Patents

Literature

39results about How to "Meet transmission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

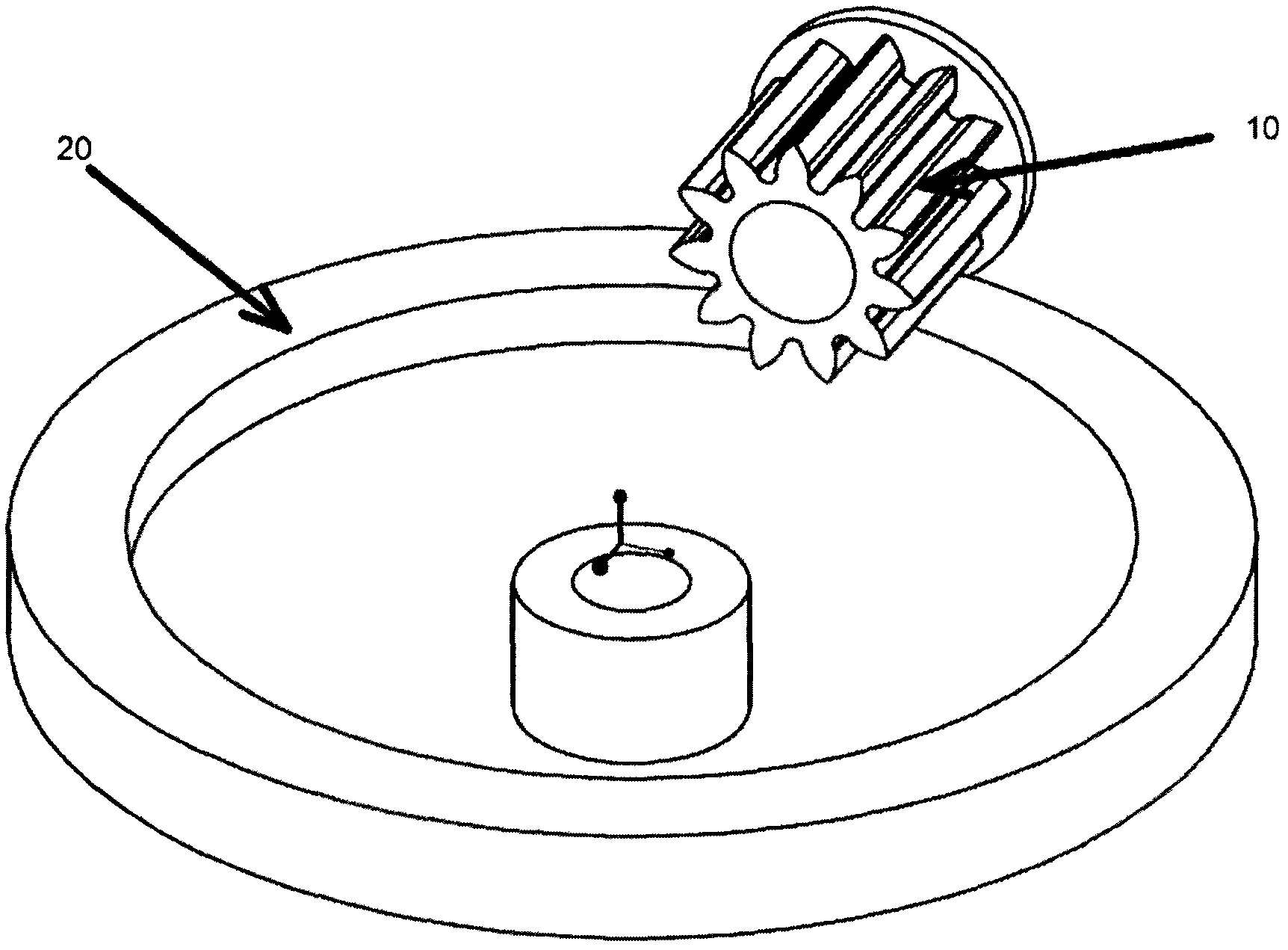

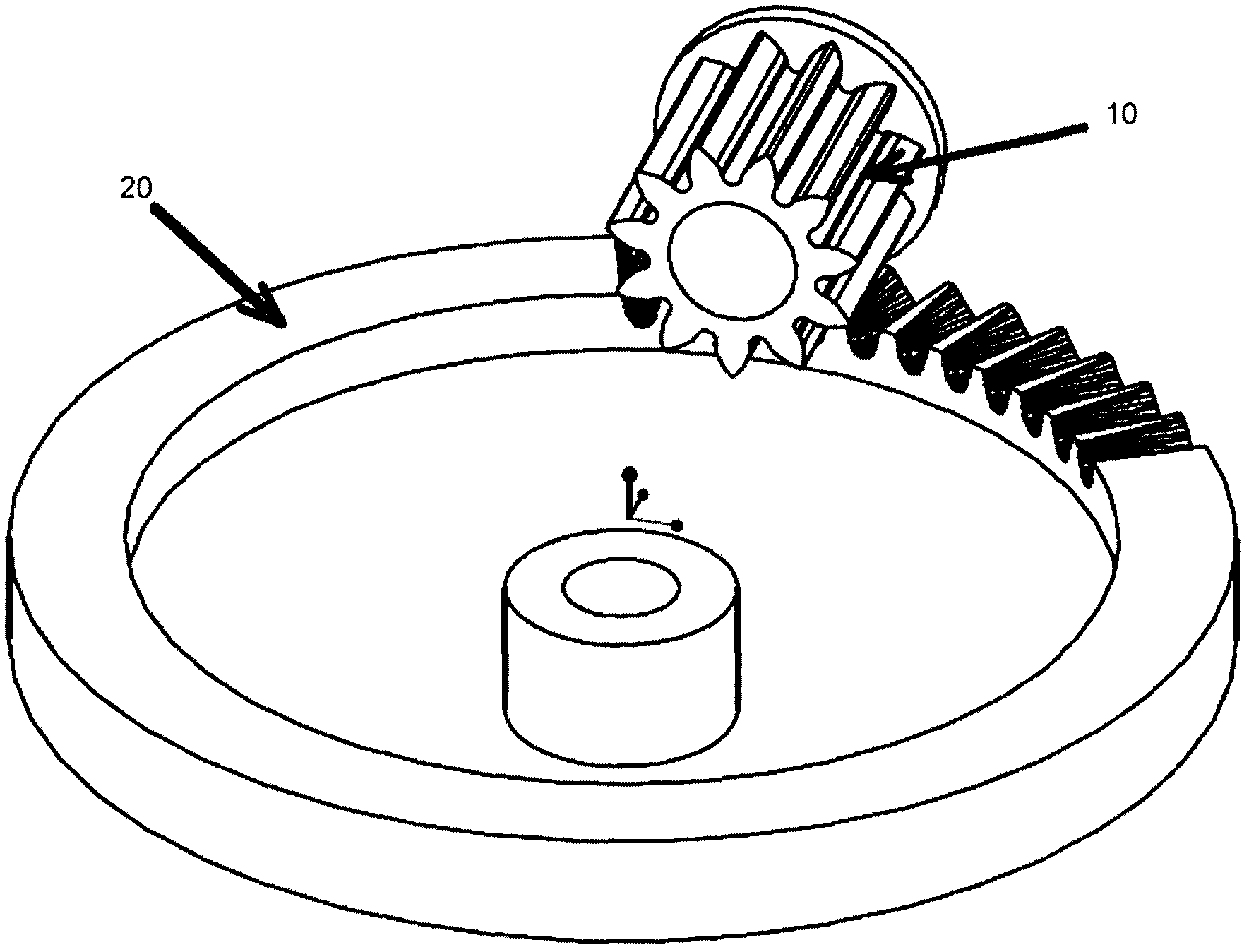

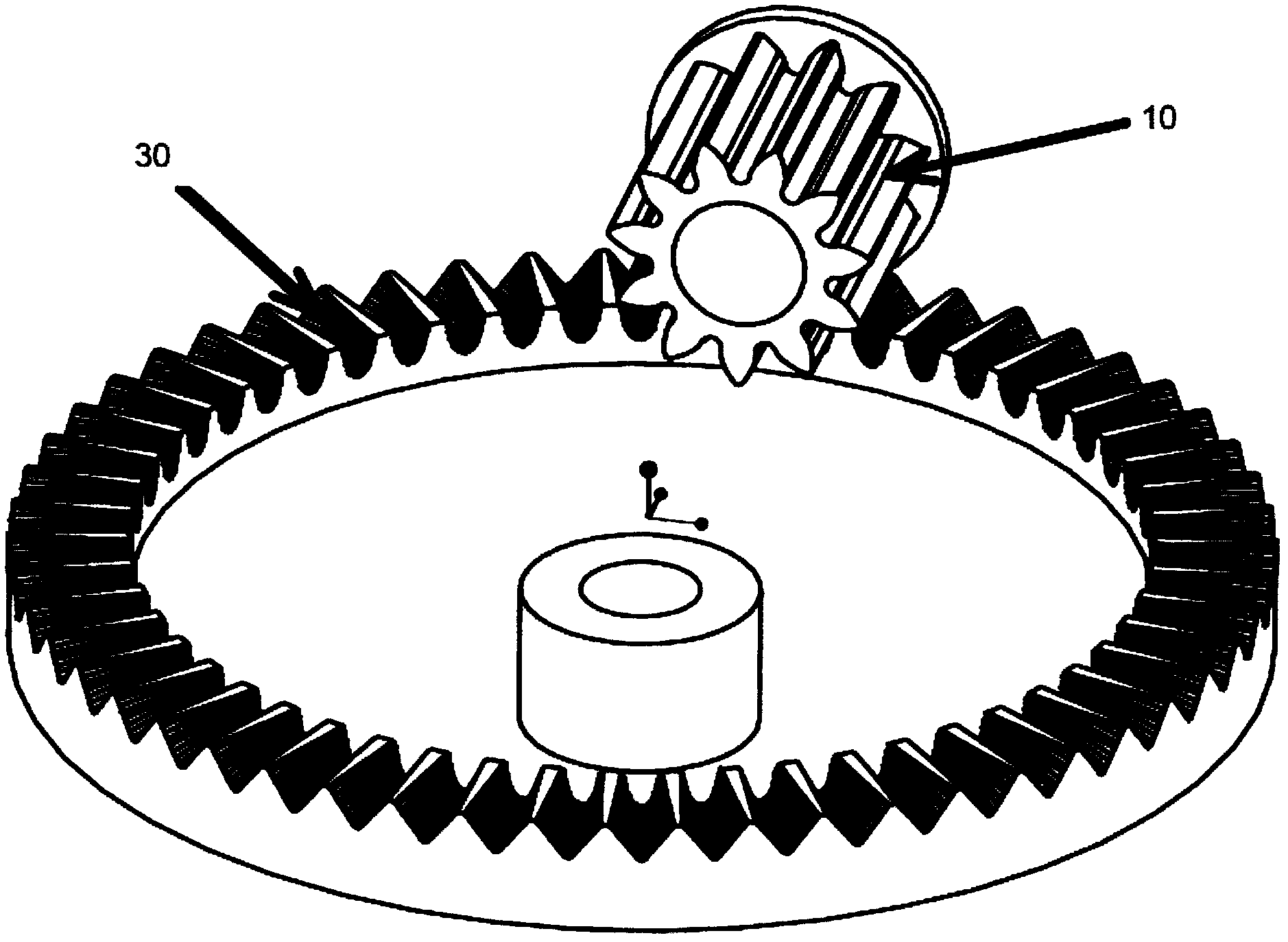

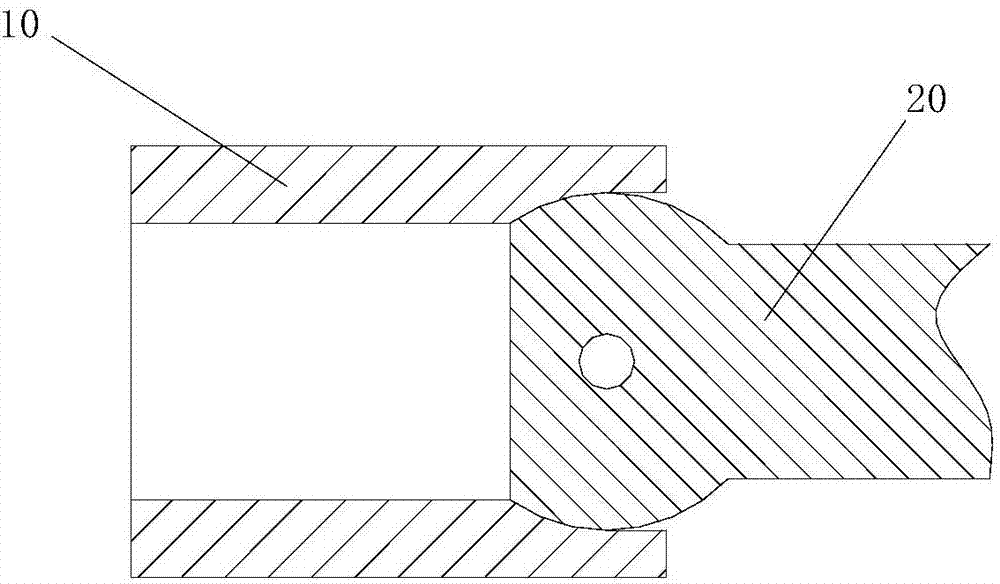

Machining method of injection molding face gear electrode and injection molding face gear

ActiveCN103128385AMeet transmission requirementsHigh precisionElectrical-based machining electrodesSpecial data processing applicationsGear grindingNumerical control

The invention provides a machining method of an injection molding face gear electrode and an injection molding face gear. A face gear transmission principle is used, a three-dimensional vector diagram of the face gear is generated in a generating method through computer-assisted software, then the injection molding face gear electrode is machined through a numerical control lathe, a mold cavity of the face gear is machined in an electric spark discharge technology, and accordingly the face gear is formed by infection molding. Due to the fact that transmission data of the face gear and a cylinder gear is simulated in a computer, the machined infection molding face gear completely meets face gear transmission requirements in practice, data is accurate, the face gear is fixed on a table face to be machined through the numerical control lathe, deformation cannot happen, and therefore the machined injection molding face gear electrode is high in accuracy and low in transmission noise. What is important is that technologies such as gear inserting or gear rolling or gear grinding are not used in machining of the injection molding face gear electrode, so that special knives are of no need, and cost is greatly lowered.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

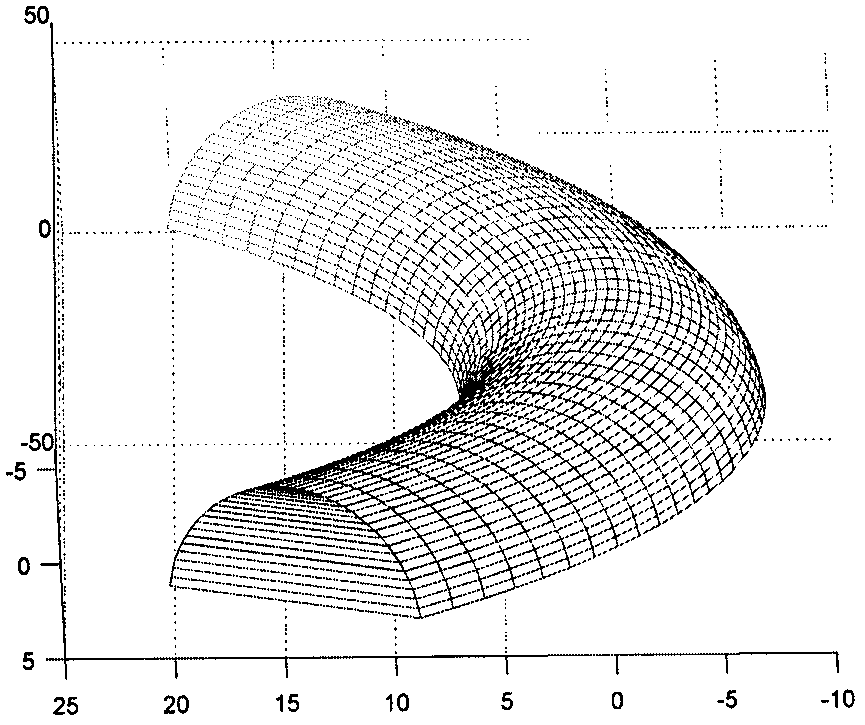

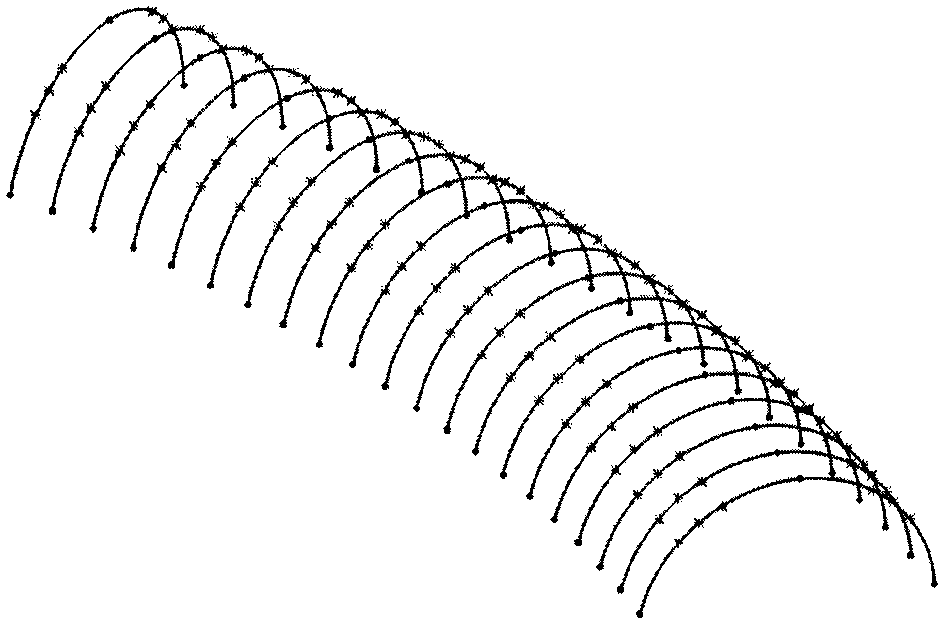

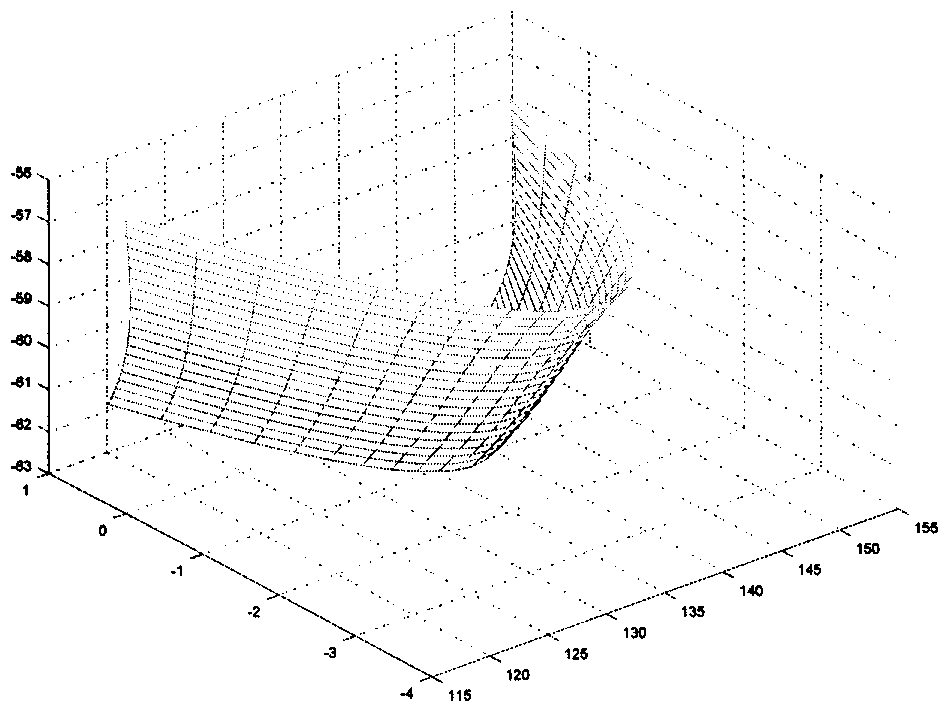

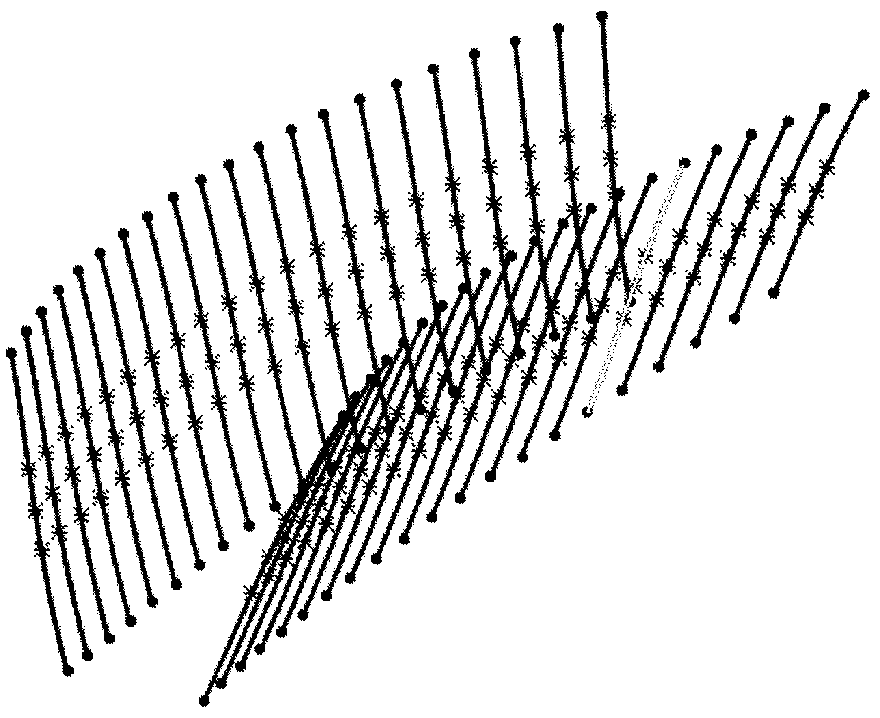

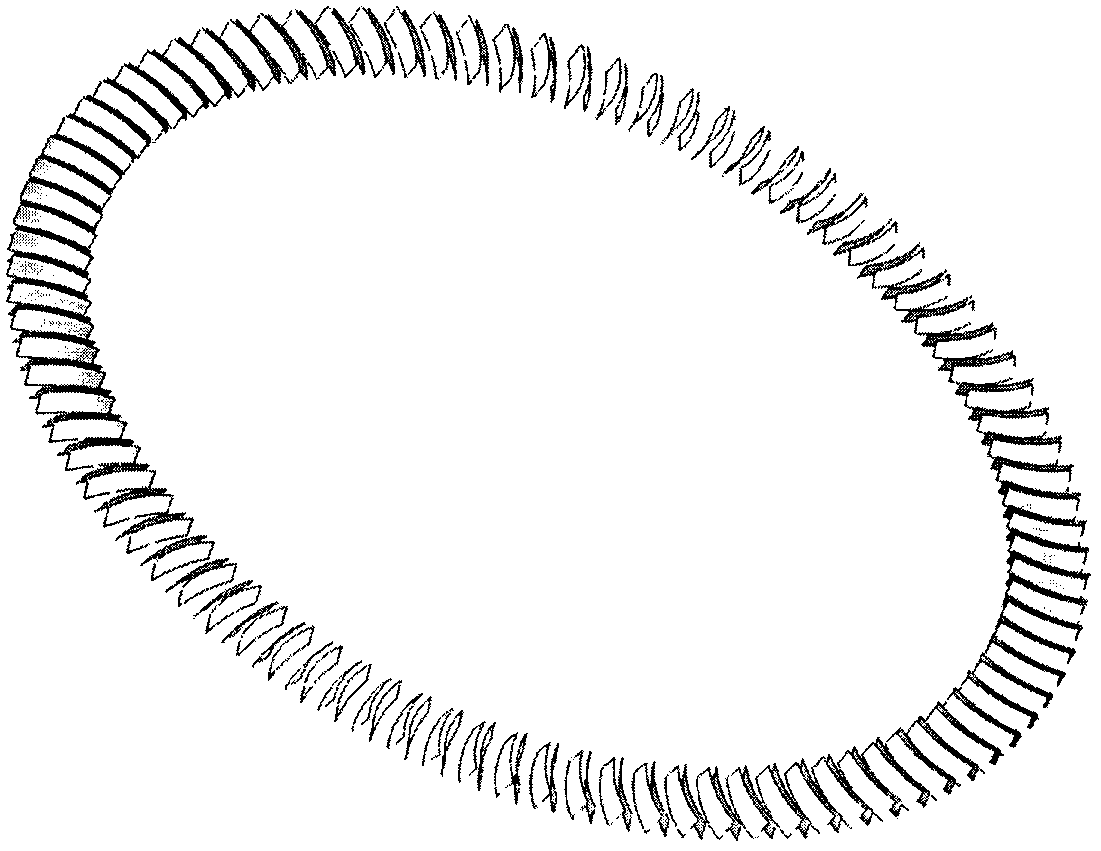

A method for generating real tooth surface of circular arc tooth profile double-arc spiral gear

ActiveCN109241670ANovel transmission principleUnique tooth shapeGeometric CADSustainable transportationPoint cloudReliable transmission

A method for generating real tooth surface of circular arc tooth profile double-arc spiral gear includes the following steps: 1, determining parameters of circular arc tooth profile double-arc spiralgear, 2, according to that relative motion relationship between the circular arc tooth profile double-arc spiral gear and the spiral tooth generating rack, establishing a space coordinate system of the circular arc tooth profile double-arc spiral gear and the spiral tooth generating rack and a space coordinate system generated by the tooth surface of the spiral tooth generating rack, 3, establishing the tooth profile equation of the arc tooth producing shape rack, 4, deriving that tooth surface equation of the arc tooth generating rack; 5, fitting the tooth surface of the arc tooth generate rack; 6, solving the meshing equation according to simulating the conjugate meshing process of the arc tooth generating rack and the arc tooth profile double-arc spiral gear; 7, deriving the tooth surface equation of the arc tooth profile double-arc spiral gear; 8, programming and calculating the tooth surface point cloud of the arc tooth profile double-arc spiral gear; The method has the advantagesof large coincidence coefficient of circular arc tooth profile double arc spiral gears, stable and reliable transmission, strong bearing capacity and meeting the transmission requirements under extreme conditions.

