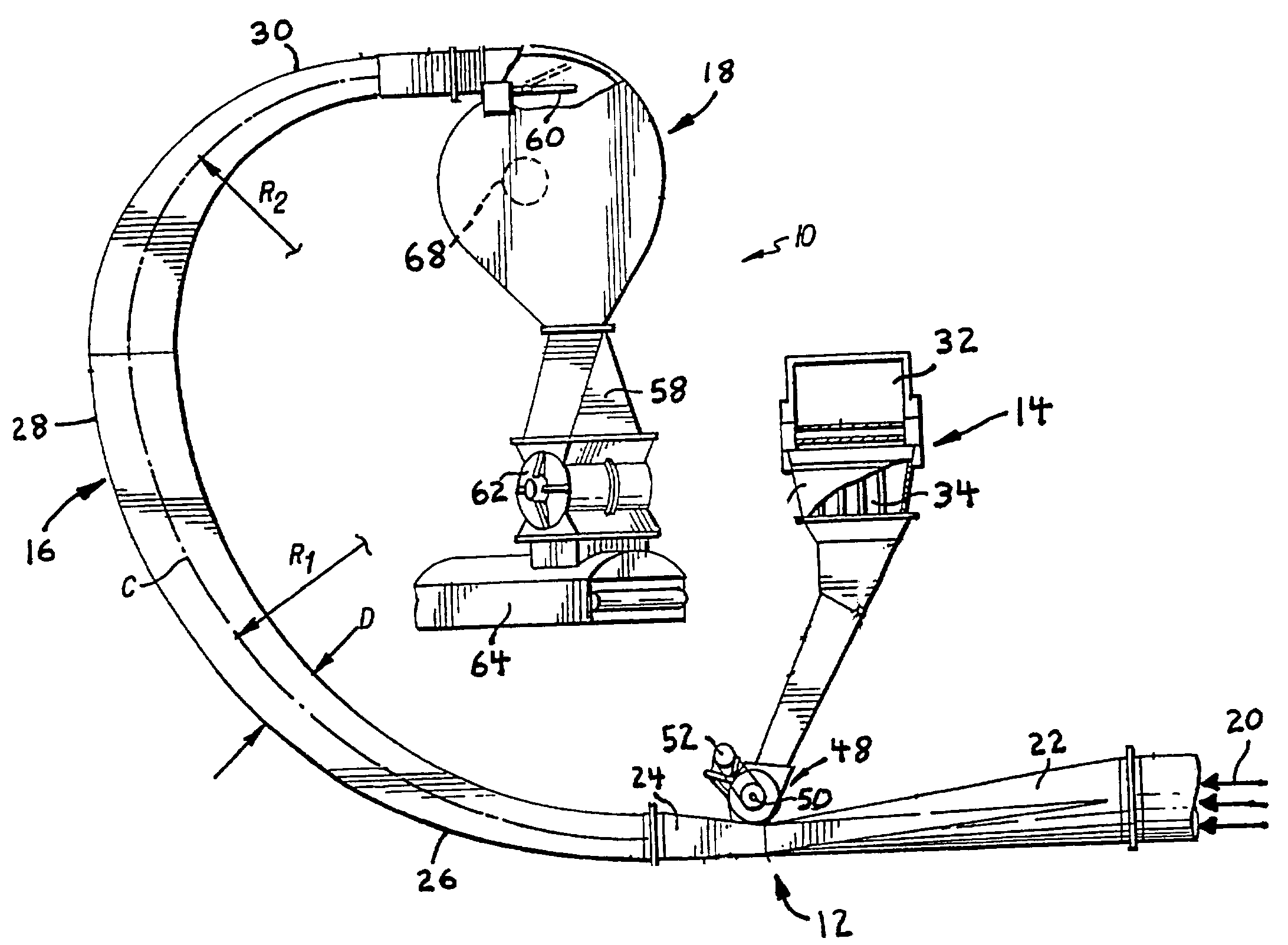

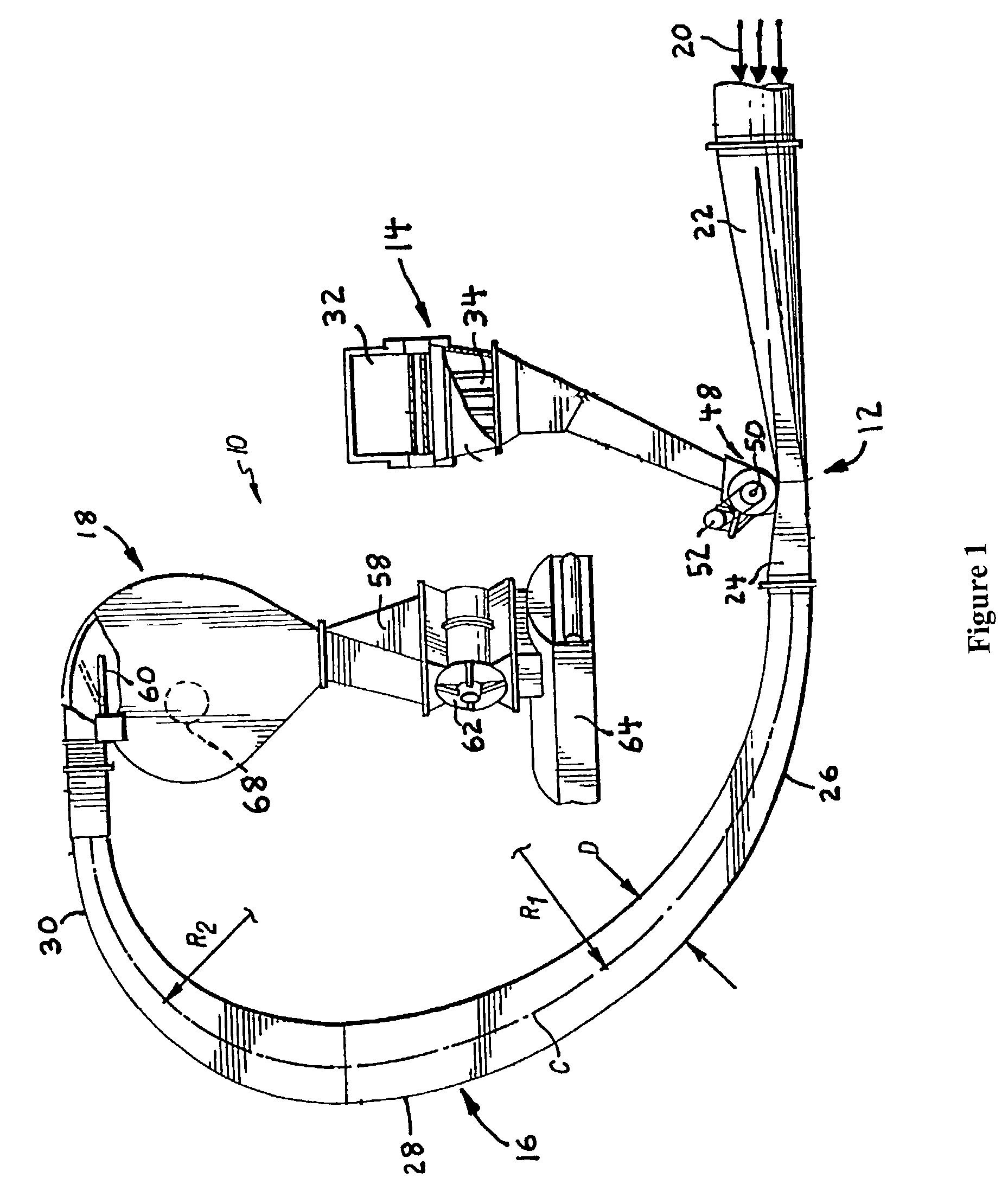

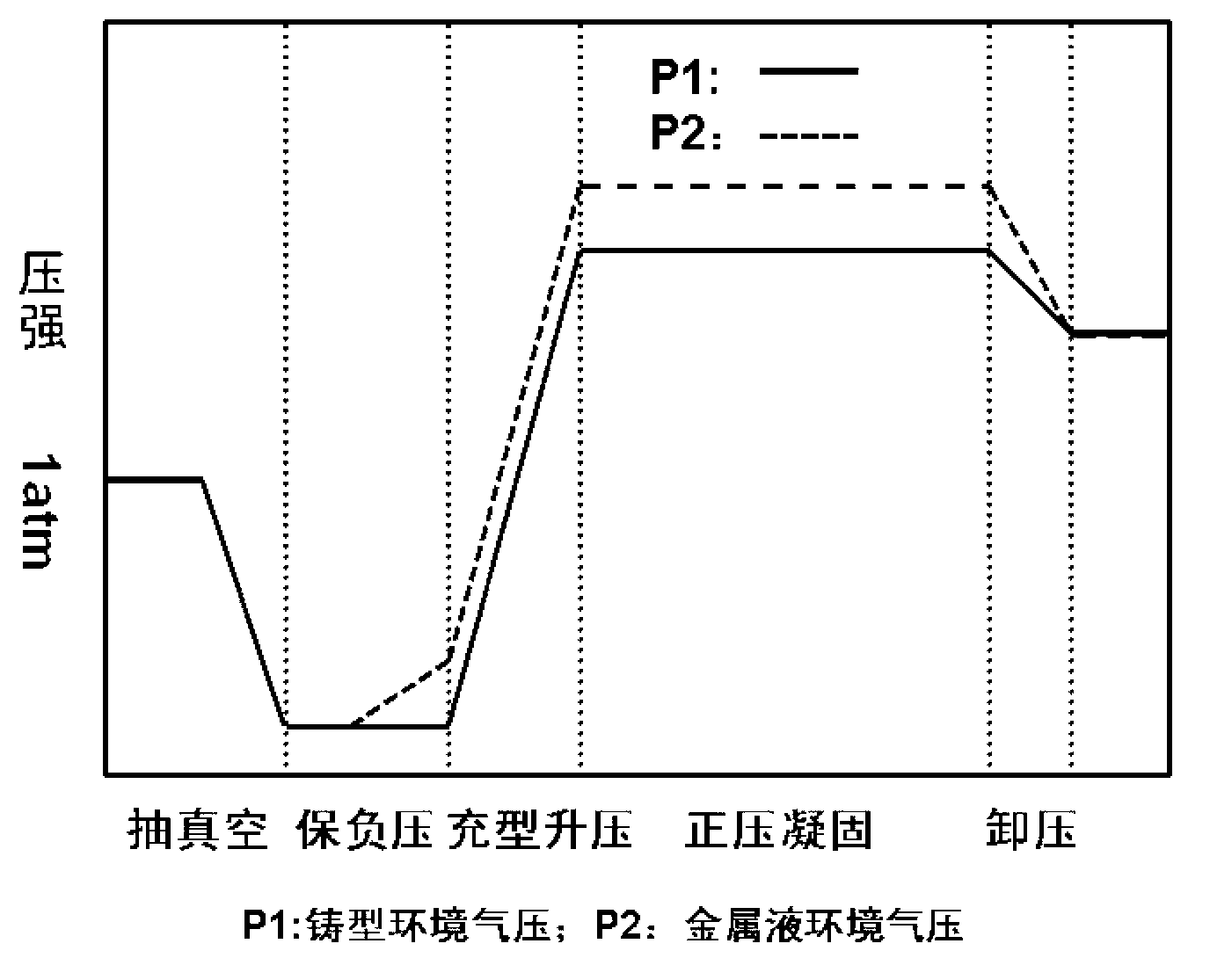

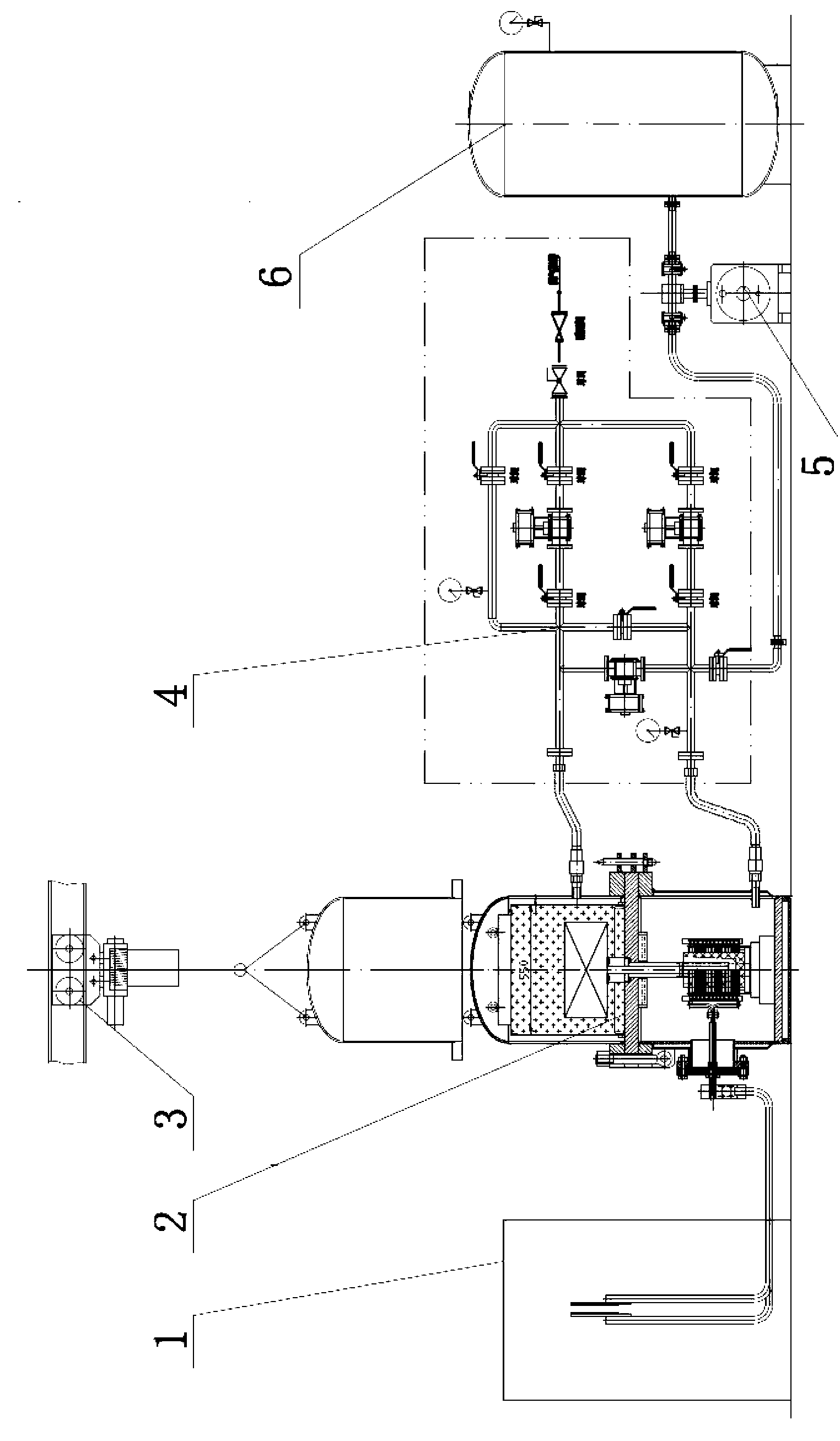

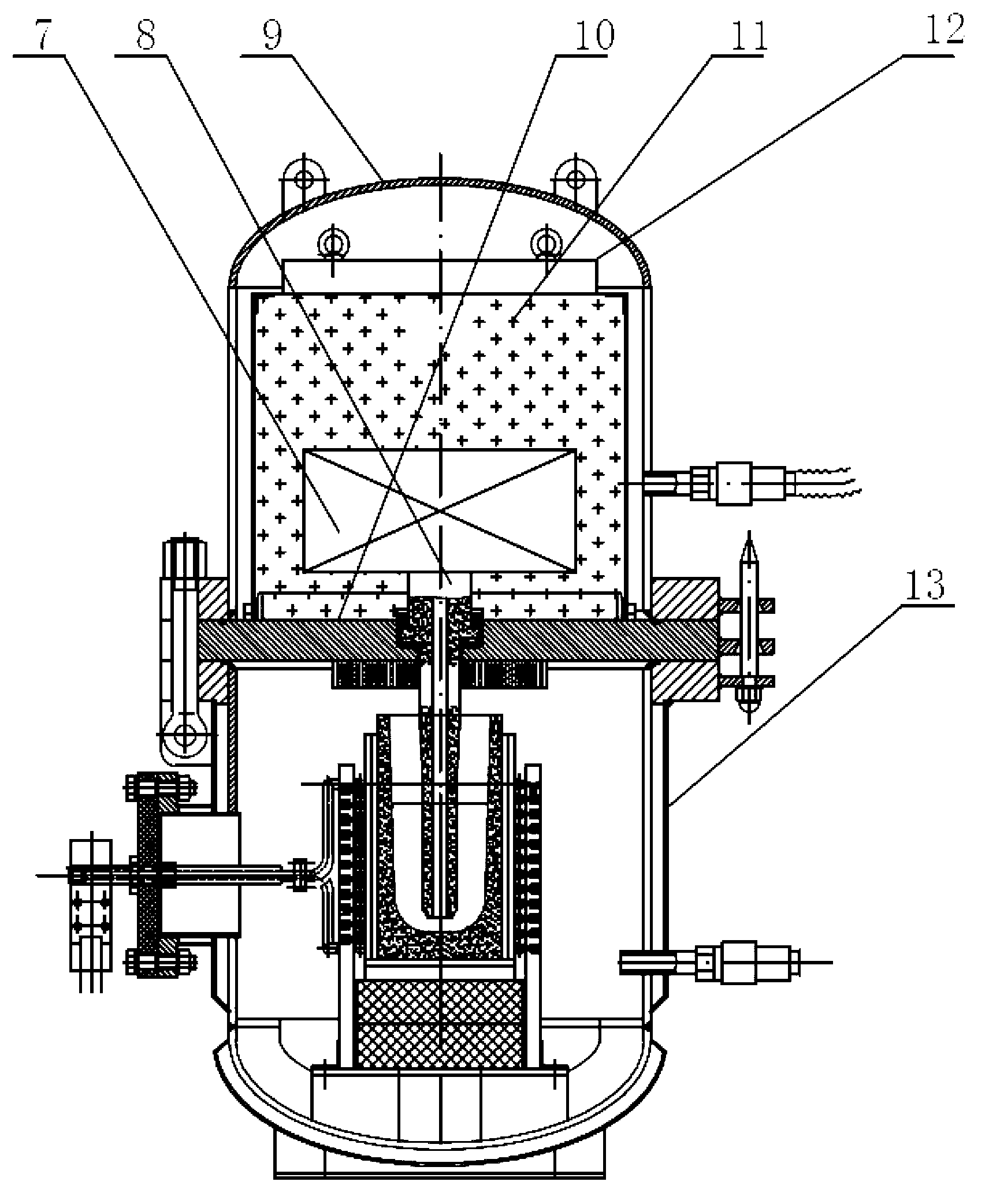

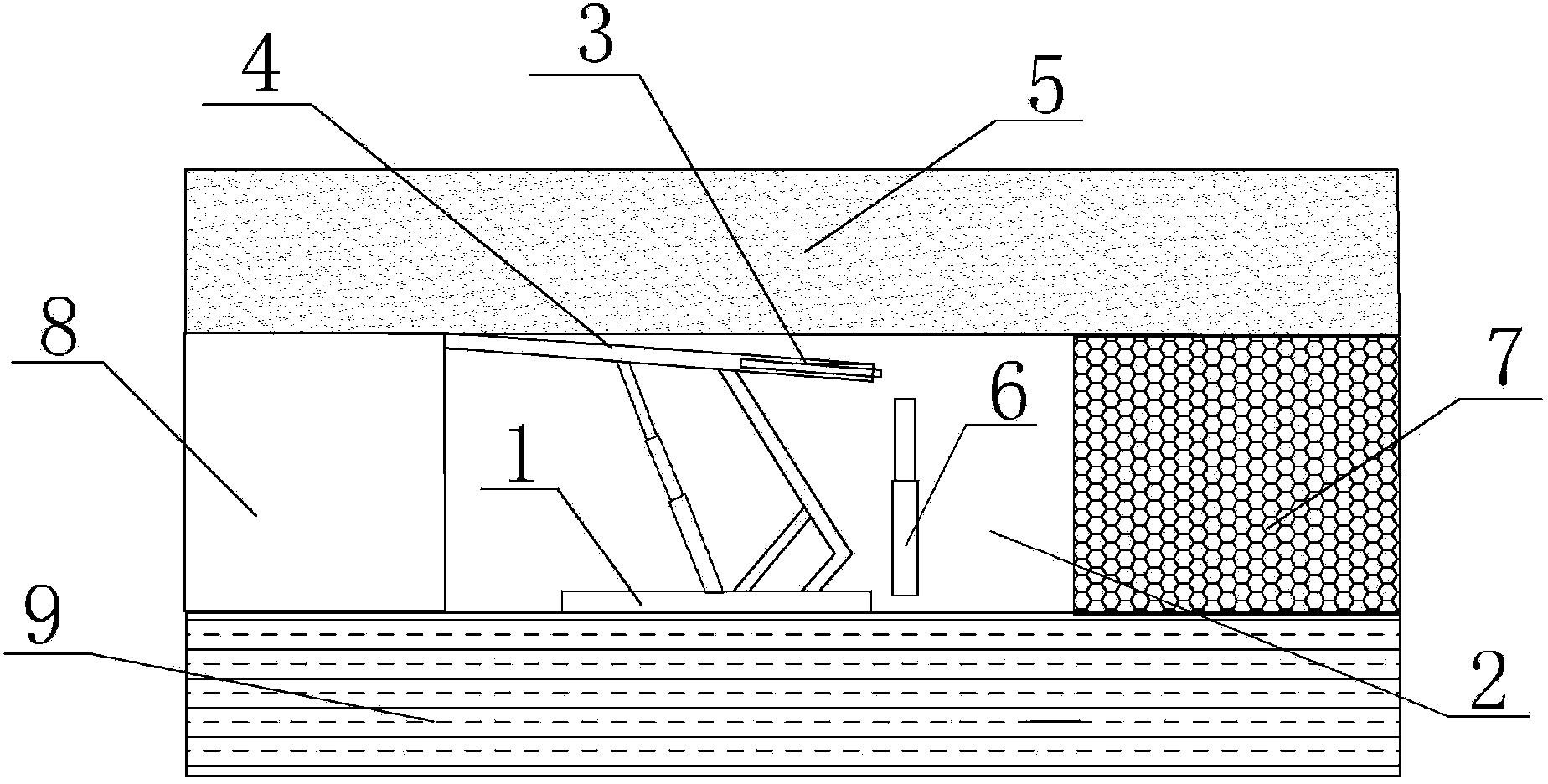

Precesion casting method for high temperature alloy complex thin-walled castings

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

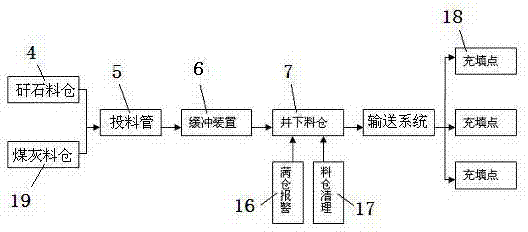

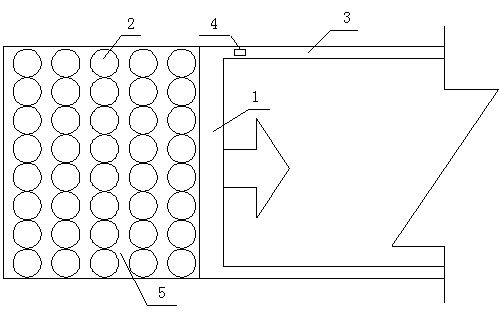

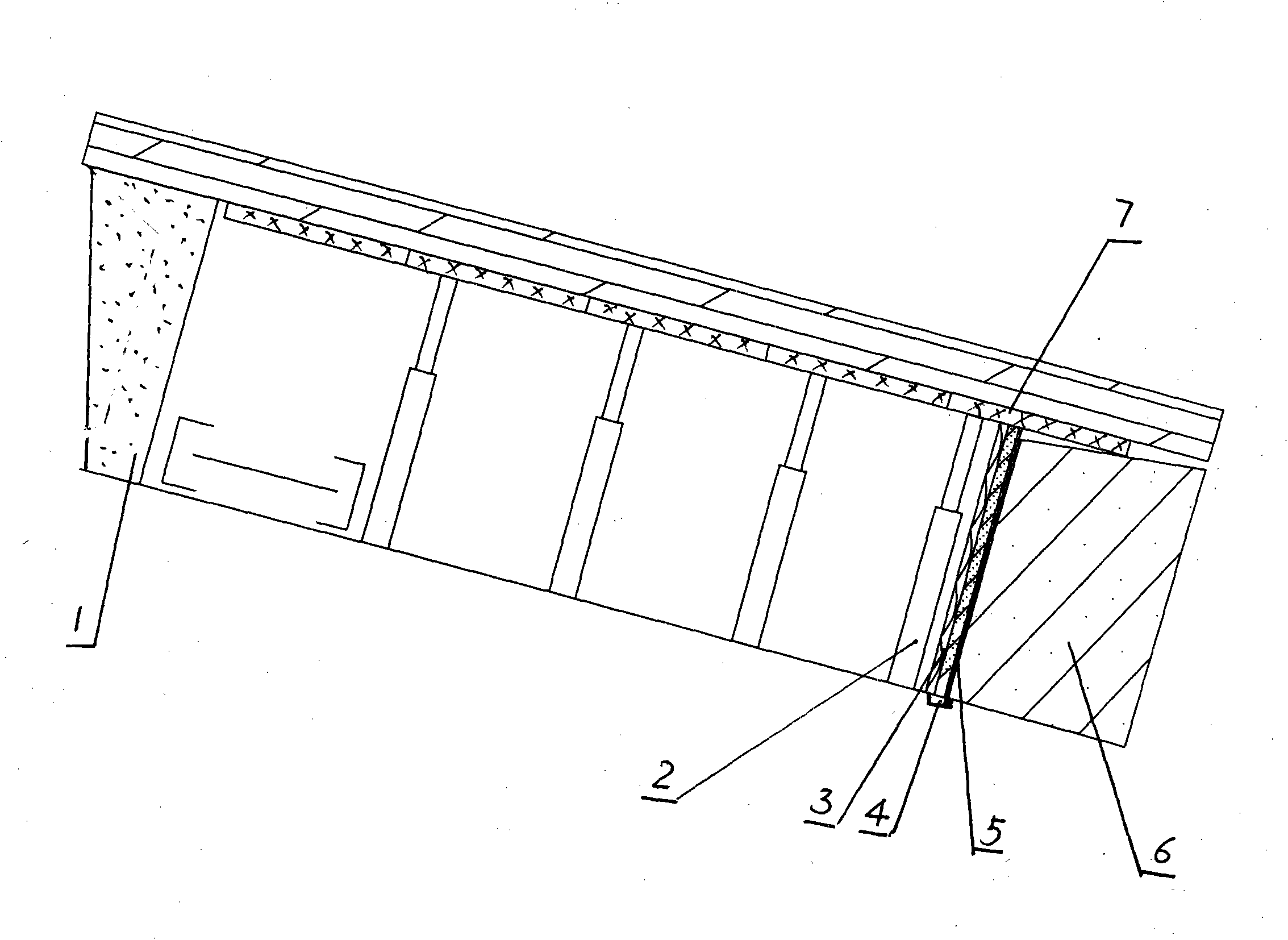

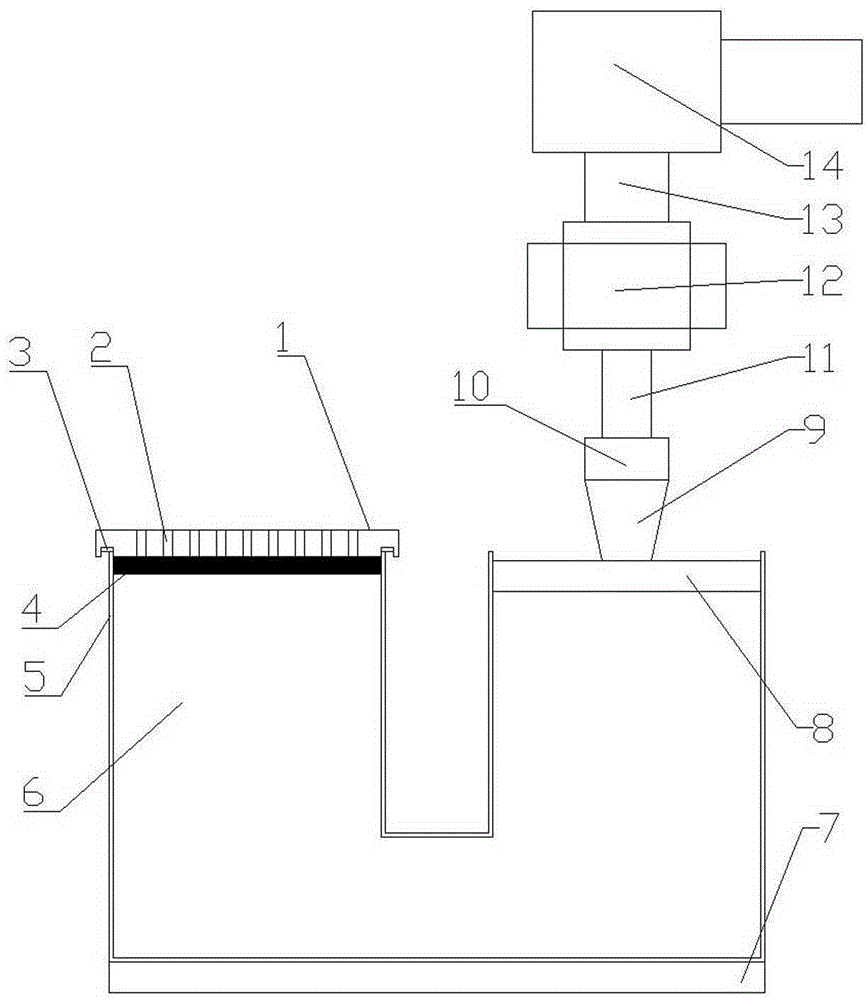

System for feeding coal mine solid filling material

InactiveCN102889097AImprove delivery capabilitiesAvoid cloggingMaterial fill-upFilling materialsClosed chamber

The invention relates to a system for feeding a coal mine solid filling material. The system comprises a filling control chamber, a gangue material bin, a coal ash material bin, a feeding pipe, an underground closed chamber, an impact resistance buffering device, an underground material bin and an underground conveying system, wherein the impact resistance buffering device is positioned at the bottom of the underground closed chamber; the feeding pipe is connected with the underground material bin through the underground closed chamber; the underground material bin is connected with the underground conveying system; the underground conveying system comprises a conveying passage and a conveyer; the conveyer is connected to a filling point; the feeding pipe consists of a protection hole wall steel pipe and a double-layer anti-abrasion pipe; a ceramic anti-abrasion pipe is sleeved on a shrinkage wall at the bottom of the underground material bin; and an outwards discharging type air guide hose is arranged at the upper opening of the underground material bin. According to the system, a large-aperture perpendicular feeding pipe is used for feeding the material, so that the feeding capacity of the filling material is improved, and a filling effect and the safety are improved; by the umbrella-shaped impact resistance buffering device, falling impact force of the filling material can be relieved; the compactness of the filling material in the bin can be reduced; and the bins can be prevented from being plugged.

Owner:HEBEI COAL SCI RES INST

Filling and mining method of coal gases

InactiveCN102155225ALow costWide variety of sourcesUnderground miningSurface miningMining engineeringHigh pressure

The invention relates to a filling and mining method of coal gases, comprising the following steps: arranging a gas pressurization room on the ground and then arranging an underground gas booster pump connected with a ground high-pressure gas storage tank pipeline in a mining region haulage way in front of an underground coal mining working face; distributing a row of cylindrical rubber airbags in a gob behind the coal mining working face when the coal mining working face is advanced for 5-8 m from the open-off cut; filling gas into the cylindrical rubber airbags till the top is tight; sealing the openings of the cylindrical rubber airbags to finish filling gas into one cylindrical rubber airbag; continuously distributing a row of cylindrical rubber airbags behind the row of gas-filling cylindrical rubber airbags when the coal mining working face is advanced for each step along with the continuous advance of the coal mining working face and charging gas in rows till finishing the gas filling and supporting in the whole gob. In the invention, the filling method is simple, the gas filling speed is high, the cost is low and the filling capacity is great, and the method is convenient for onsite underground operation.

Owner:CHINA UNIV OF MINING & TECH

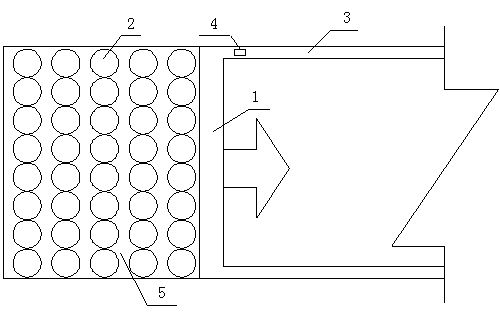

Laser induced nanometer brazing method of silicon carbide particle reinforced aluminum matrix composite with high volume fraction

ActiveCN102699465AEnhanced BrazingImprove compactnessWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalElectron

The invention provides a laser induced nanometer brazing method of a silicon carbide particle reinforced aluminum matrix composite with high volume fraction, which relates to a brazing method of the silicon carbide particle reinforced aluminum matrix composite with high volume fraction. The method comprises the following steps of: (1) preparing nano-crystal particle layers at brazed surfaces of an upper matrix and a lower matrix; (2) preparing a silver matrix, aluminum matrix or zinc matrix brazing filler metal; (3) assembling a piece to be brazed, to be specific, placing the brazing filler metal prepared in the step (2) between the brazed surfaces of the upper matrix and the lower matrix, which are treated in the step (1), so as to form the piece to be