Secondary gas filling station

A technology of gas filling station and gas filling machine, which is applied in the direction of gas/liquid distribution and storage, details of ship construction, equipment loaded into pressure vessels, etc. Hydraulic pumps are expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Only the gas storage device of the technical solution 2 is described, and the gas storage device of the technical solution 1 is similar.

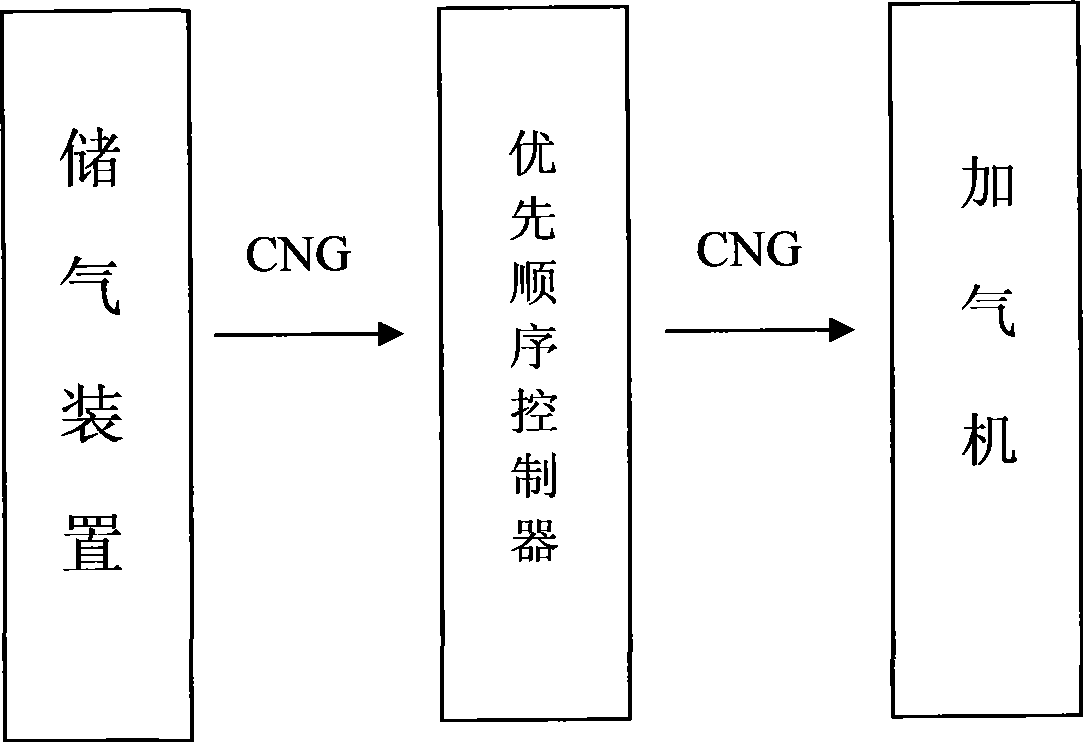

[0133] Technical solution two

[0134] The sub-gas station is composed of a gas dispenser, a priority controller, and a gas storage device. Its technical features are: the gas storage device is composed of multiple 25MPa high-pressure CNG compressed natural gas storage cylinders, and the gas storage device can be made into multiple Tube bundle containers, container analogues or multi-long tube trailers, the whole directly goes to the parent gas filling station to inflate, and after being filled with gas, it is transported back to the child gas filling station and connected to the priority controller to refuel CNG fuel vehicles through the gas dispenser.

[0135] Let's illustrate with an example

[0136] A known:

[0137] CNG tube bundle semi-trailer technical parameter table

[0138] Main components: high-pres...