Owner:TIANJIN POLYTECHNIC UNIV

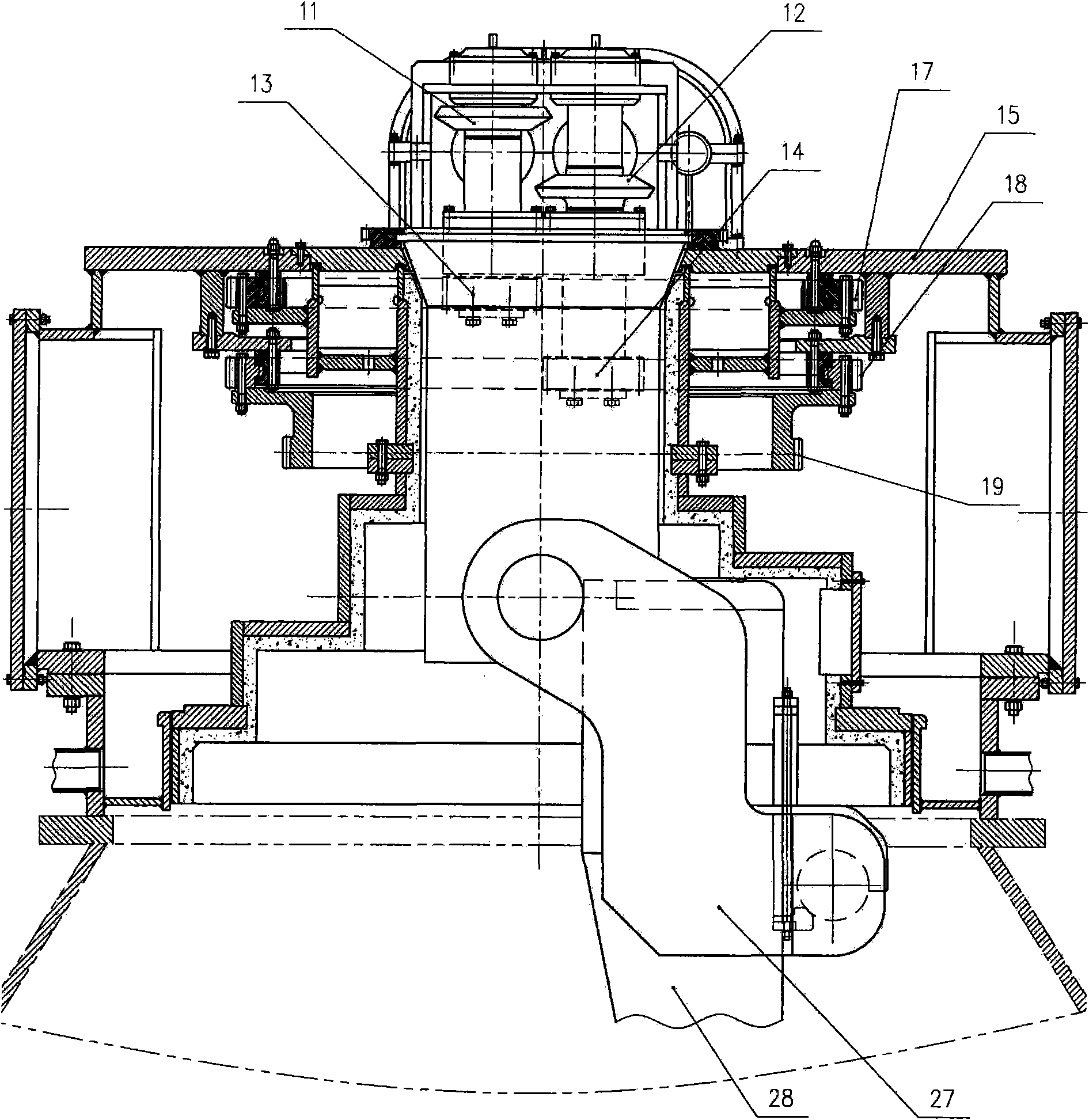

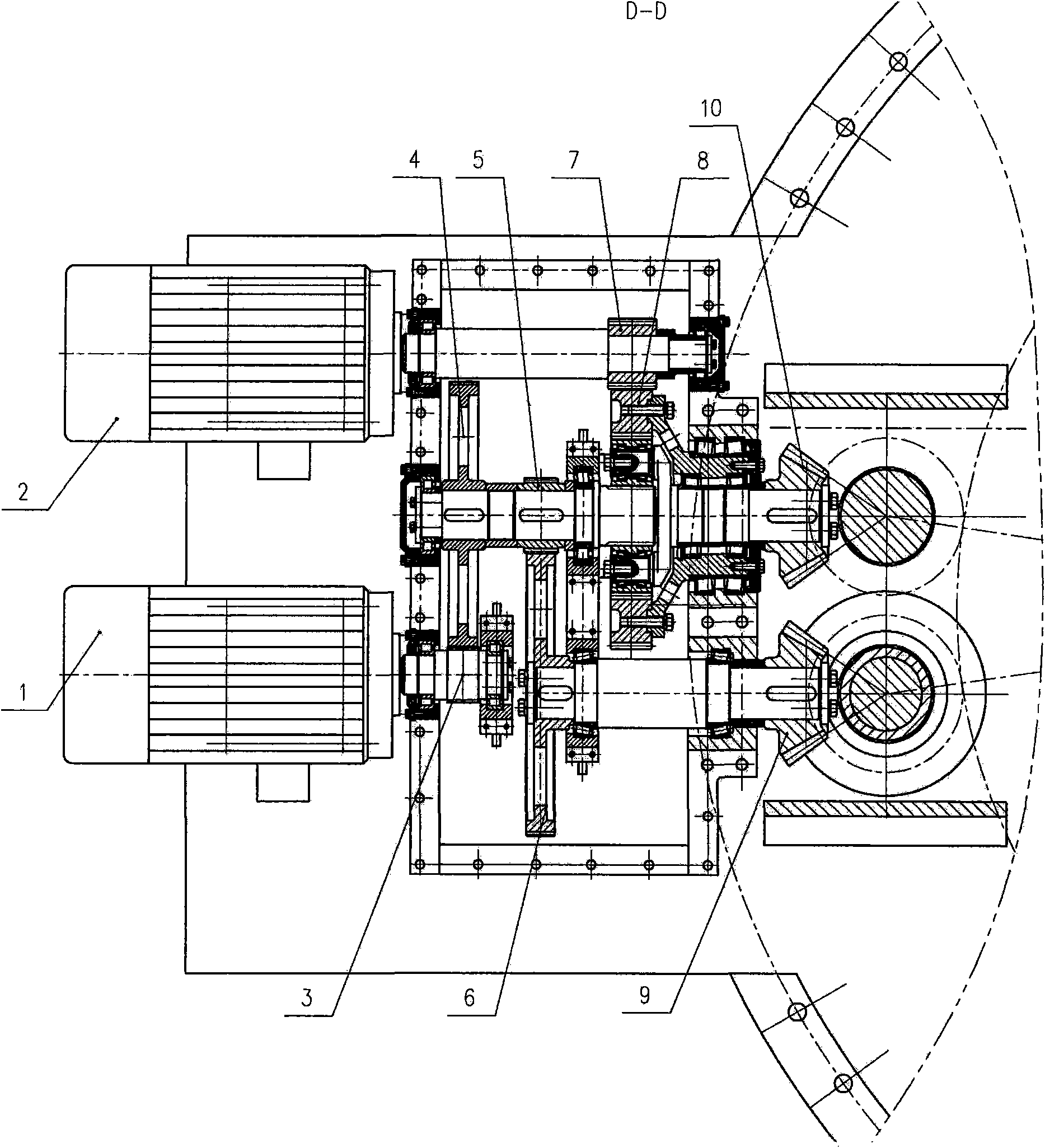

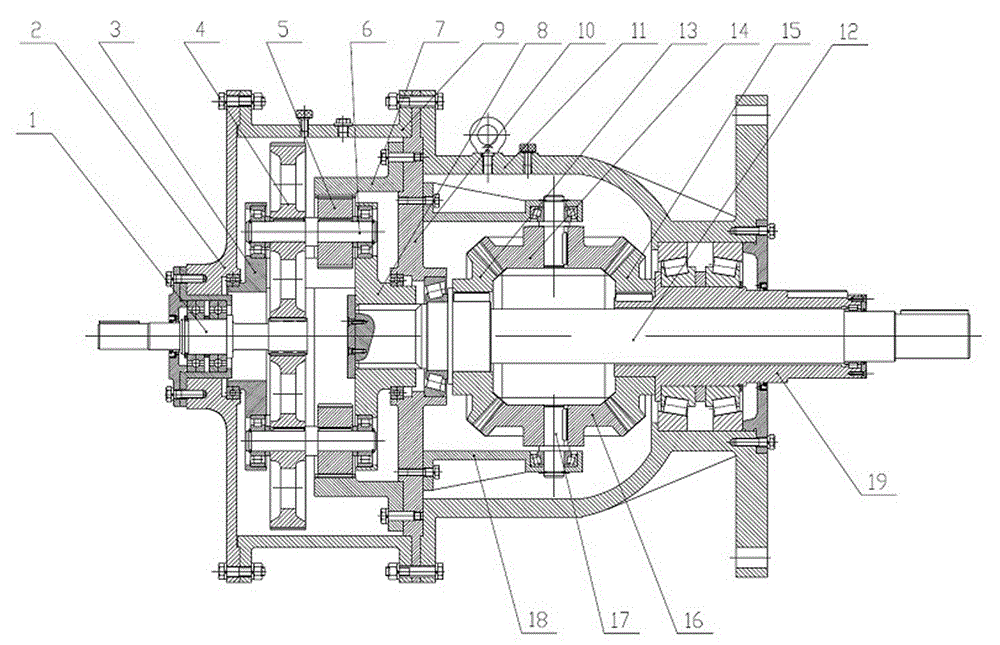

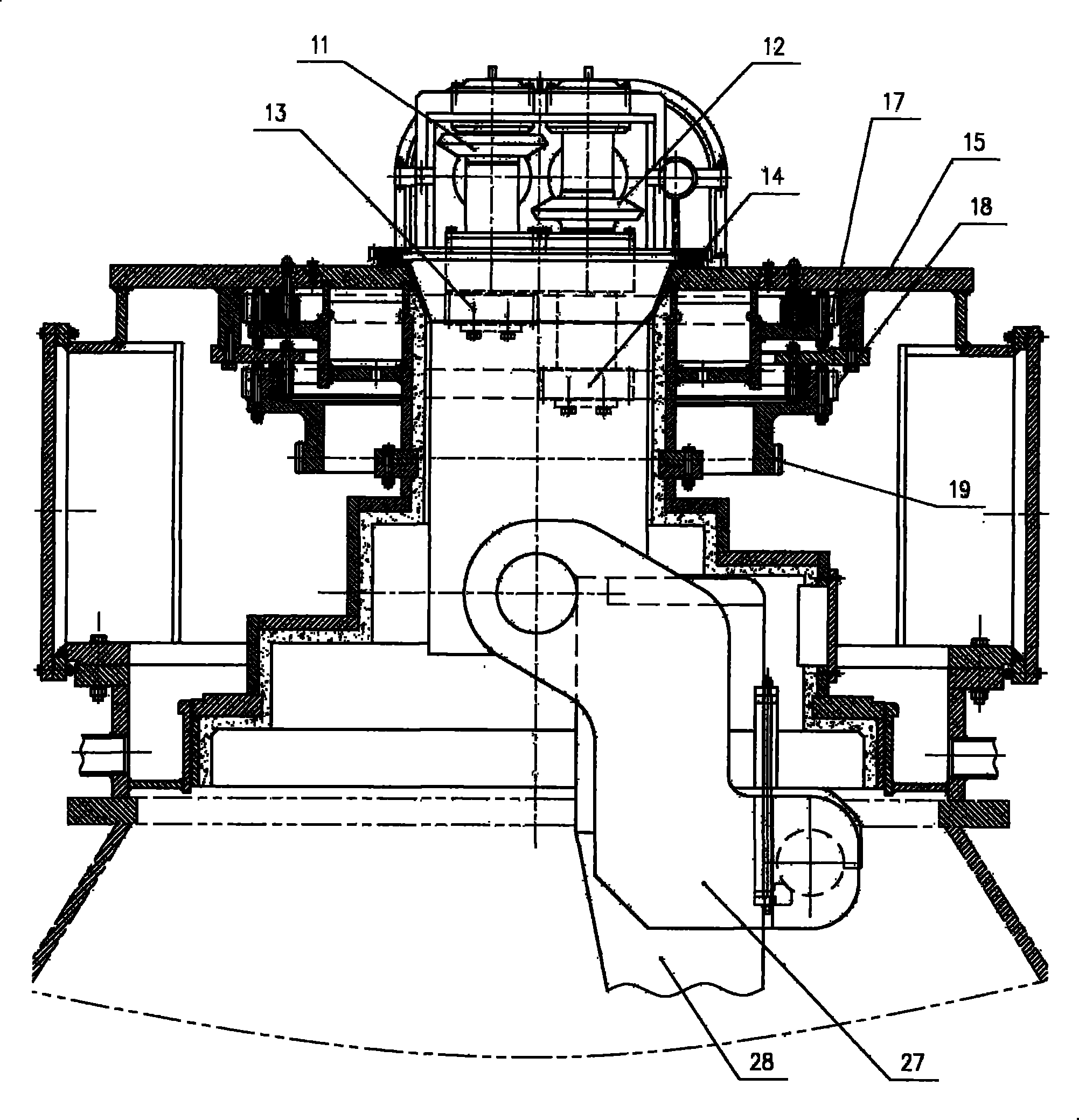

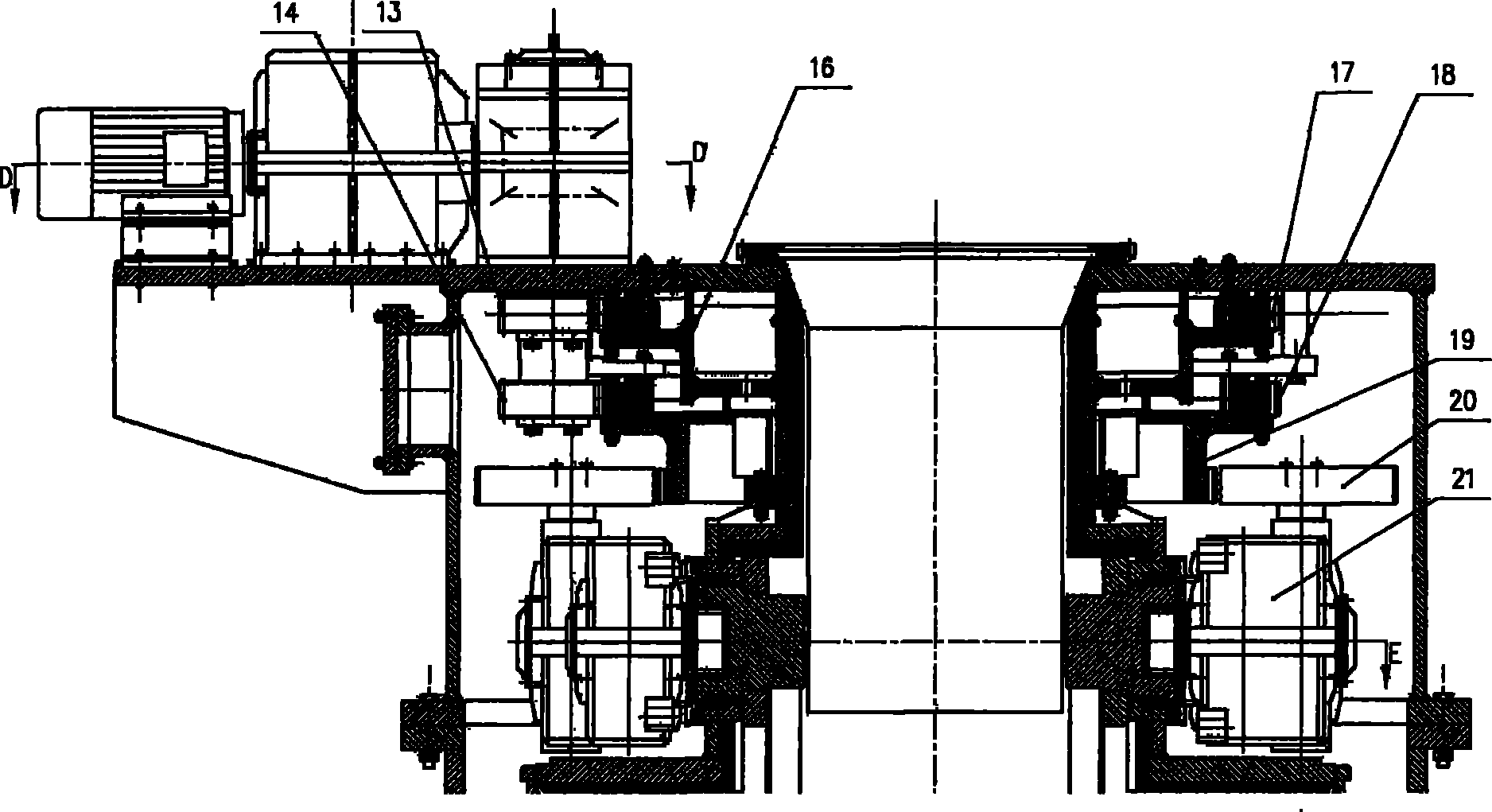

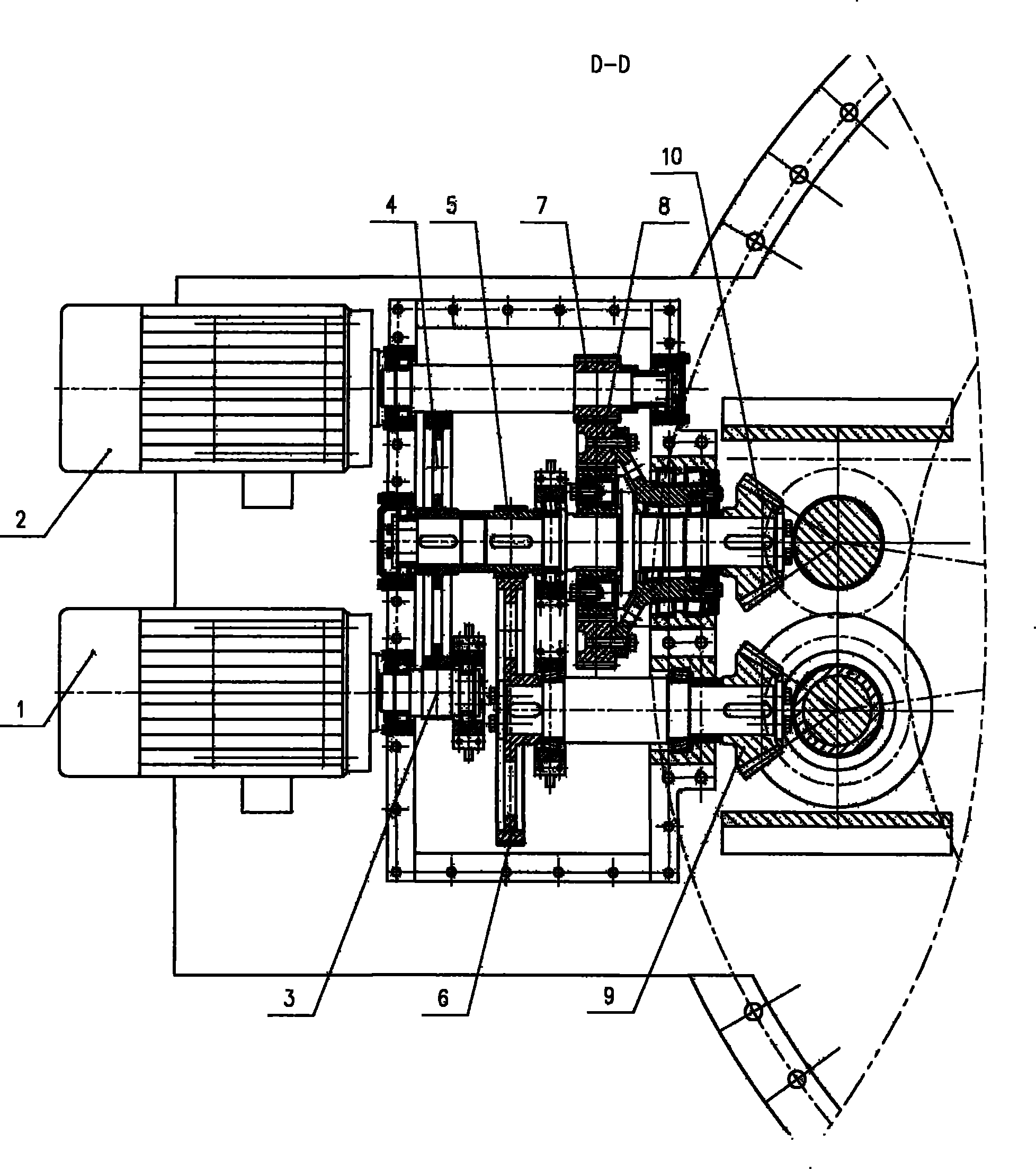

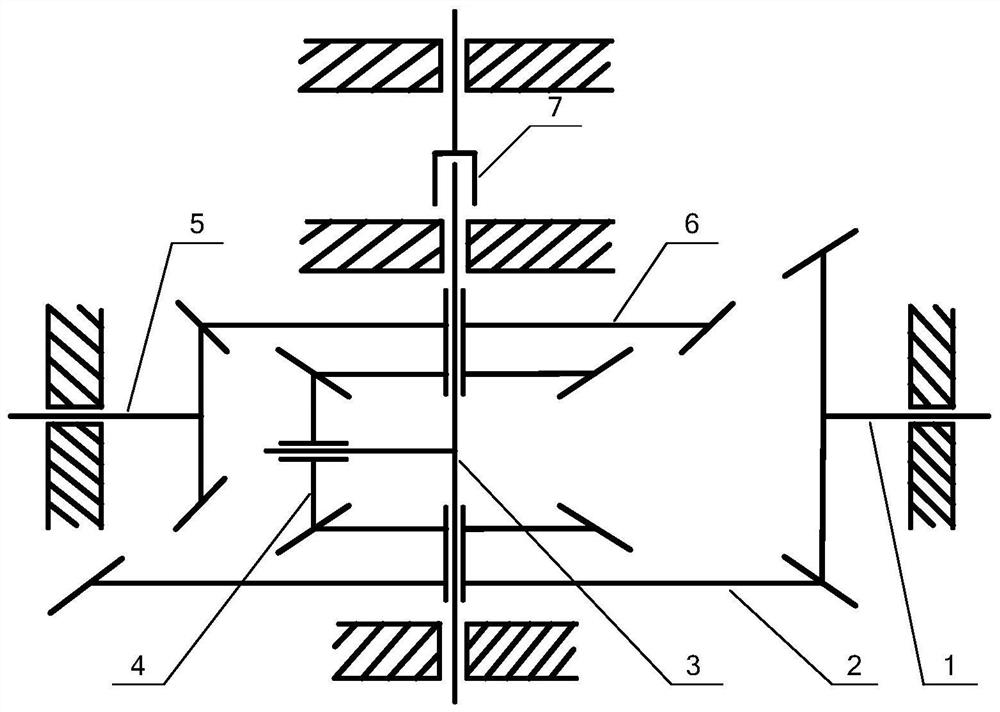

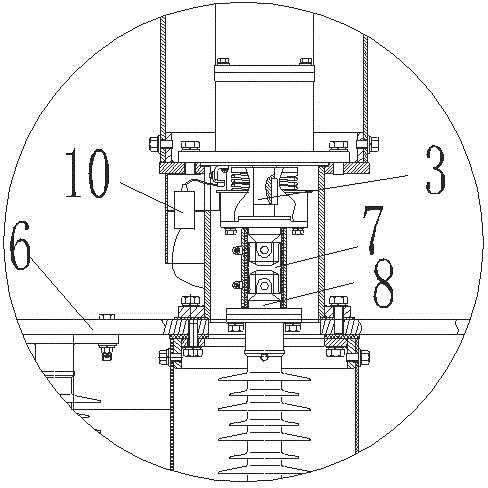

Furnace top distributing gear

ActiveCN101580885ACompact structureSmooth transmissionBlast furnace componentsBlast furnace detailsEngineeringGear drive

The invention discloses a furnace top distributing gear for distributing materials on the top of an iron-fining furnace, belonging to the technical field of mechanical engineering. A rotating motor and a tilting motor are independently driven by a set of differential mechanisms, wherein differential mechanism drive and previous-stage drive adopt all-gear drive, the previous-stage drive of a central sun wheel of the differential mechanism adopts gear drive with common drive ratio, and a furnace pot is tilted by a three-ring speed reducer. The furnace top distributing gear can realize the functions of furnace pot tilting, furnace pot rotation and furnace pot tilting and rotation, has the advantages of compact structure, reliable drive, stable work, high drive efficiency, long service life, little maintaining workload and convenient furnace pot replacement, can be used for blast furnace engineering of various types or other places where loose unpacked materials are delivered.

