Patents

Literature

166results about How to "Change gear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

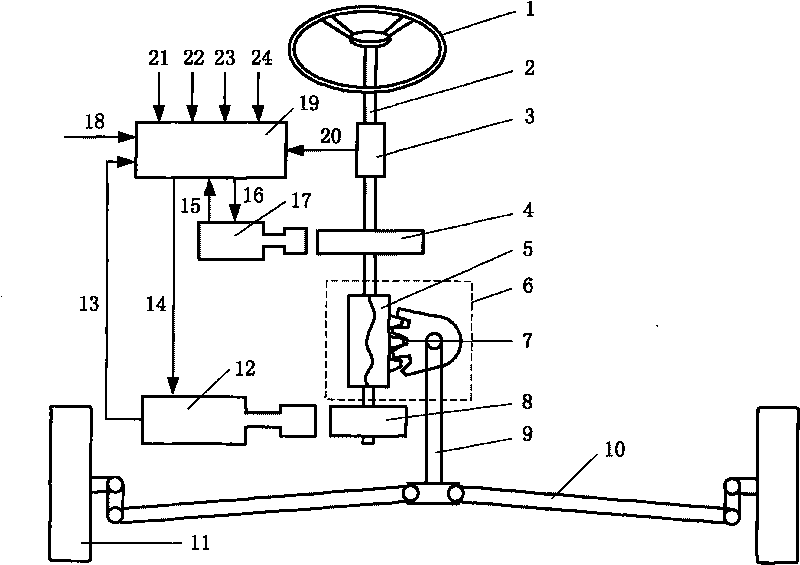

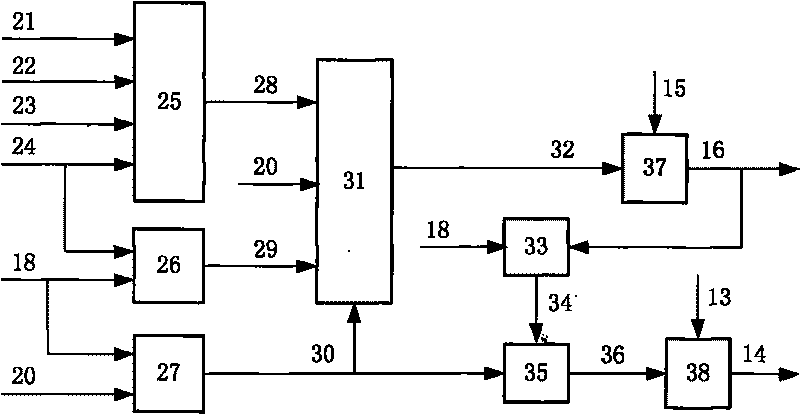

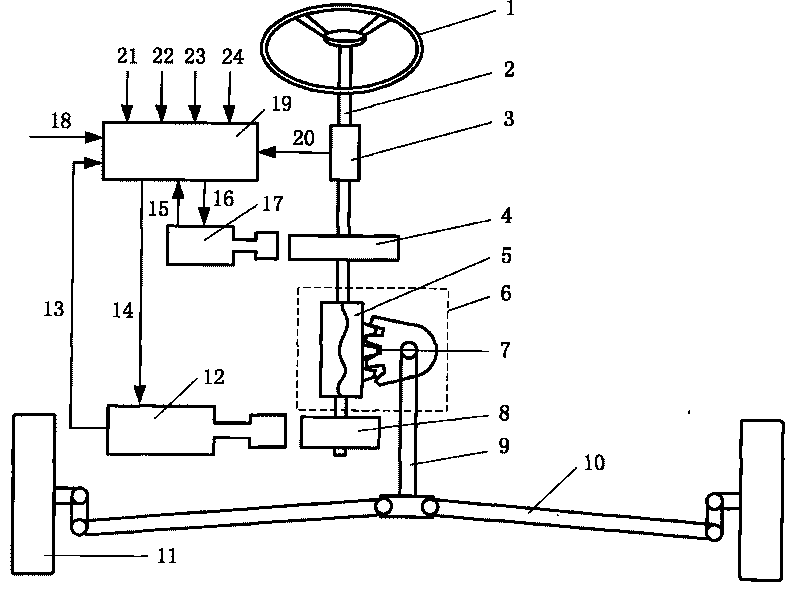

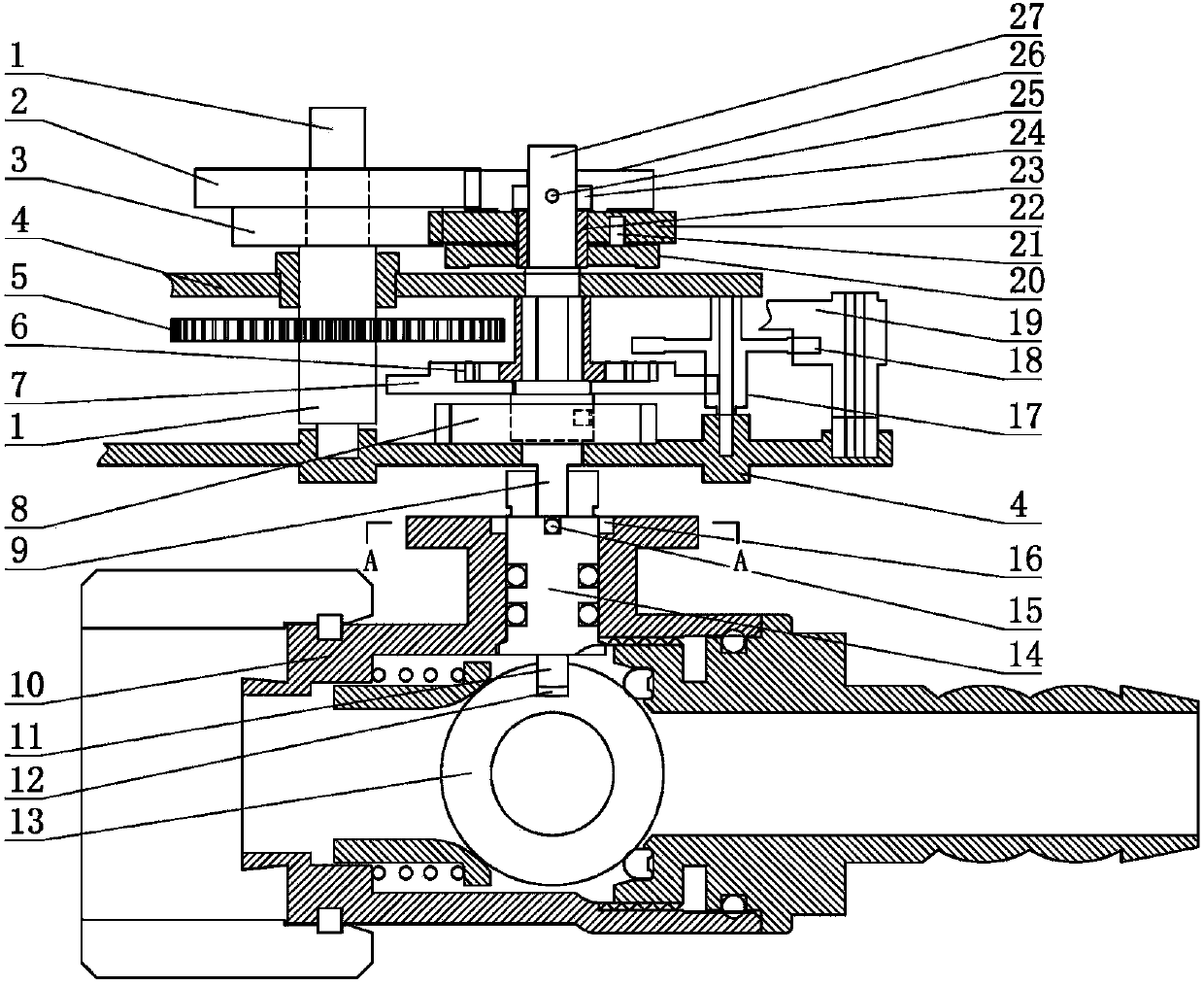

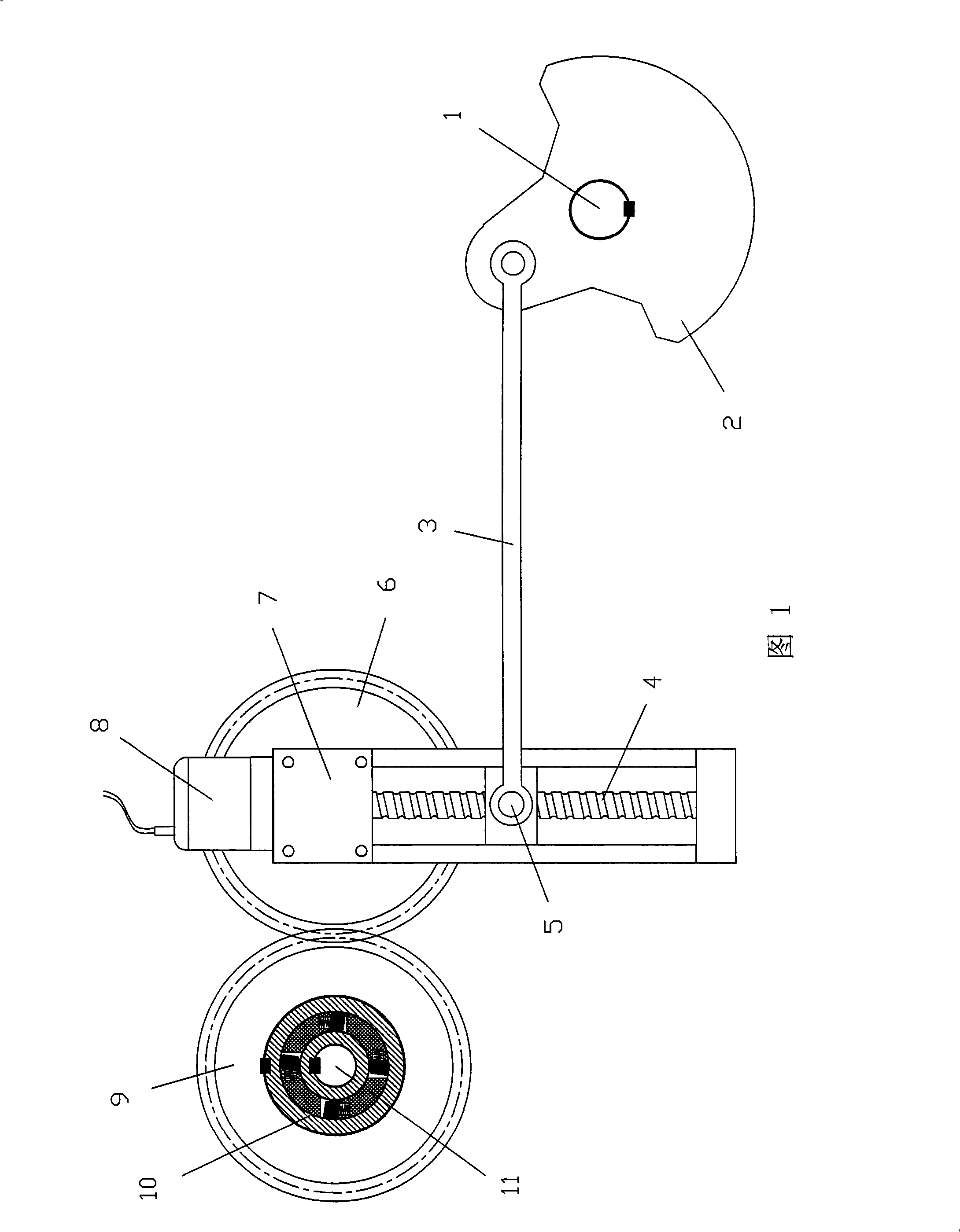

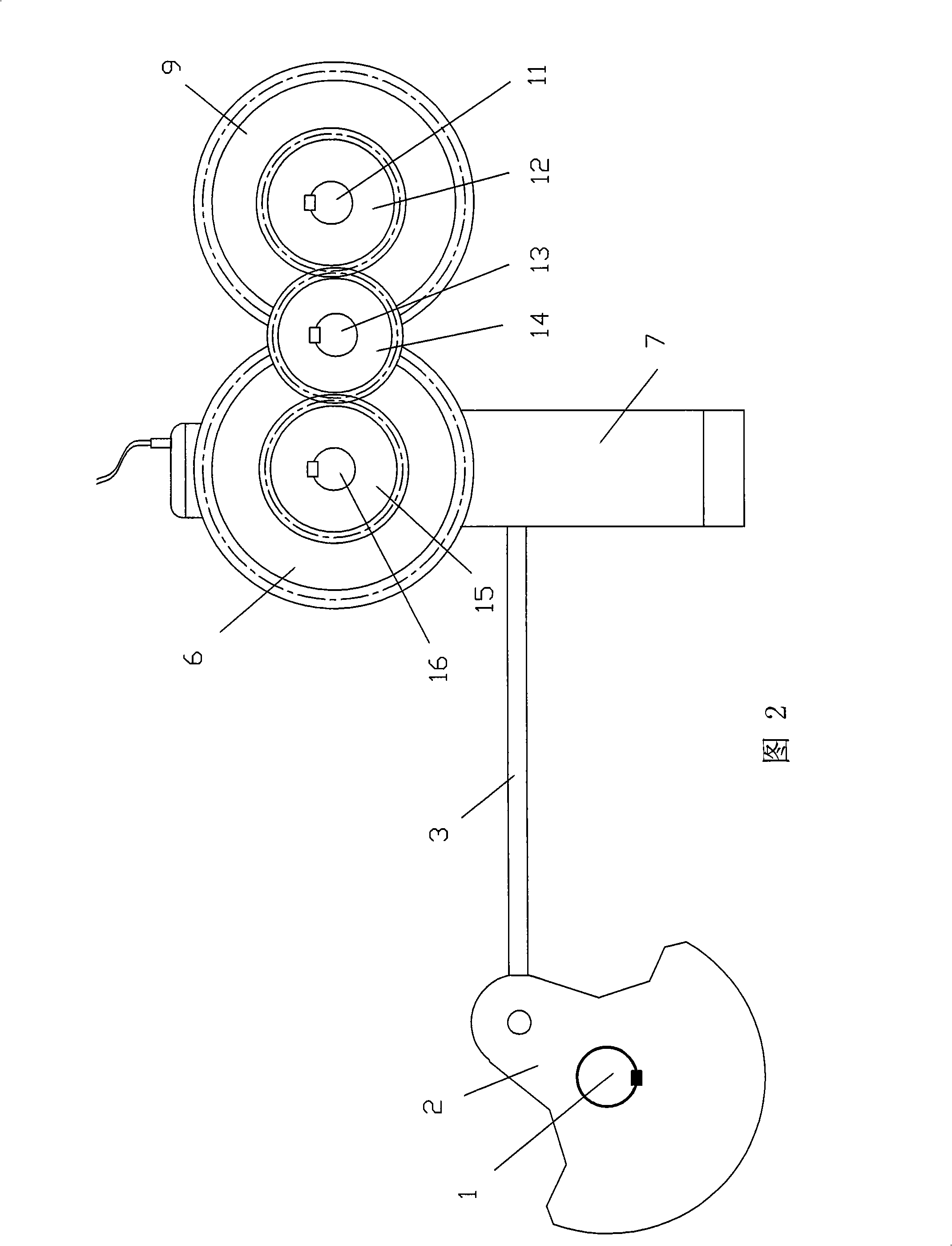

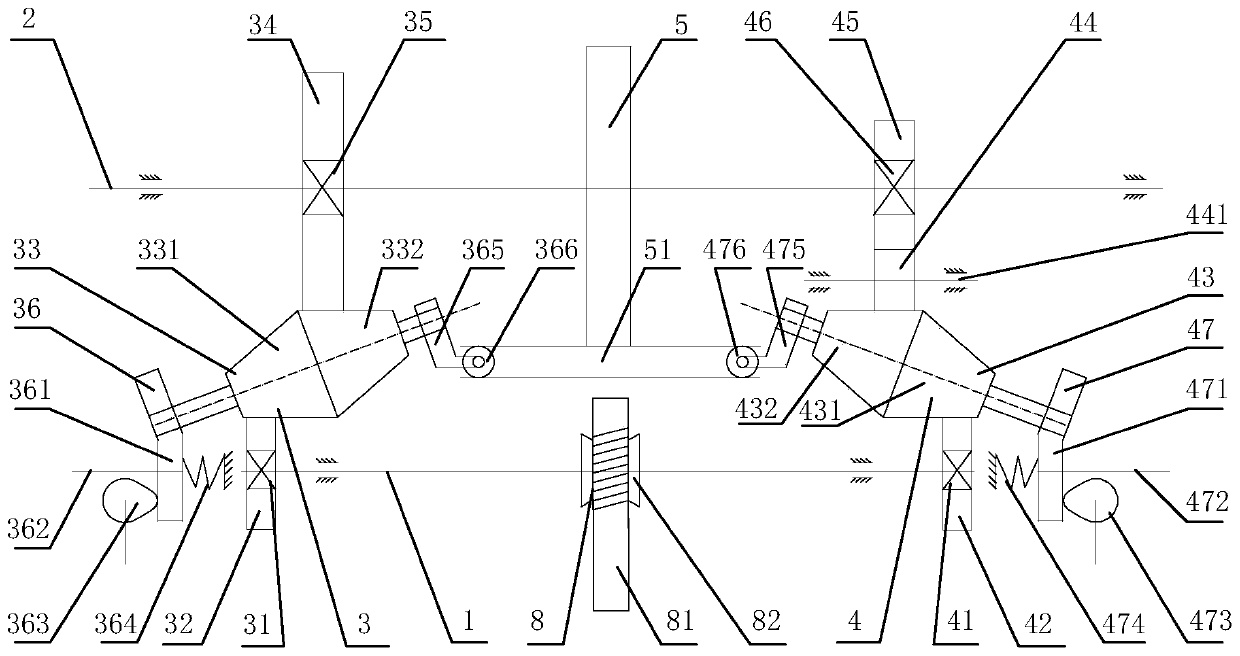

Recirculating-ball electric power-assisted steering system with variable transmission ratio for bus and control method thereof

InactiveCN101700786AImprove active driving safetyHigh sensitivityElectrical steeringElectric power steeringDriver/operator

The invention relates to a recirculating-ball electric power-assisted steering system with variable transmission ratio for a bus, belonging to the field of steering systems for buses. The system sequentially comprises a steering wheel, a steering column, a torque transducer, a power-assisted motor, a first retarding mechanism connected with the power-assisted motor, a recirculating-ball steering gear, a steering rocker shaft arm, a steering tie rod and a steering system control ECU, wherein a second retarding mechanism and a corner motor driving the second retarding mechanism are arranged between the torque transducer and the recirculating-ball steering gear. The corner motor control integrates the ideal transmission ratio control with the stability control for carrying additional corner control, thereby changing the transmission ratio from a steering wheel corner to a front wheel corner, and increasing the function of the steering wheel in the stability control; meanwhile, steering counter torque complementation control caused by the additional corner is integrated into the power-assisted control of the power-assisted motor, thereby realizing the coordination control and the matching of the corner motor and the power-assisted motor and ensuring that a driver obtains better steering handfeel.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

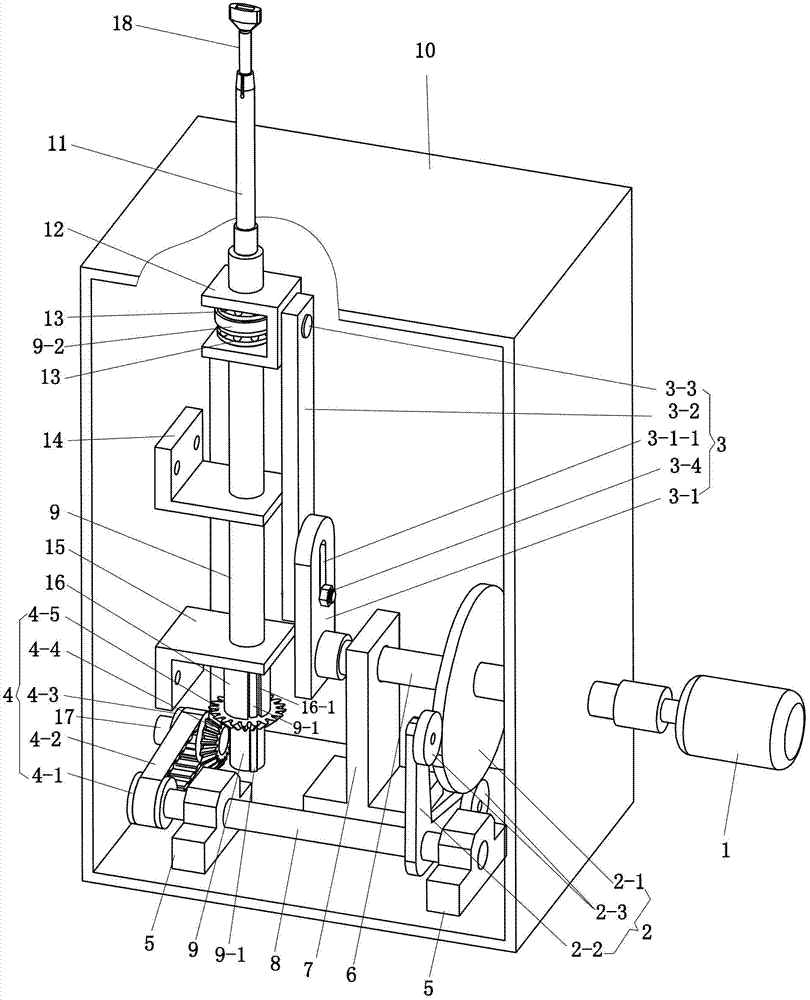

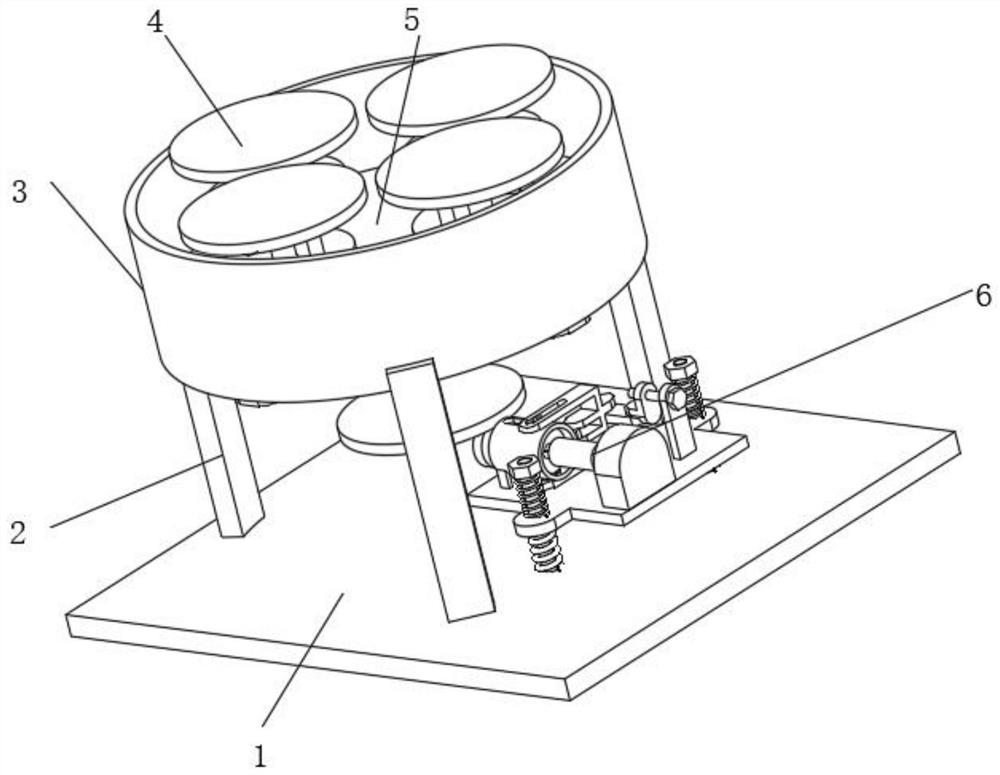

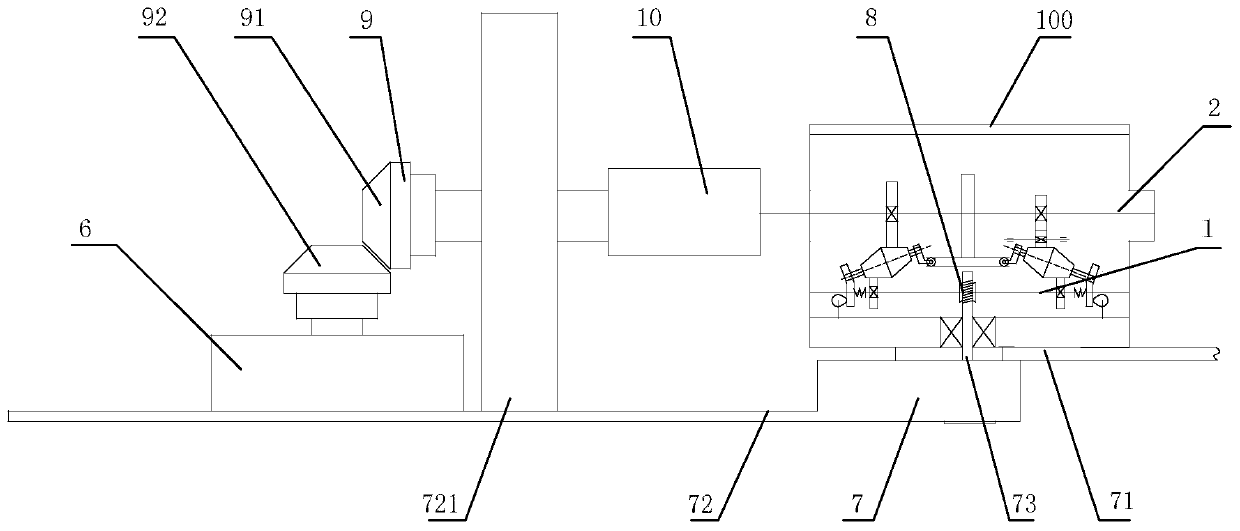

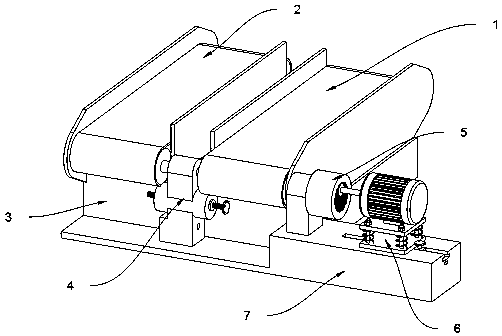

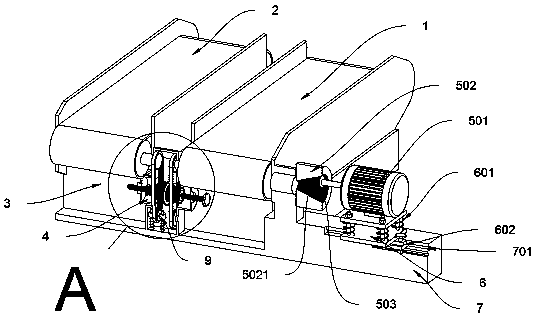

Motor stator coil winding machine

InactiveCN103199655AChange gear ratioAchieve rotationManufacturing dynamo-electric machinesLinear motionWinding machine

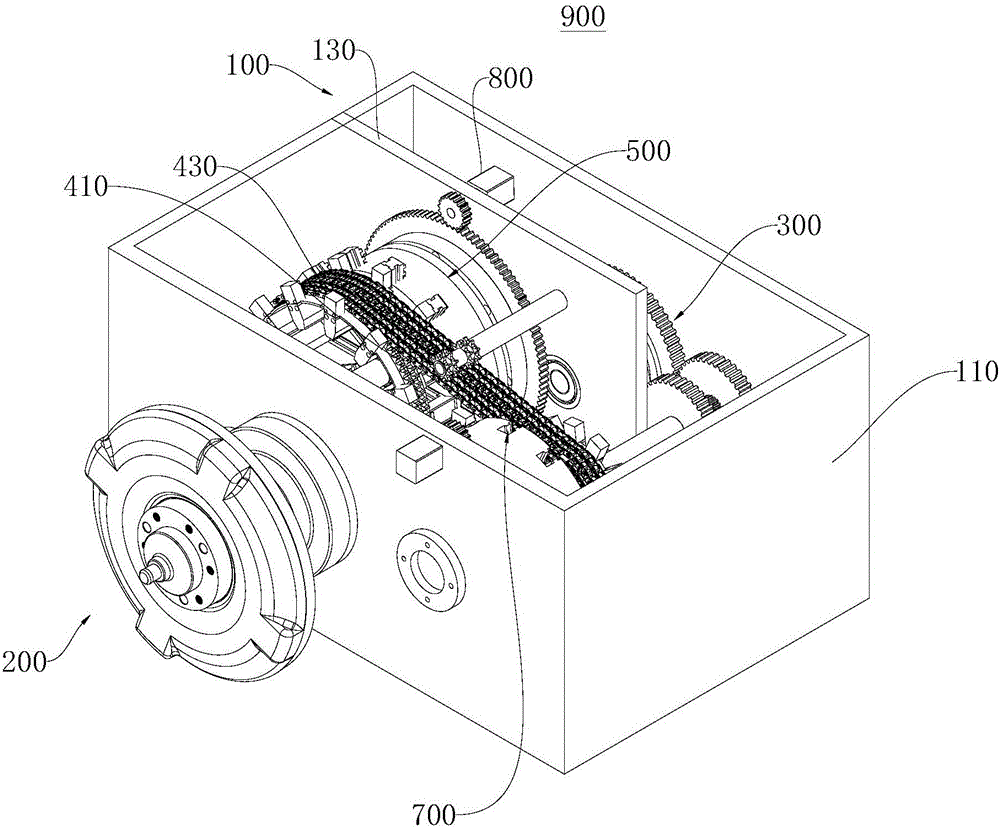

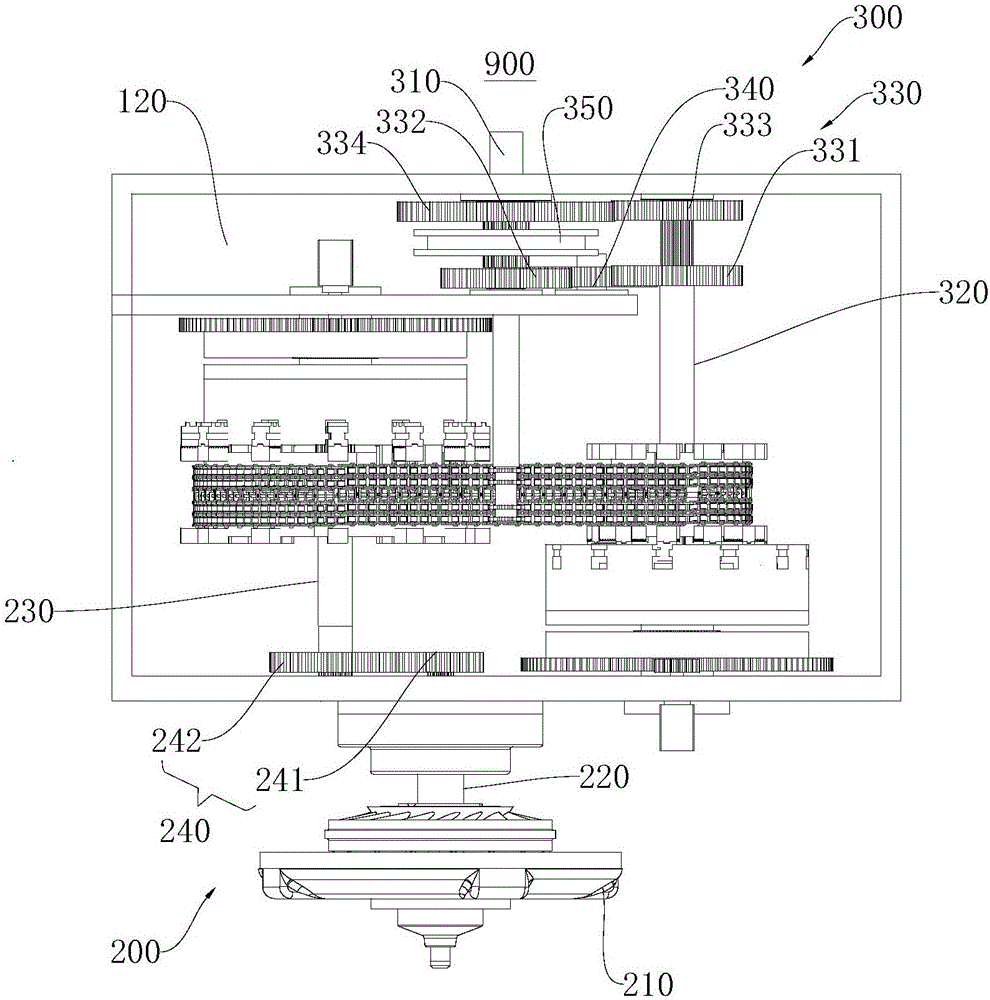

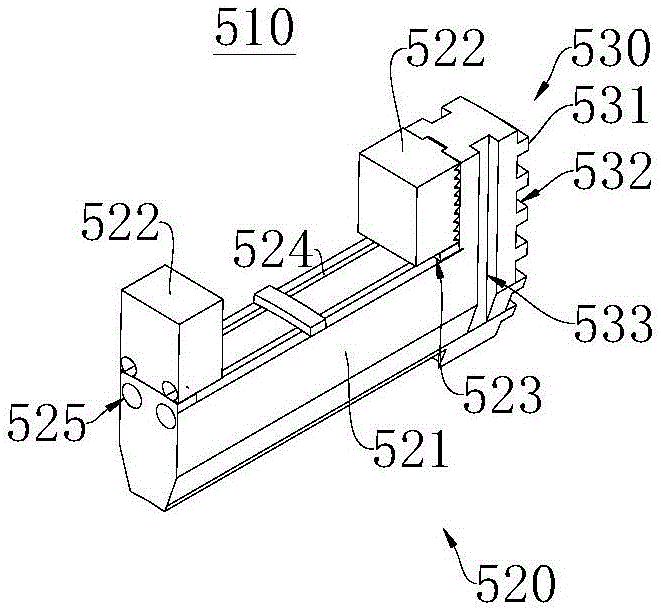

A motor stator coil winding machine comprises a box body, a driving motor, a power shaft and a main shaft, wherein a support frame and two support seats are fixed on a bottom board of the box body, the power shaft is supported by the support frame and the box body, the two support seats support a transmission long shaft, an upper installation seat and a lower installation seat are fixed on the box body, the middle portion of the main shaft is located in guide holes of the upper installation seat and the lower installation seat, a winding shaft is arranged at one end, extending upwards out of the box body, of the main shaft, a bushing is arranged at a position, extending downwards out of the lower installation seat, of the main shaft, the main shaft, the upper installation seat, the lower installation seat and the bushing are all in movable connection, the power shaft is driven by the driving motor and drives the transmission long shaft to rotate in positive and negative directions through a cam mechanism, the transmission long shaft drives the main shaft to rotate in positive and negative directions through a transmission mechanism with a bevel gear pair, a driven bevel gear is connected at the position, located below the bushing, of the main shaft, a connector is arranged at the upper portion of the main shaft, and a crank connection rod mechanism driving the main shaft to make linear motion back and forth is arranged between a power head and the connector. The motor stator coil winding machine can achieve narrow-notch and large-angle winding in a rotary mode.