brazed; and (4) under the protection of argon, carrying out double-beam laser brazing on the piece to be brazed, so as to achieve laser induced nanometer brazing of the composite. According to the invention, high temperature cannot be generated in the welding process; the shear strength of an obtained joint can reach about 260 MPa, so as to completely satisfy electronic packaging requirements or welding requirements of other materials, which contain a large quantity of ceramic phases and for which high brazing temperature is not allowed, and products thereof. The brazing method provided by the invention is used for brazing the silicon carbide particle reinforced aluminum matrix composite with high volume fraction.

Owner:TIGER TECH CO LTD

Double-component self-adhesive addition type flame retardant heat conducting room temperature curing organic silicon pouring sealant

ActiveCN103756631AHigh thermal conductivityImprove liquidityNon-macromolecular adhesive additivesHeat conductingRoom temperature

The invention discloses double-component self-adhesive addition type flame retardant heat conducting room temperature curing organic silicon pouring sealant. The double-component self-adhesive addition type flame retardant heat conducting room temperature curing organic silicon pouring sealant comprises a component A and a component B and is characterized in that the component A is prepared by mixing a basic material, a platinum catalyst and a coupling agent in mass ratio of 100:(0.00001-0.1):(0.1-1); the component B is formed by mixing a basic material, a coupling agent, an inhibitor and a tackifier in mass ratio of 100: (0.2-1.0):(0.01-1):(1-10); the basic material is formed by mixing vinyl-terminated silicone oil, heat-conducting filler and a flame retardant in mass ratio of 100: (120-160):(20-40). The double-component self-adhesive addition type flame retardant heat conducting room temperature curing organic silicon pouring sealant has good optical performance, heat conduction property and relatively good viscosity and can meet the long-term using requirements in high and low temperature environments.

Owner:西卡(江苏)工业材料有限公司

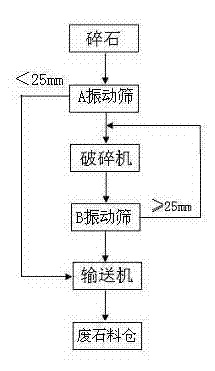

Filling method and system of coal mine goaf

ActiveCN102865101AImprove protectionAvoid missingMaterial fill-upMining engineeringPulverized fuel ash

The invention relates to a filling method and system of coal mine goaf. The filling system comprises a filling bin, a feeder, a weighing hopper, a stirrer, a slurry machine, a filling pump, a delivering pipeline, a working face pipe and a tee pipe, wherein the filling bin is respectively connected with the inlet of the stirrer through the feeder and the weighing hopper; and the outlet of the stirrer is connected to a filling point through the slurry machine, the filling pump, the delivering pipeline and a tee valve. The filling method comprises the steps that barren rocks with granularity of less than 25mm, a cementing agent, pulverized fuel ash and water are delivered to the weighing hopper through the feeder for weighing; the barren rocks, the cementing agent and the pulverized fuel ash are mixed in a mass ratio of 1:(0.22-0.80):(0.35-0.57), and are added with water to produce slurry in a mass concentration of between 70 and 83 percent through the stirrer; and the slurry is delivered to the filling point for filling through the slurry machine, the filling pump, the delivering pipeline, the working face pipe and the tee valve. According to the filling method and system, the sources of filling materials can be enlarged, the filling substance strength and durability can be increased, the filling material can be delivered to the filling point and uniformly filled by delivering and filling in a slurry state, and the filling effect can be improved.

Owner:河北充填采矿技术有限公司

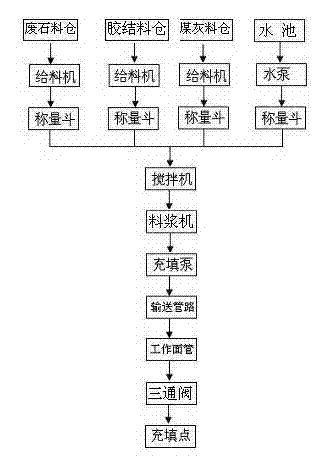

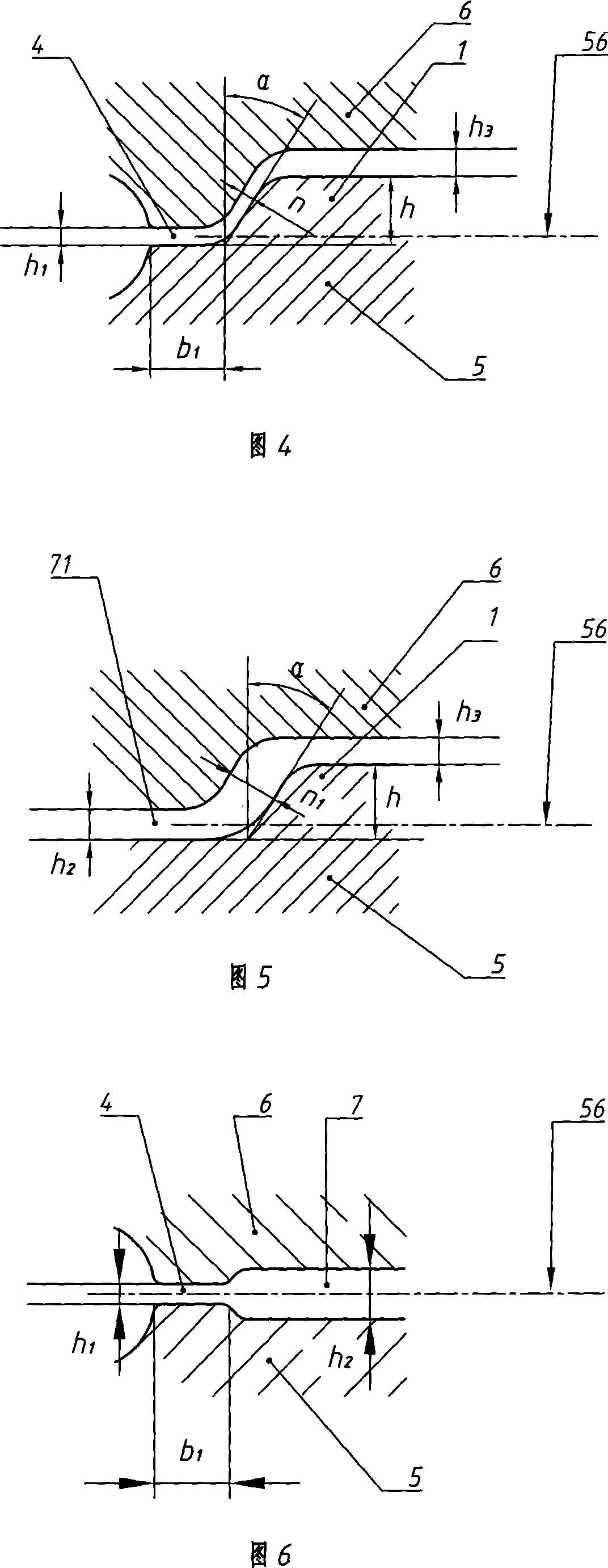

Crankshaft forging die

InactiveCN101020224AStrong horizontal flow resistanceIncrease profitForging/hammering/pressing machinesEngine componentsEngineeringBinding force

The crankshaft forging die has one flash gutter comprising one flash bridge and one flash bin set around the die cavity and in the die joint between the upper die and the lower die. Inside the flash gutter, one raised wall beyond the die joint is set in one side of the upper die or the lower die and in the location corresponding to the flash bin of die cavity for the crankshaft balancing block. Compared with available technology, the wall structure alters the metal flow direction and increases the horizontal flow resistance, and this results in the possibility of adopting relatively small size blank, raised material utilization rate and lowered energy source consumption.

