Method for filling paste behind filling hydraulic supports

A technology of hydraulic support and paste filling, which is applied in the directions of filling, mine roof support, earthwork drilling, etc., can solve problems such as insufficient airtightness, and achieve the effect of improving filling effect, simple operation process and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific drawings and specific embodiments.

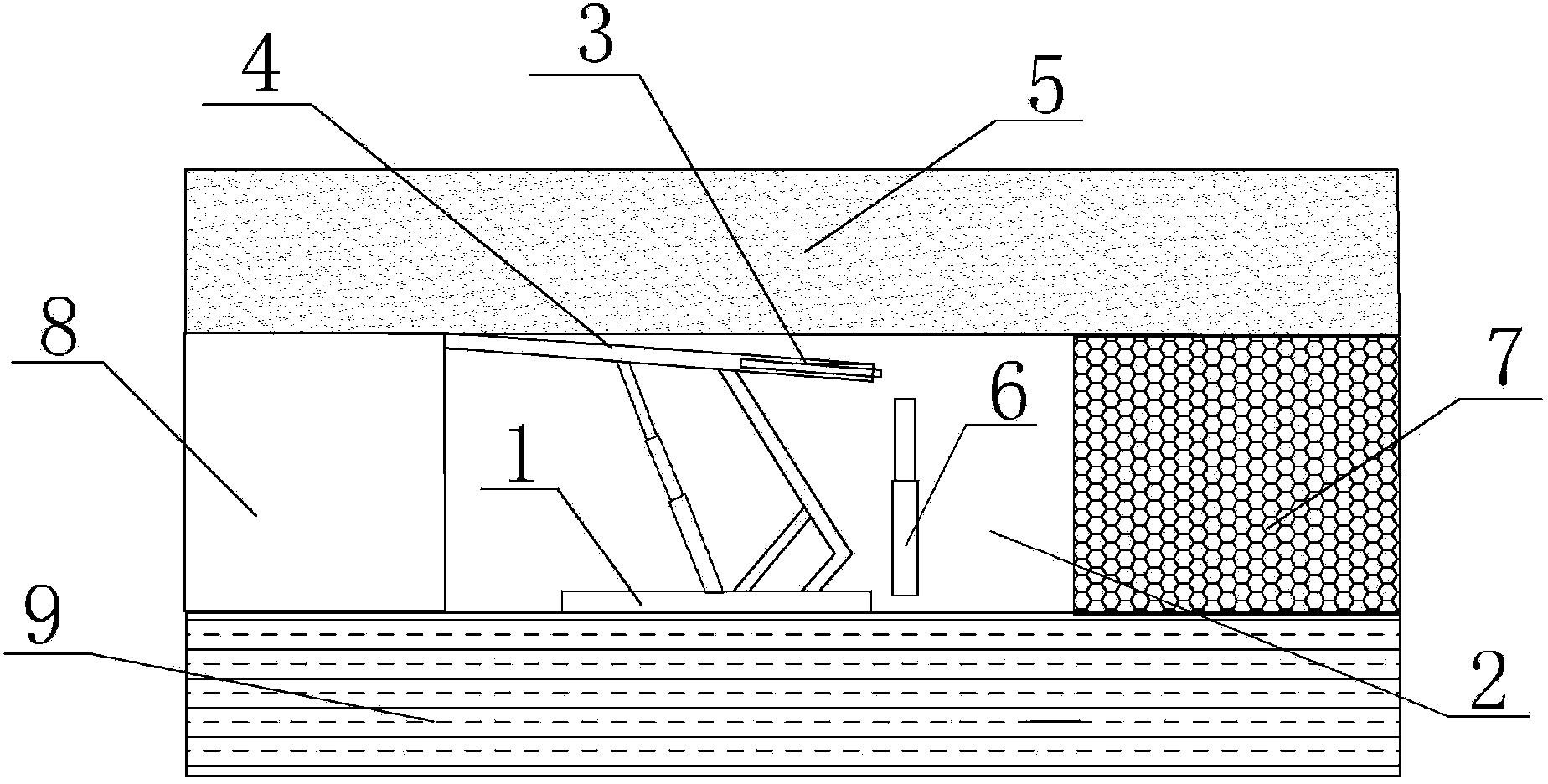

[0031] Such as figure 1 As shown, one end of the hydraulic support 1 is in contact with the coal body 8 , and the other side of the hydraulic support 1 is a filled area 7 , and a space 2 to be filled is formed between the filled area 7 and the tailgate 6 . Separate the two adjacent hydraulic supports 1, retract the telescopic beam 3, adjust the balance jack, and separate the rear end of the top beam 4 of the hydraulic support 1 from the top plate 5. The tailgate is divided into 6 parts and four parts, namely the upper left tailgate, the upper right tailgate, the lower left tailgate, and the lower right tailgate. Lower the upper left tailgate, upper right tailgate, raise the lower left tailgate, lower right tailgate.