Embodiment 2

[0176] Technical solution one

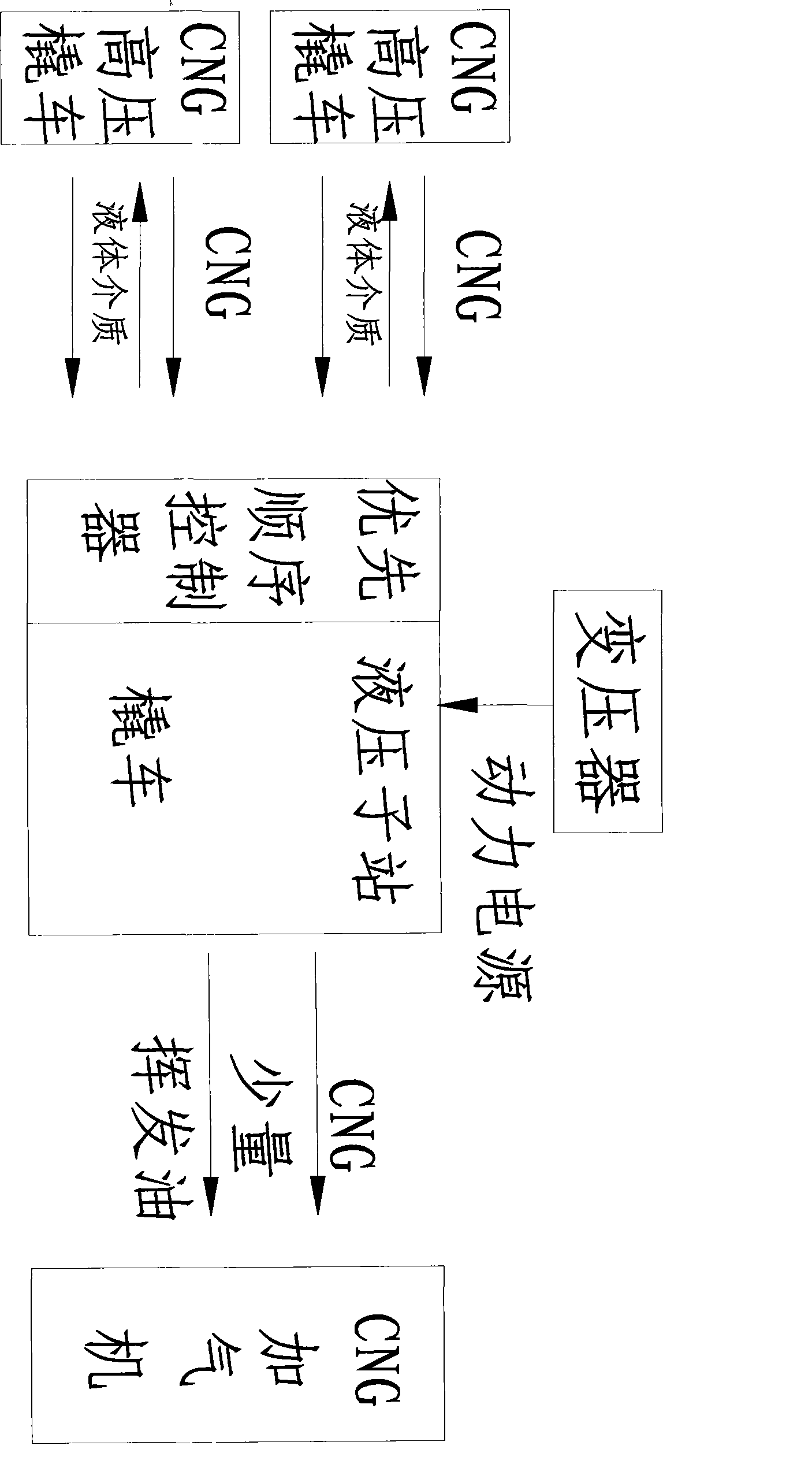

[0177] The sub-gas filling station consists of a filling machine, a priority controller, and a gas storage device to form a whole container or a container-like whole. Its technical characteristics are: the gas storage device is composed of multiple 25MPa high-pressure CNG compressed natural gas storage cylinders. , the gas storage device, gas filling machine, and priority controller form a whole to go directly to the parent gas filling station for filling, and transport it back to various places to directly fill CNG fuel vehicles.

[0178] Here it is emphasized that the sub-gas station consists of a gas dispenser, a priority controller, and a gas storage device (see Figure 4 ) constitutes a whole of a container or the like of a container (for the whole see Figure 8 ), as the working principle of the gas storage device has been described in detail in Embodiment 1, it will not be repeated here.

[0179] A known:

[0180] ...