Owner:CHONGQING UNIV

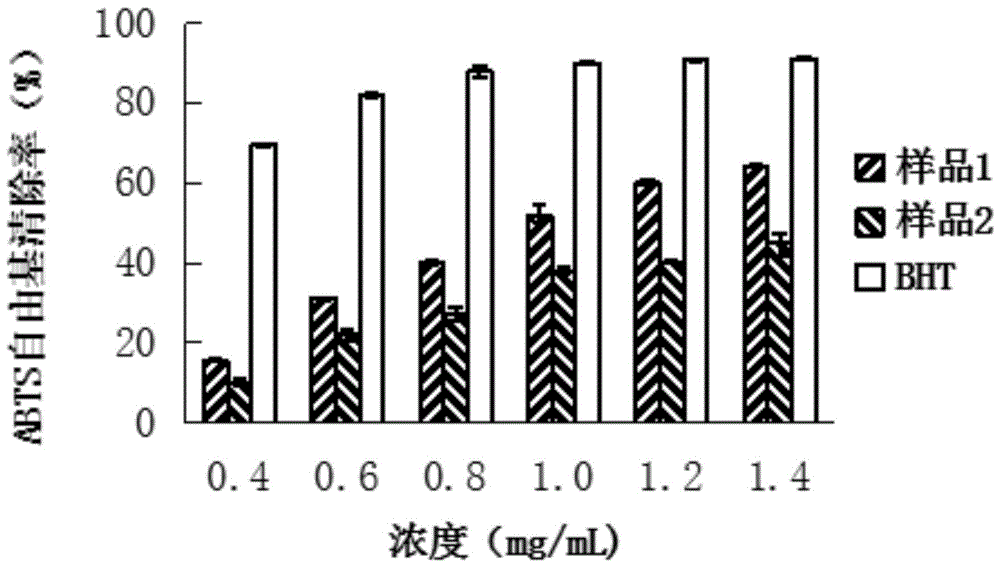

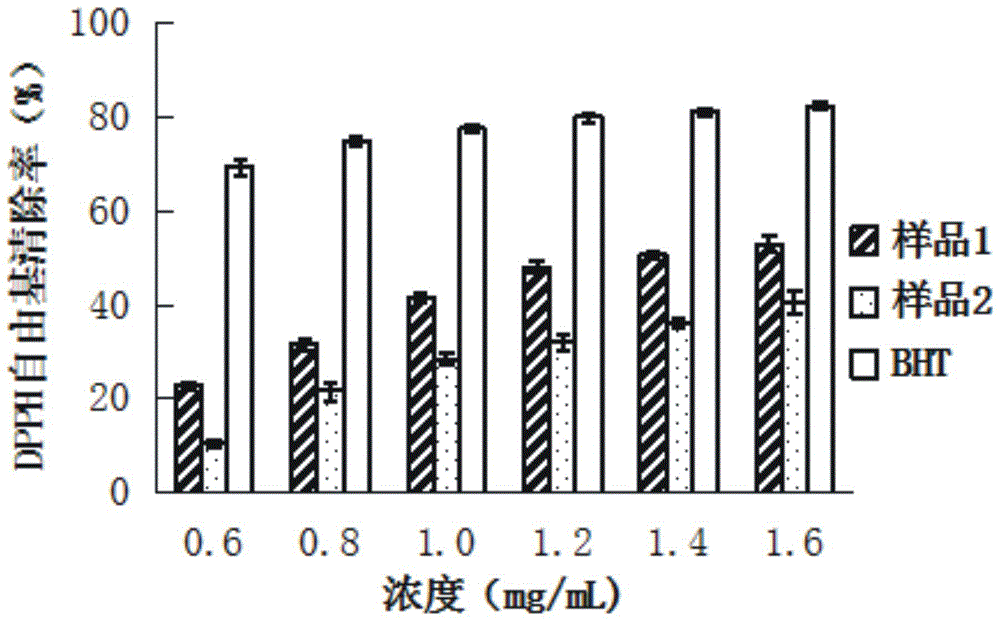

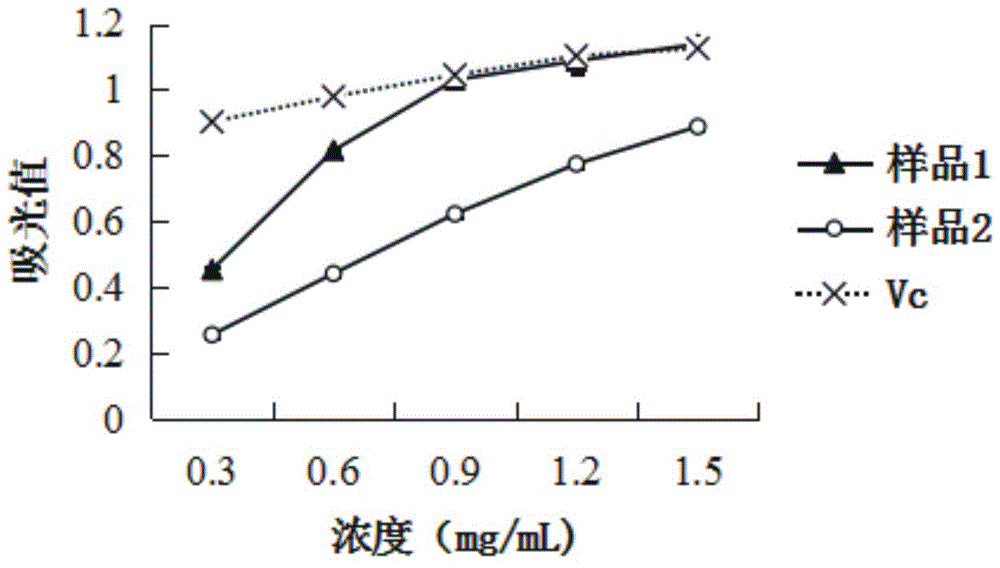

Kiwi fruit enzyme and preparation method thereof

InactiveCN105962343ASolve technical problems that are difficult to retainGuaranteed stabilityFood ingredient functionsPectinaseActinidia

The invention discloses a preparation method of kiwi fruit enzyme with high anti-oxidation activity. A formula is characterized in that fresh kiwi fruits are adopted as raw materials, fruit skin is reserved for pulping after washing and deburring the kiwi fruits, and enzymolysis is carried out on kiwi fruit pulp by adding a composite enzyme preparation (which is prepared from pectinase, cellulose, hemicellulase, protease and diastase), so that the juice yield and the production efficiency are improved; then, a multi-strain symbiotic fermentation technology and a grading inoculation process are adopted, and fermentation and ageing are carried out on a product by sequentially adding saccharomycetes, acetic acid bacteria and lactic acid bacteria; finally, the purpose of removing bacteria is achieved through the technologies of kieselguhr filter, membrane filter and the like, so that continuous fermentation of the product is ended, the stability of the shelf life is ensured, and meanwhile, the activity of active ingredients and enzyme is maximum kept. The enzyme prepared through the preparation method has the characteristics of high anti-oxidation activity, richness in enzymes and high enzyme activity; the appearance is clear and transparent, the flavor is sour, sweet and gentle, and the fruity fragrance is elegant.

Owner:成都兴食尚食品研发设计中心(有限合伙)

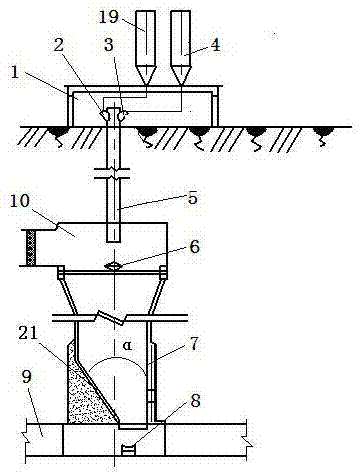

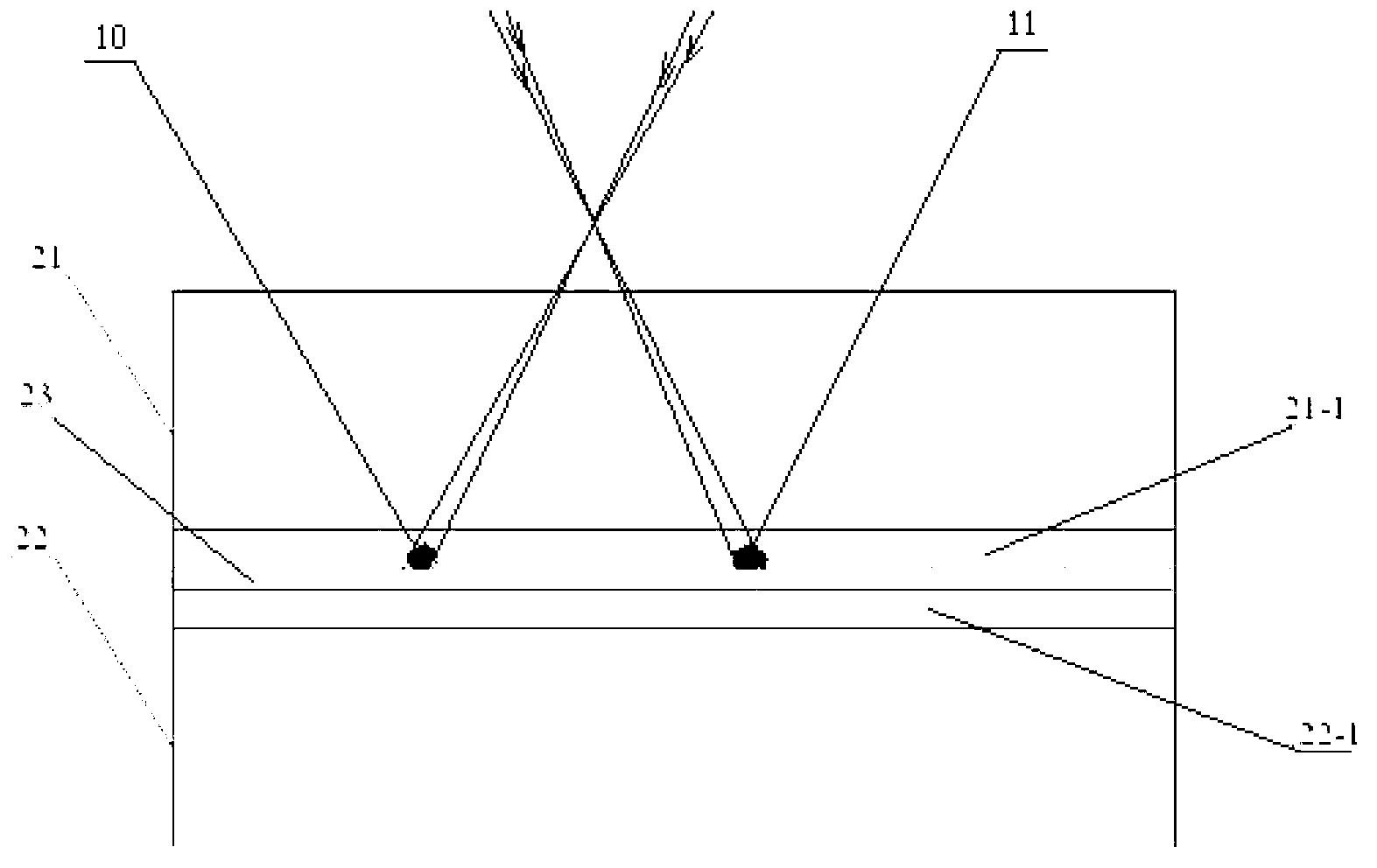

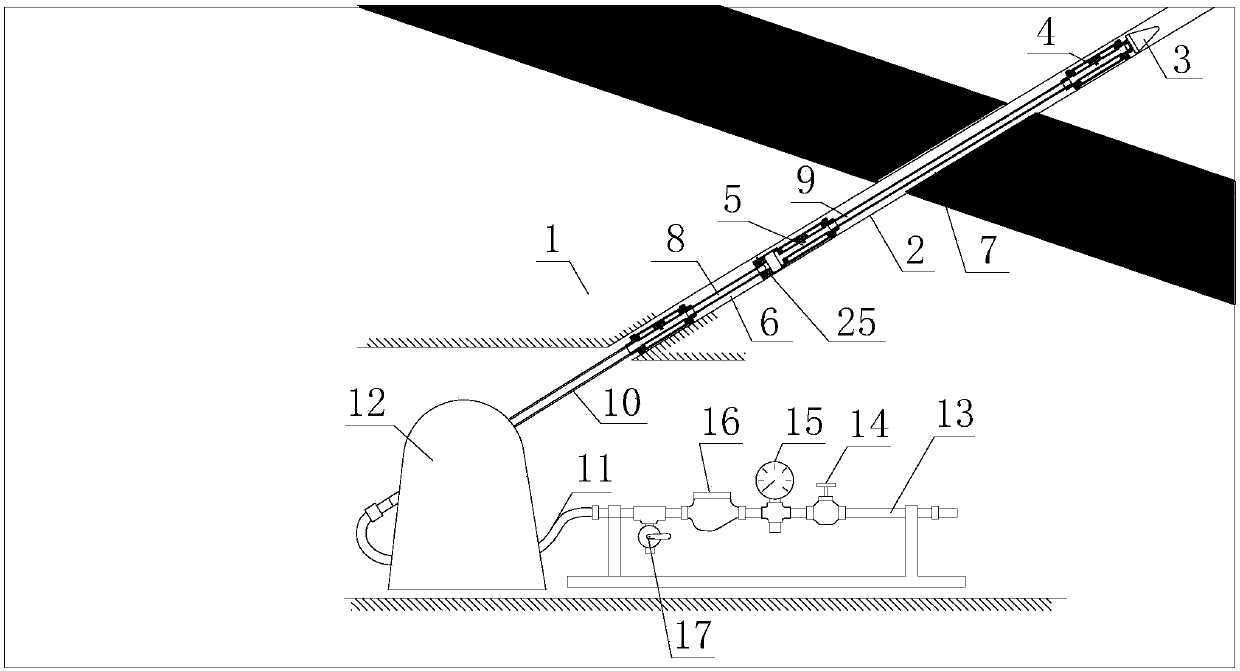

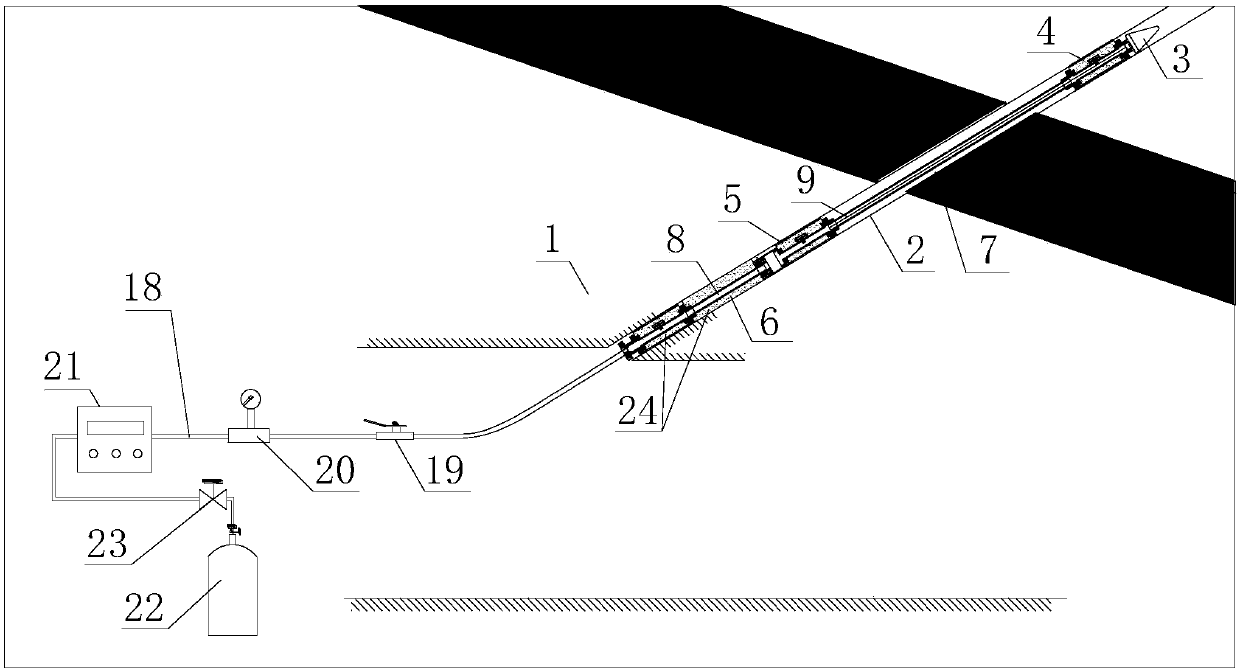

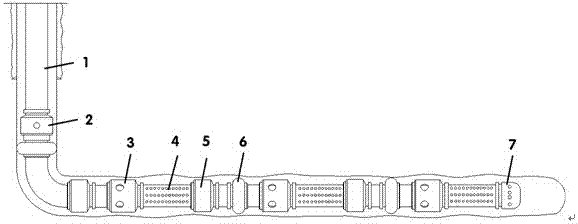

Observation method for mine rock body drill hole plugging and gas extracting integrated system

ActiveCN107605461AEffective monitoringSimple structureSurveyConstructionsObservation methodTest probe

The invention discloses an observation method for a mine rock body drill hole plugging and gas extracting integrated system. According to the observation method for the mine rock body drill hole plugging and gas extracting integrated system, the problems that in the prior art, the sealing effect of a mine rock body drill hole is poor, the extraction cost is high, and gas is difficult to collect are solved, and the effects that the stability of the plugging process and the gas extracting process is improved, and the sealing performance is enhanced are achieved. According to the technical schemeof the observation method, the observation method comprises the following steps that the gas extracting drill hole is drilled; a test probe is mounted and connected with a drill rod, and the test probe is pushed in a squeezed mode to a designated extracting area through a drill rig; the drill hole is sealed; a pressure-tight test is conducted; gas parameters are measured; and a measuring system is connected, a third switch is turned on, gas enters a collection tube and enters the measuring system through a communicating pipe, and after a gas pressure gauge is stable, the showing number on thegas pressure gauge is read and compared with a reading of an electronic pressure gauge.

