Main unit transmission device for ultra-fine pendulum powder mill

A technology of transmission device and milling machine, which is applied in the direction of transmission device, gear transmission device, mechanical equipment, etc., and can solve the problems of low transmission meshing precision and difficulty in processing bevel gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

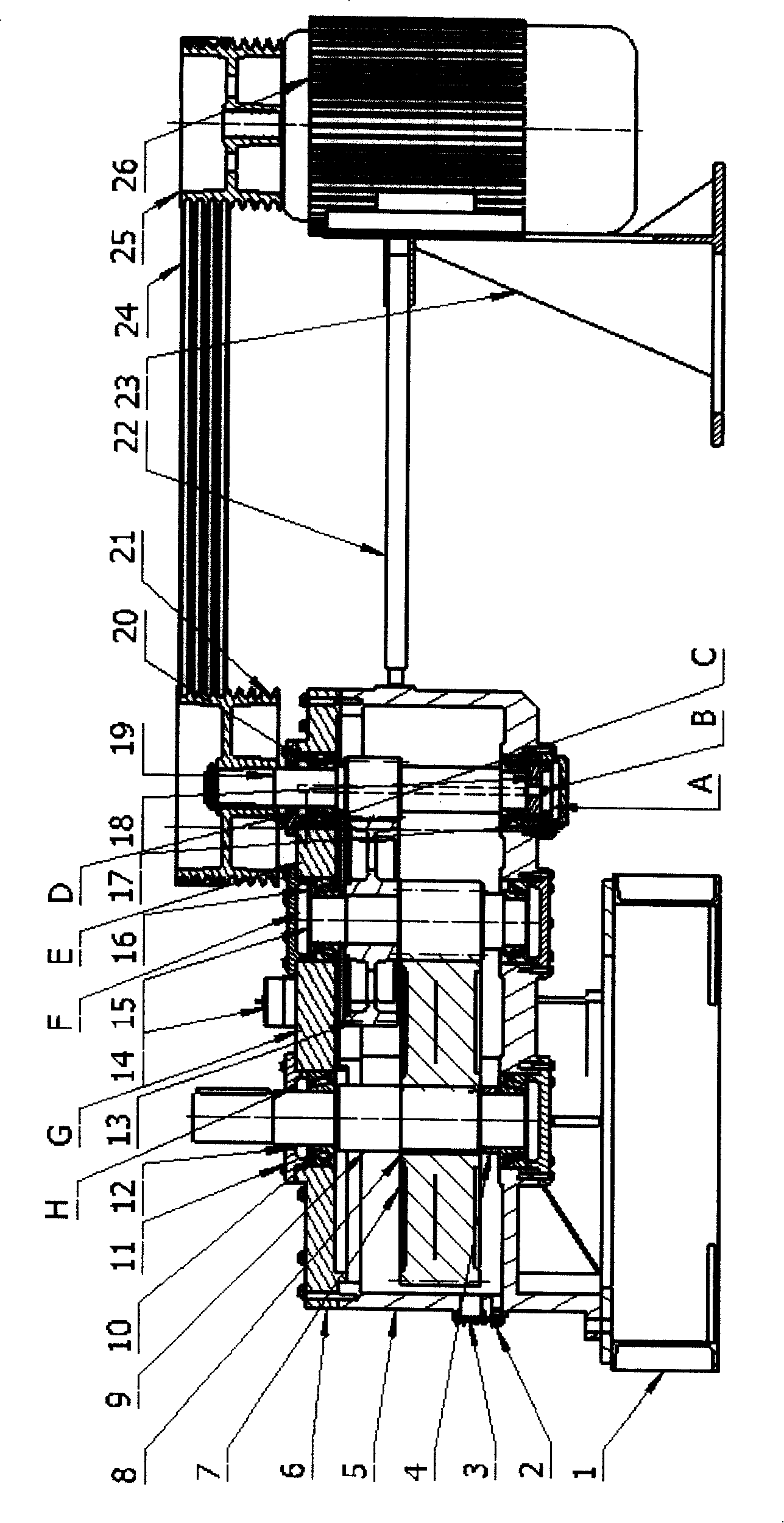

[0008] As shown in the figure, the main engine transmission device used in the ultrafine pendulum mill of the present invention includes a reduction gearbox installed on the gearbox base 1 and a motor 26 installed on the motor mounting base 23 . The motor 26 is a vertical motor, and the motor mount 23 is independently installed on the foundation. The input gear shaft 19 of the reduction box is provided with a reduction box pulley 21, and the motor 26 shaft is provided with a motor pulley 25, and one group of V-belts 24 is connected between the two pulleys 21, 25 to form a V-belt Reduced transmission mechanism. The reduction box is driven by a motor 26 through a V-belt 24 for deceleration transmission.

[0009] A jack bolt 22 for adjusting the tension of the V-belt 24 is arranged between the motor mount 23 and the reduction box.

[0010] Described reduction box is a vertical shaft type reduction box, comprises reduction box body 5, reduction box cover 6, and one to two pairs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com