Patents

Literature

166 results about "Powder mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A powder mill was a mill where gunpowder is made from sulfur, saltpeter and charcoal.

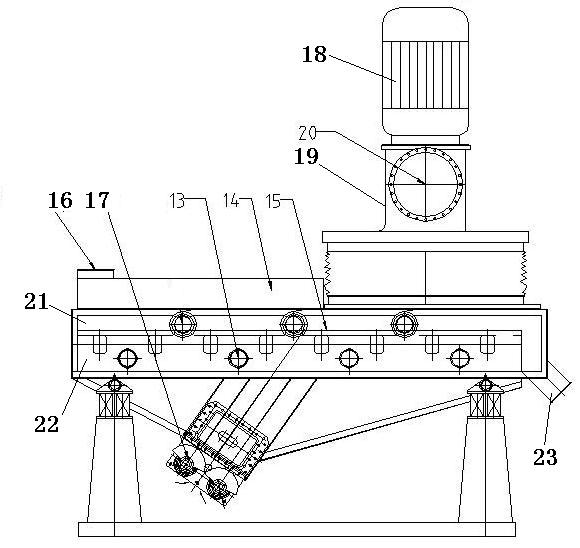

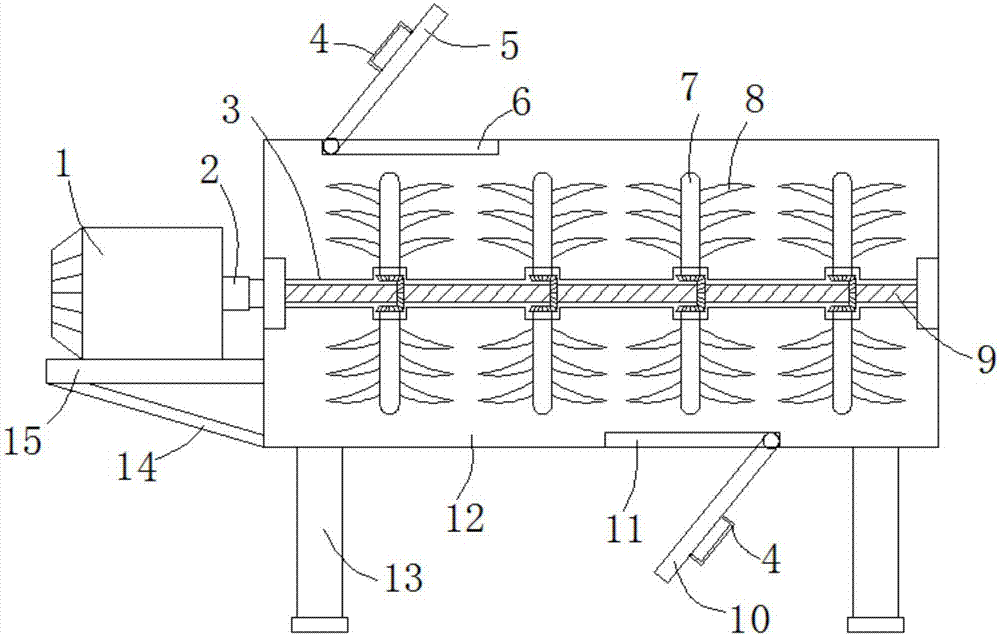

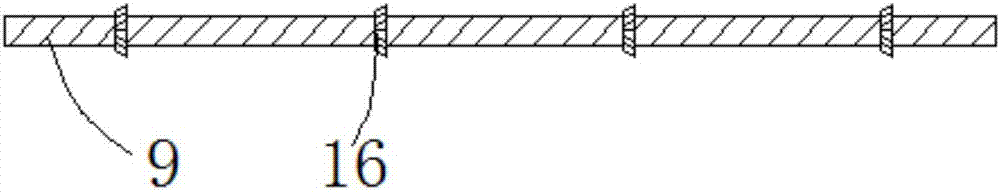

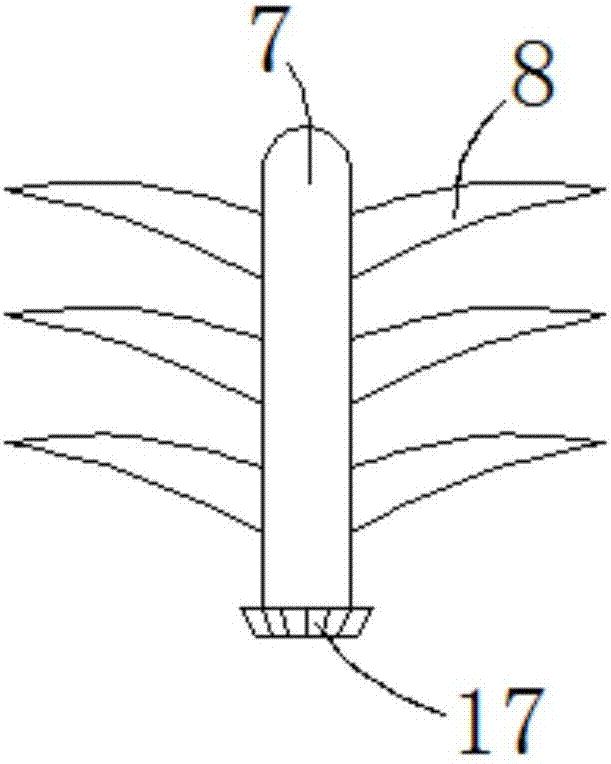

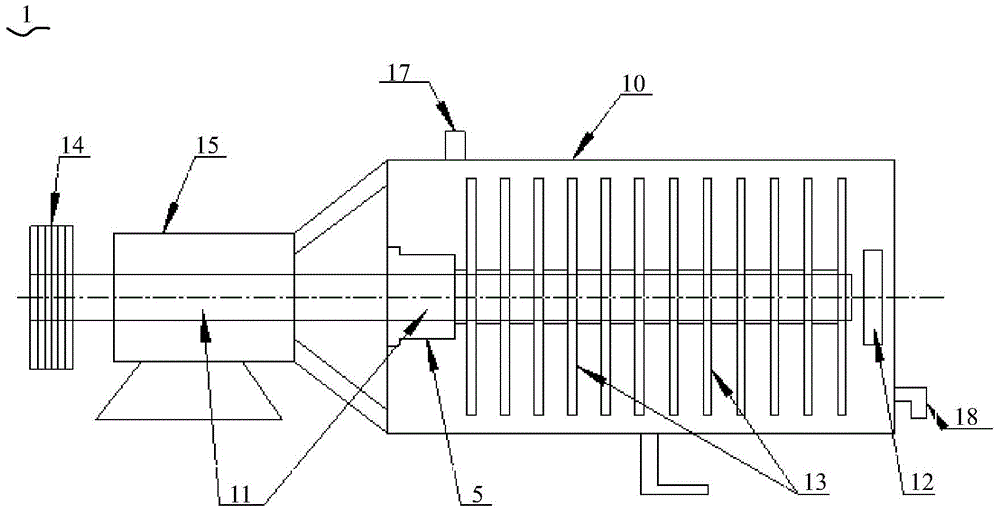

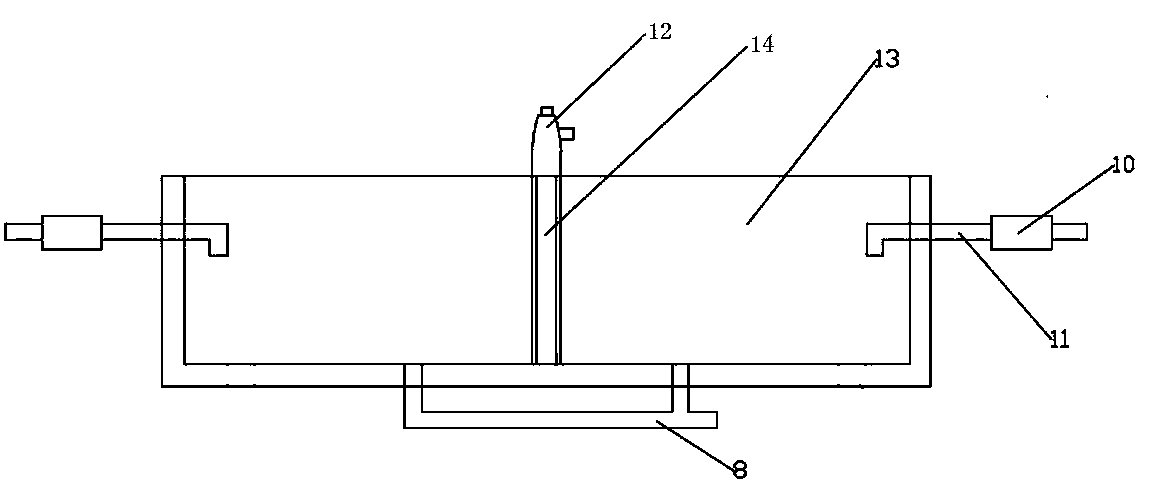

Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

ActiveCN107694135ASolve the problem of hanging on the wallSolve the problem of dry millingEvaporator accessoriesGrain treatmentsImpellerEngineering

The invention provides a Yunjie mill. The Yunjie mill adopts a Yunjie mill main engine composed of a shell body, a rotor with a powder mill and a grading function and an inner circulating pipe, so that materials are pulverized and dried at the same time in a high-speed circulating flowing process in an inner circulating channel composed of an inner circulating pipe, a pulverizing impeller, a spacebetween the pulverizing impeller and an inner wall of a barrel body and the like; a wall remaining problem of the inner circulating channel is solved by utilizing an impact effect of a high-speed material flow; the wall remaining problem of an outer circulating channel is solved by controlling the moisture content of materials, discharged by the main engine, through a grading impeller; the defects of equipment in the inventive patent 2015110139212 are overcome and a method and a product of the inventive patent 2015110139212 are economically realized; the invention provides an application method of the Yunjie mill, so that the drying and pulverizing problem of high-moisture and high-viscosity materials including vegetable materials, meat, liquid materials and the like is solved; a solutionwith good economical efficiency is provided for processing feed and preparing a medicine which takes a volatile component as a functional component.

Owner:KUNMING TEKANG TECH CO LTD

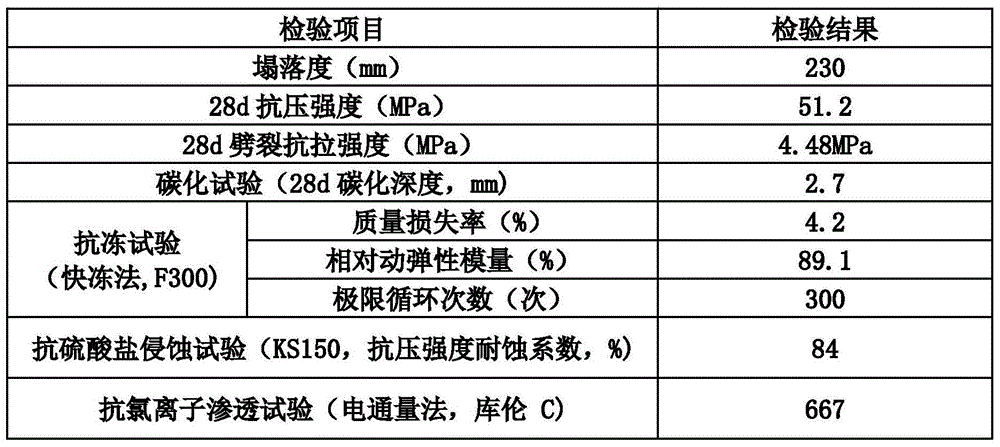

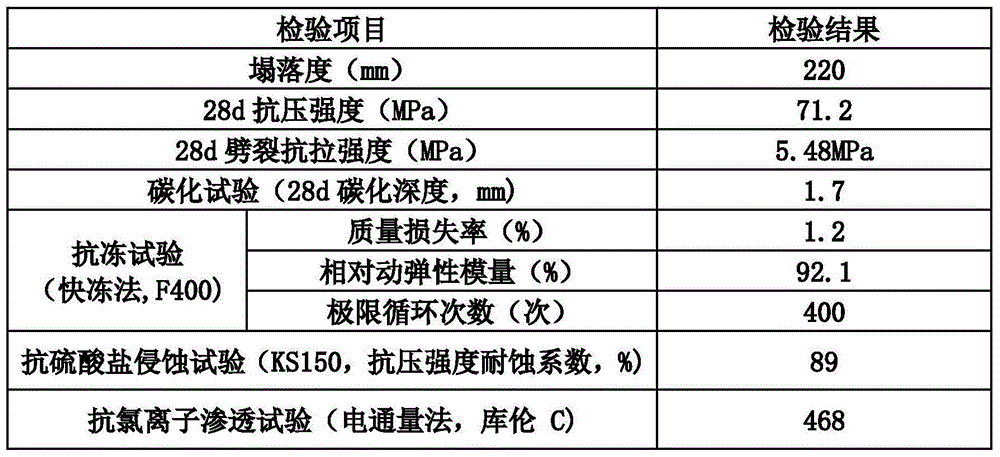

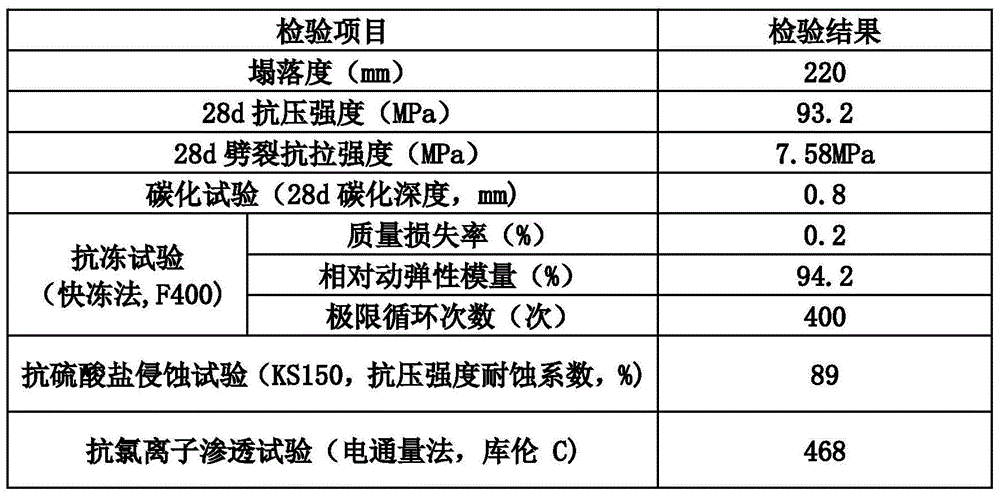

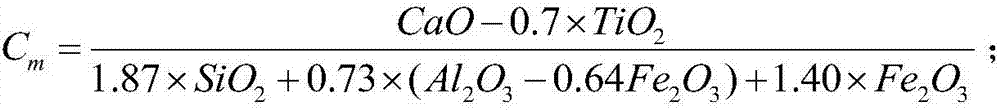

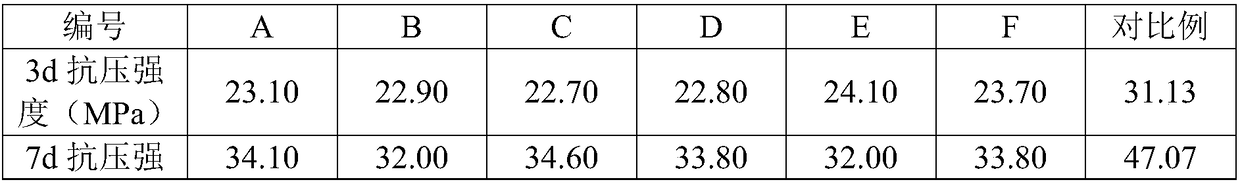

Method for preparing high-class concrete admixture with composite powder of steel slag and mineral slag

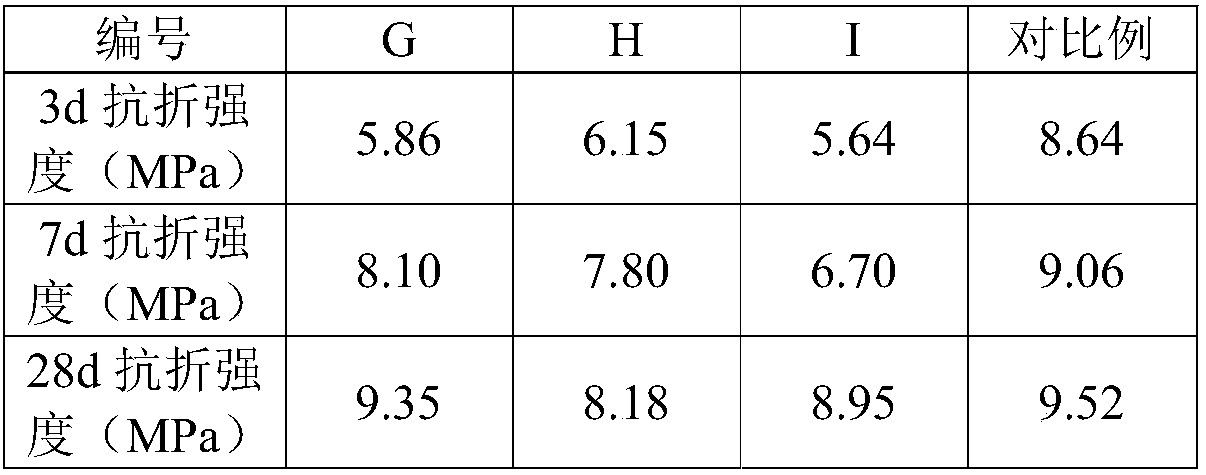

The invention discloses a method for preparing a high-class concrete admixture with composite powder of steel slag and mineral slag and belongs to the fields of solid waste resource utilization and building materials. A novel crushing machine with a high-efficiency deironing function, a vertical mill with a high-efficiency circulation deironing function or a rolling mill with the high-efficiency circulation deironing function, and a tubular mill with the high-efficiency circulation deironing function are connected in three stages in series, so that the powder mill equipment can take the synergistic and real-time circulation deironing and low-energy-consumption low-cost superfine milling in the granulated blast-furnace slag and steel slag powder milling process are achieved. In the product, steel slag micro powder accounts for 20-50%, the mineral slag micro powder accounts for 35-65%, the flue gas desulfurization gypsum micro powder accounts for 5-15%, and the specific surface area of the product is 630-750m<2> / kg. Due to the synergetic stimulation effect of the granulated blast-furnace slag micro powder, the steel slag micro powder and the flue gas desulfurization gypsum, the ratio of the admixture in a concrete gel material can be up to 60-100%, and ordinary-strength and high-property concrete, high-strength and high-property concrete and super-high strength and high-property concrete with C40-C100 can be prepared. By adopting the method, the production of high-property concrete is greatly improved, the energy is saved, the emission is reduced, and the cost is lowered.

Owner:河北科晖环境资源有限公司

Novel technique for producing concrete by using hygroscopic state sewage sludge waste slag B grade mixture material

The invention relates to a new technique by adopting two-stage ingredients of wet mud and slag to produce cement. The technique comprises the steps as follows: wet industrial waste residue or sludge at sewage of the city or water treatment sewage are adopted as raw materials after filter-press, or centrifugal dewatering or drying, two-stage dry-wet matching with the material through one-stage matching powder milling is performed, a material stick or a material ball is produced after being mixed equably, and the material stick or the material ball enters into the cement kiln to burn into clinker after being dried by waste heat. The invention has simple process, good capability of large drying and powder milling energy consumption conservation, great adoption of mud waste residue and distinct effects in reducing CO2, water resource and natural mineral resource conservation, energy conservation and environmental protection.

