Patents

Literature

267results about How to "Stable and reliable transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

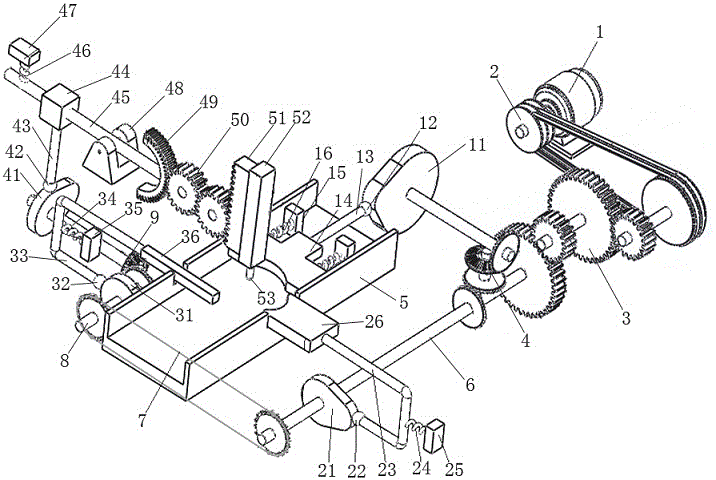

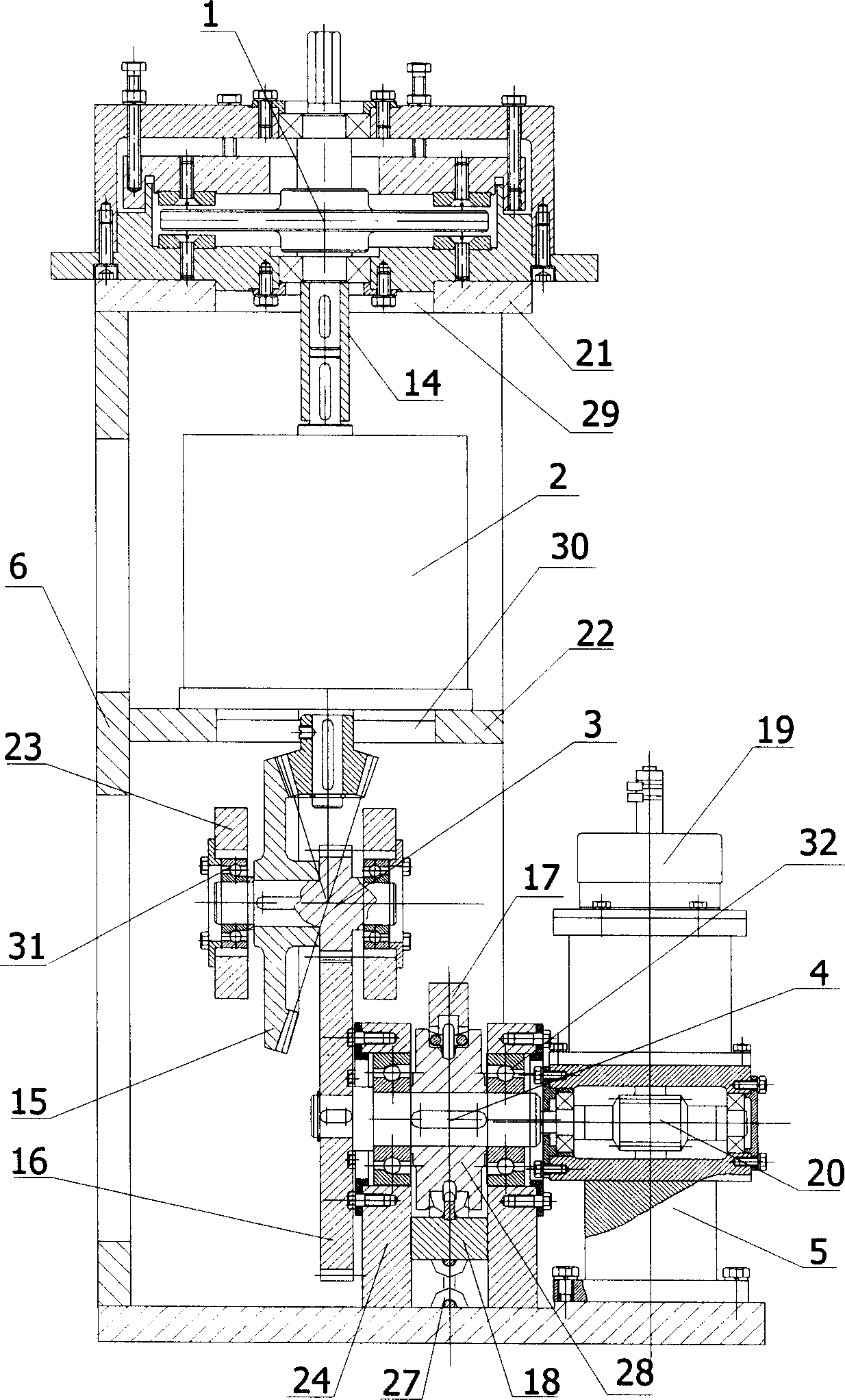

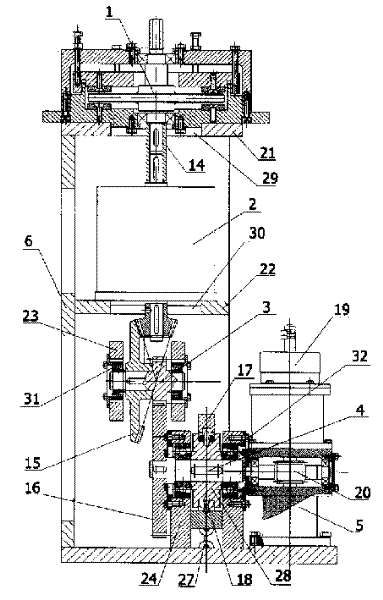

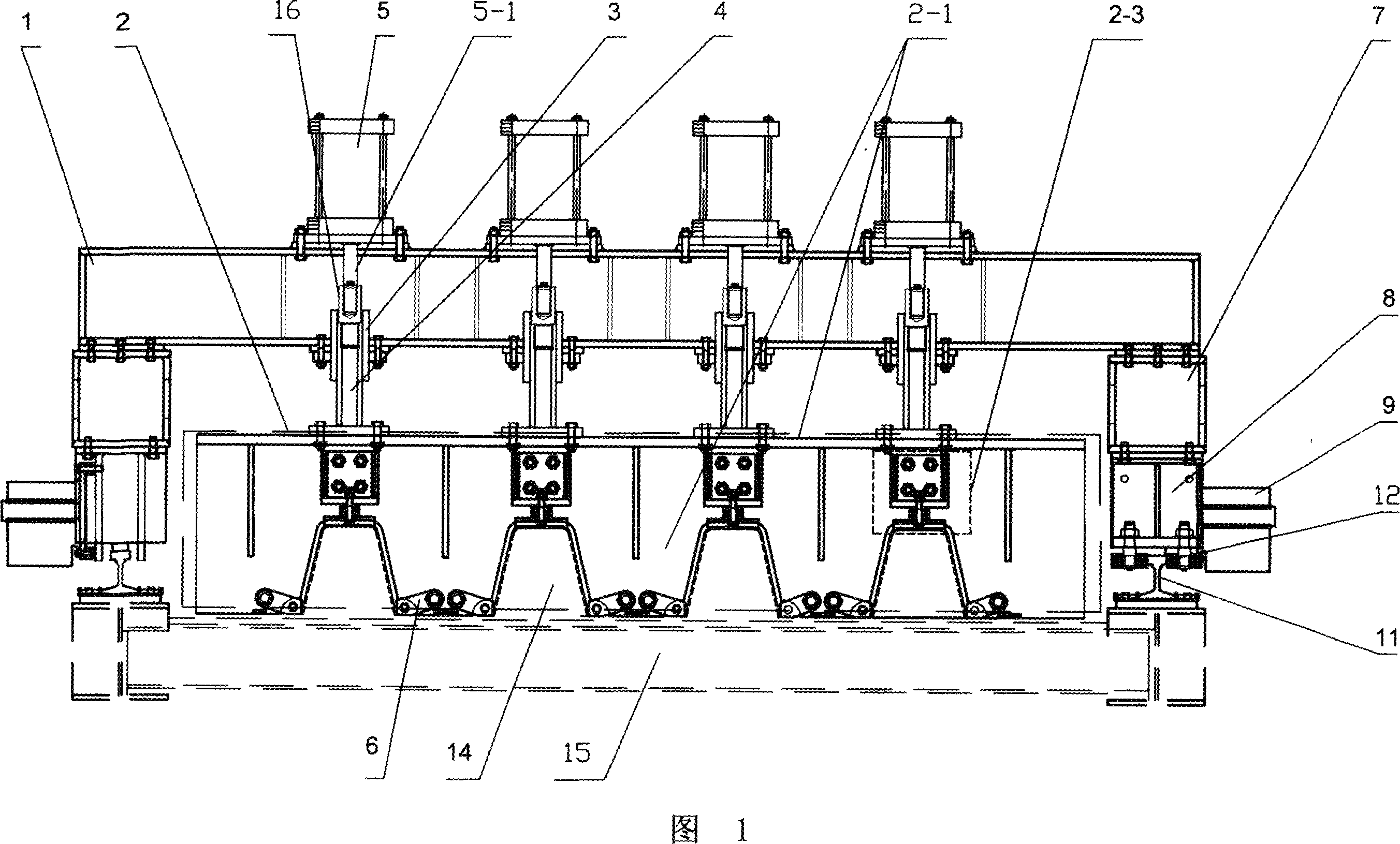

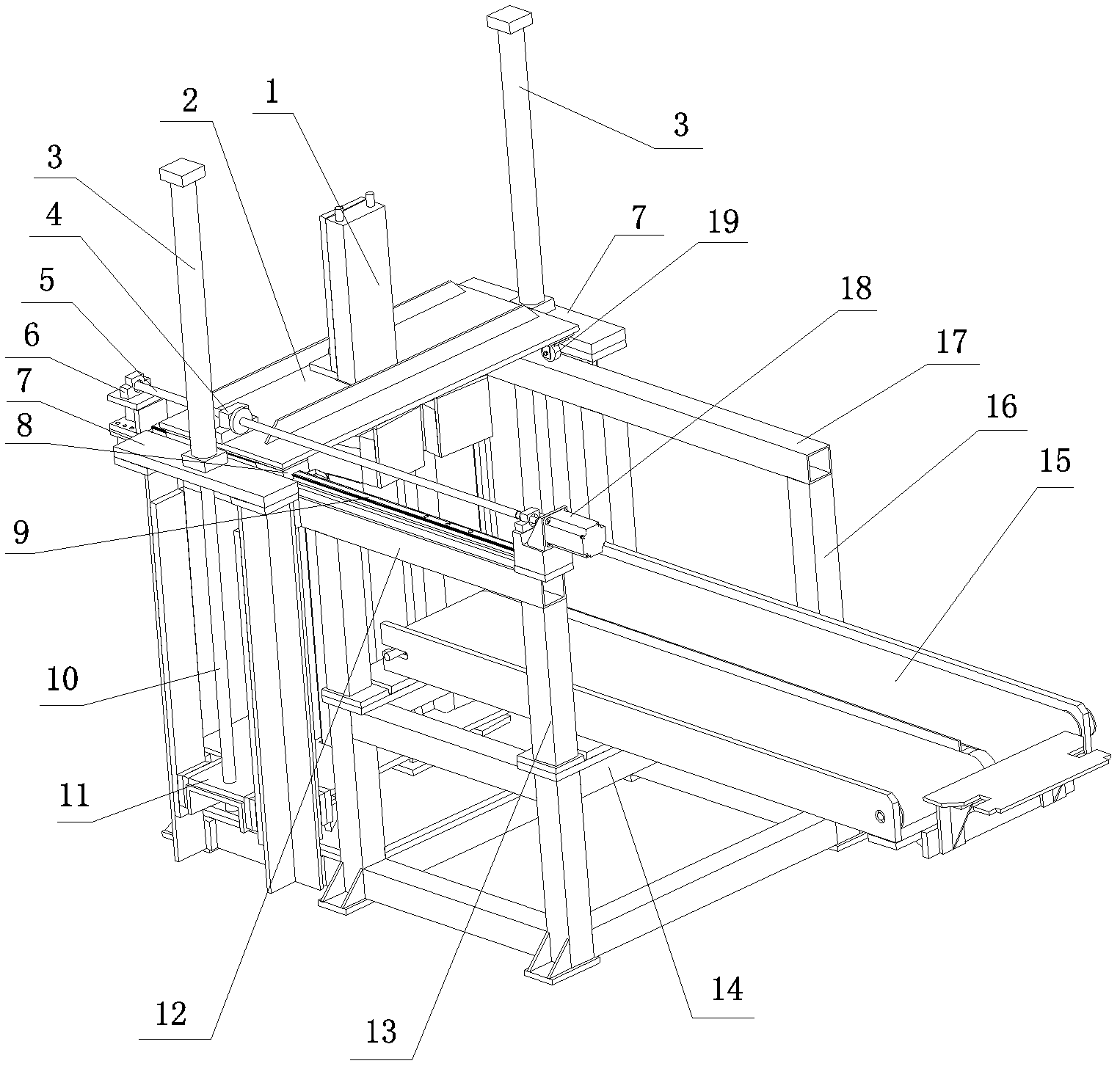

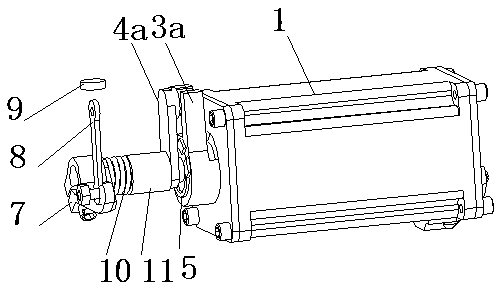

Semi-automatic drill lathe

InactiveCN104858477ASimple structureLow costFeeding apparatusPositioning apparatusLinear motionSemi automatic

The invention discloses a semi-automatic drill lathe which comprises a machine frame, a first spindle, a second spindle, a power system, a feeding mechanism, a positioning mechanism, a clamping mechanism and a knife feed mechanism, wherein the power system comprises a motor, a belt transmission unit and a gear transmission unit; power output by the motor is divided into two parts through the belt transmission unit and the gear transmission unit; one part of the power is transmitted to the feeding mechanism through a bevel gear, so as to control the feeding and withdrawing of the feeding mechanism; the other part of the power is transmitted to the first spindle; the clamping mechanism is controlled through the rotation of the cam driven by the first spindle; the first spindle transmits the power to the second spindle through chain transmission, so as to control the cam to rotate, and control the positioning mechanism to position a workpiece; a rack of the knife feed mechanism and a drill conduct reciprocating linear motion under the control of a gear. The semi-automatic drill lathe is simple in structure, compact in integral structure, stable in work, and worth of popularization.

Owner:HOHAI UNIV CHANGZHOU

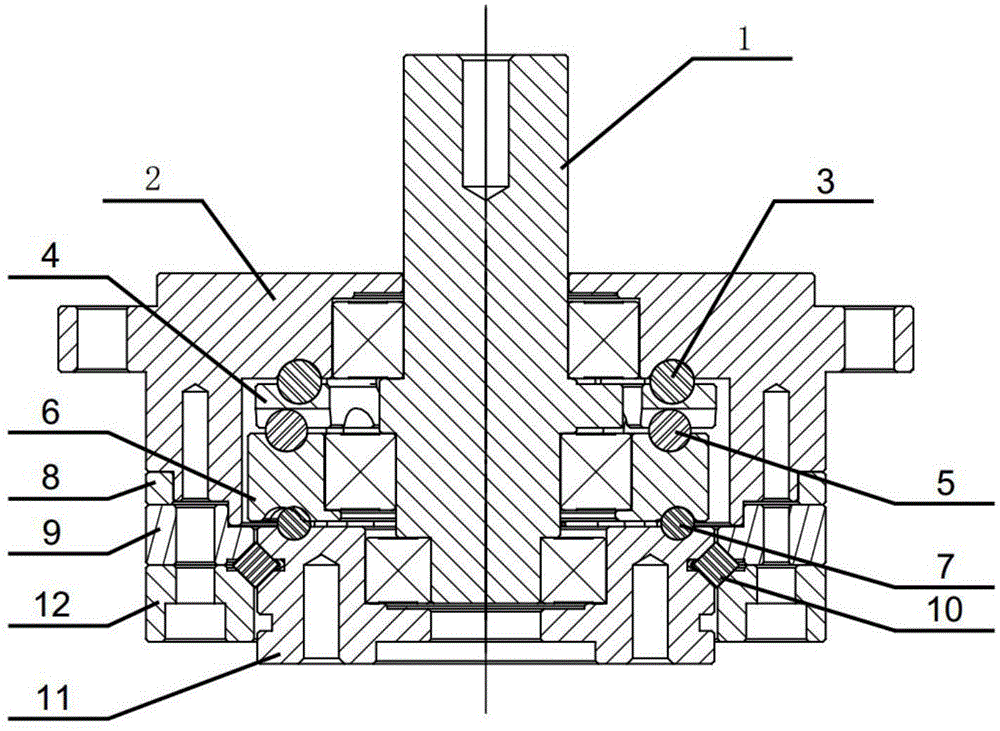

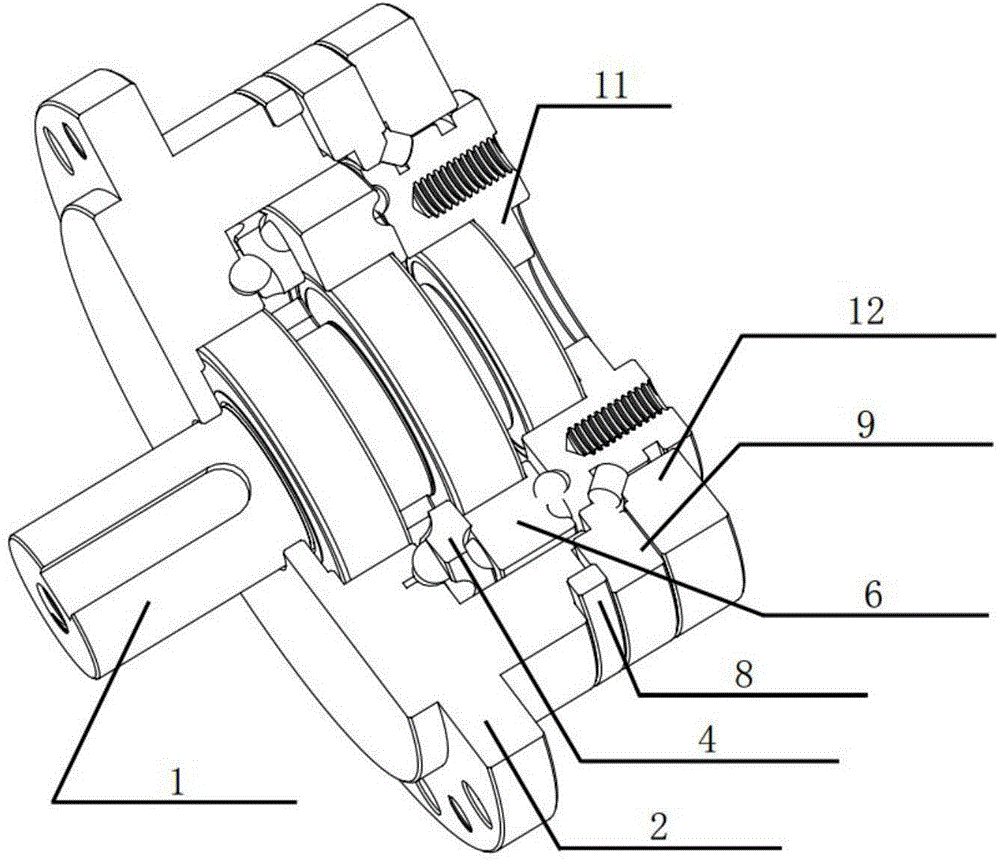

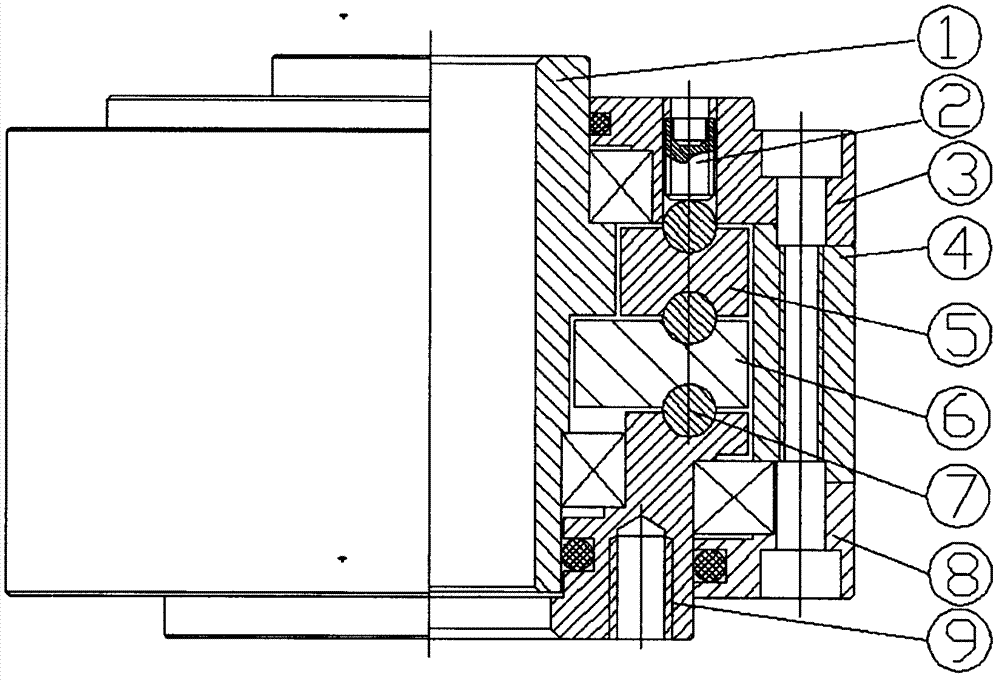

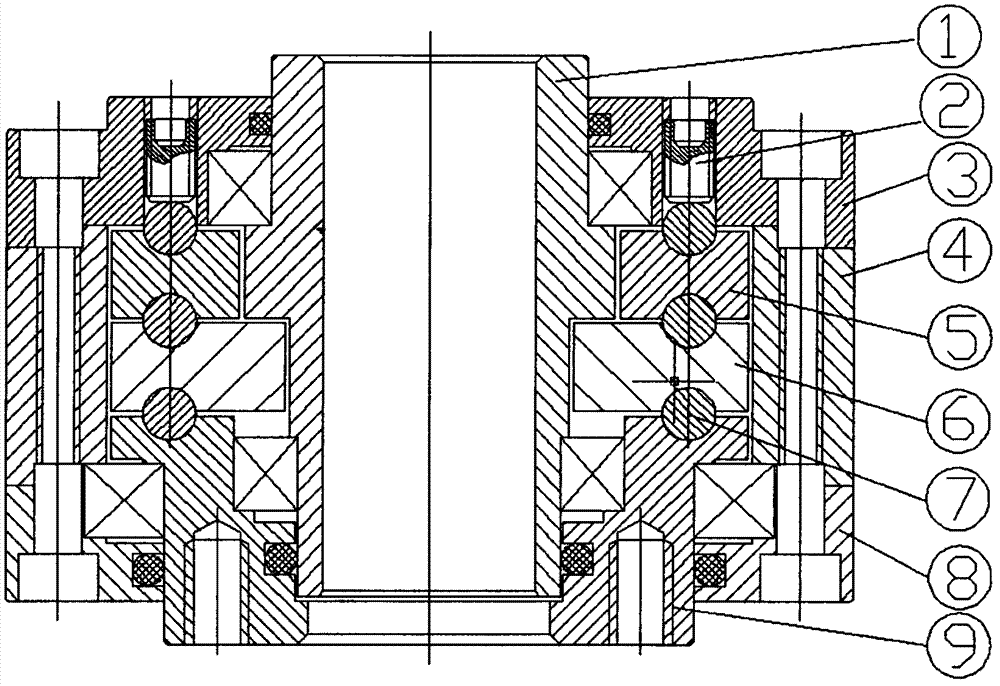

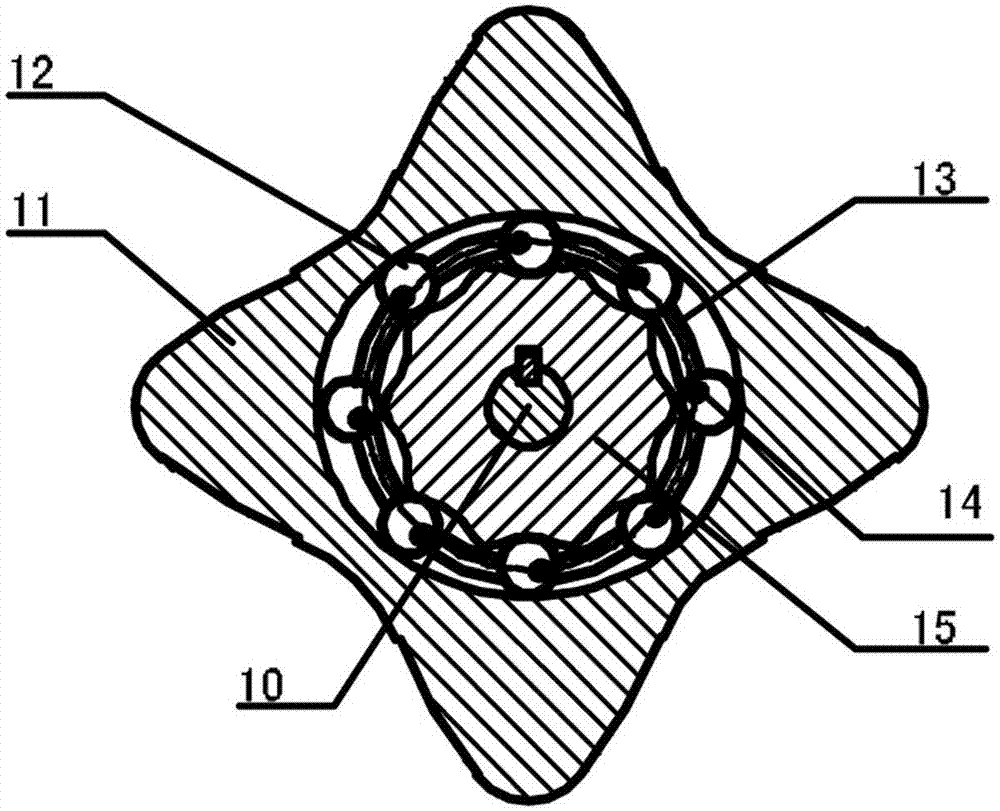

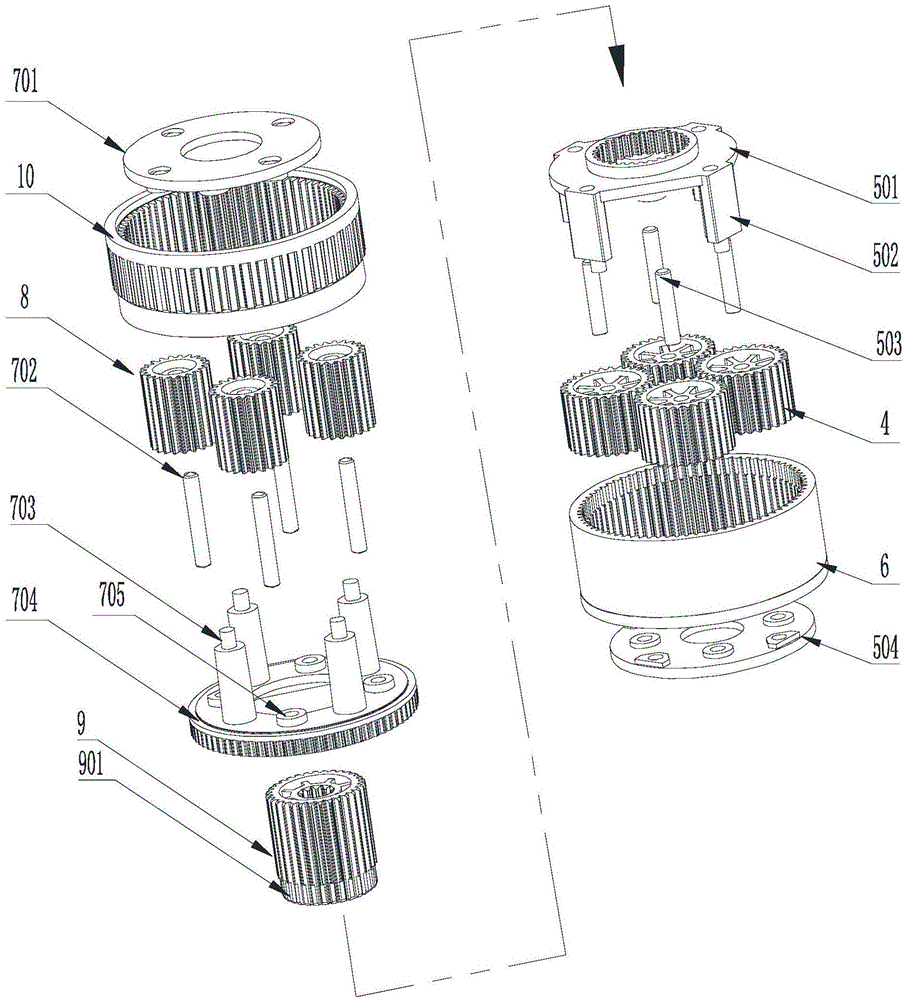

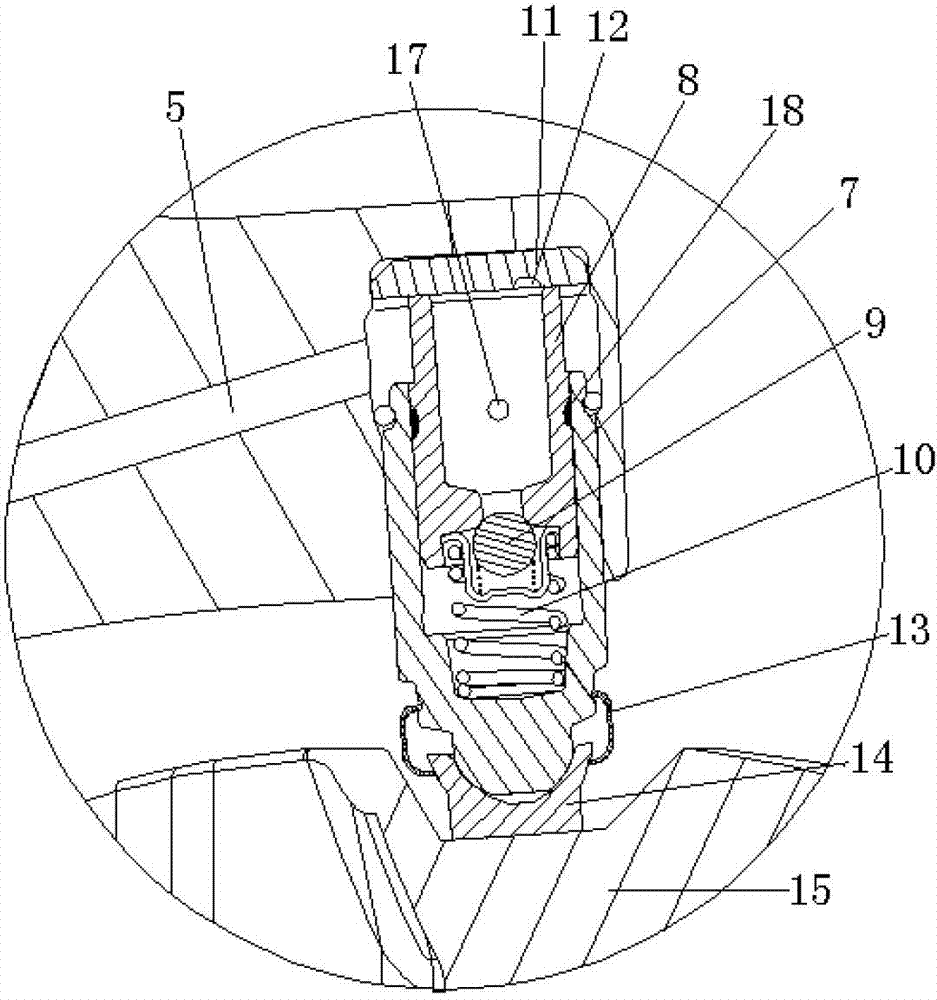

Crosshead shoes driving reducer for multi-joint robot

ActiveCN104964011ACompact structureReduce noiseGearing detailsFriction gearingsMechanical wearReducer

