Patents

Literature

89 results about "Friction cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

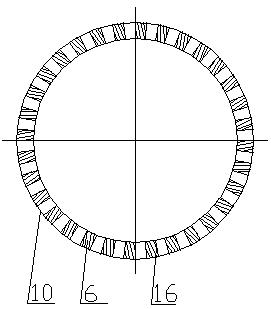

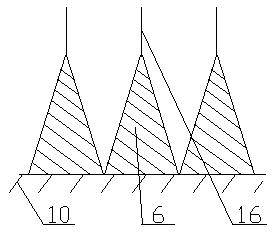

CONE OF FRICTION (FRICTION CONE) When applied force related at 360 degree about point of application total reaction (s) also rotates about the normal reaction and hence a cone is formed having semi-vertex angle equal to angle of friction.

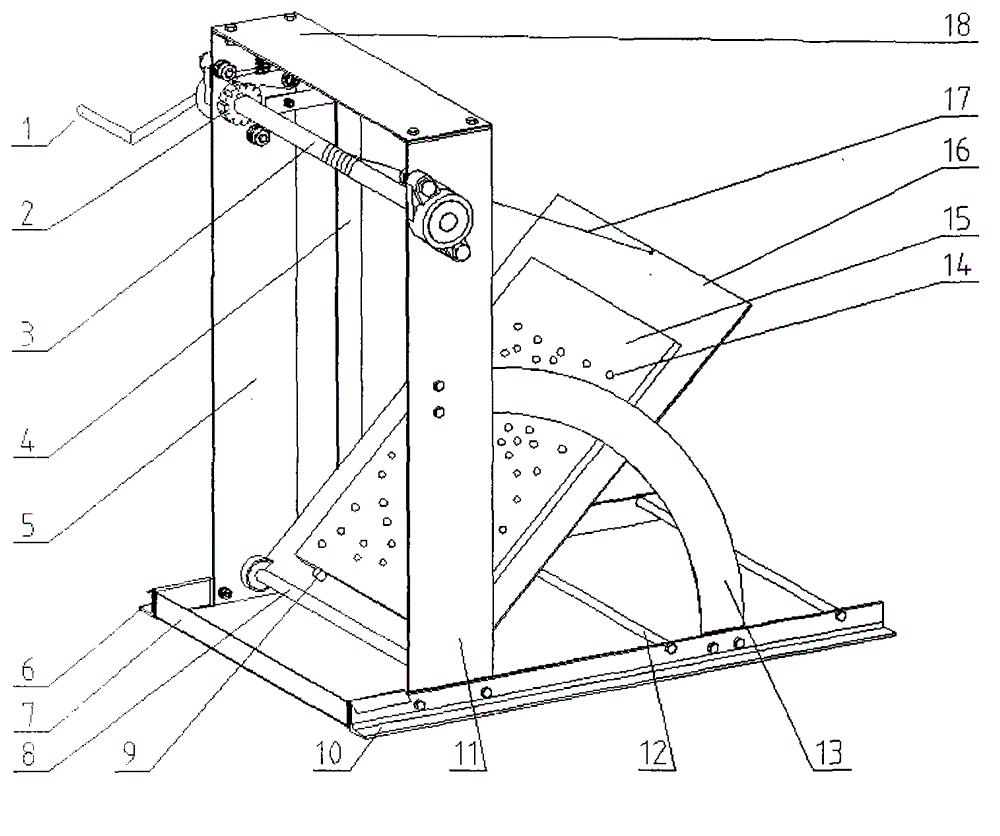

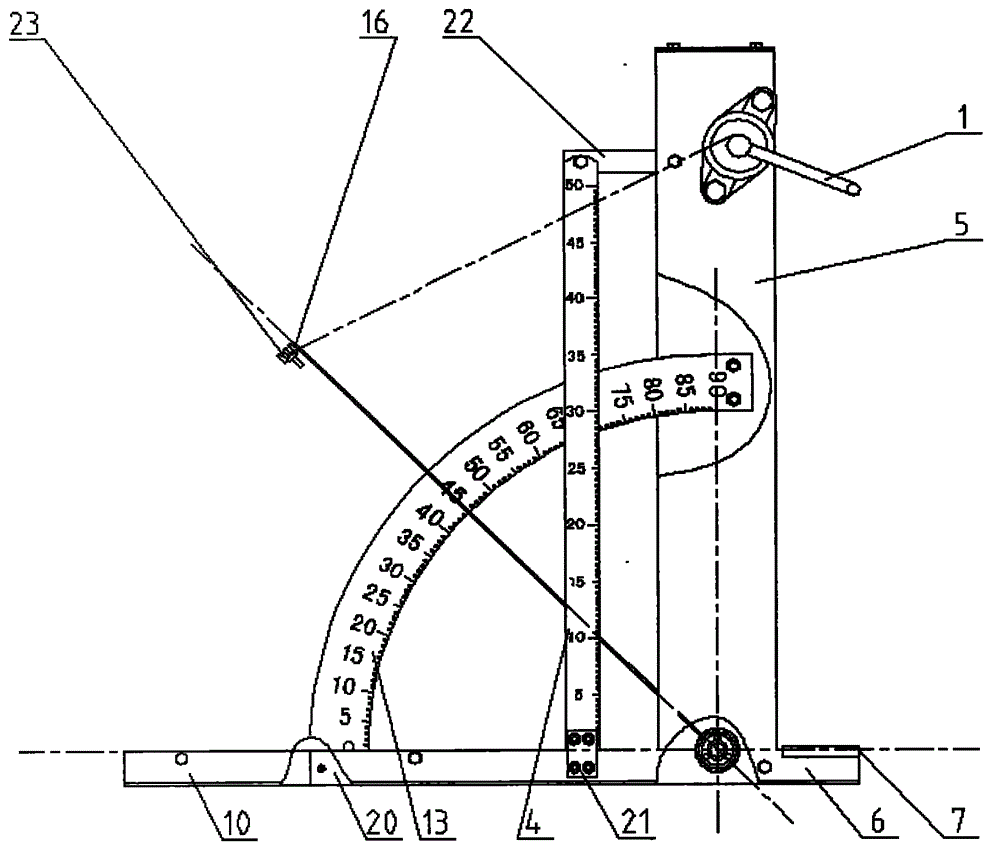

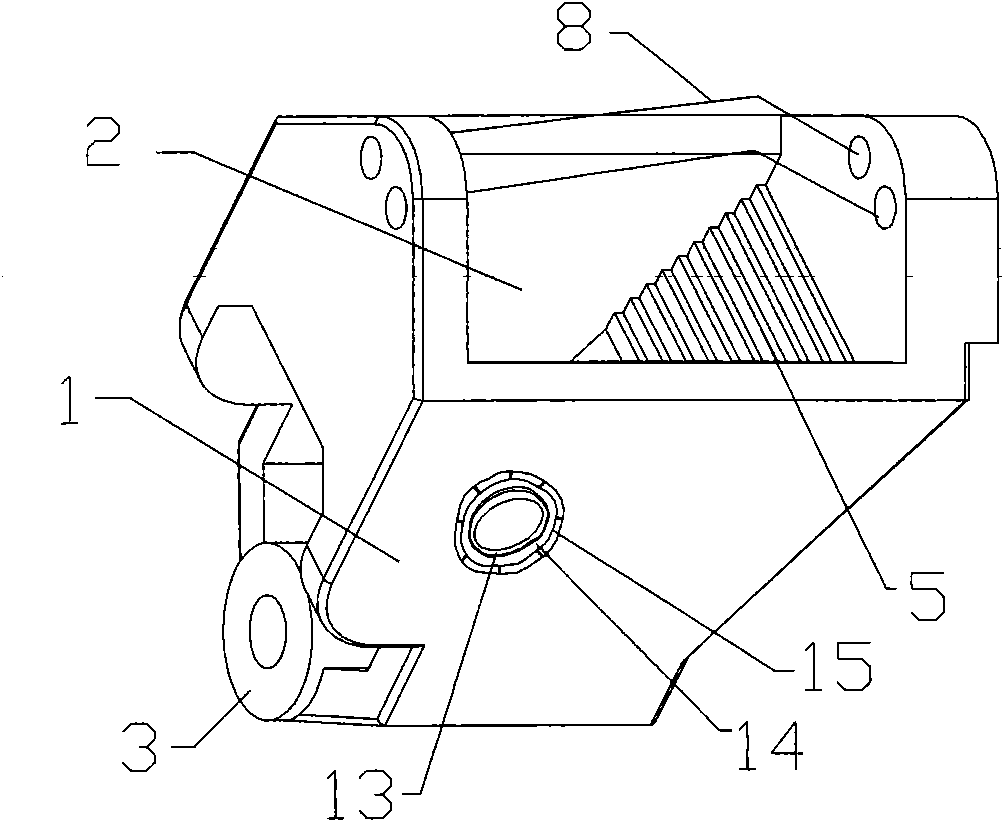

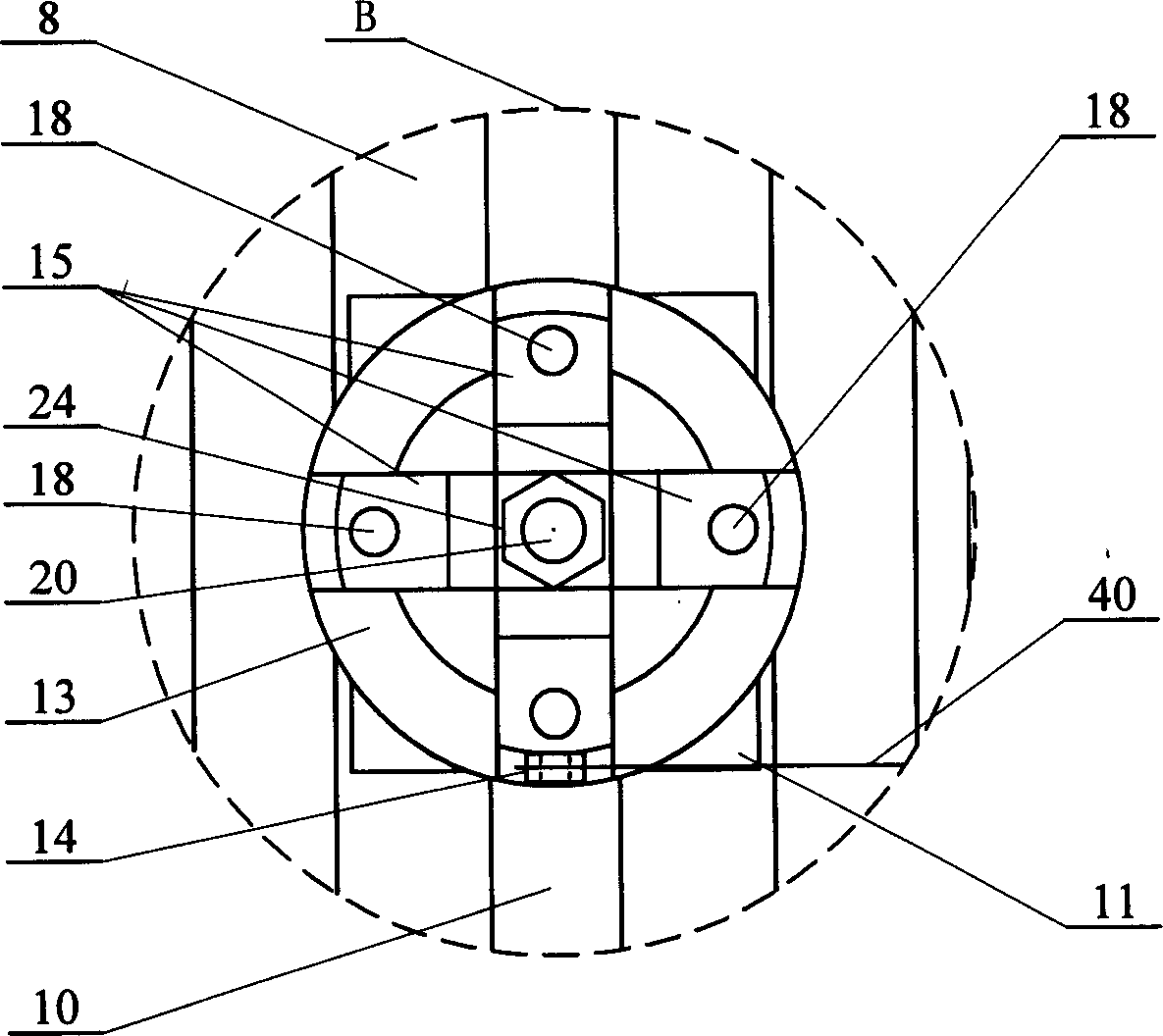

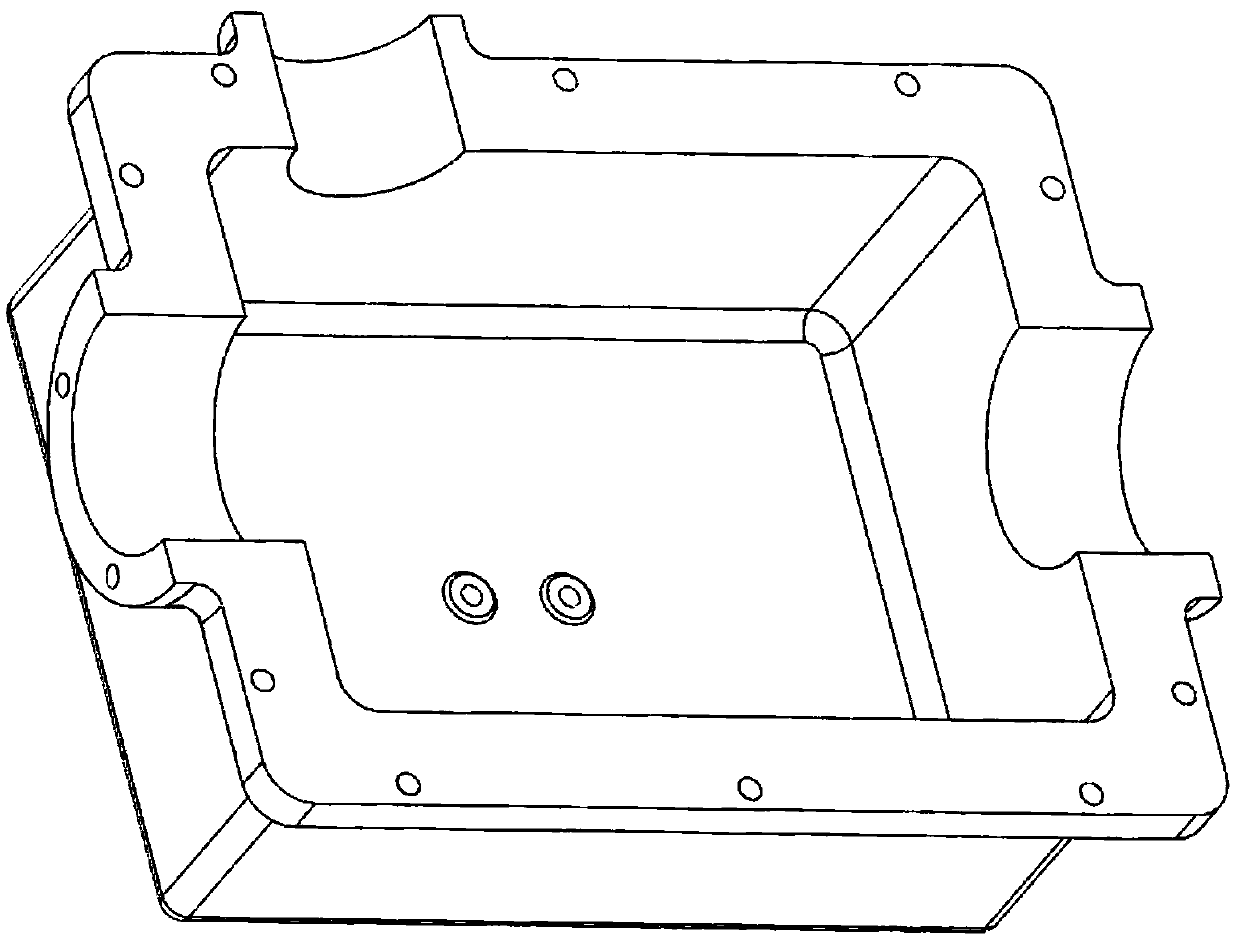

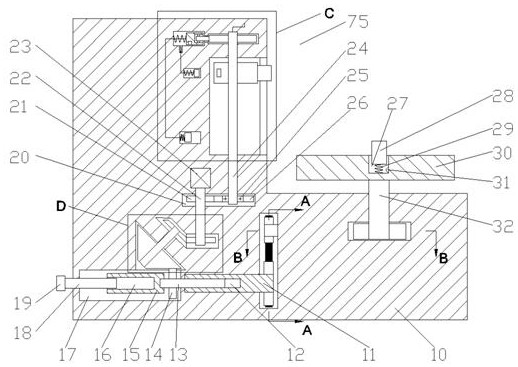

Inclined plane instrument device for measuring friction coefficient and friction angle of granular materials

InactiveCN102878910AAccurate measurementNo distortionAngles/taper measurementsMaterial analysisMeasurement deviceFriction angle

The invention belongs to the field of physical property detection of materials and particularly relates to an inclined plane instrument device for measuring the friction coefficient and the friction angle of granular materials on different material plate elements. Firstly, operators uniformly pave the granular materials to be measured onto a placed plate element, in addition, the included angle between the plate element and the horizontal plane is continuously increased until the materials on the plate element fall into a material collecting disc, and then, the friction angle or the friction coefficient is obtained through a measuring device. The device adopts a rocker mechanism and has a self locking function, and the measuring device comprises a circular arc ruler and a straight rule. Through the self locking function, the operators can release a rocker in experiments for intently regulating the sight line and observing readings. The fixed connection of the upper end and the lower end of the circular arc ruler and the straight ruler adopts a connecting plate with a certain thickness, and the warping in the vertical direction is avoided, so the measurement precision is ensured, and the effect of side plate reinforcing ribs is realized. The design of the material collecting disc at the lower part fully considers the requirements of multiple repeated experiments. The device has the advantages that the external connection of a power supply is not needed, and the device can be placed on the ground or a horizontal test table in a laboratory.