Owner:尹小林

Production process of steel slag micro-powder

InactiveCN102168155ASimple production processLess investmentRecycling and recovery technologiesProcess efficiency improvementIron powderSlag

The invention relates to a production process of steel slag micro-powder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and particle size of 0-20mm generated after crushing and magnetic separation of steel slag to enter a mill for powder milling, conveying obtained fine powder into a vibration drying and powder selecting machine for powder selection, enabling a micro-powder finished product to be discharged from an air outlet of the vibration drying and powder selecting machine and then enter a cloth bag dust collector for collection, then sending the micro-powder finished product into a finished product cabin, enabling the residual coarse powder to be discharged from a discharge port of the vibration drying and powder selecting machine, performing magnetic separation via a magnetic separation machine for removing iron powder, and then returning to the mill to perform the powder milling together with the wet steel slag powder. The production process has the benefits of shortening the process flow and reducing equipment investment. The closed loop circulation is adopted, the dust is little, and energy conservation and environment friendliness are realized.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

Production method of red mud filler

ActiveCN103483880AIncrease profitReduce pollutionPigment treatment with organosilicon compoundsPigment physical treatmentRed mudSlurry

The invention discloses a production method of red mud filler. The method includes the steps of: (1) wet levigation: sending a coarse red mud slurry from a red mud grading process into a grinding machine, conducting wet levigation to obtain a fine red mud slurry; (2) dehydration: bringing the fine red mud slurry into plate-and-frame filter press to press it into a red mud filter cake with a water content of less than 25%; (3) drying: sending the filter cake into a flash dryer to carry out crushing and drying so as to obtain powder with a water content of less than 0.5%; (4) grinding: subjecting the powder to superfine grinding in an impact type superfine powder mill to obtain 1250-6000 mesh superfine powder; (5) grading: grading the superfine ground material by a grader to obtain fine powder; and (6) modification: putting the fine powder into a modification machine, adding a modifier by spraying, and carrying out heat preservation reaction for 20-30min. The method provided in the invention realizes integration of material superfine processing and surface modification, simplifies the process, and no leakage exists in the production process. The method has the advantages of less environmental pollution, fast speed, high efficiency, environmental protection and energy saving, and no secondary pollution.

Owner:山东绿生洁环保科技有限公司

Method for preparing heat-resistant glass

The invention discloses a method for preparing heat-resistant glass, and relates to the technical field of building materials. The method includes the following steps that A, limestone, fluorite and graphite are ground into powder by a powder mill, and limestone powder, fluorite powder and graphite powder are obtained; B, the limestone powder, the fluorite powder, the graphite powder, quartz sand, sodium nitrate, high borosilicate, steel fibers, cosolvents and binding agents are mixed and stirred to be even, and a mixture is obtained; C, the mixture is melted at the high temperature, and mixing melt is obtained; D, the mixing melt enters a calender and is calendered into a glass blank; E, the glass blank is cooled to be at the temperature of 25 DEG C to 30 DEG C, and the heat-resistant glass is prepared. Compared with the prior art, the method has the advantages of being low in cost, high in strength and good in heat-resistant effect.

Owner:广西丛欣实业有限公司

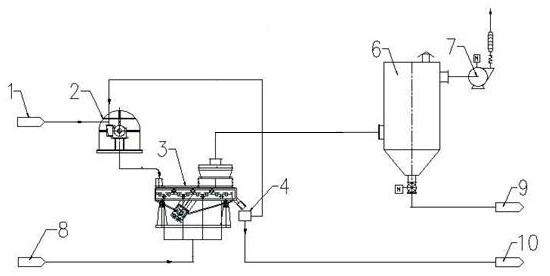

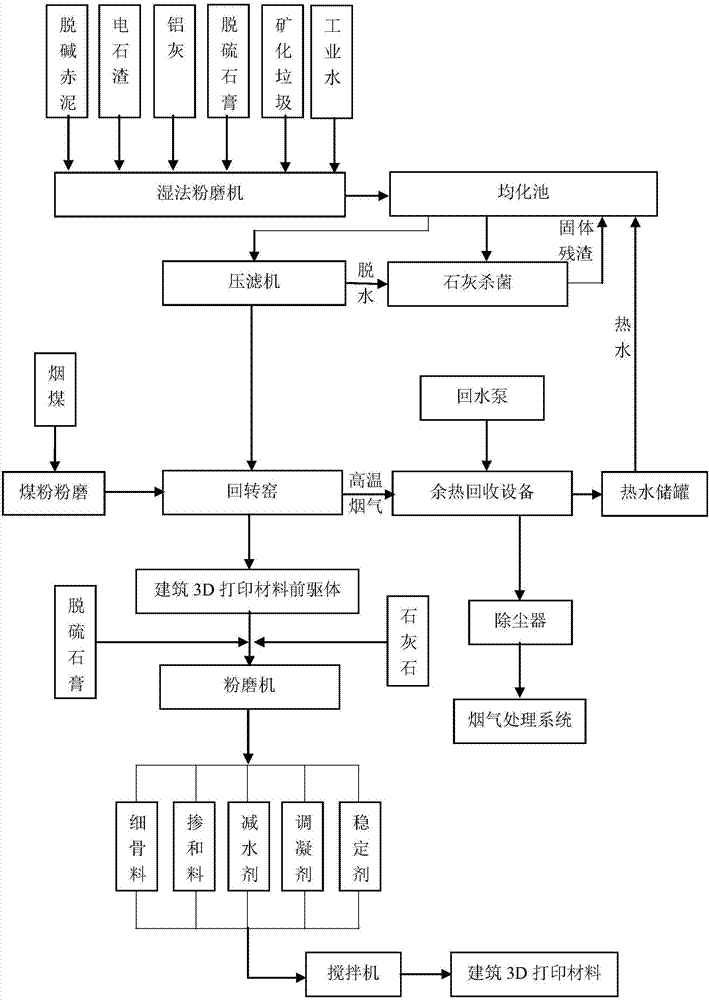

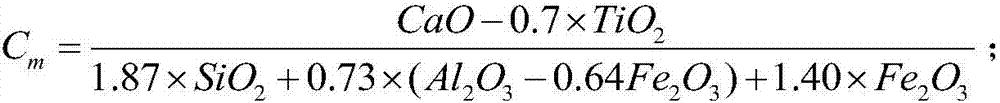

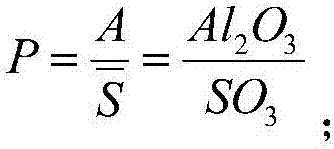

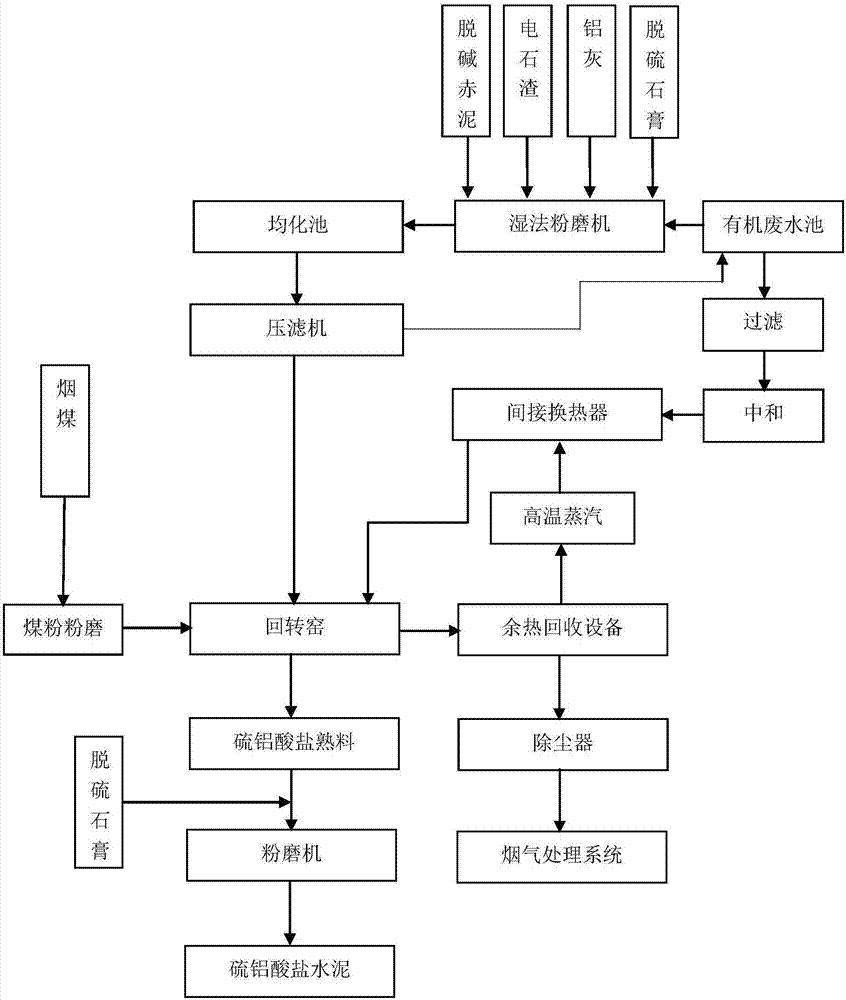

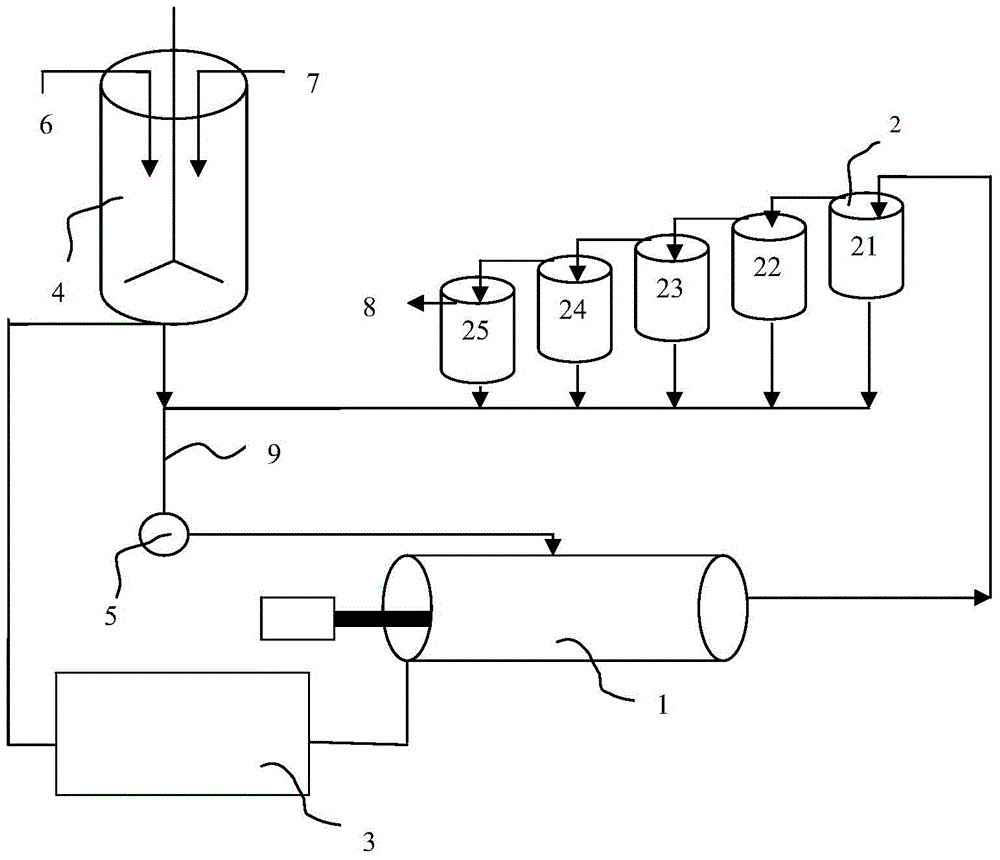

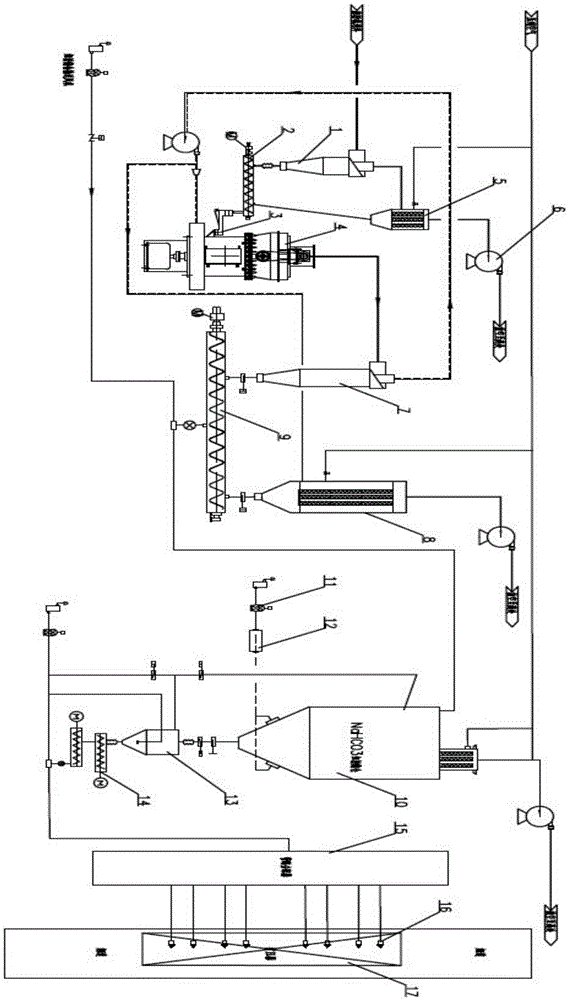

System and method for preparing building 3D printing material by using municipal waste and industrial solid waste

ActiveCN106904924ALow costReduce energy consumptionAdditive manufacturing apparatusSolid waste managementDry weightRed mud

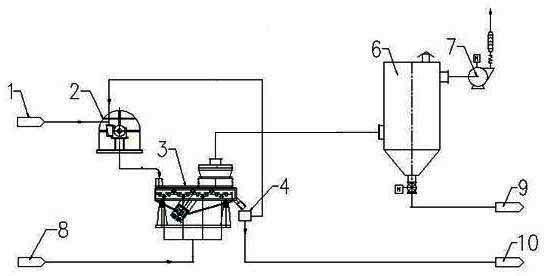

The present invention discloses a system and a method for preparing a building 3D printing material by using municipal waste and industrial solid waste. The system comprises a homogenization pool, a wet powder mill, a filter press, a rotary kiln, a powder mill and a hot water storage tank. According to the method, wet sludge produced from an urban sewage treatment plant is directly mixed with mineralized garbage, red mud, desulfuration gypsum, carbide slag and industrial water to form a mixed solution without dewatering, a dry weight ratio of the wet sludge to the mineralized garbage to the red mud to the desulfuration gypsum to the carbide slag in the mixed solution is 5-10:5-10:15-30:10-20:30-60, the solid-liquid ratio in the mixed solution is maintained at 1:3-1:4, the mixed solution is sequentially subjected to wet milling, homogenization treatment and alkali removing, the homogenization treatment temperature is 60-70 DEG C, the homogenized material is subjected to mechanical pressure filtration dehydration, and the filtered material is subjected to high temperature calcination to obtain the building 3D printing material precursor.

Owner:SHANDONG UNIV

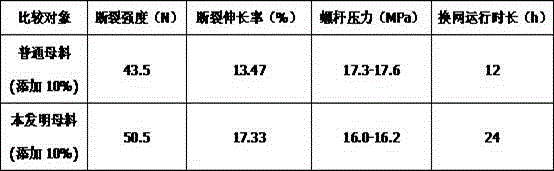

Mechanism bamboo charcoal processing apparatus

InactiveUS20200147832A1Uniform particle sizeEnsure qualityCane mechanical workingWood working apparatusCarbonizationEngineering

The invention discloses a mechanism bamboo charcoal processing apparatus, which includes a machine body. A rotating rod is rotatably connected to the top surface of the machine body. The rotating rod is provided with an oil groove, and a sliding plate is slidably connected to the oil groove. The fixed block is rotatably connected. The carbonized bamboo block and bamboo joint are first put into the feeding port through the feeding port, and then the power motor is turned on. This device can grind the initially carbonized bamboo block and bamboo joint into a uniform particle. Compared with ordinary machines, the bamboo charcoal powder milled by this device is screened layer by layer to ensure that the particle size of the milled bamboo charcoal powder can be uniform, thereby ensuring the quality of the later-processed charcoal. The bamboo charcoal powder and the combustion promoter are mixed uniformly, and then pressed into uniform-sized machine-made charcoal.

