Ultrafine grinding system for blast furnace slag

A technology of blast furnace slag and ultrafine powder, which is applied in the direction of solid separation, separation of solids from solids by air flow, grain treatment, etc. It can solve the problems of high energy consumption and low production efficiency, and achieve the goal of improving strength and comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

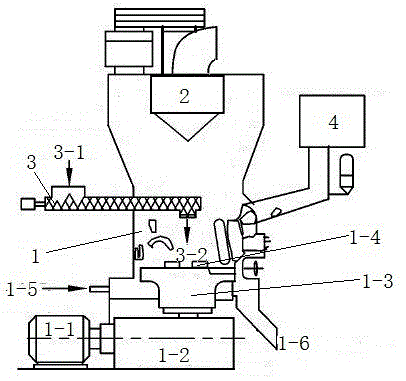

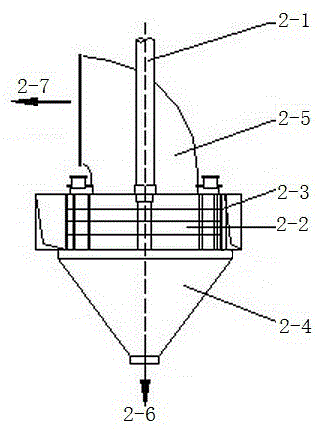

[0010] Such as figure 1 , 2 As shown, the blast furnace slag ultra-fine grinding system of the present invention includes the following components: an ultra-fine grinding machine (1), a separator (2) located in the ultra-fine grinding machine (1), and an ultra-fine powder The screw feeder (3) connected to one side of the mill (1) and the hydraulic system (4) connected to the other side of the superfine pulverizer (1), the superfine pulverizer (1) includes The motor (1-1), the reducer (1-2) connected to the motor (1-1), the grinding disc (1-3) arranged in the superfine pulverizer (1), and the grinding disc (1-3) The connected grinding roller (1-4), the air inlet (1-5) and the sundry discharge port (1-6) located at the lower part of the superfine pulverizer (1), the powder classifier (2) It is a dynamic powder separator, and the powder separator (2) includes a transmission shaft (2-1), an impeller (2-2) connected to the transmission shaft (2-1), and an impeller (2-2) connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com