Backfill type stir friction spot welding device

A friction stir and spot welding device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as large moment of inertia, vibration, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

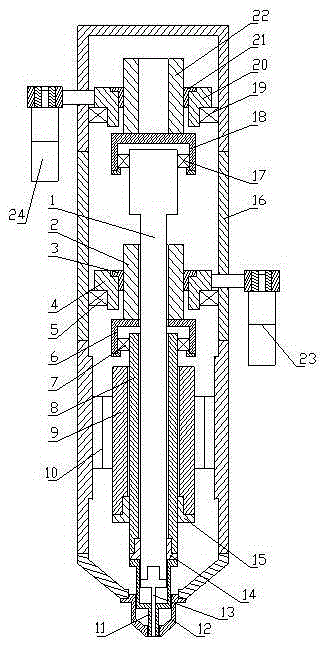

[0015] Such as figure 1 The shown backfill type friction stir spot welding device comprises an outer shell 16 and a stirring head made up of a stirring needle 13, a tubular sleeve 11 and a jacket 12, and the jacket 12 is fixed on the lower end of the outer shell 16 for compressing the Welding workpiece, sleeve 11 can freely rotate and slide up and down in the jacket 12, stirring pin 13 can slide up and down in the sleeve 11, the contact surface between sleeve 11 and stirring needle 13 and the sleeve and The contact surfaces of the jacket are all mirror surfaces, a hollow shaft motor 10 is arranged in the housing, a hollow sleeve shaft 8 is arranged in the hollow main shaft 9 of the hollow shaft motor 10, a stirring needle shaft 1 is arranged in the sleeve shaft 8, and a stirring needle shaft 1 is arranged in the sleeve shaft 8. Both the shaft 8 and the stirring pin shaft 1 are spline shafts, the hollow main shaft 9 is provided with a sleeve spline sleeve 15 matching with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com