Heavy metal mine slope spray-seeding material as well as preparation method and application thereof

A technology of heavy metals and mines, which is applied in the direction of botany equipment and methods, applications, and land preparation methods, can solve the problems of restricting the promotion and application of spraying technology, high heavy metal content in slope soil, and poor long-term growth of vegetation, so as to achieve easy The effect of large-scale production and application, high seed germination rate and survival rate, and strong cementing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

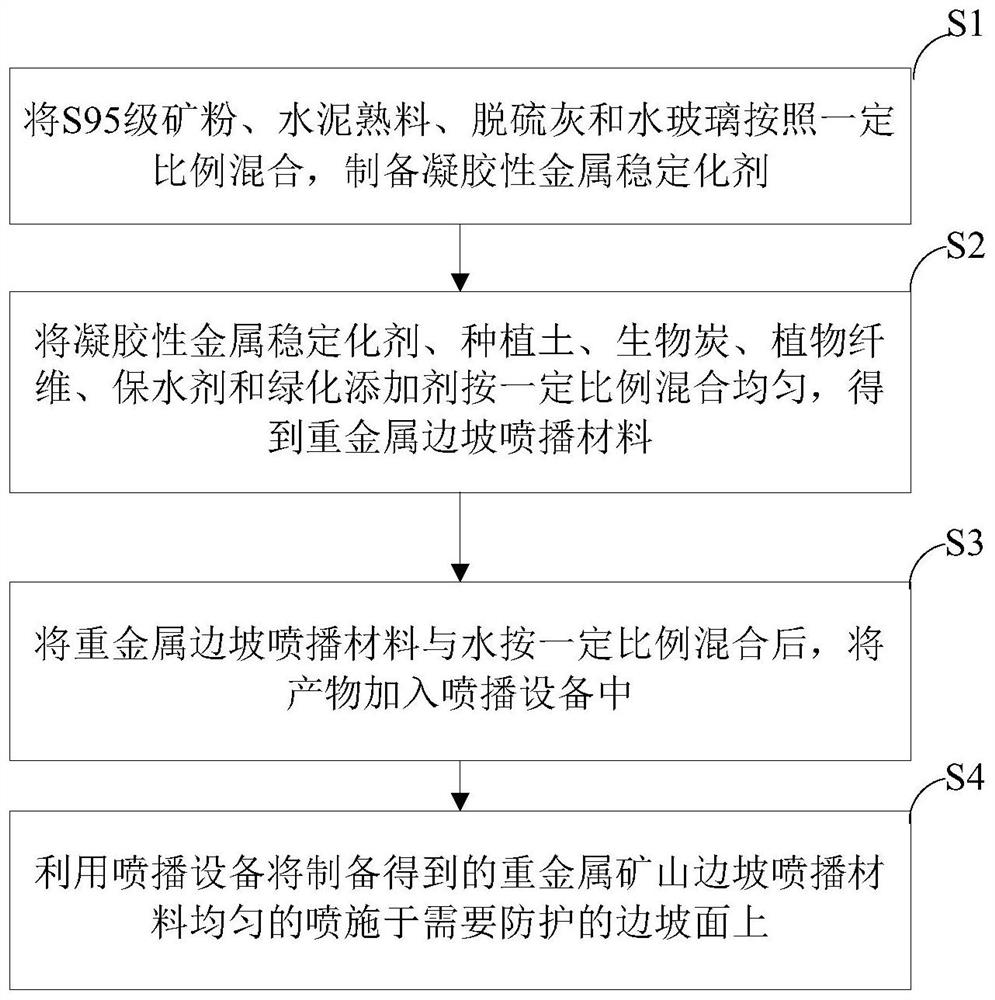

Method used

Image

Examples

Embodiment 1

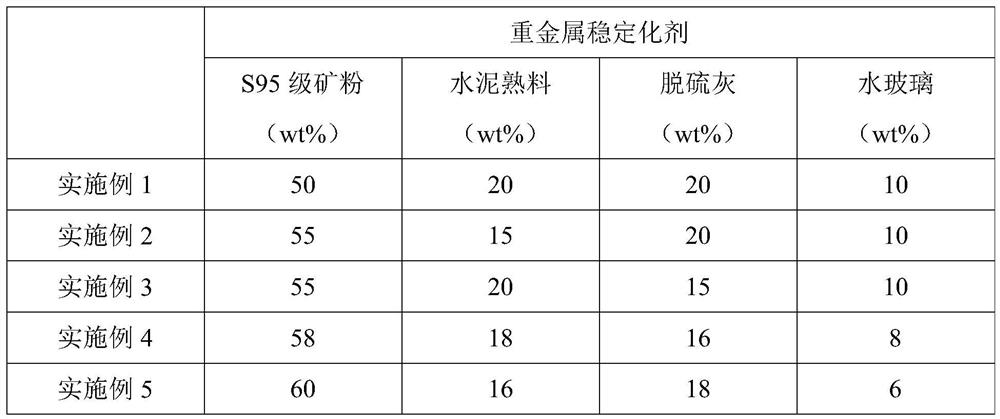

[0036] (1) S95 grade mineral powder, cement clinker, desulfurization ash and water glass are mixed according to the ratio shown in Table 1, prepare metal stabilizer;