Owner:CISDI ENG CO LTD

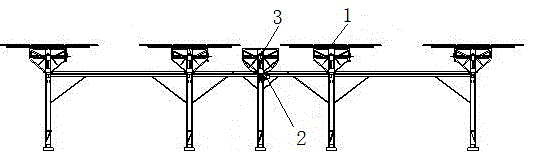

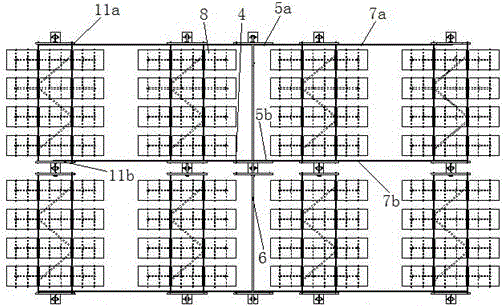

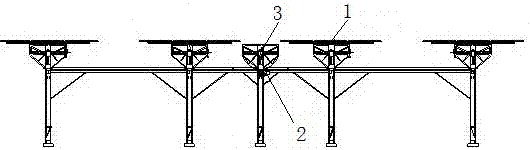

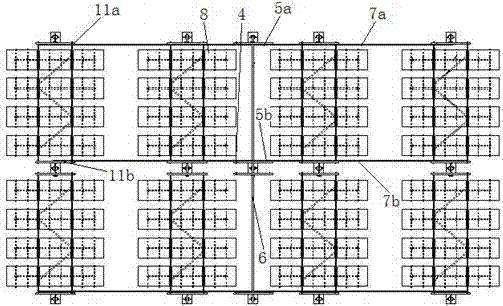

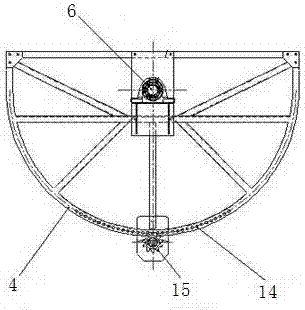

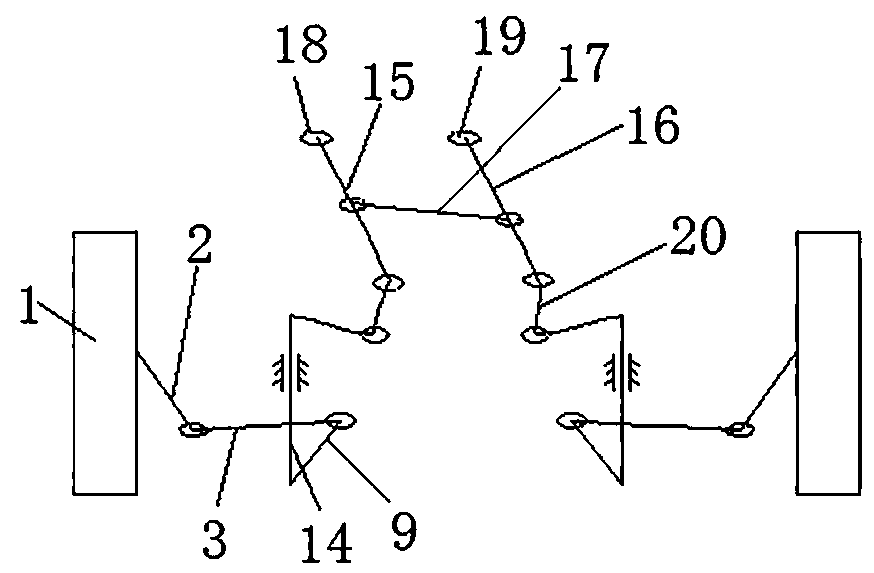

GZG-HT photovoltaic automatic tracking system

ActiveCN105656422AIncrease productivityPromote incomePhotovoltaic supportsPhotovoltaic energy generationEngineeringStationary mode

The invention provides a GZG-HT photovoltaic automatic tracking system. The system comprises a controller, one set of sensors and multiple sets of driving devices, and the controller is provided with the sensors and controls motion of the driving devices simultaneously; the system further comprises transmission devices arranged above the corresponding driving devices and multiple independent photovoltaic tracking subsystems. According to the GZG-HT photovoltaic automatic tracking system, photovoltaic modules automatically rotate and track sunlight in the latitudinal direction and are manually adjusted according to season changes in the longitudinal direction, the single controller is connected to the peripheral photovoltaic tracking subsystems simultaneously in a controlling mode, and linkage control is achieved. Meanwhile, an agriculture and light complementary photovoltaic power generation mode achieving photovoltaic power generation on the upper portion and agricultural planting on the lower portion is established, power generation units achieve bidirectional tracking in the latitudinal direction and the longitudinal direction, and large-scale cultivation of crops under frames is achieved. Compared with a traditional fixing mode, by means of the photovoltaic power generation mode, the light energy transforming rate and crop yield can be greatly increased, multiple purposes of one field are achieved, the income of farmers is increased, the benefits of enterprises are increased, the tax income of the government is increased, and the benefit of environment is increased.

