Patents

Literature

132results about How to "Stable power delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

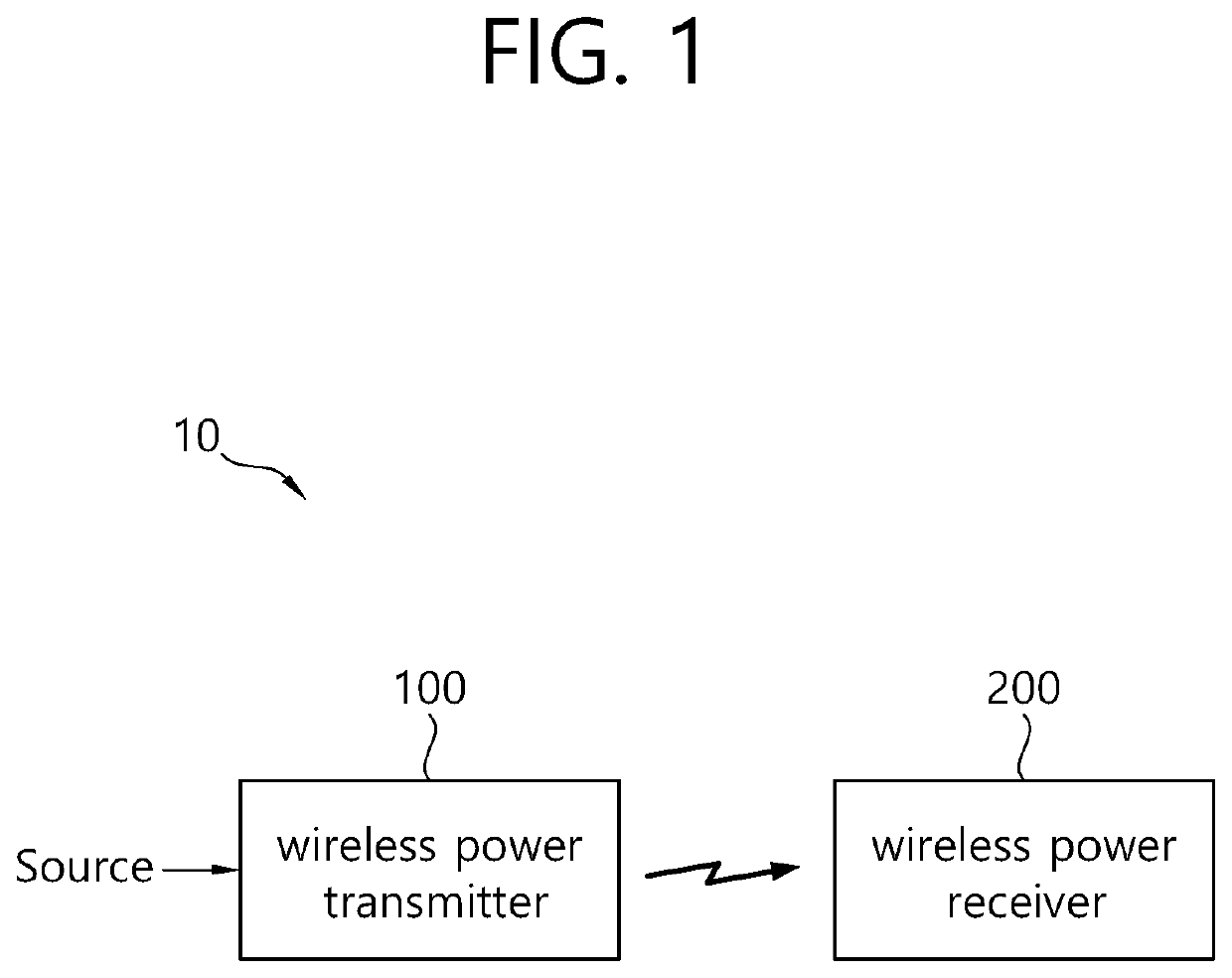

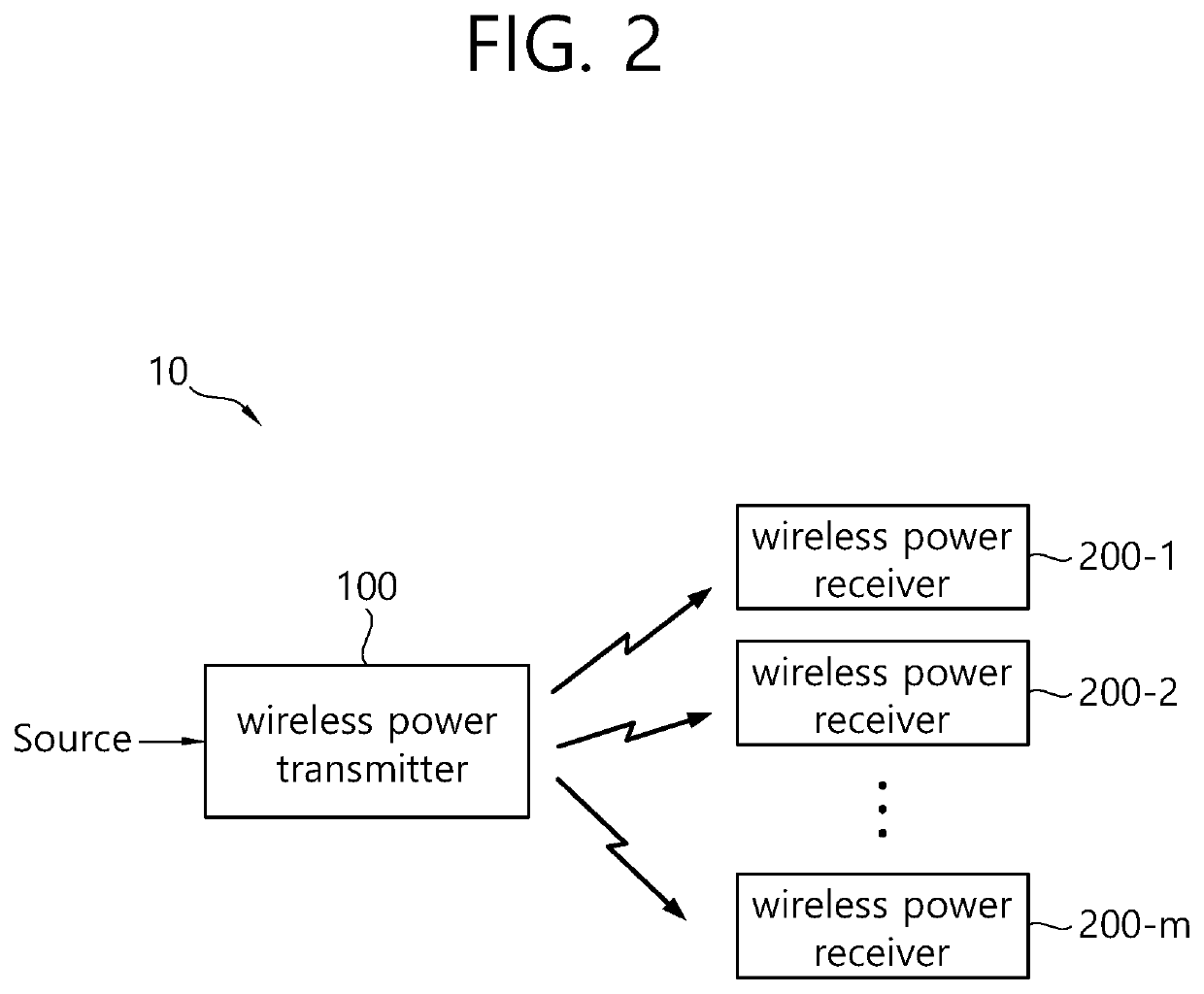

Power transmitter and wireless power transmission system

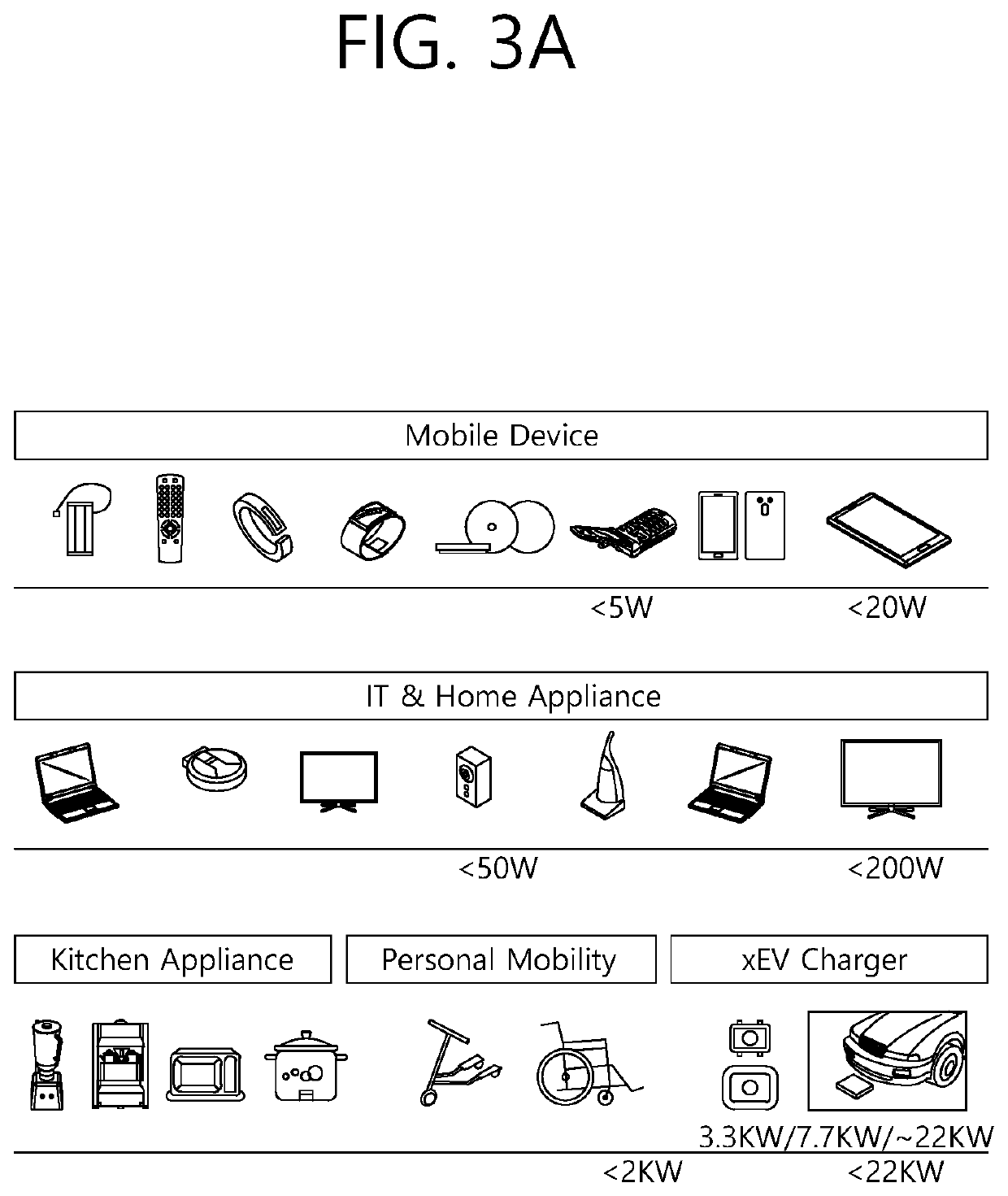

ActiveUS20120063505A1Stable wireless power transmissionStable power deliveryMicrophonesElectrical transducersElectric power transmissionTransmitted power

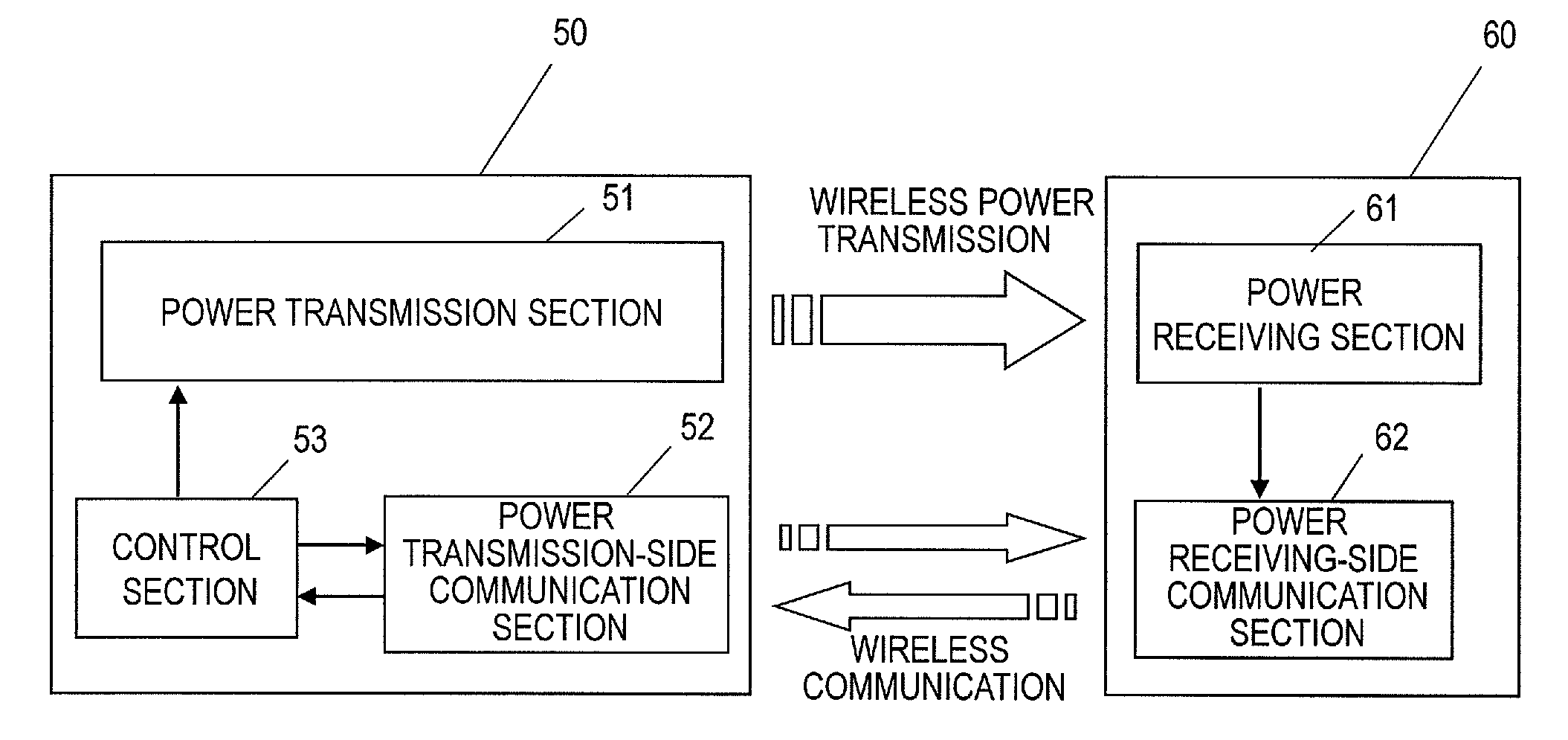

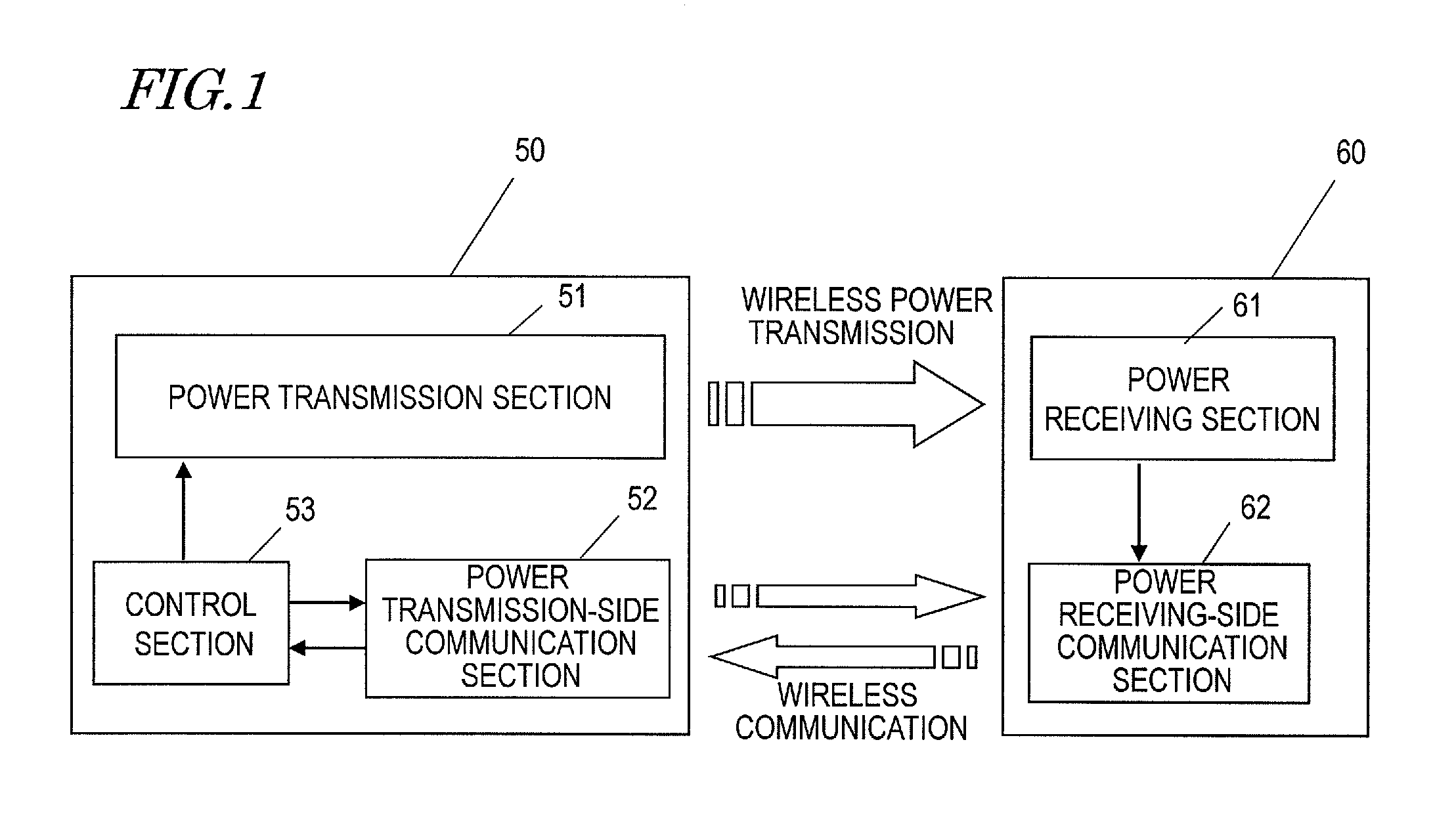

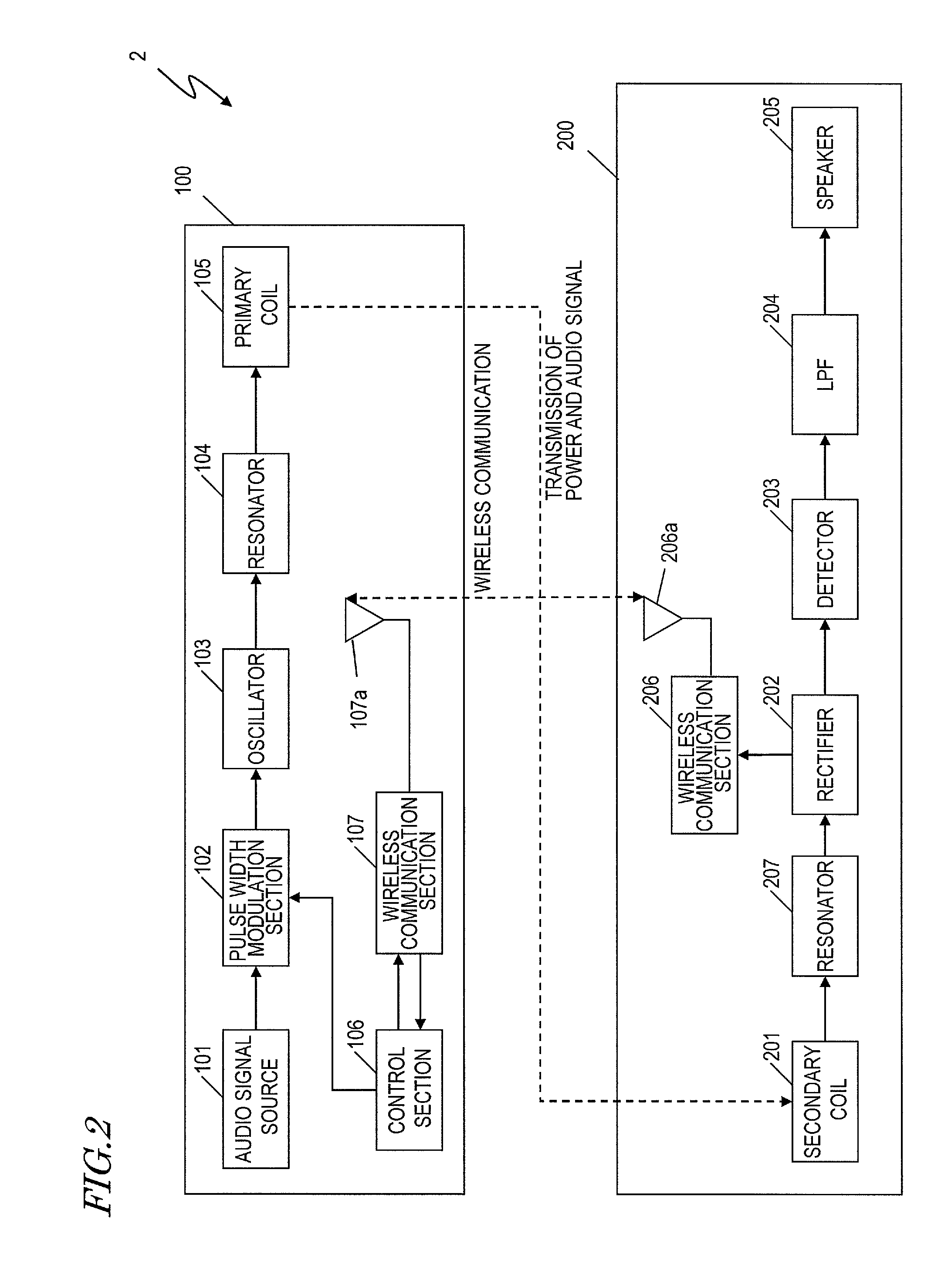

A power transmitter 50 is usable in a wireless power transmission system for transmitting power wirelessly. The power transmitter 50 includes a power transmitting section 51 for transmitting power; a communication section 52 for communicating information, for controlling the transmission of the power, with the power receiver 60; and a control section 53 for controlling the power transmitting section 51 such that the power to be sent out by the power transmitting section 51 is higher while the communication section 52 is performing the communication.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

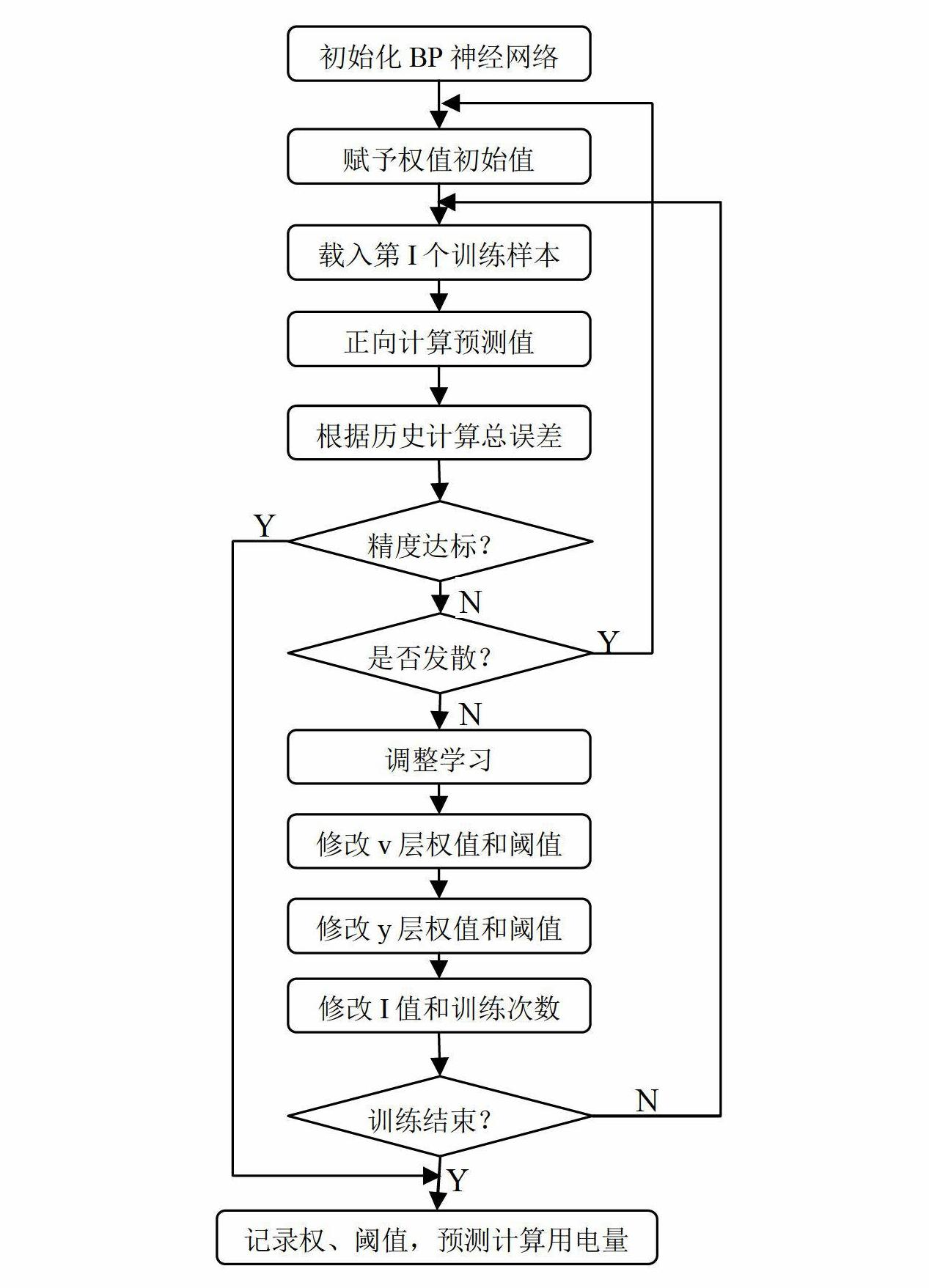

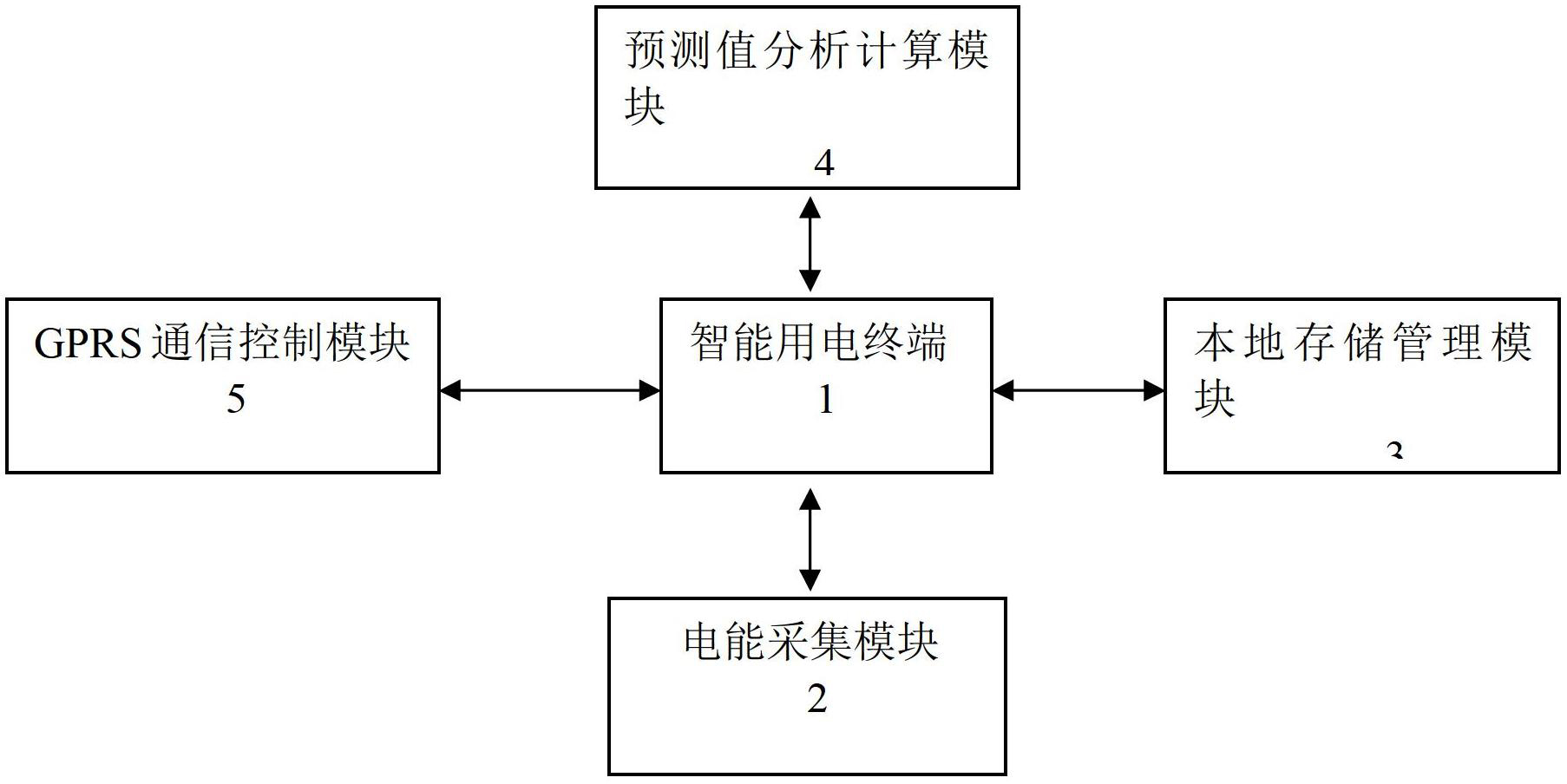

Electricity consumption intelligent prediction system and method

InactiveCN102682349AAvoid lossWide forecast horizonForecastingBiological neural network modelsGeneral Packet Radio ServiceData acquisition

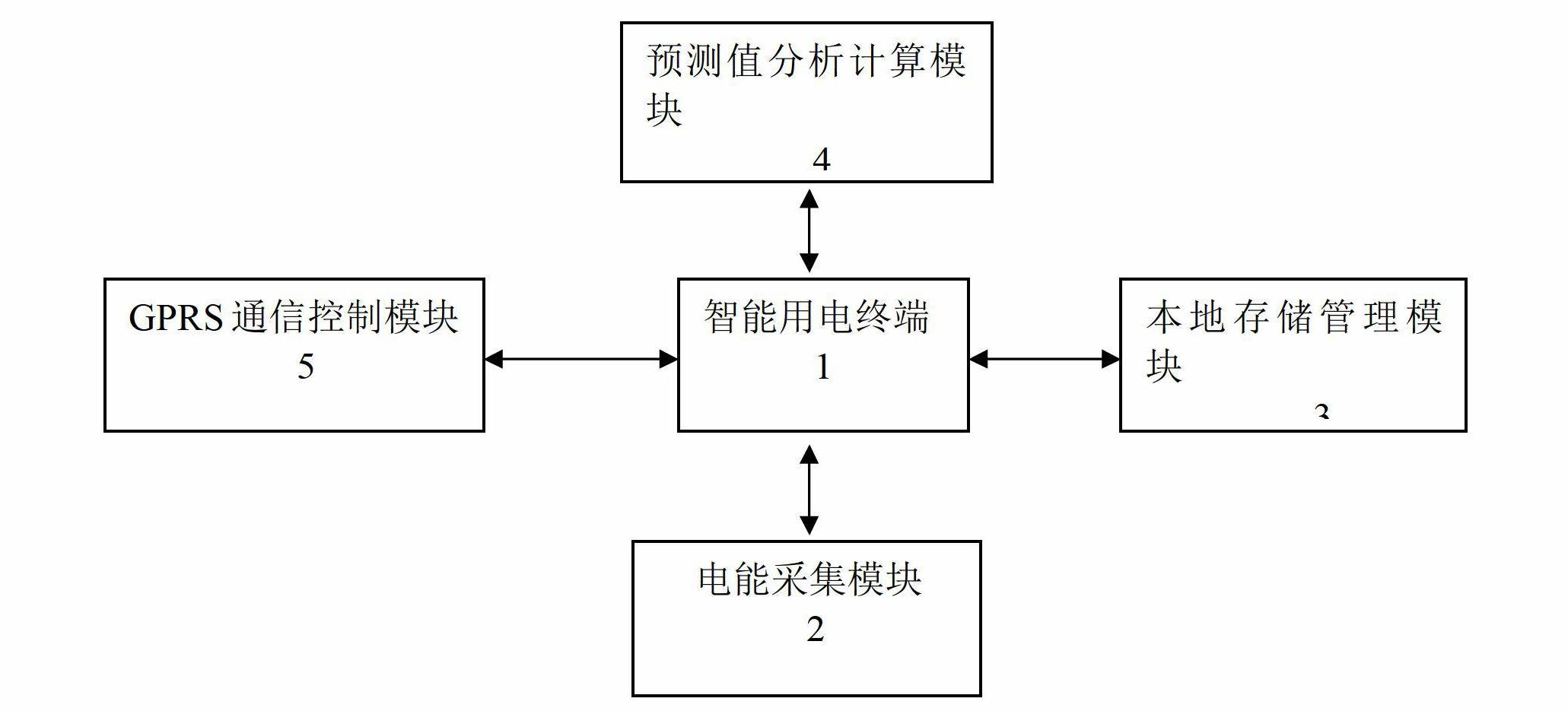

The invention discloses an electricity consumption intelligent prediction system and method, wherein the system comprises an intelligent electricity consumption terminal (1) as well as an electric energy collecting module (2) used for managing real-time data collection, a local storage management module (3), a predication point prediction value analyzing and calculating module (4) and a GPRS (general packet radio service) communication control module (5) which are respectively connected with the intelligent electricity consumption terminal (1), wherein the GPRS communication control module (5) is in charge of communication transmission control; and a core prediction processing algorithm of the predication point prediction value analyzing and calculating module (4) adopts a BP (back propogation) neural network. According to the invention, users can be informed of the electricity consumption situation in advance, and effective electricity consumption optimization suggests are provided for the users by combining with the electricity consumption optimization algorithm, the electricity consumption habits of users are improved, unnecessary electricity expenditure of electric appliances of the users is avoided, and electricity expense is saved for the users economically; and the power grid fluctuation caused by electricity consumption in peak time for the users can also be lowered, thus a power grid is more stable, more stable electricity power conveying is provided, the electricity consumption quality of residents is improved, and the production of enterprise electricity power users of production, manufacturing and the like operates stably.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