Owner:DALIAN UNIV OF TECH

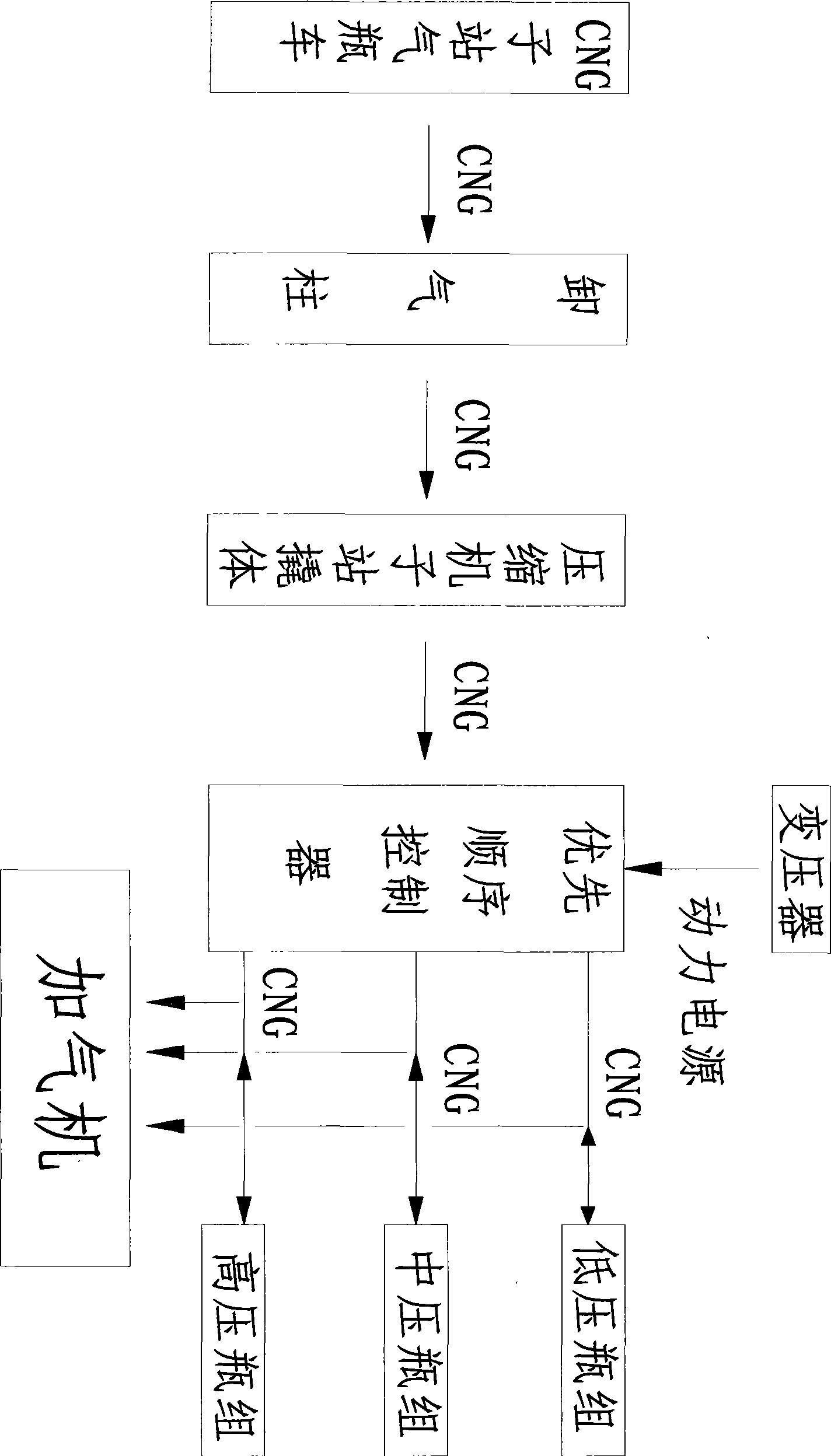

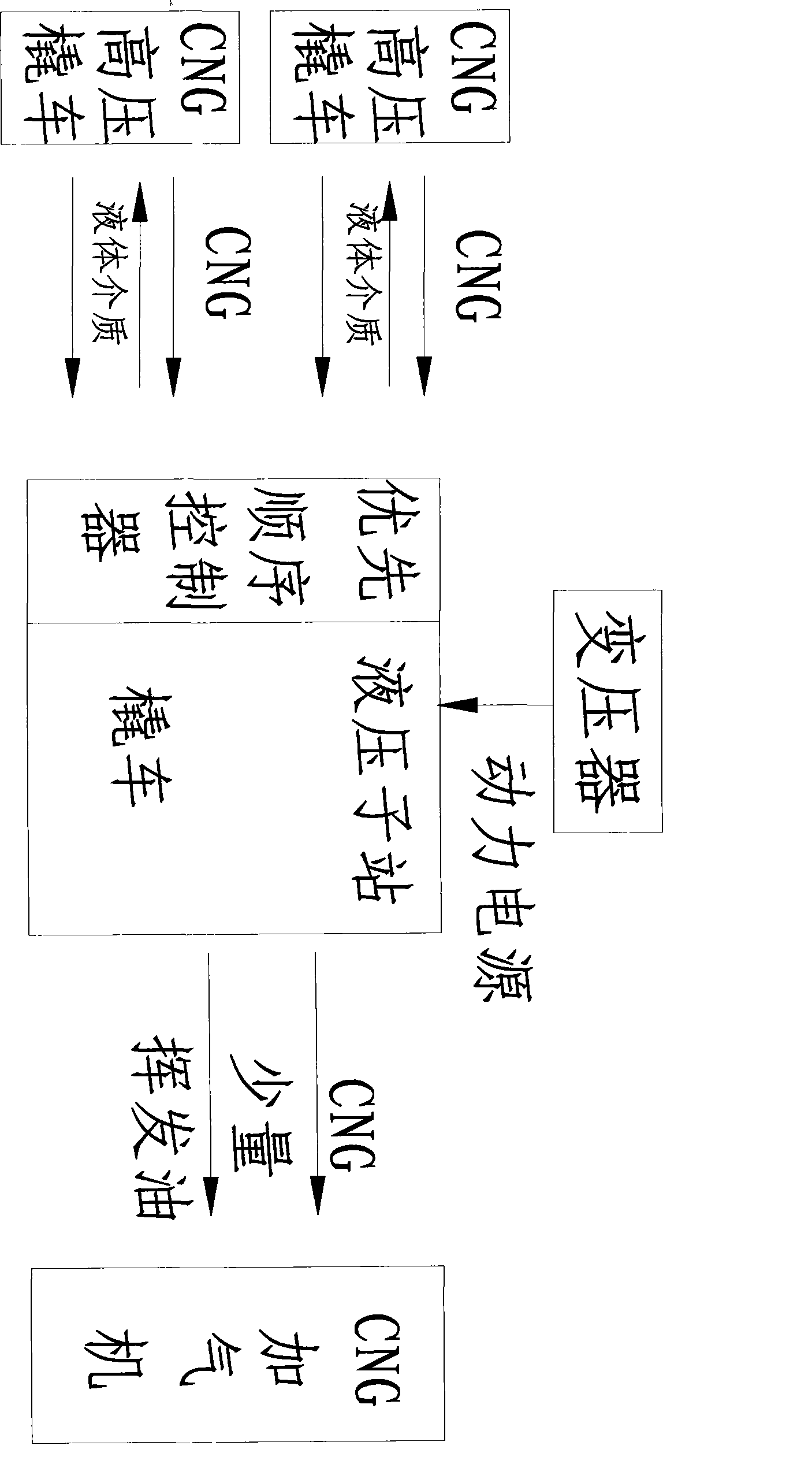

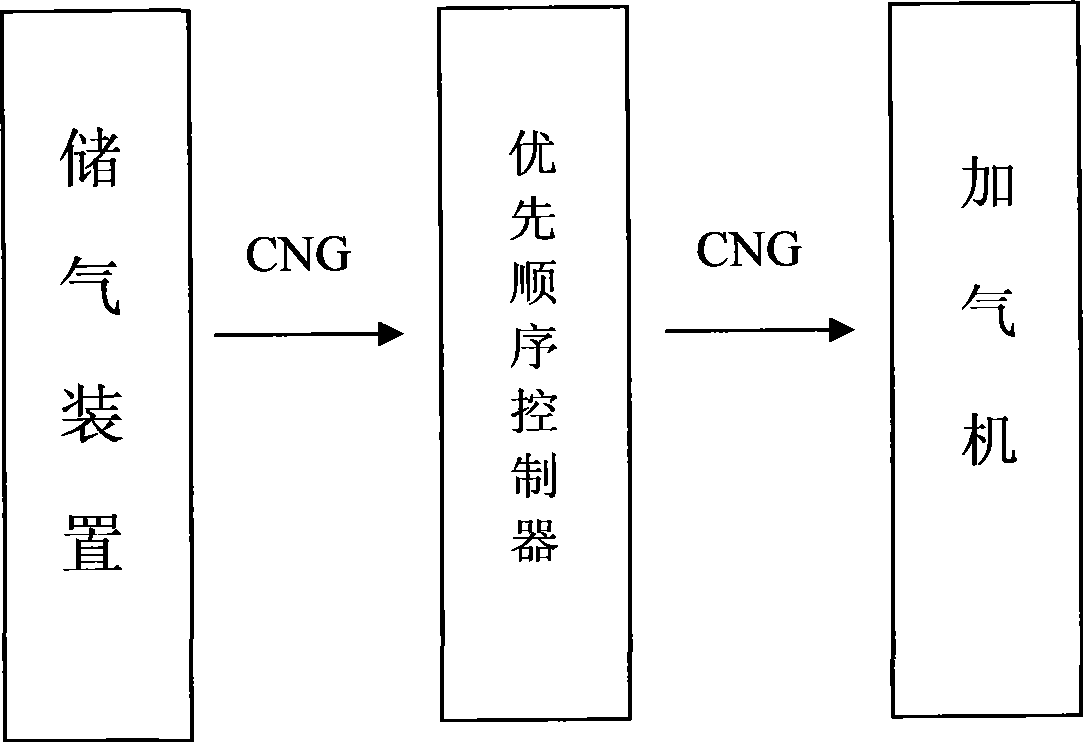

Secondary gas filling station

InactiveCN101509599ASimple structureSave peopleVessel mounting detailsFluid transferredCompressed natural gasGas cylinder

The invention relates to a brand-new branch gas station, only consisting of a gas adding machine, a priority sequence controller and a plurality of gas storage devices. The branch gas station has the technical characteristics that each gas storage device is composed of a plurality of gas tanks which are filled with high pressure compressed natural gas (CNG) of 25 MPa, the gas storage devices alternatively and cyclically provide high pressure CNG to form alternate recycle high pressure technology, solving the problem that the gas storage devices need a compressor or a hydraulic pump sell the remaining gas by pressurization, saving the massive equipment investment such as compressor, hydraulic pump, intra-station gas tank group and the like and easily standardizing the three major components: the gas adding machine, the priority sequence controller and the gas storage devices, being free from daily consumption such as power supply, mechanical wear and the like; in addition, the branch gas station is matched with a major gas station and pursues the technical road featuring L-CNG and is easily and rapidly replicated in cities throughout the country, thus enjoying the possibility of changing the backward situation at home where for the past dozens of years, CNG stations are hard to be integrated into a complete sales network.

Owner:沈军

Conductive macromolecular solution, preparation thereof, conductive polymer coated film and solid electrolyte capacitor

InactiveCN101486836AImprove conductivityHigh light transmittanceCapacitor electrolytes/absorbentsOrganic conductorsElectrolysisPolymer science

An electroconductive polymer solution contains electroconductive high molecules and polyanion. Under 25 DEG C, the oxygen content in the electroconductive polymer solution is below 8 weight ppm. An electroconductive coating film using the solution has high transmittance and low resistance. Applied to a solid electrolytic capacitor, the electroconductive polymer solution can improve the conductivity of solid electrolysis and filling behavior, therefore, a solid electrolytic capacitor with low ESR and other excellent properties is obtained.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

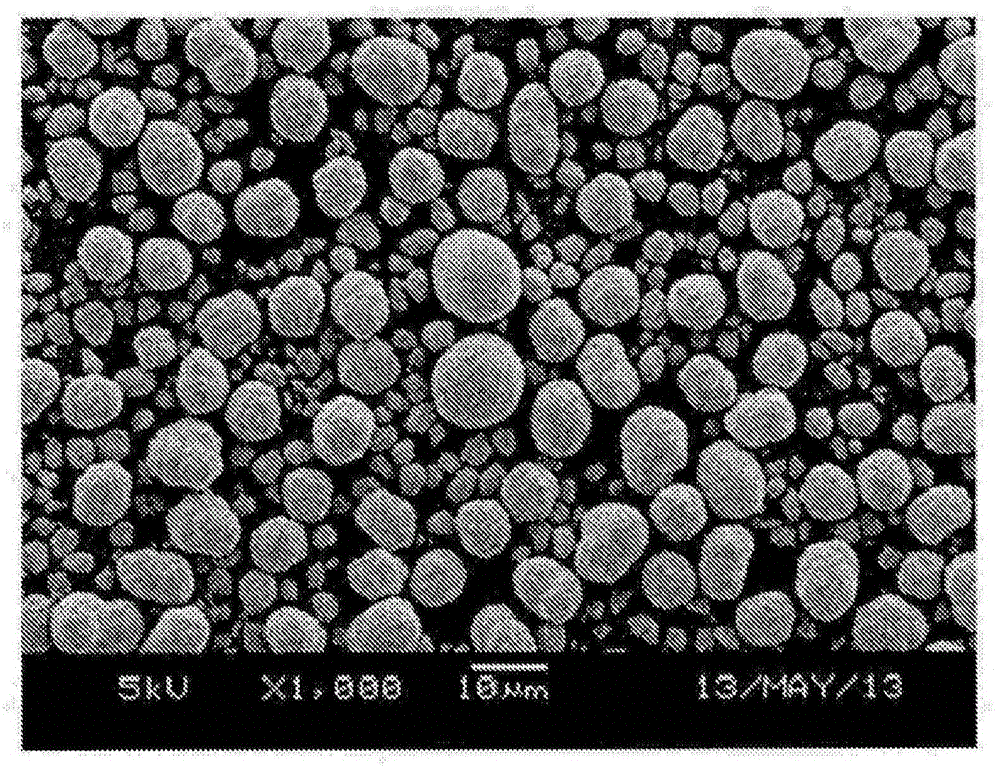

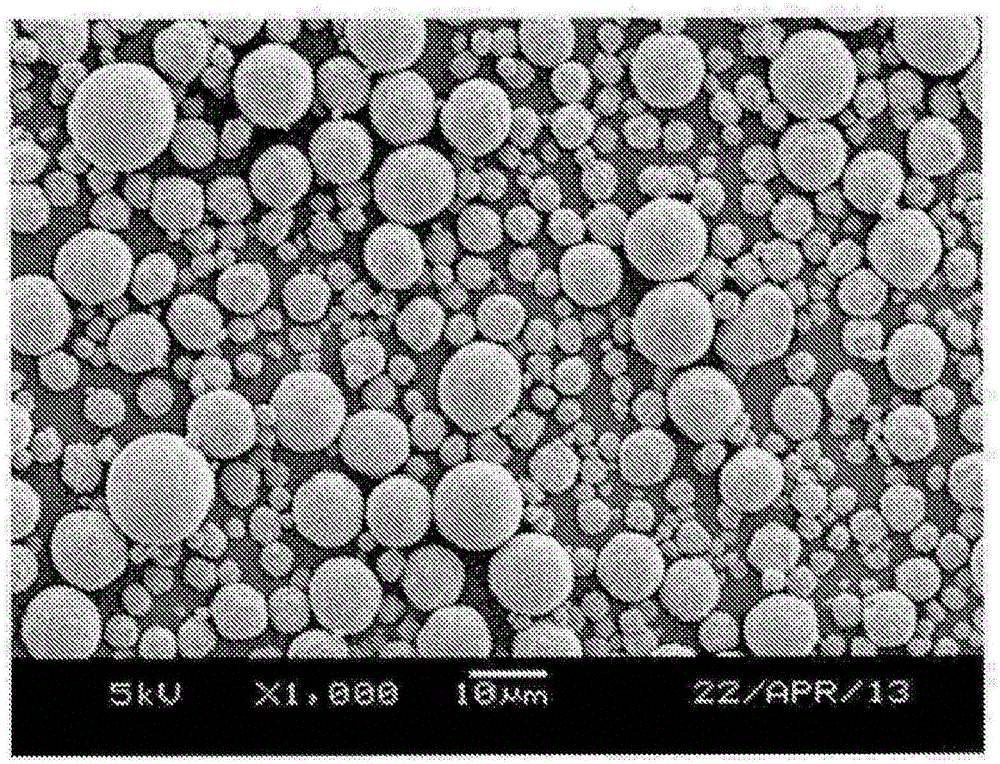

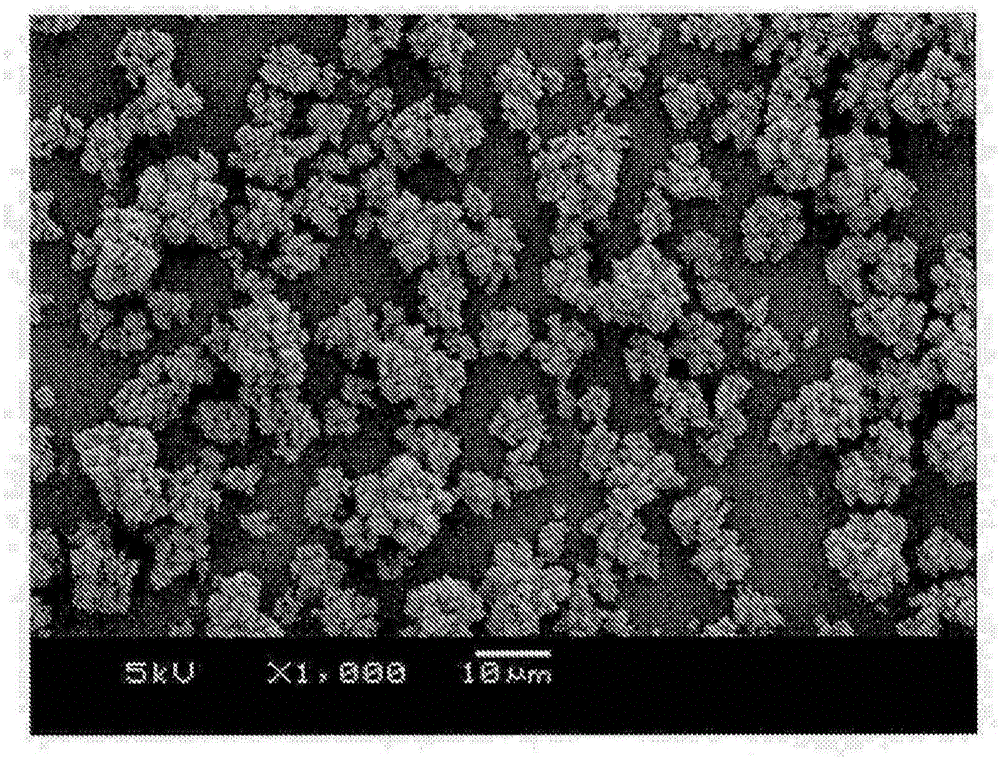

Method for preparing silver powder for touch screen silver paste

The invention relates to a method for preparing silver powder for a touch screen silver paste and belongs to the technical field of preparation of conductive metal powder. The method comprises the following steps: using silver nitrate as a raw material and controlling the speed of liquid phase reduction reaction by regulating the process conditions of reaction temperature, charging manner and charging speed so as to prepare approximately spherical or spherical particle reduced silver powder with a particle size of 300 nm to 800 nm; sufficiently stirring and modifying the silver powder in absolute ethyl alcohol solution containing two modifiers of oleic acid, stearic acid, hexadecanol, a polyacrylate dispersing agent and a graft copolymer dispersing agent, carrying out batching on the obtained modified silver powder and phi3 stainless steel beads according to a mass ratio of 1:10 after drying at a temperature of 60 DEG C, and grinding for 10 to 24 hours; and after finishing grinding, carrying out bead and material separation, sieving the obtained silver powder by 300 meshes to obtain the high dispersion approximately spherical or spherical silver powder with D50 of 1.5 to 2.5mum and tap density of 4.0 to 6.0 g / cm<3>. The silver powder prepared by the method disclosed by the invention has high crystallinity, is suitable for an addition volume of silver of 70 to 85 percent and can be used for printing capacitive screen silver paste of a thin wire with a specification below 80 mum.

Owner:云南铜业科技发展股份有限公司

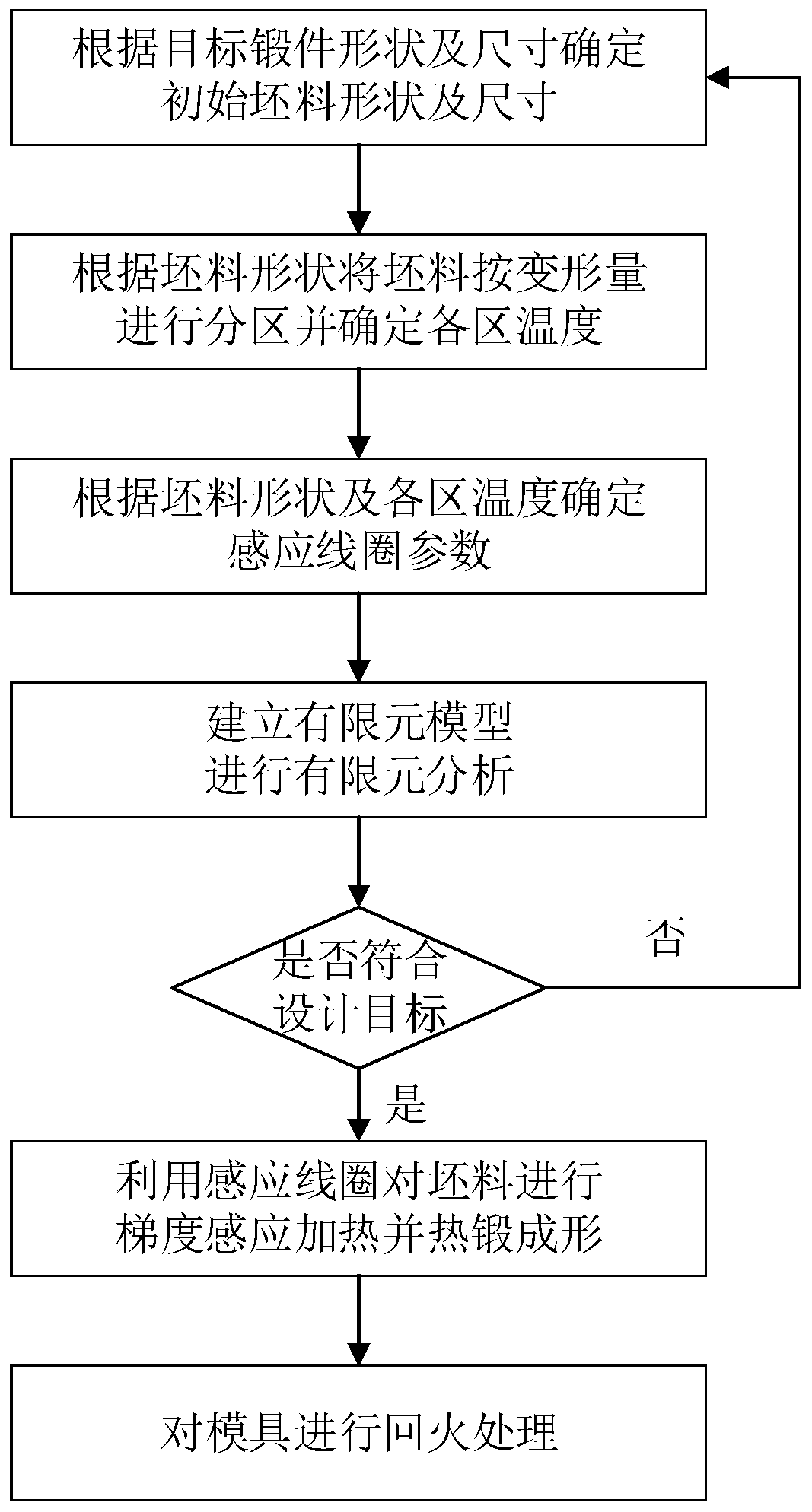

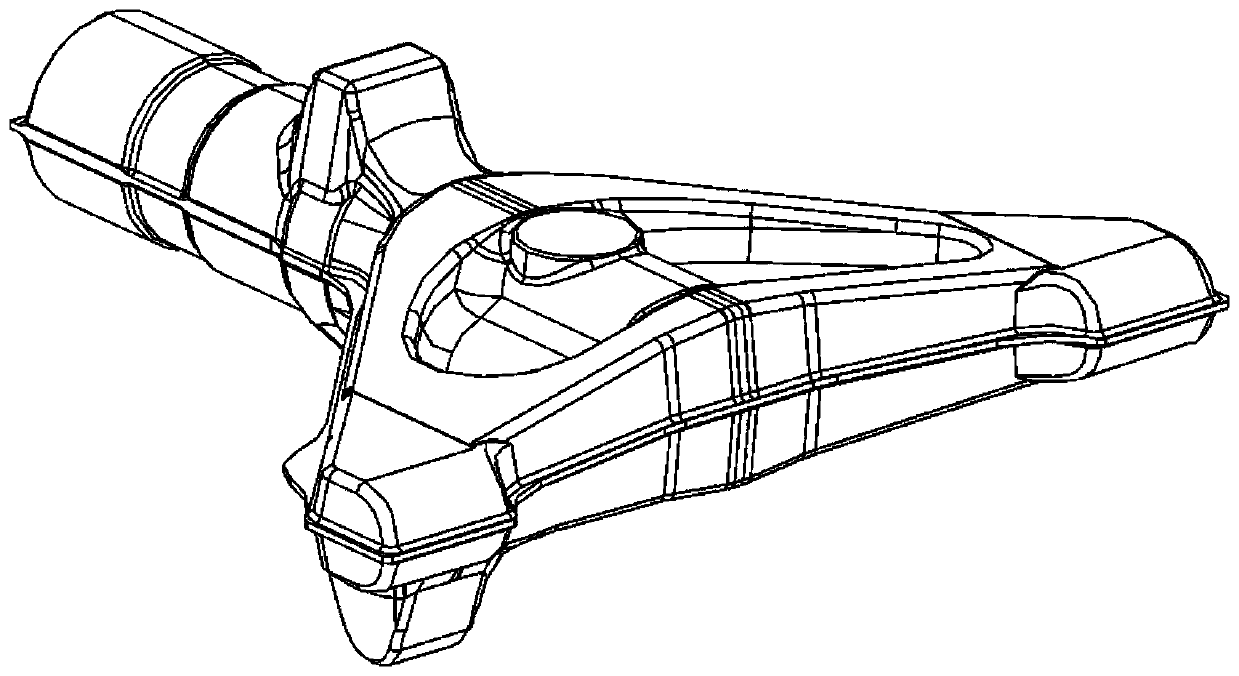

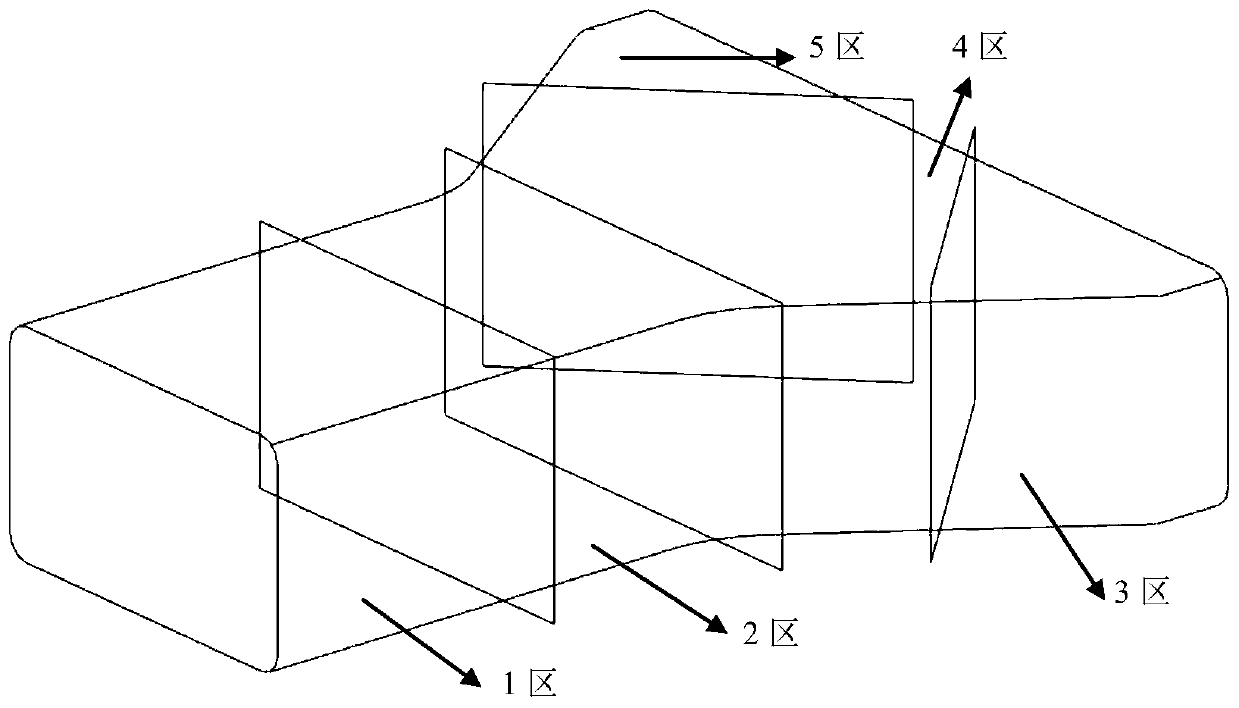

Gradient induction heating based thermal deformation workpiece blank heating method and machining method

