Formula and application method for filling cementing material

A cementing material and formula technology, applied in cement production, etc., can solve problems such as unreasonable economic prospects and resources, and achieve the effects of good segregation resistance, good fluidity, and low heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

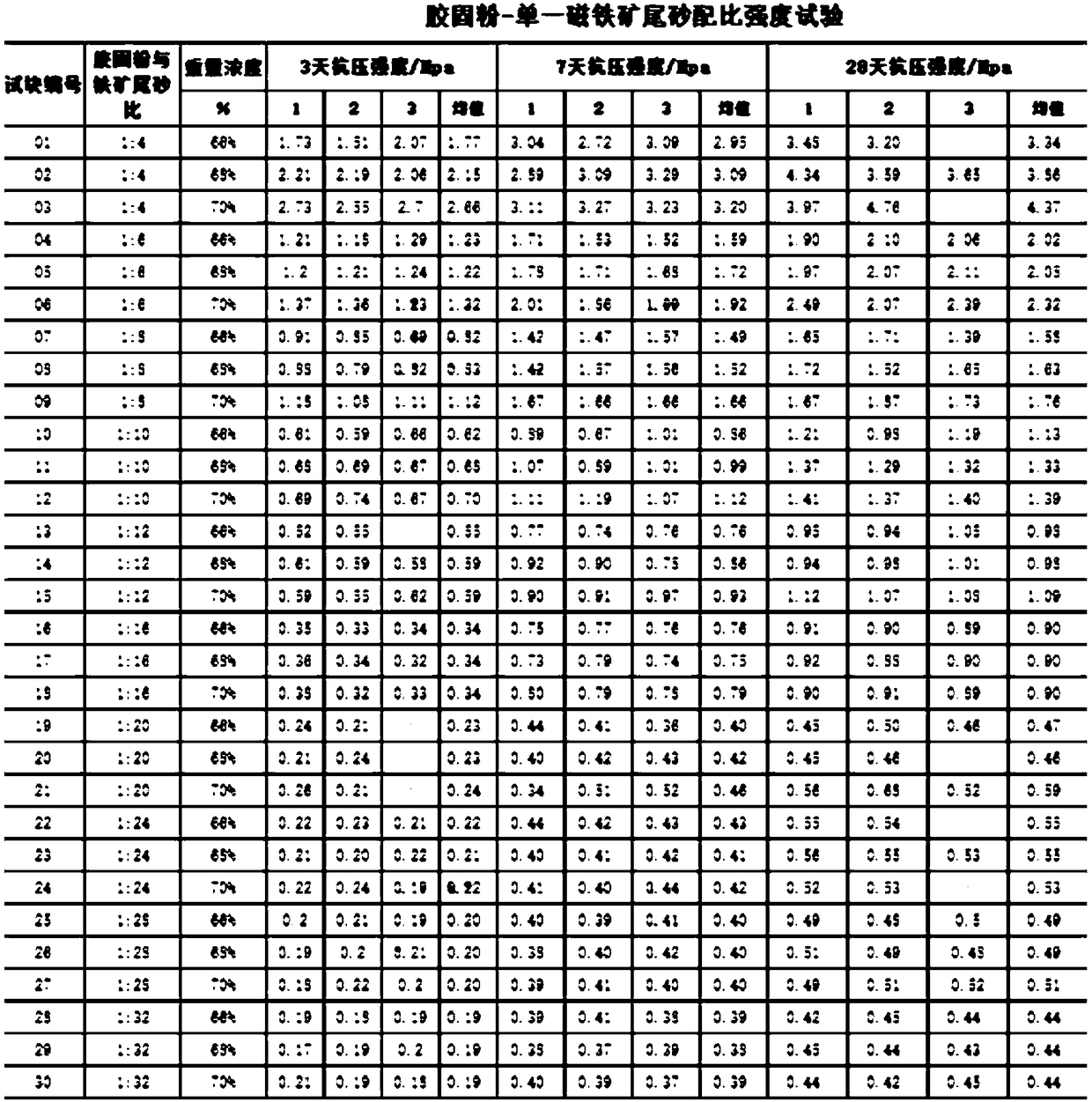

[0036] Embodiment (select different water-cement ratio materials successively, carry out strength test structure after mixing)

[0037] Embodiment range: (1:2~1:32)

[0038] The specific implementation is as follows:

[0039] A filling cement formula, the filling cement formula uses slag and other active materials as raw materials, and its main chemical components are SiO 2 、AI 2 0 3 , Fe 2 0 3 , CaO, MgO, SO 3 ; Concrete raw materials are as follows:

[0040] Blast furnace slag; content: 80.2%;

[0041] Cement clinker; content: 15.01%;

[0042] Gypsum; content: 3.63%;

[0043] Solid water glass; content: 0.65%;

[0044] Early strength agent; content: 0.51%.

[0045] The early strength agent is a mixture of one or more combinations of Na2CO3, NaNO2, Na2SO4 or NaCl.

[0046] The solid water glass is obtained by quantitatively weighing quartz sand and soda ash according to a certain proportion, mixing them with a mixer, smelting at a high temperature, and cooling.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com