The invention relates to a crosshead shoes driving reducer for a multi-joint robot. The crosshead shoe driving reducer for the multi-joint robot comprises input shafts, output shafts, reducer bodies, crosshead shoes, transmission balls, track controllers and drive balls. The input shafts, the crosshead shoes, the track controllers and the output shaft are installed in the reducer bodies. Transmission tracks used for the installation of the transmission balls are arranged in the crosshead shoes. The transmission balls move in the transmission tracks to convey the movement of the input shafts to the track controllers. Moving track used for the installation of the drive balls are arranged on the lower surfaces of the track controllers. The track controllers adjust the output of the output shafts through the drive balls. According to the crosshead shoe driving reducer for the multi-joint robot, automatic adjustment for complete consistency of movement and eccentric magnitude of an eccentric shaft is achieved, the tracks of the transmission balls and the tracks of the track controllers of the reducer are completely consistent, the output of the reducer is stable, and the mechanical wear rate is low.

Owner:中正数据技术有限公司

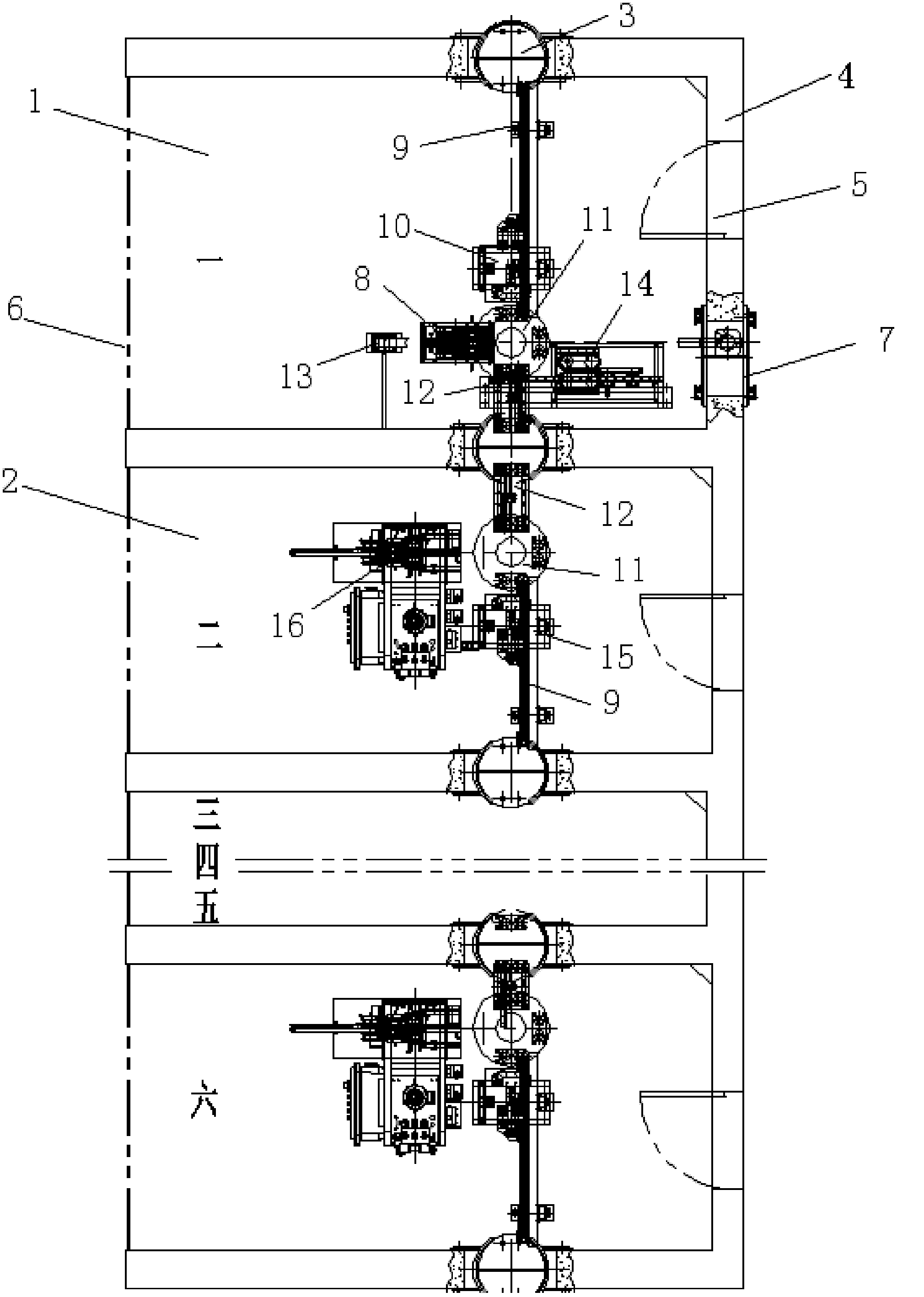

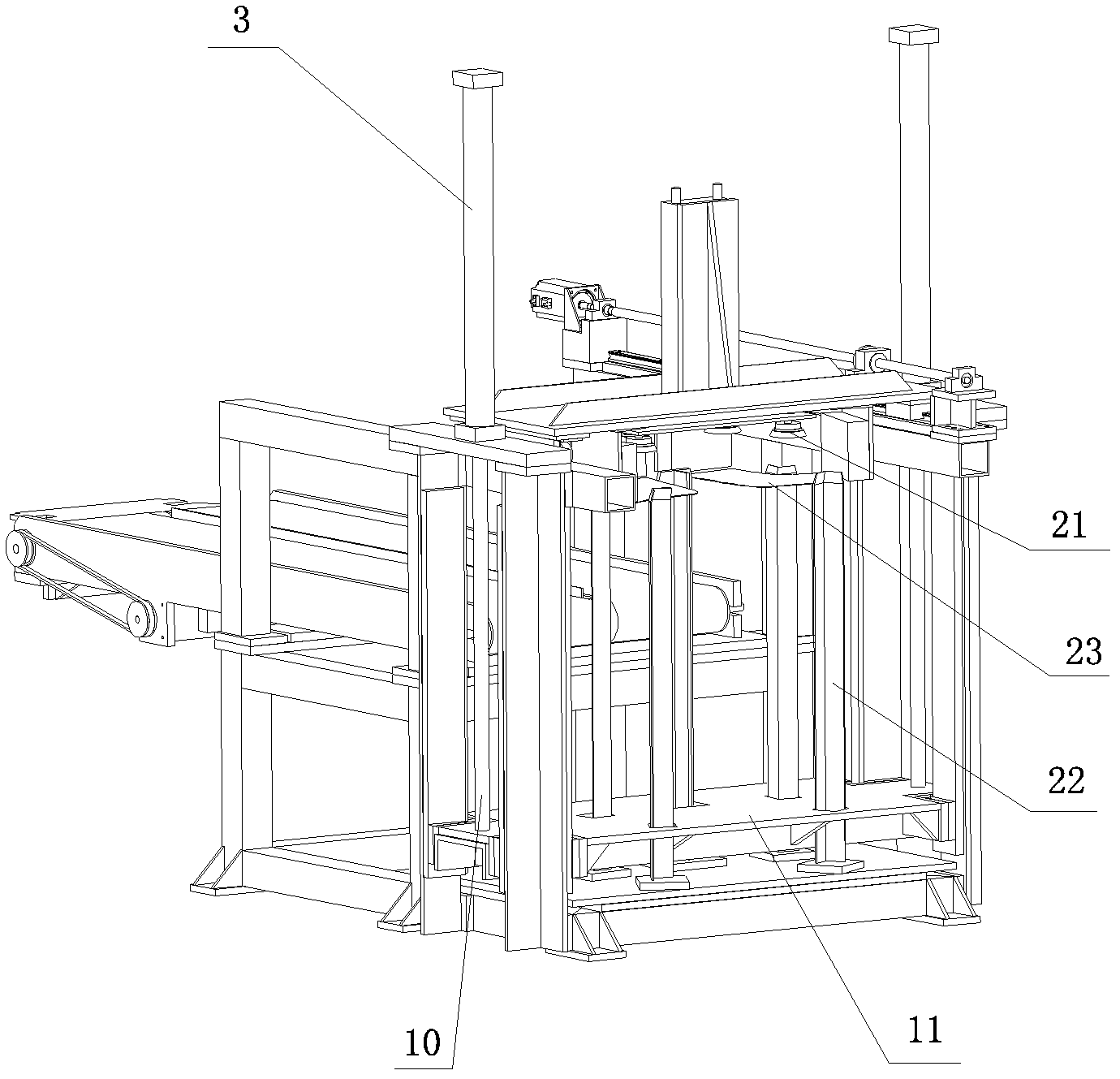

Three-level type automatic ammunition-filling ammunition-pressing production line

The invention relates to a three-level type automatic ammunition-filling ammunition-pressing production line, which comprises six anti-explosion chambers, wherein the six anti-explosion chambers are composed of three ammunition-filling chambers and three ammunition-pressing chambers which are staggered. Rotating anti-explosion doors are respectively arranged among the anti-explosion chambers and anti-explosion walls positioned at two ends of each anti-explosion chamber and outside each anti-explosion chamber. Each ammunition-filling chamber is provided with a flow line, and an ammunition conveying mechanical hand, an ammunition sleeve wiping machine, a multi-station turntable and a die delivery device are sequentially arranged on an inlet of the flow line. The other side of an ammunition-weighing ammunition-filling machine is provided with a connecting gate type anti-explosion door, and an ammunition outlet is located on an ammunition barrel conveying device positioned above the ammunition-weighing ammunition-filling machine. The ammunition-weighing ammunition-filling machine is arranged on one side of the multi-station turntable, and an ammunition-flushing wiping device is arranged on the other side of the multi-station turntable. The inside of each ammunition-pressing chamber is also provided with a flow line, and a die delivery device which is the same as the die delivery device in each ammunition-filling chamber, a multi-station turntable which is the same as the multi-station turntable in each ammunition-filling chamber, an ammunition sleeve lifting device and an ammunition conveying mechanical hand which is the same as the ammunition conveying mechanical hand in each ammunition-filling chamber are sequentially arranged on the flow line. A pressing machine and an auxiliary device are arranged on one side of each multi-station turntable. The three-level type automatic ammunition-filling ammunition-pressing production line can be widely used for production of dangerous articles which are inflammable and explosive.

Owner:廊坊智通机器人系统有限公司

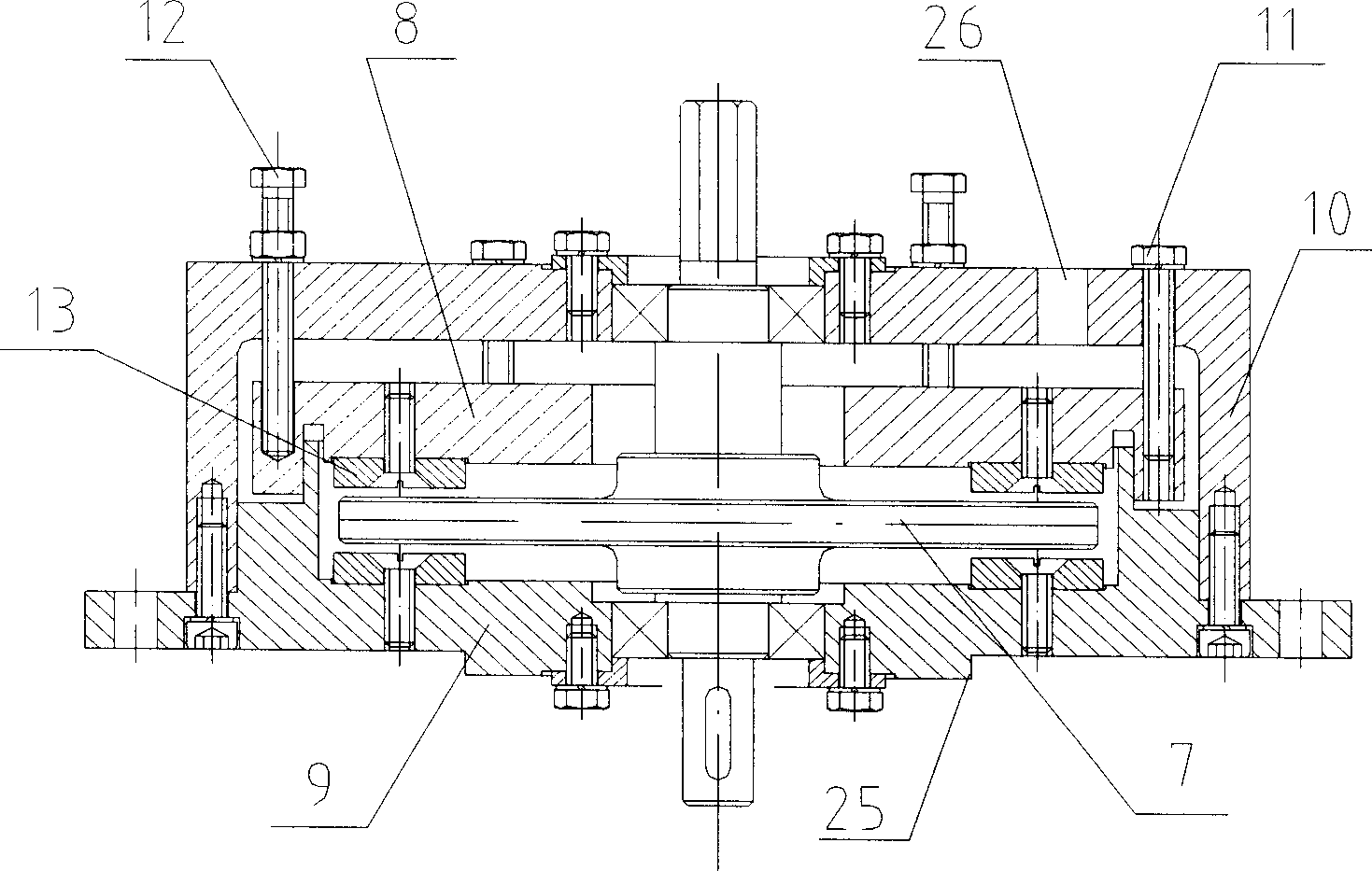

Reactor control-rod driving mechanism with adjustable magnetic damper

InactiveCN1405788ADrive chain shortIncrease radial sizeNuclear energy generationNuclear reaction controlDamping functionElectric machine

The drive mechanism comprises the drive mechanism bracket, the driving chain, the system for measuring the position of the rod and the magnetic damper. The driving chain consists of the motor, the gear reduction mechanism and the chain wheel. The magnetic champer comprises the moving disc, the upper and lower magnetic discs and the bearing seat. Since playing the damping function only without the driving function as well as the adjustable structure, the magnetic damper provides the features of shorter driving chain, smooth reliable driving and large enough brake moment. Said mechanism reduces the influence of the precision of manufacturing and assembling the control rod driving mechanism on the rod drop as well as eliminates the 'scraping' between the moving disc and the magnetic disc.

Owner:TSINGHUA UNIV

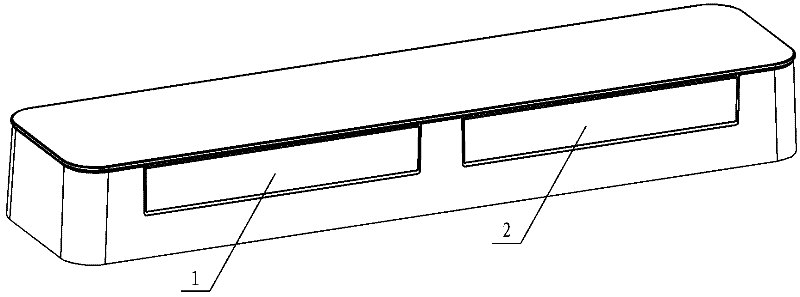

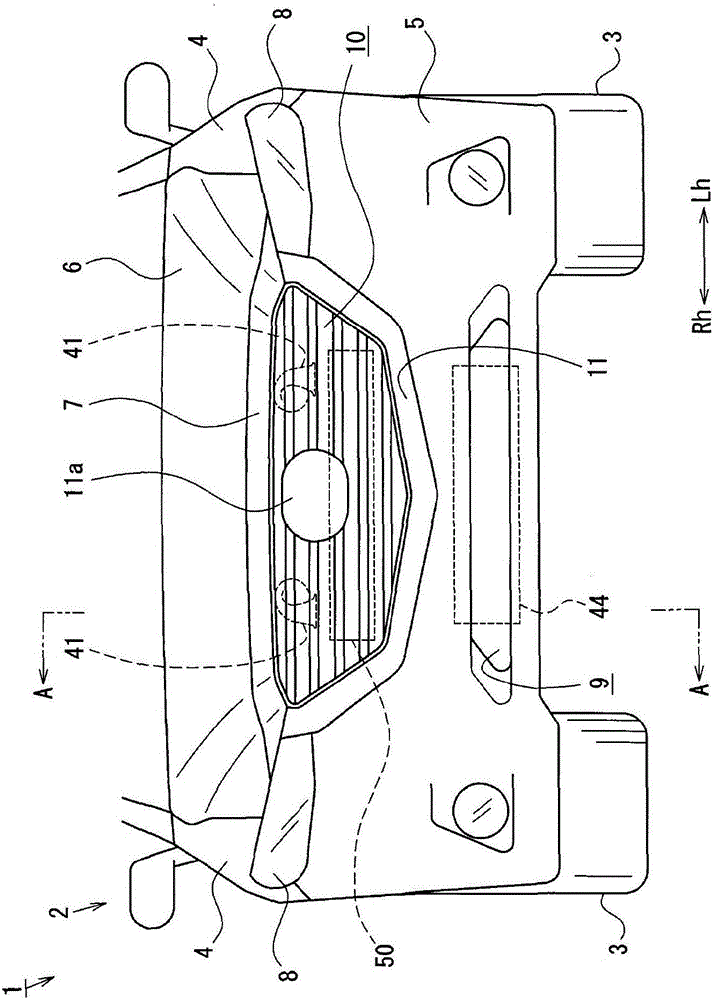

Air outlet device of air conditioner indoor machine

ActiveCN102345924ASave spaceFlexible operationDucting arrangementsAir-flow control membersDrive motorAerospace engineering

The invention discloses an air outlet device of an air conditioner indoor machine, which comprises a first air outlet and a second air outlet that are arranged in an air outlet frame, wherein the first air outlet and the second air outlet are internally respectively provided with a wind deflector and a wind deflection blade, and also internally respectively provided with a compound swing drive mechanism, each compound swing wind drive mechanism comprises a chamber enclosed by a drive upper cover and a drive lower cover, the chamber is internally provided with a first gear and a transmission rack, the first gear is meshed with one end of the transmission rack, the first gear is connected with an output shaft of a first drive motor used as left and right swing wind, a second gear is sleeved on the middle of the transmission rack, a third gear is meshed with the second gear, and a flat shaft hole matched with an output shaft of a second drive motor used as up and down swing wind is arranged on a middle shaft of the third gear. The air outlet device has the characteristics of simple and reasonable structure, small volume, easiness in assembly, wider swing wind range and more selectable swing wind modes.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

BS speed reducer

InactiveCN102767600ACompact structureReduce weightGearing detailsFriction gearingsLow noiseReliable transmission

The invention discloses a BS speed reducer, comprising an input shaft, an input shaft cover, a gap adjusting screw, a machine body, a fixing plate, a driving plate, a rolling bead, an output shaft and an output shaft cover. The BS speed reducer is characterized in that the machine body is internally provided with the input shaft, the fixing plate, the driving plate and the output shaft; S-shaped cycloid grooves are arranged on the two side faces of the fixing plate, and the driving plate is matched with S-shaped cycloid grooves which are arranged at one side of each of the input shaft cover and the output shaft; the input shaft cover is connected with the fixing plate; rolling beads are placed into the S-shaped cycloid grooves between the input shaft cover and the fixing plate, between the fixing plate and the driving plate, as well as between the driving plate and the output shaft cover; and the gap adjusting screw is arranged on the input shaft cover. The speed reducer has the advantages of compact structure, small volume, light weight, zero gap, low noises, large transmission power and stable and reliable transmission; and the transmission efficiency can reach to 88-93%. The speed reducer adopts two groups of S-shaped cycloid differential motions to realize the speed reduction and can completely change the speed reducing principle of the traditional speed change which utilizes a gear or a worm wheel tooth number to change the speed.

Owner:GUANGXI YULIN ZHENGFANG MACHINERY

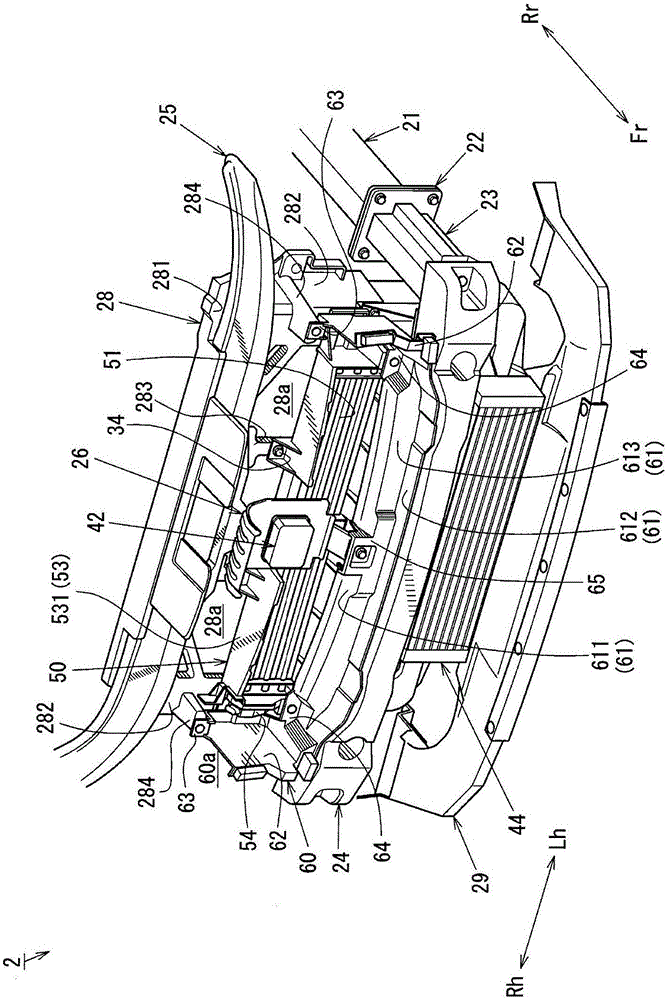

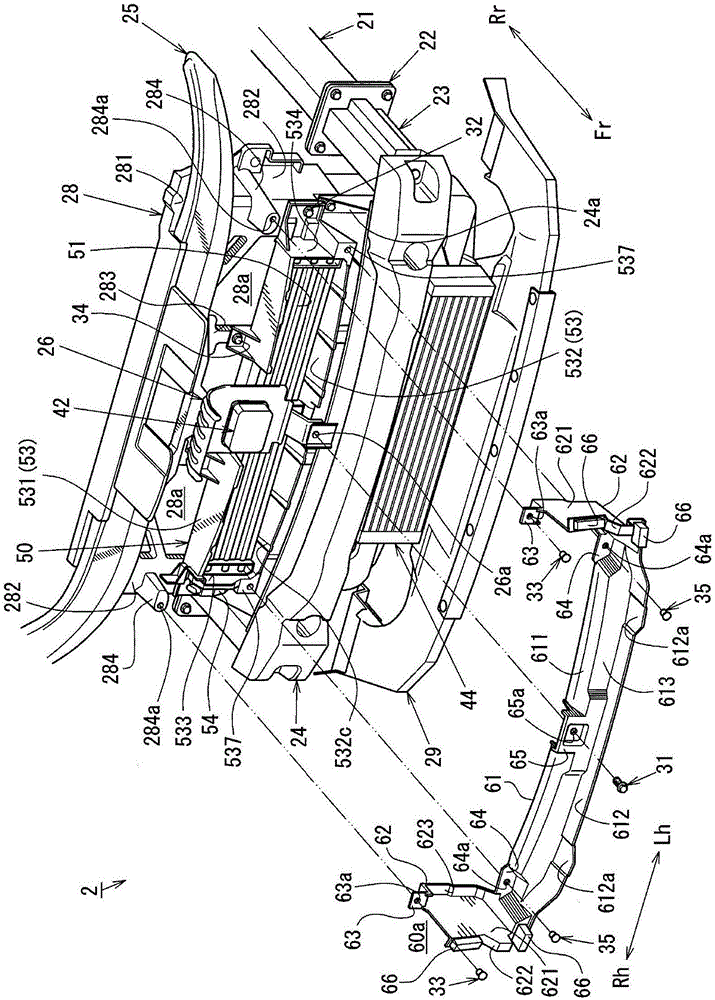

Front air-rectifying structure of automotive vehicle

ActiveCN106467016ADoes not impair air guiding performanceSuppresses vibration transmissionComponent optimizationRadiatorsWindow shutterMechanical engineering