Owner:ZENG DI

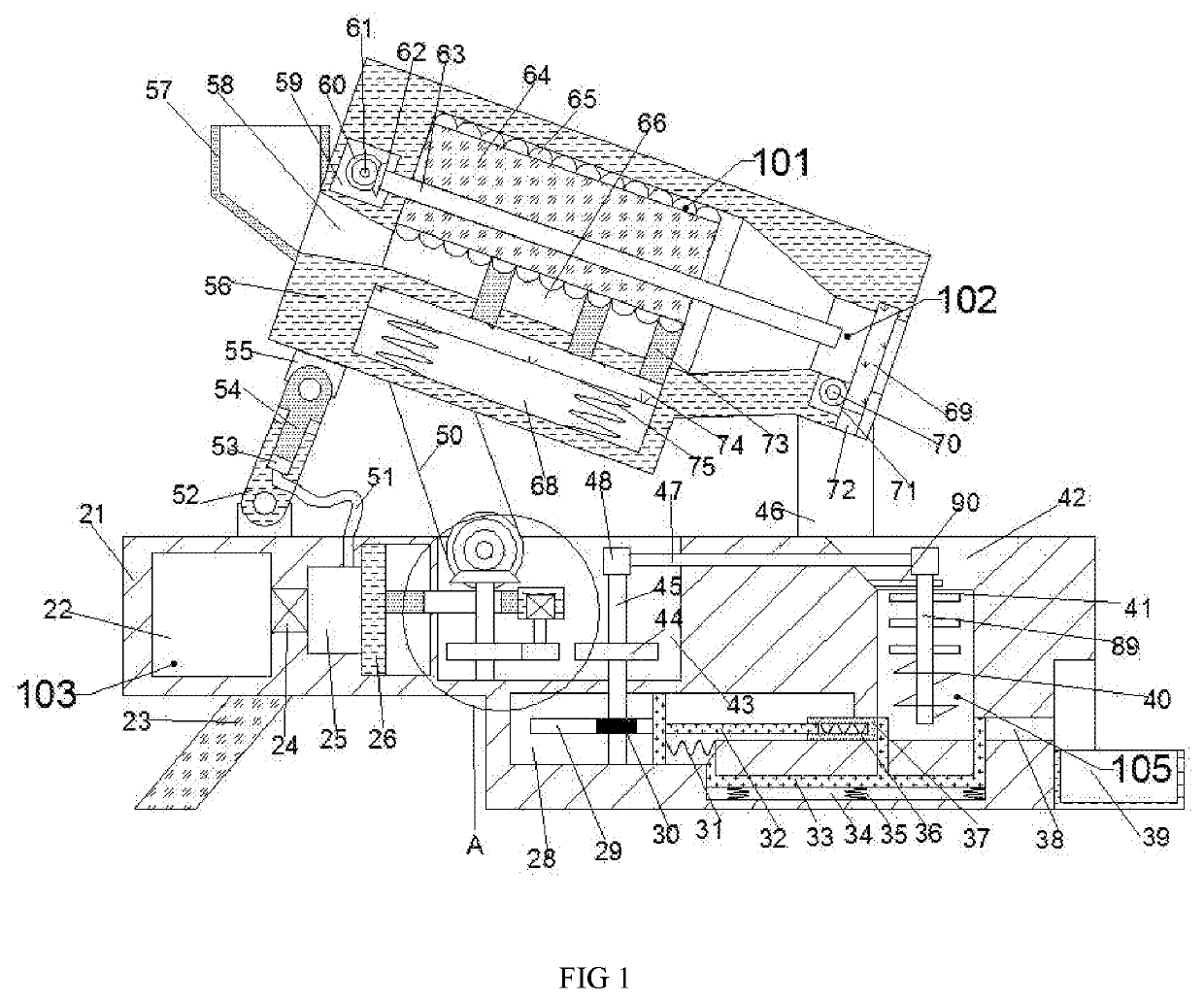

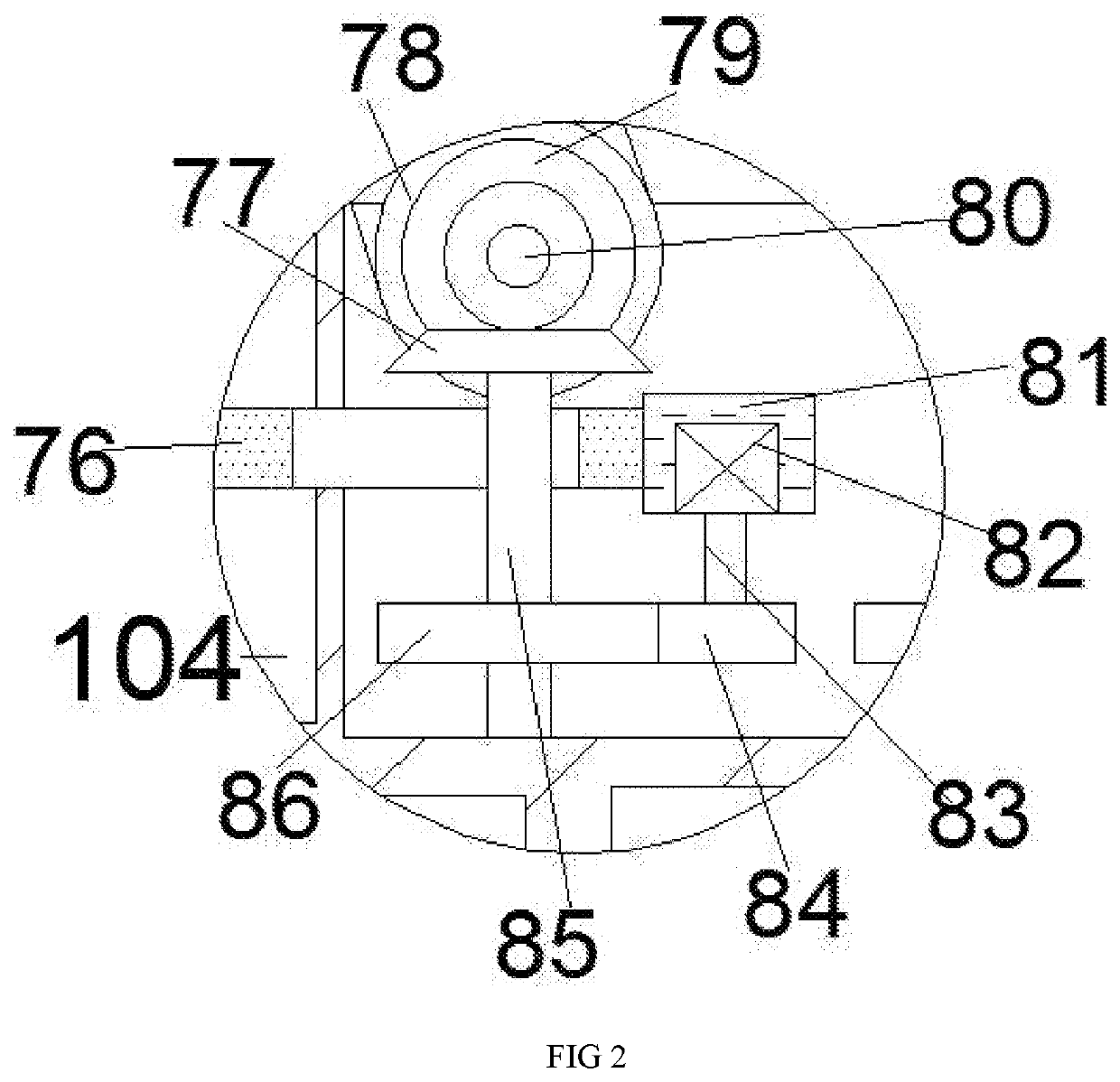

System and method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste

ActiveCN106866006ASolve the shortcomings of productionSolve the problem of difficult utilization of solid wasteClinker productionFiltrationRed mud

The invention discloses a system and a method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste. The system consists of an organic wastewater pool, a homogenizing pool, a wet powder mill, a pressure filter, a rotary kiln and an indirect heat exchanger. The method includes: mixing dealkalized red mud, carbide slag, aluminum ash, desulfurized gypsum and a part of organic wastewater to obtain a mixed solution, which has a water content of 60%-70% (mass), then conducting wet pulverizing on the mixed solution, and subjecting the wet pulverized material to homogenizing treatment so as to obtain a slurry, and performing mechanical pressure filtration dehydration to obtain a slurry, concentrating another part of organic wastewater, then sending the concentrated organic wastewater and the slurry into the rotary kiln and performing high-temperature calcination to obtain a sulphoaluminate clinker, and spraying pulverized coal into the rotary kiln during high-temperature calcination to combust organic waste in the pulverized coal and slurry and organic waste in the concentrated wastewater. The system and method realize comprehensive utilization of industrial solid waste and organic wastewater and zero-pollution emission.

