Halogen-free flame-retardant epoxy resin and preparation method thereof

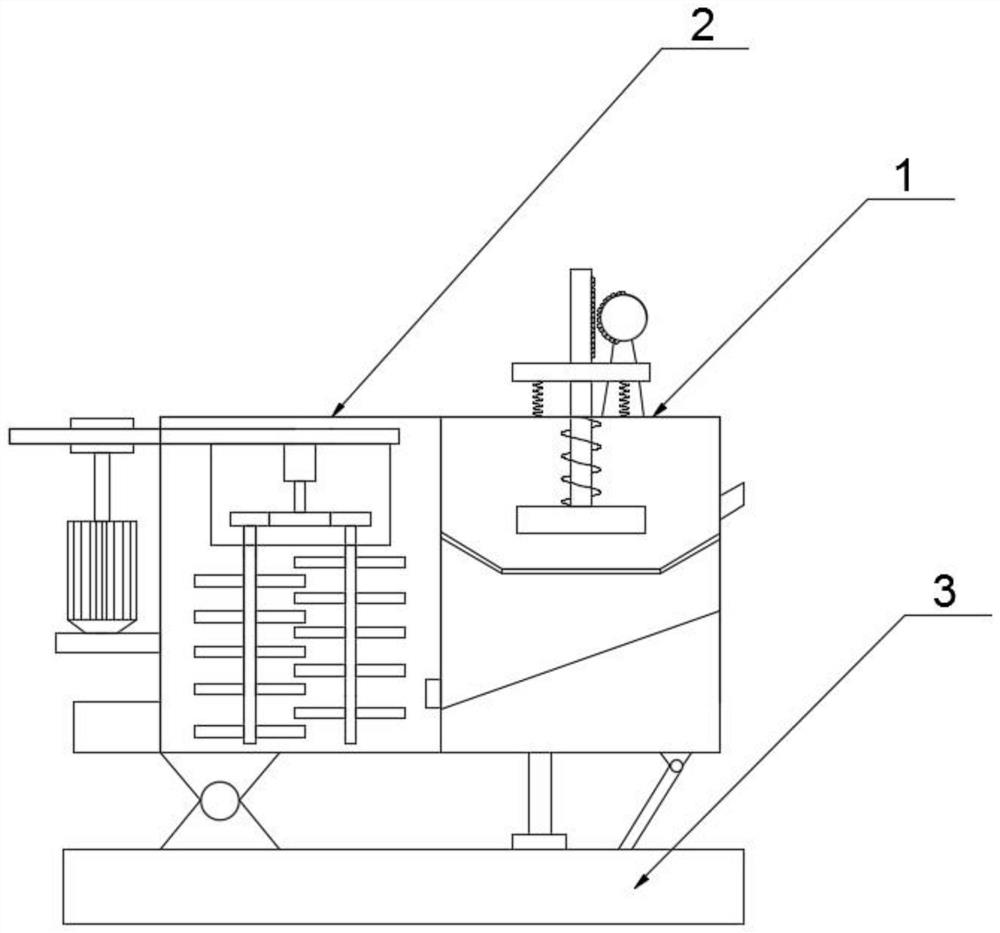

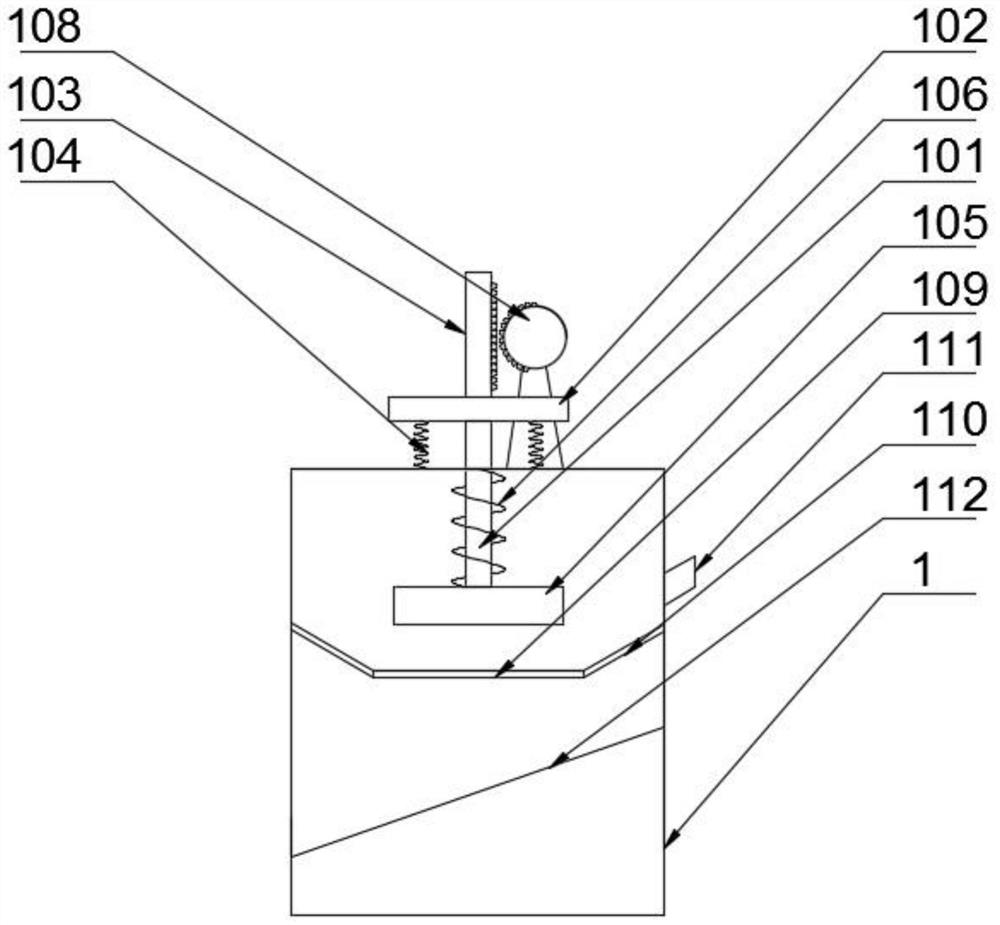

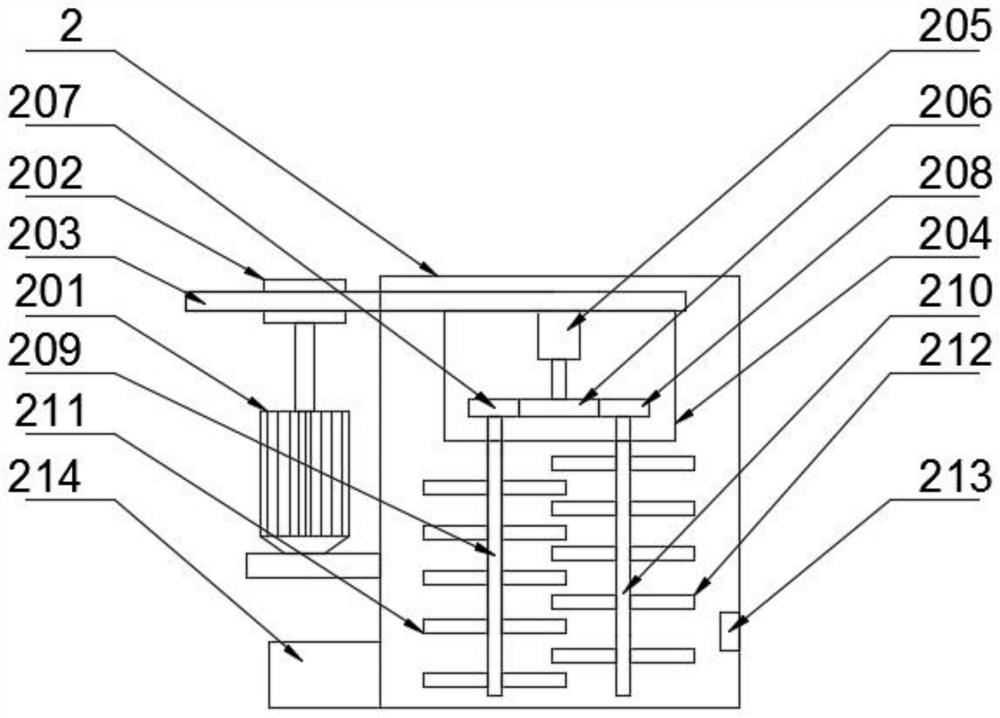

A technology of epoxy resin and flame retardant, applied in the field of halogen-free flame retardant, can solve the problems of small contact area, insufficient mixing, inconvenient feeding, etc., achieve good crushing effect, sufficient mixing, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A halogen-free flame-retardant epoxy resin, made of the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 5 parts of carboxyl-terminated nitrile rubber, 1 part of dicyandiamide and its derivatives, and cyclic benzene 10 parts of oxyphosphazene compound;

[0043] The halogen-free flame-retardant epoxy resin is made by the following steps:

[0044] The first step, mixing the raw materials, adding the raw materials into the mixing and stirring device, stirring and mixing for 5 minutes until uniformly mixed;

[0045] The second step, melt extrusion, put the mixed material obtained in the first step into the extruder to melt and extrude, and the melt kneading temperature is 70°C;

[0046] The third step, tablet forming, the molten material obtained in the second step is pressed through a tablet press, and the thickness is controlled at 1mm;

[0047] The fourth step is grinding and collecting, sending the material obtained in the third step i...

Embodiment 2

[0049] A halogen-free flame-retardant epoxy resin, characterized in that it is made of the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 25 parts of carboxyl-terminated nitrile rubber, 8 parts of dicyandiamide and its derivatives And 50 parts of cyclic phenoxyphosphazene compounds;

