Chained infinitely variable speed transmission gear

A transmission, continuously variable speed technology, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of unfixed chain pitch, total chain length is a variable, and flexible components have strict performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

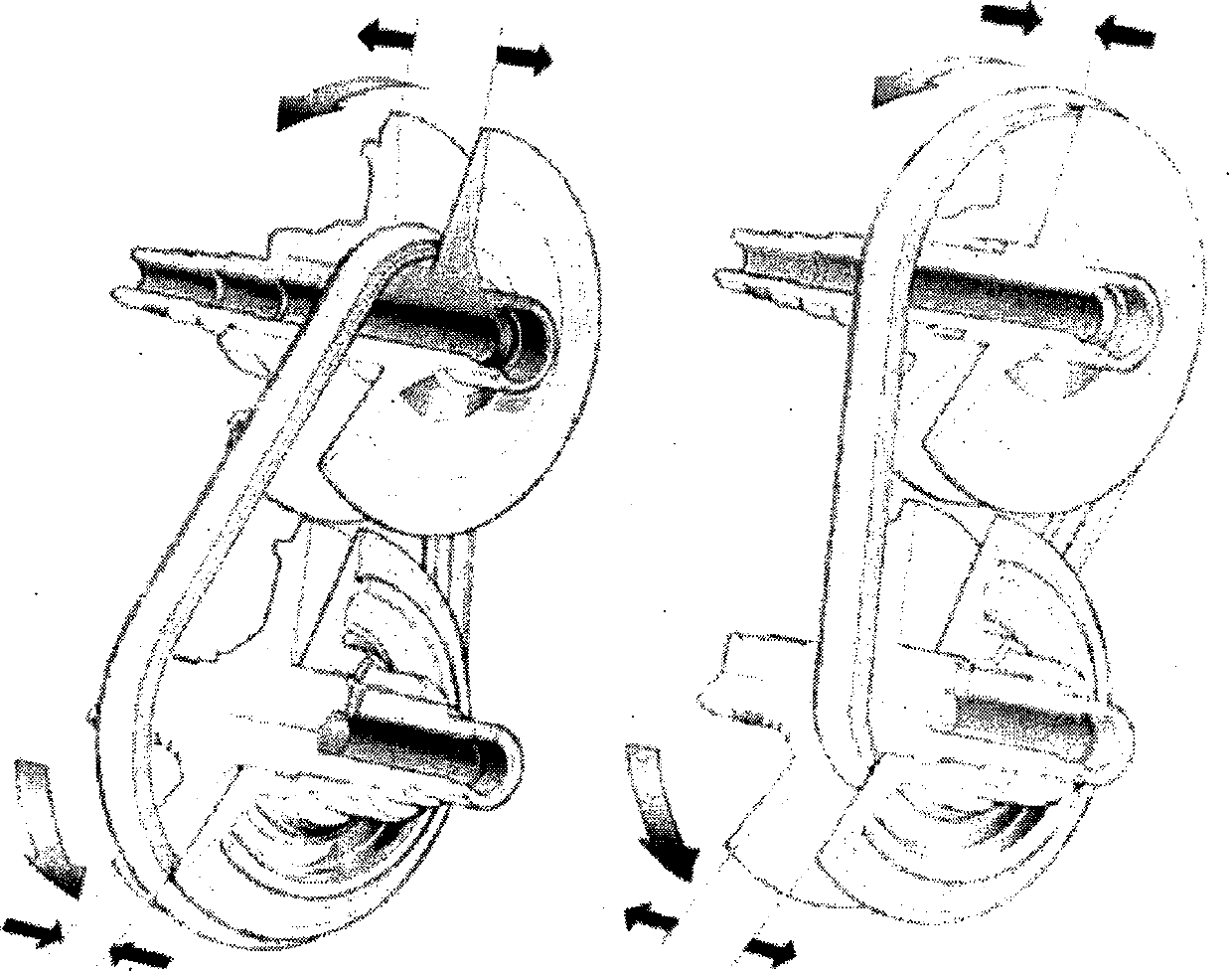

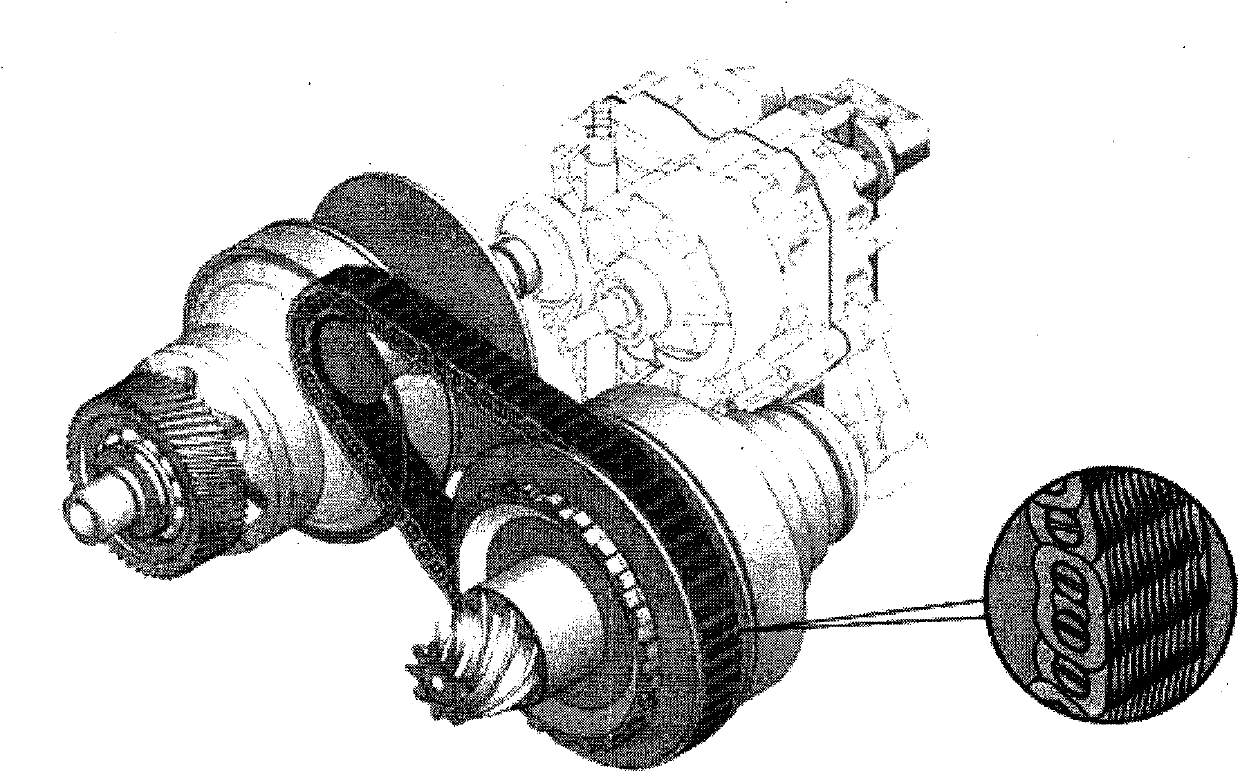

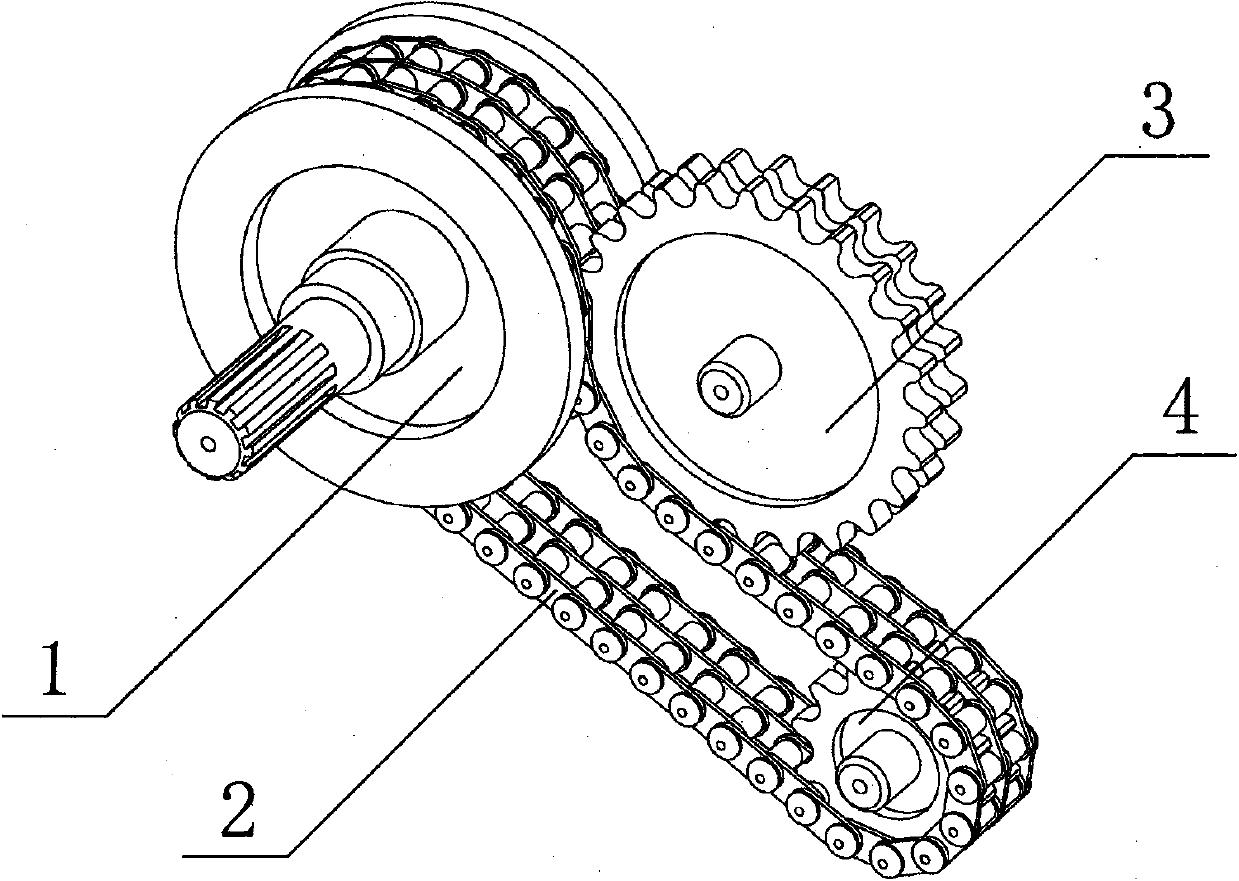

[0015] A kind of chain continuously variable speed transmission device described in the present invention can pass through the following mode ( Figure 4 , 5 6) Concrete implementation: take the friction cone wheel set (1) as the power input end as the driving wheel set, and introduce another set of passive friction cone wheel set (5) as the power output end at the same time, and the transmission chain (2) is tightened by The wheel (4) is tensioned and surrounds the friction cone wheel set (1) and the passive friction cone wheel set (5), and the friction cone wheel set (1) or the passive friction cone wheel set (5) and the transmission chain (2) The power is transmitted by friction force, wherein the friction cone wheel set (1) and the passive friction cone wheel set (5) are composed of two friction cone wheels installed opposite to each other on the same axis, and the two friction cone wheels move along the axis in the opposite direction. The effective working radius of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com