Owner:SHANDONG UNIV

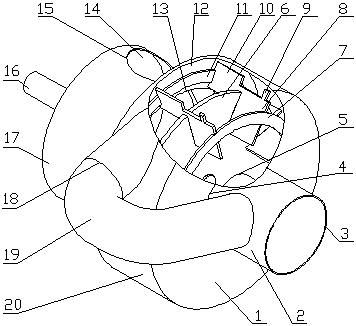

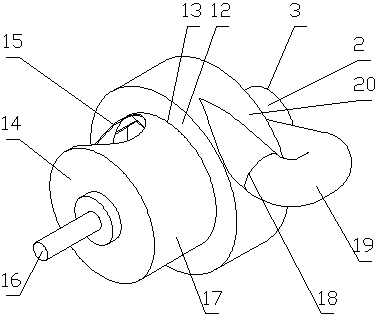

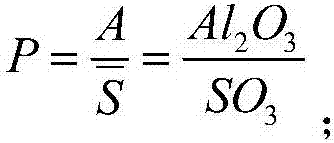

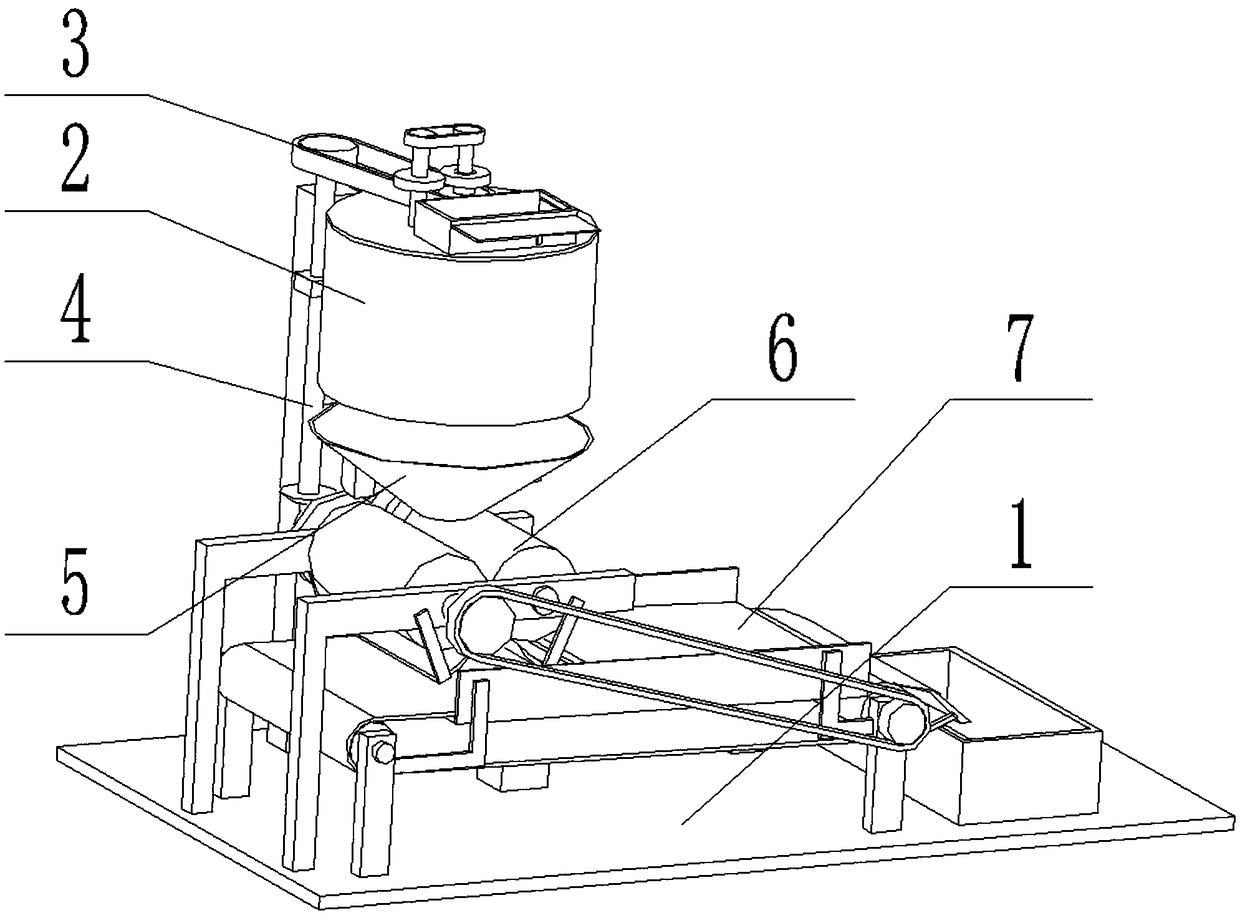

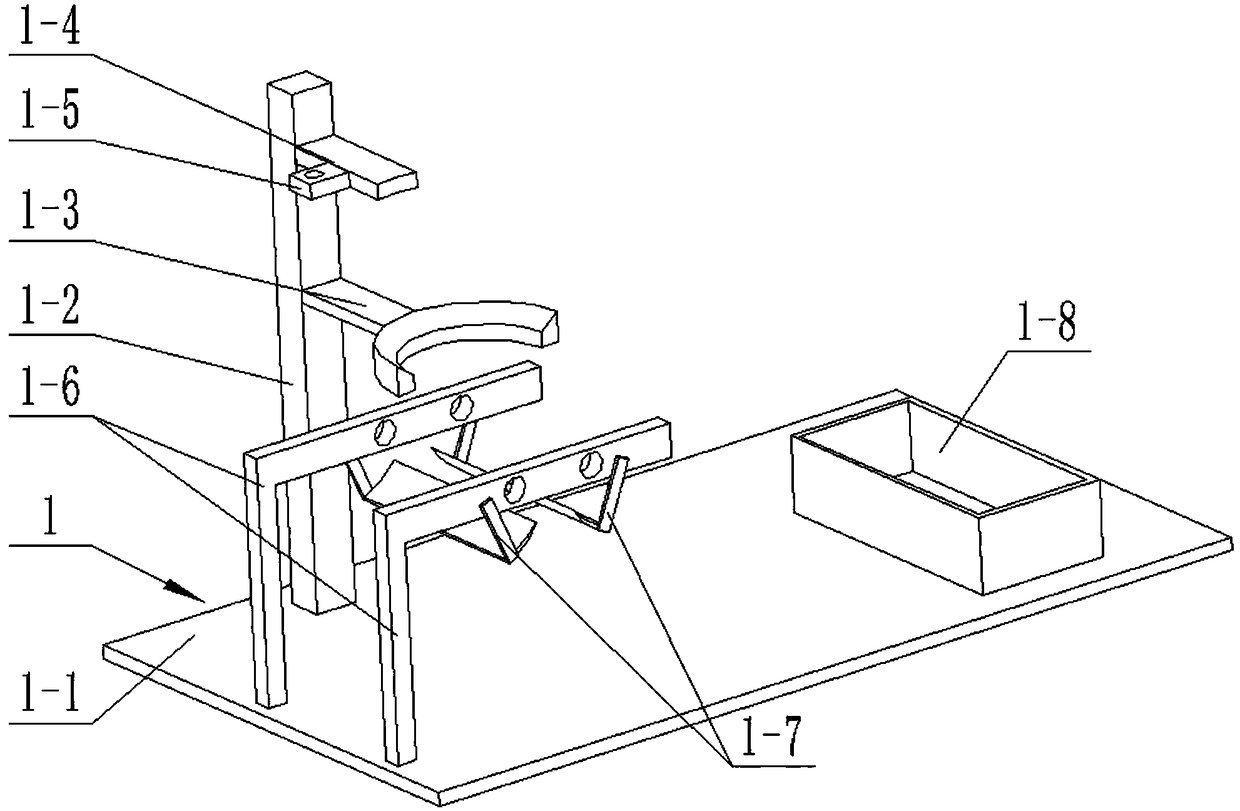

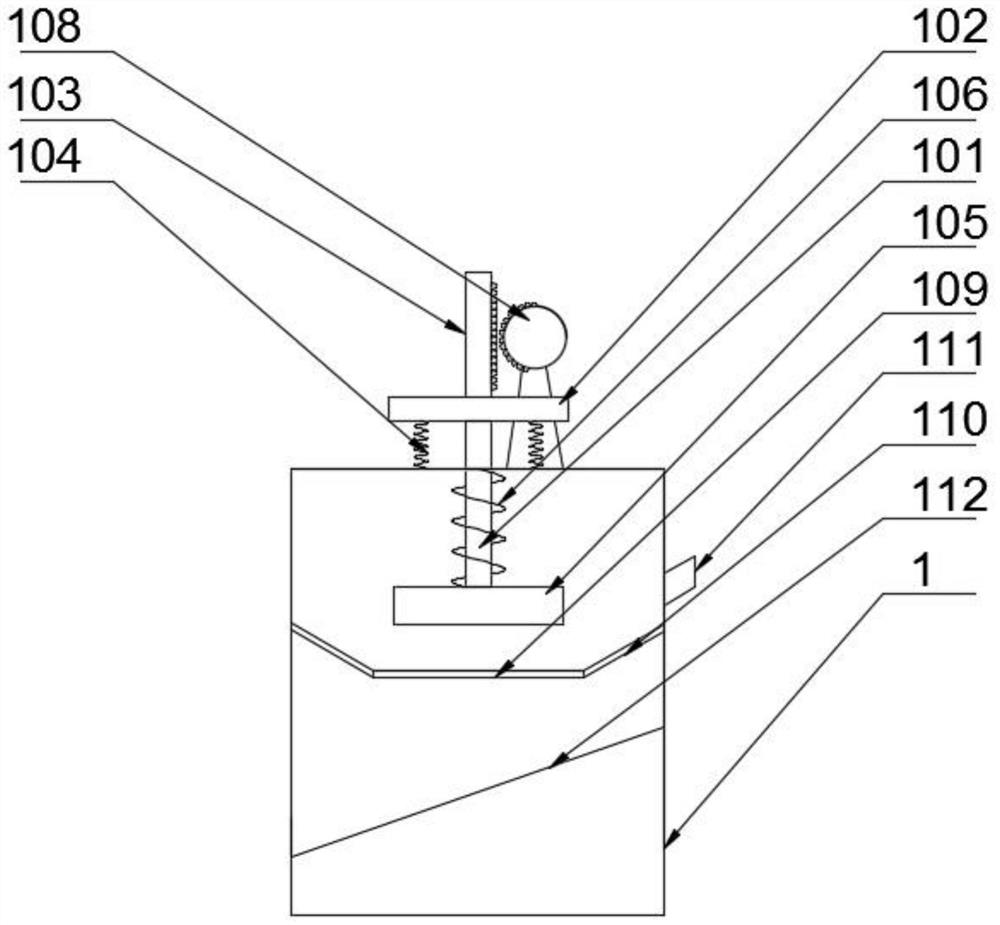

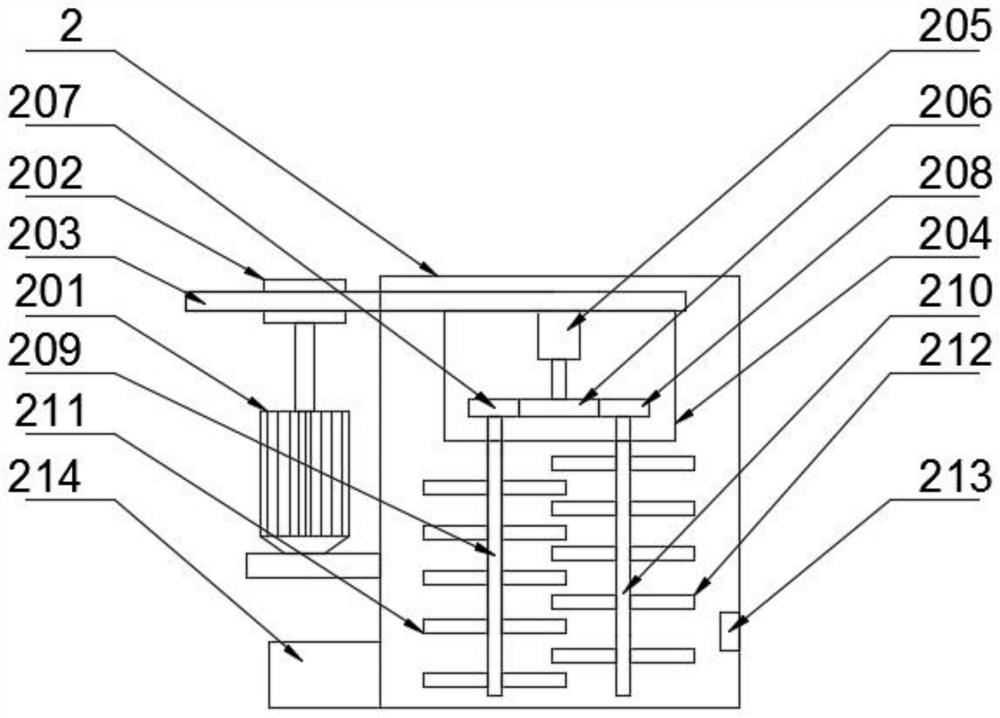

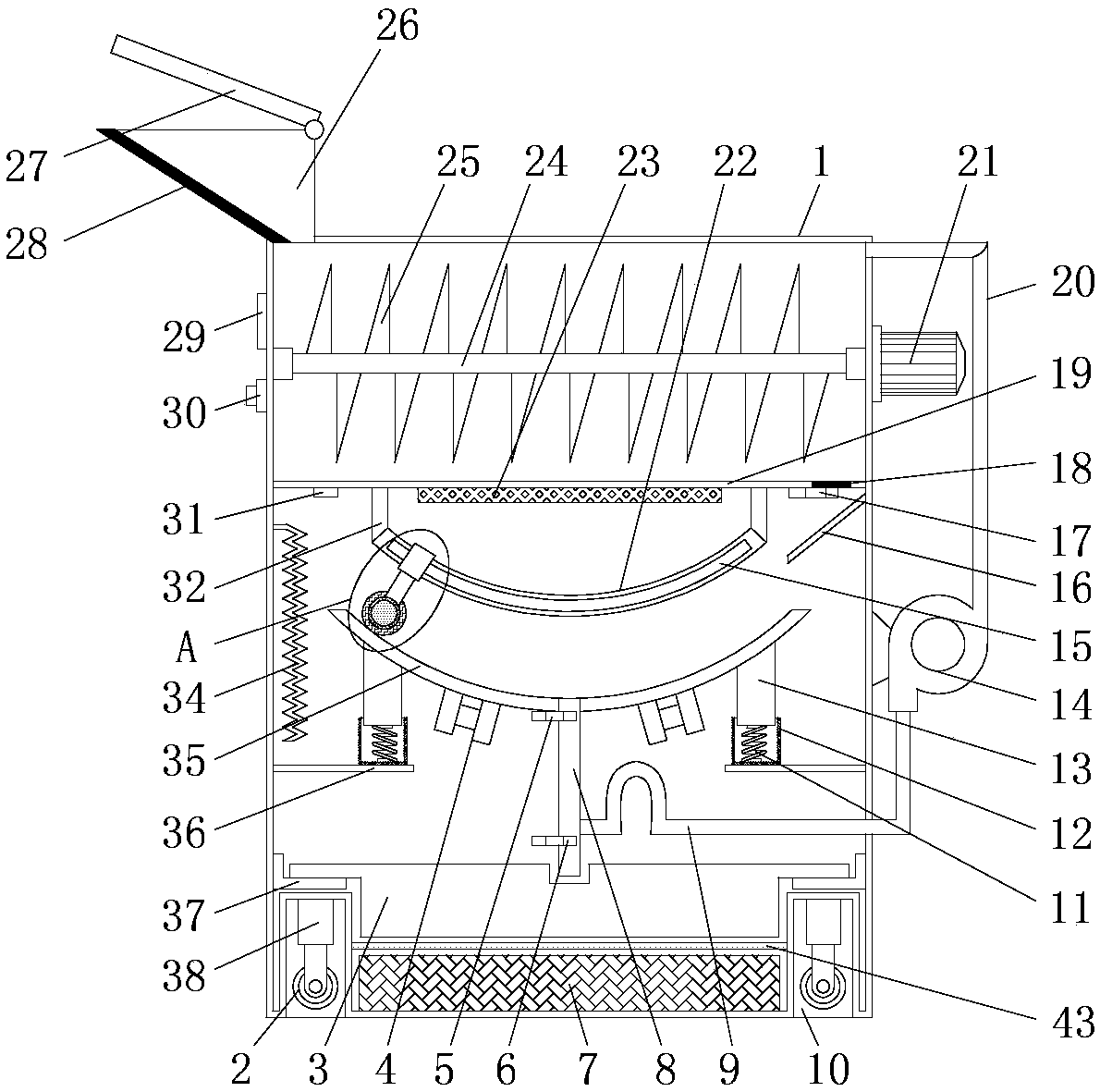

Ceramic mechanical powder mill

The invention relates to the field of ceramic powder milling devices, in particular to a ceramic mechanical powder mill. The ceramic mechanical powder mill comprises a base, a grinding cylinder, a grinding device, a transmission shaft, a collecting bucket and milling rollers. The base comprises a bottom plate, a supporting rod, a collecting bucket bracket, a grinding cylinder frame, a transmissionshaft frame and two roller brackets. The supporting rod is fixedly connected to one side of the bottom plate; the collecting bucket bracket is fixedly connected to the middle end of the supporting rod; the grinding cylinder frame is fixedly connected to the top end of the supporting rod; the transmission shaft frame is fixedly connected to the side end of the grinding cylinder frame; the two roller brackets are symmetrically disposed on both sides of the rear end of the bottom plate; the grinding cylinder comprises a grinding cylinder body and a feed inlet, and the feed inlet is connected andcommunicates with one side of the top surface of the grinding cylinder body; and the grinding cylinder body is fixedly connected to the grinding cylinder frame. The ceramic mechanical powder mill canavoid the limitation of single time single-way grinding and the difficulty of evenly grinding ceramic powder by three different ways of grinding, saves processing time, and improves production efficiency.

Owner:景德镇市珏昊瓷业有限公司

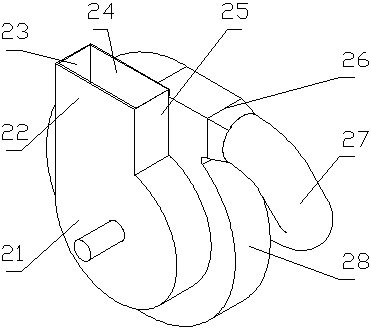

Ultra-fine pulverizing machine for pressed powder

InactiveCN106944213ASmash thoroughlyImprove crushing efficiencyGrain treatmentsGear wheelEngineering

The invention discloses a powder cake superfine pulverizer, which comprises a pulverizing cylinder, a stirring sleeve and a fixed shaft. The left part of the top surface of the pulverizing cylinder is provided with a feeding port, and the right part of the bottom surface of the pulverizing cylinder is provided with a discharge port. , the stirring sleeve is rotatably connected to the middle part of the left and right end faces of the inner chamber of the crushing cylinder, the side wall of the stirring sleeve is rotatably inserted with stirring teeth, the stirring teeth are fixedly connected with a first bevel gear, and the side walls of the stirring teeth are installed There is a blade, the fixed shaft runs through the inner cavity of the stirring sleeve, and is fixedly welded to the middle of the left and right end faces of the inner cavity of the crushing tube respectively, and the second bevel gear is installed through the fixed shaft, and the second bevel gear is connected with the first bevel gear Mesh with each other, the top surface of the support plate is fixed with a stepper motor, and the stepper motor is fixedly connected with the left end surface of the stirring sleeve through a power shaft. The invention relates to a powder cake superfine pulverizer, which realizes three-dimensional stirring and pulverization synchronously, complete pulverization, and improves pulverization efficiency.

Owner:WUXI JIAN AUTOMATION TECH CO LTD

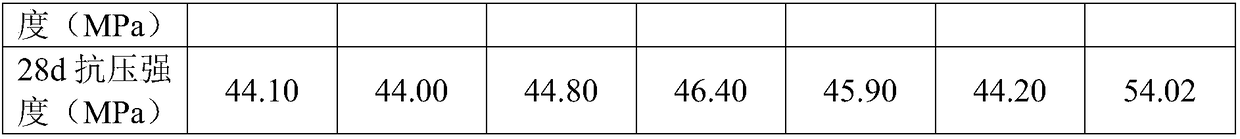

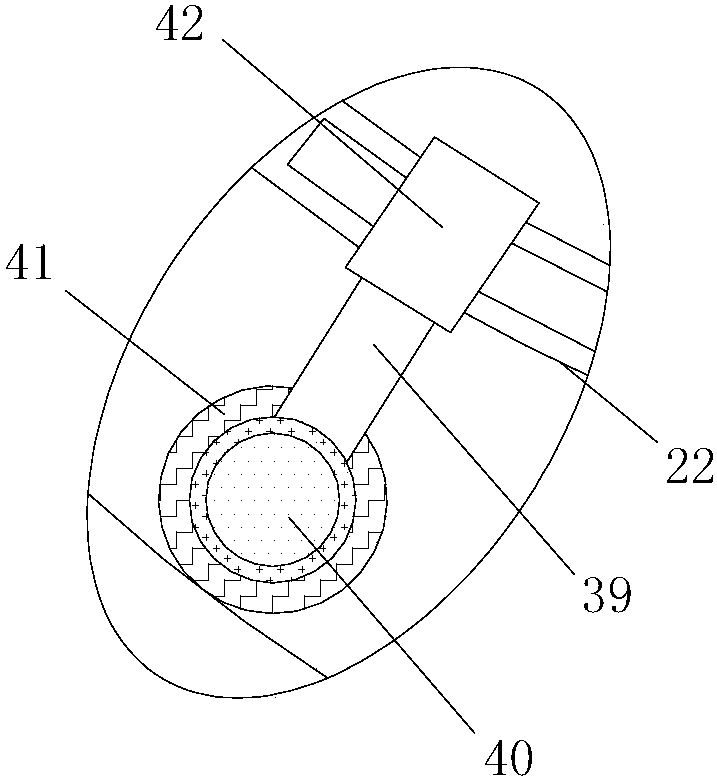

Nanometer bead milling system and nanocrystalline microsphere preparation method

ActiveCN104971801AIncrease apparent surface areaIncrease productionGrain treatmentsImpellerMicrosphere

The invention discloses a nanometer bead milling system and a nanocrystalline microsphere preparation method. The nanometer bead milling system comprises a bead mill, a plurality of centrifugal machines, a stirring tank and a central control unit. The bead mill comprises a milling cylinder. The milling cylinder is internally provided with a spindle. A centrifugal separation disk and stirring impellers are mounted on the spindle. The centrifugal machines are connected in sequence. Each centrifugal machine comprises an inlet, a heavy liquid outlet and a light liquid outlet. The inlet of the first centrifugal machine is connected with an outlet of the bead mill. The heavy liquid outlets of the centrifugal machines are connected with an inlet of a pump. The light liquid outlet of one centrifugal machine is connected with an inlet of a next stage of centrifugal machine. The stirring tank is used for containing slurry. An outlet of the stirring tank is connected with the inlet of the pump. An outlet of the pump is connected with an inlet of the bead mill. The central control unit is connected with the bead mill, the centrifugal machines, the stirring tank and the pump. The nanometer bead milling system solves the technical problems that the particle size of powder milled through an existing bead milling system cannot reach the nano-scale size, continuous charge production cannot be realized, and the output is low.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Low hydration heat copper slag based composite cementitious material and preparation method thereof

The invention provides a low hydration heat copper slag based composite cementitious material and a preparation method thereof. The low hydration heat copper slag based composite cementitious materialcomprises the following components by weight: 20-30 parts of copper slag powder; and 70-80 parts of Portland cement; with a total of 100 parts. The preparation method of the low hydration heat copperslag based composite cementitious material includes: step 1: putting copper slag in an oven for 3-4h, and setting the oven temperature at 110DEG C to obtain dried copper slag; step 2: putting the copper slag in a ball mill for powder milling for 30-120min to obtain copper slag powder with a specific surface area of 500-750m<2> / kg; step 3: by weight, adding 20-30 parts of the copper slag powder into 70-80 parts of Portland cement, and stirring the substances evenly to obtain the low hydration heat copper slag based composite cementitious material. While ensuring the quality of the cementitiousmaterial, the method improves the copper slag utilization rate, improves the environmental pollution, and reduces the energy consumption and cost of cement calcination.

Owner:JIANGXI UNIV OF TECH

Milling of energy-saving type glassed steel overglaze added with ultra-fine zro* powder body as fortifier

The invention discloses an energy-saving glass lining cover coat based on mill addition hyperfin ZrO2 powder as reinforcer, which consists of clinker clew and mill addition material, wherein the clinker clew includes 45-5% SiO2+B2O3, 7-12% Na2O+K2O, 12-16% MgO+CaO+BaO, 3. 5-6% Li2O, 1-2% CoO,6-15% ZrO2+Al2O3+TiO2; the mill addition material contains 40-60% zircon powder at 400-500 order and 3-5% suspending agent clay. The glass phase is main component of regular glass lining cover coat, which changes the structure of ceramic glaze after adding the hyperfine ZrO2 powder to harden the glass lining with more abrasion proof. The invention leads Li2O to reduce the softening point of cover coat clinker clew because the hyperfine ZrO2 powder mill addition is added into the glass lining cover coat to increase the sintering temperature, which makes the sintering temperature of cover coat nearly approach the temperature of regular glass lining cover coat.

Owner:JIANGYIN SILICON GENERAL ENAMEL

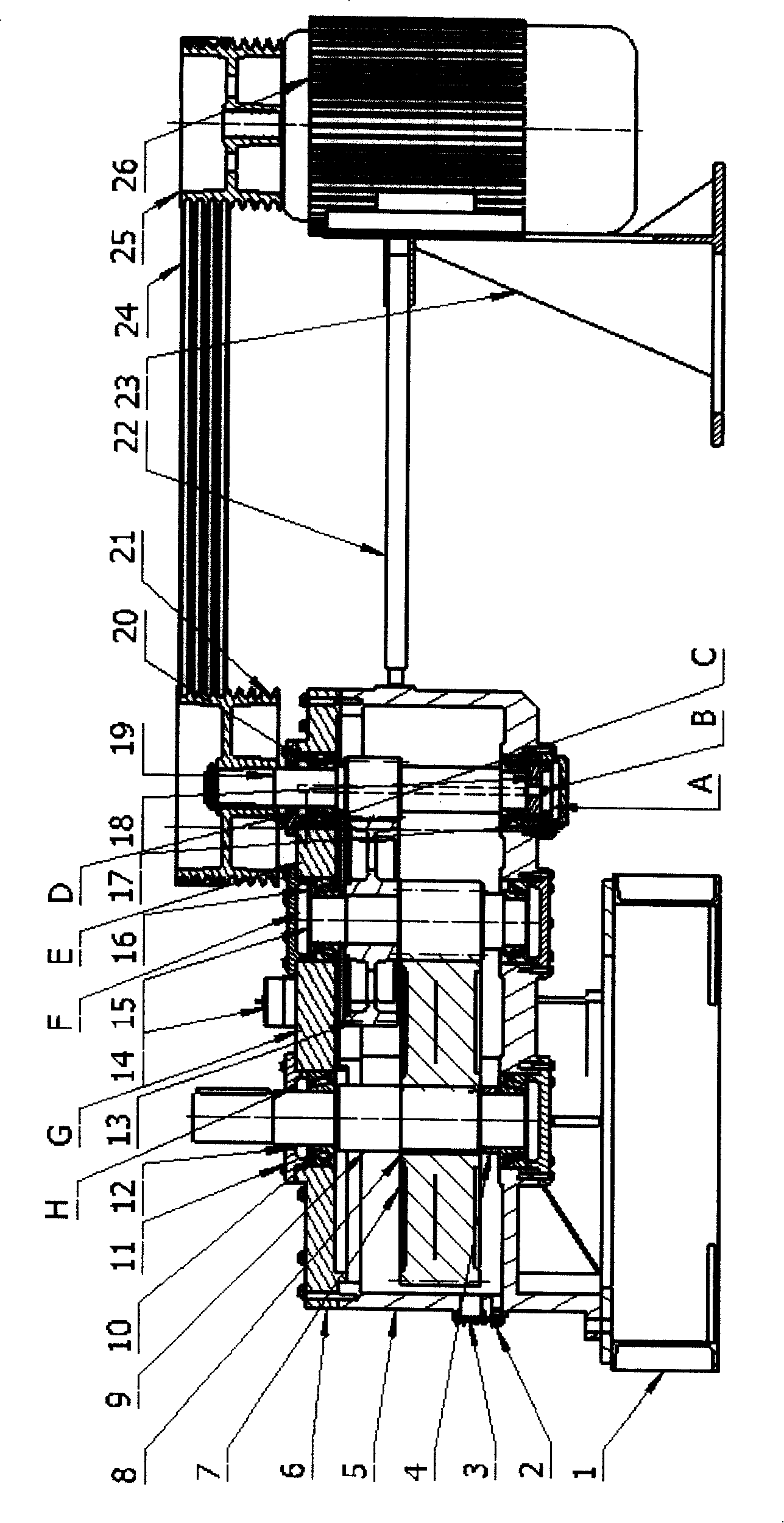

Main unit transmission device for ultra-fine pendulum powder mill

InactiveCN101195103ASmooth transmissionReduce manufacturing costGear lubrication/coolingToothed gearingsLow noiseEngineering

The invention discloses a driving device for a host machine, which is used for an ultra-fine pendulum type miller. The invention adopts a vertical shaft type reducing box, and one or two cylinder helical gears of horizontal engaging drives which are used to carry out speed reductions are installed inside the reducing box. The invention has simple structure, low cost, stable driving and low noises.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

High-speed airflow multi-stage ultra-thin powder mill

The invention relates to a kind of ultramicro fine-powder mechanical grinding apparatus, which contains motive power driving mechanism, grinding cave, recovery device of fine powder and so on. There is a turbulence disc set in the main shaft of the grinding cave in the same shaft, which is composed with rim plate and same rotating direct blade in both sides of the rim plate, and there is a wear-prevention air cushion in both sides of the turbulence disc blade. There is a rotator settled in the outset of the lay making in the grinding cave, and above the rotator there is an atmospheric pressure screen. The invention has low energy consumption, high productive output, fine product fineness, little wastage, great effective grinding function, and long service life.