[0050] The halogen-free flame-retardant epoxy resin is made by the following steps:

[0051] The first step, mixing the raw materials, adding the raw materials into the mixing and stirring device, stirring and mixing for 5 minutes until uniformly mixed;

[0052] The second step, melt extrusion, put the mixed material obtained in the first step into the extruder to melt and extrude, and the melt kneading temperature is 80°C;

[0053] The third step, tablet forming, the molten material obtained in the second step is pressed through a tablet press, and the thickness is controlled at 3mm;

[0054] The fourth step is grinding and collecting, sending the material ob...

Embodiment 3

[0056] A halogen-free flame-retardant epoxy resin, characterized in that it is made of the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 40 parts of carboxyl-terminated nitrile rubber, 15 parts of dicyandiamide and its derivatives And 90 parts of cyclic phenoxyphosphazene compounds;

[0057] The halogen-free flame-retardant epoxy resin is made by the following steps:

[0058] The first step, mixing the raw materials, adding the raw materials into the mixing and stirring device, stirring and mixing for 5 minutes until uniformly mixed;

[0059] The second step, melt extrusion, put the mixed material obtained in the first step into the extruder to melt and extrude, and the melt kneading temperature is 90°C;

[0060] The third step, tablet forming, the molten material obtained in the second step is pressed through a tablet press, and the thickness is controlled at 4mm;

[0061] The fourth step is grinding and collecting, sending the material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com