ActiveCN109773099ARealize Controlled DesignGuaranteed dimensional accuracyHeating/cooling devicesThermoplasticThermal deformation

The invention discloses a gradient induction heating based thermal deformation workpiece blank heating method and a processing method and belongs to the field of meal thermoplastic forming. Accordingto the gradient induction heating based thermal deformation workpiece blank heating method and the processing method, a blank is designed according to the shape of a workpiece; parts, with different deformations, of the blank are subjected to rapid induction heating to different temperatures through a gradient induction heating coil, the temperature difference of different deformation parts of theblank is realized, and the continuity of the temperature of the surface of the blank is ensured. The plastic deformation resistance of areas hard to deformable is effectively reduced. The equipment tonnage can also be effectively reduced. Meanwhile, under the coupling effect of the temperature and deformation of the parts with the different deformations, the uniformity of the microstructure of awhole forged piece can be ensured, and the mechanical performance of a material is remarkably improved. Besides, the labor environment can be remarkably improved, the forged piece with the high dimensional precision, the uniform microstructure and excellent comprehensive performance is integrally formed, and automated and standardized production is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

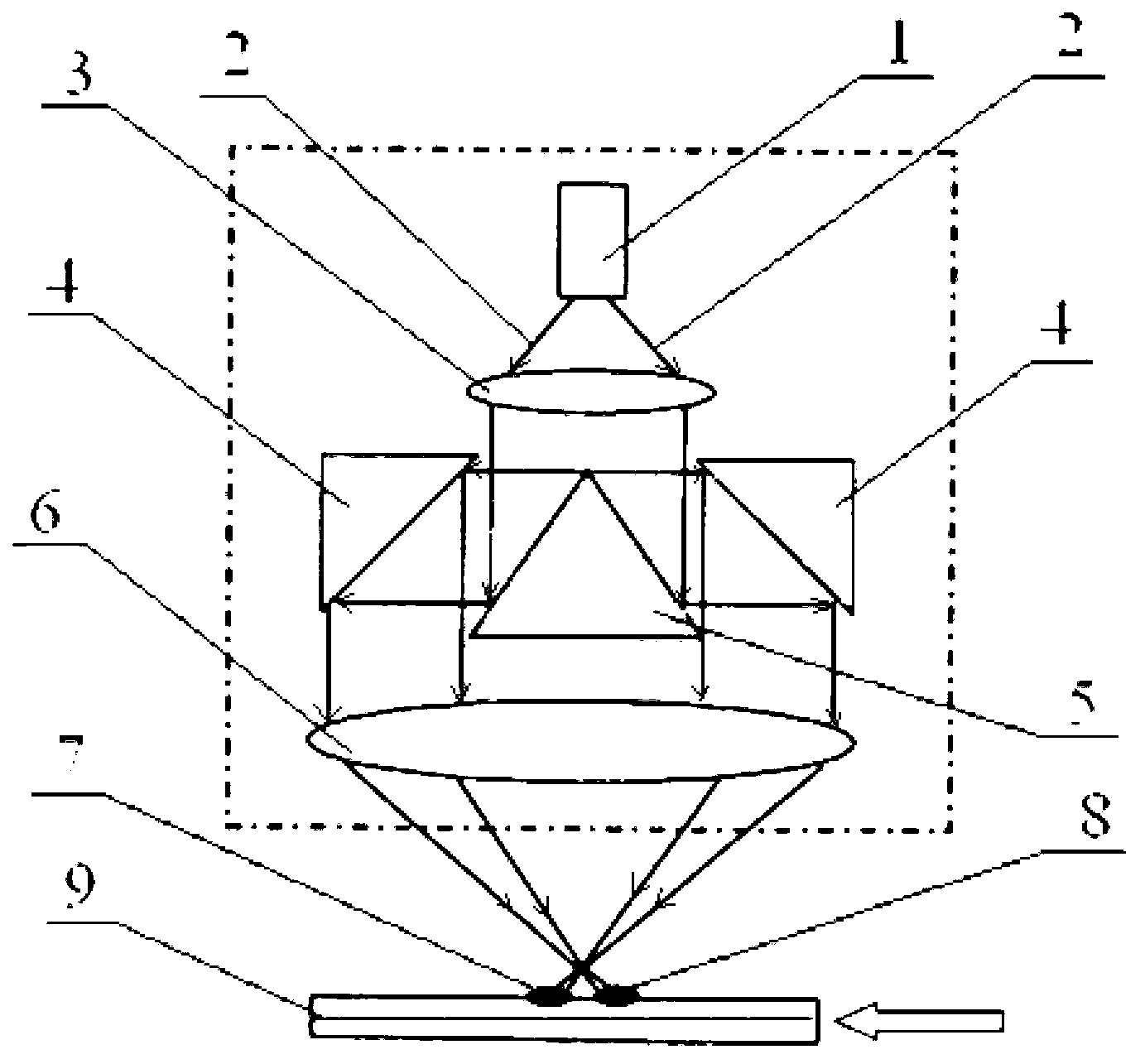

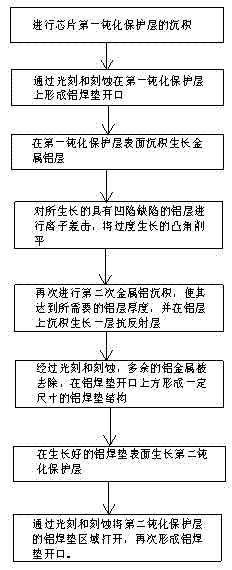

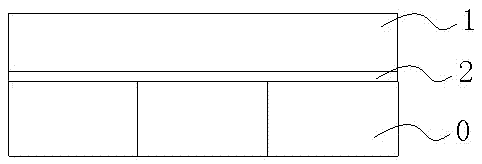

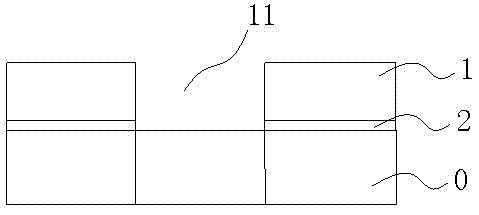

Method for manufacturing aluminum liner of double-layer passivation protection layer

InactiveCN102446757AImprove filling capacityFill smoothSemiconductor/solid-state device manufacturingIonEtching

The invention discloses a method for manufacturing an aluminum liner of a double-layer passivation protection layer. The method comprises the following steps of: depositing a first passivation protection layer of a chip; photoetching and etching the first passivation protection layer to form an aluminum weld pad opening; depositing a growth metal aluminum layer on the surface of the first passivation protection layer; ion bombardment the growth aluminum layer for scappling overgrowth convex angles; carrying out second metal aluminum deposition; photoetching and etching to form an aluminum weld pad structure above the aluminum weld pad opening; growing a second passivation protection layer on the surface of a grown aluminum weld pad; and photoetching and etching for opening an aluminum weld pad area of the second passivation protection layer to form the aluminum weld pad opening again. With the adoption of the process flow and the method and the utilization of plasma bombardment sputtering back etching and the multiple metal aluminum filling process, the filling capacity of aluminum is effectively improved, the filling of the edge area of contact holes is smoother, and the aluminum weld pad is smooth, does have a groove and has fewer defects, fewer remaining, low contact resistance and high the package reliability.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

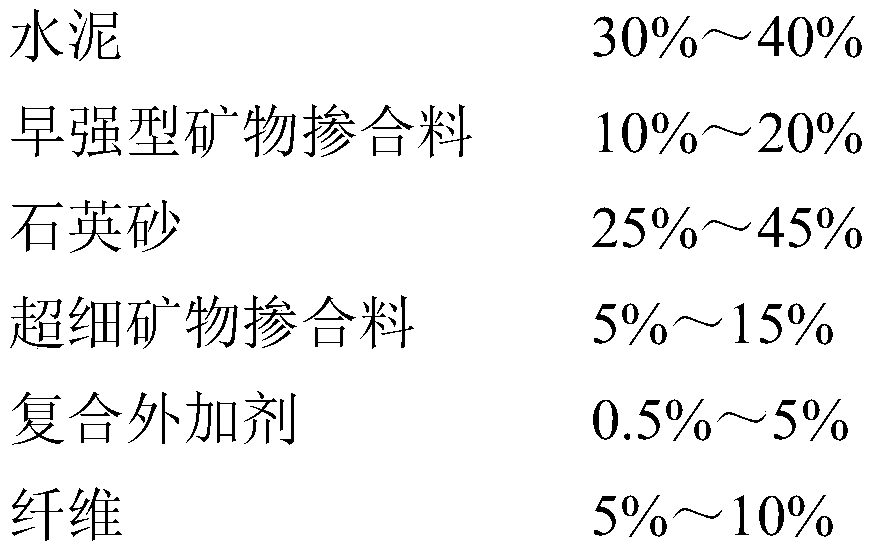

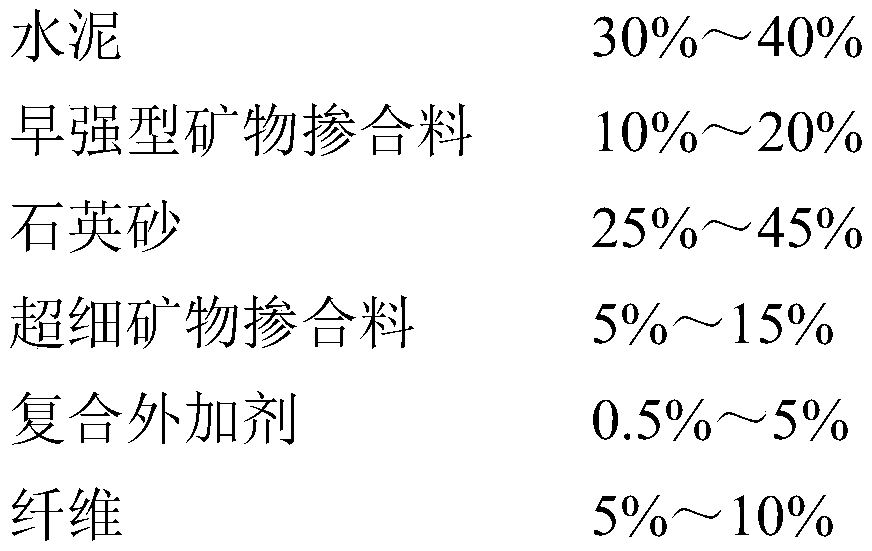

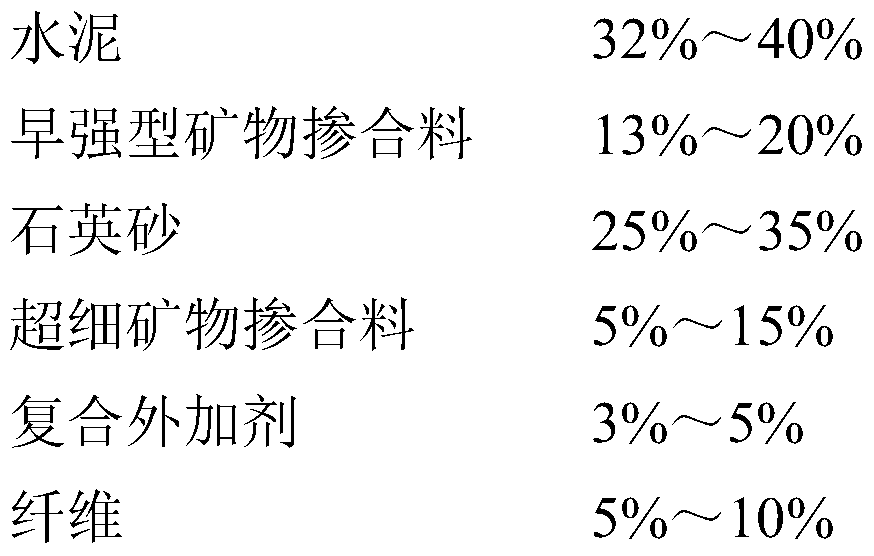

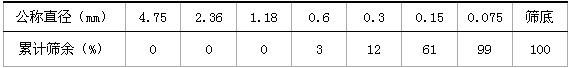

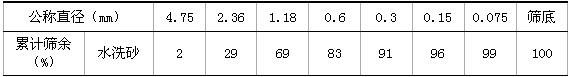

Grouting material for composite structure and fabricated building joint and preparation method thereof

InactiveCN111116132ARealize regionalized commercial supplyWith micro expansionSilicon dioxideUltimate tensile strength

The invention relates to a grouting material for composite structure and prefabricated building node pouring. The grouting material is prepared from, by mass, 30%-40% of cement, 10%-20% of an early-strength mineral admixture, 25%-45% of quartz sand, 5%-15% of a superfine mineral admixture, 0.5%-5% of a composite additive and 5%-10% of fiber, and the superfine mineral admixture is two or three of microbeads, silica fume and nano-silicon dioxide. The composite additive comprises an expanding agent, a retarder, a defoaming agent, a reinforcing agent and a water reducing agent; the fiber is a mixture of steel fibers and organic fibers. The invention also discloses a preparation method of the grouting material, and the method comprises the following steps: mixing the components of the groutingmaterial into a dry mixture, packing and packaging, and the preparation method is simple. The grouting material has the advantages of micro-expansion, high filling property, ultrahigh strength, high ductility and high vibration resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

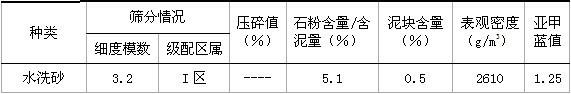

Large-flowability and high-strength concrete

The invention discloses large-flowability and high-strength concrete, which comprises the following components in part by weight: 350 to 450 parts of cement, 30 to 60 parts of wollastonite, 40 to 90 parts of slag powder, 40 to 60 parts of coal ash, 650 to 700 parts of fine aggregates, 1,000 to 1,250 parts of coarse aggregates, 150 to 180 parts of water and 10 to 15 parts of pumping agent. The concrete particularly has high flowability while meeting requirements of performance of strength, rigidity, weight and the like of high-rise and mega-high-rise buildings, and the filling performance is improved obviously; the fine aggregates formed by mixing artificial machine-made sand and sand of Yangtze River can be distributed in the granularity from 0.075 to 4.72 millimeters, and after being mixed and filled into a template to form concrete members, the fine aggregates can be filled into gaps with various pore diameters among the coarse aggregates of a stressed skeleton, so that the strength can be improved; the performance of the fine aggregates is similar to that of natural medium sand, and the fine aggregates can be prepared from local materials, so the cost is reduced by half; and the coarse aggregates are limestone gravels with the diameters of between 5 and 10 millimeters and limestone gravels with the diameters of between 10 and 25 millimeters, and form the stressed skeleton in the concrete, so that the mechanical property of the stressed skeleton can be enhanced obviously, and the strength of the concrete can be improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

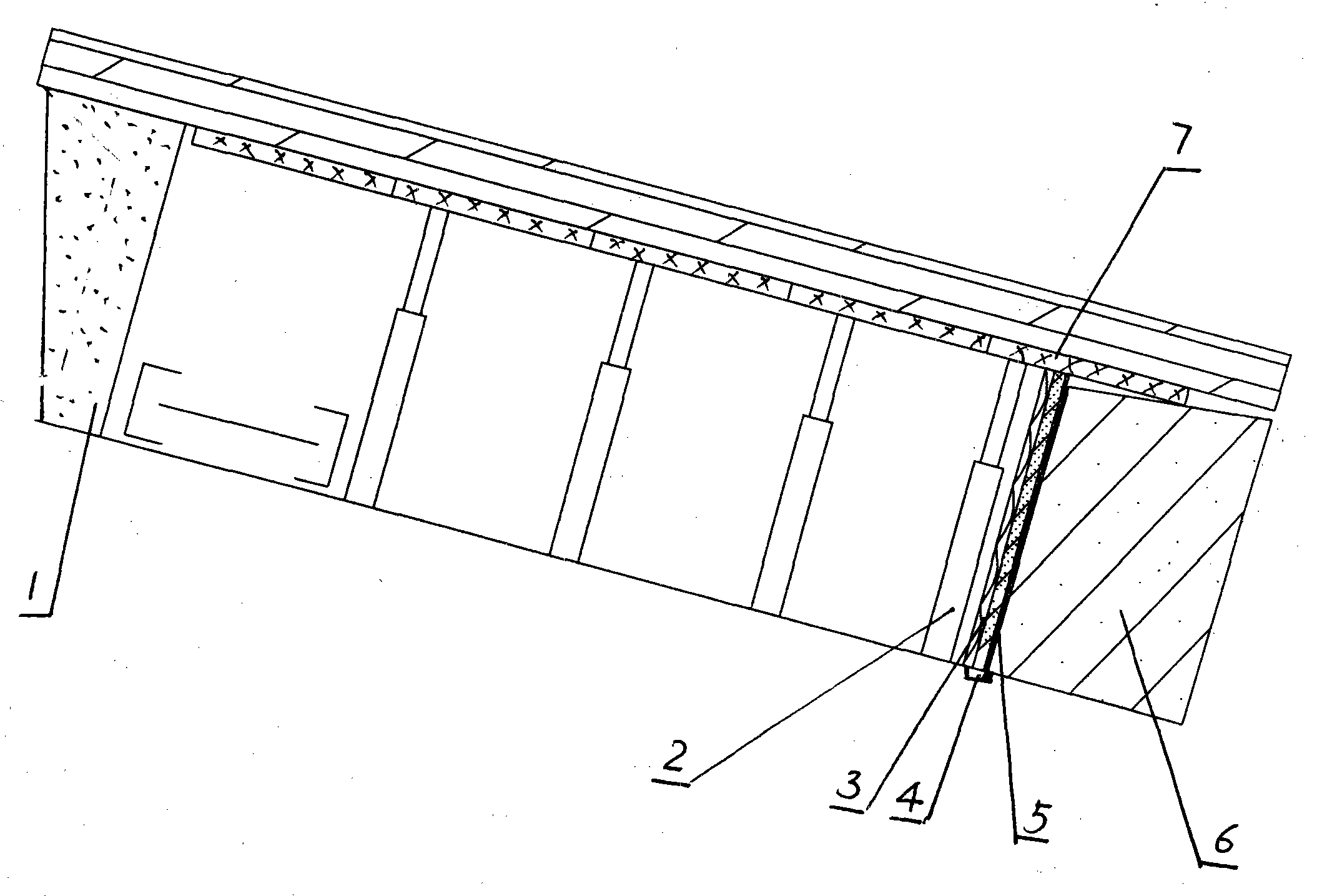

Coal face paste-like filling method and slurry-baffling device

InactiveCN101881180AIncrease each filling heightReduce the empty head distanceMaterial fill-upCoal miningEngineering

The invention discloses a coal face paste-like filling method and a slurry-baffling device. The method mainly comprises the following steps: the slurry-baffling device is arranged on a breaking-off prop of a coal face; the traditional filling method is adopted to fill paste-like until the filling height of the paste-like is as high as the height of a slurry-baffling curtain, thus the mined-out region is completely filled; when filling work is finished and the paste-like is semisolid and does not flow, the next cycle of normal coal mining is performed; when one cycle is finished, the slurry-baffling device is recycled, then the breaking-off prop is drawn back; and when the working face reaches a filling interval, the above steps are performed circularly. By using the method of the invention, each filling height of paste-like is increased, the unsupported roof distance of the mined-out region is reduced, the filling effect of the mined-out region is improved, the roof pressure of the working face and the sinking amount of the overlying roadway are reduced, the surface zero subsidence is thoroughly realized, the problems of the flooding accidents of goal water and floor water and the spontaneous combustions of the mined-out region and the hillock are effectively solved.