Owner:JIANGSU UNIV OF TECH

A planetary gear stepless transmission

InactiveCN102287498AChange gear ratioHigh torque transmissionToothed gearingsGear wheelControl theory

The invention discloses a novel gear continuously variable transmission, aiming to provide a continuously variable transmission with large transmission torque, high transmission efficiency, good reliability and good fuel economy. The present invention includes a first input shaft, a second input shaft, a one-way clutch, a gear, a planetary ring gear, a planetary gear, a first planetary carrier, a sun gear, a second planetary carrier and an output shaft, and the planetary gear continuously variable transmission passes through The power input of two degrees of freedom of the first input shaft and the second input shaft realizes the function of stepless speed change. The invention has the advantages of simple structure and convenient manufacture, and can effectively realize the stepless speed change function.

Owner:NANJING INST OF TECH

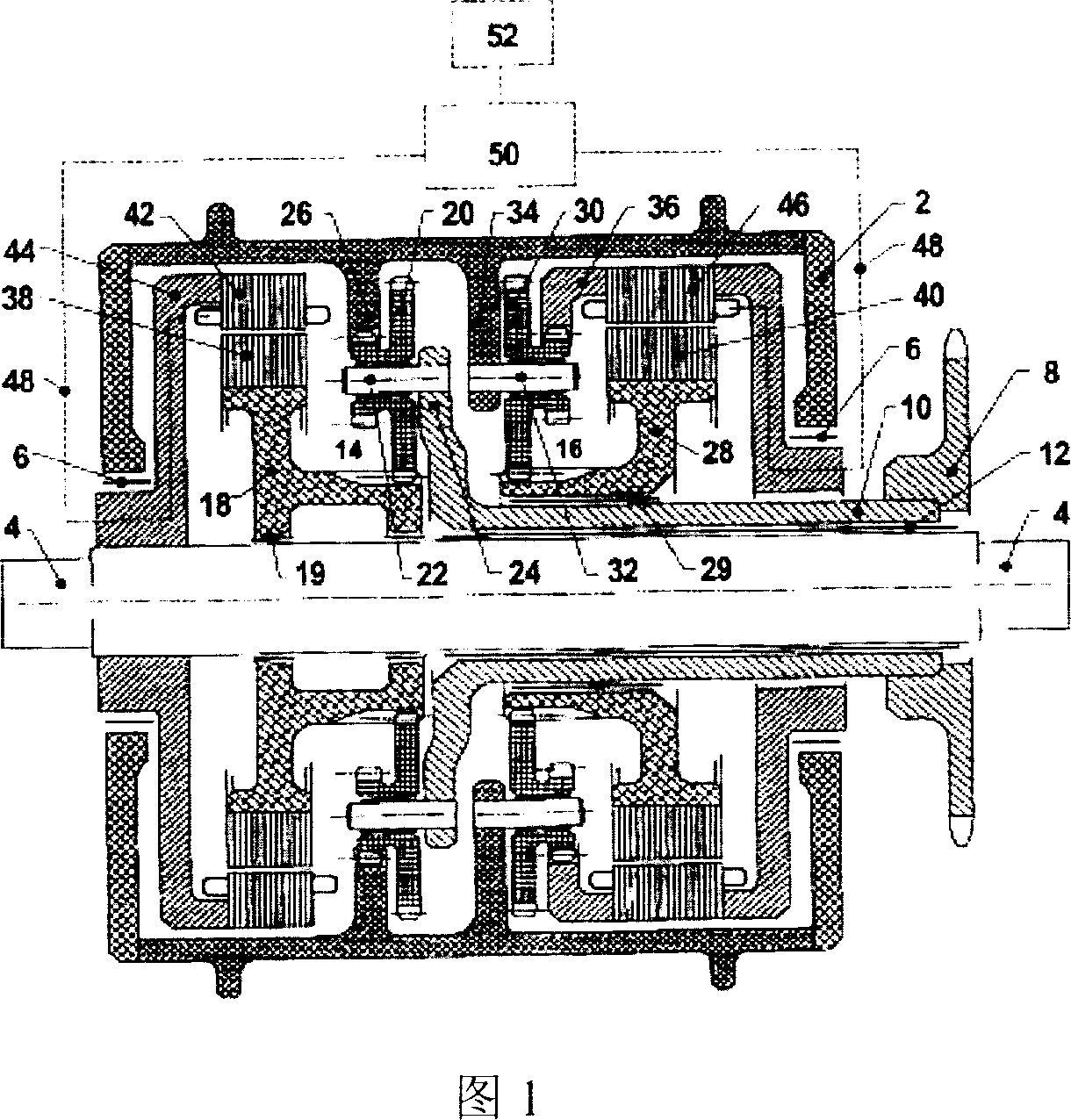

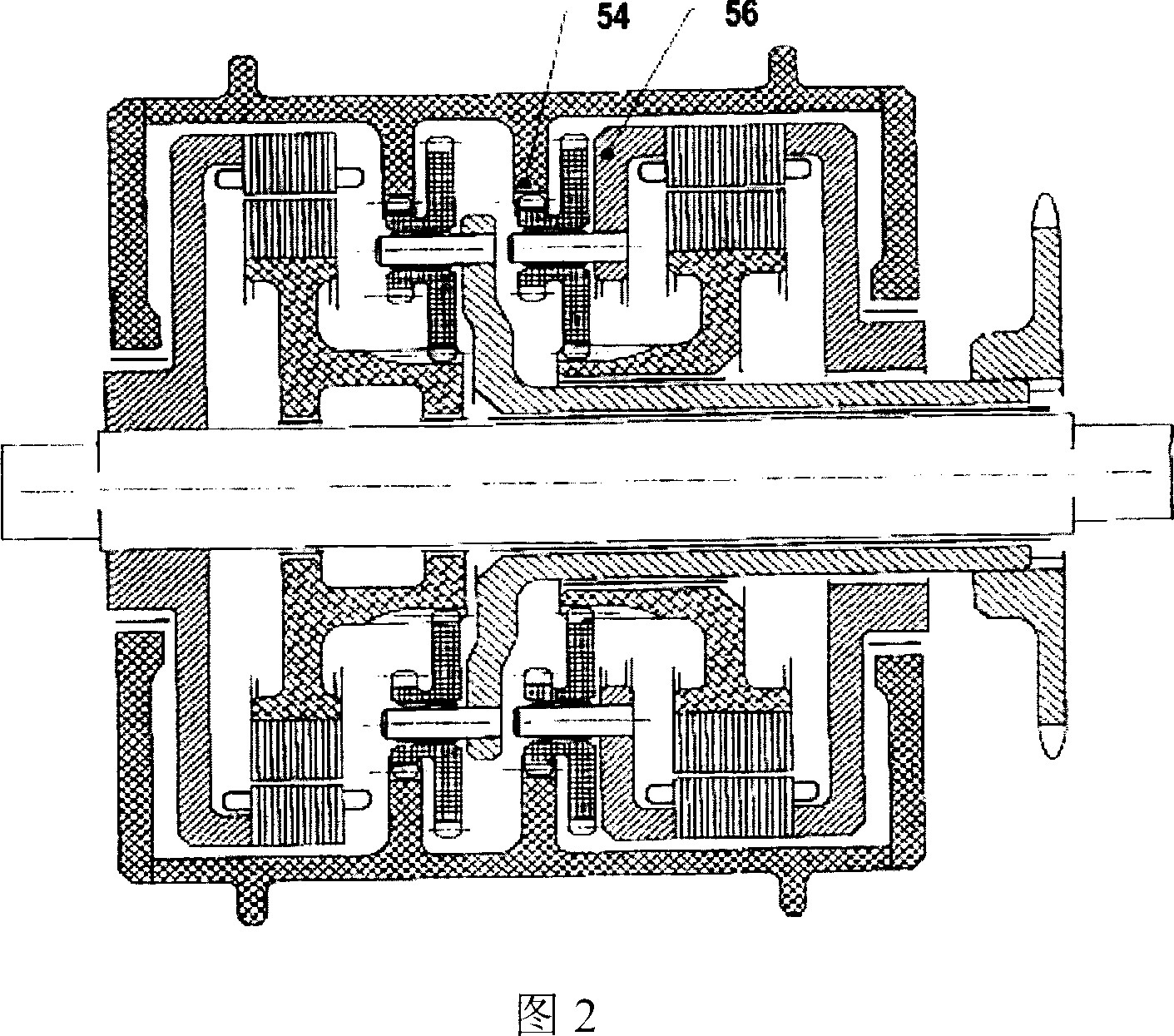

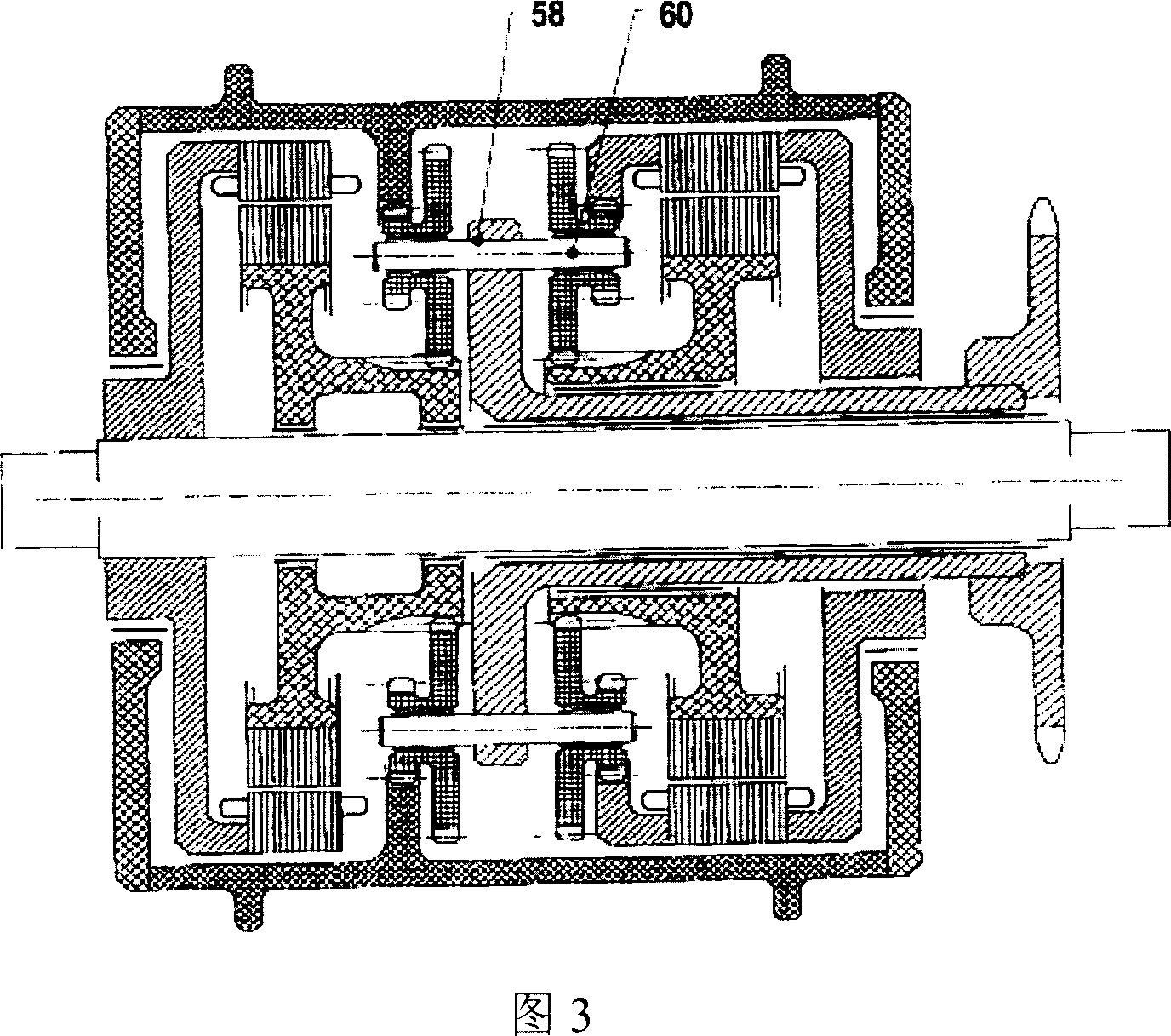

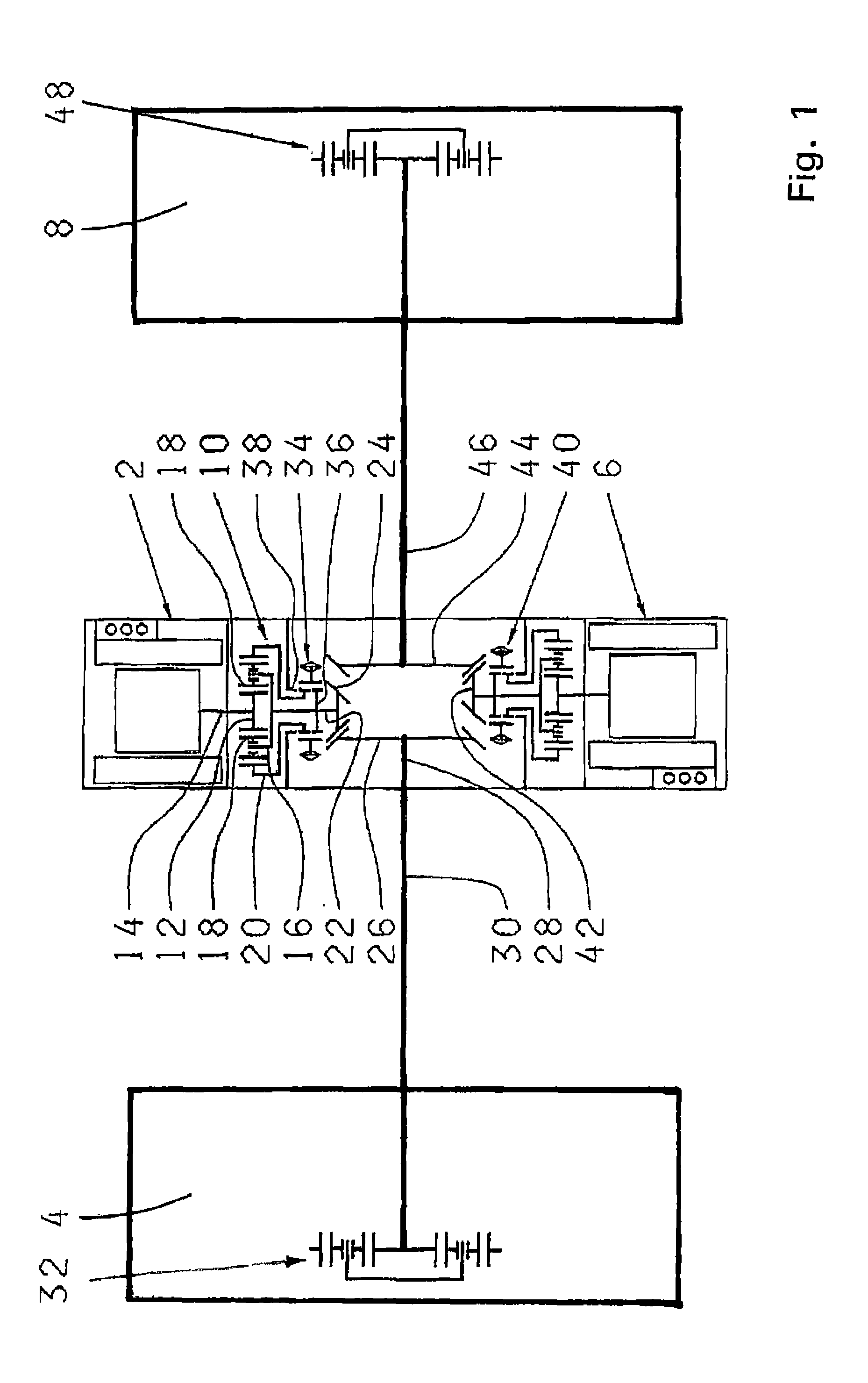

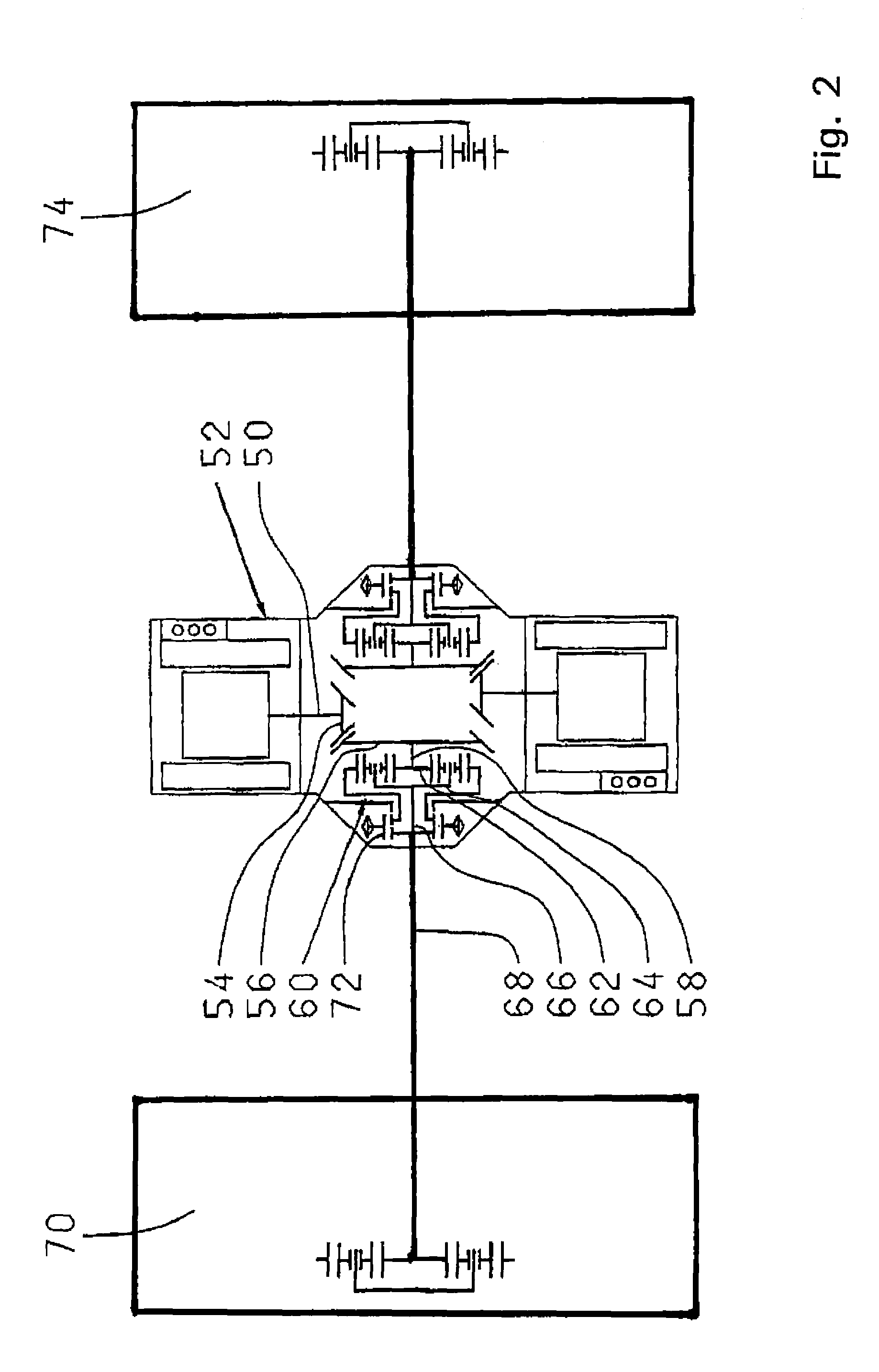

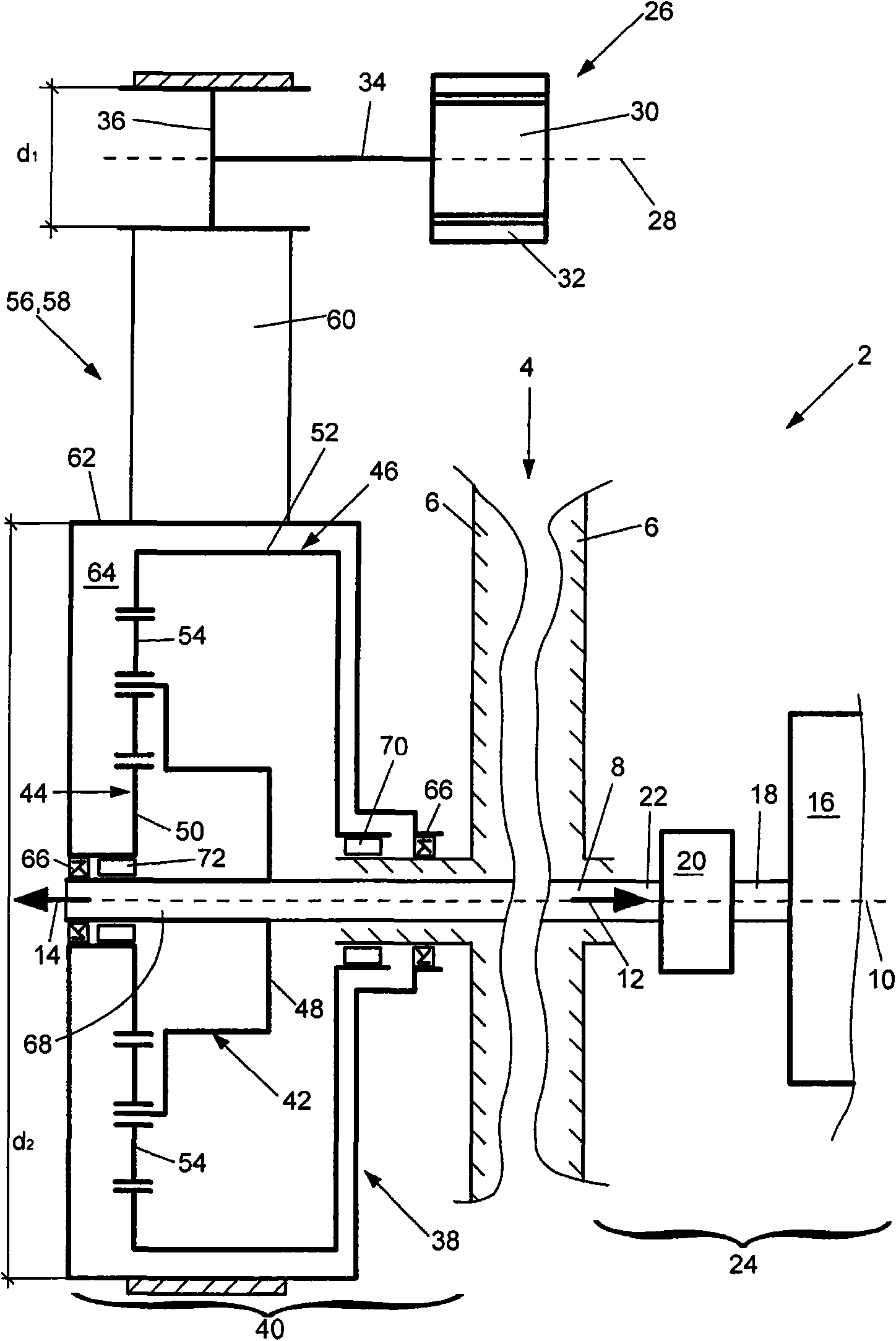

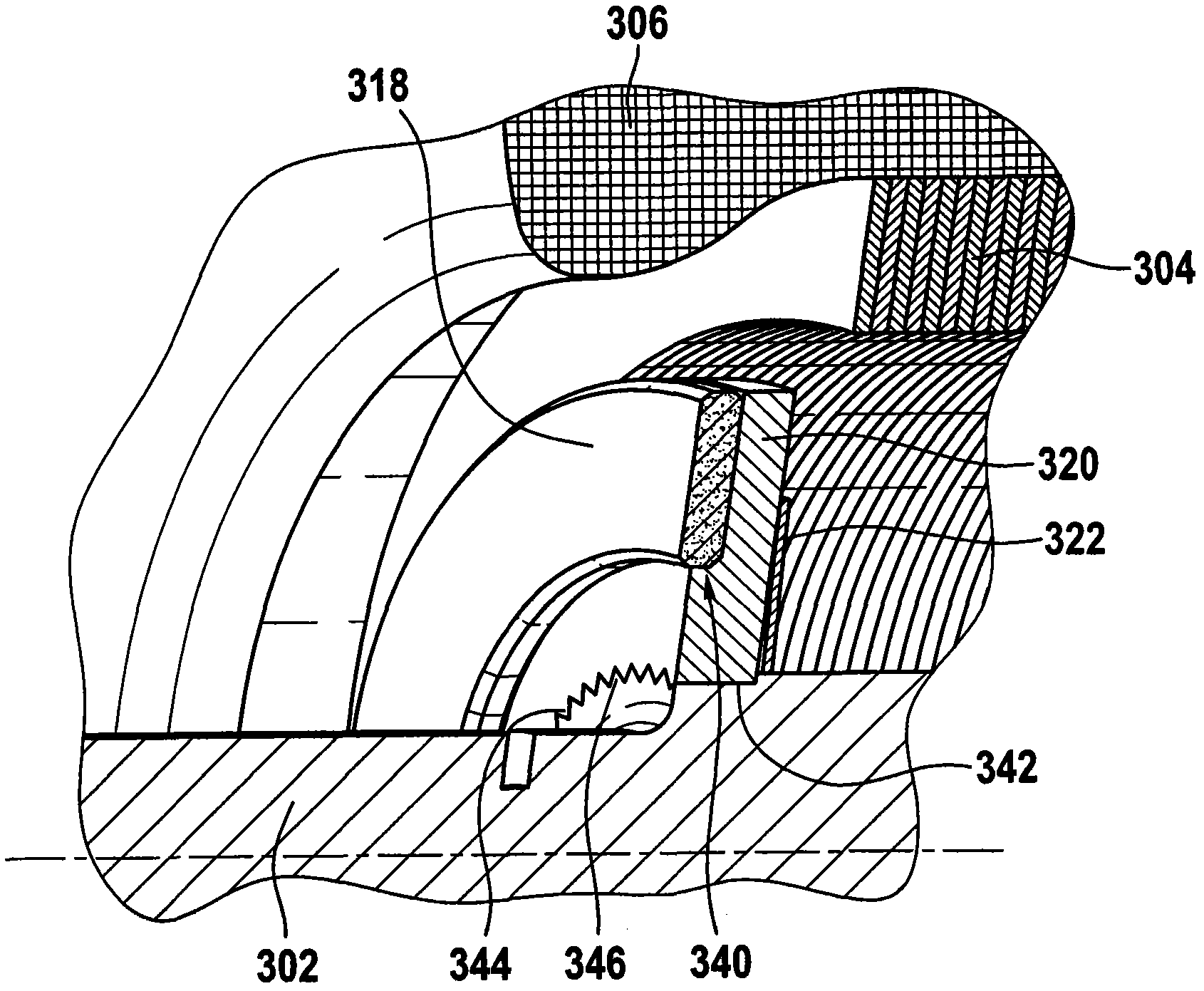

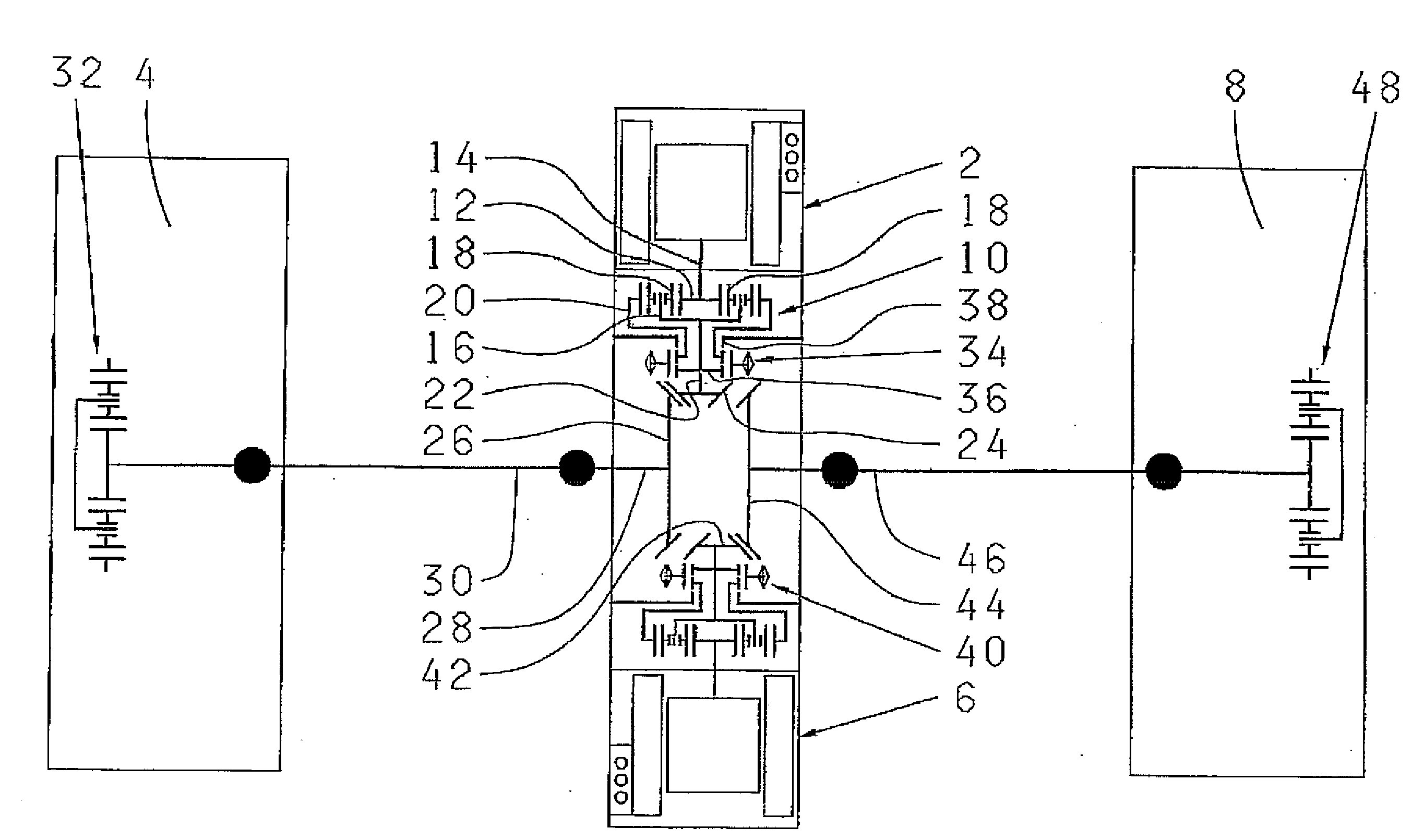

Hub incorporating a variable ratio transmission system

InactiveCN101031469AChange gear ratioAccurate operationWheel based transmissionDynamo-electric gearsCommon carrierTransmission system

