Patents

Literature

296results about How to "Reduce transmission noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

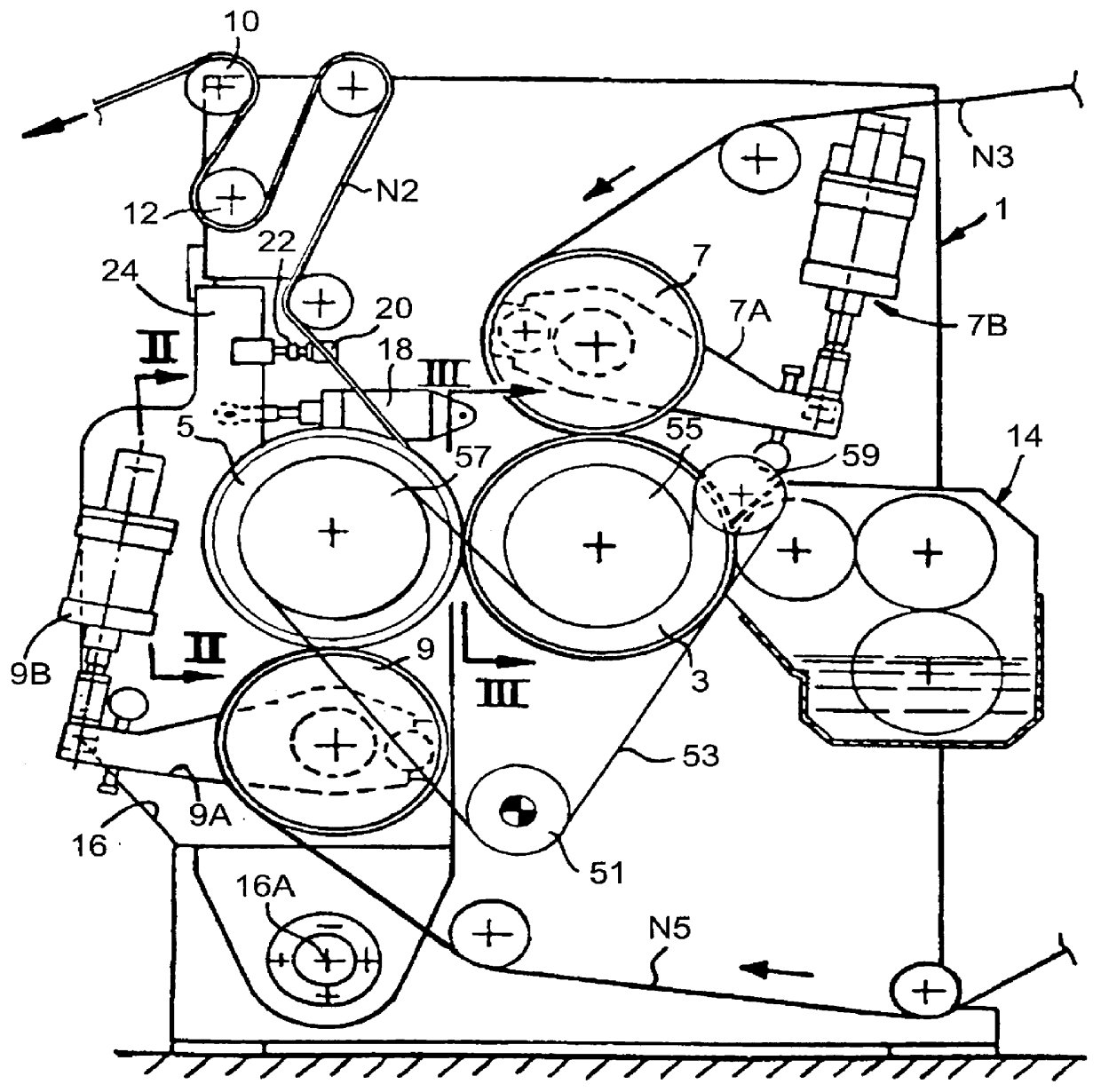

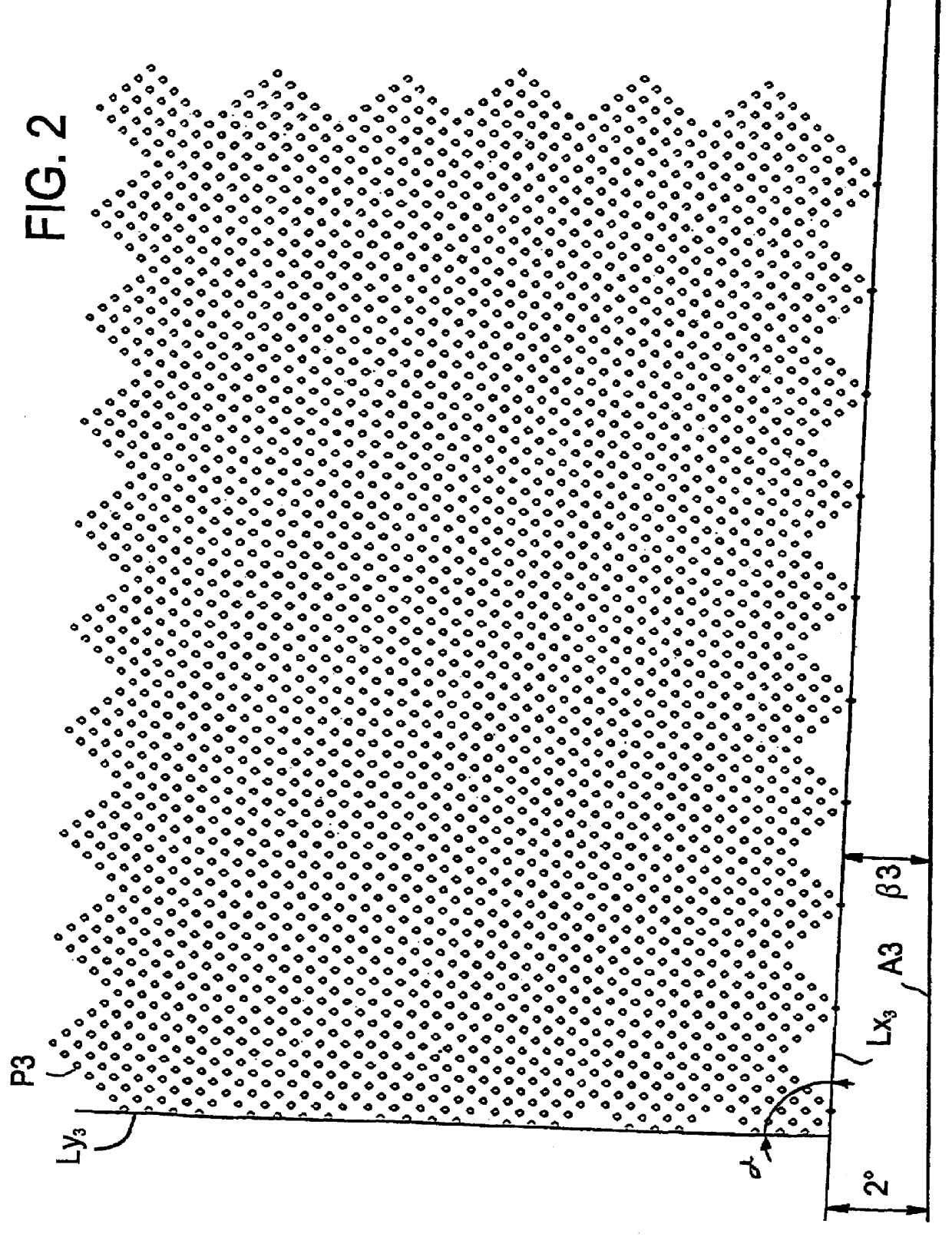

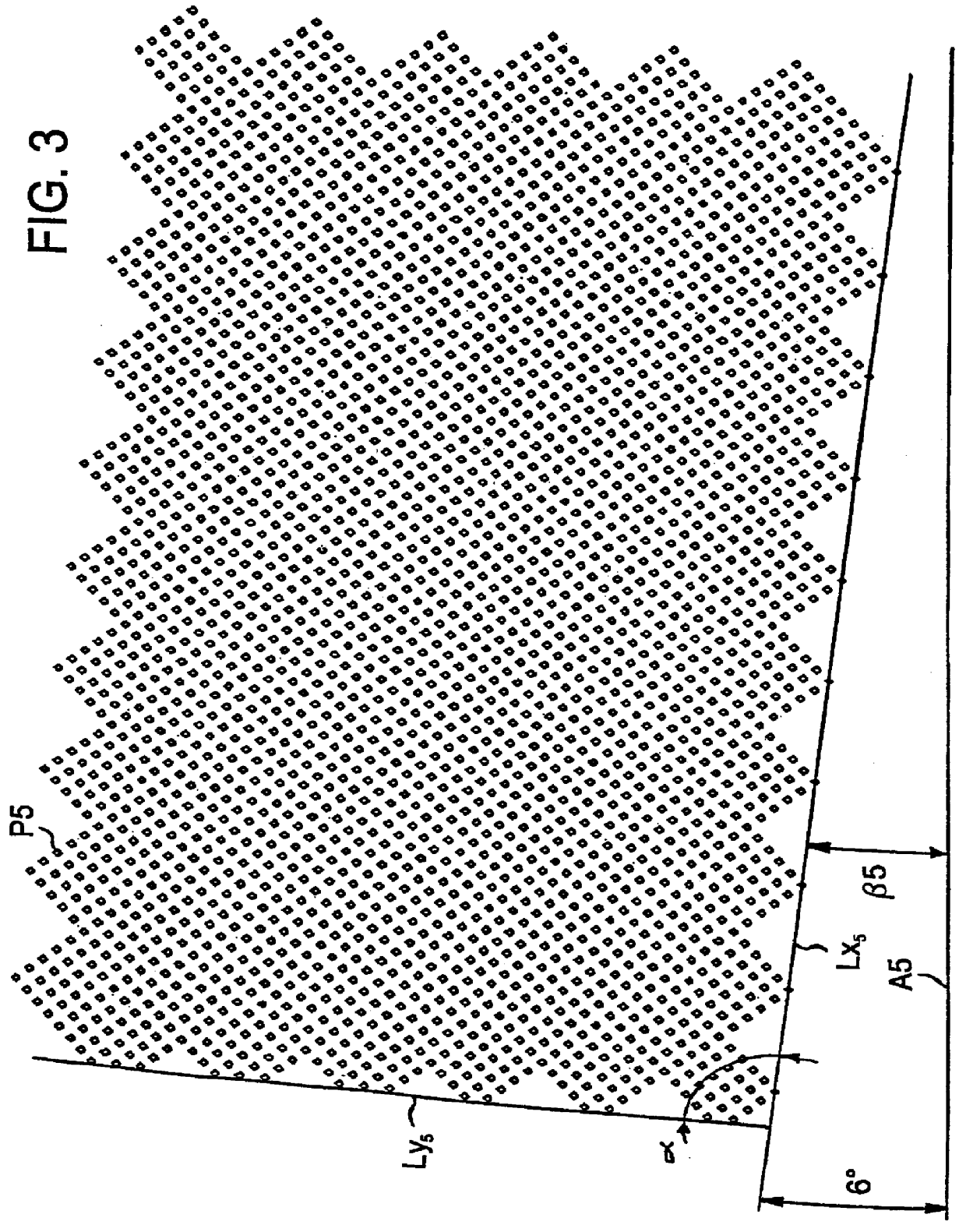

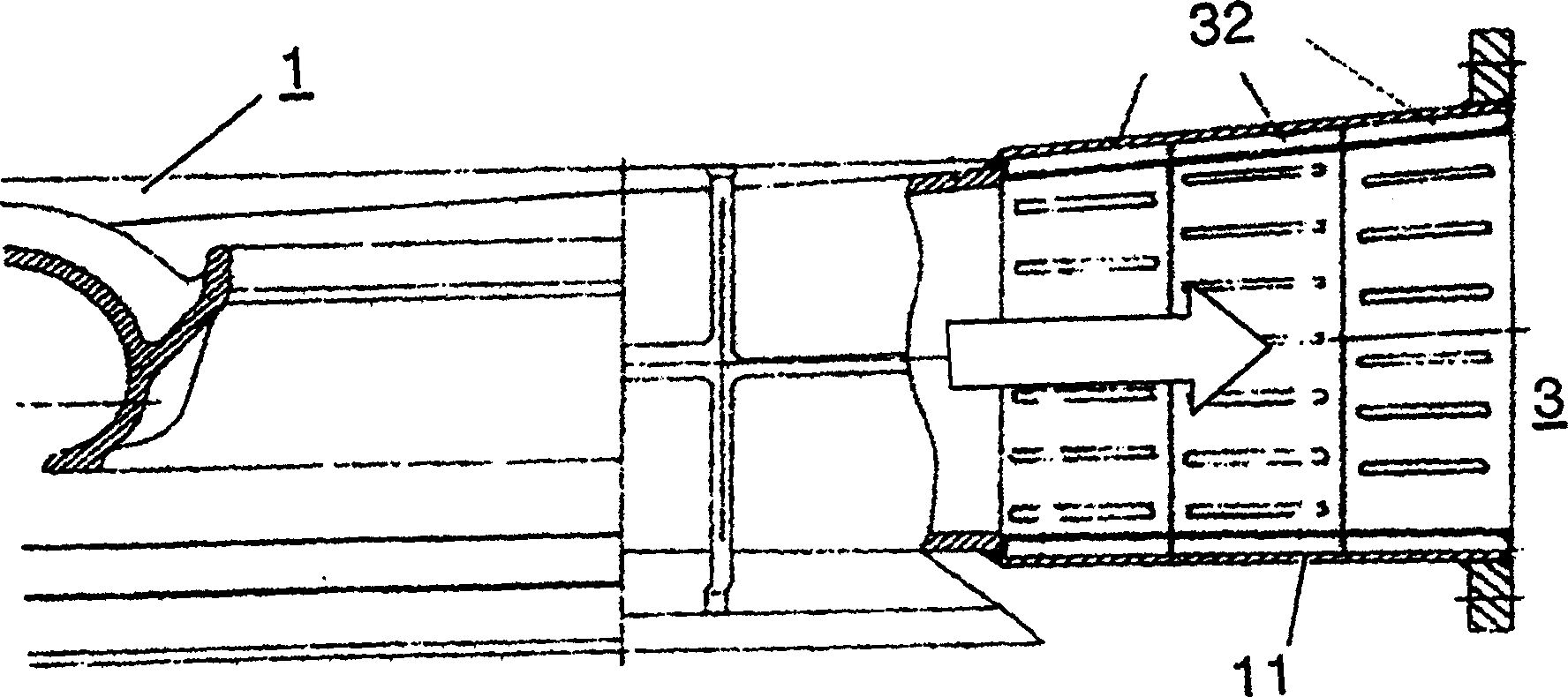

Embossing and laminating machine with embossing cylinders having different rotational speed

InactiveUS6053232AConsiderable timeReduce construction and maintenance costMechanical working/deformationWelding/cutting auxillary devicesEngineeringMechanical engineering

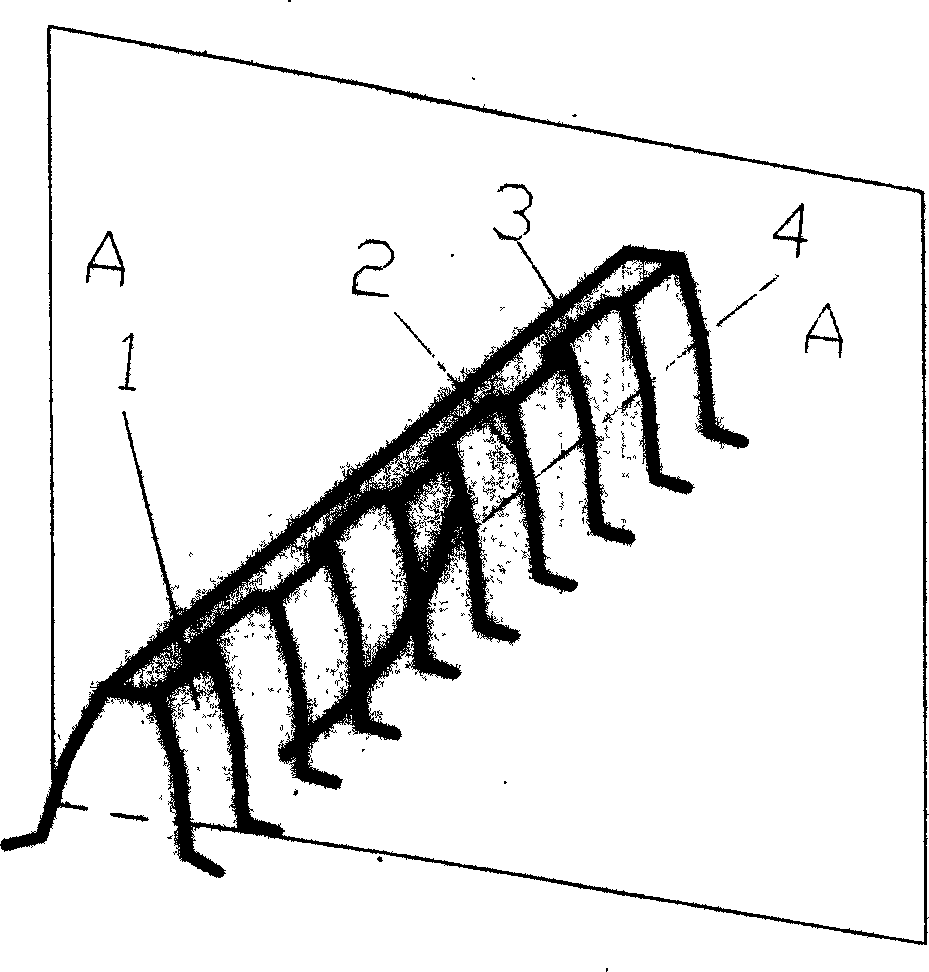

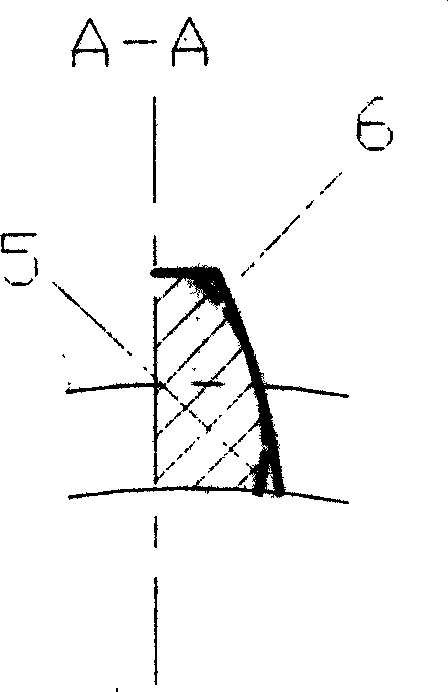

PCT No. PCT / IT96 / 00238 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Dec. 2, 1996 PCT Pub. No. WO97 / 20687 PCT Pub. Date Jun. 12, 1997An embossing and laminating machine comprising a first embossing cylinder with a surface provided with a first set of protuberances, a second embossing cylinder with a surface provided with a second set of protuberances, said two embossing cylinders forming a nip, and a first and a second pressure roller interacting with said first and second embossing cylinders respectively; and in which said sets of protuberances are made in such a way that in said nip some of said first set of protuberances coincide with some of said second set of protuberances, while other protuberances of said first set are out of phase with corresponding protuberances of said second set, wherein said embossing cylinders are mechanically connected by a transmission which does not keep the cylinders in phase and which causes slight relative slippage between said embossing cylinders.

