Hydraulic control method for COREX slag powder mill system

A control method and system pressure technology, applied in the field of hydraulic control, can solve the problems of being too simple, the hydraulic control method cannot be used, and cannot meet the COREX slag grinding process, etc., and achieves easy operation, improved hydraulic control method, and a high degree of intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

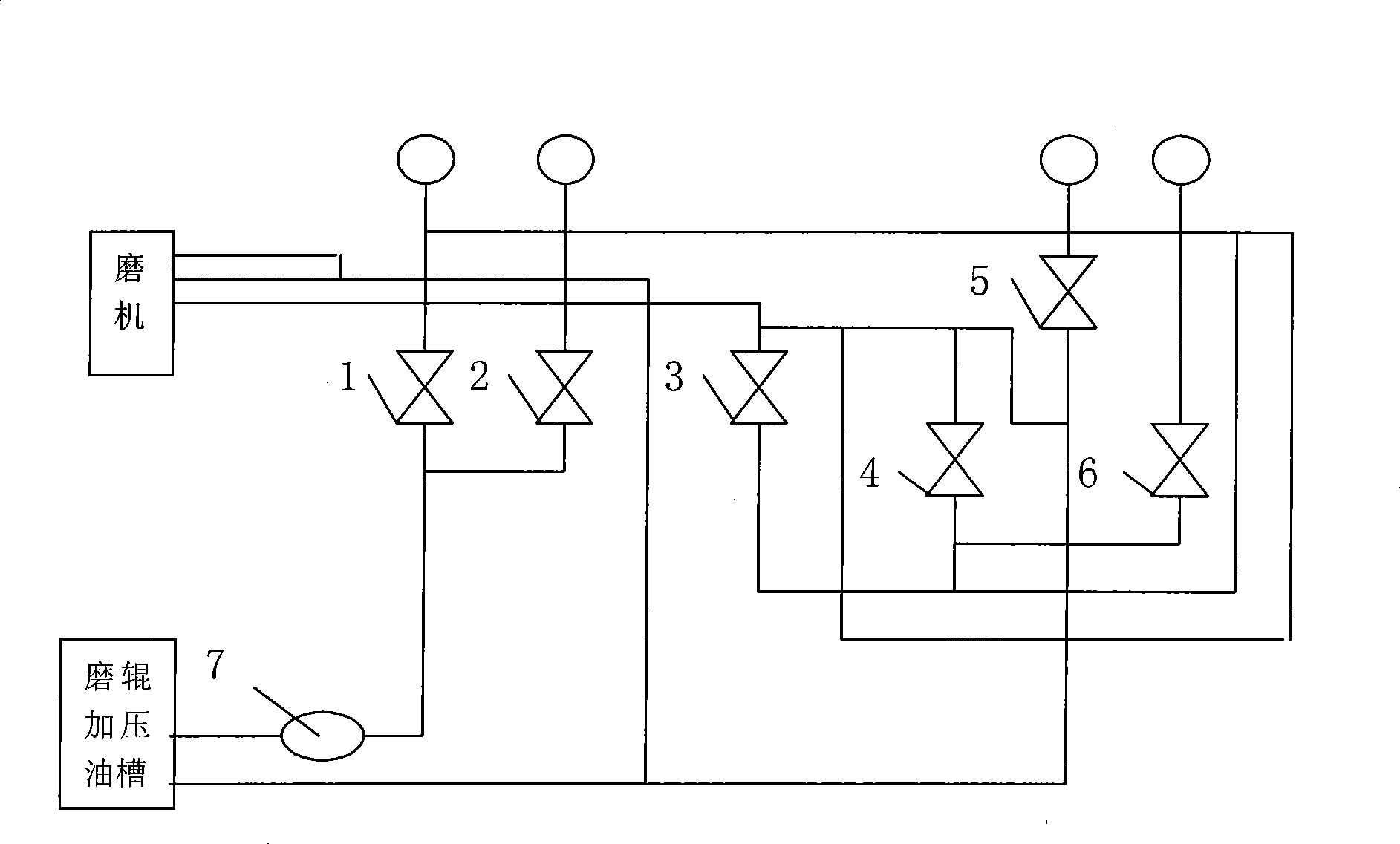

[0010] A kind of hydraulic control system for COREX slag grinding system of the present invention (as attached figure 2 As shown), the control operating system is composed of electromagnetic reversing valve 1-6, motor 7 and PT1, PT2, PT3, PT4 pressure sensors; wherein, the electromagnetic reversing valve 1 is SOL1a, and the electromagnetic reversing valve 2 is SOL1b , The electromagnetic reversing valve 3 is SOL2, the electromagnetic reversing valve 4 is SOL3-1, the electromagnetic reversing valve 5 is SOL3-2, and the electromagnetic reversing valve 6 is SOL4.