Owner:陕西航泰电气股份有限公司

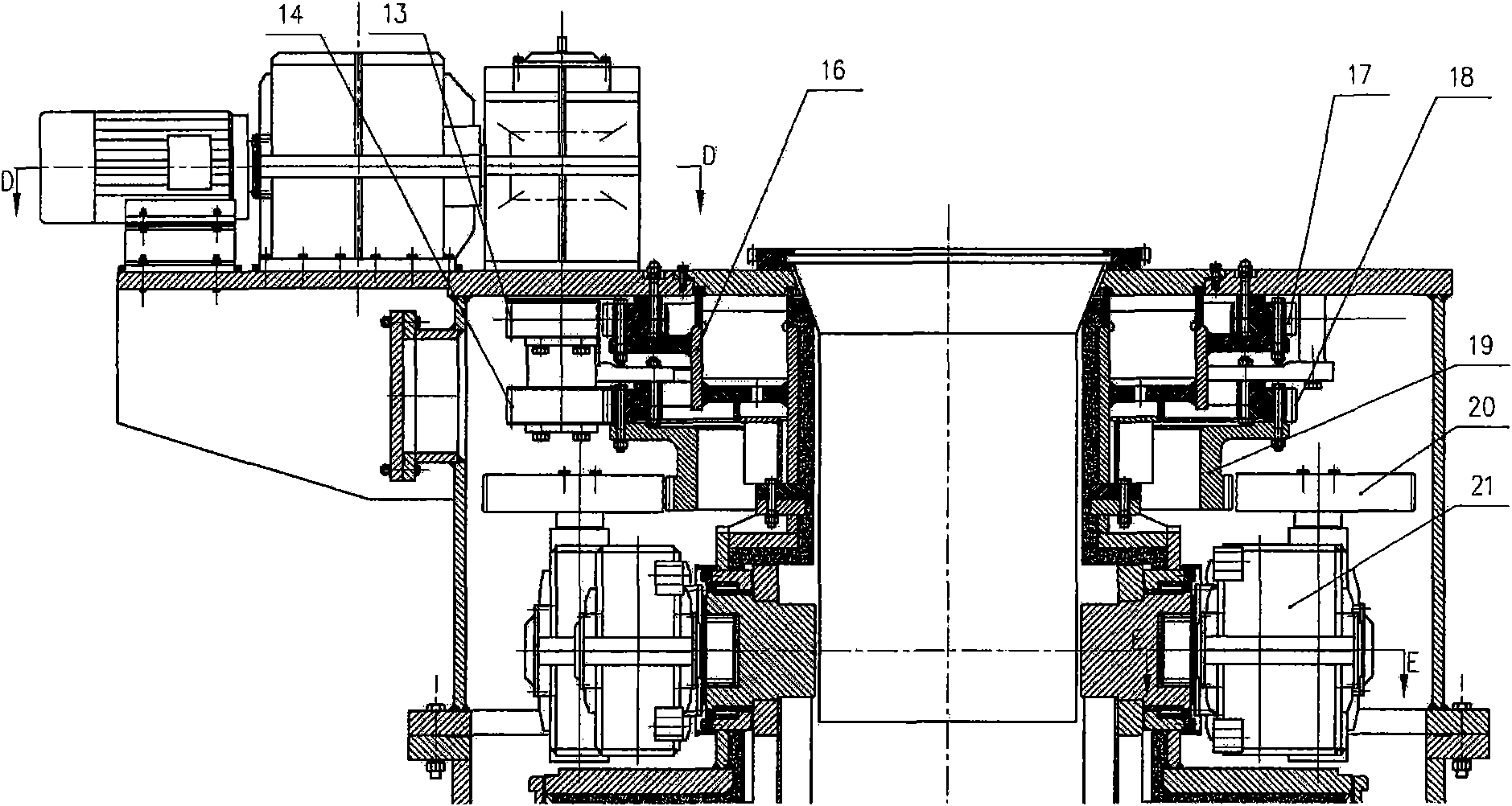

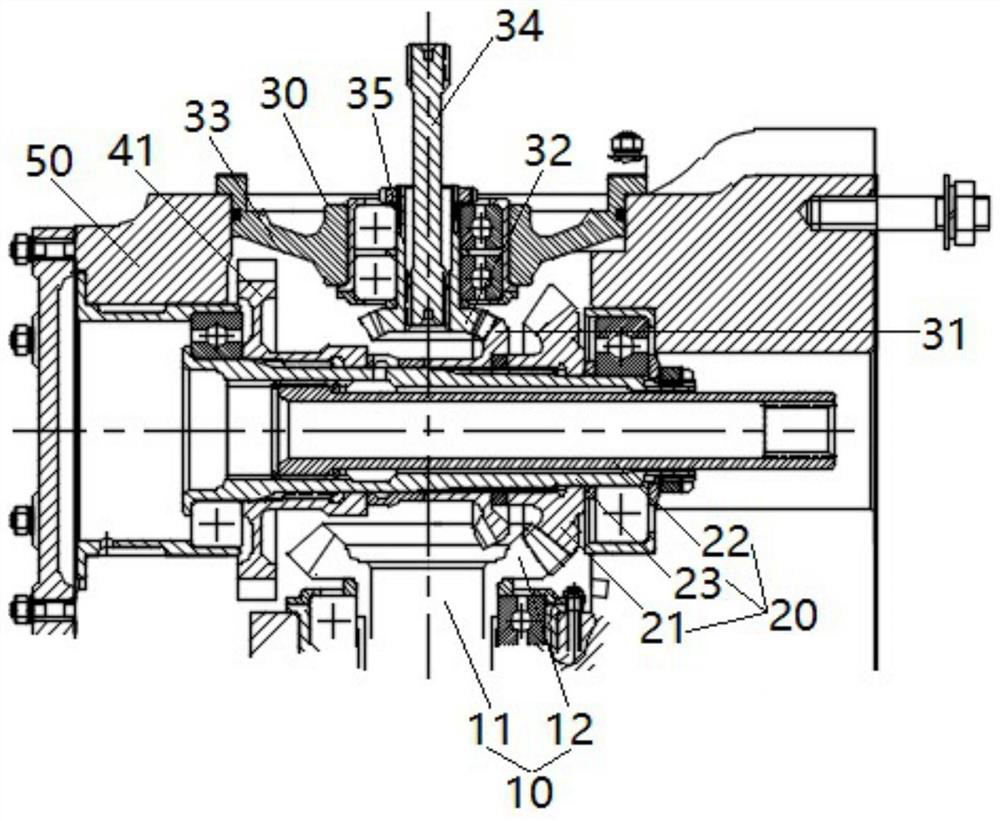

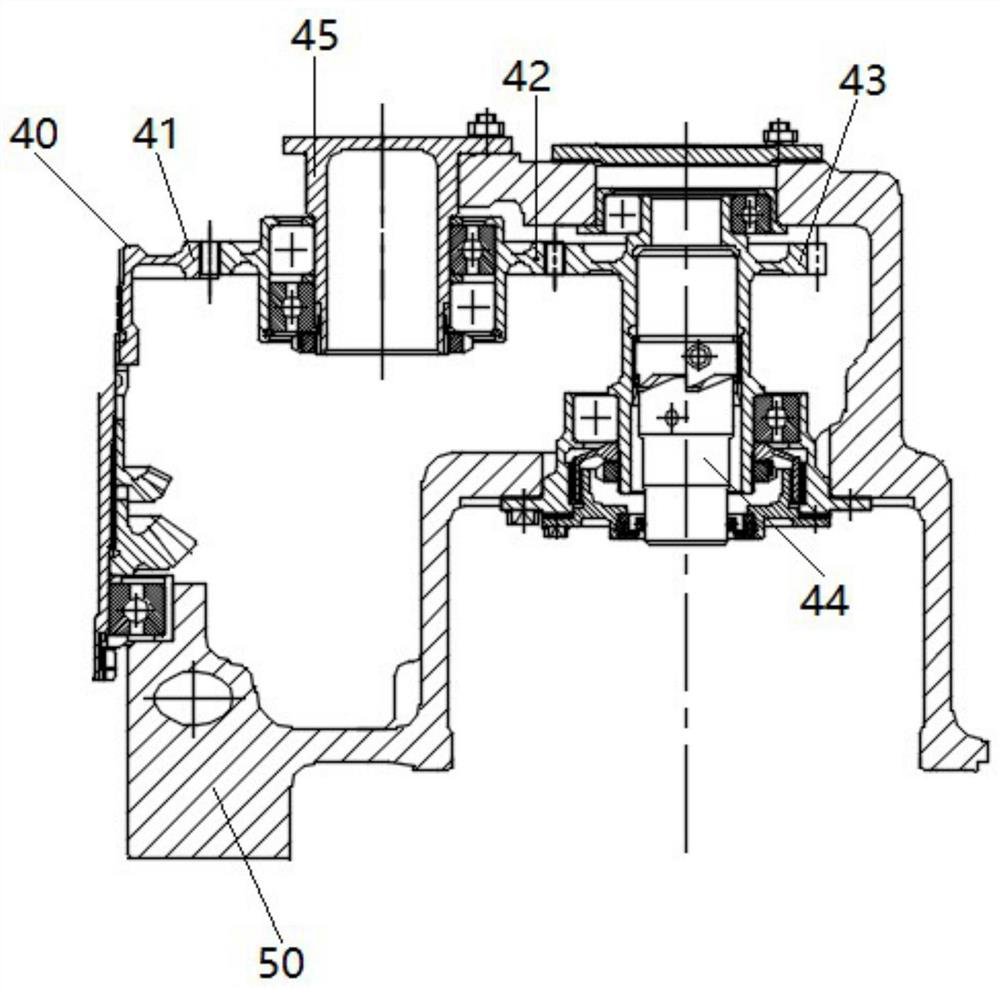

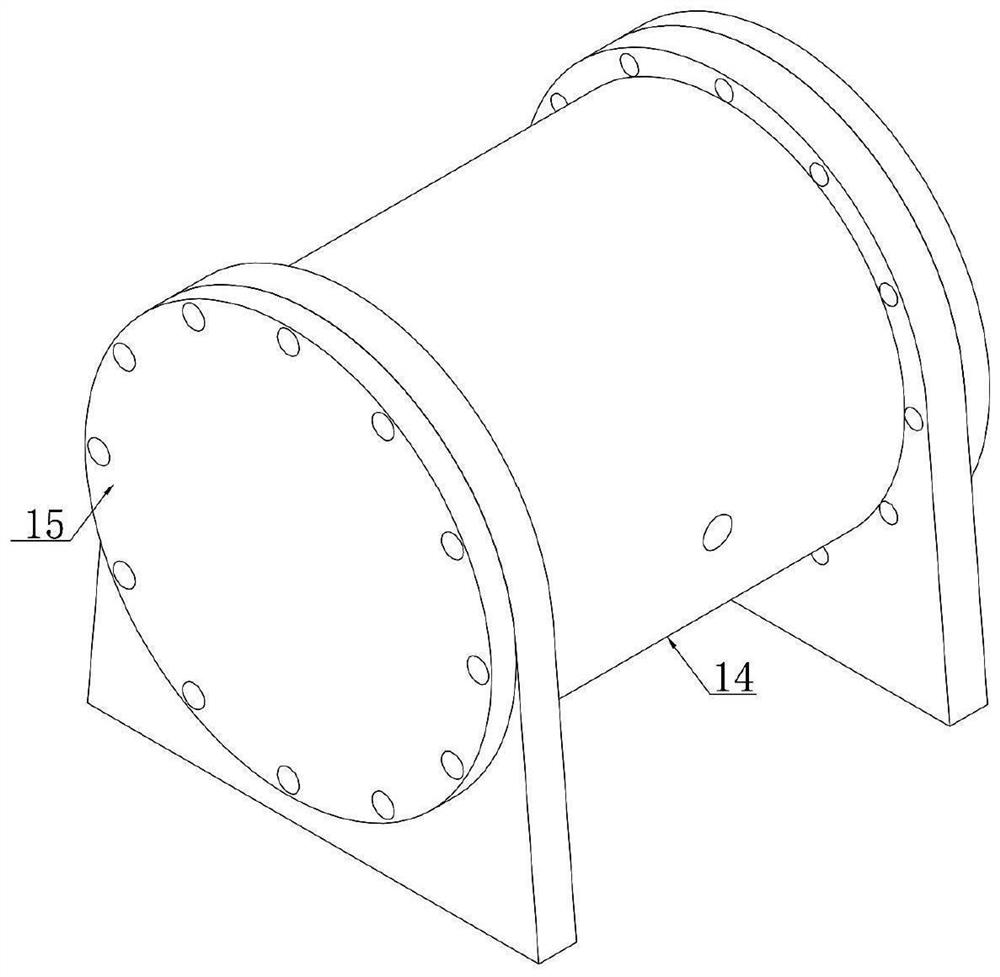

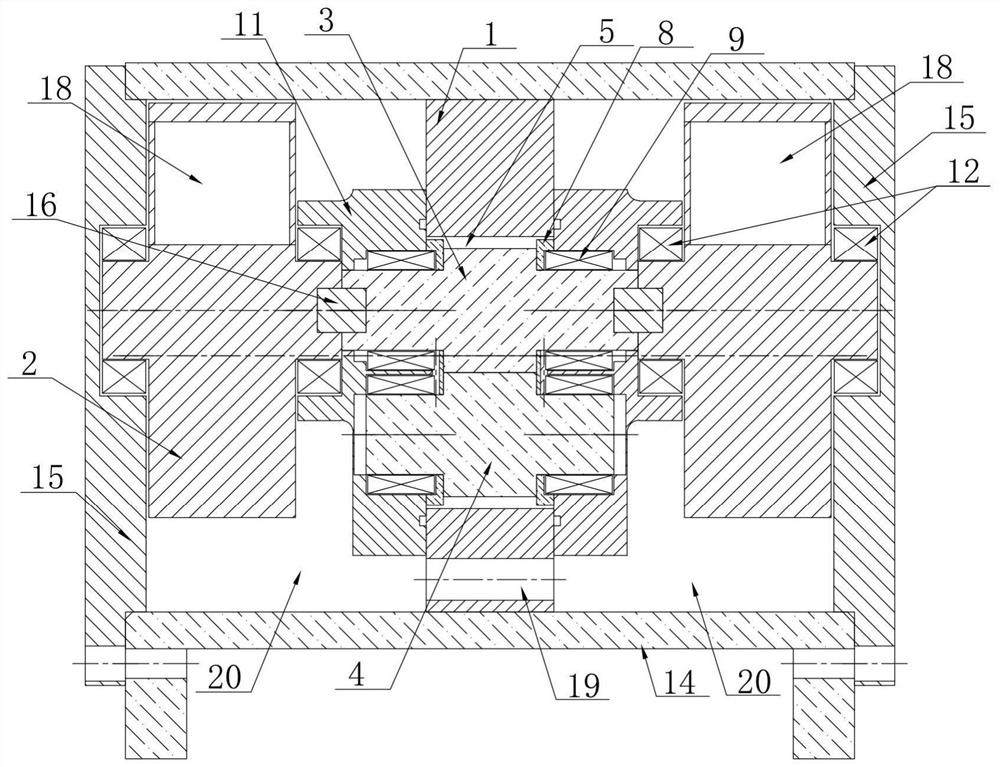

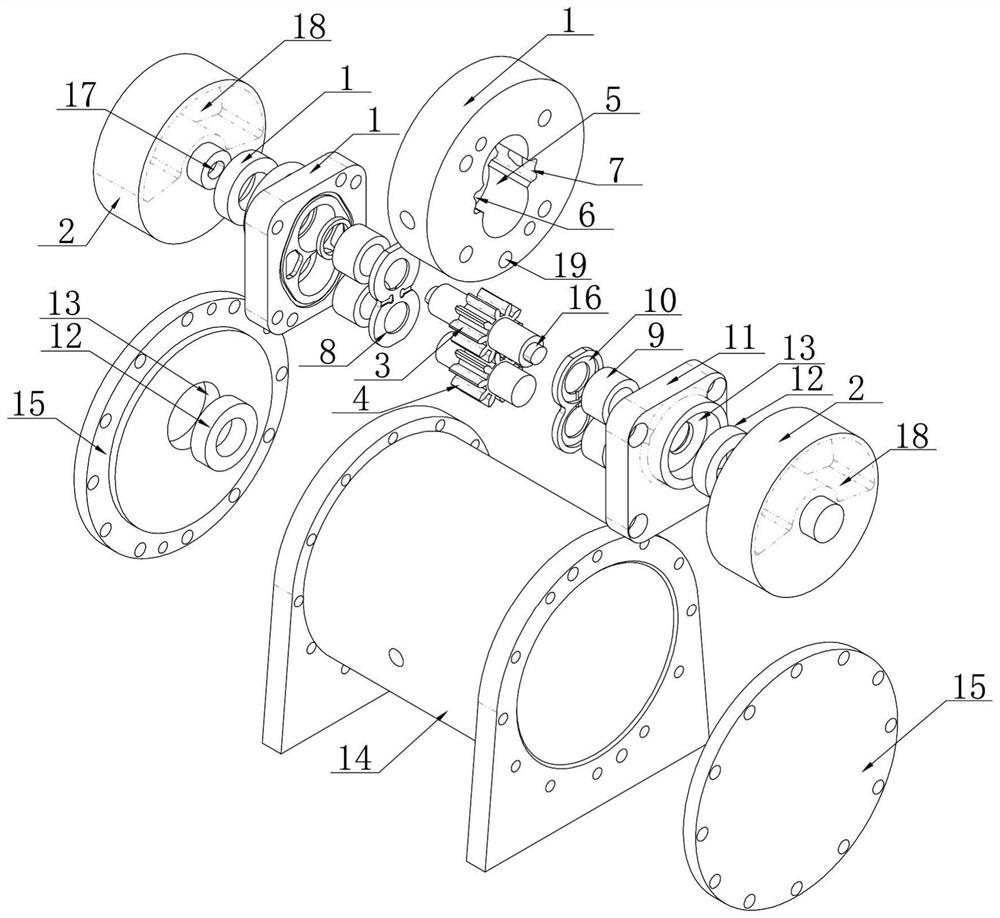

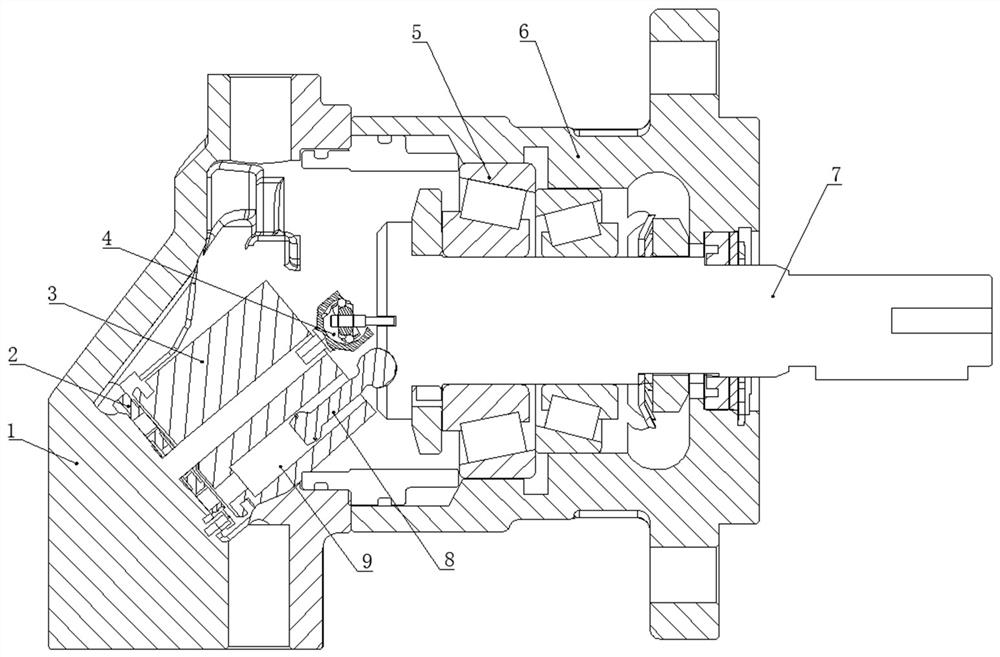

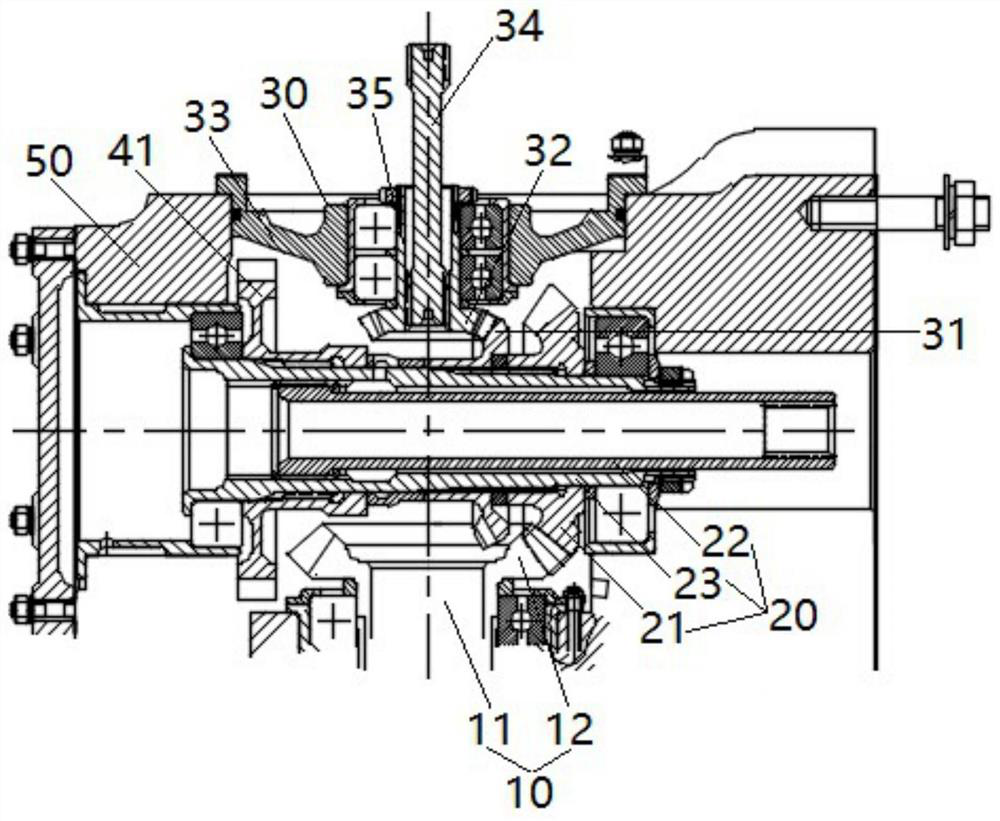

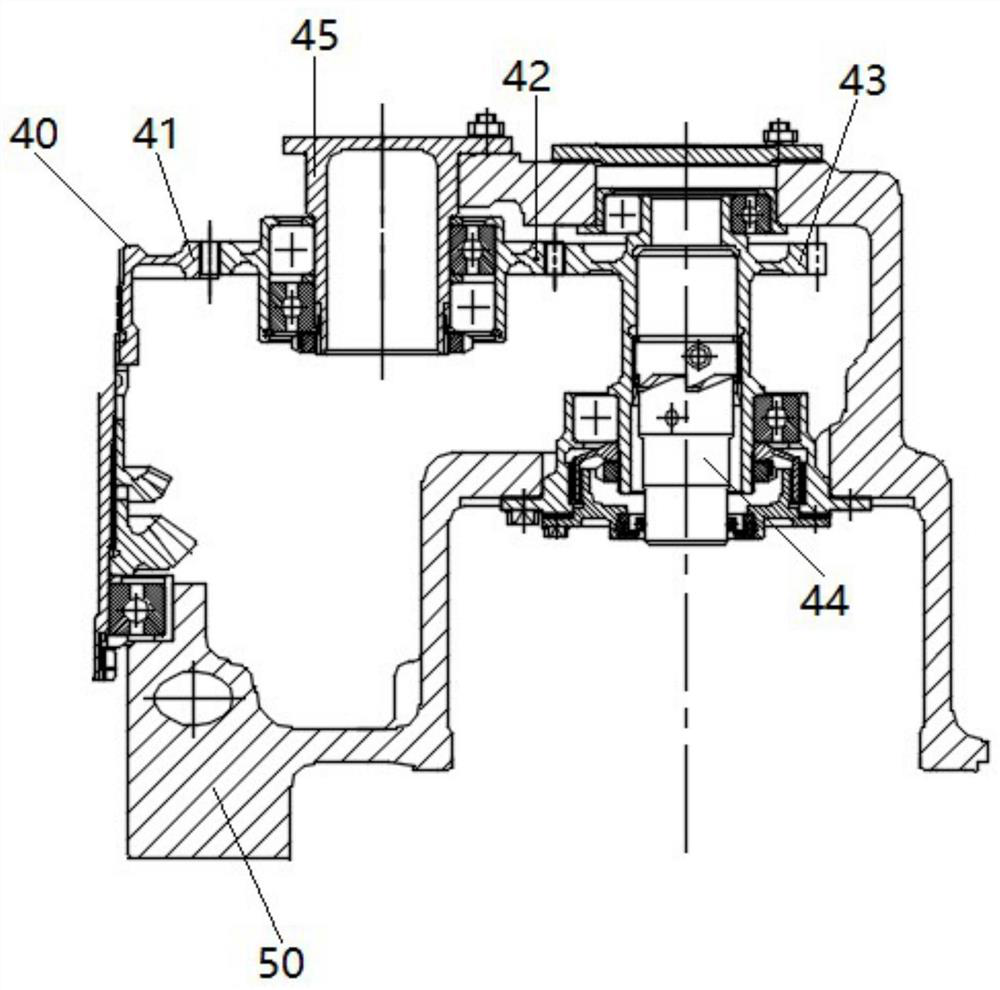

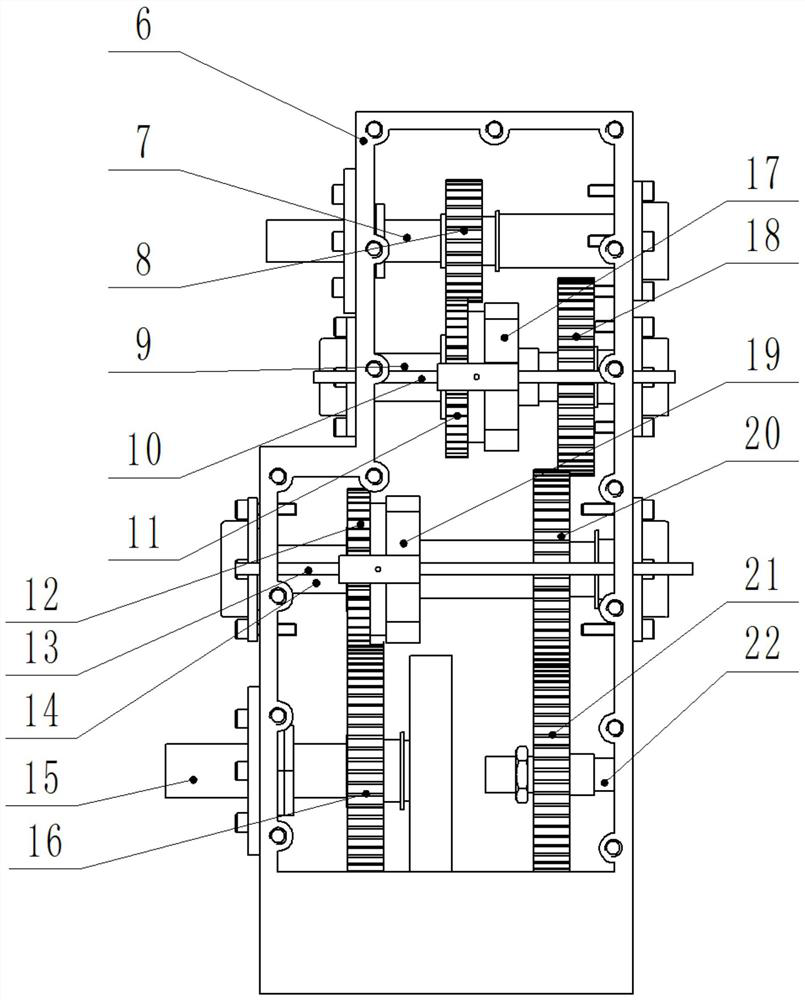

Accessory transmission structure

ActiveCN113374611ASmall form factorReduce weightPower operated startersElectric motor startersElectric machineryOil mist

The invention discloses an accessory transmission structure. The accessory transmission structure comprises a speed regulator, an oil mist separator, two starting motors, a power input transmission mechanism, a speed regulator transmission mechanism, an oil mist separator transmission mechanism and a starting motor transmission mechanism. The power input transmission mechanism is arranged along a straight line, and the power input end of the power input transmission mechanism is connected with a middle transmission mechanism in the case shell. The speed regulator transmission mechanism is perpendicular to and connected with the power input transmission mechanism. The oil mist separator transmission mechanism and the starting motor transmission mechanism are sequentially arranged in the axial direction of the speed regulator transmission mechanism, and the oil mist separator transmission mechanism is perpendicularly connected with the speed regulator transmission mechanism. The starting motor transmission mechanism is symmetrically arranged about the axis of the speed regulator transmission mechanism, and the two power output ends of the starting motor transmission mechanism are connected with the starting motors on the corresponding sides in the axial direction. By designing the accessory transmission structure, normal work of the interior of the case and an accessory transmission system can be achieved, and meanwhile the accessory can be compactly installed on the case shell.

Owner:CHINA HANGFA SOUTH IND CO LTD

A single-input coaxial double-output reducer

The invention relates to a single-input coaxial double-output speed reducer which comprises an input gear shaft, an output shaft I, a hollow output shaft II, a planetary gear speed reducing mechanism and a bevel gear diversion reversing mechanism, wherein the power is input through a sun gear on the input gear shaft; the power is transmitted into the output shaft I from a planet carrier by the planetary gear speed reducing mechanism; part of the power is directly output by the output shaft I, and the other part of the power is transmitted into the output shaft II sheathed on the output shaft I in an idle way by the bevel gear diversion reversing mechanism; the output shaft II can output the power at the speed equal to that of the output shaft I along the direction opposite to that of the output shaft I. The single-input coaxial double-output speed reducer is simple in structure and reasonable in design, and can realize the transmission requirements of mixing equipment to a concentric double-shaft mixing system only by using a set of powder device, thus greatly saving the using space and lowering the production cost.

Owner:江阴天澄机械装备有限公司

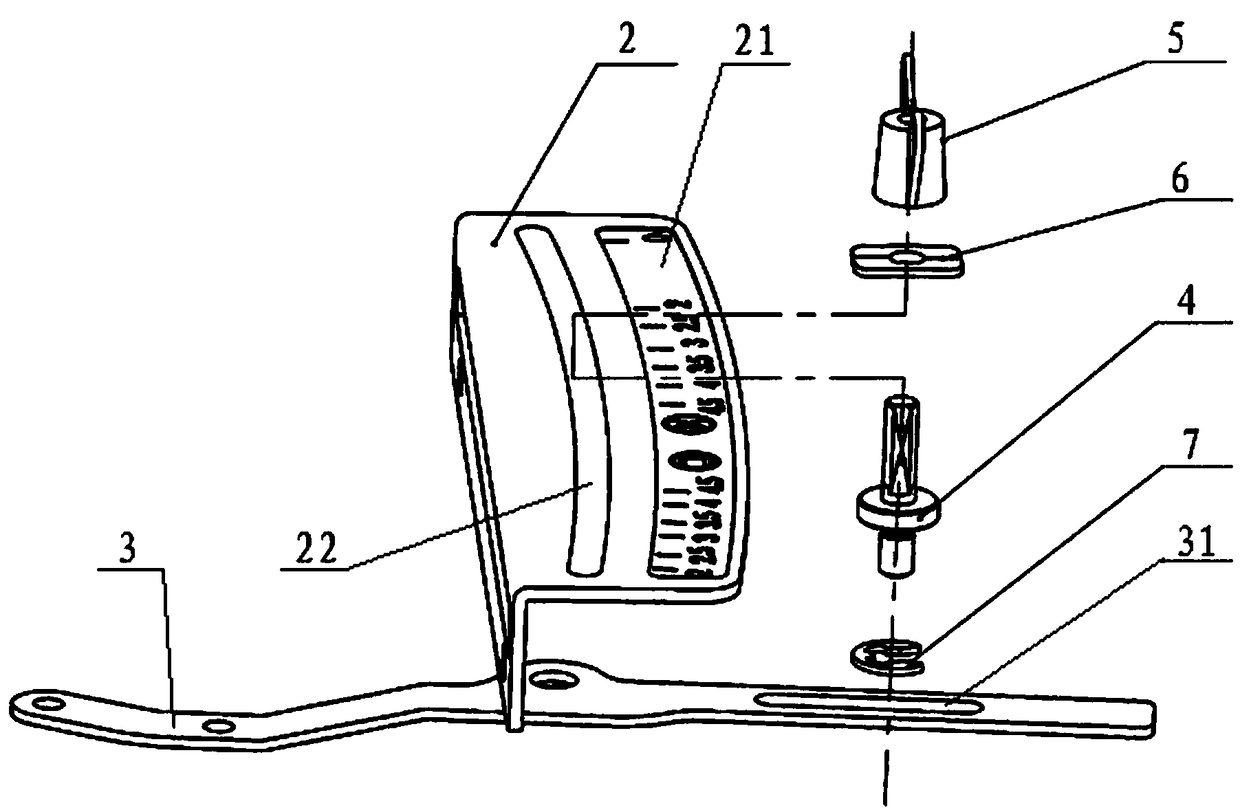

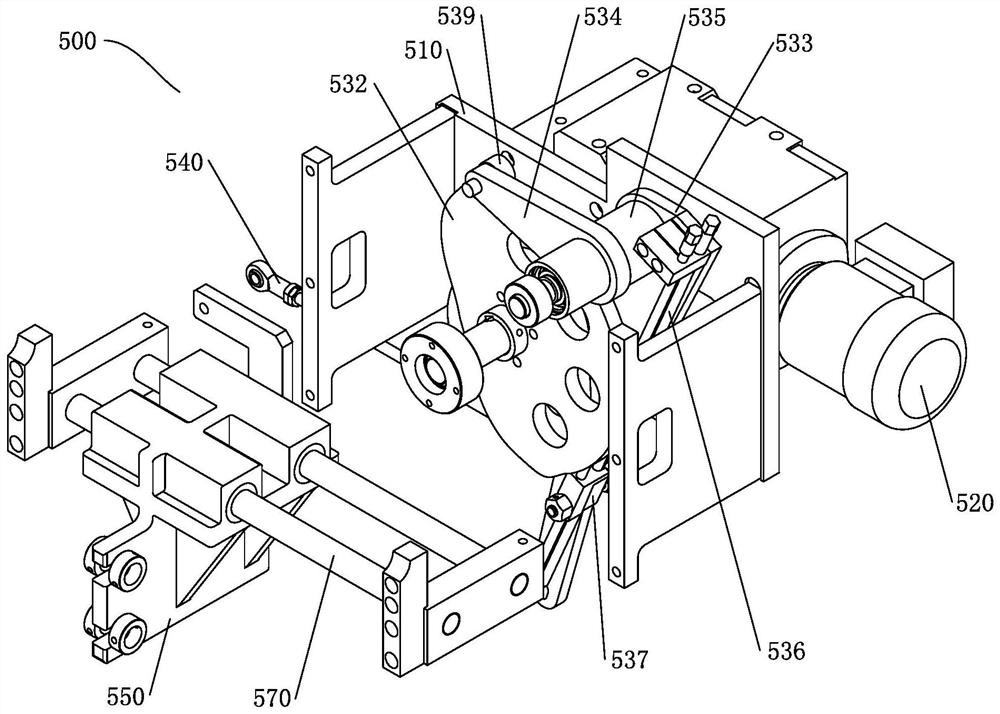

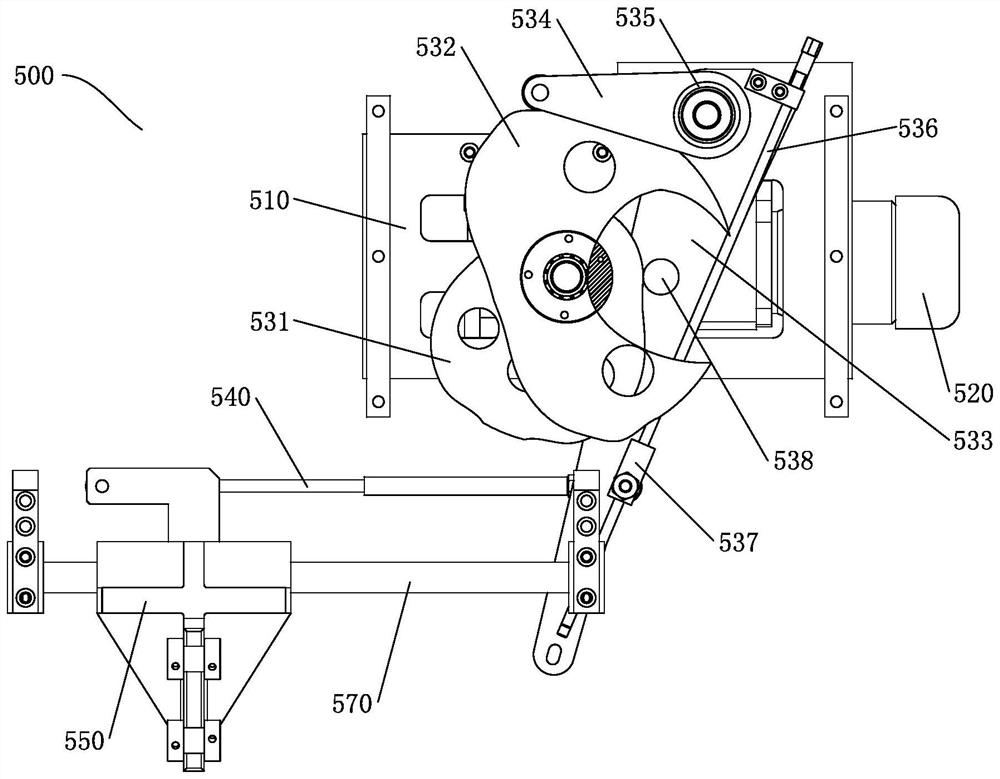

Button fastening machine and stitch length adjusting and control mechanism thereof

ActiveCN108166164AMeet transmission requirementsAchieving Linear Adjustment RangeSewing-machine control devicesNeedle barsSlide plateEngineering

The invention discloses a button fastening machine and a stitch length adjusting and control mechanism thereof. The button fastening machine comprises a housing, a feeding adjusting plate, an adjusting handle and a fastener. Scales and a sliding groove are formed in a surface of the feeding adjusting plate; one end of the adjusting handle is used for being connected to a feeding sliding plate, theother end of the adjusting handle extends below the feeding adjusting plate, and an adjustment groove extending in the length direction of the adjusting handle is formed in the other end of the adjusting handle; the fastener includes an adjustment screw and a nut; a lower end of the adjustment screw passes through the adjustment groove and is slidingly connected to the adjustment groove, and an upper end of the adjustment screw passes through the adjustment groove and is screwed and fixed on the feeding adjusting plate through the nut; the nut is loosened to allow the adjusting handle and thefastener to move along the sliding groove to perform longitudinal feeding adjustment; the adjustment handle can be stopped at any position to achieve the linear adjustment range; when the adjusting handle moves to a designated scale, the nut is screwed tightly, and at this time, a horizontal right of the adjusting handle is fixed, the stitch length is fixed, and the adjusting handle can move backand forth along the axial portion of the adjustment screw, and a transmission requirement of vertical feeding is satisfied.

Owner:BULLMER ELECTROMECHANICAL TECH

Furnace top distributing gear

ActiveCN101580885BCompact layoutMeet transmission requirementsBlast furnace componentsBlast furnace detailsGear driveMechanical engineering technology

The invention discloses a furnace top distributing gear for distributing materials on the top of an iron-fining furnace, belonging to the technical field of mechanical engineering. A rotating motor and a tilting motor are independently driven by a set of differential mechanisms, wherein differential mechanism drive and previous-stage drive adopt all-gear drive, the previous-stage drive of a central sun wheel of the differential mechanism adopts gear drive with common drive ratio, and a furnace pot is tilted by a three-ring speed reducer. The furnace top distributing gear can realize the functions of furnace pot tilting, furnace pot rotation and furnace pot tilting and rotation, has the advantages of compact structure, reliable drive, stable work, high drive efficiency, long service life, little maintaining workload and convenient furnace pot replacement, can be used for blast furnace engineering of various types or other places where loose unpacked materials are delivered.

Owner:CISDI ENG CO LTD

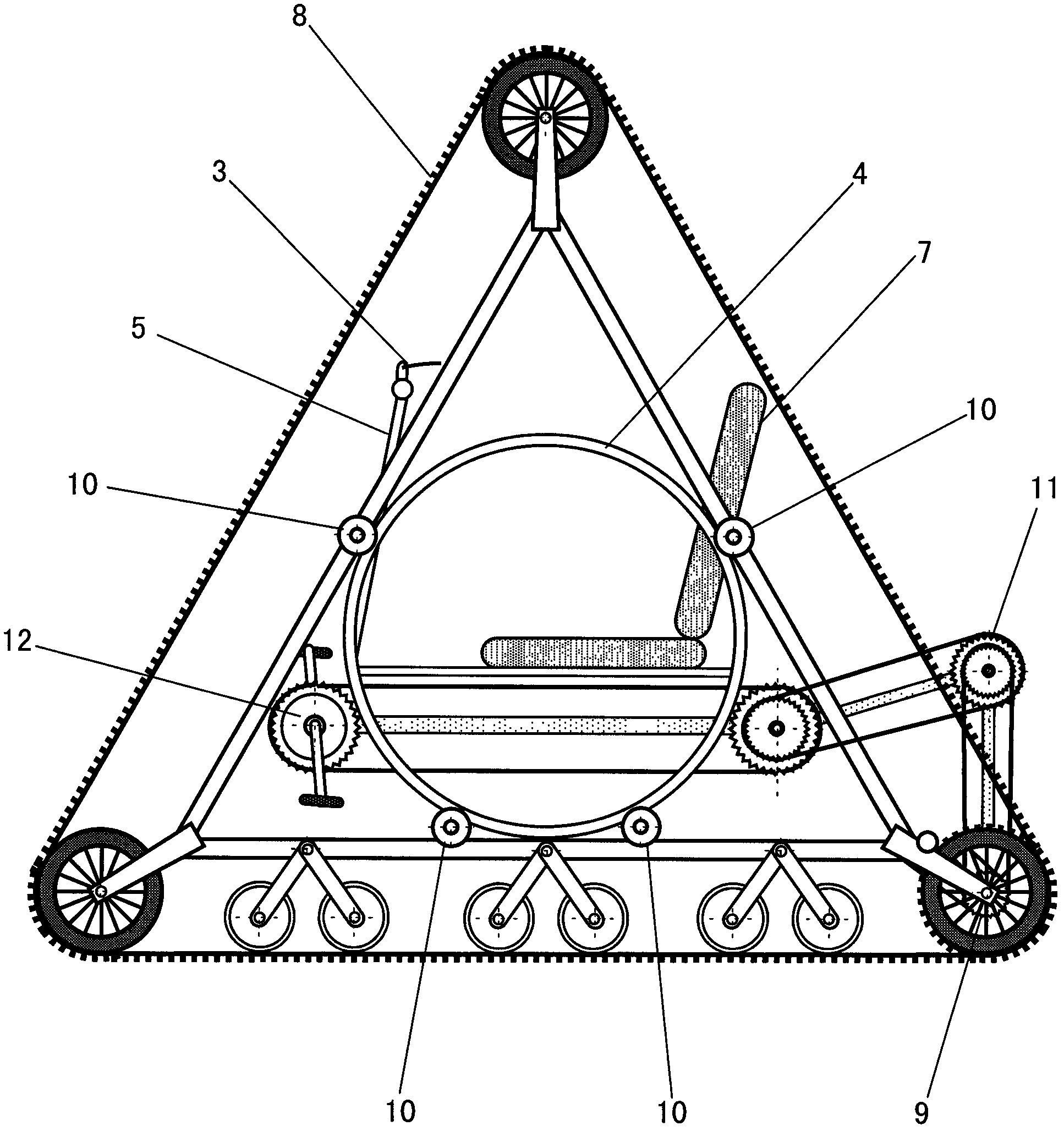

Stepless speed change system and method for rotor wing of twin-engine helicopter

PendingCN112555365AMeet transmission requirementsThe optimal speed is moreToothed gearingsGear wheelControl theory

The invention discloses a stepless speed change system and method for a rotor wing of a twin-engine helicopter. The system comprises a right driving gear, a lower duplicate gear, a planet carrier, a planet gear, a left driving gear, an upper duplicate gear and an overrunning clutch. The gears are all bevel gears. The upper duplicate gear and the lower duplicate gear are coaxially arranged and aresupported on the planet carrier through bearings. The right driving gear serves as one horizontal power input end and is meshed with a lower bevel gear of the lower duplicate gear, an upper bevel gearof the lower duplicate gear is meshed with the planet gear, the planet gear is meshed with a lower bevel gear of the upper duplicate gear, an upper bevel gear of the upper duplicate gear is meshed with the left driving gear, and the left driving gear serves as the other horizontal power input end. A rotating shaft of the planet gear is connected with the planet carrier. The rotating axis of the planet carrier is in the vertical direction, the upper end of the planet carrier serves as an output end, and the rotor wing is driven through the overrunning clutch. According to the method, the stepless speed change requirement of the planet carrier can be met by adjusting the rotating speeds of the left driving gear and the right driving gear.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

