Coal roadway rapid support method in unstable surrounding rock condition

A technology of surrounding rock and coal roadway, which is applied in the field of rapid support of coal roadway, can solve the problems of low efficiency, instability of actual excavation, and mismatch between excavation and support, so as to improve the efficiency of rapid excavation, reduce labor intensity, and ensure Sustainability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

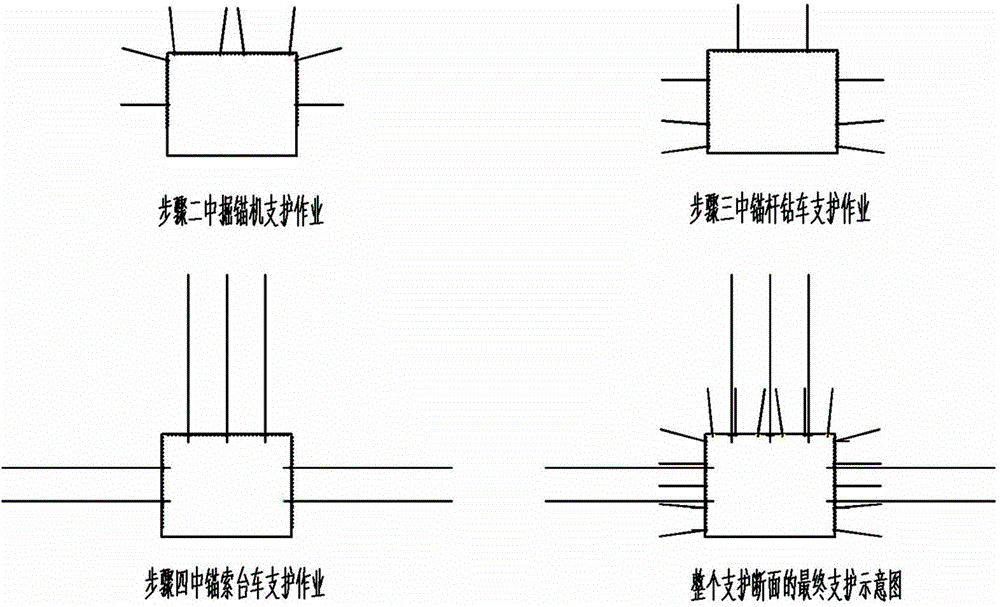

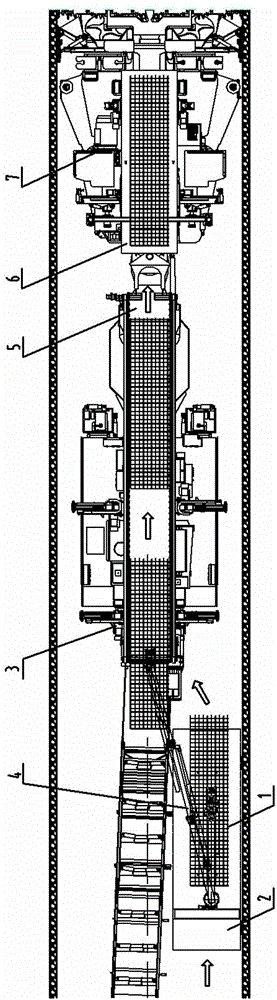

[0022] Embodiment one: if figure 1 , figure 2 As shown, in this embodiment, the rapid support method for coal roadway under unstable surrounding rock conditions, taking the excavation section with a height of 4.3m and a width of 5.6m as an example, includes the following steps:

[0023] Step 1, store the supporting material 1 on the mesh conveying frame 5 of the rock bolter 3 and the material platform of the bolter 7;

[0024] Step 2. When the bolter 7 is continuously driving the coal roadway forward, at first the roof and the two gangs of the support section are hung with metal mesh for advance support, and then the bolter on the bolter 7 is used to carry out the advance support on the support section. 4 anchor rods are drilled on the top plate, and 2 anchor rods are drilled on each of the two sides;

[0025] Step 3: Carry out step 3 at the same time as step 2, use the bolter on the bolter 3 at the rear end of the bolter 7 to make up 2 bolts on the top plate of the suppor...

Embodiment 2

[0029] Embodiment two: if figure 1 , figure 2 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that in the step 5, the explosion-proof rubber-tyred vehicle 2 sends the support material 1 to the tail of the bolter 3 , with the truck-mounted crane 4 of the explosion-proof rubber-tyred car 2 to reload to the rear end of the bolter 3 mesh delivery frame 5.

Embodiment 3

[0030] Embodiment three: as figure 1 , figure 2 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference lies in: the arrangement of the rocker rig on the rocker truck 3 in the step 3 and the anchor rod of each support section The spacing matches the spacing of adjacent support sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com