Owner:CHINA AGRI UNIV

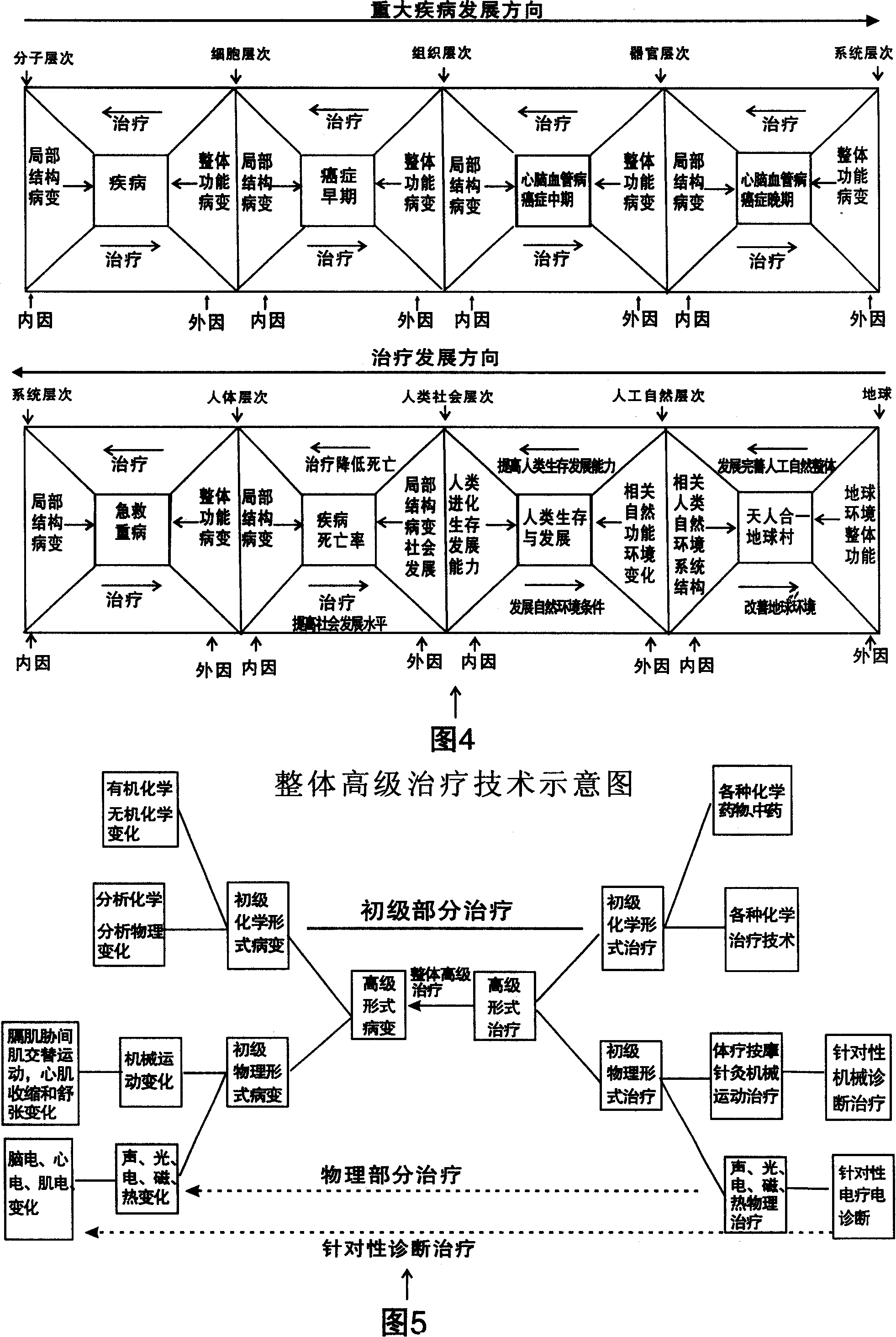

Therapeutic device for cancer diseases

ActiveCN101120904APrevent diffusion, transfer and restore functionUltrasound therapyMedical devicesEtiologyCancer prevention