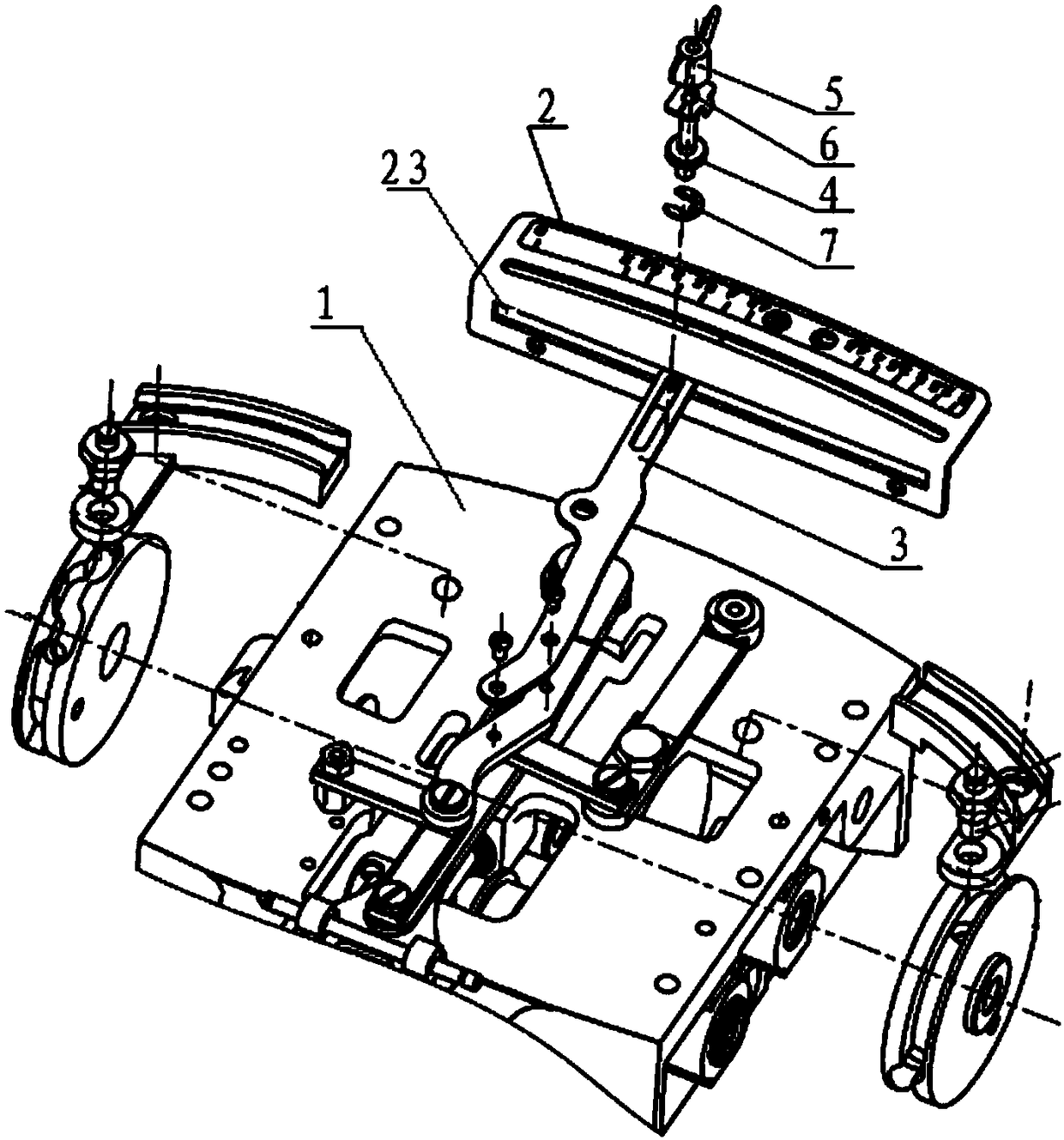

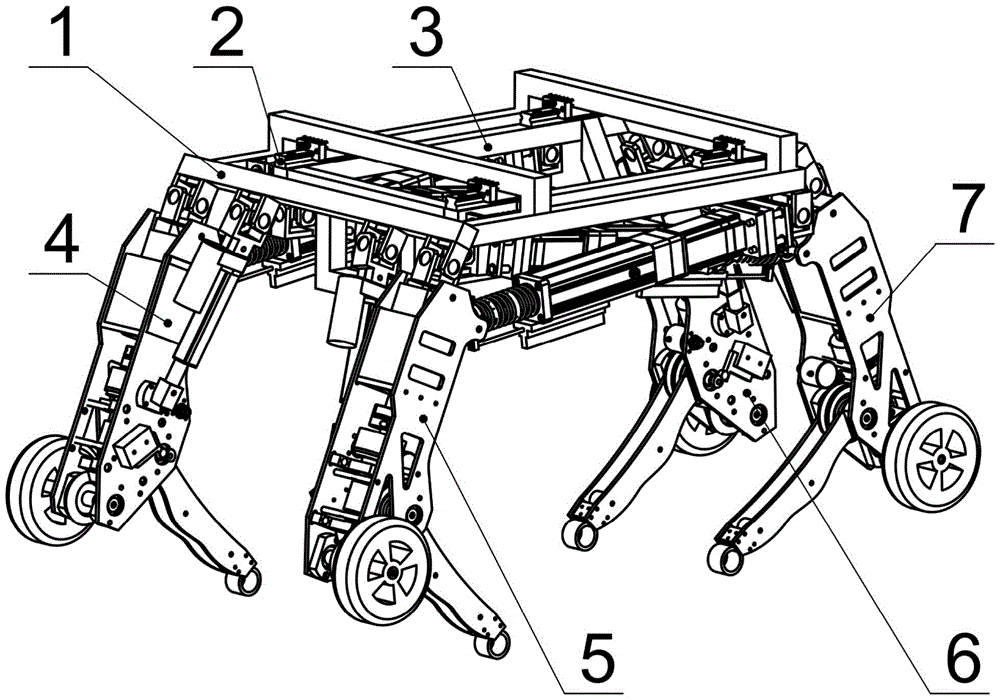

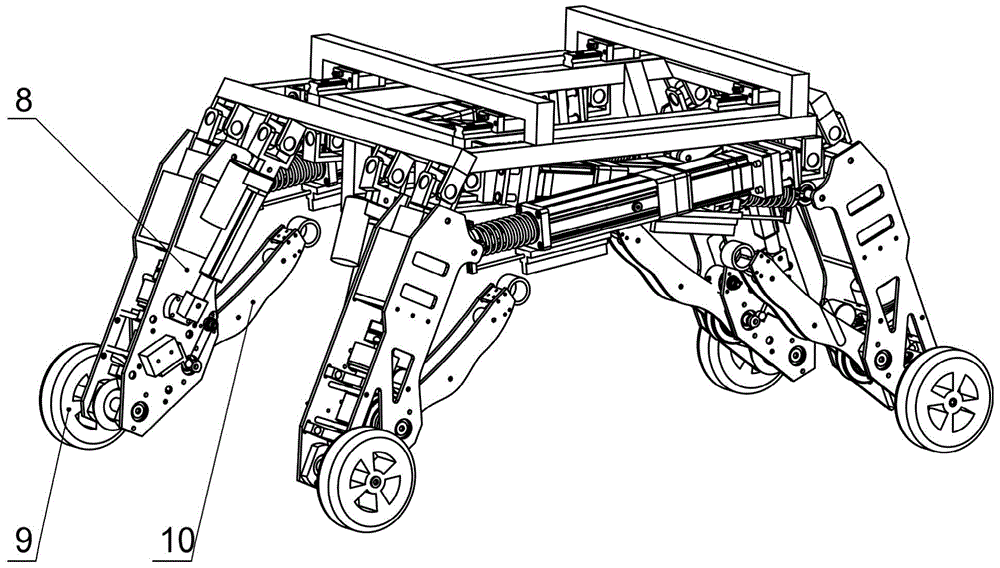

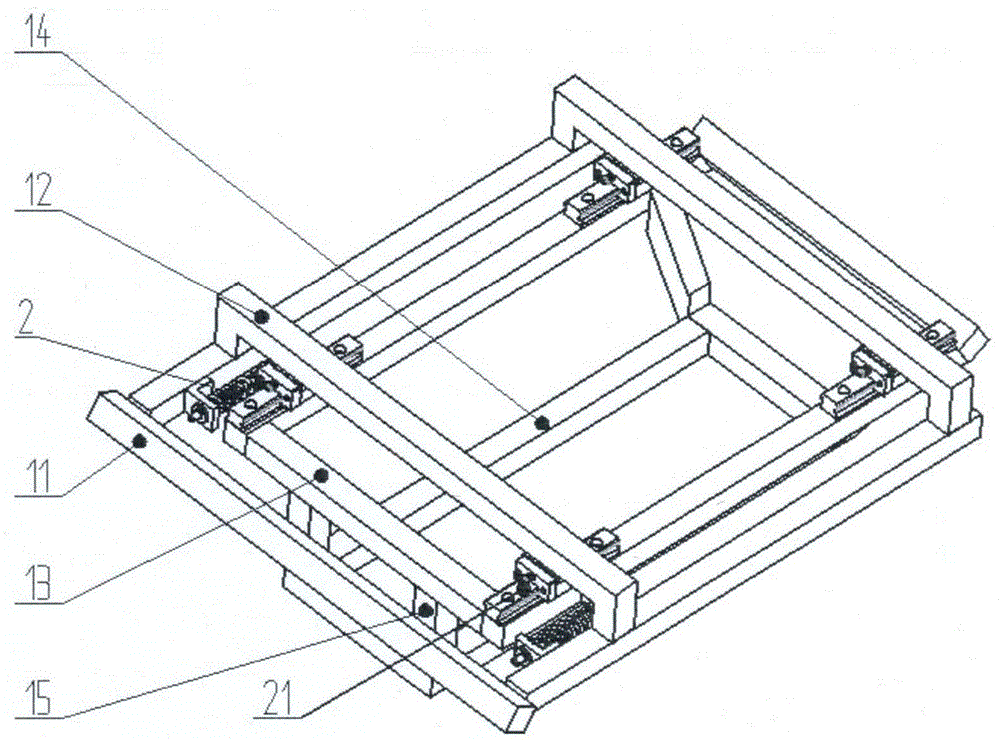

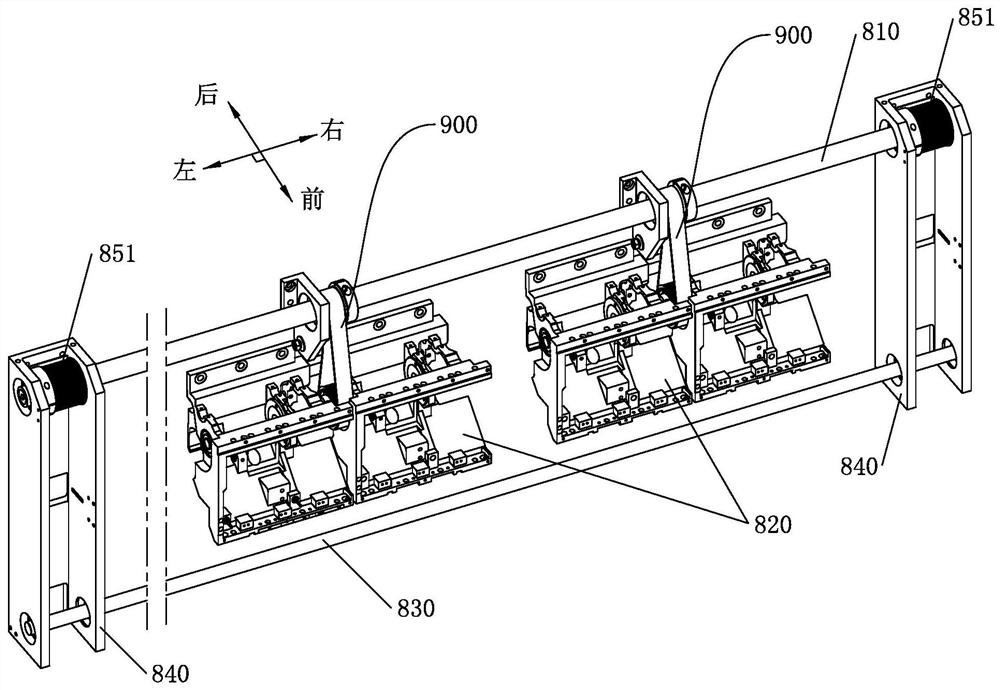

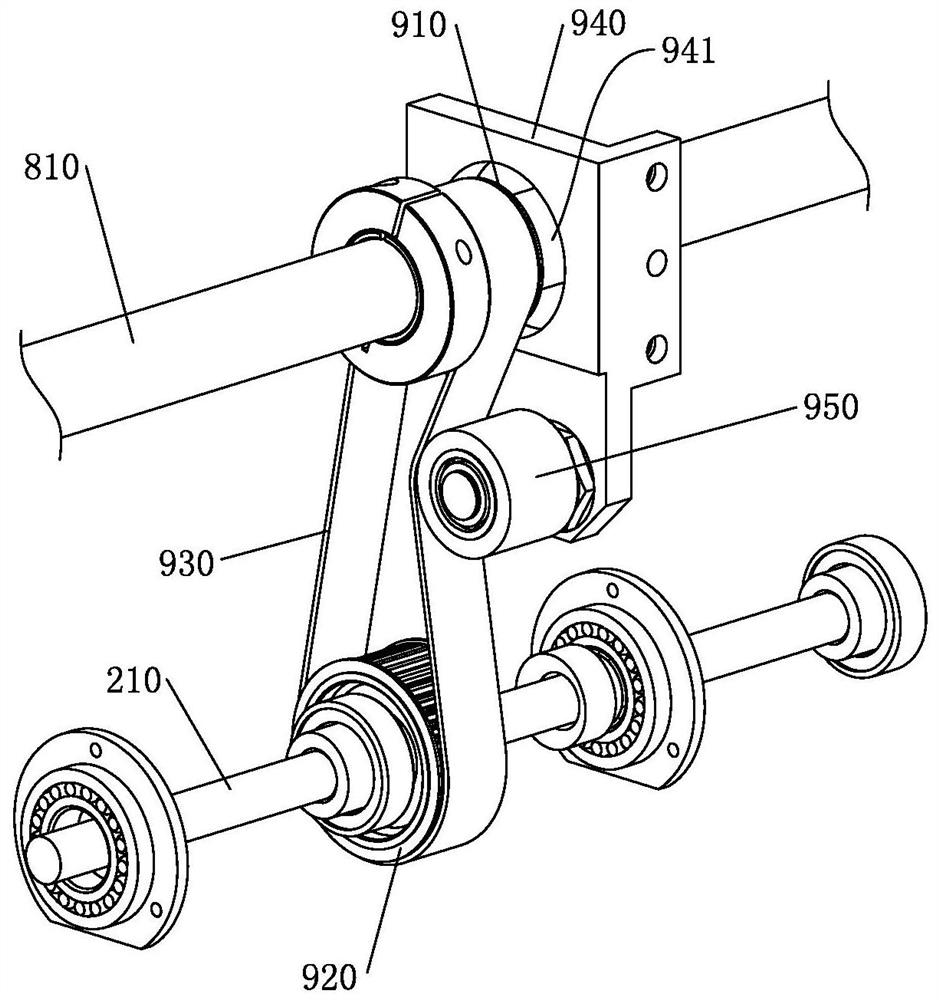

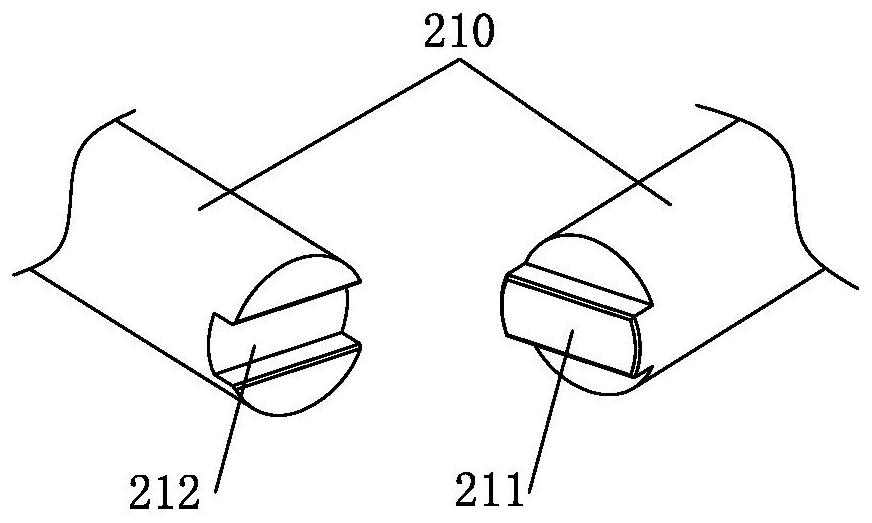

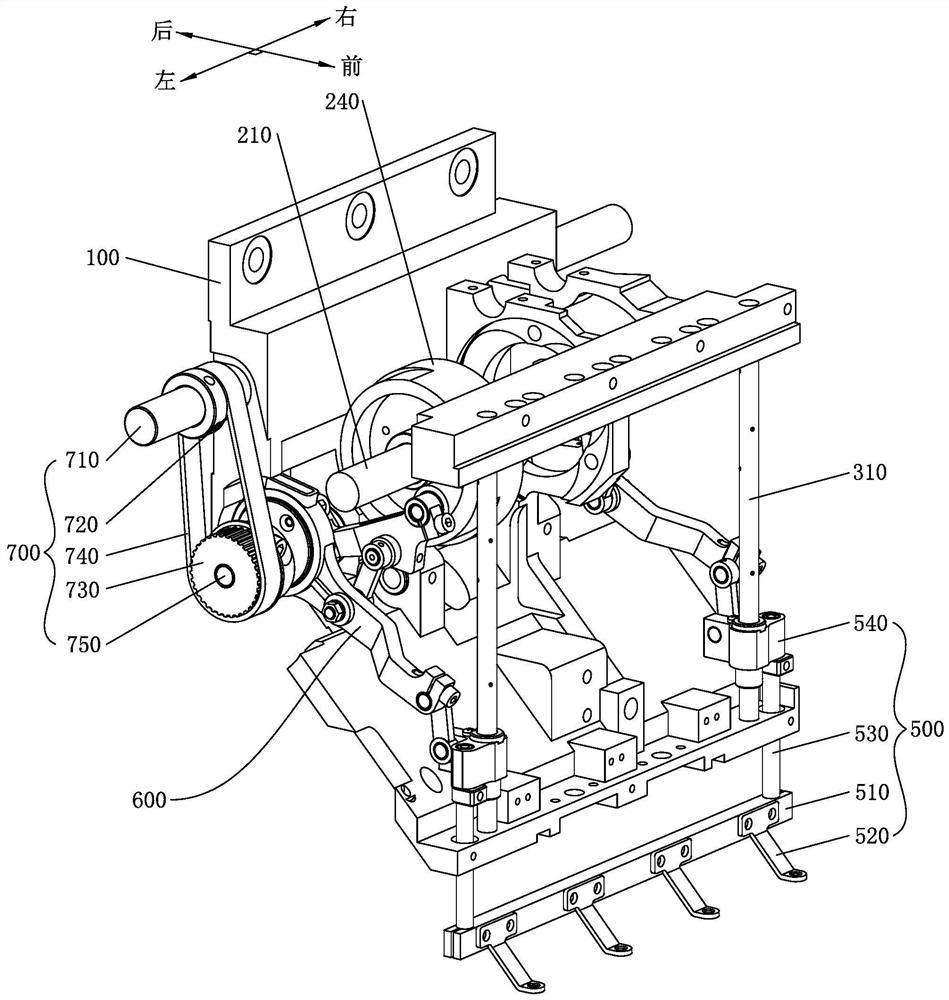

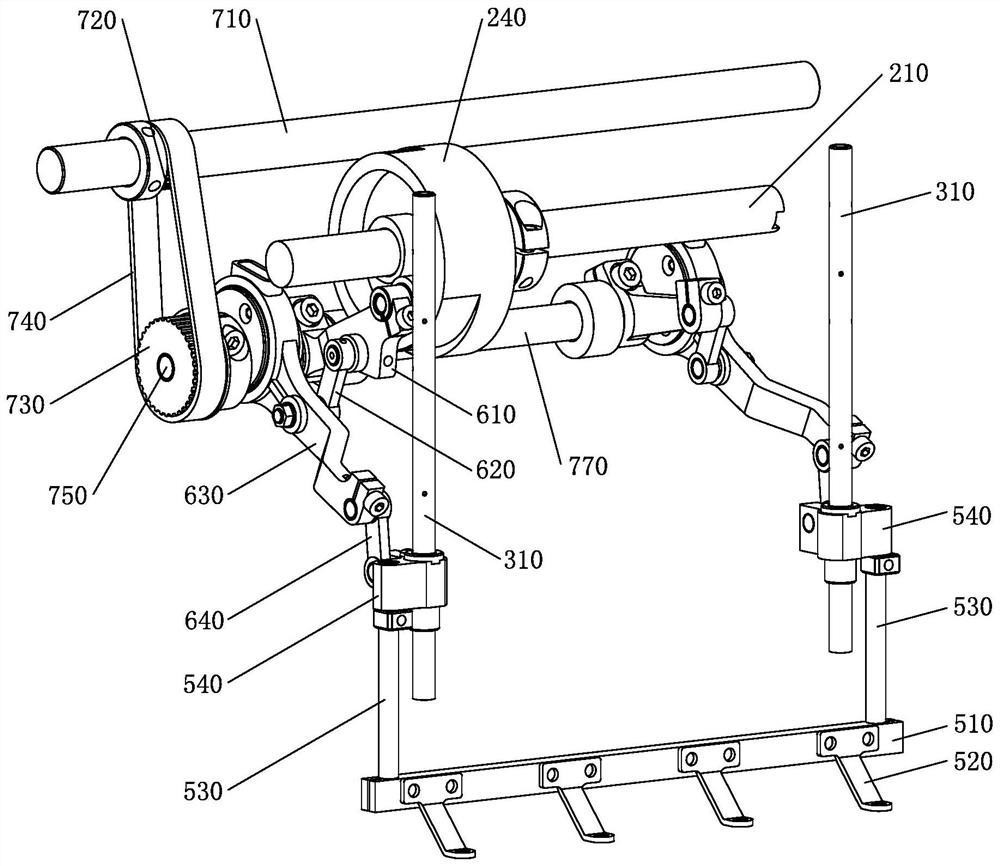

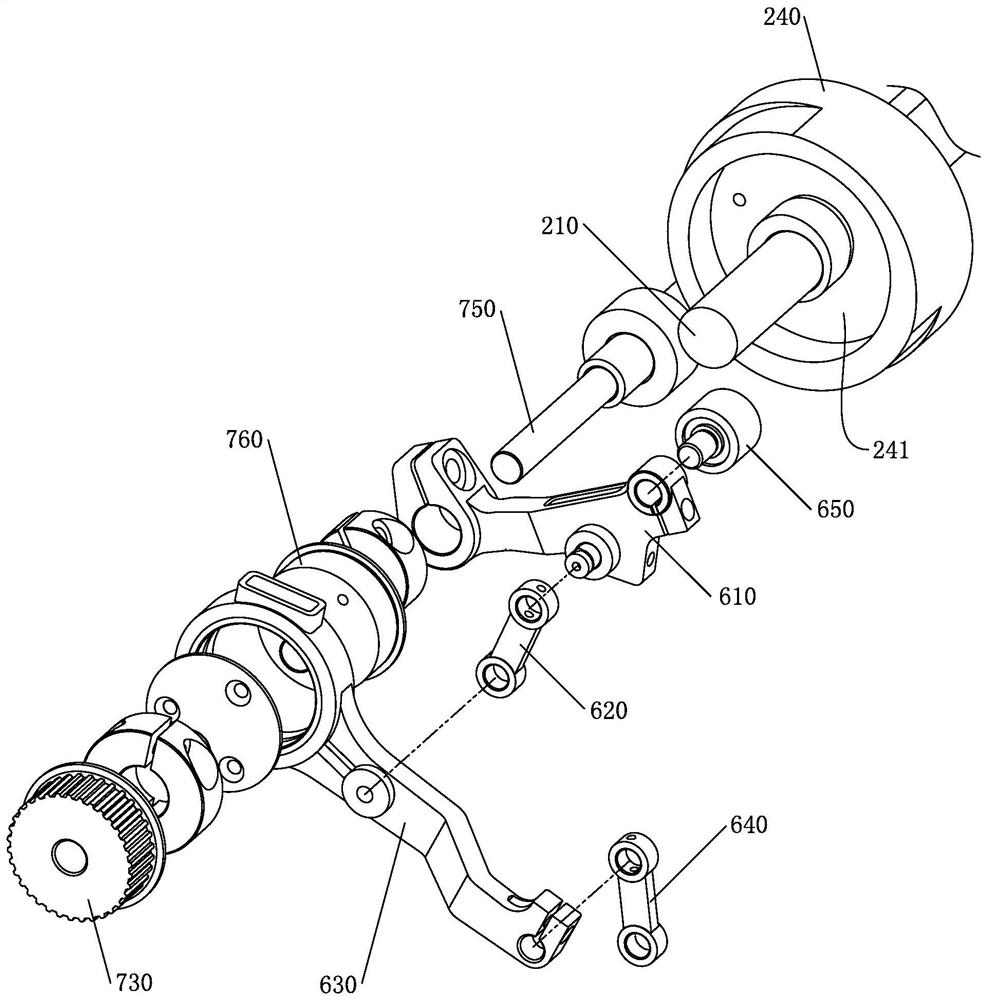

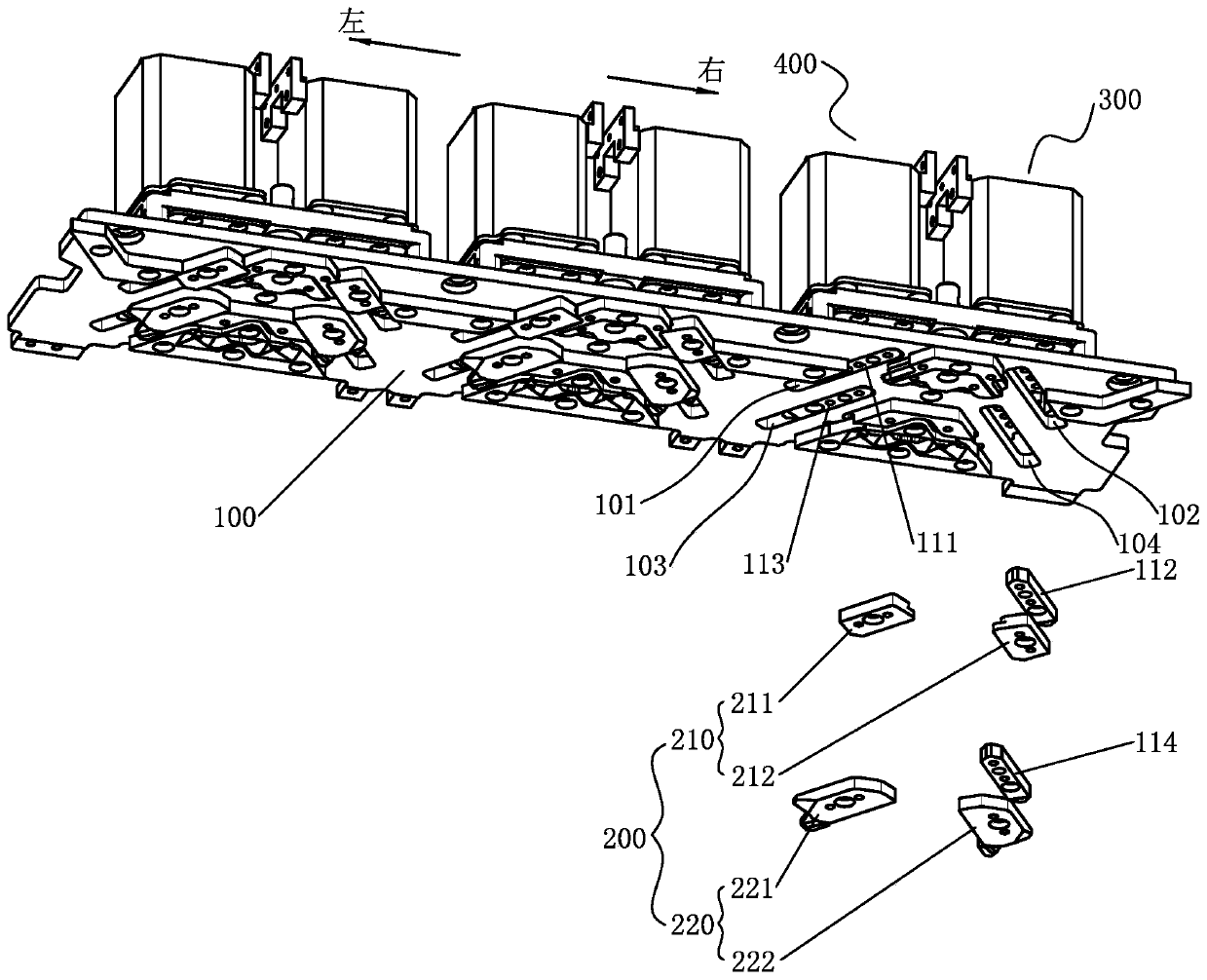

Wheel-leg hybrid quadruped robot

Provided is a wheel-leg composite type four-leg robot. The wheel-leg composite four-leg robot is characterized by comprising an inner car frame, an outer car frame, a cushioning assembly, two pairs of upper leg parallel connection assemblies and four wheel type legs with identical structures. The inner car frame is arranged inside the outer car frame. The inner car frame is connected with the outer car frame through the cushioning assembly. The upper leg parallel connection assemblies of two front legs arranged below the outer car frame are symmetric with each other in a left and right mode, and two front-wheels type legs connected with the parallel connection assemblies are symmetric in a left and right mode. The upper leg parallel connection assemblies of two rear legs arranged below the inner car frame are symmetric with each other in a left and right mode, and two rear-wheels type legs connected with the parallel connection assemblies are symmetric with each other in a left and right mode. Each leg is in a (2-UPS+U) R series and parallel hybrid connection. The wheel-leg composite type four-leg robot has the advantages that the load is big, the rigidity is good, the coupling is small, the obstacle crossing advantage of the leg mechanism is fully applied, the complexity of the control and a mechanical structure is lowered, the installation is easy and convenient, and the maintenance is convenient. The positions and stress information of upper legs and lower legs can be obtained through sensors, and the self-adaption control in an unknown environment can be achieved.

