Method for preparing high-class concrete admixture with composite powder of steel slag and mineral slag

A technology for concrete and composite powder, applied in the field of solid waste resource utilization and building materials, can solve the problem that gypsum cannot be fully formed, the potential of active silicon-oxygen tetrahedron and aluminum-oxygen tetrahedron cannot be fully utilized, and divalent metal cations cannot be fully utilized. potential and other issues to achieve the effect of improving the performance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

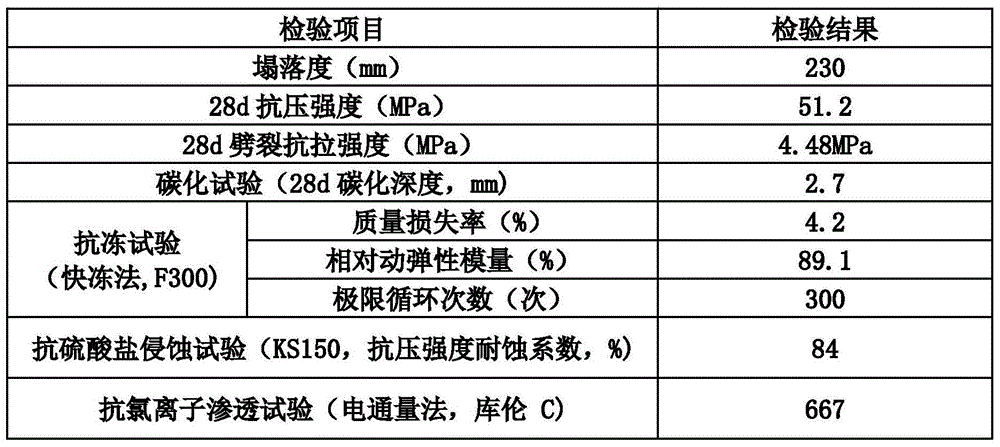

Embodiment 1

[0017] (1) The remaining steel tailing slag after multi-channel pretreatment and multiple iron selection processes in the current steel plant is crushed by an impact-type high-efficiency fine crusher until the maximum particle size is less than 3mm. The finely crushed steel tailings fine particles are passed through two fluidized broadband iron removers to remove the exposed metallic iron fine particles and the intergrowth fine particles of metallic iron and non-metallic phases. Fine particles of steel tailings after fine crushing and multi-pass iron removal are sent to a new rolling mill with high-efficiency circulation iron removal function and ground to a specific surface area of 470m 2 / kg. During the crushing and grinding process of steel slag, it is necessary to remove the large and small particles mainly composed of metallic iron in time by means of real-time circular iron removal, so as to avoid the friction between the particles and the mutual friction between the p...

Embodiment 2

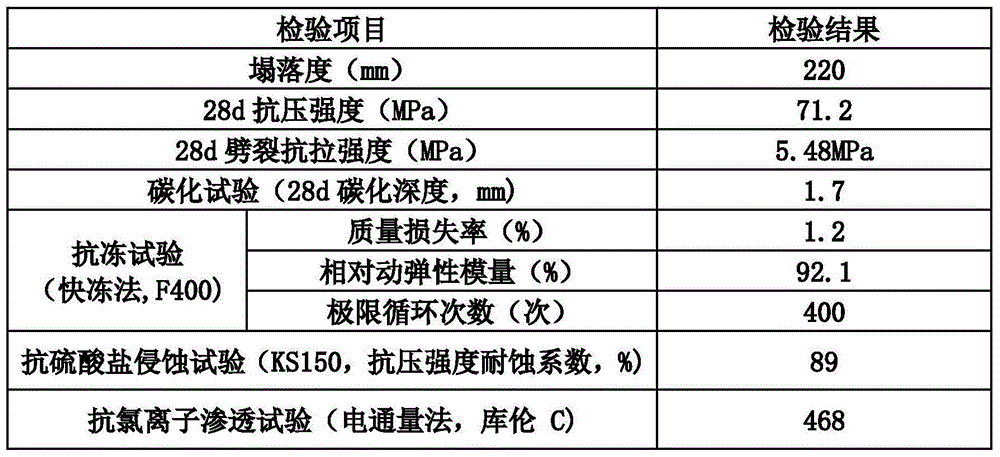

[0025] (1) The remaining steel tailings after the current steel mill has gone through multiple pretreatments and multiple iron selection processes are crushed by an impact-type high-efficiency fine crusher until the maximum particle size is less than 2mm. The finely crushed steel tailings fine particles are passed through two fluidized broadband iron removers to remove the exposed metallic iron fine particles and the intergrowth fine particles of metallic iron and non-metallic phases. The steel tailing slag fine particles after fine crushing and multi-pass iron removal are sent to a new type of vertical mill with high-efficiency circulation iron removal function and ground to a specific surface area of 480m 2 / kg. During the crushing and grinding process of steel slag, it is necessary to remove the large and small particles mainly composed of metallic iron in time by means of real-time circular iron removal, so as to avoid the friction between the particles and the mutual fr...

Embodiment 3

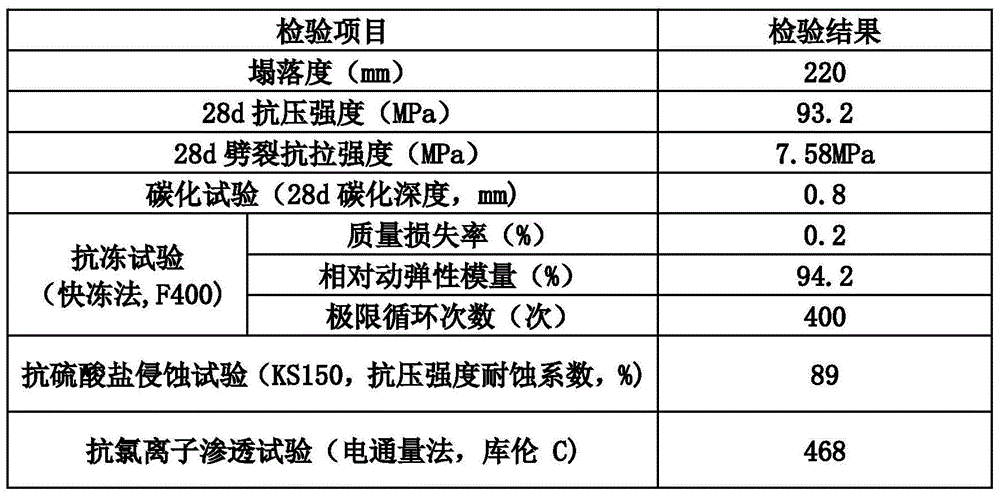

[0033] (1) The remaining steel tailing slag after multi-channel pretreatment and multiple iron selection processes in the current steel plant is crushed by a conical high-efficiency fine crusher until the maximum particle size is less than 1.5mm. Pass the finely crushed steel tailing slag through three fluidized broadband iron removers to remove the exposed metallic iron fine particles and the intergrowth fine particles of metallic iron and non-metallic phases. The steel tailing slag fine particles after fine crushing and multi-pass iron removal are sent to a new rolling mill with high-efficiency circulation iron removal function and ground to a specific surface area of 490m 2 / kg. During the crushing and grinding process of steel slag, it is necessary to remove the large and small particles mainly composed of metallic iron in time by means of real-time circular iron removal, so as to avoid the friction between the particles and the mutual friction between the particles and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com