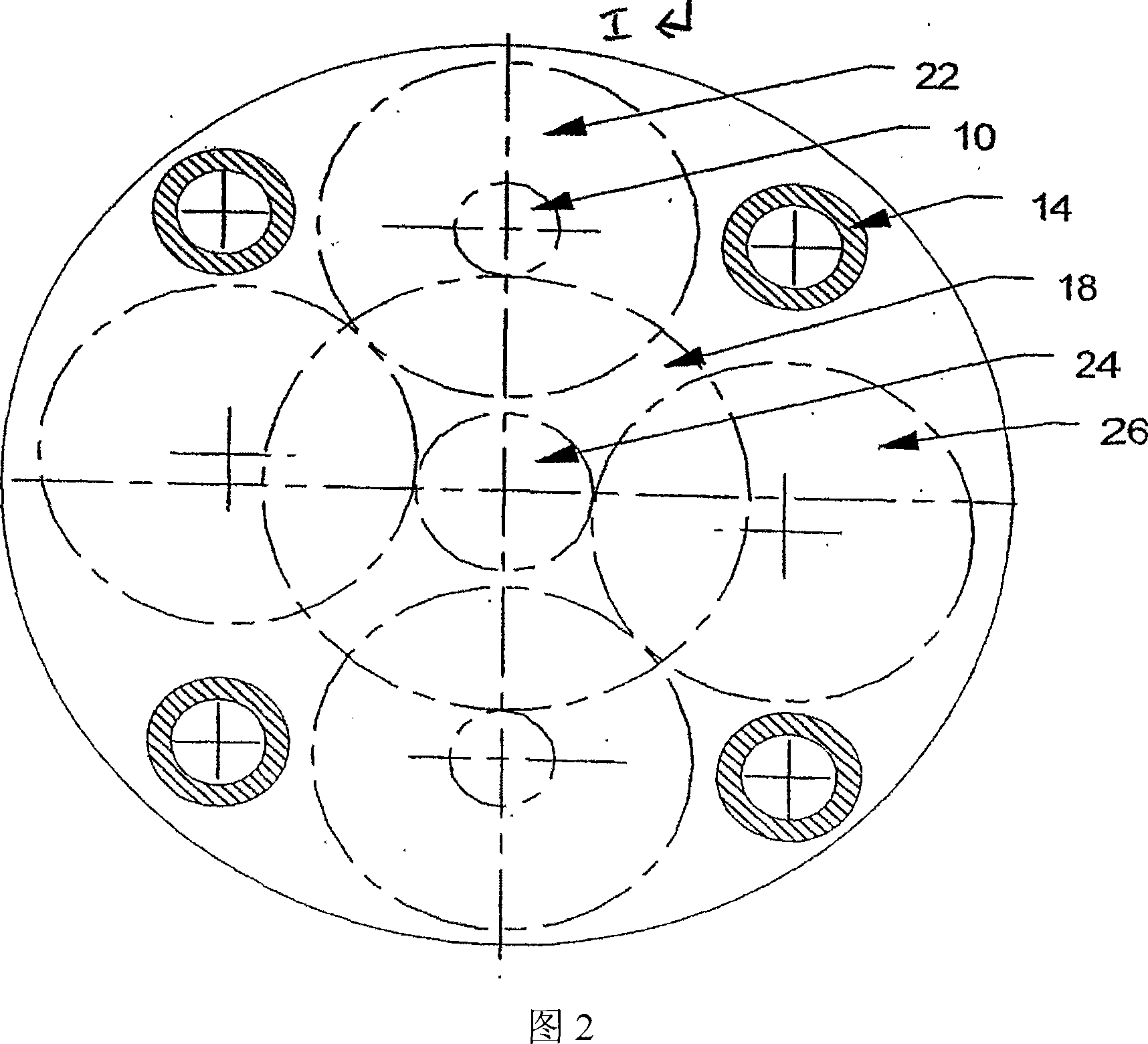

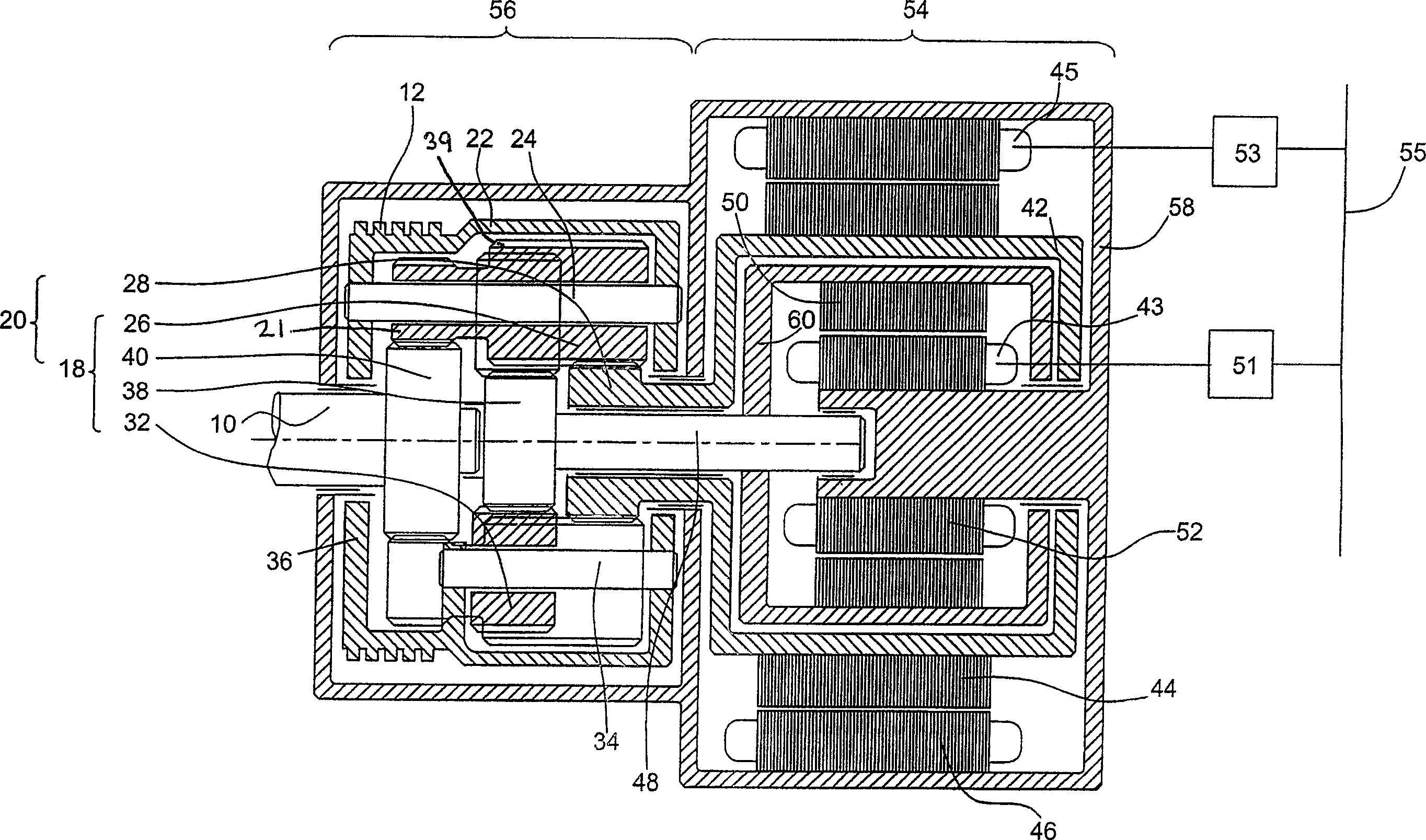

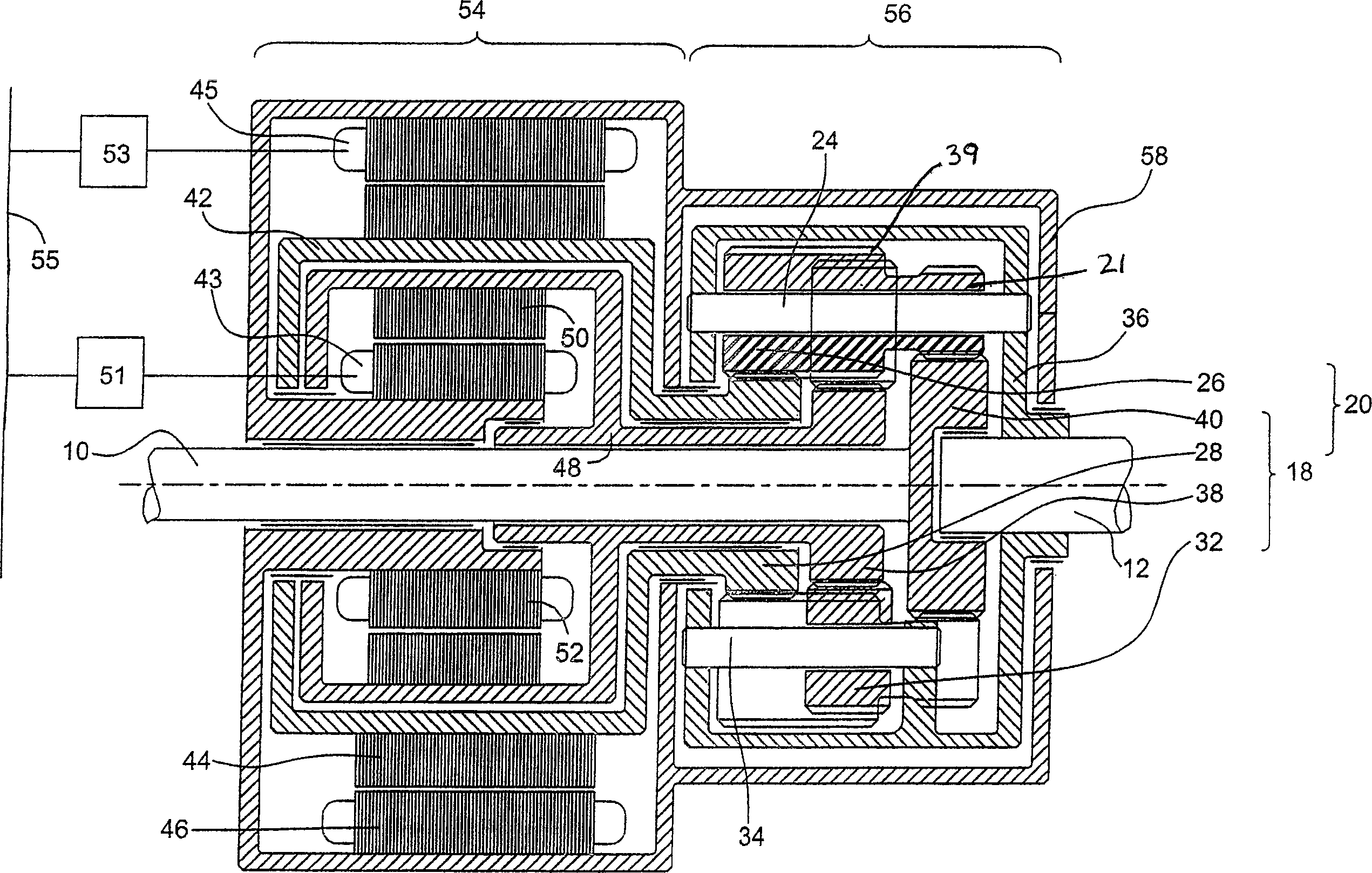

Hub comprising a cylindrical, hollow hub member (2), which is mounted to rotate about its axis and in whose interior is a transmission system having an input (10), which is mounted to rotate about the axis, and an output connected to rotate with the hub member. The transmission system comprises first and second epicyclic gearsets (14,16). The first gearset (14) comprises a first sun gear (18), which is mounted to rotate about the axis and is in mesh with a plurality of first planet gears (20) mounted to rotate about respective planet shafts (22) carried by a first common carrier (24), which is mounted to rotate about the first axis. The second gearset (16) comprises a second sun gear (28), which is mounted to rotate about the axis and is in mesh with a plurality of second planet gears (30) mounted to rotate about respective planet shafts (32) carried by a second common carrier (34). The first and second sun gears (18,28) are connected to the rotors (38,40) of first and second electric motor / generators, respectively. The power connections of the two stators (42,46) are connected via a controller (50) arranged to control the transmission of power from one motor / generator to the other.

Owner:NEXXTDRIVE LTD

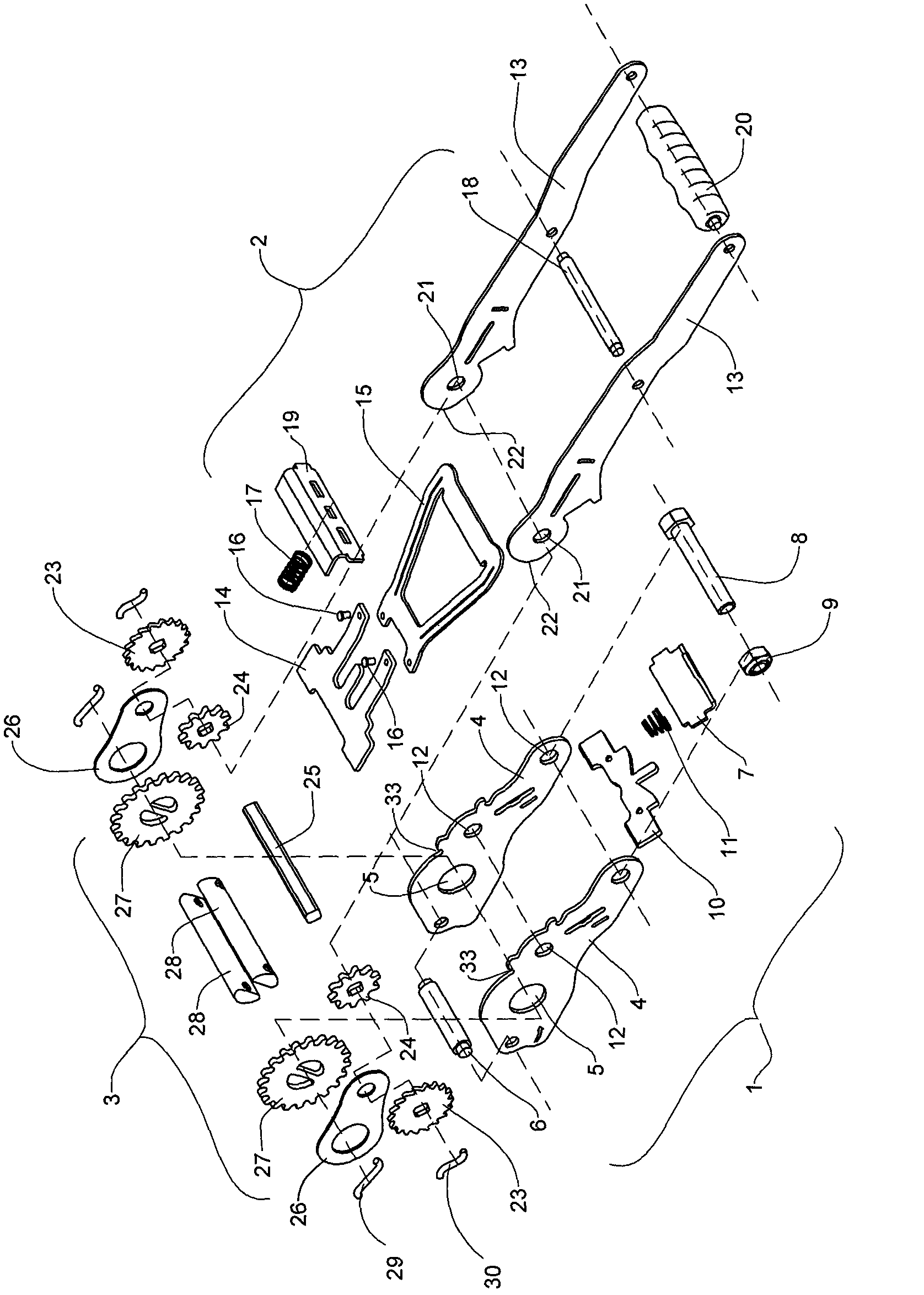

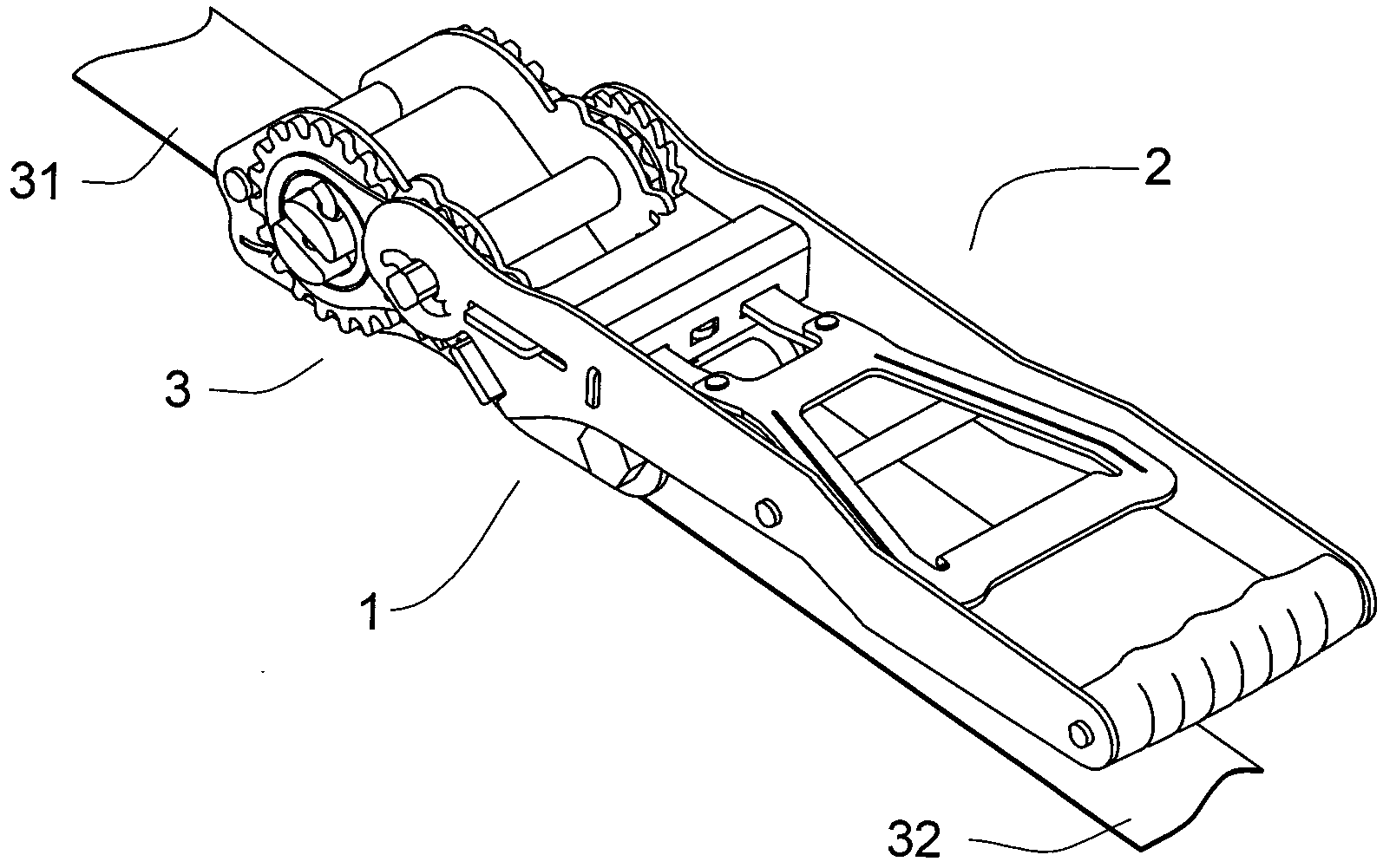

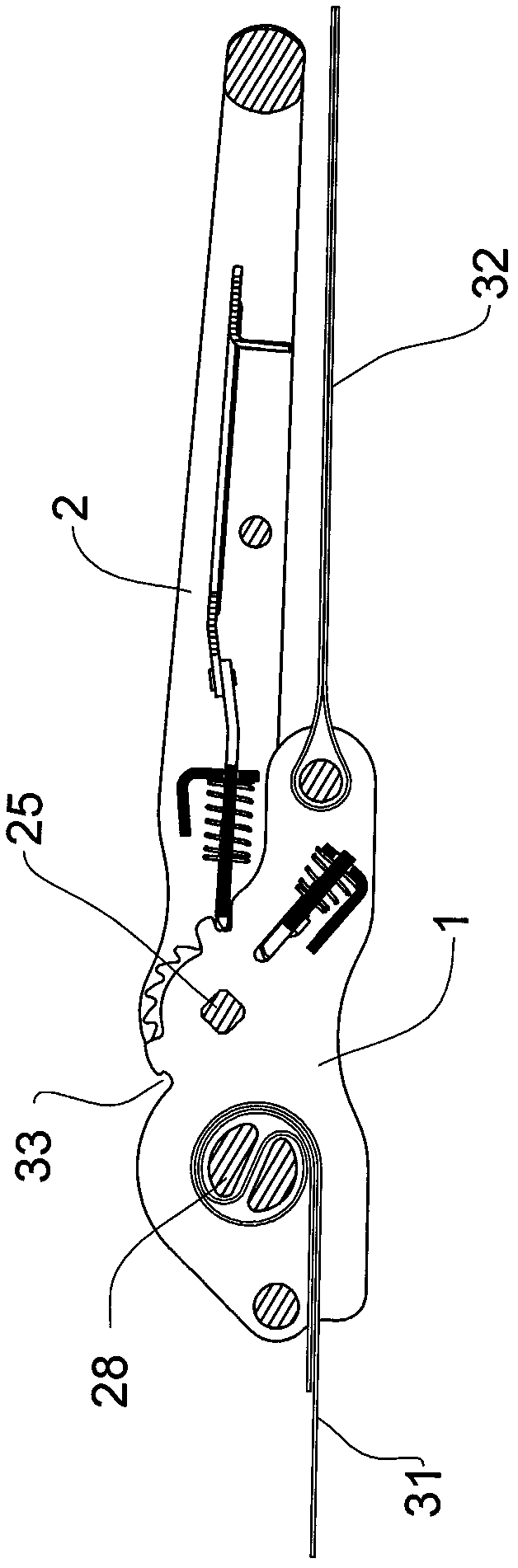

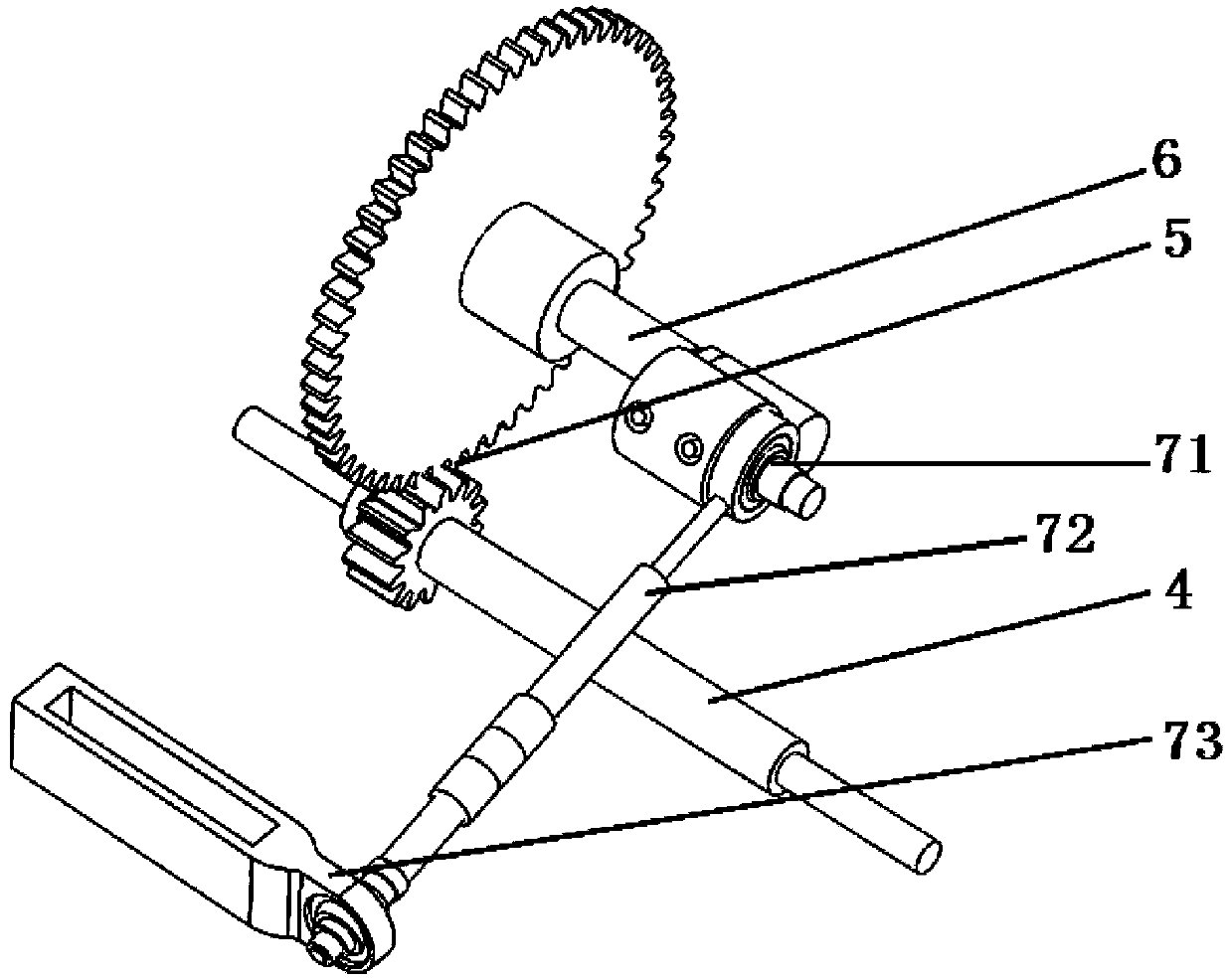

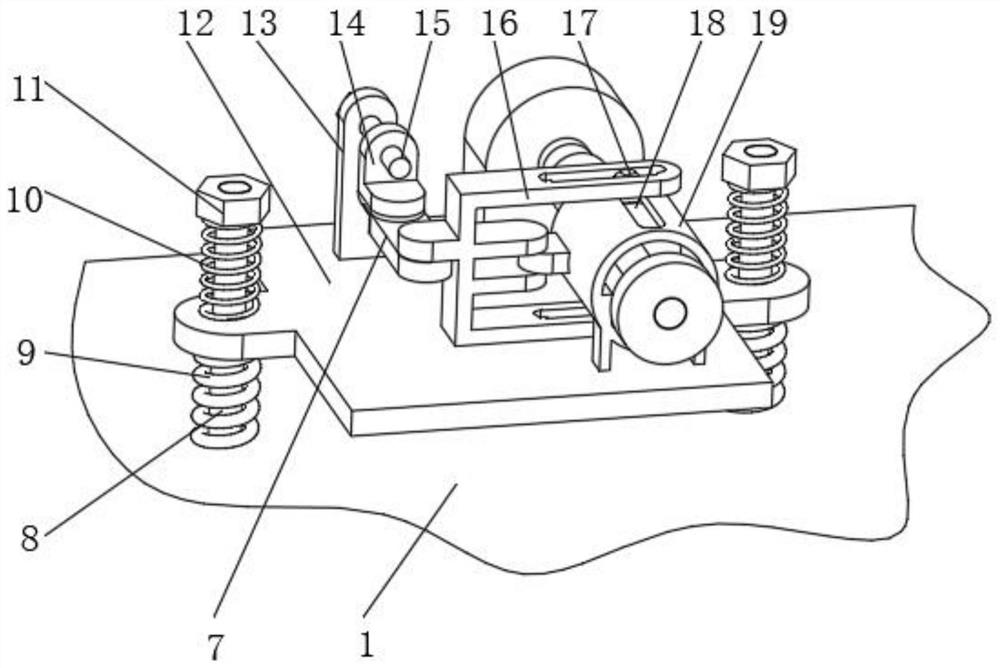

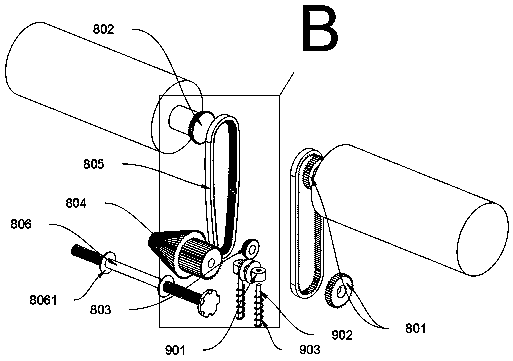

Multi-stage transmission vehicle safety tensioning device

ActiveCN102275539AIncrease or decrease the number of transmission stagesChange gear ratioLuggage carriersLoad securingDrive shaftAutomobile safety

The invention relates to an automobile safety tension device which comprises a base assembly and a handle assembly, and the two assemblies are connected by a multi-stage transmission assembly; the multi-stage transmission assembly comprises a transmission shaft and a main rotary shaft, wherein the transmission shaft is used for pivoting a base of the base assembly with a handle of the handle assembly, and the main rotary shaft is used for winding a long binding tape and is fixed on the base; the transmission shaft is fixedly provided with a transmission wheel; and the transmission wheel achieves the rotating state required by winding, the non-rotating state required by locking and the idling state required by releasing under the action of the base assembly and the handle assembly. Becauseof adopting multi-stage transmission, after a small force exerted on the handle is converted a plurality of times, a large binding force can be obtained on the binding tape finally; and through increasing or reducing the number of transmission stages and changing the transmission ratio of each-stage transmission, under the condition of applying a same handle holding force, different sizes of binding forces can be obtained.

