Laser induced nanometer brazing method of silicon carbide particle reinforced aluminum matrix composite with high volume fraction

A silicon carbide particle, high volume fraction technology, applied in laser welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as poor welding quality, and achieve improved wettability, high density, and high bonding intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

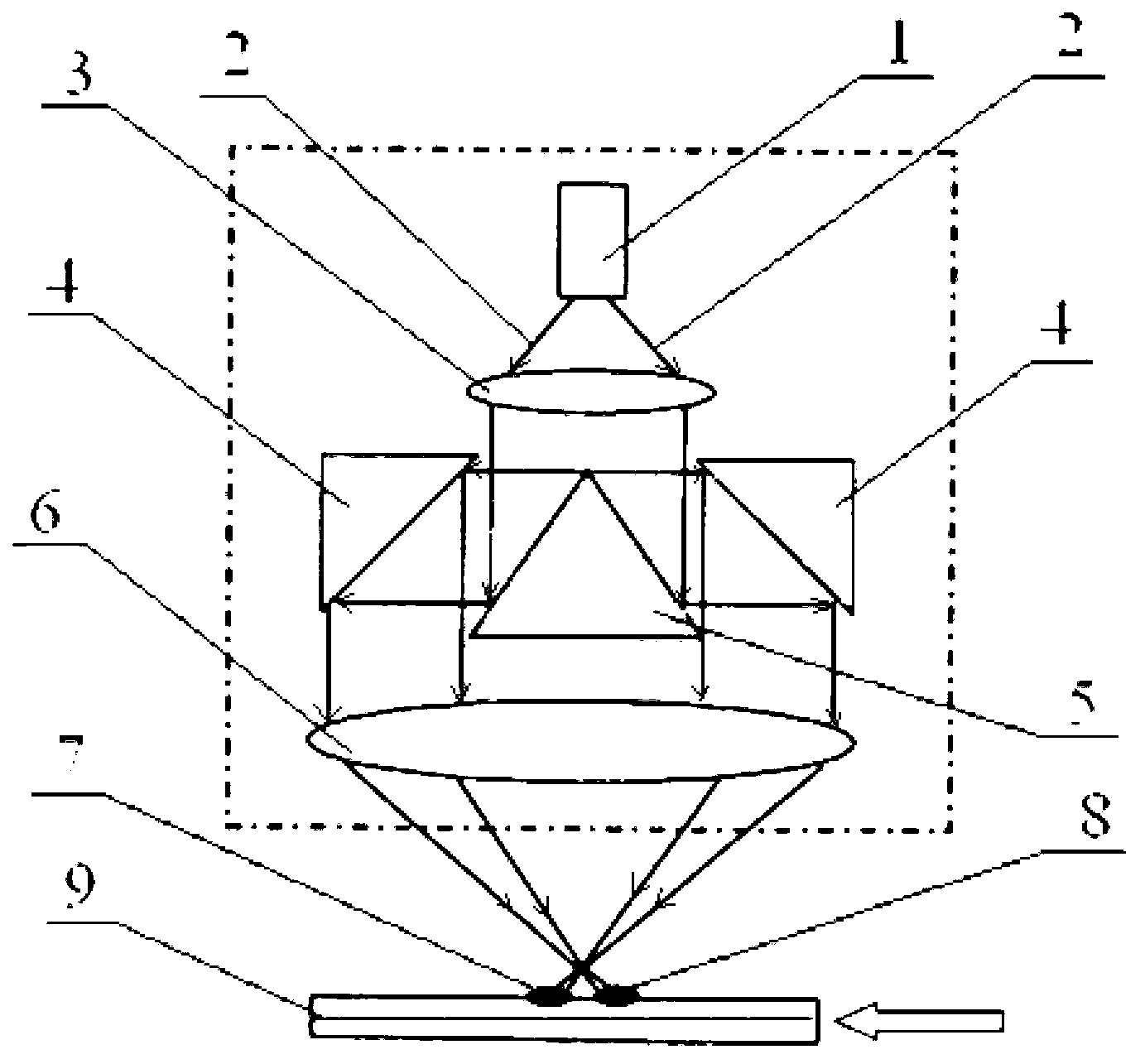