Owner:MAZDA MOTOR CORP

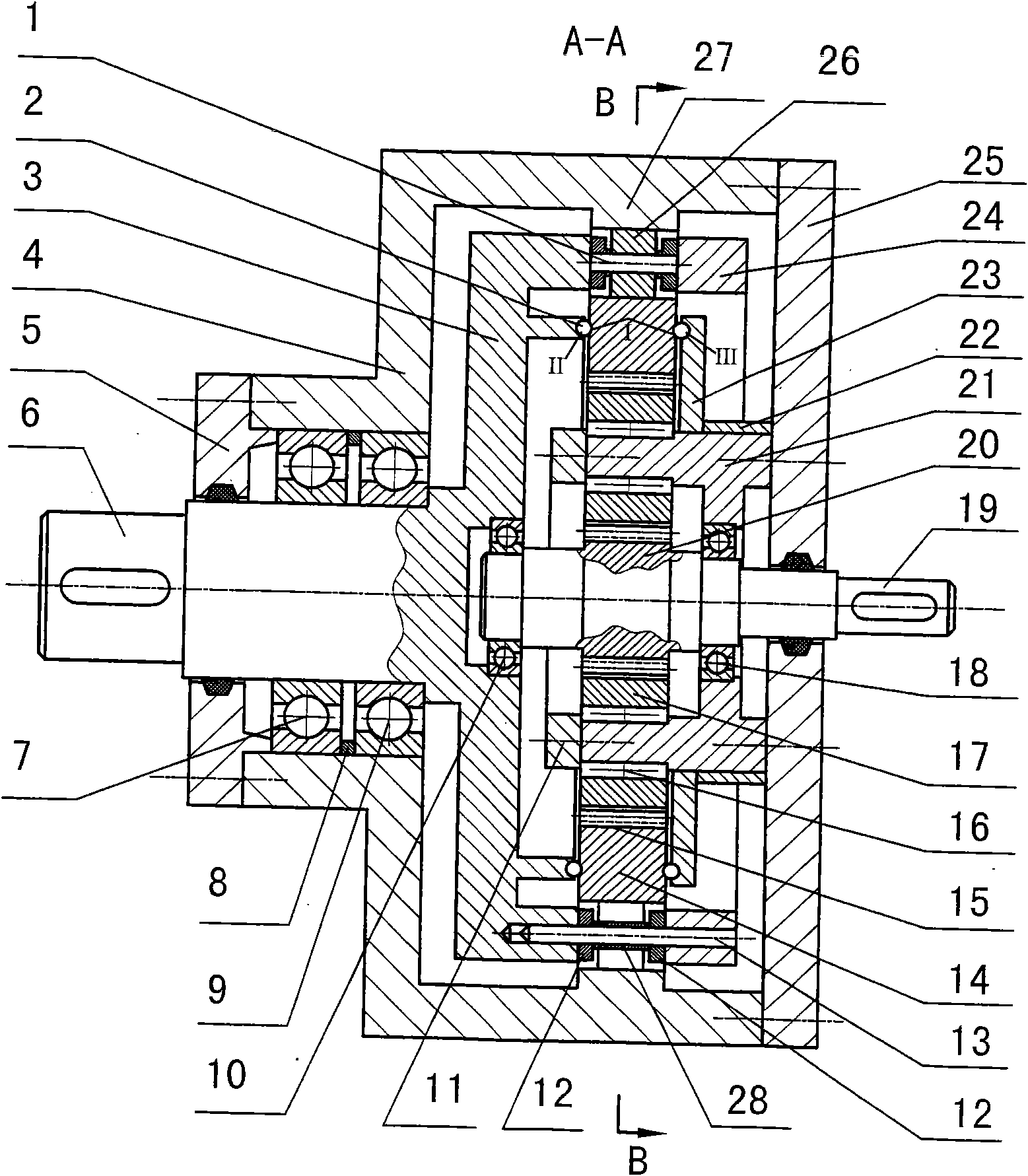

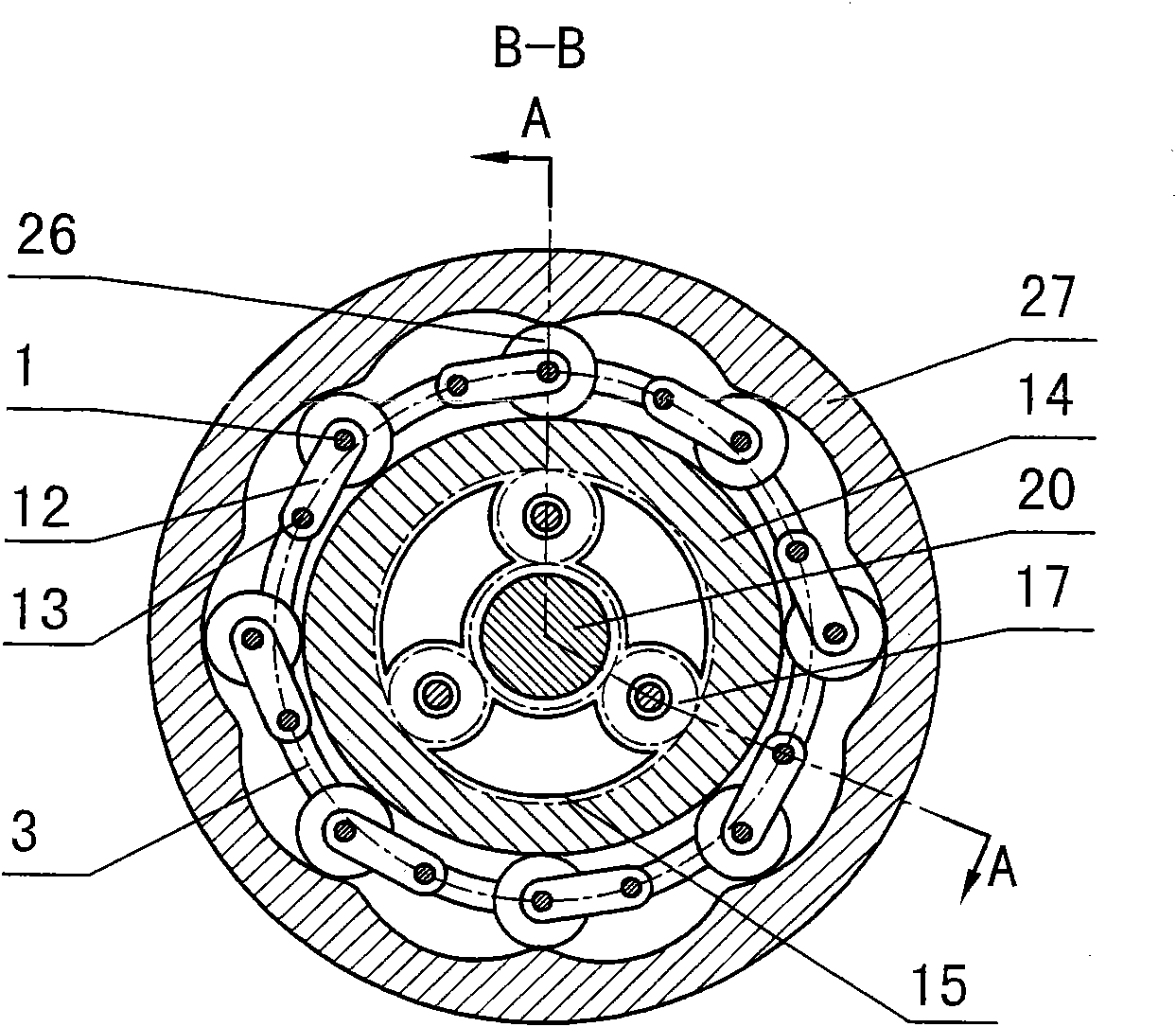

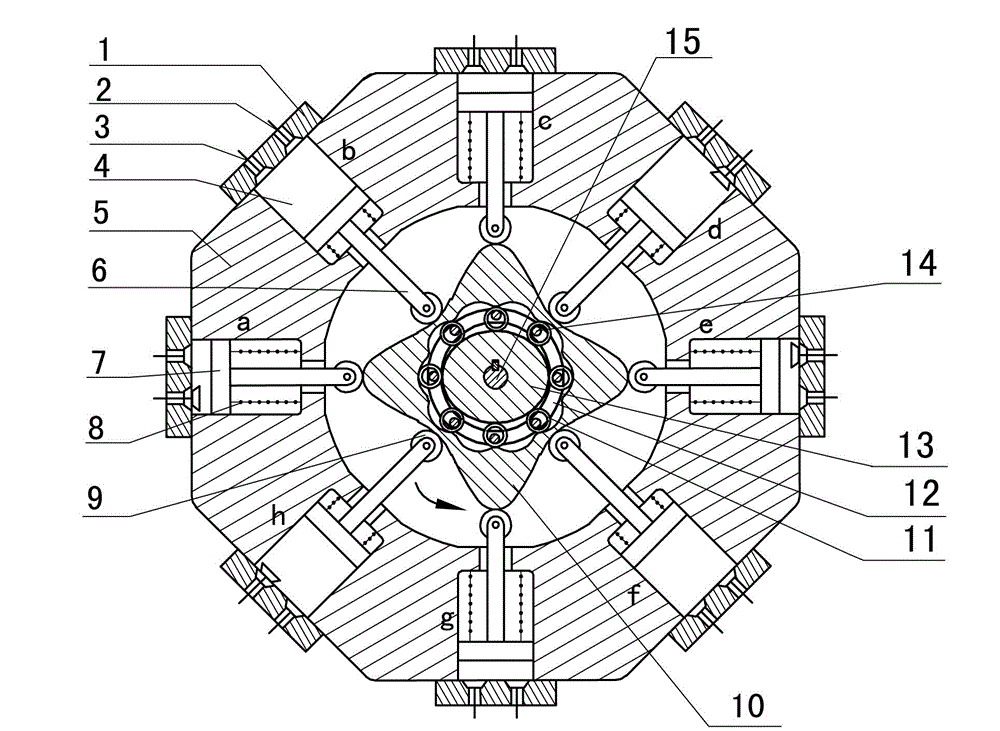

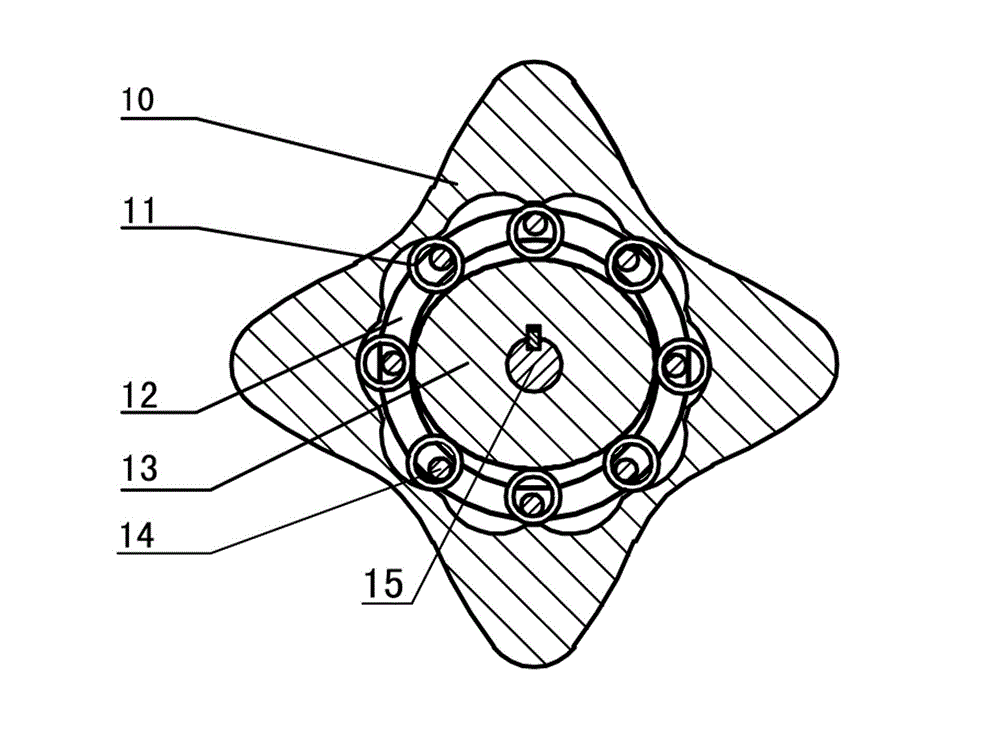

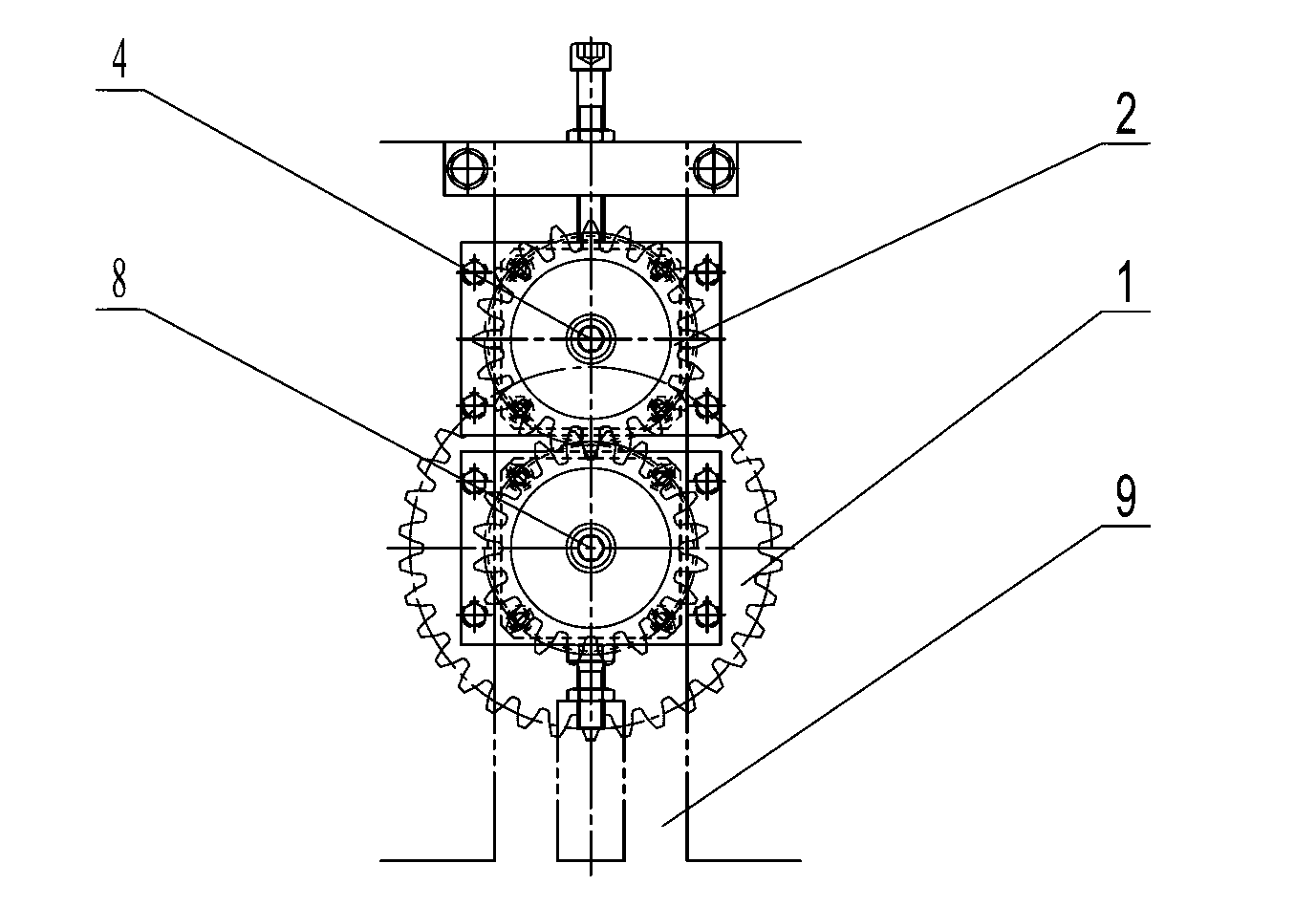

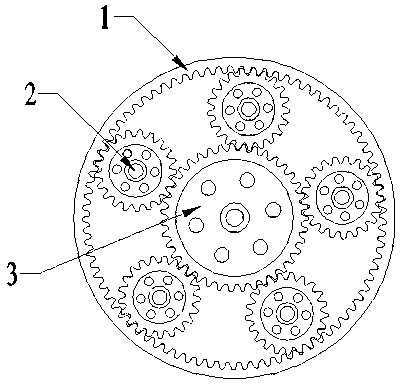

Two-phase shock wave swing link movable-teeth compound transmission speed reducer

The invention discloses a two-phase shock wave swing link movable-teeth compound transmission speed reducer and relates to the technical field of mechanical transmission. The compound transmission speed reducer mainly comprises a two-phase shock wave device, movable teeth, a swing link, a pin shaft, a movable-teeth frame, a central wheel and a fixed axis gear train which is embedded into the shock wave device. The exterior of the shock wave device has a cam profile and the interior of the shock wave device has an inner gear ring profile; an input gear is engaged with a pinion and the pinion is engaged with the inner gear ring so as to form the fixed axis gear train; the input gear and an input shaft are integrated; the rotation of the input gear is decelerated through the fixed axis gear train and drives the shock wave device to rotate; the shock wave device and the movable teeth are in rolling contact engagement, so that the movable teeth swing along with the swing link and moves along the tooth profile of the central wheel simultaneously; and the shock wave device and the central wheel coact to make the movable teeth drive the movable-teeth frame to rotate and output power through the swing link. By setting pre-deceleration in swing link movable-teeth transmission, the transmission ratio is increased, and the problem of over-high temperature rise of movable-teeth transmission is also solved; and the speed reducer has the advantages of novel and compact structure, high bearing capacity, self-balancing stress and the like, and is suitable for decelerating transmission between two coaxial shafts.