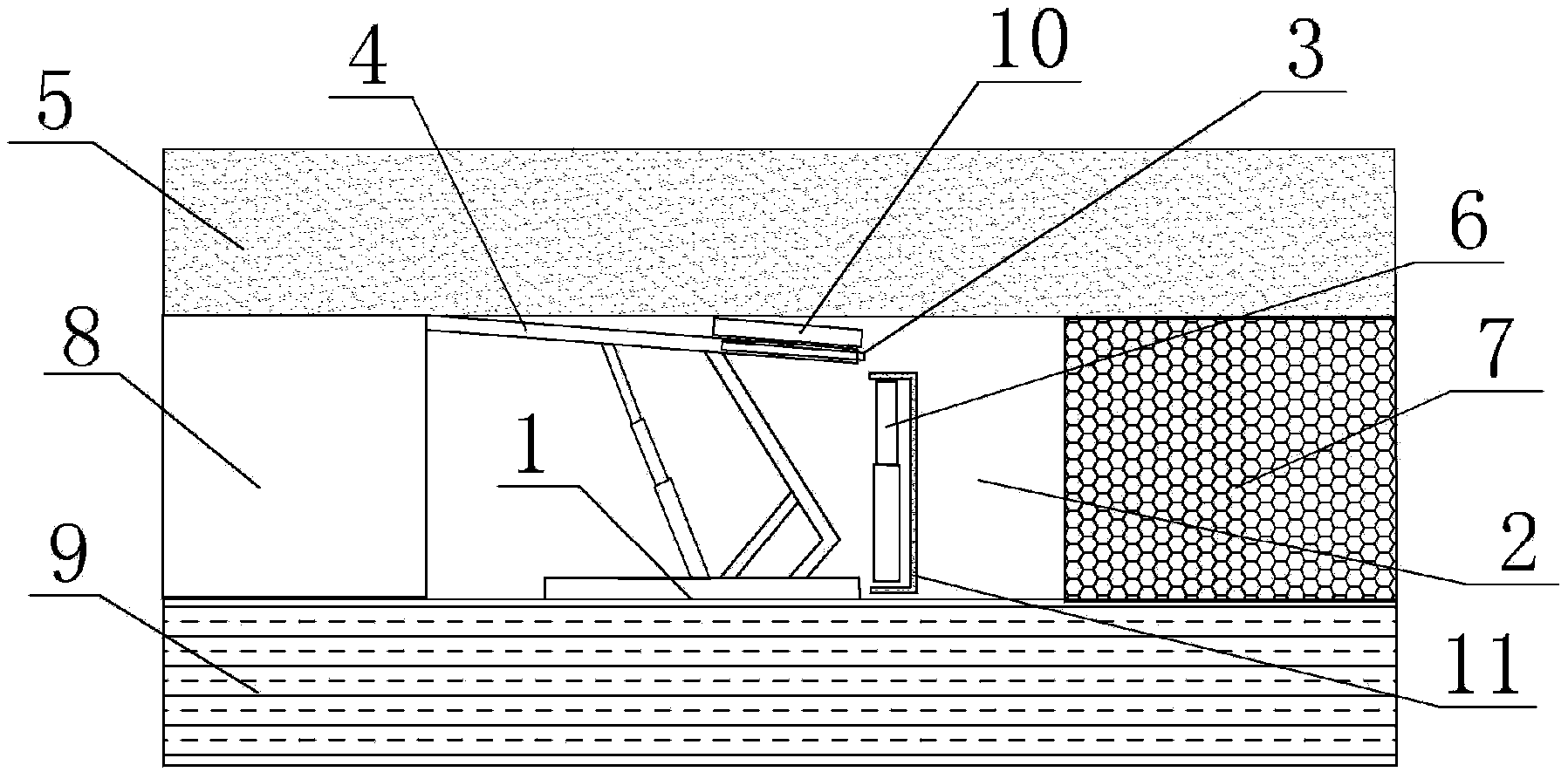

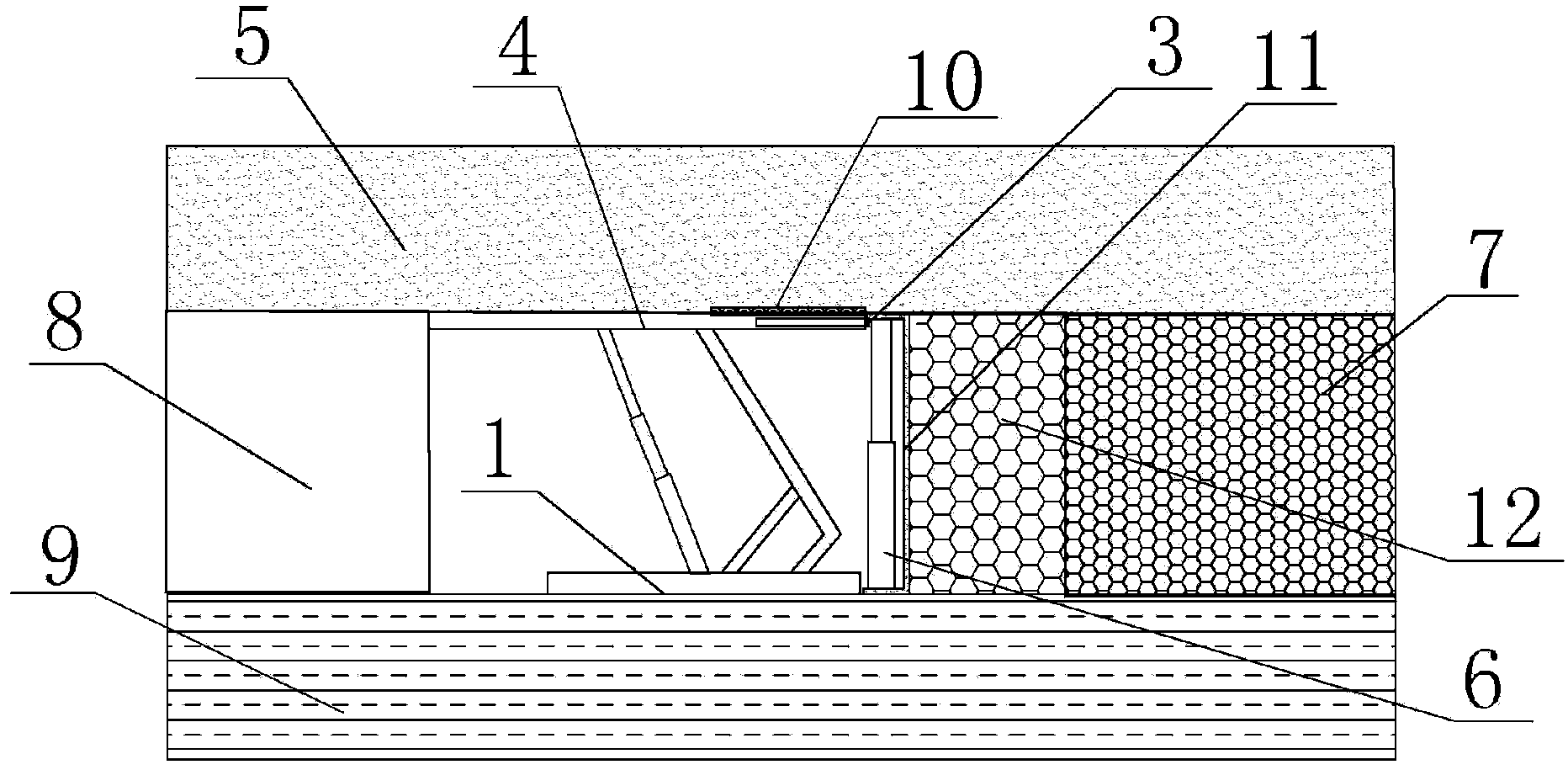

[0032] Such as figure 2 As shown, a flame-retardant sponge 10 is added to the side of the tailgate 6, fixed on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com