Owner:FABIO PERINI SPA

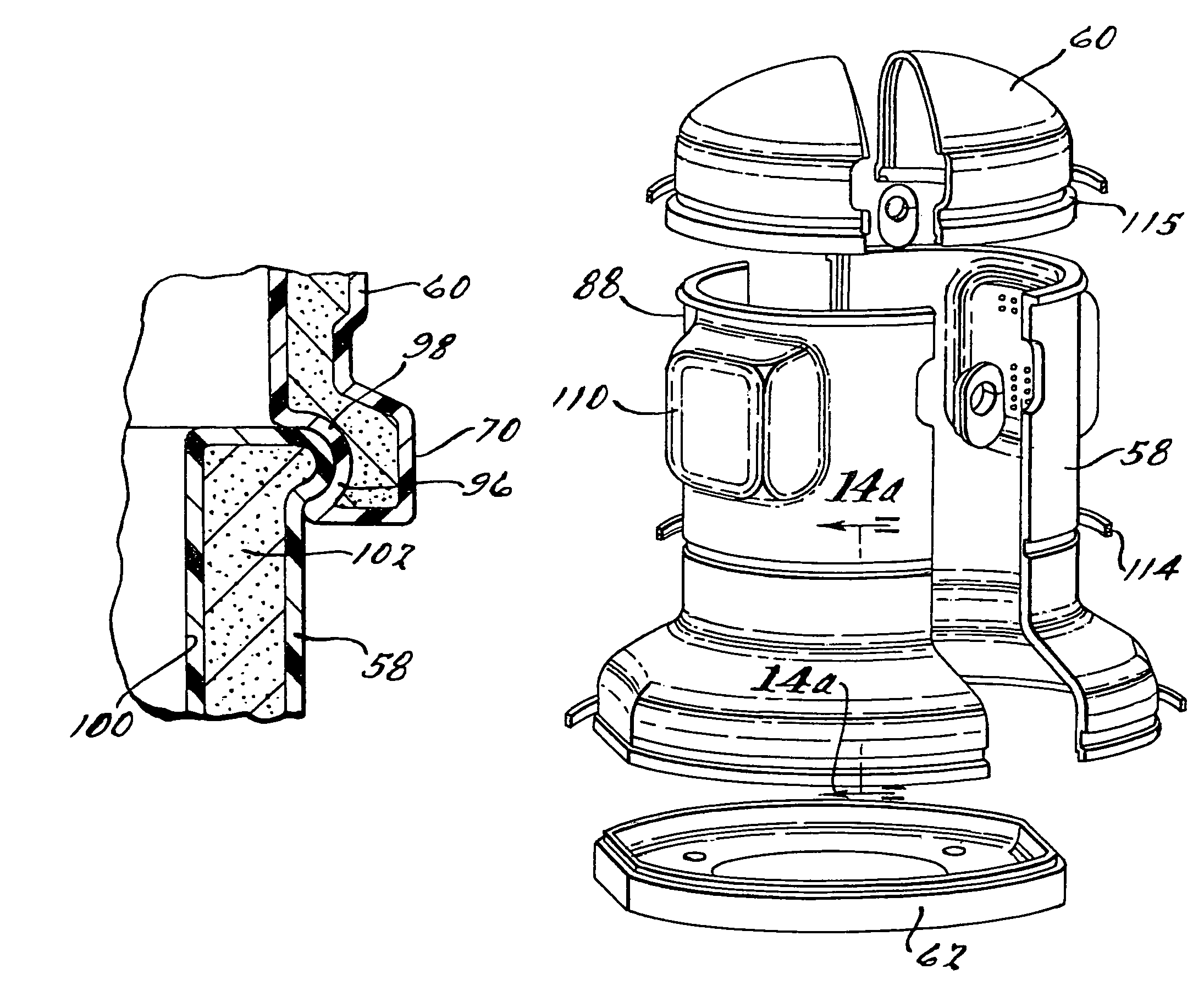

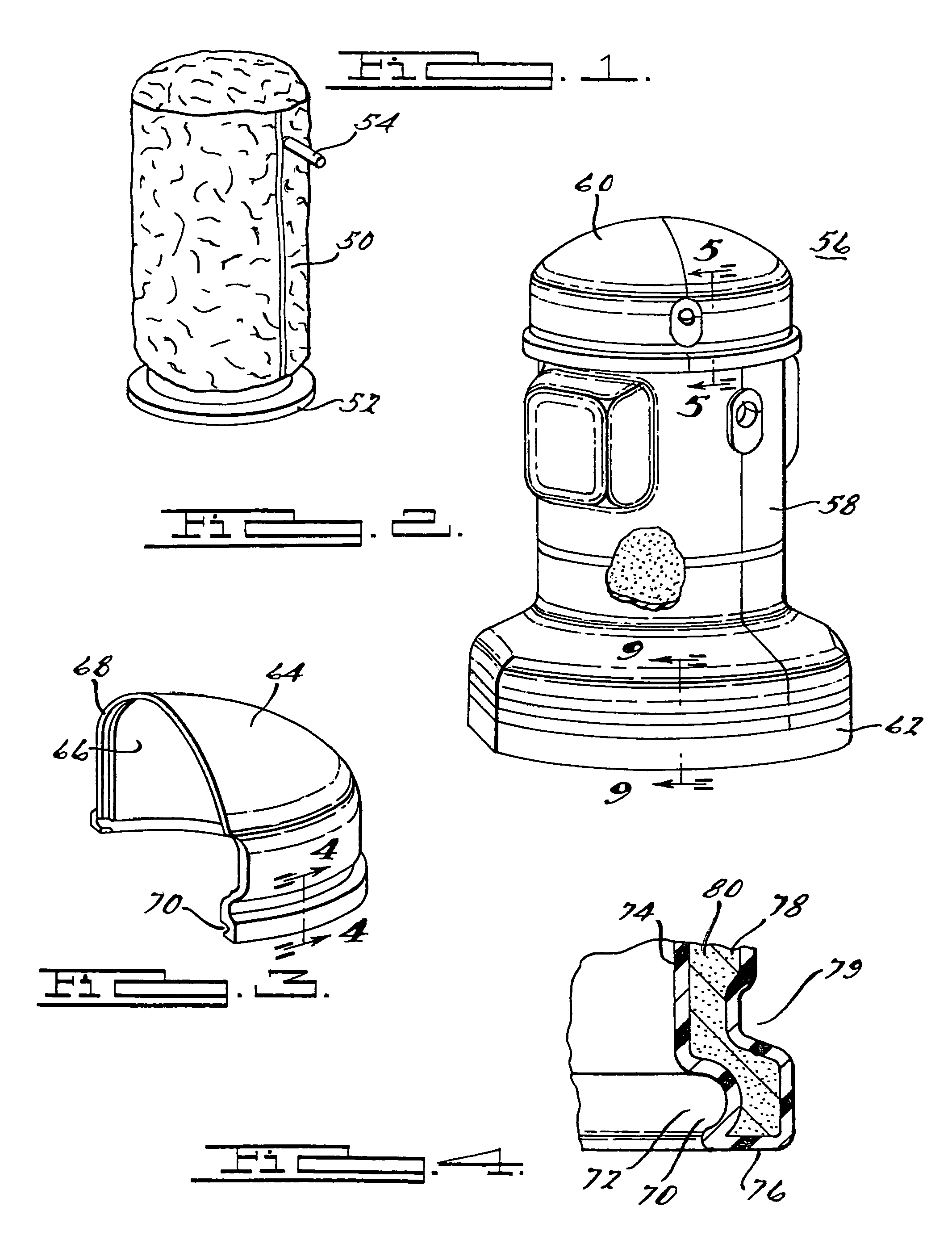

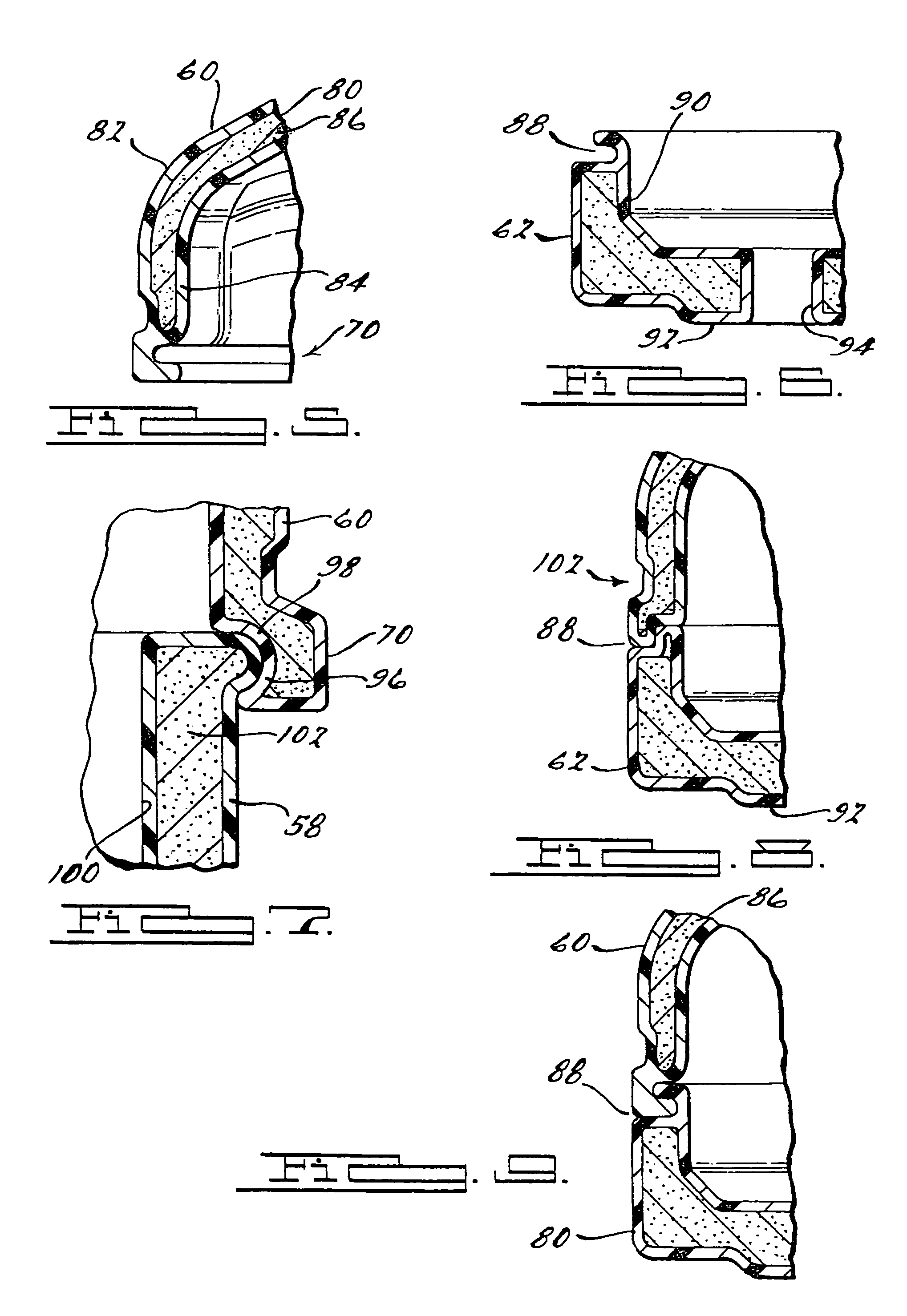

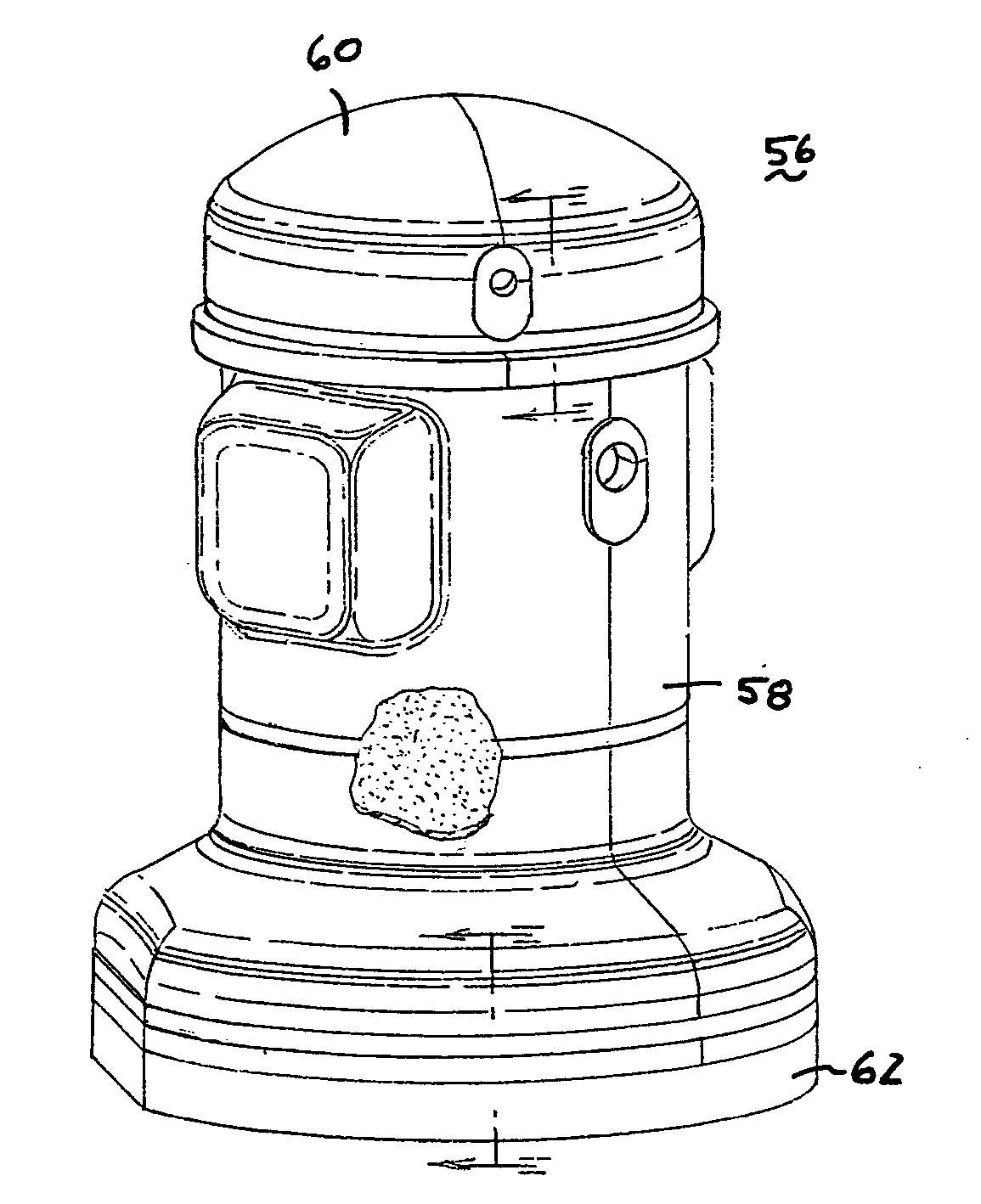

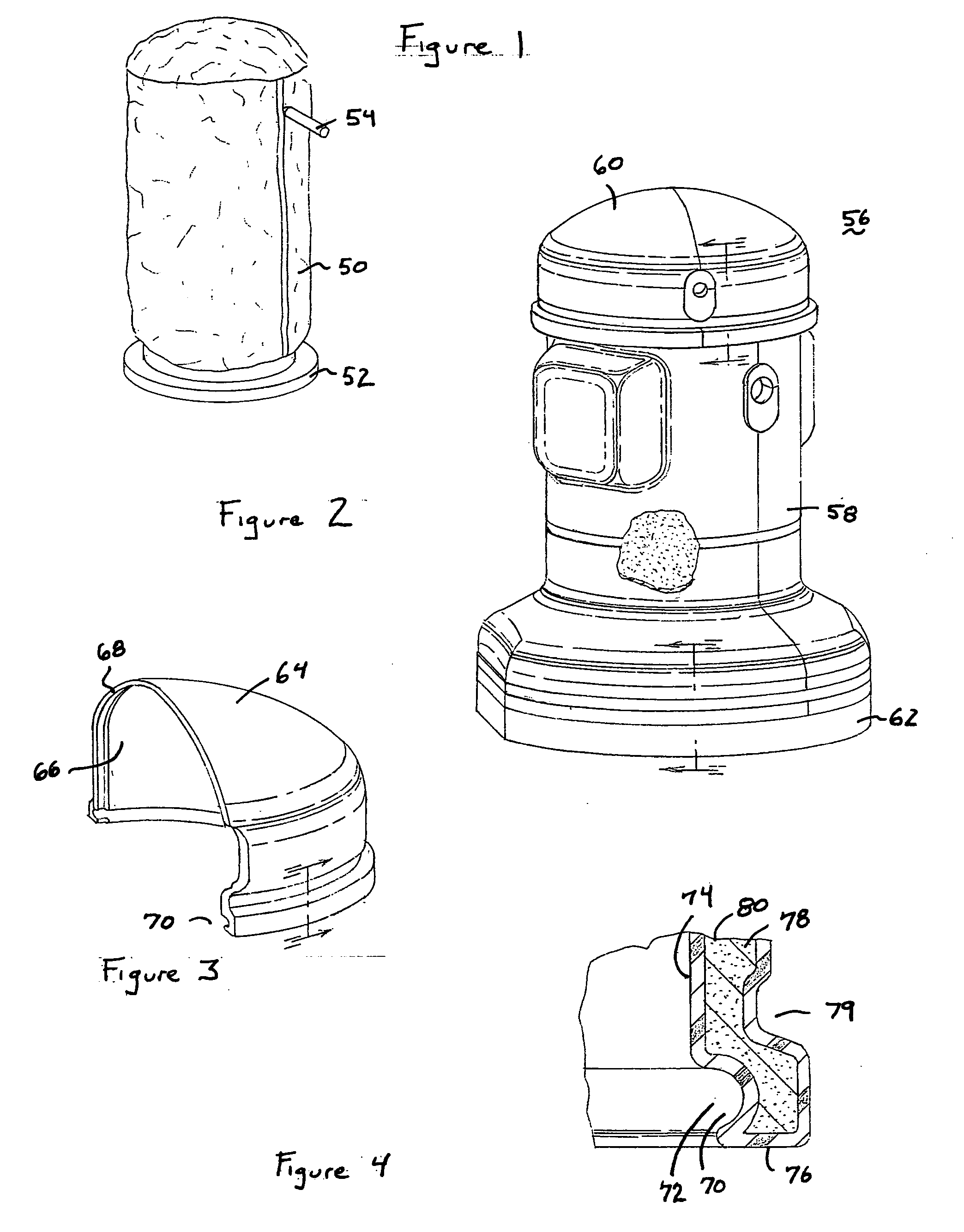

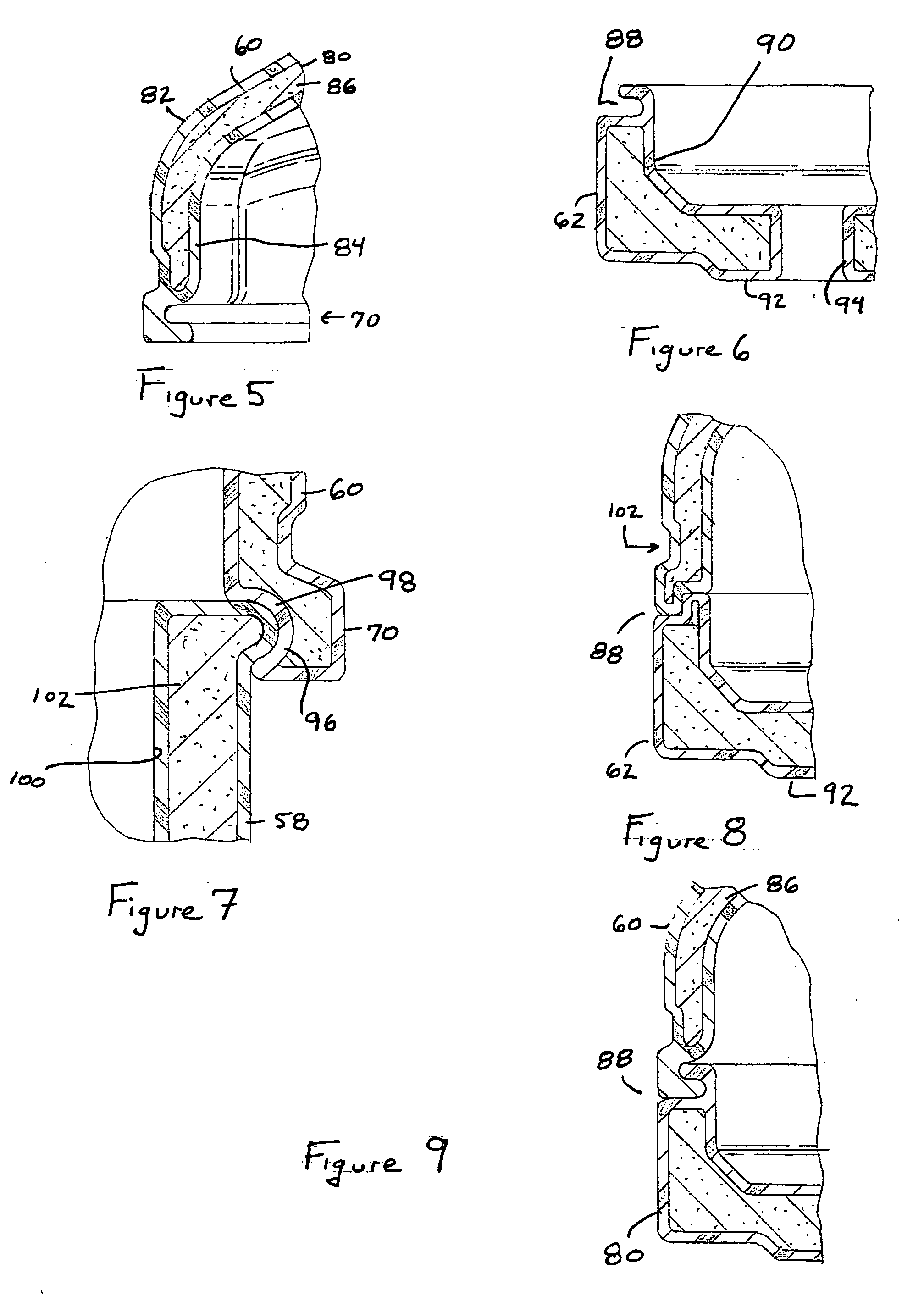

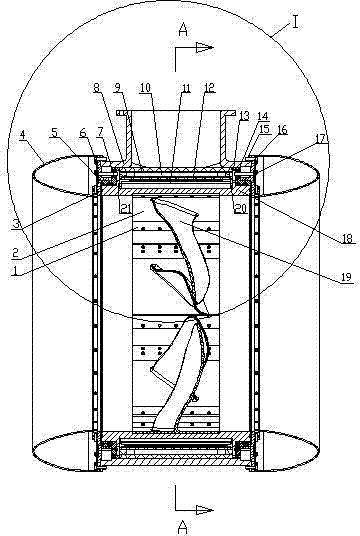

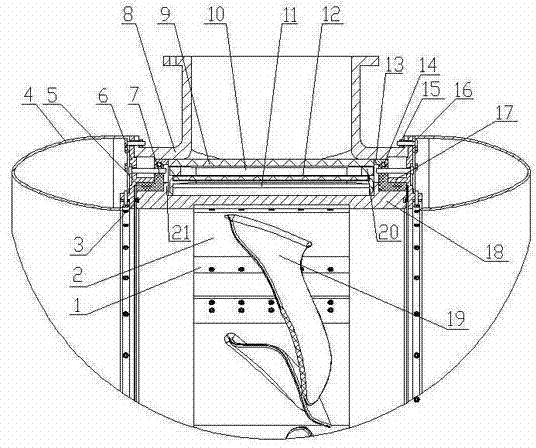

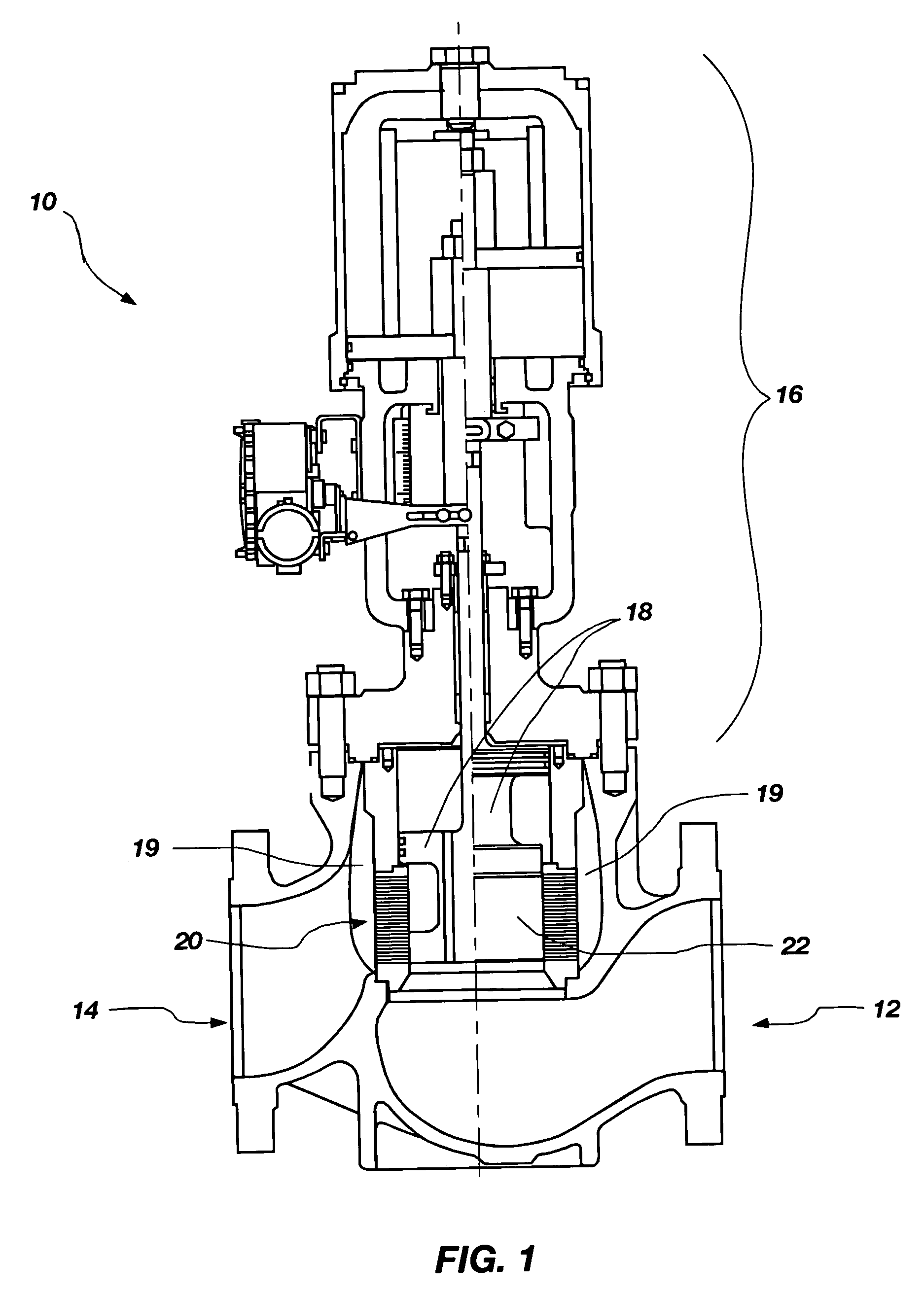

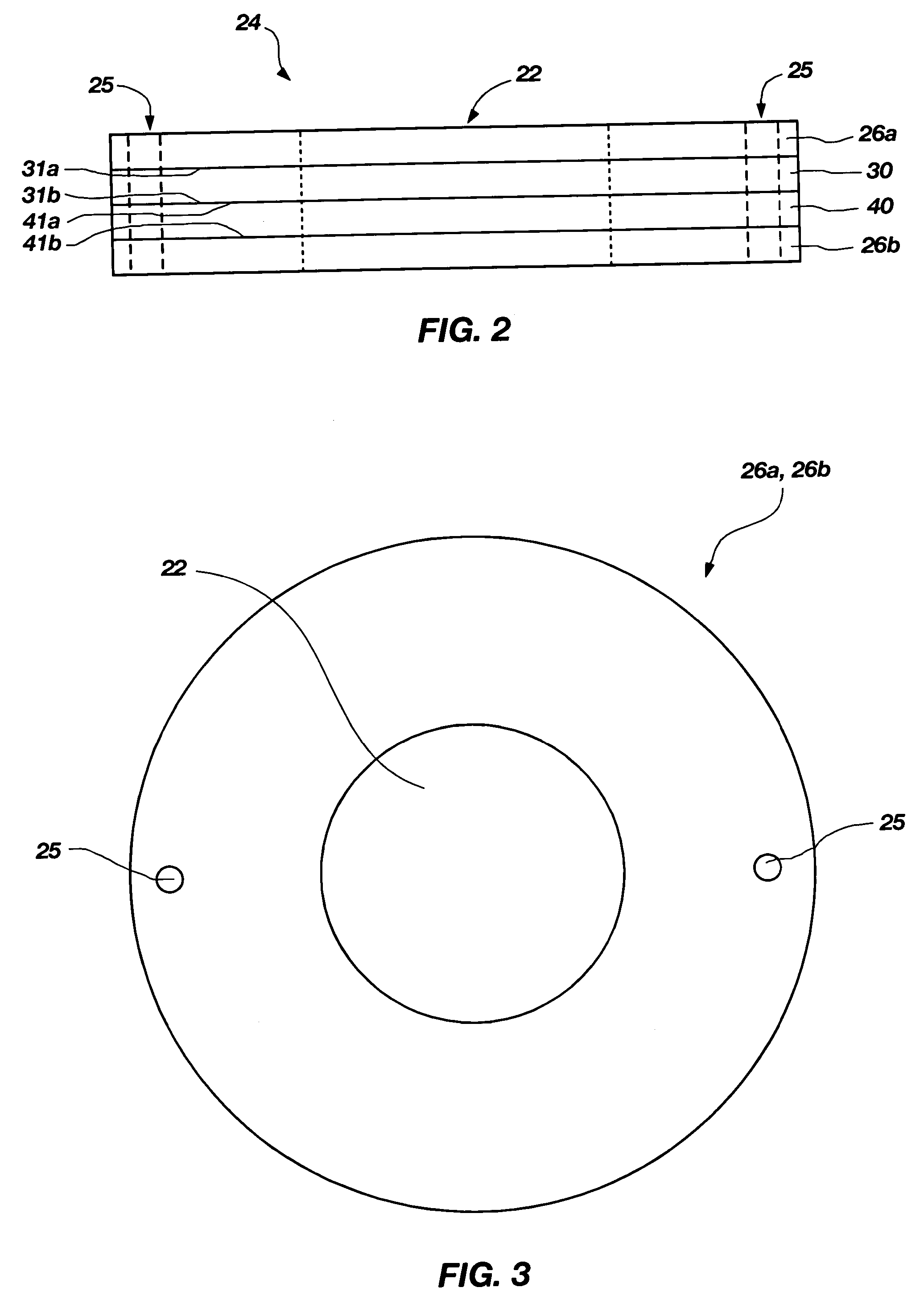

Compressor sound attenuation enclosure

InactiveUS7398855B2Improved sound attenuating shellImprove noiseRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsUltrasound attenuationEngineering

