Coal face paste-like filling method and slurry-baffling device

A working face, paste-like technology, used in fillings, safety devices, mining equipment, etc., can solve the problems of large roof area of goaf, collapse, affecting the safety of construction workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

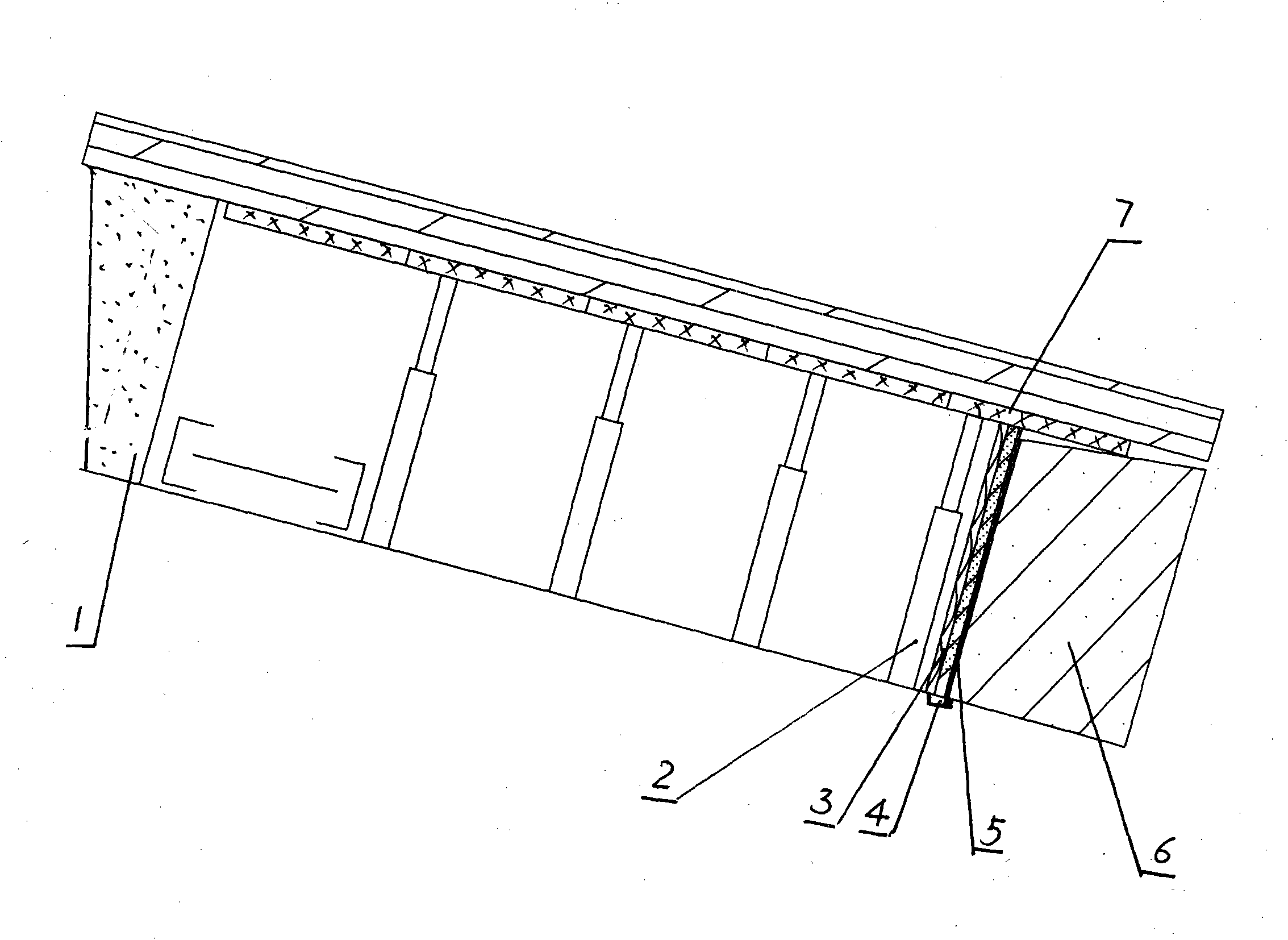

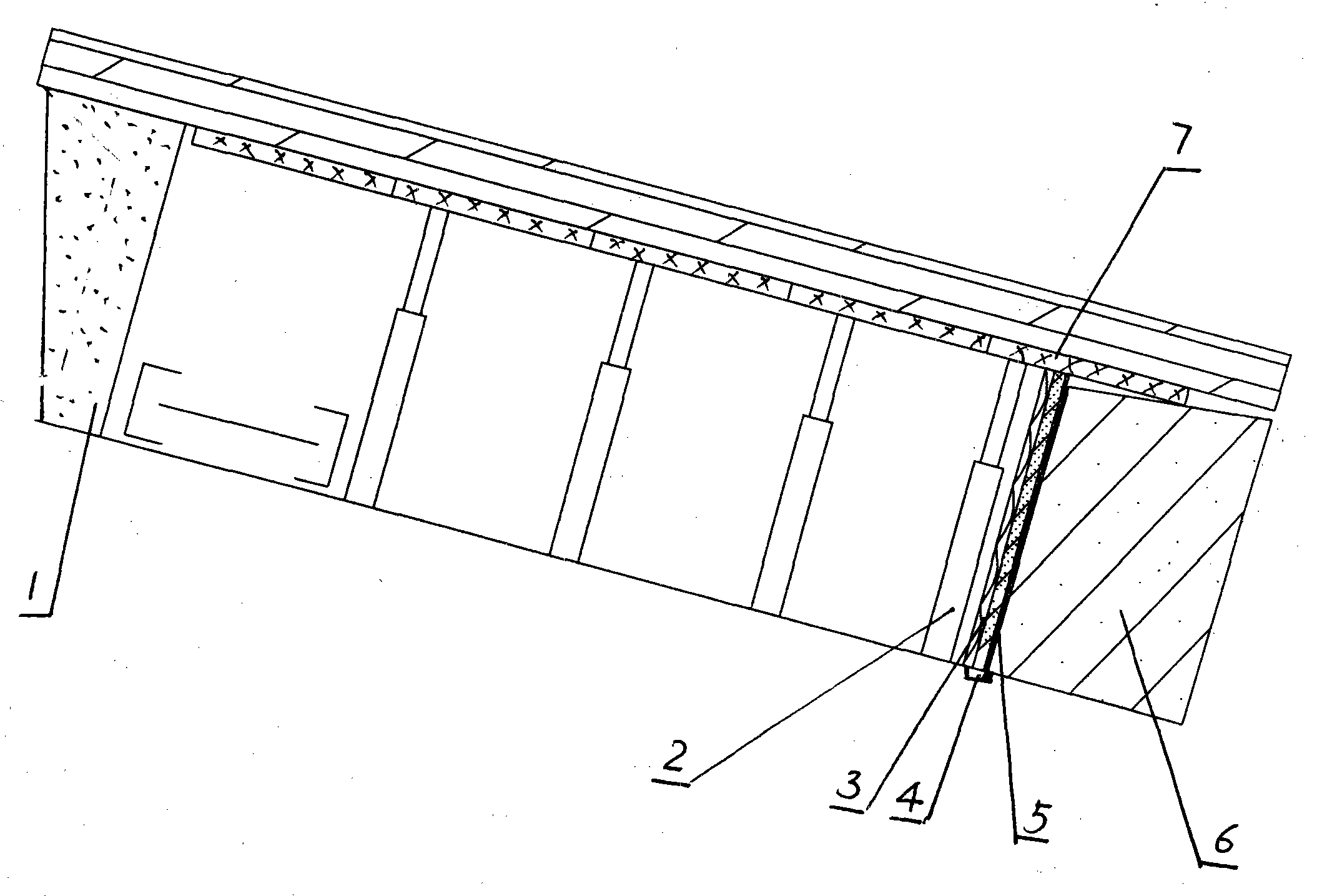

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, the filling steps are as follows:

[0013] The first step: Before filling, install a slurry retaining device on the working face. The slurry retaining device is to hang a slurry retaining curtain on the cutting top row of pillars 2 of the working face. The slurry retaining curtain is suspended on the bamboo fence 3 and Composition of nylon cloth 5. The installation method of the slurry retaining device is as follows: when the production of the working face 1 reaches a filling step, before withdrawing the top row of pillars 2, that is, the fifth row, the bottom plate is cleaned to a depth of not less than 0.3 along the inside of the fourth row of pillars. ditch 4 meters, and clean the hard bottom of the floor. When withdrawing and cutting the top row of pillars 2, fix the slurry curtain with iron wires and stick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com