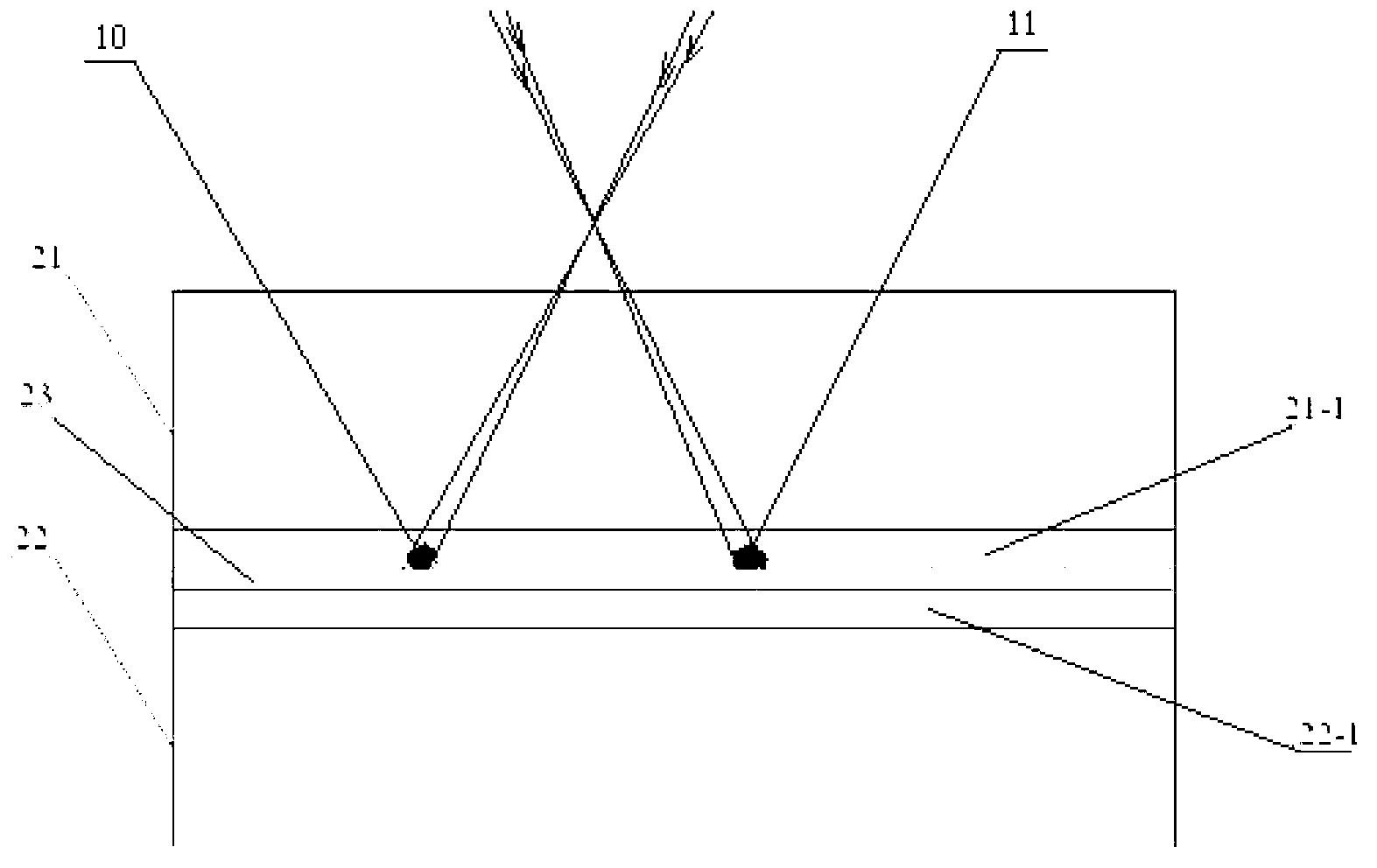

[0034] Specific Embodiment 1: In this embodiment, the laser-induced nano-brazing method of high volume fraction silicon carbide particles reinforced aluminum matrix composite material is carried out according to the following steps:

[0035] 1. Nanoization of the welded surface of the aluminum matrix composite matrix with high volume fraction silicon carbide particles:

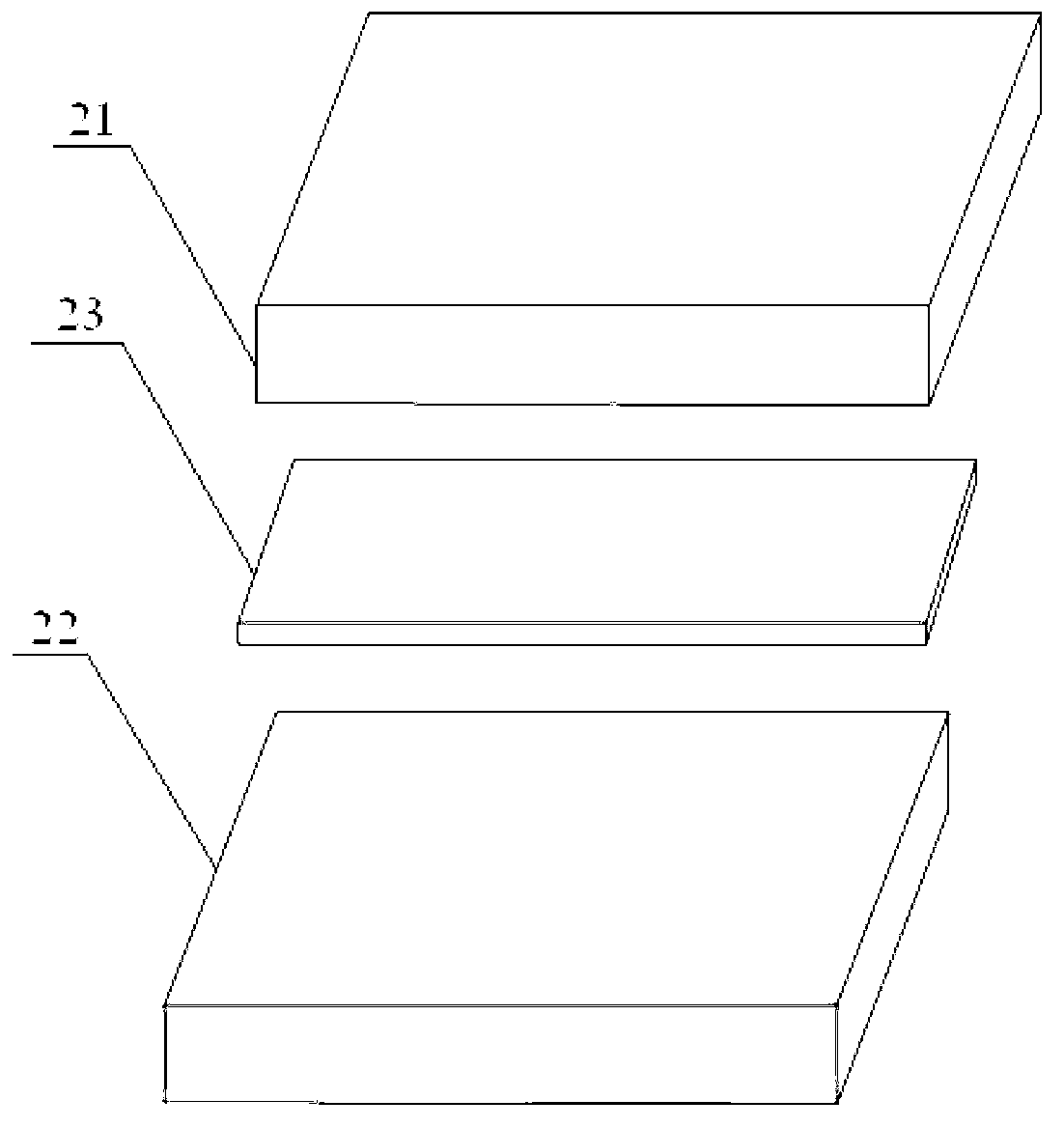

[0036] A nano-grain layer is prepared on the welded surface of the upper substrate and the lower substrate; the materials of the upper substrate and the lower substrate are both high volume fraction silicon carbide particles reinforced aluminum matrix composite materials;

[0037] 2. Preparation of solder:

[0038] Prepare silver-based, aluminum-based or zinc-based solder; wherein the silver-based solder consists of 40-50 parts of Ag, 20-25 parts of Cu, 9-12 parts of In, 16-20 parts of Sn and 2-5 parts of Mg; the aluminum-based brazing filler metal consists of 20-25 parts of Cu, 3-8 parts of Si, 1-3 parts of ...

specific Embodiment approach 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume fraction of the SiC particle-reinforced phase in the high-volume SiC particle-reinforced aluminum-based composite material is 50% to 70%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the method of preparing the nano-grain layer on the welded surface of the upper substrate and the lower substrate is mechanical grinding method, high-speed projectile jet method or pulsed laser shock method . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com