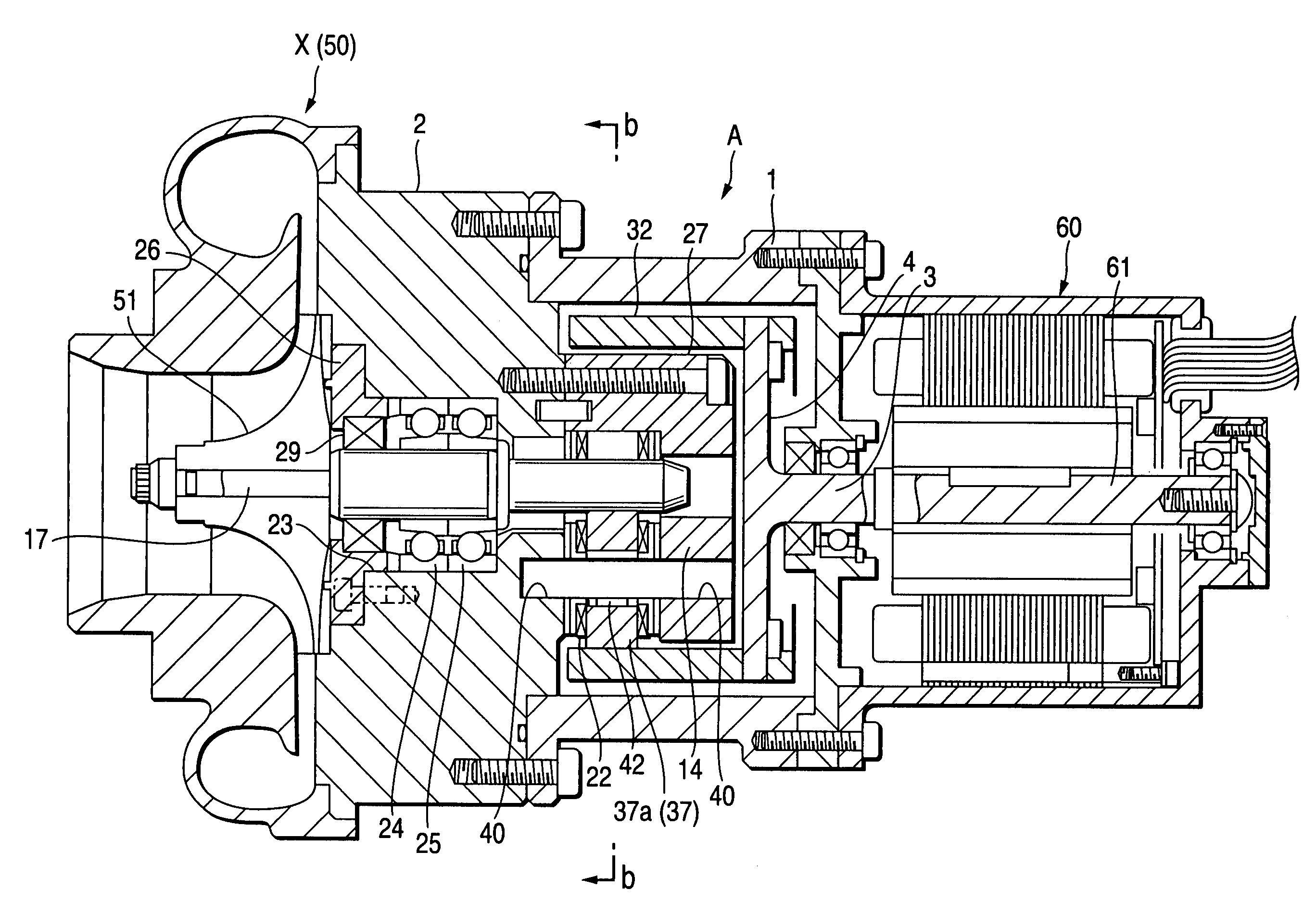

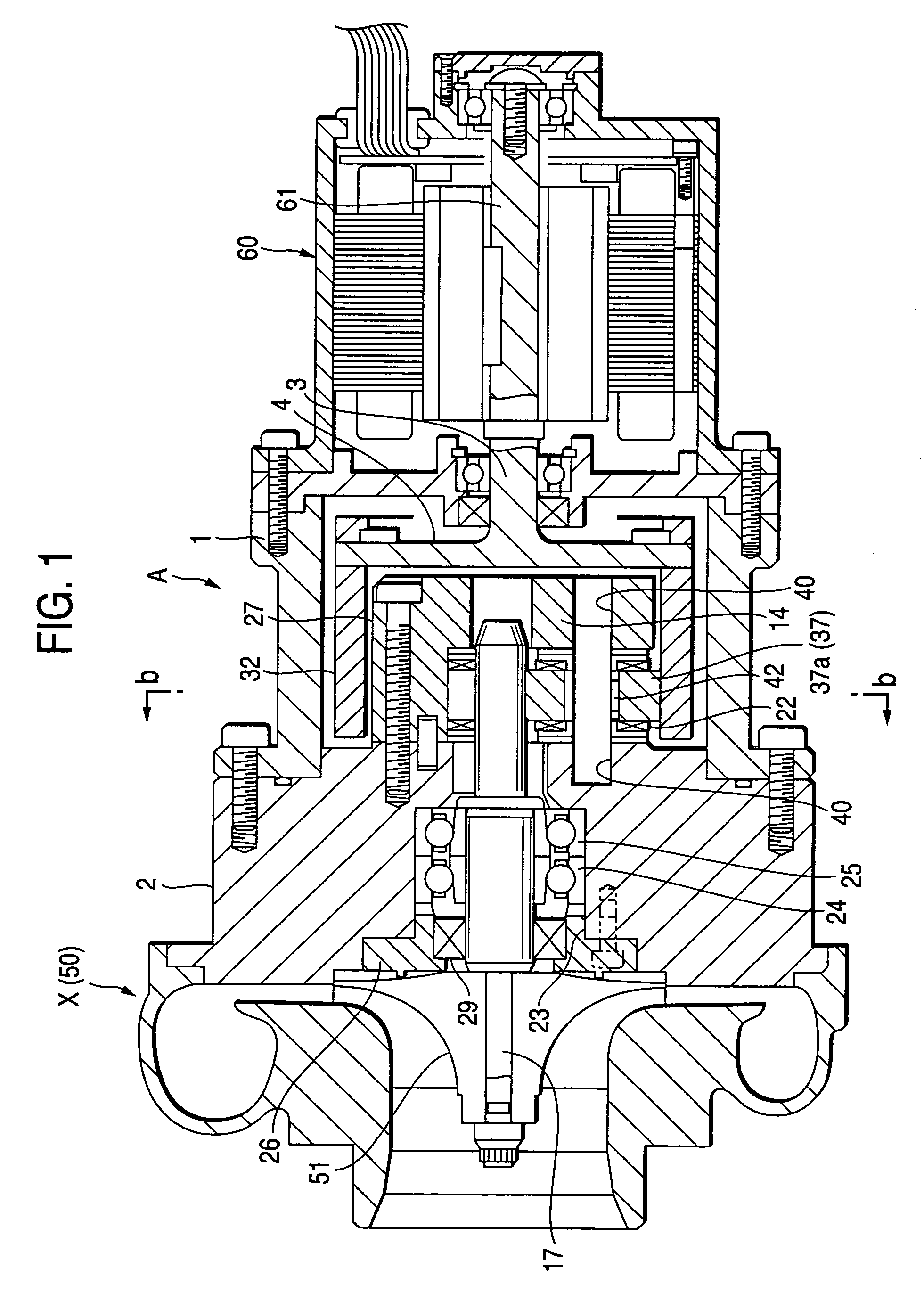

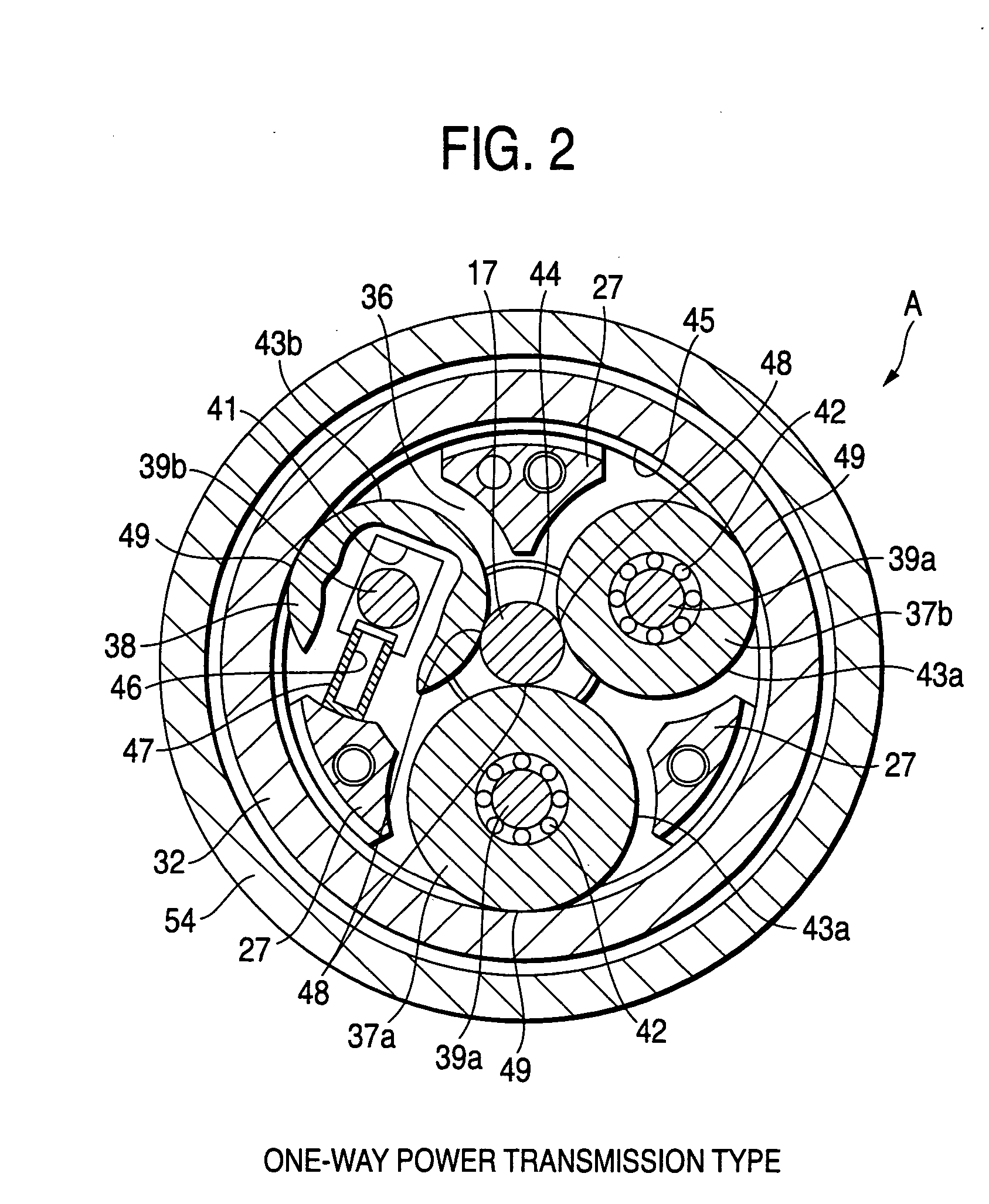

High-speed fluidic device

InactiveUS6994531B2Small sizeImprove transmission efficiencyPortable liftingCombustion enginesLow speedEngineering

A high-speed fluidic device has a friction roller type speed-increasing mechanism, an electric motor, and a high-speed fluidic machine, wherein: the friction roller type speed-increasing mechanism includes a housing, a low-speed side member having an outer ring provided at one end portion thereof, a high-speed side shaft rotatably supported by the housing so as to be eccentric to the low-speed side member and the outer ring, at least one guide roller rotatably supported between the outer ring and the high-speed side shaft, and at least one movable roller rotatably supported between the outer ring and the high-speed side shaft; the electric motor drives the friction roller type speed-increasing mechanism; and the high-speed fluidic machine is connected to the high-speed side shaft so as to be driven by the high-speed side shaft.

Owner:NSK LTD

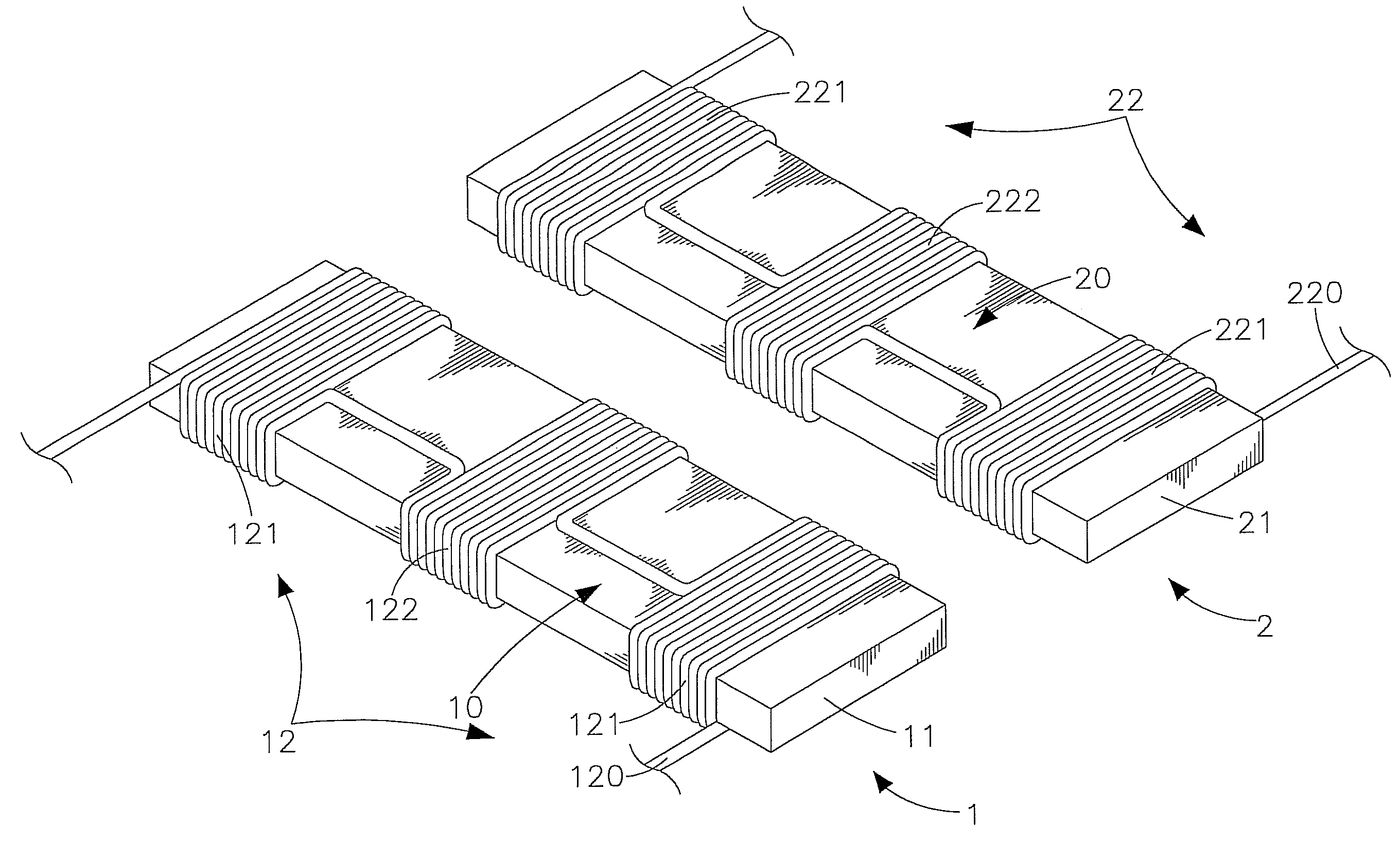

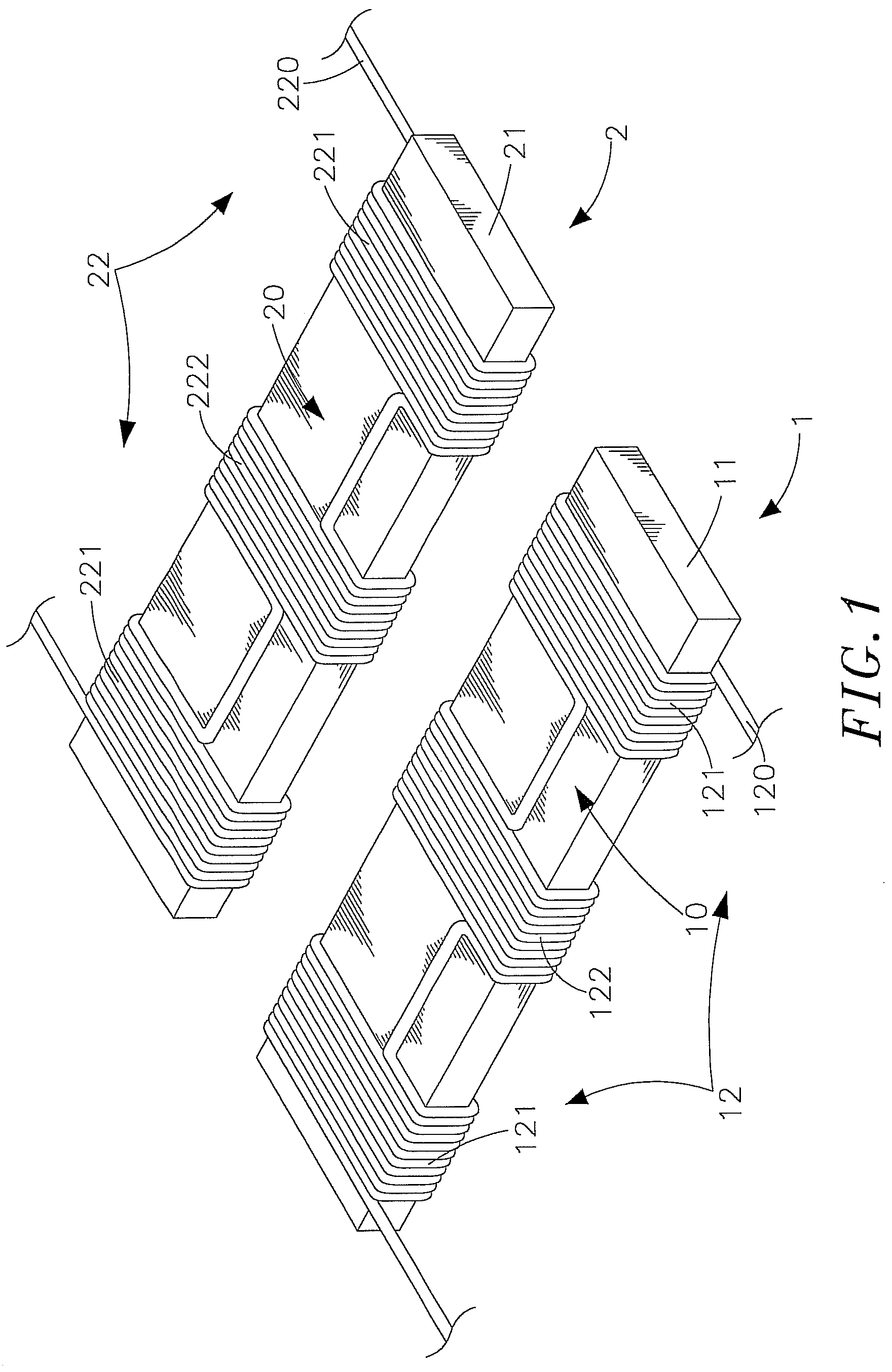

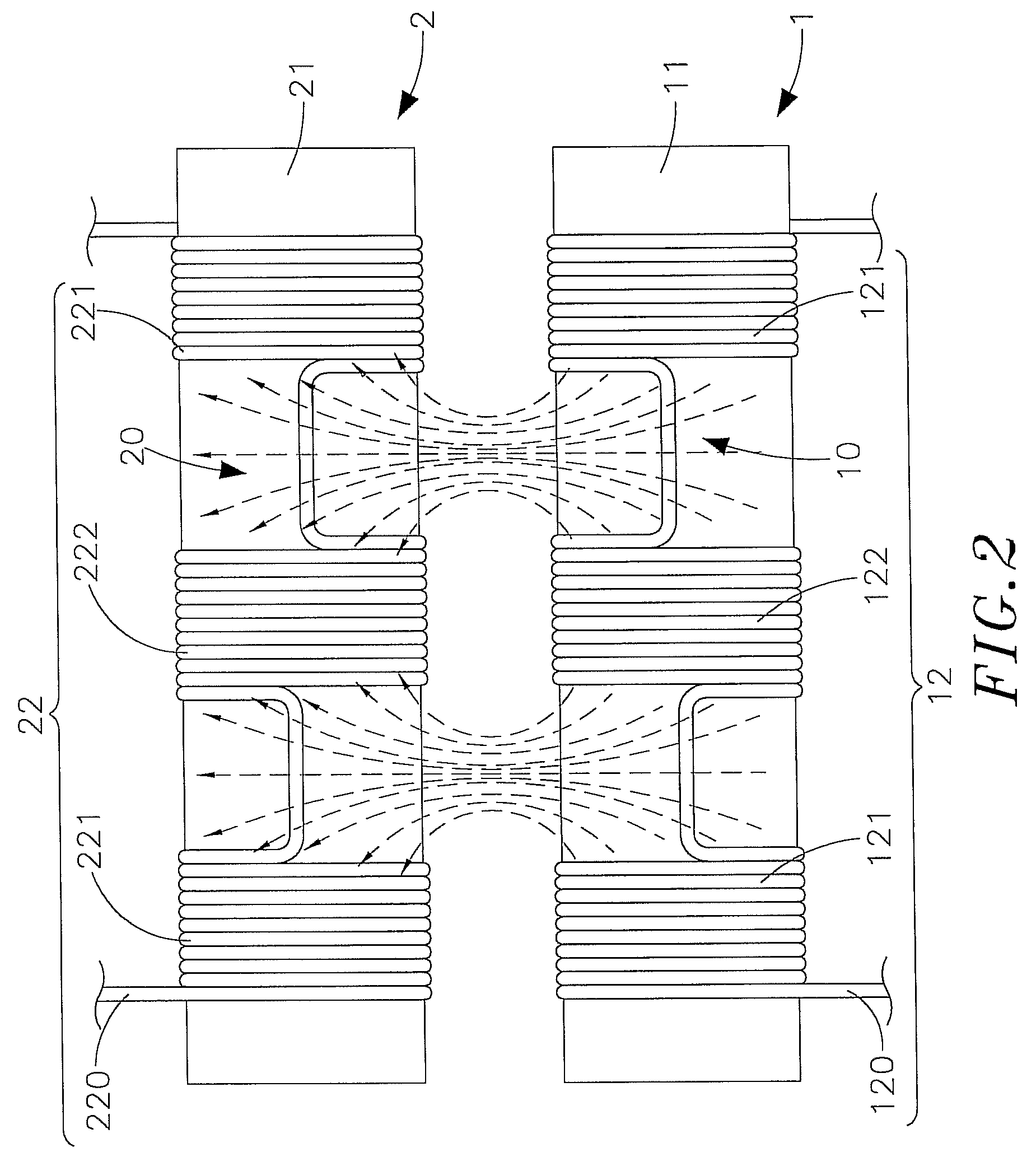

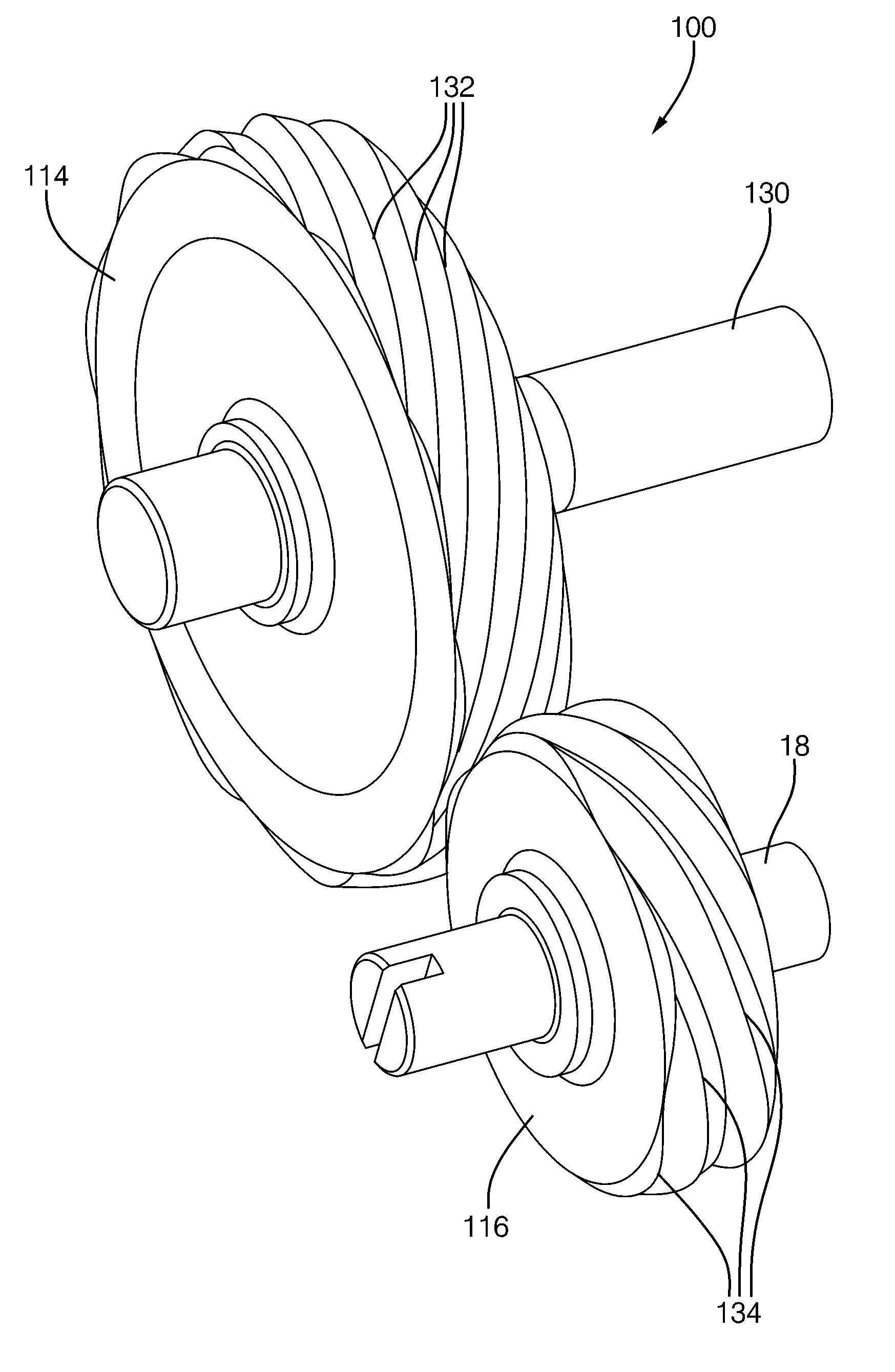

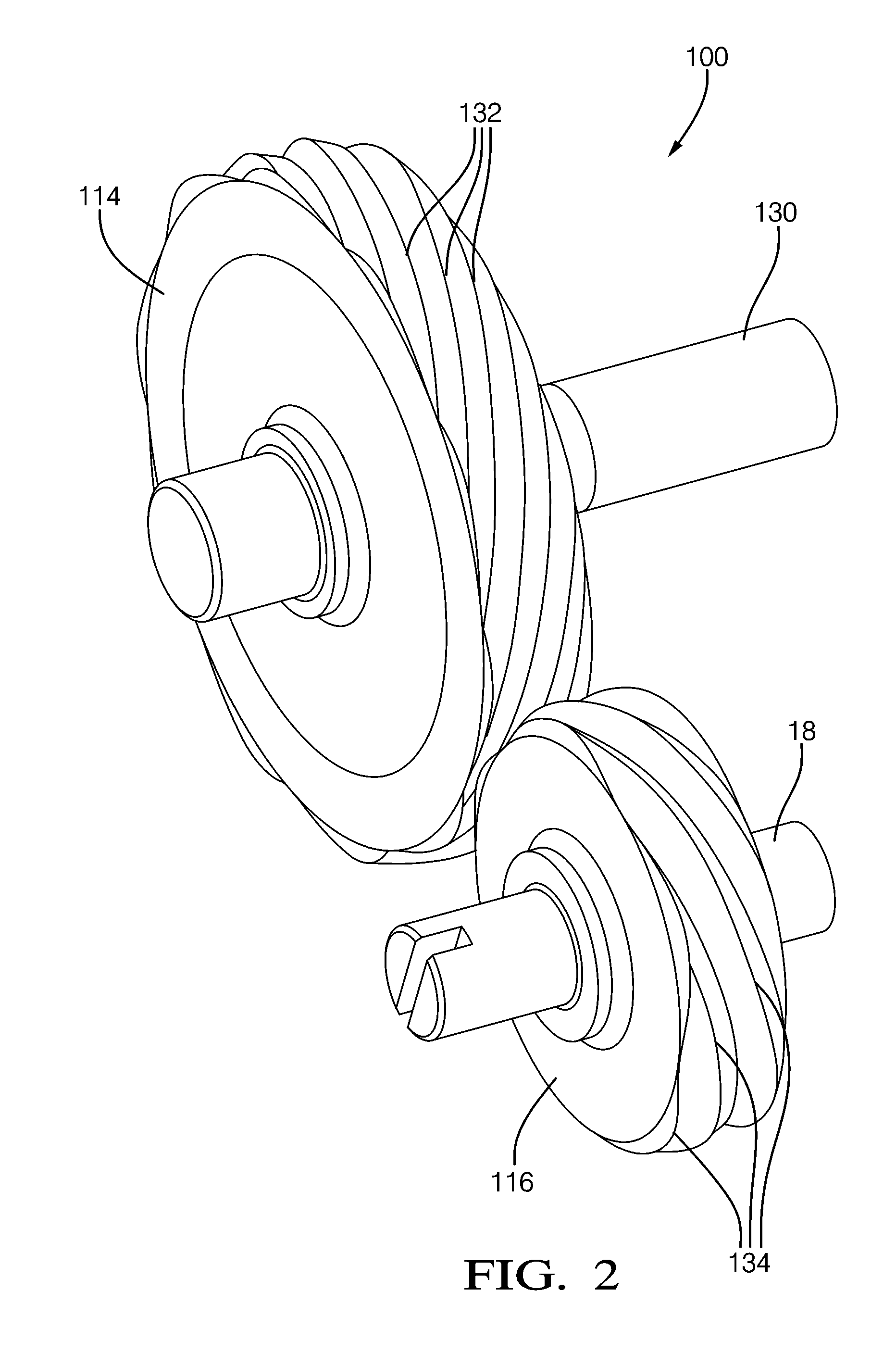

Wireless charging coil structure in electronic devices

ActiveUS8754609B2Improve permeabilityAvoid interferenceBatteries circuit arrangementsTransformersElectric forceElectric power transmission

The present inventions relates a wireless charging coil structure in electronic devices, comprising a PS coil module capable of emitting electromagnetic wave energy and a PR coil module capable of receiving power energy by electromagnetic induction. Each of the PS and PR coil modules includes a bar-shaped magnetic conductor, on which an insulated wire is wound into a first coil that is extended along the magnetic conductor to a given length and wound reversely into a second coil, thus producing an induction coil comprising at least the first and second coils. The induction range with given space formed between the first and second coils is used for electromagnetic induction to transmit signals and power energy. Such structure can be applied not only in planar handheld electronic devices, but also in other wireless power transmission systems that require narrow induction surface for power transmission.