Owner:SICHUAN UNIV

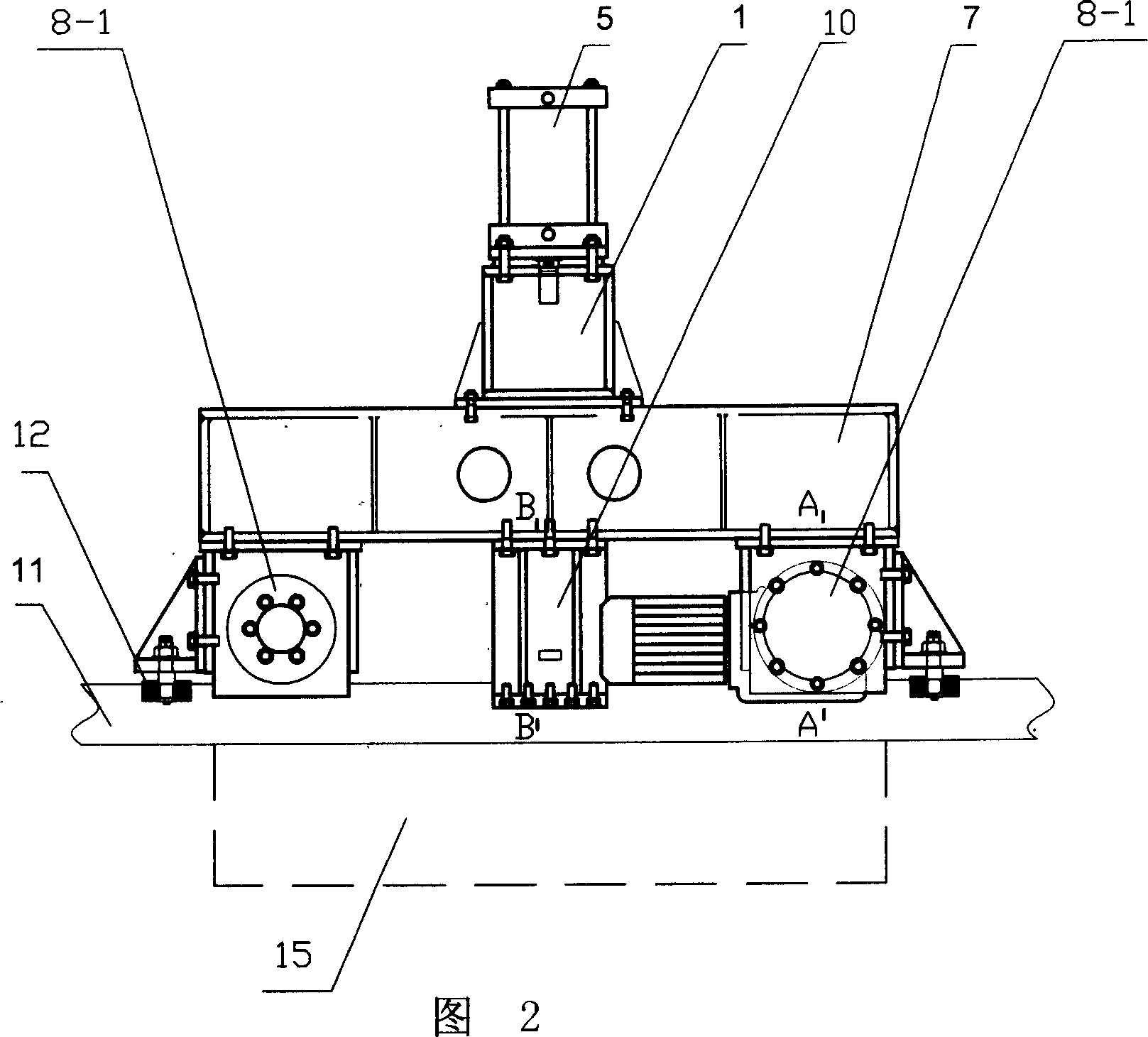

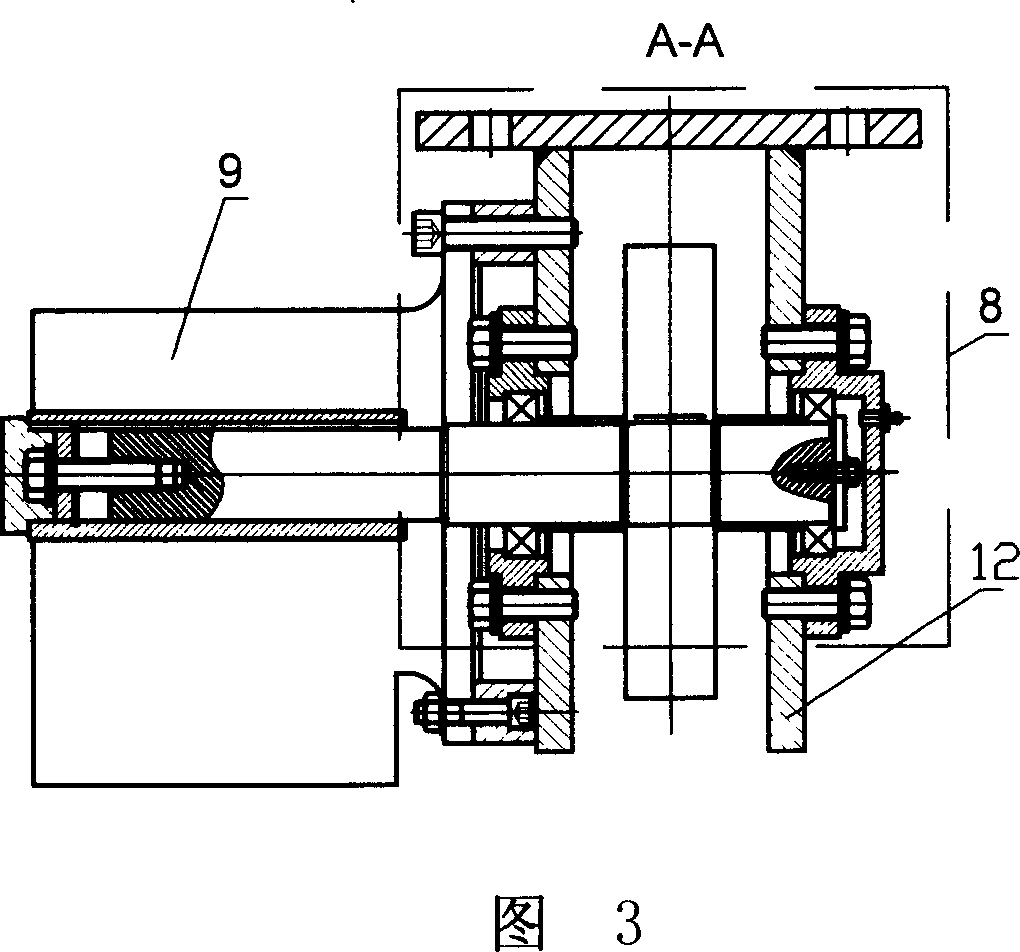

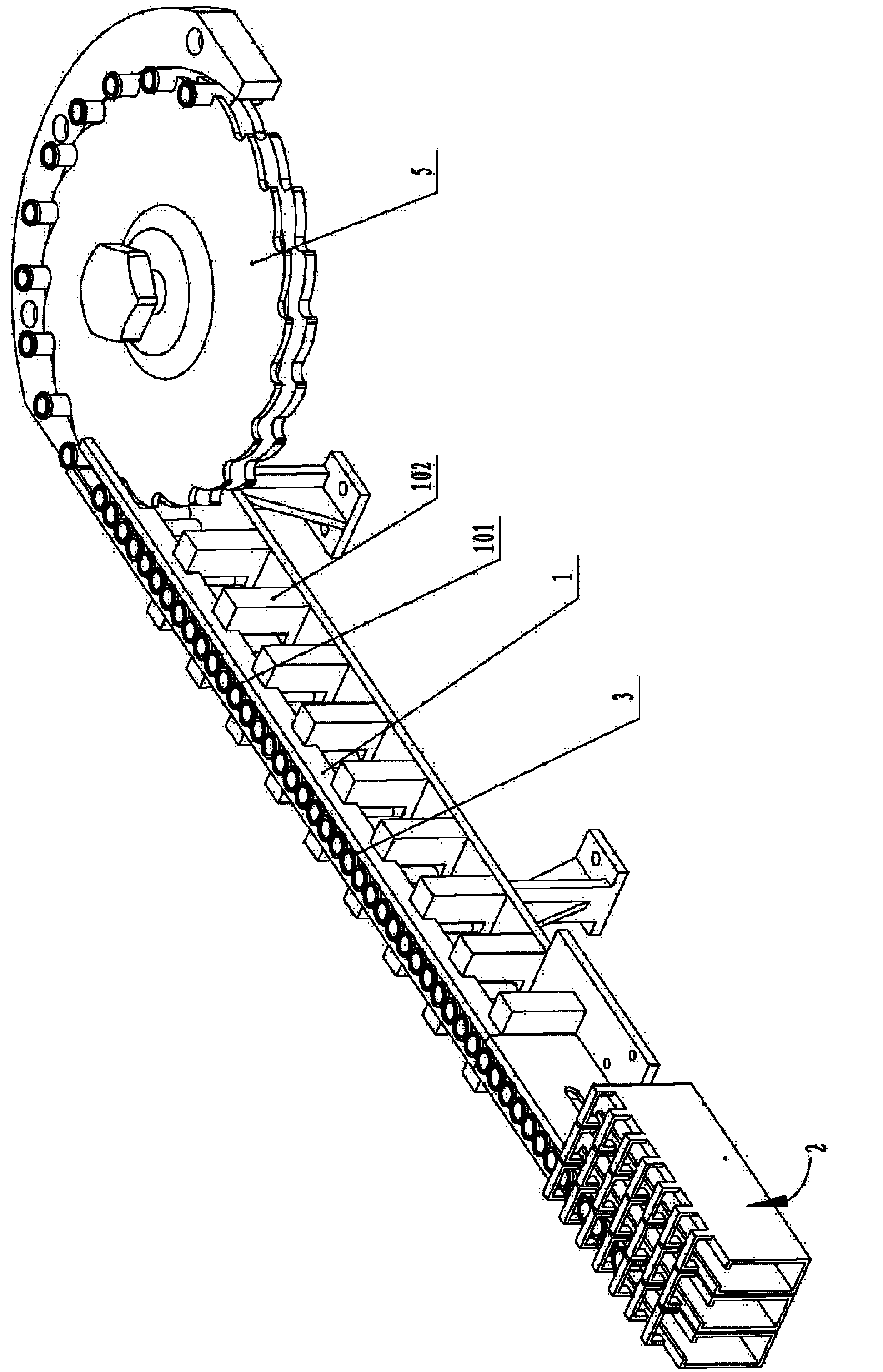

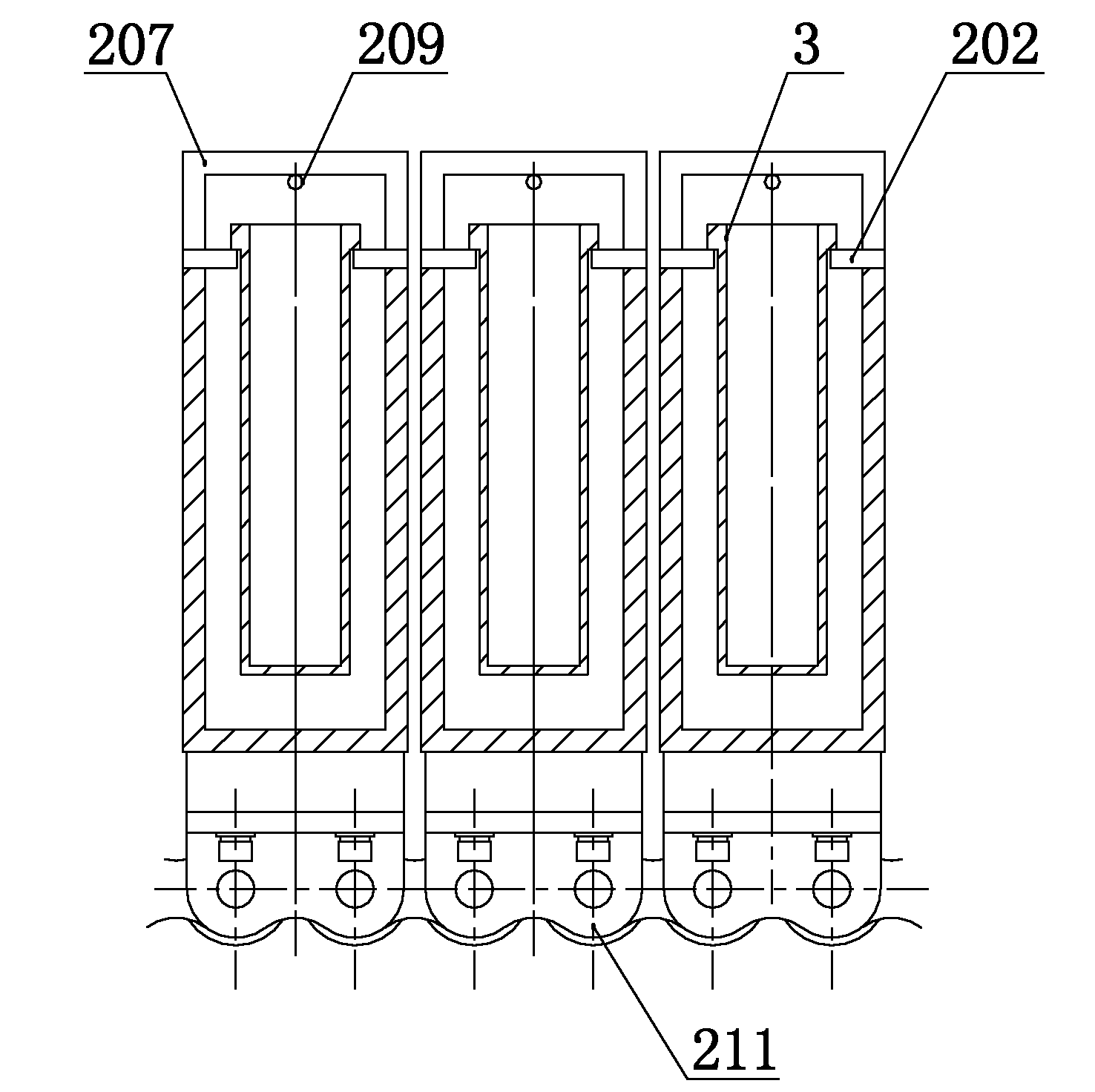

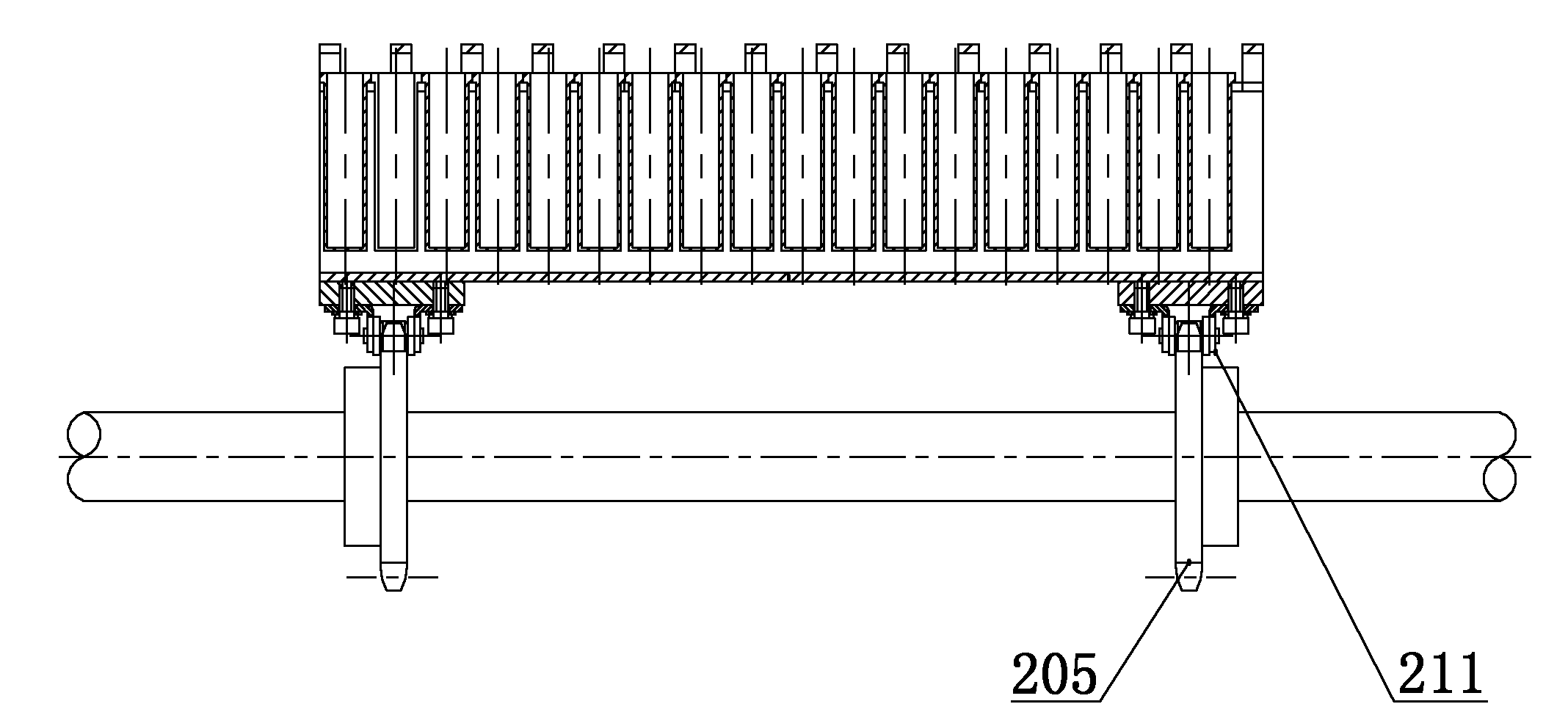

Electric pneumatic type machine for assembling U-shaped ribs of plate units

ActiveCN1947926AReduce or eliminate direct effectsExtended service lifeMetal working apparatusEngineeringPiston rod

An electrically pneumatic assembling machine for assembling the U-shaped rib onto the unit plate used for the steel structure of bridge is composed of a transverse beam, a formwork module under said transverse beam, the guide sleeves fixed to said transverse beam, the guide rods in said guide sleeves and connected between formwork module and piston rod of cylinder, and the cylinders fixed to said transverse beam.

Owner:WUCHUAN HEAVY ENG

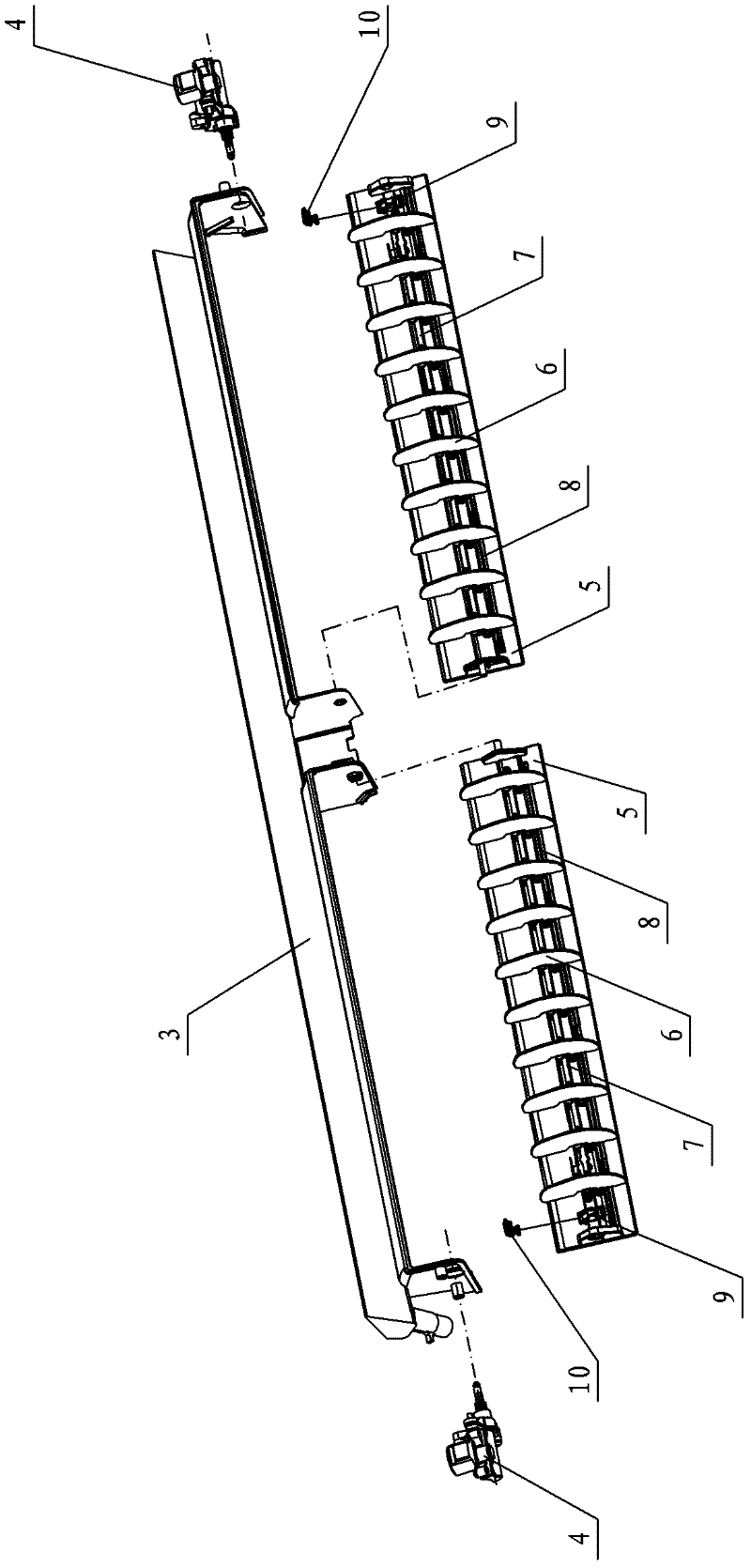

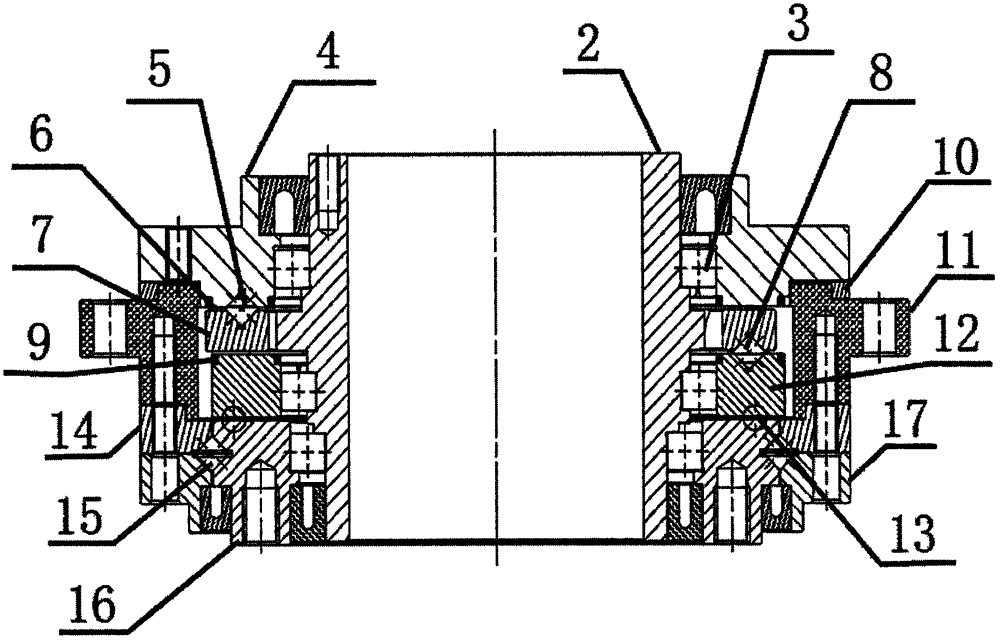

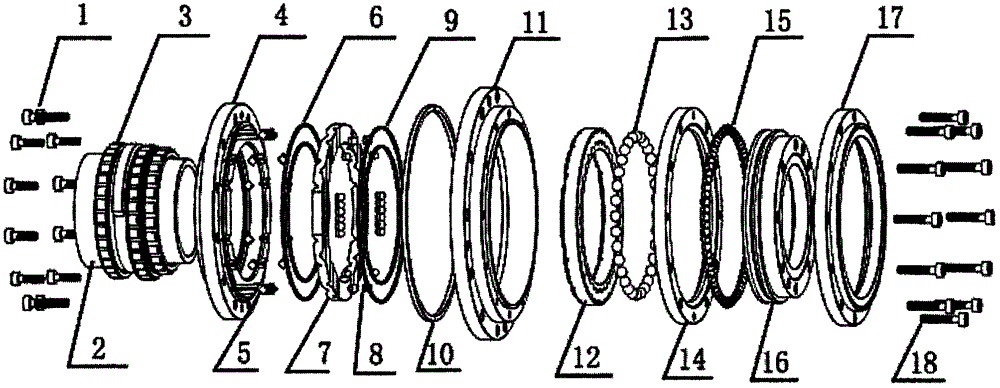

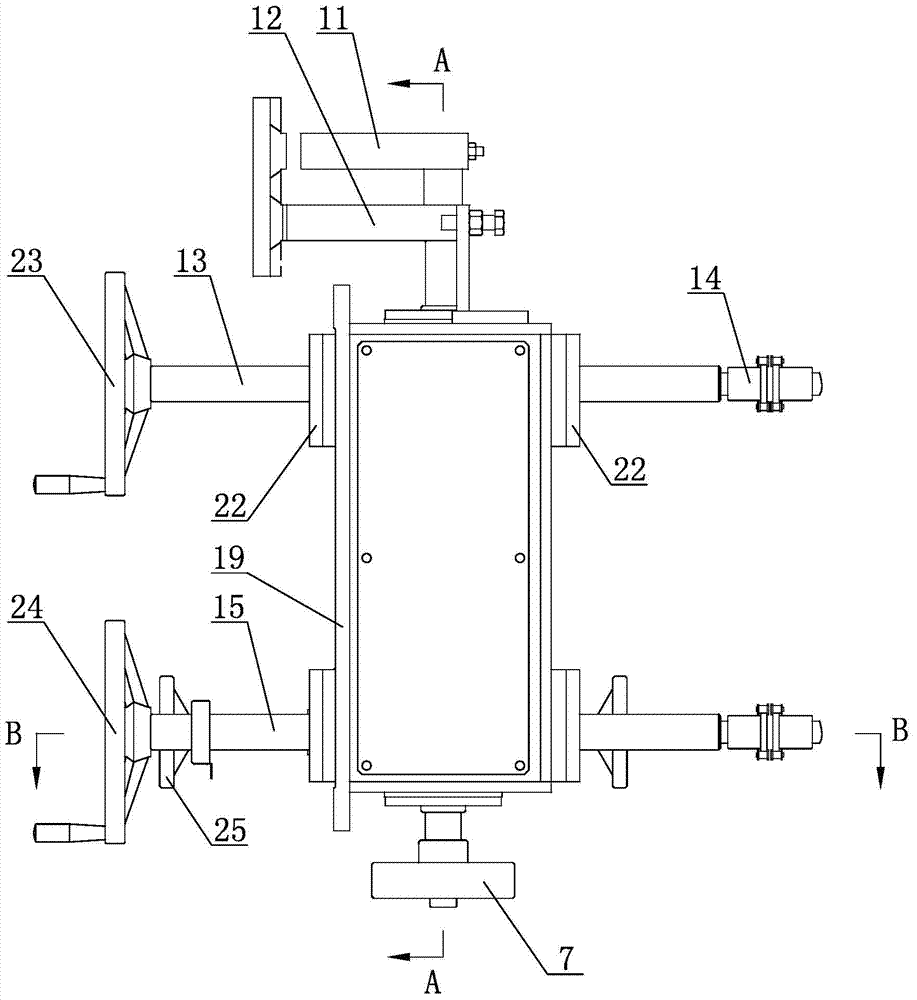

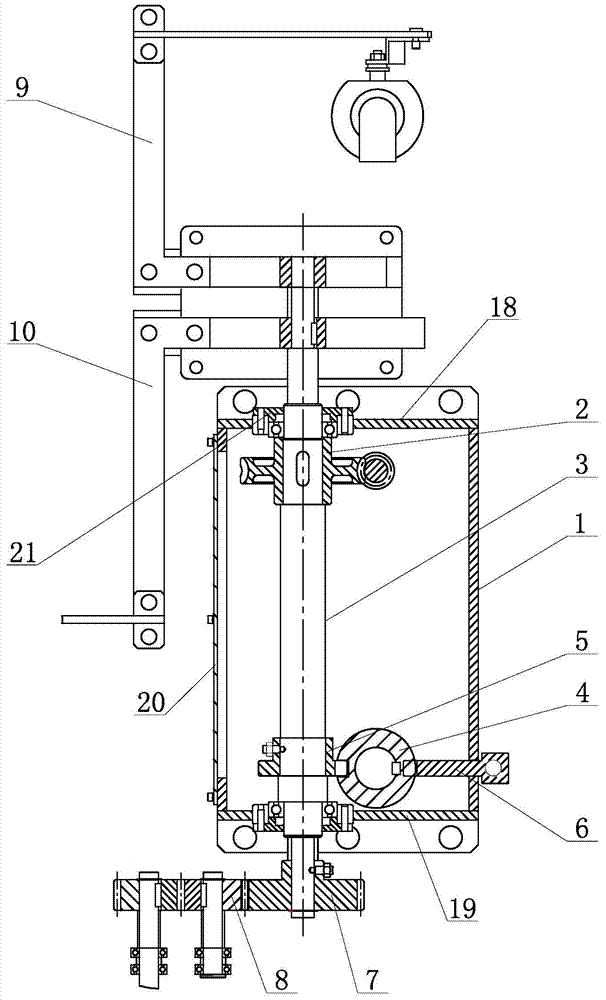

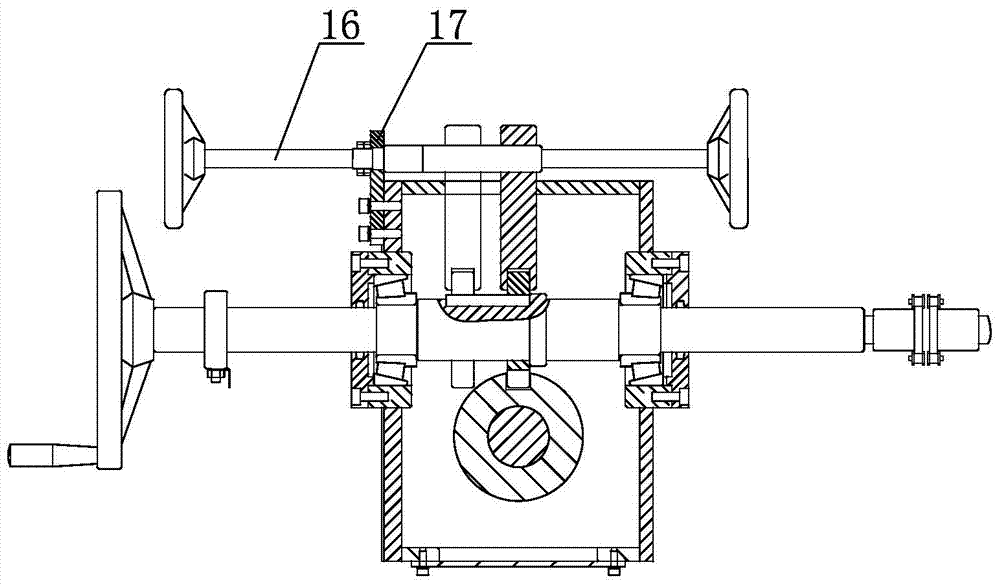

V-shaped slot follower plate of speed reducer

ActiveCN106438889AStable and reliable transmissionCompact structureFriction gearingsLow noiseReliable transmission

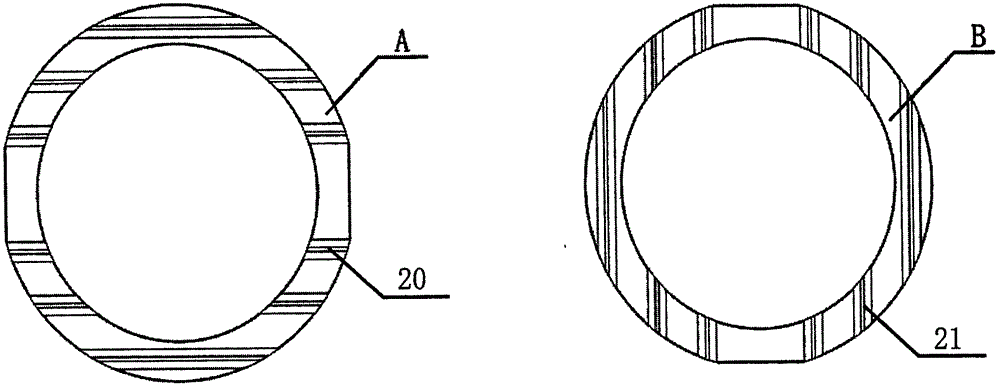

The invention relates to a V-shaped slot follower plate of a speed reducer, and the V-shaped slot follower plate is applied to joint robots. The V-shaped slot follower plate comprises a follower plate body (7), wherein a transverse V-shaped rail (20) which is used for mounting a first crossed pin roller (5) is arranged on one surface of the follower plate body; and a longitudinal V-shaped rail (21) which is used for mounting a second crossed pin roller (8) is arranged on the other surface of the follower plate body. The transverse V-shaped rail and the longitudinal V-shaped rail on the follower plate body form a cross on plane space, and a cross angle ranges from 87.5 degrees to 92.5 degrees. The speed reducer can realize automatically regulating motion of an input shaft (an eccentric shaft) to completely fit to eccentricity, so that transmission rolling balls of the speed reducer completely fit to the track of a differential transmission, the output of the speed reducer is stable and a mechanical wear rate of the speed reducer is low; and the speed reducer has the advantages of a compact structure, low noise, light weight, a small size, stable and reliable transmission, high output precision and the like.

Owner:HSOAR GRP

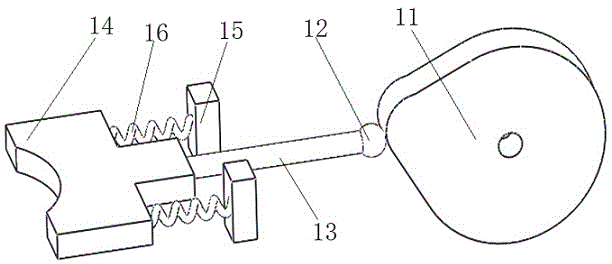

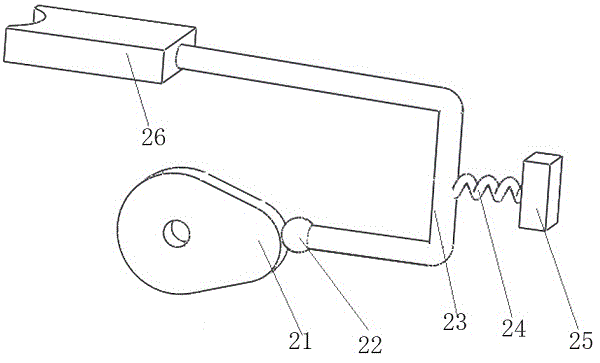

Transmission mechanism, head mounted display, and refraction adjusting method for head mounted display

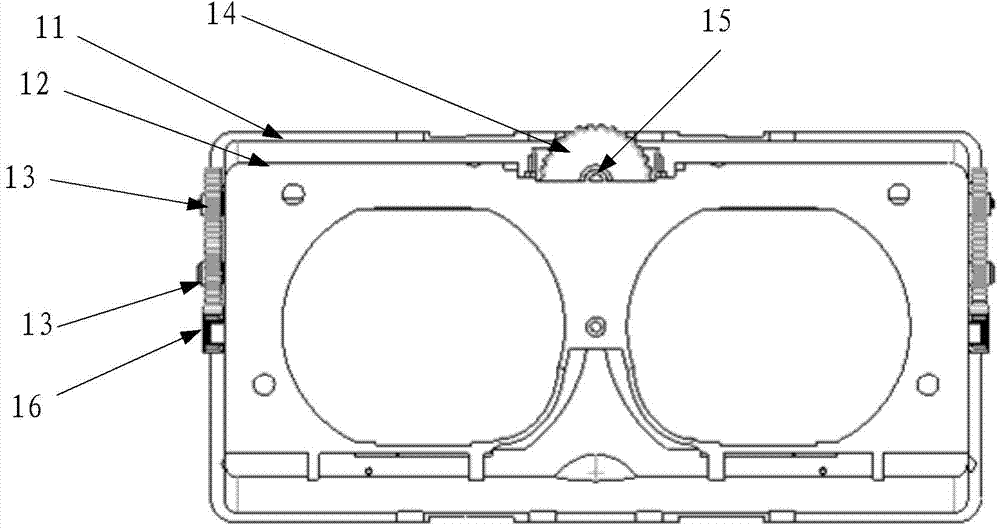

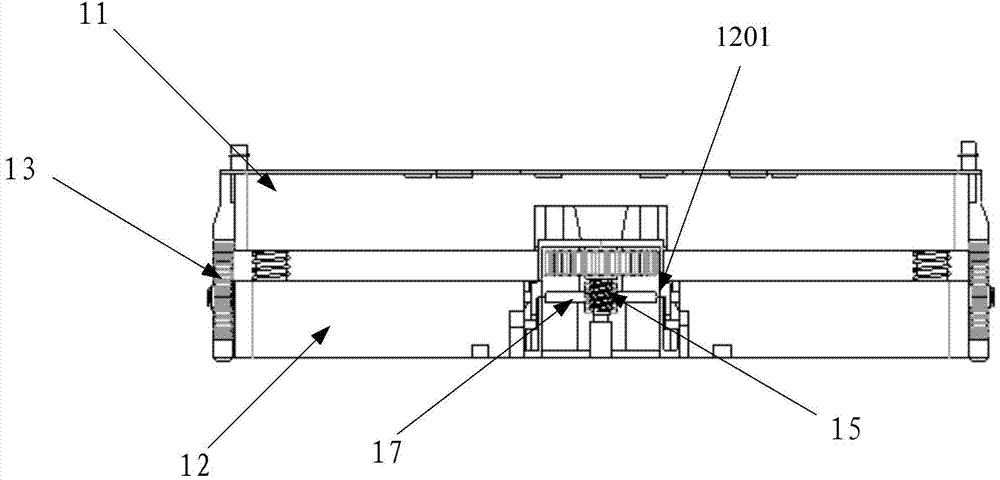

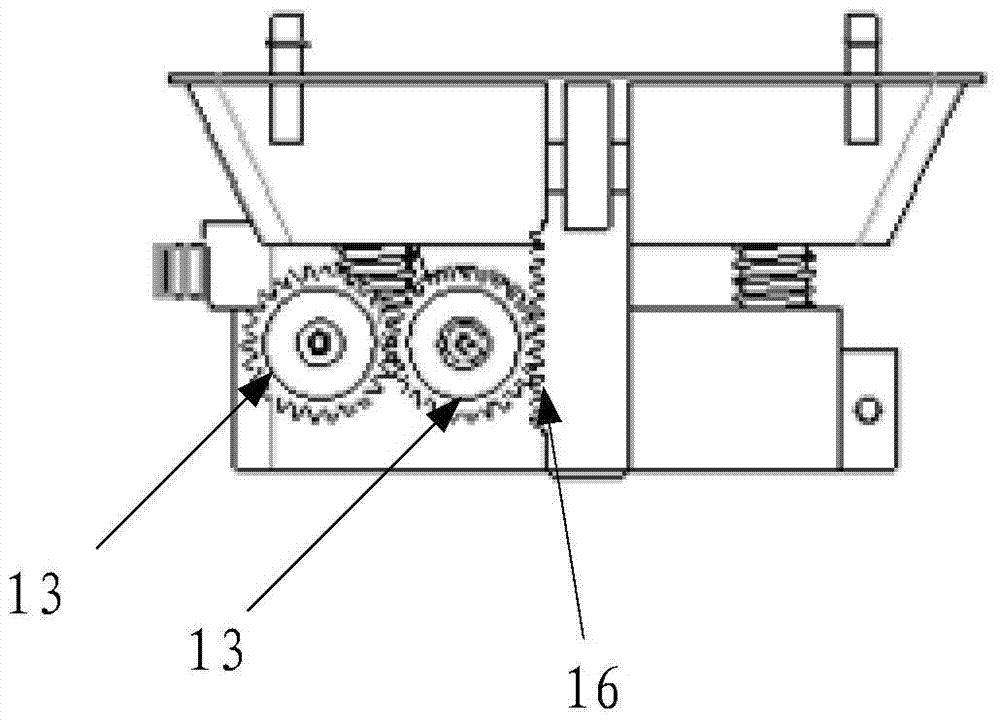

ActiveCN104849862AAchieve diopter adjustmentGuaranteed linear reciprocating motionMountingsDrive shaftGear wheel

The invention discloses a transmission mechanism, a head mounted display, and a refraction adjusting method for a head mounted display. The transmission mechanism is used for controlling movement of a first framework relative to a second framework. The first framework is connected to the second framework through a connecting member arranged on the first framework. The transmission mechanism includes a dial wheel, a worm, a turning gear, a transmission shaft and transmission gears. A horizontal frame of the second framework is equipped with a containing groove, part of the dial wheel is arranged in the containing groove and the dial wheel is arranged on the horizontal frame of the second framework with the worm being an axis. The transmission shaft is arranged on the horizontal frame of the second framework. The turning gear sleeves the transmission shaft and fits the worm. The transmission gears are symmetrically arranged on vertical frames of the second framework. The upper portion of the connecting member is equipped with tooth bars, and the tooth bars engage with the transmission gears. When the transmission gears fit the tooth bars, the connecting member drives the first framework to move in a straight reciprocating manner relative to the second framework. According to the technical solution, turning transmission and rotary to rectilinear motion are achieved, transmission is steady and reliable, and the transmission mechanism is simple in structure and low in cost.