Owner:秦皇岛燕盛智能科技有限公司

Embroidery machine

PendingCN112663236AMeet structural requirementsInfluence of internal installation spaceFeedersElectric machineryEngineering

The invention discloses an embroidery machine, and belongs to the technical field of embroidery equipment. The embroidery machine comprises an upper shaft, a main driving motor and a plurality of machine head modules, wherein a main shaft is arranged outside each machine head module, each machine head module comprises at least one machine head, the machine head comprises a machine shell, a needle rod driving shaft, a guide rod, a needle rod driver, a needle rod cam, a connecting rod structure, a presser foot structure, a presser foot driving wheel and a presser foot transmission mechanism, the connecting rod structure is arranged between the needle rod cam and the needle rod driver and used for driving the needle rod driver to move up and down, and the presser foot transmission mechanism is arranged between the presser foot driving wheel and the presser foot mechanism and used for driving the presser foot mechanism to move up and down. Due to the fact that the main shaft is arranged outside the machine head module, the strength of the main shaft can be improved by increasing the outer diameter of the main shaft, and thus the structural requirement of the embroidery machine is better met. When the main shaft needs to be replaced, only related components of a sub-drive transmission mechanism need to be detached from the main shaft, and components on the machine head module do not need to be detached.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

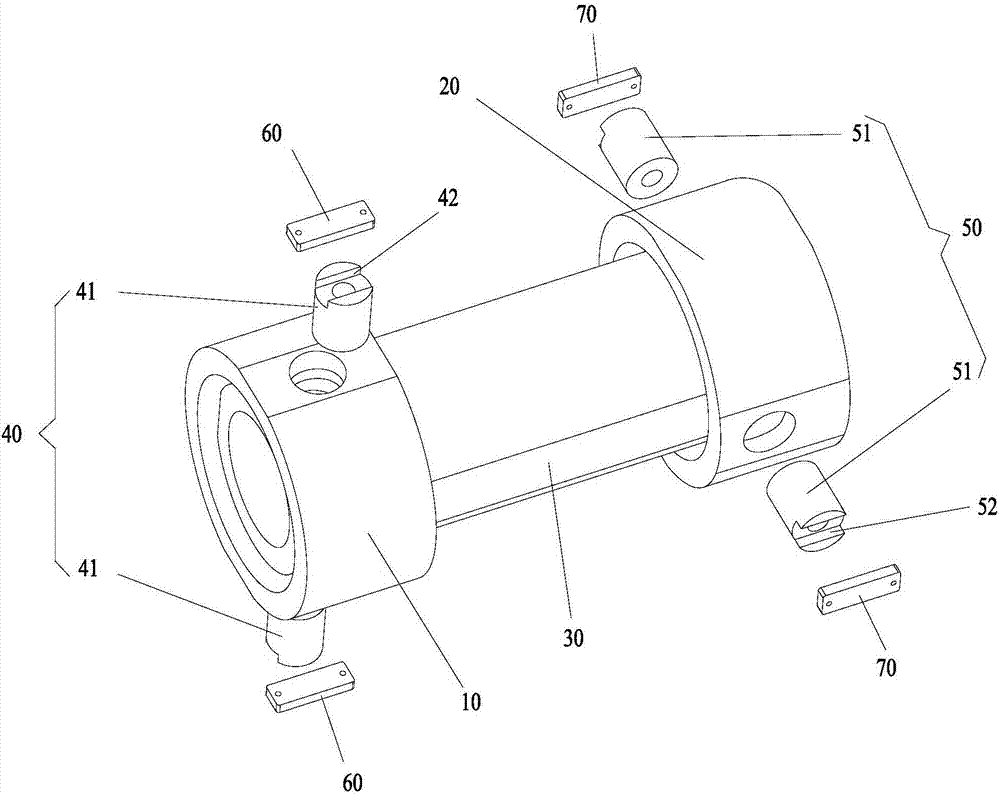

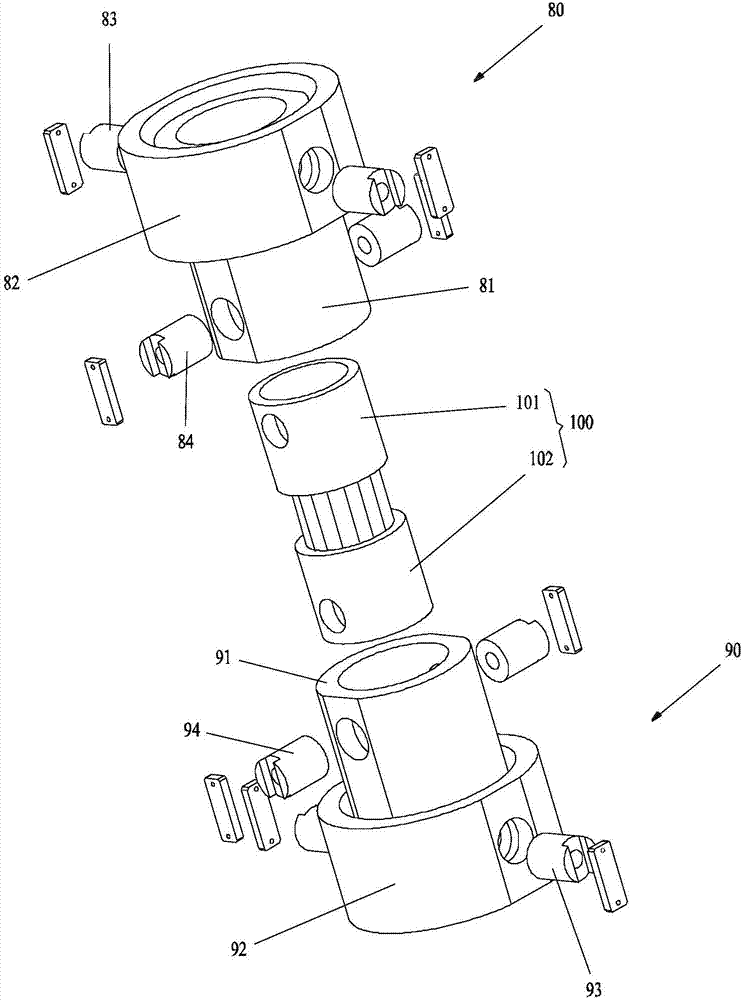

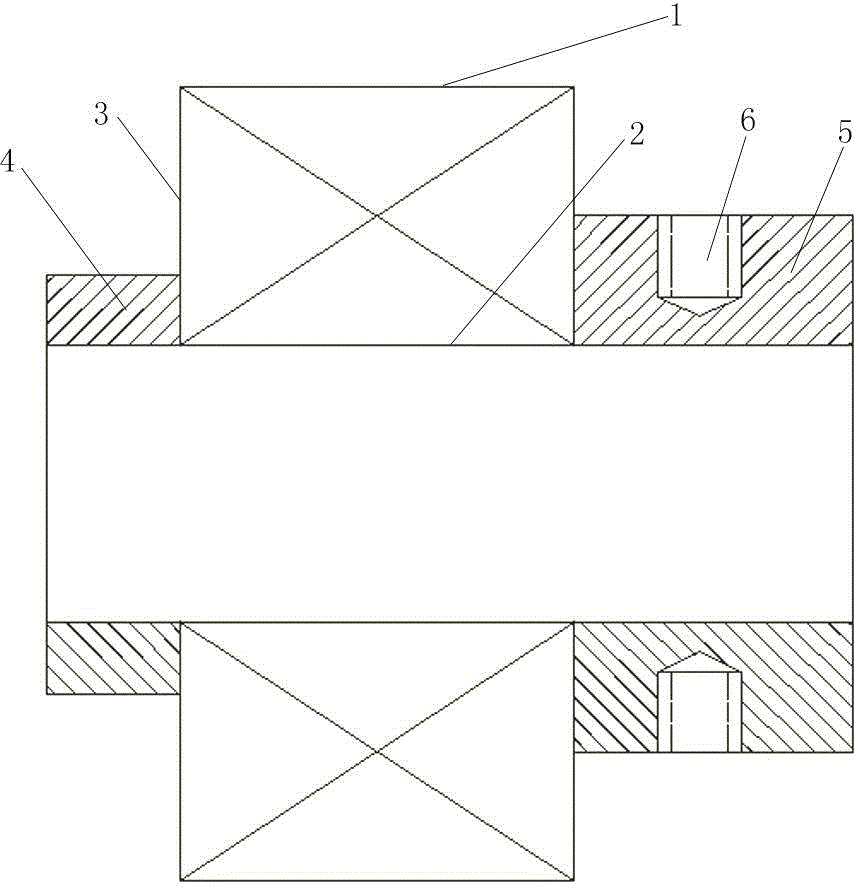

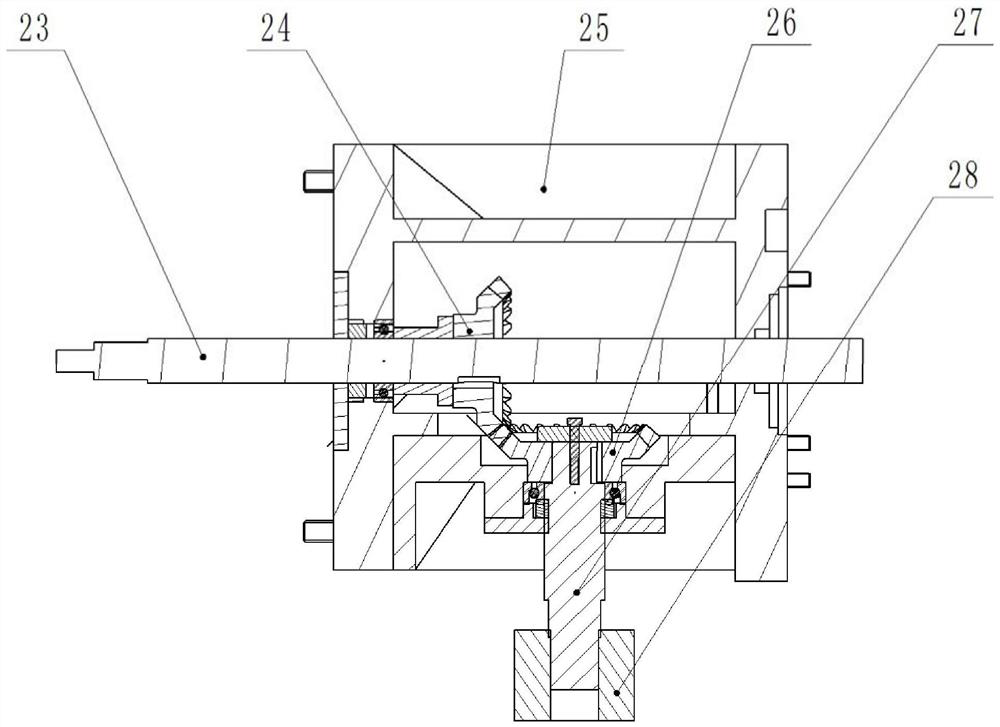

Universal coupler

ActiveCN107327509AReduce manufacturing difficultyMeet transmission requirementsYielding couplingCouplingMachining

The invention relates to a universal coupler. The coupler comprises a first coupling piece, a second coupling piece and a first coupling, wherein the first coupling is rotatably connected with the first coupling piece and the second coupling piece. One end, in the length direction, of the first coupling is rotatably connected with the first coupling piece through a first rotary shaft, and the other end, in the length direction, of the first coupling is rotatably connected with the second coupling piece through a second rotary shaft; and the first rotary shaft and the second rotary shaft are perpendicular to the length direction of the first coupling, and the first rotary shaft is perpendicular to the second rotary shaft. According to the embodiment of the universal coupler, a reasonable structural design is adopted, the machining and manufacturing difficulty of key parts is lowered, the cost is low, and therefore the whole machining and manufacturing difficulty and the cost of the universal coupler are reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

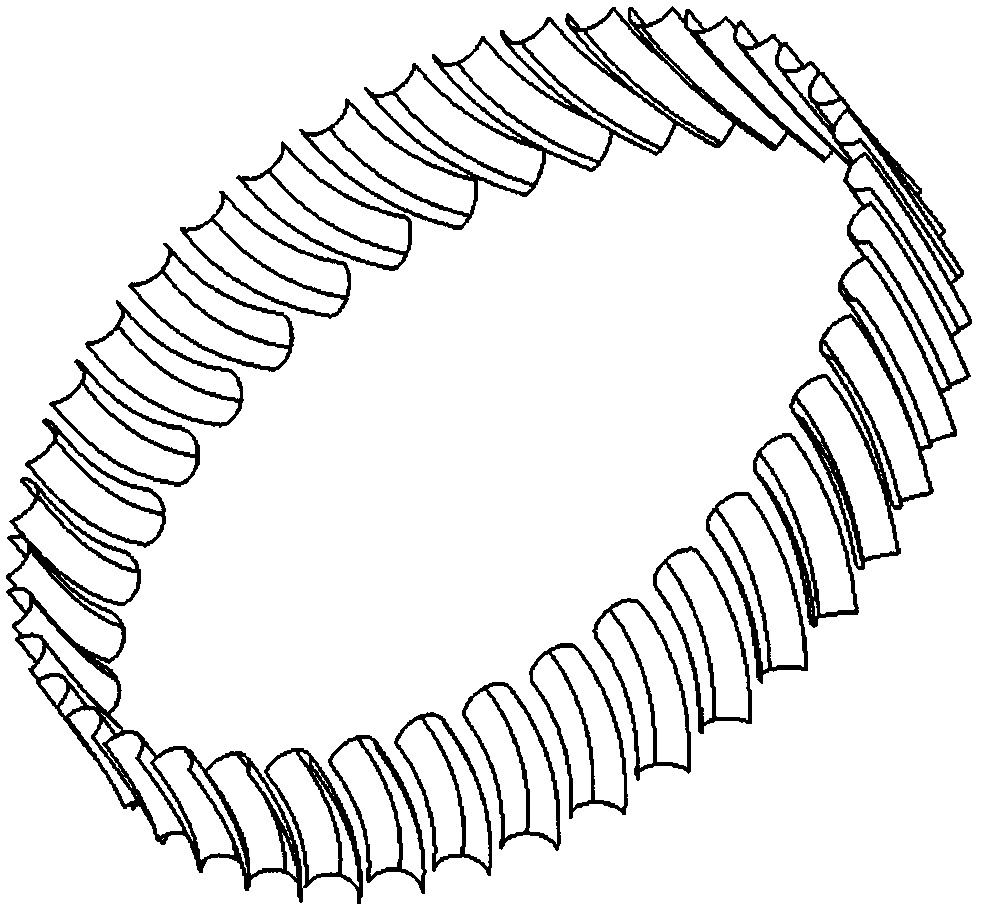

Method for generating real tooth surface of arc tooth surface gear based on circular arc tooth profile

PendingCN109063392ANovel transmission principleUnique tooth shapeGeometric CADDesign optimisation/simulationPoint cloudReliable transmission

The invention discloses a method for generating real tooth surface of arc tooth surface gear based on circular arc tooth profile, which comprises the following steps: firstly, determining model parameters of arc tooth surface gear and arc tooth generating rack; 2, establishing a spatial coordinate system according to that relative motion relation among the arc tooth produce rack, the arc tooth cylindrical gear and the arc tooth surface gear; 3, based on that tooth profile of the arc, establishing the tooth profile equation of the arc tooth generate rack; 4, deriving that equation of circular arc tooth profile arc tooth surface gear by the coordinate transformation method; 5, solving the meshing equation according to the conjugate meshing process of the simulated arc tooth cylindrical gearand the arc tooth surface gear; 6, calculating the tooth surface point cloud of the arc tooth surface gear through digital programming, and obtaining a three-dimensional model of the arc tooth surfacegear through array fitting. The utility model has the advantages of large coincidence coefficient of the tooth shape, stable and reliable transmission, strong bearing capacity, and can meet the transmission requirements under extreme conditions.

Owner:TIANJIN POLYTECHNIC UNIV

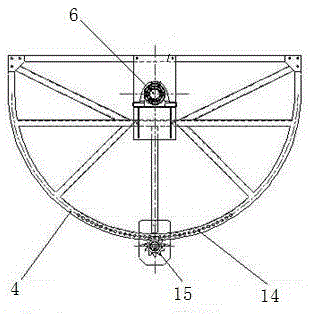

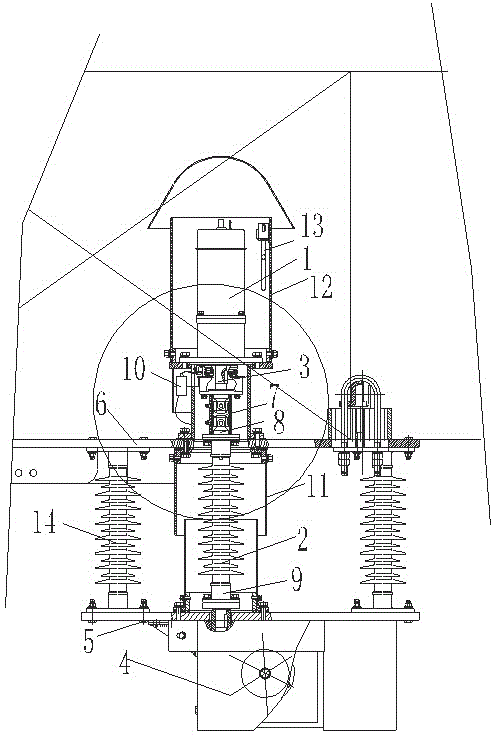

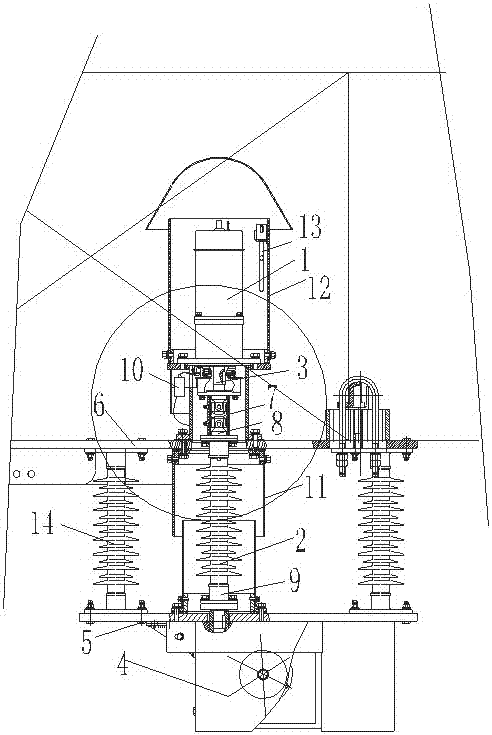

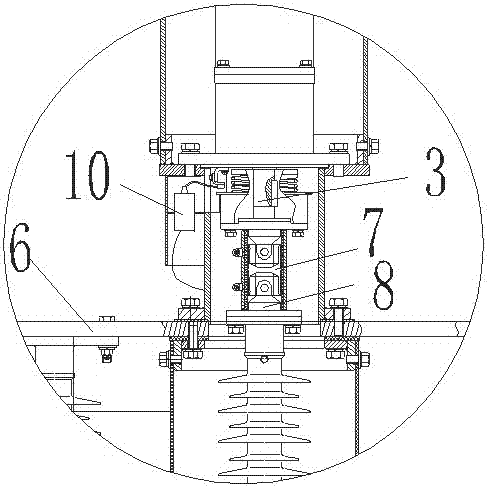

Transmission mechanism for ground wire deicing automatic wiring device

ActiveCN105207157AMeet the dielectric strengthMeet the torsional strengthOverhead installationMotor driveDrive shaft

The present invention provides a transmission mechanism for a ground wire deicing automatic wiring device. An opening and closing conduction device is driven to be led to or separated from a power taking device, and the current of an iron tower power transmission wire is used for iron tower ground wire deicing. The transmission mechanism comprises a motor, an insulation transmission shaft and a speed reducer. The motor drives the speed reducer to rotate through the insulation transmission shaft. The speed reducer is connected to one end of the opening and closing conduction device and drives the opening and closing conduction device to be in sector movement. The insulation transmission shaft is selected to be the rotation element in the transmission mechanism, the insulation and torsional strength are satisfied, and a transmission requirement is satisfied.