Owner:EMERSON CLIMATE TECH INC

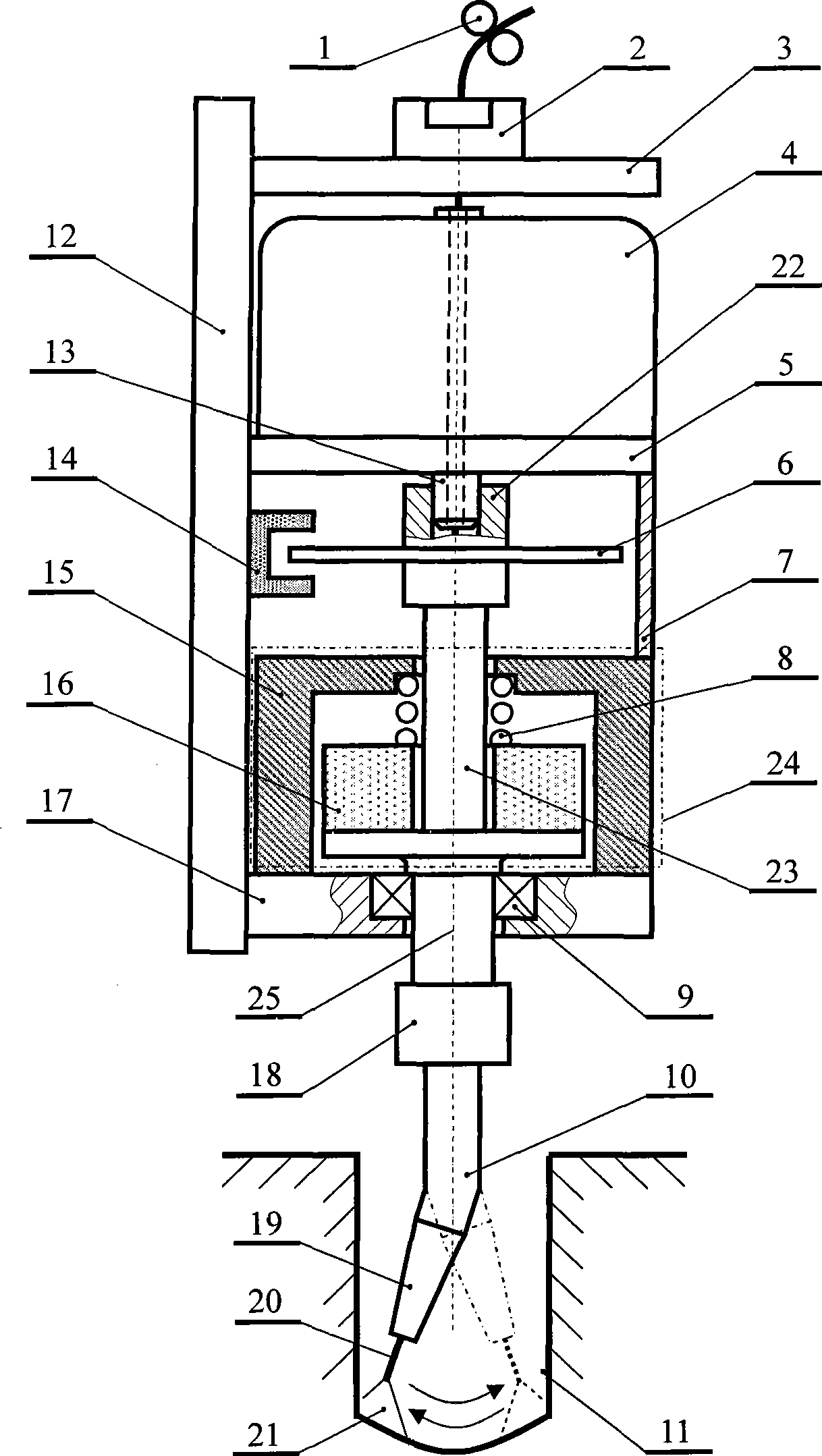

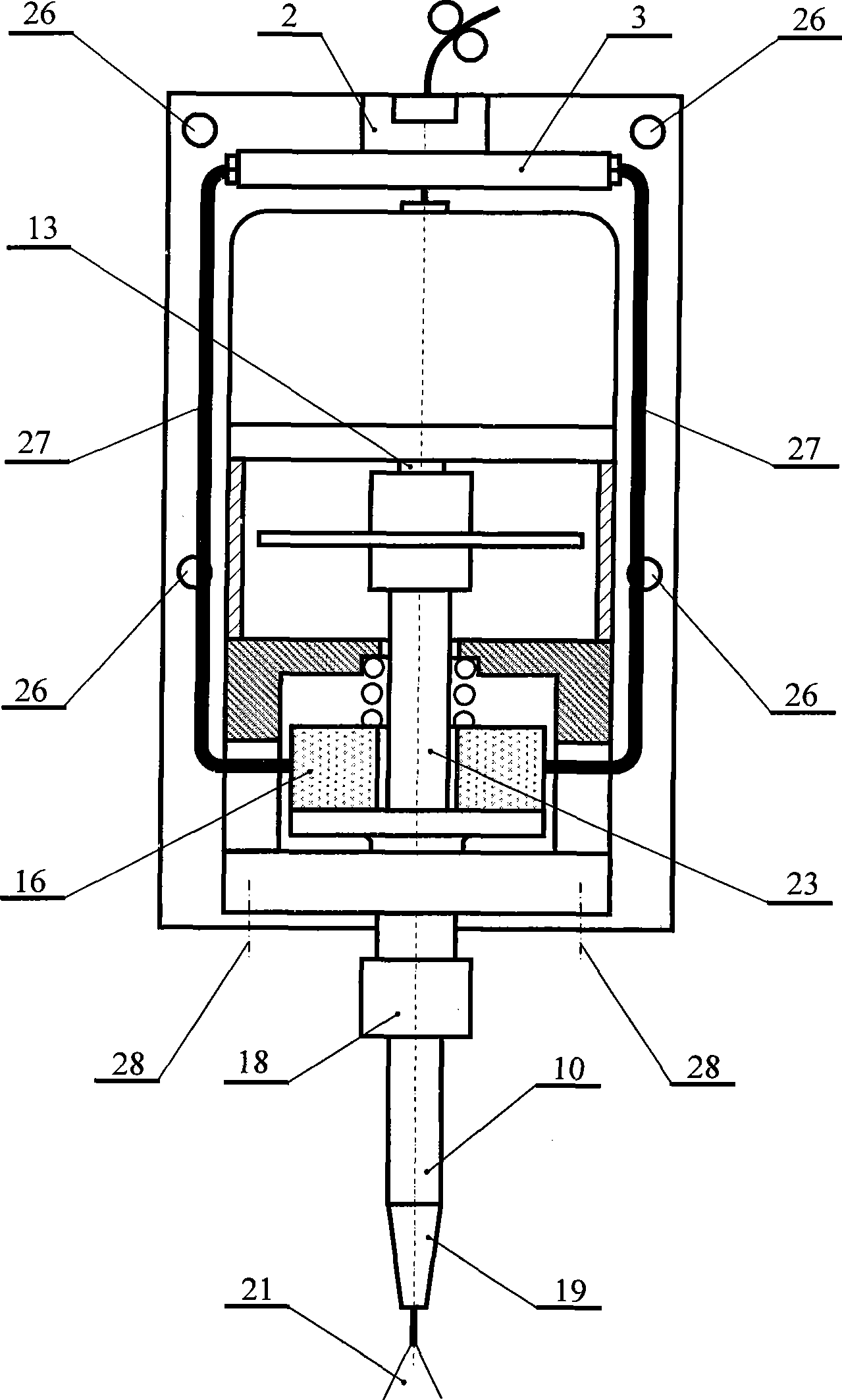

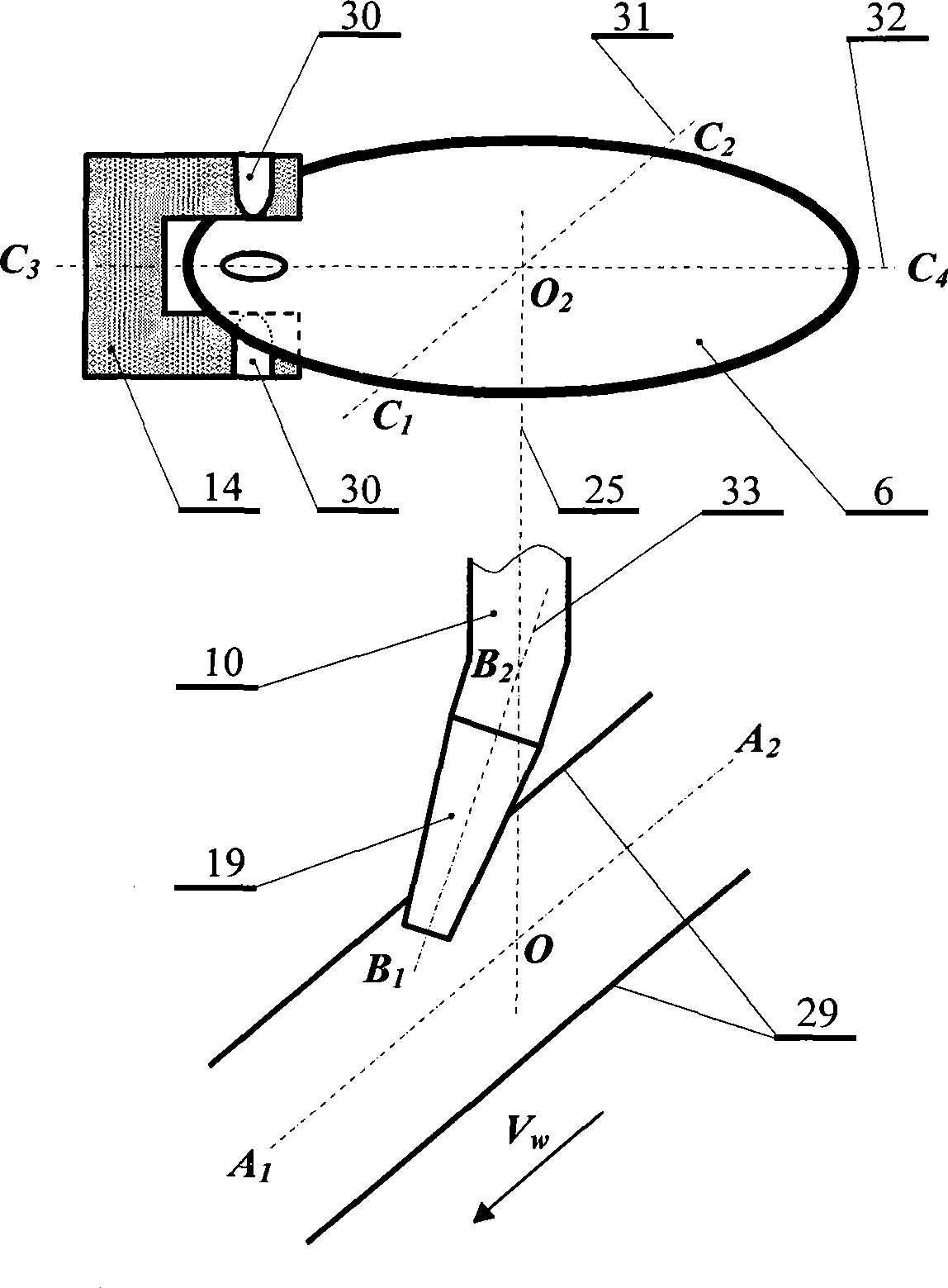

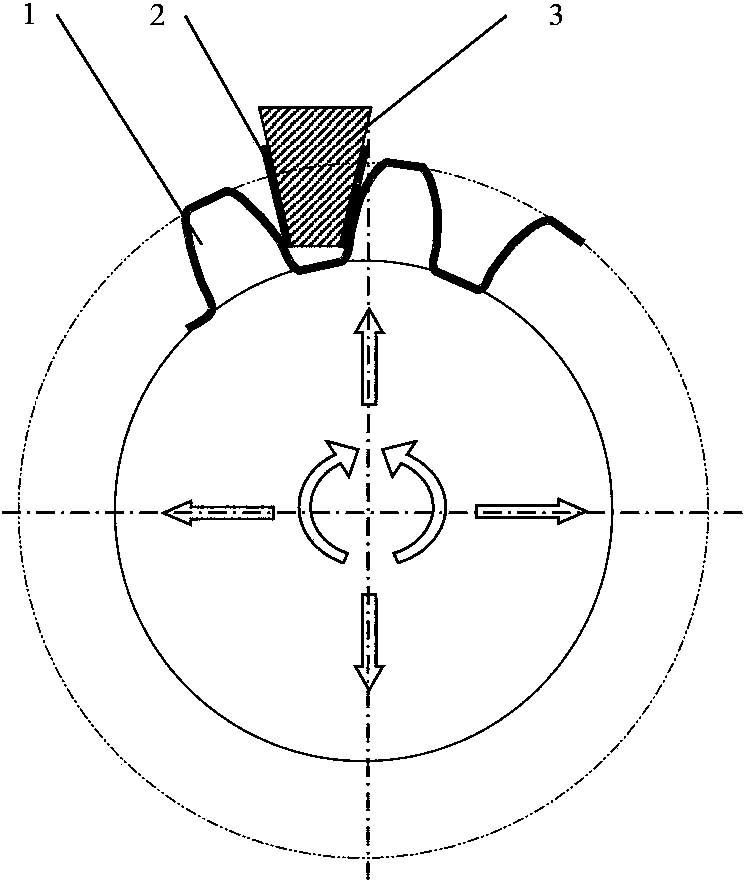

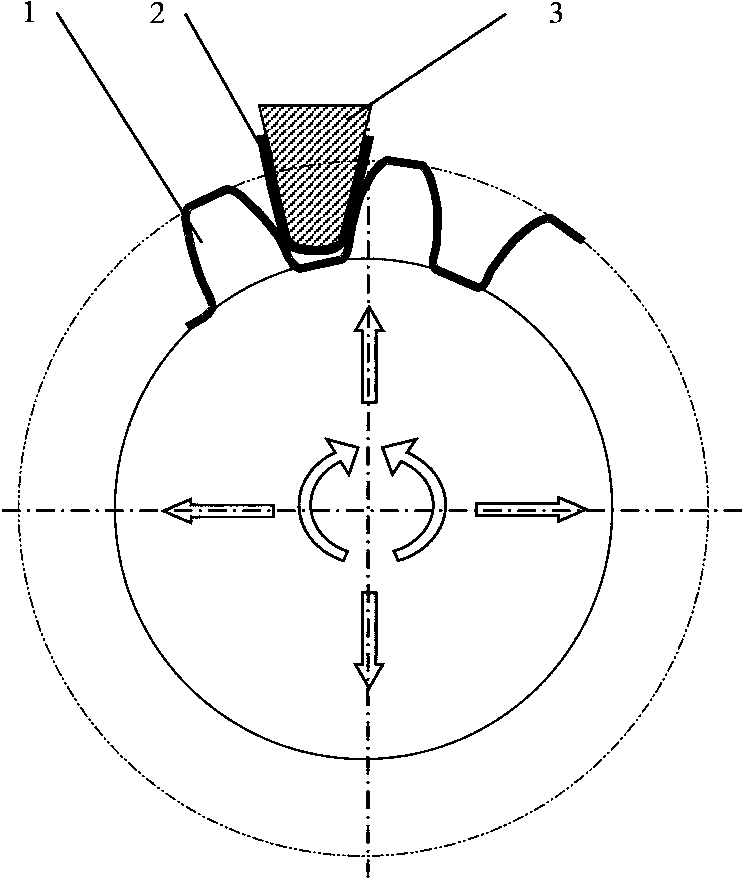

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

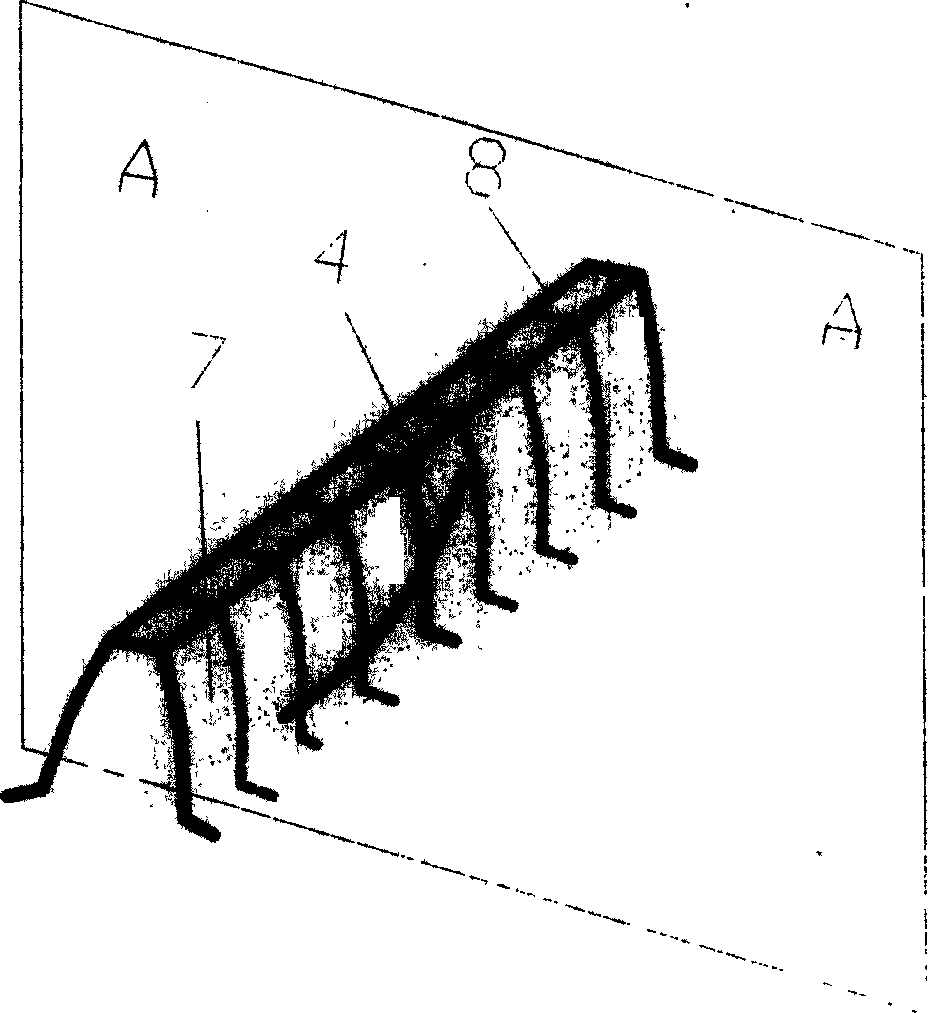

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

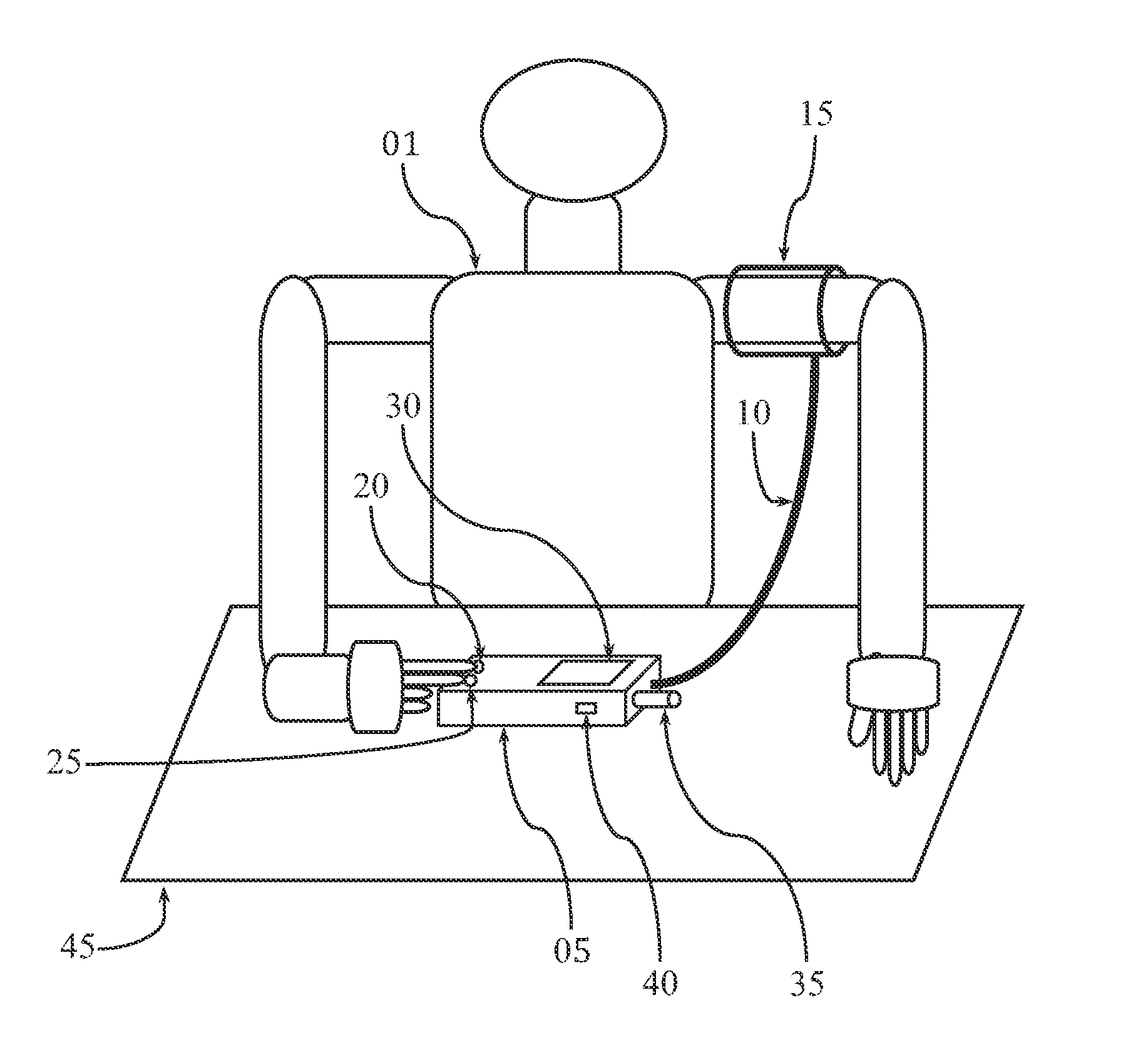

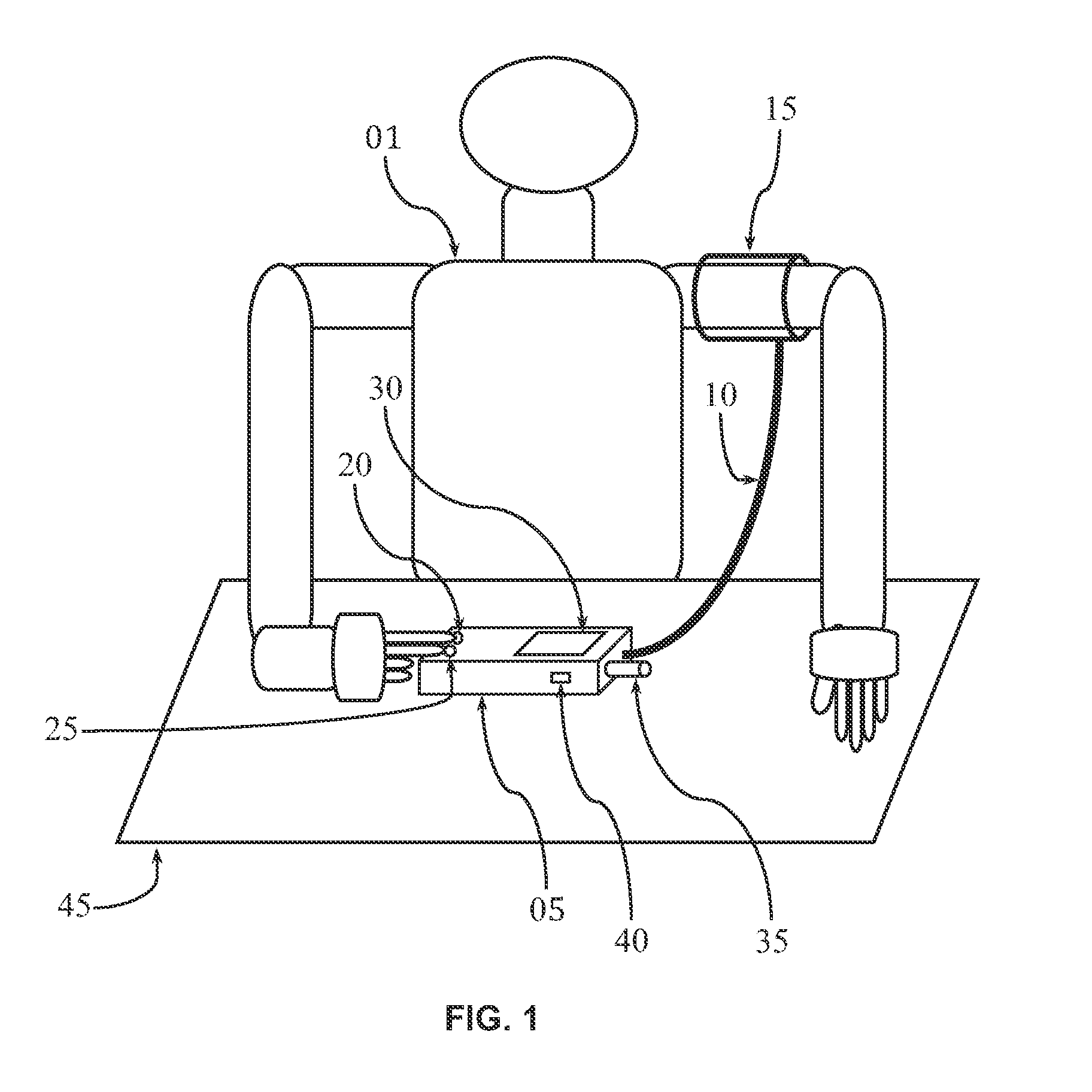

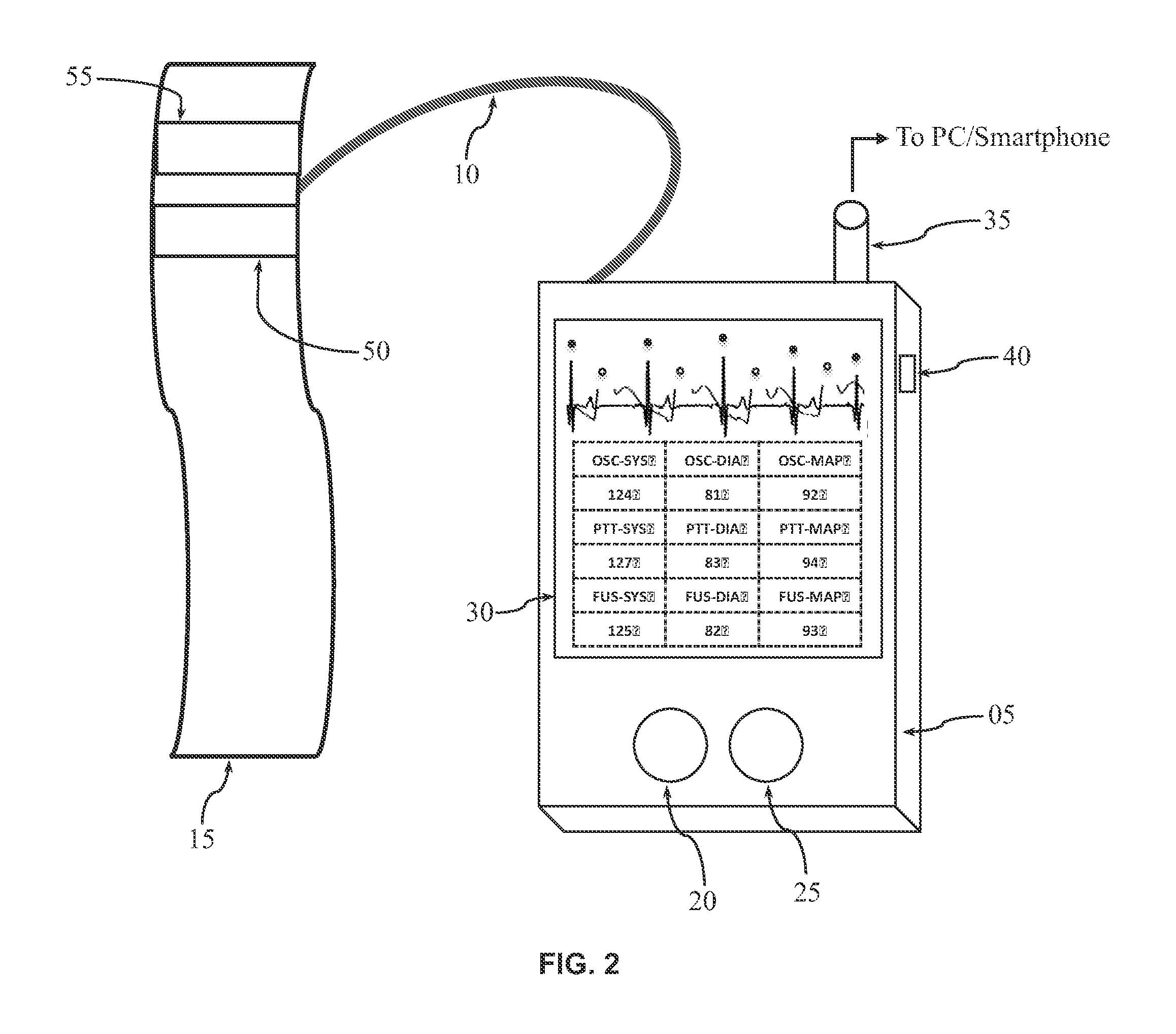

Apparatus and method for electrocardiogram-assisted blood pressure measurement

InactiveUS20120283583A1Reduce noiseReduce transmission noiseEvaluation of blood vesselsCatheterPatient managementNon invasive

Apparatus, method, and software for electrocardiogram-assisted non-invasive arterial blood pressure d stiffness measurement is disclosed including brachial cuff with flexible electrodes, control box with rigid electrodes, and associated hardware / software. Cuff is wrapped around upper arm while electrodes on device are touched with fingers of other hand. Device acquires simultaneous ECG / oscillometric data during cuff deflation. Processing unit determines ECG R-peak positions to isolate arterial pulses and calculate pulse transit time. Change in pulse amplitude as function of cuff pressure is used for constructing oscillometric envelope and calculating blood pressure using empirical coefficients. Change in pulse transit time as function of cuff pressure is used independently for constructing pulse transit time envelopes and finding blood pressure with / without empirical coefficients. Fusion algorithm combines results for robust blood pressure and vessel stiffness evaluation. Device sends physiological information to personal computer / smartphone wirelessly, for further analysis. Computer / smartphone transmits information to third party for patient management.

Owner:BATKIN IZMAIL +5

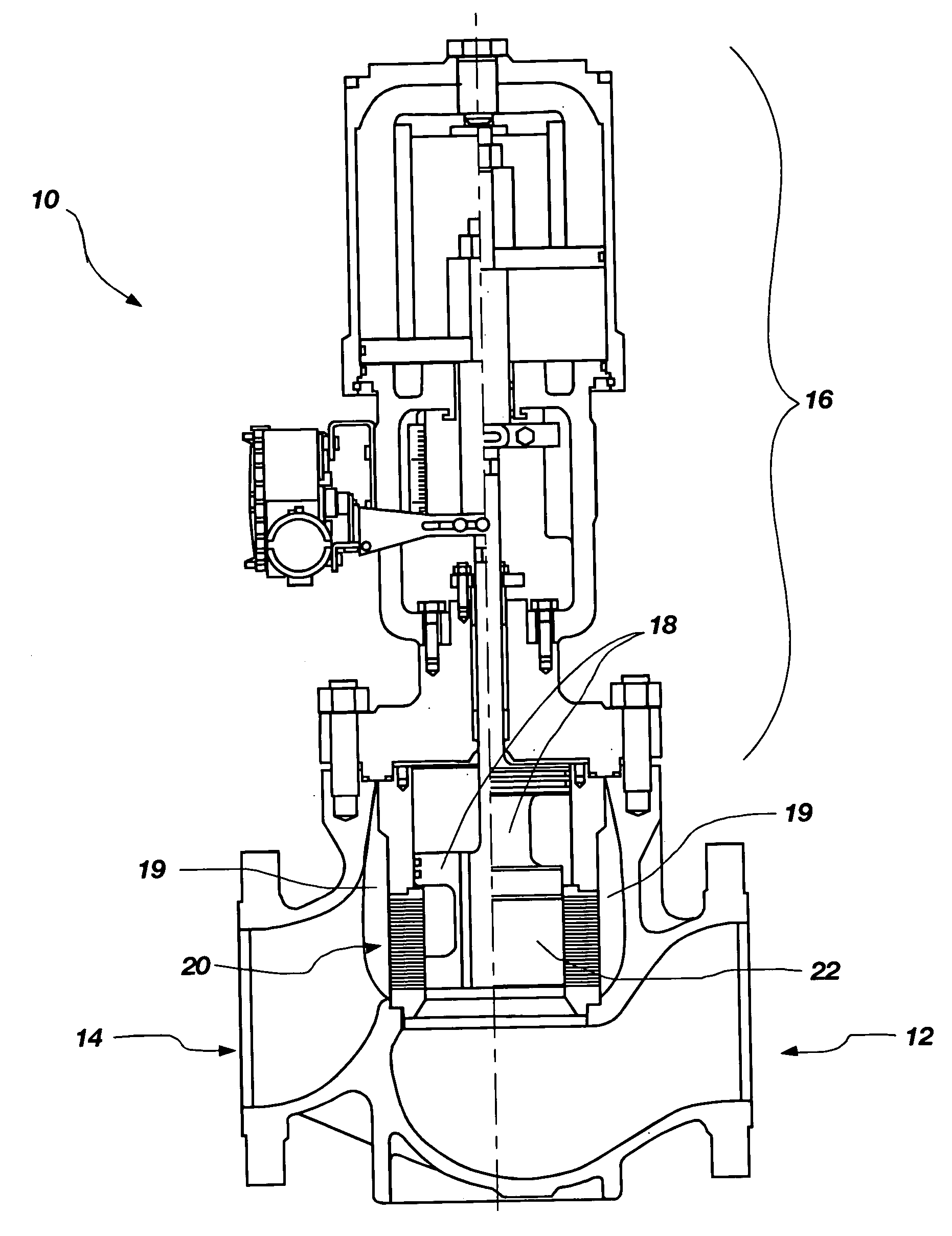

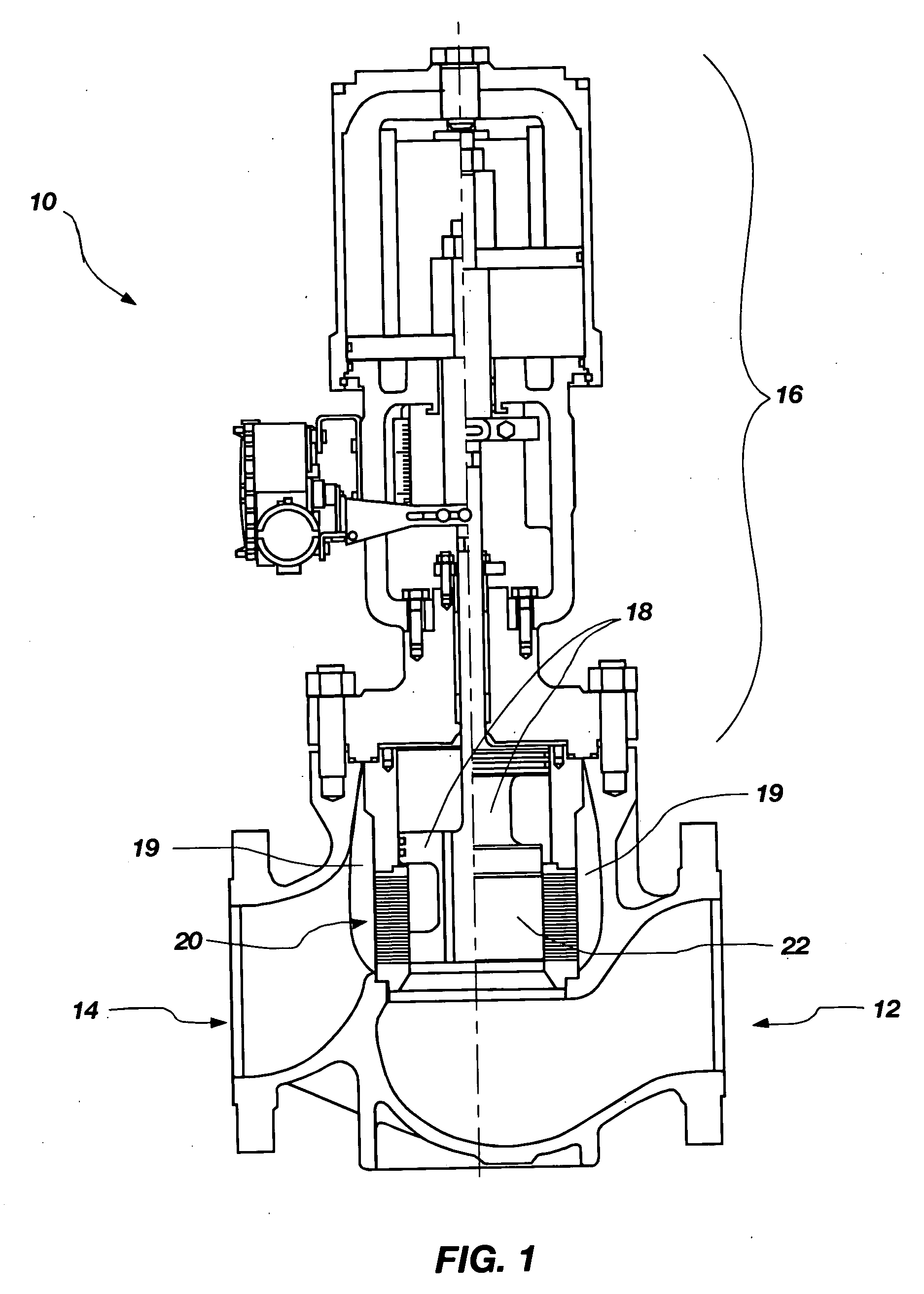

Compressor sound attenuation enclosure

InactiveUS20050274569A1Low costSuperior sound transmission loss propertyRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsUltrasound attenuationEngineering

A sound attenuating cover for a scroll compressor is provided. The cover has a base member configured to support the compressor, the base defines a first chamber filled with a sound attenuating material. The sound attenuating chamber further has a cover member configured to cover the compressor and couple to the base, said cover member defines another chamber. This chamber is additionally filled with a sound attenuating material.

Owner:EMERSON CLIMATE TECH INC

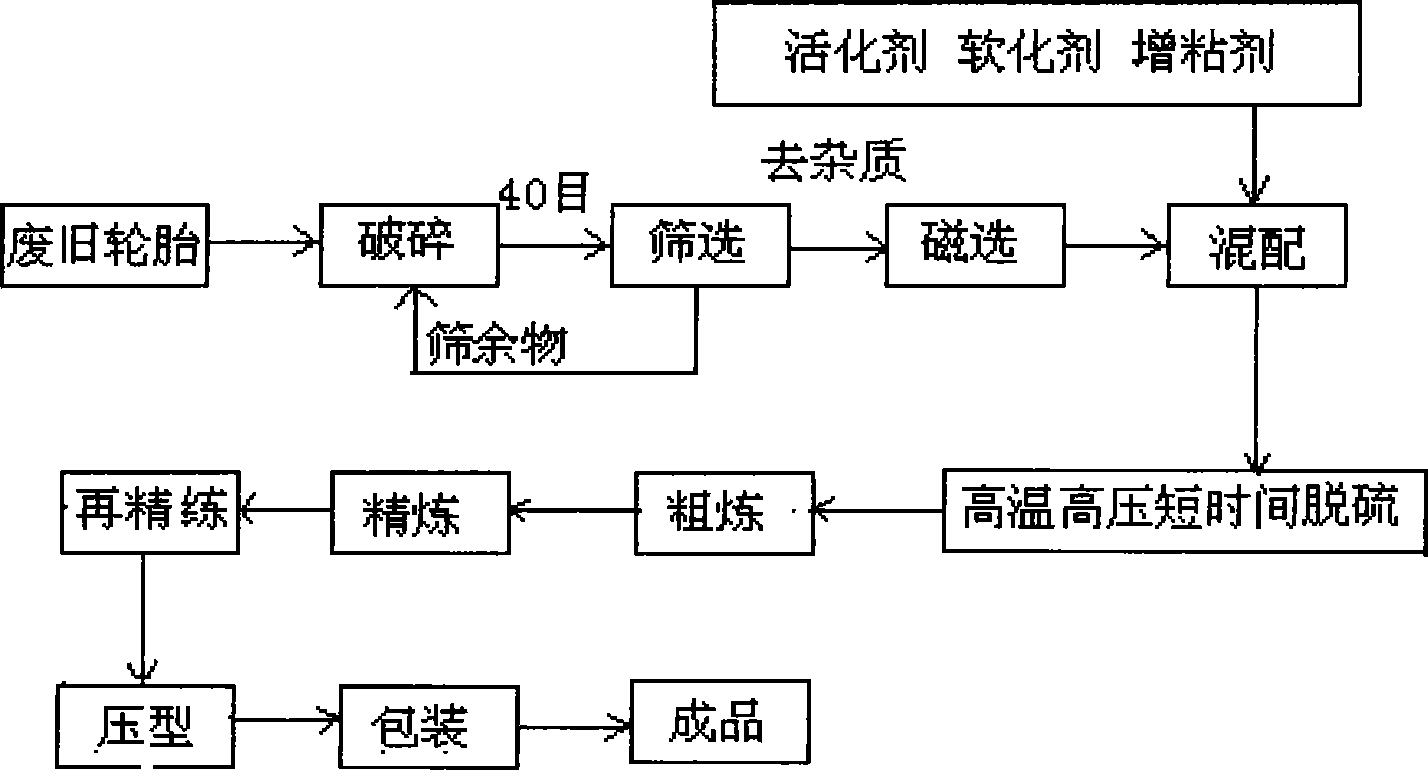

High-quality regenerated rubber and its production

InactiveCN101074302AStrong wear resistanceExtended service lifePlastic recyclingHigh pressureTemperature and pressure

A high-quality regenerated rubber and its production are disclosed. It improves composition and proportion, it adopts high-temperature and pressure desulfurizing method in short time and refining process is added. The tensile strength and breaking extensibility can be increased by 30-60%; it can substitute natural rubber or synthetic rubber and be used as various tyre and raw material of rubber products. It's simple, efficient and smokeless, has excellent abrasive performance, long life, less noise and no refused water discharge.

Owner:QINGWEI RUBBER SUQIAN

Method for manufacturing harmonic reducer of robot

The invention discloses a method for manufacturing a harmonic reducer of a robot, which belongs to the technical field of harmonic reducer processing and includes the steps of manufacturing flexible gears and the steps of manufacturing rigid gears. The steps of manufacturing the flexible gears include: forging solid billets of the flexible gears; performing heat treatment for the solid billets of the flexible gears to reach the hardness of HRC (Rockwell hardness) 38-40; turning the solid billets of the flexible gears after heat treatment into thin-wall semi-finished flexible gears; supporting inner cavities of the semi-finished flexible gears by a flexible gear tensioning fixture; and grinding the supported semi-finished flexible gears to form external gear rings of the flexible gears on a grinder. By the method, the efficiency and the precision of machining the flexible gears and the rigid gears are improved, the hardness of the flexible gears is enhanced, the service life of the harmonic reducer is prolonged, and the method is widely applied to production of harmonic reducers.