Owner:FU TONG TECH

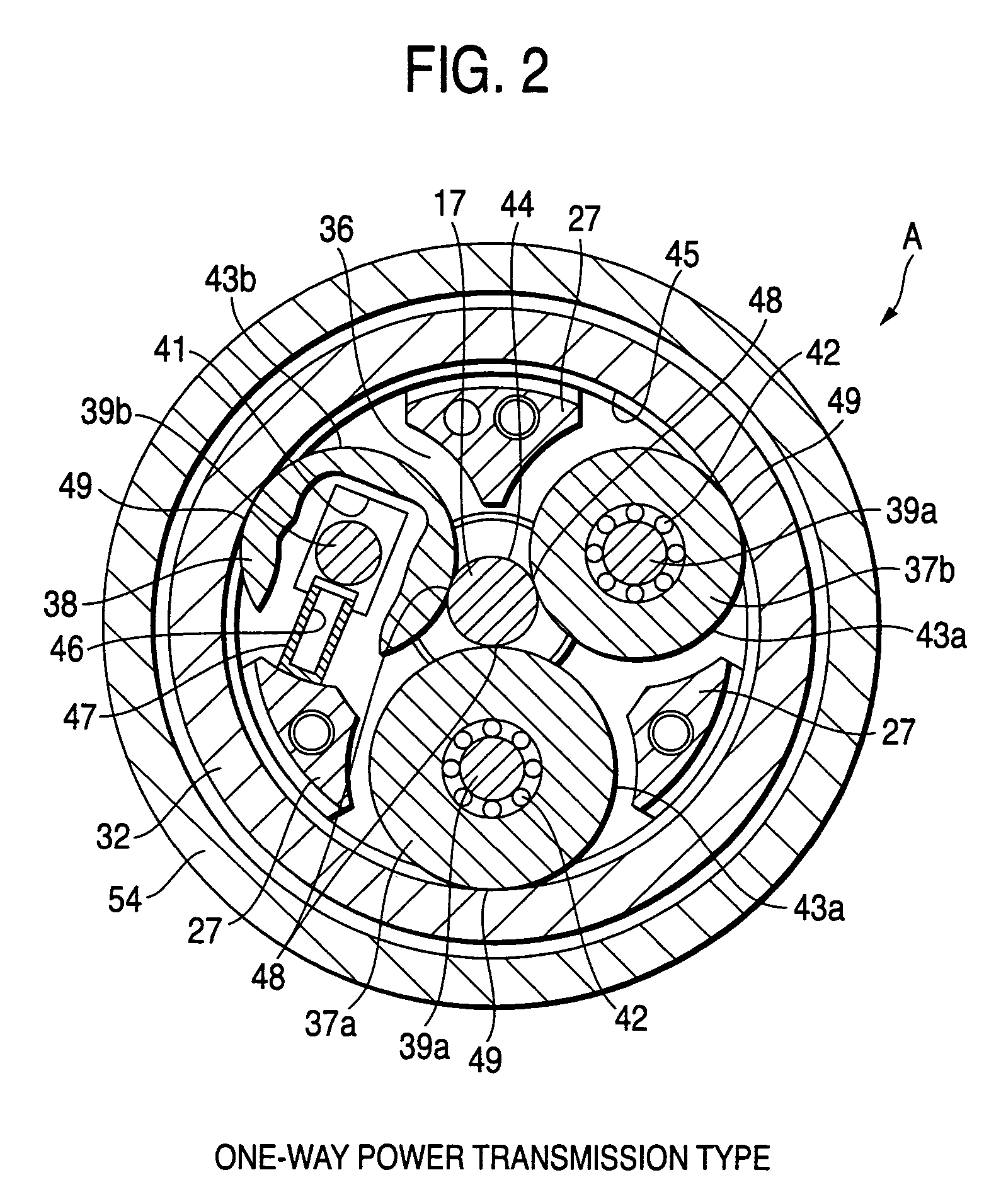

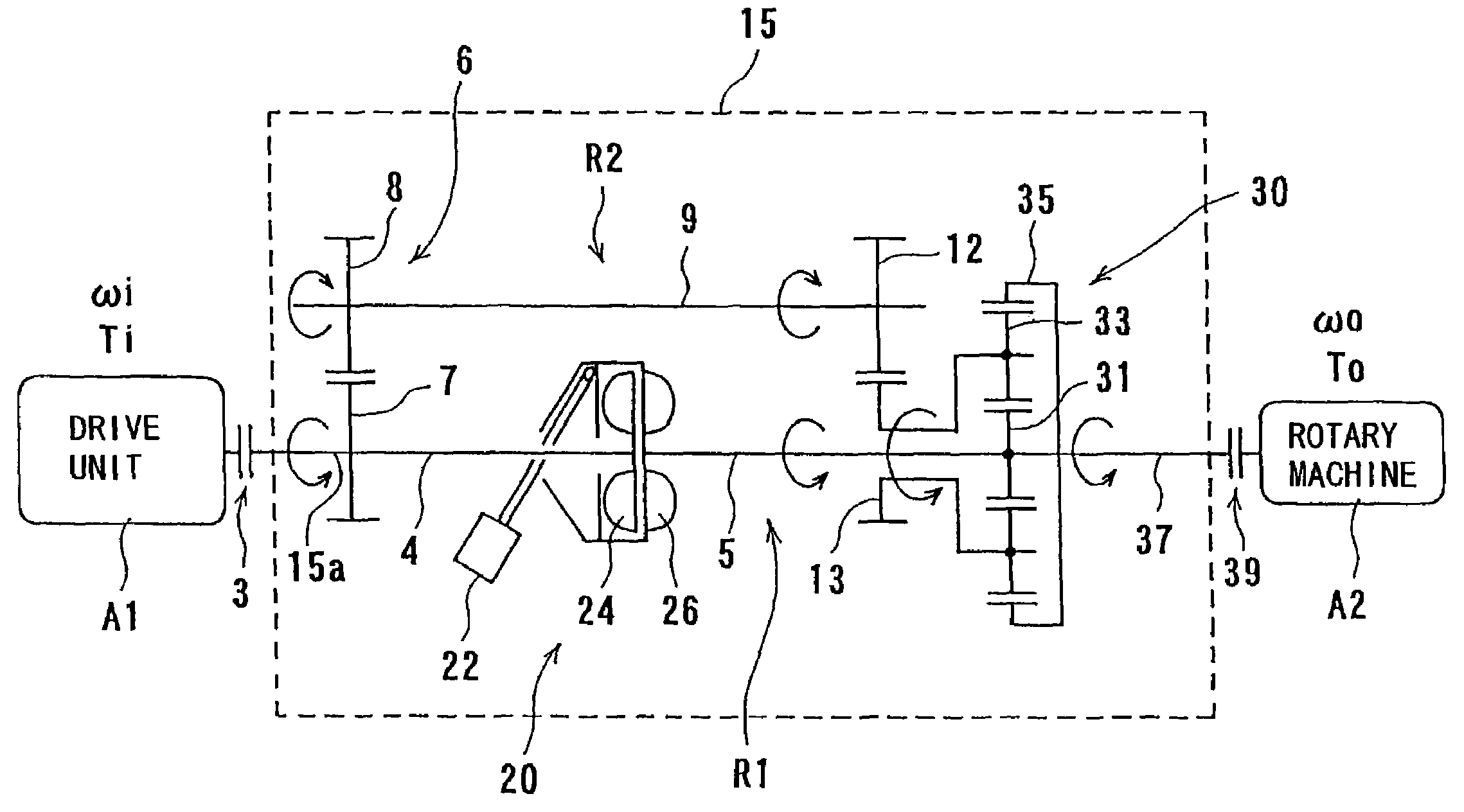

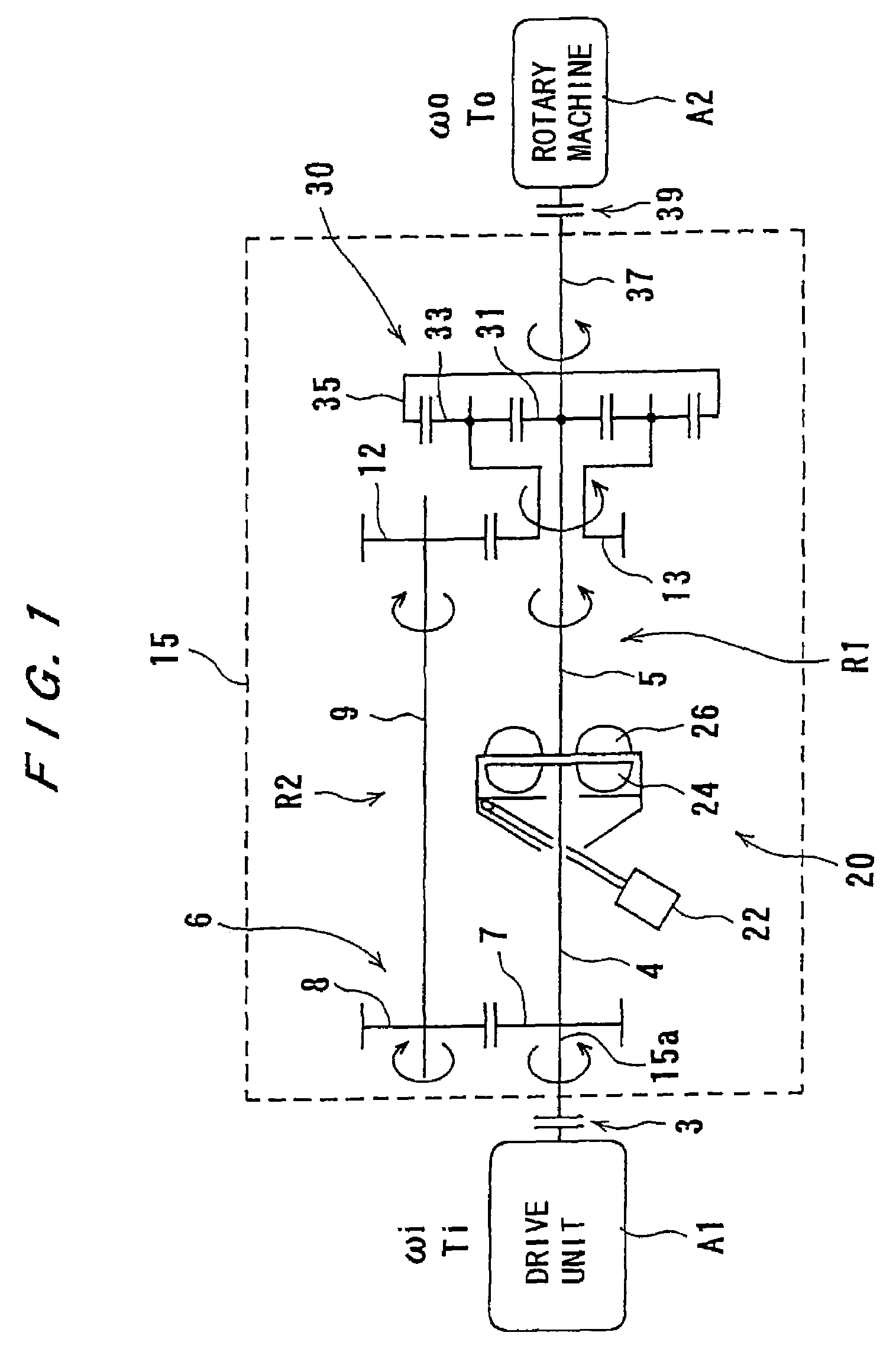

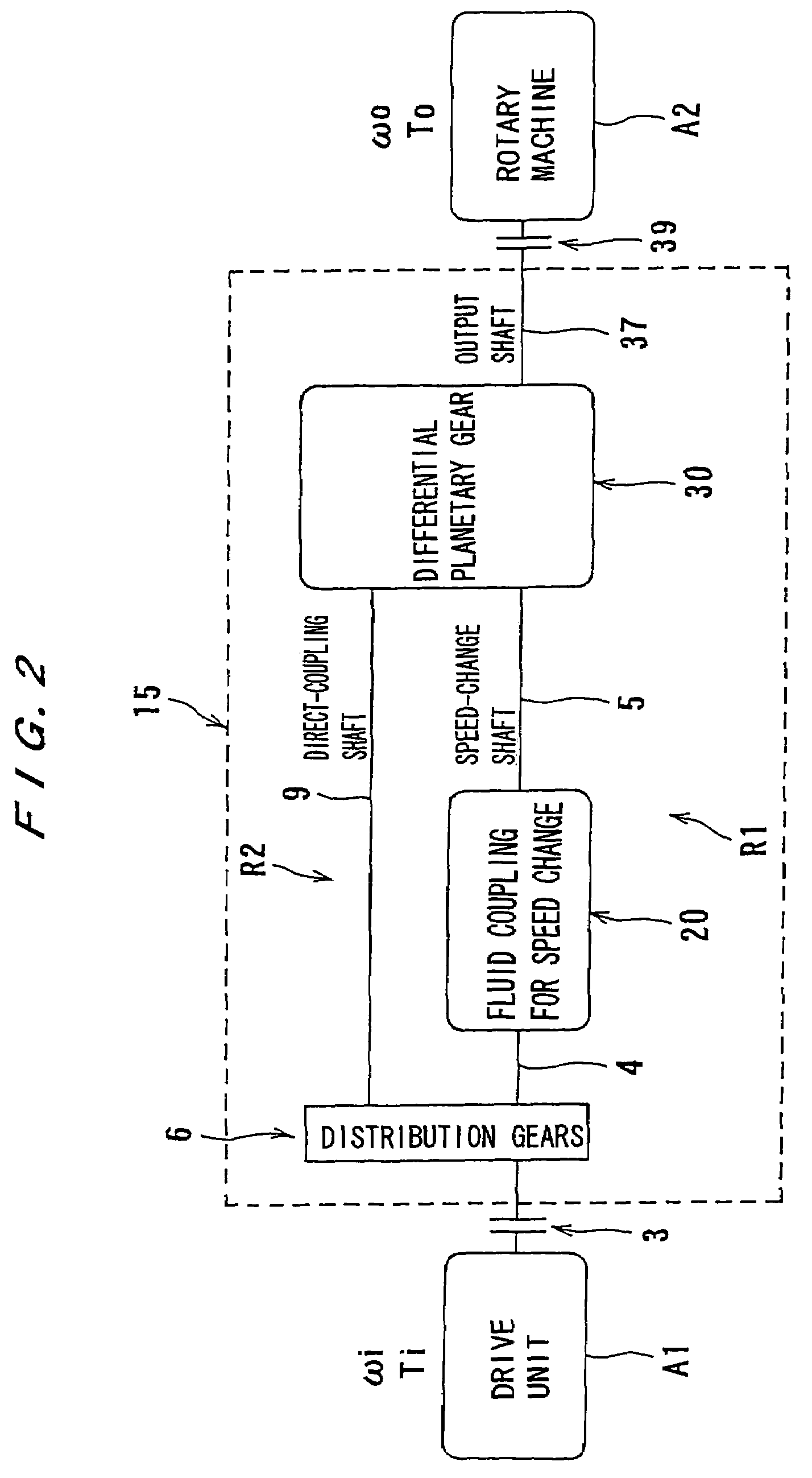

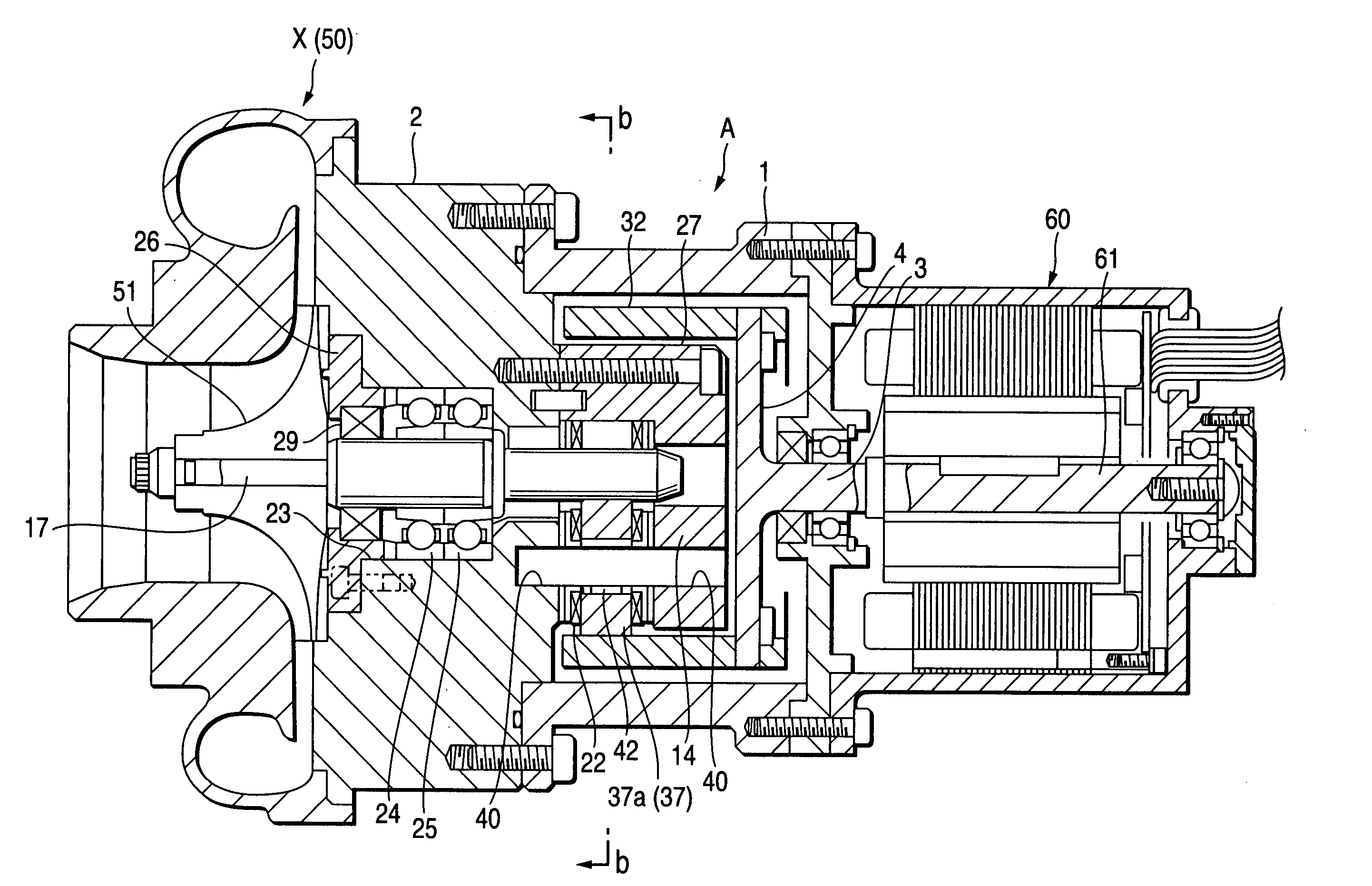

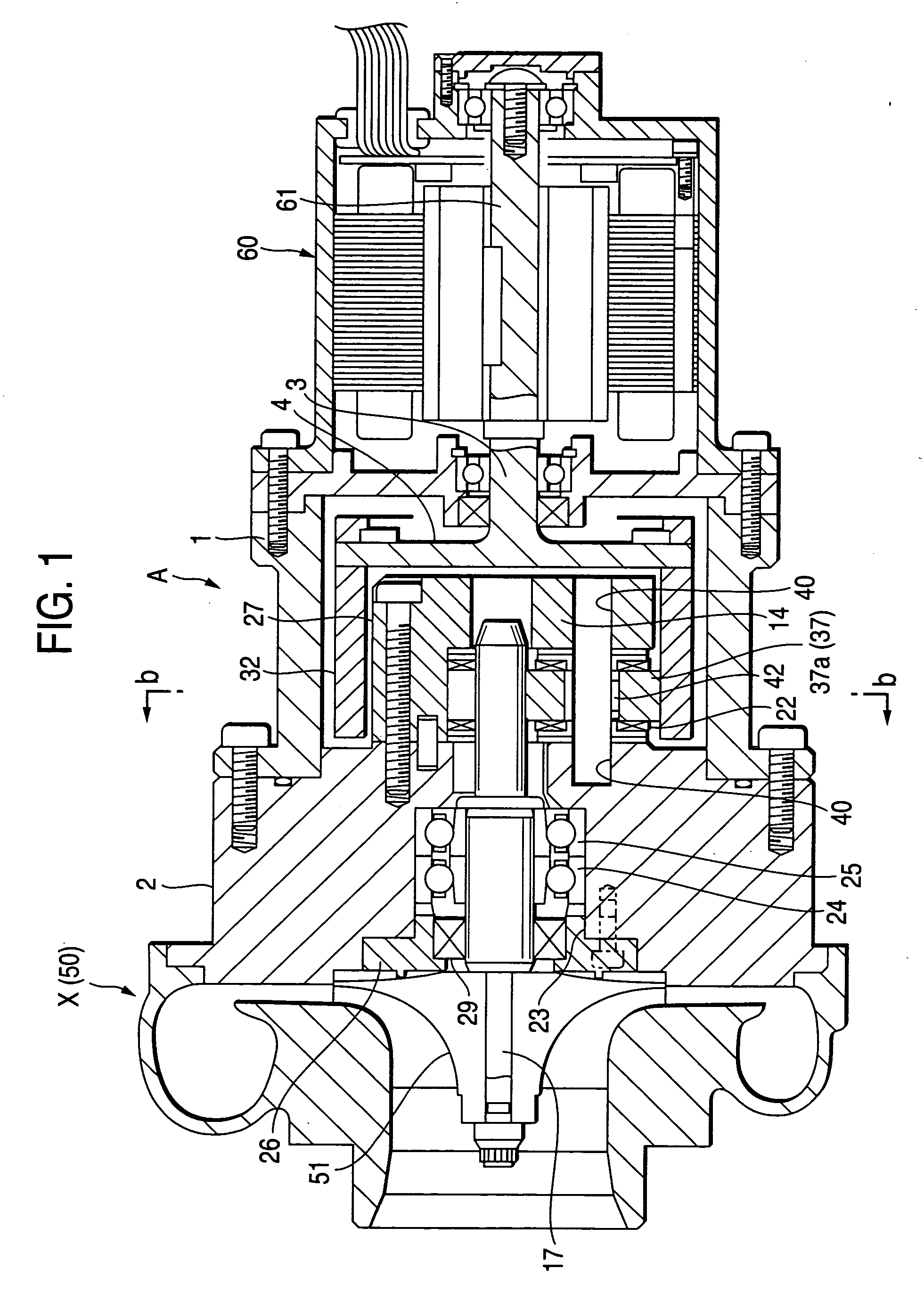

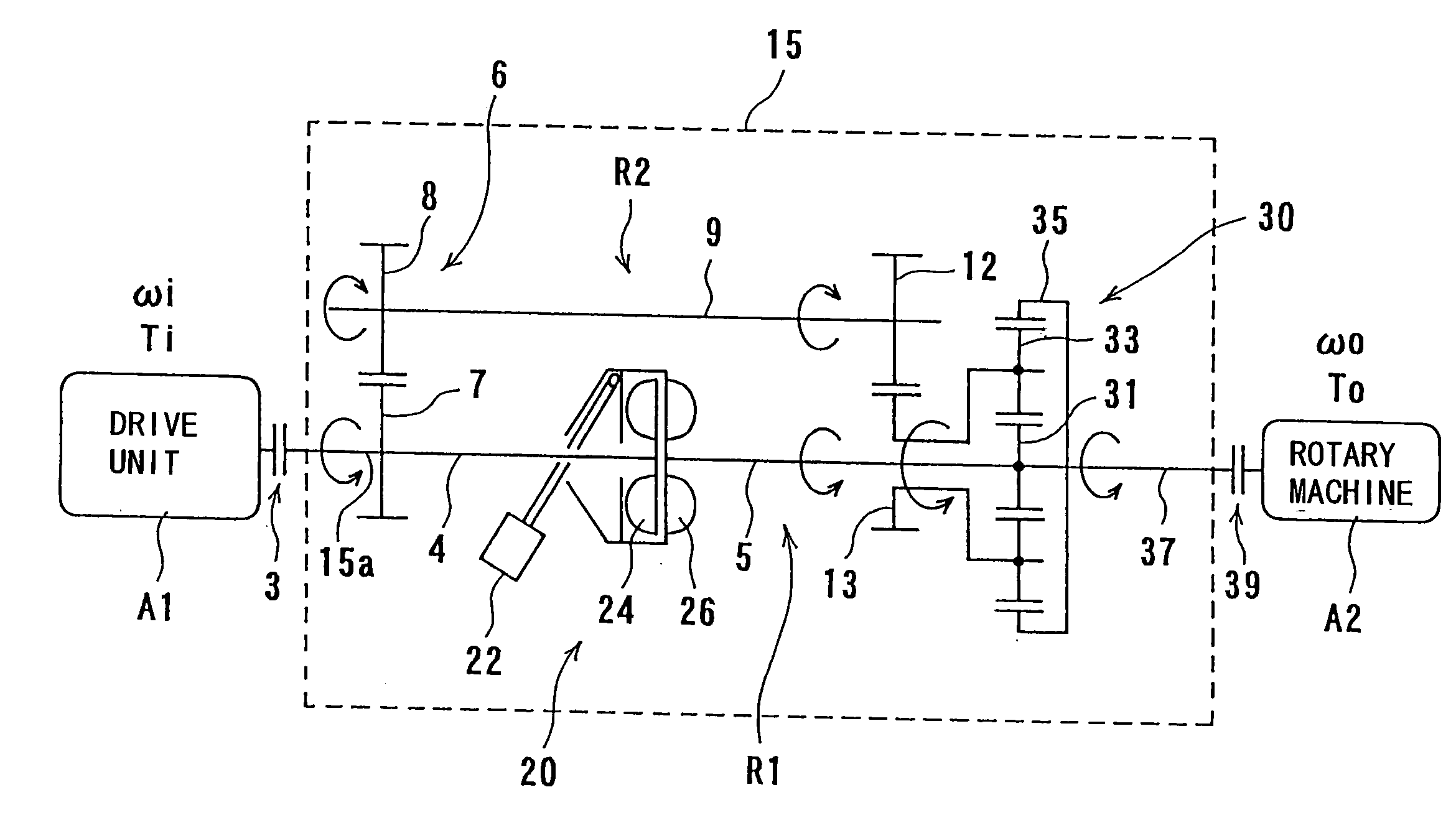

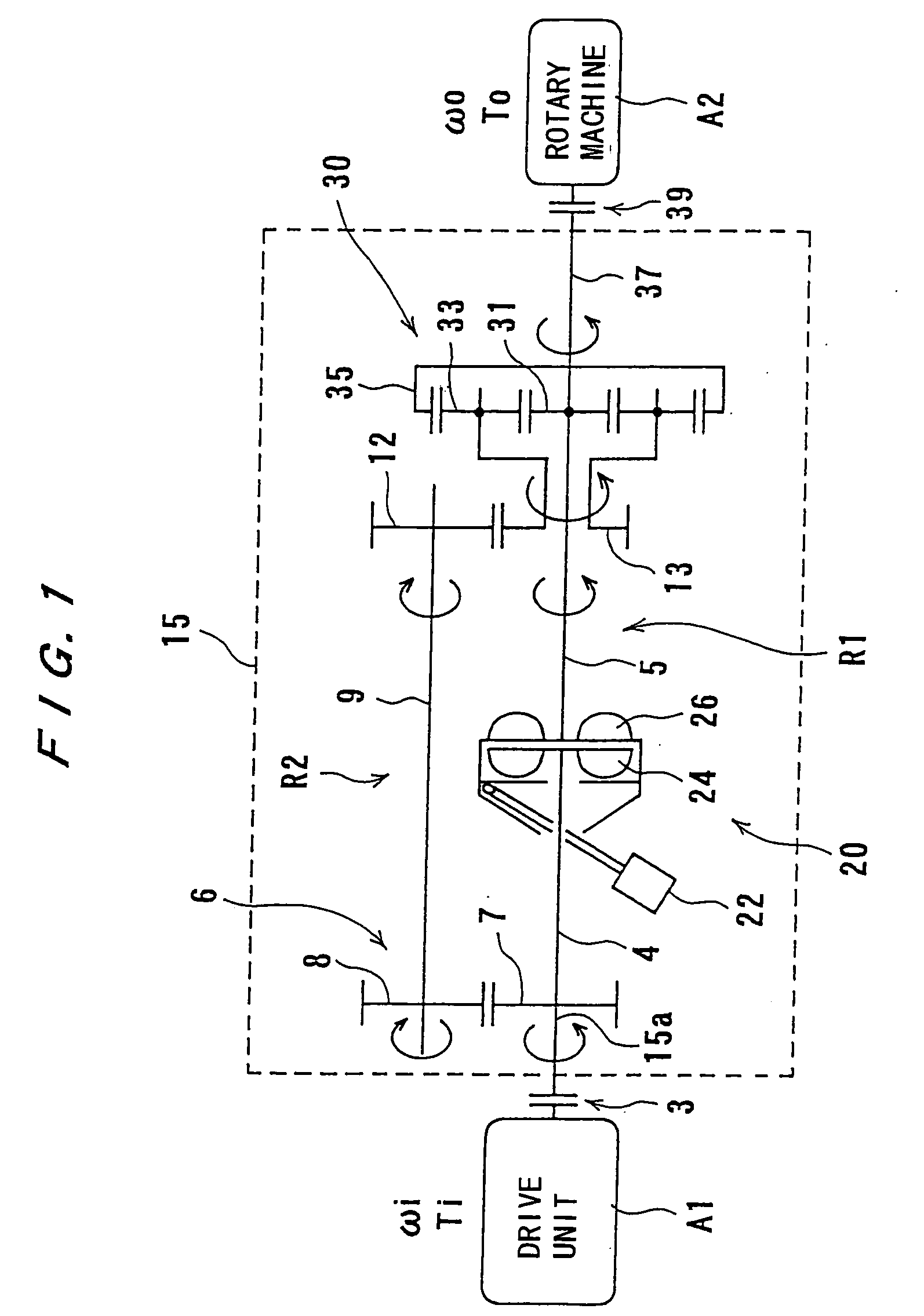

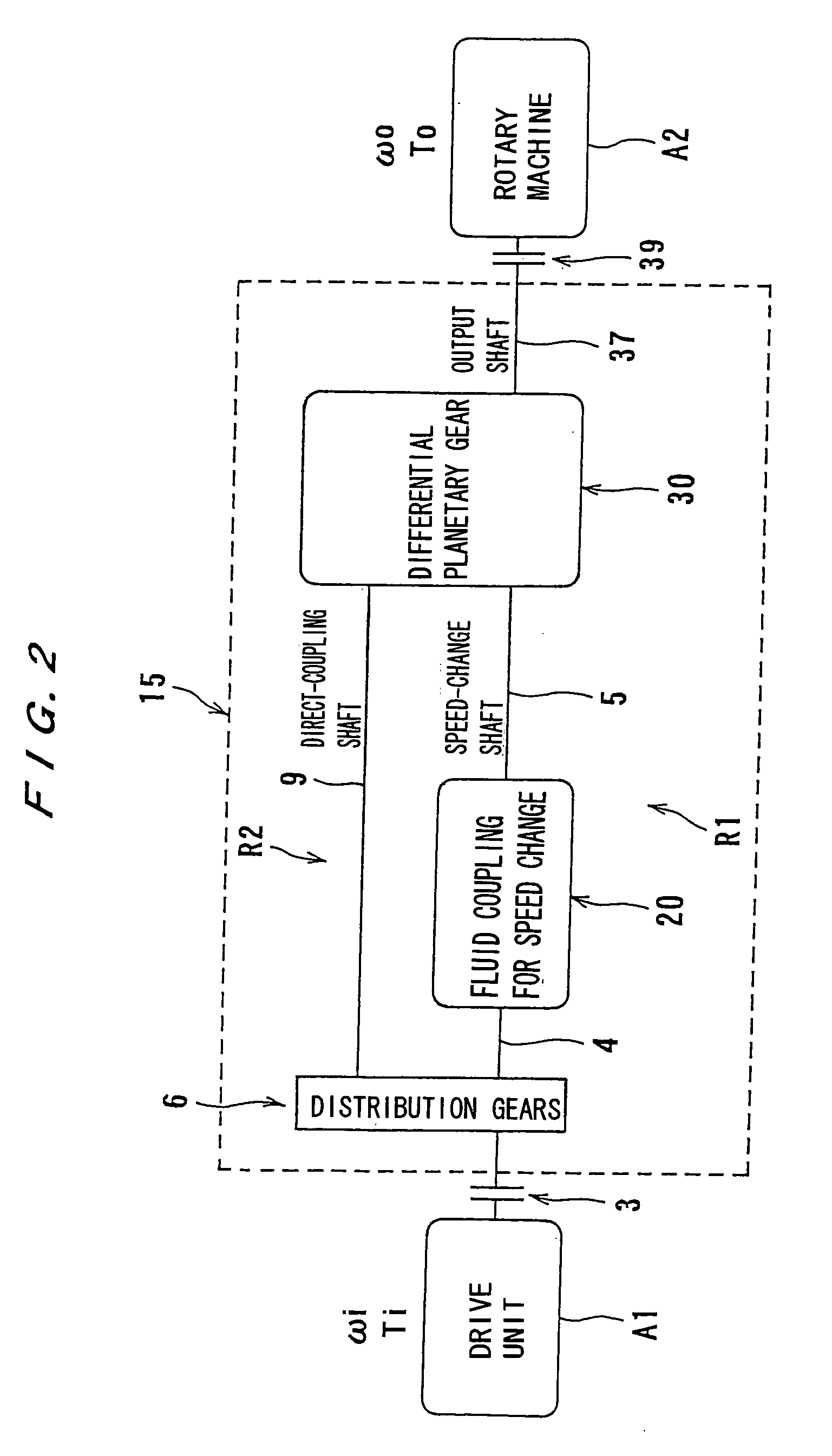

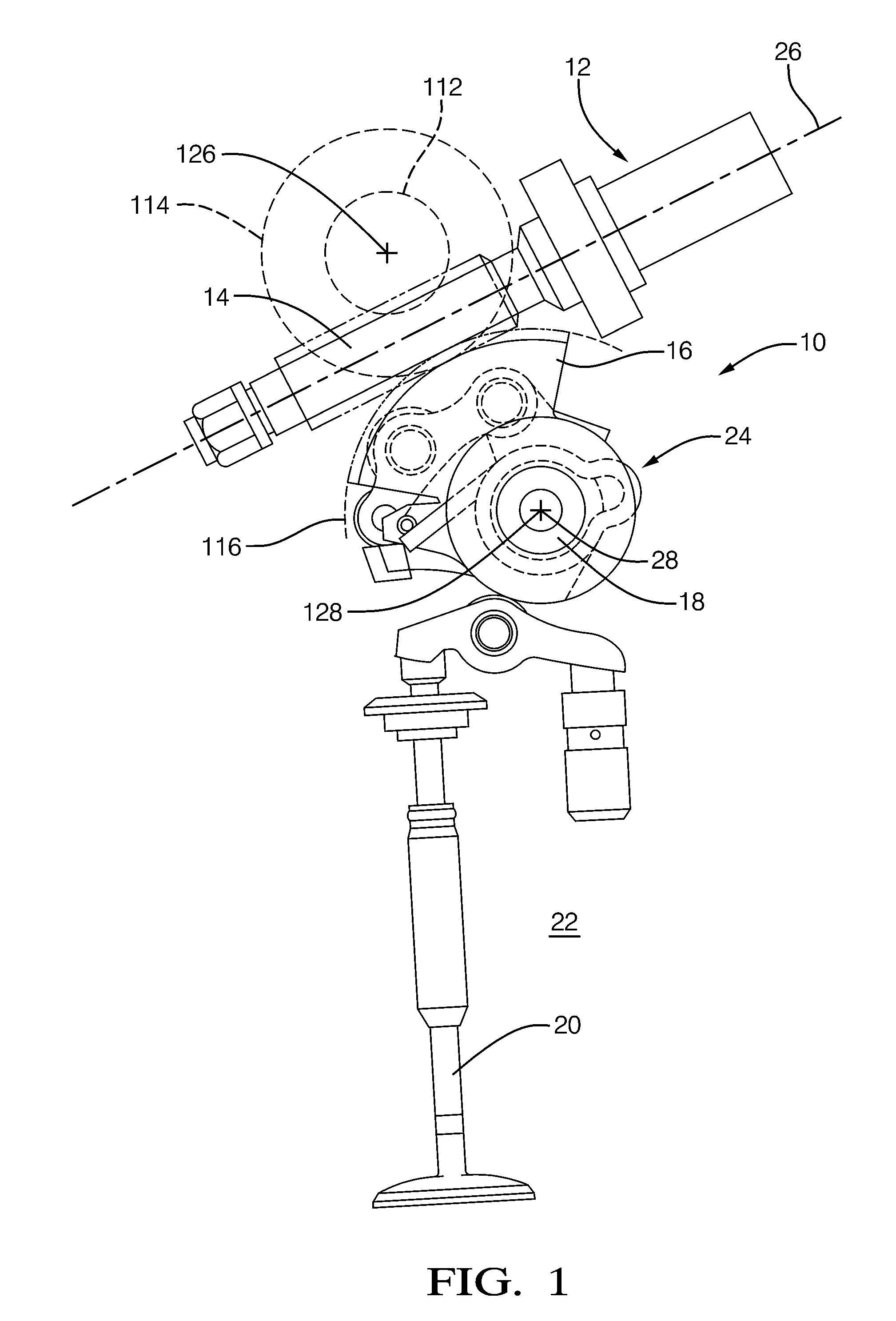

Transmission apparatus

InactiveUS7297084B2Guaranteed normal transmissionIncrease powerRotary clutchesToothed gearingsFluid couplingEngineering

The present invention relates to a transmission apparatus (15) including at least one of a dividing unit (6) and a differential planetary gear unit (30), and a joint unit (20). A rotational power, which has been input to the transmission apparatus (15), is transmitted to the joint unit (20) via the dividing unit (6) or the differential planetary gear unit (30). A rotational power to be input to the joint unit (20) is smaller than the rotational power which has been input to the transmission apparatus (15), and the joint unit comprises a fluid coupling.