Owner:NANJING POWER FITTINGS DESIGN & RES INST CO LTD

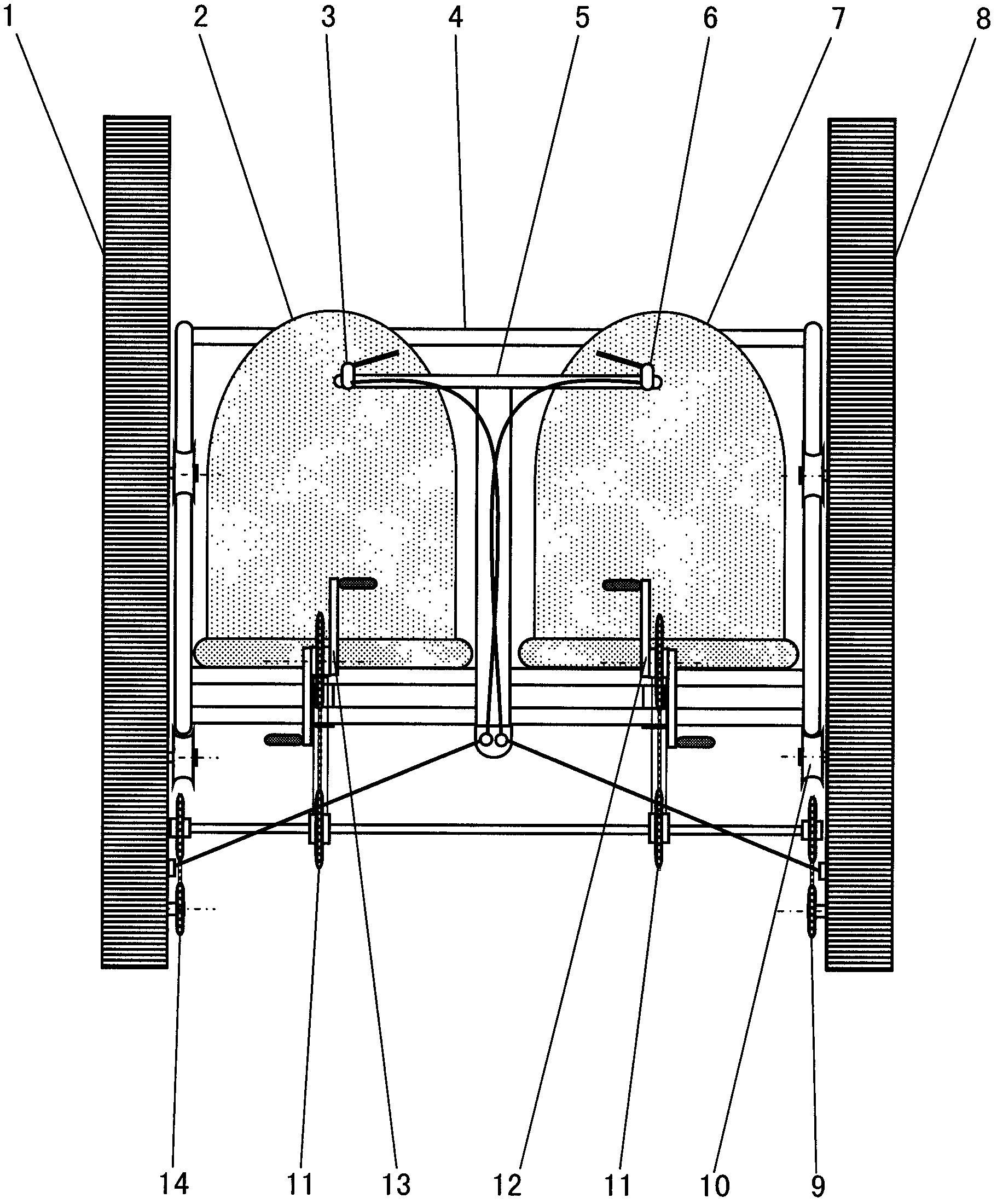

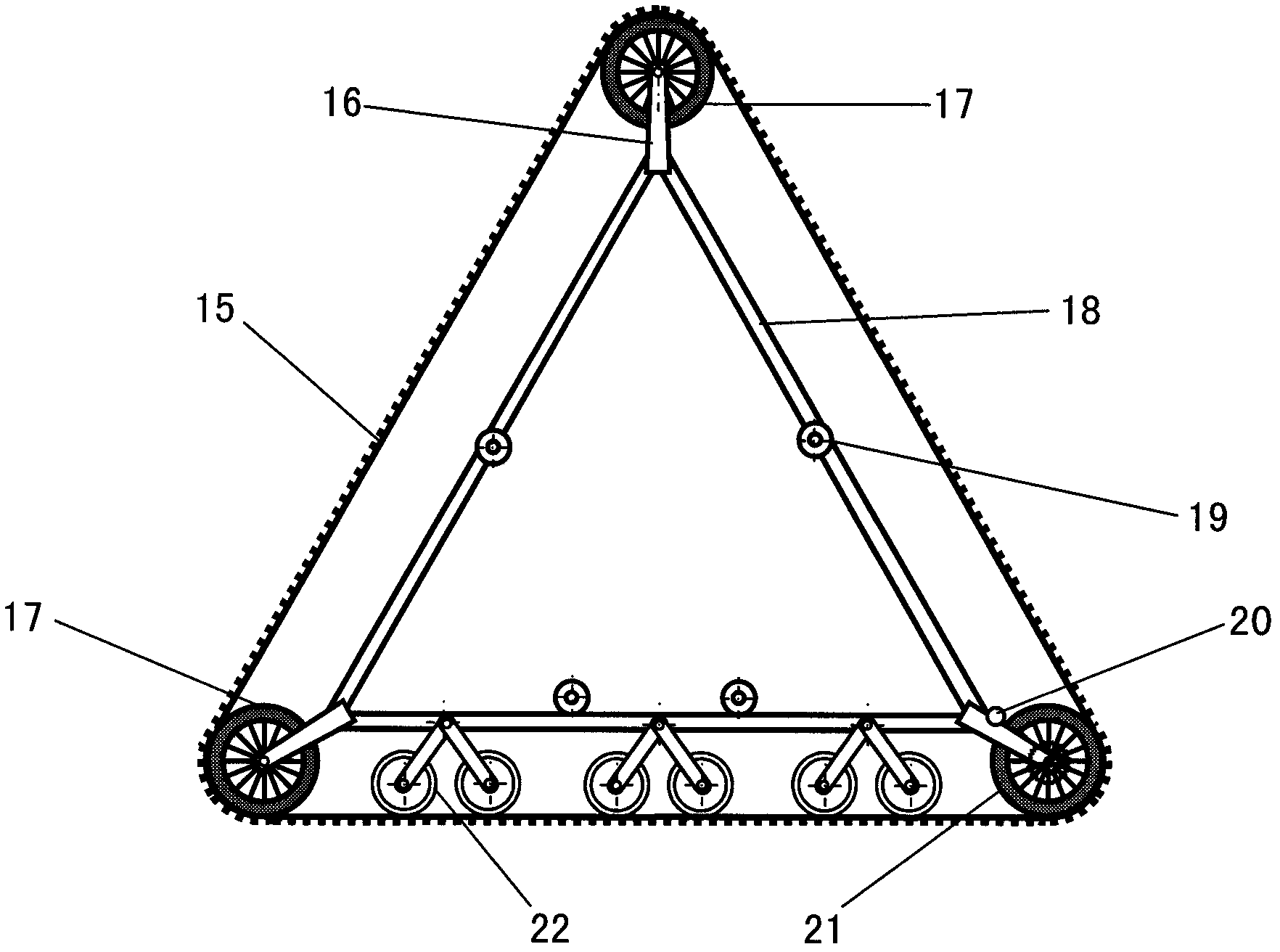

Double crawler-type recreational walking vehicle

InactiveCN103387030AMeet transmission requirementsSatisfy passing abilityCyclesChain/belt transmissionRecreationGrassland

The invention discloses a double crawler-type recreational walking vehicle. A left walking track assembly and a right walking track assembly are arranged at two sides of a cab balance roller; pedal walking mechanisms, a brake mechanism and a self-adaptive following variable pitch transmission mechanism and the like are arranged in the cab balance roller, wherein the pedal driving mechanisms are used for driving the tracks to proceed through the self-adaptive following variable pitch transmission mechanism; left and right independent pedal walking mechanisms can be used for controlling the running speed, going straight and turning of a running vehicle; the cab balance roller can be kept in a horizontal state when the walking vehicle goes up and down the slope on a road; and the self-adaptive following variable pitch transmission mechanism can automatically adjust along with the changes of the cab balance roller and the track walking mechanism, so as to satisfy the transmission requirements. The double crawler-type recreational walking vehicle is suitable for running on sand beaches, grasslands, snowfields and unsmooth pavements, is capable of intensively training skills of coordination and operation of two persons, is beneficial for leisure and recreation sports and fitness puzzle, has the characteristics of being reasonable in structure, simple to operate and flexible in riding, and has practical significances in development of fitness leisure sports instruments in our country.

Owner:HUAZHONG AGRI UNIV

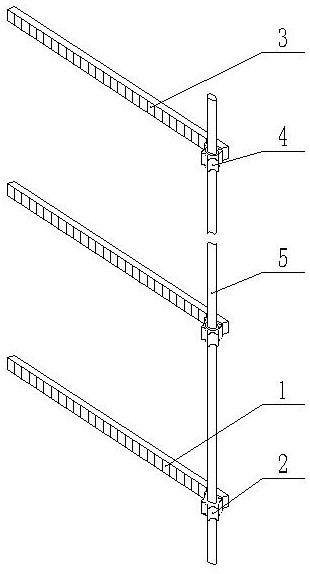

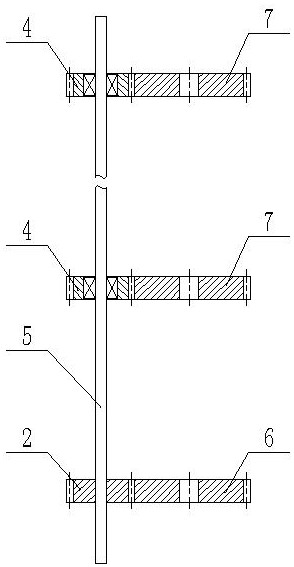

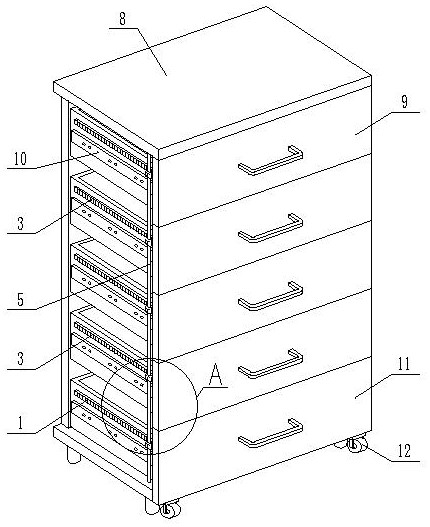

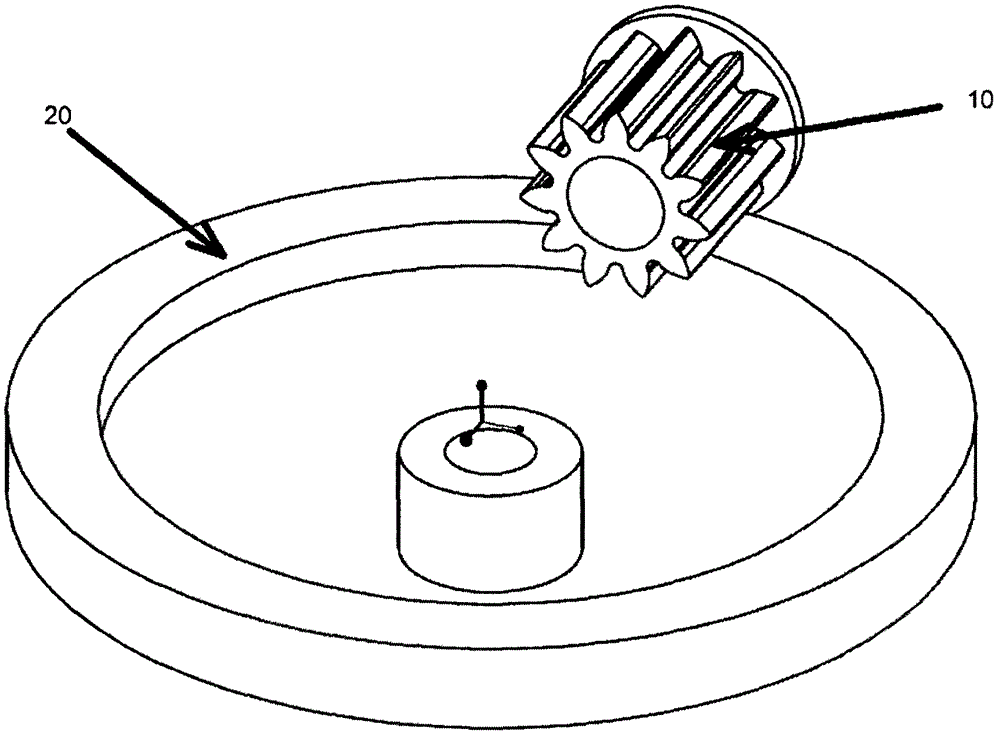

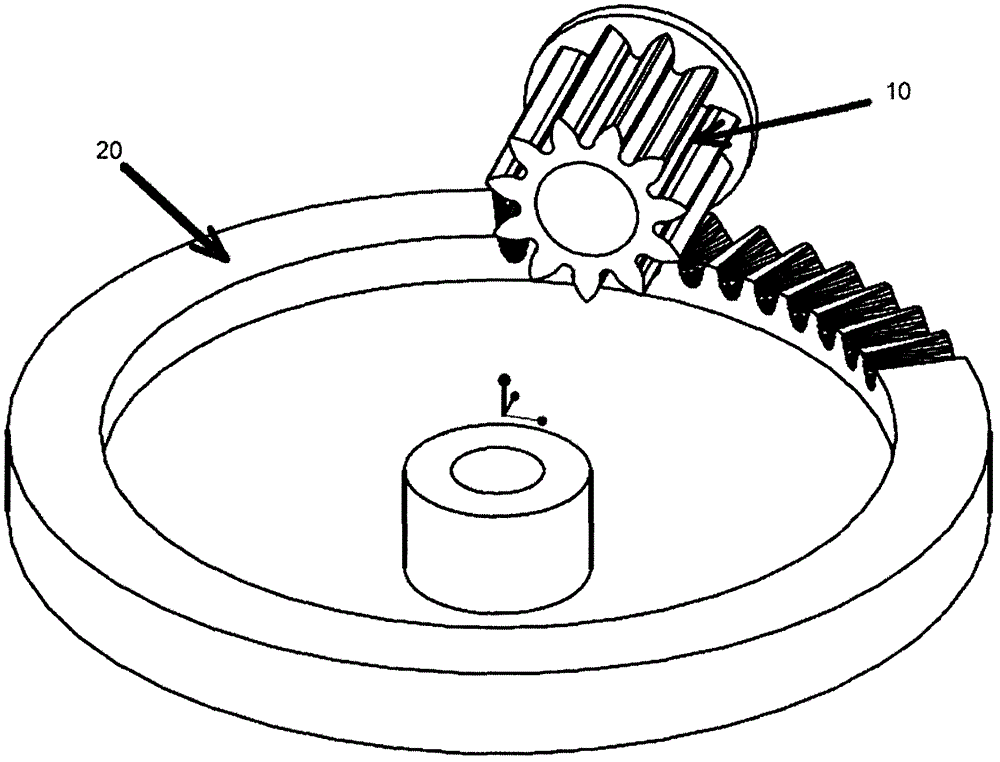

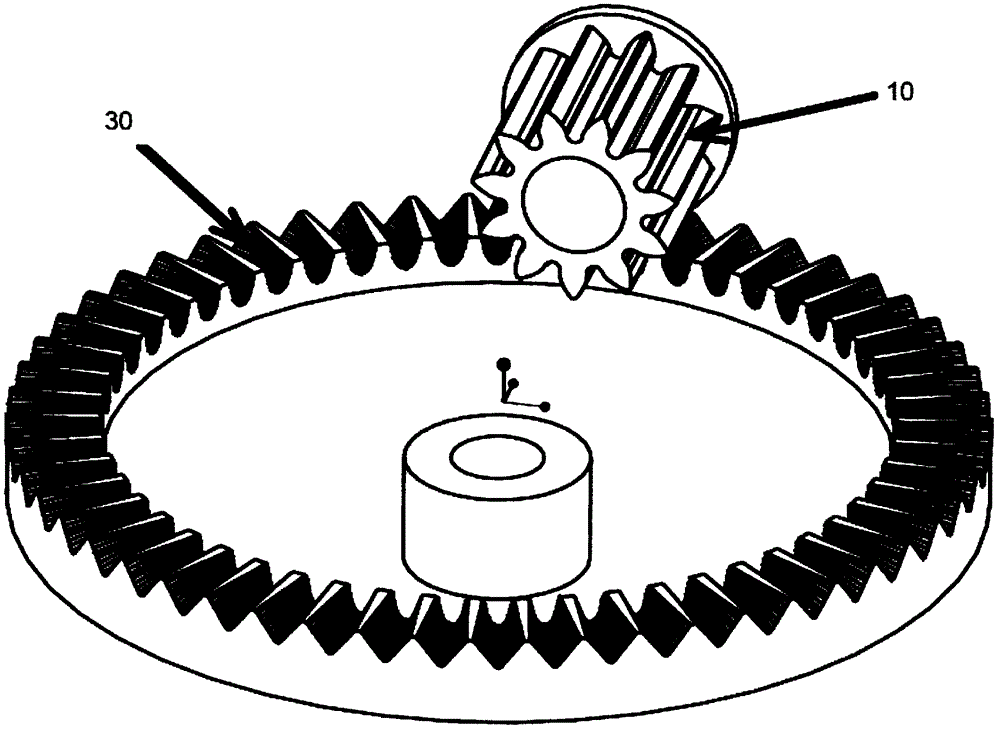

Rack and pinion transmission device and safe drawer cabinet made of it which is not easy to fall

ActiveCN108757866BMeet transmission requirementsNot easy to dumpDrawersFriction gearingsGear wheelGear tooth

Owner:韩文智

A kind of processing method of injection molding surface gear electrode and injection molding surface gear

ActiveCN103128385BMeet transmission requirementsHigh precisionElectrical-based machining electrodesSpecial data processing applicationsGear grindingNumerical control

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

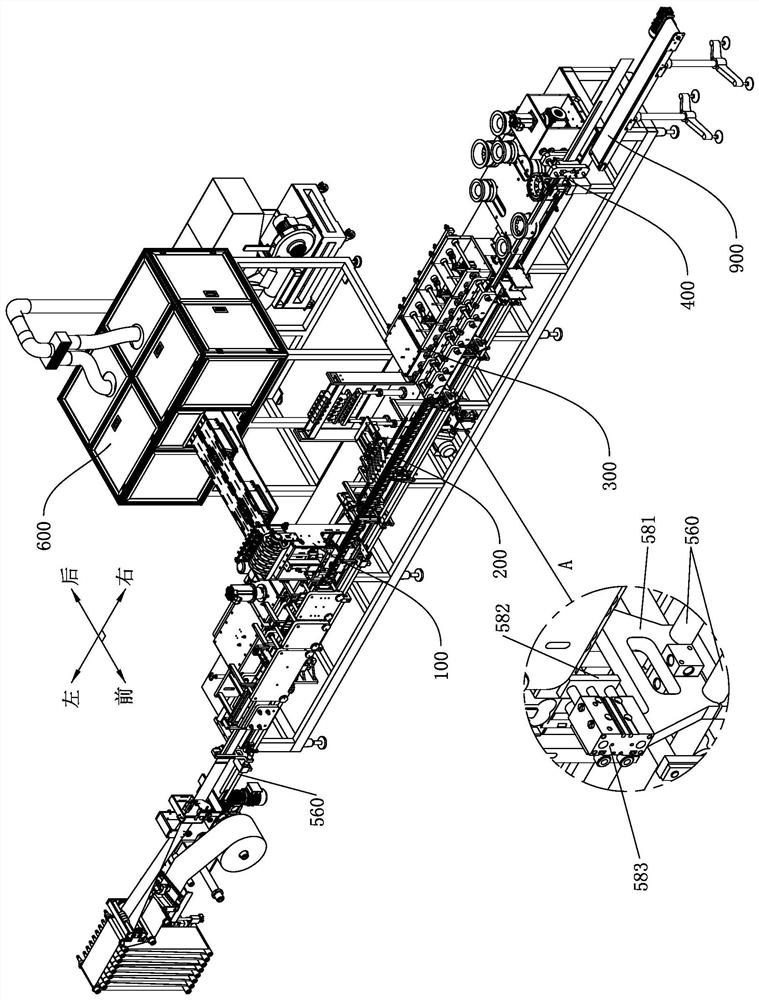

Canning equipment

PendingCN112758389AEffective croppingImprove croppingWrapping material feeding apparatusFrozen sweetsElectric machineryEngineering

The invention discloses canning equipment, and belongs to the technical field of food production equipment. The canning equipment comprises a horizontal dragging device and a cutting device; the horizontal dragging device comprises a dragging support, a dragging motor, a dragging transmission mechanism and a clamping mechanism; the cutting device comprises a cutting motor, a cutting transmission mechanism, a cutting die cutter, a front pressing plate, a rear pressing plate, a front seat plate and a rear seat plate; the front pressing plate is arranged on the rear side of the front seat plate, the cutting die cutter and the rear pressing plate are arranged on the front side of the rear seat plate, the cutting motor drives the front seat plate and the rear seat plate to synchronously move in the opposite directions or move synchronously in the front-back direction, and waste edge outlets cooperating with the cutting die cutter are formed in the rear pressing plate, the front pressing plate and the front seat plate; and the front pressing plate and the rear pressing plate make contact with a sheet and clamp the sheet, the rear pressing plate floats backwards relative to the rear seat plate under the abutting action, the cutting die cutter can cut the portion, needing to be cut, of the sheet, and cut waste is separated from the cutting device through the waste edge outlet.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

A transmission mechanism for an automatic wiring device for ground wire melting ice

ActiveCN105207157BMeet transmission requirementsPrevent deviationOverhead installationReduction driveEngineering

The invention provides a transmission mechanism for the ground wire melting automatic wiring device, which drives the opening and closing conductor to direct or separate from the electrical collector, and the current of the power transmission wire of the iron tower is used to melt the ice of the tower ground wire, including a motor and an insulated transmission shaft And the reducer, the motor drives the reducer to rotate through the insulated transmission shaft, and the reducer is connected to one end of the opening and closing conductor and drives the opening and closing conductor to move in a fan plane. The insulating transmission shaft is selected as the rotating element in the transmission mechanism, which meets the insulation and torsional strength, and can meet the transmission requirements.

Owner:NANJING POWER FITTINGS DESIGN & RES INST CO LTD

Bearing for non-textile machinery

InactiveCN104314970AMeet transmission requirementsCompact designSliding contact bearingsEngineeringScrew thread

The invention discloses a bearing for non-textile machinery. The bearing comprises an inner ring and an outer ring. The bearing is characterized by also comprising a connecting sleeve and an extension sleeve, wherein the connecting sleeve and the extension sleeve are coaxial with the inner ring and the outer ring, and a sealing ring is also arranged between the inner ring and the outer ring; four connecting threaded holes are symmetrically formed in the external diameter of the connecting sleeve; the widths of the connecting sleeve and the extension sleeve are both half of that of the bearing; the external diameter of the connecting sleeve is greater than that of the extension sleeve. With the adoption of the bearing, the structure is compact; when the requirement for transmission of the non-textile machinery is met, the structure is simple, the size of appearance is greatly reduced, and the production cost and layout of a production field are saved.

Owner:ZHANGJIAGANG CITY SHENGMEILONG CASHMERE PROD

Tamper body structure of vibro-rammer

InactiveCN113846619AMeet vibration requirementsImprove compaction efficiencyRotary piston pumpsRotary piston liquid enginesHydraulic motorGear wheel

The invention discloses a rammer body structure of a vibro-rammer. The rammer body structure comprises a box body, an eccentric mechanism and a driving mechanism, and the eccentric mechanism comprises an eccentric wheel; and the driving mechanism comprises a pump body, a pump cover, a driving gear and a driven gear, the driving gear and the driven gear are arranged in a pump cavity formed by the pump body and the pump cover, an inlet and an outlet are correspondingly formed in the box body and the pump body, the two ends of a wheel shaft of the driving gear are rotationally connected with the pump cover correspondingly, the shaft end of the driven gear extends out of the pump cover and is connected with one end of a wheel shaft of the eccentric wheel, the other end of the wheel shaft of the eccentric wheel is rotatably connected with the box body, and the two ends of a wheel shaft of the driven gear are rotatably connected with the pump cover correspondingly. A hydraulic motor is not needed on the outer side of the box body, the structure is simple, driving is convenient, the rammer body cost and the maintenance cost are reduced while the rammer body vibration requirement is met, driving is not prone to failing, hydraulic oil leakage is prevented, and the service life of the vibro-rammer is prolonged.