Owner:NINGBO XULI METAL PROD

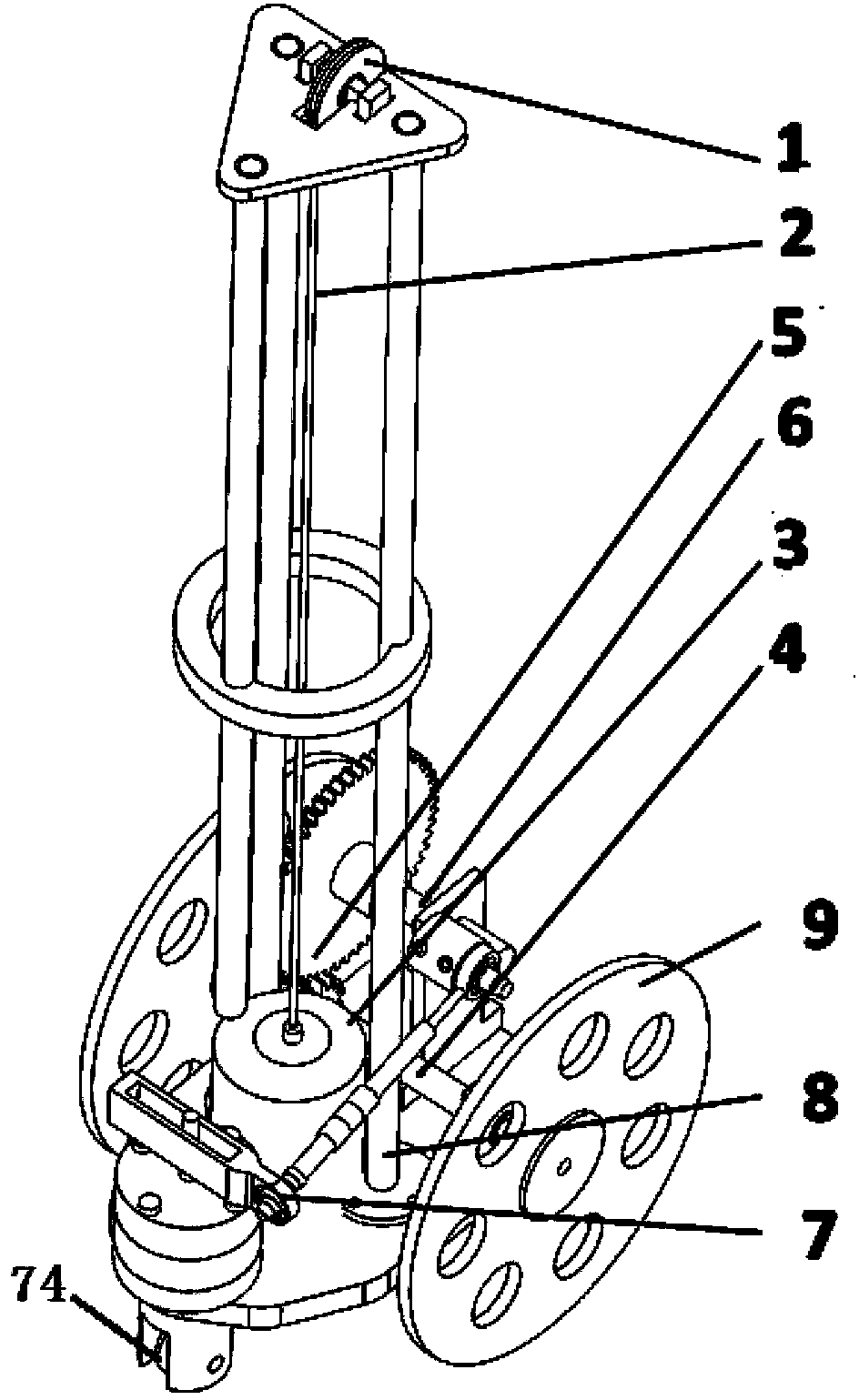

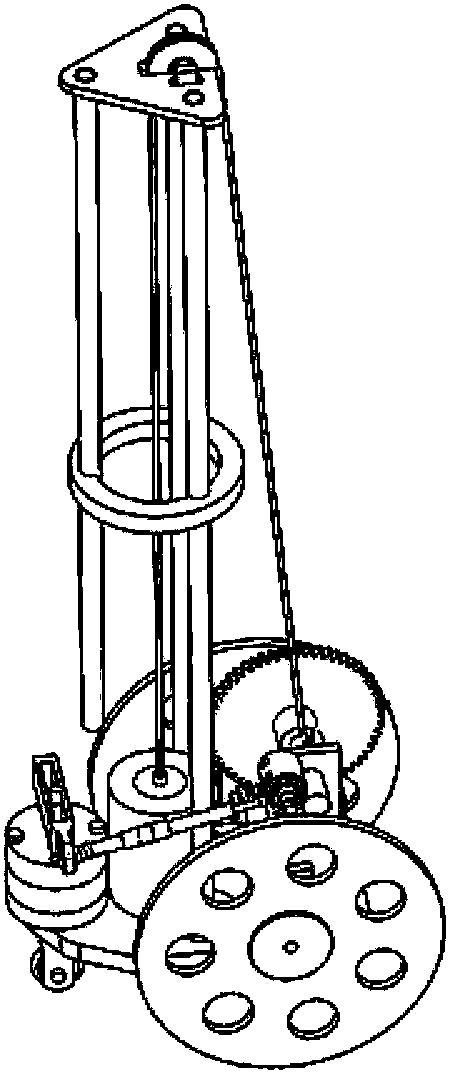

Self-propelled trolley driven by gravitational potential energy and capable of travelling around splay route

InactiveCN103394194AAccurate measurement dataSolve the problem of selecting the transmission ratio of trolley driveToy vehiclesCrankClassical mechanics

The invention relates to a self-propelled trolley driven by gravitational potential energy and capable of travelling around a splay route. The self-propelled trolley comprises a chassis with rear travelling wheels, a driving portion and a steering mechanism, wherein the driving portion and the steering mechanism are mounted on the chassis, the driving portion consists of a weight support, a weight, a drive shaft, a reel, a connecting cord, a transmission gear set and a driving shaft, and the steering mechanism consists of a set of spatial four-bar guide mechanism and a front guide wheel mounted below a tail oscillating bar of the spatial four-bar guide mechanism. In the actual travelling process, the front guide wheel of the trolley is controlled to rotate according to a set direction by adjusting the spatial four-bar guide mechanism so as to drive the trolley to be capable of travelling around the splay route, and various parameters of a crank bar are changed to further enable travelling distance and travelling track of the trolley to be changed. The self-propelled trolley has the advantages of simple and reasonable structure, convenience in operation and control, high efficiency, accurate travelling track, good stability and the like.

Owner:XIAN UNIV OF SCI & TECH

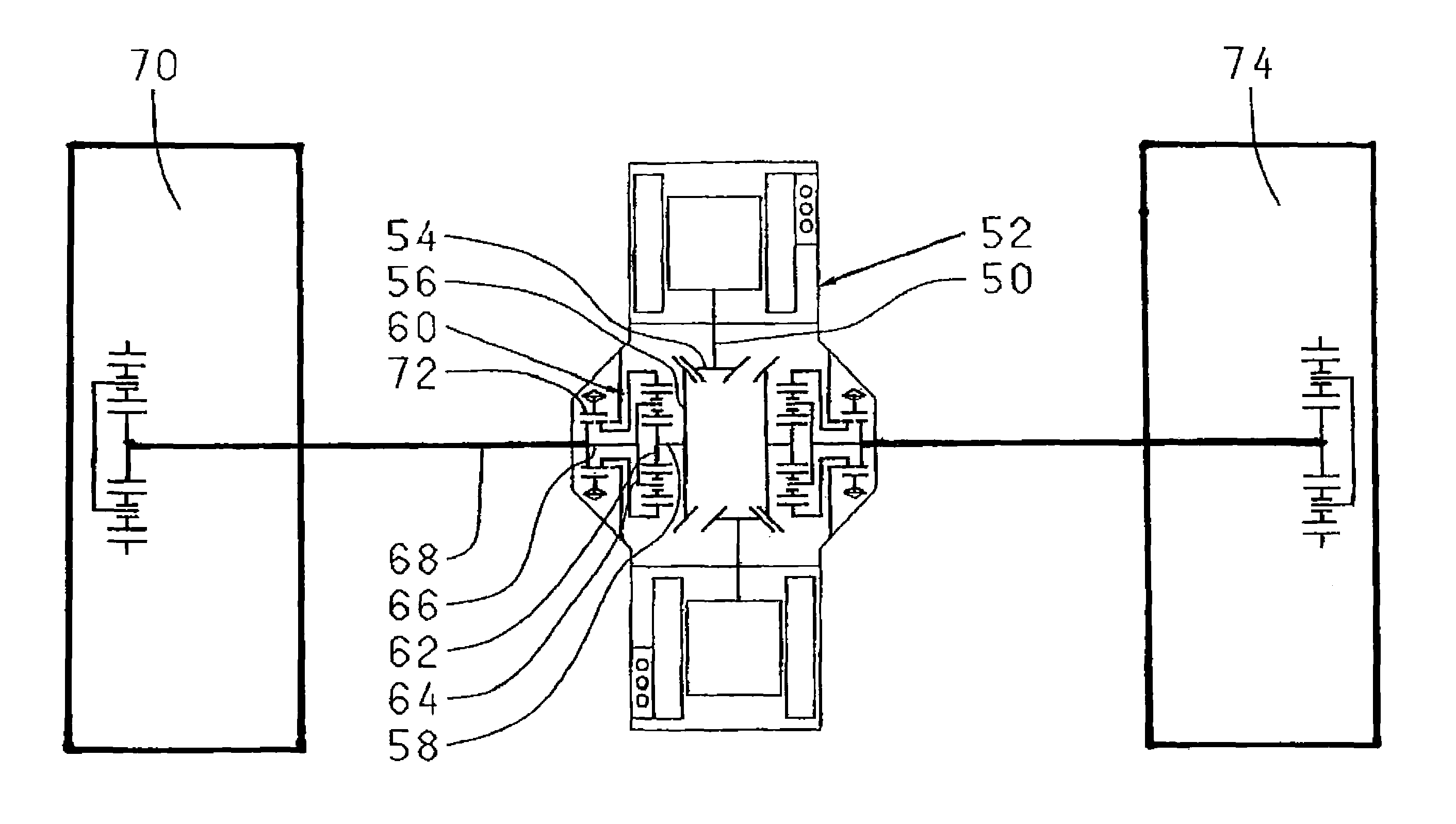

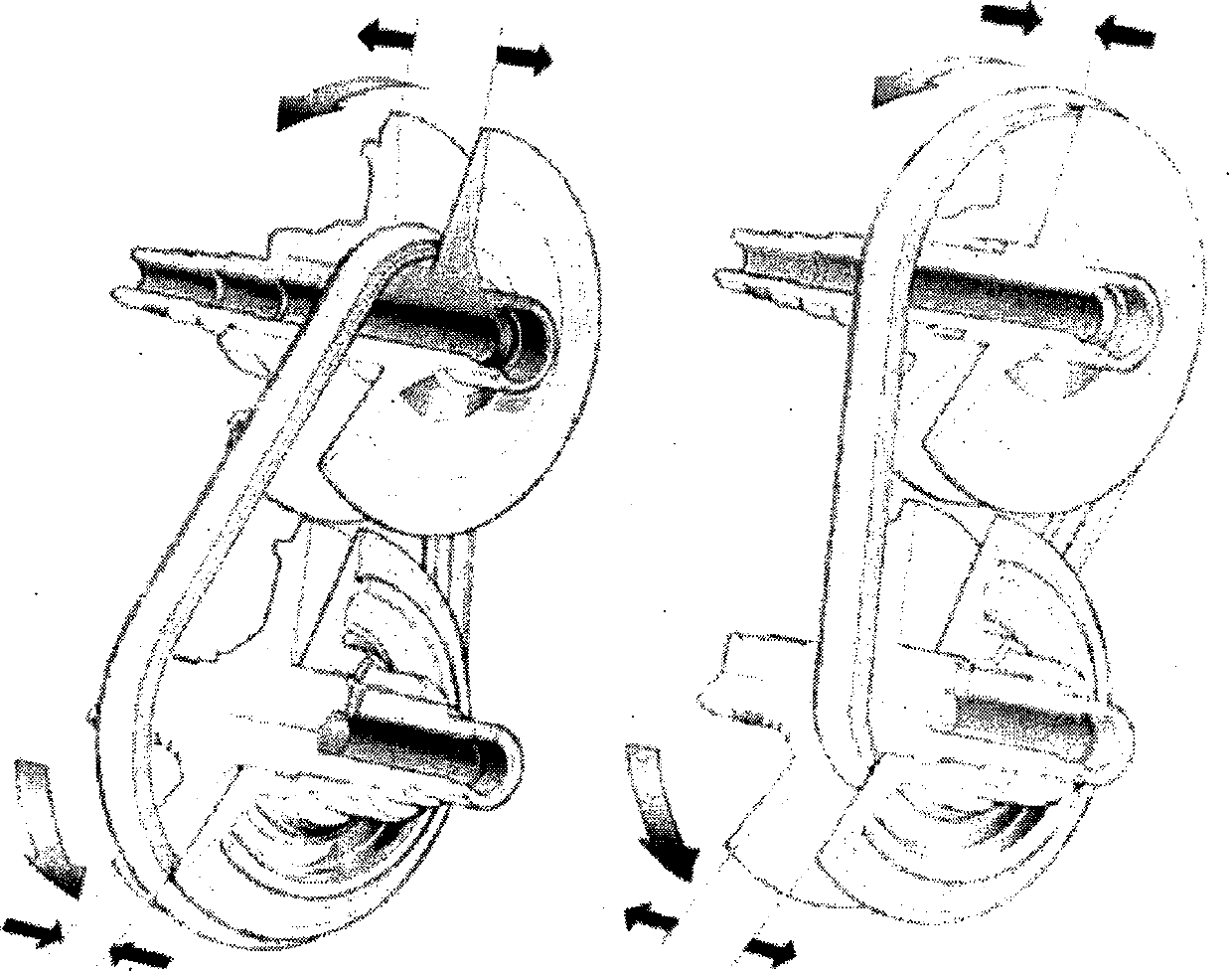

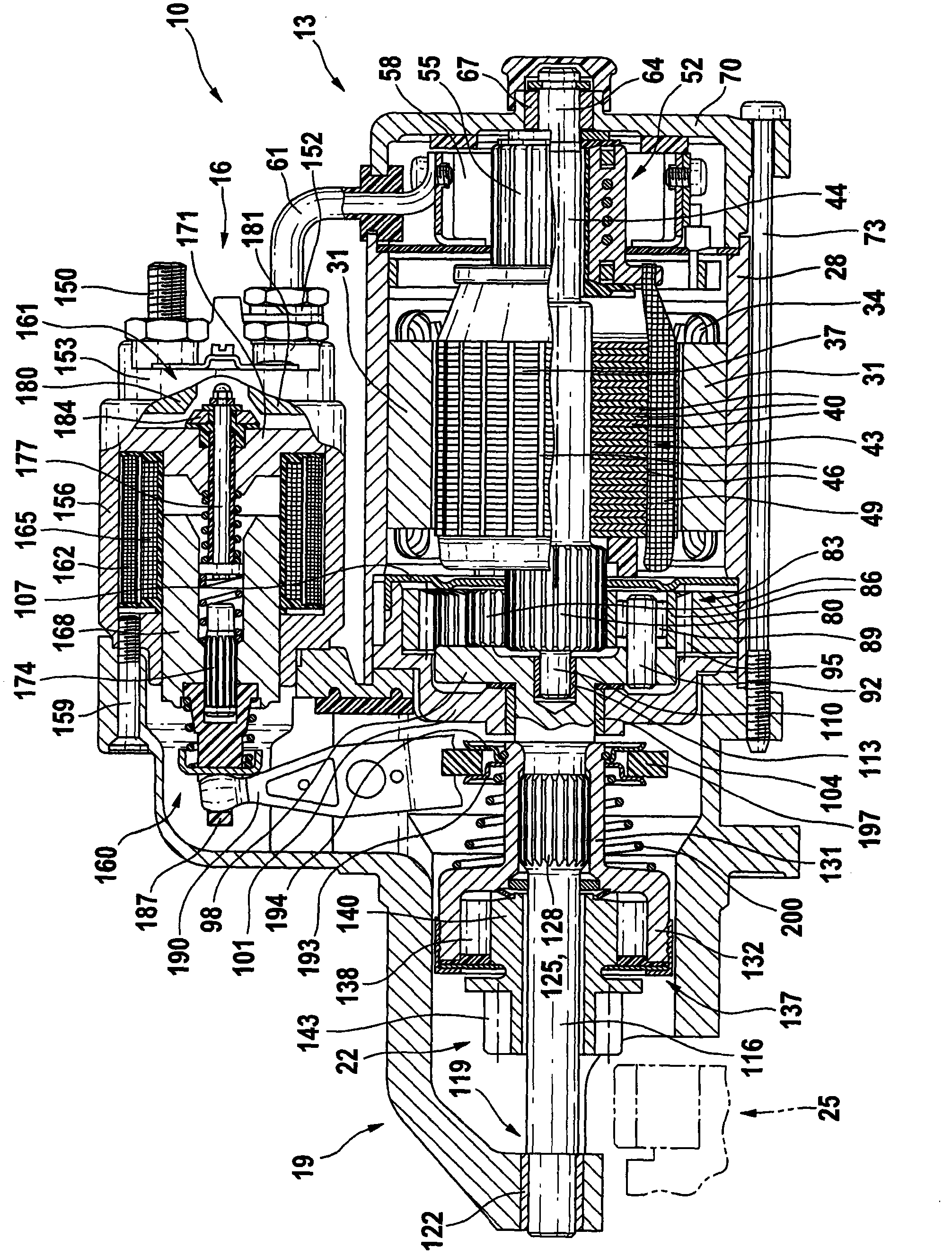

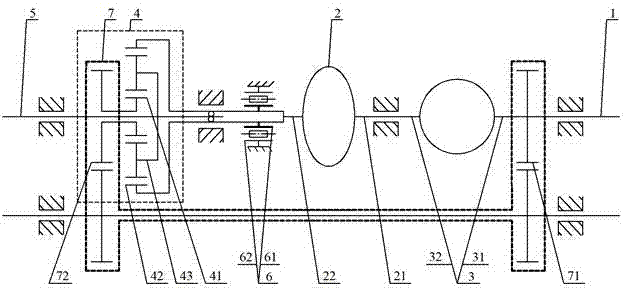

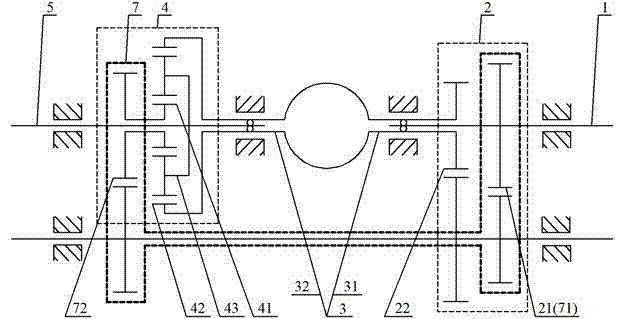

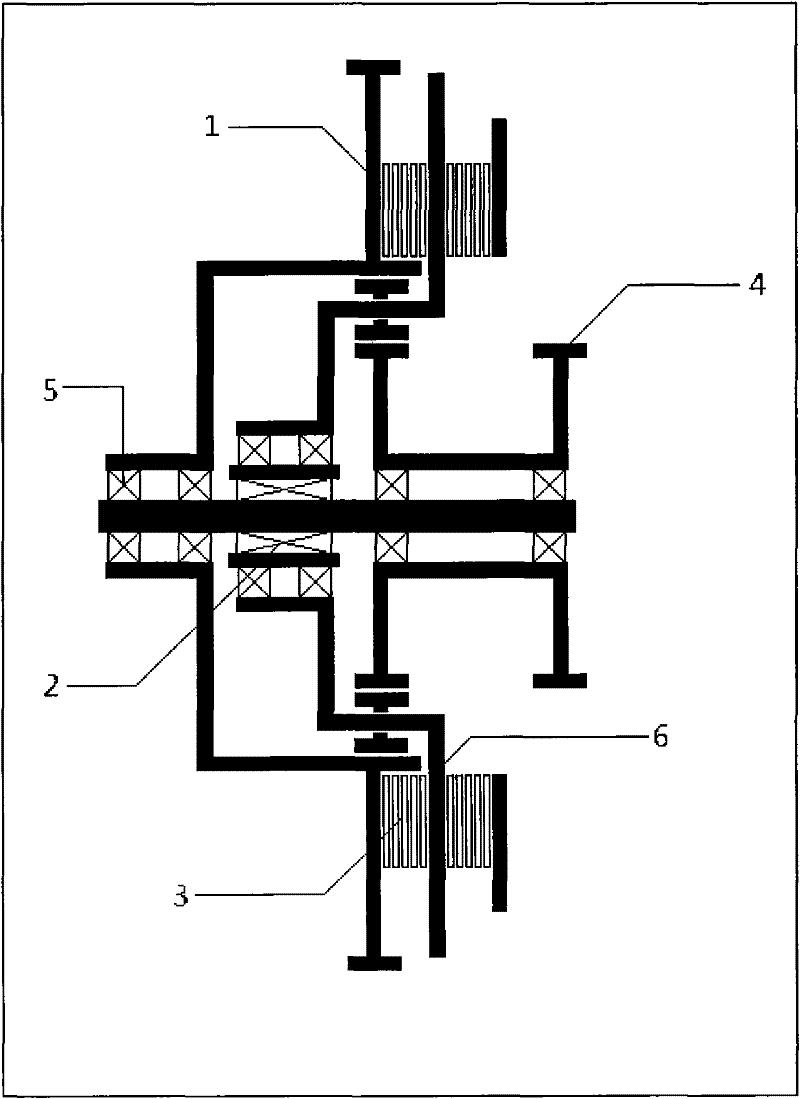

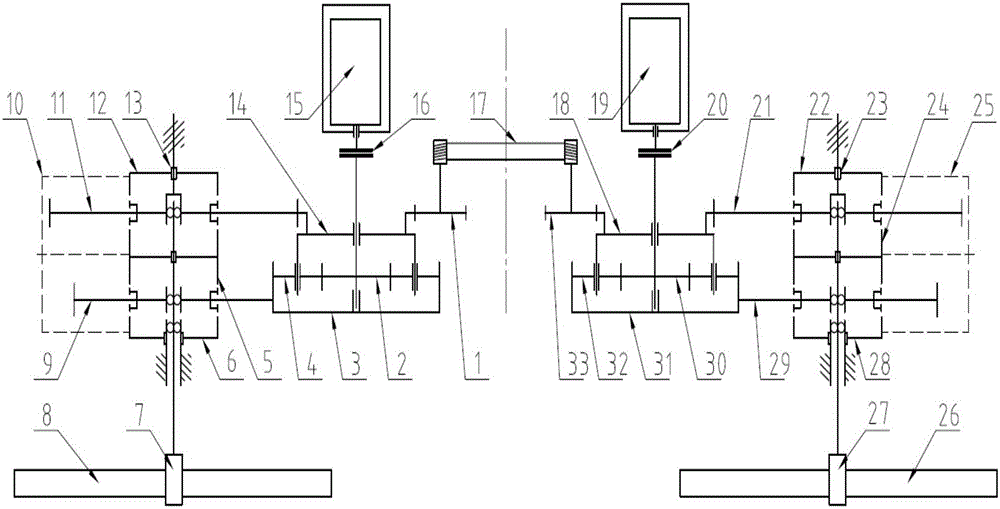

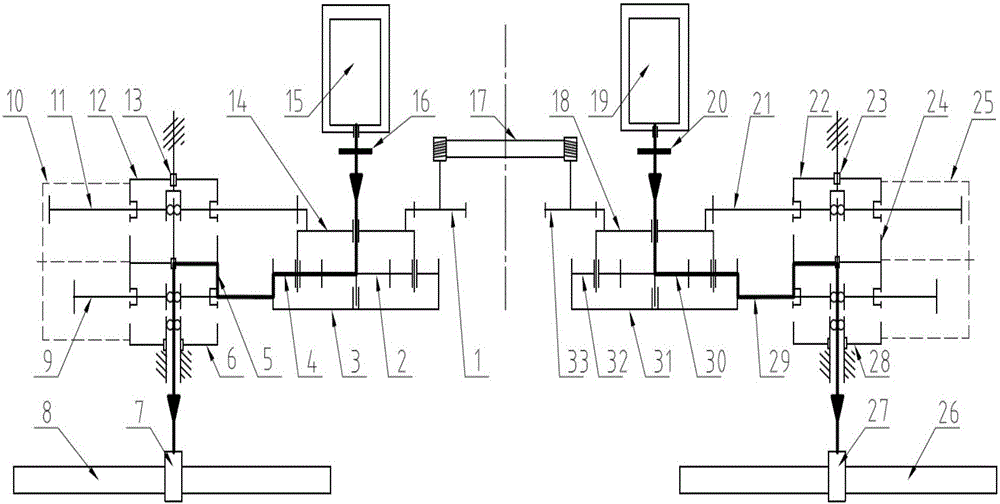

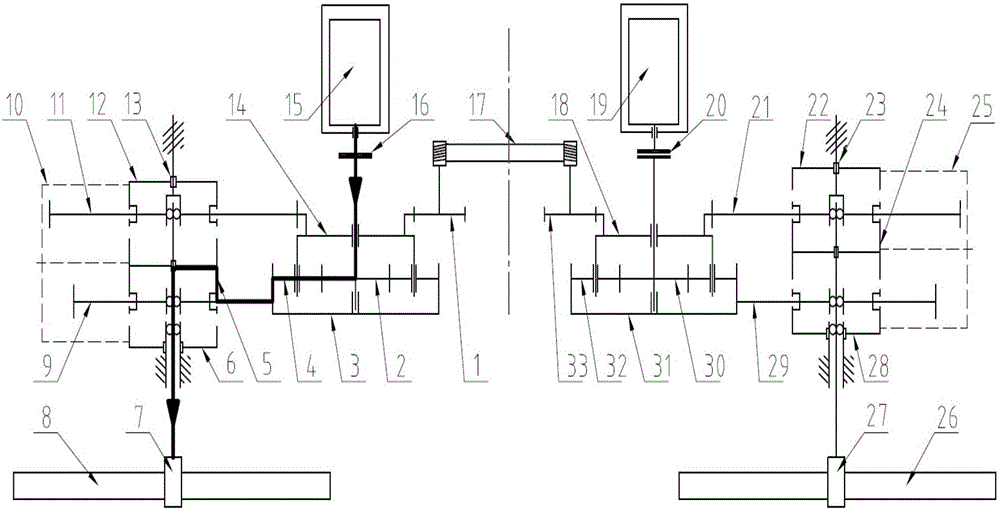

Drive system for individually driving two drive wheels of a drive wheel pair

InactiveUS7935014B2Change gear ratioImprove installation conditionsSpeed controllerElectric devicesRotational axisDrive wheel

A drive system for individually driving two wheels of a drive wheel pair of a vehicle. The drive system has two infinitely variable transmission drives which are drivingly connected, via a transmission arrangement, to an associated drive wheel. Each transmission arrangement includes two transmission units arranged one behind the other, with one of the transmission units preferably being a two-stage shiftable transmission and the other transmission unit being a bevel gear transmission. The shiftable transmission makes it possible to vary the drive transmission ratio. The bevel gear transmission makes it possible to arrange the transmission drives so that their drive shafts are at right angles to the rotational axis of the drive wheel pairs.

Owner:ZF FRIEDRICHSHAFEN AG

Drivetrain with engine, transmission, planetary gear set and electric machine

InactiveCN101966811AEasy to rotate speedOptimizationPower operated startersElectric motor startersDrivetrainGear wheel

The present invention relates to a drivetrain for a motor vehicle, compries an electric machine which can be operated in a generator mode and a starter mode; a planetary gear set, of which a first element, which forms the drive input side of the planetary gear set in the generator mode and forms the drive output side of the planetary gear set in the starter mode, is in rotationally driving connection with the engine shaft, a second element, which forms the drive output side of the planetary gear set in the generator mode and forms the drive input side of the planetary gear set in the starter mode, is in rotationally driving connection with the rotor, and a third element, which can be fixed by means of a first actuating device to a stationary housing in the starter mode, with a second actuating device also being provided which, in the generator mode, interacts with at least one of the elements in such a way that the planetary gear set performs a block rotation. The planetary gear set is arranged in front of the engine in the first axial direction, while the transmission is arranged behind the engine in the first axial direction.