Owner:EBARA CORP

High-speed fluidic device

InactiveUS20050074341A1Improve transmission efficiencyDegree of freedomCombustion enginesPortable liftingLow speedElectric motor

A high-speed fluidic device has a friction roller type speed-increasing mechanism, an electric motor, and a high-speed fluidic machine, wherein: the friction roller type speed-increasing mechanism includes a housing, a low-speed side member having an outer ring provided at one end portion thereof, a high-speed side shaft rotatably supported by the housing so as to be eccentric to the low-speed side member and the outer ring, at least one guide roller rotatably supported between the outer ring and the high-speed side shaft, and at least one movable roller rotatably supported between the outer ring and the high-speed side shaft; the electric motor drives the friction roller type speed-increasing mechanism; and the high-speed fluidic machine is connected to the high-speed side shaft so as to be driven by the high-speed side shaft.

Owner:NSK LTD

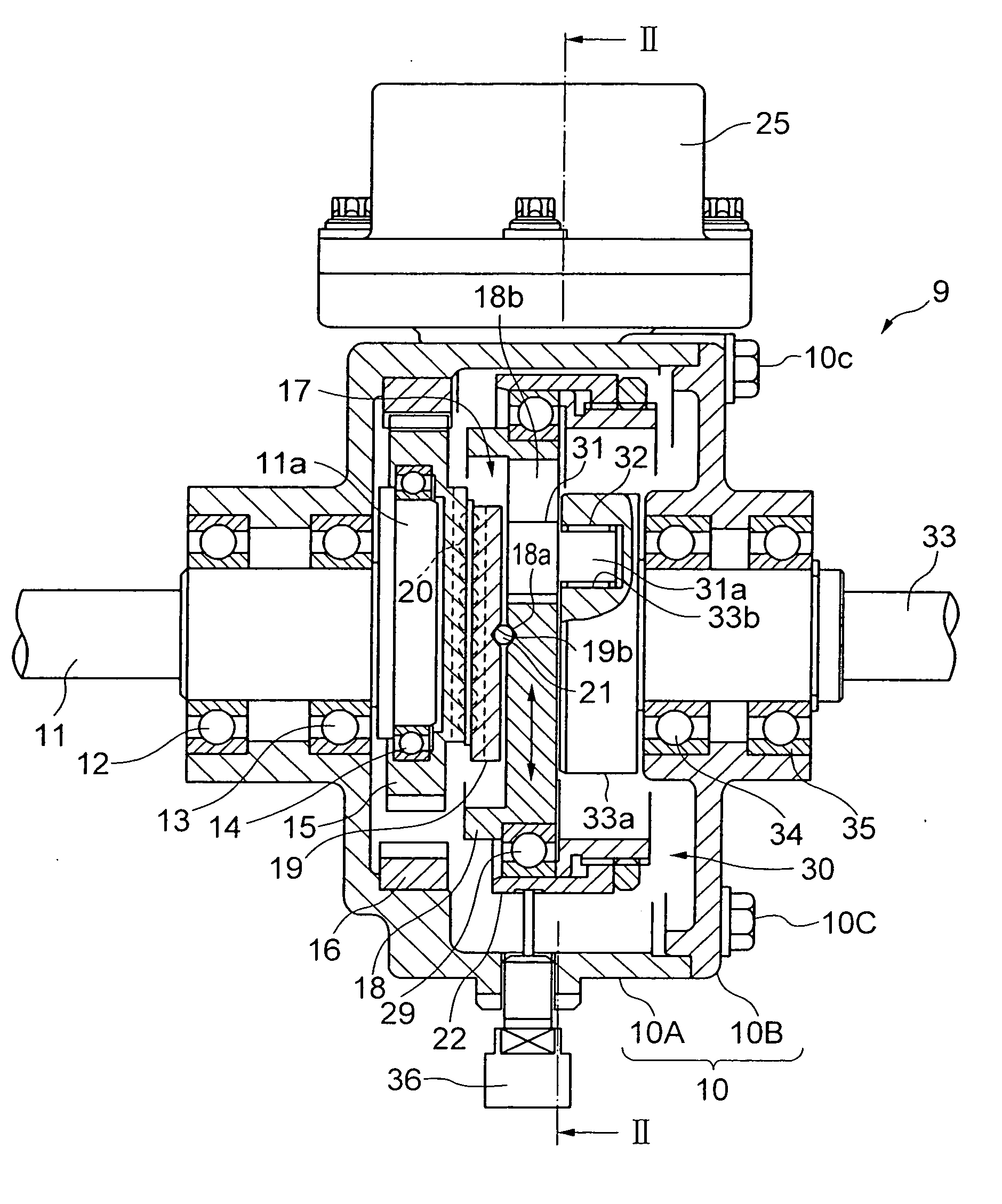

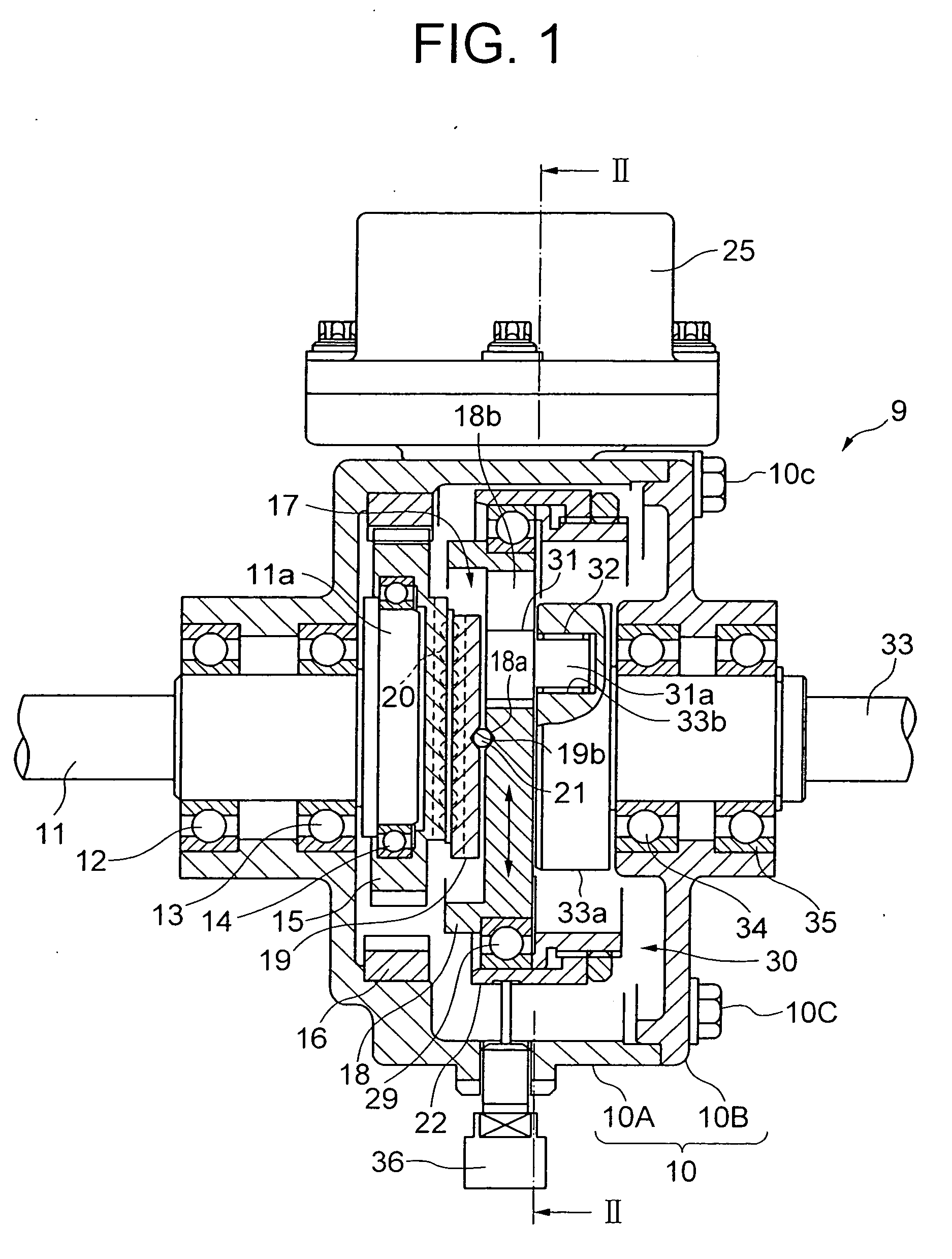

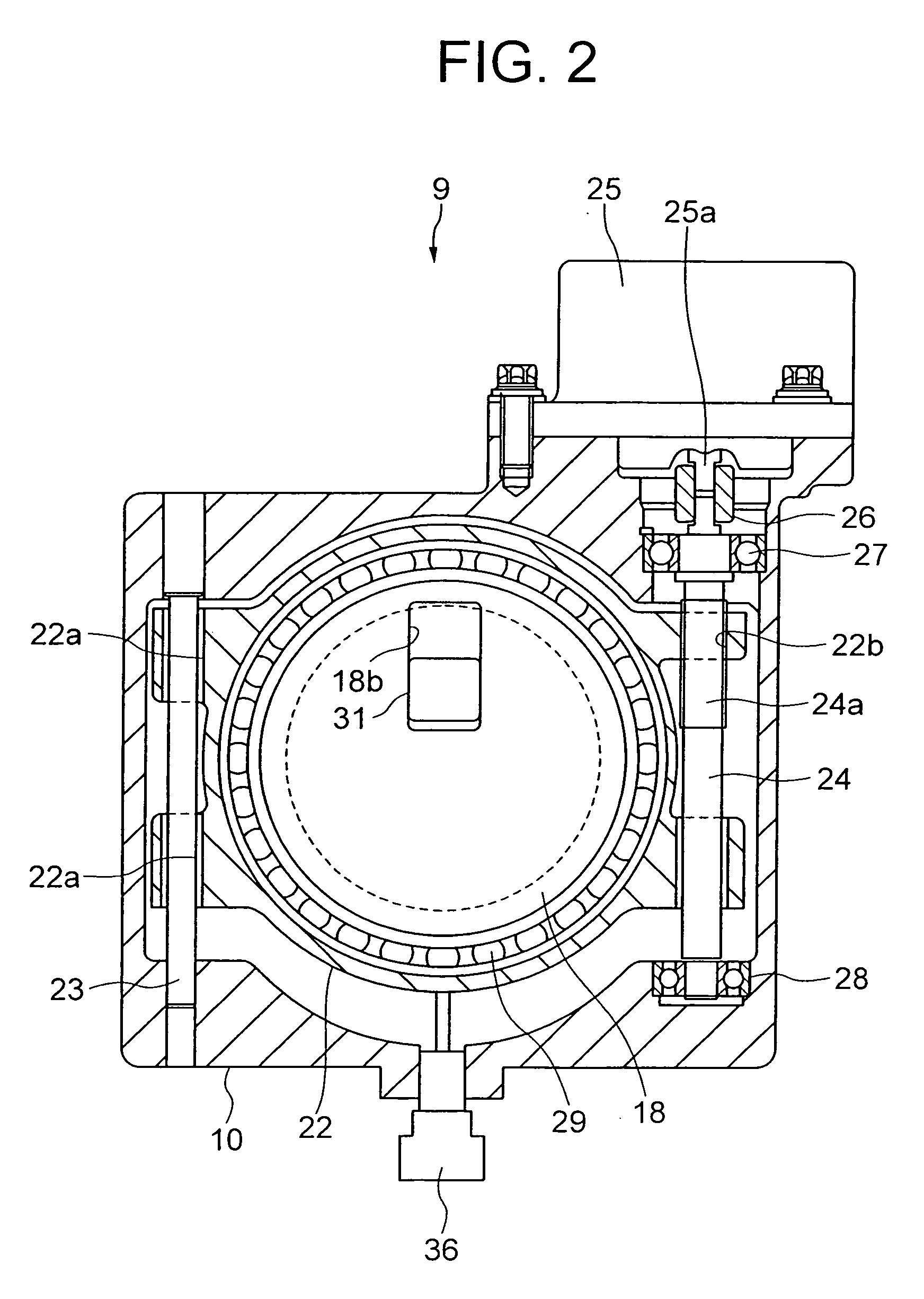

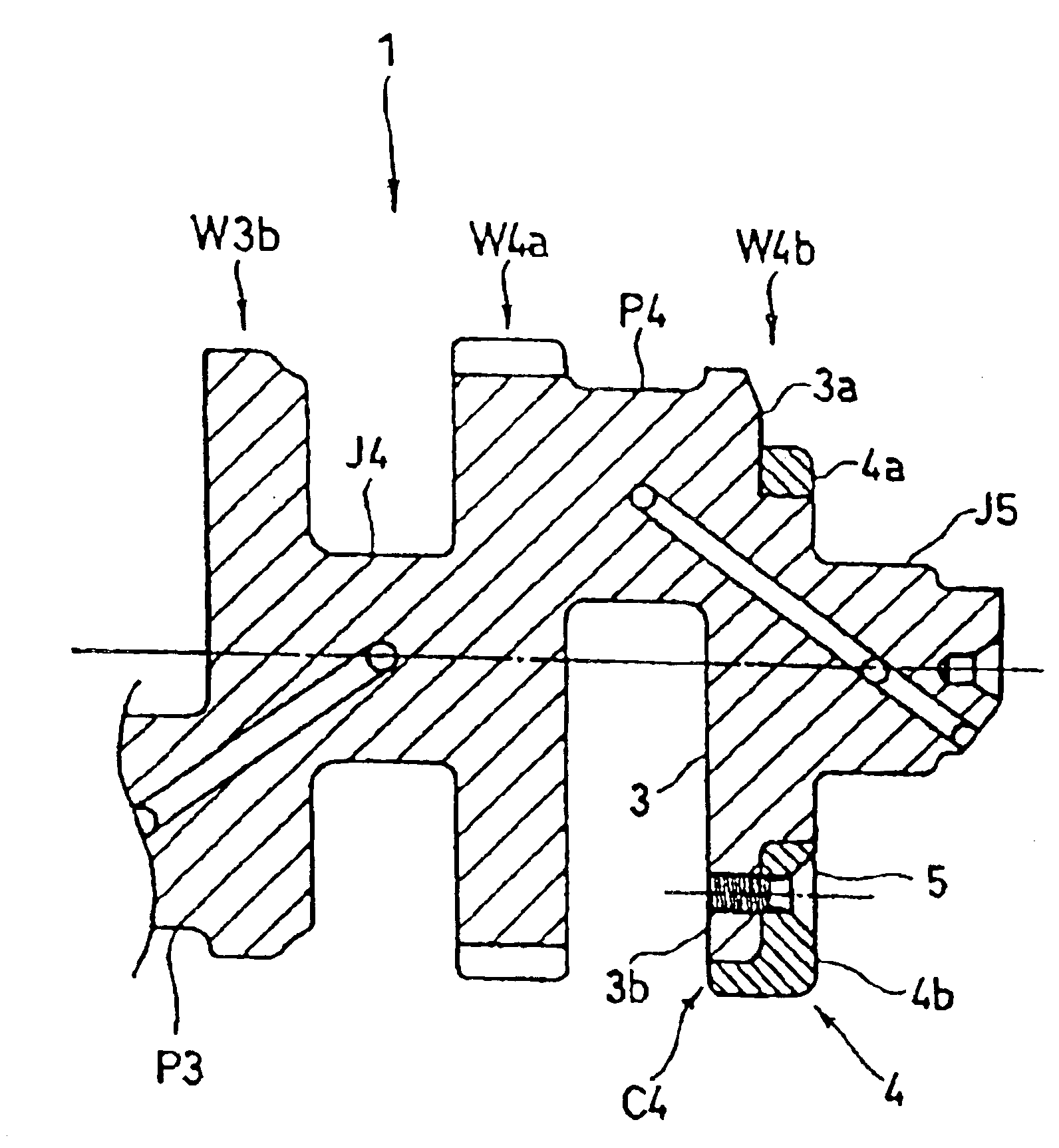

Steering device

InactiveUS20060151235A1Light weightCompact configurationControlling membersYielding couplingCouplingEngineering

A variable steering gear mechanism (9) is constructed of an external gear (15) connected to an input shaft (11), an internal gear (16) fixed to housing (10) and meshing with the external gear (15), an intermediate member (19) receiving a rotary force transmitted from the external gear (15), change means (18a, 31, 33a) capable of changing a rotation ratio of the output shaft (33) to a rotation of a guide member (18), and an Oldham coupling (17) connecting the intermediate member (19) to the guide member (18). When a speed reduction ratio thereof is set to, e.g., 6:1, it follows that the input member (18) of the change means makes a ¼ rotation (rotates through 90 degrees) during one-sided 1.5 rotations (540 degrees) of the input shaft (11), whereby a characteristic of the change means can be effectively utilized. A gear mechanism such as a hypocycloid mechanism has a characteristic capable of, though compact in configuration, obtaining a speed reduction ratio as large as 6:1, and also such a characteristic that the external gear (15), in addition to the self-rotation, revolves around the axis line of the internal gear (16), i.e., rotates while being eccentric. By contrast, according to the present invention, the use of the Oldham coupling (17) enables only the self-rotation to be extracted and transmitted by absorbing the eccentricity of the external gear (15). Additionally, a meshing length between the external gear (15) and the internal gear (16) becomes large, whereby smoother power transmission can be attained.

Owner:NSK LTD +1

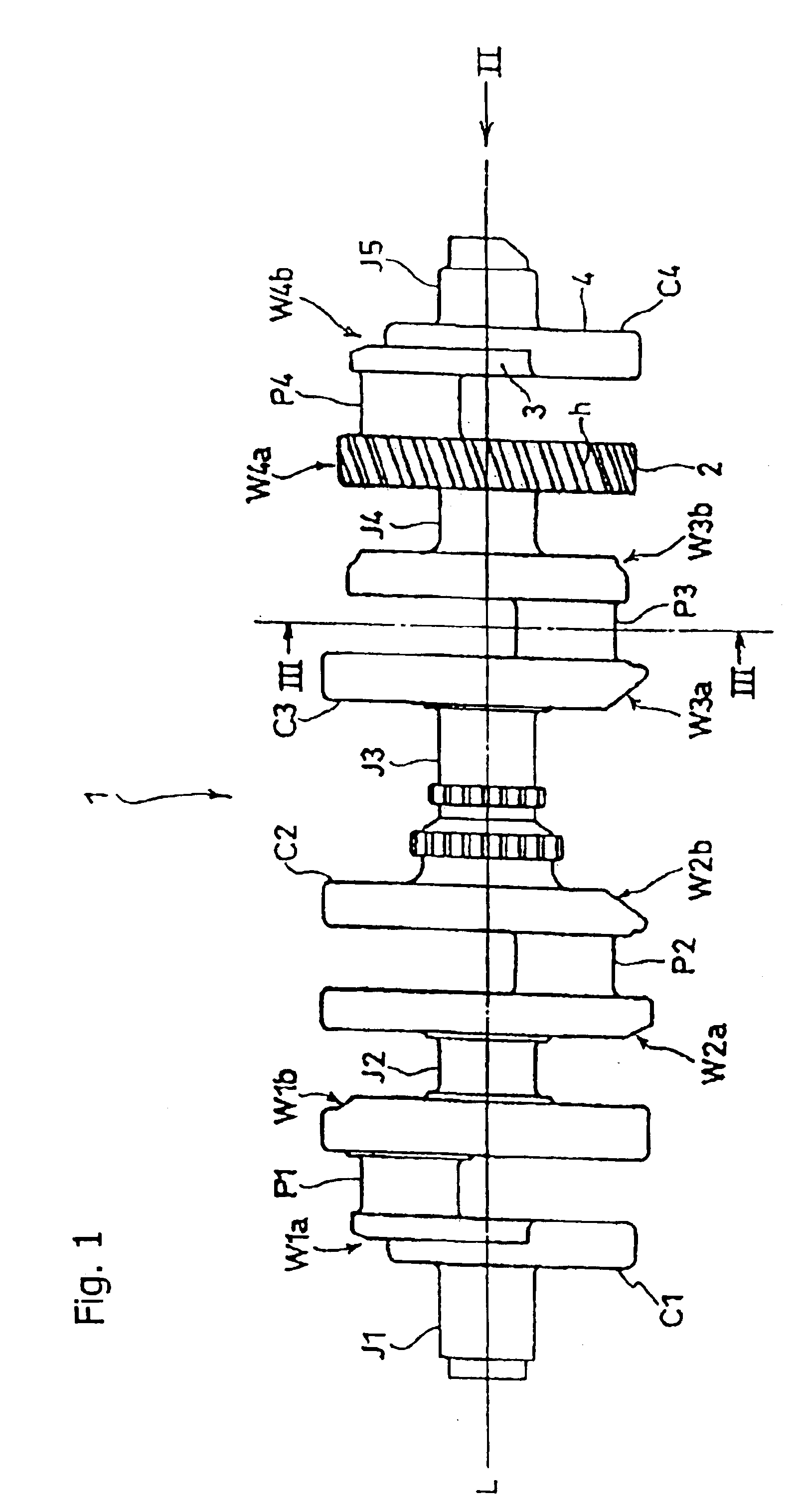

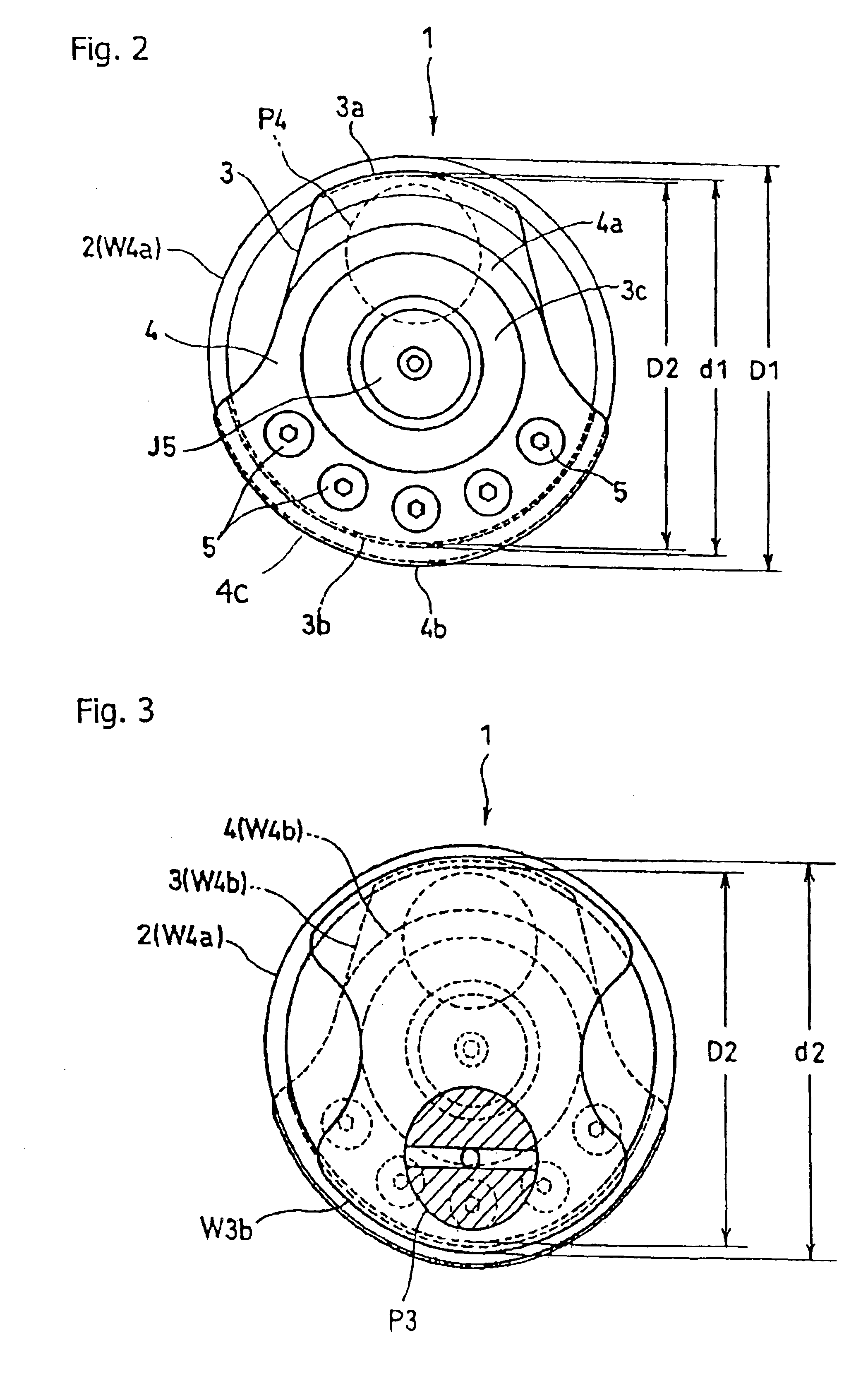

Crankshaft for an internal combustion engine

InactiveUS6959683B2Easy to useIncrease chanceCrankshaftsInertia force compensationInternal combustion engineCrankpin

A crankshaft has a helical drive gear formed as one of the crank webs at an end portion thereof. Another crank web outside of the drive gear is made in two parts, an integral balance weight mounting portion and a removable balance weight. In one embodiment, a crankshaft 12 features a crankshaft body 33 including a gear 24 for outputting rotation formed on one side of a crankpin 17d. The crankshaft also includes a first balance weight mounting portion 30g formed on the other side of the crankpin 17d and a first balance weight 31g to be mounted to the first balance weight mounting portion 30g. The crankshaft body 33 may be formed with a second balance weight mounting portion 30a separately from the first balance weight mounting portion 30g, and a second balance weight 31a mounted to the second balance weight mounting portion.

Owner:HONDA MOTOR CO LTD

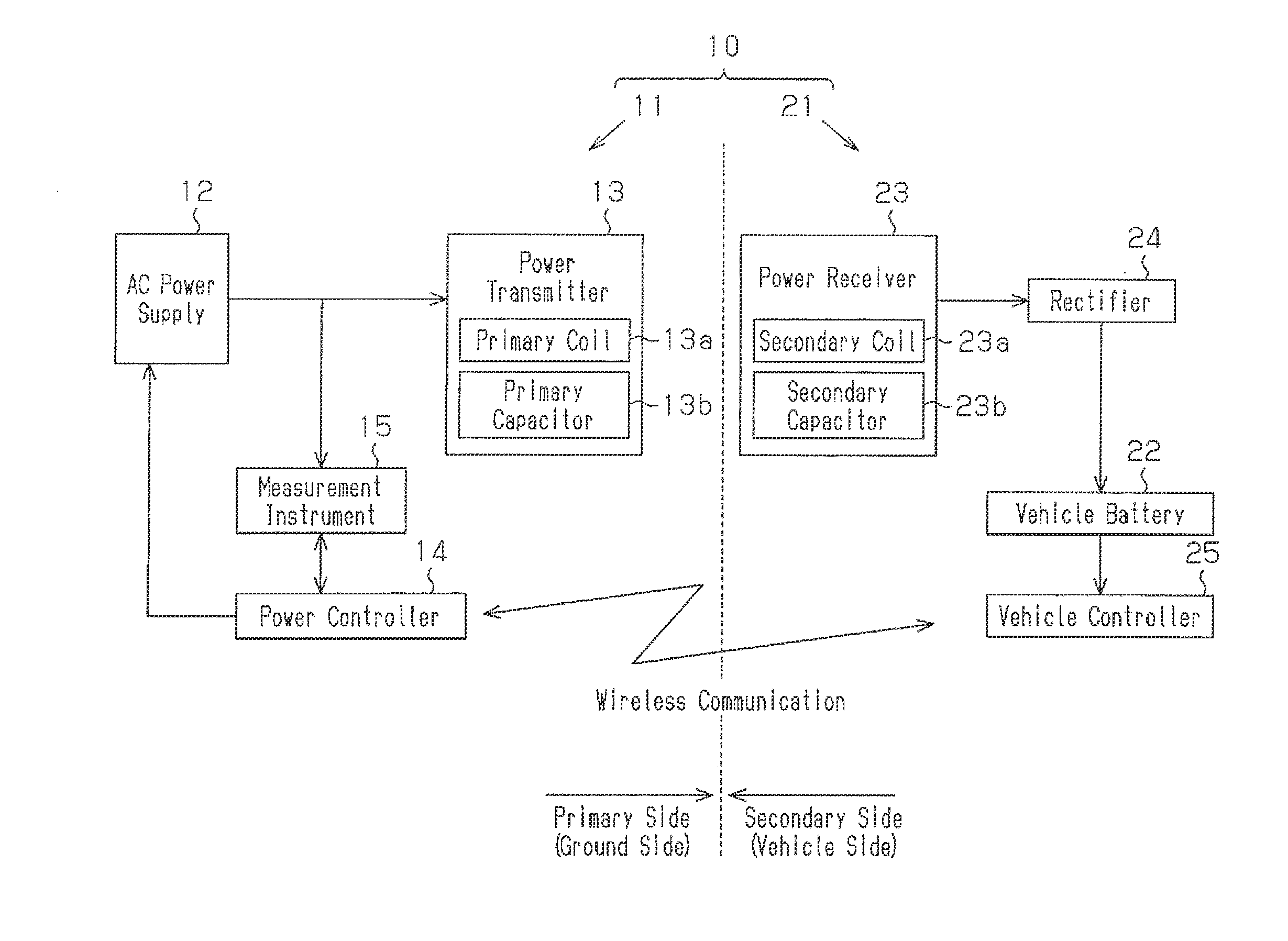

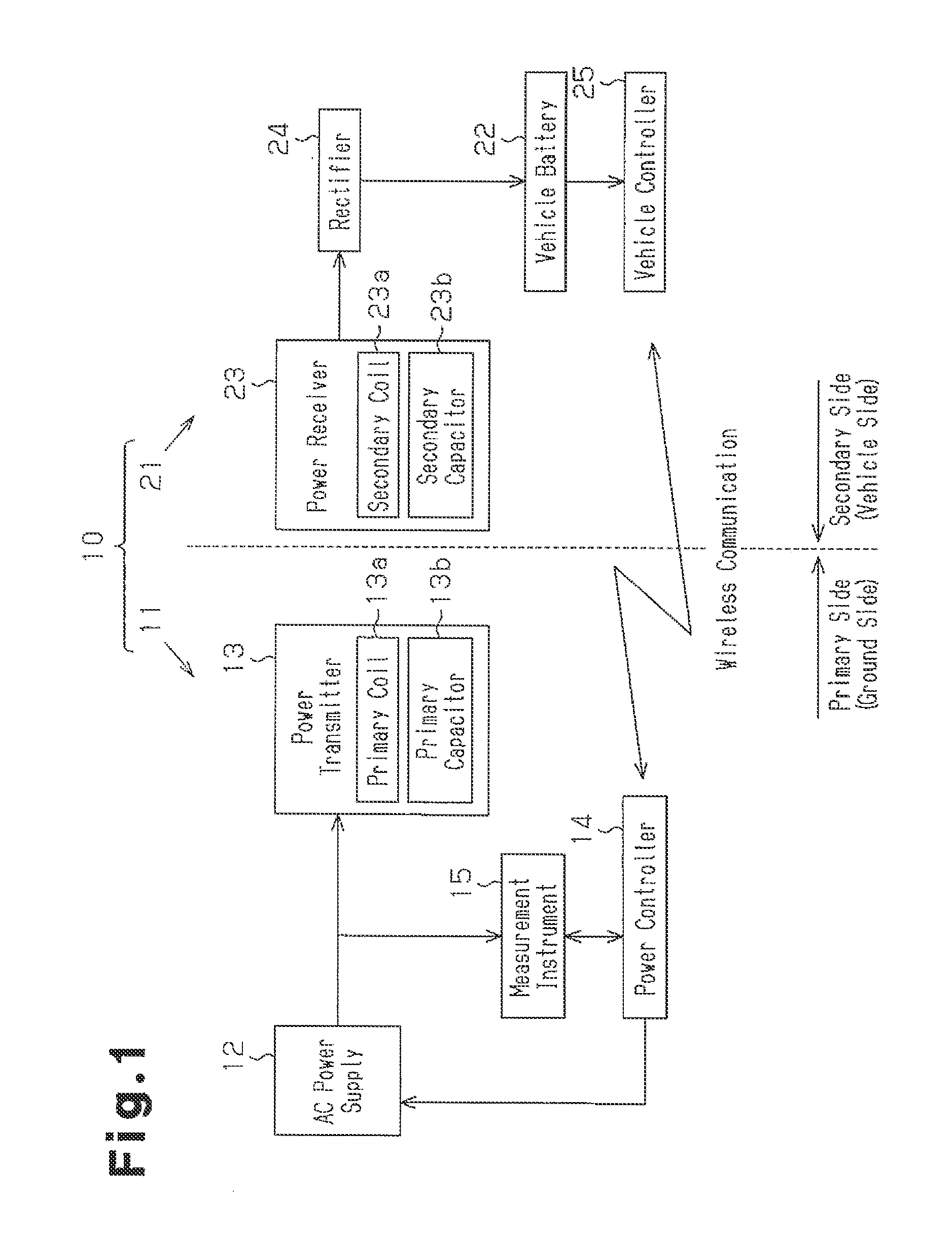

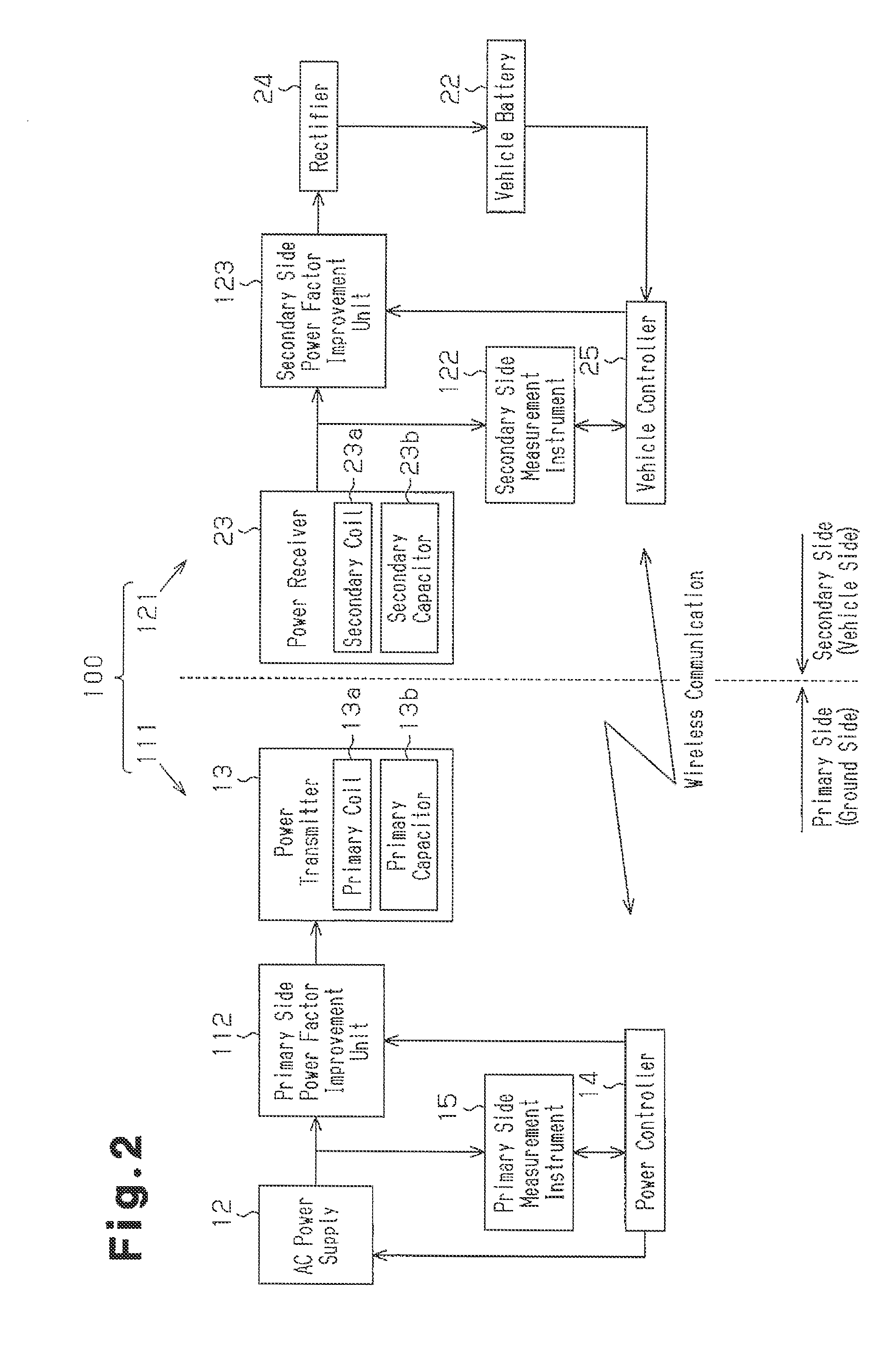

Contactless power transmission device

InactiveUS20140333258A1Reduce transmission efficiencyIncrease powerCharging stationsTransformersElectric power transmissionPower factor

A contactless power transmission device is provided with an AC power source, a primary coil, a secondary coil, an electric component and a power factor calculation unit. The primary coil is supplied with AC power from the AC power source. The secondary coil is allowed to receive AC power from the primary coil. The electric component is supplied with the AC power that is received by the secondary coil. The power factor calculation unit calculates at least either the power factor with respect to the load from the output of the AC power source to the electric component, or the power factor with respect to the load from the output of the secondary coil to the electric component.