Owner:SHANDONG SHKE MACHINERY MFG

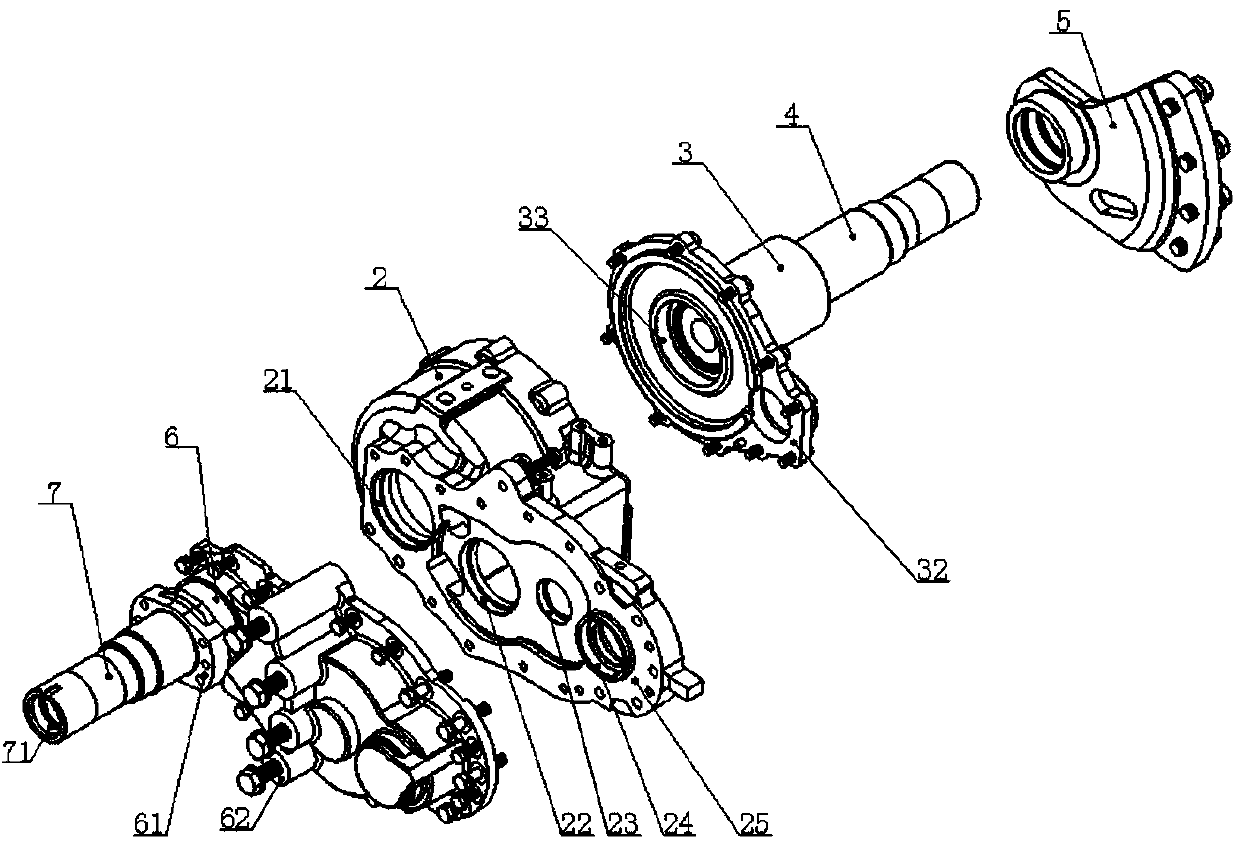

Transmission system of alternating-current storage-battery electric forklift truck

ActiveCN103434390AReduce development costsImprove versatilityAxle unitsControl devicesReduction driveGear wheel

The invention relates to a transmission system of an alternating-current storage-battery electric forklift truck. The transmission system comprises a differential mechanism assembly, a speed reducer, a driving axle housing, a left brake, a right brake, a brake drum, a wheel hub, a left half axle and a right half axle. The speed reducer comprises a dual gear, a small dual gear and a pinion. The driving axle housing comprises a left axle housing, a speed-reducer main shell and a right axle housing. The left axle housing comprises a speed-reduction box and a left tubular axle which is connected with the speed-reduction box in sequence, wherein the speed-reduction box is in a clamshell shape, and a left sleeve is located on one side of the upper portion of the speed-reduction box. The speed-reducer main shell comprises a horizontal type barrel-shaped shell, wherein the upper portion of the barrel-shaped shell is a differential mechanism cavity, the lower portion of the barrel-shaped shell is a wheel axle cavity protruded downwards, and the differential mechanism assembly is located in the differential mechanism cavity. The right axle housing comprises a right axle housing body and a right tubular axle, wherein one end of the right axle housing body is in an end cap shape, and a right sleeve is located at the other end of the right axle housing body. The transmission system is compact in structure, good in manufacturability, low in manufacturing cost, good in assembly technology, and convenient to maintain.

Owner:ANHUI HELI CO LTD

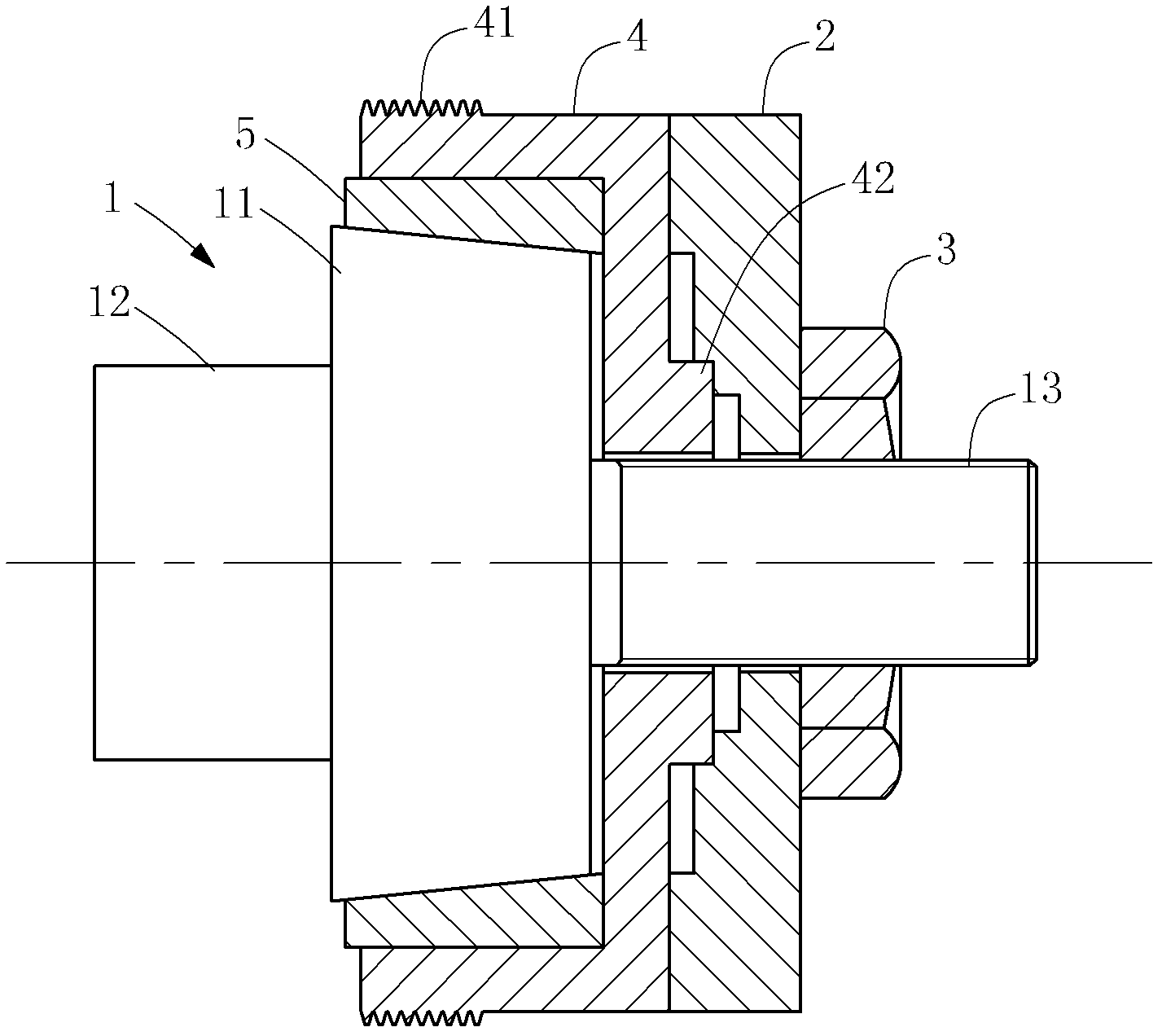

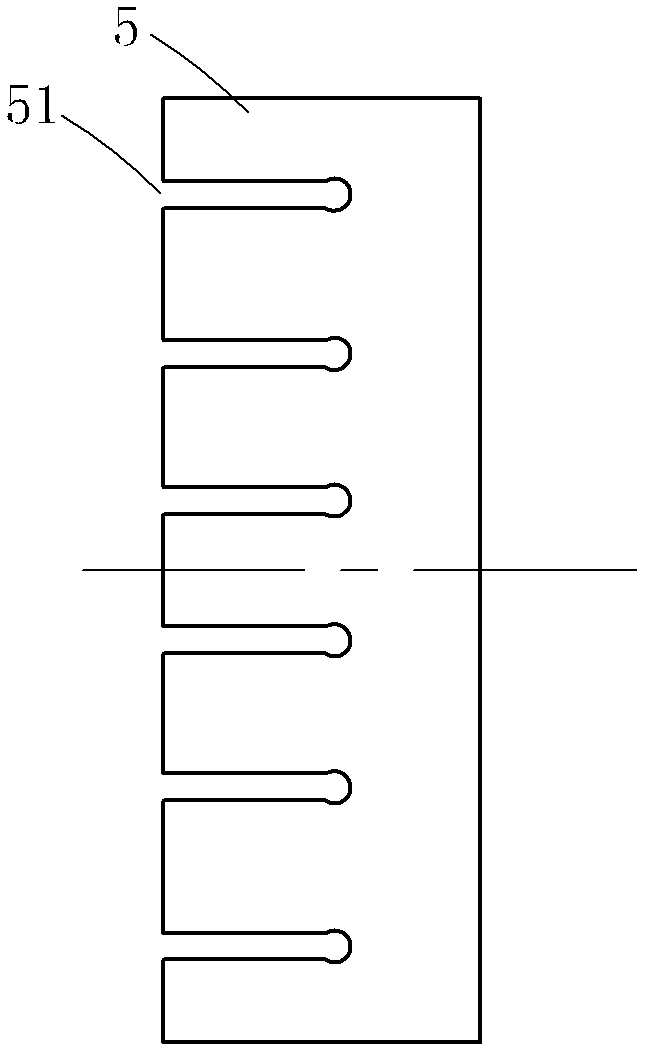

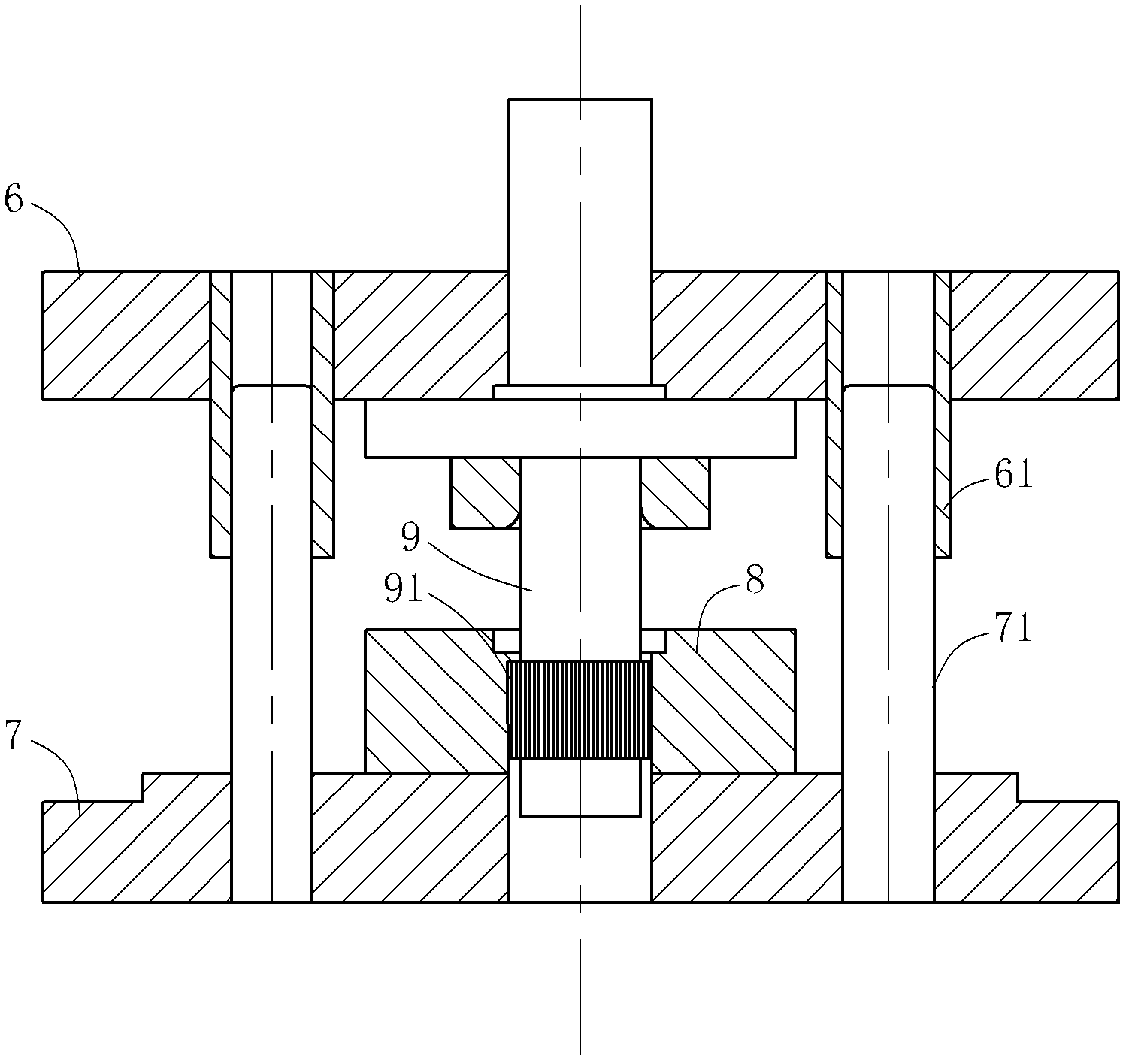

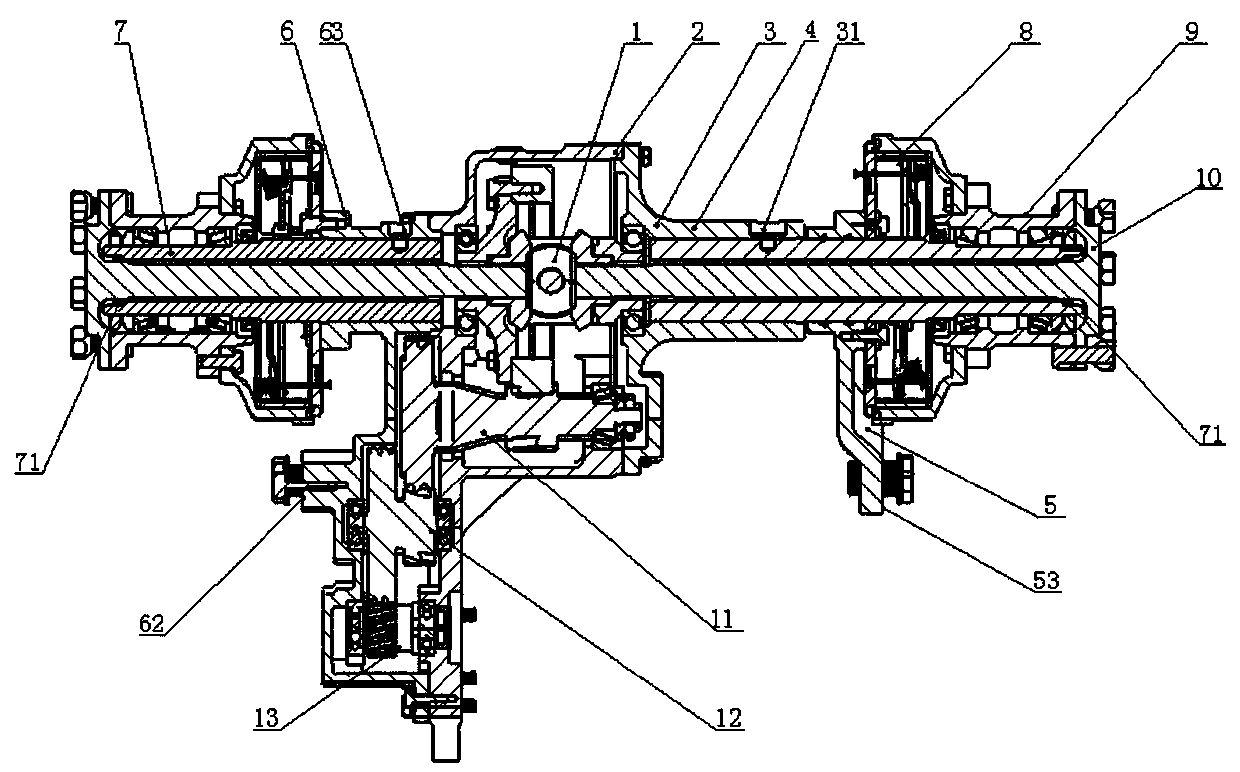

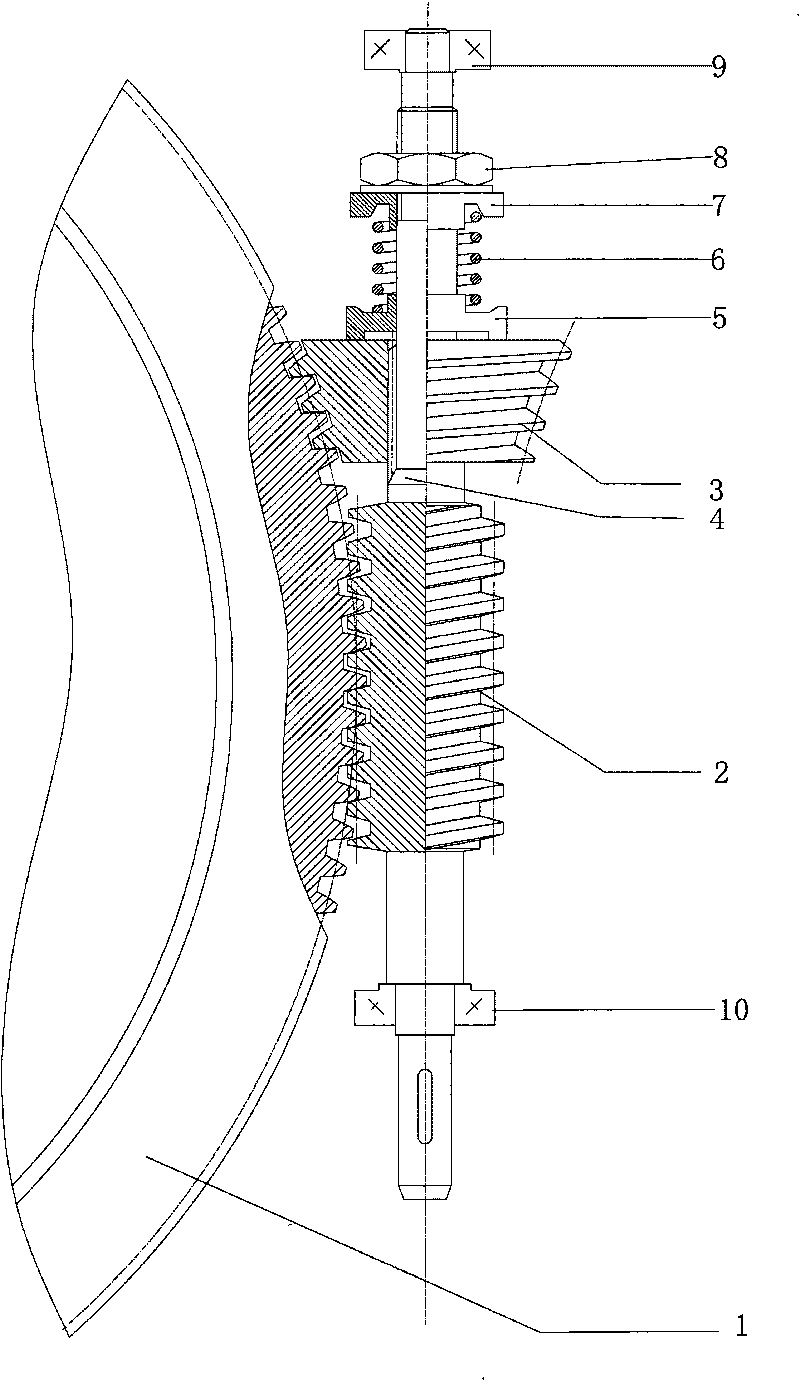

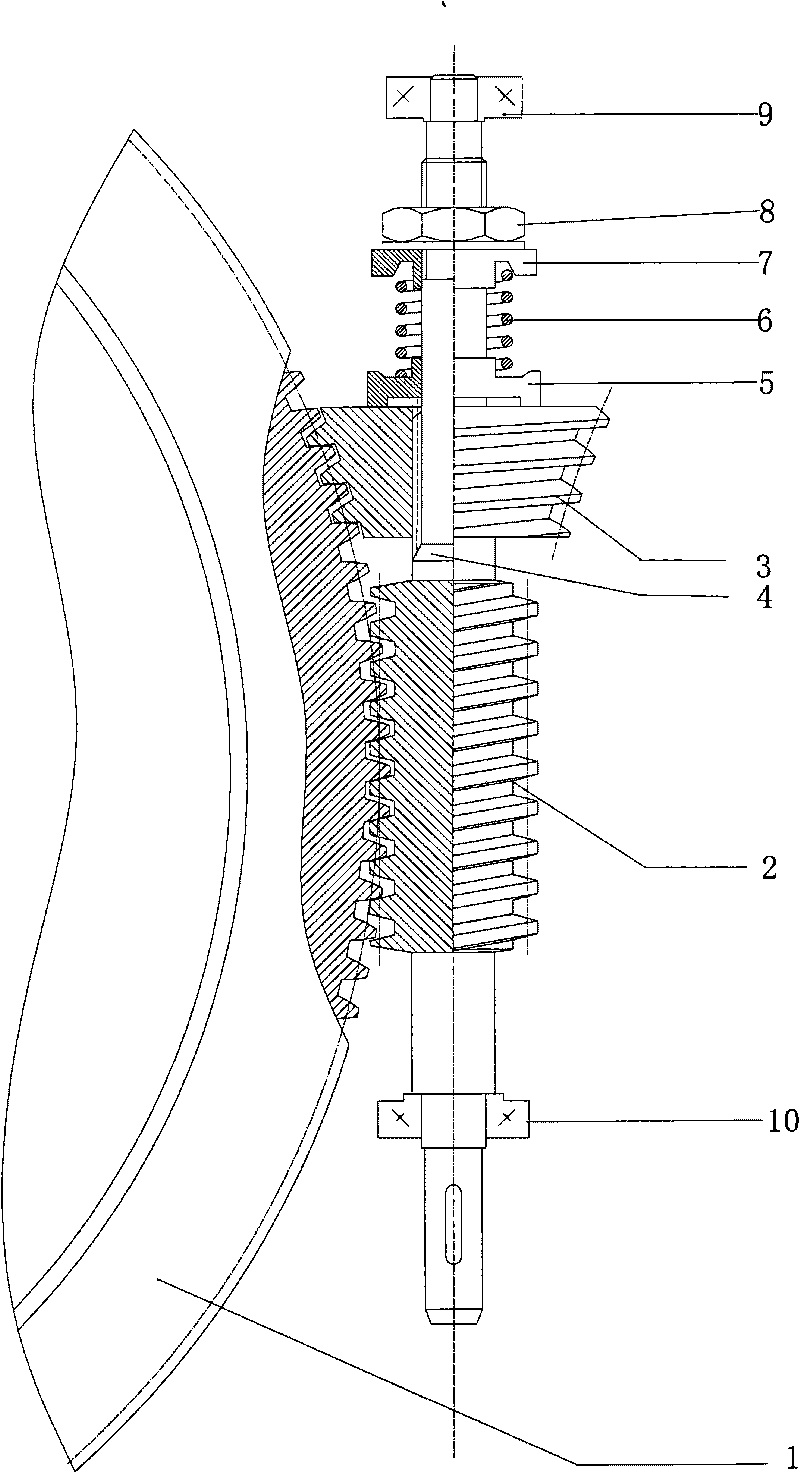

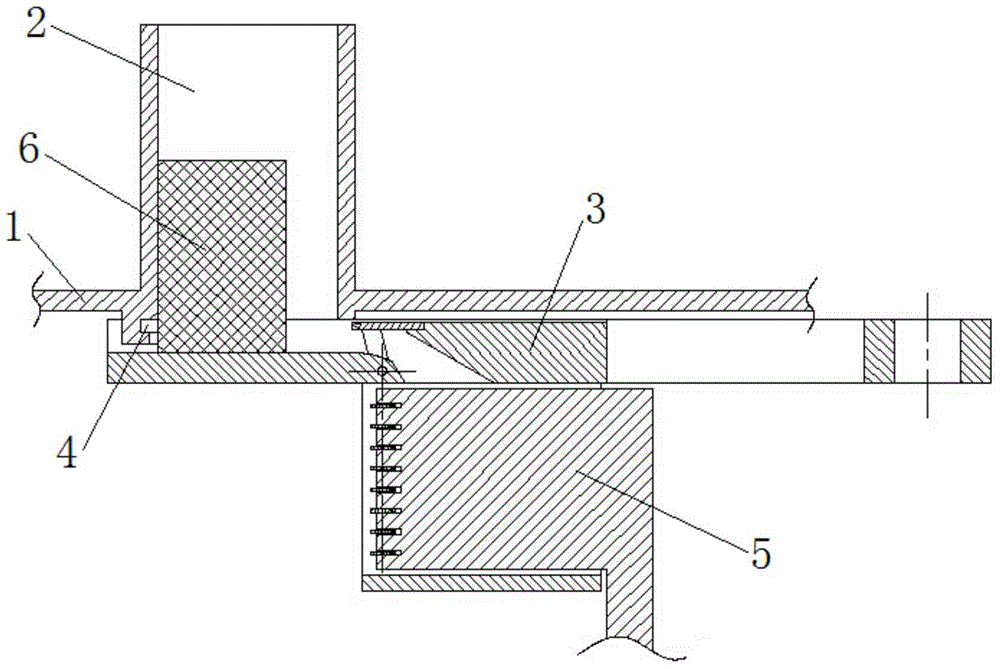

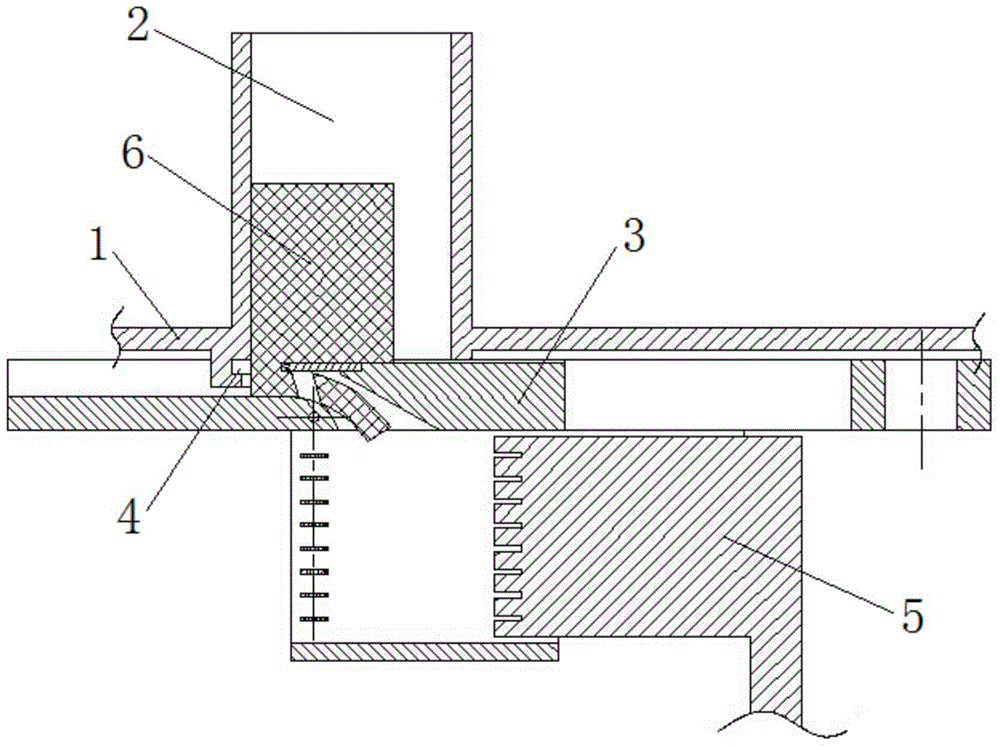

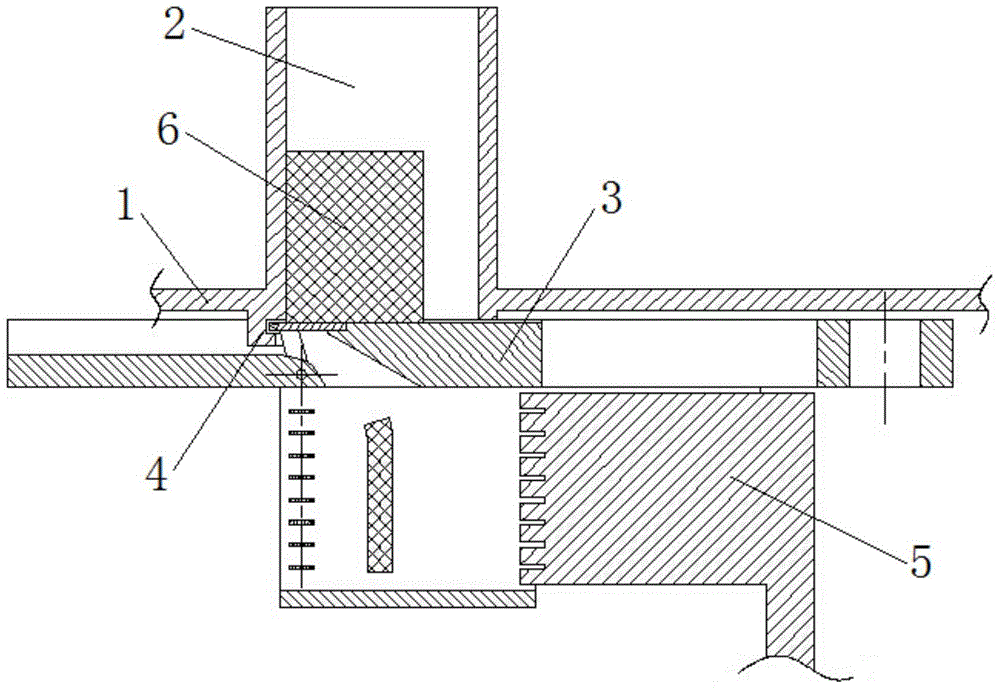

Worm gear-worm pair backlash eliminating device adopting enveloping worm

InactiveCN101705987ACompact structureReduce volumePortable liftingGearing elementsLow noiseEngineering

The invention relates to a worm gear-worm pair backlash eliminating device adopting an enveloping worm, which mainly consists of a worm gear, a cylindrical worm, the enveloping worm, an elastic pre-tightening device and a bearing. The cylindrical worm and the enveloping worm play the main force scale division role and the resistance role respectively, and the two worms are coaxially mounted and carry out the regulation and impose the pre-tightening force on a resistance worm in the axial direction through the elastic pre-tightening device. The pre-tightening device consists of a regulating nut, two spring positioning sleeves and a pre-tightening spring, regulates and pre-tightens the resistance worm in the axial direction through the regulating nut. The elastic pre-tightening device can be one of a spring device, a hydraulic device or a pneumatic device. The resistance enveloping worm and the main force worm are coaxially mounted in the worm gear-worm pair backlash eliminating device, and the axial regulation and the pre-tightening are carried out on the resistance worm through the elastic pre-tightening device, thereby providing the more stable, high-efficient and low-noise transmission and simultaneously having the advantages of compact structure, light weight, low cost and the like. The worm gear-worm pair backlash eliminating device is applied in a transmission mechanism of a rotary workbench of a machine tool and can provide better backlash eliminating effect in comparison with a single worm gear-single worm mechanism or a double-worm gear-worm mechanism.