Owner:BORGWARNER INC

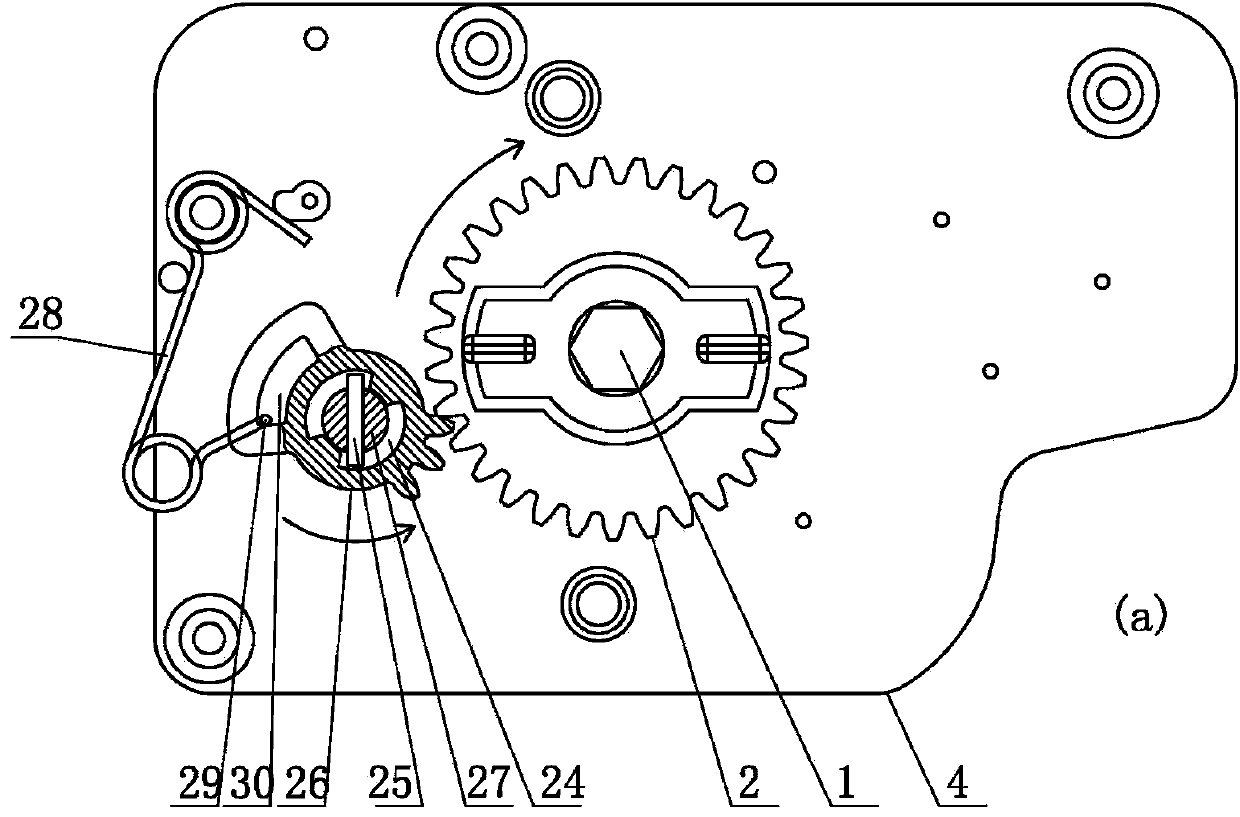

Mechanical type timing valve

ActiveCN103742704ANot easy to make mistakesImprove reliabilityOperating means/releasing devices for valvesGear wheelEngineering

The invention belongs to the technical field of valves, and discloses a mechanical type timing valve. The mechanical type timing valve comprises a mechanical type timer and a valve body. The mechanical type timer comprises a spindle, a timer cam and an escapement speed regulation mechanism, wherein the spindle is driven by a timing spring to reversely rotate, the timer cam is linked with the spindle, and the escapement speed regulation mechanism controls the revolting speed of the spindle. The valve body is driven to open or close by forward rotating or reversely rotating a rotating shaft. A valve closing spring for driving the rotating shaft to reversely rotate is arranged on the rotating shaft. The rotating shaft is in limited linkage with the spindle of the timer through a sector gear. A section gear reset mechanism pushes the dislocated sector gear to draw close to a gear connected with the sector gear. The sector gear has a free rotating angle relative to the rotating shaft. A reverse rotating limiting mechanism which limits the rotating shaft to rotate only in the valve closing direction is triggered to fail by the timer cam of the timer. According to the mechanical type timing valve, time setting and valve opening are combined, and therefore operation convenience is greatly improved; valve opening and timing are rigidly combined, and safety is high.

Owner:阮迪荣 +1

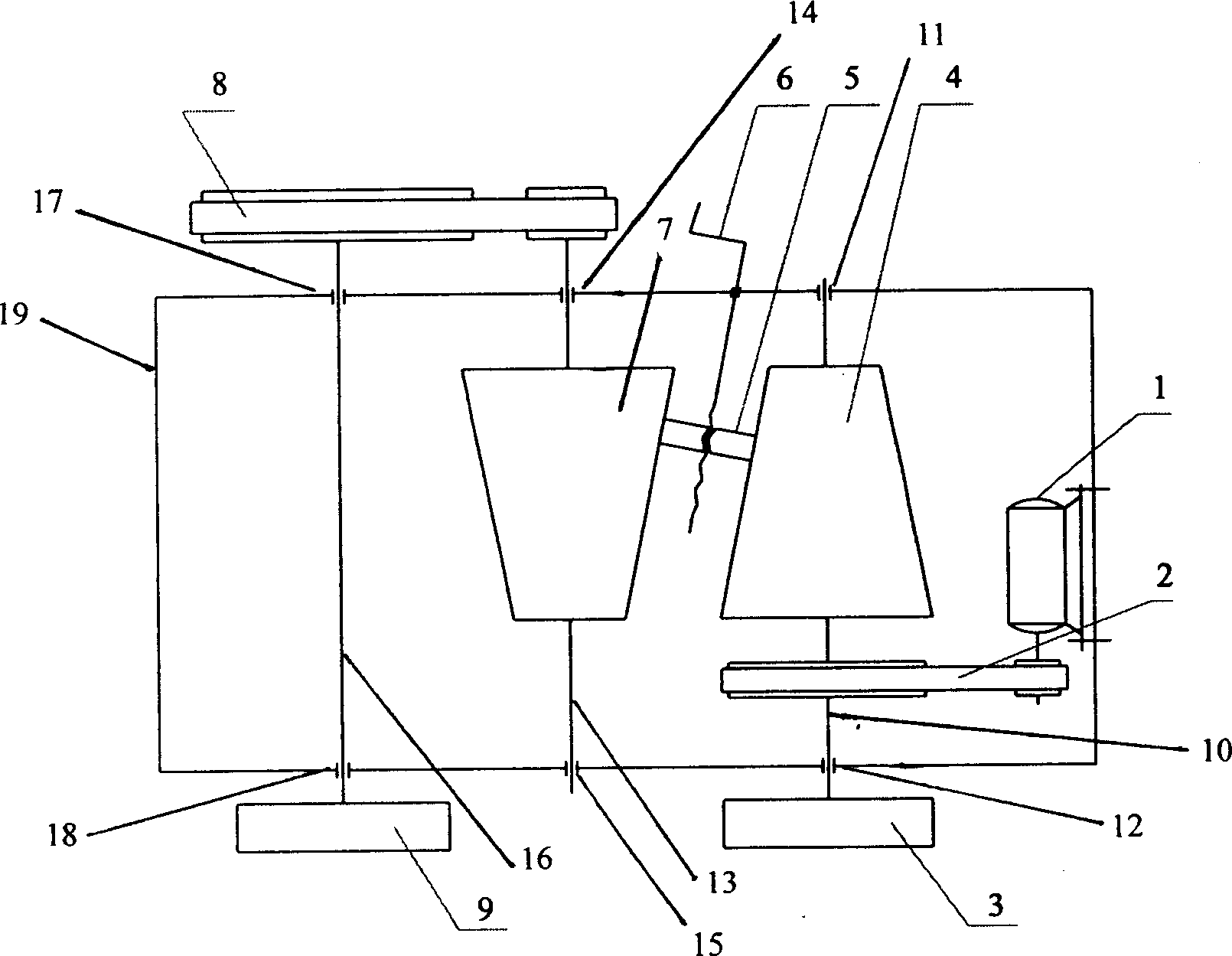

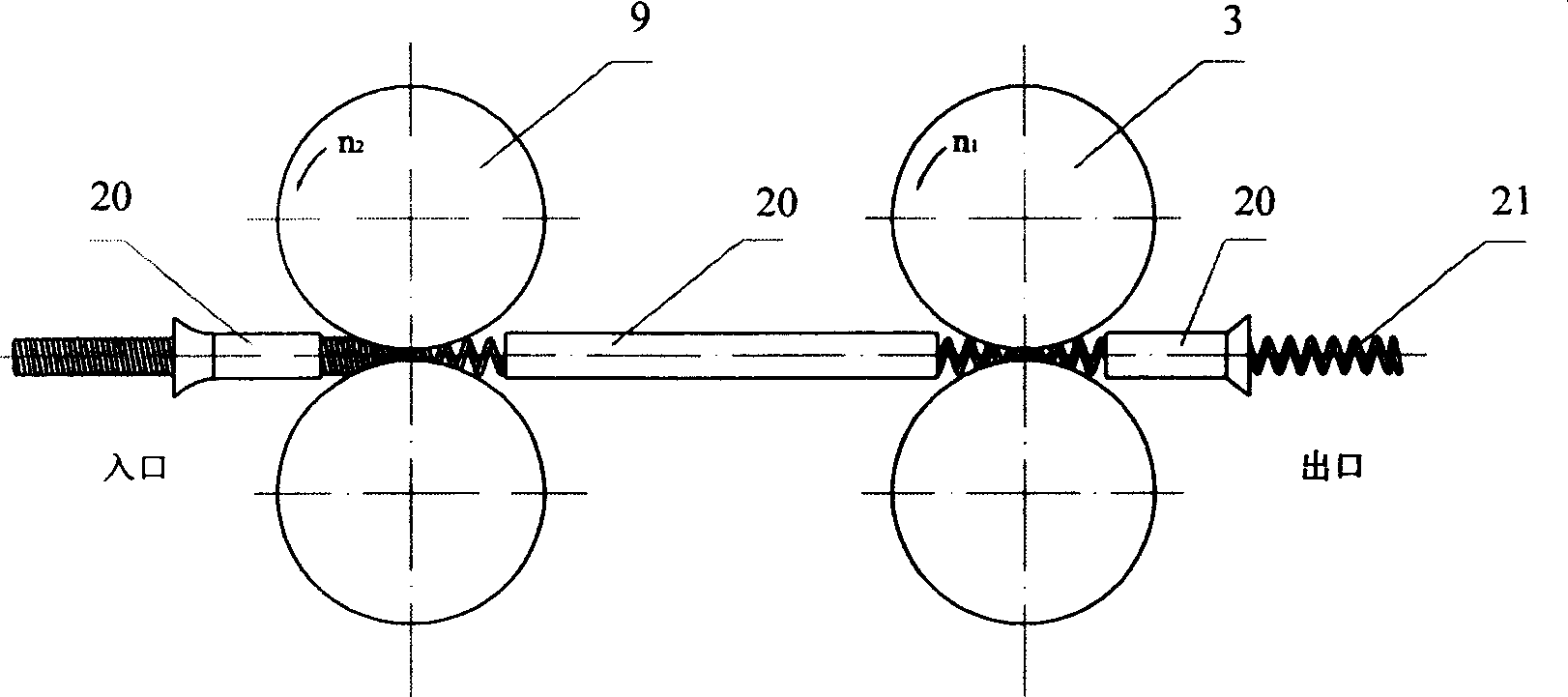

Screw roll fixed pitch stretching device

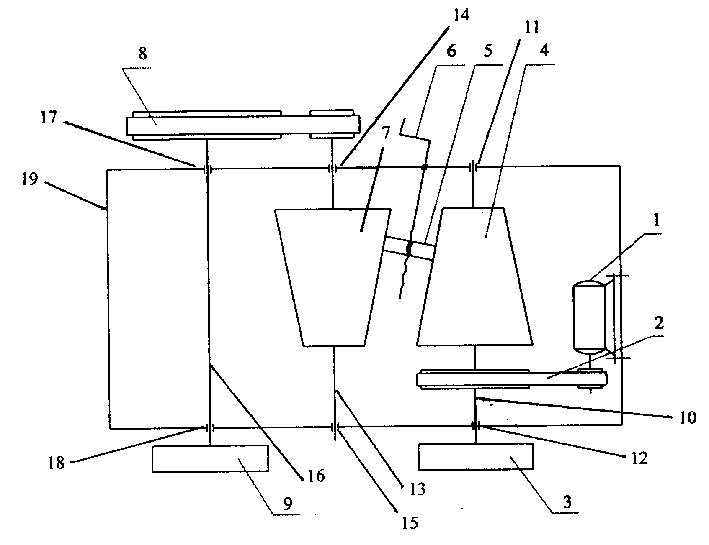

The screw roll fixed-pitch stretching equipment consists of motor, high-speed belt drive stage, low-speed belt wrive stage, driving rubber roller, differential rubber roller, driving conic roller, driven conic roller, speed-regulating screw, shaft and bearings. The motor drives the small belt pulley of high-speed belt drive stage; the driving conic roller, the large belt pulley of high-speed belt drive stage and the driving rubber roller are on the drive shaft; the driven conic roller and the small belt pulley of low-speed belt drive stage are on the middle shaft; the large belt pulley of low-speed belt drive stage and the differential rubber roller are on the driven shaft; there is speed regulating screw with control handle installed between the driving conic roller and the driven conic roller; and the bearings are mounted on the box.

Owner:HARBIN INST OF TECH

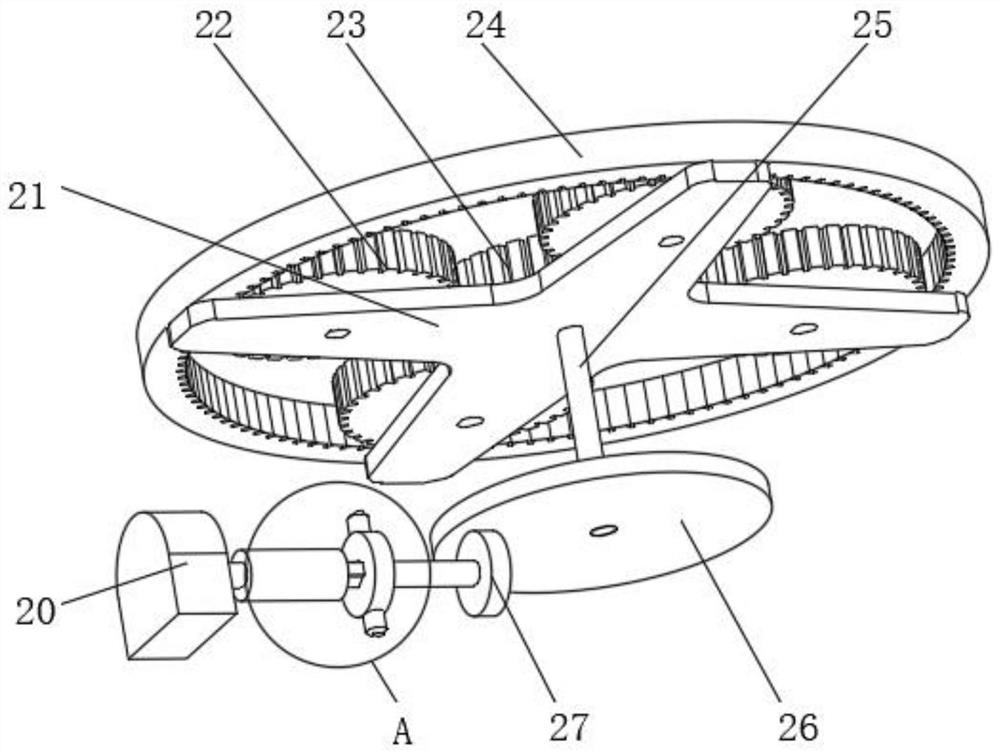

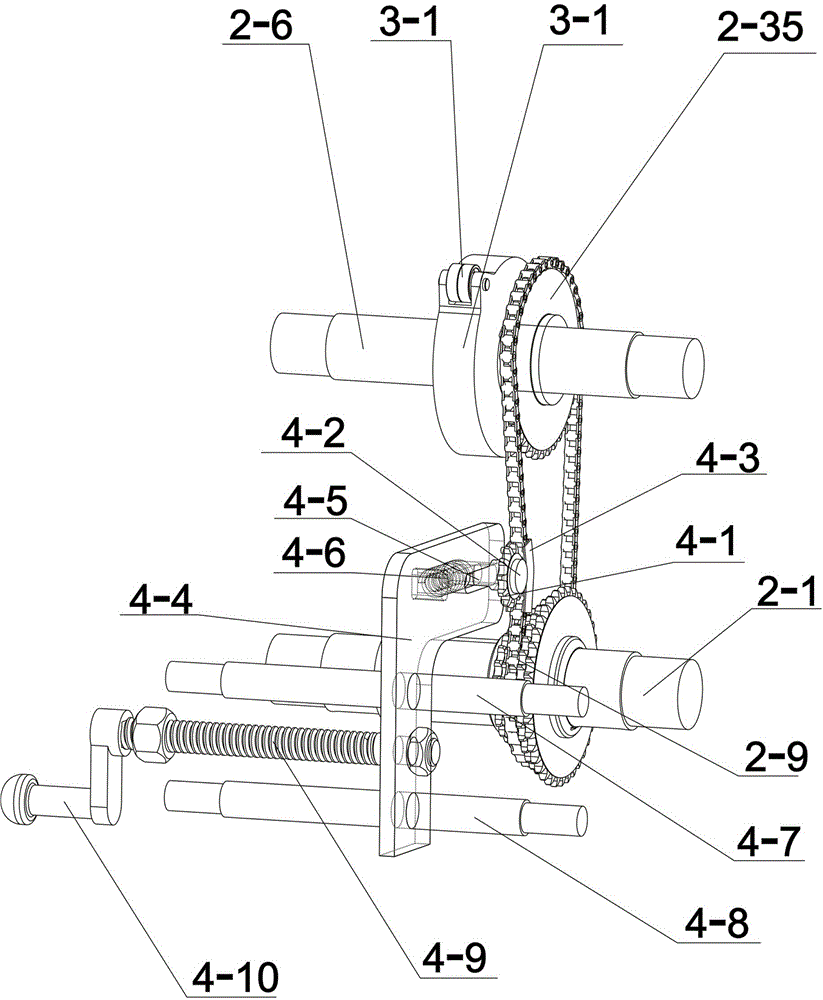

Mechanical variable chain wheel continuously variable transmission

ActiveCN106015482AChange gear ratioIncrease contact areaGearingElectric power transmissionTransmitted power

The invention provides a mechanical variable chain wheel continuously variable transmission. The mechanical variable chain wheel continuously variable transmission comprises an input device, a drive transmission device connected to the input device, a driven transmission device connected to the drive transmission device through a chain and an output device connected to the driven transmission device; the drive transmission device comprises a variable chain wheel plate, a clamping jaw connected to the variable chain wheel plate and a chuck with the clamping jaw, the clamping jaw is driven by a wire coiling crankset arranged in the chuck to move in the radius direction of the chuck, and the clamping jaw drives the variable chain wheel plate to move to change the diameter of the variable chain wheel plate; a variable chain wheel comprises the variable chain wheel plate installed to the clamping jaw and variable chain wheel teeth installed to the variable chain wheel plate. The drive transmission device and the driven transmission device transmit power through meshing of the chain and a gear, the contact surface of power transmission is increased, and power transmission is more stable and more efficient.

Owner:丁震中

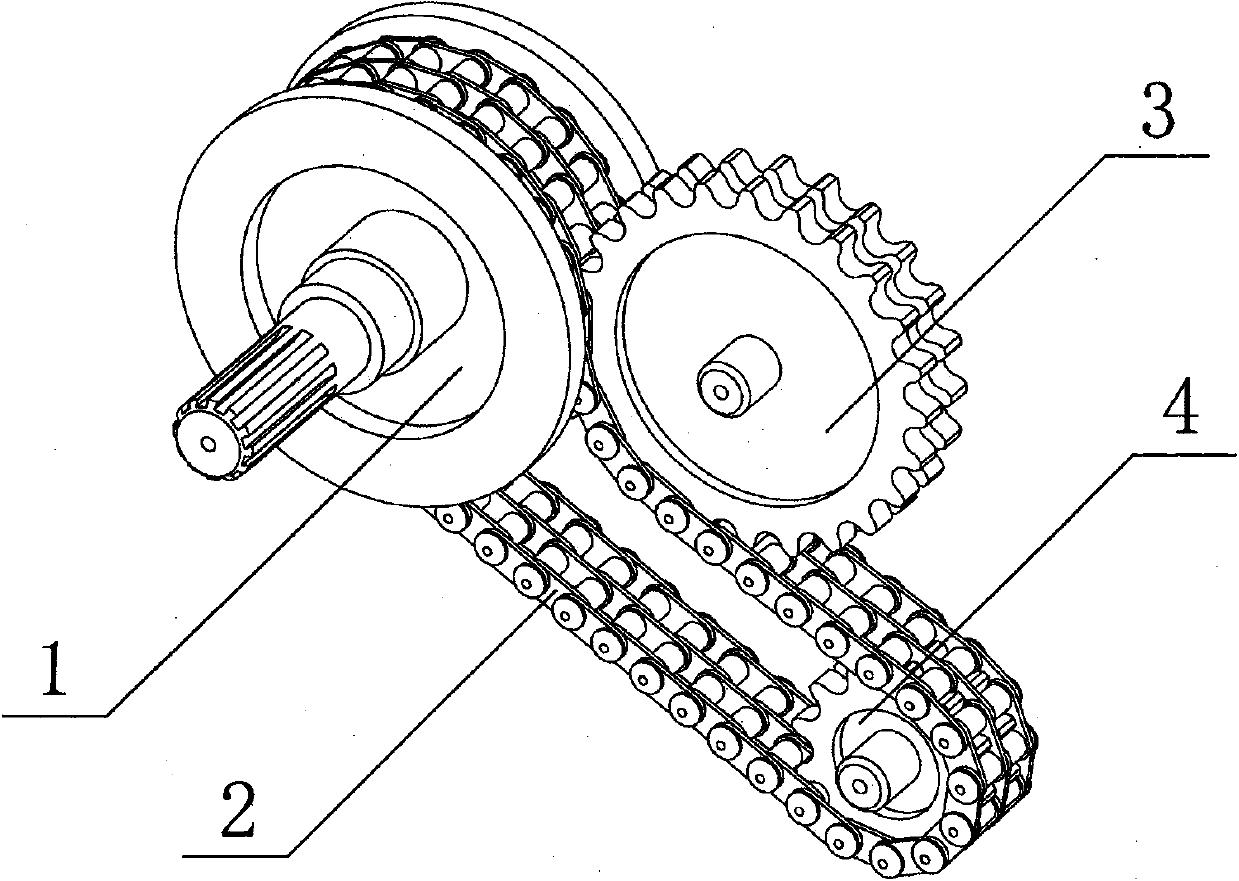

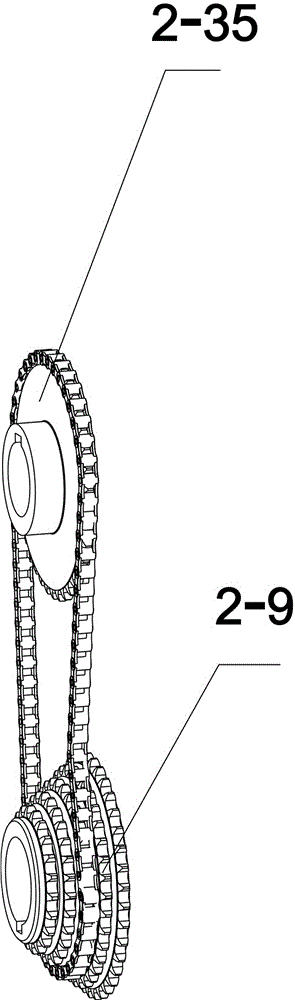

Chained infinitely variable speed transmission gear

InactiveCN103791050ALower performance requirementsChange the effective working radiusGearingSprocketControl theory

The invention discloses a chained infinitely variable speed transmission gear, belongs to an F16H9 / 24 category according to international patent classification (IPC) retrieval, and discloses a transmission gear capable of transmitting rotational movement at a variable speed ratio by the aid of a chain, a friction bevel wheel set and a sprocket. The chained infinitely variable speed transmission gear comprises the friction bevel wheel set (1), the transmission chain (2), the sprocket (3) and a tension wheel (4). The transmission chain (2) is tensioned via the tension wheel (4) and encircles the friction bevel wheel set (1), the friction bevel wheel set (1) comprises two friction bevel wheels which are coaxially and oppositely mounted, and the two friction bevel wheels can axially move in opposite directions, so that the working radius of the transmission chain (2) can be changed. The chained infinitely variable speed transmission gear is characterized in that the sprocket (3) presses the transmission chain (2) on the friction bevel wheel set (1), and rotational torque can be transmitted between the friction bevel wheel set (1) and the sprocket (3) via the transmission chain (2) and a chain shaft (6).