Owner:TOYOTA IND CORP

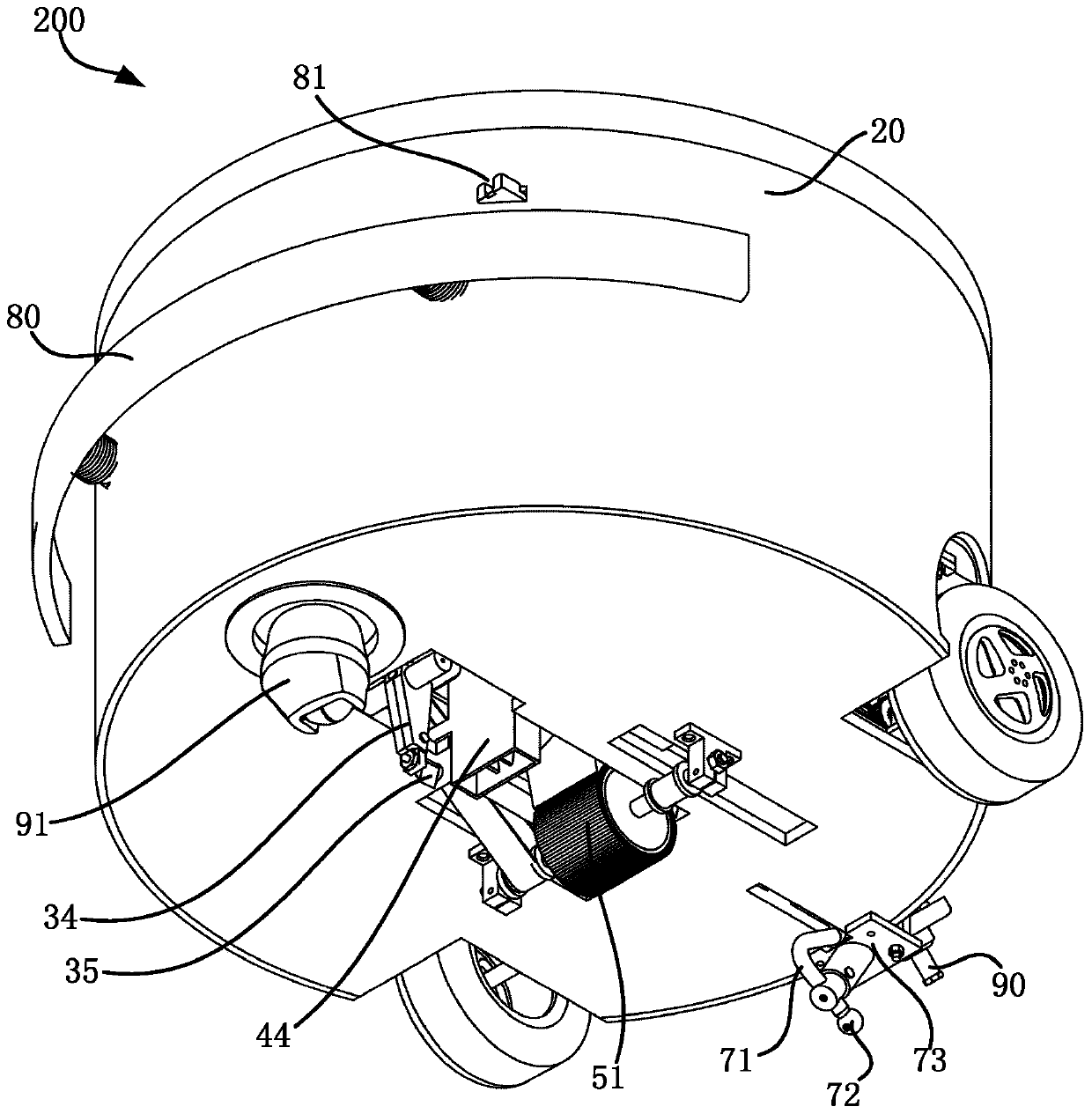

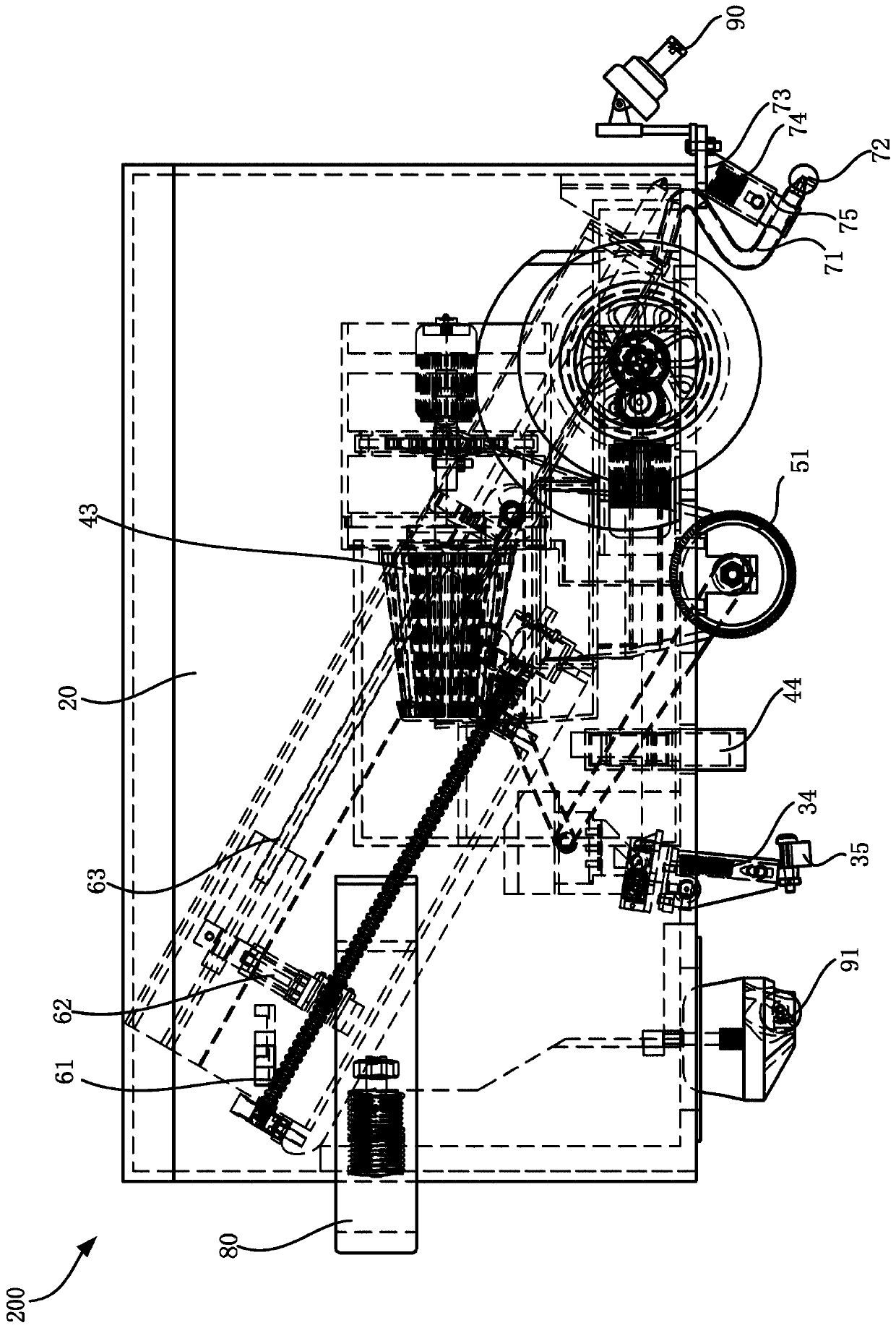

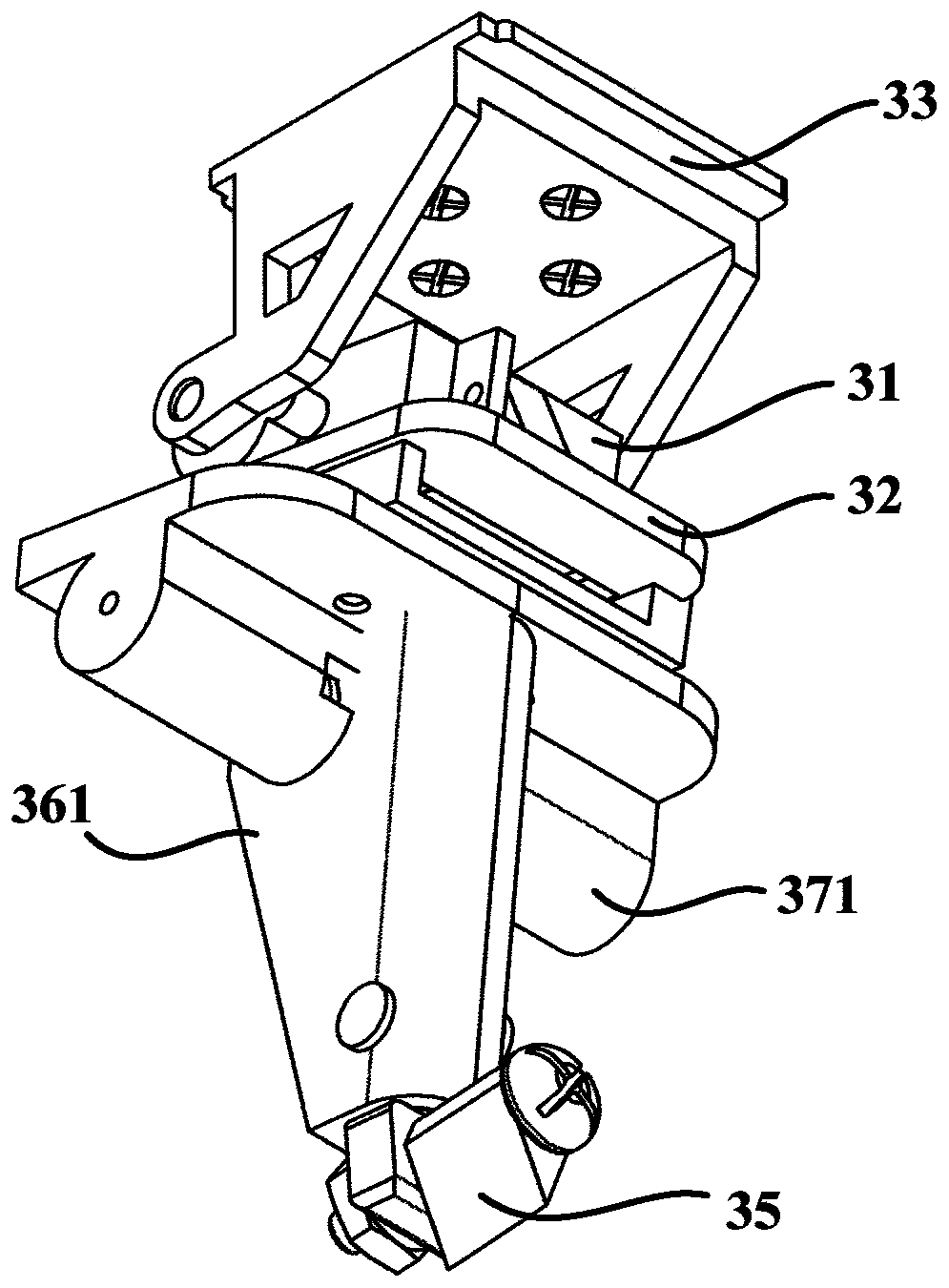

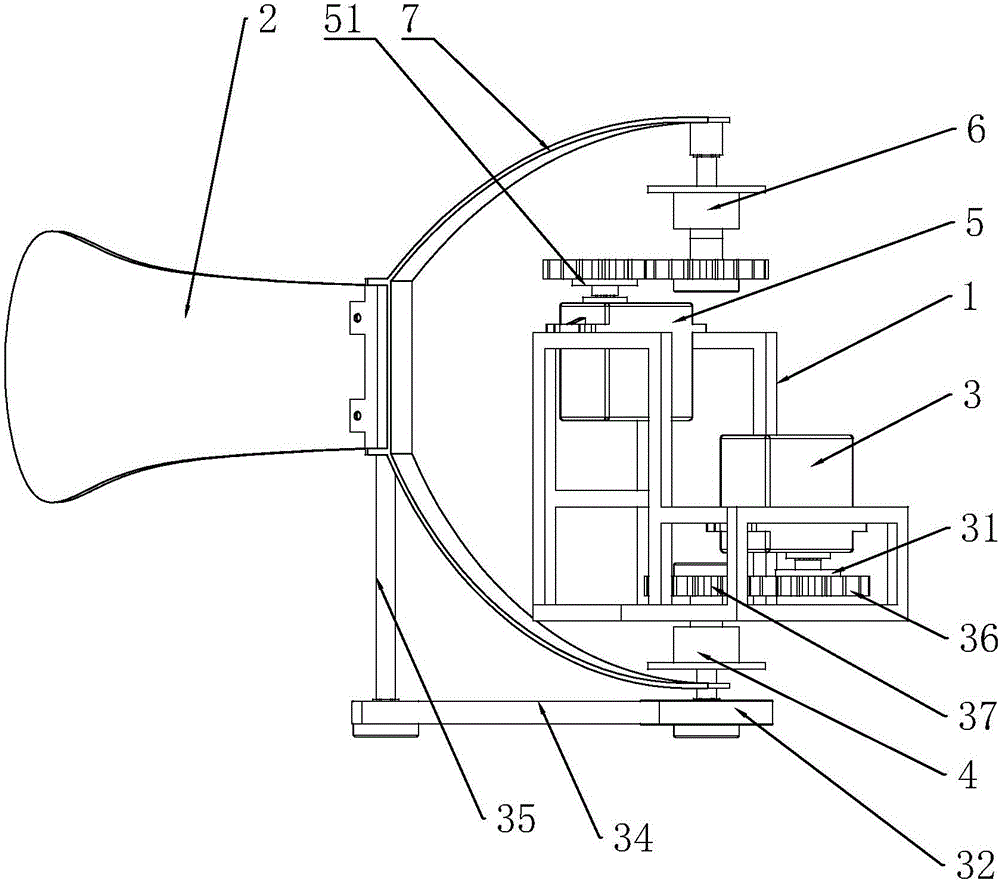

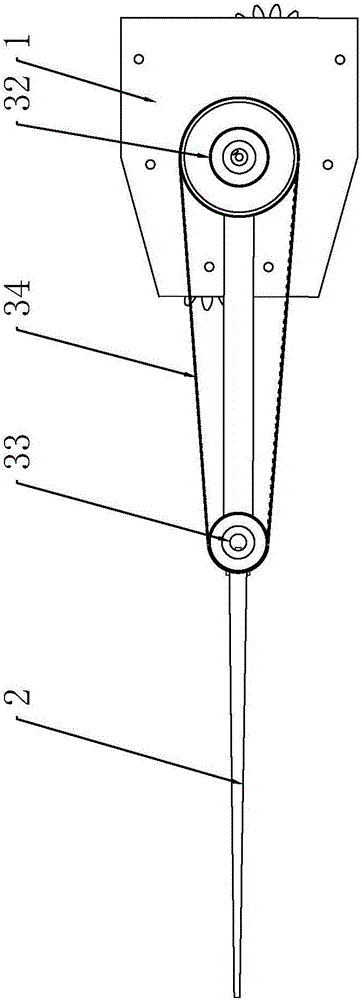

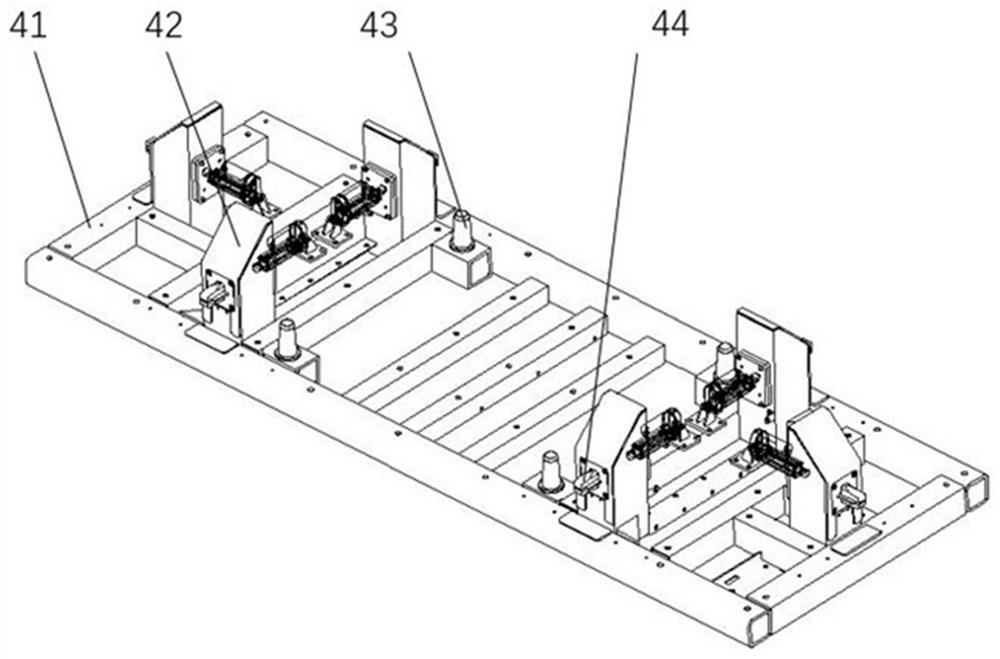

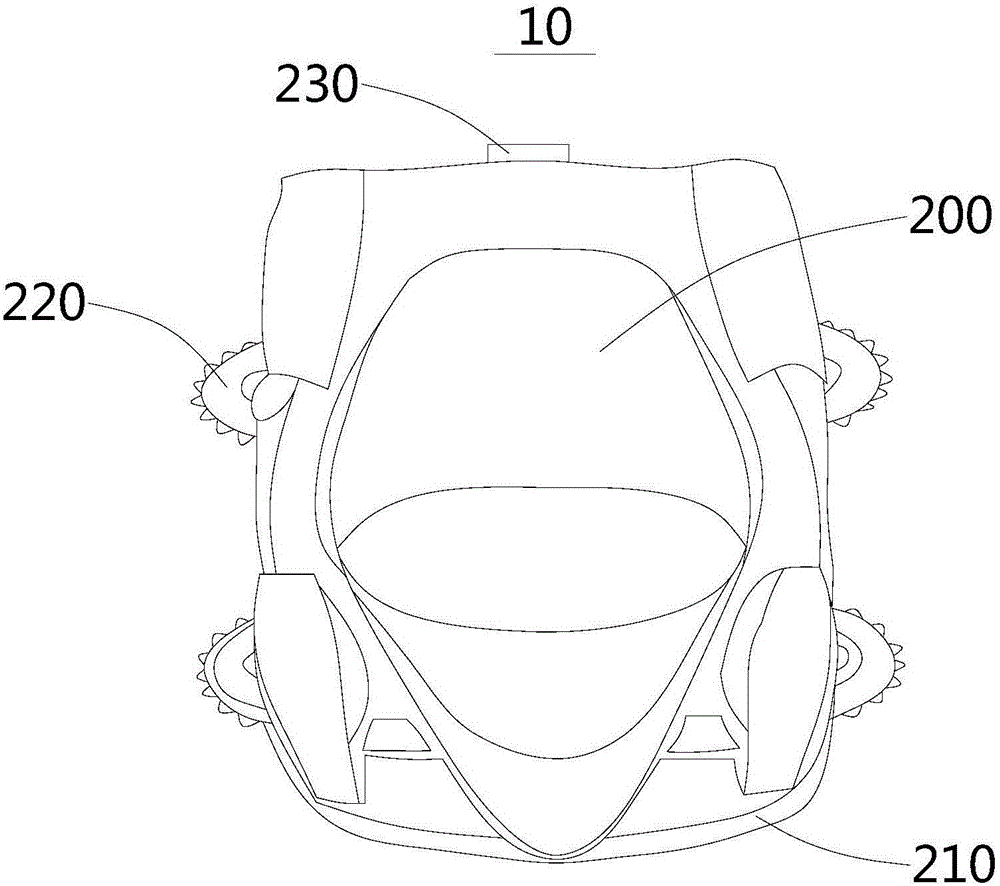

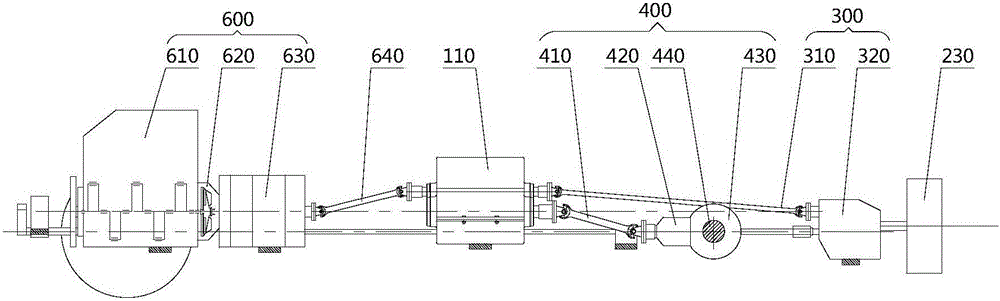

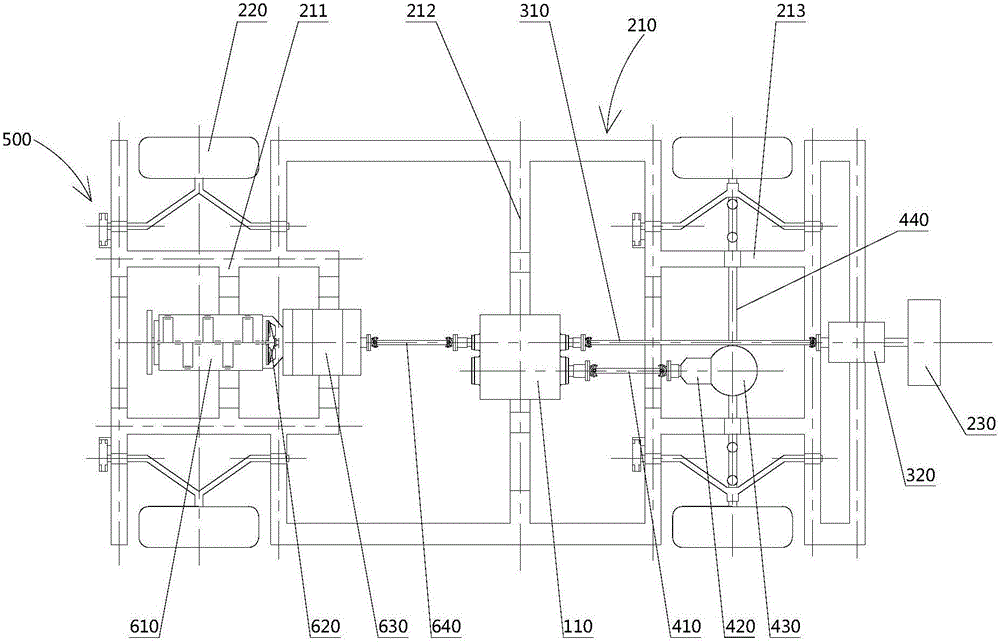

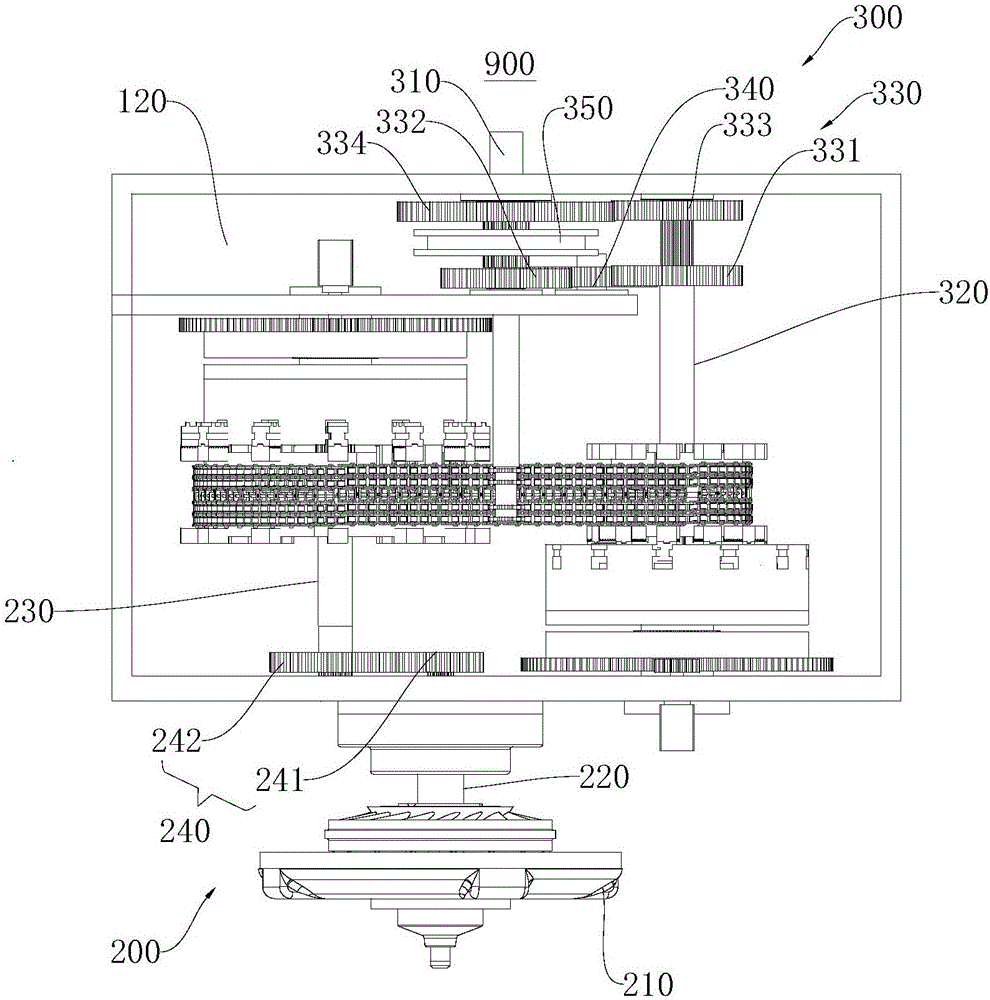

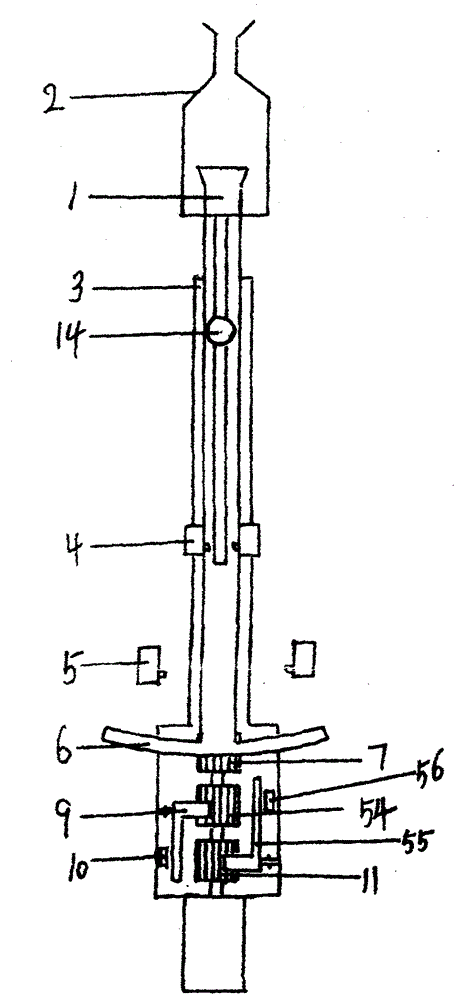

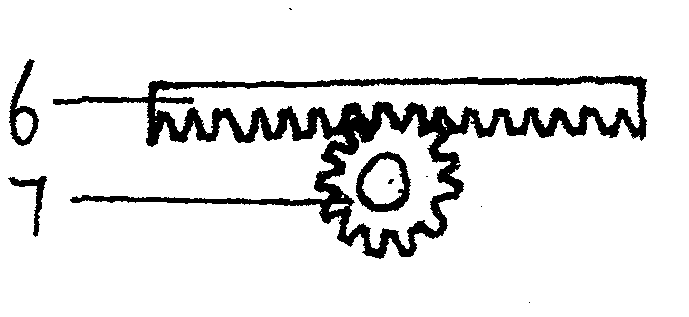

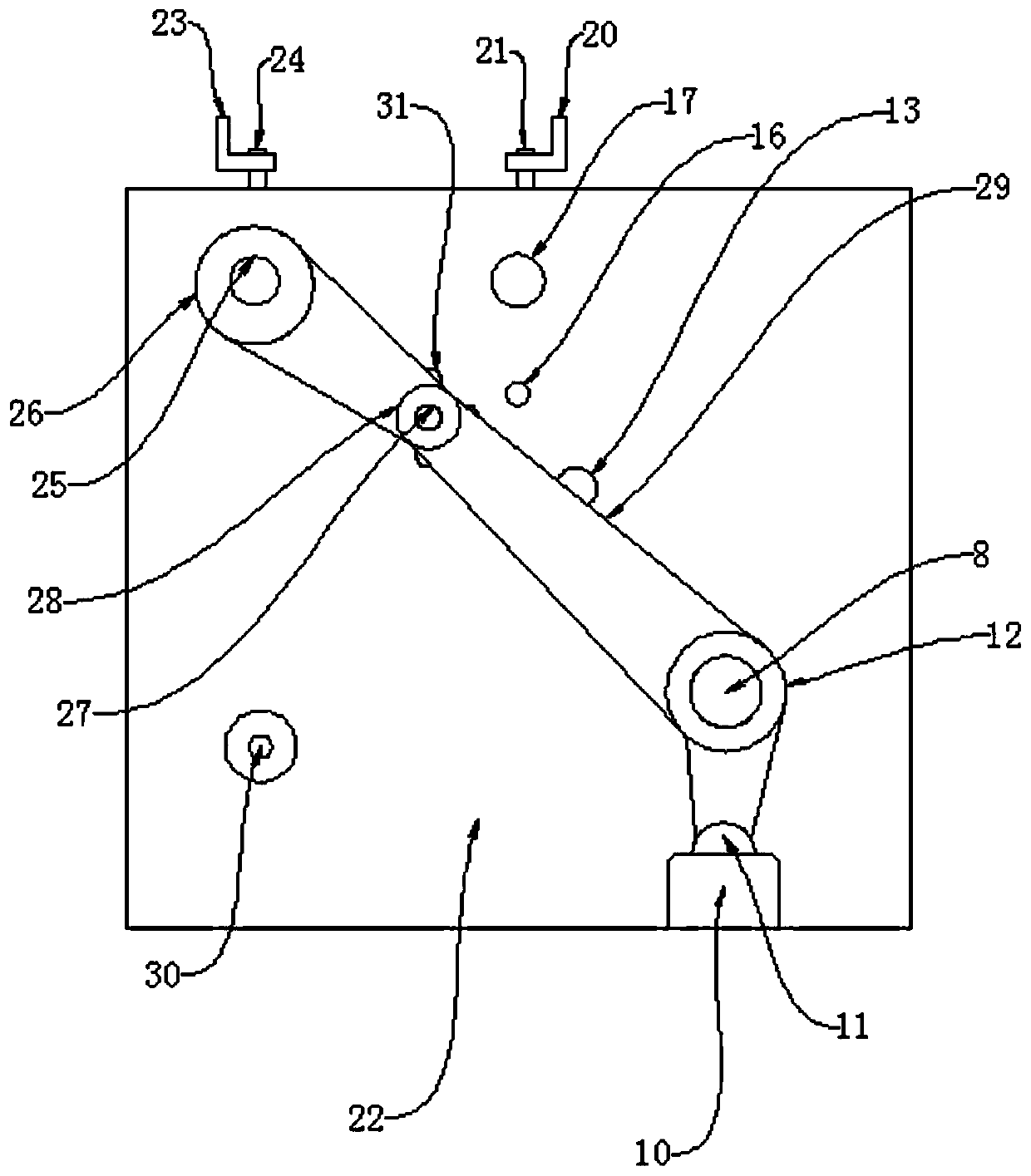

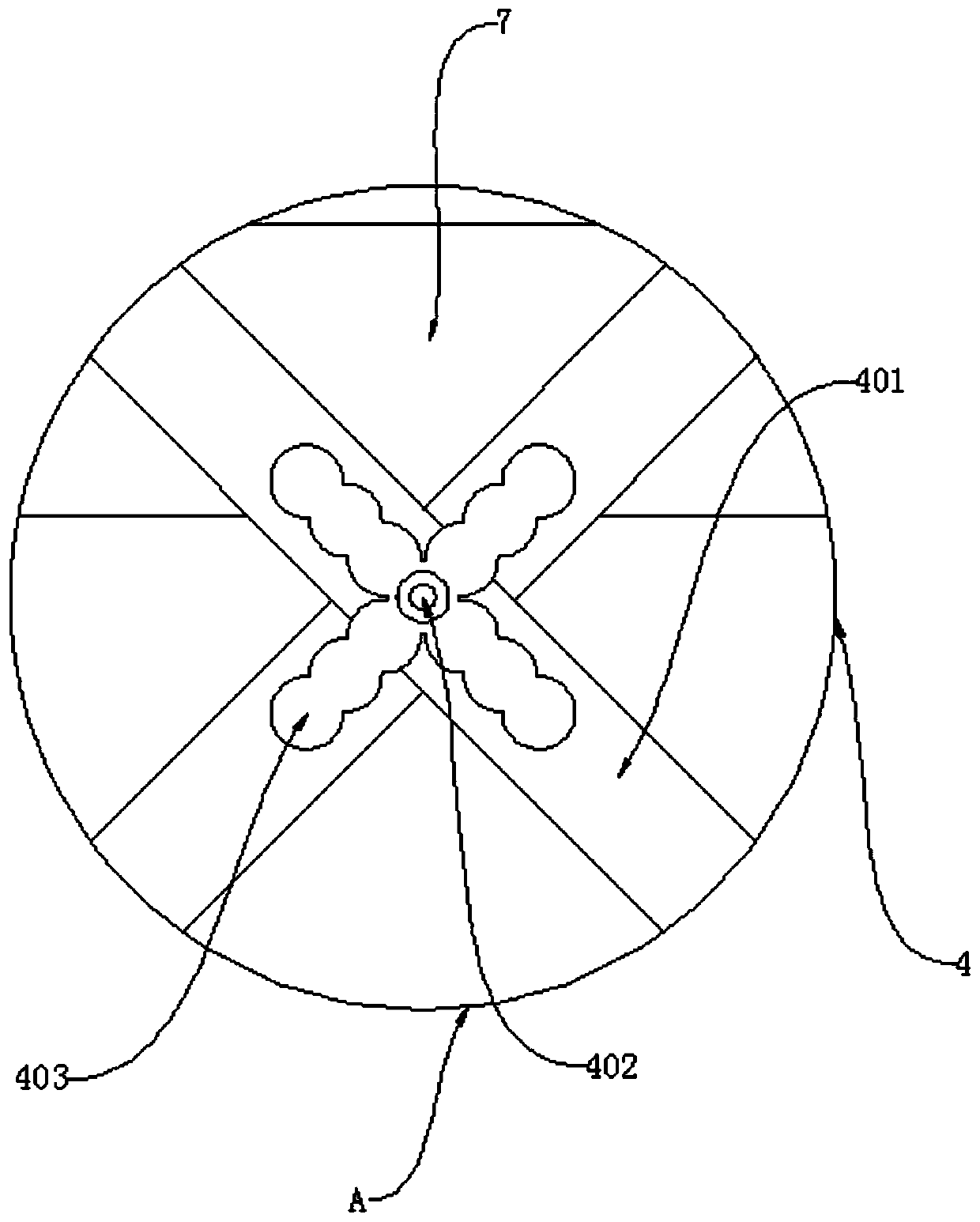

Ceramic tile seam-sealing machine

The invention provides a ceramic tile seam-sealing machine. The ceramic tile seam-sealing machine comprises a car body, a seam opening module, a dust absorption module, a wax brushing module and a filling module; the seam opening module comprises a cutter, and the cutter is used for cleaning cement chippings and dust in gaps of ceramic tiles; the dust absorption module is configured to at least collect the cement chippings and the dust in the gaps of the ceramic tiles; the wax brushing module comprises a wax brushing sponge brush located on the rear side of the cutter; and the filling module comprises an agent spraying and edge pressing component, and is configured to spray sealant into the gaps of the ceramic tiles and perform the edge pressing on the sealant in the gaps of the ceramic tiles. According to the ceramic tile seam-sealing machine, the problem existing in manual construction is solved; the construction accuracy can be improved, and the construction quality can be improved;the construction efficiency can be improved, the seam opening, the cleaning, the wax coating and the filling of the sealant are integrated into a whole; and main steps of the manual construction canbe replaced, the seam-sealing machine is remotely controlled and operated by construction personnel, the damage to the new ground surface is avoided, the limitations of the construction area and the construction accuracy to the seam-sealing are broken through, and the construction quality is greatly improved.