Owner:CHONGQING UNIV

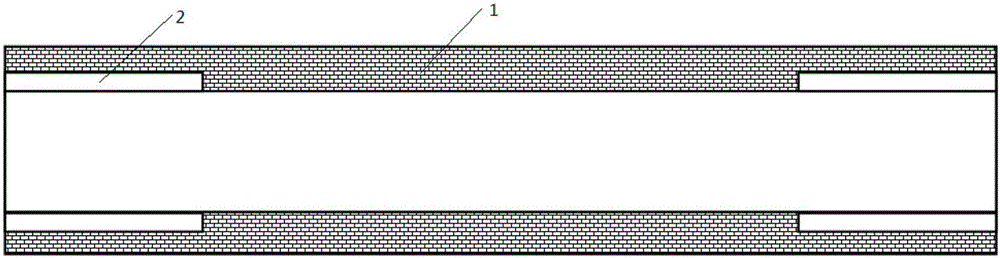

Three-dimensionally-woven composite automotive transmission shaft and manufacturing method of three-dimensionally-woven composite automotive transmission shaft

ActiveCN105690793ASmall running vibrationMeet the use requirementsYielding couplingShaftsFiberUniversal joint

The invention discloses a three-dimensionally-woven composite automotive transmission shaft and a manufacturing method of the three-dimensionally-woven composite automotive transmission shaft. A three-dimensionally-woven composite transmission shaft pipe and a universal joint are designed and the sleeve connection and combination manner of the three-dimensionally-woven composite transmission shaft pipe and the universal joint is designed according to the stress characteristic of the transmission process of the automotive transmission shaft. Three-dimensional multi-axial fabric structure combination is conducted through a hybrid fiber multi-direction weaving manner, the structural performance of the specific portion of the transmission shaft is strengthened, and finally integrated weaving of the three-dimensional prefabricated body structure is achieved. After a related three-dimensional fabric prefabricated body workpiece is manufactured, the specific fiber is selected to be subjected to thickness-direction seam laying secondary strengthening treatment so that the strength and rigidity in the thickness direction can be improved; and finally, a thermosetting resin glue solution serves as a base material, resin impregnation recombination and resin curing are conducted on the three-dimensionally-woven prefabricated body fabric by the adoption of continuous forming with vacuum infusion and quick thermocuring combined, and finally a three-dimensionally-woven composite automotive transmission shaft assembly made of the hybrid fiber fabric is formed.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

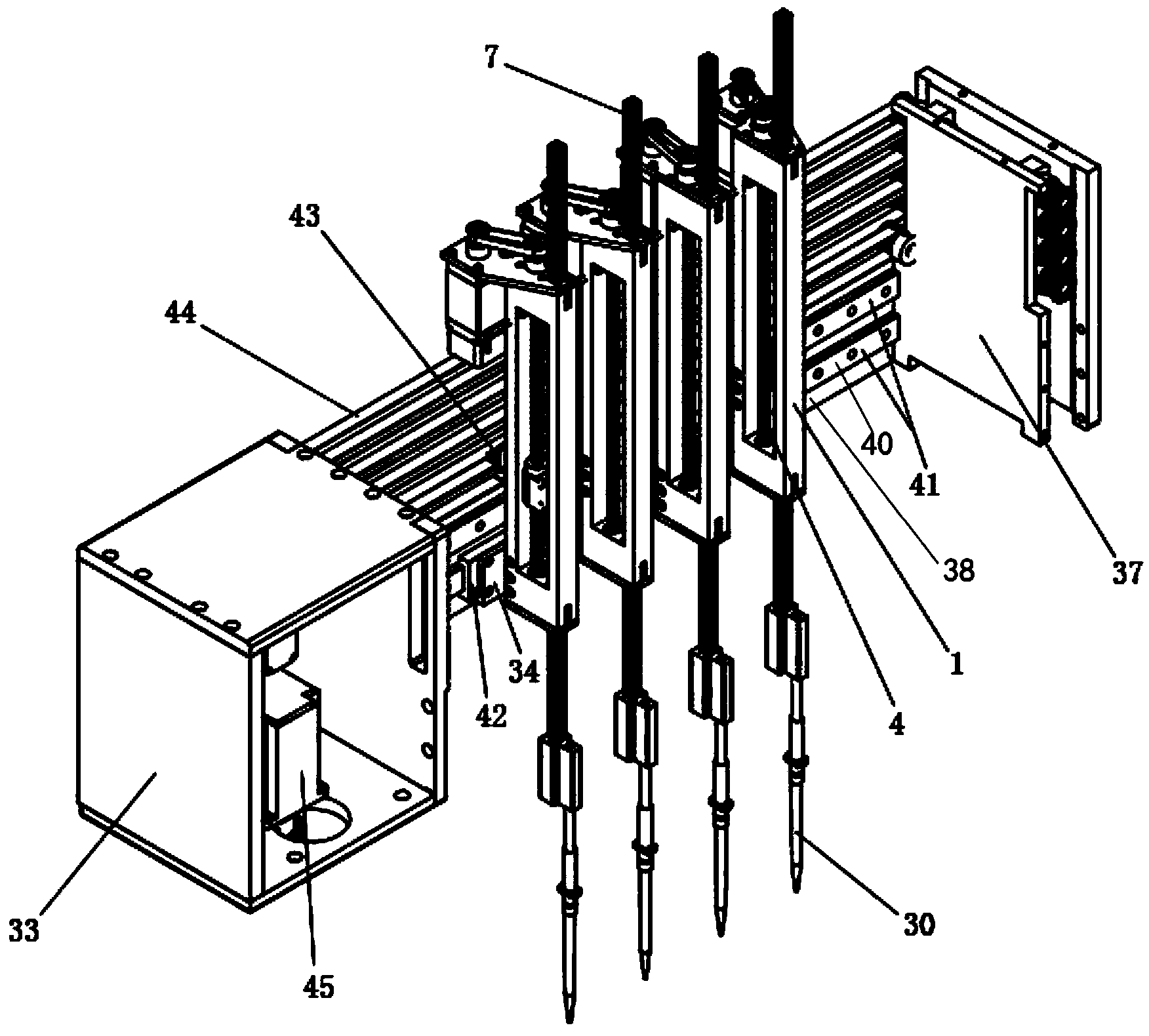

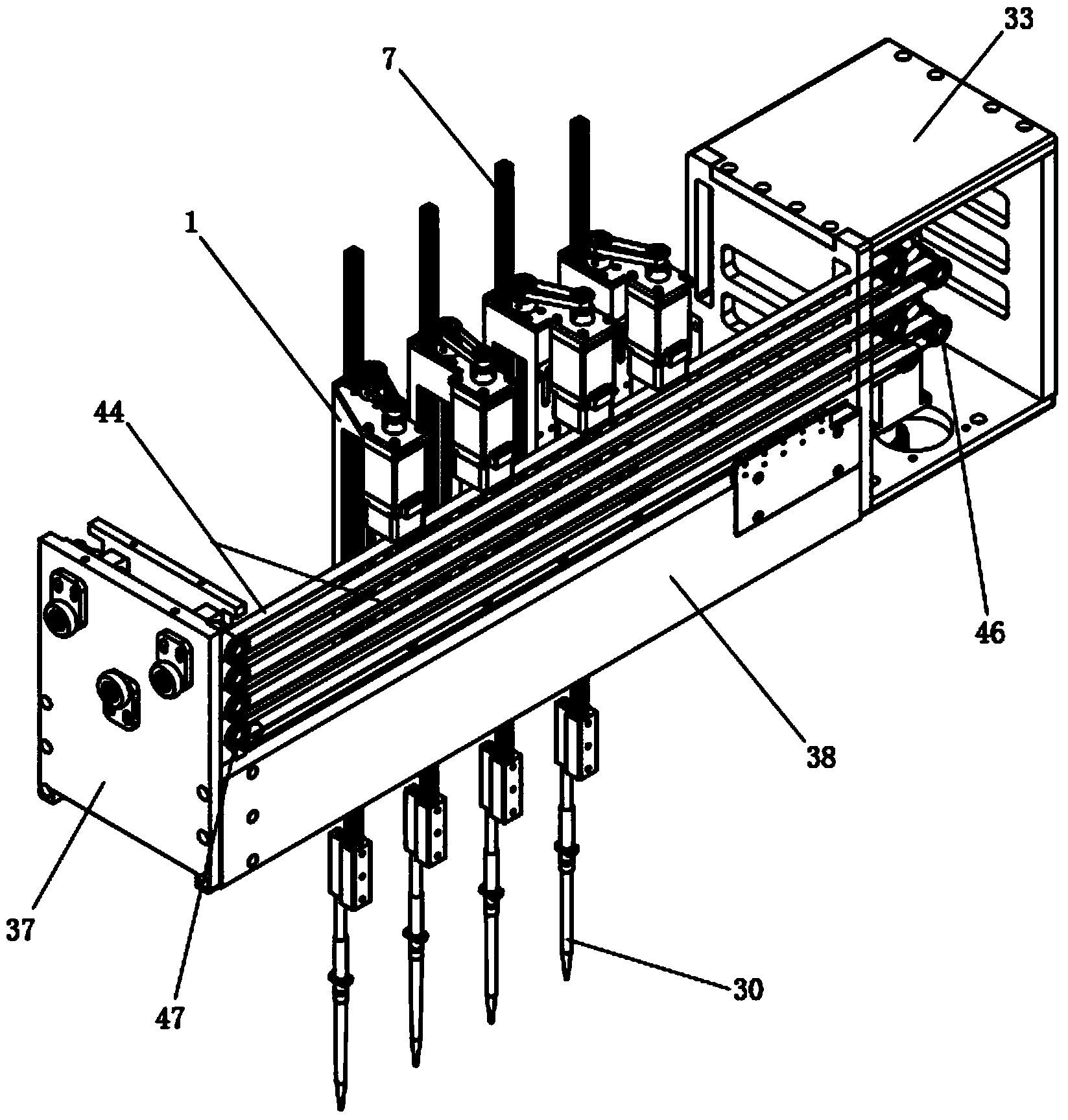

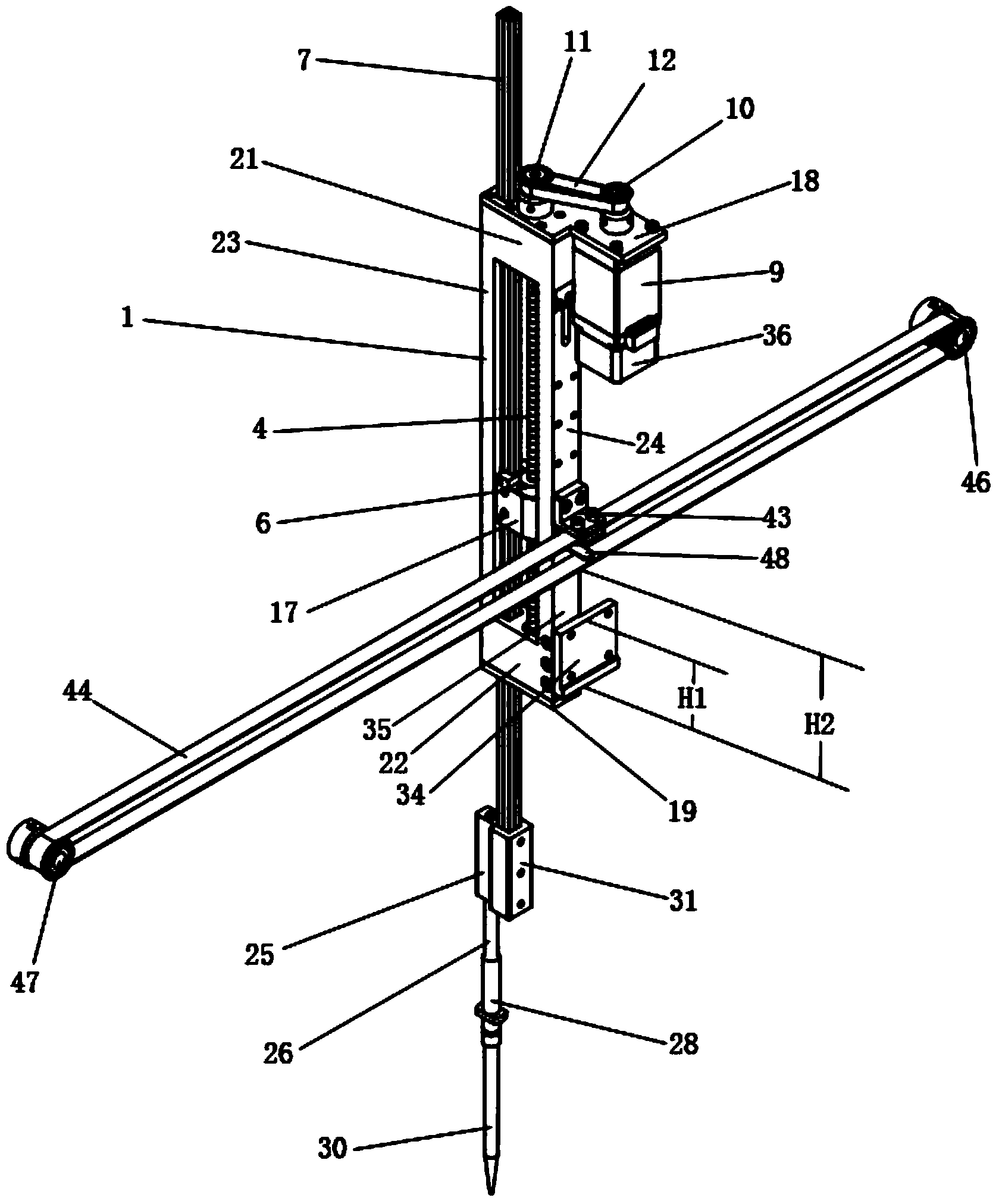

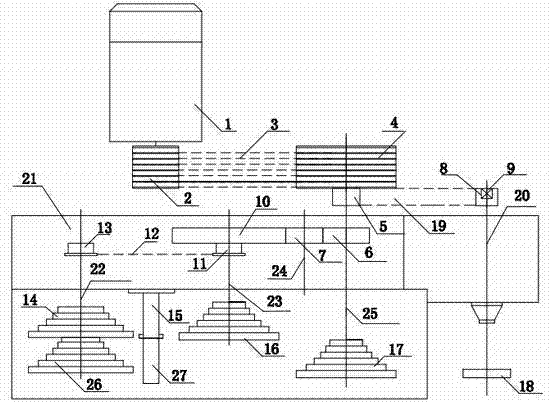

Full-automatic pipetting station and application thereof

InactiveCN103846114AReasonable layoutSmooth structureWithdrawing sample devicesBurettes/pipettesMechanical pipetteControl theory

The invention provides a full-automatic pipetting station comprising a pipetting mechanism support and a plurality of pipetting mechanisms. Each pipetting mechanism comprises a moving base, a moving rod, a moving rod driving mechanism, a linear guide rail fixing seat and a pipetting head, wherein the moving rod is movably assembled on the moving base, and the pipetting head is arranged at the lower end of the moving rod. The invention also provides an application of the pipetting station in the aspects of liquid sample injection, liquid transfer and the like. The pipetting station provided by the invention is capable of greatly buffering impact and vibration generated in an operation process, low in driving noise and stable and reliable in driving so that the pipetting mechanisms in the station can more flexibly operate and the pipetting head can operate to more plate positions.

Owner:GENMAG BIOTECH

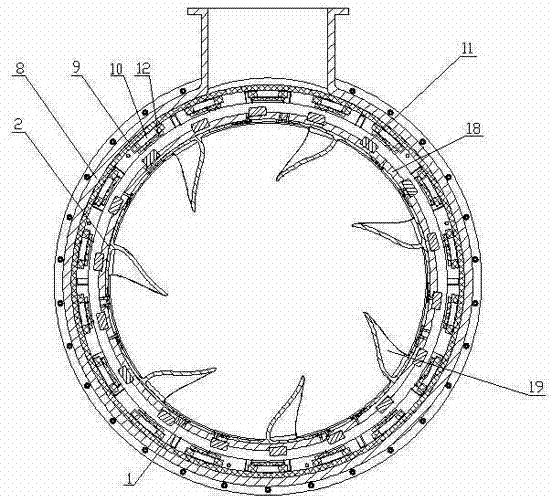

Ship-used permanent magnet motor propeller

InactiveCN104333172AAchieve advancementSimple structureMagnetic circuit rotating partsPropulsion power plantsStator coilPropeller

The invention relates to a ship-used permanent magnet motor propeller, which comprises a motor, a shell and a propeller, and is characterized in that the motor is a permanent magnet motor; the permanent magnet motor comprises a stator and a rotor; the stator comprises a stator sleeve; the stator sleeve is located inside the shell; the stator sleeve is internally, circumferentially and uniformly provided with stator coils; an insulated layer is arranged outside the stator coil; the rotor comprises a rotor sleeve; permanent magnets are circumferentially and uniformly arranged inside the rotor sleeve; a gap is left between the permanent magnet and the stator coil; bearings are arranged between two ends of the stator sleeve and two ends of the rotor sleeve; two ends of the stator sleeve and two ends of the rotor sleeve are provided with round air guide sleeves; the air guide sleeve has a nearly conical cross section, and two edges are respectively connected with the same ends of the shell and the rotor sleeve; paddle blades are circumferentially and uniformly arranged inside the rotor sleeve; and the rotor sleeve and the inner circumferential paddle blades form the propeller. The ship-used permanent magnet motor propeller is simple in structure, small in size, small in occupied space, and little in noise, facilitates health of an operator, can avoid environmental pollution, and can be applied to a ship.

Owner:WUXI HAIHE EQUIP TECH CO LTD

Rare earth and carbon co-infiltration method in continuous furnace for automobile gearbox gear

InactiveCN1654700AChange other functionsOsmoticSolid state diffusion coatingHigh concentrationCarbon potential

The continuous micro deformation RE-carbon co-penetrating process for gear of automobile gear box is realized via making the pre-treated workpiece enter the different regions with RE co-penetrant in continuous carbonizing furnace at 840-890 deg.c. The workpiece is made to enter successively region-I for preheating and pre-penetrating; region-II and region-III with carbon potential of 1.15-1.25 % for carbonizing; region-IV with carbon potential of 0.8-1.05 % for diffusion treatment; and region-V with carbon potential of 0.8-1.05 % for waiting for discharging and quenching. The present invention is one controllable low temperature RE high concentration gas carbonizing process capable of resulting in optimal metallurgical structure, and has the advantages of high carbonizing rate, high efficiency and low power consumption.

Owner:HARBIN INST OF TECH

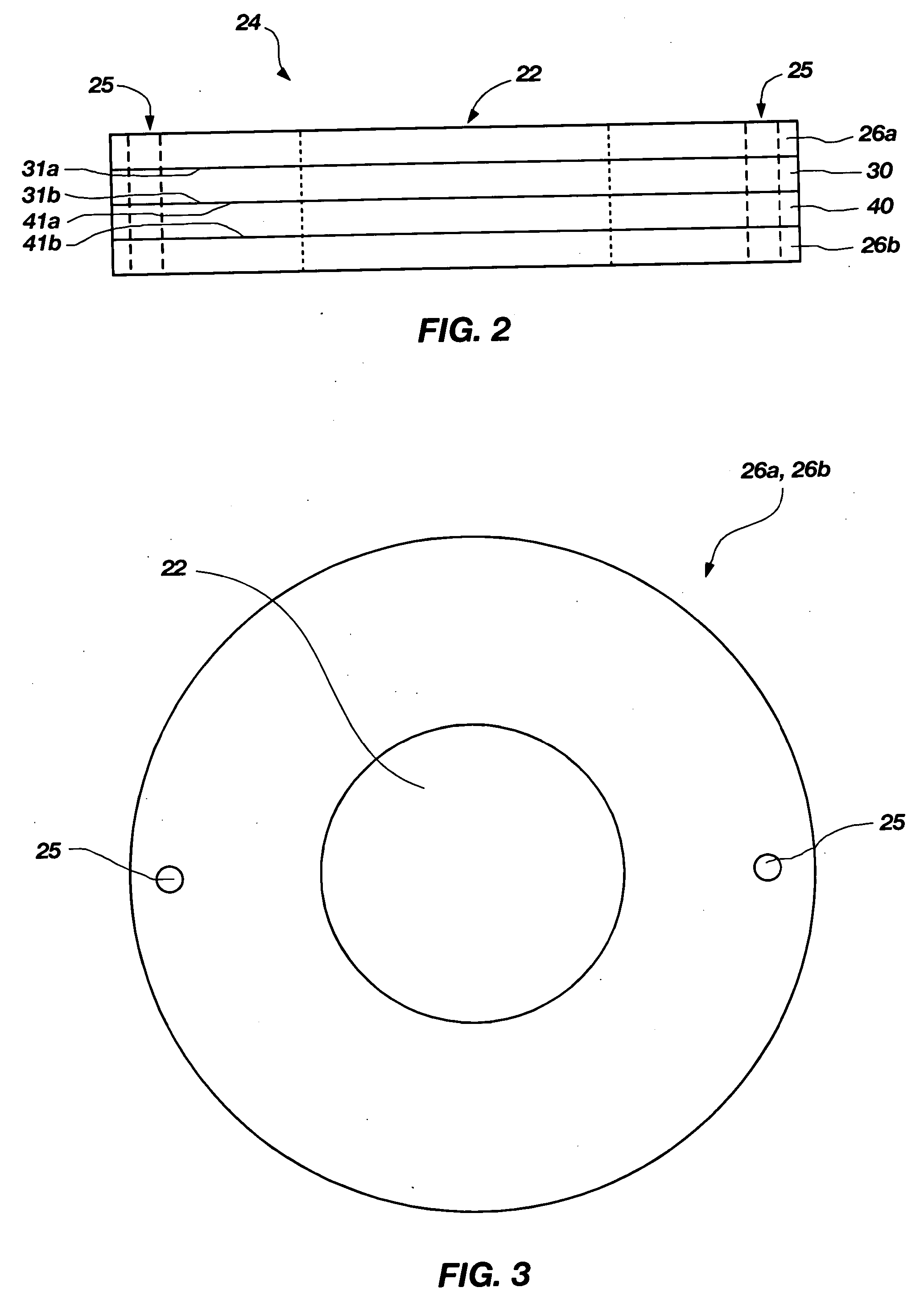

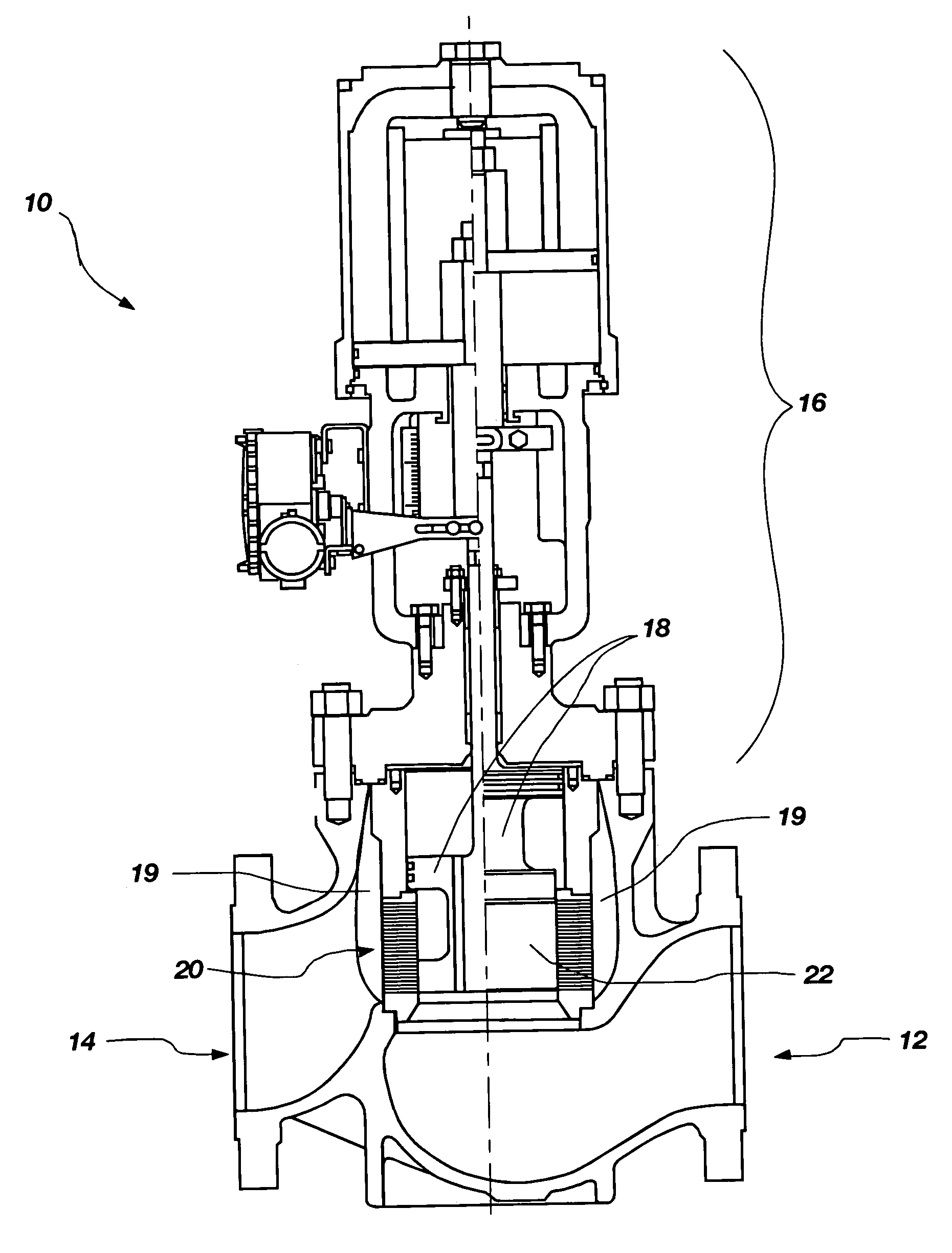

Noise reducing fluid passageways for fluid flow control devices

ActiveUS20060191584A1Reduce transmission noiseReduce componentsFluid heatersValve members for absorbing fluid energyEngineering