Owner:莫韬

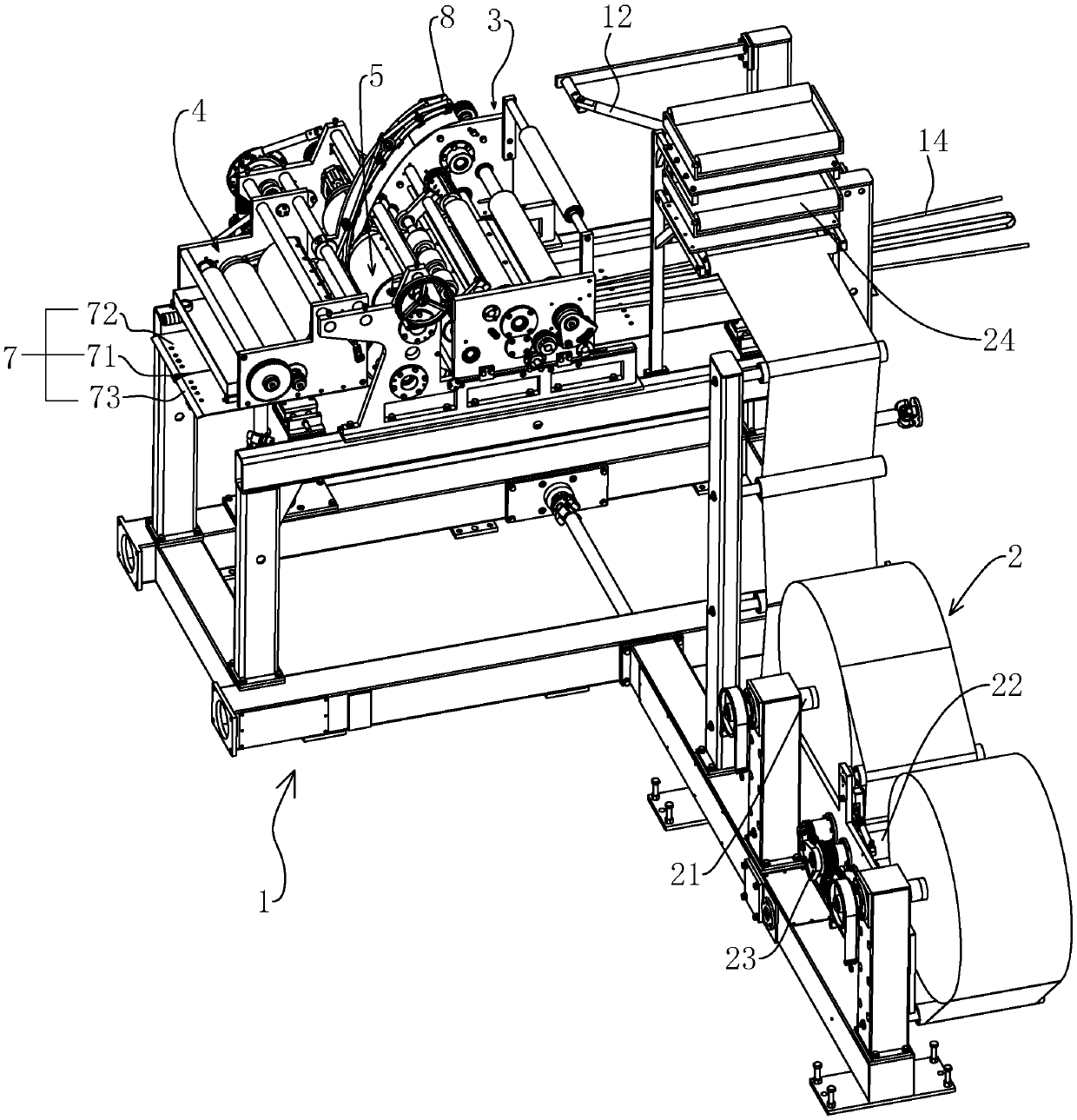

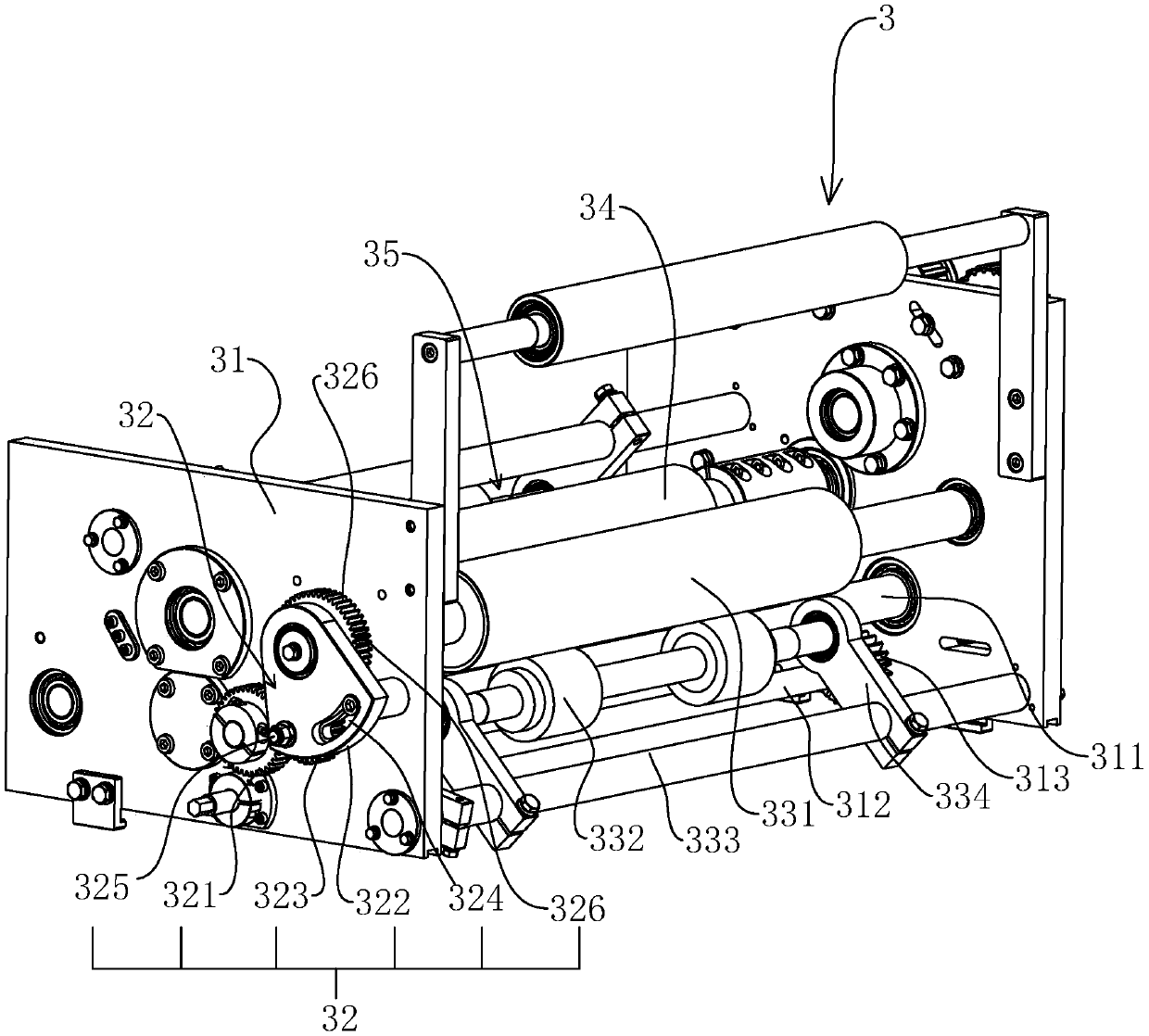

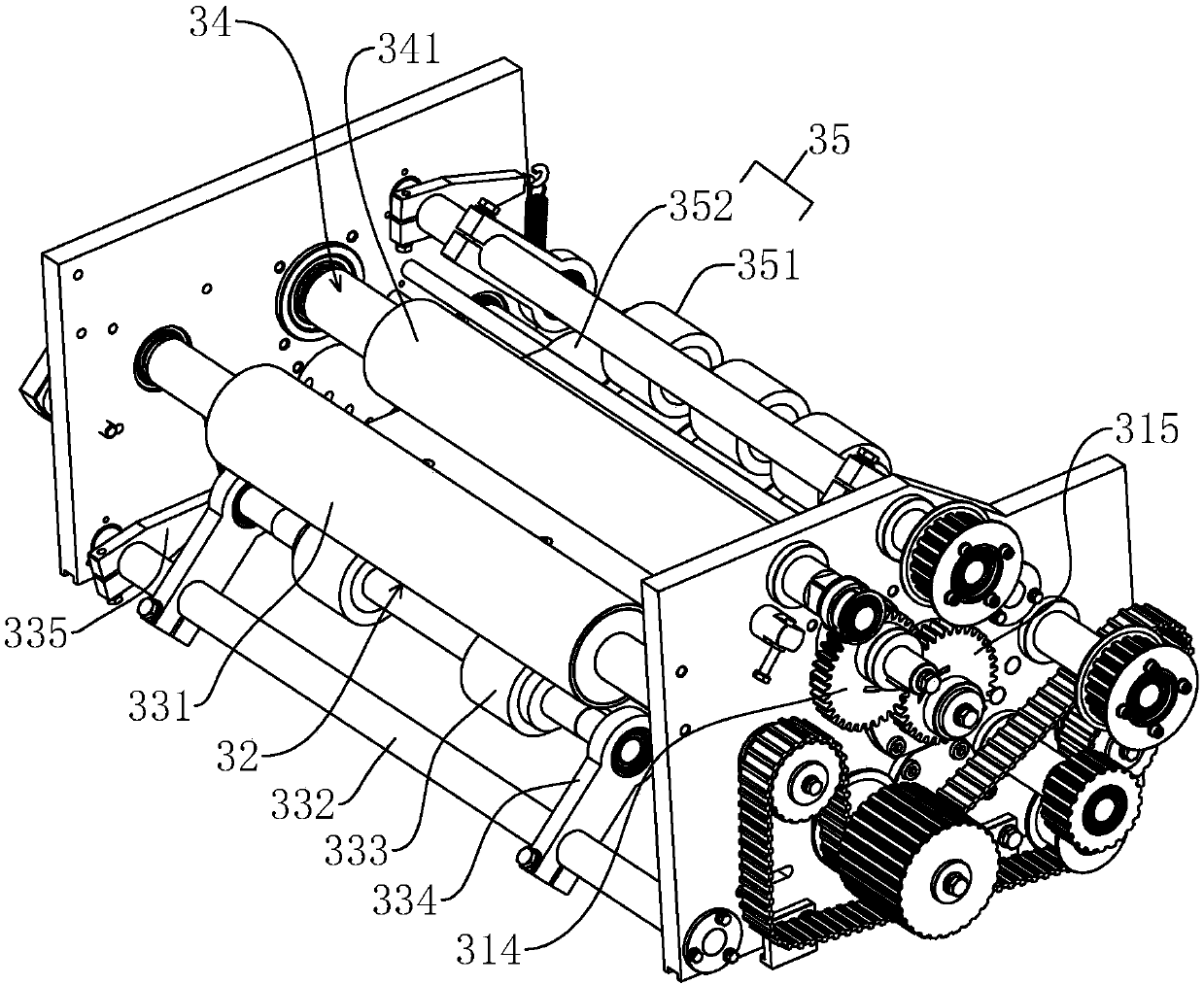

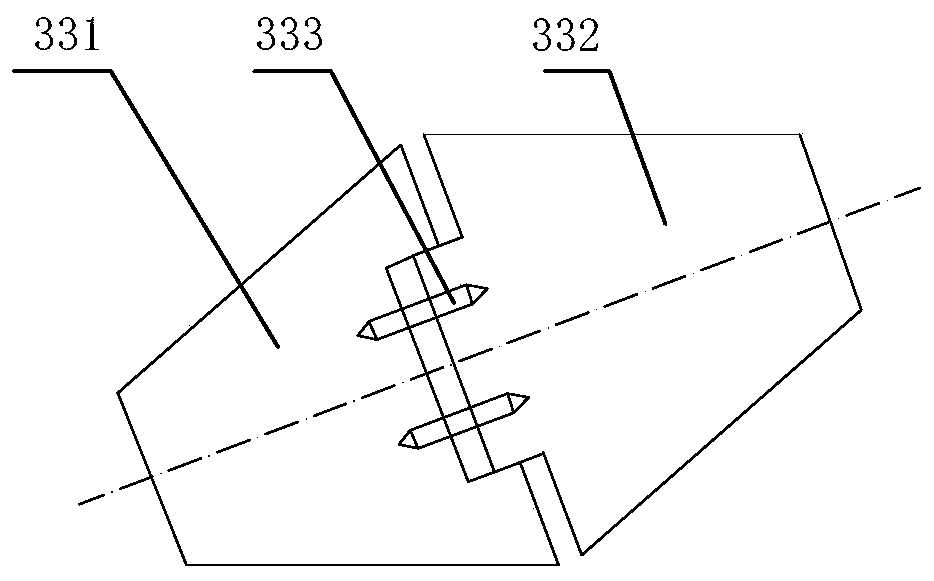

Valve port paper position adjusting mechanism of paper bag valve port inserting device

ActiveCN109532107AAccurate attachmentChange gear ratioBag making operationsPaper-makingPaper tapePulp and paper industry

The invention relates to a valve port paper position adjusting mechanism of a paper bag valve port inserting device. The mechanism is characterized by comprising a transmission mechanism for synchronously driving a glue loading and stirring mechanism, a compound paper rolling mechanism, a traction cutter mechanism, a folding roller mechanism and a paper drum pasting mechanism to operate; the transmission mechanism comprises a main driving shaft and an output shaft; a paper pasting speed change module is arranged between the main driving shaft and the output shaft; the output shaft is in transmission with the glue loading and stirring mechanism, the compound paper roll mechanism, the traction cutter mechanism, the folding roller mechanism and the paper drum pasting mechanism through belts or gears; and under the condition of keeping invariable paper bag feeding speed of a paper bag conveying mechanism, the valve port paper pasting position adjustment is finished through temporary changeof the valve port paper pasting speed and the speed difference of the two, so that valve port paper is accurately pasted in corresponding positions of paper tapes.

Owner:FOSHAN TECON PACKAGE MACHINERY

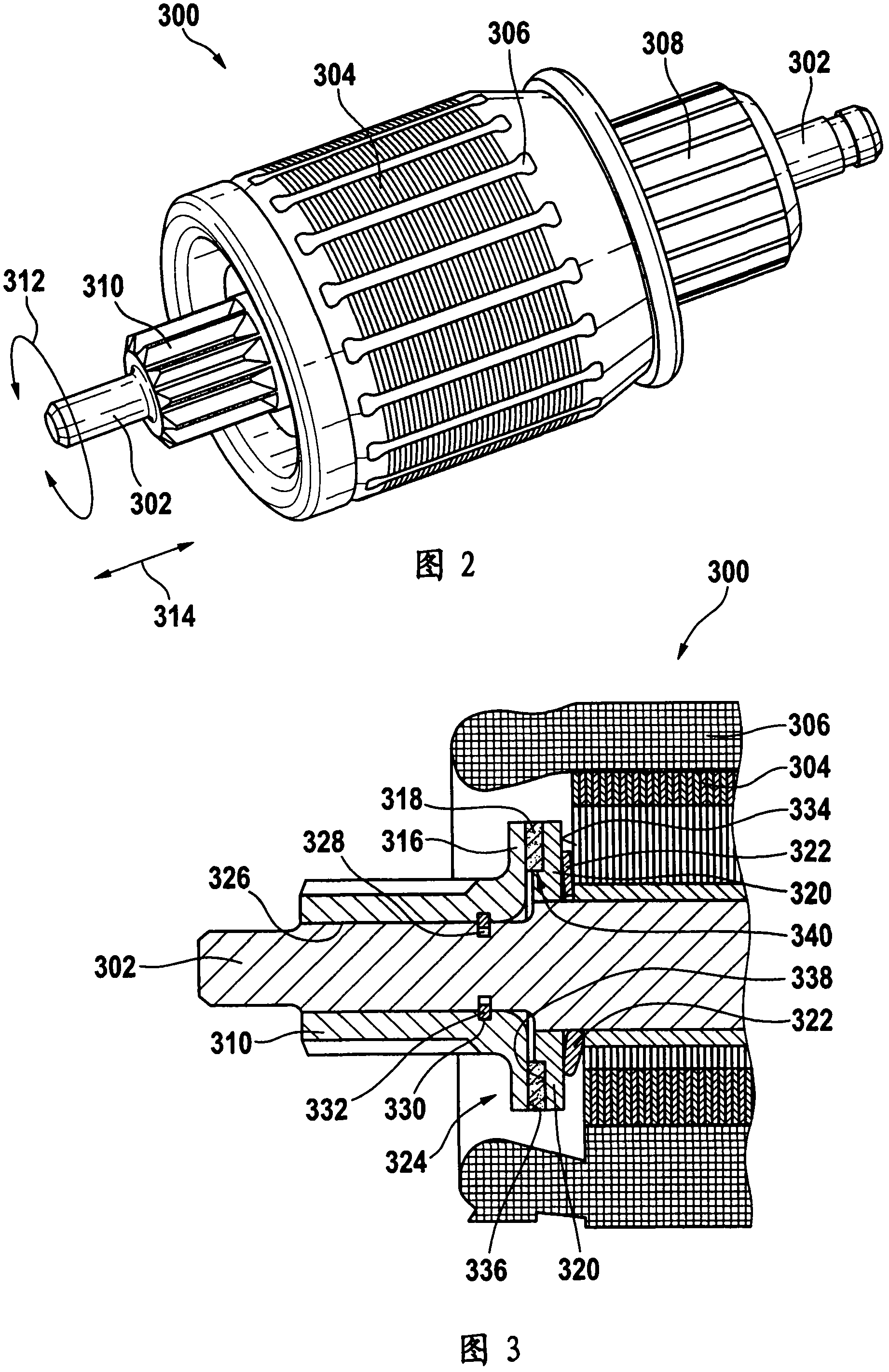

Armature for an electric motor for driving a starter device

InactiveCN102545472AEasy to replaceQuick changePower operated startersElectric motor startersMaximum torqueCombustion

The invention relates to an armature for an electric motor for driving a starter device of a combustion engine. The armature comprises an armature pinion which can be rotatably contained on an armature shaft and used for driving a middle transmission mechanism disposed at rear, and an armature iron core which is disposed on the armature shaft and has an armature winding. According to the invention, the armature pinion is positioned on the armature shaft along an axial direction, and a sliding clutch is disposed between the armature pinion and the armature shaft. The armature pinion and the armature pinion edge interact with a friction piece, a disc and a compression spring, forming the sliding clutch which slides when reaching to or exceeding a maximum torque limit Mmax determined by the structure. Furthermore, the armature pinion can be replaced by another armature pinion with different numbers of pinions without replacing the whole armature. Accordingly, gear ratio of a starter device can easily correspond to different demands.

Owner:ROBERT BOSCH GMBH

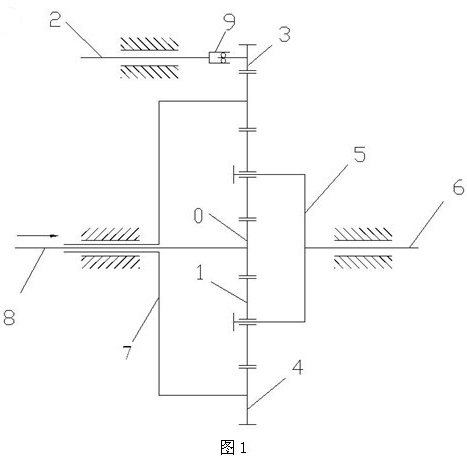

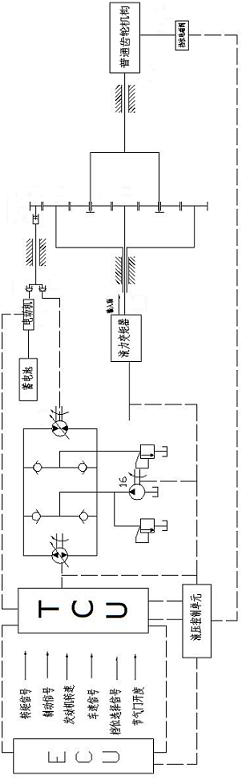

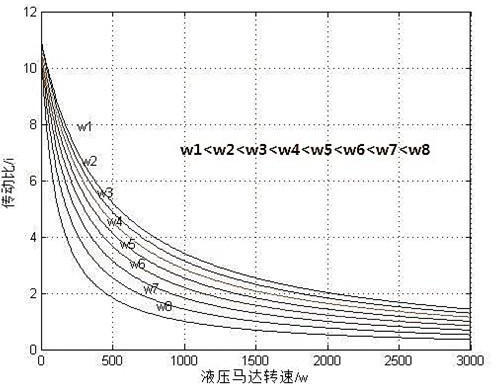

Compound type hydraulic drive device

InactiveCN103939559AMeet the needs of useChange gear ratioGearboxesFluid gearingsControl theoryMechanical engineering

Owner:吴志强

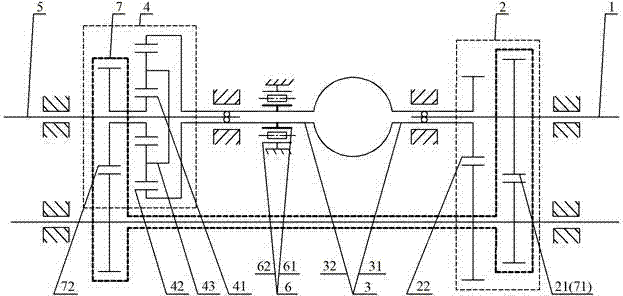

Drive System for Individually Driving Two Drive Wheels of a Drive Wheel Pair

InactiveUS20080167153A1Easy constructionImprove installation conditionsSpeed controllerElectric devicesRotational axisDrive wheel

A drive system for individually driving two wheels of a drive wheel pair of a vehicle. The drive system has two infinitely variable transmission drives which are drivingly connected, via a transmission arrangement, to an associated drive wheel Each transmission arrangement includes two transmission units arranged one behind the other, with one of the transmission units preferably being a two-stage shiftable transmission and the other transmission unit being a bevel gear transmission. The shiftable transmission makes it possible to vary the drive transmission ratio. The bevel gear transmission makes it possible to arrange the transmission drives so that their drive shafts are at right angles to the rotational axis of the drive wheel pairs, thus improving the options for installation in the vehicle.

Owner:ZF FRIEDRICHSHAFEN AG

Artwork display device with timing and charging functions

InactiveCN112155383AEnsure safetyWith time charging functionGearingApparatus for meter-controlled dispensingGear wheelDisplay device

The invention discloses an artwork display device with timing and charging functions, relates to the technical field of art display, and aims to solve a safety problem. The device specifically comprises a base, a friction transmission mechanism is arranged on the outer wall of the top of the base, a planetary gear mechanism is fixed to the outer wall of the top of the base through supporting legs,a lifting mechanism is arranged on the outer wall of the top of the planetary gear mechanism, and the friction transmission mechanism comprises a friction transmission assembly, a transmission ratioadjusting assembly and a critical pressure adjusting assembly; the friction transmission assembly comprises a friction disc and a friction wheel, and the friction disc is in power connection with theplanetary gear mechanism. When displayed artworks or other parts are touched, twined and other unsafe conditions occur, due to the fact that transmission is established between the friction disc and the friction wheel through the friction force, the transmission torque is the friction force, the rotation resistance is larger than the friction force at the moment, slipping and power interruption occur at the power connection position, and safety is guaranteed.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Screw mandrel regulation type stepless transmission apparatus

The invention discloses a screw rod regulation-typed stepless speed change device which is sleeved with a crank on a power input shaft; a driving gear is arranged on an output shaft and sleeved on the output shaft by a one-way bearing; a planker is fixed on the driving gear; a sliding block of the planker is connected with the crank in a transmission way by a connecting rod; one side of the driving gear is also provided with a driven gear which meshes with the driving gear; the driven gear is sleeved on an auxiliary shaft by the other one-way bearing with the same steering direction; on the back surfaces of the driving gear and the driven gear, the output shaft and the auxiliary shaft are fixed with two small gears respectively which transmit by the meshing of a middle gear. When in work, the crank drives the planker to cause the driving gear to make corresponding reciprocating rotation, and the output shaft is driven by the gear mechanism to rotate continuously. By regulating the swinging working radius of the planker, the transmission ratio between the input shaft and the output shaft is changed. The device transmits by the connecting rod and a swing arm, and has large transmission torque and small loss in the transmission process.

Owner:王洋

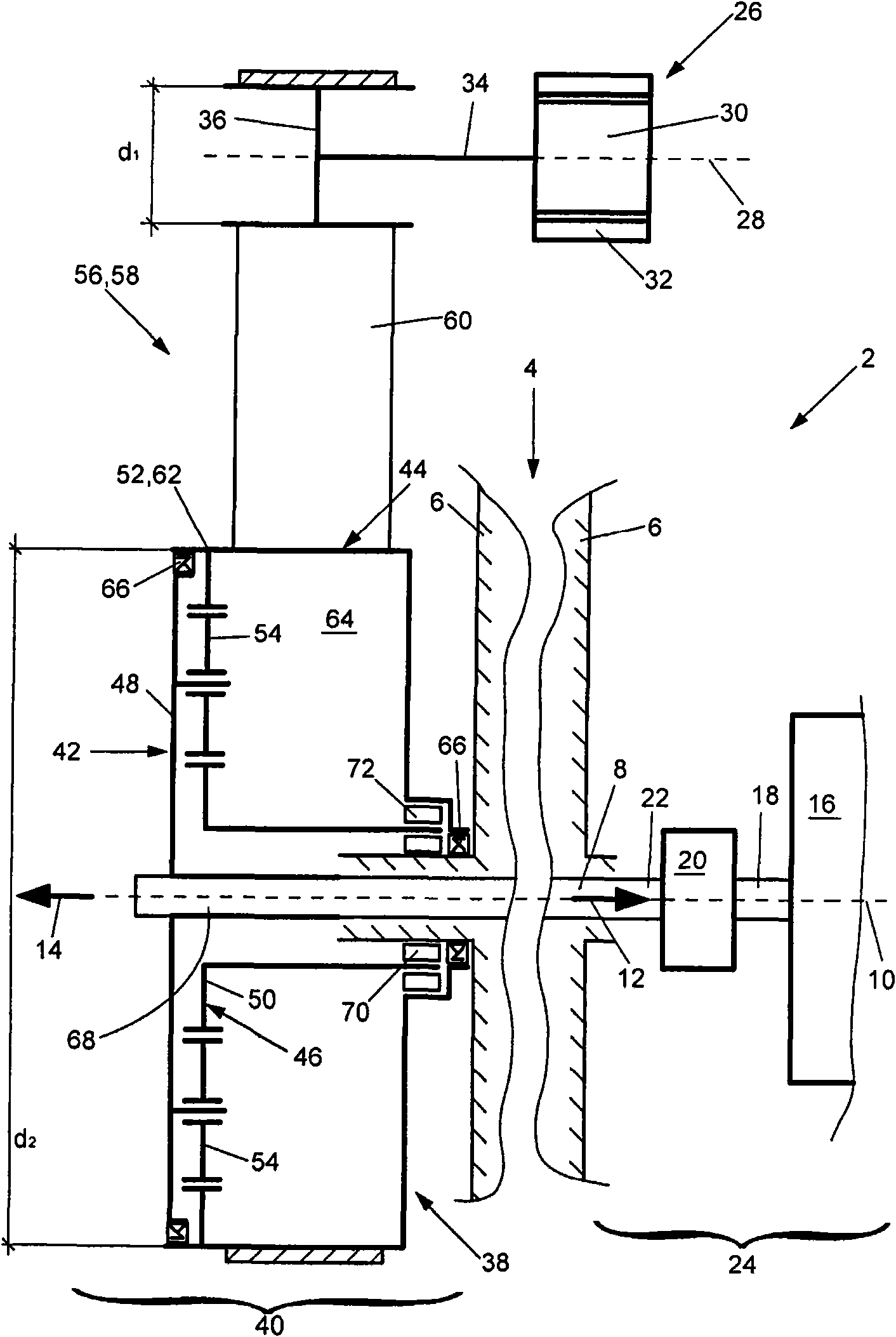

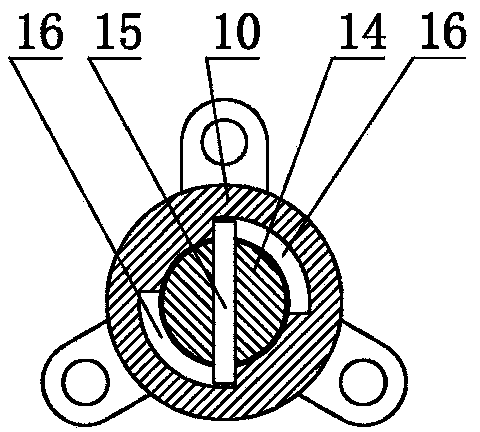

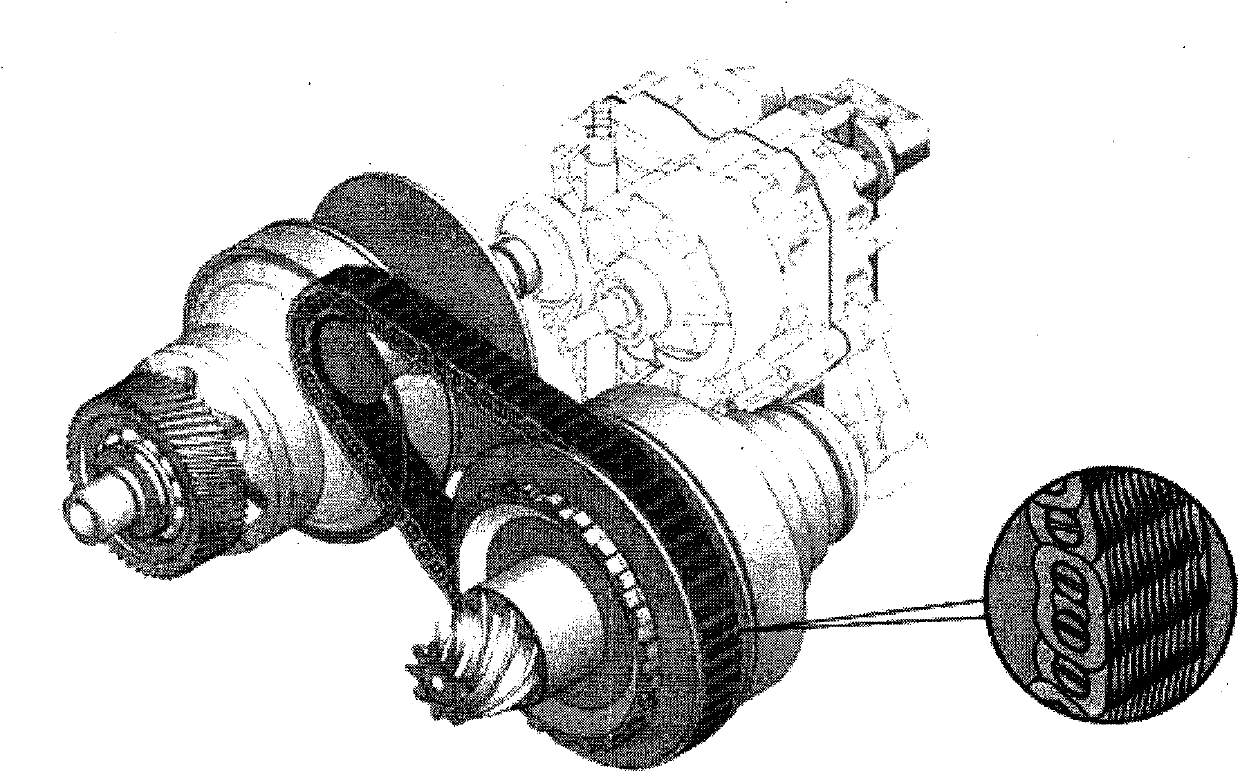

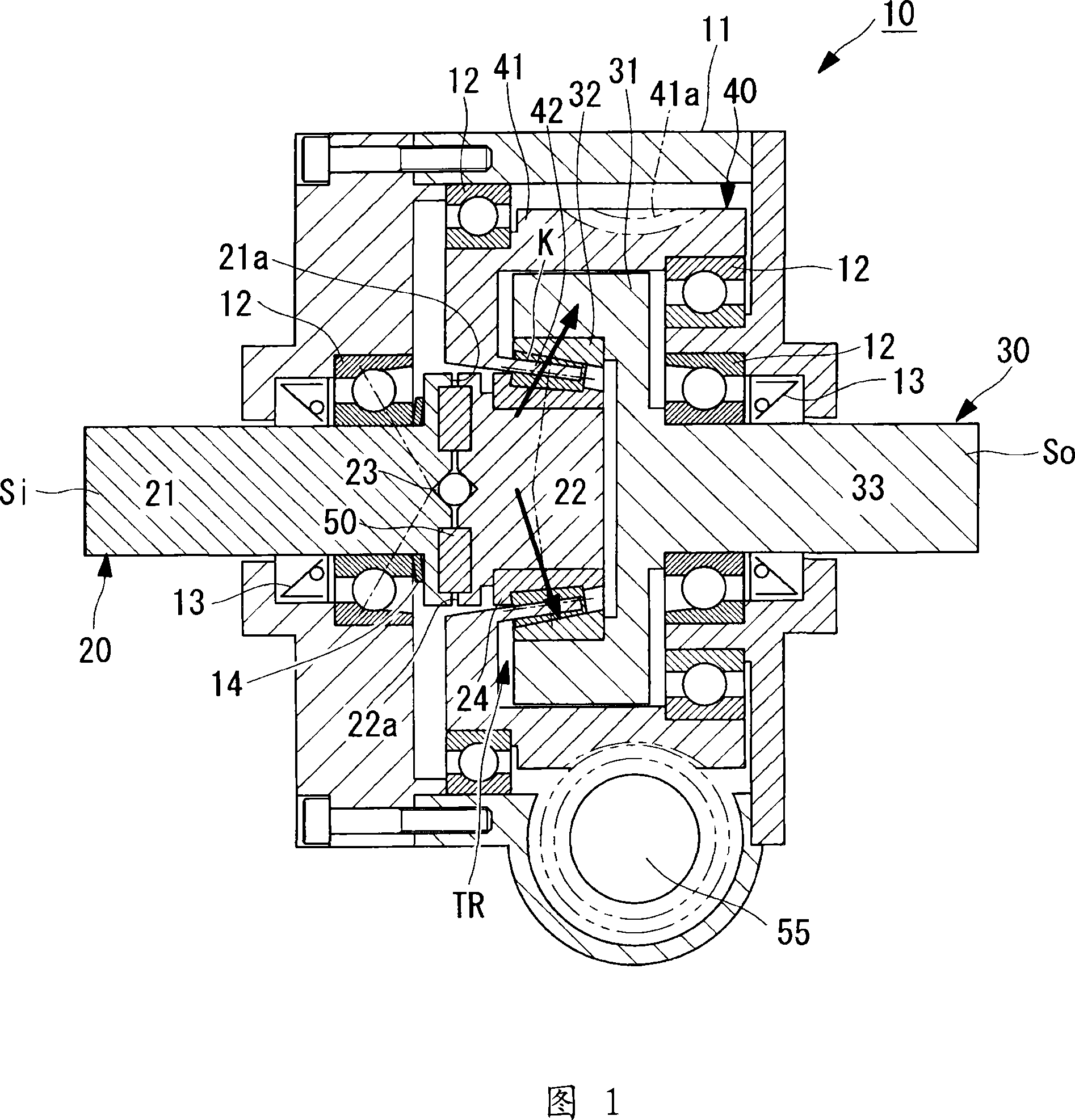

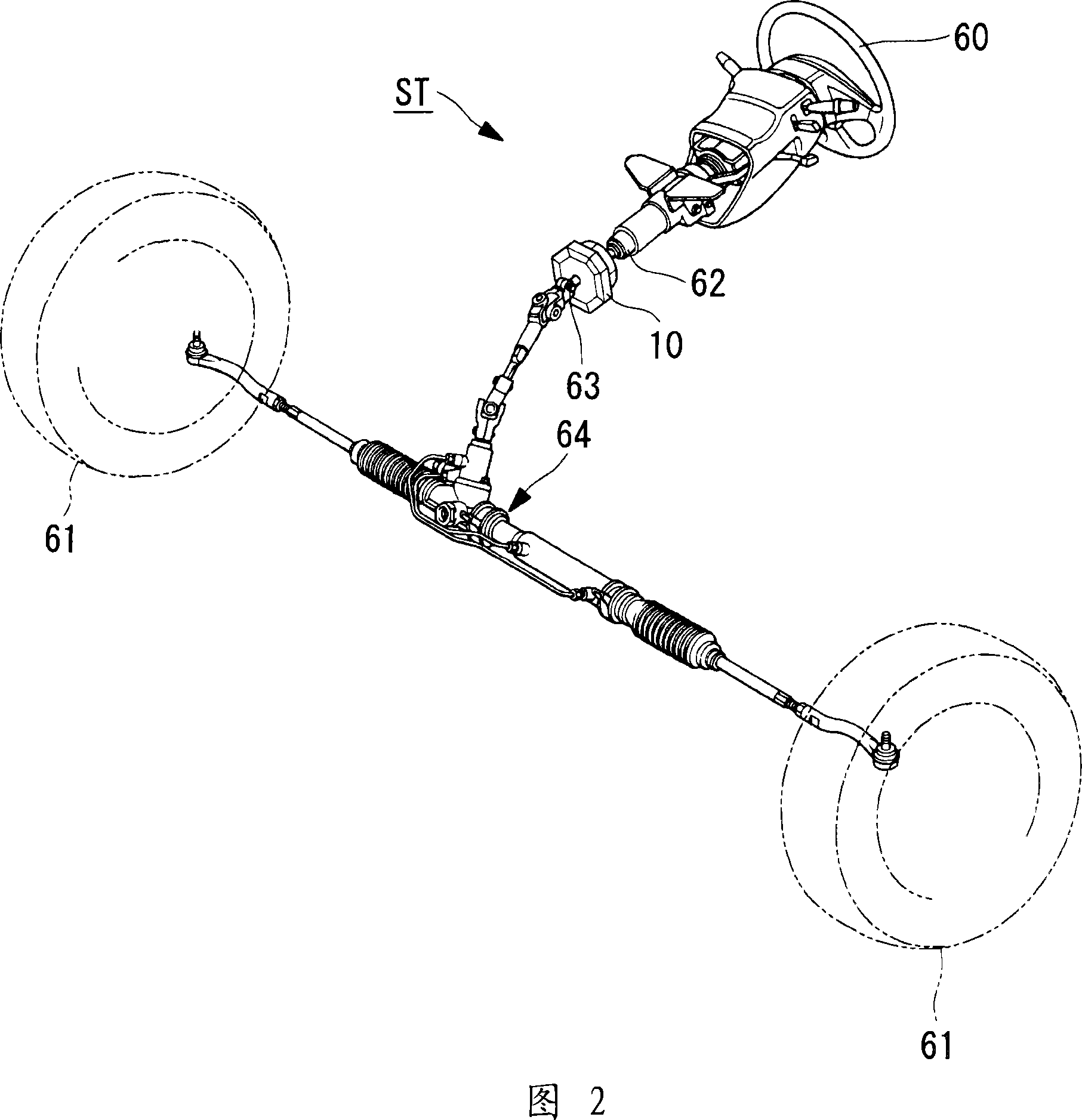

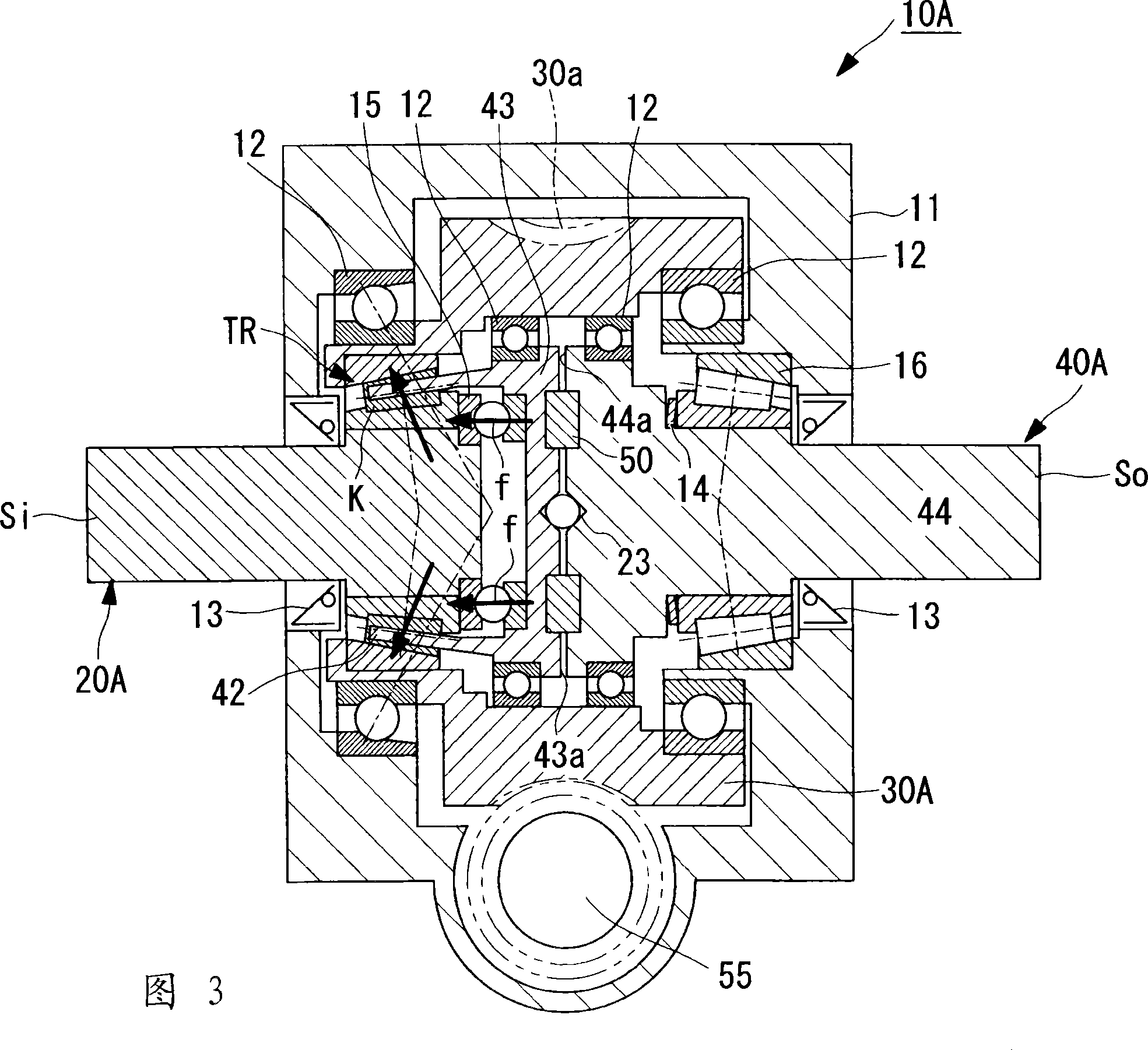

Torque transmission structure, traction drive transmission device, and steering device for vehicle