Owner:李复生

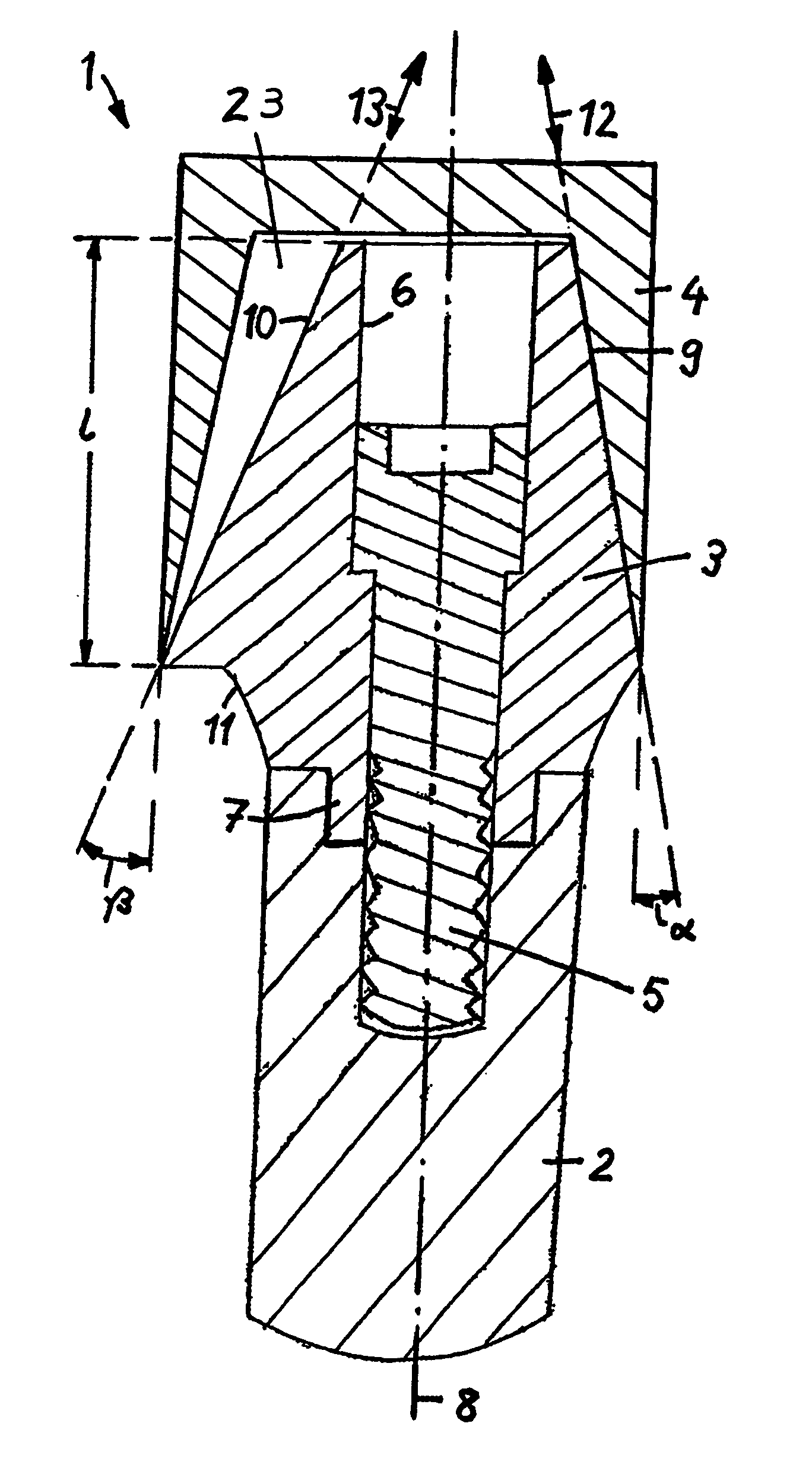

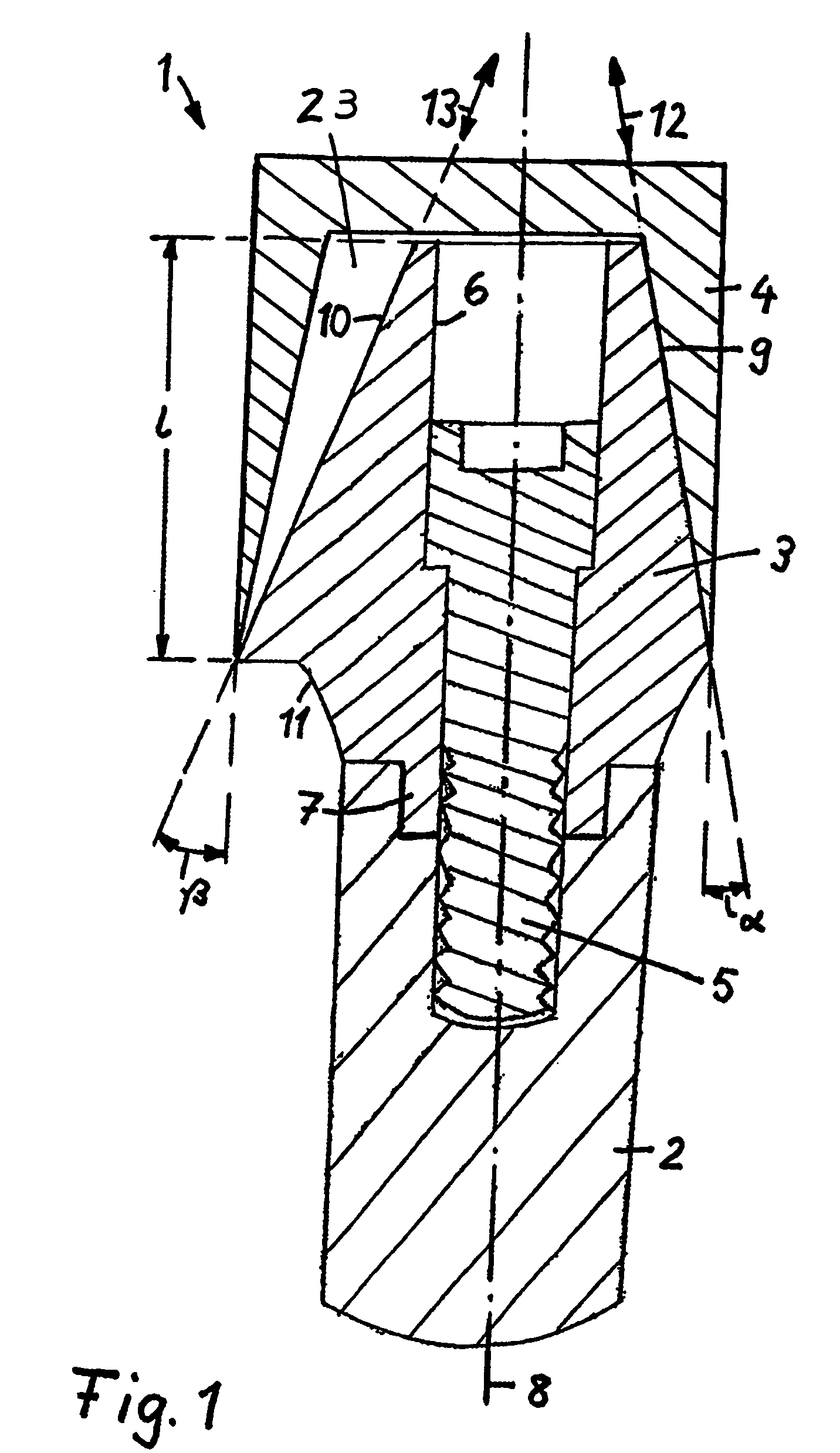

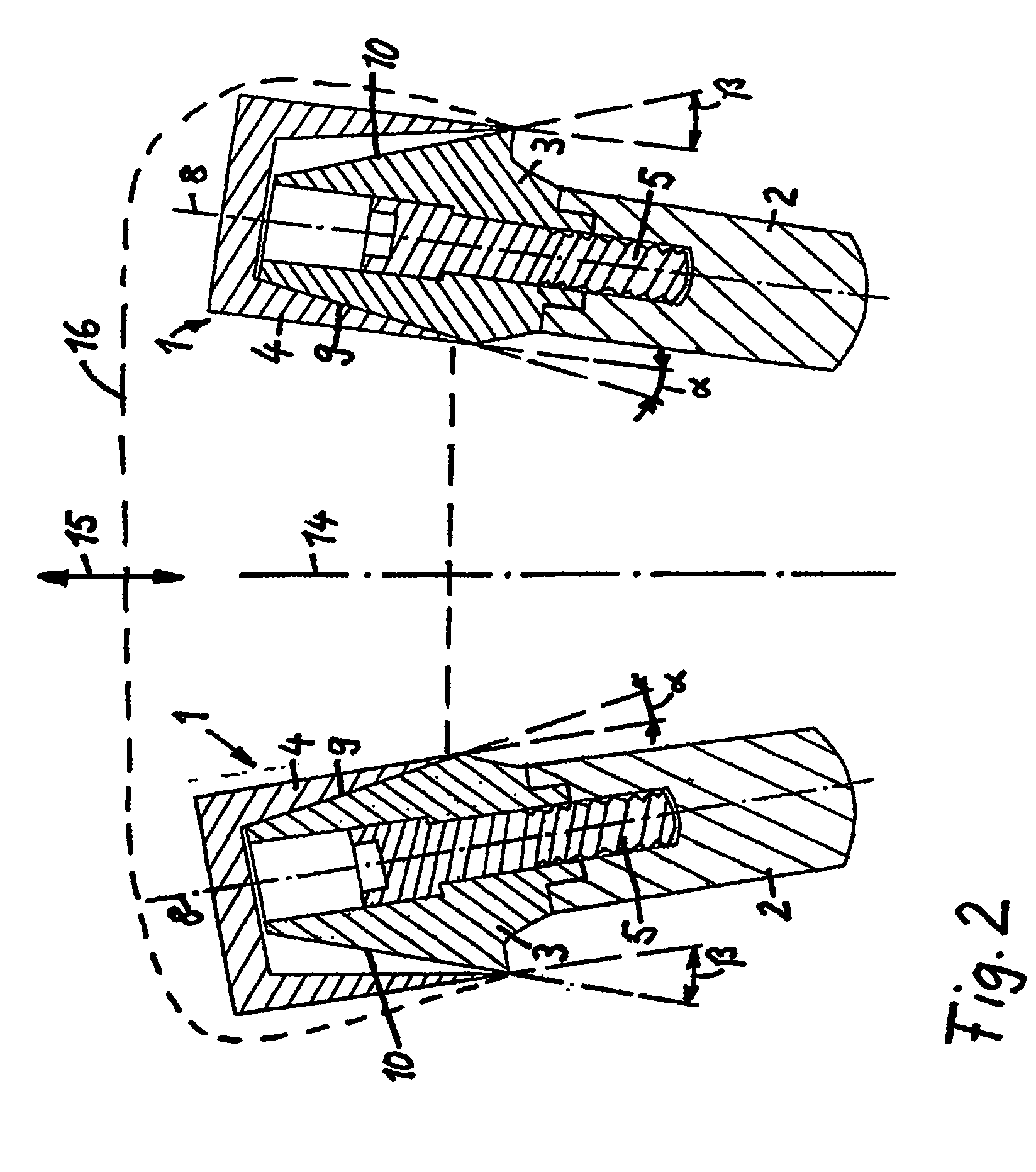

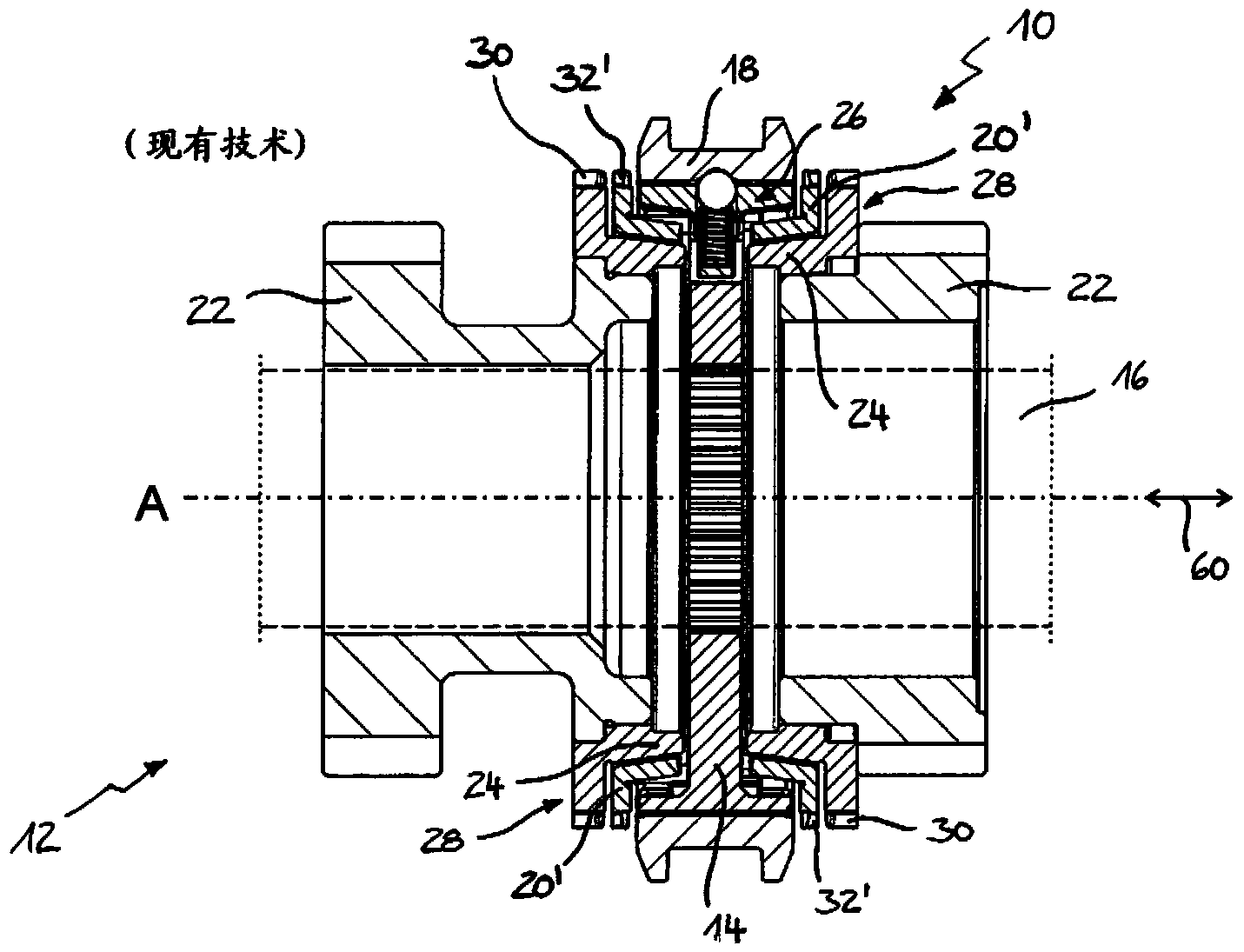

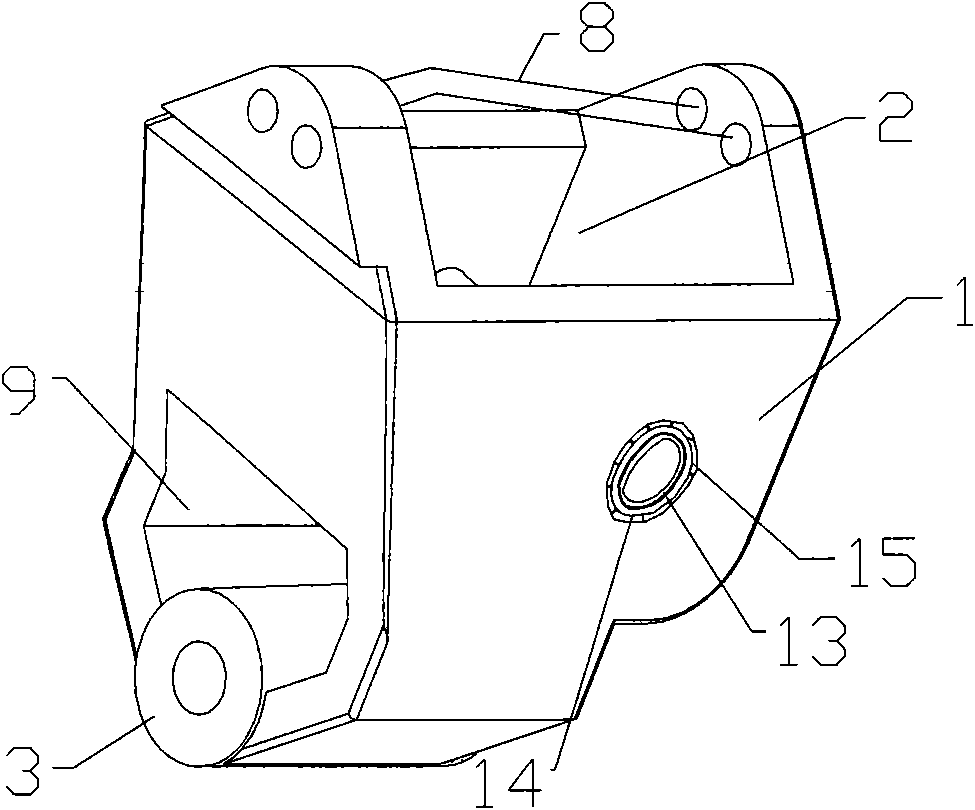

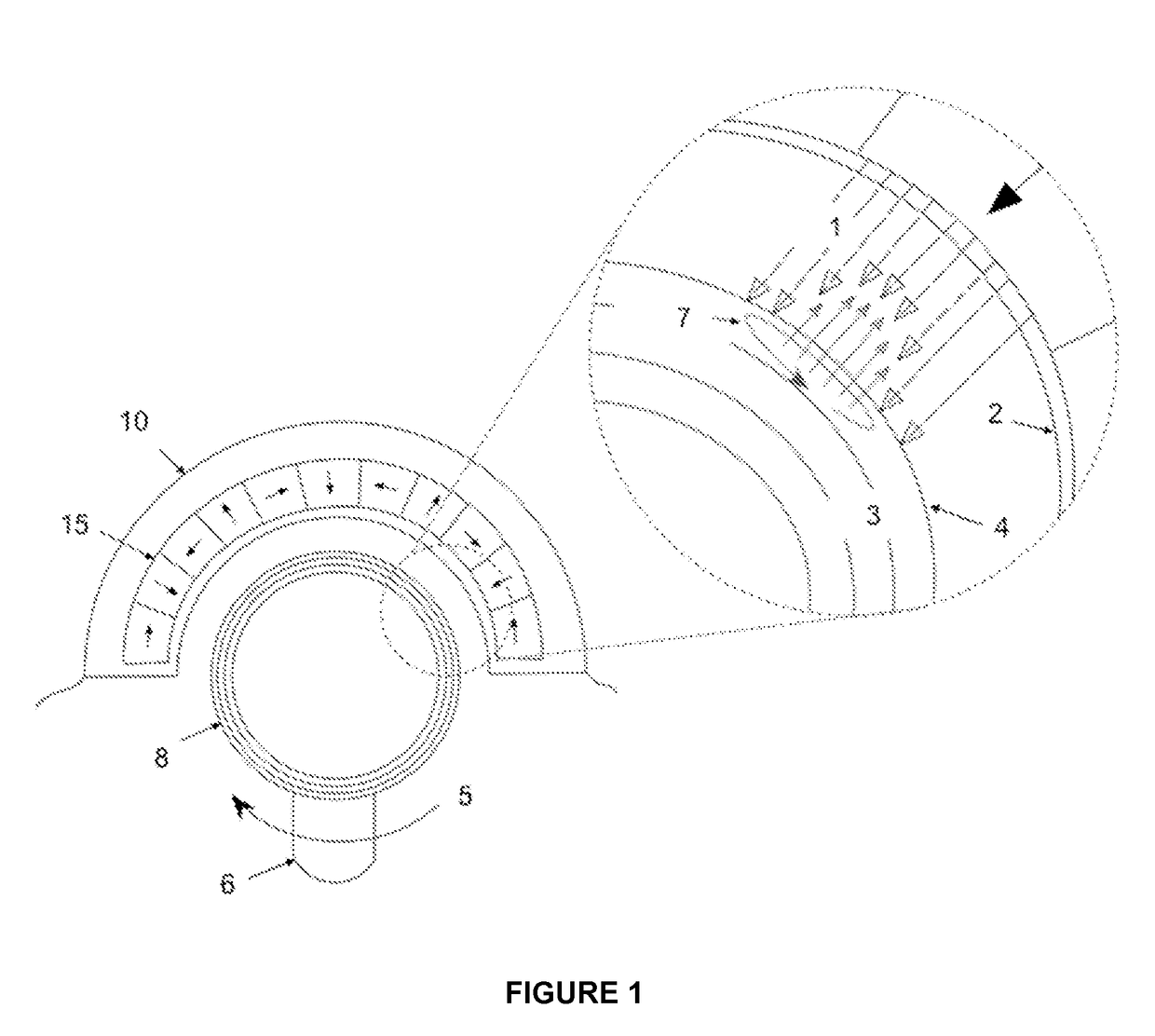

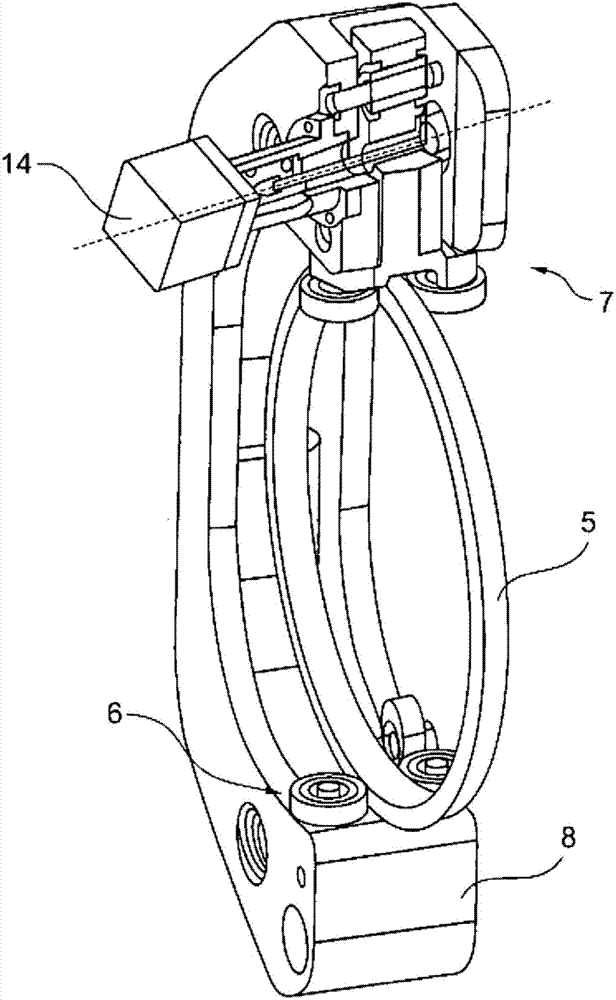

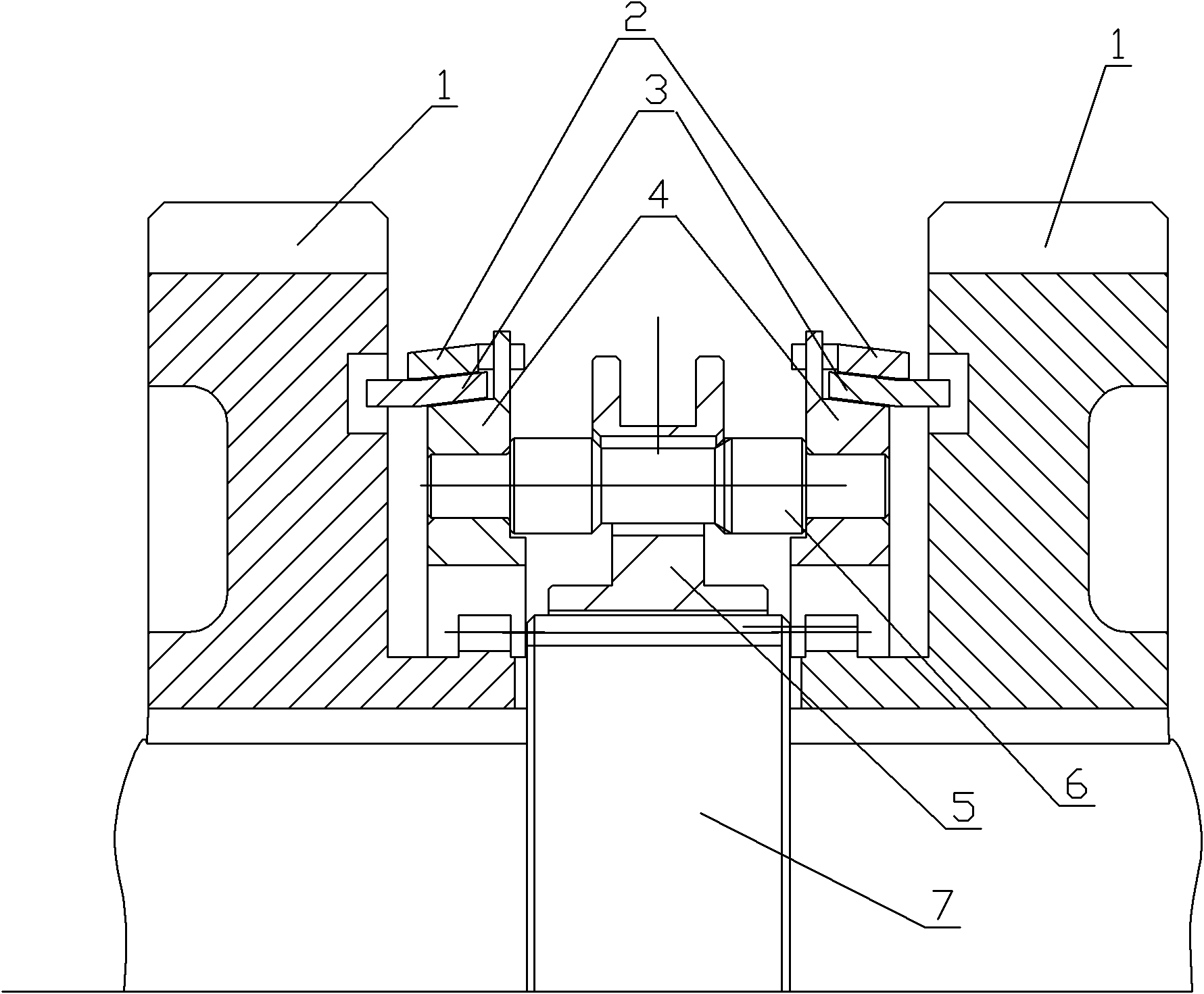

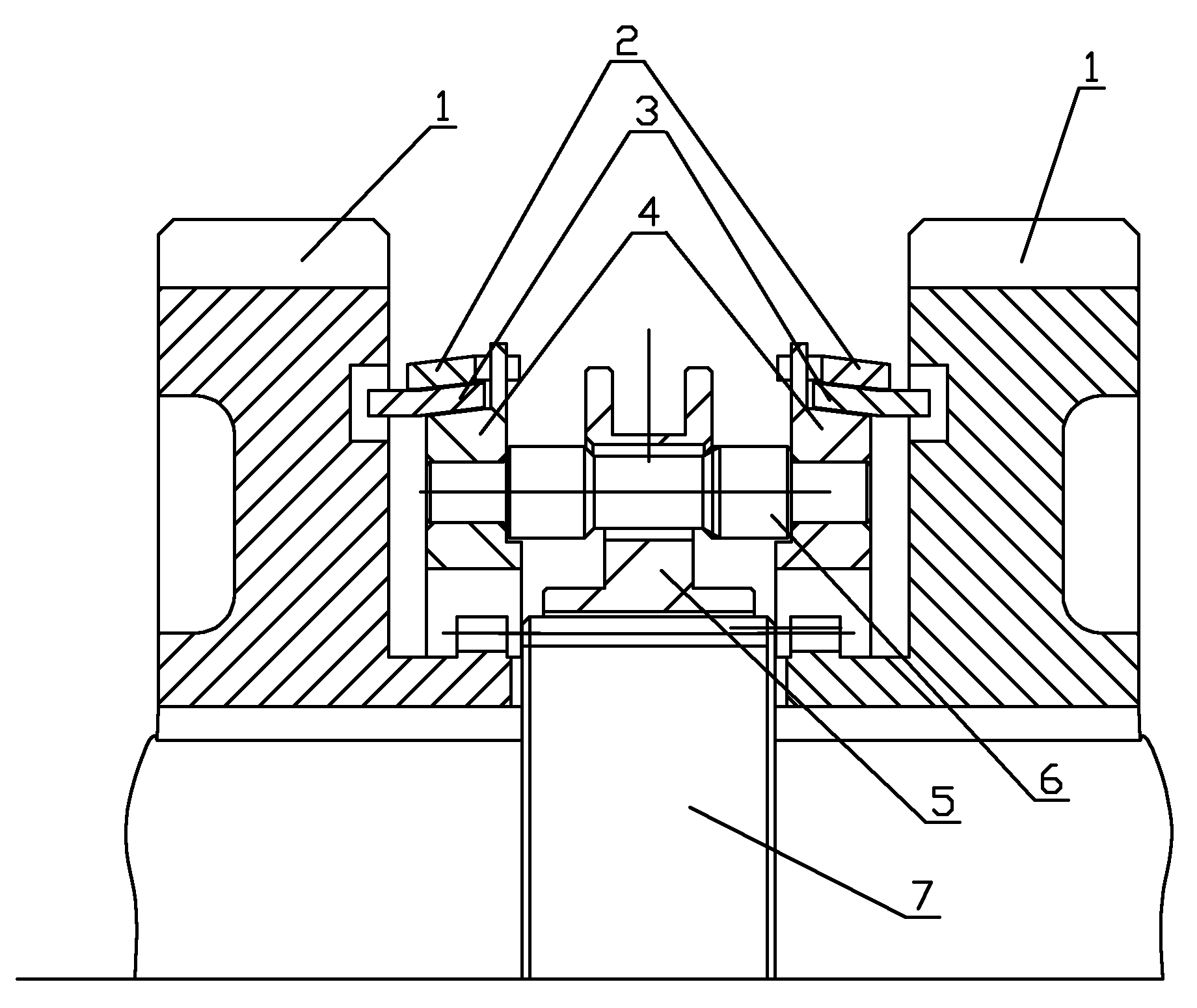

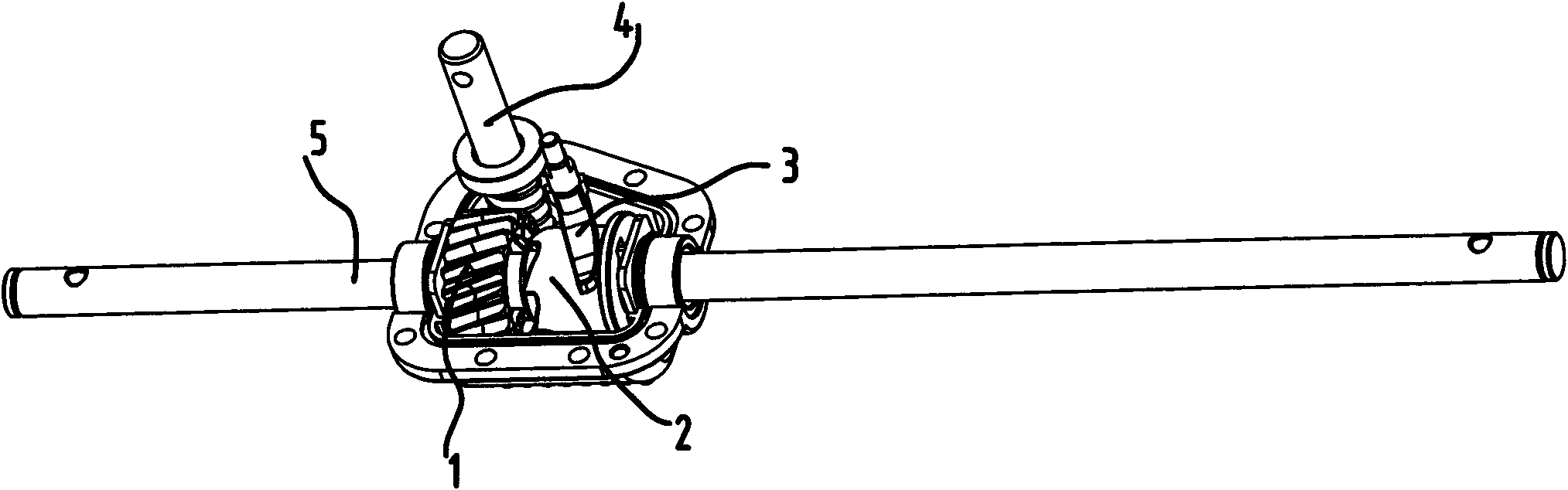

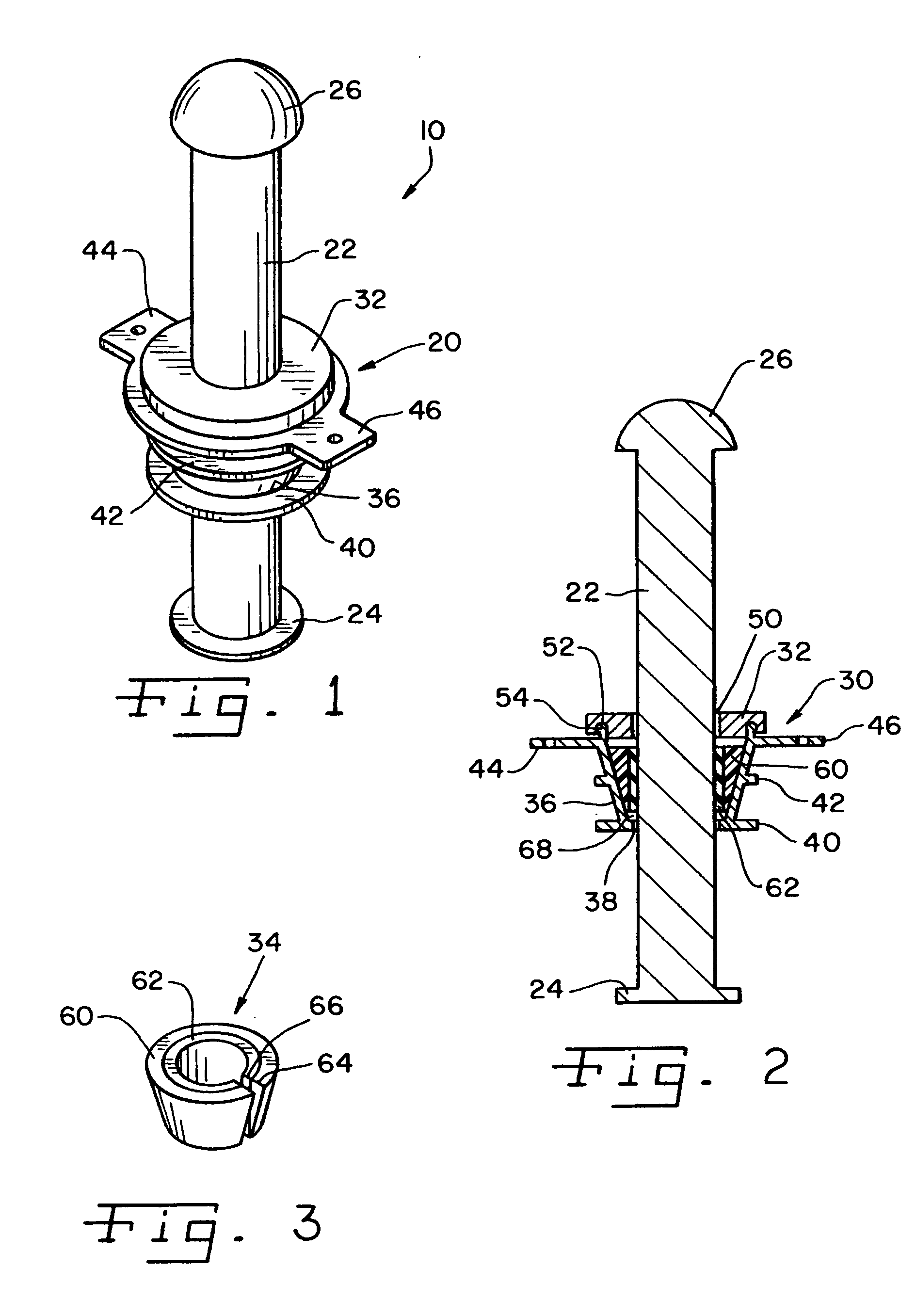

Tooth implant

InactiveUS20070111162A1Easily re-installedLarge engagement forceDental implantsEngineeringFriction cone

In a tooth implant for mounting onto an implant base carrier (2), including a support post and a crown releasably disposed on the support post, wherein the support post has a cone-shaped base body with at least a friction cone sector and an accommodation sector which, with respect to a rotationally symmetrical enveloping area as defined by the cone sector, forms a cavity under the crown upper and lower edge areas where the crown is in contact with the base body, the friction cone sector and a connecting line extending between upper and lower edge areas of the accommodation sector have, in a plane receiving the longitudinal axis of the support post, different inclination angles with respect to the longitudinal axis of the support post.