Owner:FLOWSERVE PTE LTD

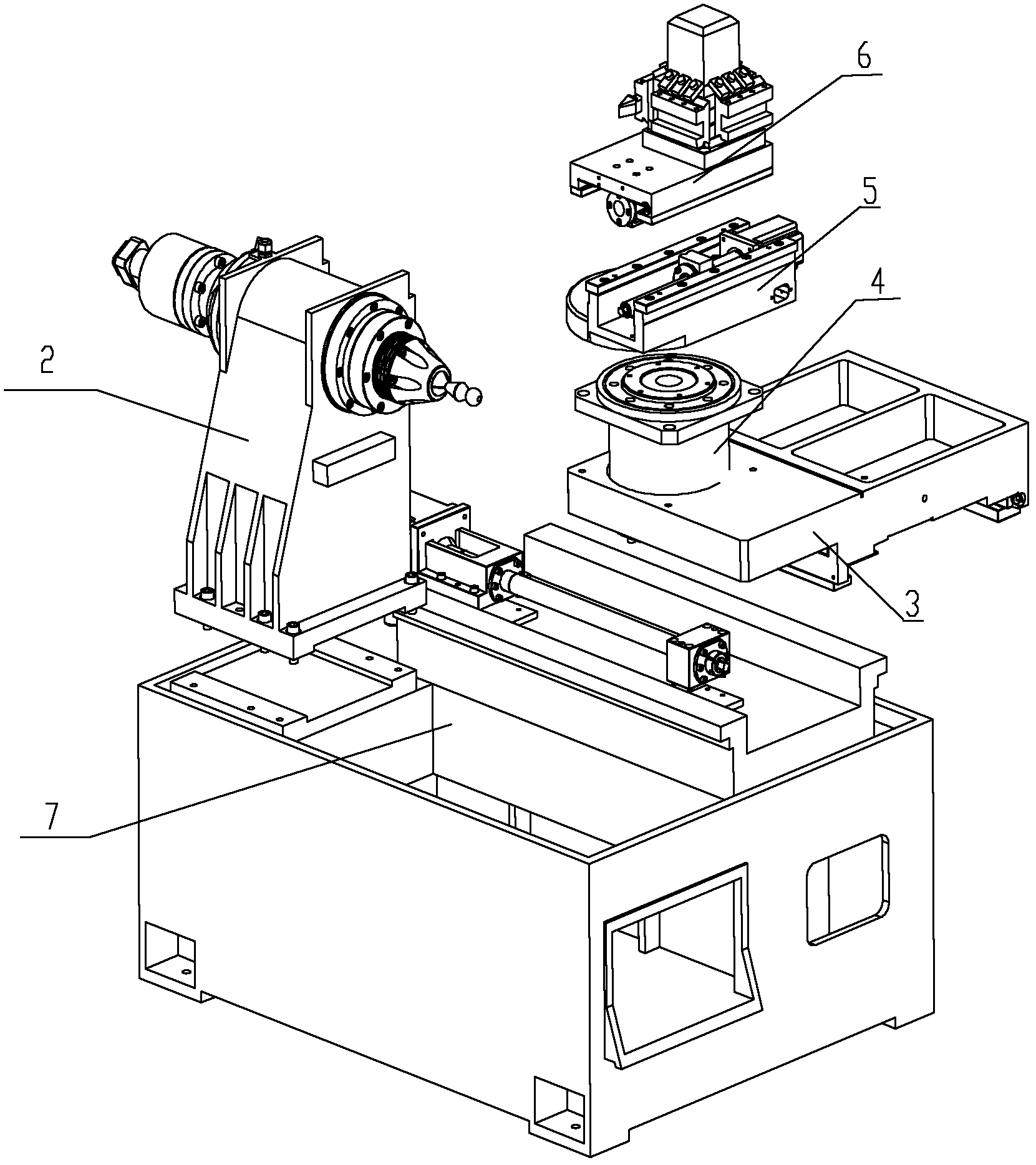

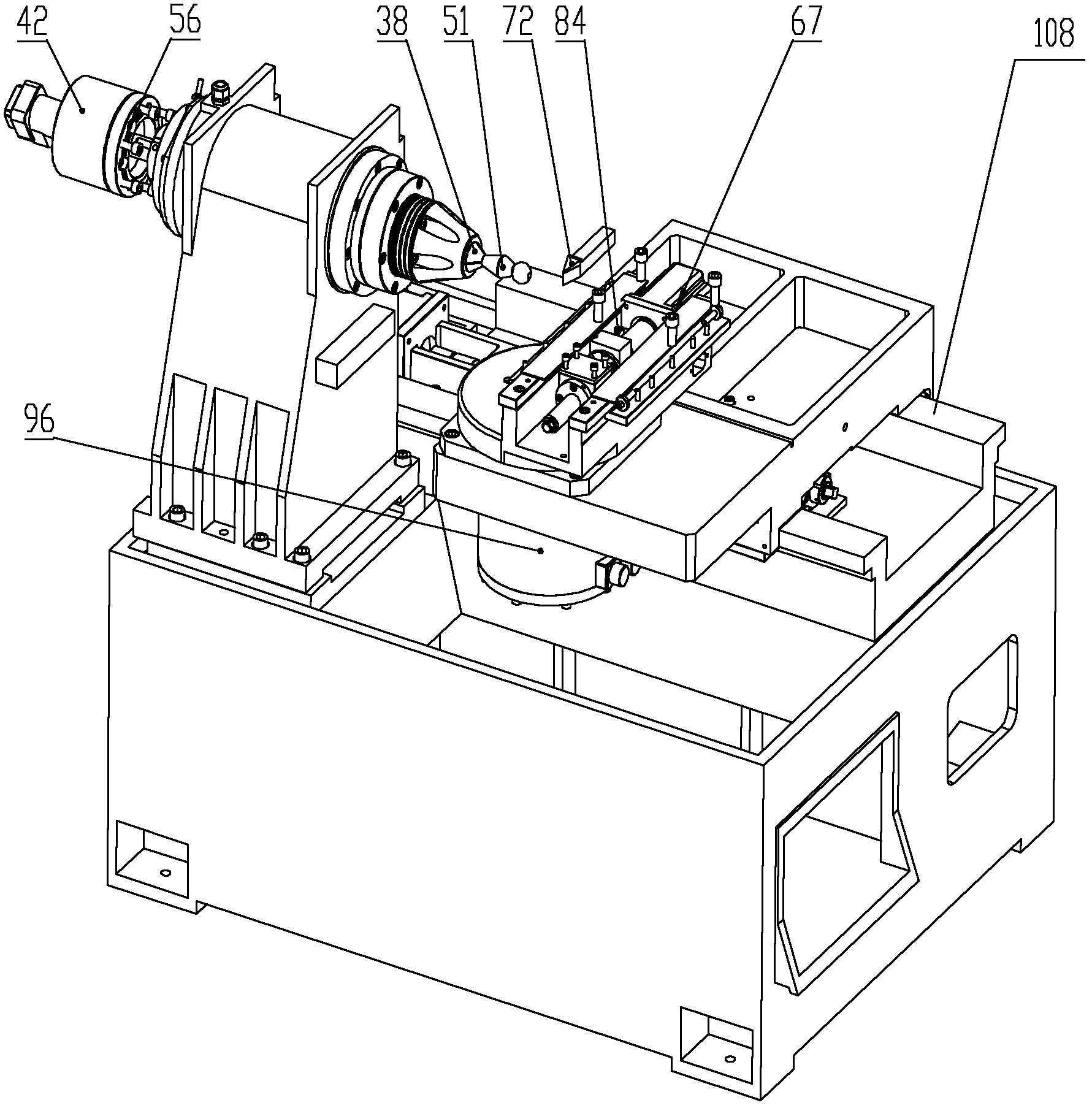

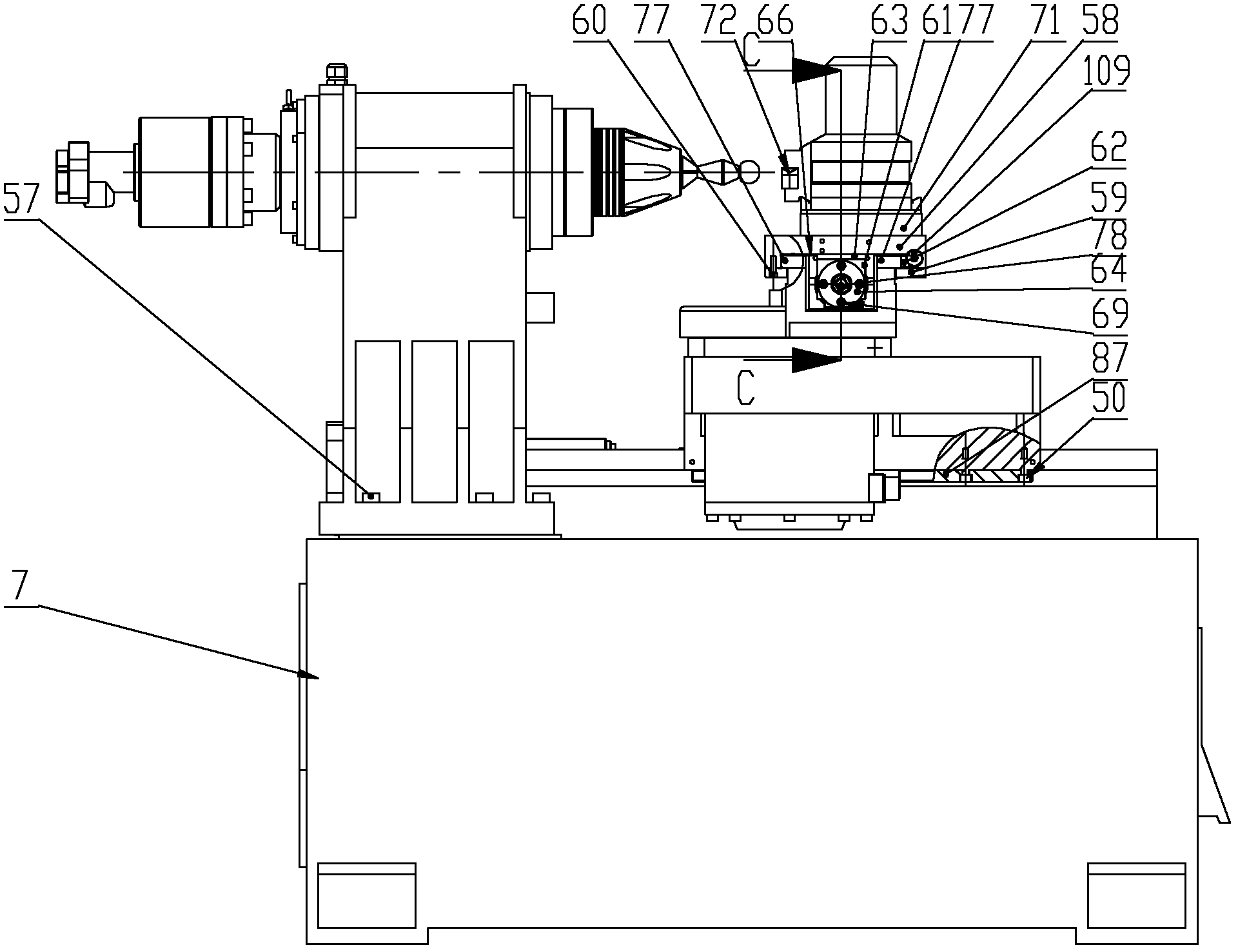

Automatic high-speed precision numerical control machine tool for cutting spherical surface

ActiveCN102366889AImprove machining accuracyReduce processOther manufacturing equipments/toolsLarge fixed membersLinear motionNumerical control

The invention provides an automatic high-speed precision numerical control machine tool for cutting a spherical surface, which is provided with a base, wherein a main shaft device is arranged on one side at the upper part of the base; a saddle dragging plate which does linear reciprocating motion along the axis of the main shaft of the main shaft device is arranged at the upper part of the base, which is positioned at the same side of the main shaft device; a direct-driving type torque motor rotary table device is arranged on the saddle dragging plate; a rotary axis of the direct-driving typetorque motor rotary table device is absolutely intersected with the rotary axis of the main shaft device; the upper end of the direct-driving type torque motor rotary table device is connected with arotary saddle device and drives the rotary saddle device to do rotary reciprocating motion around the axis of the direct-driving type torque motor rotary table device; a tool rest dragging plate device which does linear reciprocating motion along the direction perpendicular to the axis of the main shaft of the main shaft device is arranged at the upper end of the rotary saddle device; and linear motion of the tool rest dragging plate device and rotary motion of the rotary saddle device form cutting motion for workpieces, so that the workpieces clamped at the front end of the main shaft deviceis cut to form a regular spherical shape.

Owner:SHAANXI HALET PRECISION MACHINERY

Noise reducing fluid passageways for fluid control devices

ActiveUS7690400B2Reduce transmission noiseReduce componentsFluid heatersValve members for absorbing fluid energyCircular discFluid control

Owner:FLOWSERVE PTE LTD

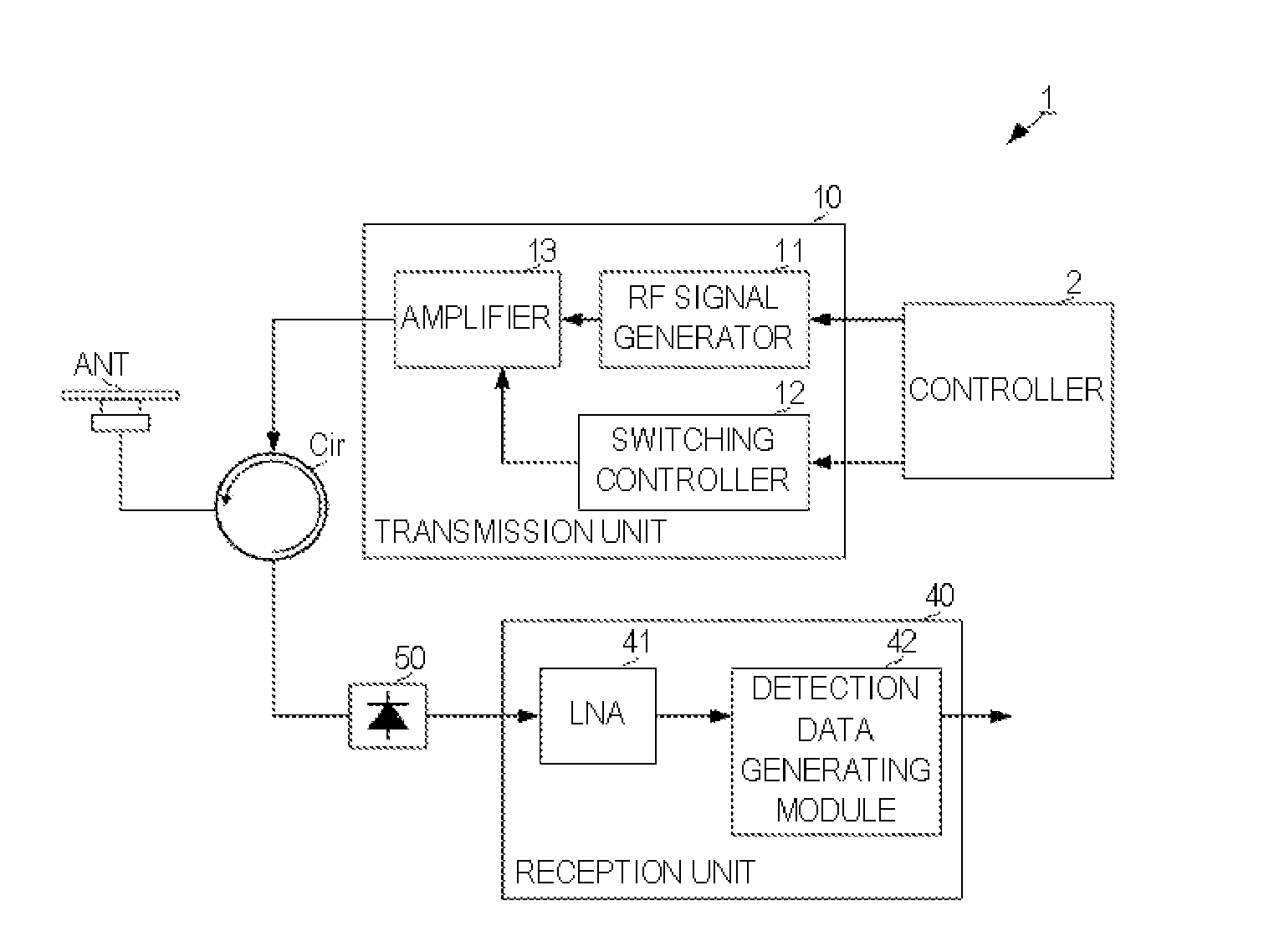

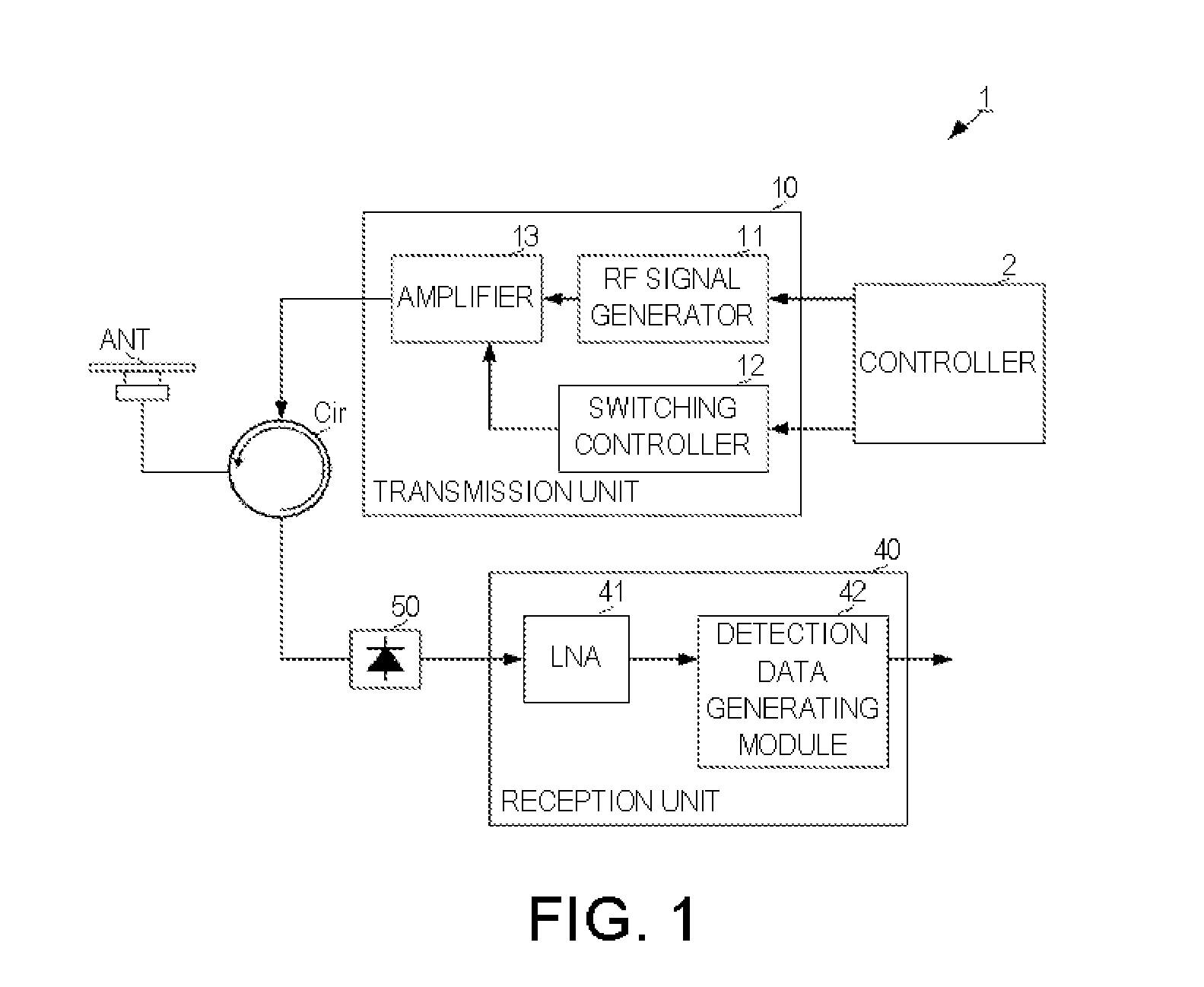

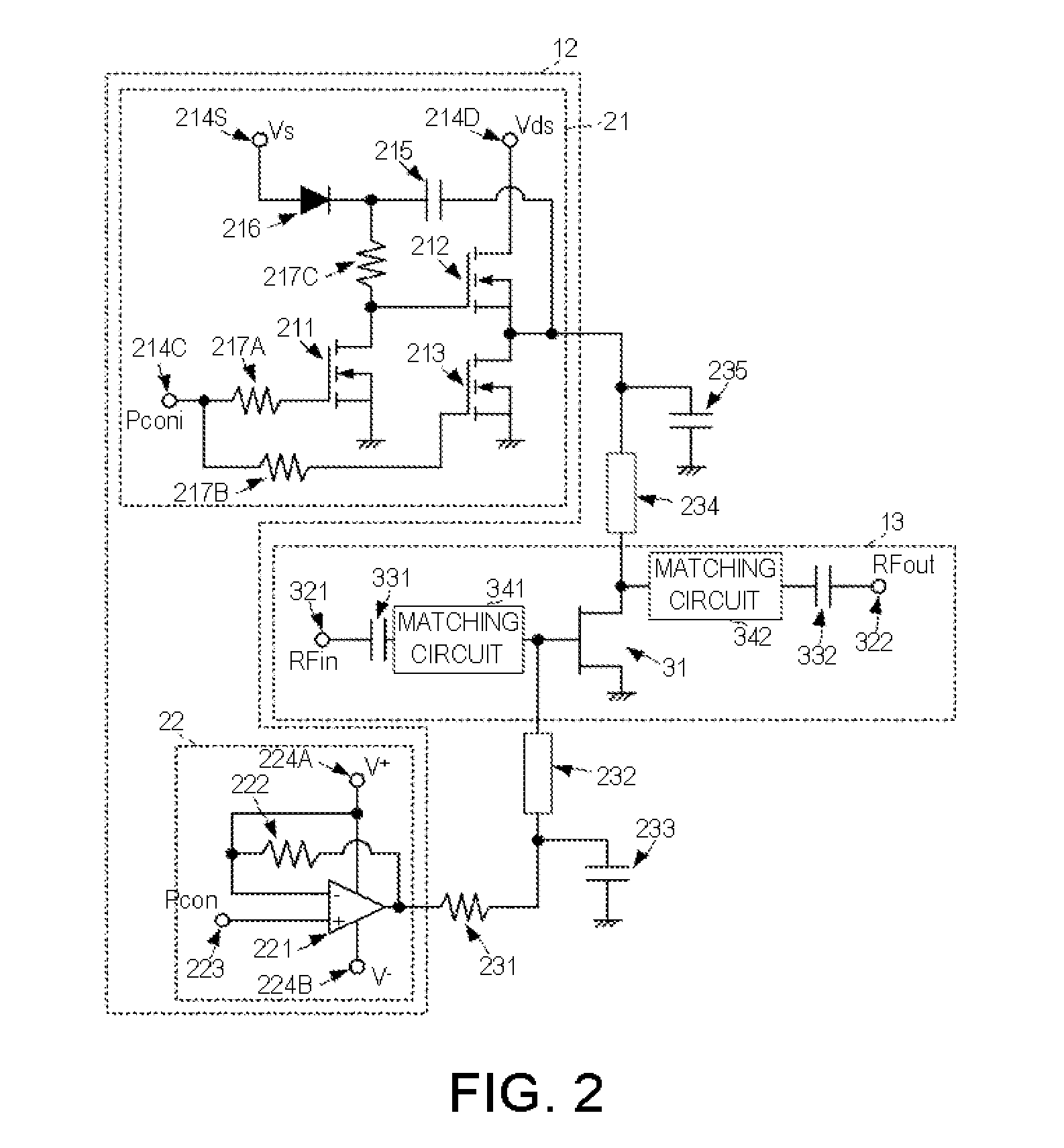

RF pulse signal generation switching circuit, RF pulse signal generating circuit, and target object detecting apparatus

ActiveUS20130088378A1Reduce transmission noiseImprove receiver sensitivityTransistorGated amplifiersPulse wavePulse waveform

An RF pulse signal generation switching circuit for controlling an output of a power FET for amplifying a high frequency signal to generate an RF pulse signal that is the high frequency signal pulse formed into a pulse-wave shape is provided. The circuit includes first and third n-type FETs of which gates are inputted with a control pulse that supplies a rise timing and a fall timing of a pulse, and a second n-type FET of which a gate is connected with a drain of the first FET. A source of the first FET and a source of the third FET are grounded, respectively. The drain of the first FET is applied with a first drive voltage via a resistor. A drain of the second FET is applied with a second drive voltage. A source of the second FET is connected with a drain of the third FET and the connection point therebetween is connected with the power FET. A capacitor is connected between the connection point and an end of the resistor from which the first drive voltage is applied.

Owner:FURUNO ELECTRIC CO LTD

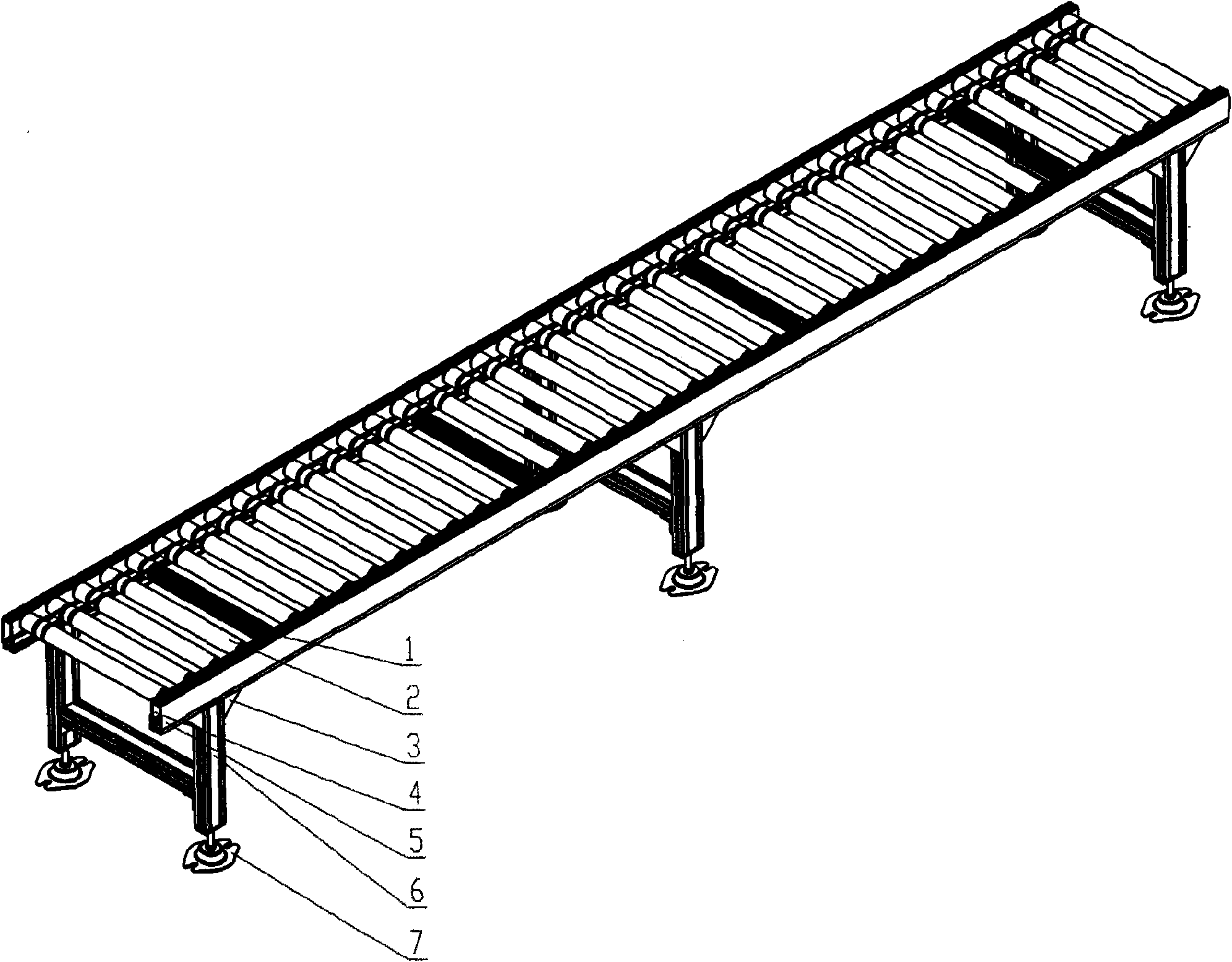

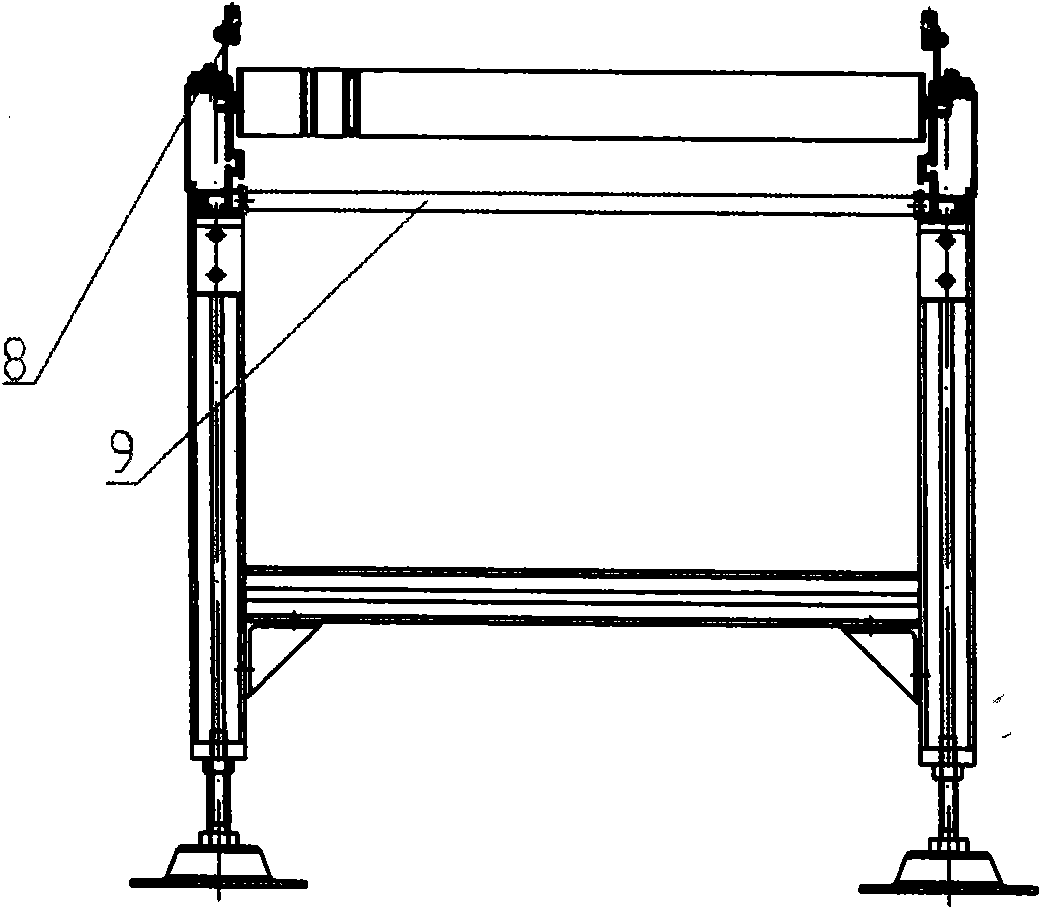

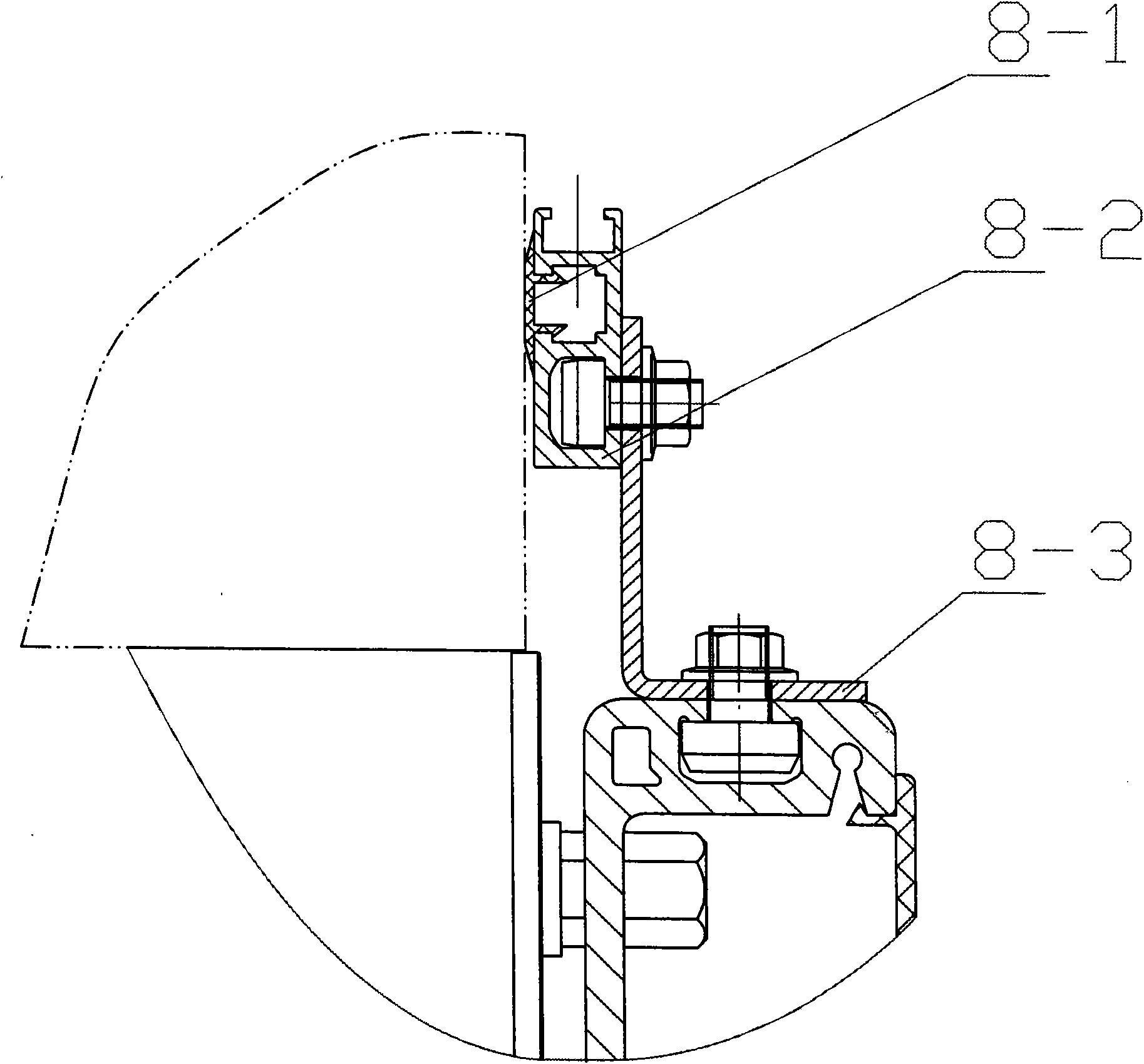

Electric roller conveyor with aluminum alloy beams

InactiveCN101590942AReduce transmission noiseSimple production processControl devices for conveyorsSupporting framesMetallurgyEnergy consumption

The invention provides an electric roller conveyor with aluminum alloy beams, which is characterized by comprising an aluminum alloy supporting leg; the upper side of the aluminum alloy supporting leg is provided with the aluminum alloy beams; at least one electric roller is arranged between two aluminum alloy beams; each electric roller and at least six unpowered rollers form a group; and the electric roller is connected with an external PLC system. The electric roller conveyor for the aluminum alloy beams has the advantages that the transmission noise of the electric roller and an O-shaped ring is low; both the aluminum alloy beams and the aluminum alloy supporting leg are made of aluminum profile, the production process is simple, and the production period is short; no motor decelerator is provided, and the whole space utilization rate is high; the power consumption for conveying unit materials is low, and the energy consumption is saved; and the structure is simple, vivid, small and beautiful.