Owner:任良勇

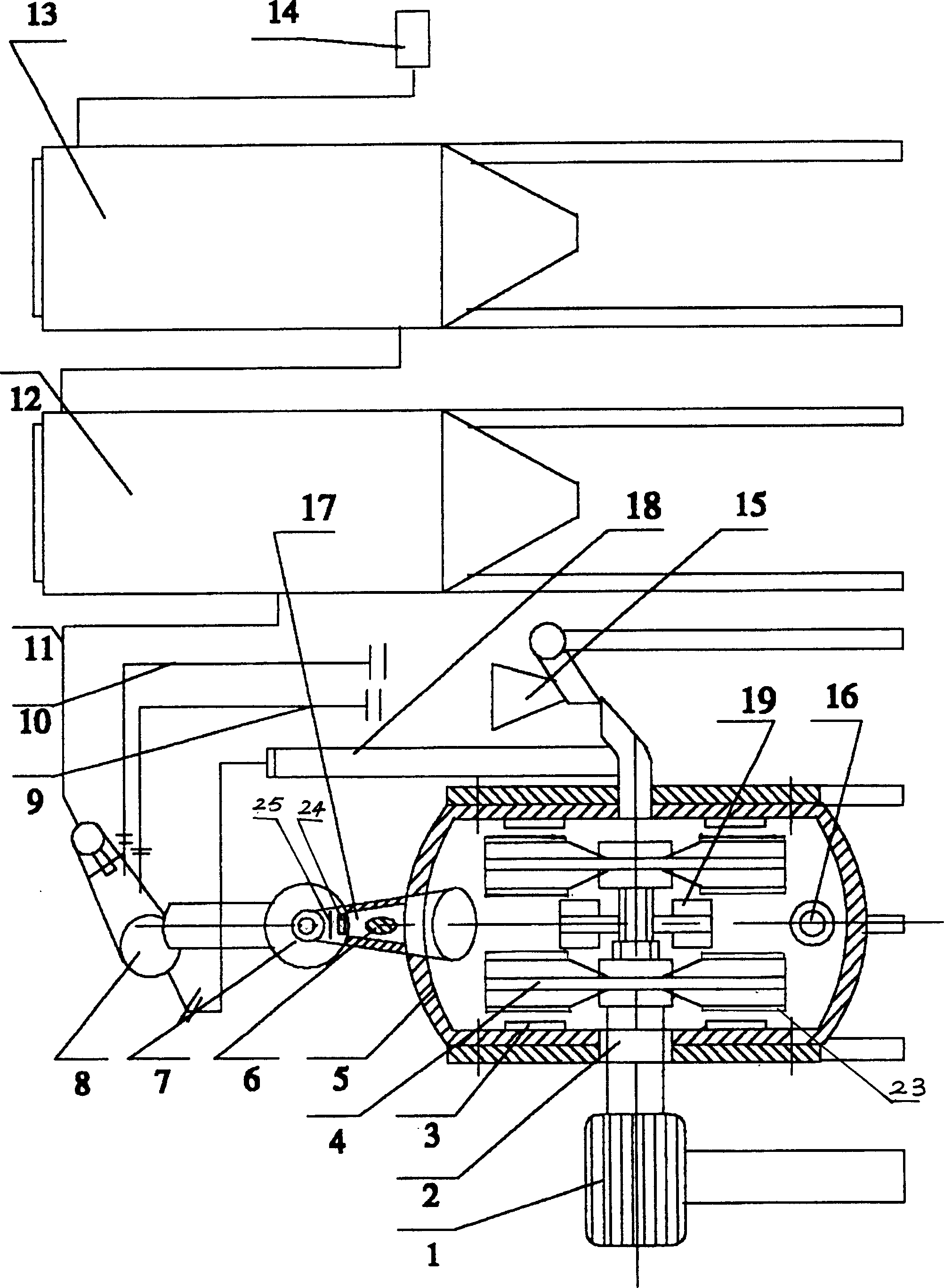

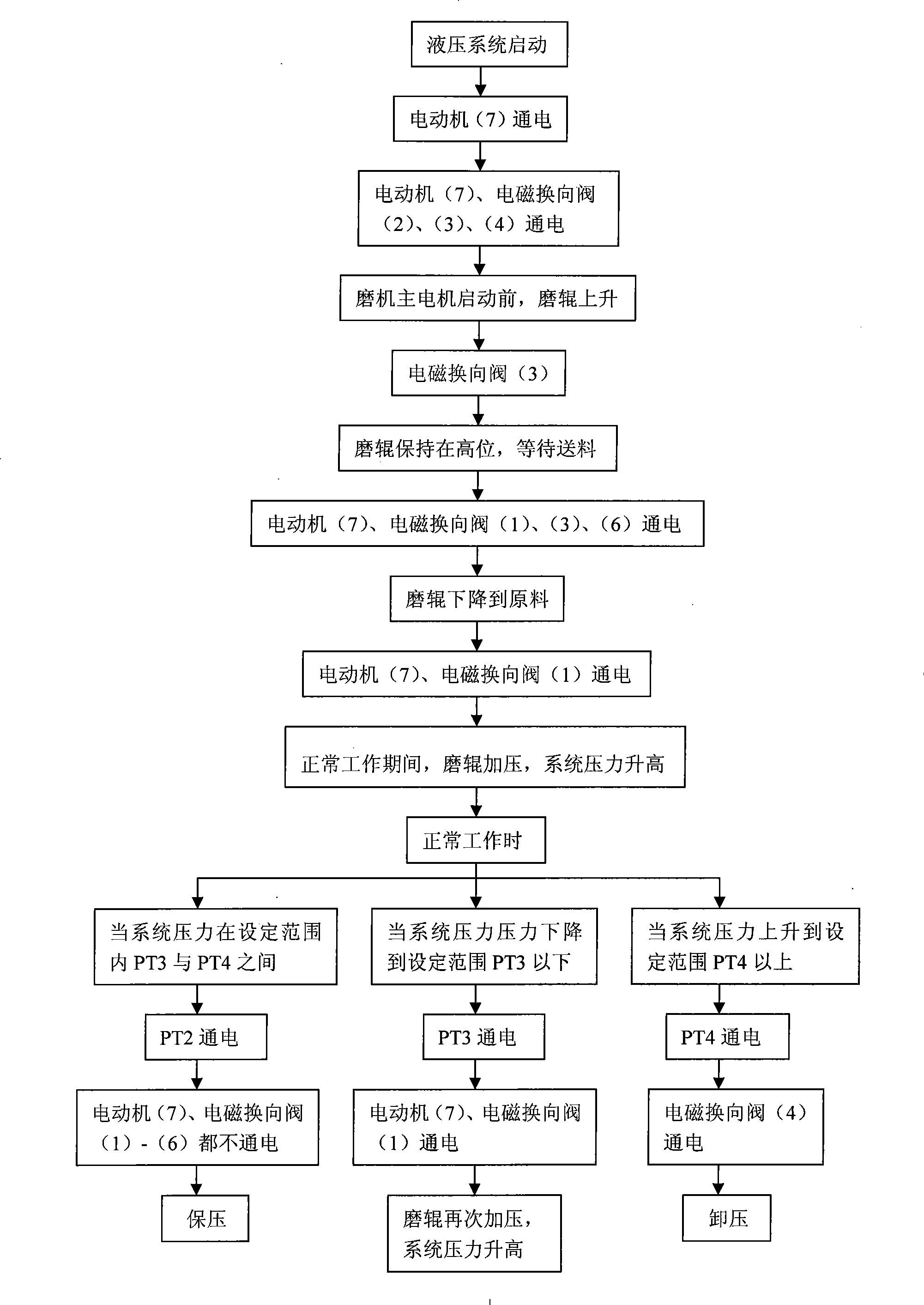

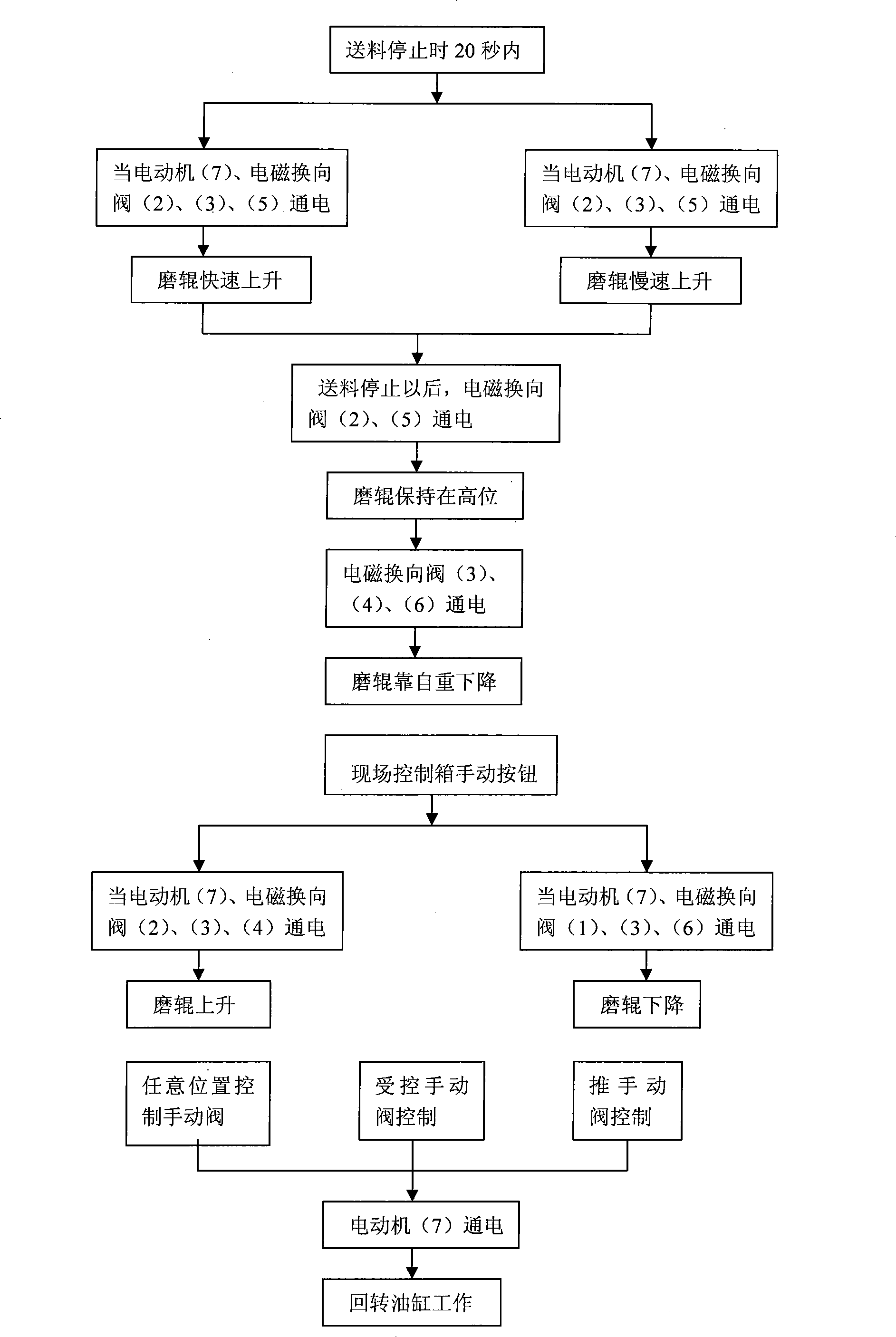

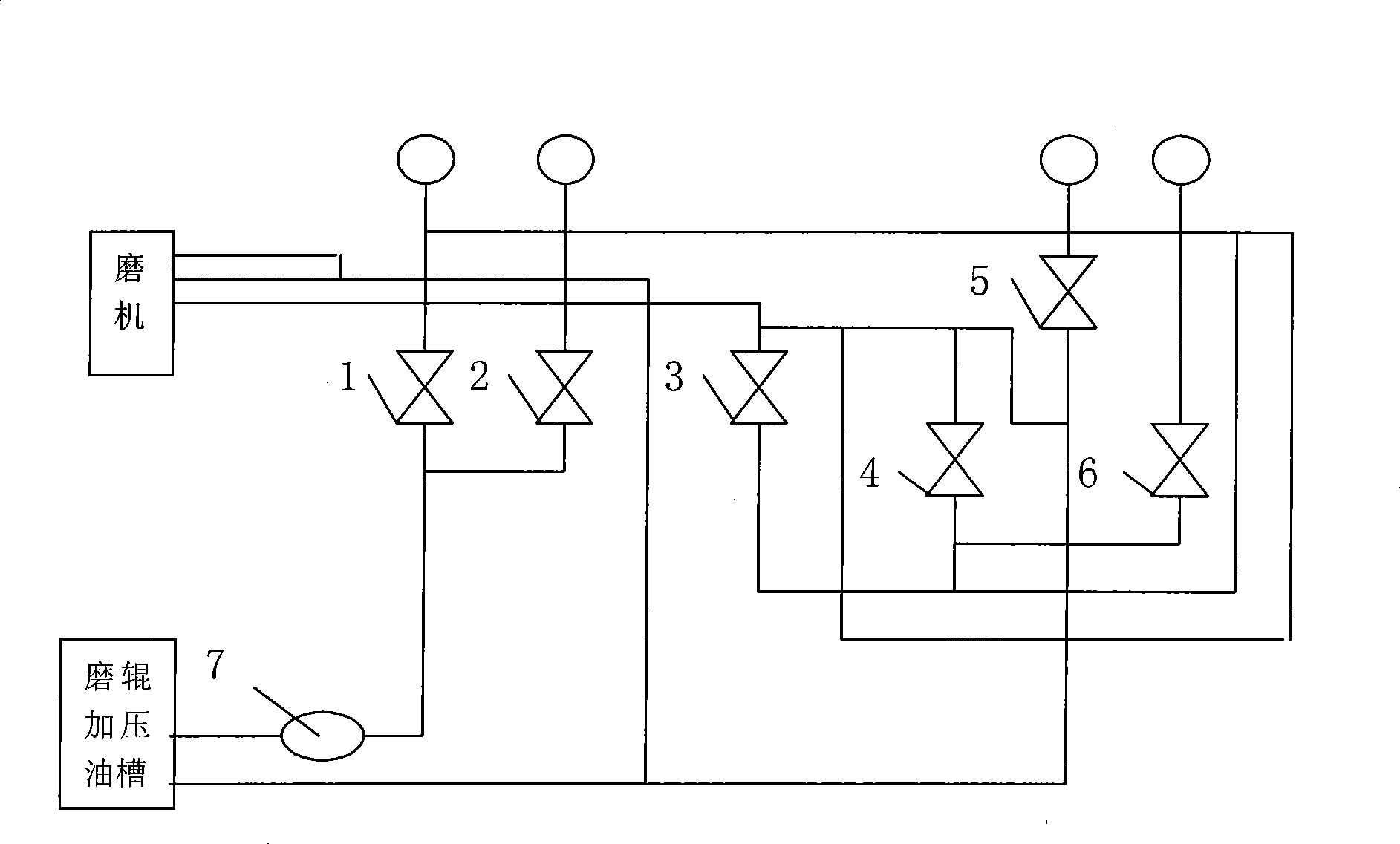

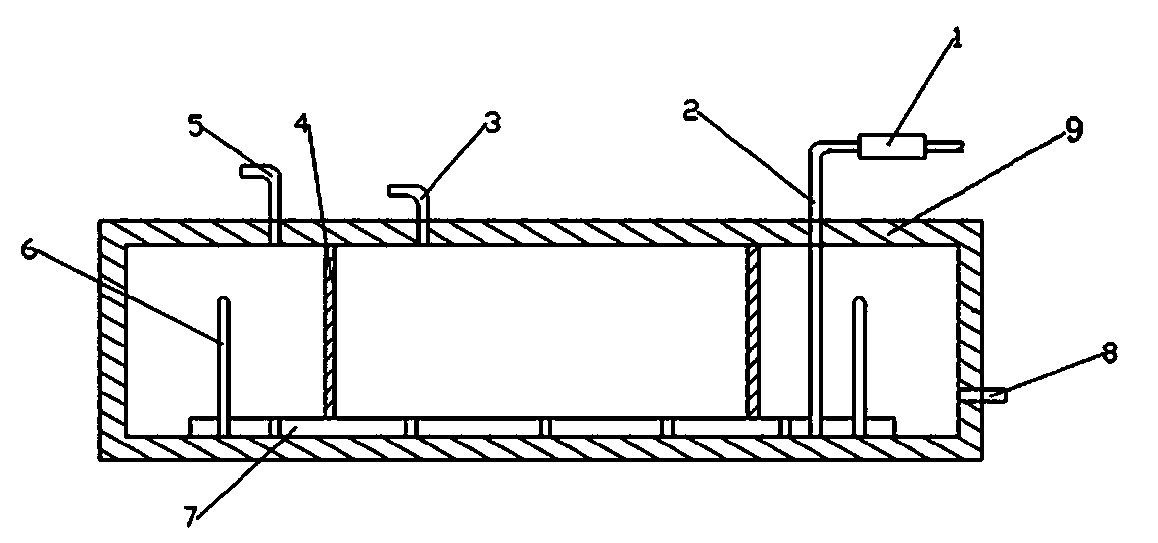

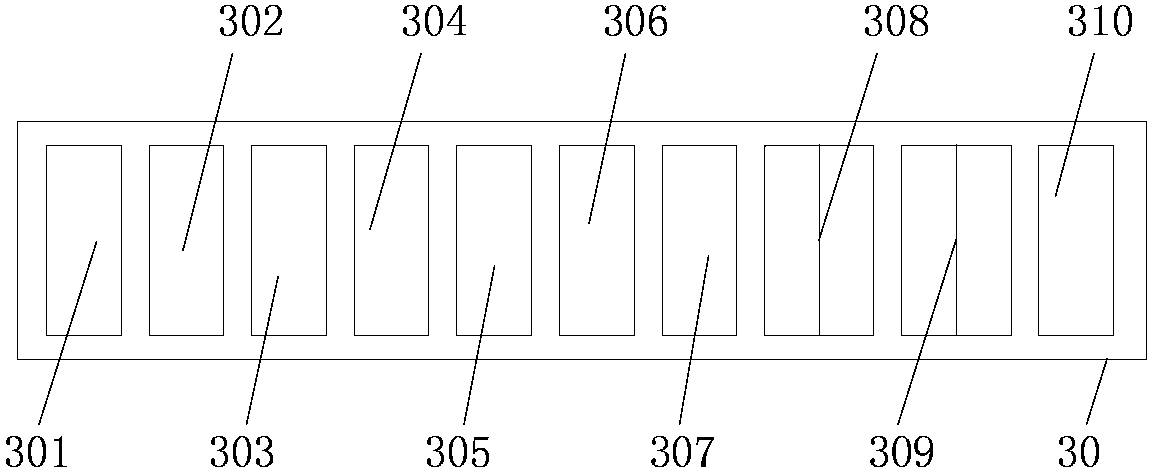

Hydraulic control method for COREX slag powder mill system

InactiveCN101424285AMeet the needs of the grinding processImproved hydraulic control methodServomotor componentsGrain treatmentsSlagEngineering

The invention discloses a hydraulic control method for a COREX slag pulverizing system and relates to the technical field of hydraulic control. A control operating system consists of an electromagnetic reversing valve (1), an electromagnetic reversing valve (2), an electromagnetic reversing valve (3), an electromagnetic reversing valve (4), and electromagnetic reversing valve (5), an electromagnetic reversing valve (6), an electromotor (7), a PT1 pressure sensor, a PT2 pressure sensor, a PT3 pressure sensor and a PT4 pressure sensor. According to the process flow, the hydraulic control method forms a logic relation of different working states through central control DCS operation, realizes a series of actions including the rising, declining, pressure maintaining of a grinding roller through controlling the switches of a plurality of the electromagnetic reversing valves, can automatically judge the needed adjustment under various operating conditions and realize the actions through controlling the electromagnetic reversing valves so as to make the whole system more intelligent. The hydraulic control method improves the prior inapplicable hydraulic control method, meets the requirement of the COREX slag pulverizing process, and has the characteristics of convenient operation, high intelligence degree and the like.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Device for desulfurizing electrolyzed water coal slurry to produce hydrogen

ActiveCN104327902AHigh purityAvoid secondary pollutionElectrolysis componentsMixersElectrolytic agentCo2 storage

The invention provides a device for desulfurizing electrolyzed water coal slurry to produce hydrogen, which has the advantages that the hydrogen is produced in a process of desulfurizing coal and the desulfurizing speed is high. The device comprises a material distribution system, an electrolysis system, a gas recycling system and a coal recycling system, wherein the material distribution system comprises a funnel feeding machine, a microwave drying machine, a belt conveyor, a powder mill, a material distribution funnel, a dry powder agitator and a slurry agitator; the electrolysis system comprises agitation tanks, an electrolysis tank, a direct-current pulse power supply cabinet, a microwave irradiation device, ultrasonic vibration rods, an electrode and a pipe net; a submerged pump is arranged in a separation plate between the two agitation tanks; the outlet of the pump is communicated with the pipe net at the bottom of the electrolysis tank by an electrolyte pipe; the electrode is vertically arranged at the center of the electrolysis tank and is of a closed square shape surrounded by four sets of electrode plates; the ultrasonic vibration rods are arranged on the two sides of the electrode in the electrolysis tank; and the gas recycling system comprises a carbon dioxide storage tank, a hydrogen storage tank, a pressure gauge, a flow meter, a check valve, a stop valve, a gate, a hydrogen analyzer, an emptying valve, a buffering tank and a boosting pump.

