Nanocrystalline microsphere additive and preparation method thereof

A technology of nanocrystalline microspheres and additives, which is applied in the direction of electrodes, grain processing, electrolysis, etc., can solve the problems affecting the dispersion effect of powder pulverizers, manufacturing difficulties, and unreasonable design of grinding chambers, etc., to increase the apparent surface area , Increase product output and achieve the effect of increasing production targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

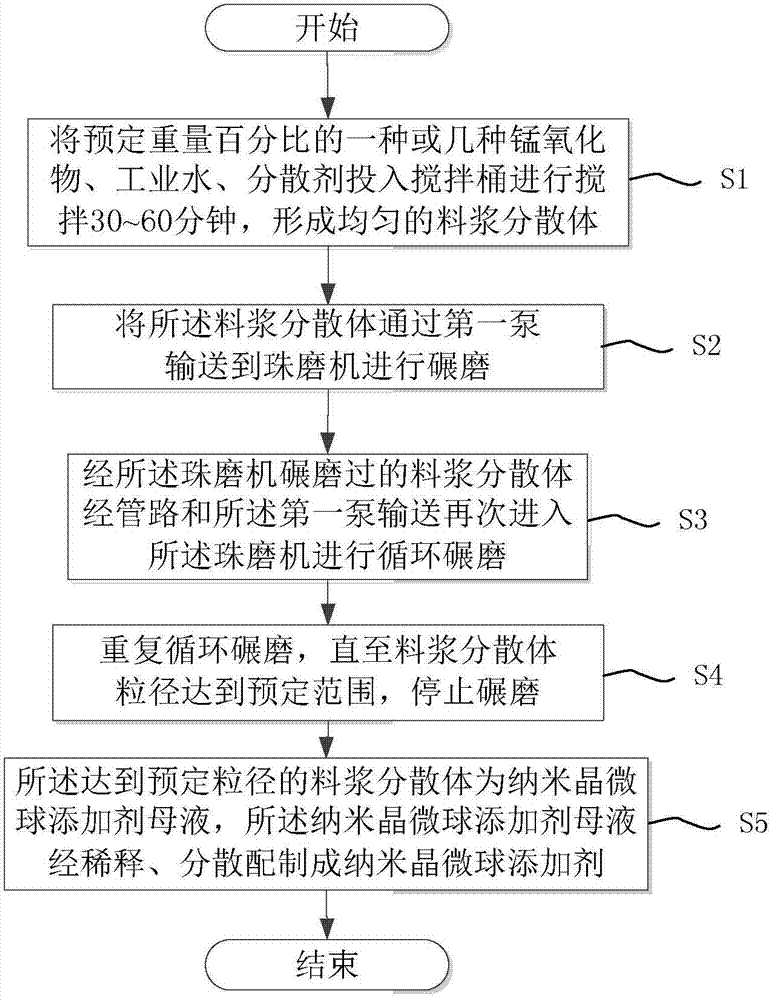

[0031] figure 1 The process flow chart of the preparation process of the nanocrystalline microsphere additive of the present invention.

[0032] The preparation process flowchart of the nanocrystalline microsphere additive provided by the invention comprises the following steps:

[0033] Step S1, put one or several kinds of manganese oxides, industrial water, and dispersants with a predetermined weight percentage into the mixing tank and stir for 30 to 60 minutes to form a uniform slurry dispersion; the prepared slurry dispersion has a weight percentage of The content is 10%-30%, and the concentration of dispersant is 0.1-1.0mg / l.

[0034] Step S2, the slurry dispersion is transported to the bead mill by the first pump for grinding; the motor power of the bead mill is 55KW, the power of the first pump is 4KW, the grinding medium is zirconia beads, and the zirconia The particle size of the beads is 0.5mm-2.0mm, and the filling rate is 60%-80%.

[0035] Step S3, the slurry di...