Owner:新汶矿业集团有限责任公司孙村煤矿

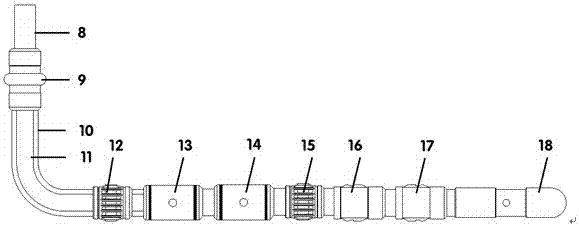

Horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string and method

The invention discloses a horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string and a method. The horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string comprises a well completion pipe string body and a pack sand-proof service pipe string body, wherein the pack sand-proof service pipe string body is arranged in the well completion pipe string body; the pack sand-proof service pipe string body comprises a drilling-free plug stage collar, a packing sliding sleeve assembly and sand filtering tubes, and the drilling-free plug stage collar, the packing sliding sleeve assembly and the sand filtering tubes are sequentially connected from front to back; the pack sand-proof service pipe string body comprises a liquid separation sealing device, a double-layer pipe, an upper positioning device, a packing assembly, a circulation assembly, a lower positioning device, a closing tool and an opening tool which are sequentially connected from the front to the back. At least two sand filtering tubes are arranged, and a heat-sensitive compensator and an open-hole packer are connected between every two sand filtering tubes. The tail end of the well completion pipe string is connected with a well washing valve. One-time multi-section packing can be achieved, infinite series packing can be achieved, segmented packing is achieved outside a pipe in a real sense for the first time, and the packing effect is improved. Horizontal section segmentation is completed, and requirements of post-selective production, segmented steam injection and other measures can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

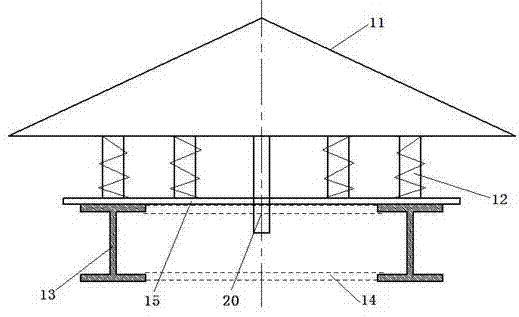

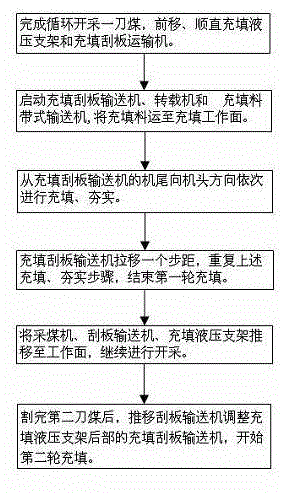

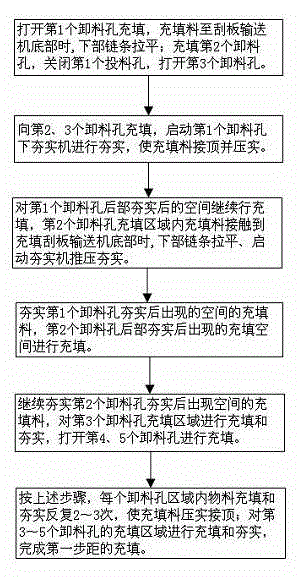

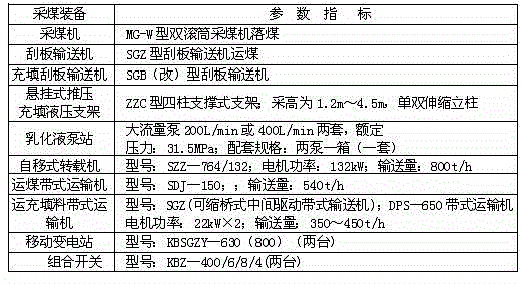

Coal mine bulk stock cut and fill mining method

InactiveCN102943689APromote recoveryExpand sourceMaterial fill-upUnderground transportCut and fillMechanical engineering

The invention relates to a coal mine bulk stock cut and fill mining method, and the mining and cutting and filling process is as follows: (1) circularly mining web on a working plane; (2) starting a cut-fill and transportation machine, and transporting the filler to the cut-fill working plane; (3) sequentially filling a first charging hole to a fifth hole on the tail part of a scraper conveyor to be compacted, repeatedly filling and compacting the filler inside each charging hole for 2 to 3 times, compacting the filler to the roof, and completing the filling of a first step; (4) pulling the filling scraper conveyor for one step, repeating the filing and compacting step, adequately filling the filler to the roof and adequately compacting the filler, and completing the filling of a first turn; (5) pushing a mining machine to the working plane, setting the coal mining step of 0.5 to 0.8m, and carrying out the mining; and (6) adjusting the cut-fill machine after second web, and carrying out the filling of a second turn. A coal mining system and a filling system are integrated through a filling hydraulic support, the mining of the work plane is synchronously carried out with the filling operation, and the integration of the mining and the filling operation is realized.

Owner:HEBEI COAL SCI RES INST

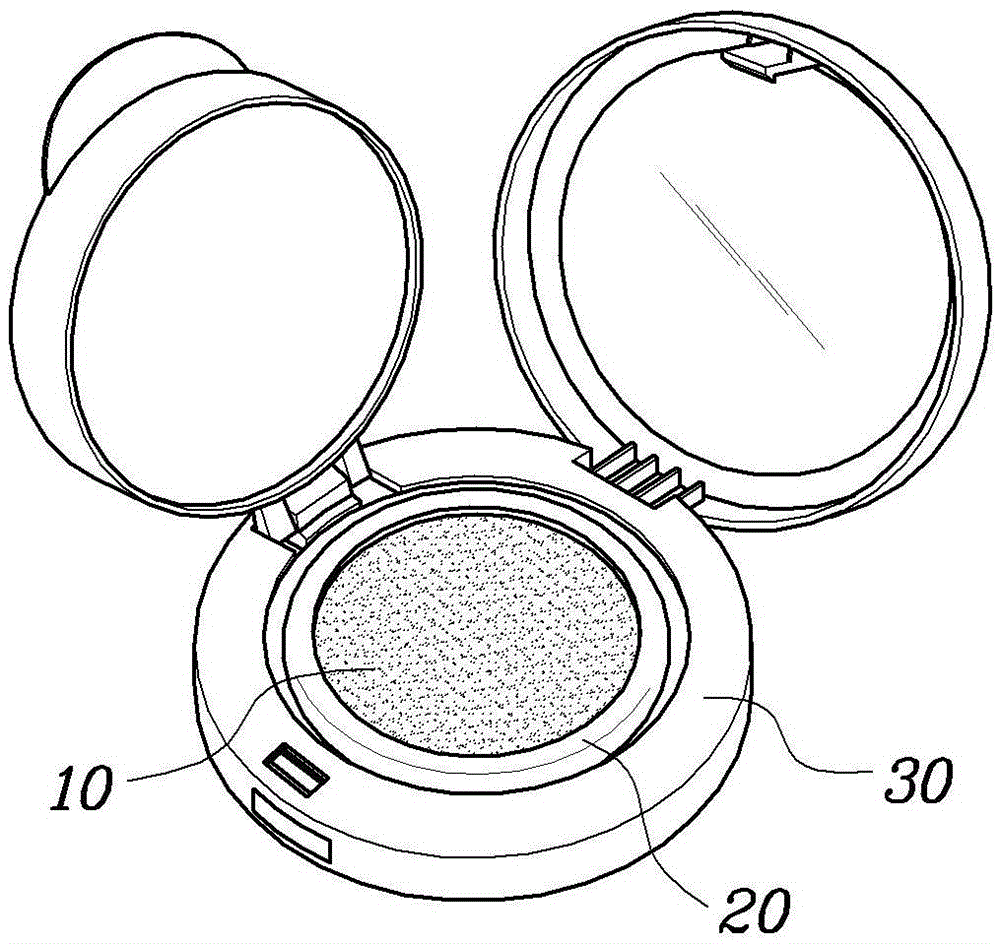

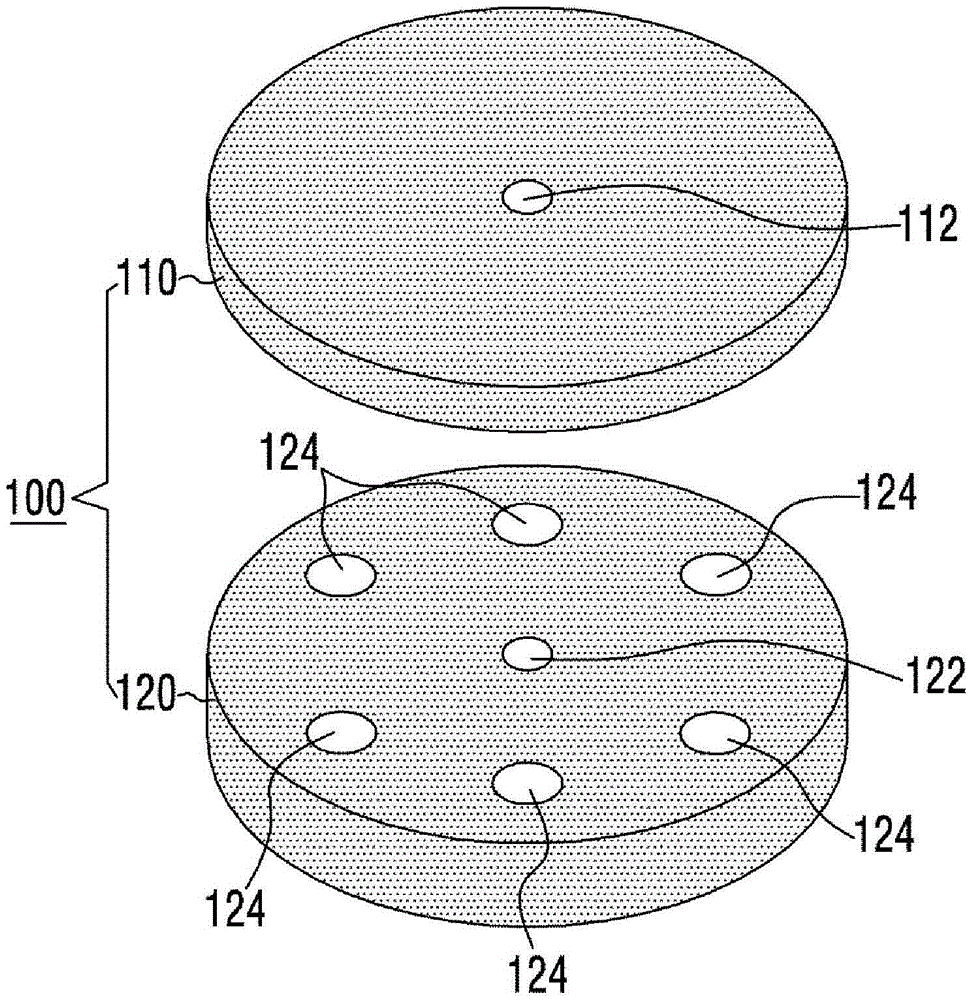

Porous pad for impregnation of liquid cosmetic composition and liquid-cosmetic-composition impregnating method using the same

ActiveCN105658108AFast fillImprove filling capacityCosmetic preparationsToilet preparationsMaterials scienceCosmetics

Owner:CTK CO LTD +1

Method for filling paste behind filling hydraulic supports

InactiveCN103382849AMake up for the disadvantages of easy pulp running and complicated operationLow priceMaterial fill-upMine roof supportsEngineeringMechanical engineering

The invention discloses a method for filling paste behind filling hydraulic supports. The method comprises the steps of (1), separating two adjacent hydraulic supports and taking a rear telescopic girder, so that back ends of top beams of the hydraulic supports are separated from a top plate; (2), adding flame-retardant sponges tosides of back baffles, placing flame-retardant sponges in gaps between back ends of the top beams and the top plate, lifting the back ends of the hydraulic supports to enable the flame-retardant sponges to be clamped between the top beams and the top plate, and controlling a side-pushing jack to seal the two hydraulic supports; (3) placing waste non-flammable adhesive tapes in gaps between the top plate and the back baffles, and placing lower ends of the waste non-flammable adhesive tapes in gaps between a bottom plate and the back baffles; (4) forming a separation wall between the back of the hydraulic supports and an area to be filled to completely seal the space to be filled; (5), filling the space to be filled with paste from top to bottom, removing the hydraulic supports after a filling body solidifies and meets requirements for support force, and performing the next filling. Materials used in the method are the flame-retardant sponges and the waste non-flammable adhesive tapes, the materials are cheap, the operation process is simple, and the implementation is easy.

Owner:ANHUI UNIV OF SCI & TECH

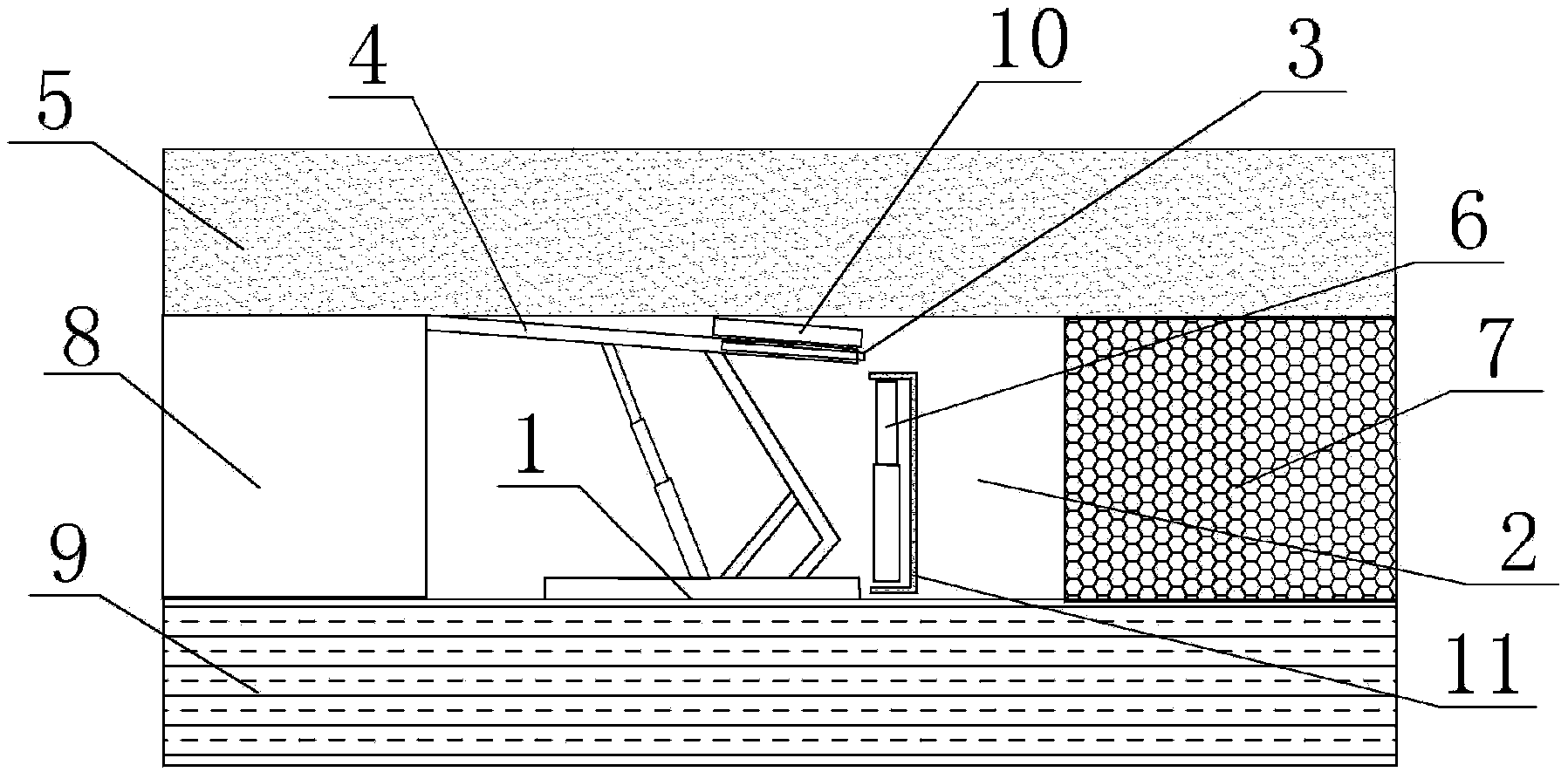

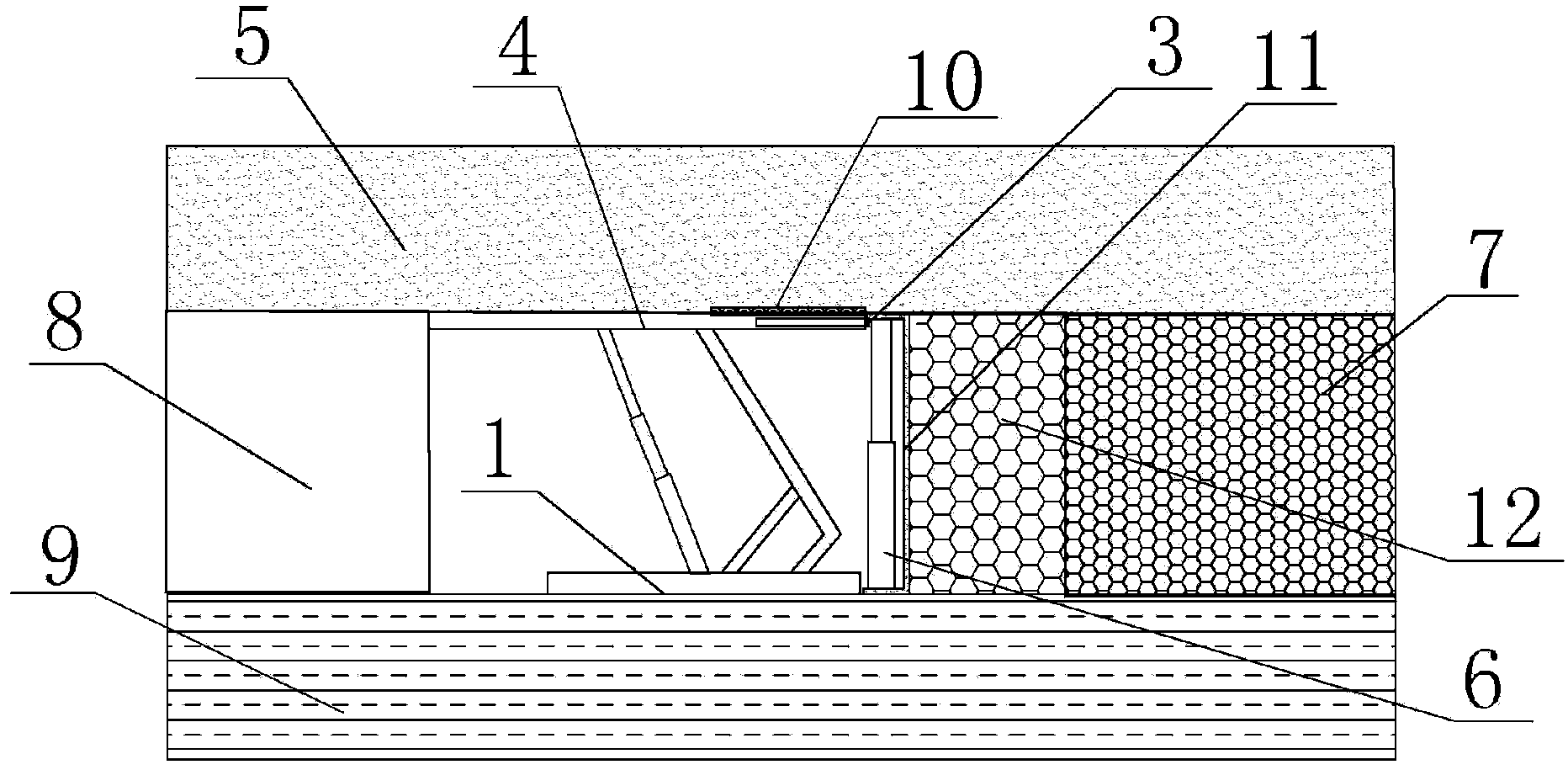

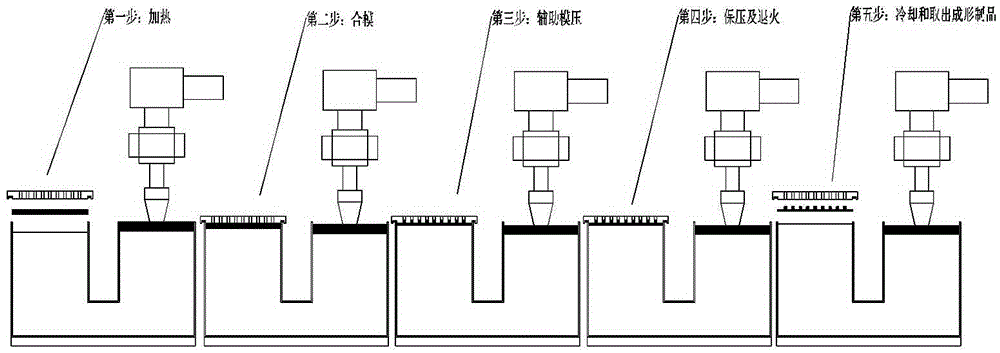

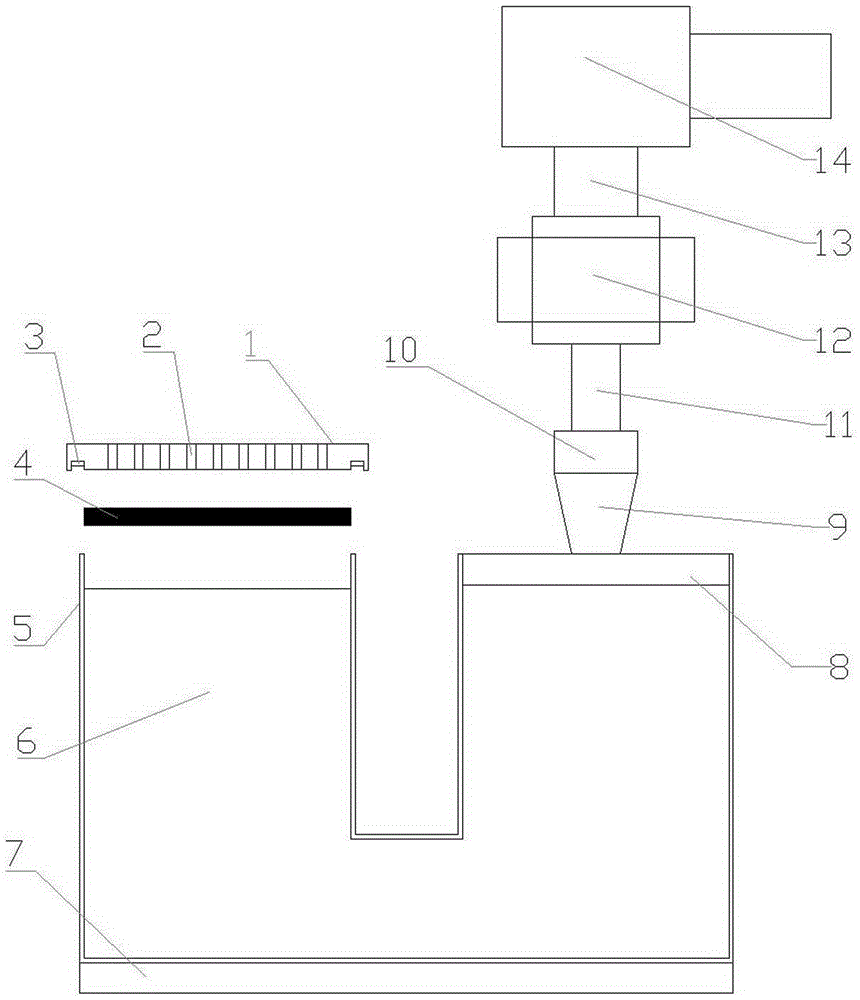

Ultrasonic vibration-assisted mould pressing forming method based on tin liquid medium and special forming device thereof

InactiveCN105366918AImprove liquidityImprove uniformityGlass pressing apparatusMolten stateLiquid medium

The invention discloses an ultrasonic vibration-assisted mould pressing forming method based on a tin liquid medium and a special forming device thereof, and mainly aims at solving the technical problems that an existing mould pressing forming is low and inconsistent in filling ratio and the like. According to the technical scheme, the tin liquid medium which is better in heat conducting property is introduced between a heating plate and a preformed glass body, the pressure of a piston is transmitted to the surface of the preformed glass body through the tin liquid medium, and then glass in a molten state is driven to be evenly filled in a mould which is installed at one port of a tin liquid container, wherein the forming surface of the mould is arranged to be in a microstructural shape; an ultrasonic vibration assistant system is installed over a piston of the other port of the tin liquid container and can apply assistant vibration with the certain frequency and the controllable amplitude to the piston, and ultrasonic vibration of the piston is transmitted to the preformed glass body through the tin liquid medium. Accordingly, the filling ratio of the glass in the molten ratio is increased, and then high-precision mould pressing forming of microstructural thin glass elements is achieved.