InactiveCN101006293AAdjust gear ratioIncrease high torque outputFriction gearingsTorque transmissionCam

The invention provides a variable-speed traction drive transmission device compact and having high durability. The traction drive transmission device (10) varies, by the use of traction of rolling bodies (K) arranged between an input shaft (Si) and an output shaft (So), the speed of rotation of the input shaft (Si) into a desired transmission ratio to output the result by the output shaft (So). The traction drive transmission device (10) is placed inclined so that the rotation axes of the rolling bodies (K) are not orthogonal to the axes of the input shaft (Si) and the output shaft (So), and has a load regulation cam (50) and a transmission ratio variation mechanism of a differential type using a worm gear (55). The load regulation cam (50) automatically varies a preload applied to the rolling bodies (K) according to torque of the input shaft (Si). The transmission ratio variation mechanism is connected to a retainer (40) as the traction input-output member of the rolling bodies (K) and varies a transmission ratio by controlling the speed of rotation of the retainer (40).

Owner:MITSUBISHI HEAVY IND LTD

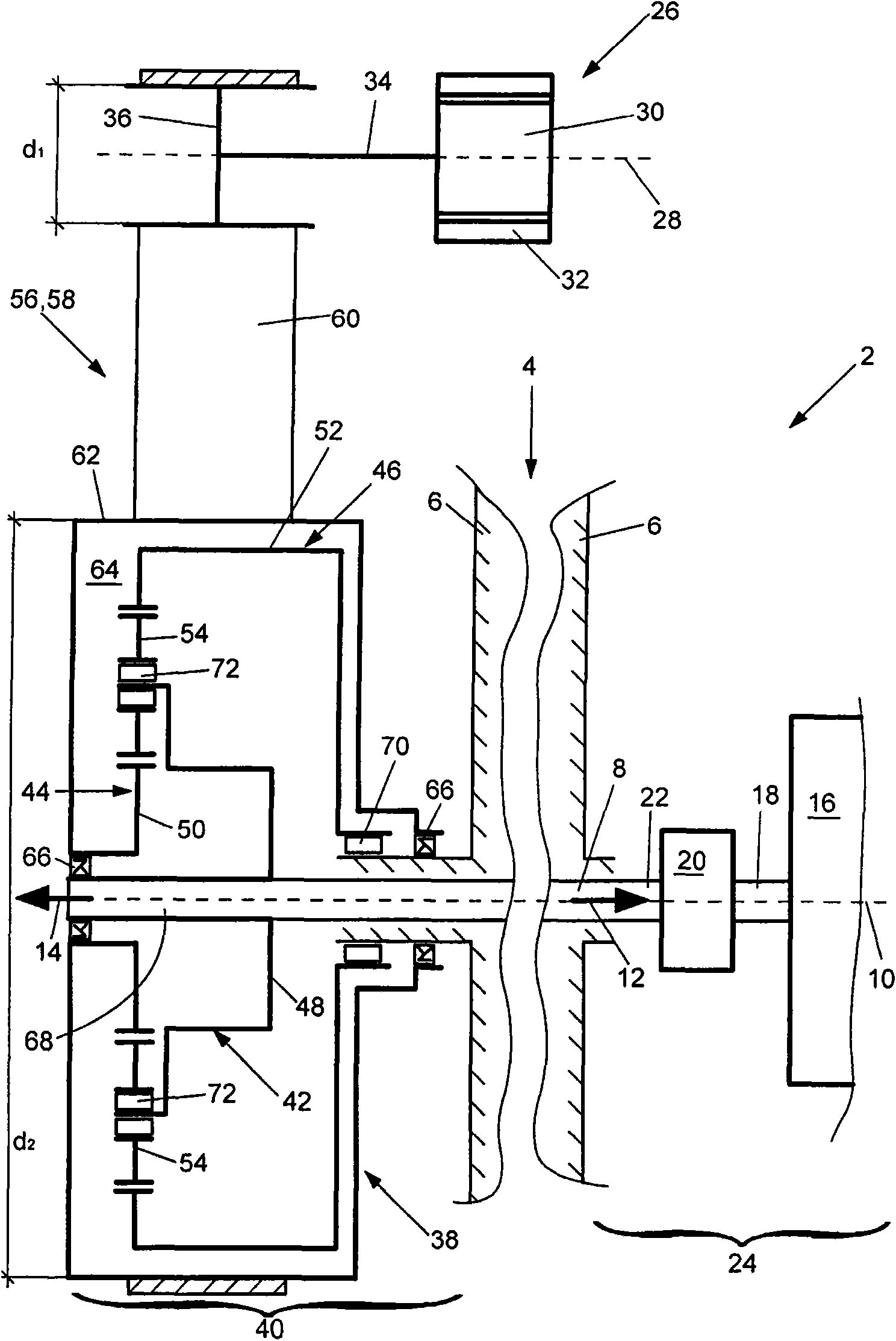

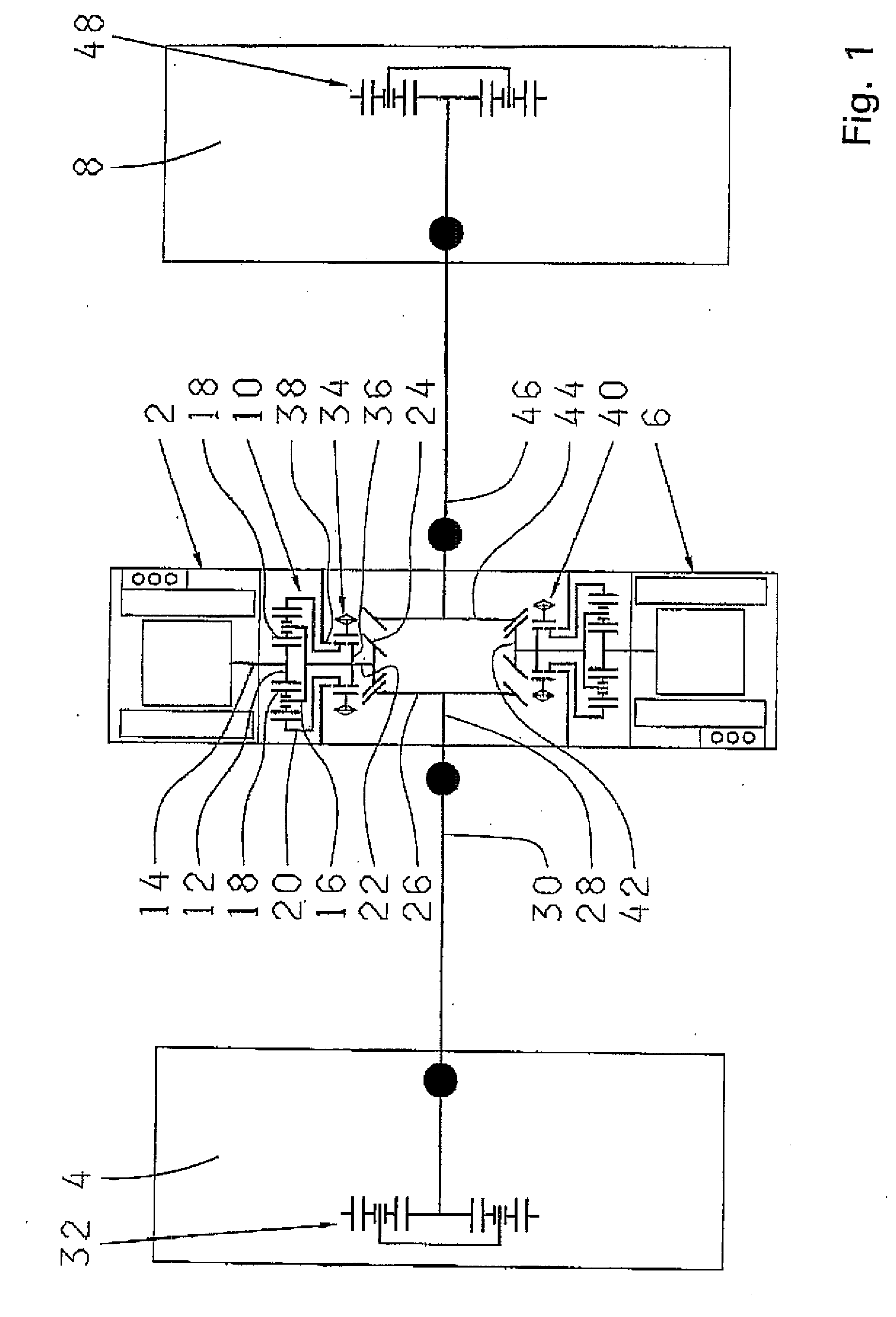

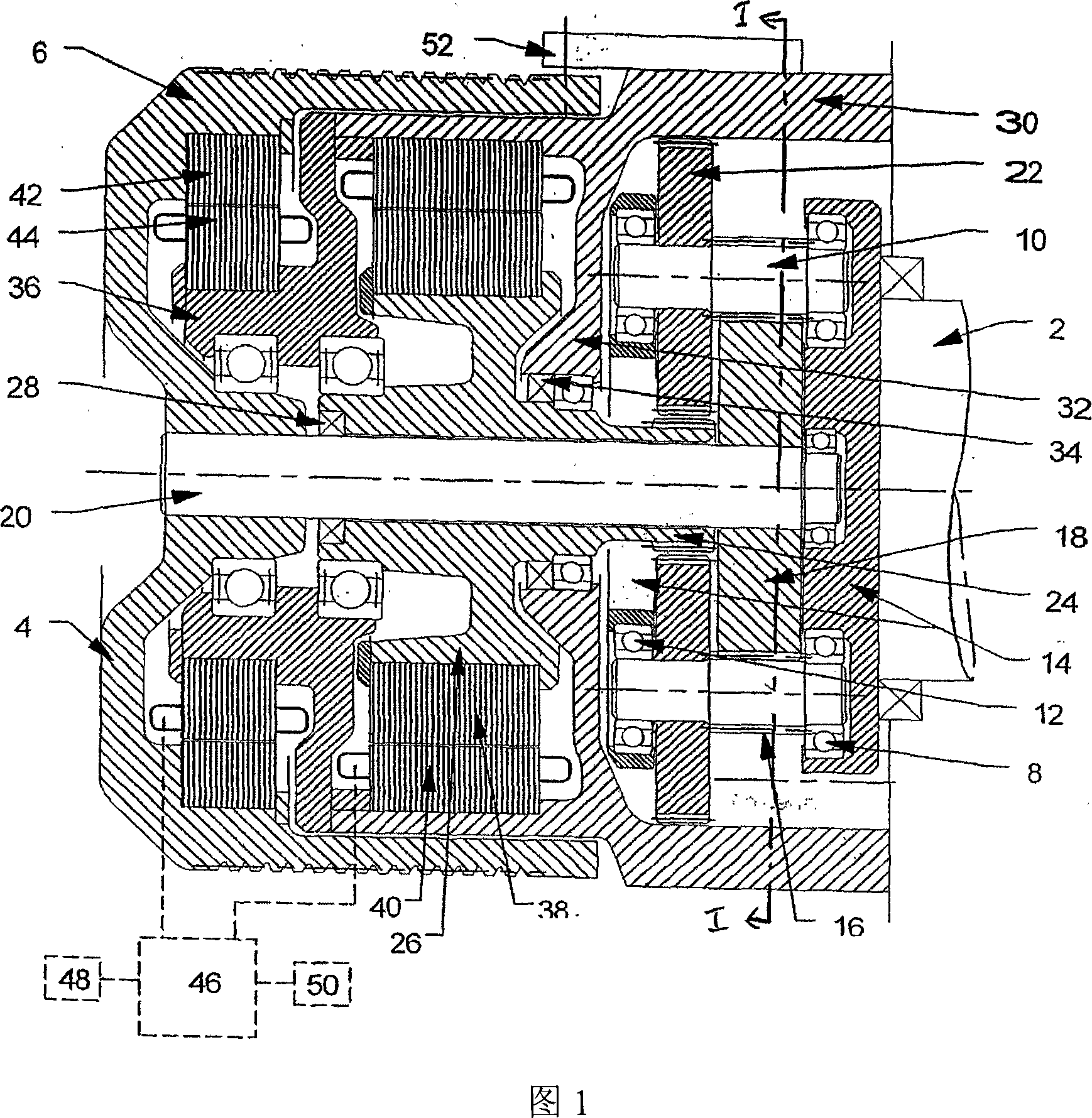

Drive pulleys

InactiveCN1973116ASmall diameterSimple designMechanical energy handlingEngine cooling apparatusCommon carrierEngineering

A drive pulley for a cooling pump or the like of an .engine includes an input (14) for connection to the engine and an output comprising a hollow cylindrical member (4), whose outer surface (6) constitutes a pulley belt engagement surface. The input and output are connected by a transmission system comprising an epicyclic gearset including two or more first planet gears (16), which are connected to respective planet shafts (10) to rotate about the axis thereof and are in mesh with a first sun gear (18). The gearset also includes two or more second planet gears (22), which are connected to rotate with respective first planet gears (16) and are in mesh with a second sun gear (24). The planet shafts (10) are connected to a common carrier (14) which constitutes the input. The first sun gear (18) is connected to the output (4). The transmission system further includes two electric motor / generators (38, 40; 42, 44), the rotors (38, 42) of which are connected to the second sun gear (24) and the output(4), respectively, and the electrical stator connections of which are connected to a controller (46) arranged selectively to control the flow of electrical power between them. The transmission system is at least partially accommodated within the hollow cylindrical member (4).

Owner:NEXXTDRIVE LTD

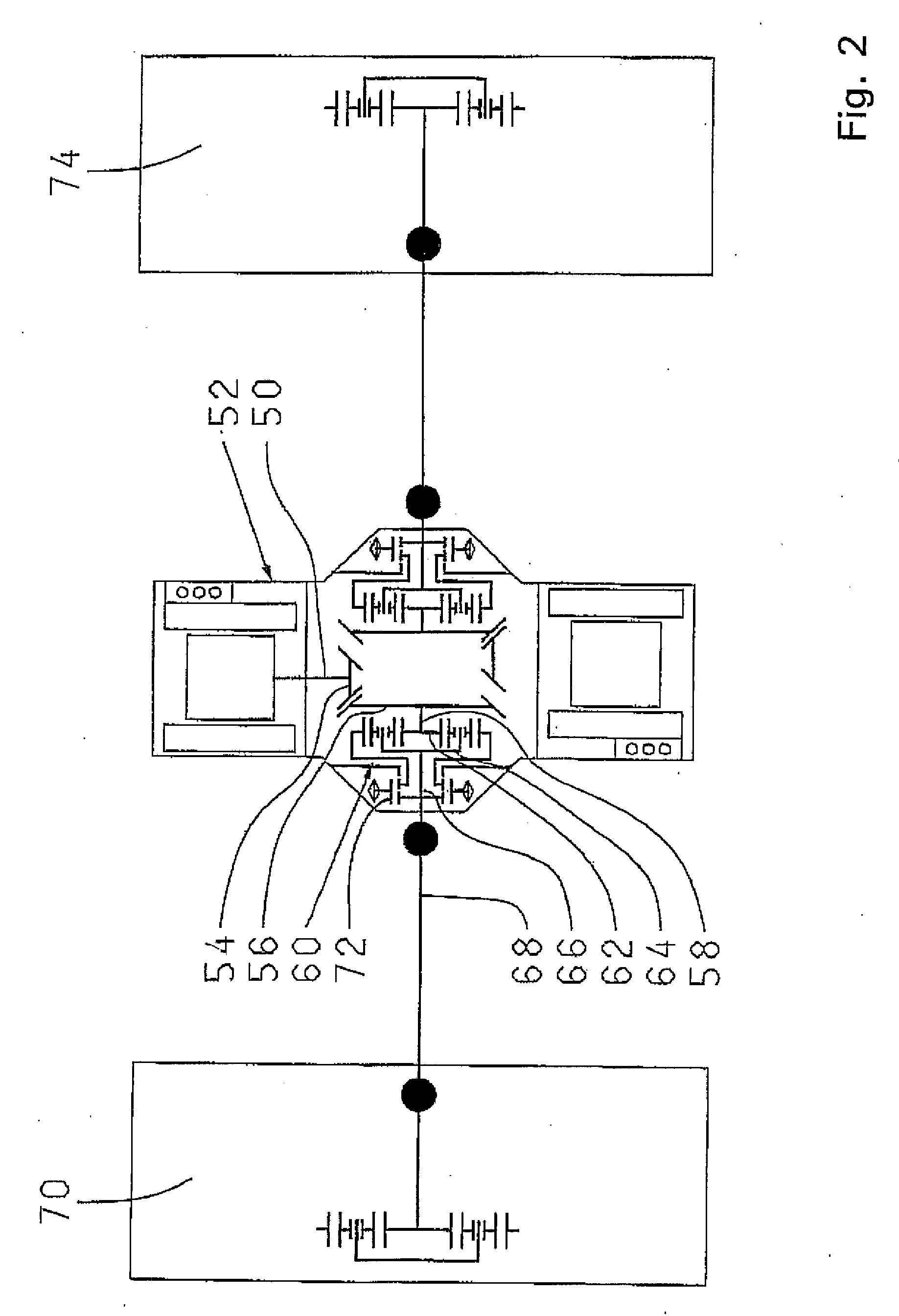

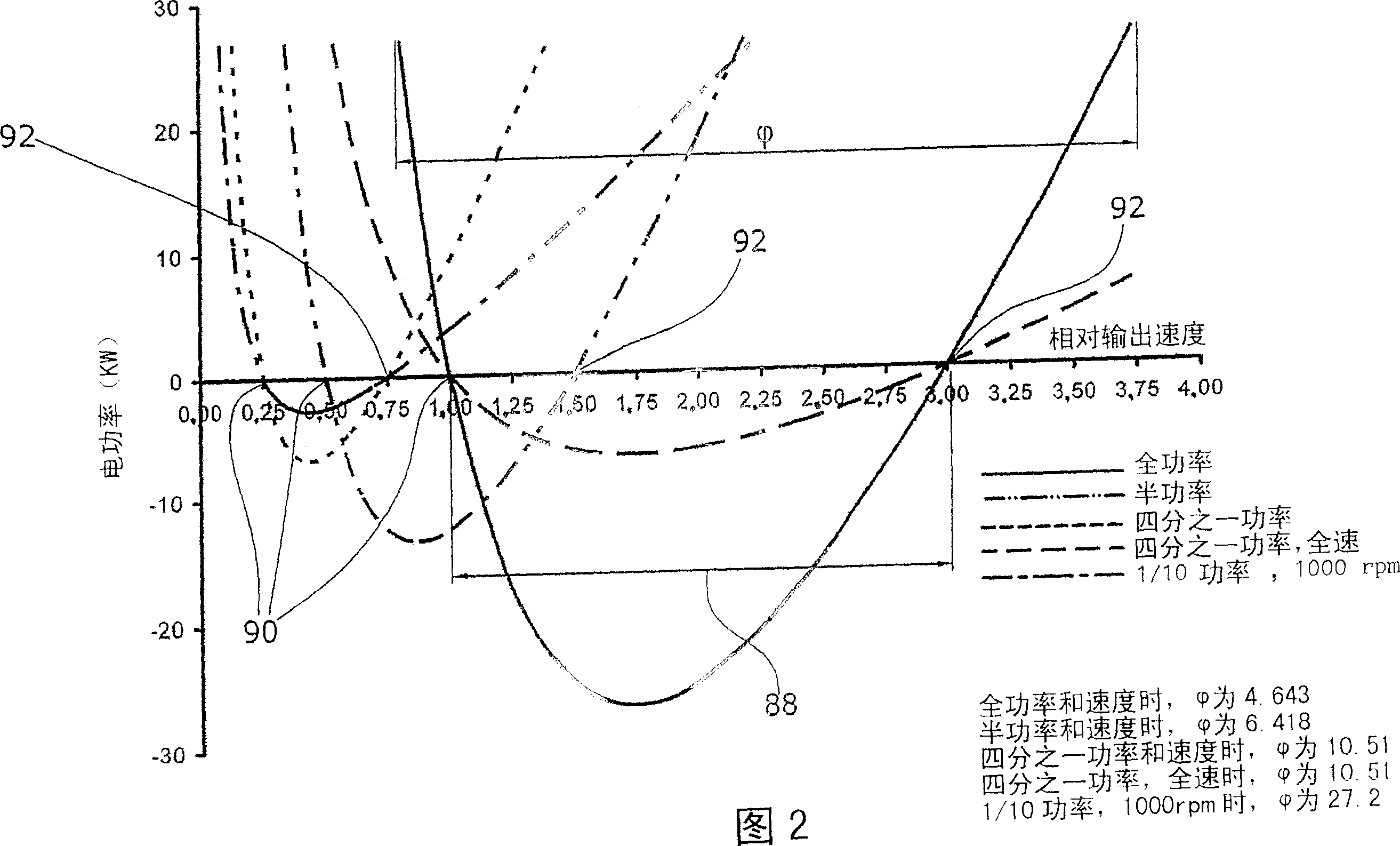

Four branch differential transmission systems.

InactiveCN1768212AReduce usageSmall diameterRailway vehiclesToothed gearingsGear wheelDifferential transmission

The four branch differential Transmission System, ("FBD"), comprises a first input shaft and a second output shaft. Furthermore there are third and fourth shafts which are respectively connected to first and second variators which control the speed (or torque) of the shaft, to which they are connected. Each variator can, for instance, be an electric motor which can adjust the speed of these shafts. The four shafts (branches) of the FBD are connected directly or indirectly via gears. The FBD comprises spur gear planetary gearsets. There is no requirement for a ring gear. The FBD includes two planetary gearsets using several spur gear suns and planets, which form a combination of a plus planetary gearset and a minus planetary gearset.

Owner:ALVI AUTOMOTIVE ENG TECH CO LTD

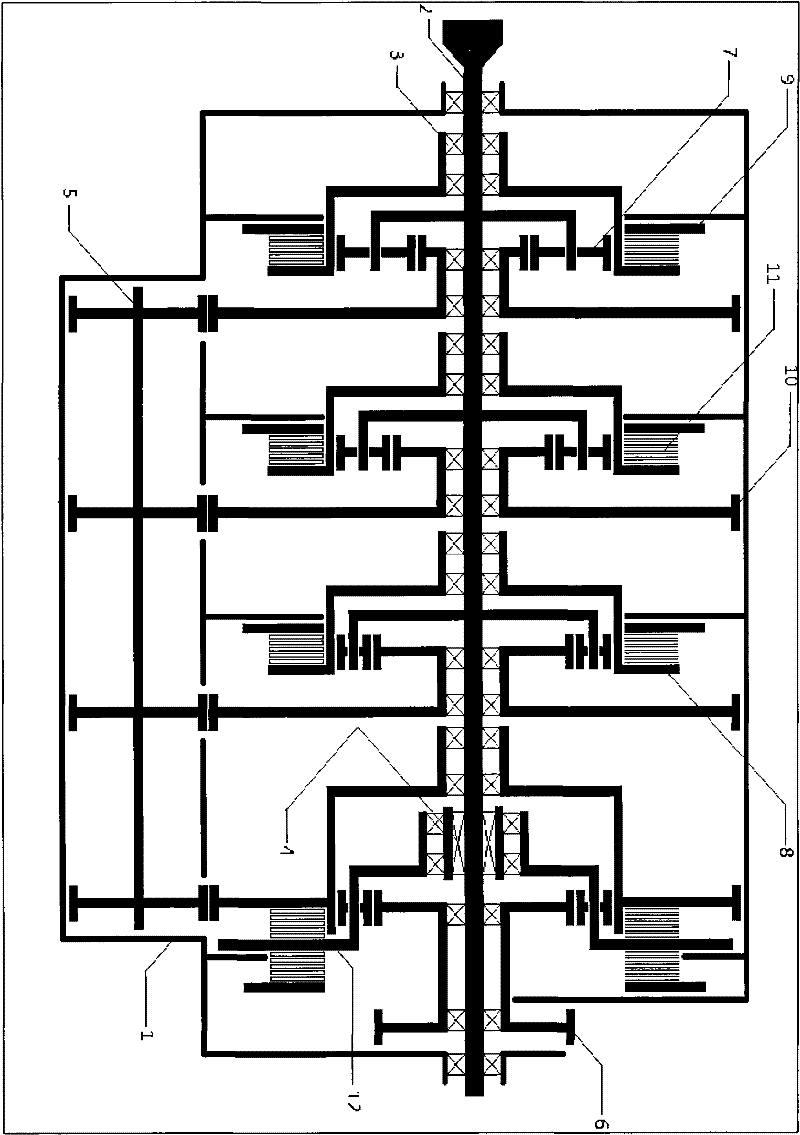

Modularized full-meshed brake type transmission

InactiveCN102128238AImprove structural rigidityCompact structureToothed gearingsGearing controlGear trainControl theory

The invention relates to a modularized full-meshed brake type transmission which is composed of planet gear trains with different transmission ratios and a forth and back controller; power transmitted from a motor is controlled by the forth and back controller so as to be output in a positive and negative rotation mode; all downstream planet gear trains are driven simultaneously by the output power; in the downstream planet gear trains, if gear rings are braked and the power is output from a planet frame; and if the gear rings are not braked, and the idling running is carried out. Through controlling the braking of the gear rings in the planet gear trains with different transmission ratios, the transmission purpose of variable moment and variable speed is achieved.

