Sodium bicarbonate gathering, transporting and injecting method

A technology of sodium bicarbonate and injection method, applied in the direction of separation method, chemical instrument and method, conveyor, etc., can solve the problems of no industrial application, no industrial products, etc., achieve optimized flow field, high degree of automation, and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

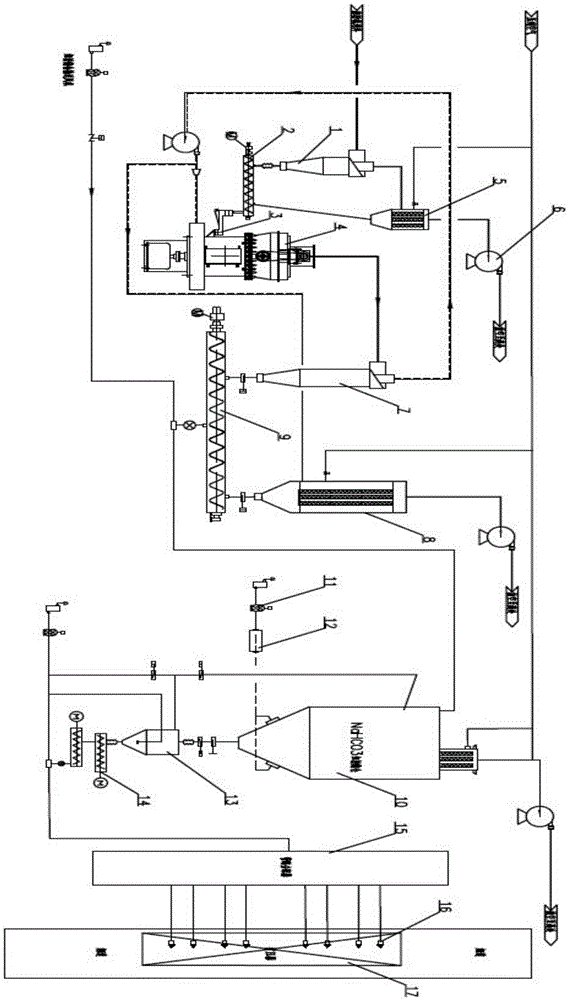

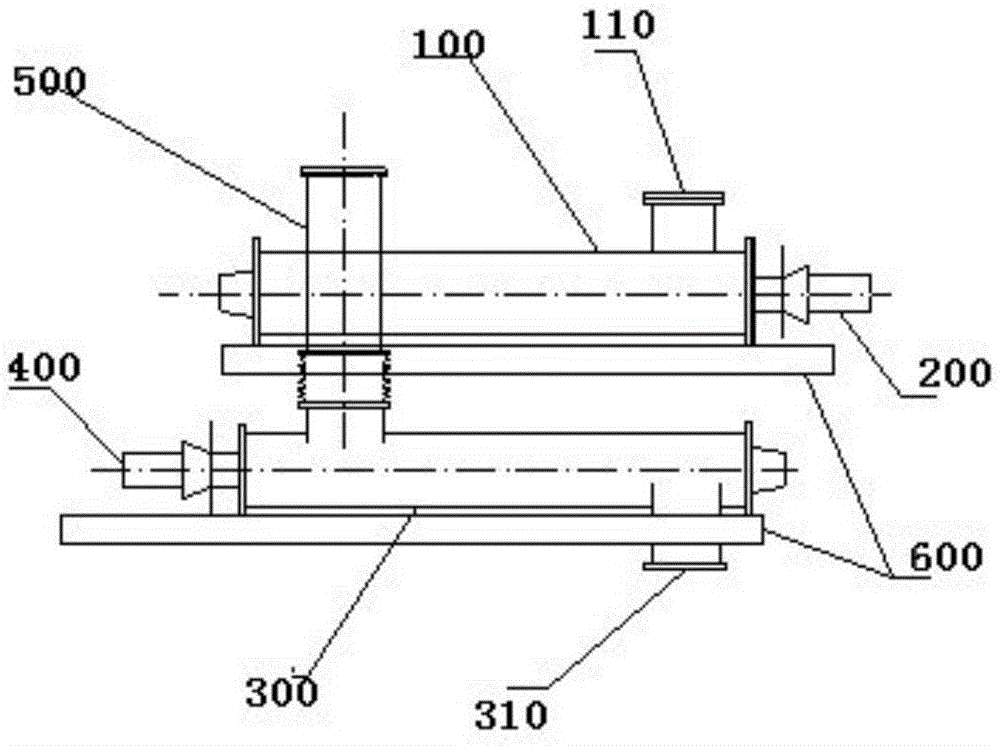

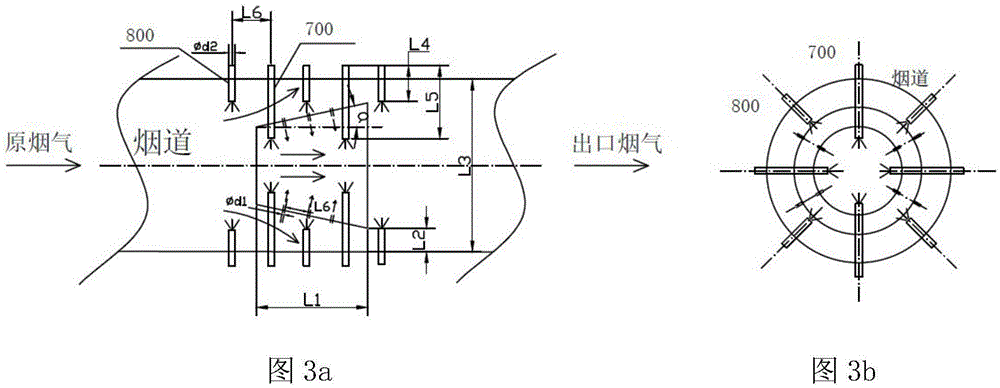

[0033] refer to figure 1 and figure 2 , a sodium bicarbonate collection and injection method, comprising: a powder conveying device, the powder conveying device includes a coarse powder cyclone separator 1 for separating coarse powder particles, and the coarse powder cyclone separator passes through a pipeline Connect the coarse powder pneumatic screw conveyor 2, the coarse powder pneumatic screw conveyor 2 is connected with the ultrafine mill 4 through the vibrating feeder 3, and the ultrafine mill 3 grinds the coarse particles into ultrafine powder; It also includes a fine powder cyclone separator connected to the output end of the ultrafine pulverizer 4, and the ultrafine powder that is ground into the standard enters the fine powder screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com