Owner:BEIJING PICO TECH

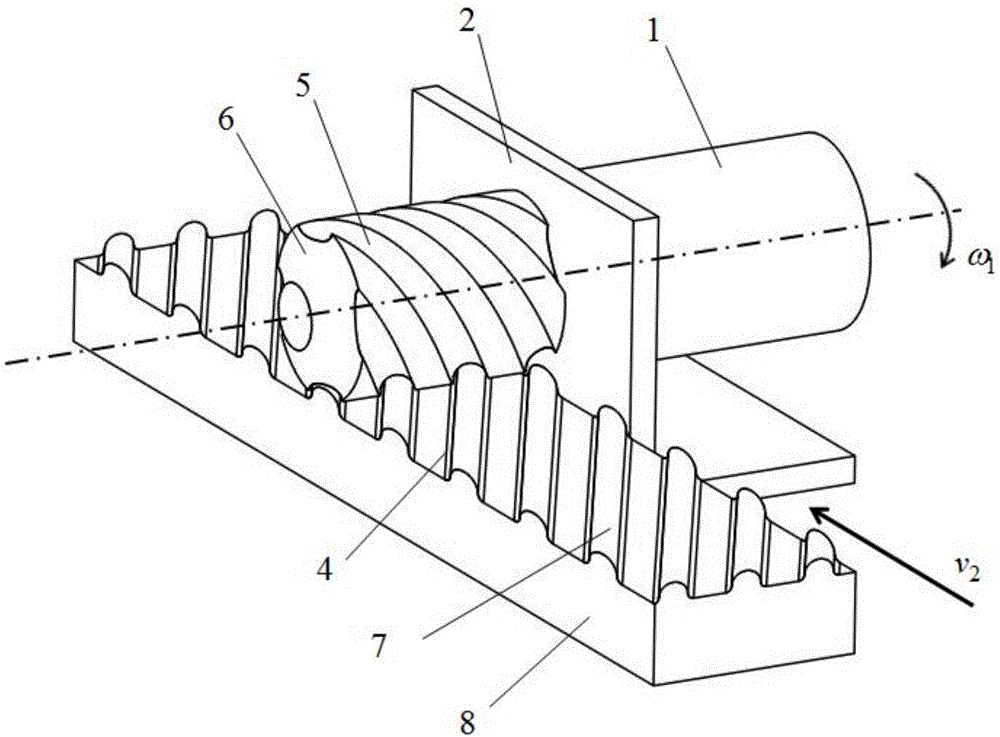

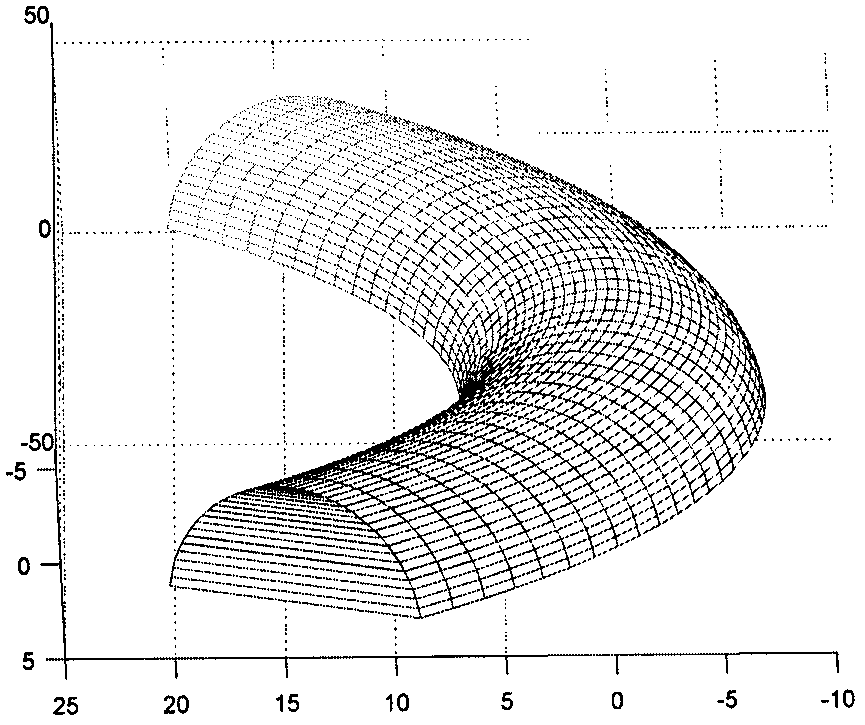

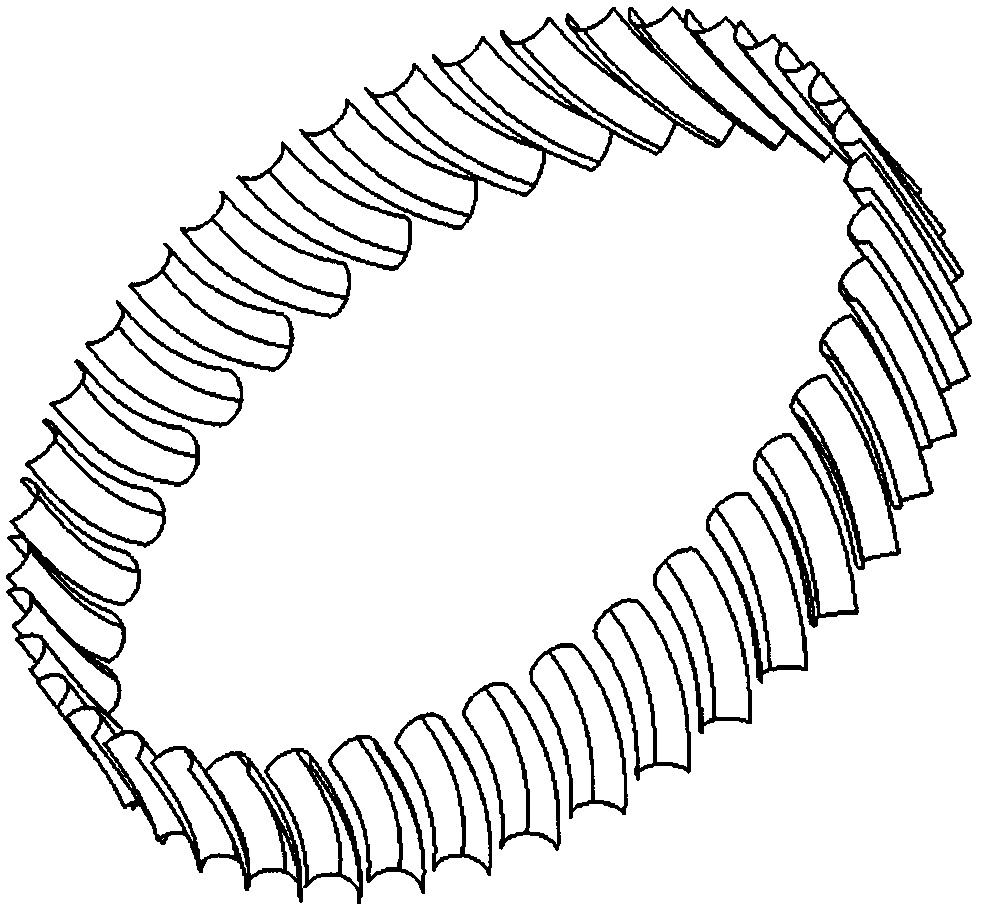

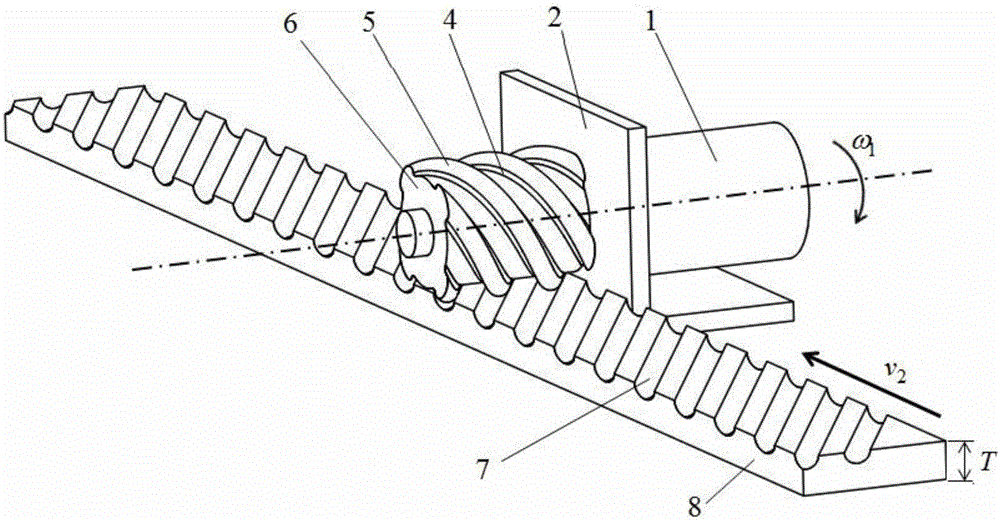

Circular-arc concave-convex engaged gear and rack mechanism without relative slide

ActiveCN106763592AImprove transmission efficiencyAvoid wear and tearGeometric CADPortable liftingGear wheelOverlap ratio

The invention relates to a circular-arc concave-convex engaged gear and rack mechanism without relative slide. The circular-arc concave-convex engaged gear and rack mechanism comprises a transmission pair consisting of a spiral circular-arc gear and a circular-arc rack, wherein spiral concave circular-arc tooth sockets are uniformly distributed in the outer surface of the spiral circular-arc gear; convex circular-arc teeth are uniformly distributed on the surface of the circular-arc rack; the spiral concave circular-arc tooth sockets are matched with the convex circular-arc teeth; the spiral circular-arc gear is connected with a rotating shaft of a driving device; the center line of each spiral concave circular-arc tooth socket is equal-lifting-distance cylindrical helix; and the structural shape of the spiral circular-arc gear and the structural shape of the circular-arc rack are determined by design parameters. When the mechanism is mounted, correct engagement of the spiral concave circular-arc tooth sockets and the convex circular-arc teeth needs to be guaranteed to realize the transmission of the circular-arc gear and the circular-arc rack. When the gear and rack mechanism disclosed by the invention is in transmission, failures modes, such as the slide of tooth surfaces, agglutination of the tooth surfaces, wear of the tooth surfaces, and plastic deformation of the tooth surfaces are avoided; the gear and rack mechanism has the advantages of being high in overlap ratio, simple in structure, easy to process, high in transmission efficiency, high in bearing capacity and the like; and the gear and rack mechanism is suitable for being popularized and applied in the field of mini machinery, micro-machinery and conventional machinery.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

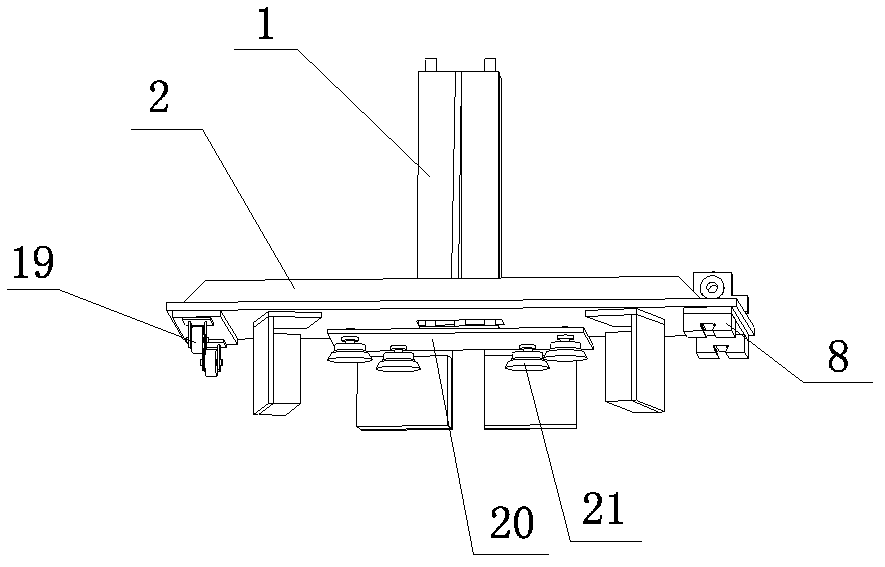

Electromagnetic feeding device

The invention discloses an electromagnetic feeding device and relates to a feeding device. The electromagnetic feeding device comprises two rows of support frames, supporting beams I and II and a movable platform, wherein the supporting beams I and II are respectively arranged at the top ends of the two rows of support frames and are parallel to each other; the movable platform is supported on the supporting beams I and II; the middle part of the movable platform is connected with a cylinder I; a piston push rod of the cylinder I passes through the movable platform to be connected with a connection plate positioned at the bottom of the movable platform; the bottom surface of the connection plate is connected with an electromagnet for attracting a workpiece; a slide rail is fixedly connected on the supporting beam I; the bottom surface of the side of the movable platform, which corresponds to the supporting beam I, is fixedly connected with a sliding block which is sleeved on the slide rail and can slide relative to the slide rail; the bottom surface of the side of the movable platform, which is far away from the supporting beam I is connected with a wheel capable of rolling on the supporting beam II through a bracket; one end tail of the supporting beam I is provided with a servo motor and the other end tail of the supporting beam I is provided with a bearing seat; a ball screw is arranged between the output end of the servo motor and the bearing seat; and the top surface of the side of the movable platform, which corresponds to the supporting beam I, is fixedly connected with a screw connection seat matched with the ball screw.

Owner:LIUZHOU GAOHUA MACHINE

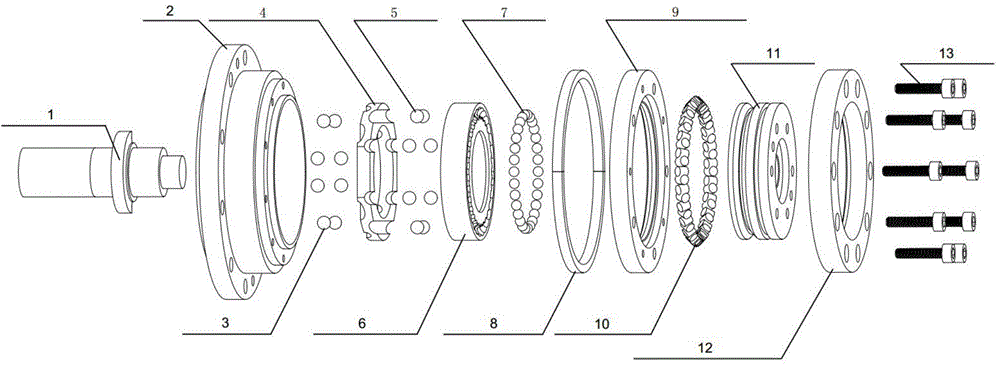

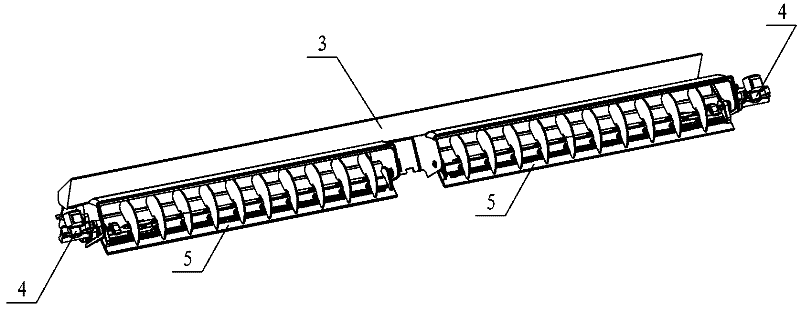

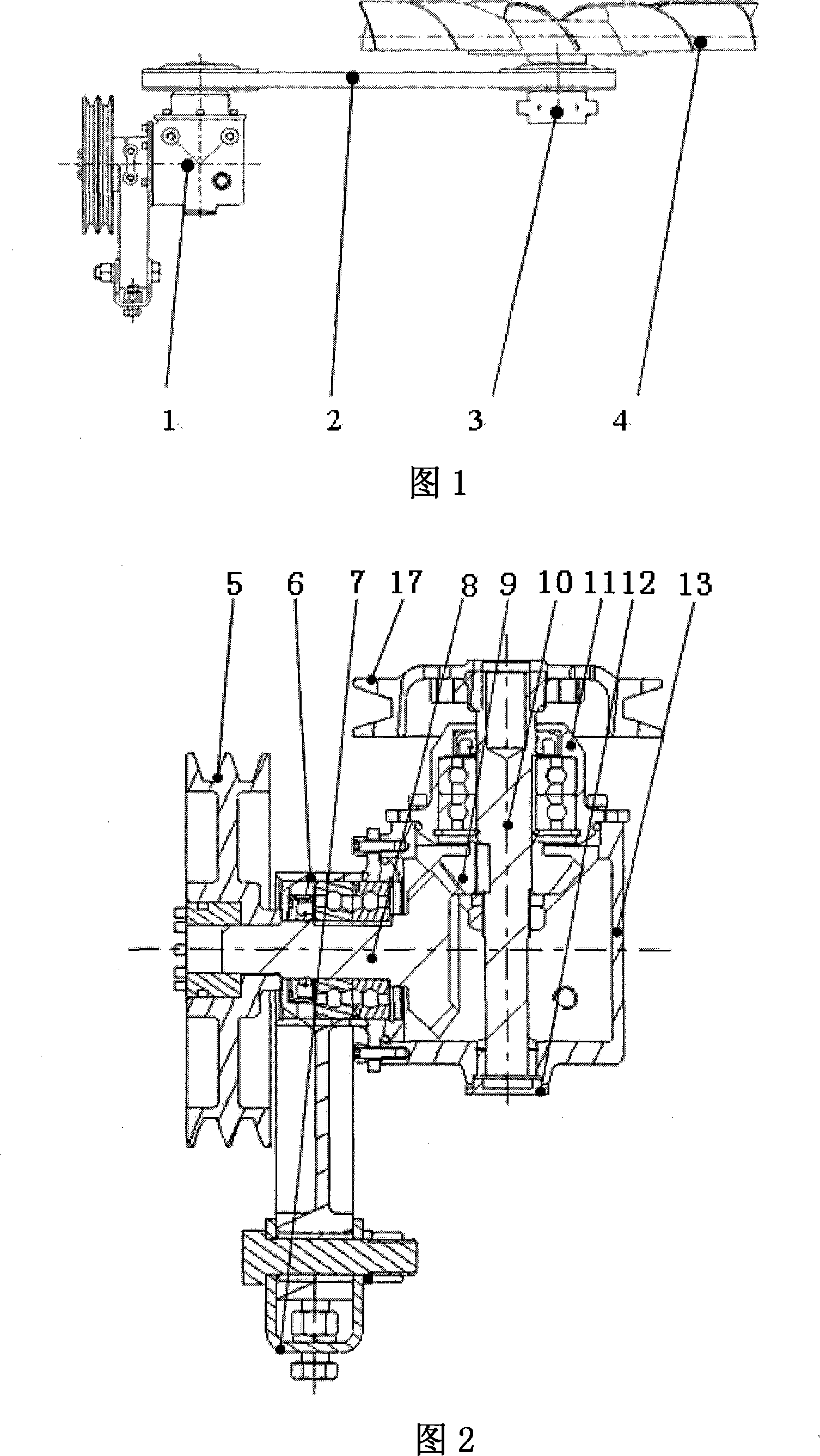

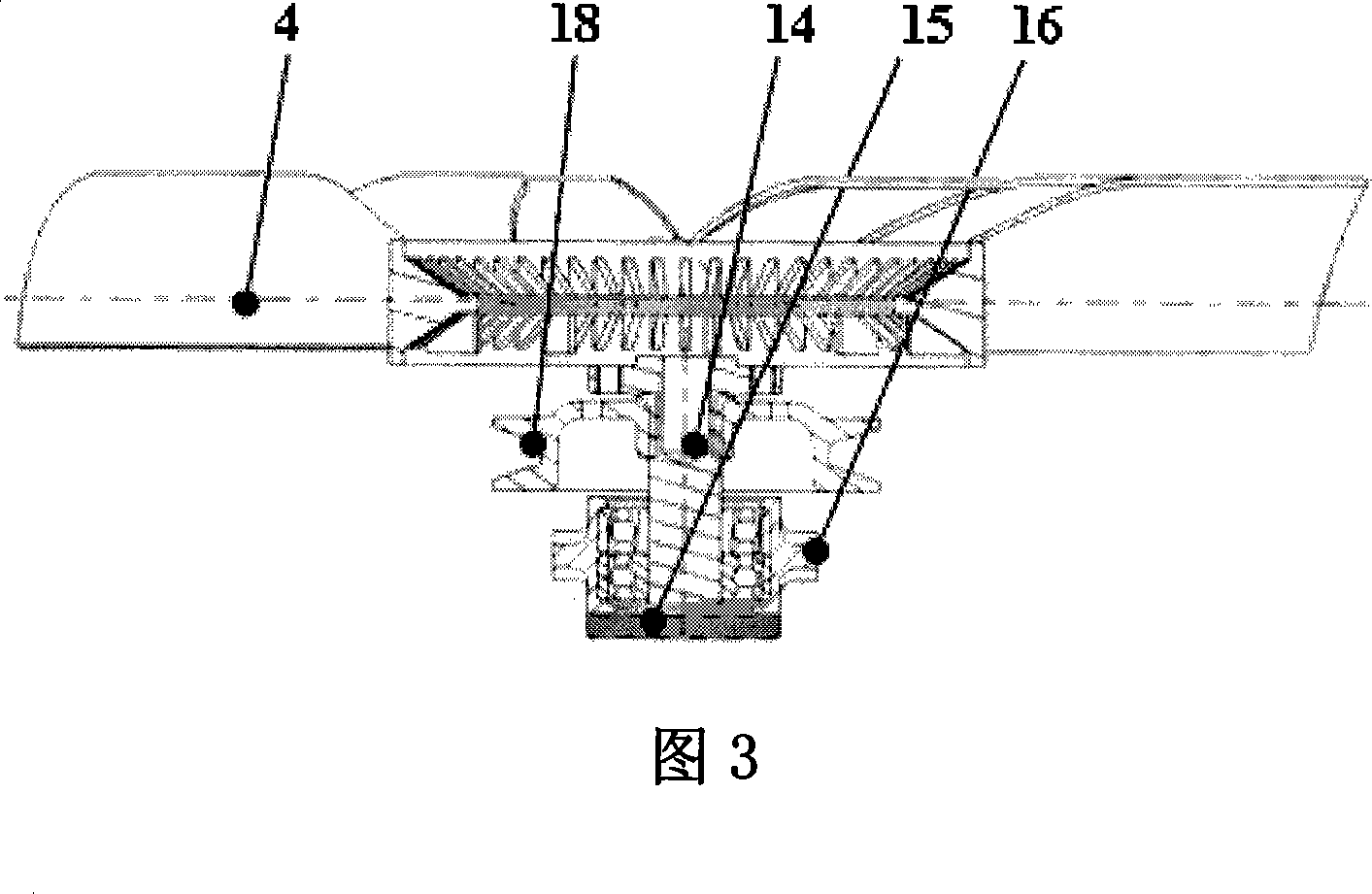

Angle transmission mechanism of car engine cooling fan

An angle actuating mechanism on the cooling fan of the automobile engine belongs to the side engine cooling device. The fan unit assemblage 4 connects with its belt pulley unit assemblage 3. The fan belt pulley 18 on its belt pulley unit assemblage 3 links the actuating belt pulley 17 on the angle actuating mechanism unit assemblage of the belt pulley 1. A power belt pulley 5 is set against to the actuating belt pulley 17. It has low required precision on the installation site, convenient arrangement and assemblage of the engine and the crank pulley. The belt driving is adopted between the angle actuating mechanism unit assemblage of the belt pulley 1 and the fan belt pulley unit assemblage 3, which has simple structure, good vibration resistance, low noise, convenient installation and maintenance, stable and reliable actuating performance. The transmission speed ratio can be adjusted by changing the size of the external diameter of the belt pulley, which has good versatility.

Owner:DONGFENG MOTOR CO LTD

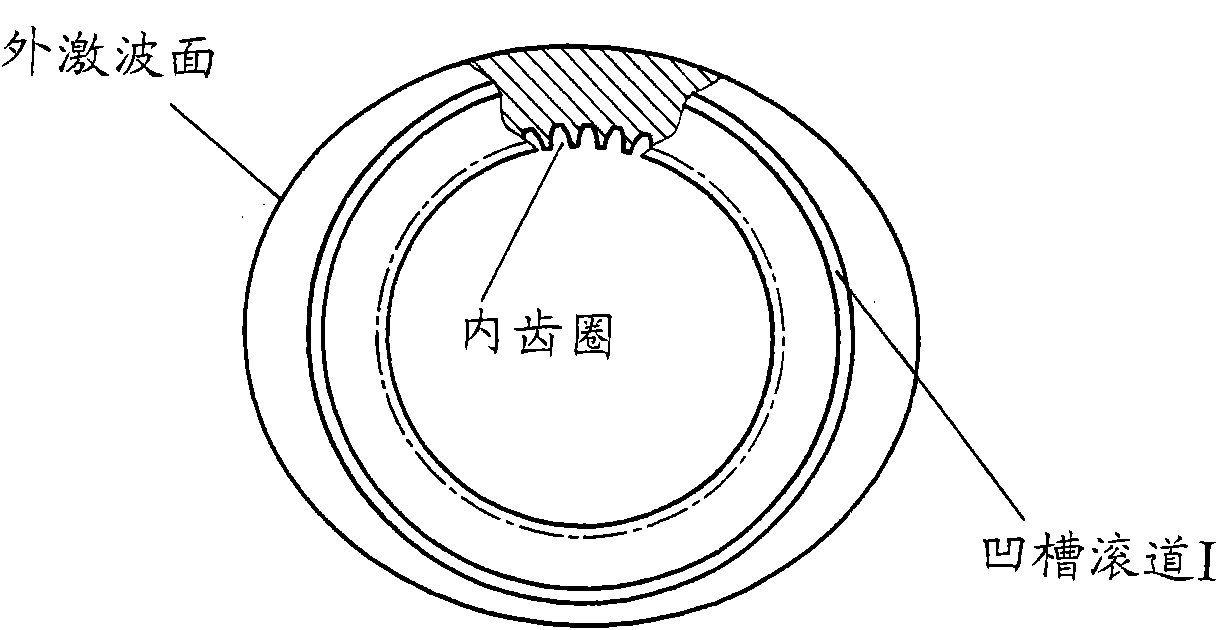

Two-phase outer cam sleeve type high-rotational-speed internal-combustion engine

InactiveCN102877942AHigh speed outputReduce axial sizeGearingMachines/enginesEngineeringInternal combustion engine

The invention discloses a two-phase outer cam sleeve type high-rotational-speed internal-combustion engine, and relates to the field of power of fuel gas. The invention provides a novel internal-combustion engine. Eight cylinders are annularly, symmetrically and uniformly distributed around an outwards convex inner gear ring, so that resultant force from which the outwards convex inner gear ring is suffered is zero; pistons of the cylinders directly act on the outwards convex inner gear ring through push rods; and power is transferred to an output shaft connected with a symmetric two-phase cam through a key by the outwards convex inner gear ring through the drive of a two-phase outer cam type sleeve oscillating tooth. By using the internal-combustion engine, a connecting rod and a crankshaft in a conventional internal-combustion engine are omitted; a two-phase outer cam sleeve driving mechanism of the outwards convex inner gear ring of the internal-combustion engine does not have an eccentric mass; the internal-combustion engine has the characteristic of the self balancing of inertia force and a working load; the rotational speed of the output shaft depends on the drive ratio of the drive of the oscillating tooth; if a dowel pin frame is fixedly arranged, the symmetric two-phase cam carries out output at a high speed; the internal-combustion engine can be widely applied to the field of high rotational speeds, such as engines of helicopters, and miniature engines; and when an output rotational speed is constant, the emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, small in axial dimension and self-balancing in stress, and is stable to run.