Owner:YANTAI UNIV

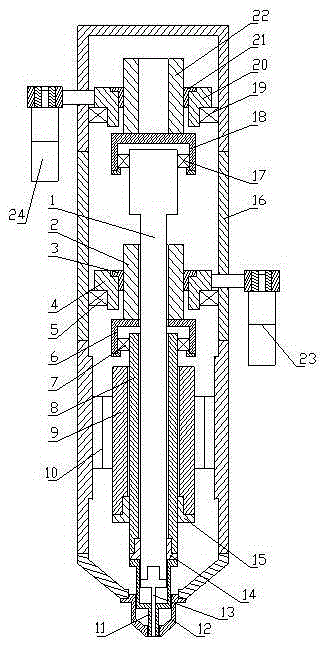

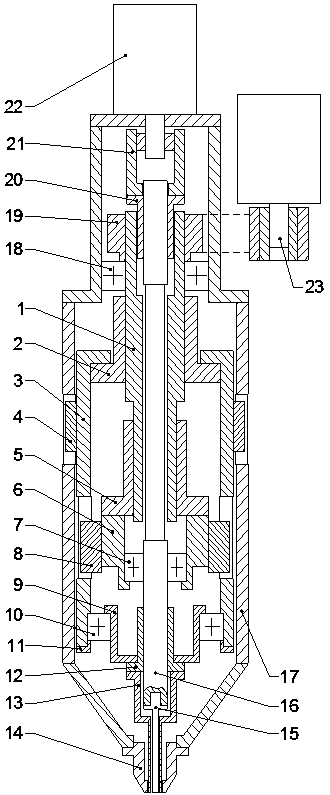

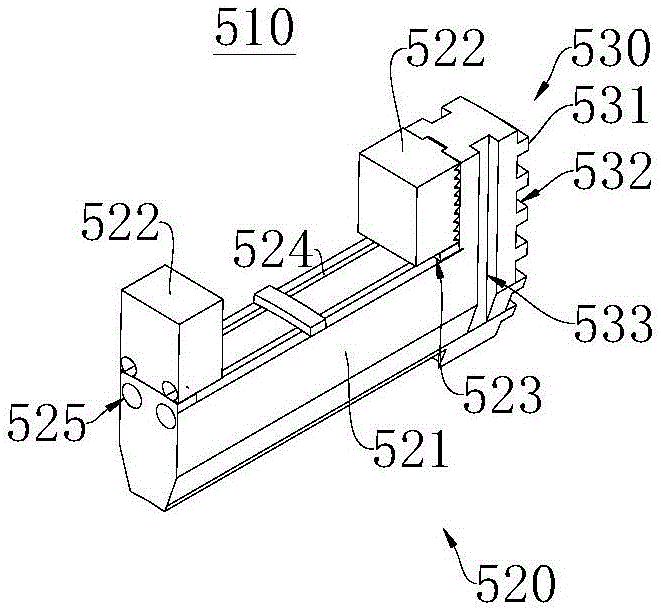

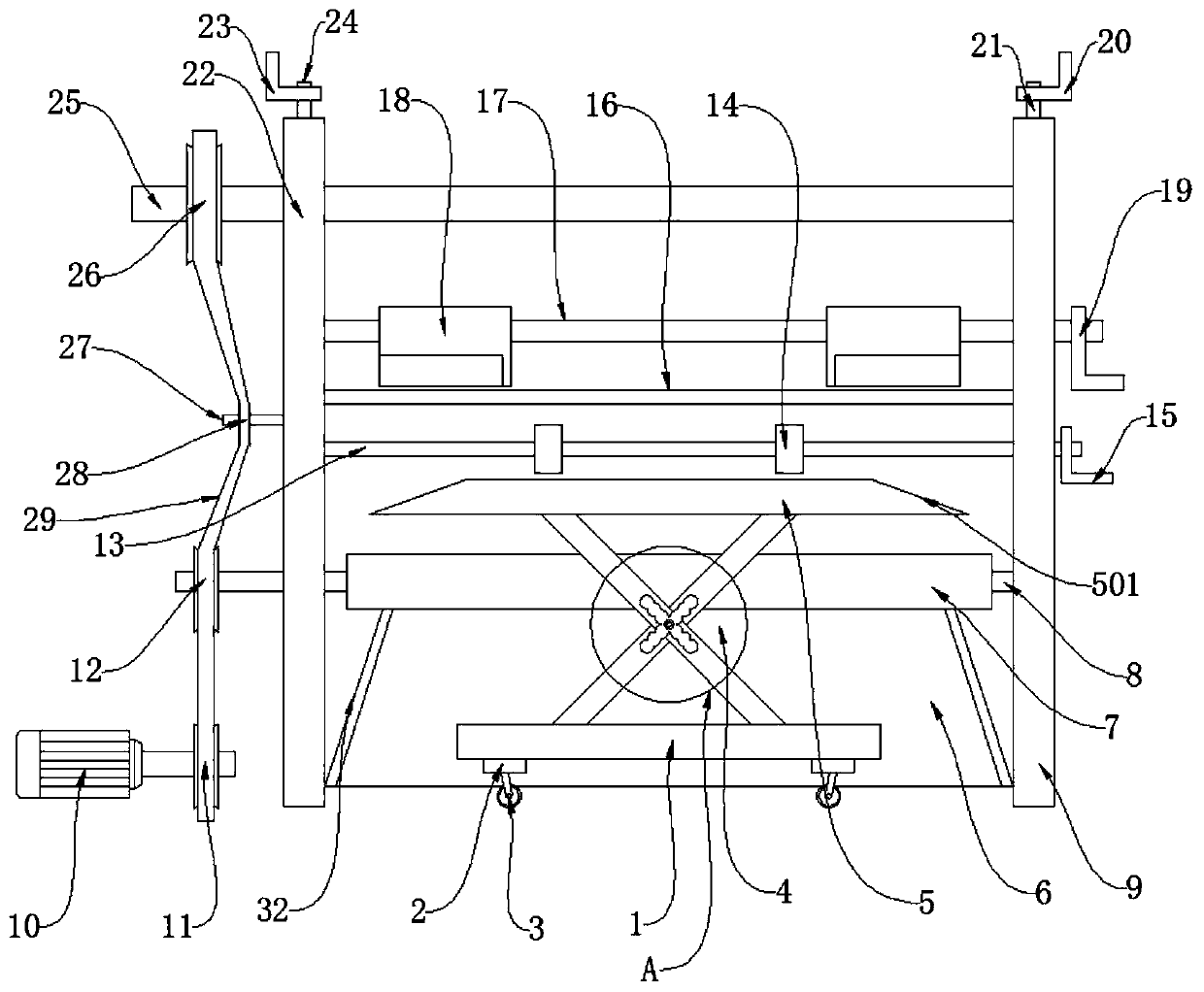

Backfill type stir friction spot welding device

The invention discloses a backfill type stir friction spot welding device, and relates to the technical field of stir friction welding. A jacket is fixed at the lower end part of an outer shell; an arm cover is arranged in the jacket; a stirring needle is arranged in the arm cover; a hollow shaft motor is provided; a hollow arm cover shaft is arranged in the hollow shaft motor; a stirring needle shaft is arranged in the arm cover shaft; the arm cover shaft is connected with the arm cover; the stirring needle shaft is connected with the stirring needle; a first ball screw with a screw rod as a hollow screw rod is arranged above the arm cover shaft; the stirring needle shaft is inserted in the screw rod of the first ball screw; a first bearing frame is arranged at the lower end of the screw rod of the first ball screw; the upper end part of the arm cover shaft is mounted on the first bearing frame; a second ball screw is arranged above the stirring needle shaft; a second bearing frame is arranged at the lower end of a screw rod of the second ball screw; the upper end part of the stirring needle shaft is mounted on the second bearing frame; and a first power source and a second power source are respectively connected with nuts of two lead screws. The backfill type stir friction spot welding device has such advantages as simple structure, high system stability, high welding precision, good effect and long service life.

Owner:苏州市哈工万洲自动化有限公司

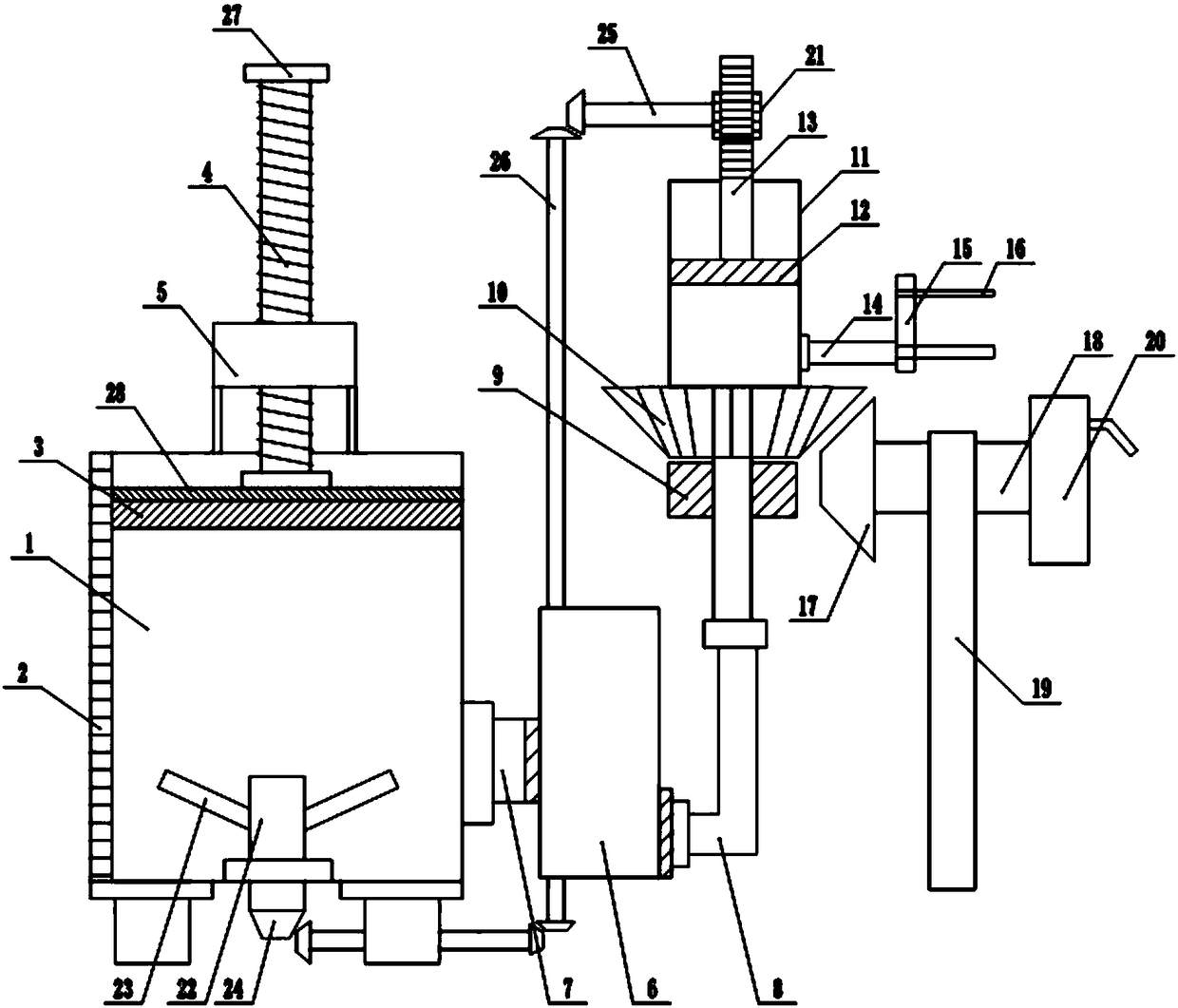

Oil-feed pump for robot

PendingCN108518577AAvoid wastingPrevent oxidationLubricating pumpsConduits/junctionsFuel tankPiston rod

The invention relates to an oil-feed pump for a robot. The oil-feed pump comprises a machine frame, an oil storage mechanism and a bevel gear table, wherein the oil storage mechanism comprises an oilstorage tank provided with scale marks, a first piston is slidably connected in the oil storage tank, a threaded rod is rotationally connected to the first piston, the threaded rod is sleeved with a nut through threads, one side of the oil storage tank communicates with a cache box through an oil guide pipe, and the lower part of the cache box communicates with an oil supply pipe; an oil filling tank is fixedly connected to the bevel gear table, the other end of the oil supply pipe communicates with the oil filling tank, a second piston is slidably connected in the oil filling tank, the secondpiston is rotationally connected with a piston rod, and the piston rod is connected with a driving mechanism; the lower part of the oil filling tank communicates with an oil filling pipe, the other end of the oil filling pipe is movably connected with an oil filling disc, and an oil injecting pipe communicates with the oil filling disc; and the bevel gear table is meshed with a first bevel gear,the first bevel gear is coaxially and fixedly connected with a connecting shaft, and the other end of the connecting shaft is coaxially and fixedly connected with a rotating disc. According to the oil-feed pump for the robot, the problem that the lubricating effect of the robot is affected due to the fact that lubricating oil in an existing oil injecting machine is prone to oxidization is solved.

Owner:重庆合聚达智能装备有限公司

Transmission apparatus

InactiveUS20050164818A1Guaranteed normal transmissionIncrease powerRotary clutchesToothed gearingsFluid couplingEngineering

The present invention relates to a transmission apparatus (15) including at least one of a dividing unit (6) and a differential planetary gear unit (30), and a joint unit (20). A rotational power, which has been input to the transmission apparatus (15), is transmitted to the joint unit (20) via the dividing unit (6) or the differential planetary gear unit (30). A rotational power to be input to the joint unit (20) is smaller than the rotational power which has been input to the transmission apparatus (15), and the joint unit comprises a fluid coupling.

Owner:EBARA CORP

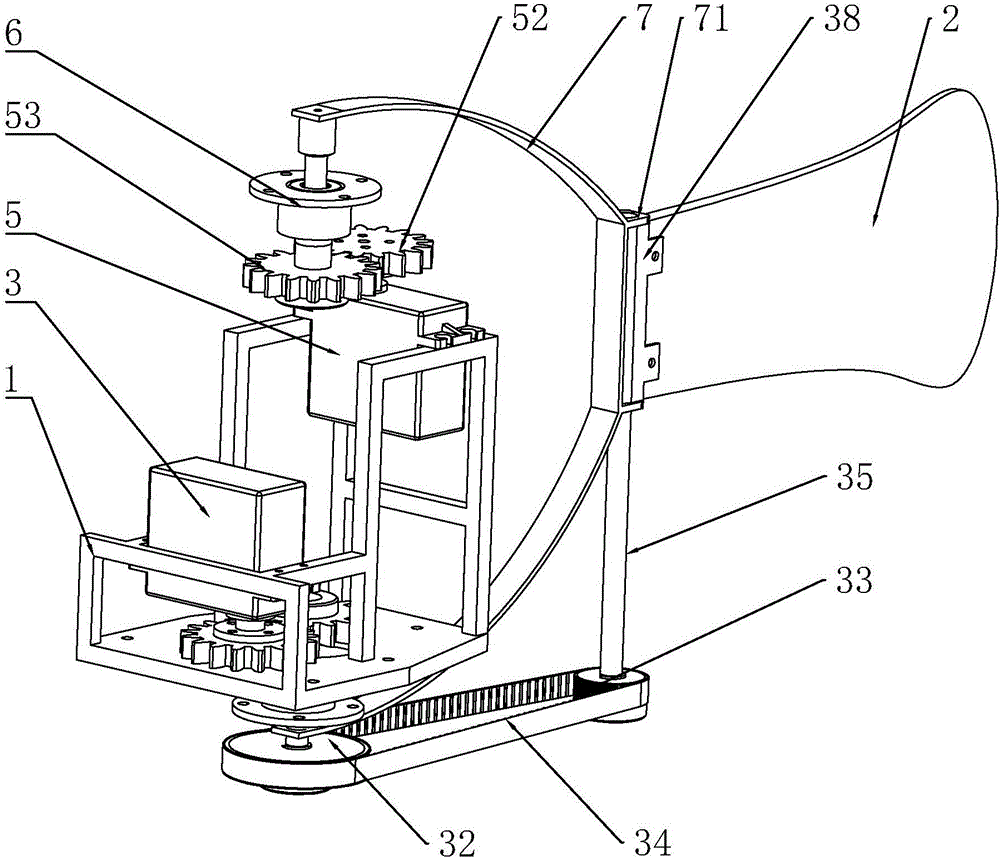

Family ostraciidae fish-based double degree-of-freedom bionic caudal fin propulsion mechanism

InactiveCN106043644AImprove mobilityImprove applicabilityPropulsive elements of non-rotary typeOstraciidaeEngineering

The invention belongs to the technical field of underwater autonomous bionic robotic fish, and aims to provide a dual-degree-of-freedom bionic caudal fin propulsion based on boxfish family fish that enables the boxfish-like robotic fish to have higher propulsion efficiency and good maneuverability The mechanism transmits the rotation of the first steering gear through the first gear set and the first power transmission module, and realizes the swing of the bionic tail fin through the action of the large and small synchronous pulleys and the toothed belt, and the bionic tail fin can swing left and right by a β angle; The rotation of the second steering gear is transmitted through the second gear set and the second power transmission module, and converted into the overall swing of the C-shaped bracket and the tail fin. The C-shaped bracket can swing left and right at an angle of α. The superposition of swings is the final swing state of the caudal fin. By adopting the bionic caudal fin with two degrees of freedom, the boxfish-like robotic fish has higher propulsion efficiency and good maneuverability characteristics, and realizes multi-modal movement.

Owner:PEKING UNIV

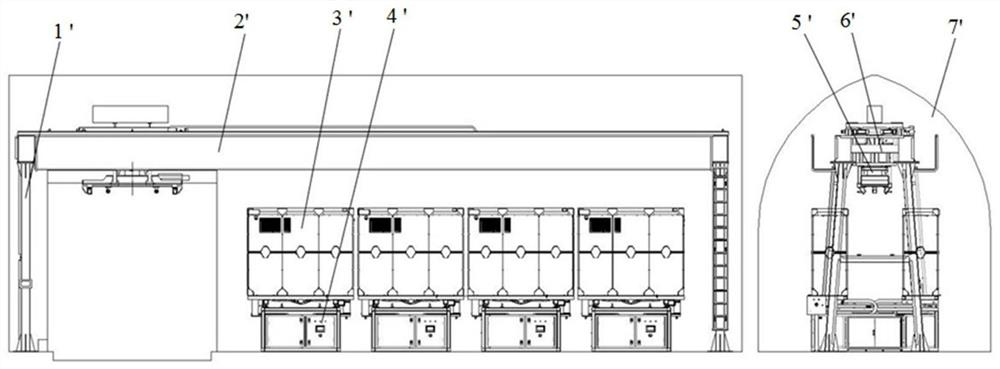

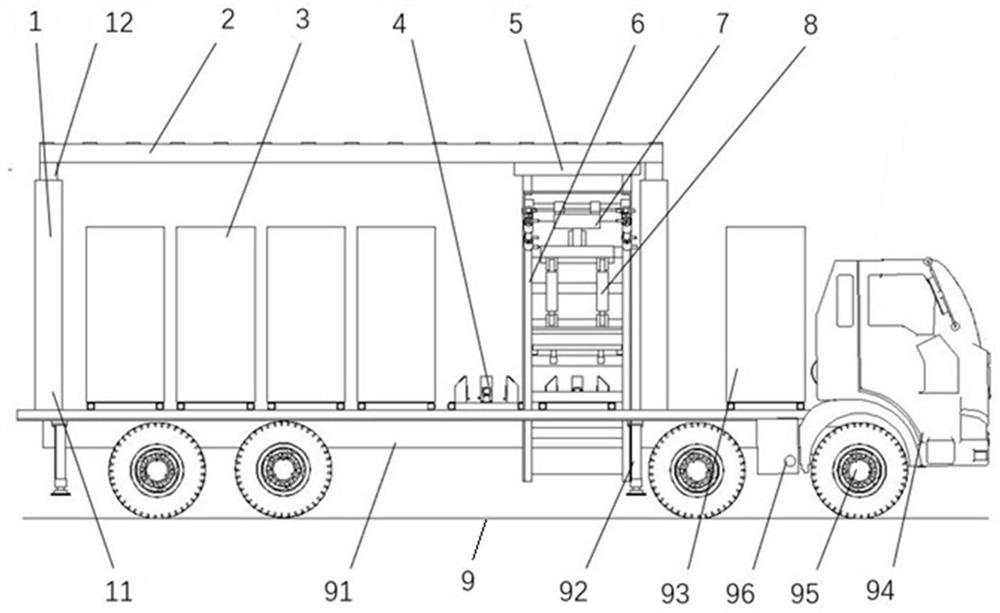

Novel mobile battery replacing equipment

PendingCN112406622ASolving Unsolvable Roadside Assistance ProblemsWide range of sources of structureCharging stationsVehicular energy storageNew energyCentralized management

The invention relates to the technical field of new energy, and discloses novel mobile battery replacing equipment which comprises a chassis, a supporting mechanism, a foldable rail, a first trolley and a driving mechanism. A battery pack base is arranged on the chassis, and the supporting mechanism is arranged on the chassis. The foldable rail is connected to the supporting mechanism and has an unfolded state and a folded state. Wherein the first trolley is movably arranged on the foldable rail, a gripping apparatus is connected to the first trolley, and the driving mechanism is in transmission connection with the foldable rail to drive the foldable rail to move, so that the foldable rail is in the unfolded state or the folded state. According to the mobile battery replacing equipment provided by the invention, the conventionally used battery pack base is mounted on the chassis, so that the problems of large occupied area, capital construction requirement and high cost of a fixed charging station are solved. In addition, the battery replacing equipment can be moved to a unified station for centralized management, and the problems that charging piles are distributed disorderly andare inconvenient to maintain are solved.

Owner:上海融和智电新能源有限公司

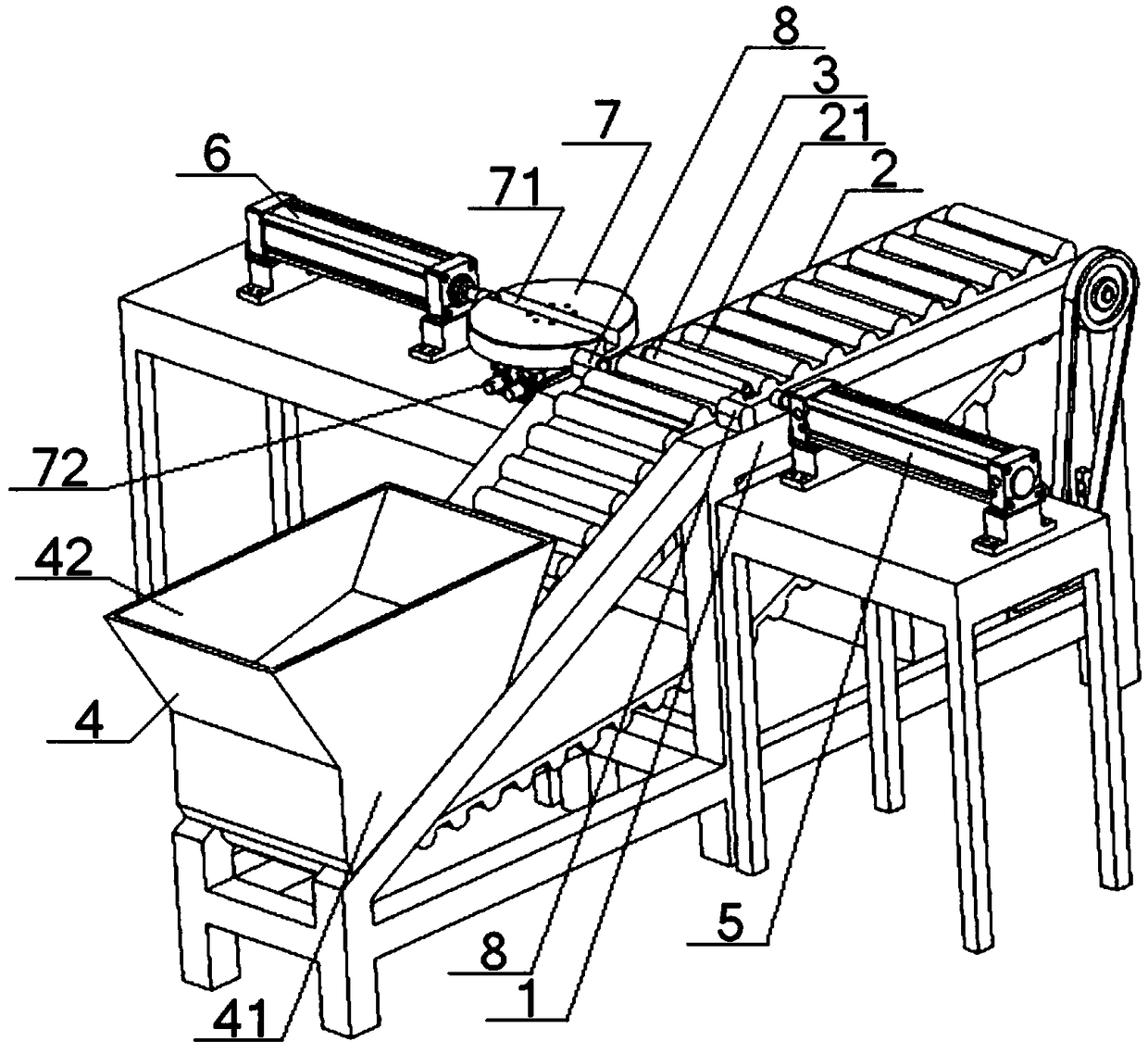

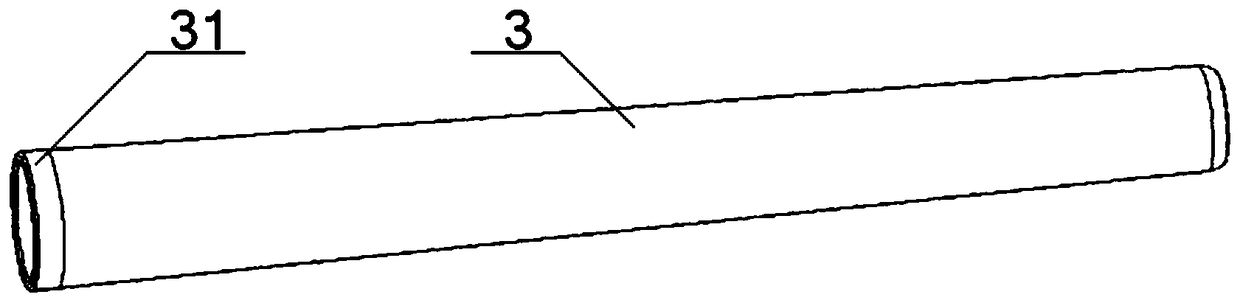

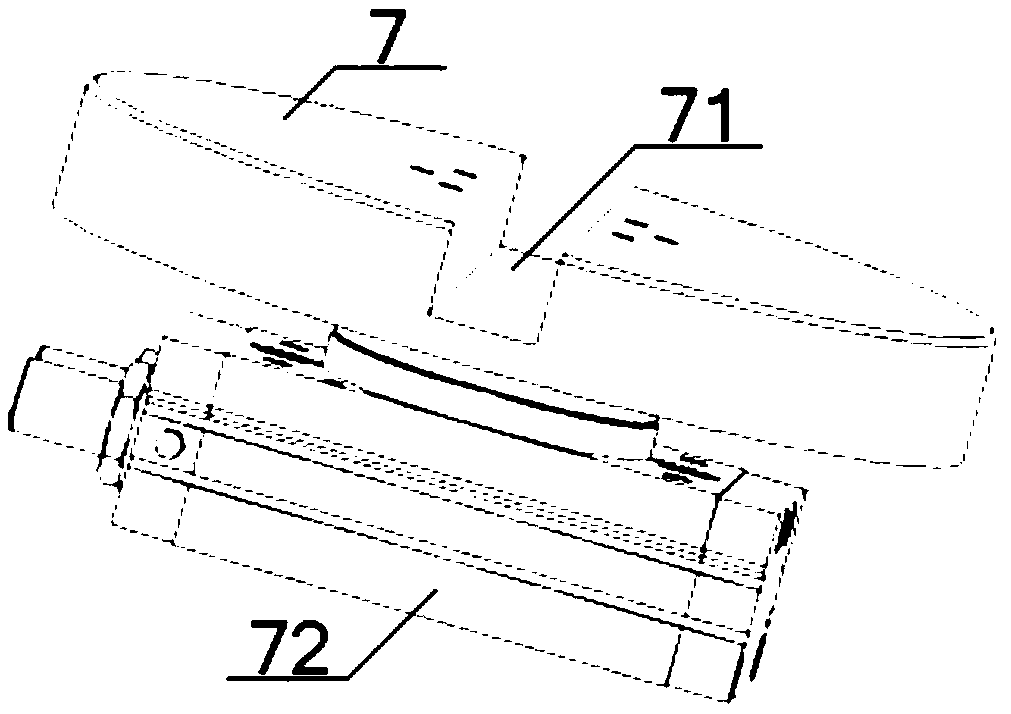

Feeding conveying device of ring bobbin and control method thereof

ActiveCN109230373AReduce labor intensityImprove the efficiency of residual yarn cleaningConveyorsConveyor partsYarnEngineering

The invention discloses a feeding conveying device of ring bobbin. The device comprises a bracket and a conveying belt arranged on the bracket, a plurality of storage cases are uniformly arranged on the periphery surface of the conveying belt, and the ring bobbin is arranged in one of the storage cases and is of a circular truncated cone structure; a hopper is arranged on the portion, located above the conveying belt, of the bracket, a first air cylinder is arranged on one side of the conveying belt, and the output end of the first air cylinder is aligned with the ring bobbin; a second air cylinder is arranged on the other side of the conveying belt, a revolving turntable is arranged between the second air cylinder and the conveying belt, and a groove is formed in the top of the revolvingturntable in the diameter direction of the revolving turntable; two opening ends of the groove are respectively aligned with the output end of the second air cylinder and the ring bobbin, and a revolving air cylinder is arranged at the bottom of the revolving turntable; a metal ring sleeves the large diameter end of the ring bobbin, and metal sensors are arranged on the portions, located on the two sides of each storage case, of the bracket. The design of the device not only reduces the labor intensity of residual yarn cleaning but also improves the efficiency of cleaning residual yarns away.

