Method for generating real tooth surface of arc tooth surface gear based on circular arc tooth profile

A technology of arc-shaped teeth and face gears, which is applied in the field of gears and can solve problems such as cumbersome parametric modeling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

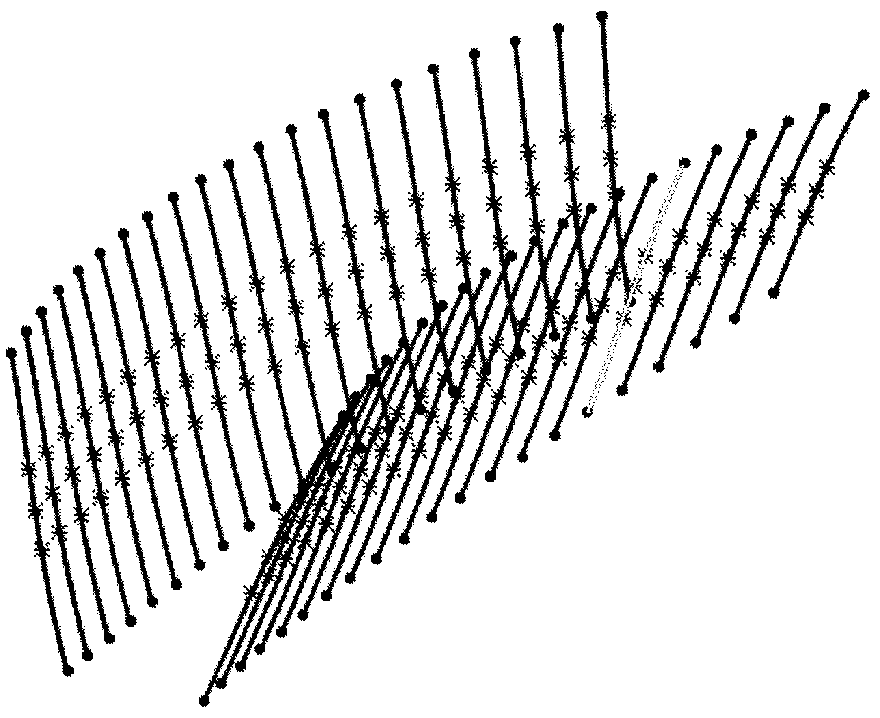

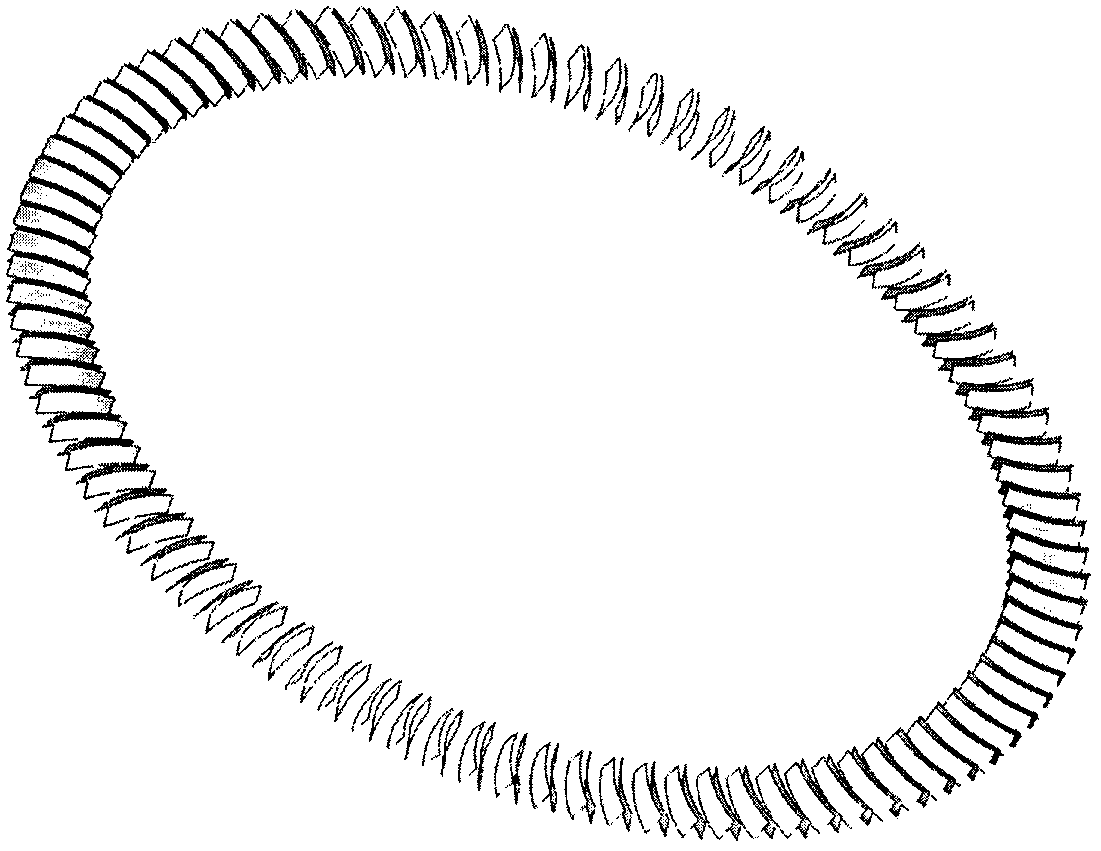

[0061] The embodiments of the present invention are described with reference to the accompanying drawings, and further detailed descriptions are given below with reference to the accompanying drawings and examples.

[0062] A method for creating the true tooth surface of an arc tooth surface gear based on a circular arc tooth profile, which includes the steps:

[0063] (1) Determine the required model parameters of the arc tooth profile arc tooth surface gear and the arc tooth profile rack:

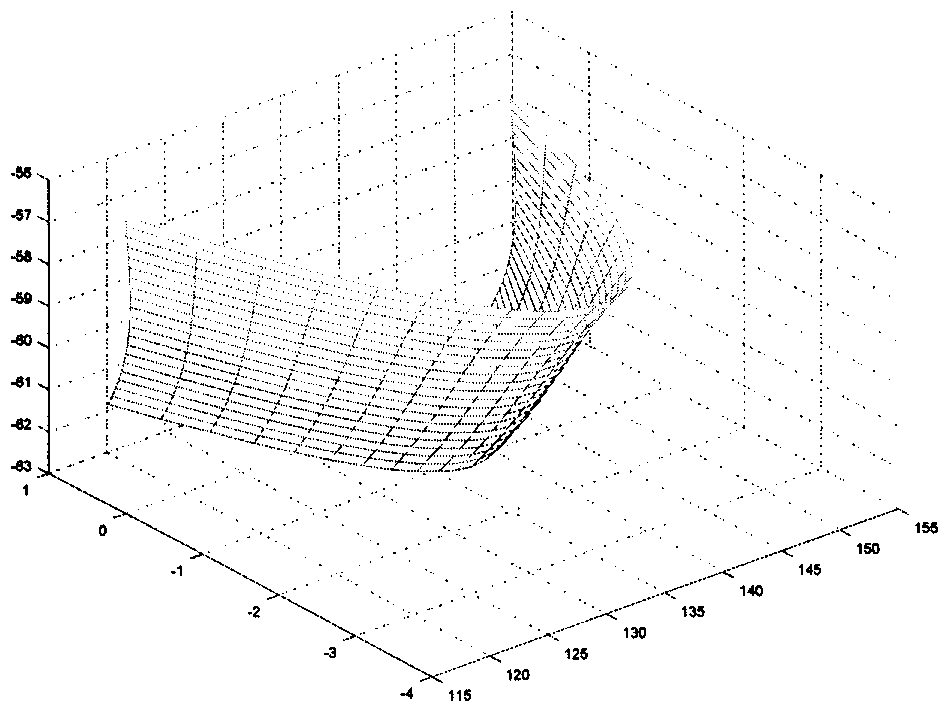

[0064] Module m=3; cylindrical gear tooth number ns=40; face gear tooth number n2=90; face gear inner radius R 2min =125; outer radius of face gear R 2max =145; rack arc tooth radius rG=60; arc tooth profile radius P=30; tooth top height ha=3; tooth bottom height hf=3.75; between the arc tooth coordinate origin Oa and the arc tooth profile center Vertical distance E=10; the horizontal distance between the origin Oa of the arc tooth coordinate and the center of the arc tooth profile F=25.92; α c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com