Owner:王号德

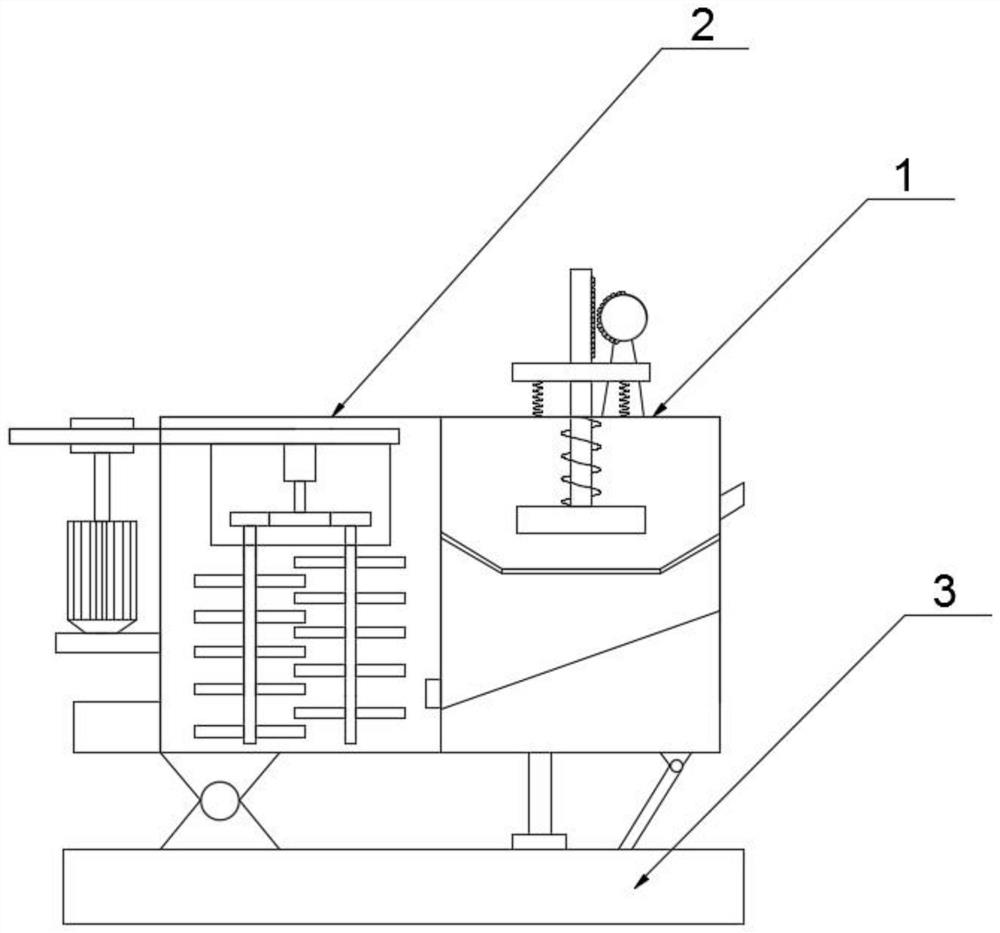

Special master batch for plastic weaving high-speed wire drawing machines and method for preparing special master batch

The invention discloses special master batch for plastic weaving high-speed wire drawing machines. The special master batch comprises carrier resin, calcium carbonate, surface treating agents, dispersing agents, grinding additives and beta crystal form nucleating agents. A method for preparing the special master batch includes secondarily crushing the calcium carbonate and the grinding additives on a ring-roll micro-powder mill to obtain a semi-finished product; sequentially adding the surface treating agents, the dispersing agents, the beta crystal form nucleating agents and the carrier resin into a high-speed mixing machine and mixing the surface treating agents, the dispersing agents, the beta crystal form nucleating agents and the carrier resin with one another at a high speed to obtain mixtures; internally mixing the mixtures in an internal mixer to obtain materials; pouring the materials into a double-wrist (double-cone) feeding machine by the aid of a lift hopper, feeding the materials into a single-screw (double-screw) extruder by the aid of the double-wrist (double-cone) feeding machine and extruding and granulating the materials to obtain the special master batch. The special master batch for the plastic weaving high-speed wire drawing machines and the method have the advantages that the special master batch prepared by the aid of the method is good in dispersibility and flowability, high in tensile strength and easy to plasticize, accordingly, the cost of products can be lowered to a great extent, and the quality of the products can be enhanced.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

Halogen-free flame-retardant epoxy resin and preparation method thereof

The invention discloses halogen-free flame-retardant epoxy resin and a preparation method thereof. The halogen-free flame-retardant epoxy resin is prepared from the raw materials of, by weight, 100 parts of epoxy resin, 5-40 parts of toughening agent, 1-15 parts of curing agent and 10-90 parts of halogen-free flame retardant. The halogen-free flame-retardant epoxy resin is prepared through the following steps that firstly, the raw materials are mixed, specifically, the raw materials are added into a mixing stirring device, and stirring mixing is conducted for 1-5 minutes till mixing is uniform; secondly, melting extrusion is conducted, specifically, mixed materials obtained in the first step are added into an extruder for melting extrusion, and melting mixing temperature is 70-90 DEG C; thirdly, tablet-pressing forming is conducted, specifically, molten materials obtained in the second step are subjected to tablet pressing operation through a tablet press, and the thickness is controlled to 1-4 mm; and fourthly, powder grinding and collection are conducted, specifically, materials obtained in the third step are fed into a powder mill to be crushed and graded, and powder obtained after cyclone separation is screened to obtain the halogen-free flame-retardant epoxy resin. According to the halogen-free flame-retardant epoxy resin and the preparation method thereof, the mixing stirring device is more convenient and faster to operate, human and material resources are saved, and mixing is conducted more fully.

Owner:安徽大松树脂有限公司

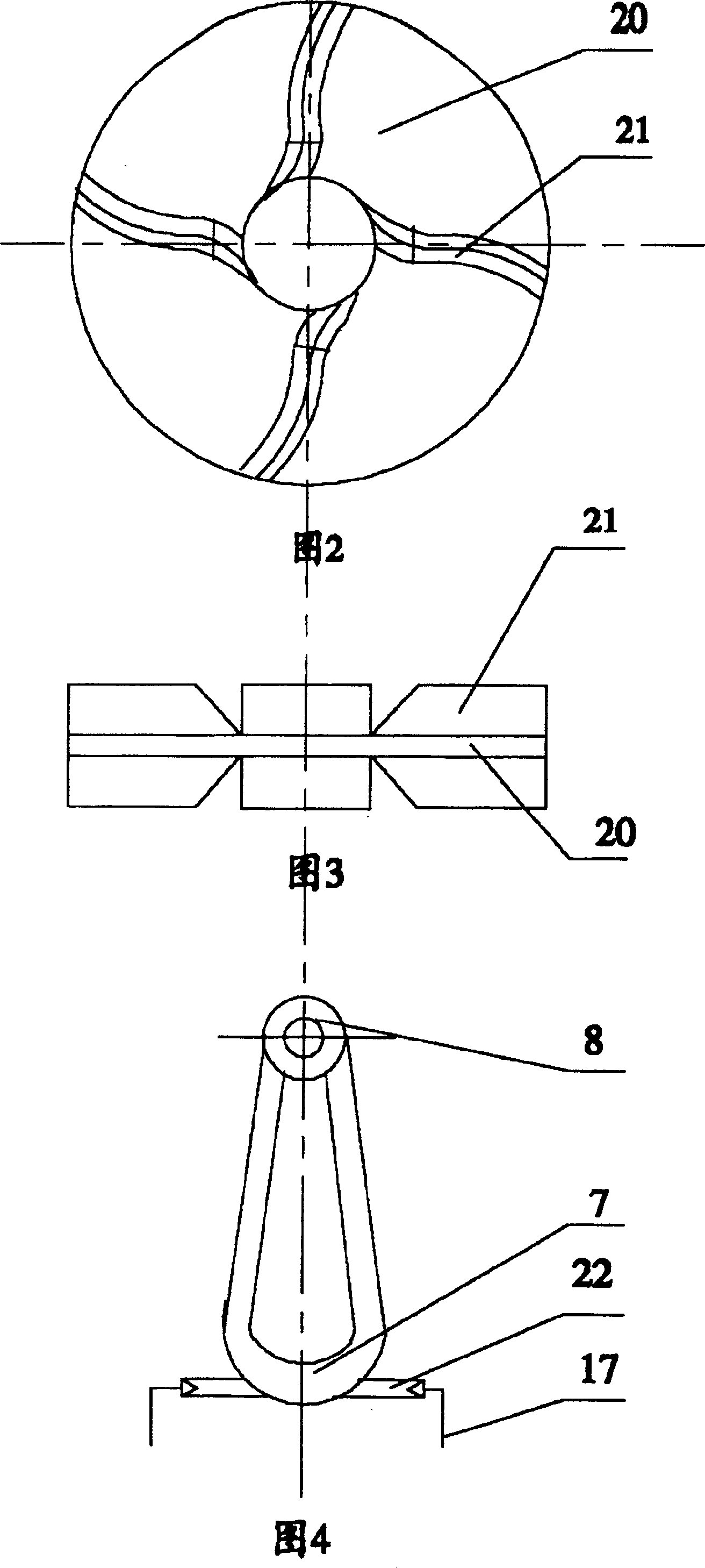

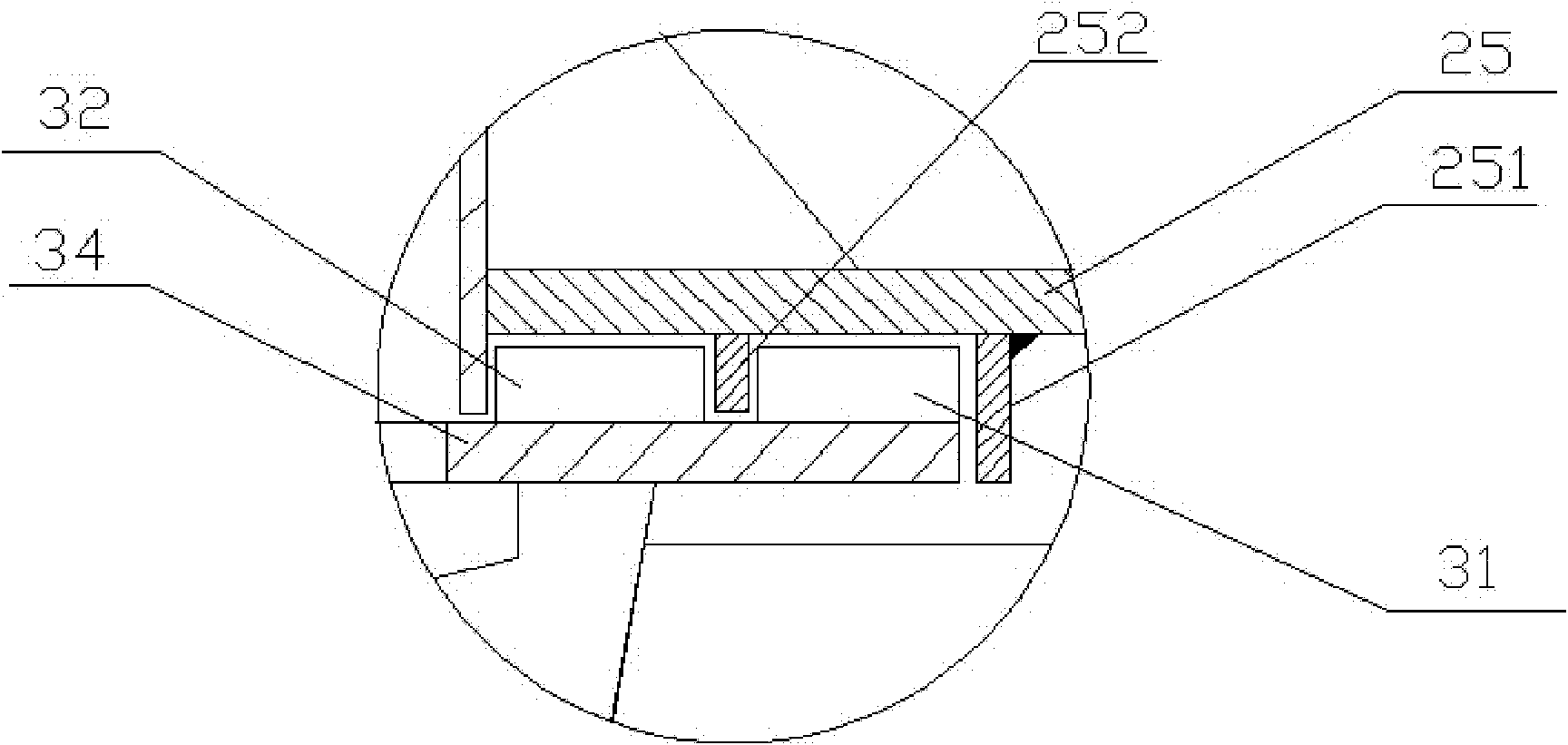

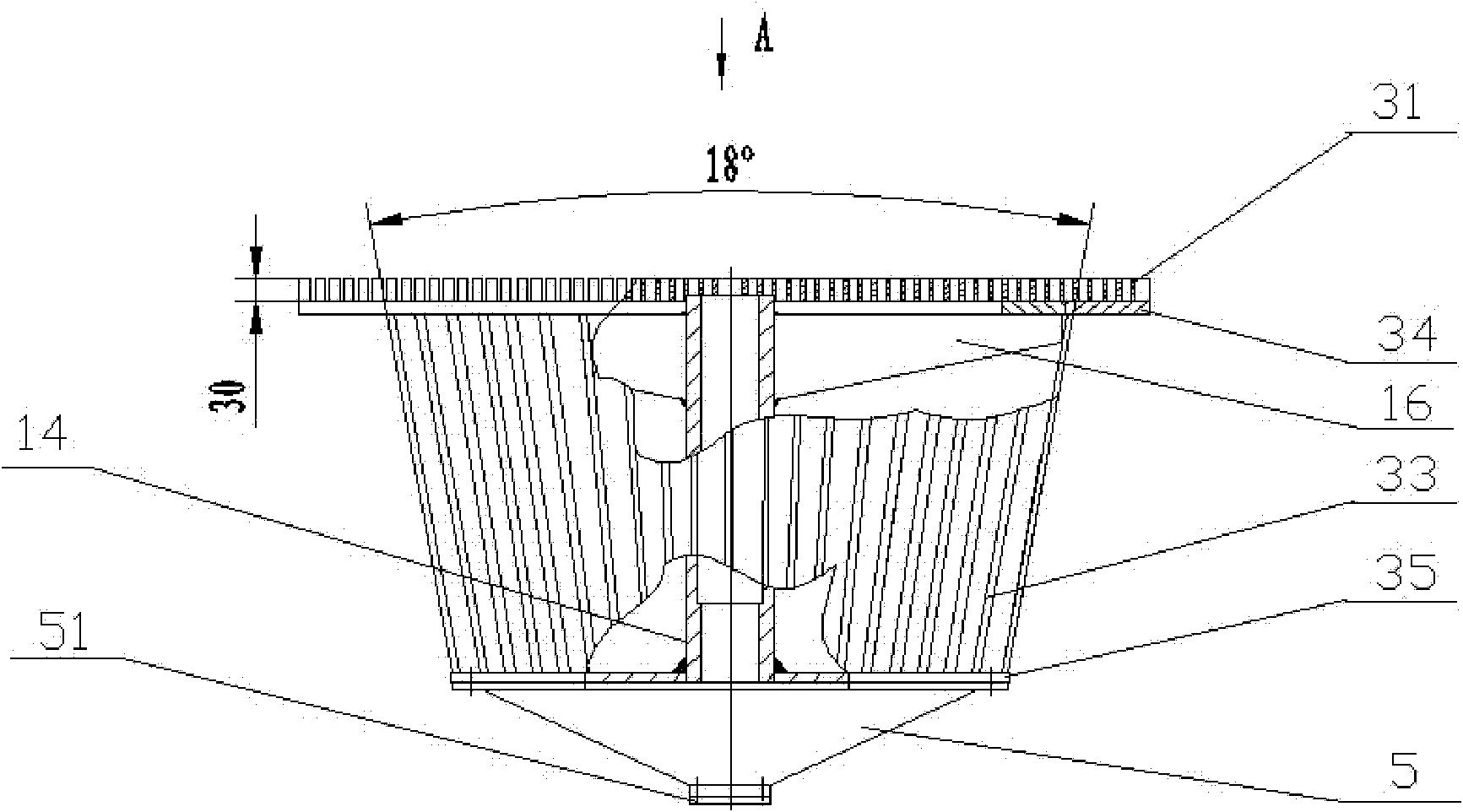

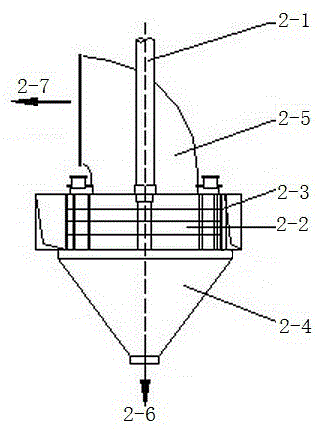

Ultrafine Turbine Classifier

ActiveCN102274826AIncrease line speedStrong windGas current separationGrain treatmentsRadial planeEngineering

The invention provides a superfine turbine classifier, which is characterized in that, the housing of a powder outlet chamber is connected on a classifying chamber, the powder outlet chamber is connected with a dust collector. A main shaft extends out from the upper part of the powder outlet chamber to be connected with a power mechanism, and is fixed in the powder outlet chamber via a bearing, abearing seat, and flanges. The main shaft extending into the classifying chamber is provided with a shaft sleeve connecting an upper plate of a classifying turbine assembly, the upper and lower ends of the classifying blades are respectively fixedly connected with an upper plate and a lower plate, each classifying blade is perpendicular to the horizontal and at an oblique angle with a radial plane, and the external shape of the classifying turbine assembly is a conical table. The lower end of the classifying chamber is connected with a powder mill. An inner sealing ring and an outer sealing ring of an annular sealing groove plate at the lower end of the housing of the powder outlet chamber are matched with an inner sealing blade and an outer sealing blade of the upper plate to form a mazesealing. The lower part of the lower plate of the classifying turbine assembly is connected with a flow guiding cover in the shape of an inverted conical surface. The main shaft drives the classifying turbine assembly to rotate, and the wind power of the classifying blades makes the powder spiral upward, fine powder ascends to the powder outlet chamber, and coarse powder descends to return to thepowder mill. The superfine turbine classifier is advantaged by high precision of classifying, no short-connection powder, small loss of system wind power, and no influence upon efficiency of the powder mill.