Owner:HUBEI TIANMEN TEXTILE MACHINERY

Amphicar structure

ActiveCN106080069AReduce resistanceSmooth transmissionAmphibious vehiclesTransmission with mechanical gearingTransfer casePropeller

The invention provides an amphicar structure, which comprises an amphicar body, a chassis, a plurality of wheels, a propeller, a power system and a drive system, wherein the amphicar body is connected with the chassis; the power system and the drive system are installed on the chassis; the drive system comprises a power conversion device and a wheel collecting and releasing device; the power conversion device comprises a first drive mechanism, a second drive mechanism and a transfer case; the power system and the transfer case are connected; the transfer case can be independently connected with the first drive mechanism or the second drive mechanism; the first drive mechanism is connected with the propeller; the second drive mechanism is connected with the wheels; the wheel collecting and releasing device is connected with the wheels. The amphicar structure can realize stable drive and smooth conversion, power can be stably transmitted, driving is more stable, and the power conversion of an amphicar in water and on land can be perfectly realized. In addition, the collection and the release of the wheels can be realized, the wheels are collected when the amphicar is driven on water, resistance between the amphicar body and the water surface can be reduced, and the amphicar can be more stably and quickly driven on the water.

Owner:YANCHENG INST OF TECH

Lightweight backfill-type friction stir spot welding device

ActiveCN108857044AEasy to integrateIncrease frictionNon-electric welding apparatusFriction weldingDrive shaft

The invention discloses a lightweight backfill-type friction stir spot welding device, and relates to a friction stir welding device. The device comprises an outer shell, a stirring needle, a sleeve and a jacket; the outer shell is internally provided with a transmission lead screw, and the transmission lead screw is a hollow two-way lead screw, wherein the ratio of the screw pitch of the upper portion to the screw pitch of the lower portion is equal to the inverse ratio of the cross-sectional area of the sleeve to the cross-sectional area of the stirring needle; an upper nut of the transmission lead screw is connected with the sleeve through a sleeve cylinder, bearings, a first bearing frame and a sleeve rolling spline nut; a stirring needle shaft capable of freely sliding in the transmission lead screw up and down and cooperating with the sleeve rolling spline nut is installed on a lower nut of the transmission lead screw through a second bearing frame and the bearings, and the lowerend of the stirring needle shaft is connected with the stirring needle; the device is provided with a transmission shaft sleeve in spline connection with the upper end of the stirring needle shaft, afirst power source and a second power source are arranged, the first power source is connected with the transmission shaft sleeve, and the second power sources is connected with the transmission leadscrew. The device has the advantages of light structure, high system stability and welding precision, good effect and long service life.

Owner:山东格物智能科技有限公司

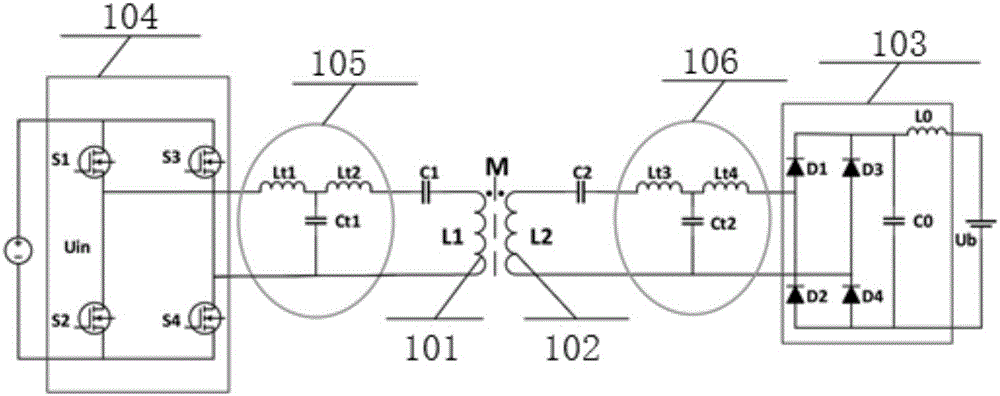

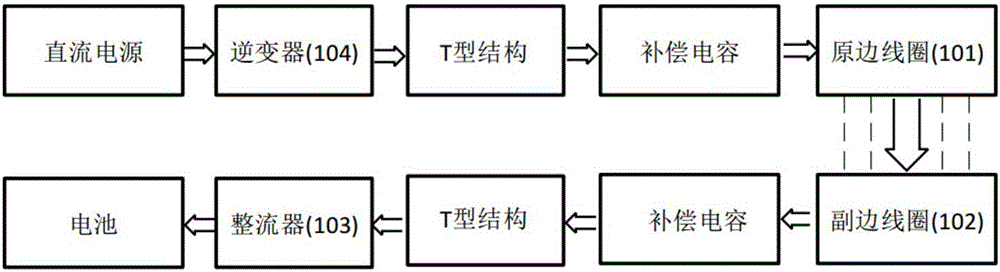

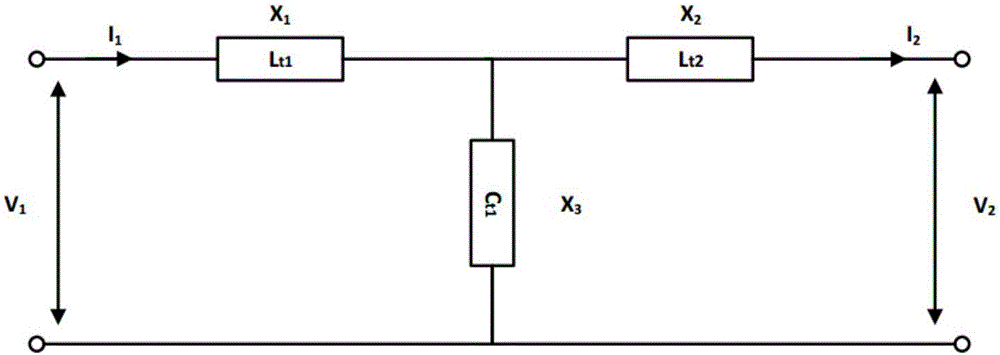

Double-side T-S compensation topology and parameter matching method for wireless electric energy transmission

ActiveCN106100345AStable power deliveryAchieving distance independenceCircuit arrangementsDc-dc conversionAlternating currentDirect current

The invention provides a double-side T-S compensation topology and parameter matching method for wireless electric energy transmission, and the method employs a scheme that the method employs an inverter, a first T-shaped structure, a receiving and transmitting module, a second T-shaped structure and a rectifier, wherein the inverter, the first T-shaped structure, the receiving and transmitting module, the second T-shaped structure and the rectifier are connected sequentially; the inverter is connected to a DC power output end, and is used for inverting a direct current into an alternating current and transmitting the alternating current to the first T-shaped structure; the first T-shaped structure is used for obtaining a stable current and stabilizing the transmission power of a transmitting end; the receiving and transmitting module is used for transmitting the inverted alternating current to the second T-shaped structure in a wireless mode; the second T-shaped structure is used for obtaining a stable current and stabilizing the transmission power of a receiving end; and the rectifier is used for carrying out the rectification processing of the alternating current of the receiving end and outputting a corresponding direct current. The method solves problems of transmission power level and power transmission stability well; achieves the purposes that a current of a primary coil and an output current are stable and do not change with a load; and achieves a purpose that the resonant frequency is independent of the load and the distance of primary and secondary coils through parameter matching.

Owner:SHANGHAI JIAO TONG UNIV

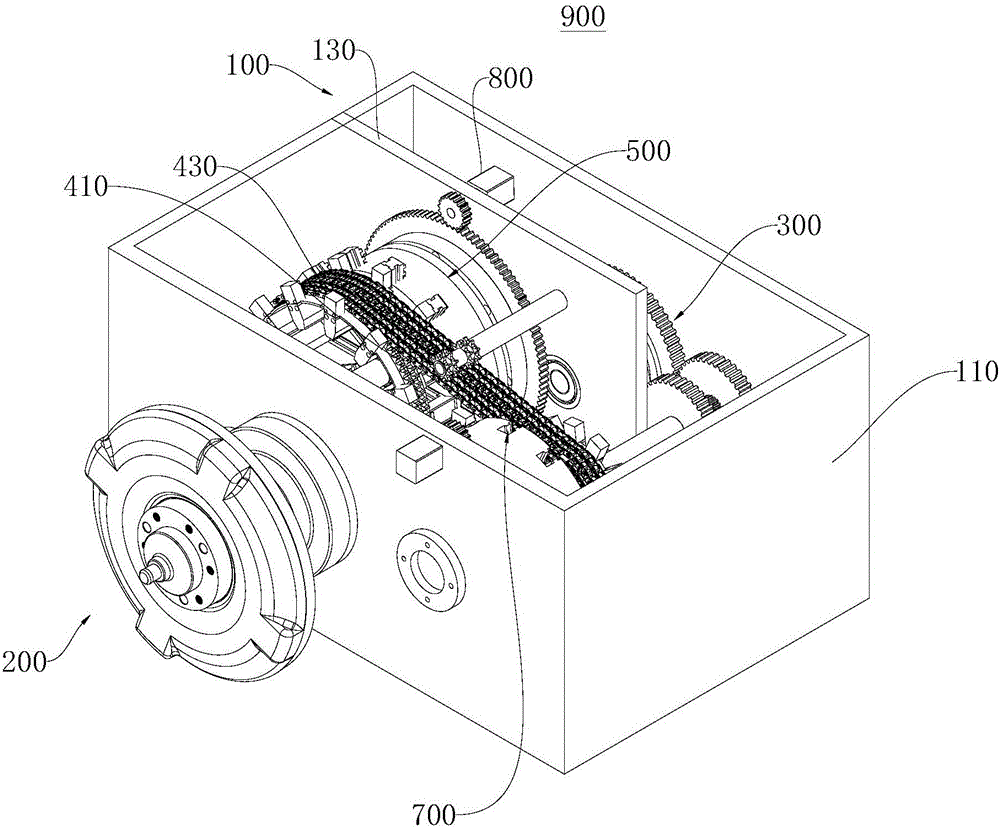

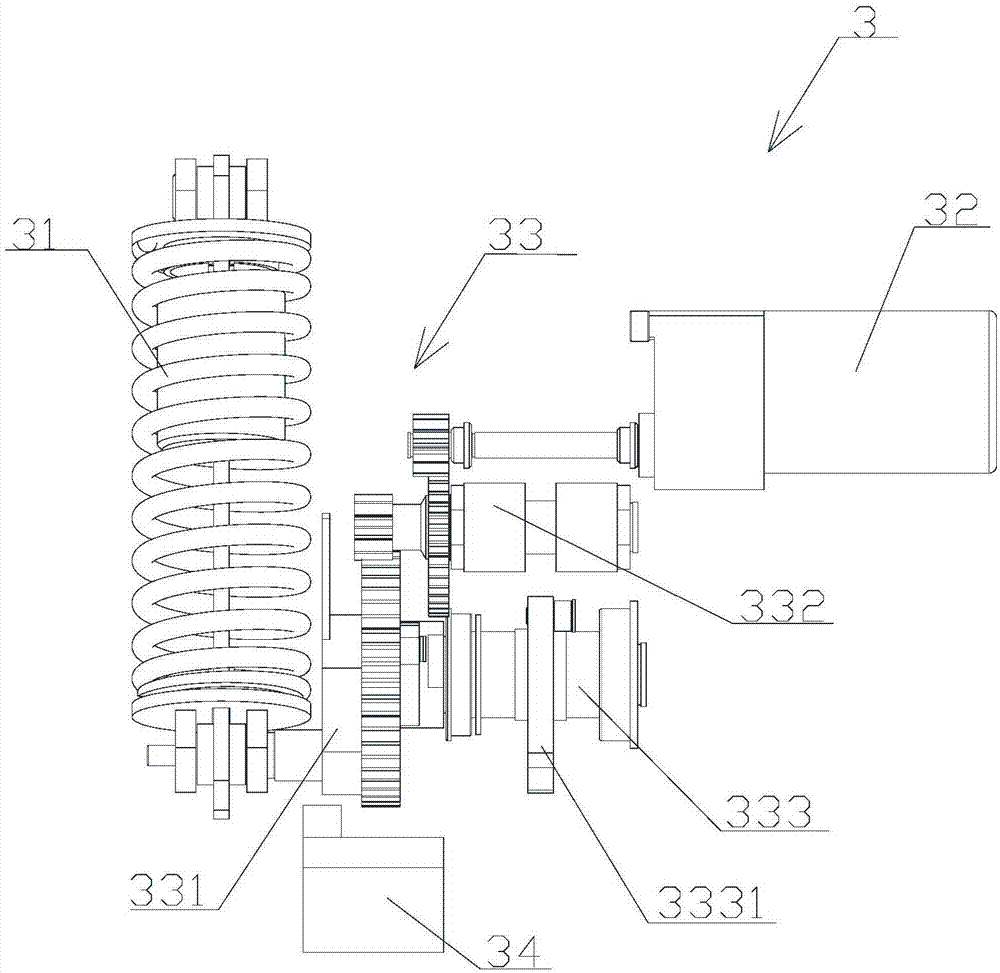

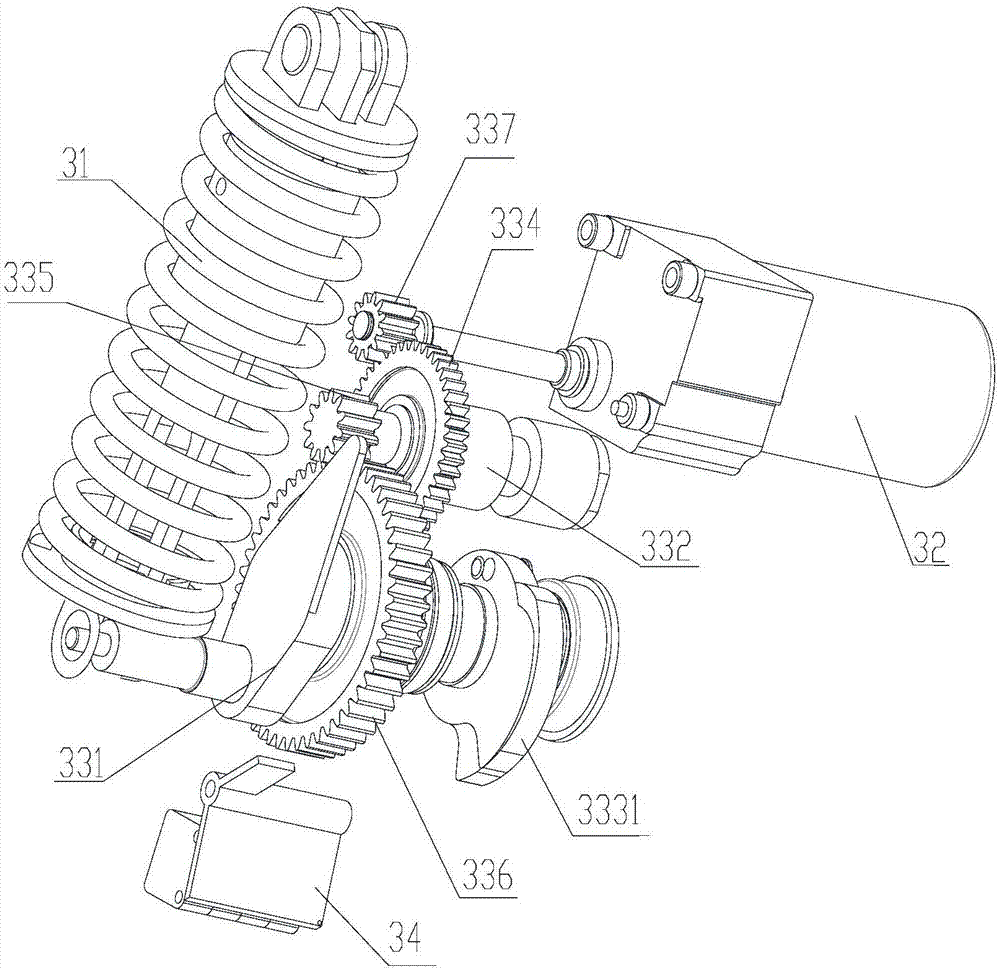

Mechanical variable chain wheel continuously variable transmission

ActiveCN106015482AChange gear ratioIncrease contact areaGearingElectric power transmissionTransmitted power

The invention provides a mechanical variable chain wheel continuously variable transmission. The mechanical variable chain wheel continuously variable transmission comprises an input device, a drive transmission device connected to the input device, a driven transmission device connected to the drive transmission device through a chain and an output device connected to the driven transmission device; the drive transmission device comprises a variable chain wheel plate, a clamping jaw connected to the variable chain wheel plate and a chuck with the clamping jaw, the clamping jaw is driven by a wire coiling crankset arranged in the chuck to move in the radius direction of the chuck, and the clamping jaw drives the variable chain wheel plate to move to change the diameter of the variable chain wheel plate; a variable chain wheel comprises the variable chain wheel plate installed to the clamping jaw and variable chain wheel teeth installed to the variable chain wheel plate. The drive transmission device and the driven transmission device transmit power through meshing of the chain and a gear, the contact surface of power transmission is increased, and power transmission is more stable and more efficient.

Owner:丁震中

Actuator with self-locking helical gears for a continuously variable valve lift system

InactiveUS20090283062A1Increase output torqueImprove forwarding efficiencyValve arrangementsToothed gearingsVolumetric Mass DensityActuator

A CVVL system including a self-locking helical gear pair with, optionally, a transmission to increase output torque of the actuator. The self-locking helical gear pair provides high forward efficiency and a fully mechanically self-locking feature. The actuator therefore requires a smaller motor to perform the same actuation as a prior art worm-gear system. The CVVL system comprises two helical gears having a radial pressure angle {acute over (α)} between 45° and 75° and a helix angle β between 60° and 80°. An asymmetric tooth profile is presently preferred, reducing contact stress and permitting higher torque density. Preferably, the helical gears are discontinuous and comprise laminated spur gear slices and hence are less costly to produce than continuous helical gears. Configurations are possible within the scope of the present invention include a single stage gear system; a multiple stage gear system; a planetary gear system; and an internal or external gear system.

Owner:TAYE ELIAS

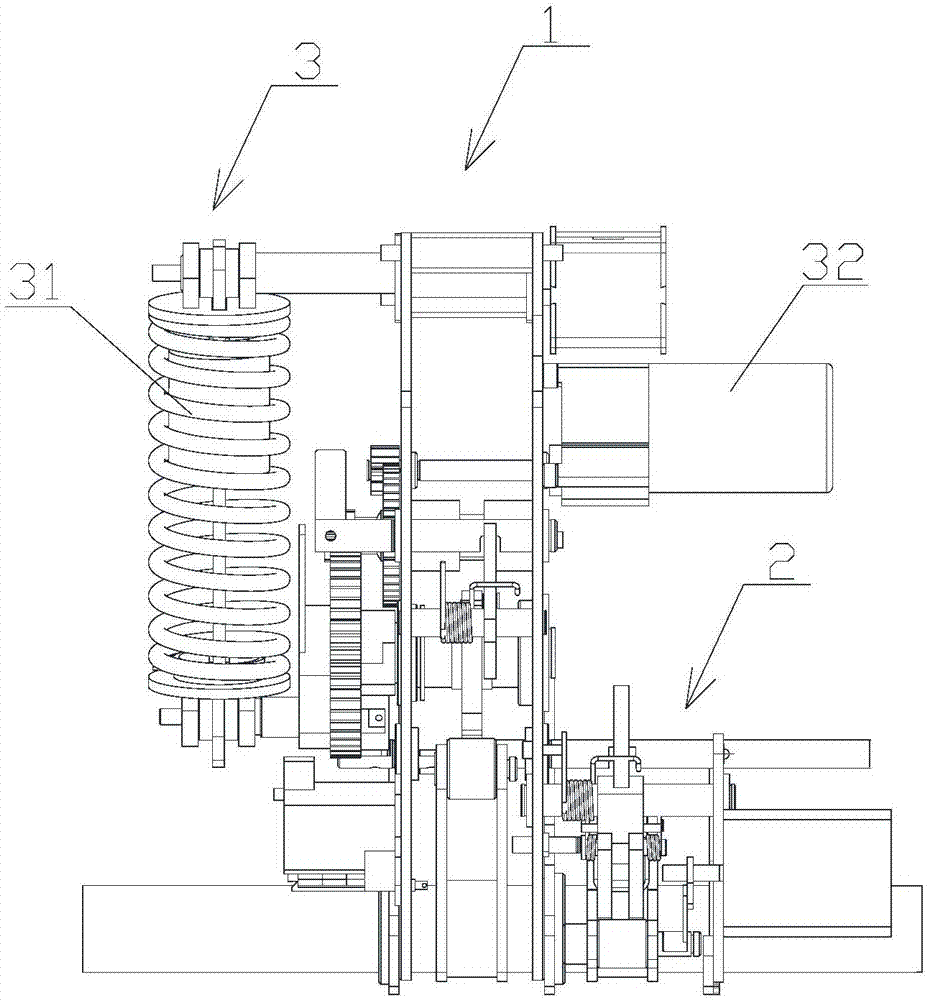

Single modularization circuit breaker

PendingCN107993881ACompact structureReduce volumeHigh-tension/heavy-dress switchesAir-break switchesComputer moduleEnergy storage

The invention relates to the field of circuit breakers, in particular to a single modularization circuit breaker. The single modularization circuit breaker comprises a switch-on mechanism, a switch-off mechanism and an energy storage mechanism, wherein the energy storage mechanism comprises an energy storage spring and a driving device; the driving device drives the energy storage spring to storeenergy by means of a transmission assembly; the energy storage spring and the transmission assembly are arranged at one side of a wall board; the switch-on mechanism and the switch-off mechanism are sequentially arranged at the other side of the wall board and form a module main body; the driving device is positioned above the switch-off mechanism. The single modularization circuit breaker solvesthe problems that in the prior art, the circuit breakers are large in volume and more in structural modules.

Owner:常州阿斯博开关有限公司

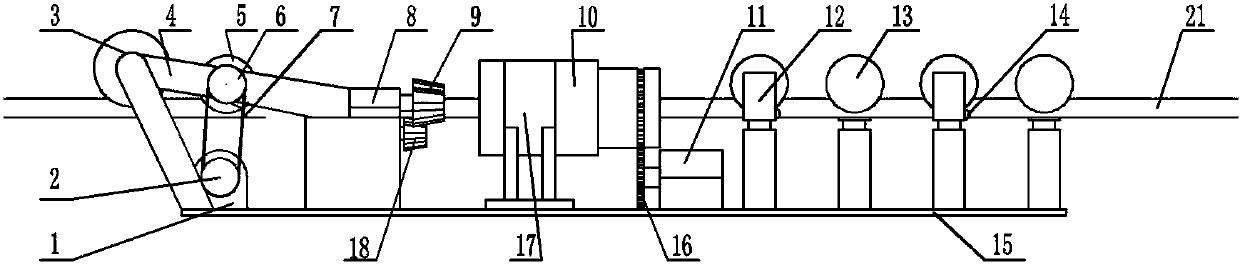

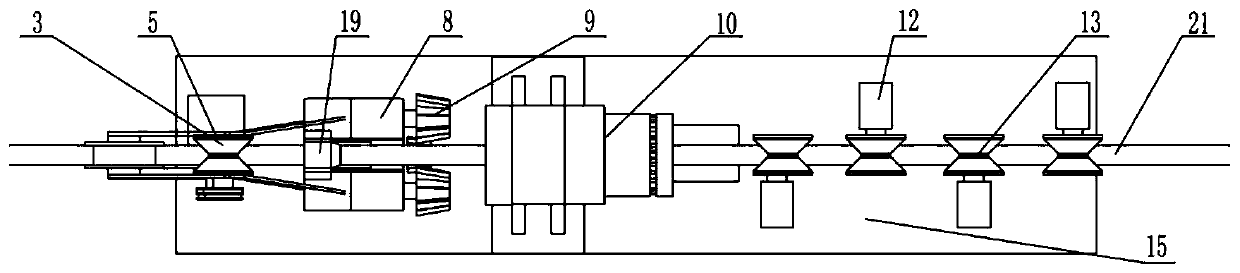

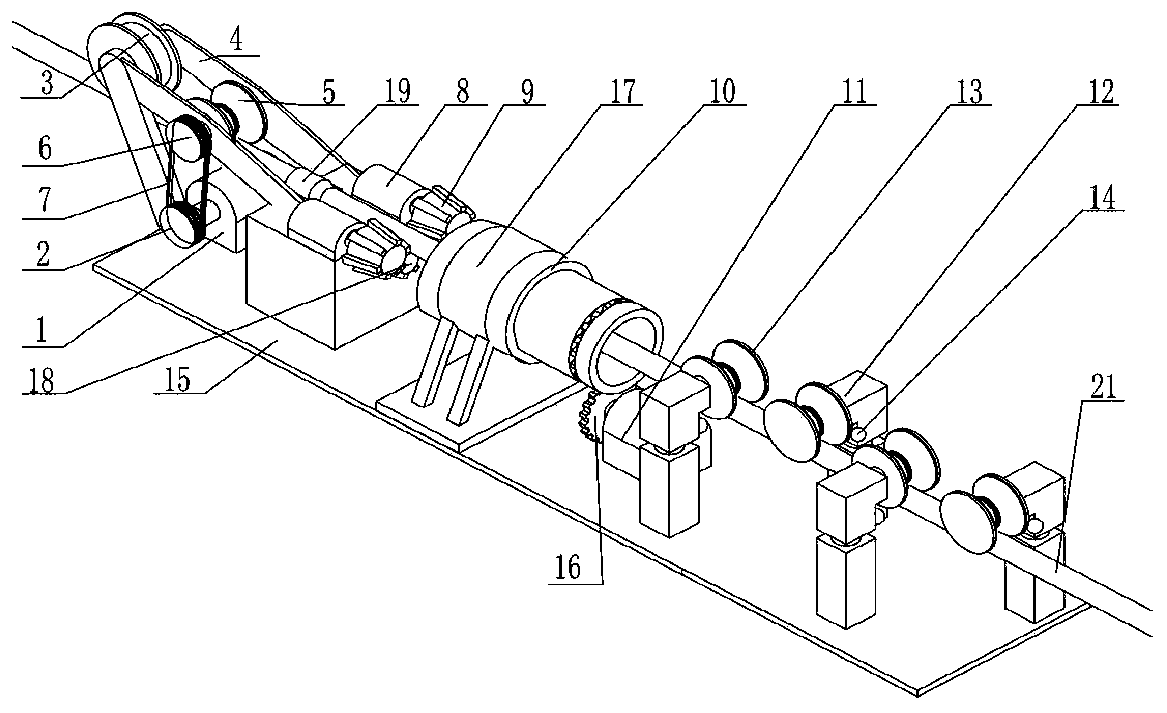

Cable deicing robot and deicing method thereof

ActiveCN111244868ADifficult problem solving for manual deicingGood deicing effectOverhead installationApparatus for overhead lines/cablesStructural engineeringControl theory

The invention discloses a cable deicing robot and a deicing method thereof. The robot comprises a base, a front guide wheel mechanism, a first-stage deicing mechanism, a second-stage deicing mechanism, a rear guide wheel mechanism and a walking driving mechanism, wherein the front guide wheel mechanism, the first-stage deicing mechanism, the second-stage deicing mechanism, the rear guide wheel mechanism and the walking driving mechanism are fixed on the base and are sequentially arranged in the cable deicing advancing direction. The cable deicing robot is reasonable in overall structure. A step-by-step deicing mode is adopted. Higher safety, higher efficiency and higher stability are achieved, and cables are effectively protected at the same time.

Owner:CHINA UNIV OF MINING & TECH

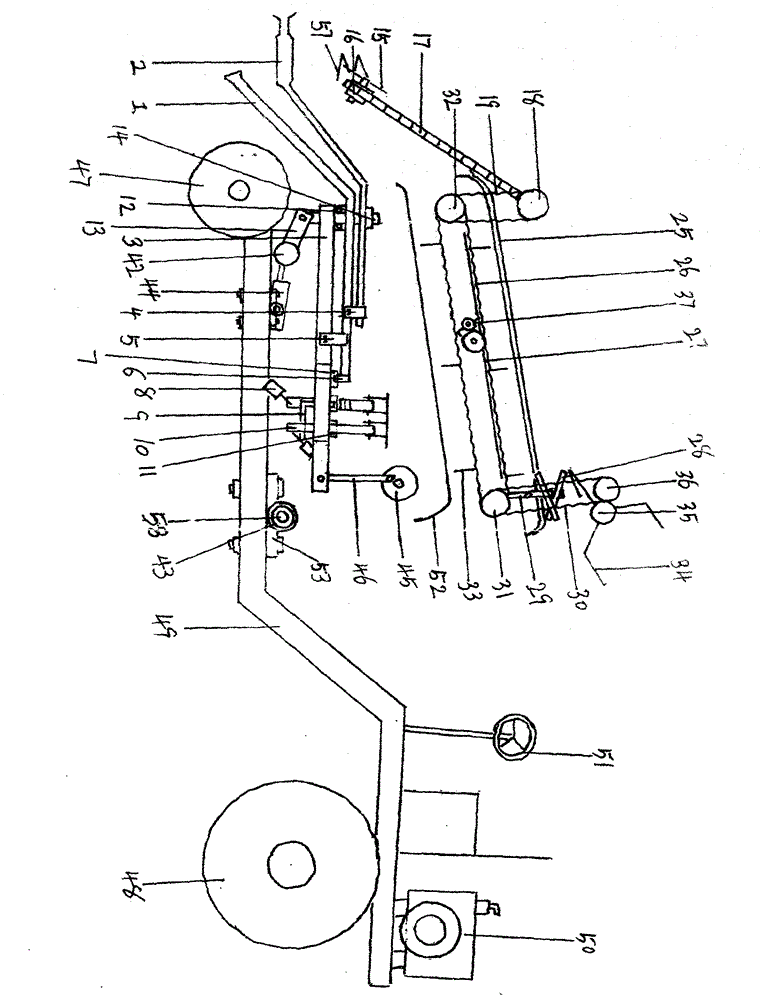

Garlic Combine Harvester

InactiveCN102726161BImprove protectionStable power deliveryLiftersTopping machinesAgricultural engineeringCombine harvester

The invention relates to a garlic combined harvester, which comprises a garlic shoveling system, a garlic pull-out system, a transfer and shear system, a lifting system and a traveling system. The garlic shoveling system includes a main shovel frame, the main shovel frame and an auxiliary shovel blade and a sensor both at the back of the main shovel frame are positioned via a positioning shaft at the front end of the main shovel frame, the rear end of the main shovel frame is connected with an eccentric wheel on the machine frame via a link rod, and an auxiliary shovel blade adjusting device is installed on the main shovel frame. The garlic pull-out system includes a garlic supporting frame located at the front end, the front end of a garlic pull-out frame is located above a shovel blade edge, and the rear end of the garlic pull-out frame is fixed at the upper part of the machine frame. The transfer and shear system includes a garlic bulb push frame fixed on a conveyor chain, a garlic root shear located at the middle part of the conveyor chain, and a garlic stem shear located at the tail part of the conveyor chain. The lifting system adopts hydraulic lifting. The traveling system adopts back driving and steering. The inventive harvester is high in automation degree, time-saving and labor-saving, can cut off garlic roots and stems at one time to complete all garlic harvesting procedures, and is suitable for interplanting land blocks.