Owner:SICHUAN UNIV

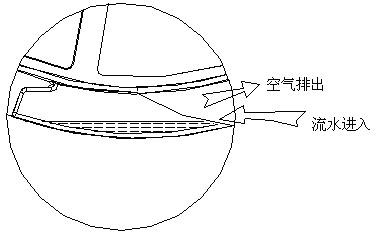

Humidification water wheel and air purification humidifier

ActiveCN102679519AEasy to fixThe connection is firmly fixedLighting and heating apparatusSpace heating and ventilation detailsWater storageWater wheel

The invention provides a humidification water wheel and an air purification humidifier. The humidification water wheel comprises a first water wheel, a second water wheel and humidification cloth. The humidification water wheel is characterized in that the circumference edge of the first water wheel is provided with a water storage groove; the middle of the first water wheel is provided with a shaft hole; the second water wheel comprises a disc body and a circular ring edge which is protruded on the circumference of the inner side surface of the disc body; the middle of the disc body is provided with a circular cylinder which is inserted in the shaft hole of the first water wheel; the outer side surface of the circular cylinder is provided with a positioning block; the humidification cloth is embedded into the second water wheel and is in contact with the inner side surface of the disc body; the first water wheel and the second water wheel are inserted in the shaft hole through the circular cylinder in the middle, and are positioned through the positioning block; the humidification cloth is clamped between the first water wheel and the second water wheel for fixing; the first water wheel and the second water wheel are connected and fixed through peripheral edges, thus net cloth on the humidification water wheel is fixed reliably; and additionally, air exhaust holes are formed on the circumference edge of the first water wheel along the water inlet end of the water storage groove, thus the water bringing effect of the humidification water wheel is good, and air trapping phenomenon is prevented from occurring.

Owner:HAIER GRP CORP +1

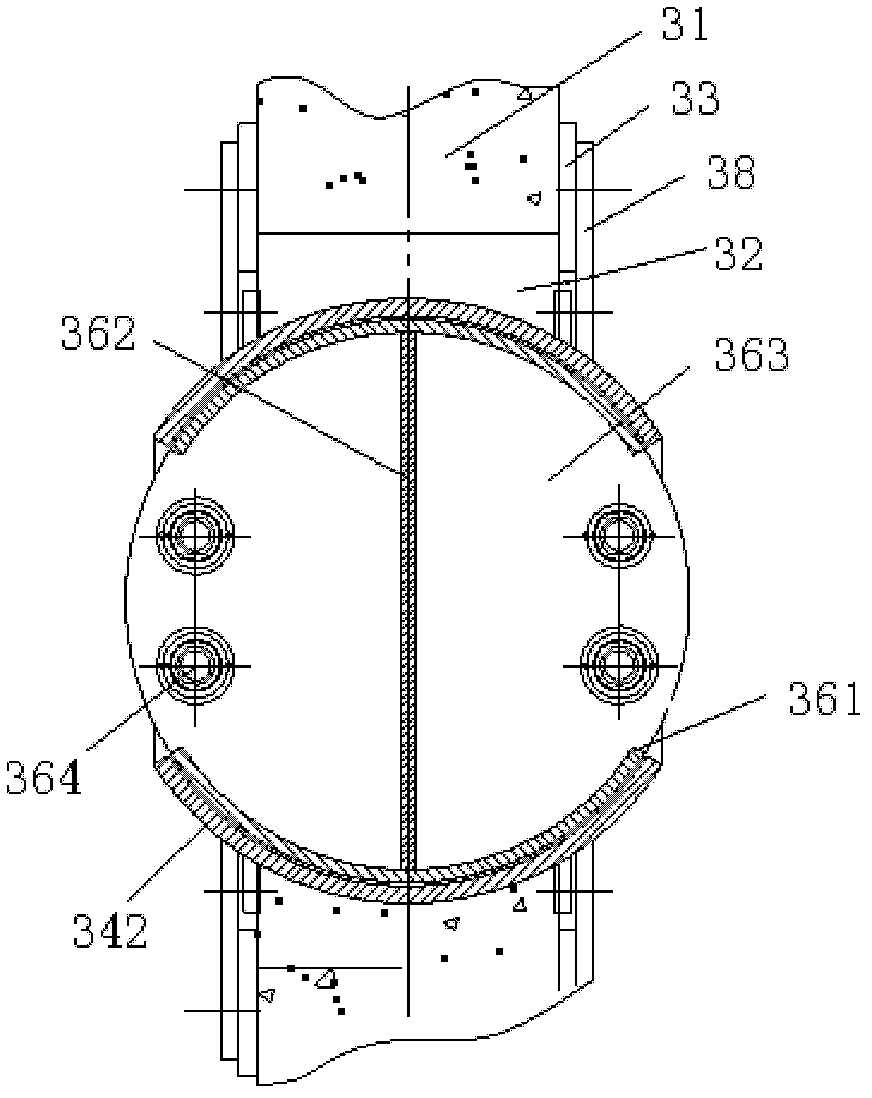

Transmission cases on two sides of personnel airlock

ActiveCN103670112AWith self-locking functionSimple structureBuilding locksMan-operated mechanismEngineeringAirlock

The invention provides transmission cases on two sides of a personnel airlock. The transmission cases solve the technical problems that transmission cases on two sides of an existing personnel airlock are complex in structure, large in adjustment difficulty coefficient and poor in practicability and time and labors are wasted in operation. Each transmission case is provided with an upper cover plate, a lower bottom plate, side cover plates, a worm, a worm-wheel shaft, a rotating shaft and an interlocking device; the worm-wheel shaft is provided with a bearing and longitudinally penetrates through a box body and is fixedly connected with the box body through the bearing; the worm and the rotating shaft transversely penetrate through the box body and are fixedly connected with the box body, and the worm is meshed with a worm wheel. The transmission cases on the two sides of the personnel airlock can be widely applied to the transmission field.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

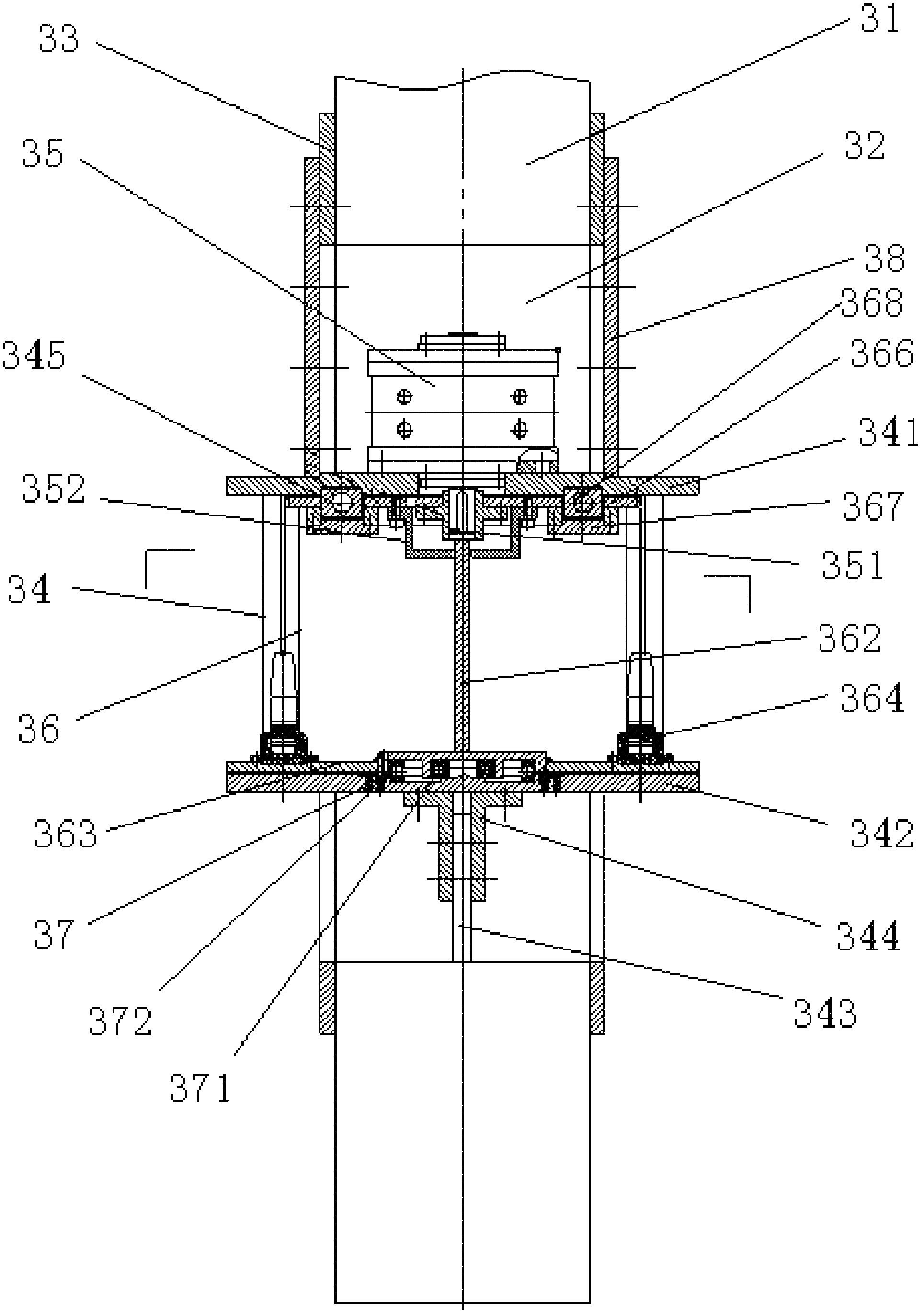

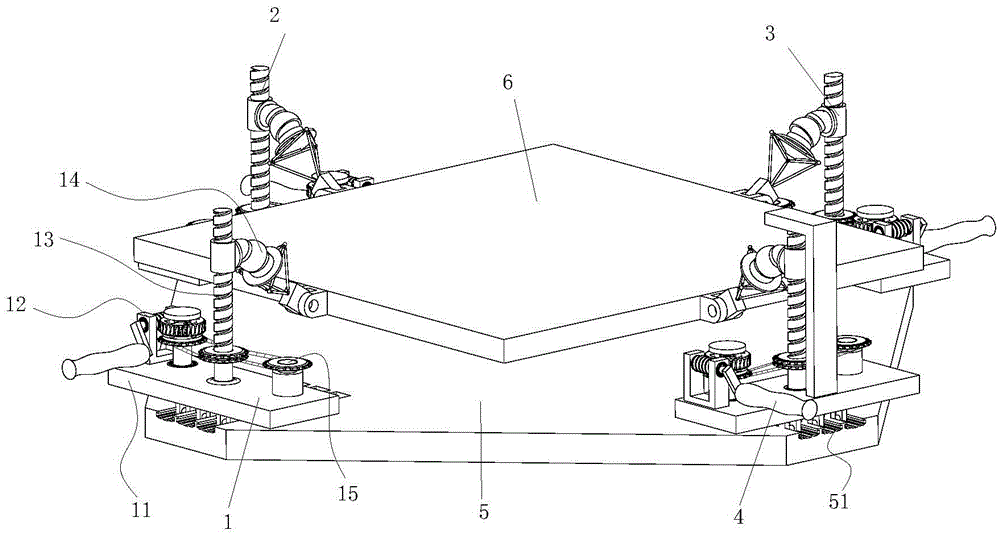

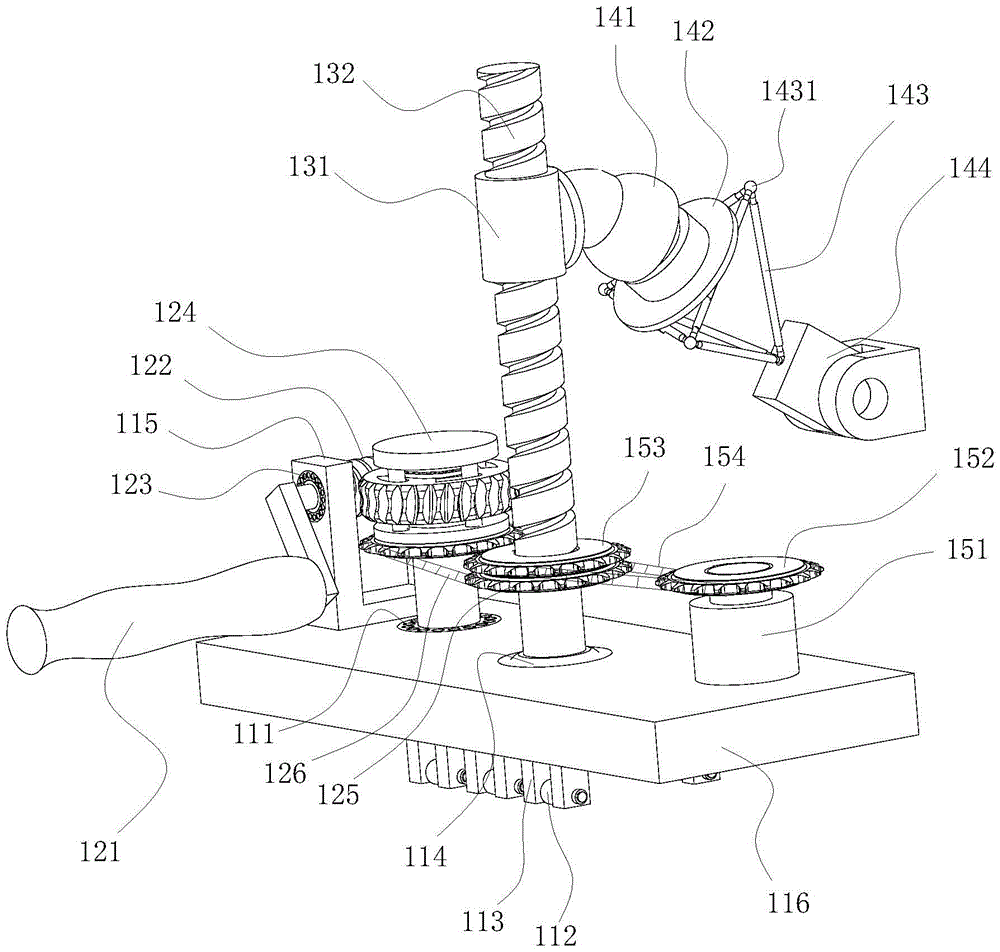

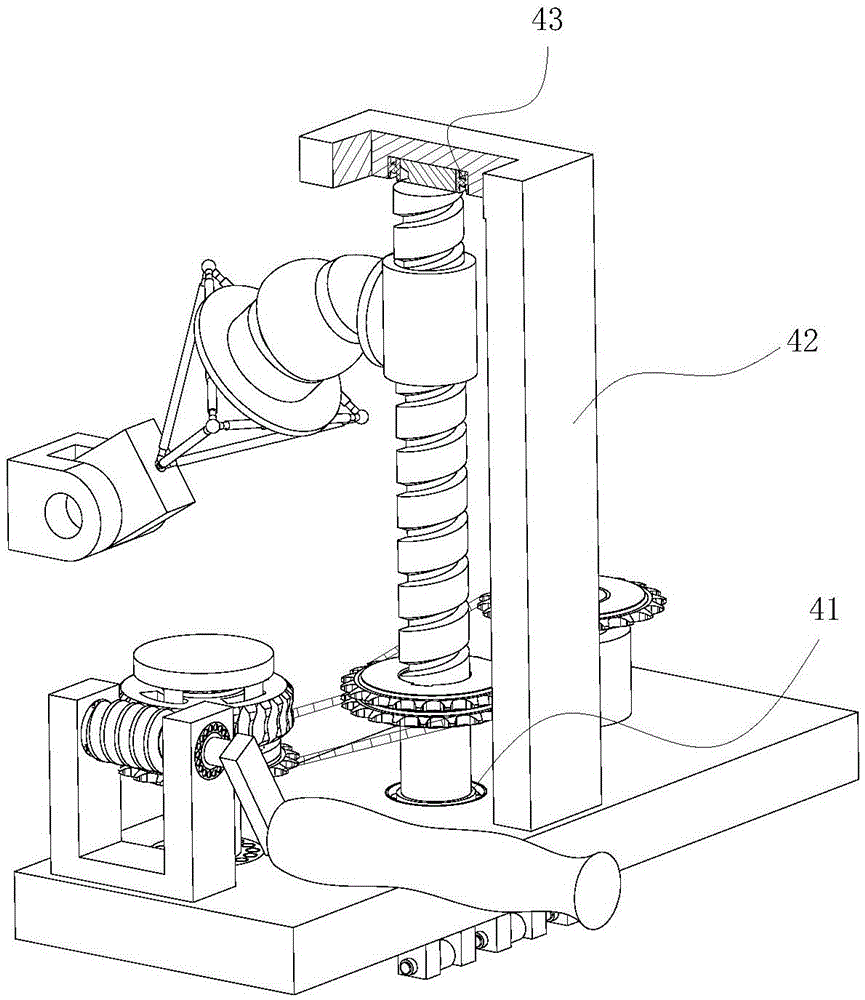

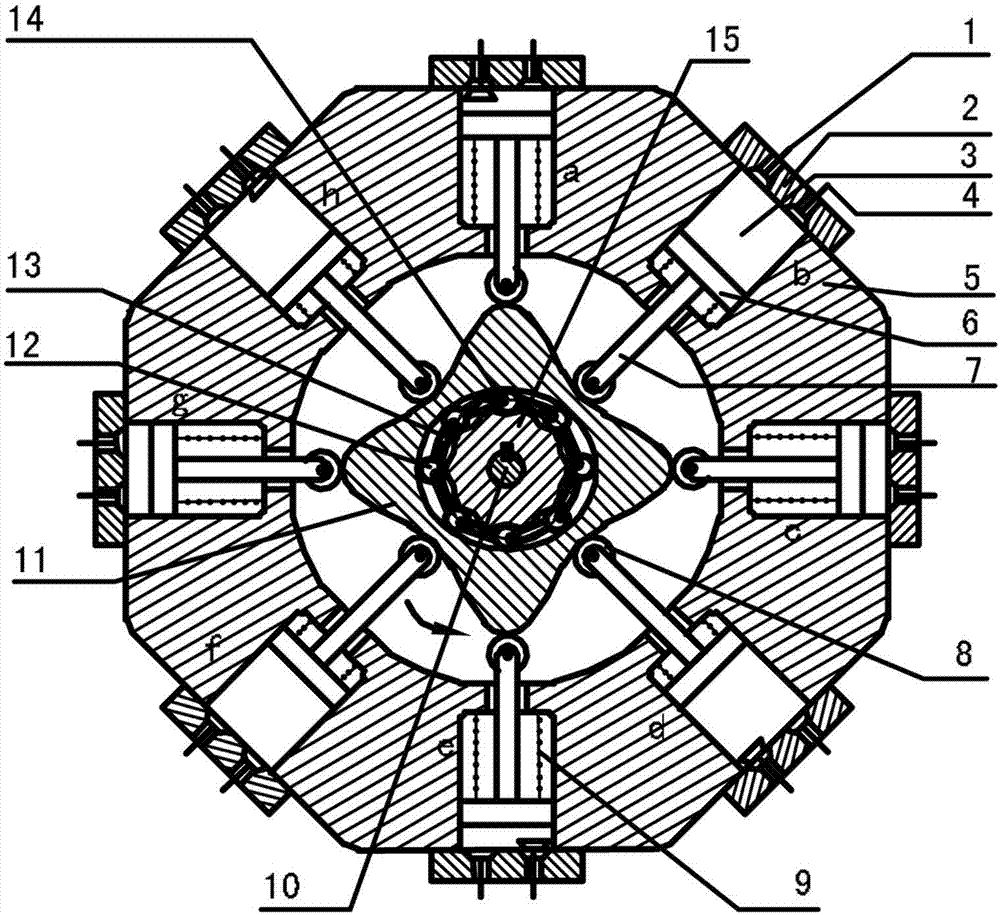

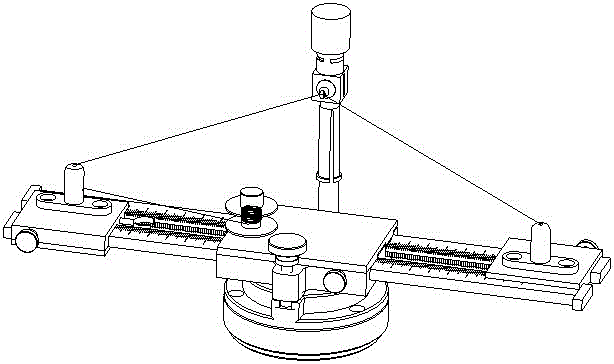

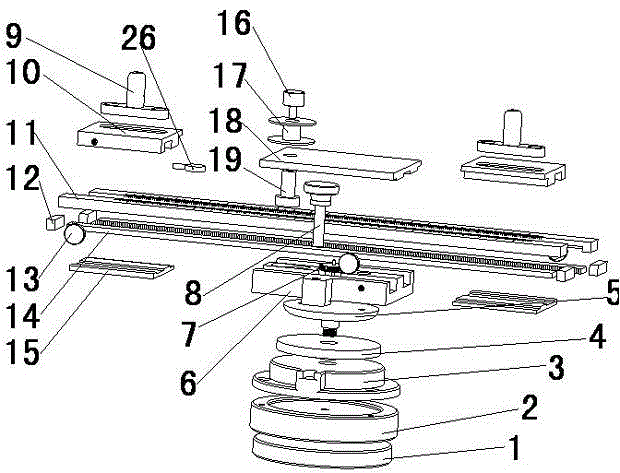

Precise horizontal adjustment device

ActiveCN105538263AImprove applicabilityEasy to useProgramme-controlled manipulatorWork benchesBall screwPetroleum engineering

The invention discloses a precise horizontal adjustment device. The precise horizontal adjustment device comprises a first chain, a second chain, a third chain, a fourth chain, a supporting base plate and an adjusting platform, wherein the four chains are uniformly distributed at the periphery of the supporting base plate, three of the four chains are the same, and the other chain is used for positioning a screw rod at a vertical position through a screw rod fixing frame, and the rest structure of the different chain is the same as that of the three chains; through a manual / electric switcher, the horizontal adjustment device can realize horizontal adjustment operation through a manual operation or an electric operation. The precise horizontal adjustment device adopts flexible joint assembly connection, so that a stuck phenomenon in a horizontal adjustment process of the adjusting platform is avoided, worm gears are matched with the ball screw rods to enable the horizontal adjustment process to be more stable and horizontal adjustment accuracy to be higher.

Owner:阜宁丰隆机电制造有限公司

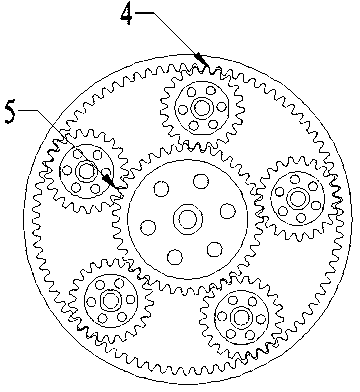

Two-phase inner cam type swinging transmission internal combustion engine

InactiveCN102828824AForce self-balancingLarge transmission ratioGearingMachines/enginesLow speedEngineering

The invention provides a two-phase inner cam type swinging transmission internal combustion engine, which relates to the field of gas motive power and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, eight air cylinders are annularly, symmetrically and uniformly distributed around an outer convex inner two-phase inner cam, the resultant force of the outer convex inner two-phase inner cam is zero, an air cylinder piston directly acts on the outer convex inner two-phase inner cam through a push rod, and the motive power is transferred to an output shaft connected with a center wheel key through a two-phase inner cam type swinging movable tooth via the outer convex inner two-phase inner cam. The internal combustion engine has the characteristics that a connecting rod and a crankshaft in the traditional internal combustion engine are omitted, and an outer convex inner two-phase inner cam type swinging transmission mechanism does not have the eccentric mass, and has the inertia force and work load self balance characteristic. The rotating speed of the output shaft depends on the transmission ratio of the movable tooth transmission, when the movable tooth frame is fixed, a center wheel realizes low-speed and large-torque output, and the internal combustion engine can be widely applied to engineering machinery, armored car and the like with high-powder requirements. The internal combustion engine has the advantages that the structure is simple and compact, the axial dimension is small, the self balance of the stress is realized, and the operation is stable.

Owner:SICHUAN UNIV

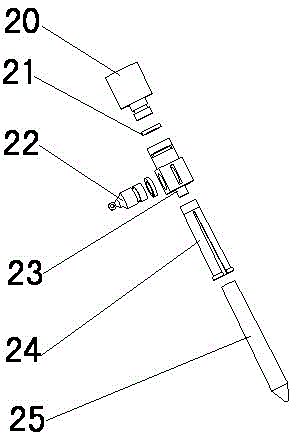

Napier's compasses

ActiveCN104527272AHigh precisionEasy to carryNon-circular curve drawing instrumentsCircular curve drawing instrumentsMagnetGear drive

The invention discloses a pair of napier's compasses. The pair of napier's compasses comprises a telescopic adjusting mechanism and a pencil clamp fixing mechanism. The telescopic adjusting mechanism comprises a rotating locking mechanism, a sliding focal length adjusting mechanism and a thread rope locking mechanism, wherein the sliding focal length adjusting mechanism is arranged on the rotating locking mechanism in a sliding mode, the thread rope locking mechanism is fixed on the rotating locking mechanism, and the pencil clamp fixing mechanism is connected to the thread rope locking mechanism. In this way, a continuous curve can be rapidly and accurately drawn up at one time through the pair of napier's compasses, circles and ellipses can be drawn, and multiple purposes of the pair of napier's compasses are achieved; due to the fact that gear drive is adopted, stability and reliability are achieved, and accuracy is high; due to the fact that magnets at the bottom end can attract on a blackboard, labor is saved in the drawing process, drawing can be rapidly conducted, and the pair of napier's compasses is convenient to carry.

Owner:SUZHOU VOCATIONAL UNIV

Conveying device for bottle bodies

The invention discloses a conveying device for bottle bodies, which comprises a bottle sending assembly, a bottle conveying rail and a bottle conveying assembly that are sequentially connected, wherein a rail bottle mouth suspending part is arranged on the bottle conveying rail, the bottle conveying assembly comprises more than one bottle body accommodating cavity used for accommodating the bottle bodies and a drive assembly used for driving the bottle body accommodating cavities and communicated with the bottle conveying rail, and the tops of the bottle body accommodating cavities are provided with bottle mouth suspending parts. The invention has the advantages of simple and compact structure, low cost and the like, and can be used for bearing and conveying the bottle bodies with suspending structures.