Owner:广西桂林航大重工机械有限公司

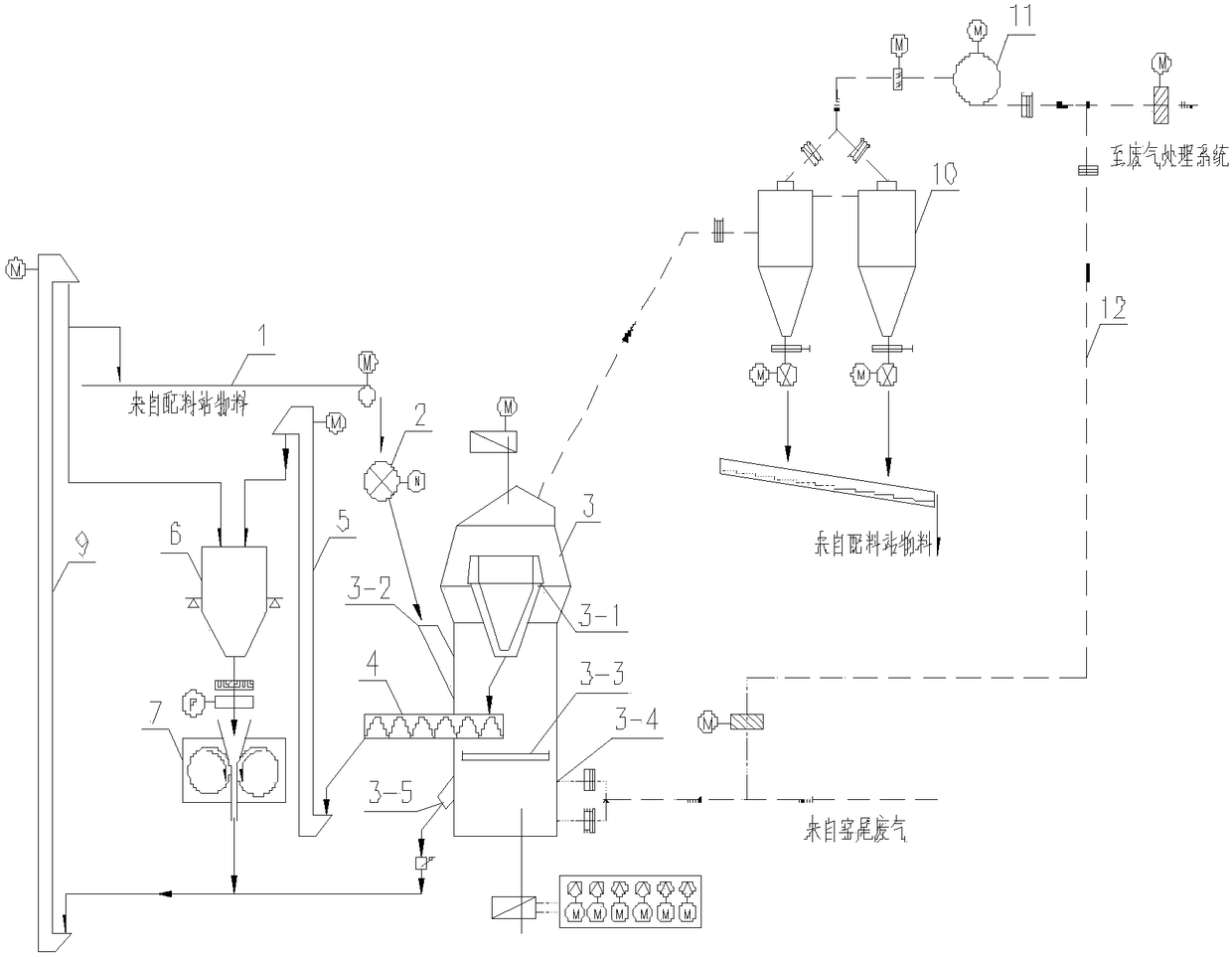

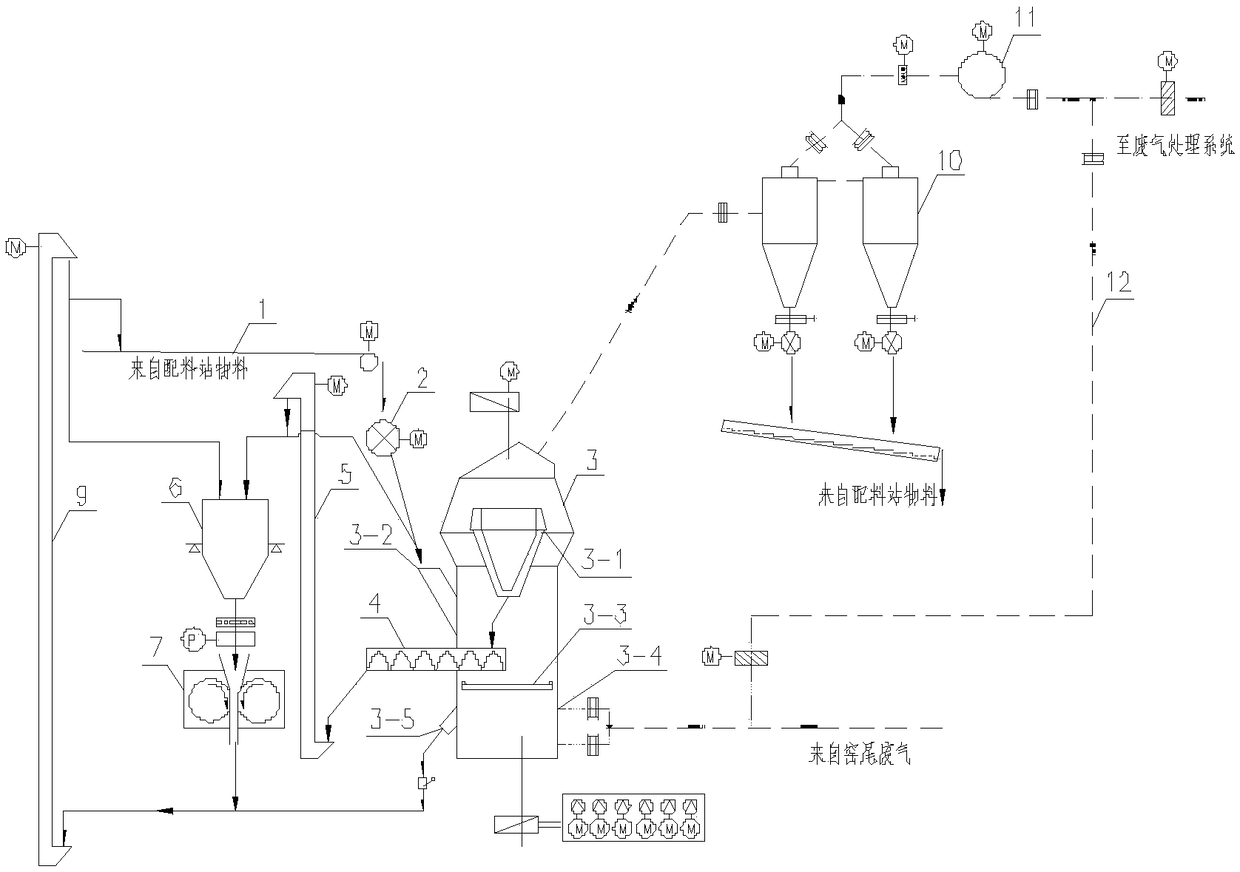

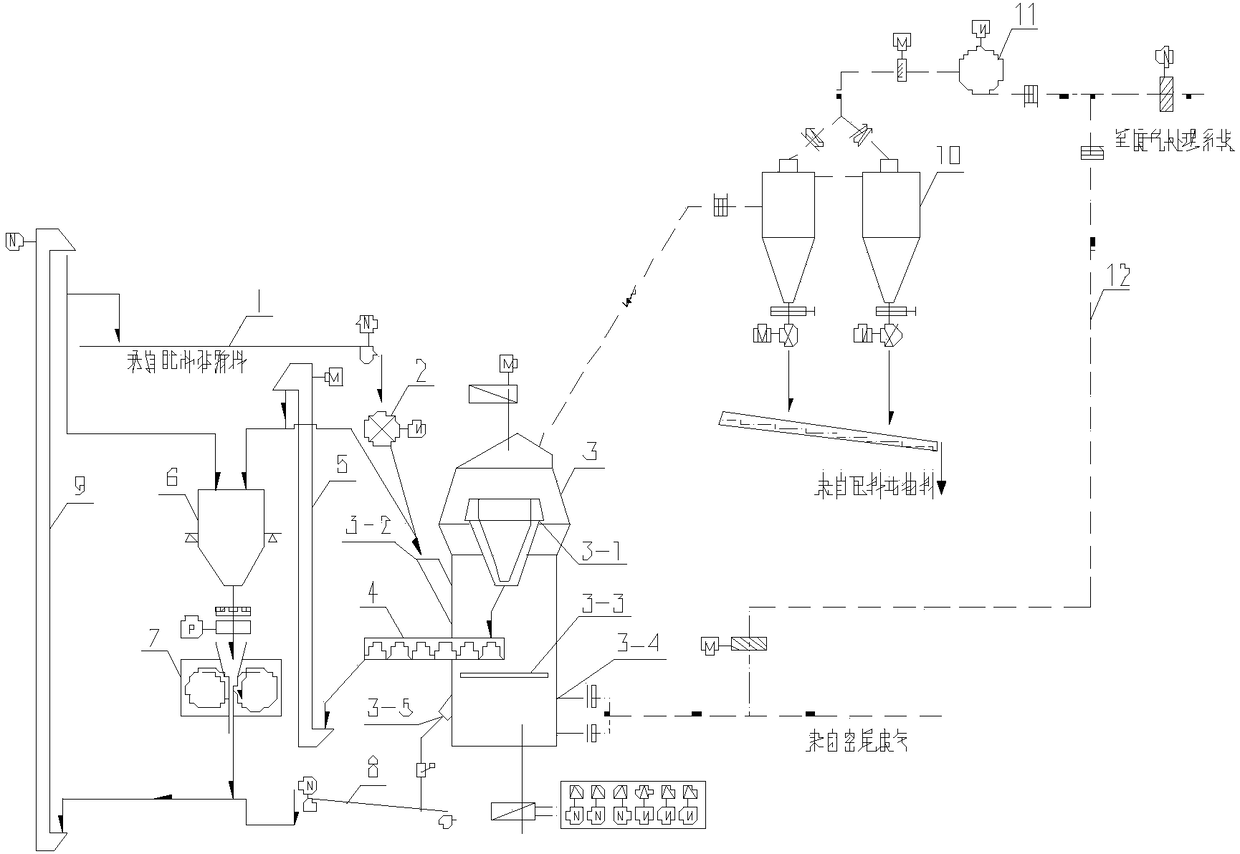

Novel raw material vertical milling and preparing system

PendingCN108273643AReduce the burden of grindingImprove grinding effectGrain treatmentsSystem impactSlag

The invention provides a novel raw material vertical milling and preparing system which comprises a feeding belt, an airlock feeding device, a vertical mill, a whirlwind cylinder, a circulating fan and a circulating air pipe connected sequentially, and further comprises a spiral reamer, an elevator, a roller press feeding bin, a roller press and a roller press discharging hopper elevating machineconnected sequentially. The spiral reamer is connected with a coarse powder discharging pipe of a vertical mill powder concentrator in the vertical mill; a discharge hole of the roller press discharging hopper elevating machine is connected with the feeding belt; a slag rejection port of the vertical mill is connected with a feed inlet of the roller press discharging hopper elevating machine; andan air outlet of the circulating air pipe is connected with an air inlet in the bottom part of the vertical mill through a kiln tail hot waste gas conveying pipe. According to the novel raw material vertical milling and preparing system provided by the invention, a set of small roller press is additionally arranged outside the vertical mill through a special manner and is matched with the verticalmill for assistantly milling, so that the yield of the system can be improved, the powder milling power consumption of the system is reduced, and the novel raw material vertical milling and preparingsystem is a reconstruction method which is capable of improving the yield of the system, low in investment, short in construction period and less to influence an original vertical milling system.

Owner:NANJING KISEN INT ENG

Cosmetics grinding machine

InactiveCN107737652AOverall small sizeImprove grinding efficiencyGrain treatmentsSolenoid valveEngineering

The present invention discloses a grinding machine for cosmetics, including the shell, which has the first partition the upper end of the internal cavity of the shell.The bottom activity of the mouth is installed with the first solenoid valve. The left end of the first partition bottom is fixed with a temperature sensor. The mid -end fixing connection at the bottom of the first partition has ultraviolet lamps.The outer side of the UV lamp tube is fixed with a slide.The exterior of the invention is fixed on the outer surface of the rolling axis, which can be connected to crushing teeth, which can be crushed to the materials, reducing the volume of the material, and improving its grinding efficiency. At the same timeThe role of pipes and raw management can meet people's repeated grinding needs for materials, so that people can obtain different particle size materials, which brings great convenience to the grinding of cosmetics.

Owner:吕丽娅

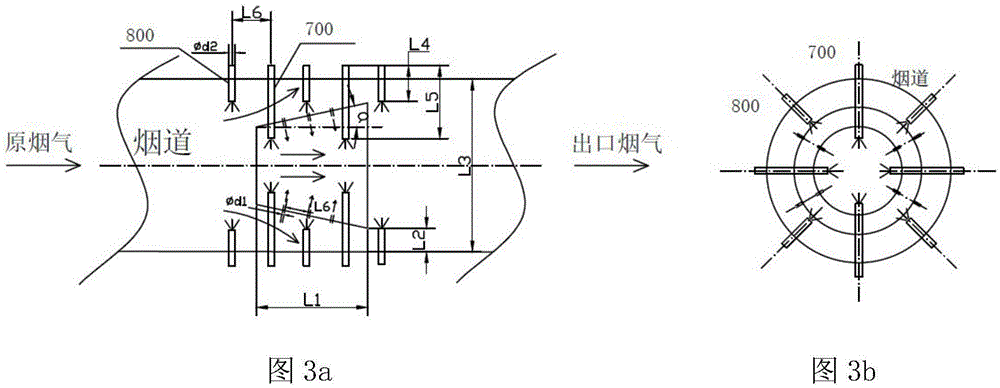

Sodium bicarbonate gathering, transporting and injecting method

ActiveCN105645113ALarge velocity differenceAchieving shrinkage accelerationDispersed particle separationBulk conveyorsSodium bicarbonatePowder mill

The invention discloses a sodium bicarbonate gathering, transporting and injecting method. The sodium bicarbonate gathering, transporting and injecting method comprises the steps that firstly, sodium bicarbonate is manufactured into coarse powder particles through a coal mill; secondly, fine powder is separated, materials with the particle size meeting the standard enter a fine powder screw conveyor, and fine powder which does not meet the standard continues to return to an ultrafine powder mill to be milled; thirdly, the materials with the particle size meeting the standard in the second step are fed to a fine powder pulse bag-type dust collector through the fine powder screw conveyor to be separated, ultrafine particles obtained through separation are conveyed to a storage bin, and gas is exhausted to the air through the pulse bag-type dust collector; fourthly, the ultrafine powder in the storage bin in the third step enters a dual screw metering scale through an intermediate bin, and powder flow is accurately metered; and fifthly, the powder metered in the fourth step firstly enters a pipe distributor to be injected into a flue through an injector, the mixing effect of flue gas and the powder is increased through the flue, so that pollutants in the fuel gas are removed, and the aims of energy saving and emission reduction are achieved.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Method of separating feldspar and quartz from granite materials

The invention relates to a method of separating feldspar and quartz from granite materials, and belongs to the technical field of separation and mineral beneficiation. The method comprises the steps of an ore breakage working procedure, an ore grinding working procedure, a screening working procedure, a photoelectric color sorting working procedure, a powder milling working procedure and a magnetic separation working procedure. The feldspar, the quartz and magnetic materials in granite are thoroughly separated by use of the physical technology, no any waste gas or waste water or other substances which pollute the environment are generated in the process of operation, and the damage caused by the floatation technology in the prior art to the environment is effectively avoided. In addition,the feldspar which is separated and purified by use of the method and the quartz which is separated and purified by use of the method can be applied to the ceramic industry instead of natural feldsparand natural quartz, the source of raw materials in the method is sufficient, and the method is suitable for large-scale industrial production.

Owner:内蒙古华宸再生资源科技有限公司

Full-penetration micro-powder polishing tile and preparation method thereof

The invention discloses a fully transparent micropowder polished ceramic tile and a preparation method thereof, which is made of the following raw materials in parts by weight: 45-55 parts of low-temperature feldspar, 30-40 parts of expanded perlite, 15-25 parts of calcined kaolin, soft soil 5‑10 parts, water ground potassium feldspar powder 2‑8 parts, borax 8‑15 parts, porcelain sand 5‑10 parts, silica 2‑6 parts, washed albite 1‑5 parts, selected sand 5‑15 parts and 50‑60 parts of water. Its preparation method: (1) ball milling; (2) removing stale iron; (3) milling; (4) pressing; (5) firing; (6) polishing. The invention solves the poor surface level, three-dimensionality and blurred stone-like effect of traditional polished tiles, and develops the application of super-transparent materials, so that the stone-like effect is more realistic, and at the same time, it has better permeability resistance and gloss.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