Owner:时丕护

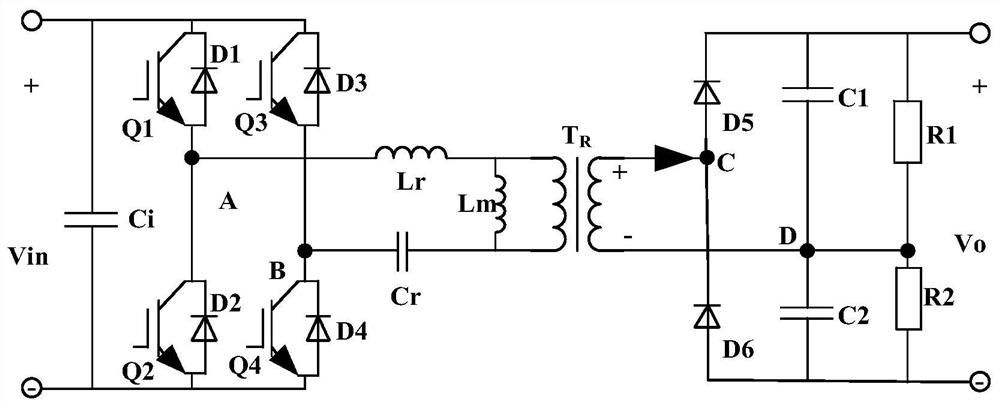

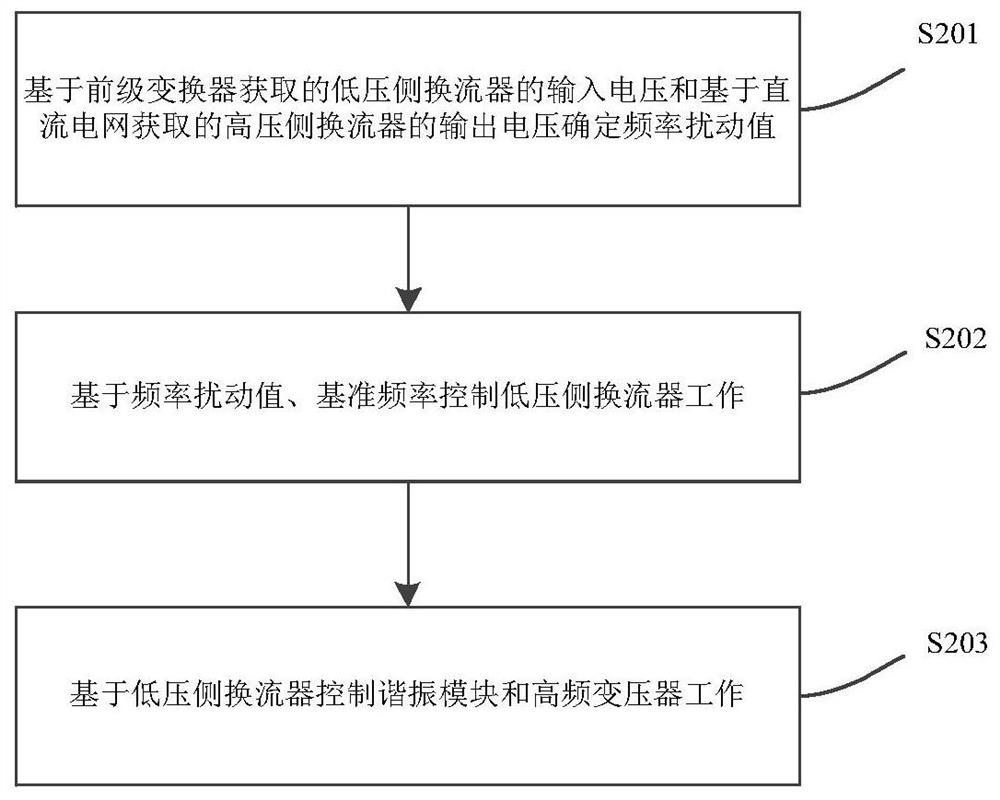

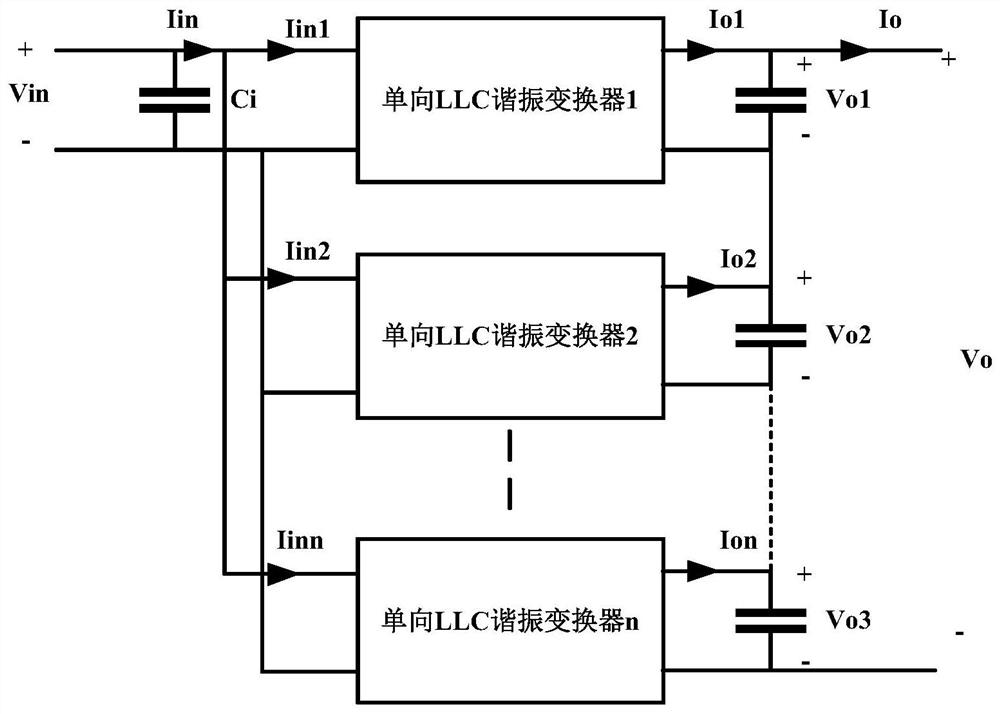

One-way LLC resonant converter, frequency conversion control method thereof and IPOS direct-current converter

PendingCN112467986AReduce design difficultyReduce the ratioEfficient power electronics conversionDc-dc conversionFrequency conversionPower grid

The invention provides a one-way LLC resonant converter, a frequency conversion control method thereof, an IPOS DC converter and a one-way LLC resonant converter, and is characterized in that the one-way LLC resonant converter comprises a low-voltage side converter, a resonant module, a high-frequency transformer and a high-voltage side converter which are connected in sequence; and the input endof the low-voltage side converter is connected with the output end of a preceding-stage converter, and the output end of the high-voltage side converter is connected with a direct-current power grid.According to the invention, the transformation ratio of the high-frequency transformer can be greatly reduced, the design difficulty of the one-way LLC resonant converter is reduced, the stability ofthe output side voltage and the input side voltage of the IPOS direct-current converter is ensured, the safe and stable operation of the IPOS direct-current converter is ensured, the reliability is high, and the energy loss is reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

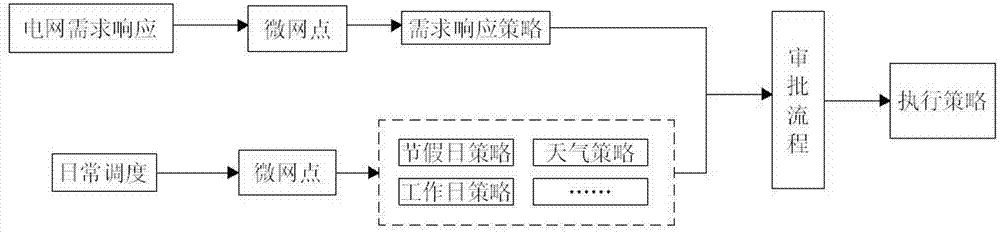

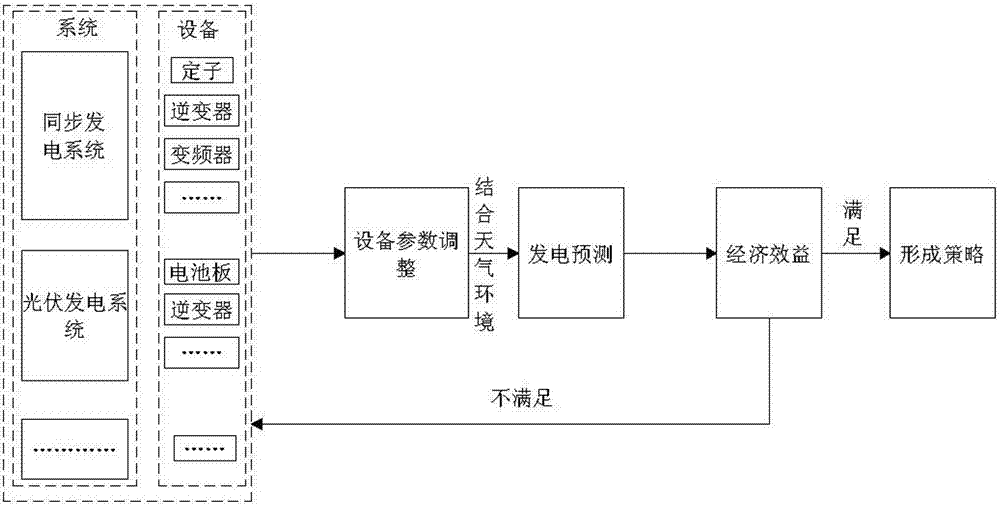

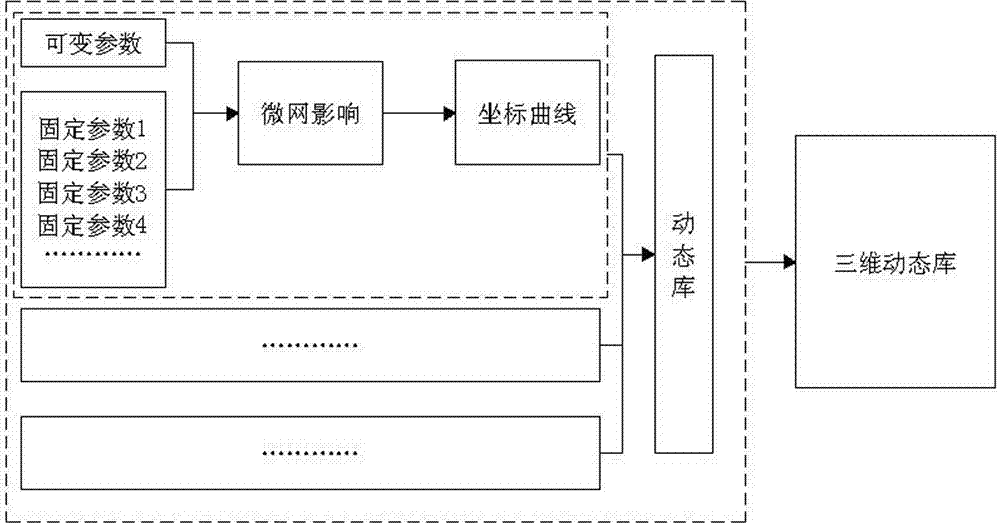

Management method for connecting distributed power supplies and micro grid to main power grid

ActiveCN104124704AImprove power supply reliabilityReduce power generation costsForecastingSingle network parallel feeding arrangementsElectricity pricePower grid

The invention discloses a management method for connecting distributed power supplies and a micro grid to a main power grid. The management method comprises the steps of power grid demand response or daily scheduling; response to demands; strategy making which comprises the steps of simulating a simulation micro grid system, performing parameter adjustment of each micro power supply device of the micro grid, responding to a parameter influence table according to a parameter adjustment value, obtaining power generation prediction according to a matching algorithm, obtaining economic benefit brought by parameter adjustment by combination with information such as electricity price, adjusting parameters according to results, finally obtaining a reasonable maximum benefit model, and forming a corresponding strategy; scheduling process approval; and strategy execution. The demand response, a scheduling process and a micro grid strategy form a closed loop, power supply reliability is improved, the uniform scheduling process during power grid demand response execution at power utilization rush hours is solved, stability and controllability of power transmission between the distributed power supplies and the micro grid and between the micro grid and the main power grid and coordinated control between a plurality of distributed power supplies are guaranteed, and united strategy control is performed on integral running of the micro grid.

Owner:SICHUAN ZHONGDIAN AOSTAR INFORMATION TECHNOLOGIES CO LTD

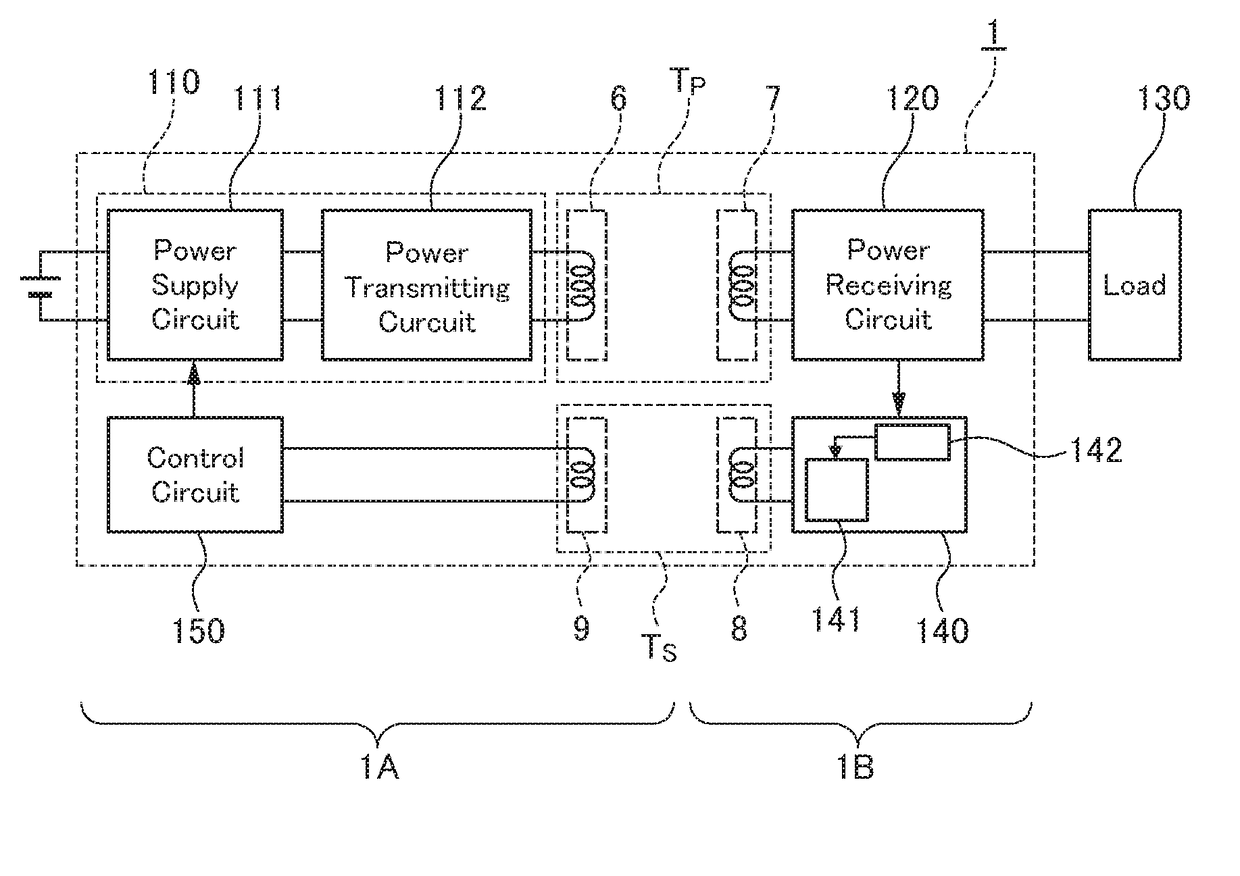

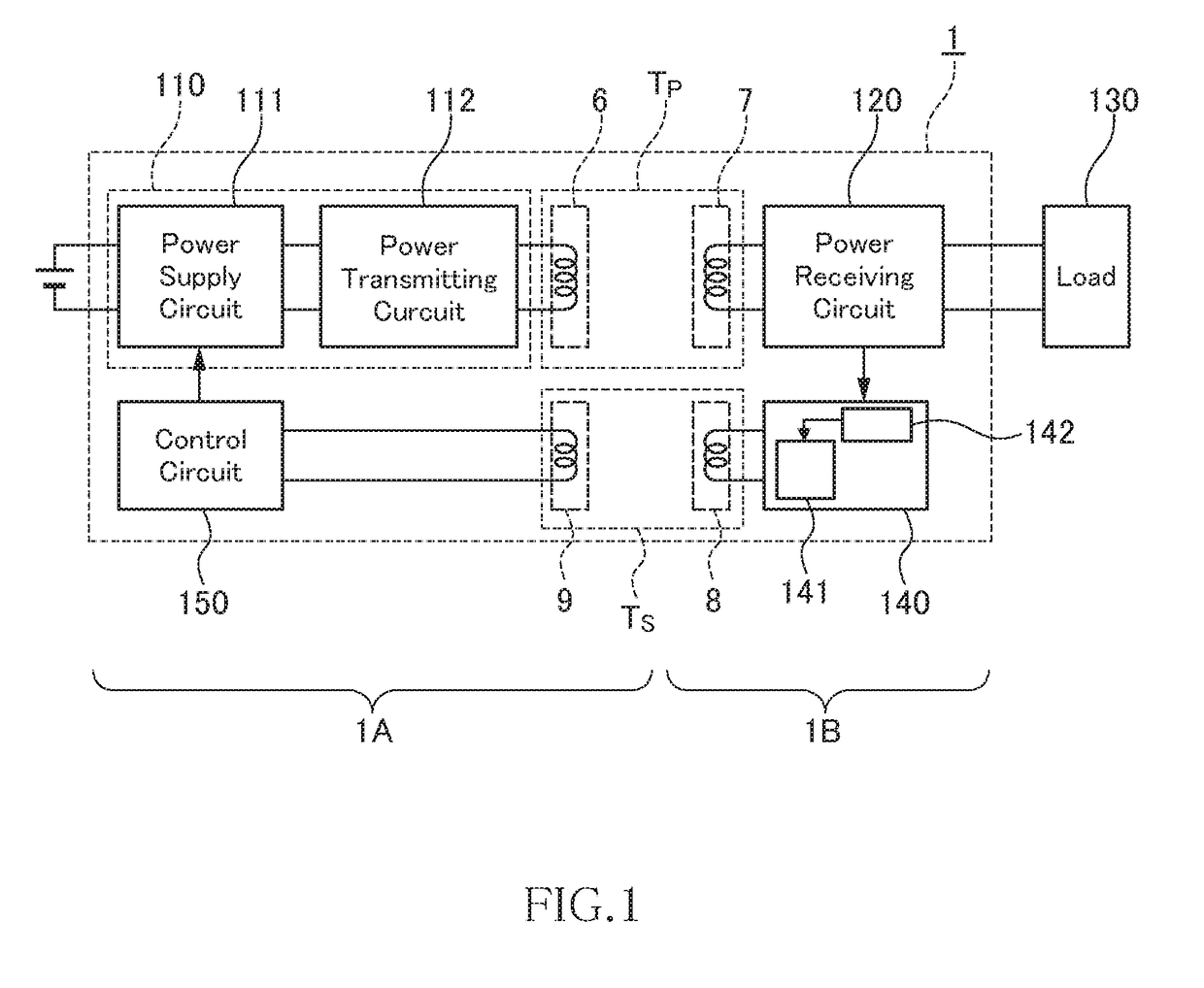

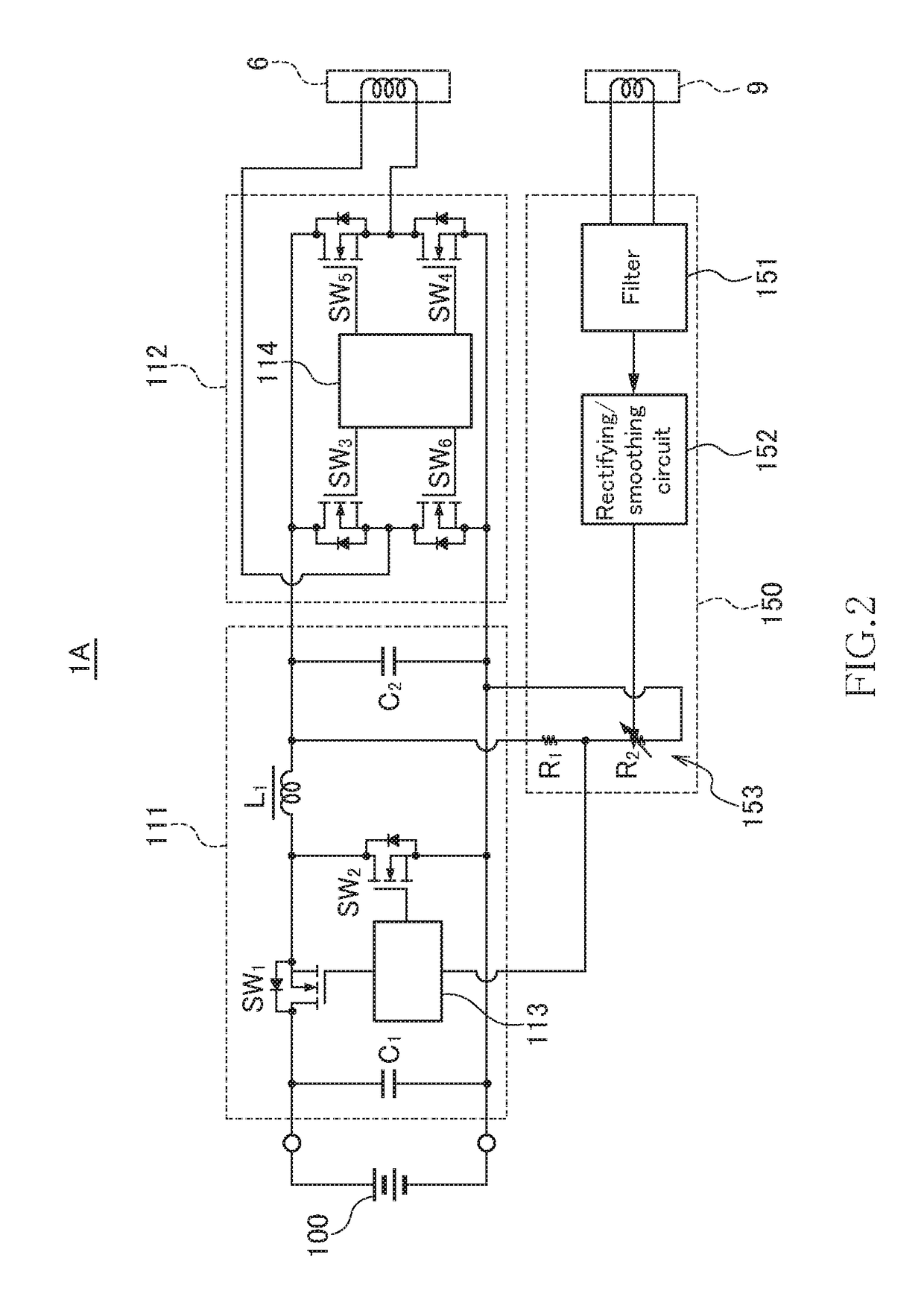

Wireless power transmission device

ActiveUS20180102674A1Reduce interactionSmooth power transmissionBatteries circuit arrangementsAc-dc conversion without reversalElectric power transmissionPower flow

Disclosed herein is a wireless power transmission device includes a power transmitting transformer coupled between a power transmitting circuit and a power receiving circuit, and a signal transmitting transformer coupled between a signal generating circuit provided at the power receiving circuit side and a control circuit provided at the power transmitting circuit side. The frequency of an AC signal transmitted by the signal transmitting transformer is equal to or more than ten times the frequency of an AC voltage transmitted by the power transmitting transformer. The signal generating circuit converts the magnitude of the output voltage or output current of the power receiving circuit into a magnitude of an amplitude of the AC signal.

Owner:TDK CORPARATION

Waste cloth collecting device for loom

InactiveCN111118875APrevent inconsistent width resultsResults in inconsistent widthSevering textilesMetal working apparatusSteering wheelDrive wheel

The invention discloses a waste cloth collecting device for a loom, relates to the technical field of cloth collecting devices, and aims to solve the problem that an existing waste cloth collecting device for the loom easily causes cloth blockage in use so that cloth cutting is inconsistent. A supporting plate is arranged below the base plate, steering wheels are arranged below the supporting plate, a left baffle plate is arranged on one side of the base plate, a left ball screw is arranged in the left baffle plate, a motor is arranged on one side of the left baffle plate, a driving wheel is arranged at the top end of the motor, a right baffle plate is arranged on the other side of the base plate, a right ball screw is arranged in the right baffle plate, an adjusting mechanism is arrangedabove the base plate, a driving belt shaft is arranged above the adjusting mechanism, a conveying belt is arranged outside the driving belt shaft, and a small belt wheel is arranged on one side of thedriving belt shaft.

Owner:戴博超

Wireless power transmitter and method for detecting rfid/nfc card

ActiveUS20210265867A1Stable wireless power transmissionAvoid damageNear-field transmissionCircuit arrangementsEmbedded systemReceiver

Disclosed in the present application is a wireless power receiver comprising: a power pickup unit configured to receive, in a power transfer phase, wireless power generated by magnetic coupling from a wireless power transmitter; and a communications / control unit configured to transfer, in a negotiation phase, a first end-of-power-transfer (EPT) packet to the wireless power transmitter for detecting an RFID / NFC card, and to detect the RFID / NFC card during a re-ping time secured on the basis of the first EPT packet, wherein the first EPT packet instructs requesting the removal of a power signal for a predetermined time. As the process for detecting communication cards, such as RFID or NFC, between the wireless power transmitter and receiver is clearly defined, such RFID / NFC cards can be protected against getting destroyed by the wireless power, and a stable wireless power transfer can be achieved.

Owner:LG ELECTRONICS INC

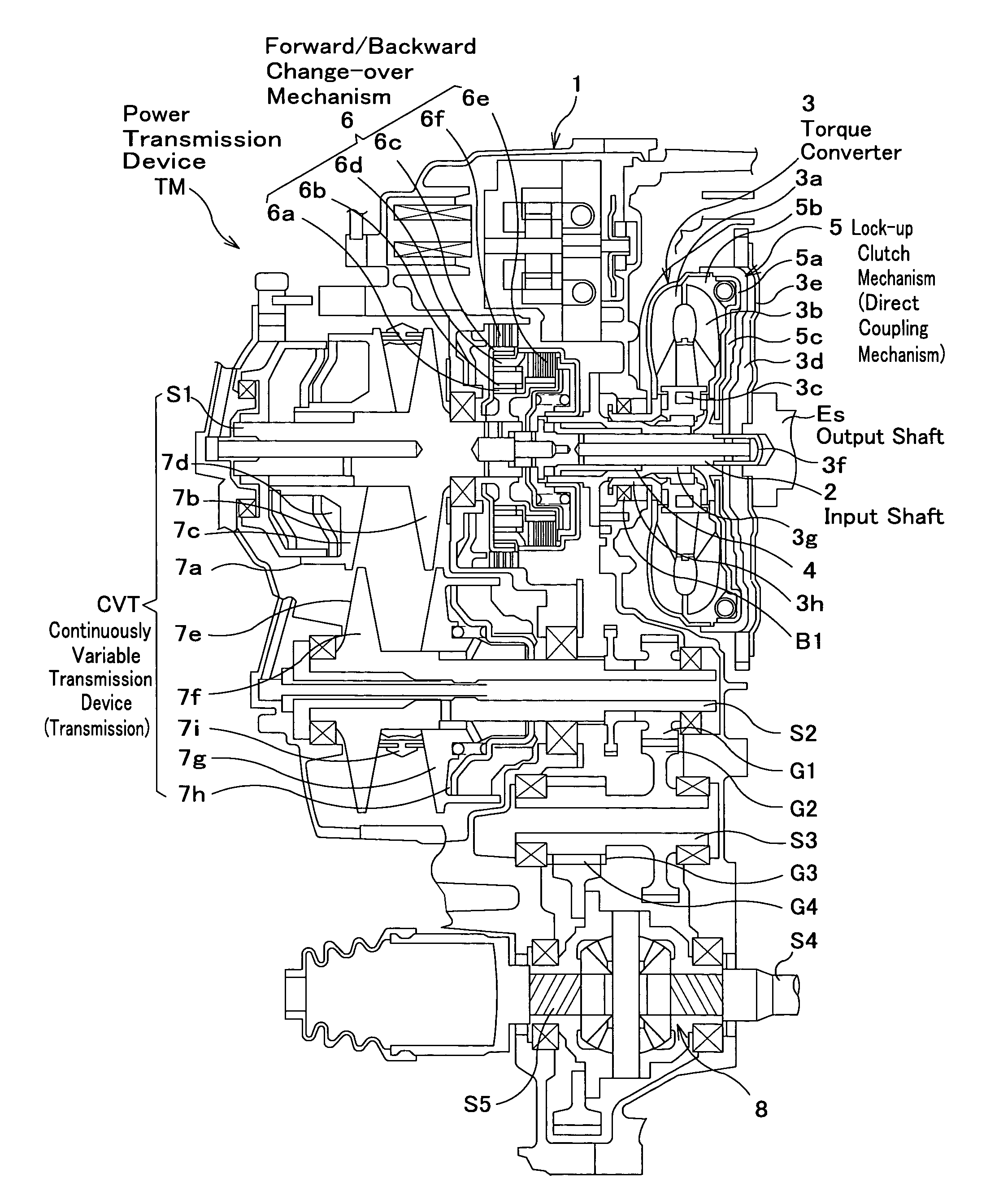

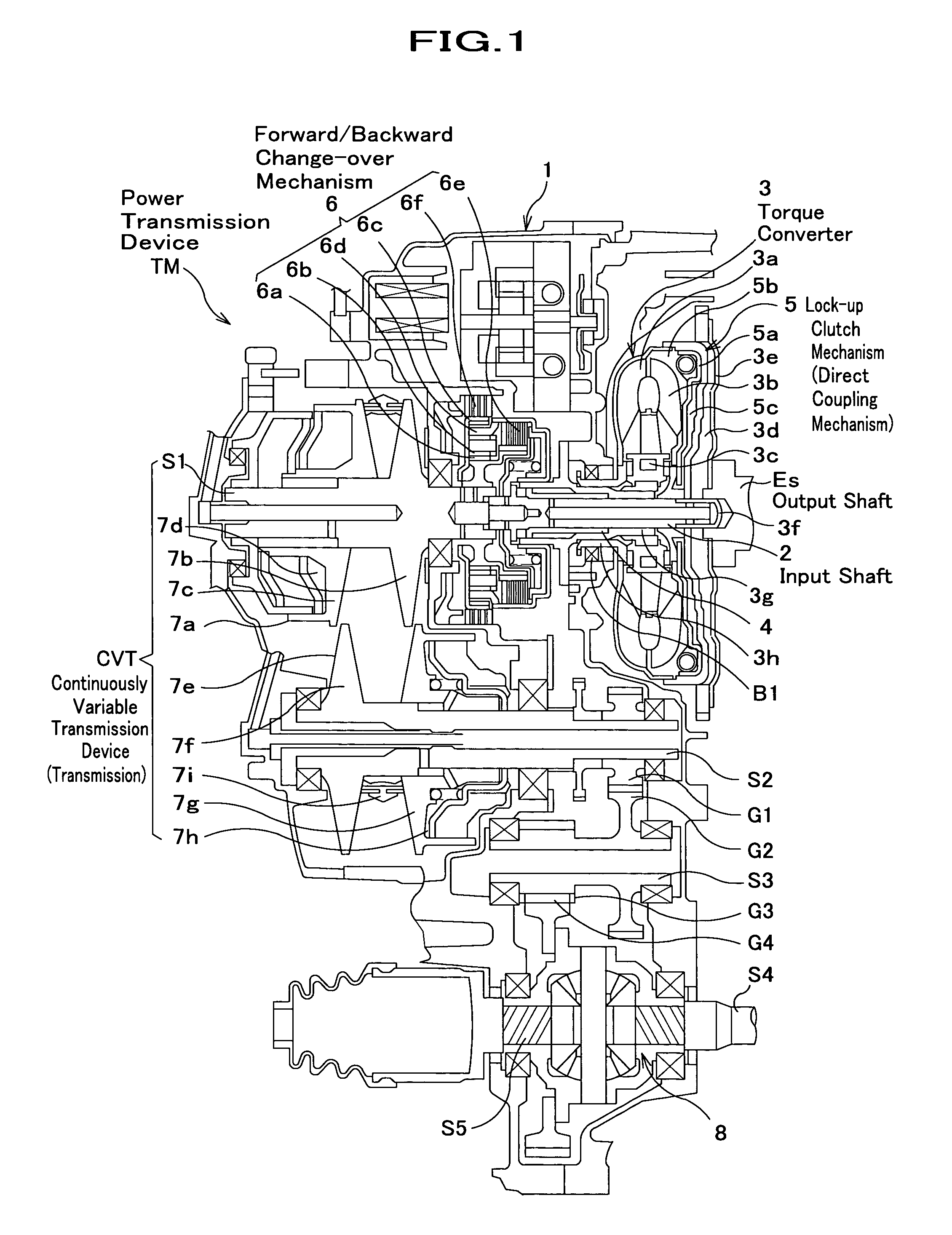

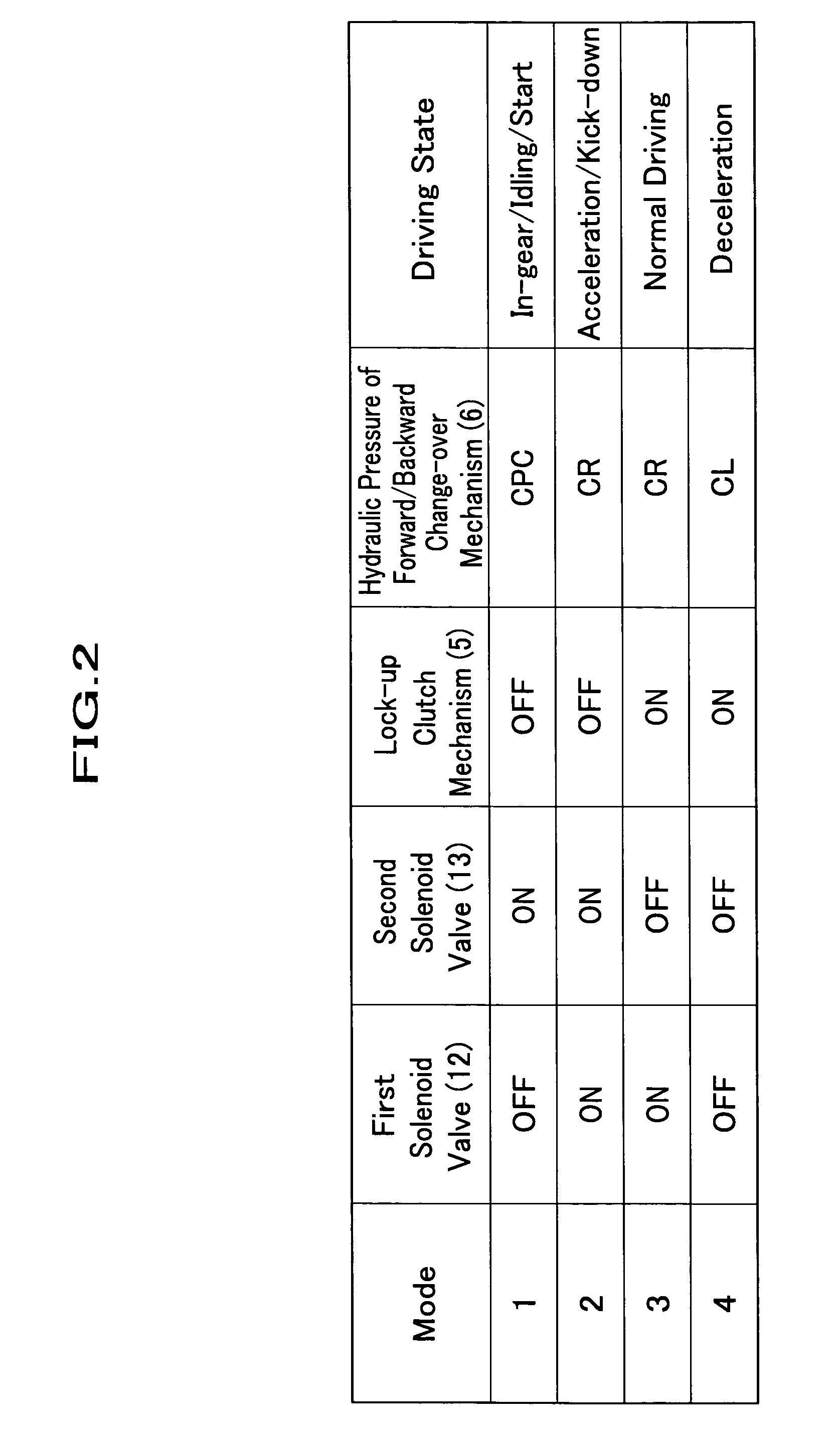

Hydraulic controller of power transmission device

ActiveUS7074148B2Reduce hydraulic pressureLoosen an engagement stateClutchesGearing controlSolenoid valveDirect coupling

A hydraulic controller of a power transmission device is equipped with a transmission for changing a rotation speed of motor power input from a motor and outputting the motor power; a forward / backward change-over mechanism provided between an input shaft, where the motor power of the motor is input and the transmission; and a torque converter having a direct coupling mechanism for transmitting the motor power between an output shaft and the input shaft of the motor; a solenoid valve for adjusting an original pressure and generating a control pressure; and a change-over element for changing over a hydraulic pressure supplied to the forward / backward change-over mechanism so as to become a low pressure during deceleration driving when the direct coupling mechanism is controlled by the solenoid valve, wherein any one of engagement states of the forward / backward change-over mechanism and the direct coupling mechanism is controlled by the control pressure.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com