Embodiment 1

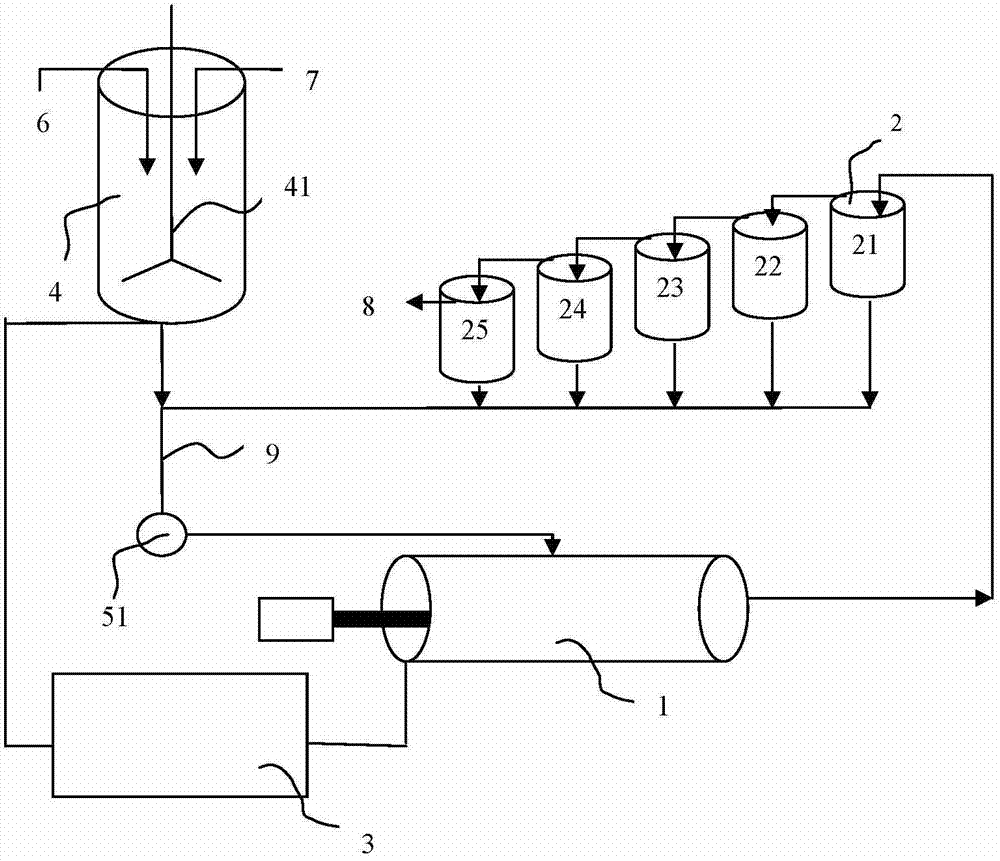

[0039] figure 2 It is a schematic diagram of the structure of the nano-bead milling system in the embodiment of the present invention; Figure 4 It is a schematic structural diagram of a bead mill in an embodiment of the present invention.

[0040] See figure 2 and Figure 4, The nano-bead mill system used in this embodiment is composed of a nano-bead mill 1, a high-speed centrifugal separator 2, a central controller 3, a pipeline 9, a first pump 51 and a stirring tank 4.

[0041] The nano-bead mill 1 adopts a screenless design, including a grinding cylinder 10. The grinding cylinder 10 is equipped with a main shaft 11, a centrifugal separation disc 12, and 10-15 pieces are connected to the main shaft 11 at a certain inclination, and have round holes of different apertures. The stirring impeller 13; the centrifugal separation disc 12 is set on the main shaft 11 of the inner tail of the grinding cylinder 10, replacing the screen of the existing bead mill to separate the gr...

Embodiment 2

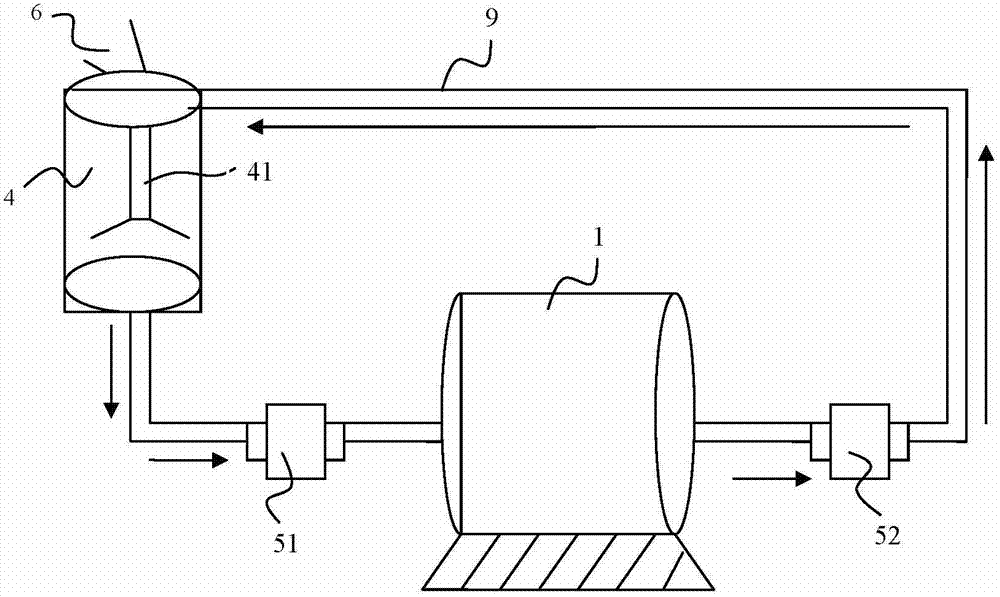

[0048] image 3 It is a schematic diagram of the structure of the nano-bead milling system in another embodiment of the present invention; Figure 4 It is a schematic structural diagram of the nano bead mill in the embodiment of the present invention.

[0049] See image 3 and Figure 4 , the nano-bead milling system provided by the present invention includes a stirring tank 4, a bead mill 1, a first pump 51 and a second pump 52, the outlet of the stirring tank 4 is connected to the inlet of the first pump 51 through a pipeline 9, and the first The outlet of the pump 51 is connected to the inlet 17 of the bead mill 1 through the pipeline 9, the outlet 18 of the bead mill 1 is connected to the inlet of the second pump 52 through the pipeline 9, and the outlet of the second pump 52 is connected to the stirring tank through the pipeline 9. The inlet of tank 4 is connected.

[0050] The nano-bead mill 1 adopts a screenless design. In the present embodiment, preferably, it incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com