Owner:XIANGTAN UNIV

Photo-curing compound resin used for dental repair and using diatomite as stuffing and preparation method thereof

InactiveCN101804012AImprove filling capacityImprove mechanical propertiesImpression capsDentistry preparationsGlycidyl methacrylateGas phase

The invention relates to a photo-curing compound resin used for dental repair and using diatomite as stuffing and preparation method thereof. The component of the compound resin comprises a resin matrix and stuffing. The stuffing is the modified diatomite and modified gas phase method silicon dioxide OX-50. The preparation comprises: (1) the resin matrix: BPA-methacrylic acid glycidyl ester, dimethyl crylic acid TEG ester, camphorquinone and EDB are mixed evenly, (2) the diatomite and the silicon dioxide are modified, (3) the resin matrix, the modified diatomite and the modified gas phase method silicon dioxide are manually stirred, premixed to the extent that powder is completely wetted by the resin matrix and mixed evenly in a three-roll machine and then the compound resin is obtained. The mechanical performance of the compound resin is improved greatly, the flexural strength can reach 135MPa and the elastic modulus reaches 7.5GPa. The preparation method is simple and the invention is applicable to industrial production.

Owner:DONGHUA UNIV

Bonding filling material and method for carrying out downhole filling using the same

ActiveCN102020979AEasy to transportGood filling effectMaterial fill-upDrilling compositionBond propertiesHigh effectiveness

The present invention relates to a bonding filling material and a method for carrying out downhole filling using the same, wherein the said gangue bonding filling material comprises: 68.6-82.2% by weight of gangue; 12.7-21.8% by weight of coal ash; and 1-18.7% by weight of water. Pressure intensity of the rammer compacter for filling and compacting in filling the bonding filling material is more than or equal to 20 Mpa. According to the invention, filling effect and filling quality are improved, and the movement of the overlying strata can be effectively controlled. The bonding filling material is filled directly without any additives, and the bonding property of the bonding filling material is increased due to the addition of coal ash as one filling material. The conveying system in the invention has simple requirements and enables continuity and high effectiveness of the filling. Downhole treatment of gangue and coal ash is fulfilled, and ecological and living environment around mining area are improved.

Owner:JIZHONG ENERGY +1

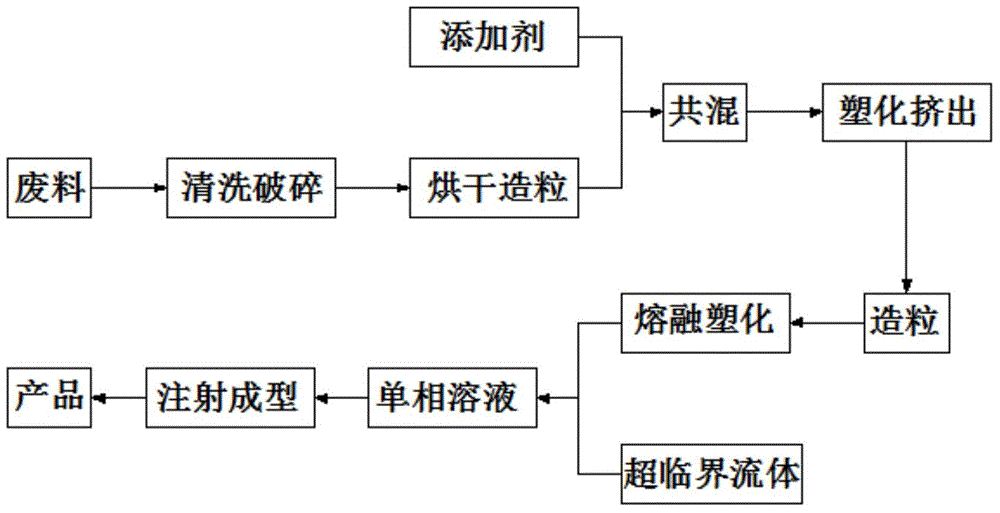

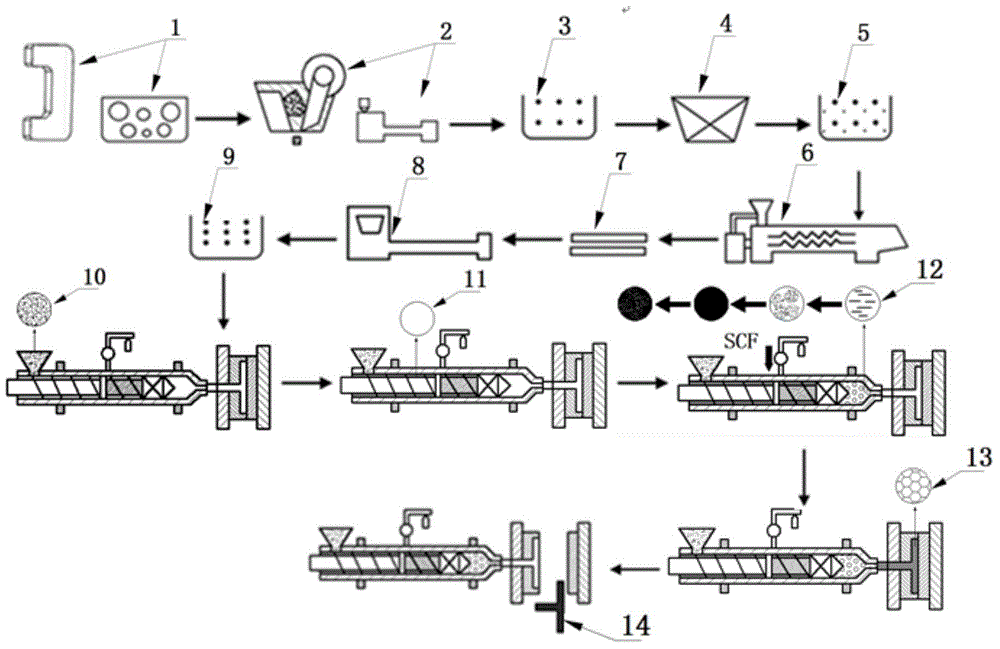

Microcellular foaming recycling method of waste car plastics

InactiveCN104476698AGeneral decline in mechanical propertiesImprove stress distributionPlastic recyclingProduct gasEngineering

The invention discloses a microcellular foaming recycling method of waste car plastics. The method comprises the following steps: preparing the recovery of wastes, modifying the plastics, preparing the recovered material and gas mixed melt, and carrying out the injection molding. By controlling the consumption of additives and key process parameters in the microcellular injection molding, the forming performance and mechanical properties of the recycled plastics can be improved, and especially the mobility and flexibility of the recycled plastics can be improved. According to the method, the waste plastics can be molded into products with a complicated structure and various shapes, such as household appliance shells, car bumpers, and interior and exterior ornaments of cars; the consumption of materials can be reduced, the injection molding thermodynamics can be improved, and the forming period can be shortened.

Owner:WUHAN UNIV OF TECH

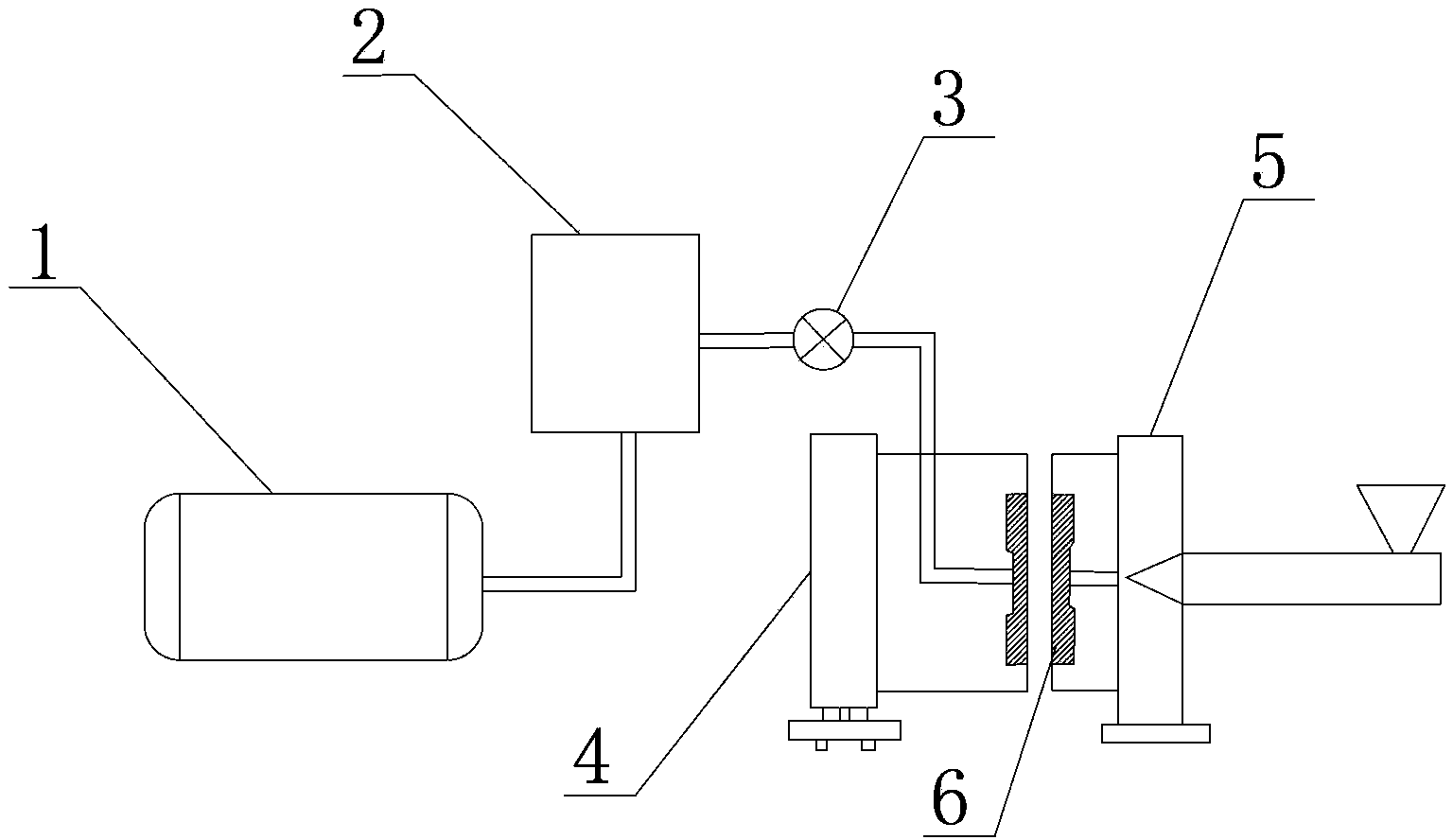

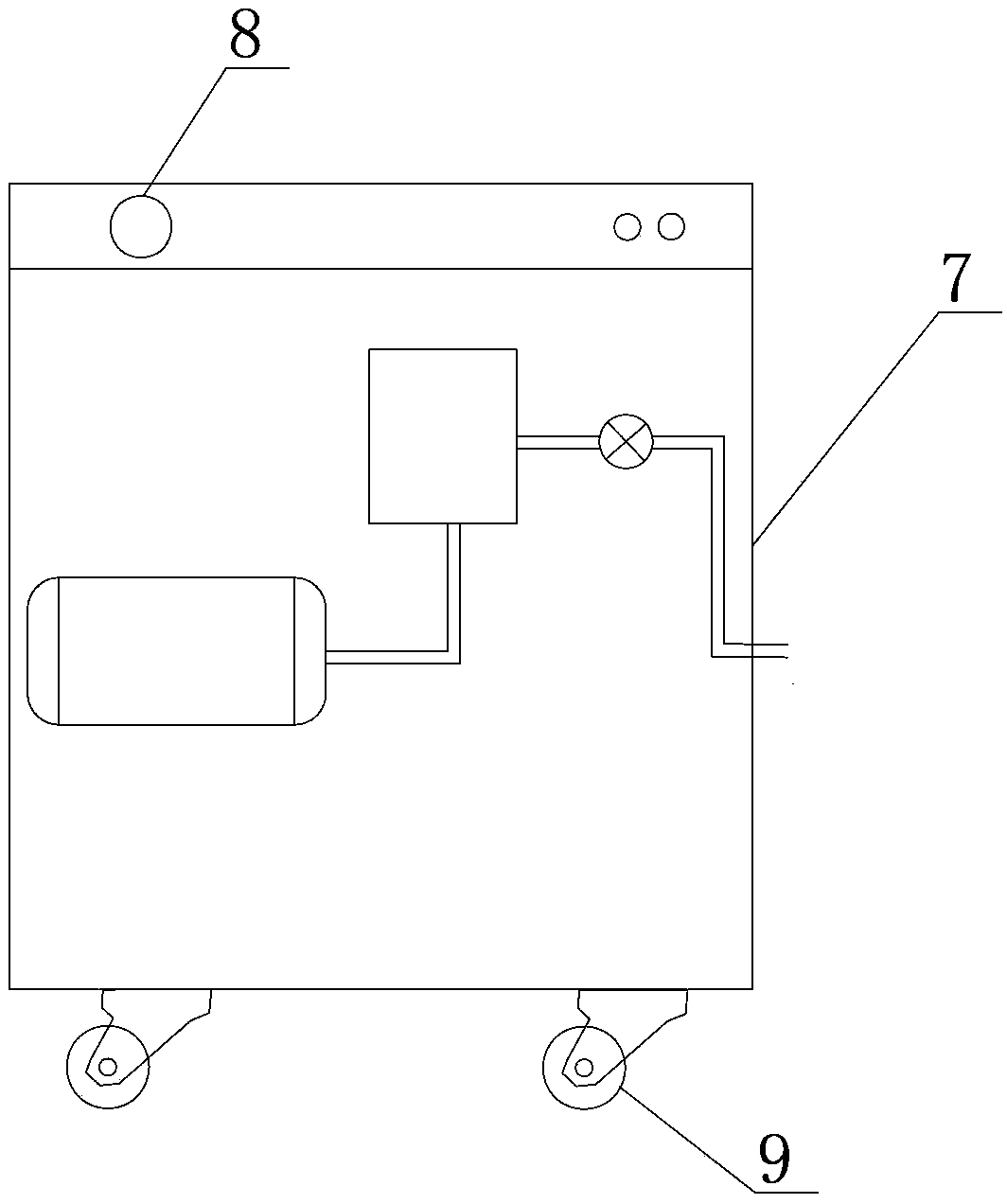

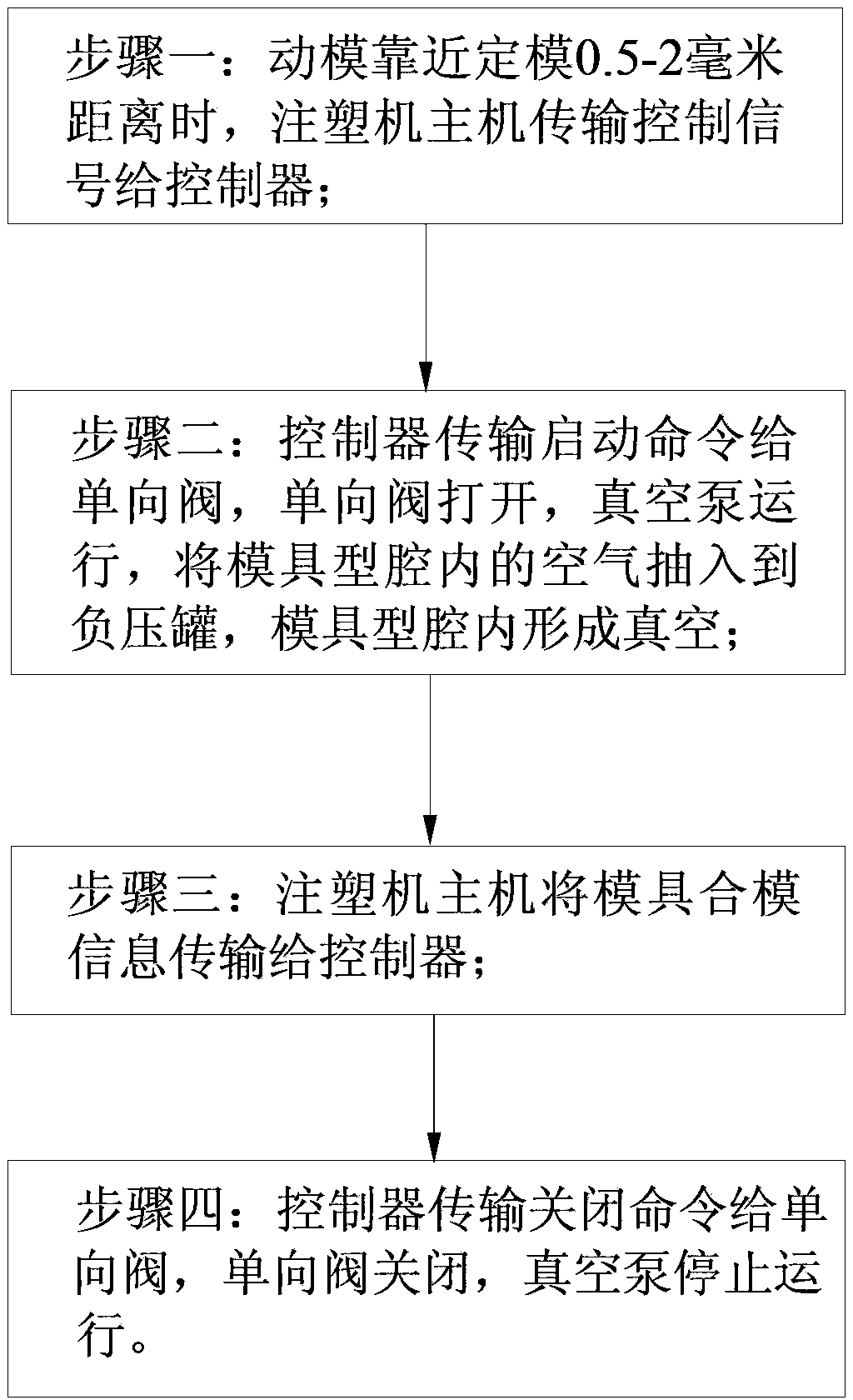

Mold evacuating device for injection molding machine and operating method of mold evacuating device

The invention provides a mold evacuating device for an injection molding machine, and an operating method of the mold evacuating device. The mold evacuating device comprises an equipment main body, a vacuum pump, a negative pressure tank, a one-way valve and a controller. The operating method of the mold evacuating device for the injection molding machine comprises the steps that when a movable mold is 0.5-2mm away from a fixed mold, an injection molding machine host transmits a control signal to the controller; the controller transmits a start-up command to the one-way valve; the one-way valve is opened; the vacuum pump runs; air in a mold cavity is drawn into the negative pressure tank; the interior of the mold cavity is vacuum; the injection molding machine host transmits mold assembly information to the controller; the controller transmits a close command to the one-way valve; the one-way valve is closed; and the vacuum pump stops running. With the adoption of the technical scheme, the density and surface accuracy of a mold product can be improved; the problem that exhaustion, a flow line, charring and mold filling are poor is solved; a product filling effect can be improved greatly; and the product quality is improved.