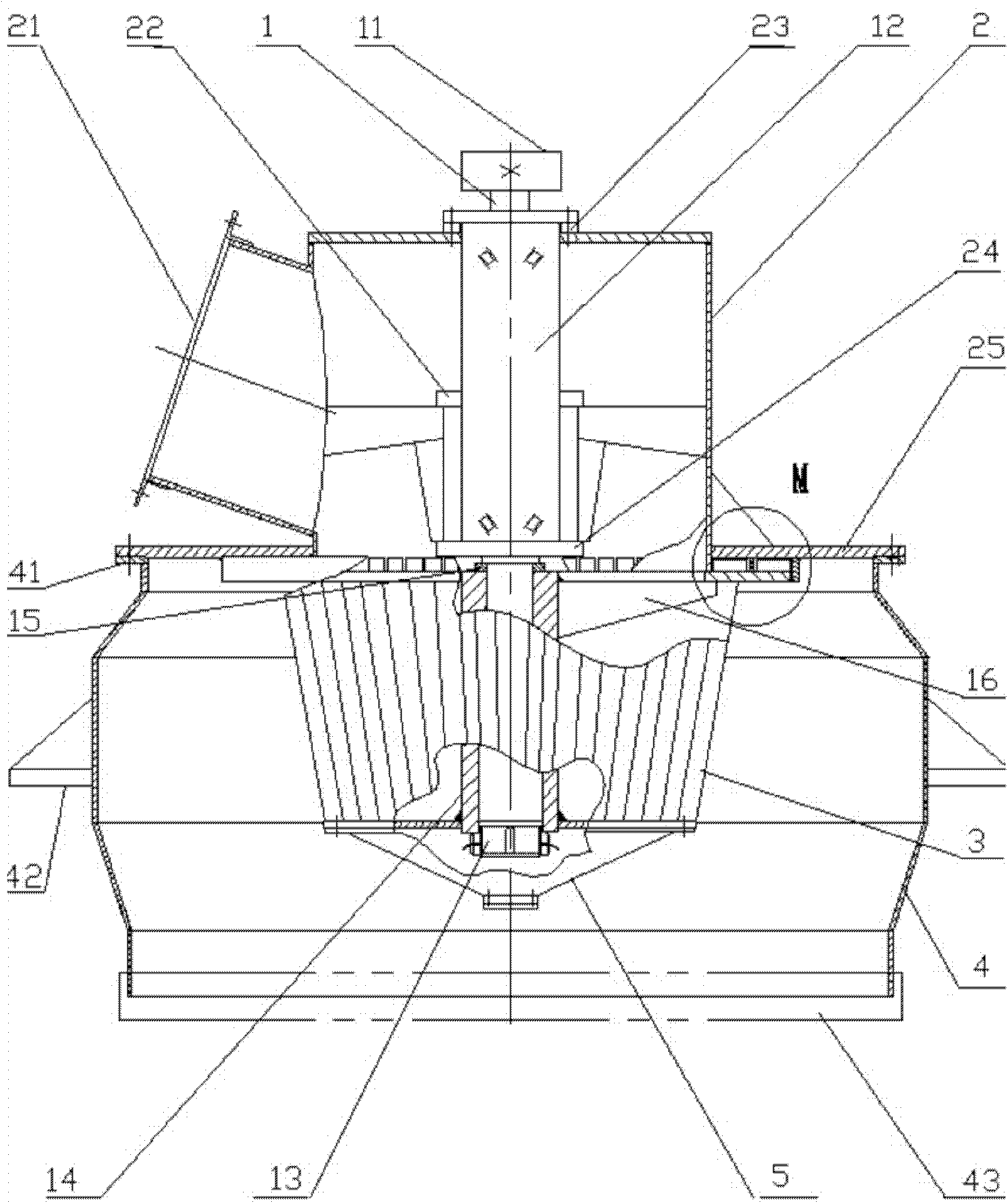

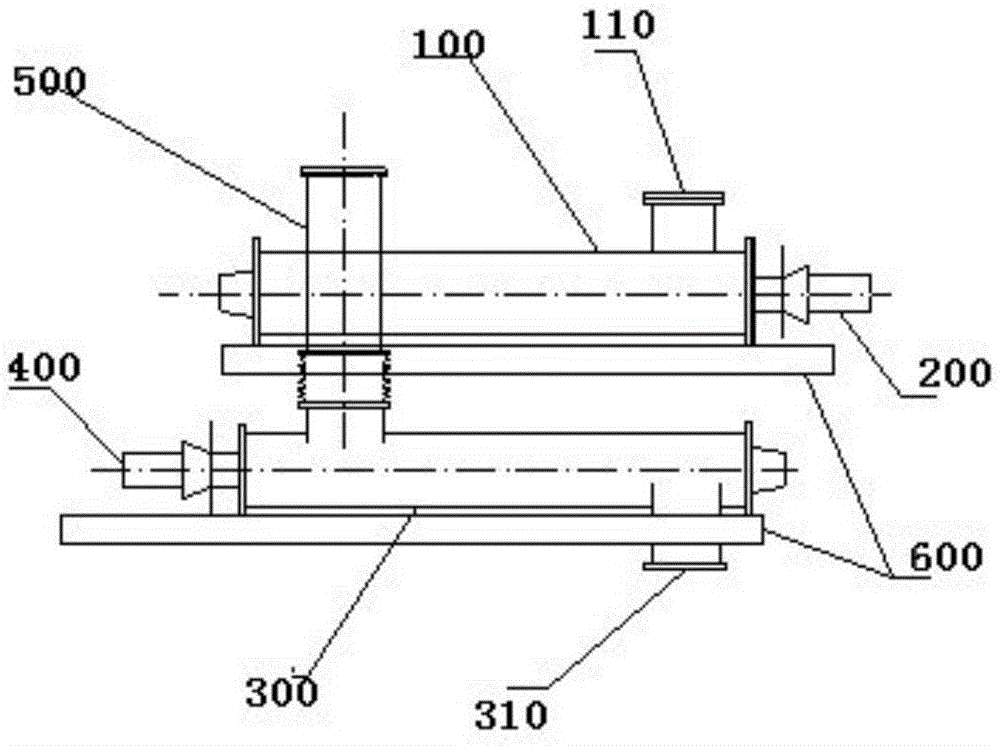

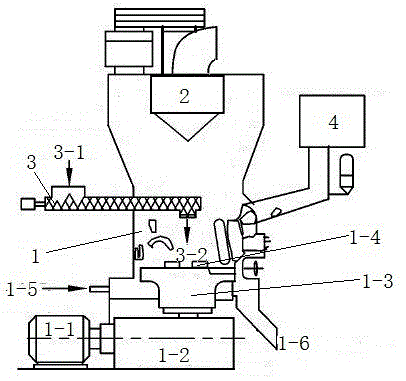

Ultrafine grinding system for blast furnace slag

InactiveCN105597880AHigh strengthImprove performanceGas current separationCement productionSlagReducer

The invention provides an ultrafine grinding system for blast furnace slag, which comprises an ultrafine powder mill (1), a powder concentrator (2), a screw feeder (3) and an oil hydraulic system (4), wherein the powder concentrator (2) is arranged in the ultrafine powder mill (1); the screw feeder (3) is connected with one side of the ultrafine powder mill (1); the oil hydraulic system (4) is connected with the other side of the ultrafine powder mill (1); the ultrafine powder mill (1) comprises a motor (1-1), a speed reducer (1-2), a grinding disc (1-3), a grinding roller (1-4), an air inlet (1-5) and an impurity discharging port (1-6); the speed reducer (1-2) is connected with the motor (1-1); the grinding disc (1-3) is arranged in the ultrafine powder mill (1); the grinding roller (1-4) is connected with the grinding disc (1-3); the air inlet (1-5) and the impurity discharging port (1-6) are formed on the lower part of the ultrafine powder mill (1); and the powder concentrator is a dynamic powder concentrator. The ultrafine grinding system provided by the invention is used for grinding the slag to a certain particle size and due to the excellent hydrating capacity, the superfine slag powder is utilized as a main material of cement products and a main mineral admixture of concrete, so that the strength and comprehensive property of the building material products are increased.

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG

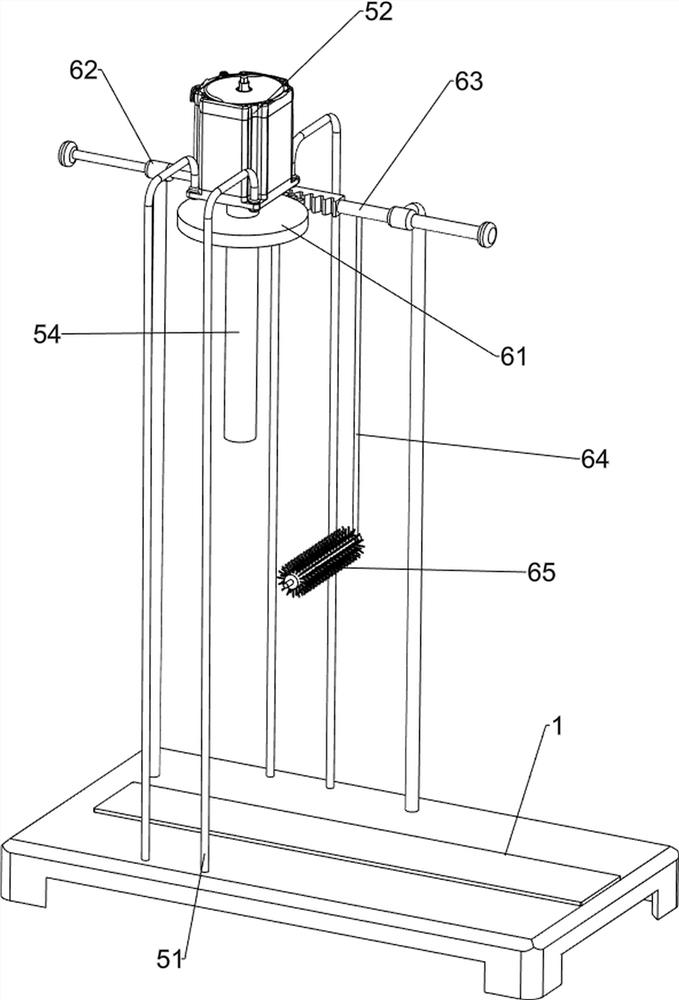

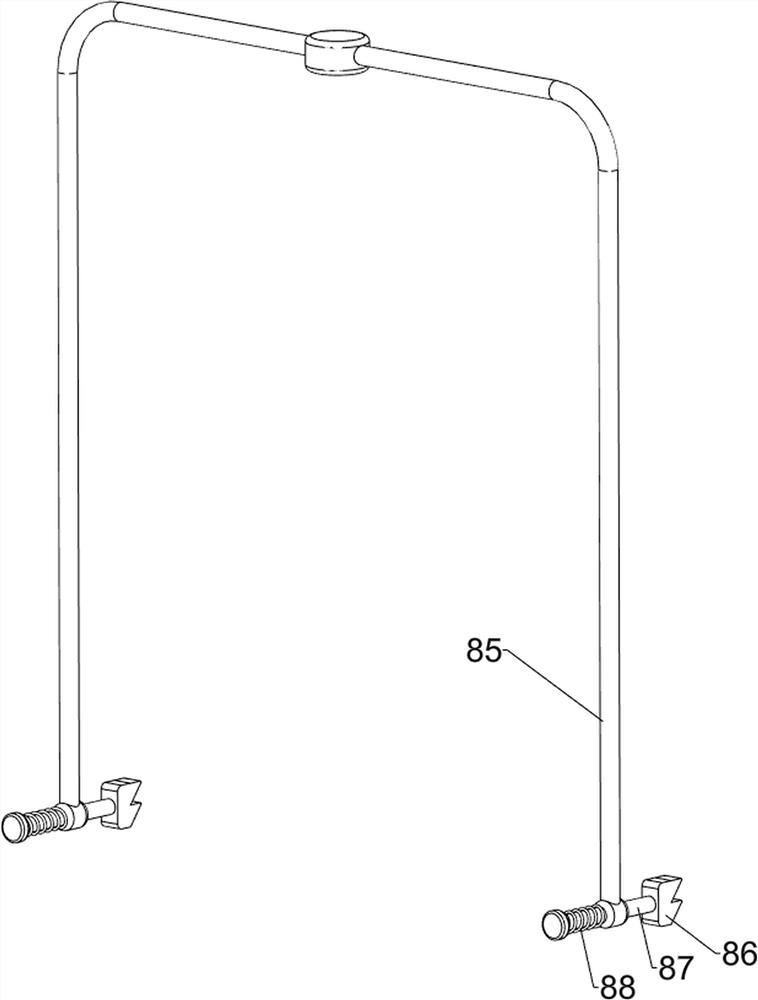

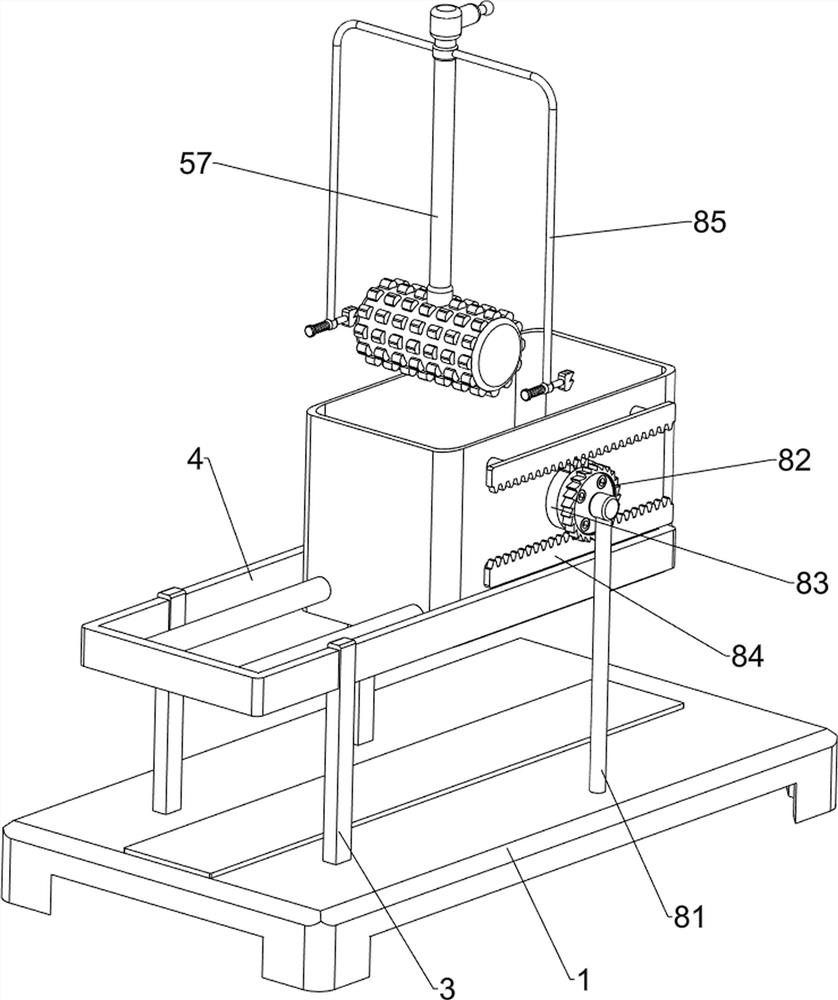

Powder milling device for chemical production

PendingCN112427069AAchieving a grinding effectImprove cleanlinessCleaning using toolsGrain treatmentsPowder millRaw material

The invention relates to a powder milling device, in particular to a powder milling device for chemical production. The invention provides the powder milling device for chemical production, which is delicate, is better in powder milling effect, automatically cleans the dust on the surface of a milling part, and is beneficial for powder collection. The powder milling device for chemical productioncomprises a base, a grinding mechanism and a clearing mechanism, wherein a slide frame for collecting powder-shaped chemical raw materials is arranged on the base in a sliding mode; the grinding mechanism for chemical raw material grinding is arranged on the base; the clearing mechanism for clearing accumulated powder on the grinding mechanism is arranged on the base; and the clearing mechanism isconnected to the grinding mechanism. A first movable block slides up and down along a roller to drive a pressure hammer to slide up and down, and the pressure hammer cracks the chemical raw materialsin a discharge frame below while moving downwards, so that the effect of grinding the chemical raw materials is achieved.

Owner:尹家琴

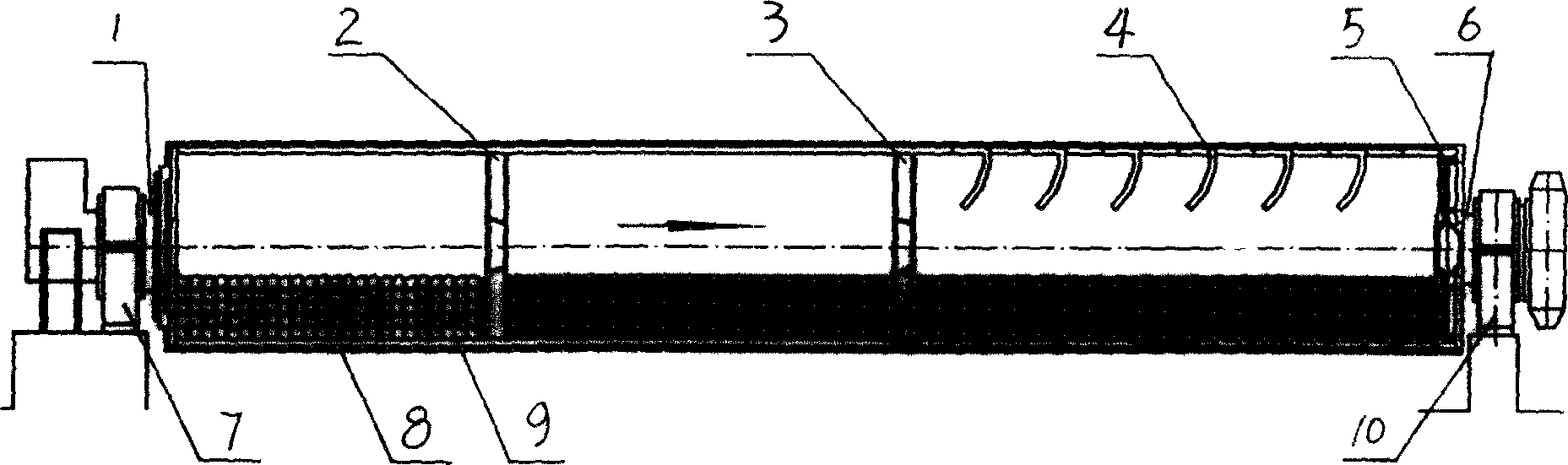

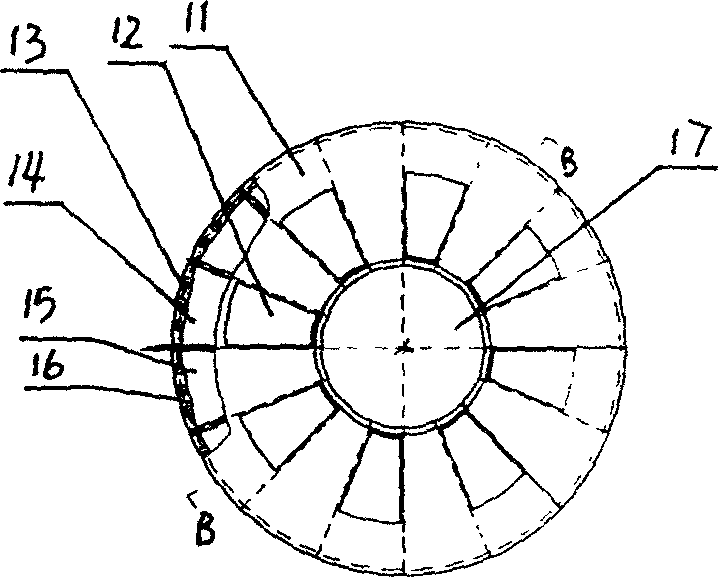

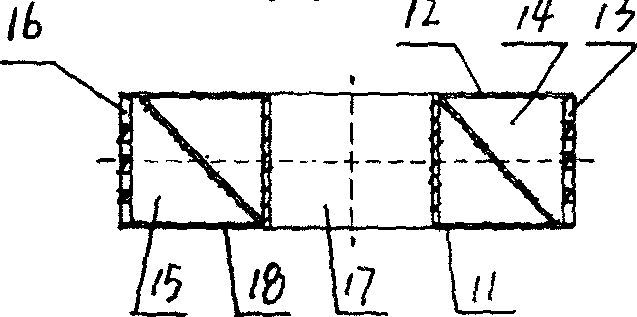

Open-flow powder mill

InactiveCN1709578AAvoid overgrindingImprove grinding efficiencyCement productionGrain treatmentsElectricityEngineering

This invention belongs to the power engineering, referring to cement and mineral sophistication production equipment. It includes revolving canister(8),front axletree seat(7),back axletree seat(10).The front of (8) is connected to (7) by axletree, the back to (10).There are feed-in meatus (1) and feed-out meatus (6) in (8).The character is that in (8) there are 1-3 picking power equipments. This invention integrates levigation and picking to increase output, reduce energy sourse, decrease expenditure. Comparing with the same scale equipment, its output increases by more than 20% and the consumption of electricity decreases by more than 30%.

Owner:WUHAN UNIV OF TECH

Colored powdery compound fertilizer anti-caking agent prepared from inorganic pigment and application thereof

InactiveCN105418244AColor stableUniform colorLayered/coated fertilisersFertilizer mixturesPowder millInorganic pigments

The invention relates to a colored powdery compound fertilizer anti-caking agent prepared from an inorganic pigment and application thereof. The agent comprises the following ingredients in percentage by mass: 1-3% of iron oxide red, iron oxide yellow, iron oxide blue, iron oxide green, iron oxide purple, iron oxide brown or iron oxide black and 99-97% of modified talcum powder, and is prepared by uniformly mixing the ingredients by adopting a powder mill. The agent is applied to compound fertilizer coating, and 2.5-3.5 kilograms of the agent are used in each ton of a compound fertilizer, so that a corresponding color of red, yellow, blue, green, purple, brown or black is shown in the appearance of the compound fertilizer. The agent has the advantages that the agent with the corresponding color of red, yellow, blue, green, purple, brown or black can be provided for compound fertilizers with different appearance colors, so that the inside and outside colors of each compound fertilizer are consistent, color difference and materials with inconsistent colors are avoided, and the color is stable and uniform; meanwhile, light resistance and heat resistance are achieved, and the agent is colourfast and anti-fade, and can serve as a fertilizer anti-counterfeiting mark; the agent is simple in preparation method, relatively low in using cost and high in anti-caking property; when the agent is applied to compound fertilizer coating, the fertilizer loosening rate reaches 90% or above; the agent can be degraded biologically, and thus is beneficial to environmental protection.

Owner:HUBEI FORBON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com