Owner:LAUX ROBERT

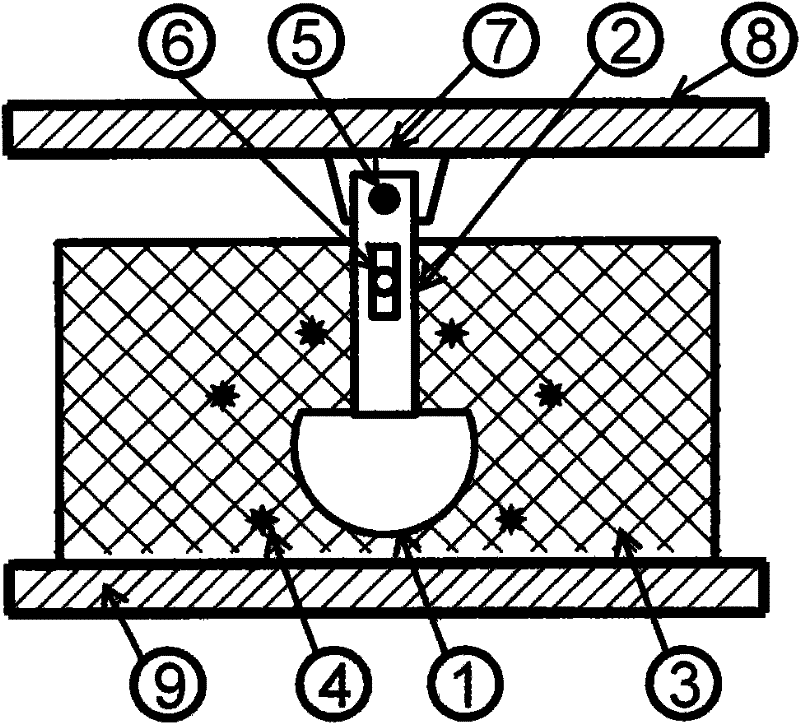

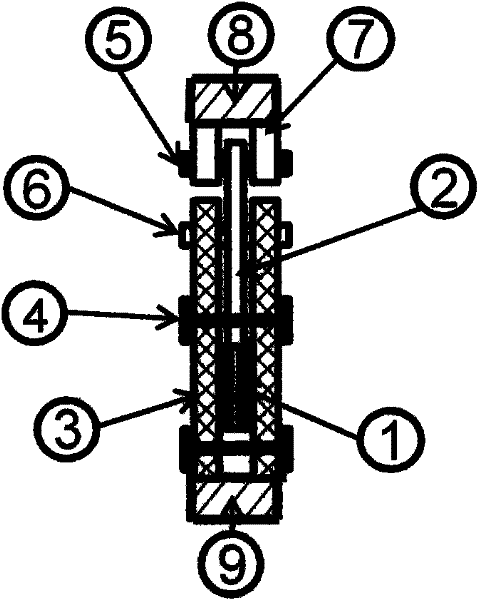

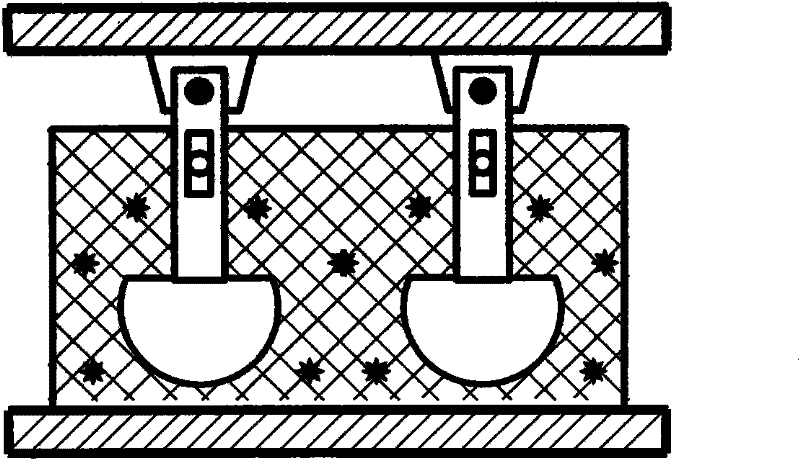

pendulum friction wall

InactiveCN102287016AZoom in displacementAmplified output forceShock proofingFriction reductionHouse building

The invention relates to a pendulum type friction wall. The friction wall is used for energy dissipation of house buildings. The pendulum type friction wall comprises upper and lower beams, a pair of connection plates, a friction pendulum, a pair of lightweight walls, a hinge axis, a chute and split bolts. The friction wall has the following beneficial effects: the friction wall can be installed in the structure as a segmentation element with building functions and does not bear vertical load; under the action of wind load or seismic load, the energy input by the wind load or seismic load is dissipated by friction generated when the friction pendulum swings, thus protecting the main members of the structure; and the friction force can be increased through leverage of a swing arm, and lower pressure can be maintained on the friction surface, thus reducing abrasion of the friction pair.