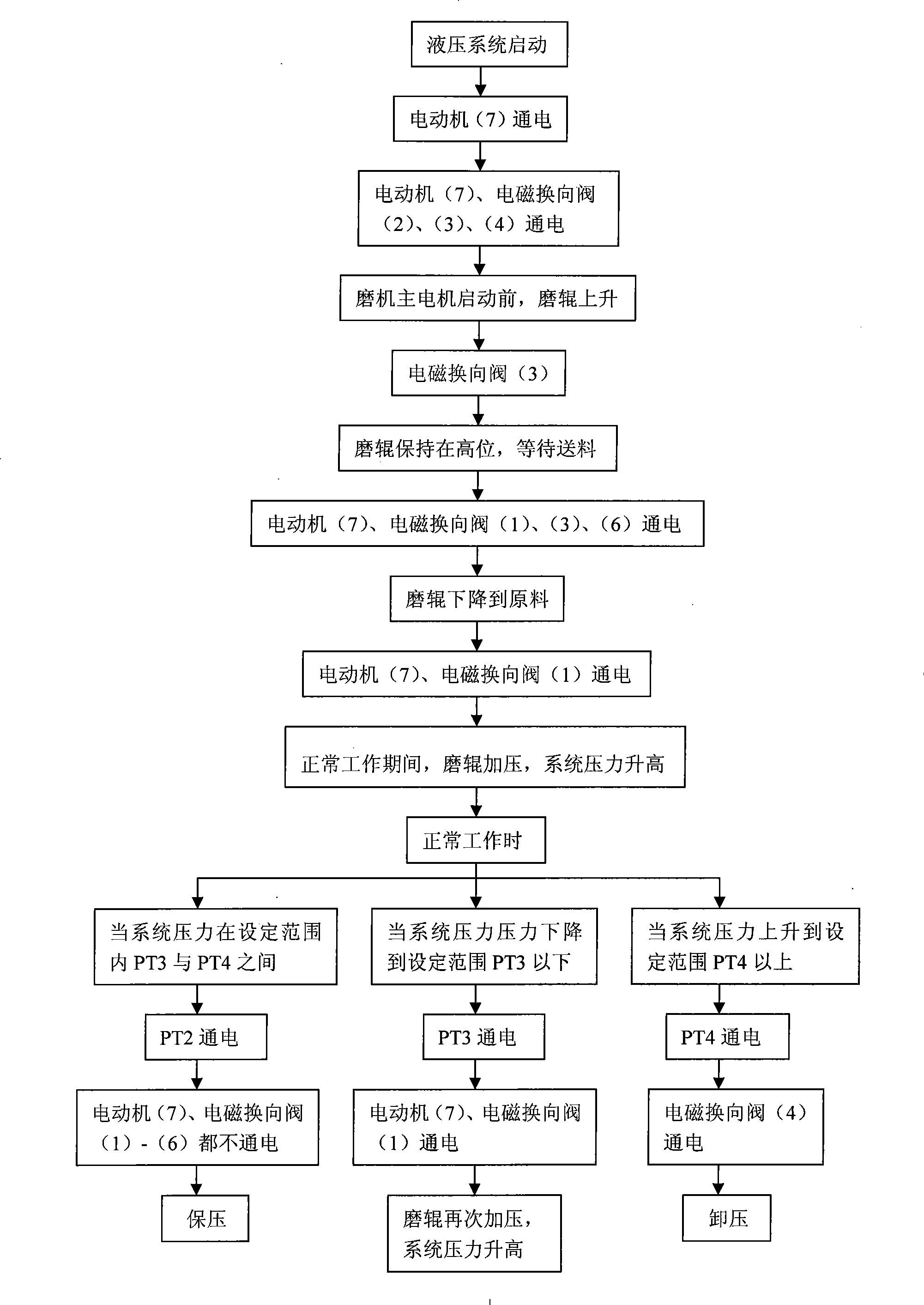

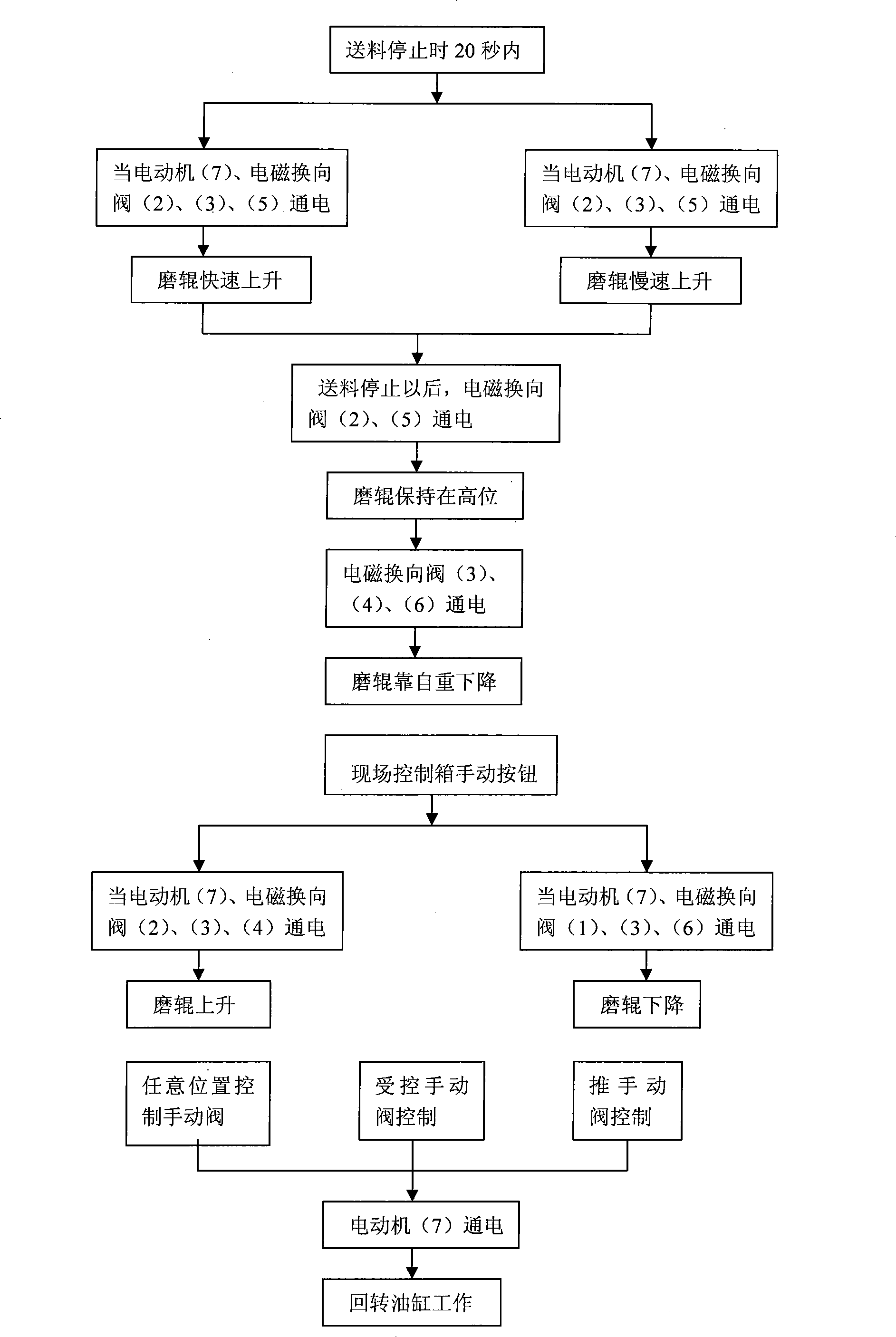

[0011] According to the technological process, the present invention forms the logical relationship of different working states through the central control DCS operation, and realizes through the following steps (as attached figure 1 shown):

[0012] A. Start the hydraulic system → electrify the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com