Structure and manufacturing method of anode current collector in cylindrical zinc-air battery

A current collector and anode current technology, applied in the direction of electrode carrier/collector, fuel cell half-cell and primary battery half-cell, etc., can solve the problem of increased battery ion migration or diffusion path, which is not conducive to high battery current Discharge, increase electron transfer resistance and other issues, to achieve the effect of increasing the apparent surface area, improving the discharge capacity and output power, and shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

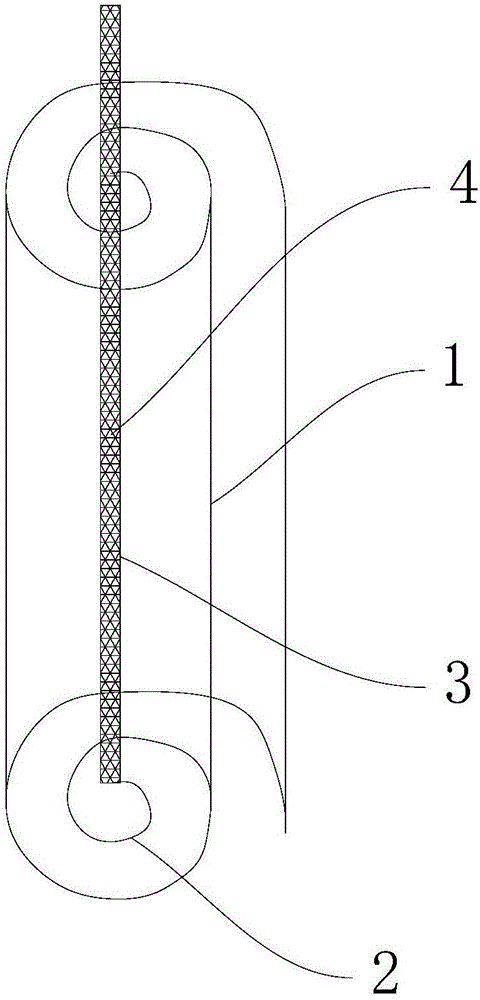

[0017] The manufacturing method of the anode current collector structure in the cylindrical zinc-air battery described in this embodiment is to take a piece of red copper material 1 with a thickness of 0.15 mm and a mesh structure, and cut the material into a rectangle: 26 mm long and 25 mm wide. Under the control of stainless steel cylindrical rollers, they are lightly rolled together to form a multi-layer cylindrical shape, and then stretched radially to form a concentric spiral structure 2, the innermost end 3 of the spiral structure 2 is connected to the anode tab 4 welding, and the end of the anode tab 4 is embedded in the anode plastic sealing ring and connected with the circular anode cap, and the surrounding is provided with a sealing plastic ring to form the anode cap of the anode current collector of the AA battery.