Owner:王涛 +2

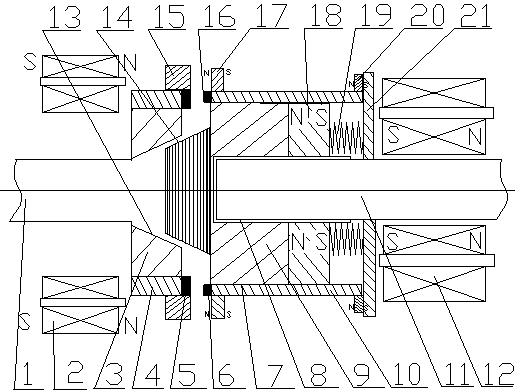

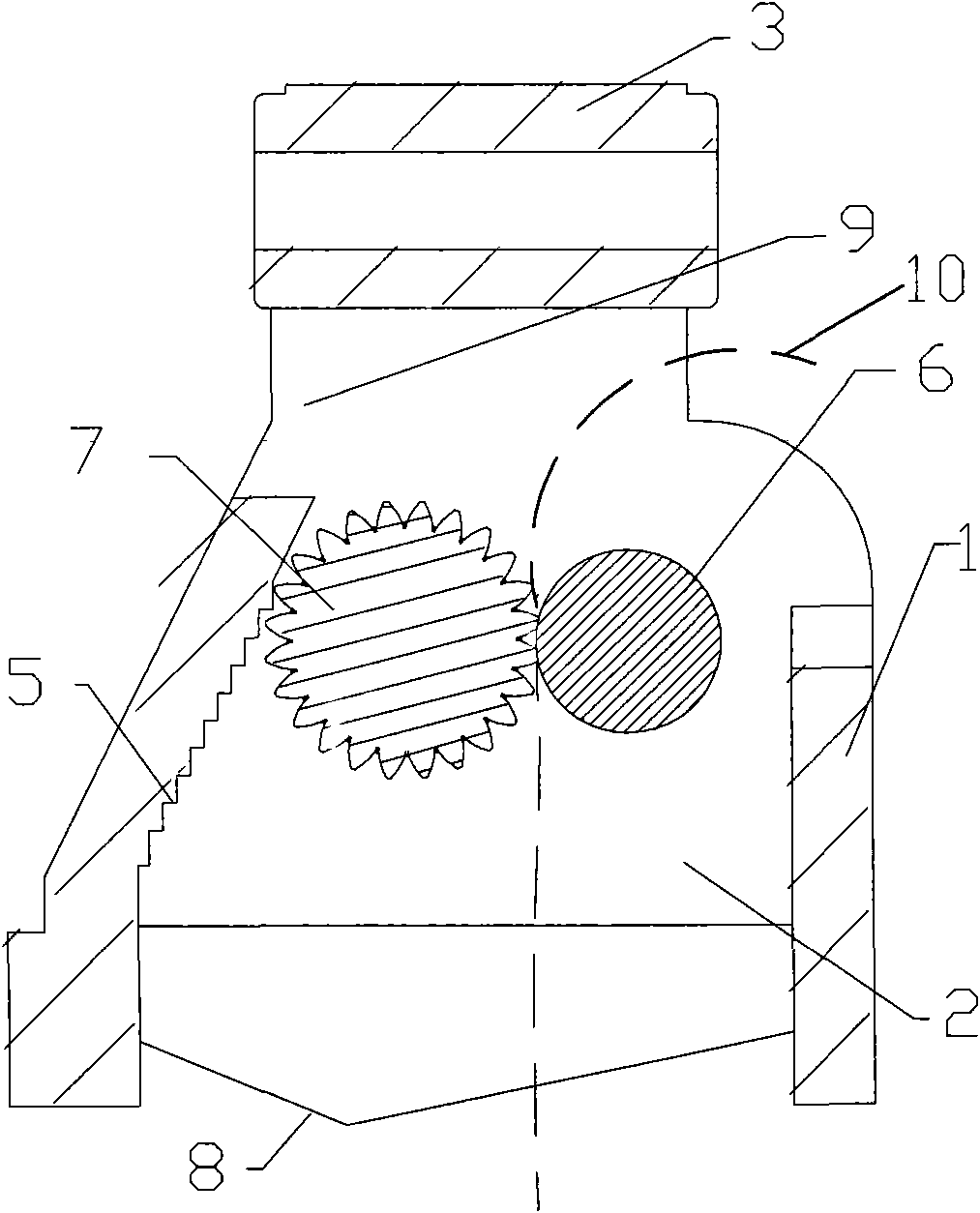

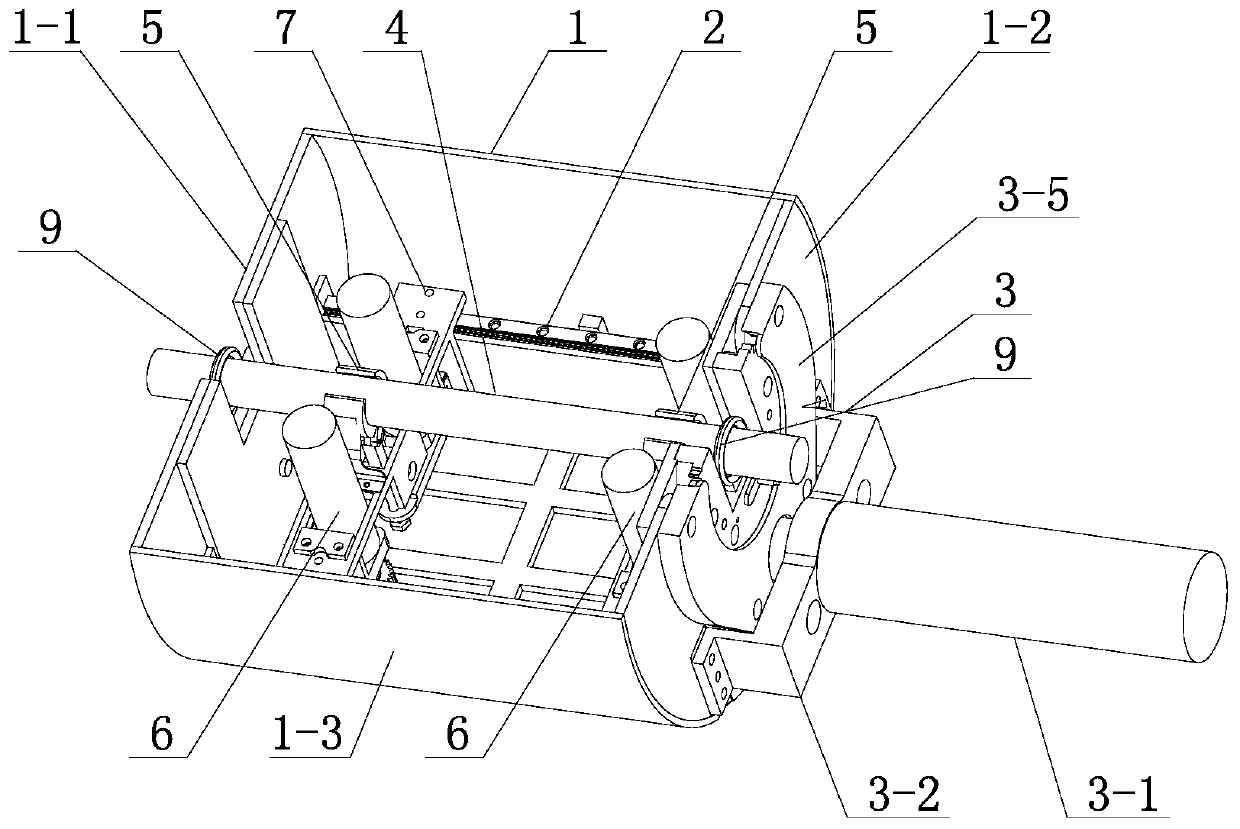

Automatic clutch device adopting end surface bevel gear engagement

InactiveCN102537123ANo more power consumptionImprove transmission efficiencyMagnetically actuated clutchesDrive shaftControl manner

An automatic clutch device adopting end surface bevel gear engagement magnetic control includes a driven shaft wheel sleeved on a driven shaft wheel out spur gear in a magnetic control manner and capable of sliding axially, a driven shaft wheel outer ring sleeved on the sleeved on the driven shaft wheel out spur gear in the magnetic control manner and capable of sliding axially, as well as an endsurface bevel gear at the head part, wherein the end surface bevel gear is engaged with an end surface bevel gear of a driving shaft wheel on a driving shaft wheel outer ring. The automatic clutch device is characterized in that a driven shaft wheel outer friction cone is arranged at one end of the driven shaft wheel, the other end is connected with a driven shaft wheel magnet ring and a driven shaft wheel magnet return spring as well as a driven shaft wheel upper fixing large iron ring sequentially, and a plurality of electromagnetic coils are symmetrically mounted near a driven shaft on theother side of the driven shaft upper fixing iron ring; and a driving shaft wheel inner friction taper hole is arranged at a center zone of one end of the driving shaft wheel, the driving shaft wheel outer ring and the driving shaft wheel end surface bevel gear are arranged on the outer side, and a plurality of electromagnetic coils are symmetrically mounted near a driving shaft outside on the other side of the driving shaft wheel.