Embodiment 3

[0196] Technical solution three

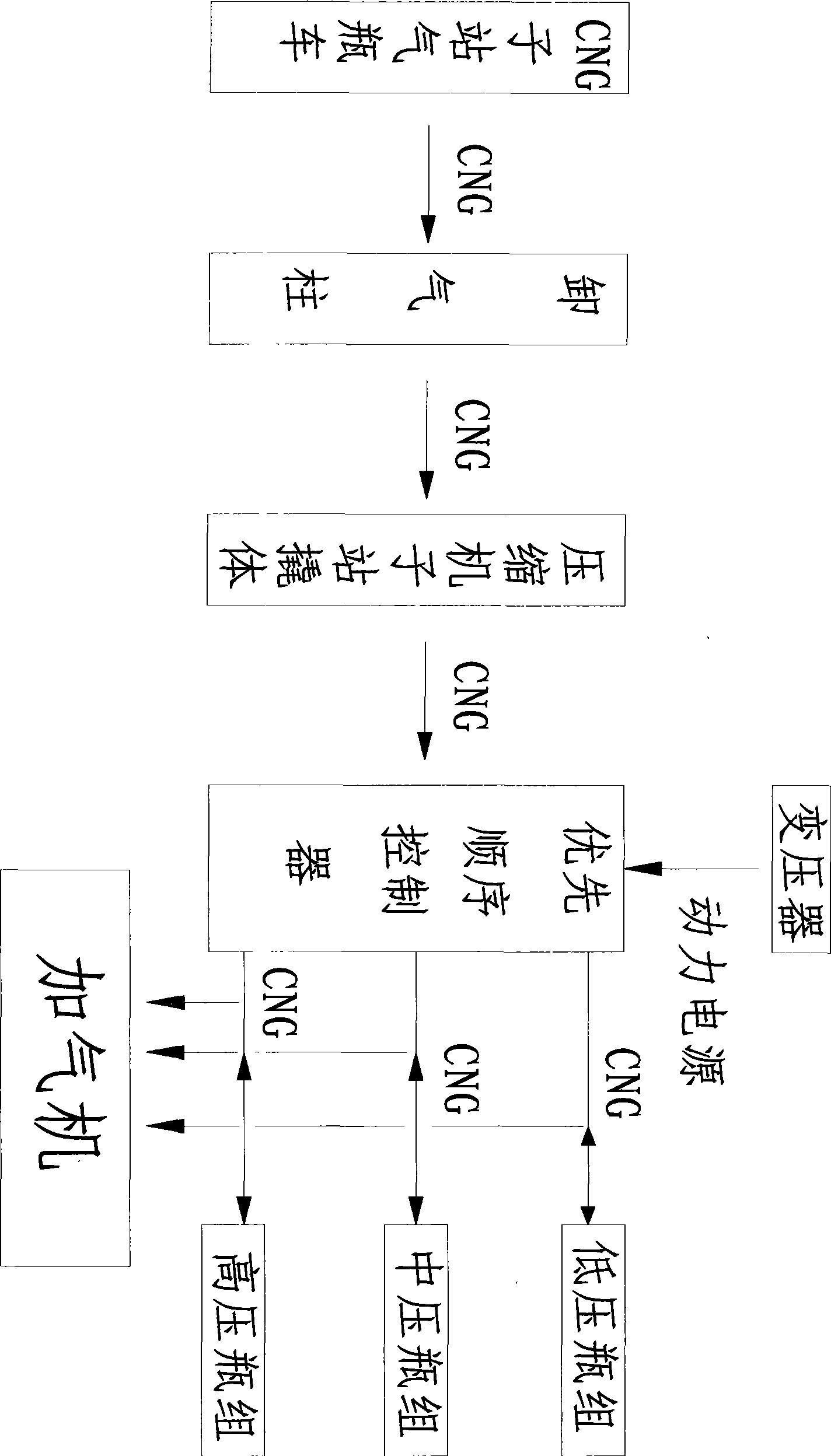

[0197] The sub-gas filling station is composed of a filling machine, a priority controller, and multiple gas storage devices. Its technical characteristics are: multiple gas storage devices, each of which is composed of multiple 25MPa high-pressure CNG compressed natural gas storage Composed of cylinders, multiple gas storage devices are connected to the priority controller and under its control, the CNG fuel vehicle is refueled through the gas dispenser. When the previous gas storage device runs out of CNG compressed natural gas, the next gas storage device needs to provide high pressure. CNG compressed natural gas, after the last gas storage device runs out of CNG compressed natural gas, go to the parent gas filling station to inflate, transport it back to the sub gas filling station and connect it with the priority controller, and use it as the next gas storage device of this round for the previous gas storage The device (the next gas stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com