Owner:PINGXIANG GREENLONG IND

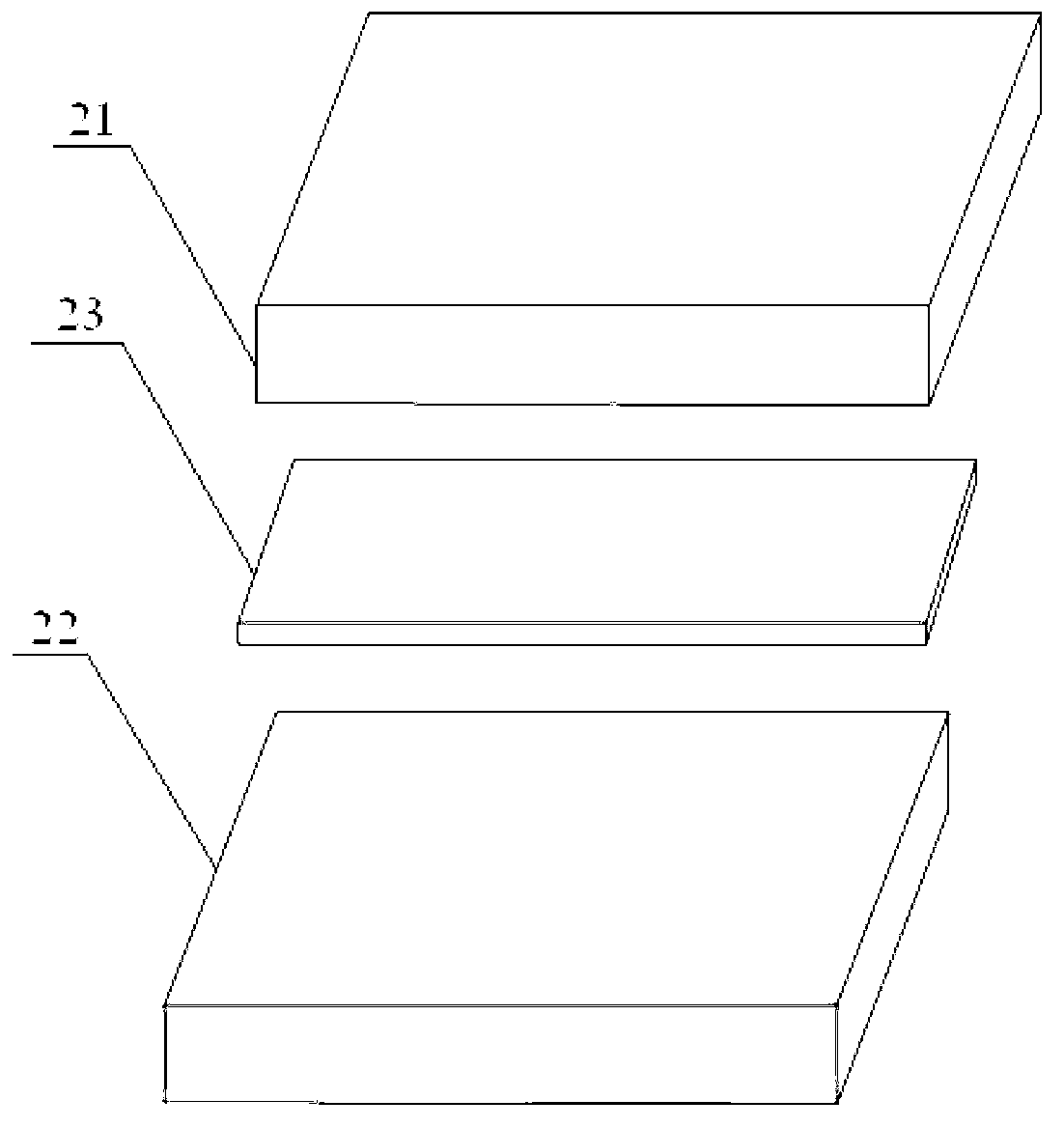

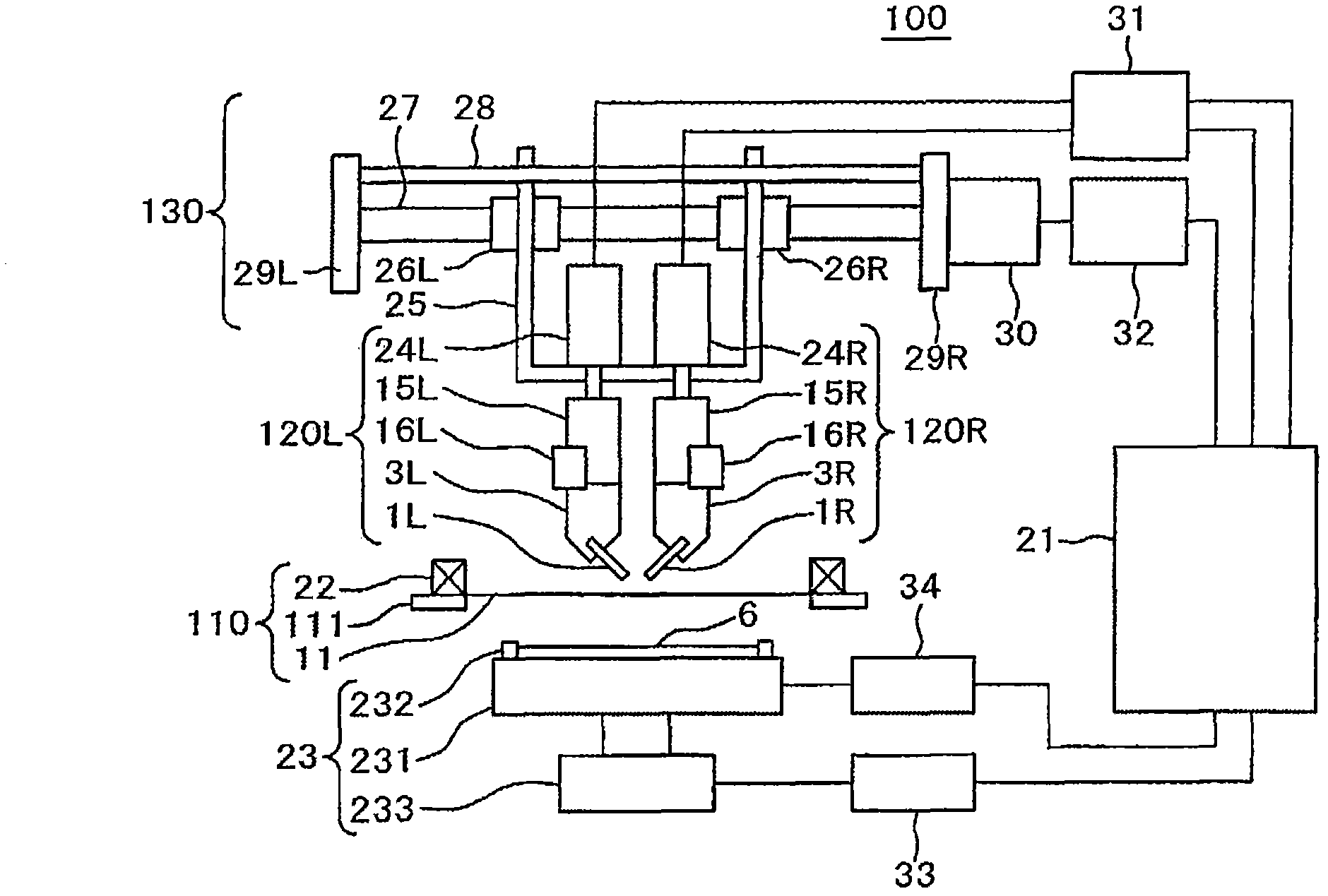

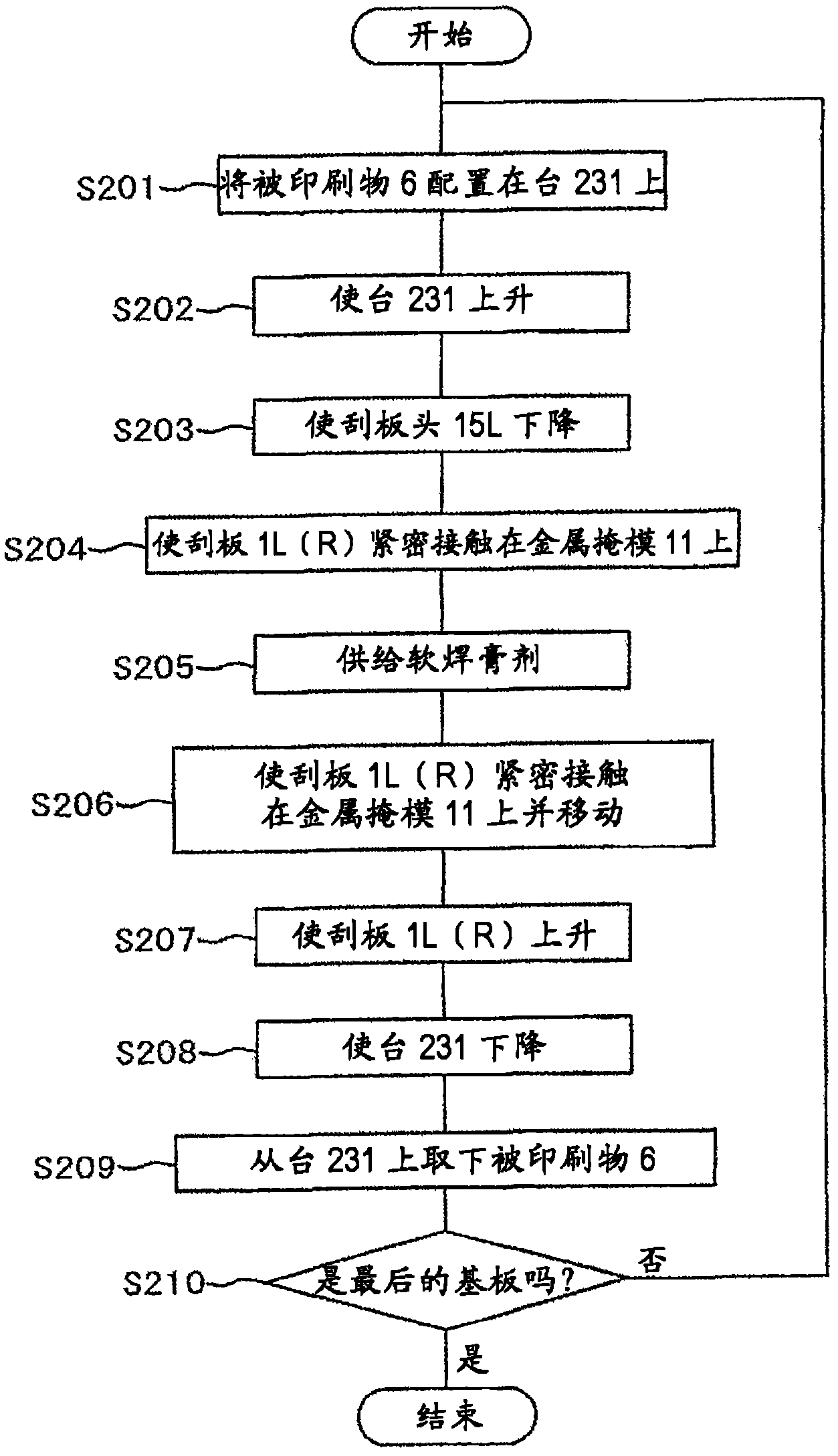

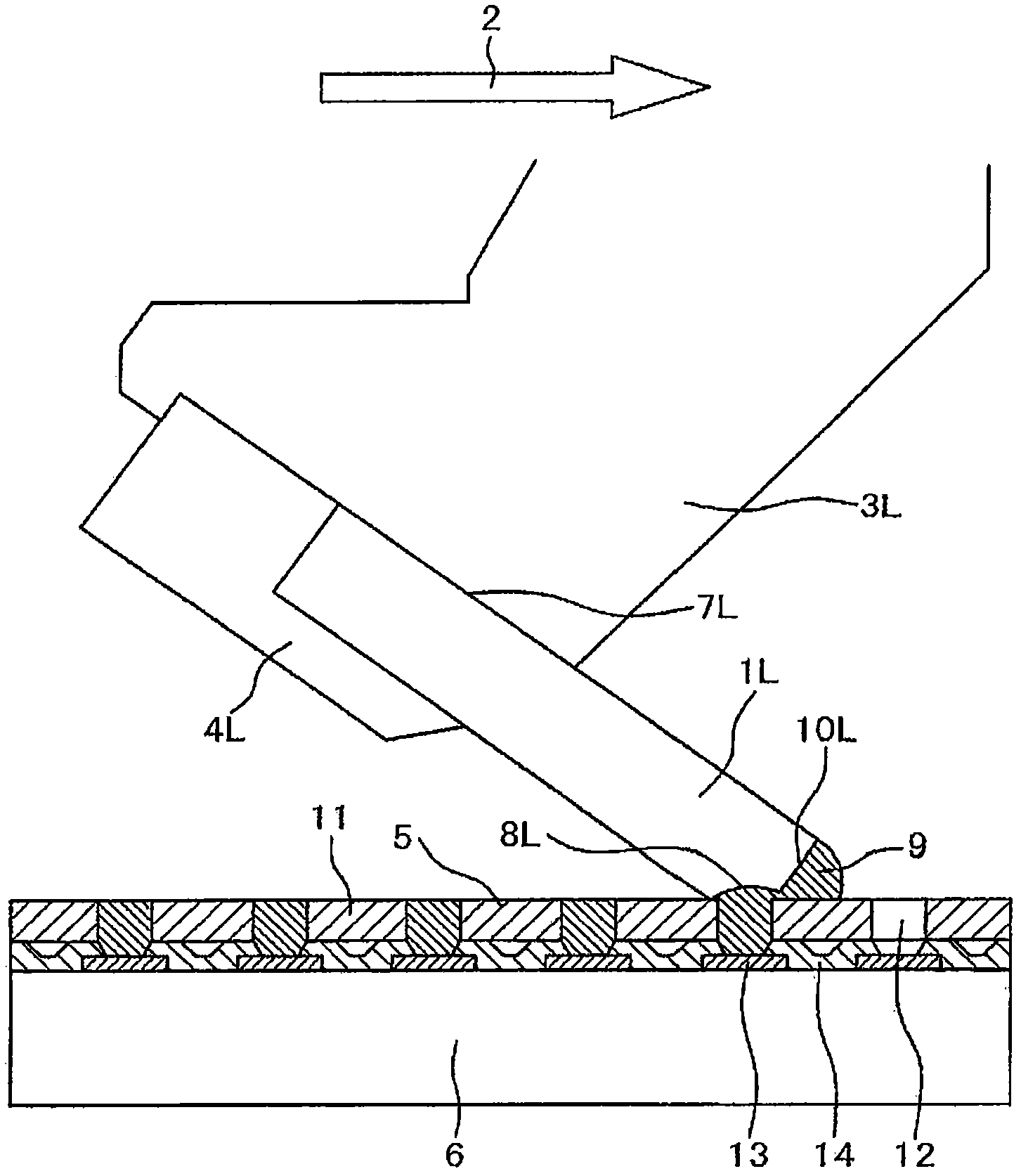

Screen printing method and device thereof

InactiveCN102267278APrinting is good and stableIncrease scrollingScreen printersScreen printingEngineering

PROBLEM TO BE SOLVED: To provide a printing method and an apparatus for the printing method, in which a squeegee can be mounted, wherein the squeegee is shaped such that regardless of the size of the opening area of the opening of a printing mask, the rolling of paste is accelerated when paste is filled and transferred to a printing mask with a required pattern opening and the filling property of the paste into the pattern opening of the printing mask is also accelerated in order to achieve accurate and stable printing, in addition, force is applied vertically to the paste with respect to the opening of the printing mask.SOLUTION: In the printing apparatus, by using the squeegee, paste is transferred to a predetermined part of an object to be printed, which is fixed on a table, from the printing mask that has an opening in a predetermined position. In the printing apparatus, the corner of one of squeegee ends has an arcuate and concave shape. An attack angle between the squeegee and the printed side of the object to be printed is made to be smaller than the mounting angle of the squeegee. Accordingly, satisfactory printing can be achieved in the printing method and the apparatus for the printing method.

Owner:HITACHI HIGH TECH INSTR CO LTD

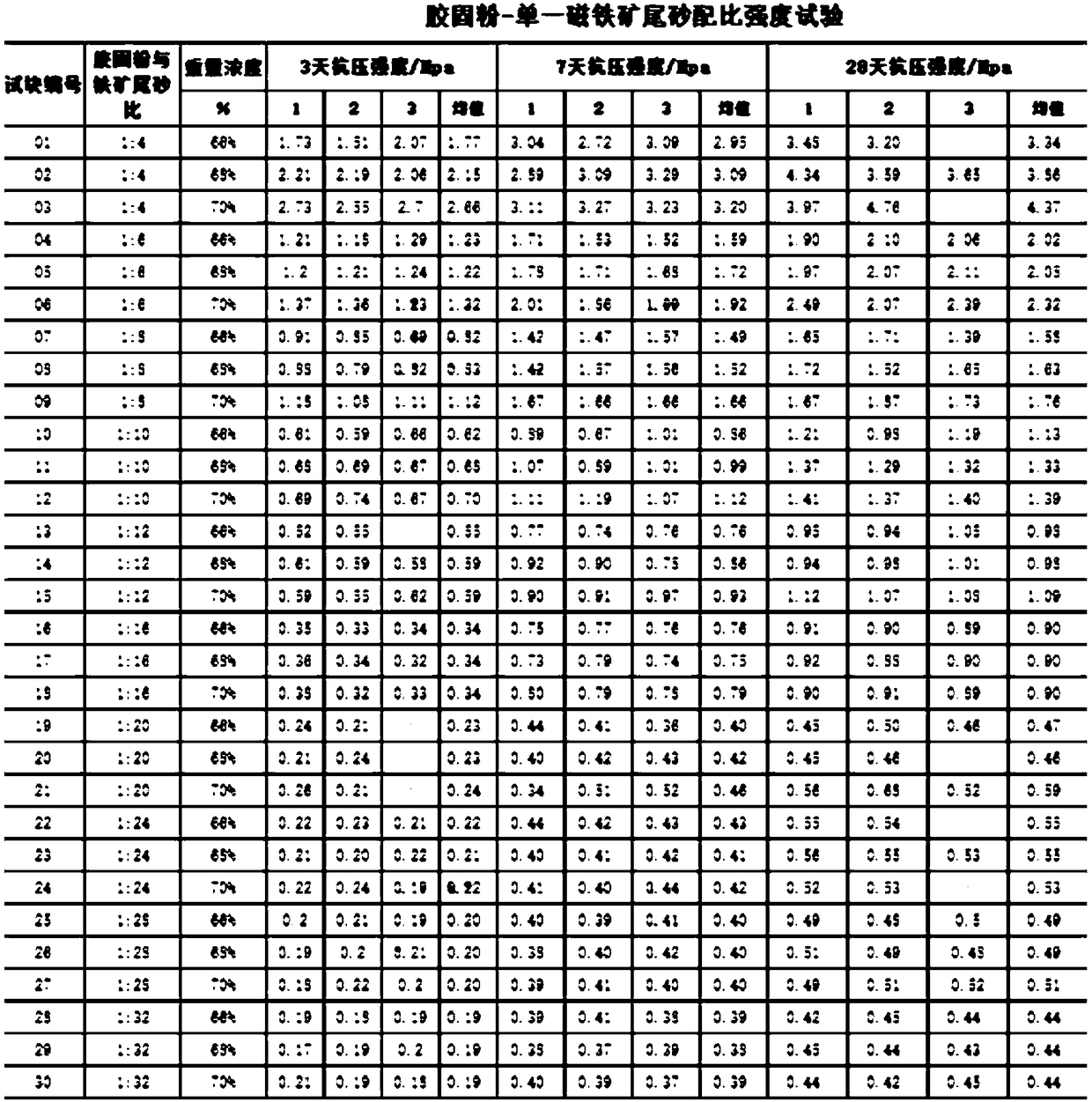

Formula and application method for filling cementing material

InactiveCN108147684AStrong cementing abilityHigh filling strengthCement productionSlagFlexural strength

The invention discloses a formula and application method for a filling cementing material. The formula for the filling cementing material adopts slag and other active materials as raw materials, and main chemical components of the formula comprise SiO2, Al2O3, Fe2O3, CaO, MgO and SO3; the formula comprises the following specific raw materials of: 80.2% of the slag, 15.01% of cement clinker, 3.63%of gypsum, 0.65% of solid sodium silicate and 0.51% of an early strength agent. The formula has the following advantages that the filling strength is high, the mortar strength of the cementing material is high, and after tests are conducted, flexural strength, compressive strength and the like can reach standards of P.O 42.5 ordinary cement; it is shown by actual application results that the cementing material has strong cementation ability for fine-grained tailings, and when the same cement-sand ratio and filling concentration are adopted, the filling strength of the filling cementing material is 40-60% higher than that of ordinary cement.

Owner:临沂会宝岭铁矿有限公司

Nickel-manganese composite hydroxide particles, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing positive electrode active material for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN105934409AImprove circularityImprove filling capacityElectrode thermal treatmentSecondary cellsElectrical batteryManganese

A staring material aqueous solution containing at least Ni and Mn, an aqueous solution containing an ammonium ion donor and an alkali solution are supplied into a reaction vessel, and are mixed so as to obtain an aqueous reaction solution and to have nickel-manganese composite hydroxide particles crystallized. In this connection, the oxygen concentration in the reaction vessel is controlled to be 3.0% by volume or less, the temperature of the aqueous reaction solution is controlled to be 35-60 DEG C, and the nickel ion concentration is controlled to be 1,000 mg / L or more. Consequently, there are obtained nickel-manganese composite hydroxide particles which are represented by general formula NixMnyMt(OH)2+alpha (wherein 0.05 < / = x < / = 0.95, 0.05 < / = y < / = 0.95, 0 < / = t < / = 0.20, x + y + t = 1, 0 < / = alpha < / = 0.5 and M represents one or more elements selected from among Co, Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and W), and which are composed of secondary particles, each of said secondary particles being composed of a plurality of primary particles aggregated together. The average circularity of the secondary particles having particle diameters that are 70% or more of the average particle diameter is 0.82 or more, and the tap density of the nickel-manganese composite hydroxide particles is 2.20 g / cm3 or more.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com