Owner:魏伯卿

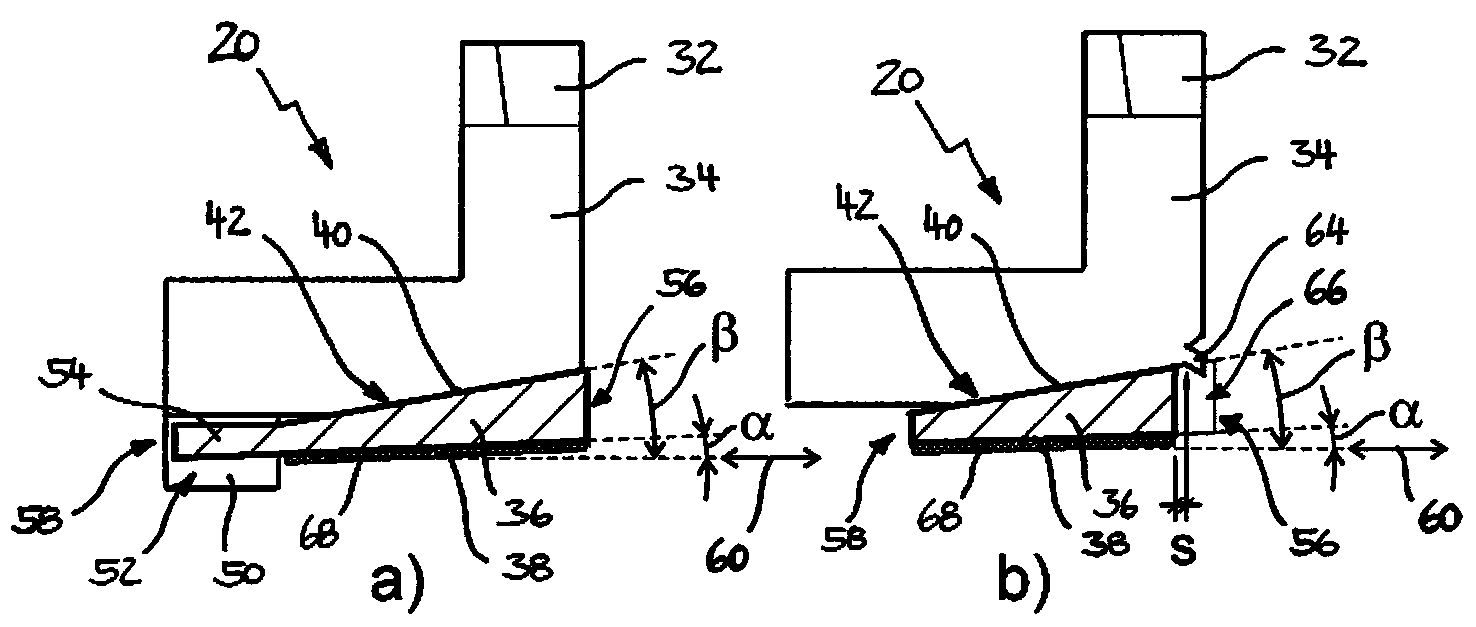

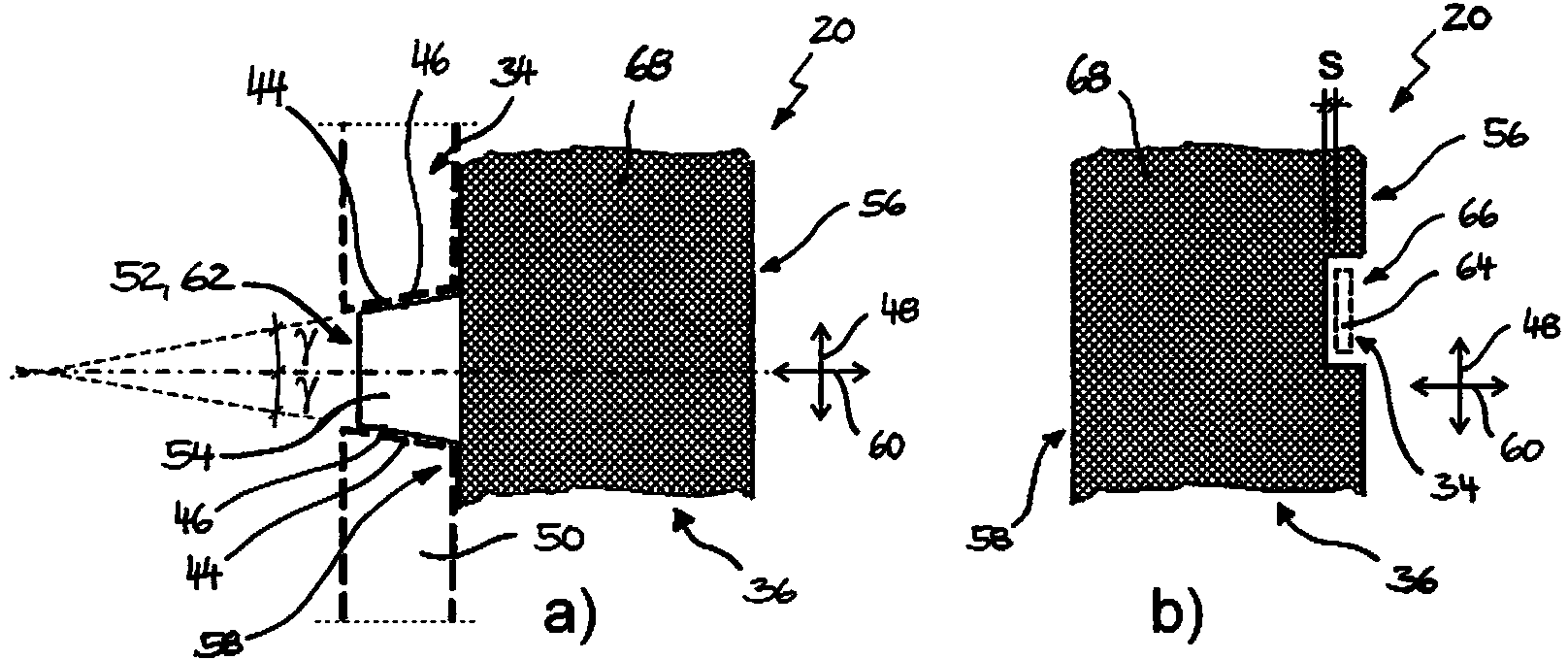

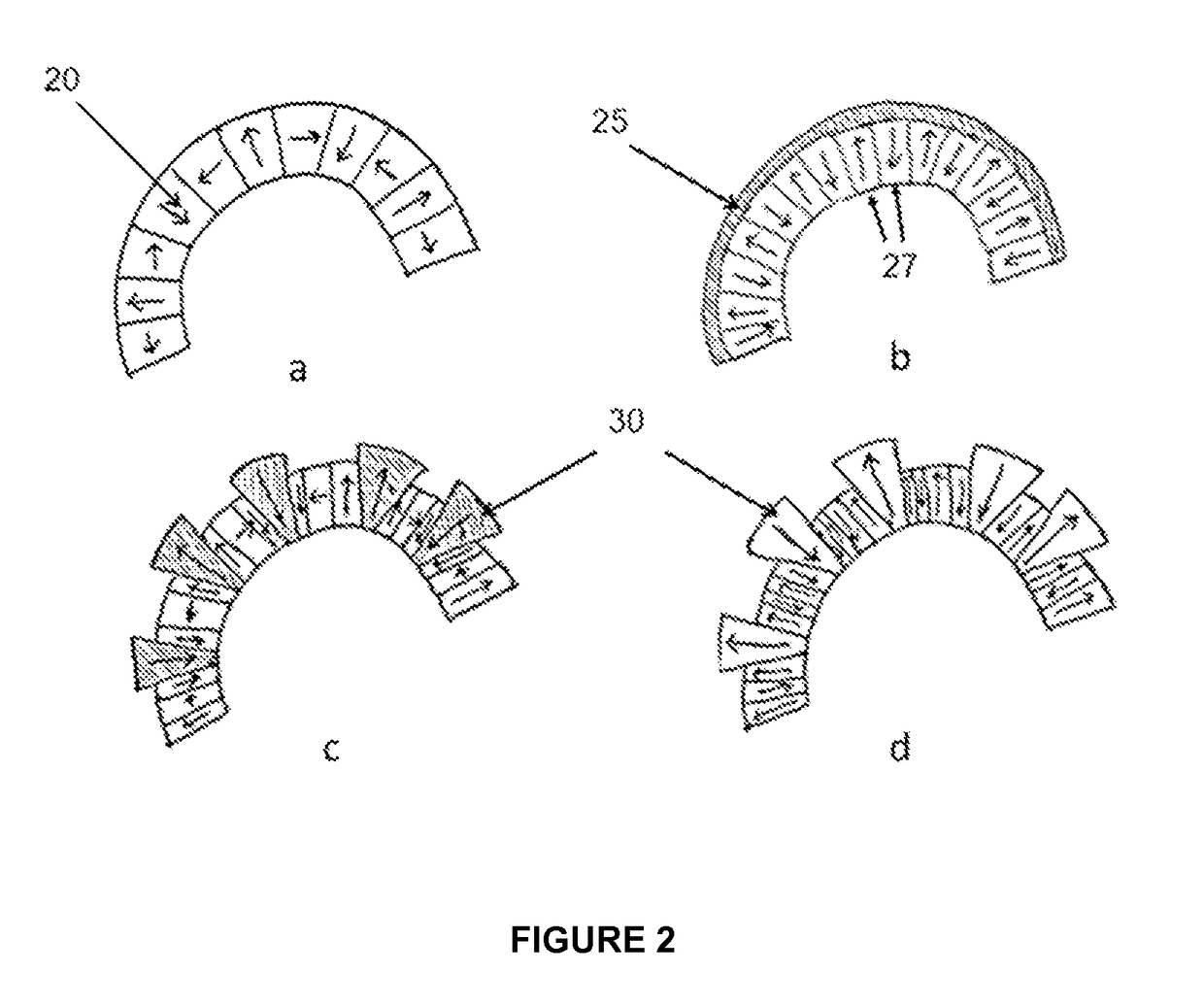

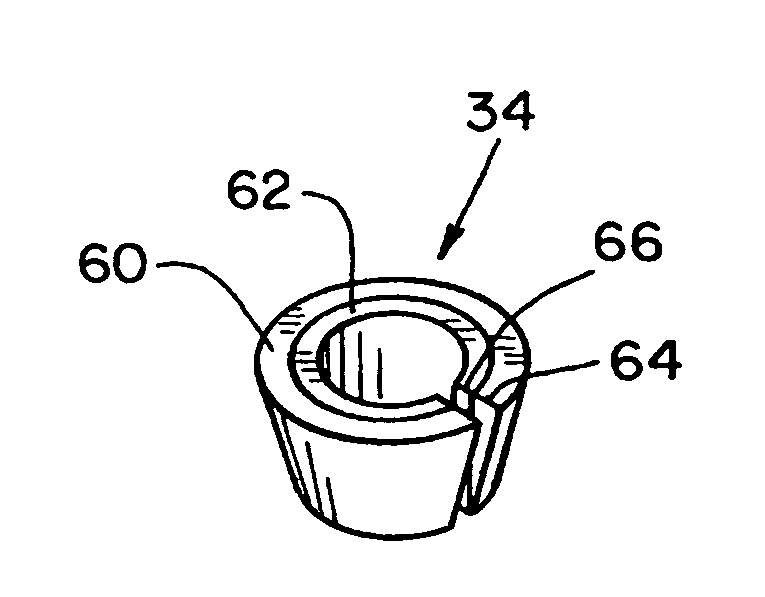

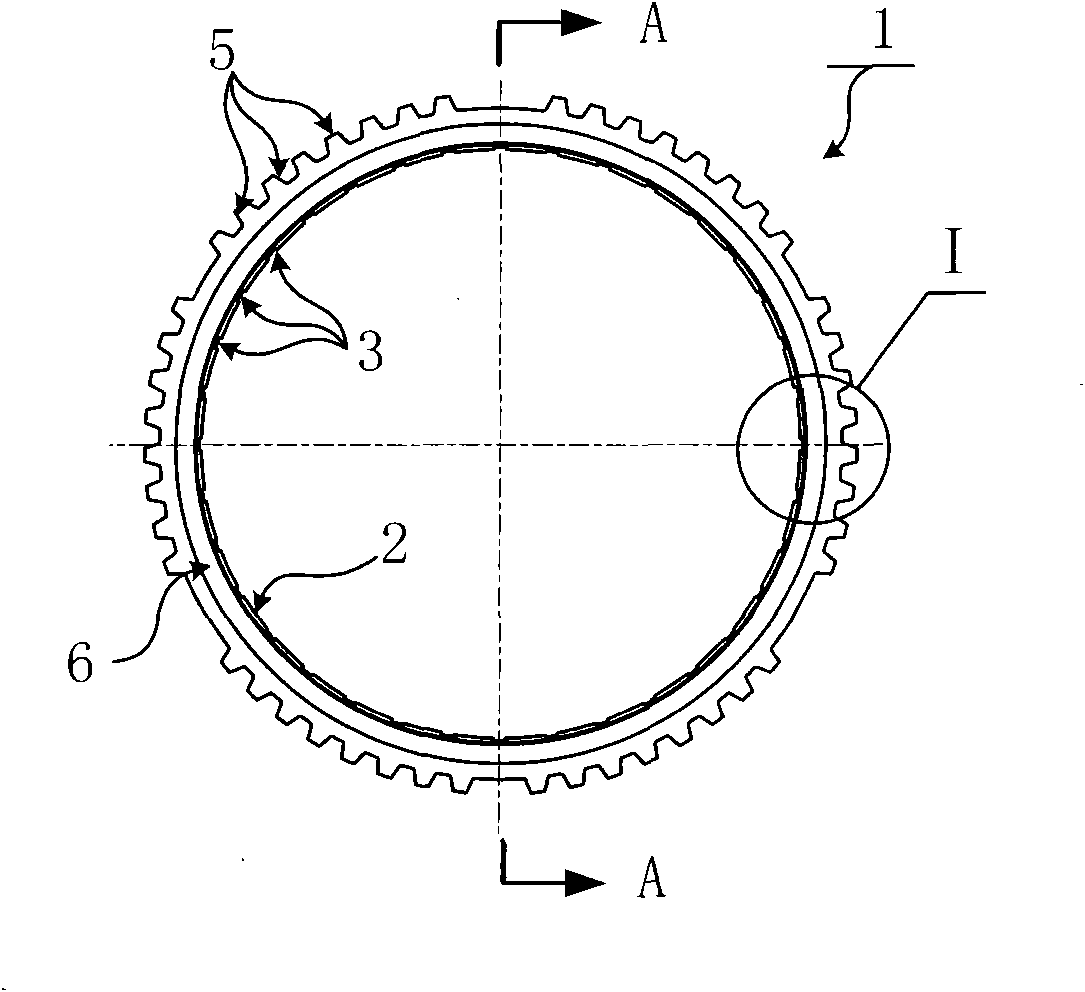

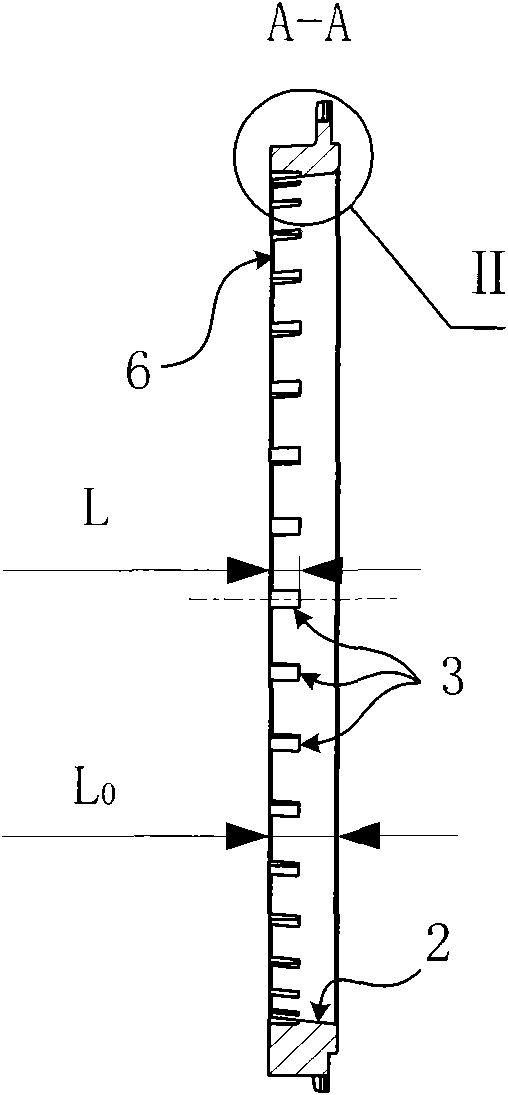

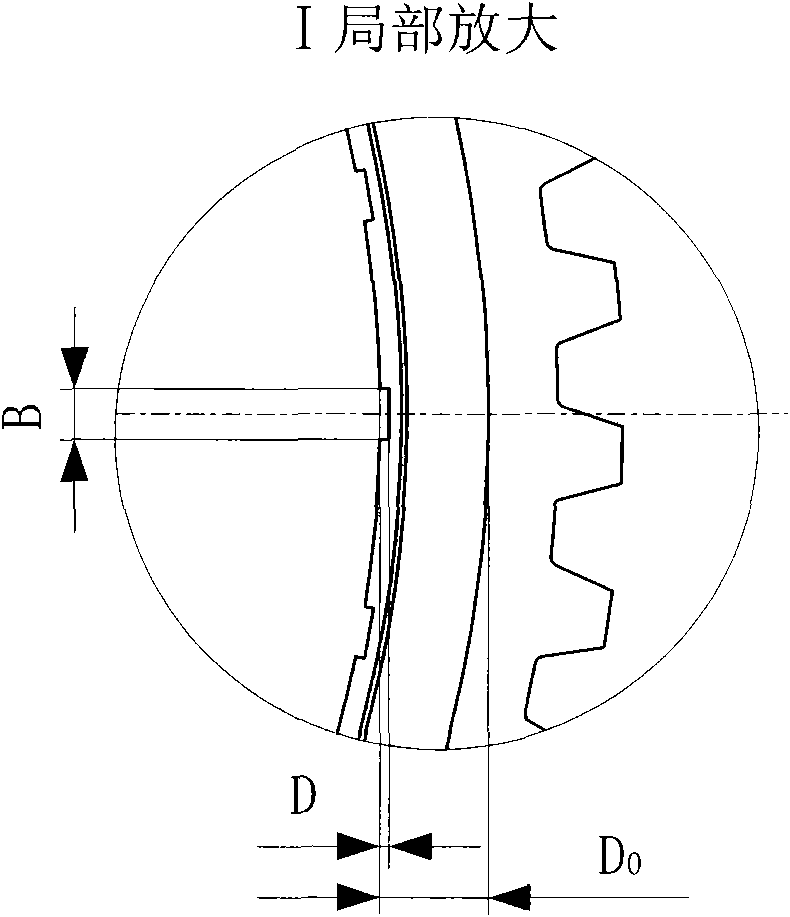

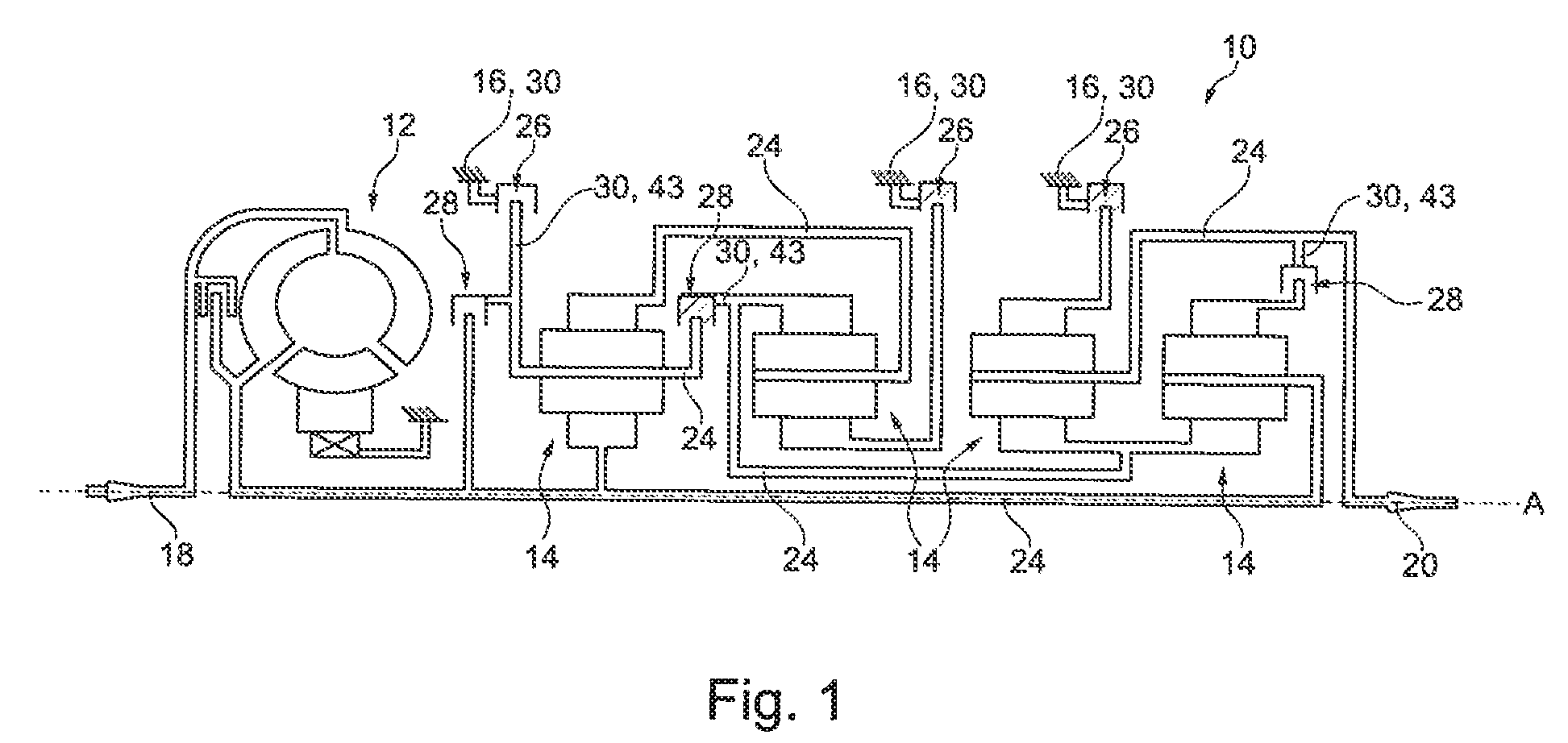

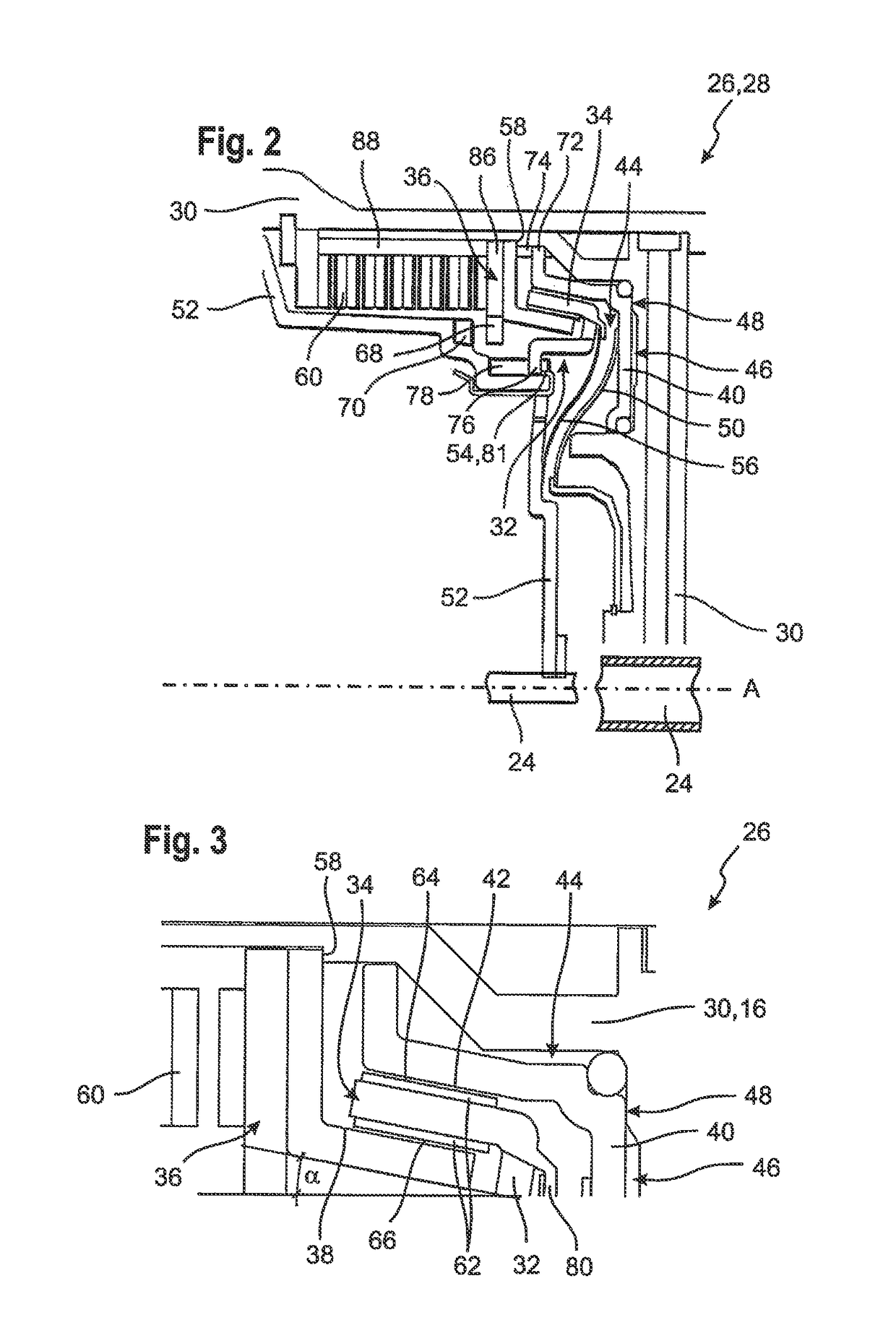

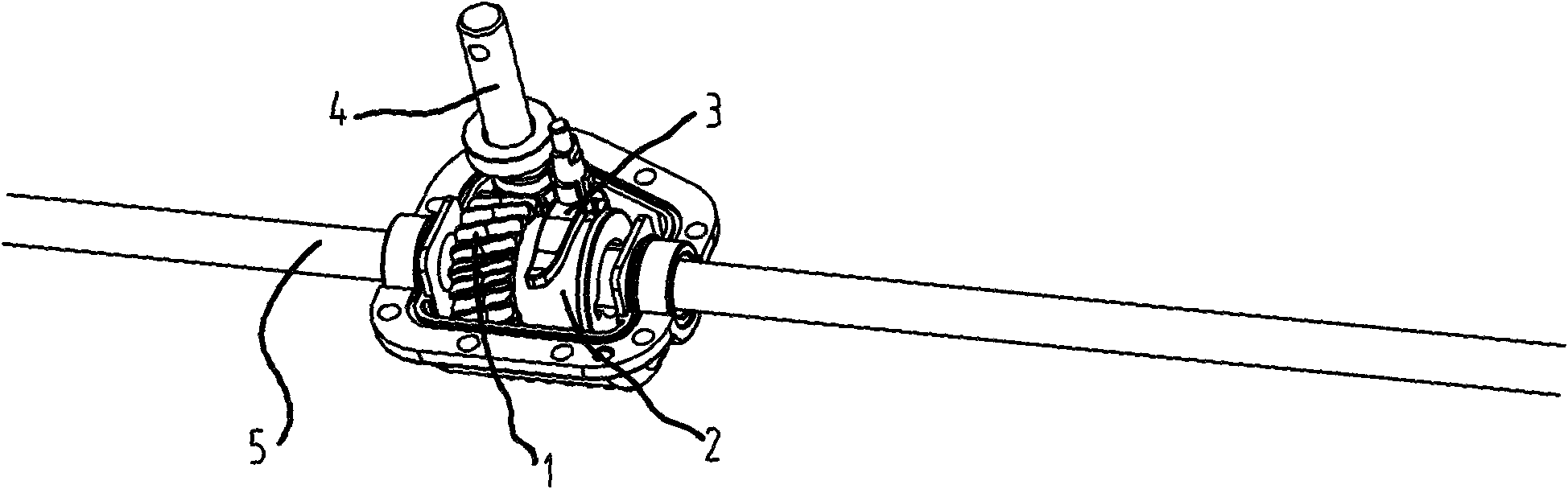

Synchronizer ring for a synchronization unit of a manual transmission and synchronization unit with such a synchronizer ring

ActiveCN104235221AFriction torque preventsSelf-locking preventionMechanical actuated clutchesGreek letter betaEngineering

The invention relates to a synchronizer ring (20) for a synchronization unit (10) of a gearbox (12), with a locking ring (34) having an annular axis (A) and a locking toothing (32) and a coaxial with the lock ring (34) disposed separate cone ring (36) having a first conical surface (38) having a first cone angle ([alpha]) and a radially opposite second conical surface (40) with a second cone angle ([beta]), wherein the first cone surface (38) in the installed state of the synchronizer ring (20) to a gangradseitigen friction cone (24) of the synchronization unit (10) and the second conical surface (40) at a conical counter surface (42) of the locking ring (34) abuts, wherein the locking ring (34) and the cone ring (36) mutually associated abutment surfaces (44, 46) which couple the locking ring (34) and the cone ring (36) in the circumferential direction (48) , and wherein the stop surfaces (44, 46) of the locking ring (34) and / or of the cone ring (36) relative to the ring axis (A) are at least partially inclined such that the second conical surface (40) and the conical counter surface (42) at a acting between the locking ring (34) and the cone ring (36) are torque loaded axially away from one another.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