Owner:TRUKING TECH LTD

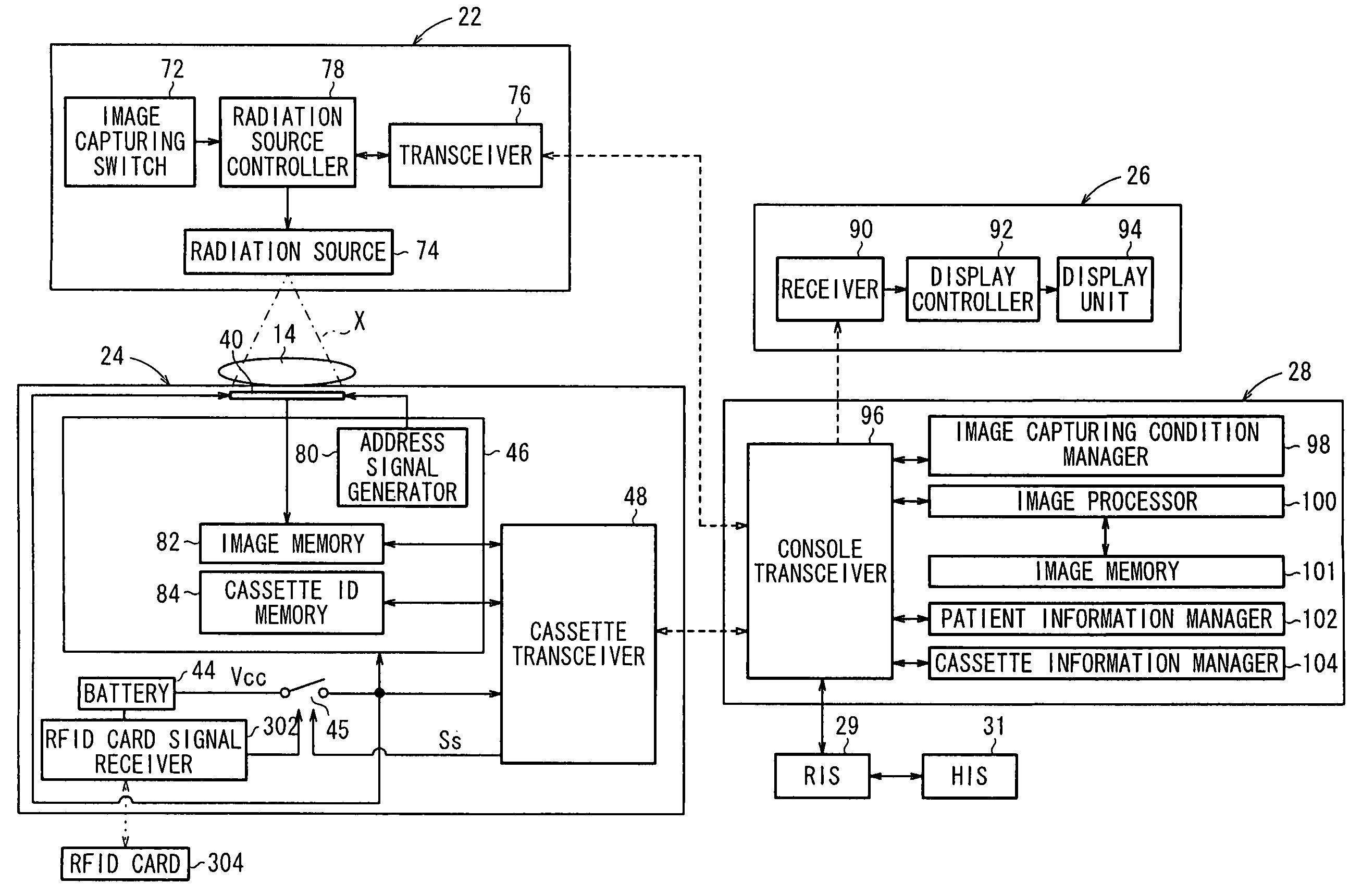

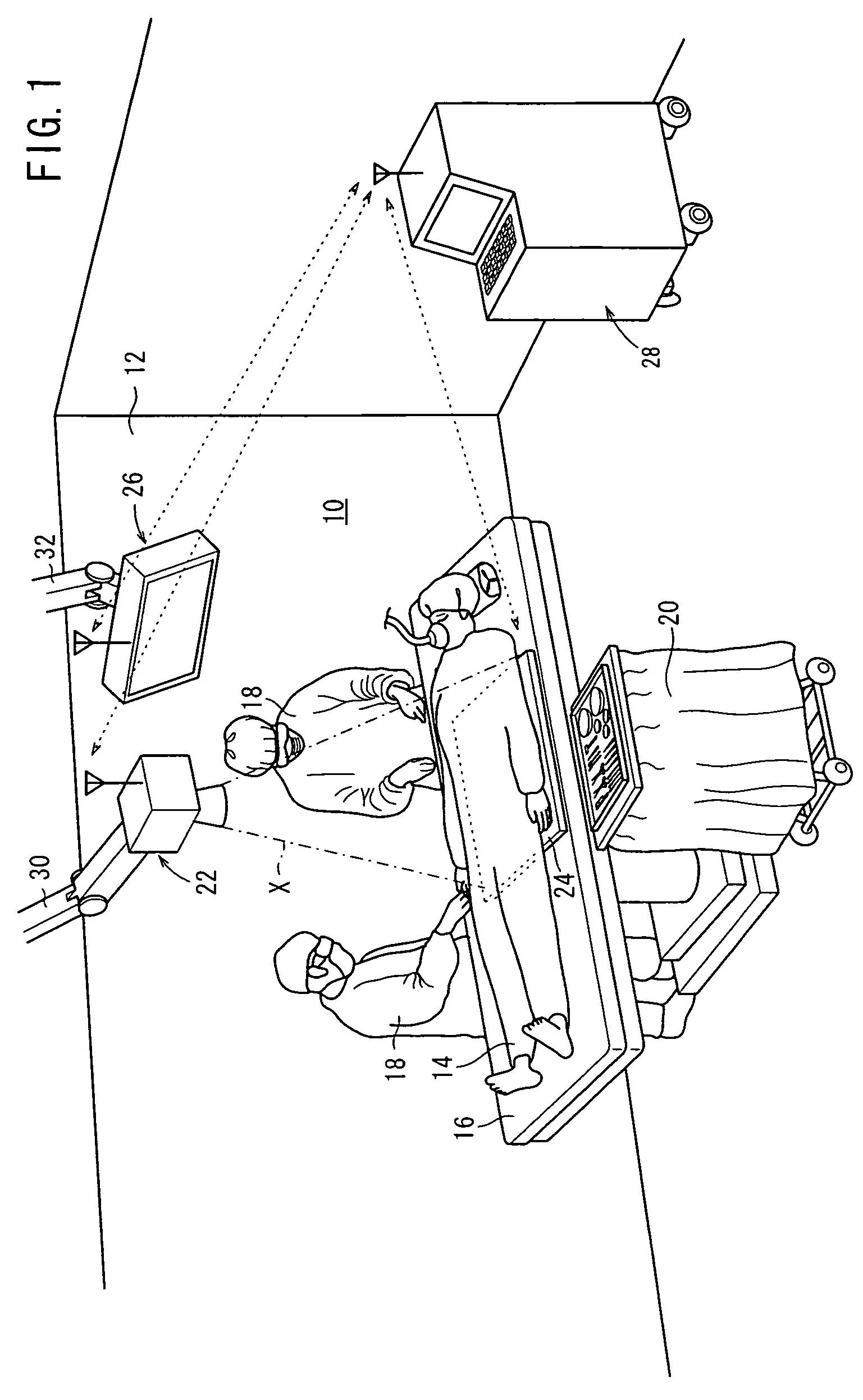

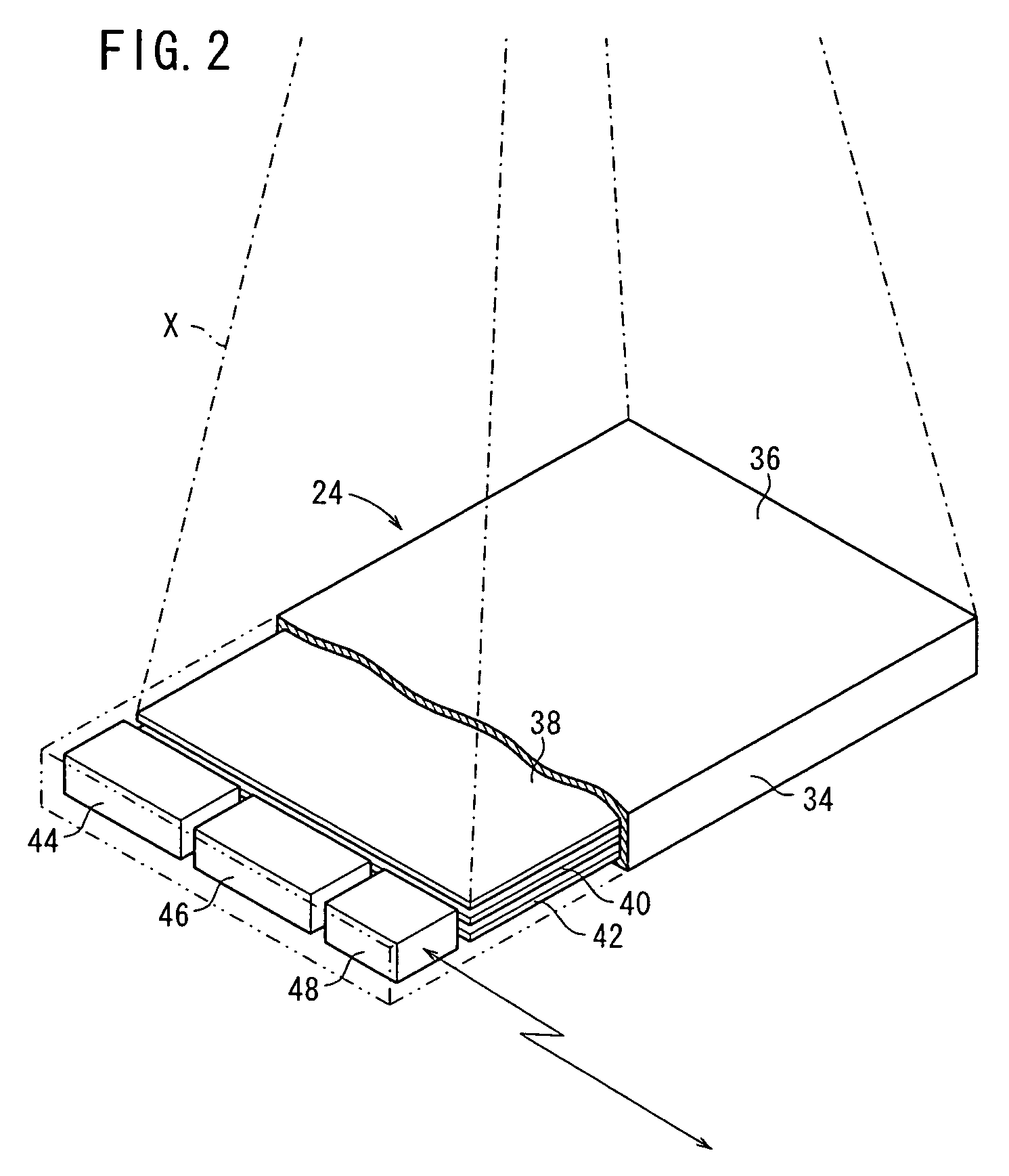

Radiation image capturing system

ActiveUS7655916B2Save battery powerReduce the amount requiredSolid-state devicesMaterial analysis by optical meansTransceiverAudio power amplifier

The power consumption of a battery for supplying electric power to a cassette having a radiation detector for detecting radiation image information is greatly reduced. When a cassette transceiver of the cassette starts transmitting the radiation image information to a console transceiver of a console, the cassette transceiver changes the gain of a variable-gain amplifier to change a transmission radio-wave intensity, and transmits a test signal at the changed transmission radio-wave intensity. When the console transceiver receives the test signal, the console transceiver transmits a reception acknowledgement signal generated by a reception acknowledgement signal generator. In response to the reception acknowledgement signal, the cassette transceiver sets its own transmission radio-wave intensity to a value at the time the cassette transceiver received the reception acknowledgement signal, and transmits the radiation image information at the set transmission radio-wave intensity.

Owner:FUJIFILM CORP

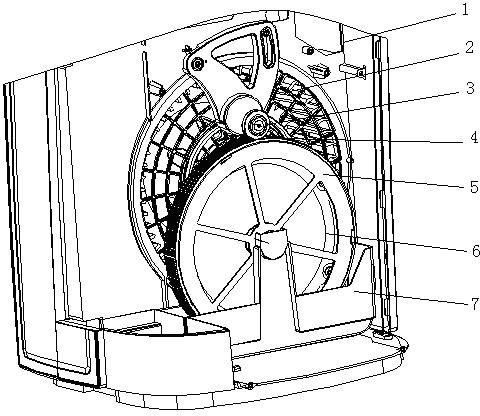

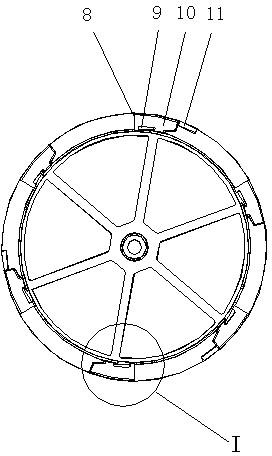

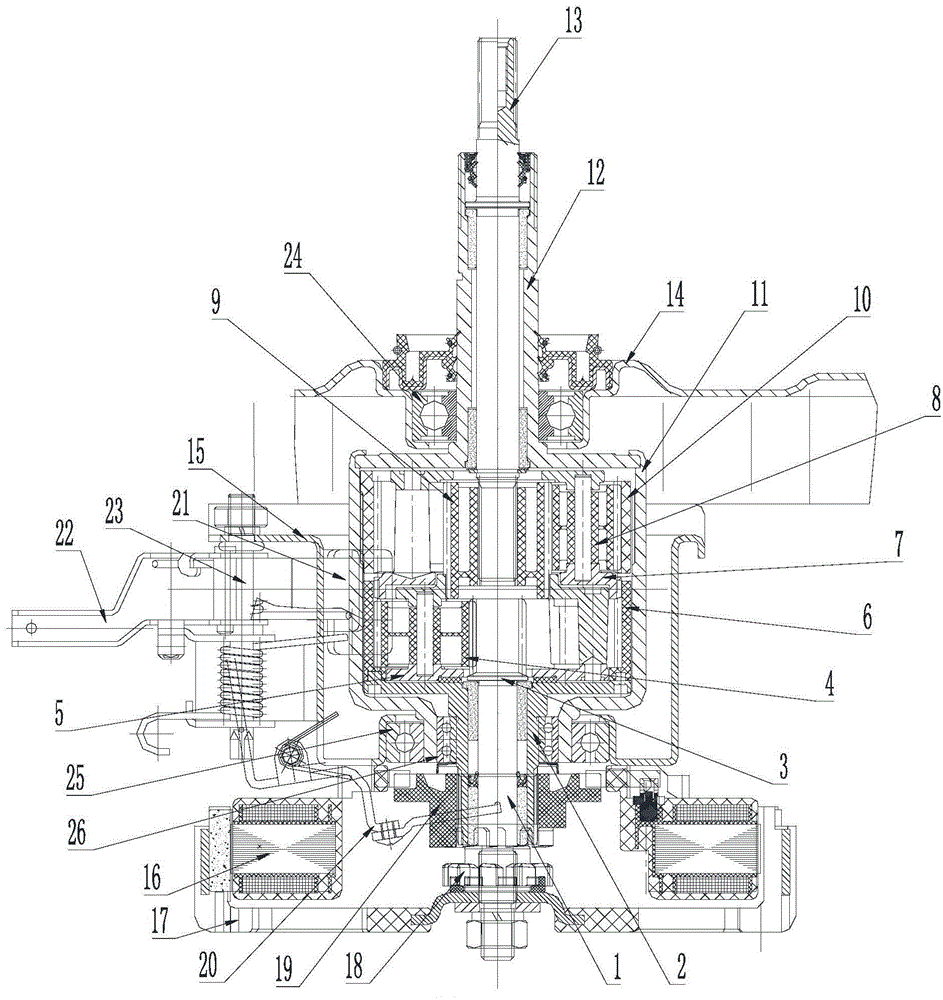

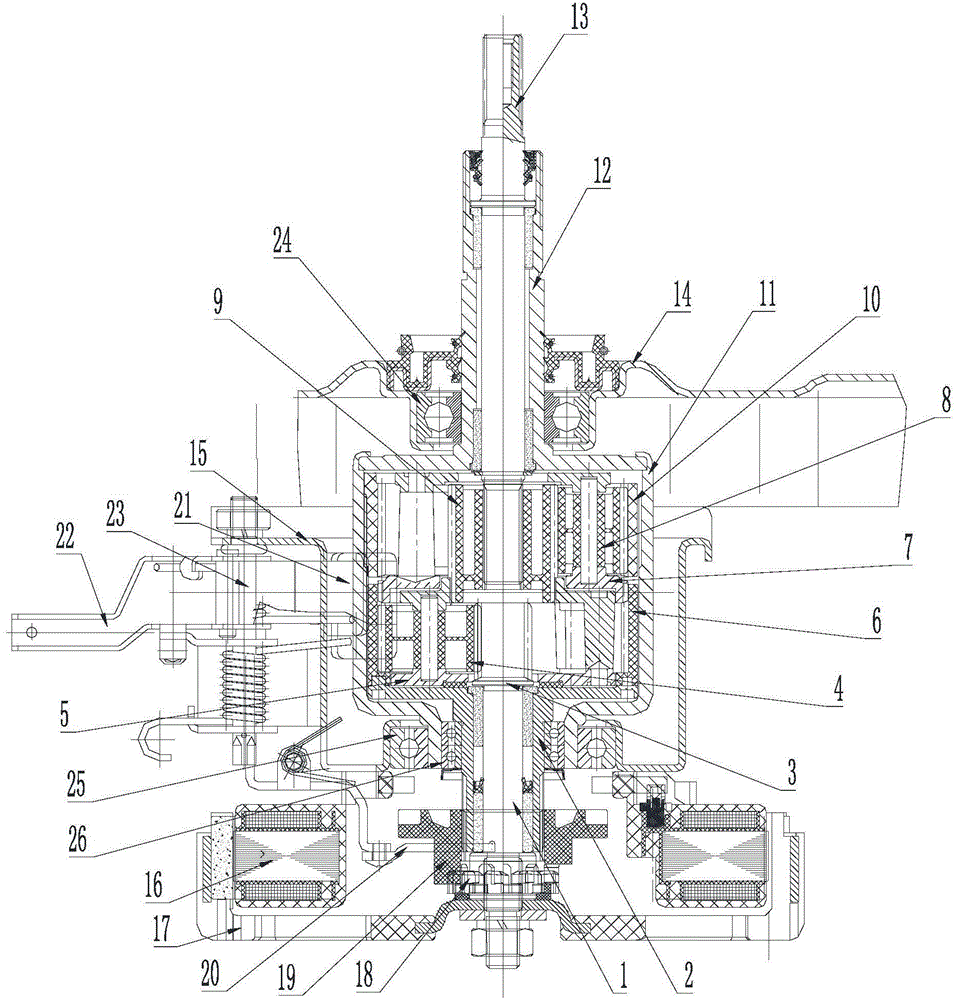

Washing machine speed reduction clutch and washing machine

ActiveCN105734905AStable power deliveryExtended service lifeOther washing machinesToothed gearingsEngineeringGear train

The invention provides a washing machine speed reduction clutch which comprises a braking wheel and a double-layer planetary gear train arranged in the braking wheel. A lower gear train of the double-layer planetary gear train comprises a lower center gear, a lower planet gear meshed with the lower center gear, a lower planet carrier and a lower internal gear ring. The lower center gear is fixedly connected with an input shaft. The lower planet gear is meshed with the lower internal gear ring. The lower portion of the lower internal gear ring is fixedly connected with an input shaft sleeve. An upper gear train of the double-layer planetary gear train comprises an upper center gear, an upper planet gear meshed with the upper center gear, an upper planet carrier and an upper internal gear ring. The upper center gear is connected with an output shaft. The upper planet gear is meshed with the upper internal gear ring. The periphery of the upper internal gear ring is fixedly connected with the braking wheel. The lower planet carrier is fixedly connected with the upper center gear. The upper planet carrier is fixedly connected with the lower internal gear ring. According to the specific structure of the washing machine speed reduction clutch, transmission is stable and reliable, and the whole structural strength is higher.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

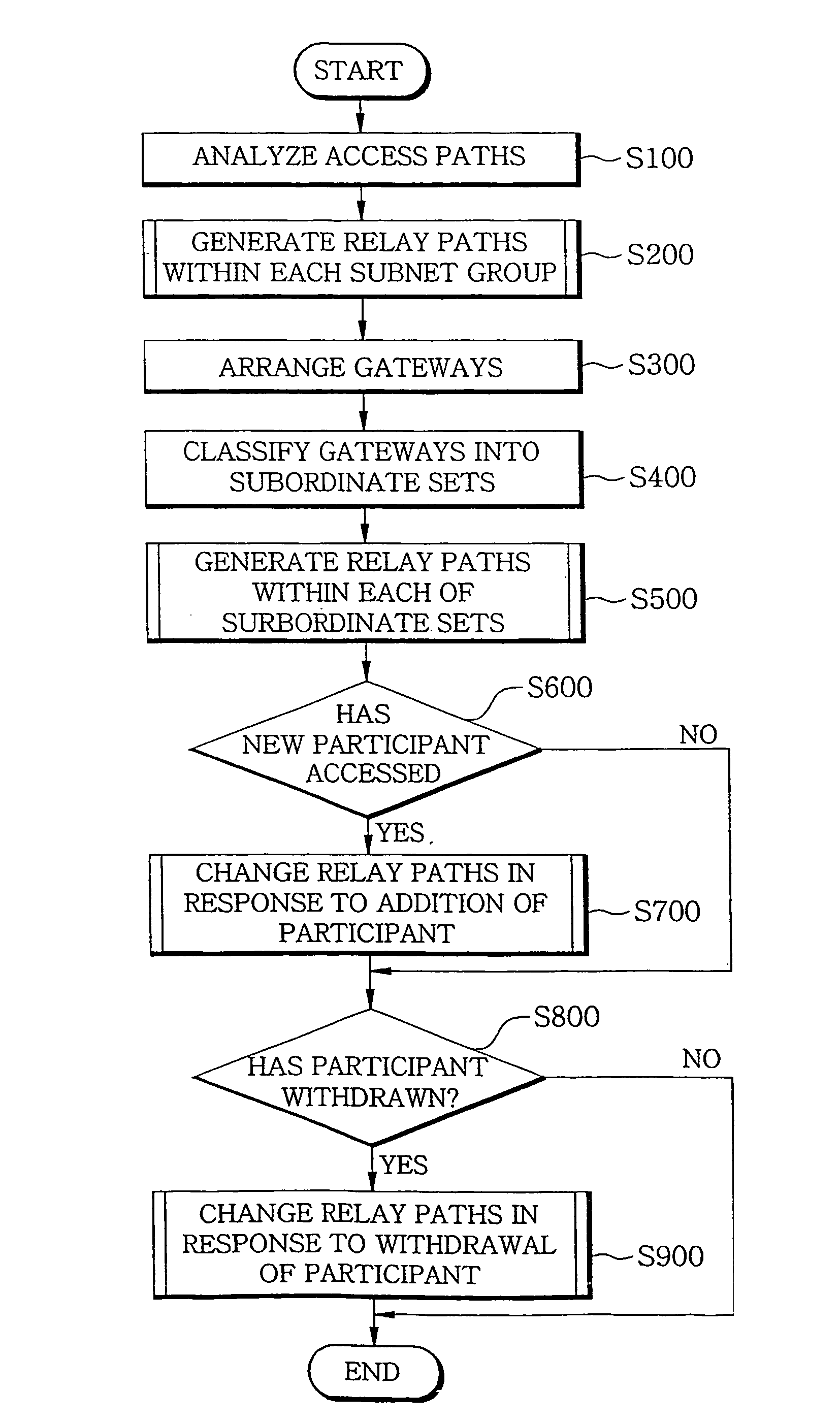

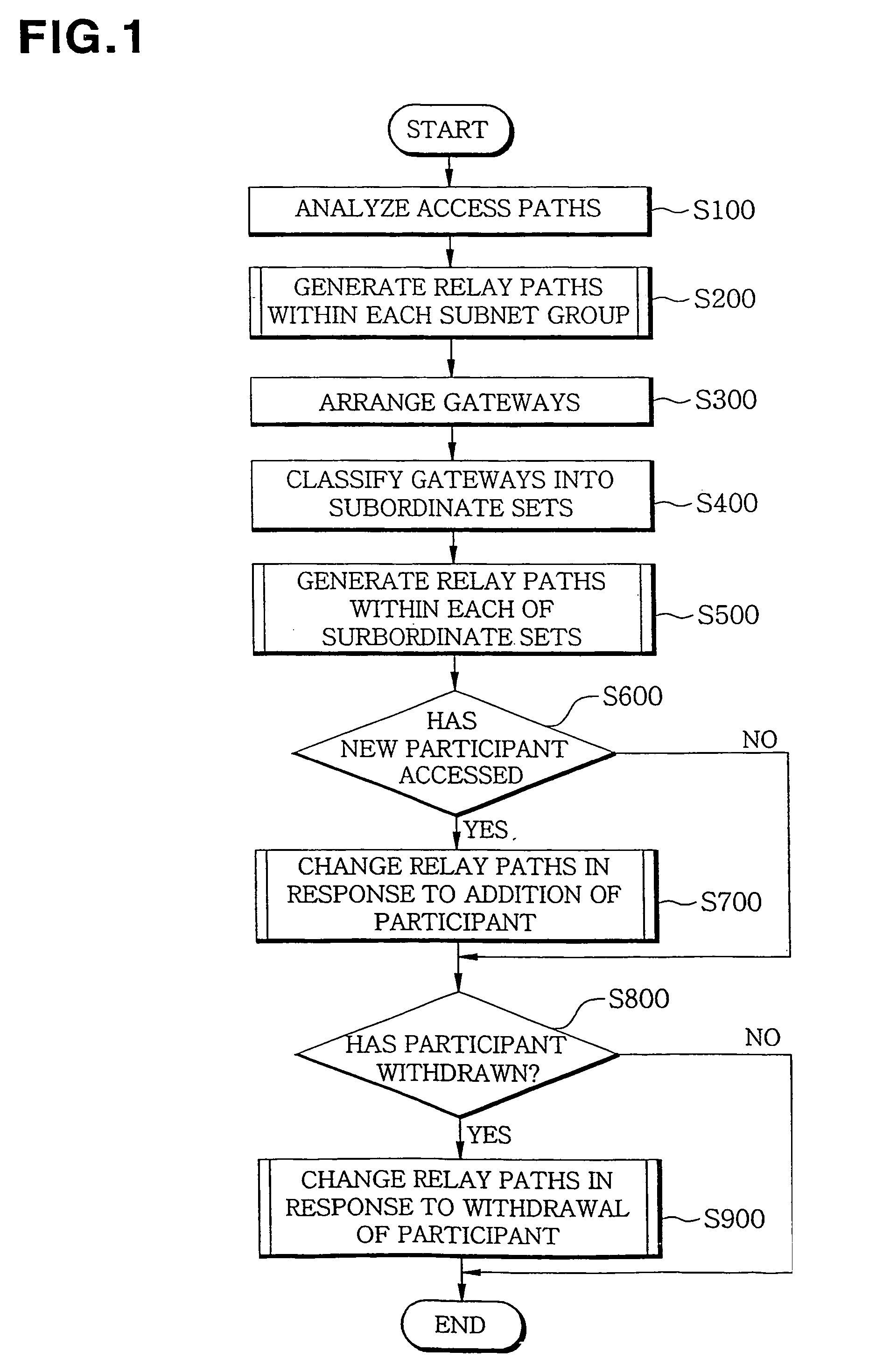

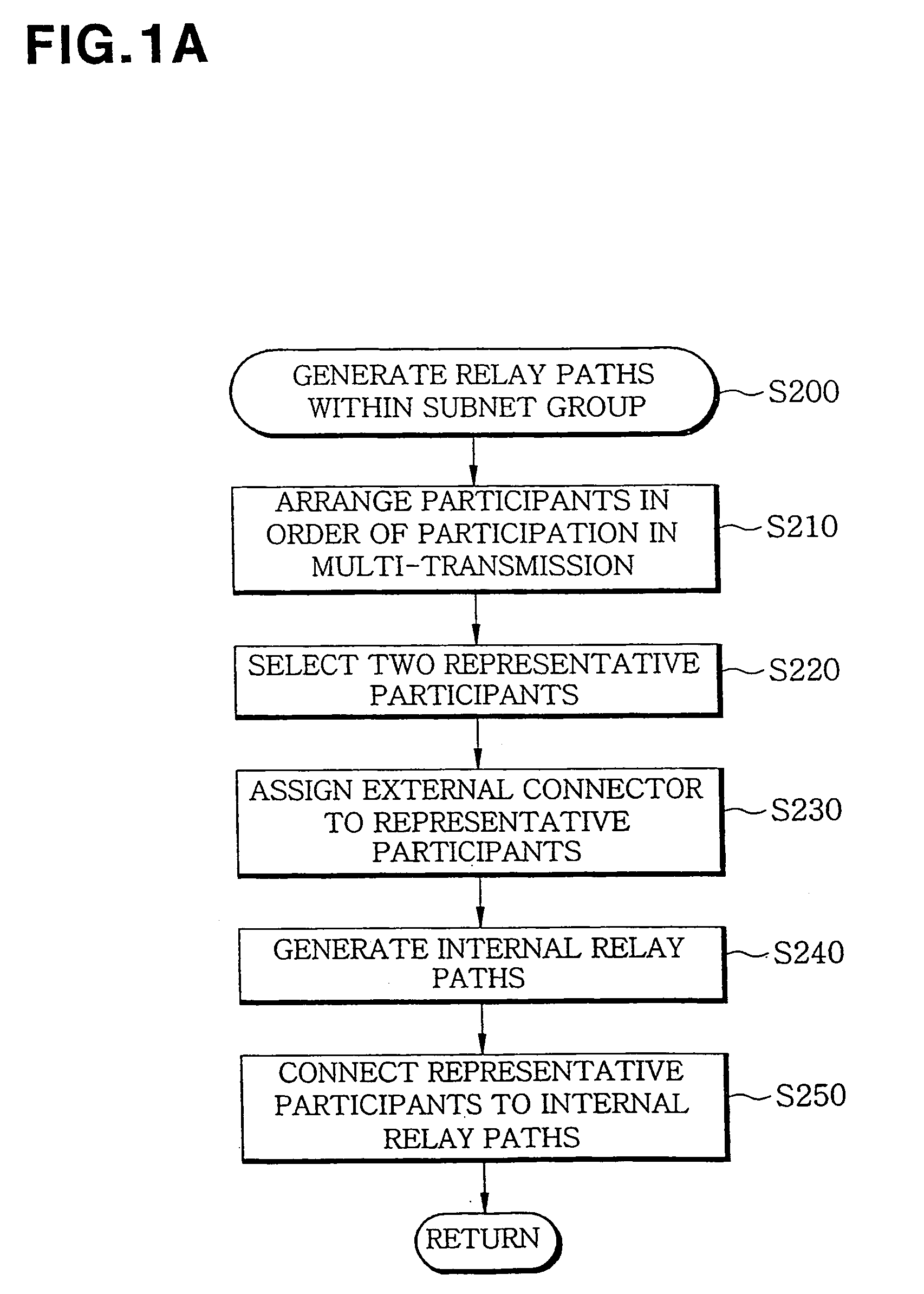

Method for generating casting path among participants for multicasting

InactiveUS7315516B2Stable and reliable data transmissionMinimize changesSpecial service provision for substationStar/tree networksPathPingTrunking

A method of generating relay paths among a plurality of participants in multi-transmission is provided for transmitting predetermined data to the participants. The method includes a first step of analyzing access paths of the participants; a second step of generating a binary tree structure of relay paths among participants belonging to each subnet group; a third step of arranging gateways on the access paths of the participants according to the order on a connection path connecting the gateways to a data server; a fourth step of classing gateways, which are connected to the same upper gateway and are at the same level as a result of the arrangement, as a subordinate set of the upper gateway; and a fifth step of calculating the number of hops of each gateway within the subordinate set to a corresponding subnet group and generating a binary tree structure of relay paths starting from a gateway having relatively fewer hops toward a gateway having relatively more hops.