Owner:黄骐

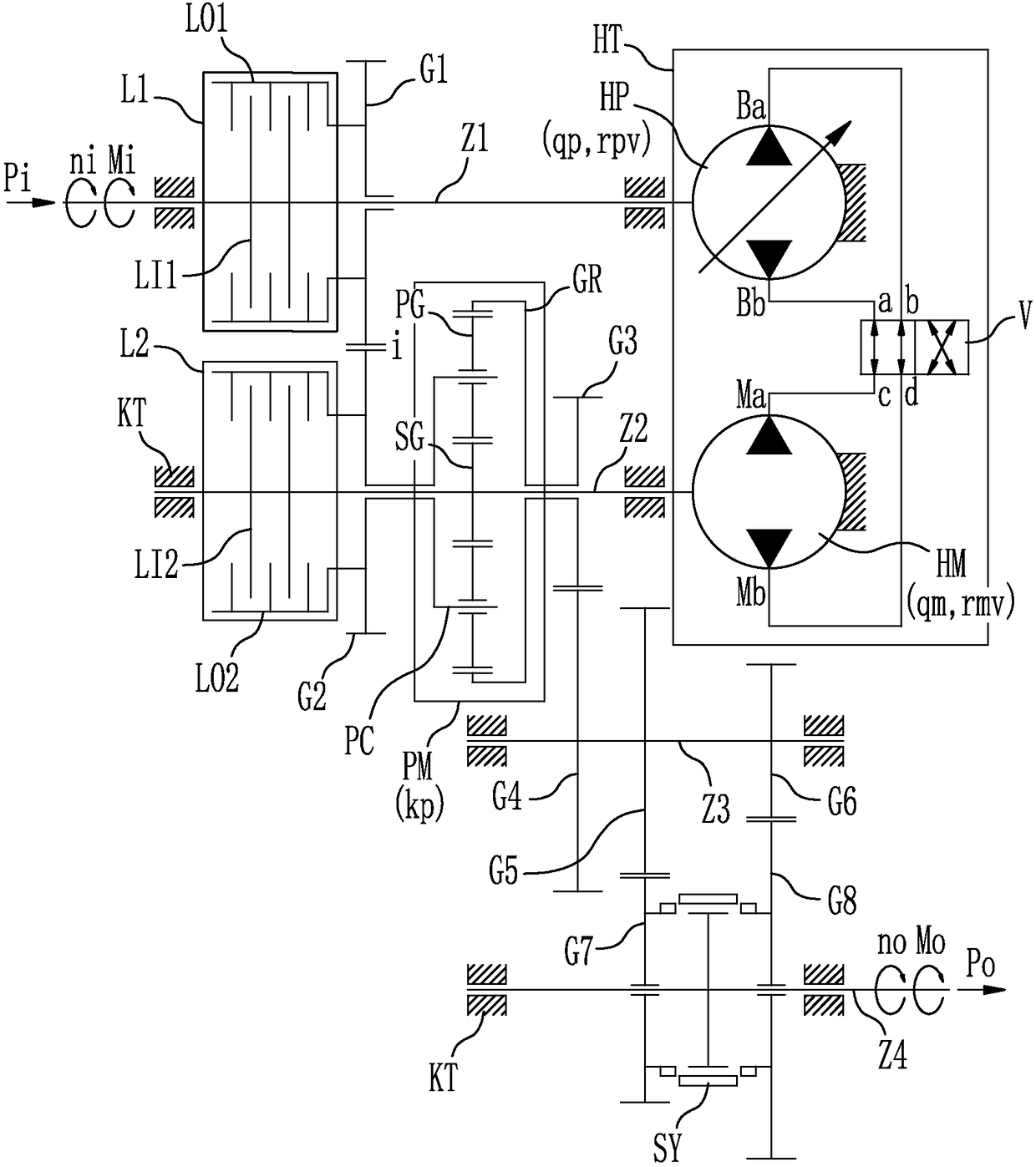

Transmission system capable of achieving three variable transmission processes

ActiveCN108591411AAdapt to variable speed transmission needsMeet variable speed transmission needsFluid gearingsHydraulic pumpMechanical equipment

A transmission system capable of achieving three variable transmission processes comprises an input shaft, a sun gear shaft, an input gear, a linkage gear, an intermediate driving gear, a first clutch, a second clutch, a planetary mechanism, a hydraulic pump and a hydraulic motor. The input shaft and the sun gear shaft are arranged in parallel. The input gear is meshed with the linkage gear. The input end of the first clutch is in transmission connection with the input shaft. The driven end of the first clutch is fixedly connected with the input gear. The input end of the second clutch is in transmission connection with the sun gear shaft, and the driven end of the second clutch is fixedly connected with the linkage gear. A sun gear in the planetary mechanism is fixedly connected with thesun gear shaft. A tooth ring is fixedly connected with the intermediate driving gear. A planet carrier is fixedly connected with the linkage gear. A rotor of the hydraulic pump is fixedly connected with the input shaft. A rotor of the hydraulic motor is fixedly connected with the sun gear shaft. The hydraulic pump and the hydraulic motor are connected into an oil supply loop in series. The transmission system capable of achieving the three variable transmission processes enables the variable-speed transmission process to both have the features of mechanical transmission and hydraulic transmission, and therefore the transmission system capable of achieving the three variable-speed transmission processes can meet the variable transmission needs of different types of mechanical equipment.

Owner:HEFEI UNIV OF TECH +1

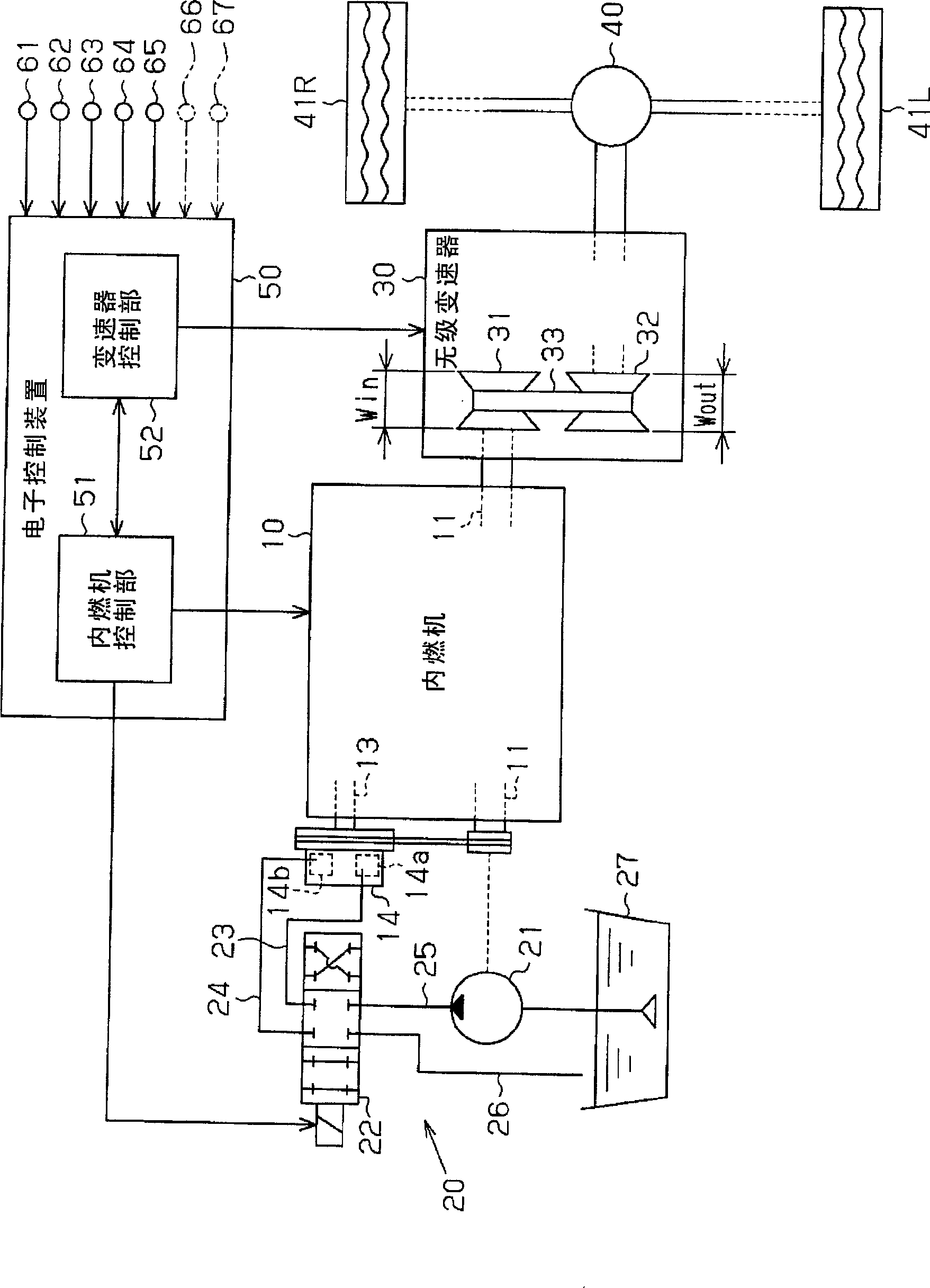

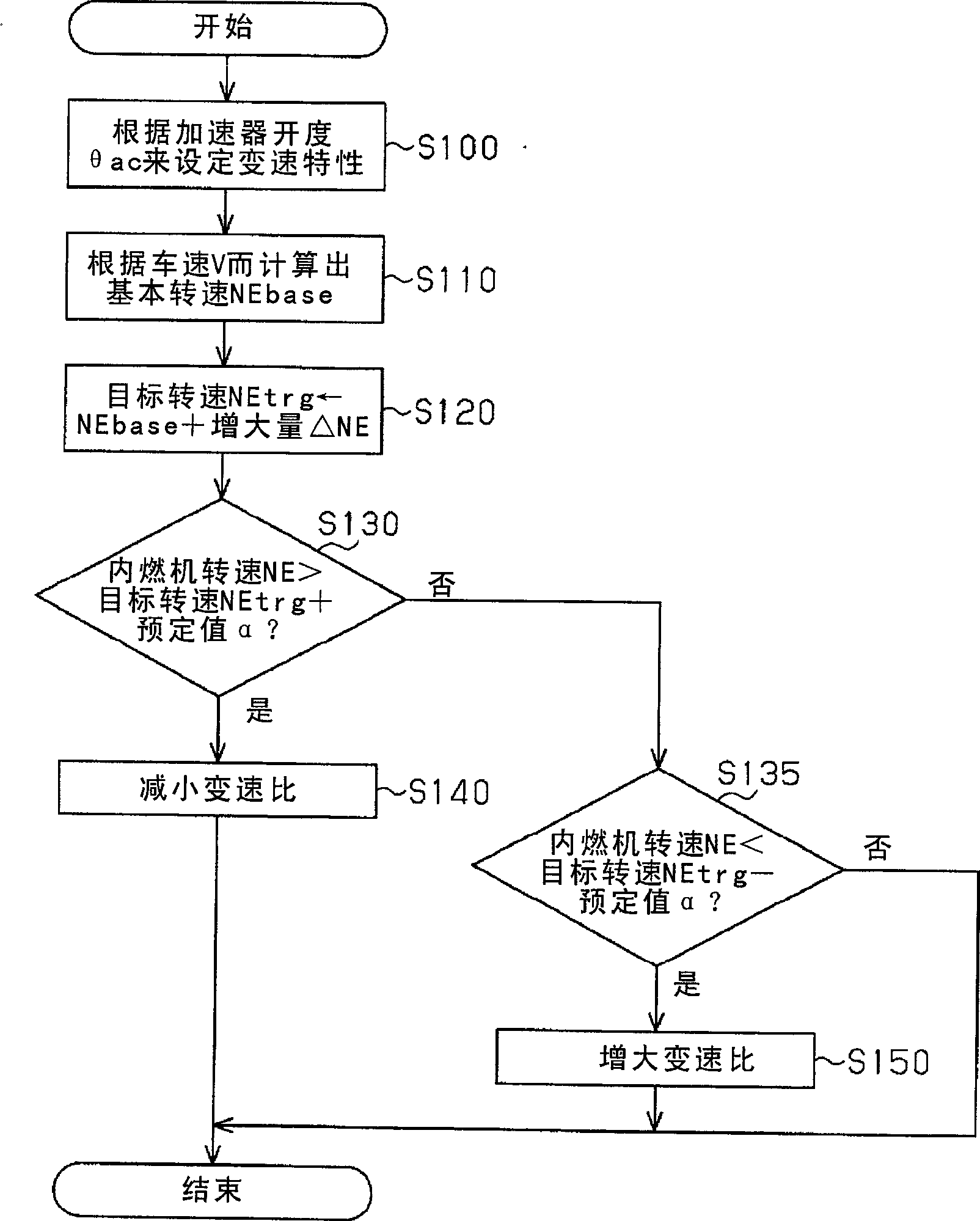

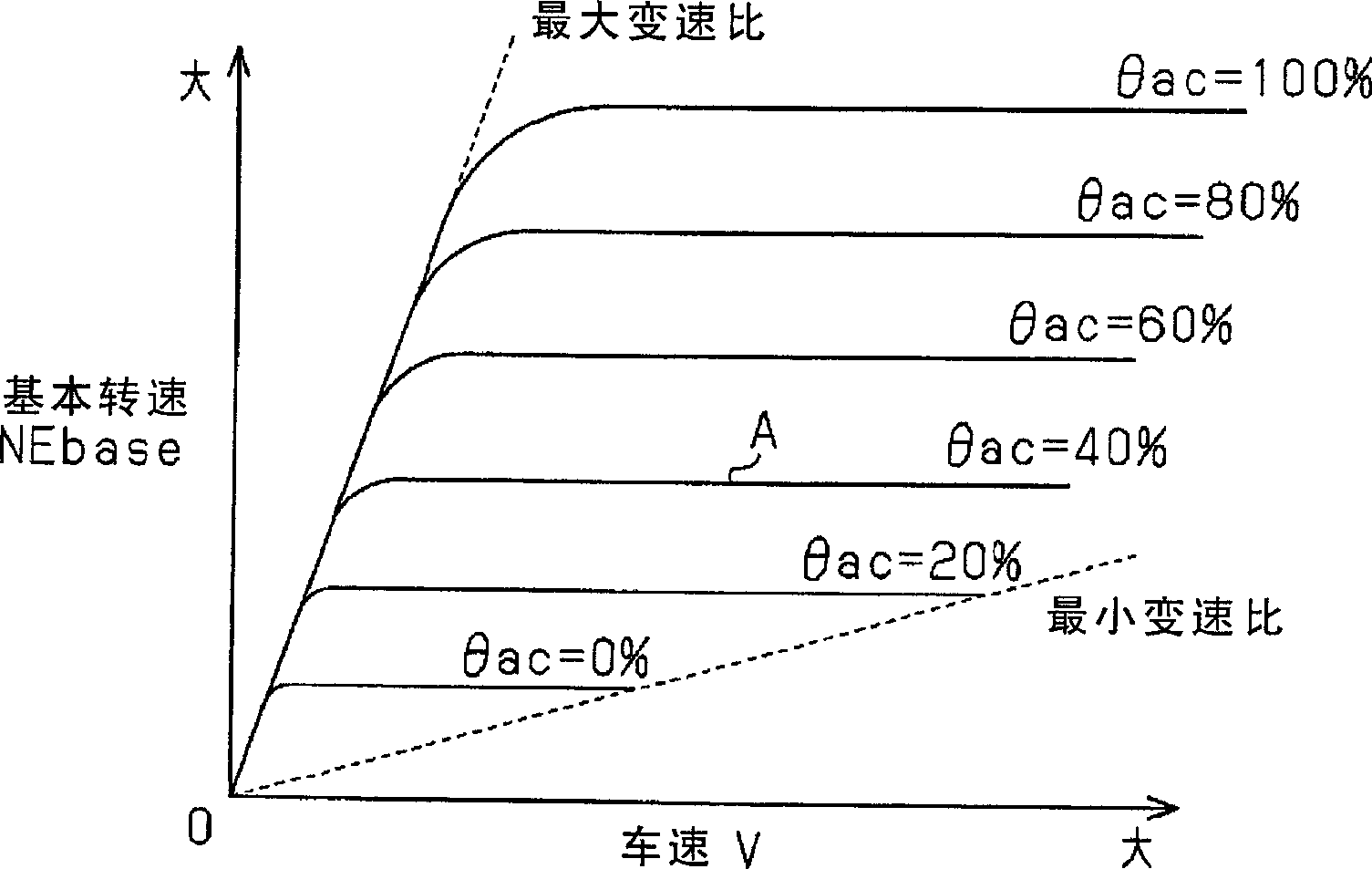

Vehicle controller

InactiveCN101501369AIncrease speedChange gear ratioAuxillary drivesElectrical controlInternal combustion engineHydraulic pressure

Owner:TOYOTA JIDOSHA KK

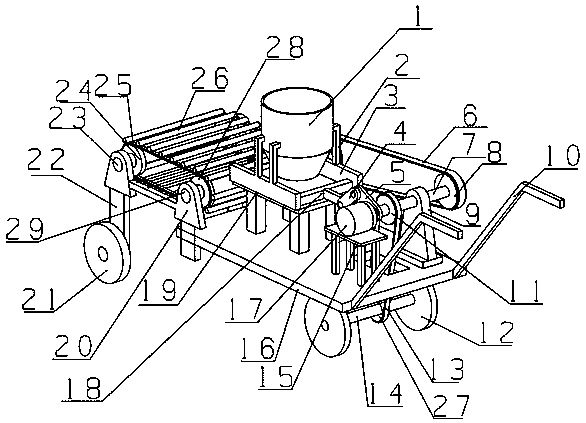

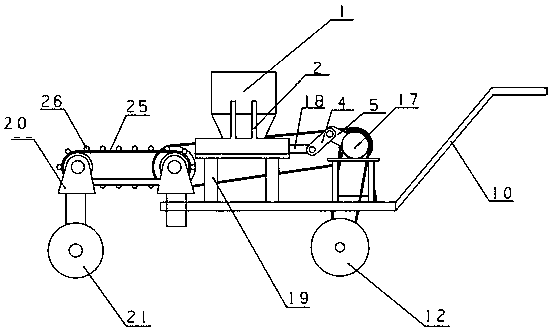

Pine needle laying device special for radix notoginseng

PendingCN108293535AGuaranteed uniformityRealize laying mechanizationPlant protective coveringsElectric machineryEngineering

The invention relates to a pine needle laying device special for radix notoginseng, belonging to the technical field of agricultural product processing machinery and equipment. The pine needle layingdevice includes a running mechanism, a pushing mechanism and a laying mechanism. The running mechanism includes a motor, an output shaft, a pulley II, a belt II, a pulley IV, a fixed shaft, a rear wheel, a supporting frame II, a supporting plate, a bearing block I, a front wheel, a supporting frame III, a handle and a bearing block II. The pushing mechanism includes a storage box, a supporting rod, a sliding groove, a connecting rod I, a connecting rod II, a supporting frame I and a push rod. The laying mechanism includes a pulley I, a belt I, a pulley III , a rotating shaft I, a chain wheel I, a chain, a fixed rod, a rotating shaft II, a rotating shaft I, a chain wheel II and a bearing support. According to the pine needle laying device, pine needles in the storage box are pushed to the laying mechanism through the pushing mechanism; the laying mechanism can lay the pine needles on the ground of a radix notoginseng planting area under the driving of the motor, and the pine needle laying device is further provided with the running mechanism driven by the motor, which can greatly reduce labor.

Owner:KUNMING UNIV OF SCI & TECH

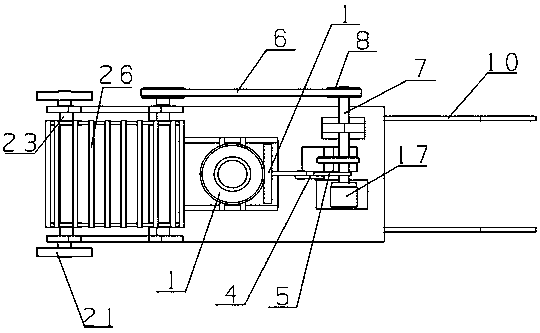

Speed changing device capable of adjusting feeding length

The invention discloses a speed changing device capable of adjusting feeding length. The speed changing device comprises a cam transmission shaft, a power shaft and a sliding shaft, wherein a speed changing chain wheel is mounted on the cam transmission shaft; a multistage speed changing chain wheel is mounted on the power shaft; an adjusting chain wheel is mounted on the sliding shaft; the sliding shaft is mounted on a control panel and is connected to one end of a compression spring; the other end of the compression spring is fixed on the control panel; one end of an adjusting screw rod is fixed on the control panel; an L-shaped rocking handle is mounted at the other end of the adjusting screw rod. Through the speed changing device capable of adjusting the feeding length, the control panel moves forth and back so as to drive the adjusting chain wheel mounted on the speed changing control panel to translate forth and back; the translation of the adjusting chain wheel enables the chain to be engaged with chain wheels with different diameters on the multistage speed changing chain wheel, so that the transmission ratio of the device is changed, thus the speed changing function of the device is achieved.

Owner:CHINA THREE GORGES UNIV

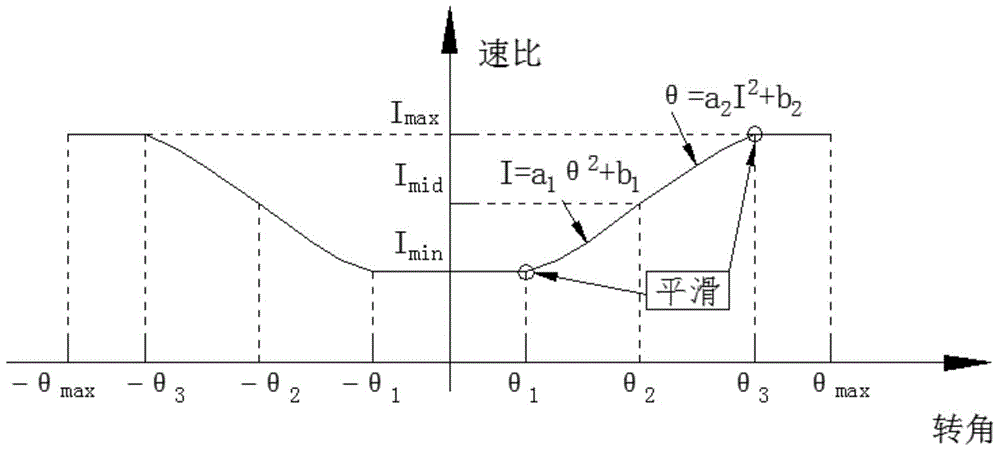

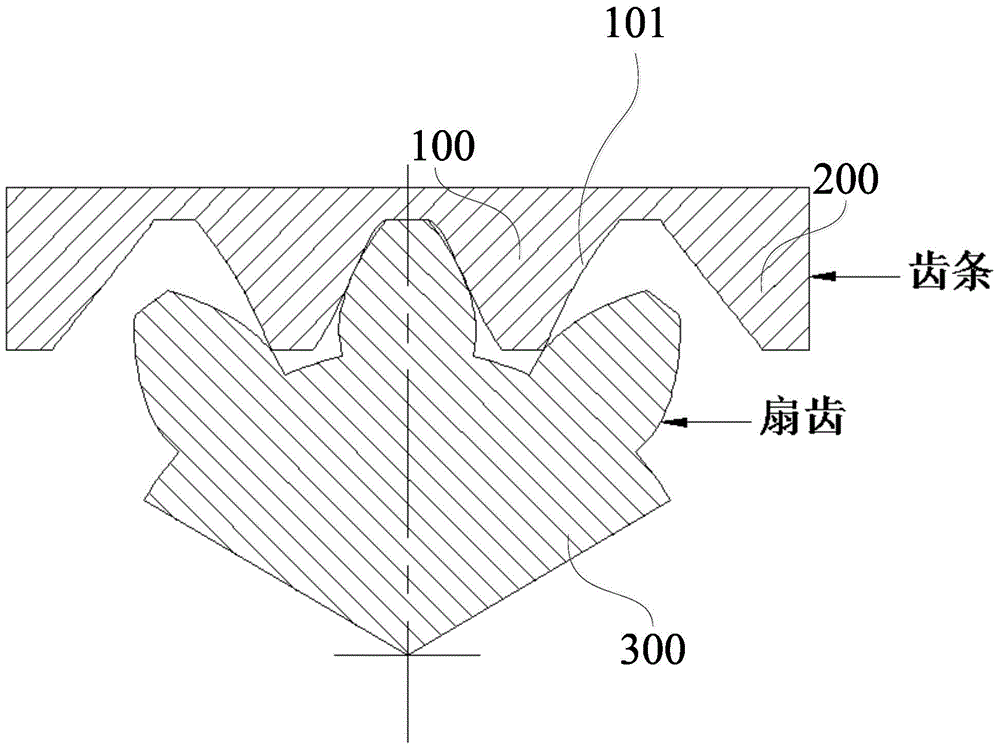

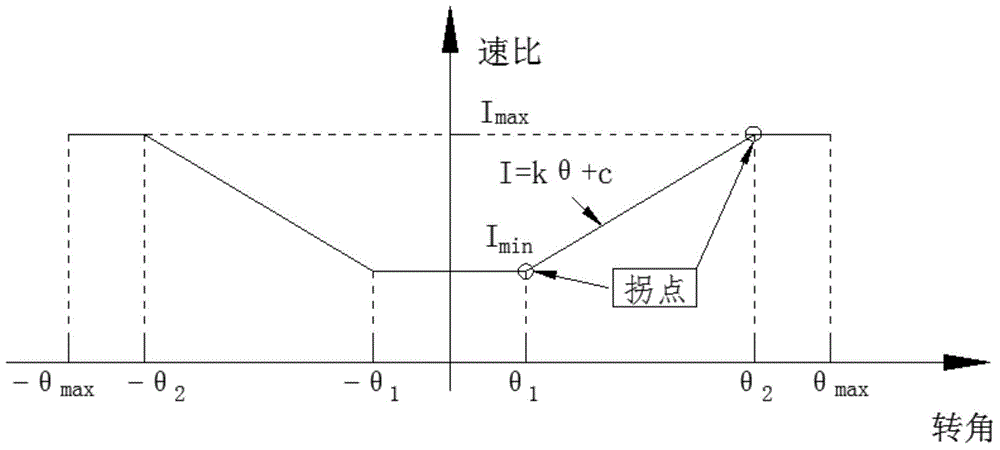

Variable ratio rack and power steering gear

The invention relates to a power steering component of a motor vehicle, and discloses a variable ratio rack. The rack at least comprises gear teeth I and gear teeth II adjacent to the gear teeth I, wherein the gear teeth I and the gear teeth II have different transmission gear ratios Imin and Imax with a gear engaged with the gear teeth I and the gear teeth I respectively; tooth surfaces, close to the gear teeth II, of the gear teeth I have such a tooth surface shape that the variable ratio rack and the gear can be in smooth transition in a change interval {Imin, Imax} of a transmission gear ratio I; the radial sections of the tooth surfaces are envelope lines which are obtained by moving the gear relative to the variable ratio rack according to a motion trail X. The variable ratio rack and the power steering gear have the advantages that the gear is in smooth transition between different transmission gear ratios and is stable in transmission and a blockage phenomenon in a variable ratio process can be eliminated better.

Owner:HANGZHOU SHIBAO AUTO STEERING GEAR

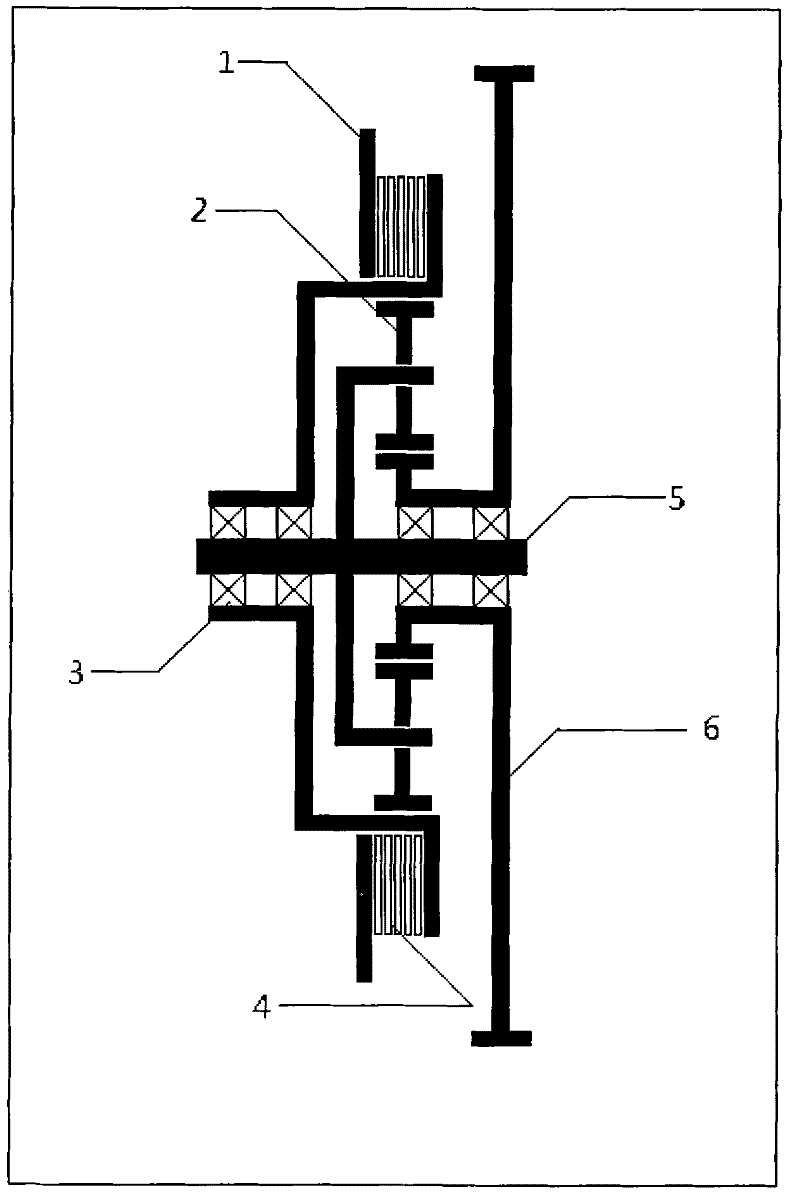

Continuously variable transmission and human body power generation device

ActiveCN110307317AChange gear ratioRealize stepless speed changeFrom muscle energyMachines/enginesEngineeringClutch

The invention relates to the technical field of human body power generation devices, and discloses a continuously variable transmission and a human body power generation device. The continuously variable transmission comprises an input shaft and an output shaft which are parallel to each other, and a first speed change mechanism which is arranged between the input shaft and the output shaft; the first speed change mechanism comprises a first overrunning clutch, a first friction wheel, a first biconical roller, a second friction wheel, a second overrunning clutch and a first speed regulating bracket; the locking directions of the first overrunning clutch and the second overrunning clutch are the same; the first biconical roller comprises a first cone wheel and a second cone wheel which arecoaxially connected; the input shaft sequentially passes through the first overrunning clutch, the first friction wheel, the first conical wheel, the second conical wheel and the second friction wheelto transmit rotation to the output shaft; and the first speed regulating bracket is used for driving the first biconical roller to translate. The human body power generation device using the continuously variable transmission can convert bidirectional swinging motion input of a human body into unidirectional rotating motion output, and can also realize continuously variable speed.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Mechanical automated double-station asynchronous feeding mechanism

The invention discloses a mechanical automated double-station asynchronous feeding mechanism, and relates to the technical field of feeding mechanisms. The feeding mechanism solves the problem that one machine can not be multipurpose due to the fact that a driving device needs to be added to drive a required conveyor belt independently when an existing feeding mechanism needs asynchronous feeding.The mechanical automated double-station asynchronous feeding mechanism comprises a primary speed regulating mechanism and a secondary speed regulating mechanism, wherein the primary speed regulatingmechanism consists of a driving motor, a speed regulating block and a power gear, and the secondary speed regulating mechanism consists of a transmission wheel set, a top transmission wheel, a bottomtransmission wheel, a speed regulating gear, a telescopic rack and an adjusting rod. According to the device, a single driving device can be used for driving a main conveyor belt and an auxiliary conveyor belt to rotate at different speeds to realize the function of asynchronous feeding, so that the power is saved and the waste of the driving device is reduced; and the mode of changing the feedingspeed of the device is realized by changing the gear ratio, the device is simple in structure, convenient to maintain, and the practicability of the device is improved.

Owner:赣州科帕机电自动化有限公司

Drive-by-wire independent steering operation device aiming at unilateral motor fault, and operation method of drive-by-wire independent steering operation device

InactiveCN106080754AChange gear ratioSufficient steering self-rescue capabilityMechanical steering gearsMechanical steeringClutchMotor shaft

The invention discloses a drive-by-wire independent steering operation device aiming at unilateral motor fault, and an operation method of the drive-by-wire independent steering operation device. The device comprises a steering motor, a clutch, a planetary gear, a variable-speed gear, a linkage shifting fork and a gear-rack transmission mechanism, wherein two ends of the clutch are respectively connected with a motor shaft of the steering motor and a gear shaft of a sun gear of the planetary gear; the linkage shifting fork is connected with a first combination sleeve, a second combination sleeve and a third combination sleeve; the first combination sleeve and the third combination sleeve are in sleeve connection with a fixed shaft, and the second combination sleeve is in sleeve connection with a gear shaft of a third gear; a first gear and a second gear sleeve the gear shaft of the third gear in an empty way, the first gear is meshed with a planet carrier gear, and the second gear is meshed with a gear ring of the planetary gear. After the device and the method are used, the steering motor with a certain stand-by power can provide enough steering force for two steering mechanisms in the case of failure by changing a transmission ratio, so that a vehicle provided with the faulted unilateral steering motor is enabled to have enough steering travel self-rescue ability.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com