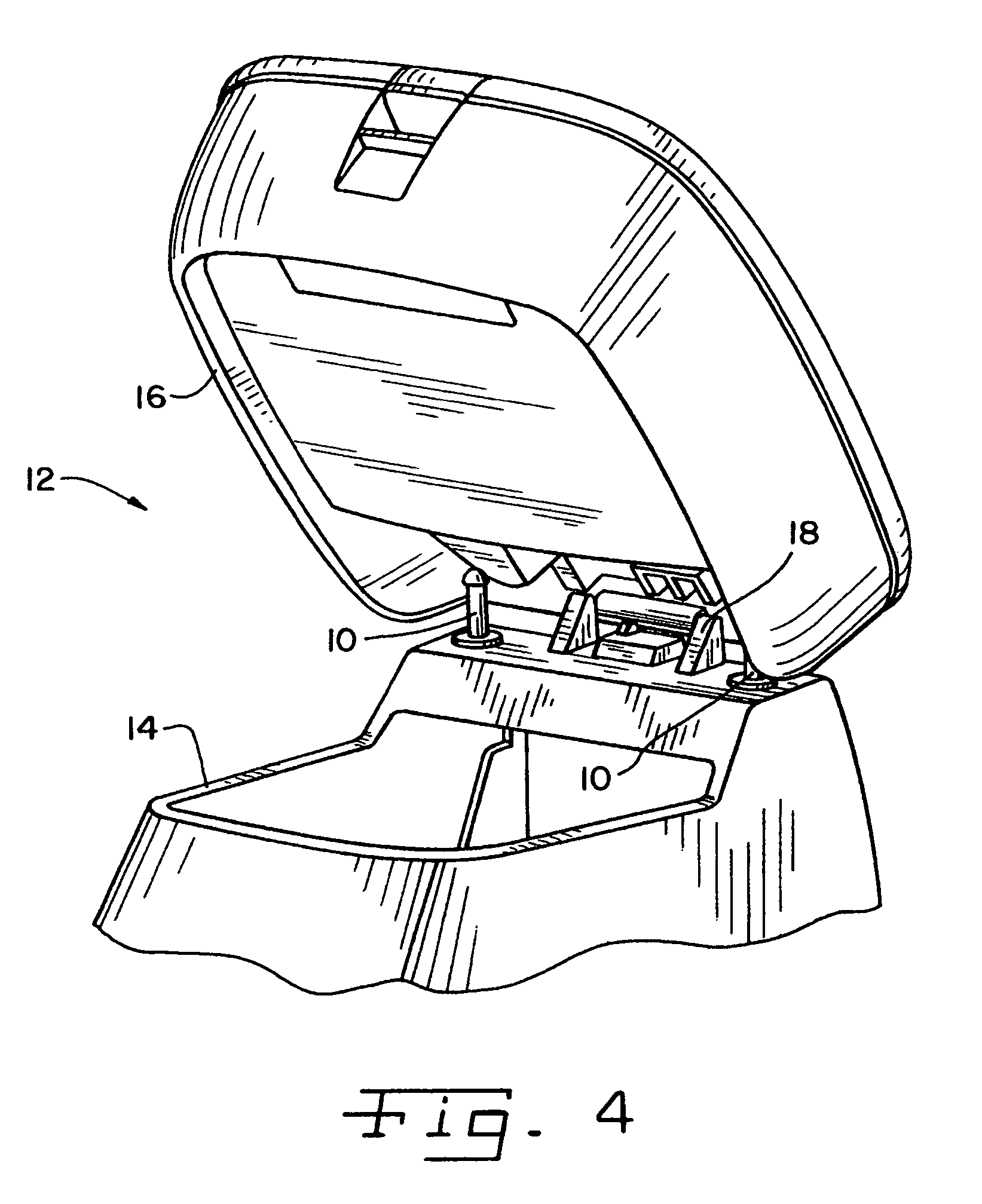

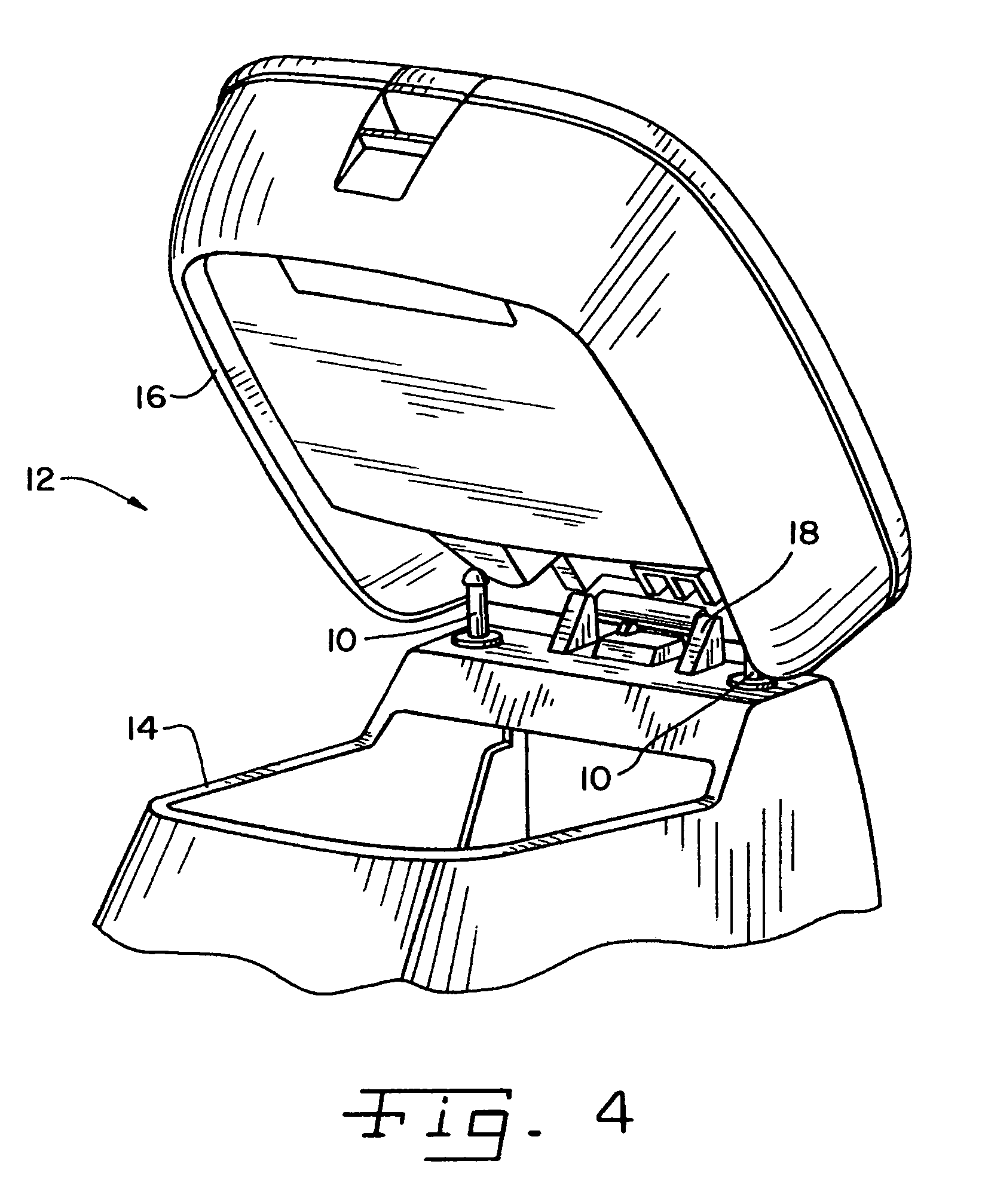

Meal stove lid buffer device

The invention discloses a meal stove lid buffer device which comprises a supporting frame arranged on a stove grate. The supporting frame is provided with a working cavity; a rotatable friction core is arranged in the working cavity; the friction core is provided with a rotating arm fixed with an overturning cover; a plane is arranged on the lateral surface of the friction core; and an elastic sheet which corresponds to the plane and inward protrudes is arranged on the inner wall of the working cavity. The meal stove lid buffer device buffers the action of overturning a lid by the compression fit between the friction core and the elastic sheet when the lid is opened or closed, thereby the collision noise between the overturning lid and a water pond can be reduced and the damage of the overturning lid caused by collision is avoided.