Owner:GHIZI SOFT CO LTD

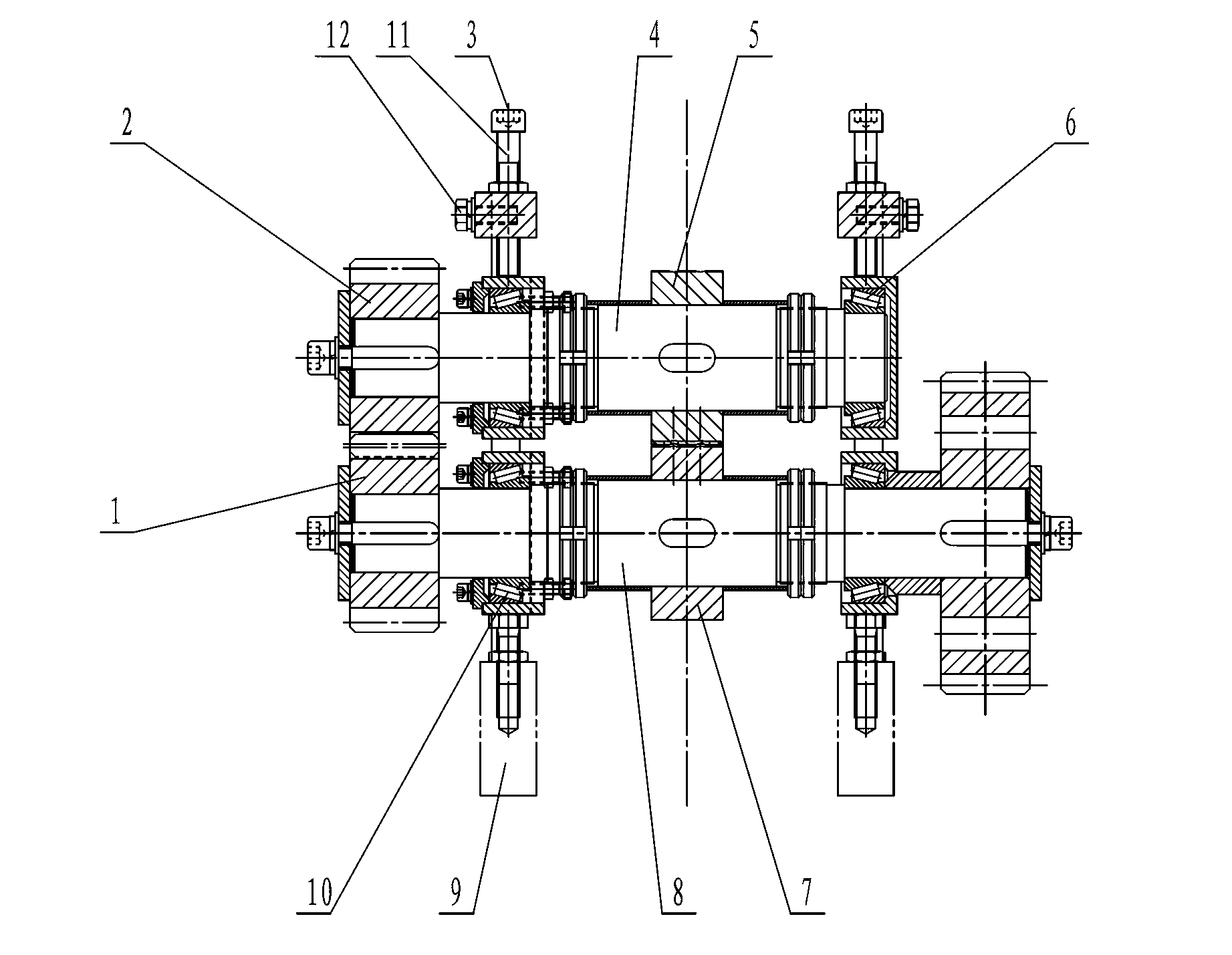

Gear transmission device with variable center distance

InactiveCN102853035AStable and reliable transmissionMeet the requirements of roll forming of flat steel with different thicknessGearboxesToothed gearingsEngineeringMechanical engineering

The invention relates to a gear transmission device with a variable center distance. The gear transmission device comprises a rack, and is characterized in that an upper roll shaft and a lower roll shaft are arranged on the rack, wherein the upper roll shaft is arranged on the rack through an upper supporting bearing; the lower roll shaft is arranged on the rack through a lower supporting bearing; an upper pressing roll an d a lower pressing roll are assembled on the upper roll shaft and the lower roll shaft respectively; the upper roll shaft is provided with an upper gear; the lower roll shaft is provided with a lower gear; the upper gear is engaged with the lower gear; and the upper supporting bearing is provided with an adjusting mechanism capable of adjusting a vertical position of the upper supporting bearing. The adjusting mechanism comprises an adjusting rod which is connected with the upper supporting bearing; and the adjusting rod is fixed with the rack through a fastening bolt. The gear transmission device has the advantages that (1) the center distance of the gear transmission can be adjusted to meet roller forming requirements of flat steel with different thicknesses, and (2) stable and reliable gear transmission is guaranteed by applying a deflection technology when the center distance of the gears is adjusted within a certain range.

Owner:WUXI WEIHUA ELECTRIC WELDING MFG

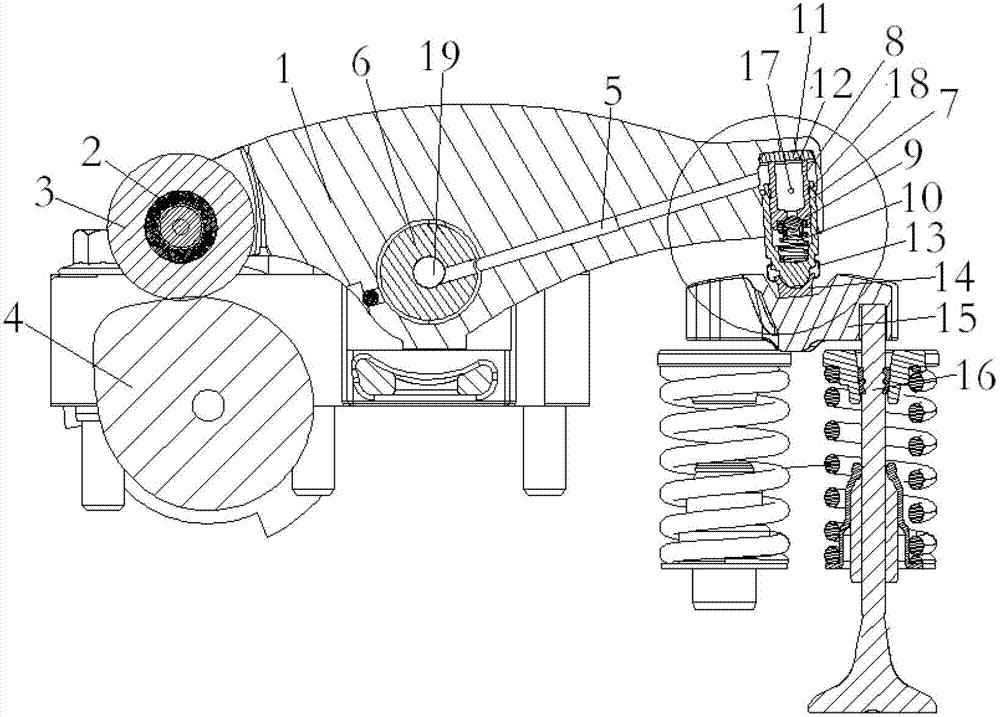

Roller-type hydraulic rocking arm component

InactiveCN102733875ARealize air intakeRealize exhaust functionValve arrangementsLubrication of auxillariesEngineeringCam

The invention discloses a roller-type hydraulic rocking arm component. The structure is as follows: one end of a rocking arm is provided with a short shaft, a bearing is embedded outside the short shaft and into the roller, and the roller and a camshaft form a transmission pair; an oil duct is arranged in the rocking arm, the middle part of the rocking arm is provided with a rocking arm shaft, the other end of the rocking arm is provided with a plunger bushing, and a plunger, a check valve and a return spring are sequentially arranged in the plunger bushing; the upper end of the plunger bushing is provided with a plunger cover plate, and the plunger cover plate is provided with an oil return channel; and the plunger bushing is connected with a slider through a cutting sleeve, the slider closely contacts a valve bridge, and the valve bridge contacts a valve push rod mechanism. The invention is suitable for an overhead camshaft mechanism, and the structure is simplified since the valve support column, the push rod and other parts connected with the cam are reduced. The rocking arm forms a zero-clearance fit with the camshaft and the valve push rod, thereby lowering the noise. On the premise of enhancing the strength of the engine block, cylinder head and the like, the volume of the engine is reduced, so that the structure is more compact reasonable, and the economical efficiency and power performance of the engine are enhanced.

Owner:东风朝阳朝柴动力有限公司

Differential gear train of double circular arc modified cycloid gear

InactiveCN103234006AFlexible transmissionNot easy to get stuckToothed gearingsPortable liftingMechanical equipmentEngineering

The invention relates to a differential gear train of a double circular arc modified cycloid gear and belongs to the technical field of gear transmission designs and gears of mechanical equipment. The differential gear train comprises an inner gear ring, planet gears and a central gear, wherein the planet gears are mounted between the inner gear ring and the central gear; the meshing between the planet gears and the inner gear ring is internal contact and internal meshing; and the meshing between the planet gears and the central gear is external contact and internal meshing. According to the differential gear train, lateral clearance and top clearance are larger, so that the transmission is flexible; the tooth addendum and the tooth dedendum are smaller, so that clamping stagnation is not prone to occur; the tooth thickness of a gear root is wider, so that the bending strength of the gear root is larger; and the processing cost can be greatly reduced, the transmission efficiency is high, and the contact stress can be effectively reduced.

Owner:KUNMING UNIV OF SCI & TECH

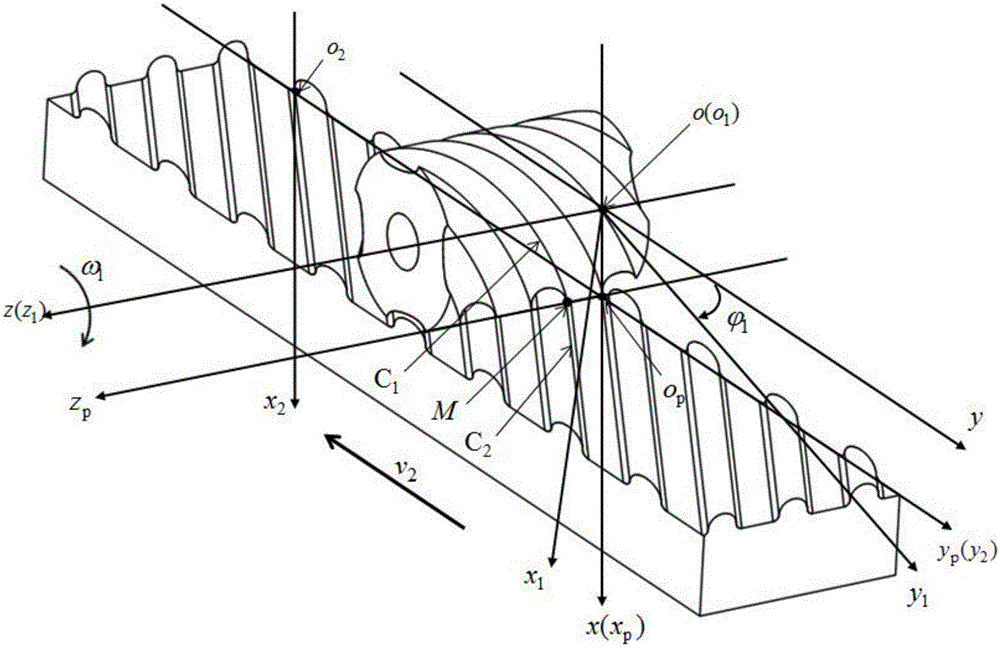

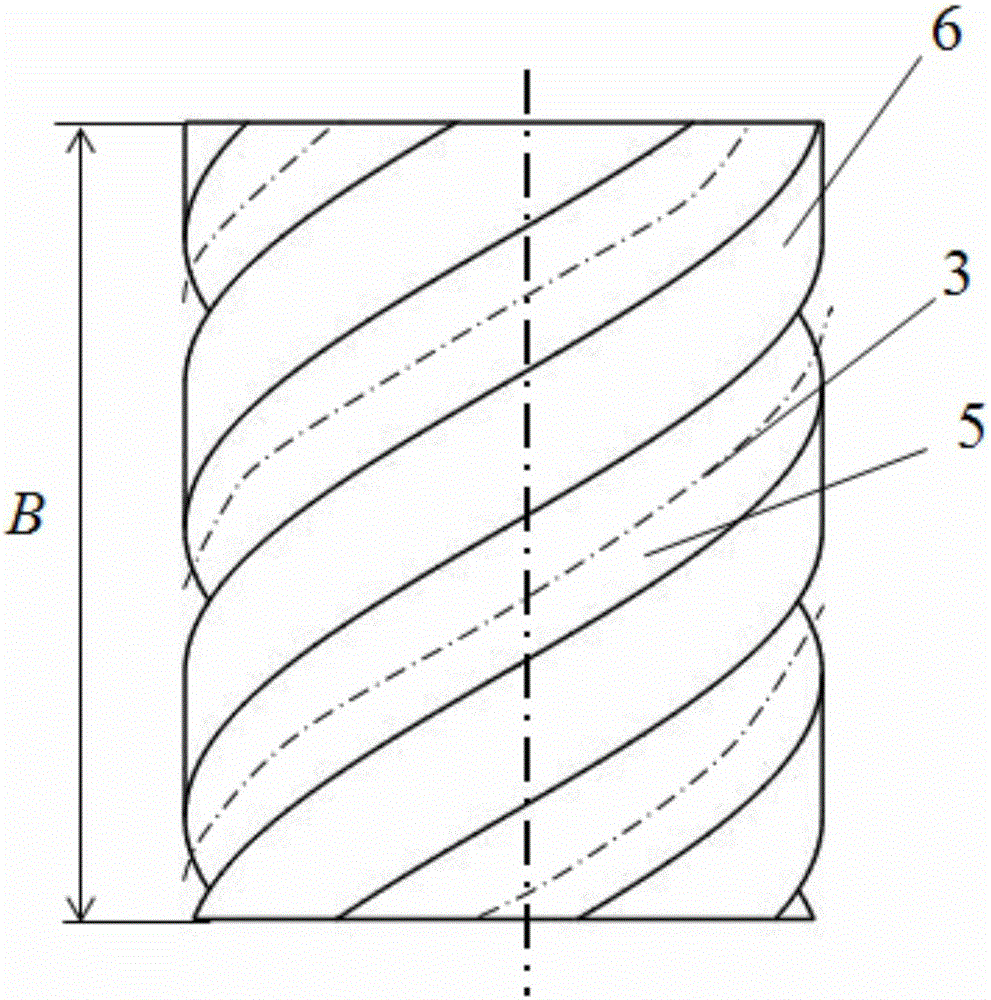

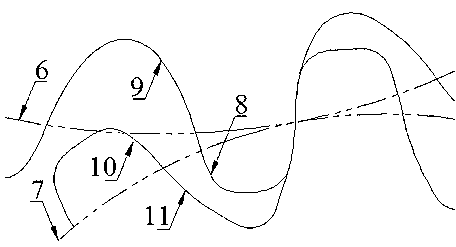

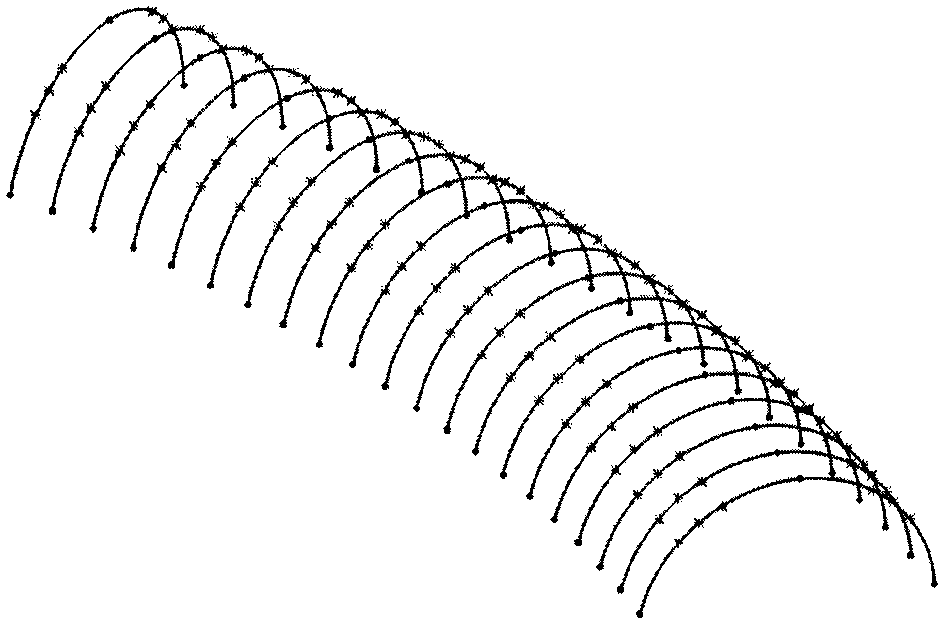

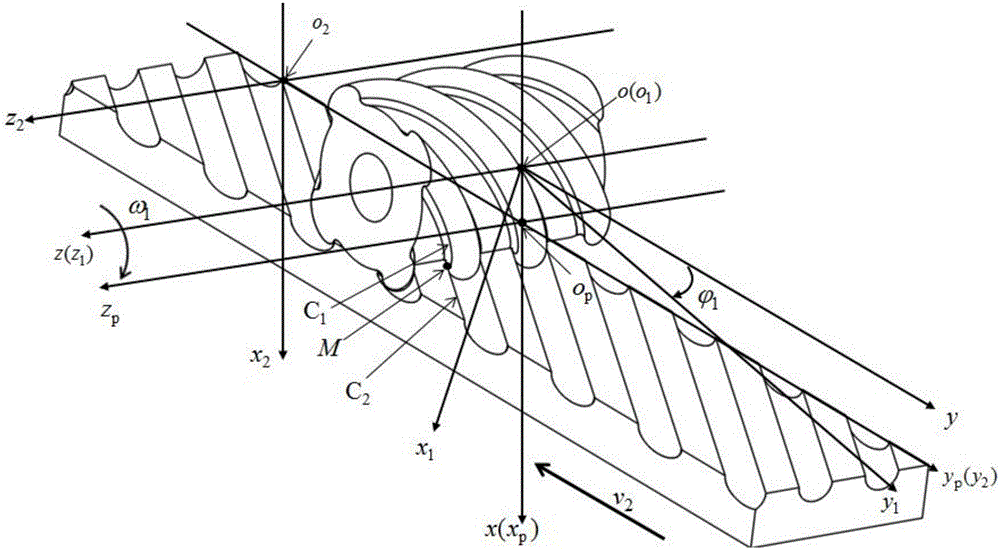

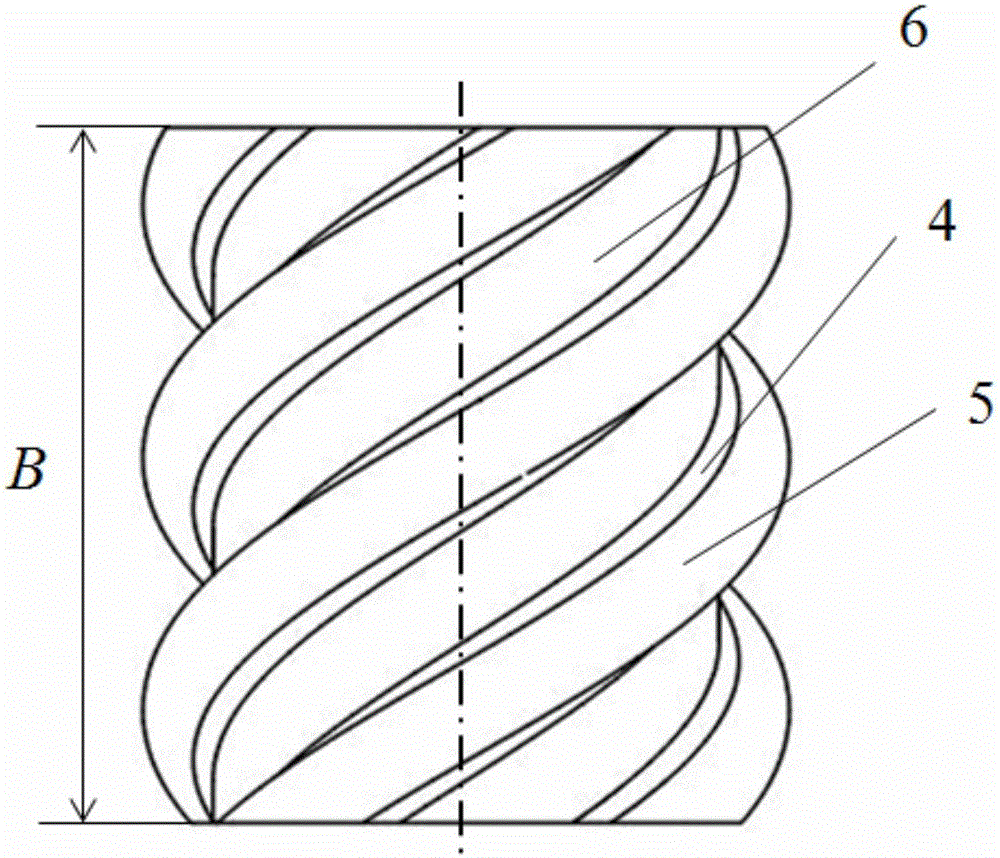

A method for generating real tooth surface of circular arc tooth profile double-arc spiral gear

ActiveCN109241670ANovel transmission principleUnique tooth shapeGeometric CADSustainable transportationPoint cloudReliable transmission

A method for generating real tooth surface of circular arc tooth profile double-arc spiral gear includes the following steps: 1, determining parameters of circular arc tooth profile double-arc spiralgear, 2, according to that relative motion relationship between the circular arc tooth profile double-arc spiral gear and the spiral tooth generating rack, establishing a space coordinate system of the circular arc tooth profile double-arc spiral gear and the spiral tooth generating rack and a space coordinate system generated by the tooth surface of the spiral tooth generating rack, 3, establishing the tooth profile equation of the arc tooth producing shape rack, 4, deriving that tooth surface equation of the arc tooth generating rack; 5, fitting the tooth surface of the arc tooth generate rack; 6, solving the meshing equation according to simulating the conjugate meshing process of the arc tooth generating rack and the arc tooth profile double-arc spiral gear; 7, deriving the tooth surface equation of the arc tooth profile double-arc spiral gear; 8, programming and calculating the tooth surface point cloud of the arc tooth profile double-arc spiral gear; The method has the advantagesof large coincidence coefficient of circular arc tooth profile double arc spiral gears, stable and reliable transmission, strong bearing capacity and meeting the transmission requirements under extreme conditions.

Owner:TIANJIN POLYTECHNIC UNIV

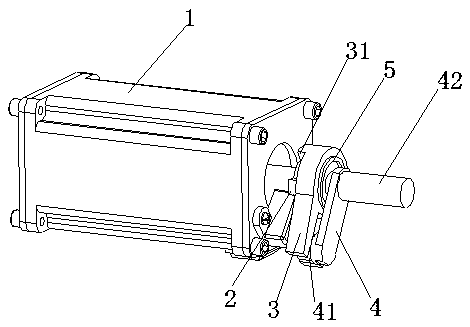

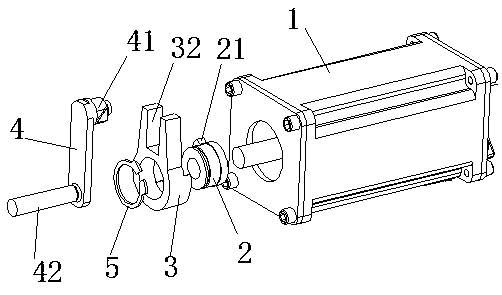

Thread shearing or presser foot lifting drive mechanism of sewing machine and thread shearing or presser foot lifting device

PendingCN111074441AImprove stabilityReduce shakingNeedle severing devicesSewing-machine control devicesCrankElectric machinery

The invention discloses a thread shearing or presser foot lifting drive mechanism of a sewing machine. The drive mechanism comprises a motor, a clutch mandrel, a clutch yoke and a drive crank. A motordrive mode replaces a high-power electromagnet, the clutch mandrel with a short force arm is adopted and the clutch yoke is driven to rotate by output of a motor shaft, so that the effect of the large torque on the motor shaft due to a long moment arm of a cam or the crank is reduced, and the overall transmission stability and reliability are high. In addition, the invention discloses a thread shearing or presser foot lifting device. The actions of a thread shearing mechanism and a presser foot lifting mechanism are controlled through a double-end motor, and compared with the prior art, drivesources are reduced, the structure is simpler, the occupied space is small, installation is convenient, and the cost is reduced; moreover, compared with an electromagnet, motor drive has the advantages that the noise is reduced; and further, by combination with an anti-vibration pad, the stability of the whole device is improved, and shake and noise are reduced.

Owner:台州市福崎缝纫机有限公司

Convex-concave engaged arc gear and rack mechanism without relative sliding

ActiveCN106523632AAvoid wear and tearAvoid gluingPortable liftingGearing elementsEngineeringSpiral line

The invention relates to a convex-concave engaged arc gear and rack mechanism without relative sliding. The convex-concave engaged arc gear and rack mechanism without relative sliding comprises a transmission pair consisting of a spiral arc gear and an arc rack, wherein the spiral arc gear is connected with a rotating shaft of a driver; spiral convex arc teeth are uniformly distributed on the outer surface of the spiral arc gear; center lines of the spiral convex arc teeth of the spiral arc gear are equal-lift cylindrical spiral lines; concave arc tooth grooves are uniformly distributed in the upper surface of the arc rack; the spiral convex arc teeth are matched with the concave arc tooth grooves; and the structural shape of the spiral arc gear and the structural shape of the arc rack are determined by design parameters. When the mechanism is mounted, the spiral convex arc teeth are correctly engaged with the concave arc tooth grooves, and therefore, arc gear and rack transmission is realized. The arc gear and rack mechanism does not have failure modes such as tooth surface relative sliding, tooth surface gluing, tooth surface abrasion and tooth surface plastic deformation, has the advantages of high contact ratio, simple structure, high transmission efficiency, high bearing capacity and the like, and is suitable for being popularized and used in the fields of tiny machines, micro-machines and conventional machines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com