Owner:SHANGHAI JINGXING LOGISTICS EQUIP ENGCO

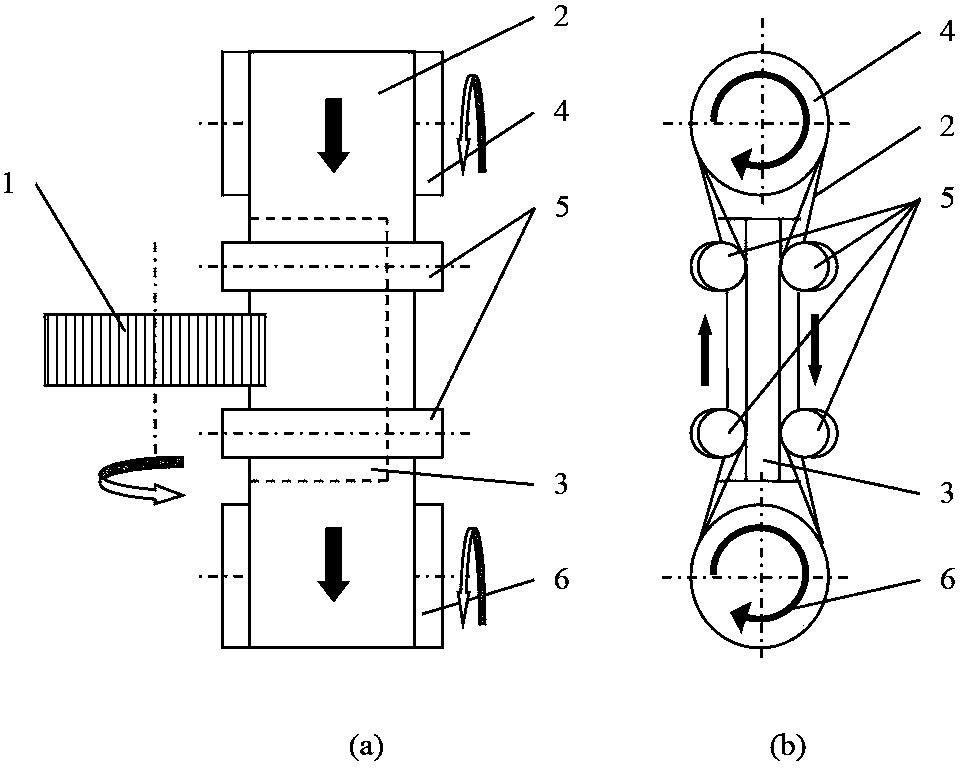

High-speed metal wire drawing machine

The invention relates to a high-speed metal wire drawing machine, and belongs to the technical field of a metal wire drawing machine. The high-speed metal wire drawing machine comprises a rack and a motor, wherein a low-speed guide wheel set, a low-speed mould base, a high-speed guide wheel set, a high-speed mould base and the like are arranged on the rack; the motor is sequentially connected with a driving pulley, a driven pulley and a high-speed cone pulley set; the high-speed cone pulley set is in transmitted connection with a constant-speed wheel and is in meshed and transmitted connection with a low-speed cone pulley set; the low-speed guide wheel set is connected with the low-speed cone pulley set. The chain or gear transmission of the constant-speed wheel and the high-speed cone pulley set is changed into synchronous belt transmission, synchronous belt wheels are connected with shafts through taper locks, the replacement is convenient, and therefore the different speed ratios between the constant-speed wheel and the high-speed cone pulley set is obtained, so that only one mould is needed when customers draw a variety of specifications of metal wires. The mould cost is greatly reduced. The high-speed metal wire drawing machine has the advantages of simple design, high wire drawing speed, low energy consumption, good economic benefit and strong practicality, greatly reduces transmission noises, and brings security assurance to the personal safety of operating personnel.

Owner:HANGZHOU XINGGUAN MACHINERY

Gear grinding machining method and device

InactiveCN103737119AImprove grinding efficiencyAvoid easy cloggingGear-cutting machinesGear teethGear grindingGear wheel

The invention provides a gear grinding machining method and device. The method adopts an abrasive belt which is high in grinding efficiency, the abrasive belt is in high-speed motion along the tooth width direction of a gear to conduct grinding, and the abrasive belt is in generating motion relative to a gear blank to grind each tooth socket tooth surface sequentially and swings slightly relative to the generatrix of the tooth surface to achieve crowned tooth surface shape correction. The device for achieving the grinding machining method is provided and comprises a bed body, a lifting table, a gear blank rotation dividing head, a gear blank flat moving work table, a gear blank dip angle table, an abrasive belt feeding work table and an abrasive belt deflection rotary disc. A numerical control system controls all the portions to be in linkage and conducts complementation of abrasive belt abrasion loss, machining of various gears can be achieved by using suitable press grinding plates and belt guiding wheels or guiders, disc-shaped or worm-shaped grinding wheels are not required, and the method and device has high machining efficiency and machining quality.

Owner:湖北光辉节能科技有限公司

Multipurpose vegetable cutting mechanism and multifunctional vegetable cutting machine

InactiveCN104440984AQuality improvementCut off smoothlyMetal working apparatusAgricultural engineeringVegetable fibers

The invention discloses a multipurpose vegetable cutting mechanism and a multifunctional vegetable cutting machine and belongs to the technical field of vegetable cutting machines. According to the multipurpose vegetable cutting mechanism, an inclined vegetable guiding opening is formed between a vegetable baffle and a slicing knife fixing part which is horizontally provided with a slicing knife located on a vegetable inlet of the vegetable guiding opening, and a secondary vegetable cutting cavity is formed below a vegetable outlet of the vegetable guiding opening; a blade assembly is installed below a vegetable hopper, and a horizontal movement starting point and an end point of the slicing knife are located on the two sides of a vegetable entrance of the vegetable hopper respectively; longitudinal shredding knifes which are vertically arranged and located on the vegetable inlet of the vegetable guiding opening are selectively installed on the vegetable baffle; transverse shredding knifes which are horizontally arranged and used in cooperation with a cutting-off chopping board are selectively installed in the secondary vegetable cutting cavity. The invention further discloses the multifunctional vegetable cutting machine. On the basis that the principle of the cutting mechanism and the cutting machine is similar to that of manual vegetable cutting, vegetables are fast cut off, vegetable fiber texture is kept intact, the cut vegetables taste good, and the problem that vegetables are seriously extruded when the vegetables are shredded and cut into blocks through single procedures is solved in the aspect of the principle.

Owner:吴守林

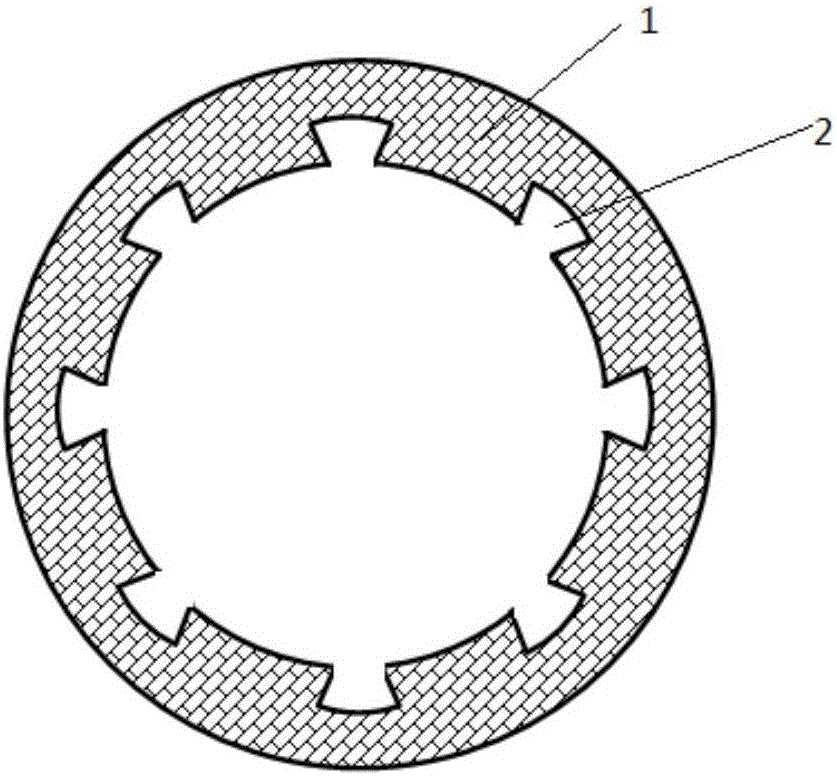

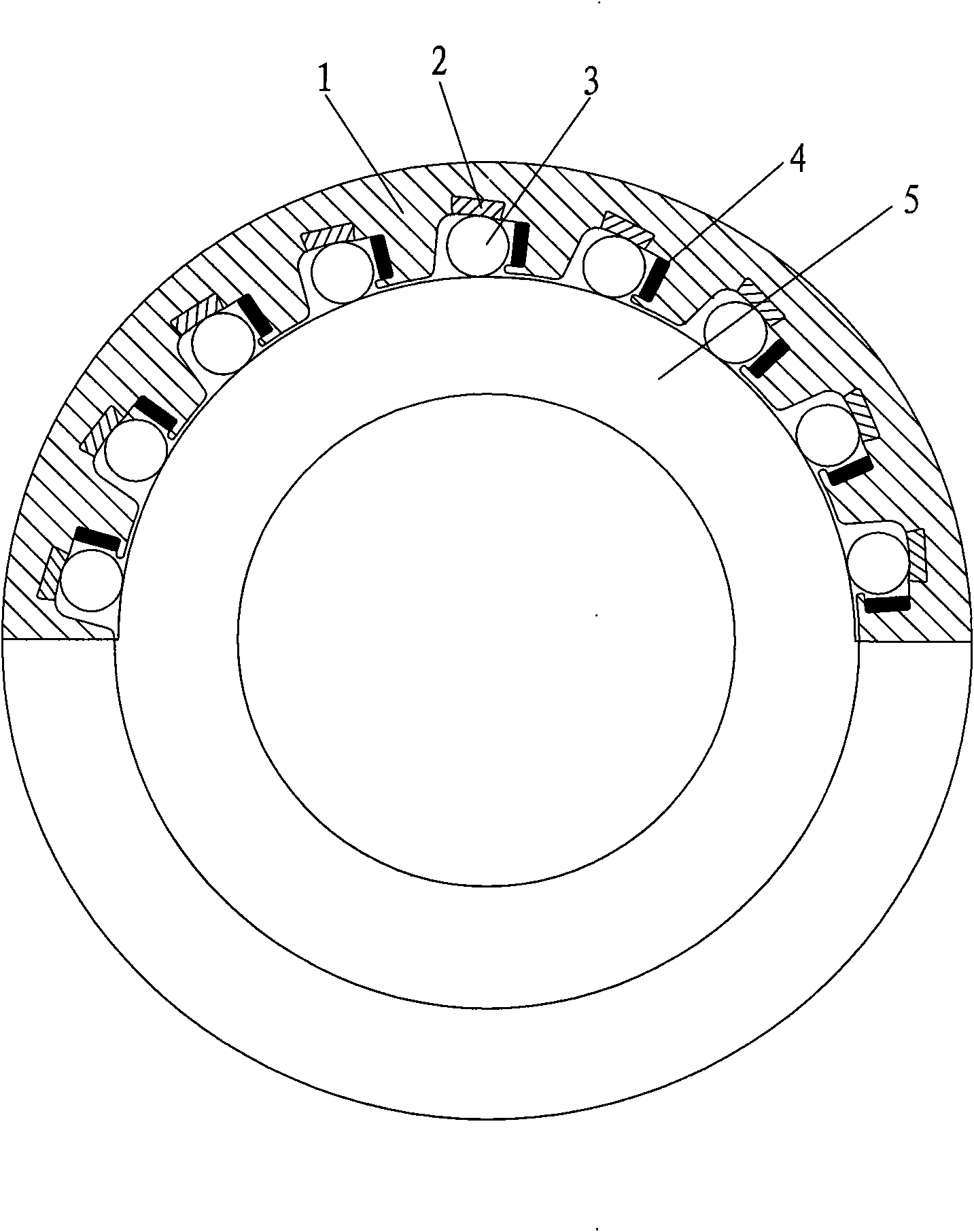

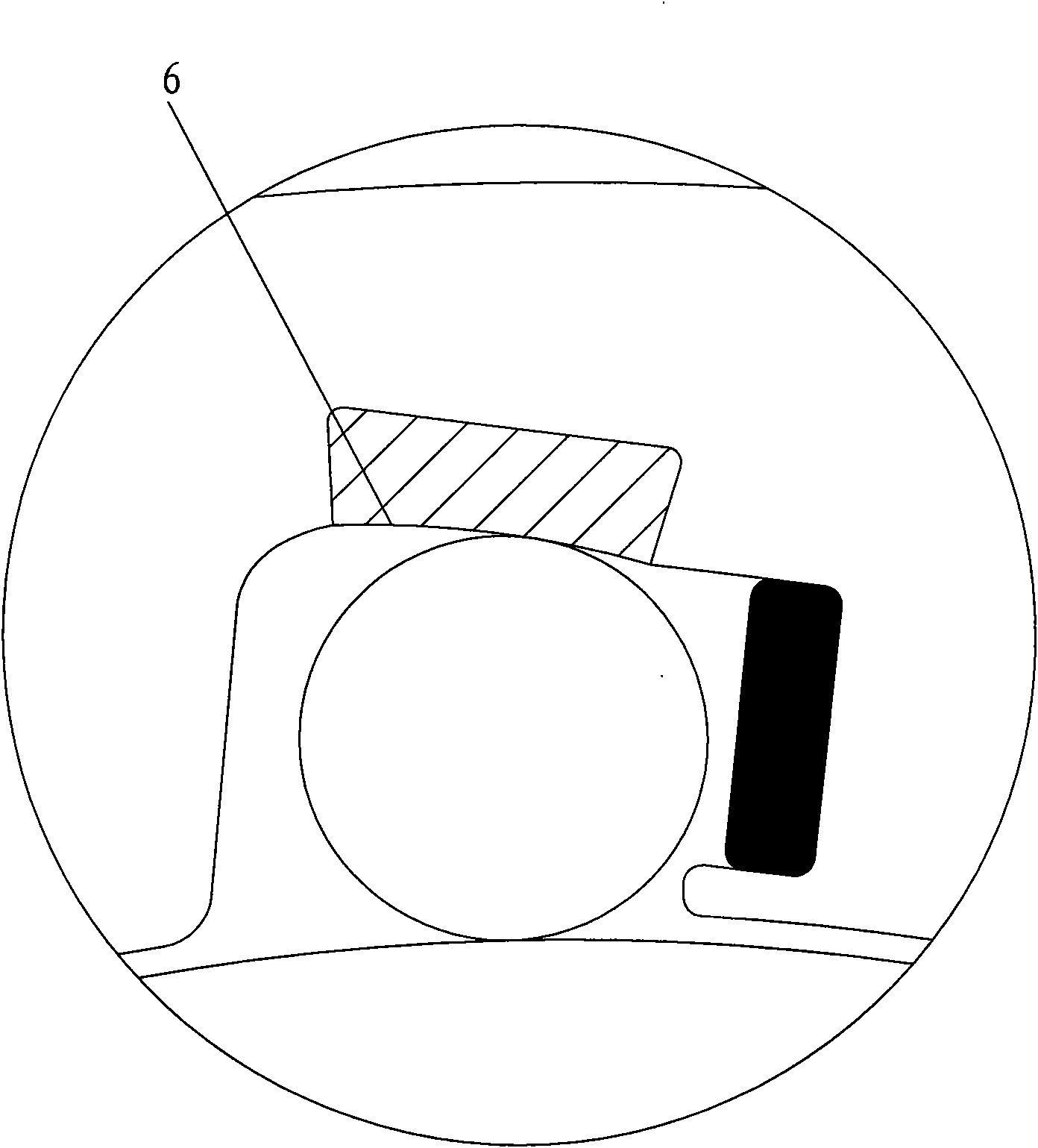

External star wheel type overrunning clutch

The invention discloses an external star wheel type overrunning clutch, and belongs to the technical field of clutch manufacture. The external star wheel type overrunning clutch is provided with an external star wheel (1), an embedded block (2), a pin roller (3), a permanent magnet (4) and an inner ring (5), wherein one side of the external star wheel is provided with a groove for accommodating the permanent magnet, a start wheel working face of the external star wheel is provided with a dovetail groove-shaped embedded alloy (2) (embedded block for short), and the working face is a logarithmichelical curved surface. The clutch has the advantages of simple manufacturing process, high working reliability, large bearing torque and long service life, can bear large torque force and impact force, and can work for long time under high-speed heavy load.

Owner:厦门恒瑞达机械有限公司

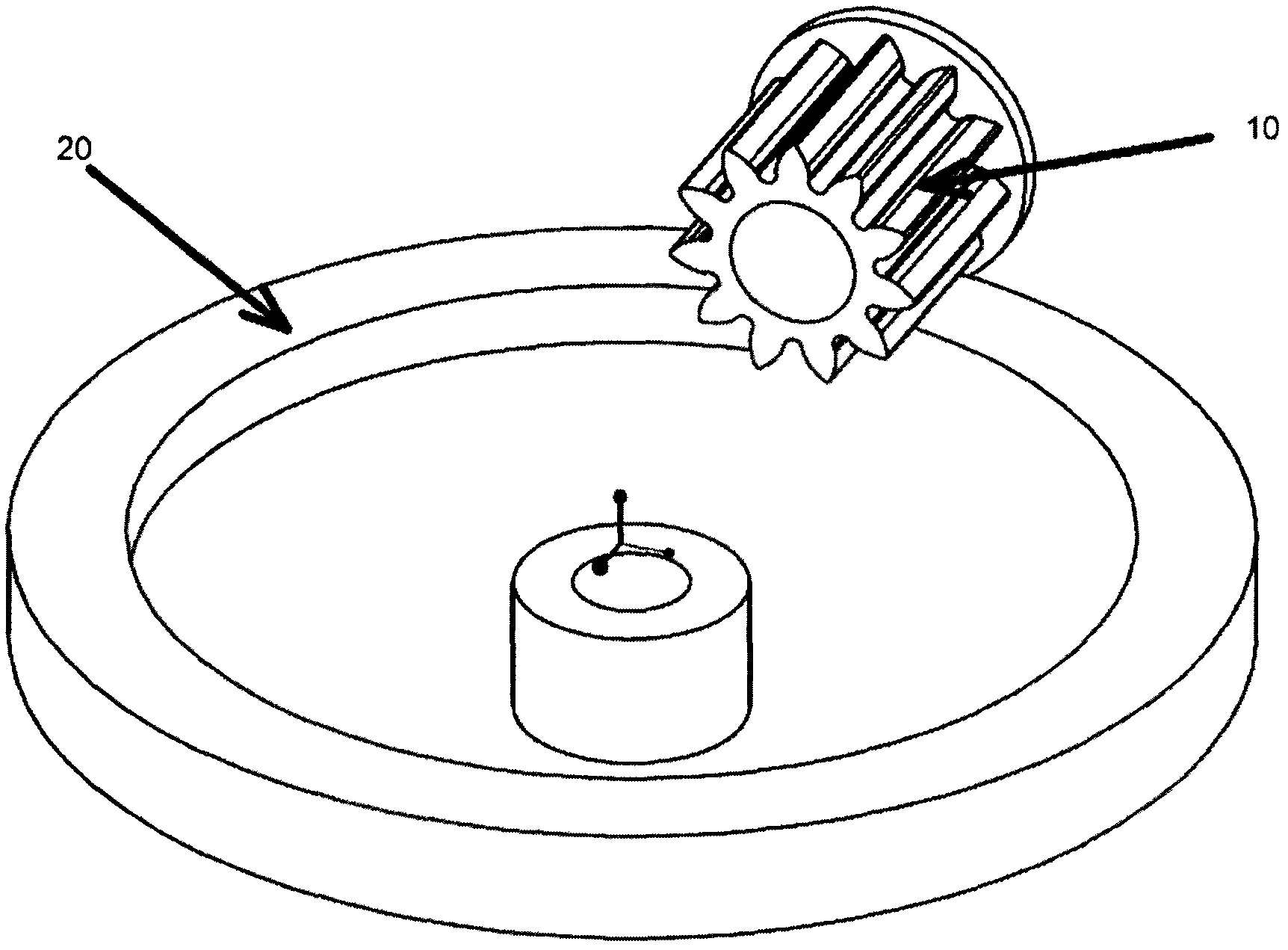

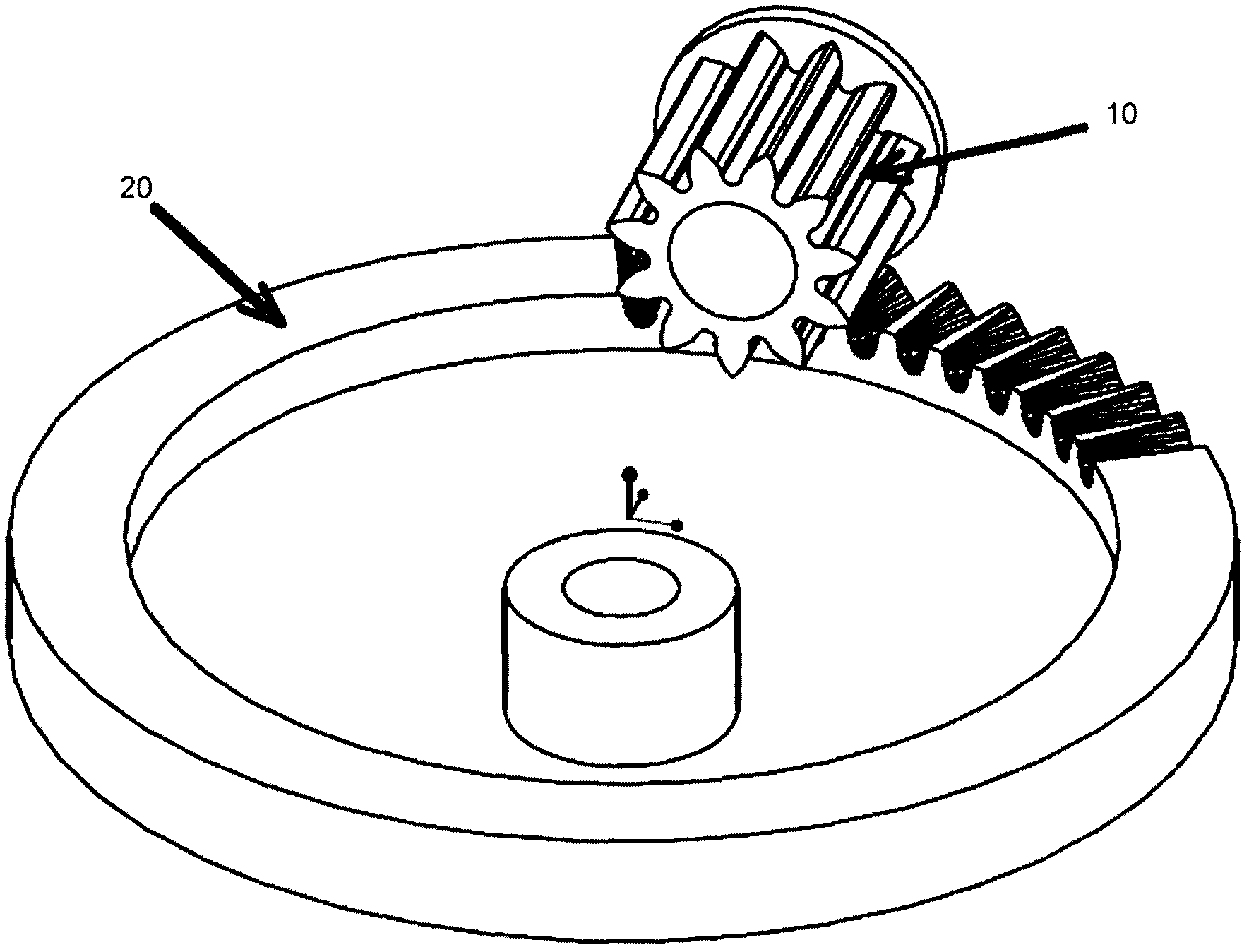

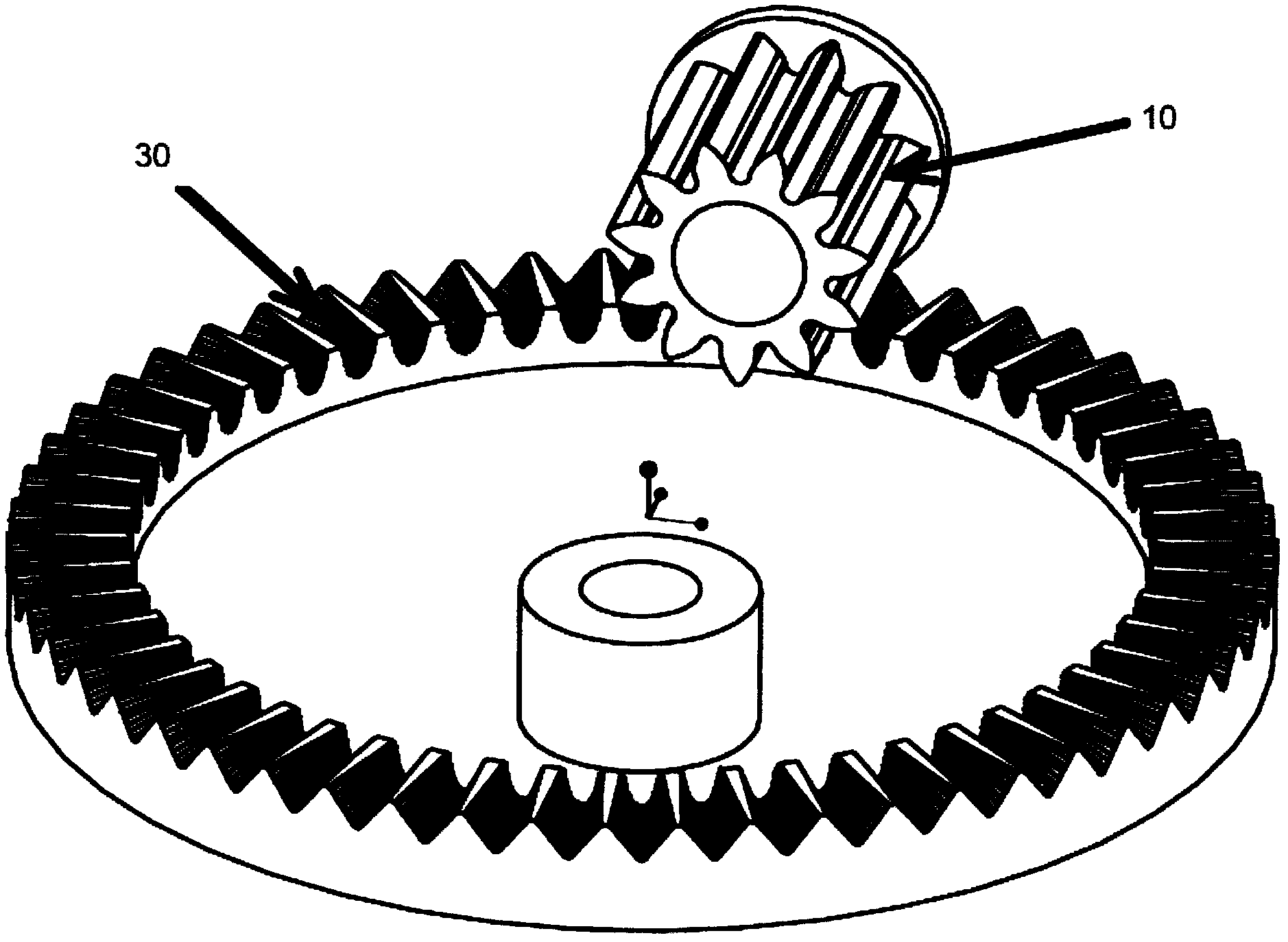

Machining method of injection molding face gear electrode and injection molding face gear

ActiveCN103128385AMeet transmission requirementsHigh precisionElectrical-based machining electrodesSpecial data processing applicationsGear grindingNumerical control

The invention provides a machining method of an injection molding face gear electrode and an injection molding face gear. A face gear transmission principle is used, a three-dimensional vector diagram of the face gear is generated in a generating method through computer-assisted software, then the injection molding face gear electrode is machined through a numerical control lathe, a mold cavity of the face gear is machined in an electric spark discharge technology, and accordingly the face gear is formed by infection molding. Due to the fact that transmission data of the face gear and a cylinder gear is simulated in a computer, the machined infection molding face gear completely meets face gear transmission requirements in practice, data is accurate, the face gear is fixed on a table face to be machined through the numerical control lathe, deformation cannot happen, and therefore the machined injection molding face gear electrode is high in accuracy and low in transmission noise. What is important is that technologies such as gear inserting or gear rolling or gear grinding are not used in machining of the injection molding face gear electrode, so that special knives are of no need, and cost is greatly lowered.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

Completely cutting tool for shaving and honing gear and its usage

InactiveCN1608777AReduce concave amountPlay the role of automatic edge trimmingGear teeth manufacturing toolsGear teethSpecial designGear manufacturing

The present invention relates to gear manufacturing technology, and is especially completely cutting gear shaped gear shaving cutter with involute end section edge for finishing of gear before quenching, completely cutting gear shaped honing wheel for machining hard gear surface after quenching and their usage. The present invention includes skewed-tooth gear shaving cutter and skewed-tooth honing wheel, and features that each edge can cut from the dedendum to addendum continuously and that each tooth shape curve of the skewed-tooth gear shaving cutter and the skewed-tooth honing wheel is fitted into approaching involute. The present invention is realized with the special design program PICM.

Owner:TAIYUAN UNIV OF TECH

Gear hub motor lubricated by liquid lubricating oil

ActiveCN106208588ASmall air gap flux densityIncrease speedDC commutatorMechanical energy handlingFully developedReducer

The invention discloses a gear hub motor lubricated by liquid lubricating oil. The gear hub motor comprises a left end cover, a right end cover, a main shaft an a hub, wherein the left end cover sleeves the main shaft through a first bearing and a first oil seal; an oil filling opening is formed in the left end cover, the right end cover or the hub; the right end cover sleeves the main shaft through a second bearing and a second oil seal; the left end cover is connected with the right end cover through a seal ring and the hub; the left end cover is connected with a solar gear ring through a reducing mechanism; the solar gear ring is fixed on the motor; and the solar gear ring is driven to rotate through the motor, so that the left end cover is driven to rotate through the reducing mechanism to drive the hub to rotate. A two-stage reduction planetary gear reducer mechanism is adopted under the premise of keeping a through shaft structure, so that the reliability of the hub motor structure is ensured; the high-speed performance of a disc-type coreless DC motor can be fully developed; the reducing mechanism is lubricated by the liquid lubricating oil; and the transmission efficiency of the motor is high.

Owner:眭华兴

Silencer

ActiveCN1590725AReduce transmission noiseAct quicklyInternal combustion piston enginesPump componentsEngineeringMechanical engineering

Openings in the covering sheet of the chamber (32) are formed as slots orientated along the flow direction. The open areas (33) amount to about 6-14% of the total area (31) of the chamber. Slot length to width ratio exceeds 3, and the slots differ in length.

