Nanometer bead milling system and nanocrystalline microsphere preparation method

A nano-bead and bead mill technology, applied in grain processing and other directions, can solve the problems of unreasonable design of grinding chamber, affecting the dispersion effect of powder pulverizer, unrealizable screen structure, etc., and achieves controllable quality and other indicators. The effect of increasing apparent surface area and achieving production goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

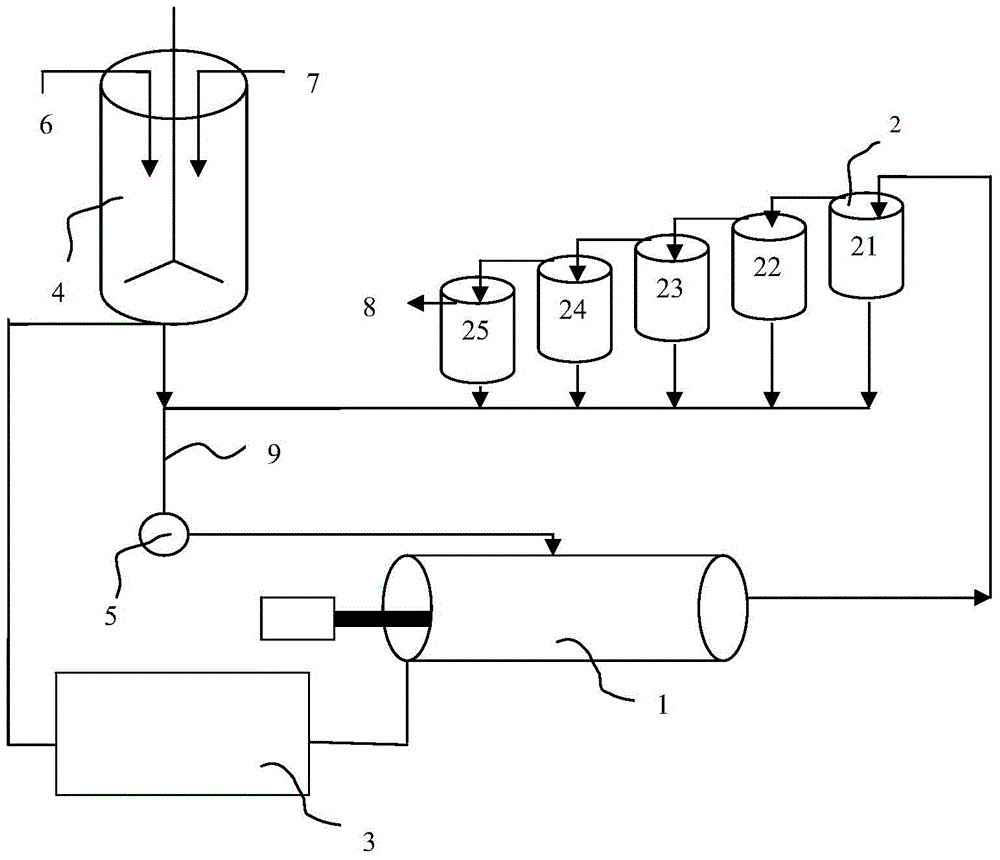

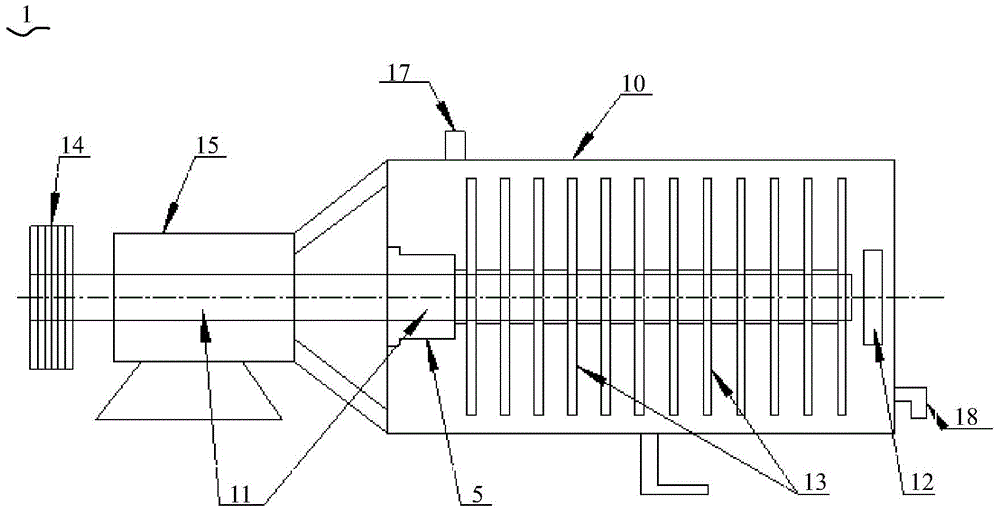

[0027] figure 1 It is a structural schematic diagram of the nano bead milling system of the present invention; figure 2 It is a schematic structural diagram of a bead mill in an embodiment of the present invention.

[0028] See figure 1 and figure 2 , The nano-bead mill system provided by the present invention is composed of a nano-bead mill 1, a high-speed centrifugal separator 2, a central controller 3, a pipeline 9, a pump 5 and a stirring tank 4.

[0029] The nano-bead mill 1 adopts a screenless design, including a grinding cylinder 10. The grinding cylinder 10 is equipped with a main shaft 11, a centrifugal separation disc 12, and 10-15 pieces are connected to the main shaft 11 at a certain inclination, and have round holes of different apertures. The stirring impeller 13; the centrifugal separation disc 12 is set on the main shaft 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com