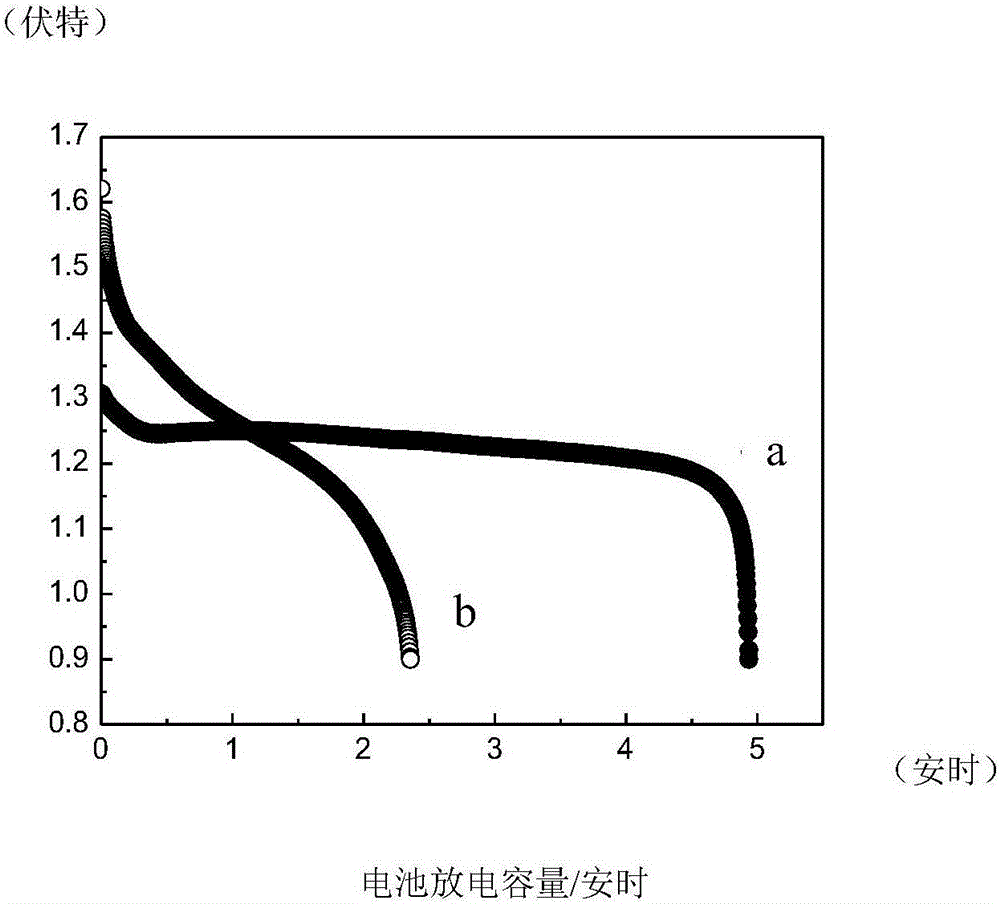

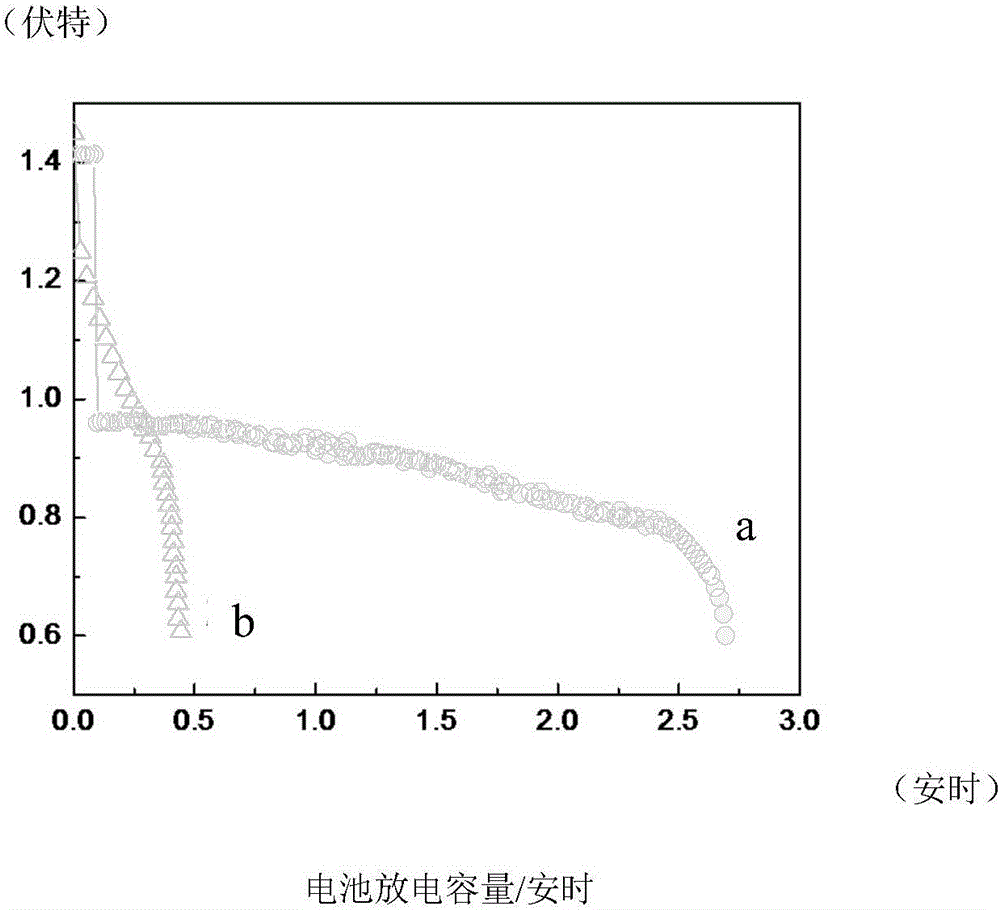

[0018] According to the calculation, the weight of the AA-type spiral anode current collector copper material is 0.38 grams, and the apparent surface ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com