Owner:山东北国宏峰机电科技有限公司

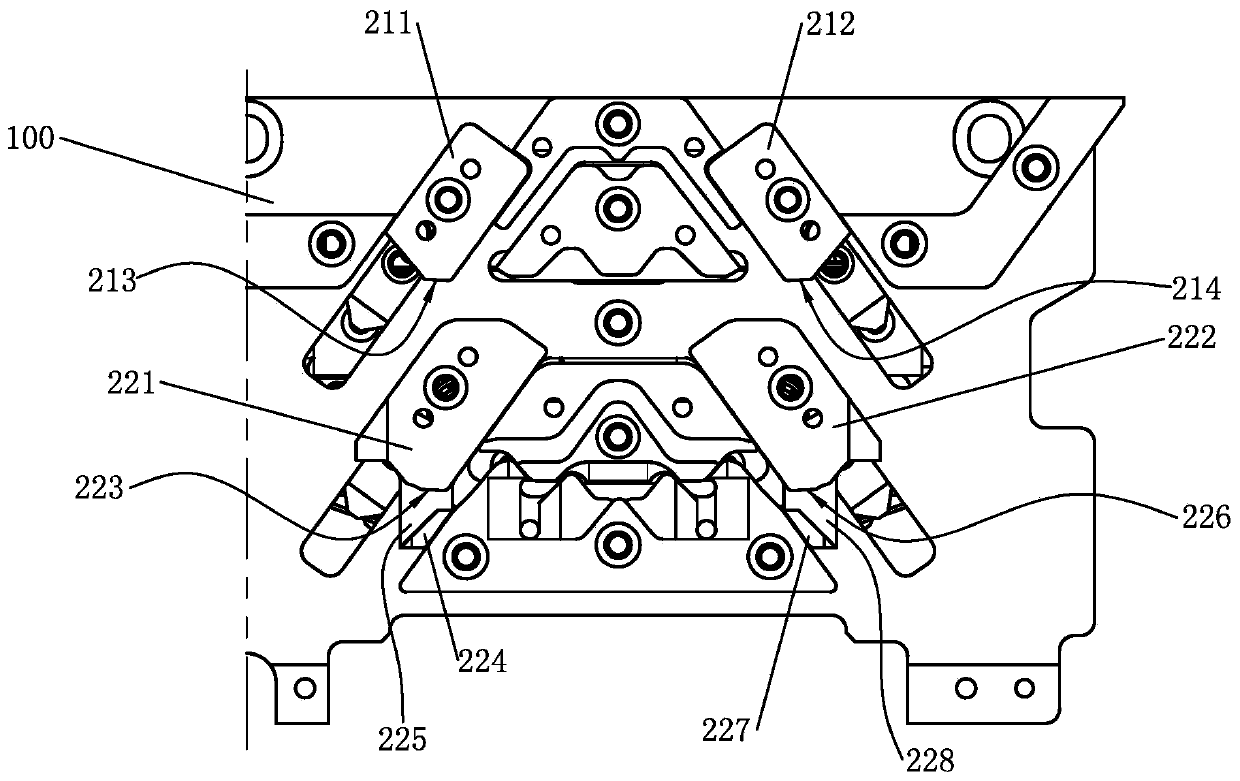

Multi-needle presser foot embroidery machine head and embroidery machine

PendingCN112663235AImprove scalabilityEfficient compressionFeedersPhysical medicine and rehabilitationEngineering

The invention discloses a multi-needle presser foot embroidery machine head and an embroidery machine, and belongs to the technical field of embroidery machines. The embroidery machine head comprises a machine shell, a needle rod driving shaft, a presser foot driving wheel, a presser foot mechanism, a presser foot transmission mechanism and a presser foot adjusting mechanism, wherein the presser foot mechanism comprises a presser foot strip, a presser feet and a presser foot lifting rod; the presser foot transmission mechanism is arranged between the presser foot driving wheel and the presser foot lifting rod and used for driving the presser foot mechanism to move up and down; and the presser foot adjusting mechanism is arranged on the machine shell and adjusts the vertical position of the presser foot mechanism through the presser foot transmission mechanism. The needle rod driving shaft drives the presser foot mechanism to move up and down through the presser foot driving wheel and the presser foot transmission mechanism, so that the presser foot mechanism can effectively press an upper thread when the embroidery machine works, and thus the embroidery quality is improved. The presser foot adjusting mechanism can adjust the vertical position of the presser foot mechanism through the presser foot transmission mechanism, the presser foot mechanism is convenient to lift, and thus the presser foot mechanism is prevented from interfering with embroidery cloth replacement and other operations.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

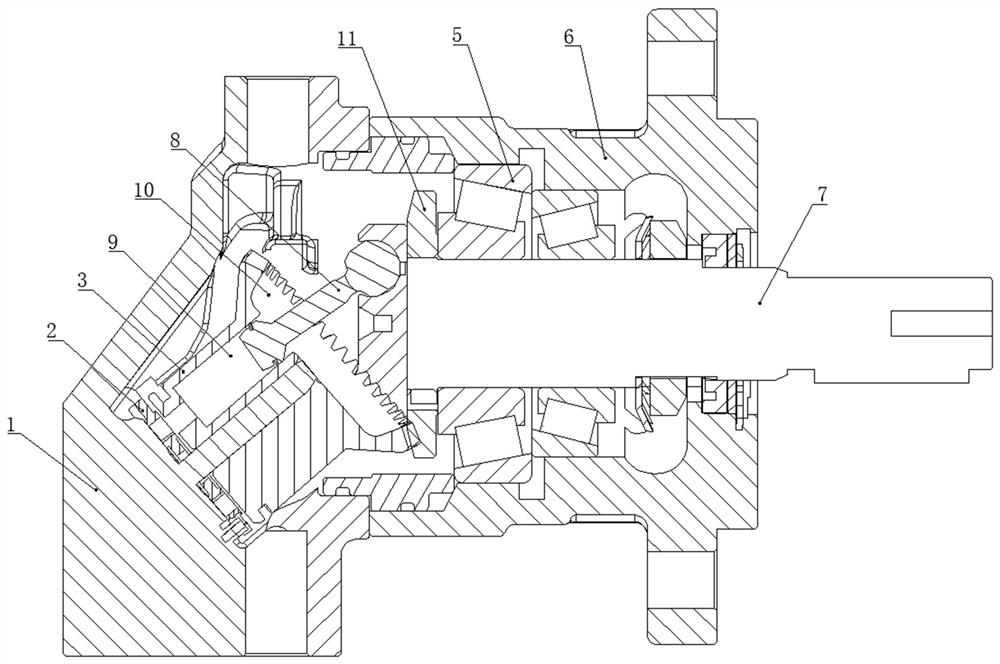

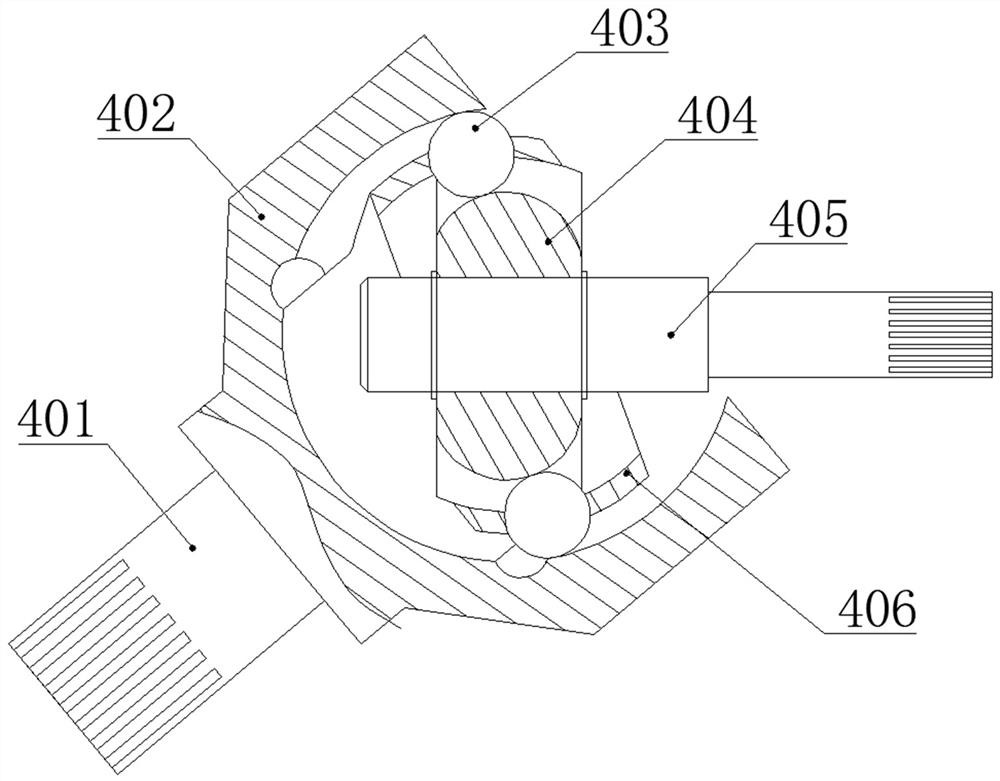

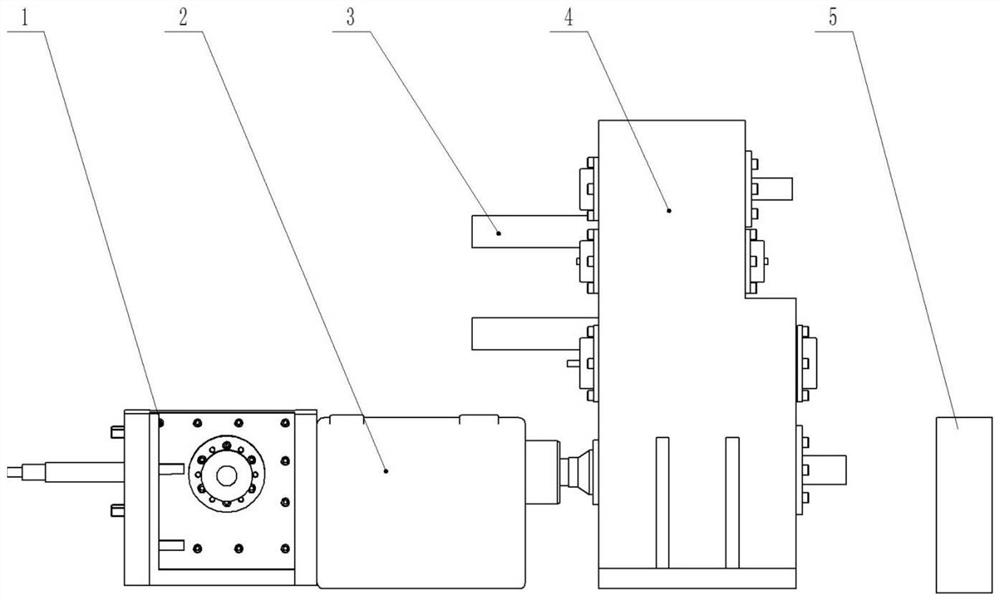

Universal joint transmission inclined shaft type plunger pump

PendingCN114576124AImprove carrying capacityImprove impact resistancePositive-displacement liquid enginesMulti-cylinder pumpsGear driveUniversal joint

The invention belongs to the technical field of hydraulic systems of engineering machinery, and discloses an inclined shaft type plunger pump driven by a universal joint. Comprising a pump body, a main shaft and a cylinder body, the main shaft and the cylinder body are arranged in the pump body, a plunger is arranged between the main shaft and the cylinder body, the main shaft and the cylinder body are connected through a universal joint, the universal joint is a constant-velocity universal joint, and the two ends of the universal joint are arranged on the central axis of the main shaft and the cylinder body respectively; the invention solves the problems of poor interchangeability and high manufacturing cost when the cylinder body and the main shaft are in gear transmission in the prior art.

Owner:SHIJIAZHUANG TIEDAO UNIV

A gzg-ht photovoltaic automatic tracking system

ActiveCN105656422BIncrease productivityPromote incomePhotovoltaic supportsPhotovoltaic energy generationStationary modeControl mode

The invention provides a GZG-HT photovoltaic automatic tracking system. The system comprises a controller, one set of sensors and multiple sets of driving devices, and the controller is provided with the sensors and controls motion of the driving devices simultaneously; the system further comprises transmission devices arranged above the corresponding driving devices and multiple independent photovoltaic tracking subsystems. According to the GZG-HT photovoltaic automatic tracking system, photovoltaic modules automatically rotate and track sunlight in the latitudinal direction and are manually adjusted according to season changes in the longitudinal direction, the single controller is connected to the peripheral photovoltaic tracking subsystems simultaneously in a controlling mode, and linkage control is achieved. Meanwhile, an agriculture and light complementary photovoltaic power generation mode achieving photovoltaic power generation on the upper portion and agricultural planting on the lower portion is established, power generation units achieve bidirectional tracking in the latitudinal direction and the longitudinal direction, and large-scale cultivation of crops under frames is achieved. Compared with a traditional fixing mode, by means of the photovoltaic power generation mode, the light energy transforming rate and crop yield can be greatly increased, multiple purposes of one field are achieved, the income of farmers is increased, the benefits of enterprises are increased, the tax income of the government is increased, and the benefit of environment is increased.

Owner:陕西航泰电气股份有限公司

Accessory drive structure

ActiveCN113374611BSmall form factorReduce weightPower operated startersElectric motor startersElectric machineryOil mist

Owner:CHINA HANGFA SOUTH IND CO LTD

Multi-output shaft gearbox based on electric clutch

ActiveCN108036029BMeet transmission requirementsToothed gearingsGearing controlElectromagnetic clutchControl system

The invention provides a multi-output-shaft gearbox based on electric clutch. The multi-output-shaft gearbox based on electric clutch comprises a direction change transmission case connected with a fan module, a speed change transmission case connected with the direction change transmission case, and a main transmission case connected with the speed change transmission case, and connected with a travelling module and a picking module. Compared with the prior art, the multi-output-shaft gearbox based on electric clutch has the following beneficial effects: disengagement and engagement in the transmission of the gearbox and the travelling module, the picking module and the fan module of a vehicle are carried out through the control of a control system for the movement of a motor and an electromagnetic clutch; and transmission is carried out on the fan module through the direction change transmission case, the transmission ratio of the gearbox is controlled through the speed change transmission case, and transmission is carried out on the travelling module and the picking module through the main transmission case, so that the transmission requirement of a medium-sized cotton picker can be met.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

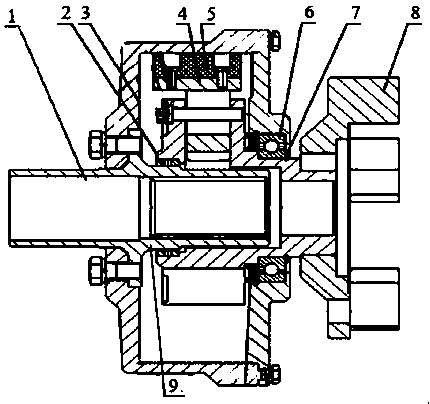

Centrifugal friction coupler

InactiveCN103511507AExtended service lifeMeet transmission requirementsSlip couplingAutomatic clutchesCouplingMechanical equipment

The invention discloses a centrifugal friction coupler. The centrifugal friction coupler comprises a driving coupling device, a driven coupling device, a connecting sleeve, a movement, centrifugal friction blocks, a bearing and a shell, wherein the driving coupling device is connected with the driven coupling device through the connecting sleeve, the movement is located on the driven coupling device, the centrifugal friction blocks are installed on the movement, the bearing is installed in the gap between the shell and the driven coupling device, the number of the centrifugal friction blocks is three, and the three centrifugal friction blocks are evenly distributed on the movement and provided with anti-static and anti-abrasion material layers. The centrifugal friction coupler has the advantages that centrifugal force can be adjusted in time due to the fact that the three centrifugal friction blocks are evenly distributed, and transmission requirements of large-power mechanical equipment are met; meanwhile, due to the fact that the anti-static and anti-abrasion material layers are arranged on the centrifugal friction blocks, danger caused by the rising of temperature of the surfaces of the centrifugal friction blocks can be avoided, and the service life is effectively prolonged.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

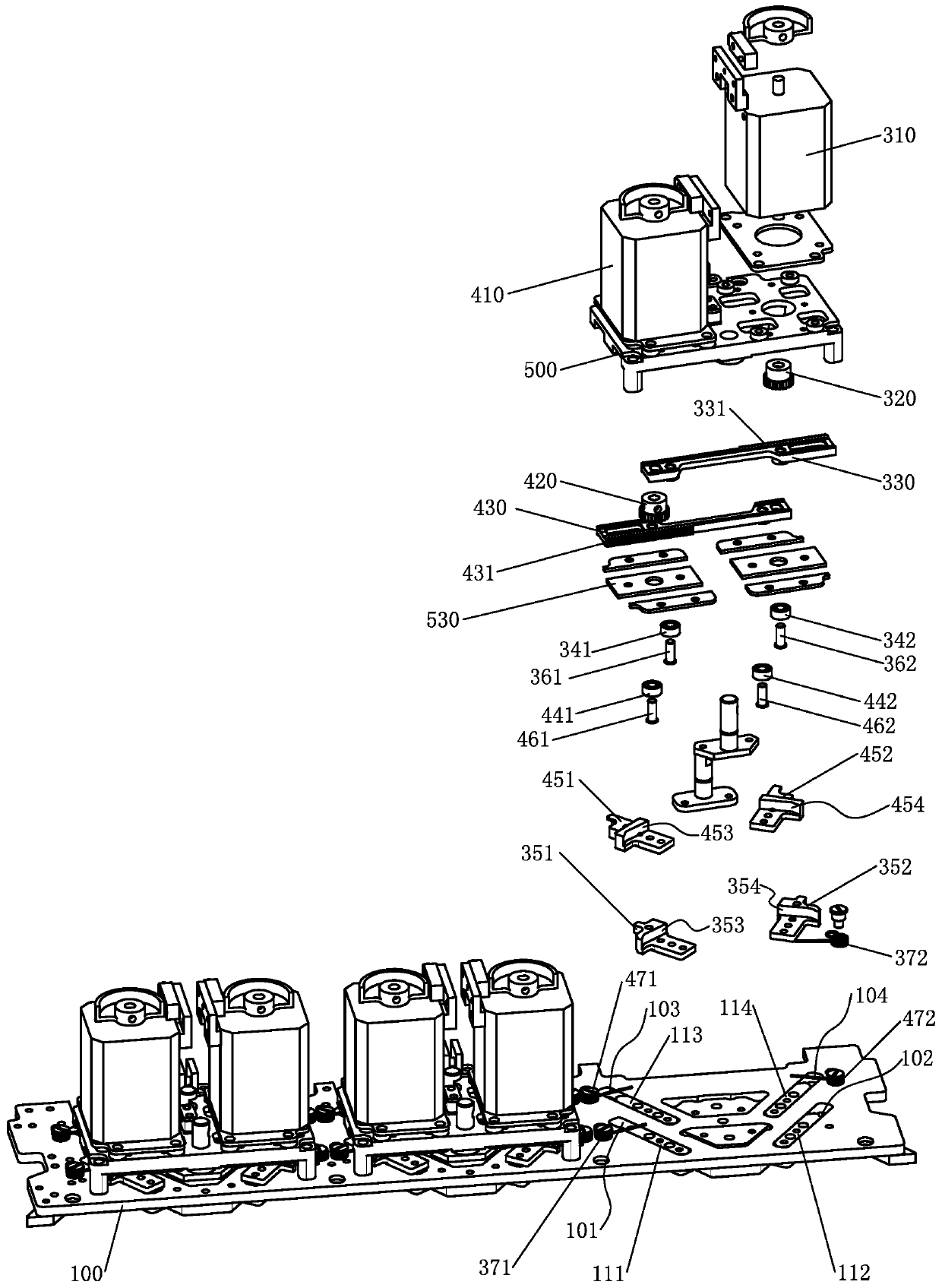

Flat knitting machine two-stage stitch controlling device and flat knitting machine

PendingCN110219091AImprove synchronicityAvoid getting stuck when moving back and forthWeft knittingEngineeringCam

The invention discloses a flat knitting machine two-stage stitch controlling device and a flat knitting machine and belongs to the field of flat knitting machines. The flat knitting machine two-stagestitch controlling device comprises at least one group of stitch cams and driving mechanisms corresponding to the group of stitch cams; the group of stitch cams are composed of an upper group of stitch cams and a lower group of stitch cams, the upper group of stitch cams are composed of an upper left stitch cam and an upper right stitch cam, and the lower group of stitch cams are composed of a lower left stitch cam and a lower right stitch cam; the driving mechanisms comprises a first driving mechanism and a second driving mechanism. The flat knitting machine two-stage stitch controlling device replaces a vertical double-layer overlapped arrangement manner with a horizontal arrangement manner with the upper and lower groups of stitch cams, thereby effectively enlarging the contact area between every stitch cam and butts of knitting needles, reducing wearing of the needle butts, avoiding releasing of the needle butts, and further reasonably increasing sinking depth as well as effectively improving the operation stability of the knitting needles. Driven by the two driving mechanisms separately, the flat knitting machine two-stage stitch controlling device can simplify the structure and meanwhile effectively enlarge the stitch adjusting range.

Owner:ZHEJIANG FENGFAN NC MACHINERY

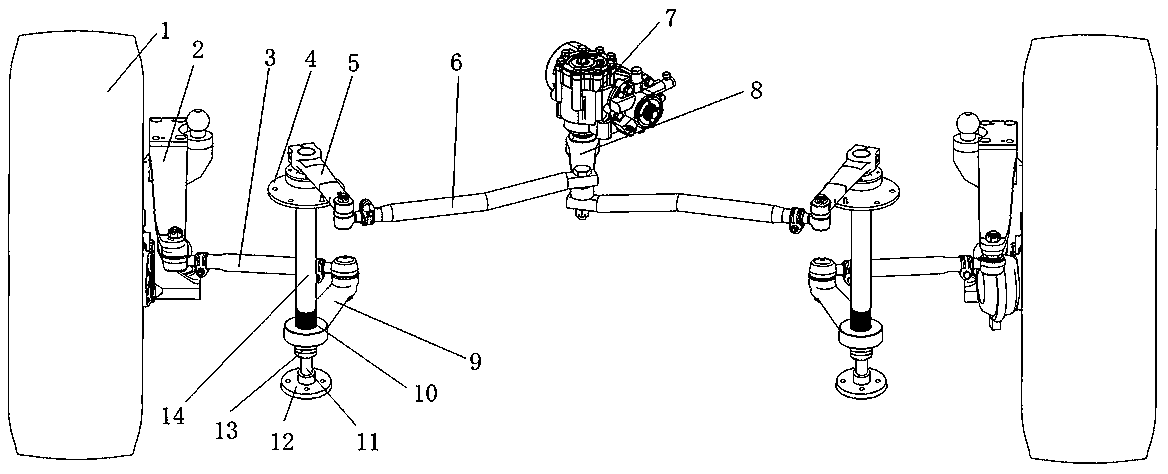

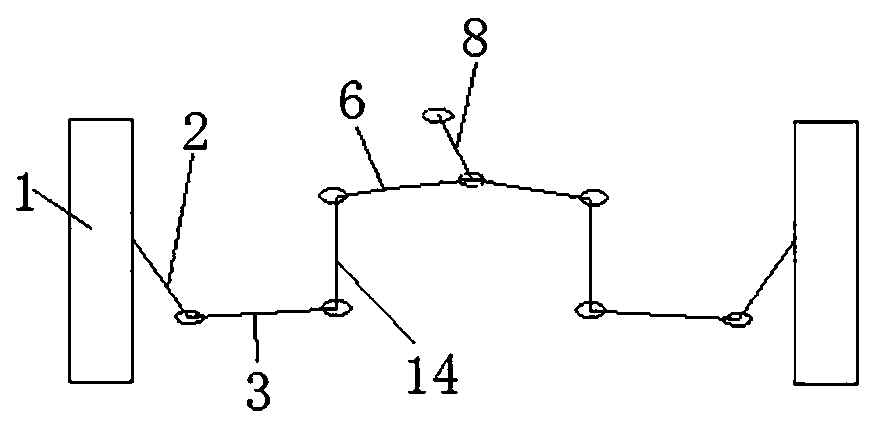

Vehicle and steering transmission system thereof

ActiveCN111114617AAdjust angleEven by forceSteering linkagesMechanical steering gearsBogieVehicle frame

The invention relates to a vehicle and a steering transmission system thereof. The steering transmission system comprises a bogie, two steering knuckle arms, knuckle arm pull rods and vertical arms, wherein the bogie is provided with a driving connection part, and the driving connection part is used for being in transmission connection with a steering gear; the two steering knuckle arms are arranged on the two sides of the bogie respectively; the knuckle arm pull rod is arranged between the bogie and the corresponding steering knuckle arm; the knuckle arm pull rod is in transmission connectionwith the bogie through the vertical arm, and the height of the bogie is larger than that of the knuckle arm pull rod, so that the bogie avoids components on the frame; or the vertical arm is in transmission connection between the knuckle arm pull rod and the corresponding knuckle arm, and the height of the knuckle arm pull rod is larger than that of the knuckle arm, so that the bogie avoids components on the frame. The bogie can be lifted to a certain height, layered arrangement of the bogie and the steering knuckle arm is achieved, then the bogie avoids components on the frame, and interference between the bogie and the components on the frame is avoided.

Owner:ZHENGZHOU YUTONG HEAVY IND

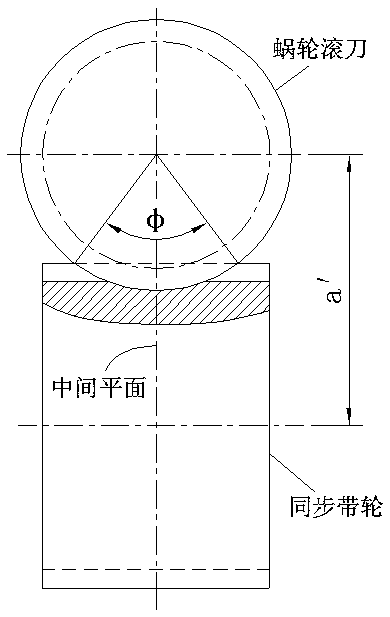

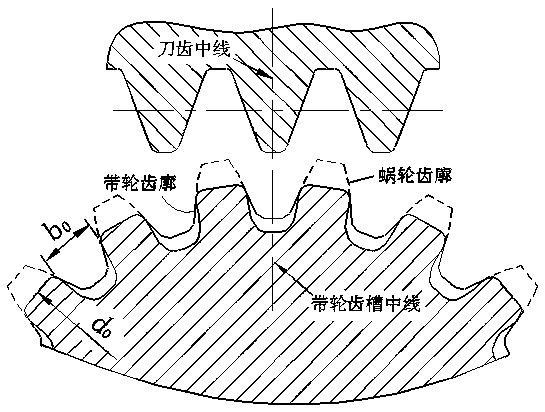

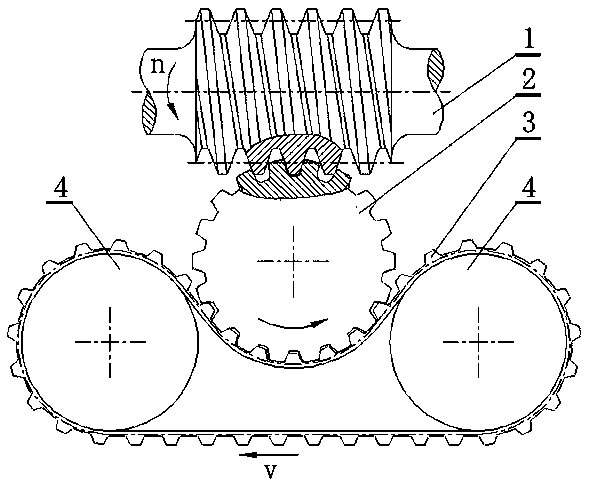

Synchronous belt-worm gear and its transmission

The invention relates to a synchronous belt-worm gear and a transmission device thereof. The synchronous belt-worm gear is a cylindrical gear-shaped part. The gear tooth face of the synchronous belt-worm gear consists of a worm gear tooth face and a synchronous pulley tooth face, wherein the worm gear tooth face can be meshed with a worm, and the synchronous pulley tooth face can be meshed with a synchronous belt. The synchronous belt-worm gear comprises two structures, wherein one of the two structures is that all tooth faces respectively comprise part of the worm gear tooth face and part of the synchronous pulley tooth face, and the other structure is that one side tooth face of gear teeth is the complete synchronous pulley tooth face, and one part of the other side tooth face of the gear teeth is the worm gear tooth face, and the other part of the other side tooth face of the gear teeth is the synchronous pulley tooth face. Through the transmission device formed by the synchronous belt-worm gear, the synchronous belt-worm gear is meshed with the worm to obtain movement and power, and the synchronous belt-worm gear is meshed with the synchronous belt to transmit the movement and the power to the synchronous belt. The transmission device provided by the invention has the characteristics that the structure is simple, and manufacturing is convenient. The rotation of the active worm can be converted into the low-velocity movement of the synchronous belt in the axial plane of the worm, or the low-velocity rotation of the synchronous pulley in a compact space, wherein the synchronous pulley and the worm are arranged at an axial alternate angle of 90 degrees.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com