Owner:TURBO SYST SWITZERLAND LTD

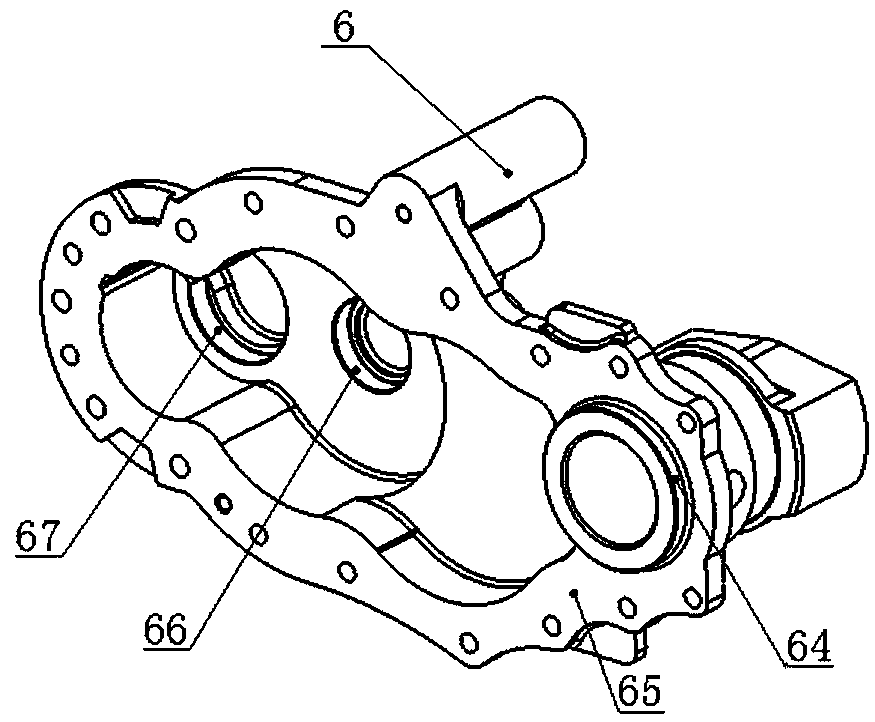

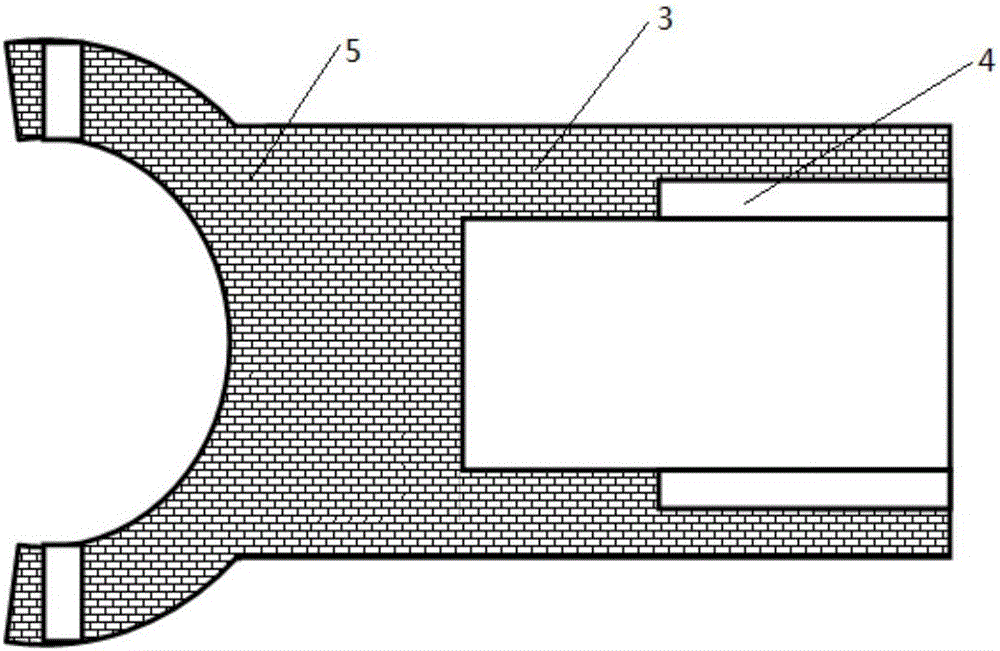

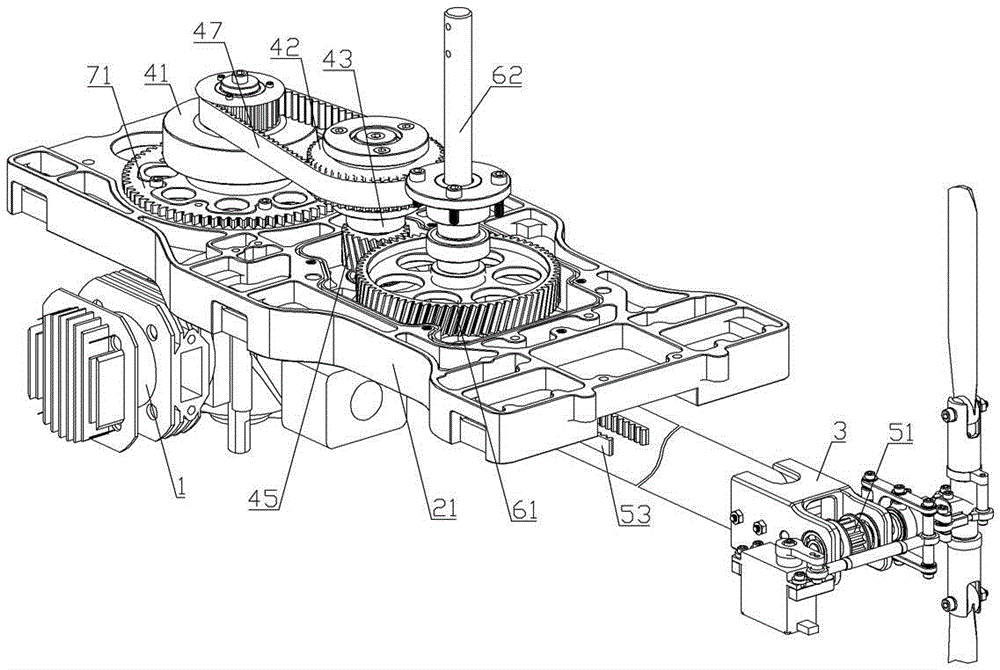

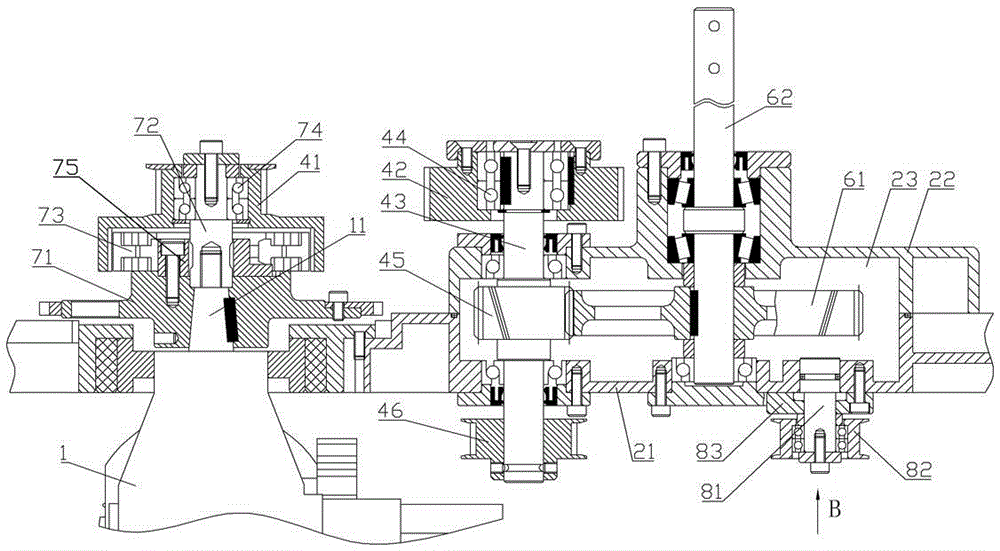

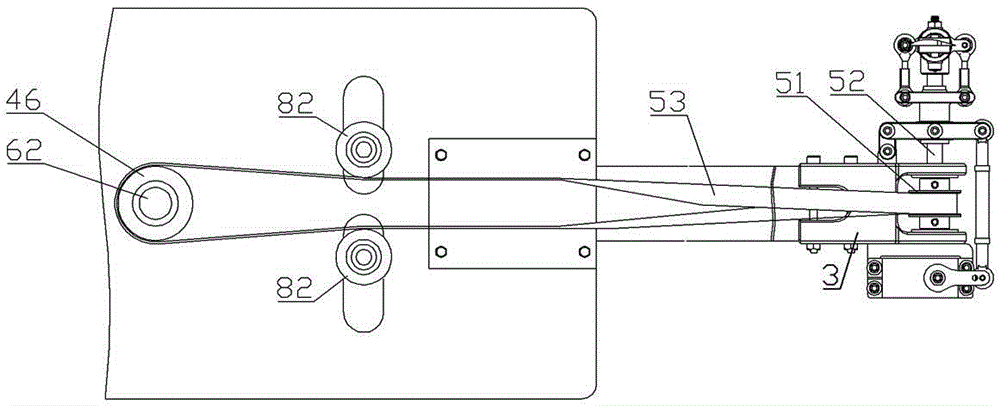

Small-sized single-rotor unmanned helicopter speed change system

PendingCN105346712AReduce distractionsReduce the number of transmission stagesAircraft power transmissionRotocraftThree stagePropeller

The invention provides a small-sized single-rotor unmanned helicopter speed change system, which comprises an engine, a gearbox and a tailing box, wherein the gearbox comprises a box base and a box upper cover; the box upper cover is arranged on the box base in a sealed way; an inner cavity is formed between the box upper cover and the box base; and the small-sized single-rotor unmanned helicopter speed change system also comprises a one-stage transmission mechanism, a tail rotor mechanism and a propeller mechanism. The small-sized single-rotor unmanned helicopter speed change system has the advantages that a transmission system only has two-stage transmission; and a tail rotor and a propeller obtain power from two-stage transmission. Compared with the three-stage transmission of the existing small-sized single-rotor unmanned helicopter speed change system, the small-sized single-rotor unmanned helicopter speed change system has the advantages that the transmission stages are reduced; the transmission noise is reduced; the transmission efficiency is improved; components are reduced; the weight is reduced; the load on the engine during the flight is reduced; the gearbox part only comprises one-stage transmission; during the operation, the vibration is reduced, so that the interference of the vibration on electronic equipment is reduced; and the flight safety and the flight reliability are guaranteed.

Owner:衡阳云雁航空科技有限公司

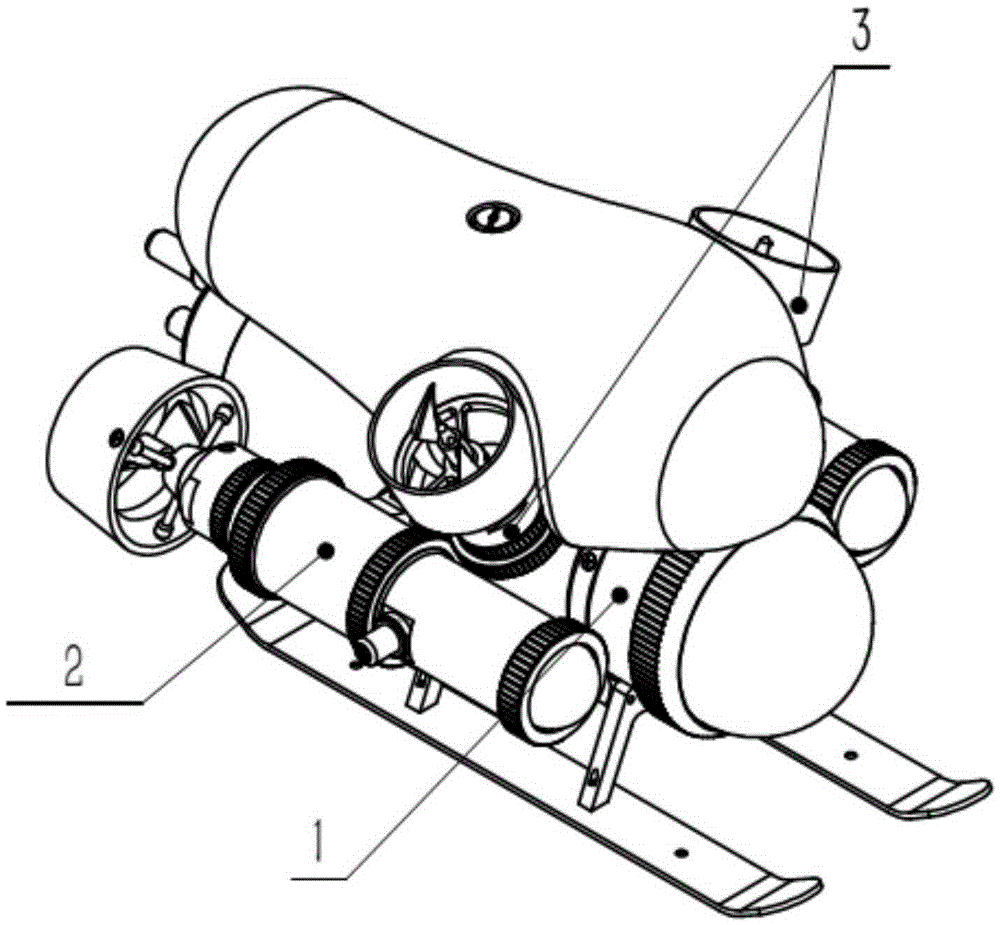

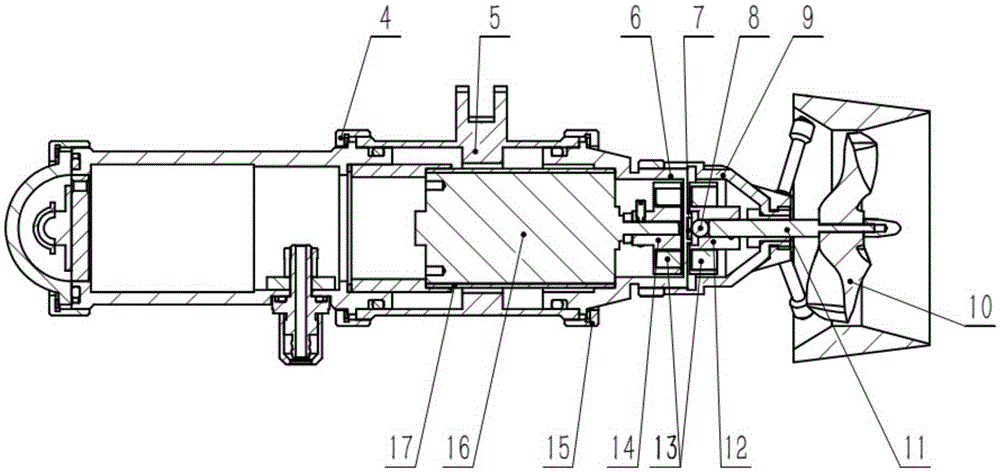

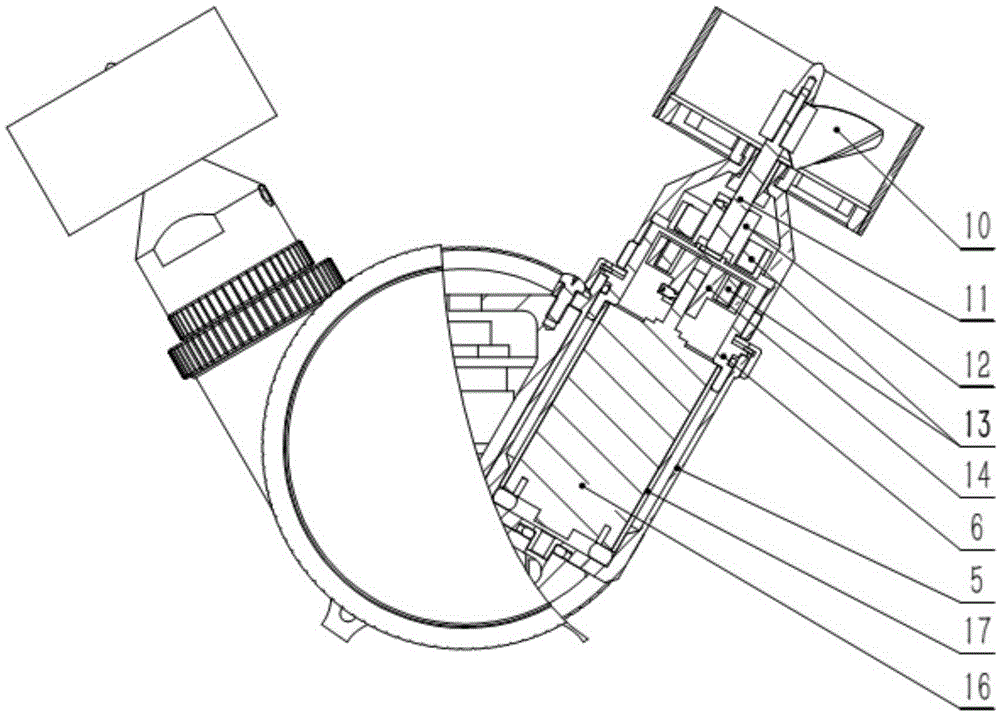

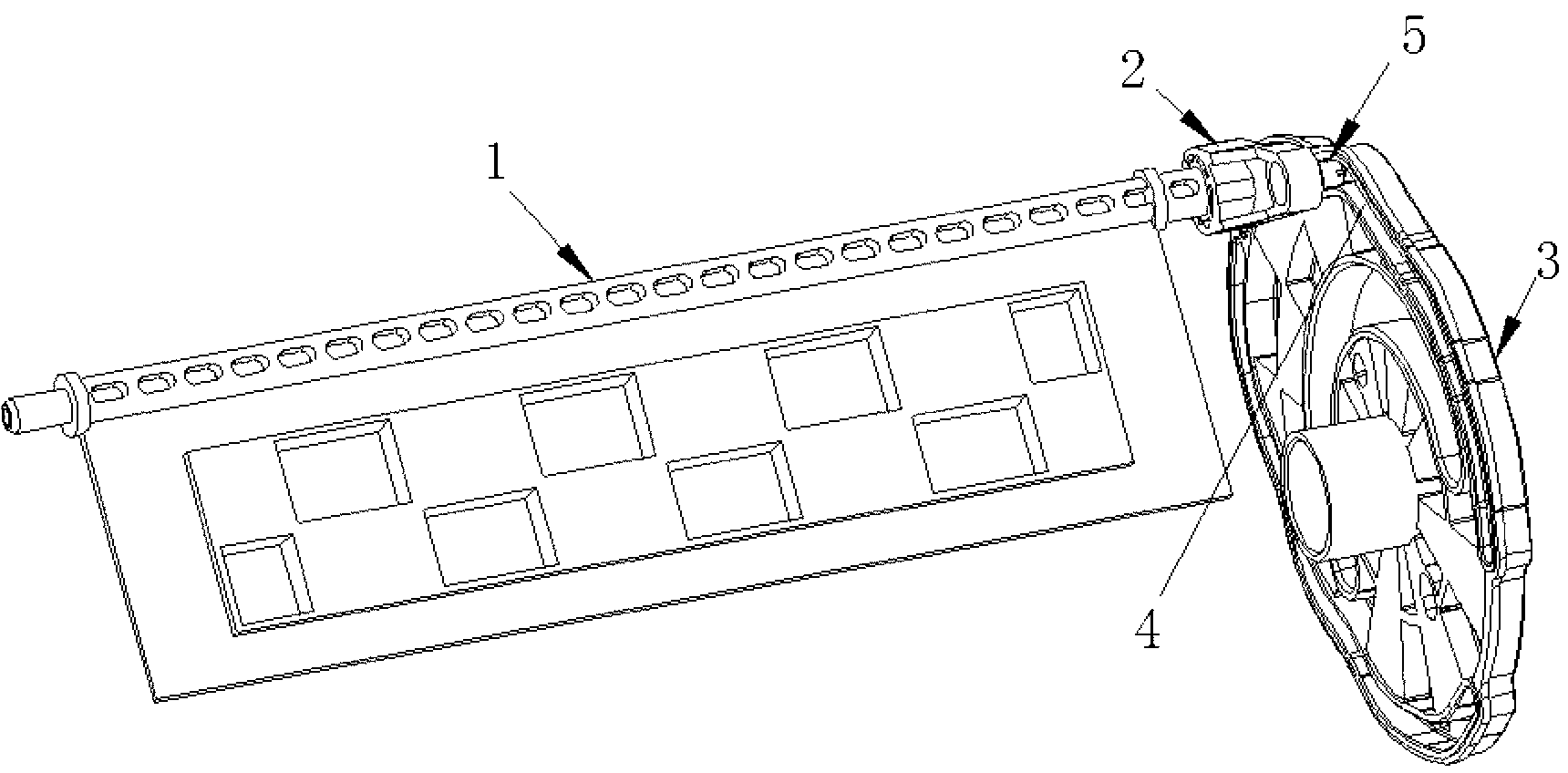

Underwater robot propulsion system

InactiveCN105292414AImprove mobilityImprove mechanical transmission efficiencyUnderwater vesselsUnderwater equipmentDrive shaftCoupling

The invention discloses an underwater robot propulsion system. The underwater robot propulsion system comprises two horizontal propulsion modules and two inclined propulsion modules, wherein the two horizontal propulsion modules are symmetrically arranged on the two sides of a robot main cabin in parallel; the two inclined propulsion modules are embedded into the two sides of the middle part of the robot main cabin in the form of V shape in a crossed way within a plane vertical to the axis of the robot main cabin; the horizontal propulsion modules and the inclined propulsion modules all use propeller propulsion modules; the propeller propulsion modules comprise motors and sealed cabins; output shafts of the motors are connected with driven shafts through disc type magnet couplings; and propellers are mounted on the driven shafts. According to the invention, motion capacity of 5 degrees of freedom can be provided to a robot and the flexibility of the robot is improved; as the propeller propulsion modules use the disc type magnet couplings, the axial length of the system can be effectively reduced so that the structure of the underwater robot propulsion system is compact and stable and the underwater robot propulsion system is convenient to machine.

Owner:SHENZHEN HONGYANG HUIZHI INNOVATION TECH CO LTD

Automotive air conditioning damper moving mechanism

InactiveCN103062878AStable structureSmooth motionAir-flow control membersRolling resistanceControl theory

The invention discloses an automotive air conditioning damper moving mechanism which comprises a damper, a damper poking rod and a drive plate. A track groove is arranged on the drive plate, an end of the damper poking rod is provided with a cylindrical boss extending into the track groove and having rolling friction with an inner wall of the track groove, and a sheath is sleeved on an outer wall of the cylindrical boss. By means of the structure, the automotive air conditioning damper moving mechanism has the advantage that the sheath structure enables two components in the drive plate, the poking rod and the sheath to be in opposite rolling motion, materials of the two opposite moving components are different, moving is stable, friction resistance is small, and transmission noise is low; the moving mechanism is compact, simple in transmission process, simple and clever in structure; the damper can be taken to a preconceived design position, and control is precise and stable and noise is low during the process; and all components of the transmission mechanism rotate around the normal axis of the casing, and occupied space is small.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

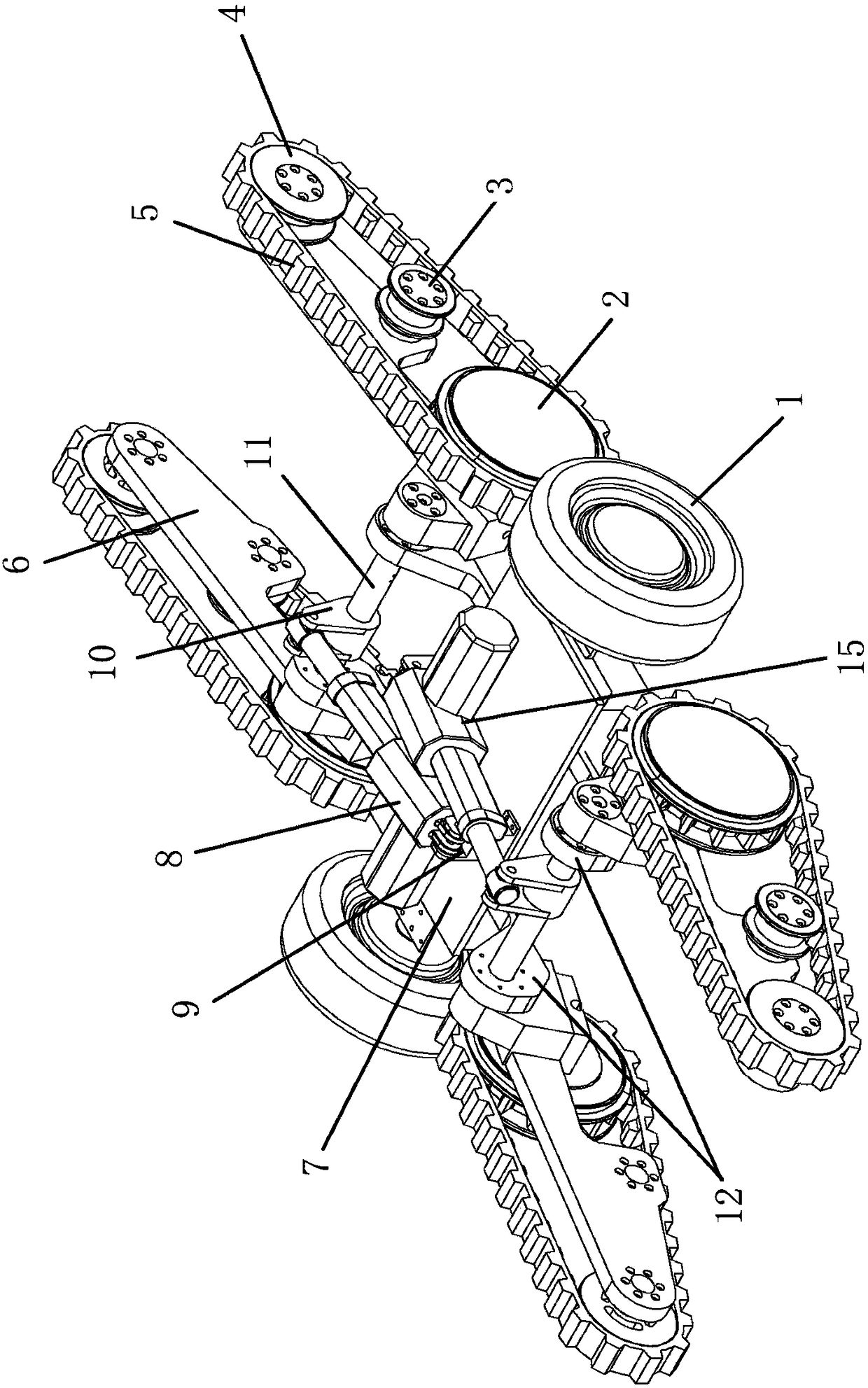

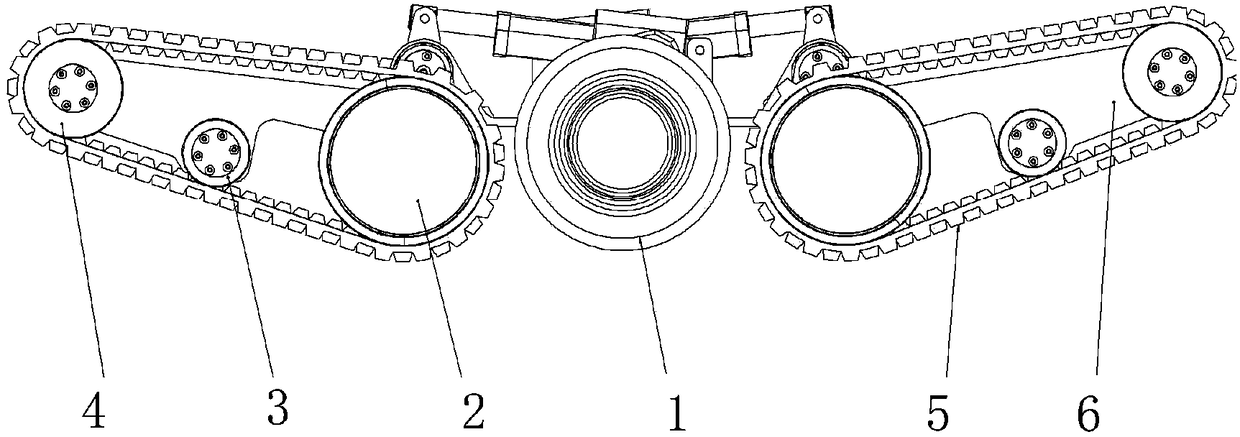

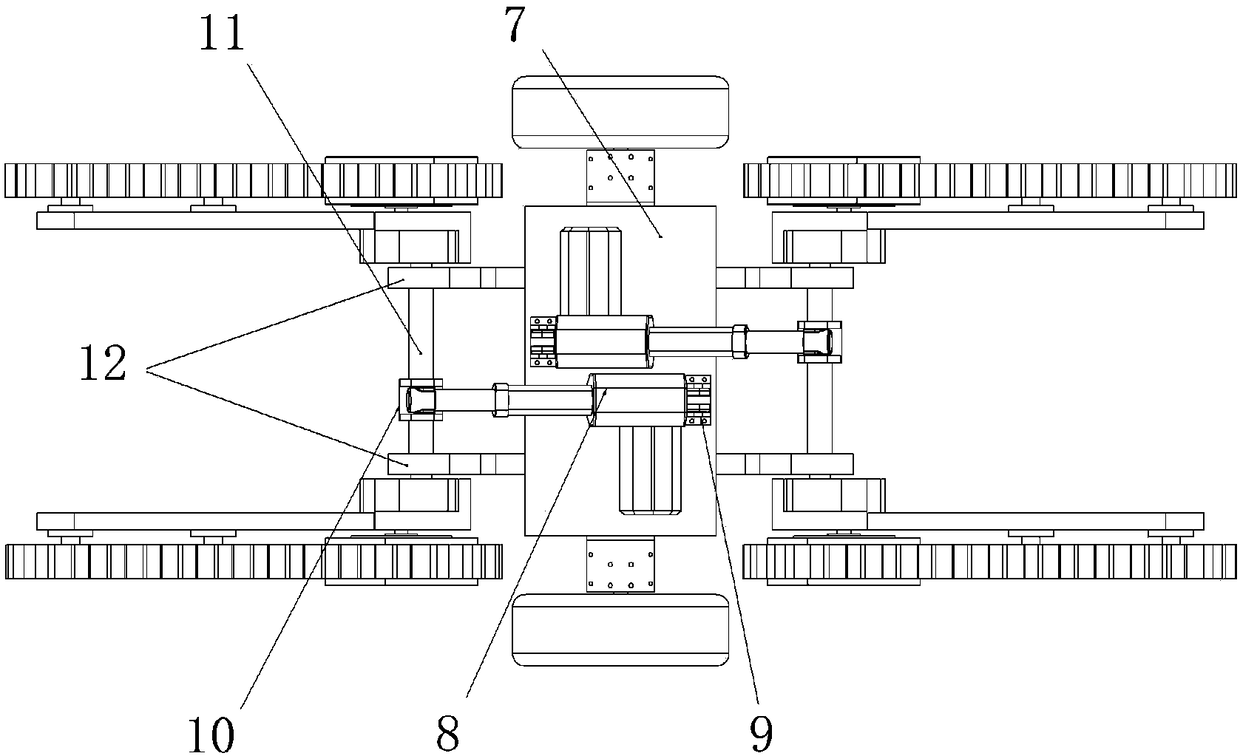

Two-wheel-leg-caterpillar band compound type movement mechanism

ActiveCN108791548AImprove mobile efficiencyAchieve direct driveEndless track vehiclesTerrainDrive shaft

The invention relates to the technical field of specialized robots, in particular to a two-wheel-leg-caterpillar band compound type movement mechanism. The two-wheel-leg-caterpillar band compound typemovement mechanism comprises a movement seat body, walking wheels, swing leg drive mechanisms and swing leg assemblies. The two walking wheels are installed at the left end and the right end of the movement seat body. Walking wheel drive motors are arranged in the walking wheels. The swing leg assemblies are arranged on the front side and the rear side of the movement seat body. The two swing legdrive mechanisms are arranged on the movement seat body. The swing leg assemblies on the two sides of the movement seat body are driven by the different swing leg drive mechanisms to swing. The swingleg assemblies located on the same side of the movement seat body are connected through a swing leg drive shaft. The swing leg drive shafts are driven by the swing leg drive mechanisms to rotate anddrive the swing leg assemblies to swing. The swing leg assemblies are provided with caterpillar bands. When the walking wheels make contact with the ground to rotate, the caterpillar bands leave the ground, and when the caterpillar bands make contact with the ground to rotate, the walking wheels leave the ground. The problems that an existing robot movement mechanism is poor in maneuvering flexibility, low in movement efficiency and the like on a complex terrain are solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com