A kind of plugging agent and its preparation method and application

A technology of plugging agent and plugging slurry, applied in the field of plugging agent, can solve the problems of poor cementing ability, low viscosity of cement plugging agent, loss of gel properties, etc. The effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

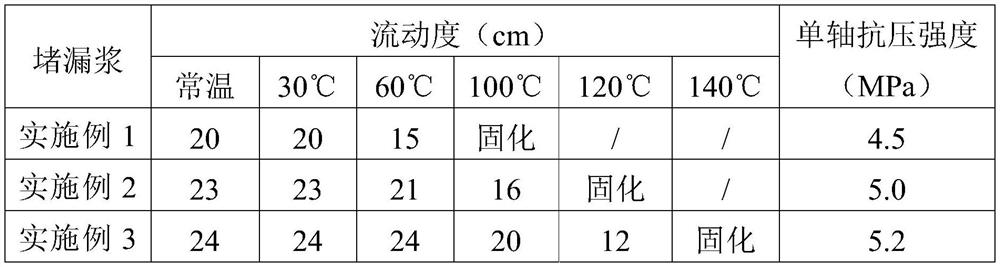

Examples

Embodiment 1

[0023] 1. Preparation of curing agent

[0024] Mix blast furnace slag, gypsum, and aluminum silicate fibers in a mass ratio of 25:1:4, then dry and grind them. The drying temperature is 90°C and the drying time is 24 hours to obtain a curing agent.

[0025] 2. Preparation of filler

[0026] Calcium carbonate, asphalt, and nano-silicon powder are mixed according to the mass ratio of 6:2:2 to prepare the filler; among them, the particle size of calcium carbonate is 400 mesh; the particle size of asphalt is ≤40 mesh; the average particle size of nano-silicon powder The particle size is 30nm.

[0027] 3. Preparation of plugging agent

[0028] Mix sodium-based bentonite, the above-mentioned curing agent, alloy fiber, expansion agent, and the above-mentioned filler according to the mass ratio of 4:40:1:4:50 to prepare the plugging agent. Among them, the alloy fiber is polyethersulfone / polytetrafluoroethylene alloy fiber modified by silicon dioxide, activated calcium carbonate and...

Embodiment 2

[0032] 1. Preparation of curing agent

[0033] Mix blast furnace slag, gypsum, and silicate fiber in a mass ratio of 15:1:5, then dry and grind at a drying temperature of 90°C and a drying time of 24 hours to obtain a curing agent; among them, silicate The fiber is made by mixing aluminum silicate fiber and asbestos wool according to the mass ratio of 1:1.

[0034] 2. Preparation of filler

[0035] Calcium carbonate, asphalt, and nano-silicon powder are mixed in a mass ratio of 9:1:3 to obtain a filler; the particle size of calcium carbonate is 800 mesh; the particle size of asphalt is ≤40 mesh; the average particle size of nano-silicon powder The particle size is 50nm.

[0036] 3. Preparation of plugging agent

[0037] Mix the calcium-based bentonite, the above-mentioned curing agent, alloy fiber, expansion agent and the above-mentioned filler uniformly according to the mass ratio of 4:45:1:5:41 to prepare the plugging agent; wherein, the alloy fiber is made of silica, Ac...

Embodiment 3

[0041] 1. Preparation of curing agent

[0042] Mix blast furnace slag, gypsum, and silicate fiber in a mass ratio of 22:1:2, then dry and grind at a drying temperature of 90°C and a drying time of 24 hours to obtain a curing agent; among them, silicate The fiber is made of aluminum silicate fiber, sepiolite mineral fiber and asbestos wool in a mass ratio of 1:1:1.

[0043] 2. Preparation of filler

[0044] Calcium carbonate, asphalt, and nano-silicon powder are mixed in a mass ratio of 10:3:3 to obtain a filler; the particle size of calcium carbonate is 1250 mesh; the particle size of asphalt is ≤40 mesh; the average particle size of nano-silicon powder The particle size is 80nm.

[0045] 3. Preparation of plugging agent

[0046] Mix sodium-based bentonite, the above-mentioned curing agent, alloy fiber, expansion agent and the above-mentioned filler according to the mass ratio of 3:40:1:7:48 to prepare a plugging agent; wherein, the alloy fiber is made of silica, Activated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com