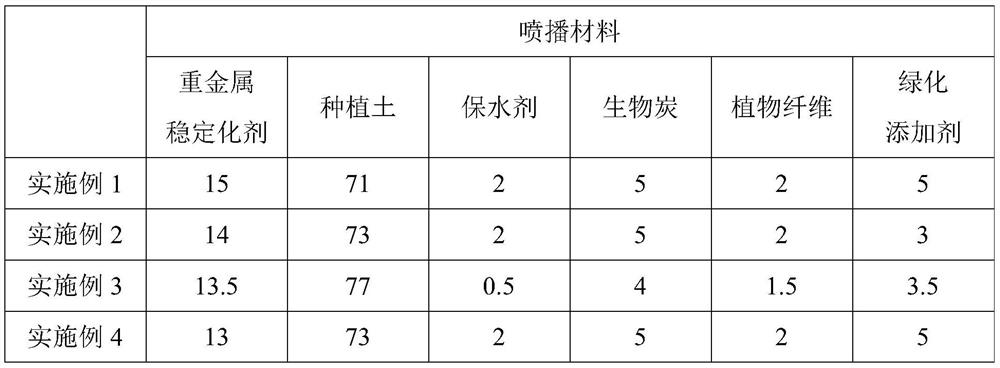

[0037] (2) Metal stabilizer, planting soil, biochar, plant fiber, water-retaining agent and greening additive are mixed uniformly by the ratio shown in table 2, obtain heavy metal slope spraying material; Wherein, water-retaining agent is polyacrylamide; The greening additive includes 60wt% of humus, 20wt% of compound bacterial agent and 20wt% of bentonite,

[0038] (3) After mixing the heavy metal slope spraying material with water in a ratio of 1:3, add it to the spraying equipment;

[0039] (4) Use the spraying equipment to evenly spray the prepared heavy metal mine slope spraying material on the slope surface that needs to be protected. Among them, the output capacity of the pump body of the equipment is 100L / min, the volume of the tank is 330 liters, the working time at full load is 3 minutes, and the spra...

Embodiment 2

[0041] (1) S95 grade mineral powder, cement clinker, desulfurization ash and water glass are mixed according to the ratio shown in Table 1, prepare metal stabilizer;

[0042](2) Metal stabilizer, planting soil, biochar, plant fiber, water-retaining agent and greening additive are mixed uniformly by the ratio shown in table 2, obtain heavy metal slope spraying material; Wherein, water-retaining agent is polyacrylamide; Greening additives include humus 70wt%, composite bacterial agent 20wt% and bentonite 10wt%,

[0043] (3) After mixing the heavy metal slope spraying material with water in a ratio of 1:4, add it to the spraying equipment;

[0044] (4) Use the spraying equipment to evenly spray the prepared heavy metal mine slope spraying material on the slope surface that needs to be protected. Among them, the output capacity of the pump body of the equipment is 80L / min, the volume of the tank is 400 liters, the working time at full load is 5 minutes, and the spraying radius is...

Embodiment 3

[0046] (1) S95 grade mineral powder, cement clinker, desulfurization ash and water glass are mixed according to the ratio shown in Table 1, prepare metal stabilizer;

[0047] (2) Mix metal stabilizer, planting soil, biochar, plant fiber, water-retaining agent and greening additive in the ratio shown in Table 2, to obtain heavy metal slope spraying material; wherein, water-retaining agent is starch grafted acrylic acid Salt; Greening additives include humus 80wt%, composite bacterial agent 10wt% and bentonite 10wt%,

[0048] (3) After mixing the heavy metal slope spraying material with water in a ratio of 1:2, add it to the spraying equipment;

[0049] (4) Use the spraying equipment to evenly spray the prepared heavy metal mine slope spraying material on the slope surface that needs to be protected. Among them, the output capacity of the pump body of the equipment is 50L / min, the volume of the tank is 300 liters, the working time at full load is 6 minutes, and the spraying rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com