Owner:曹兆文

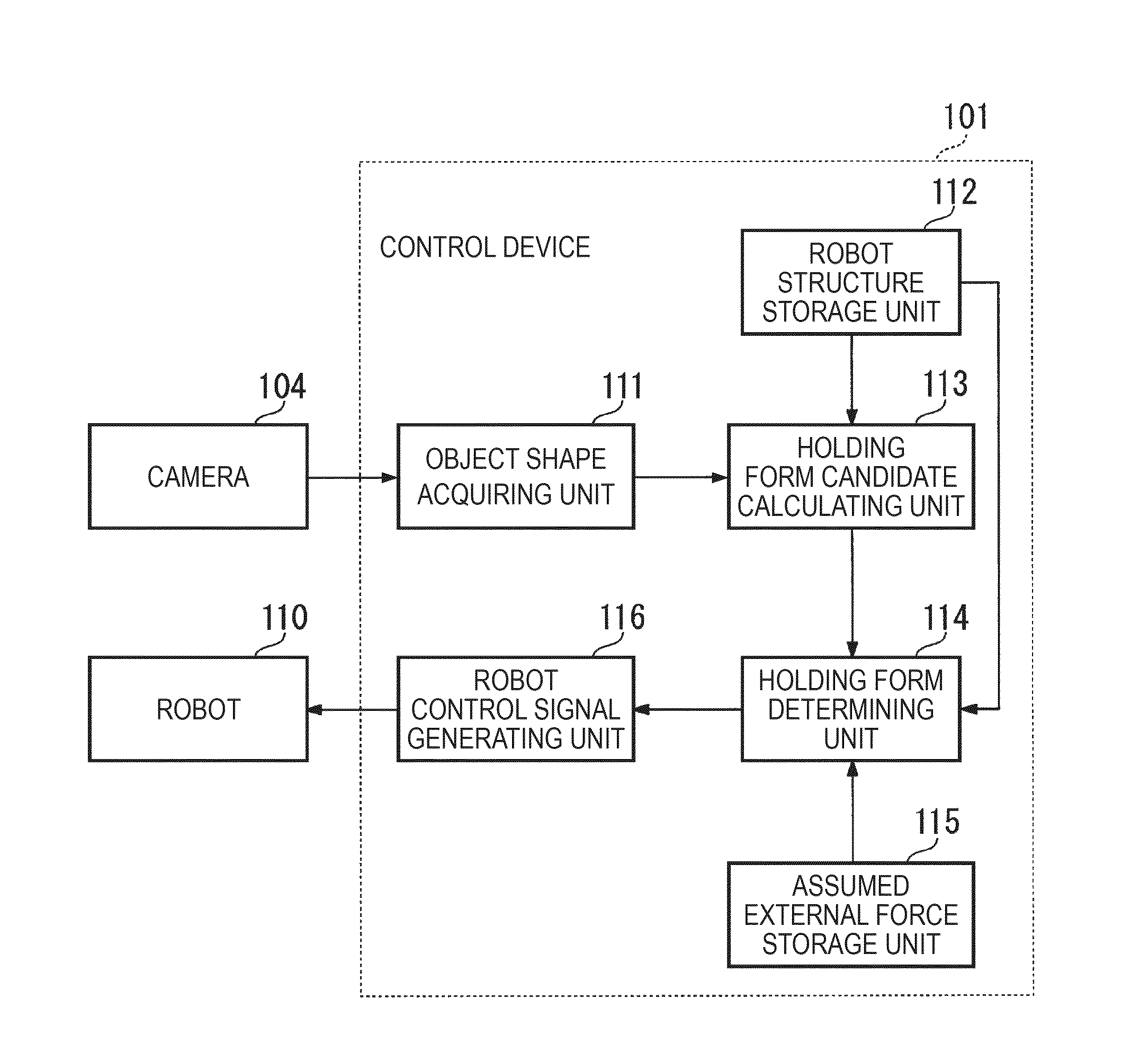

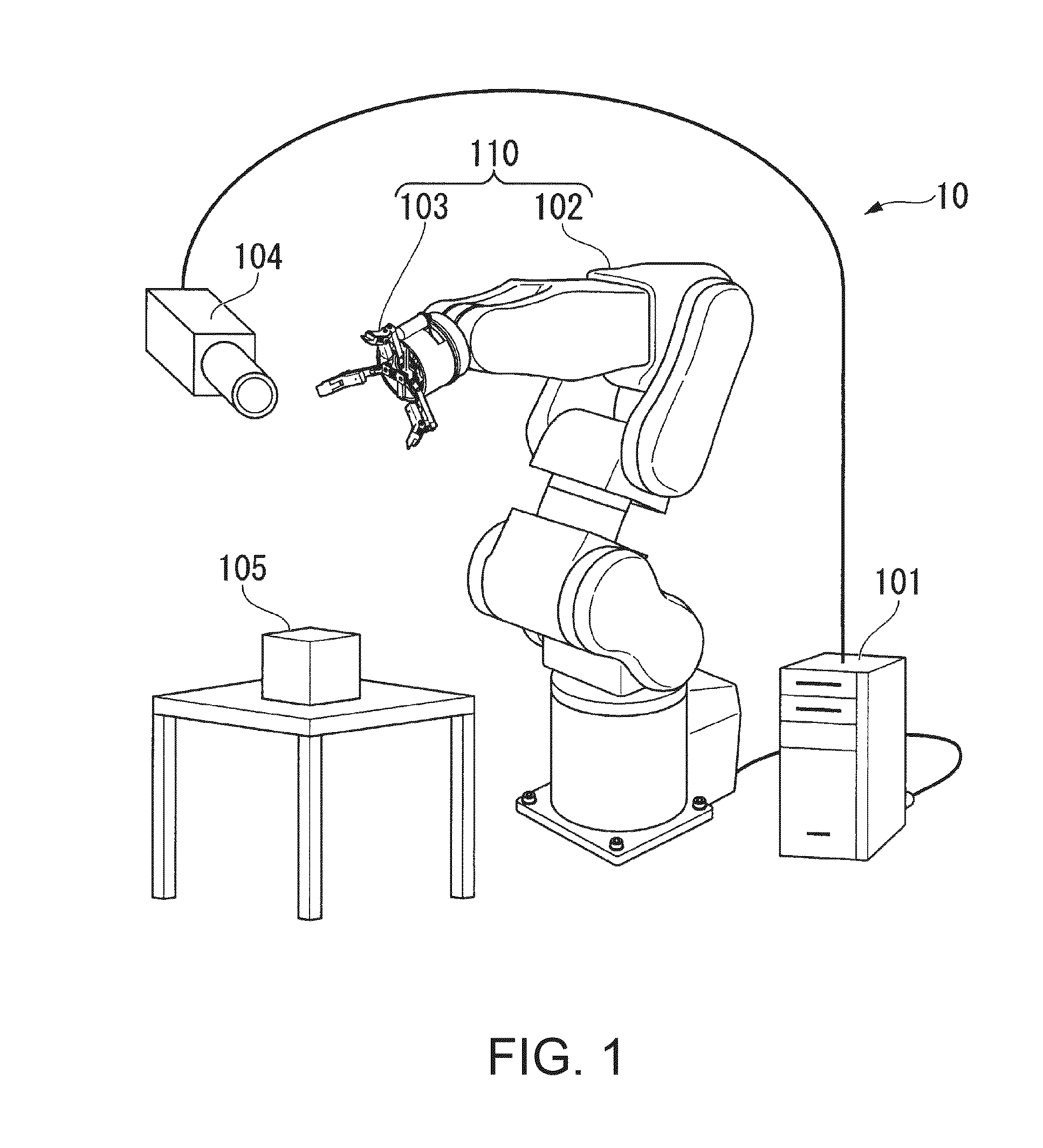

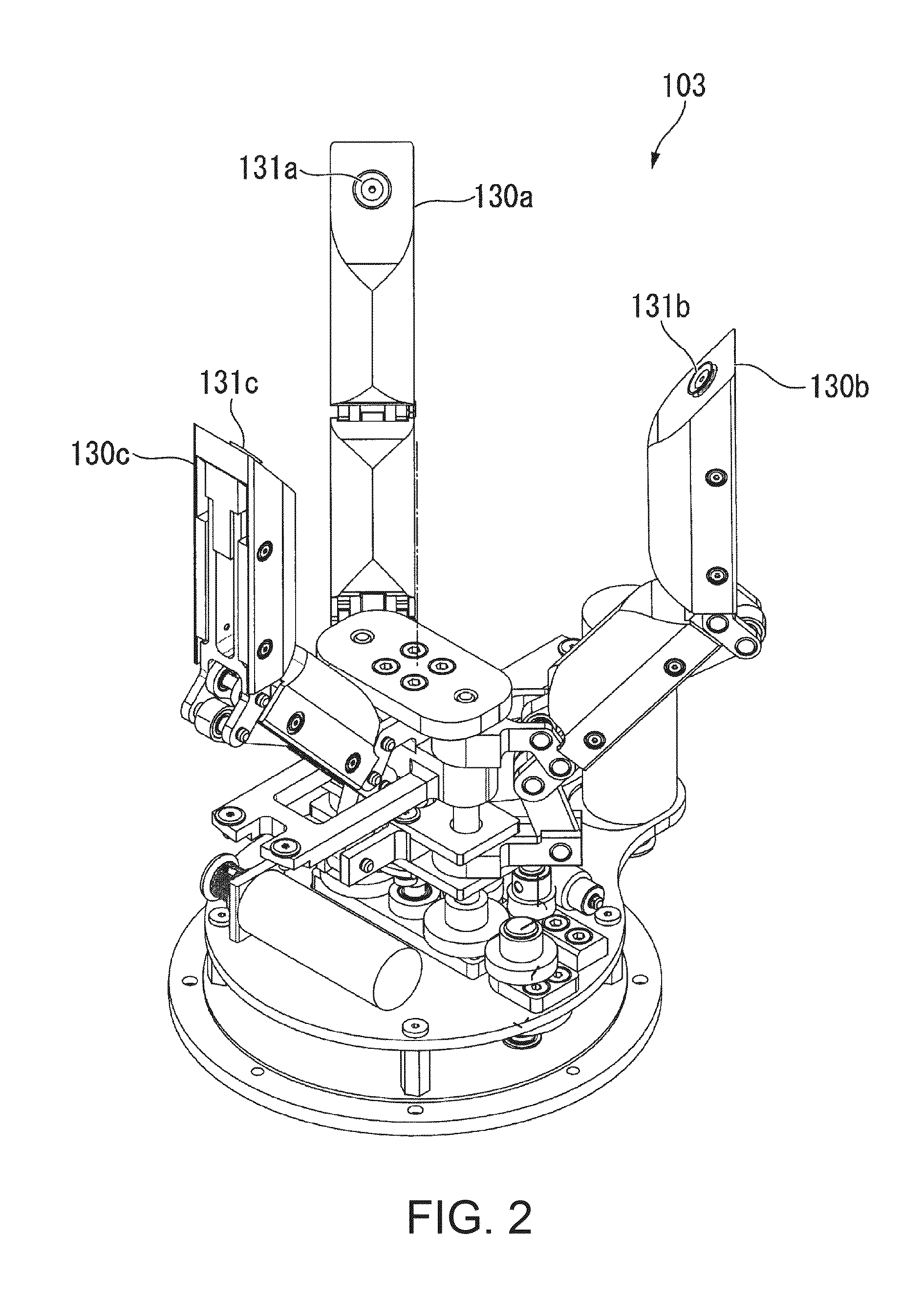

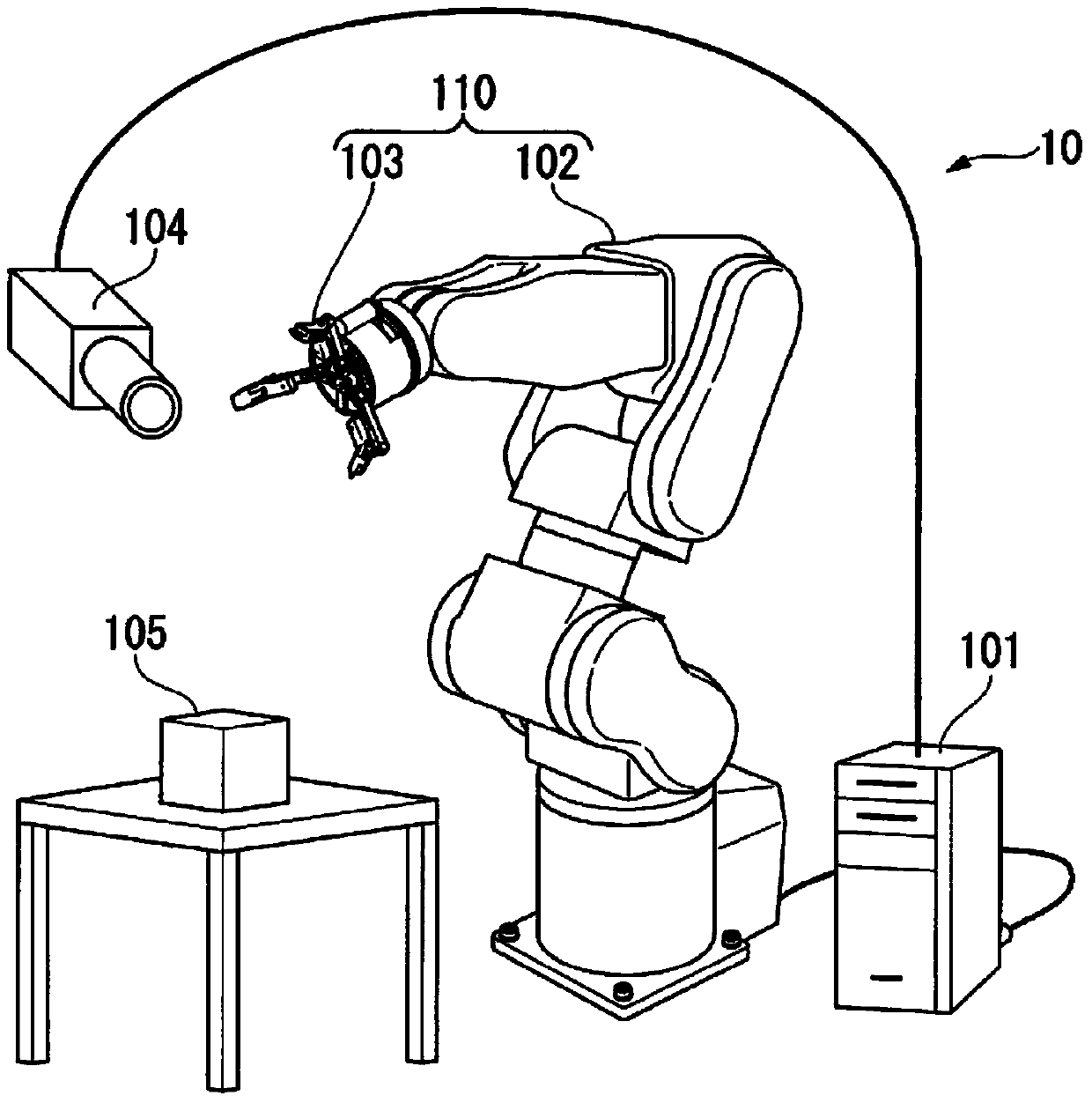

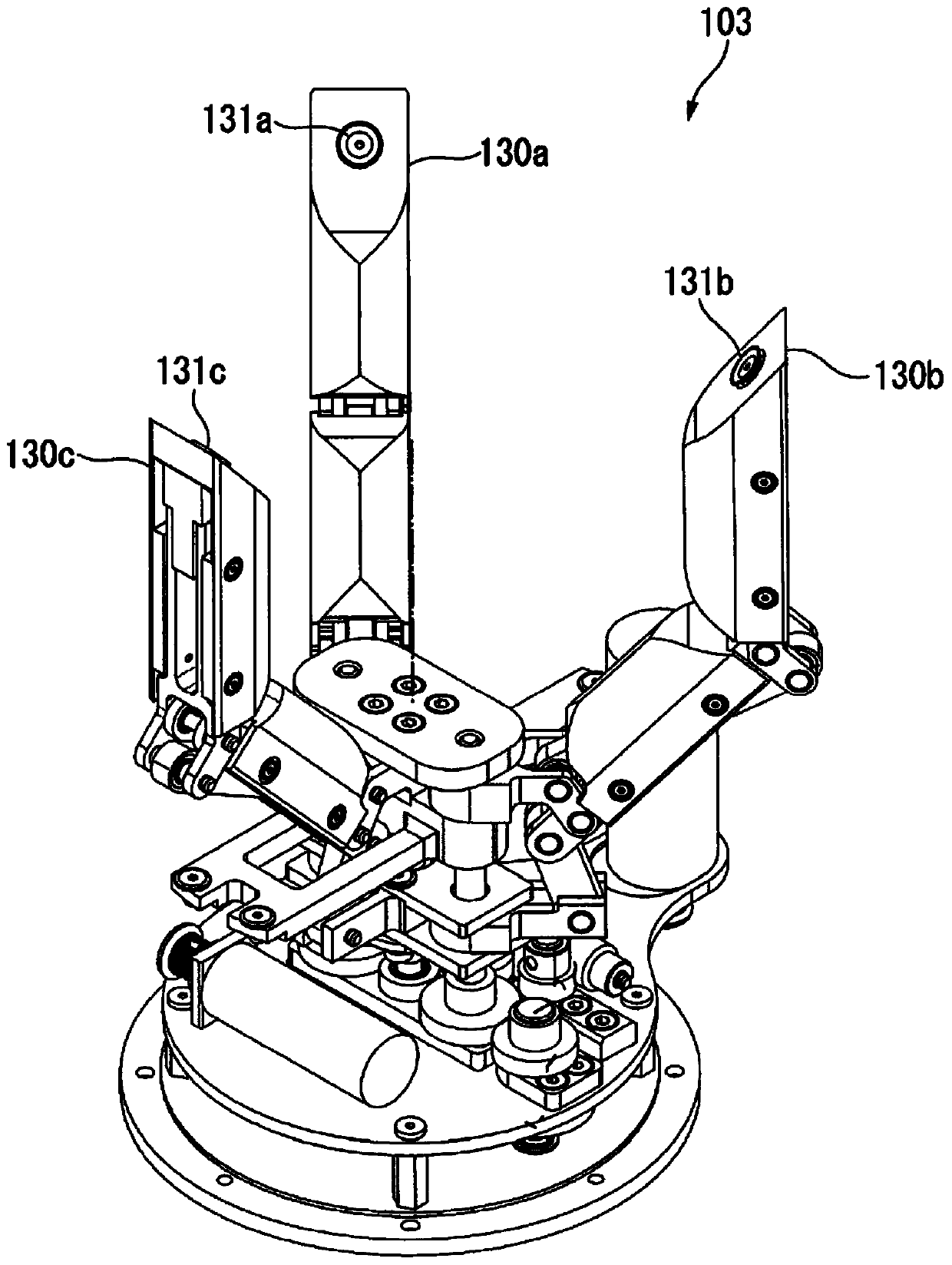

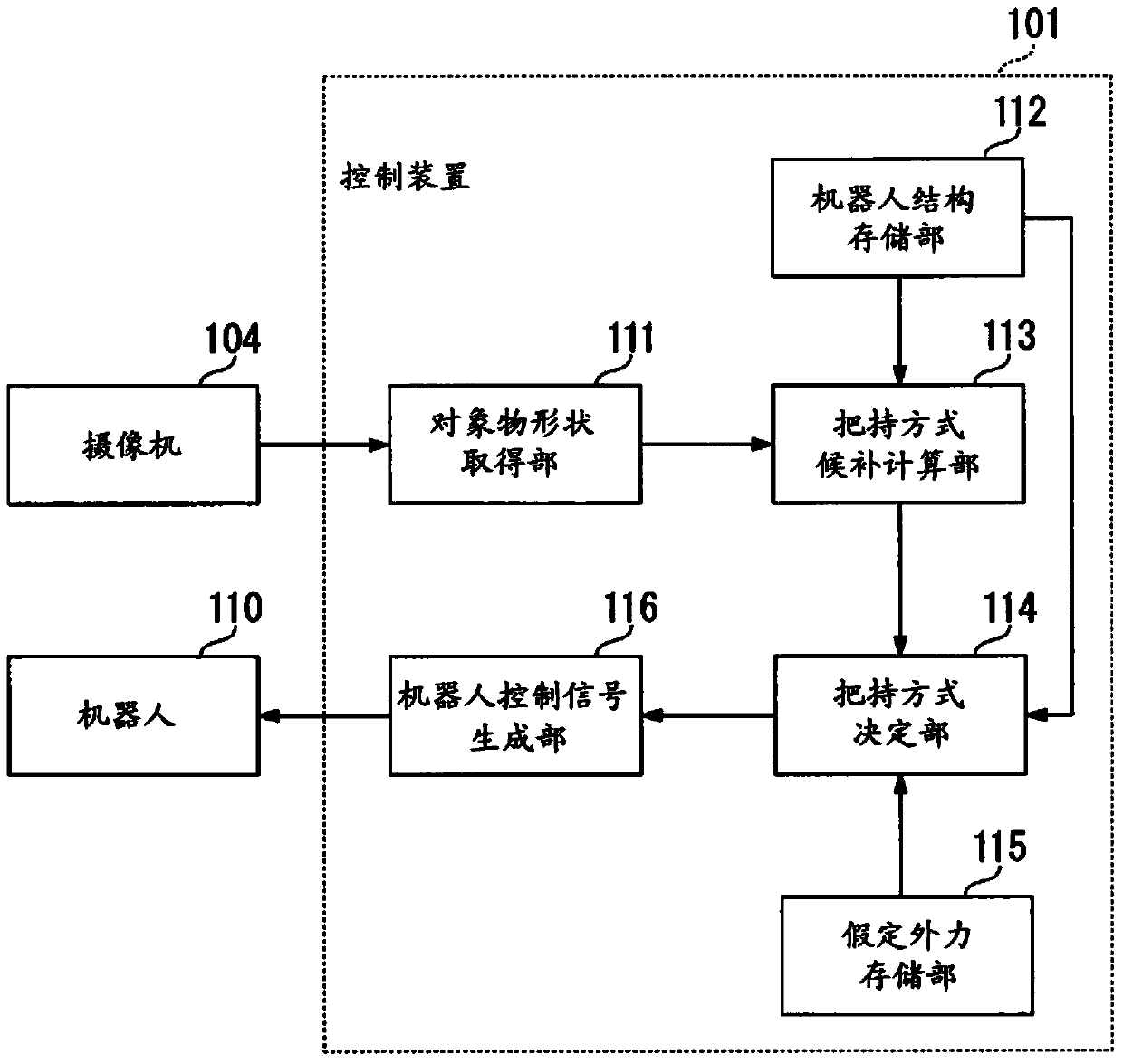

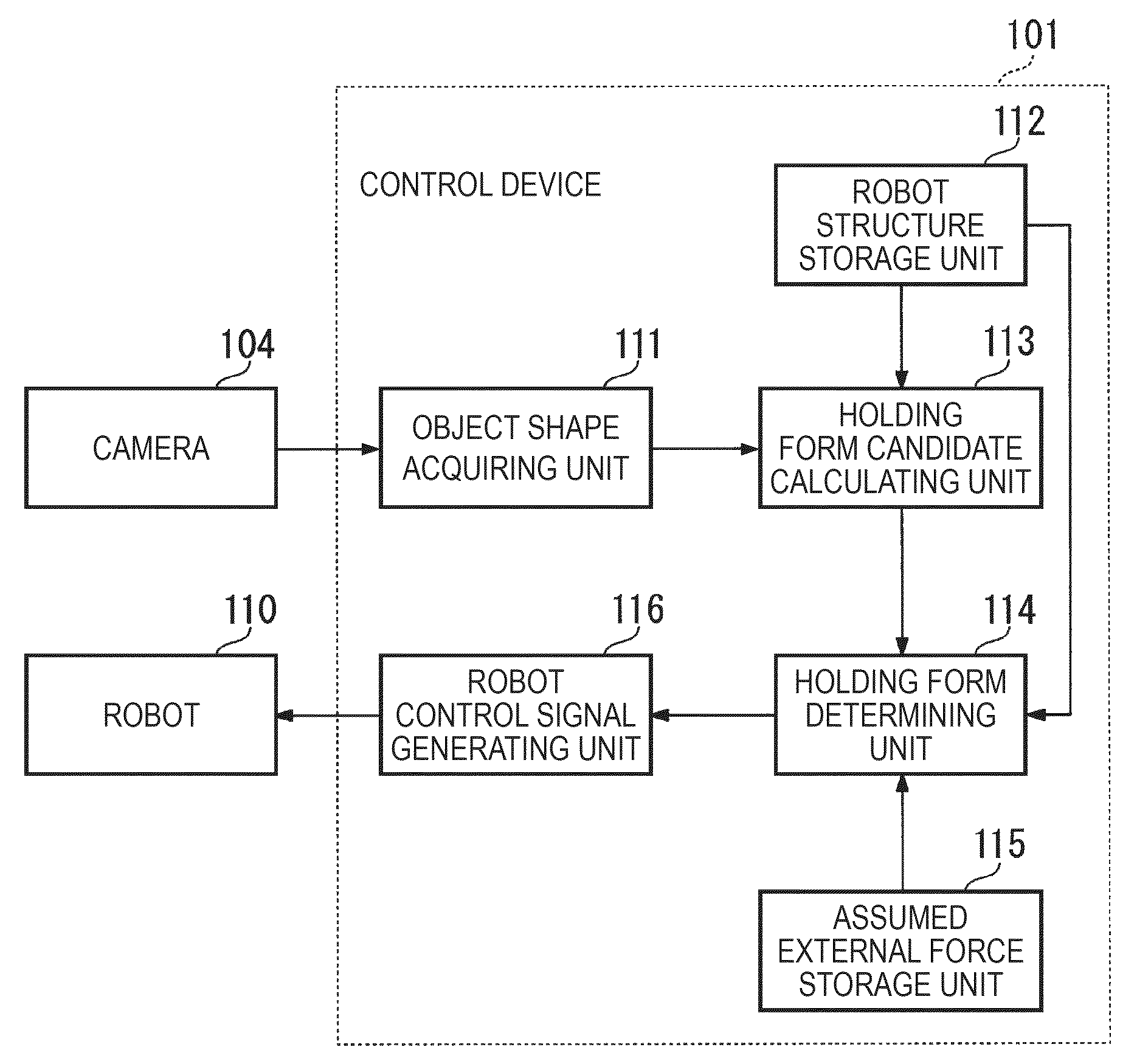

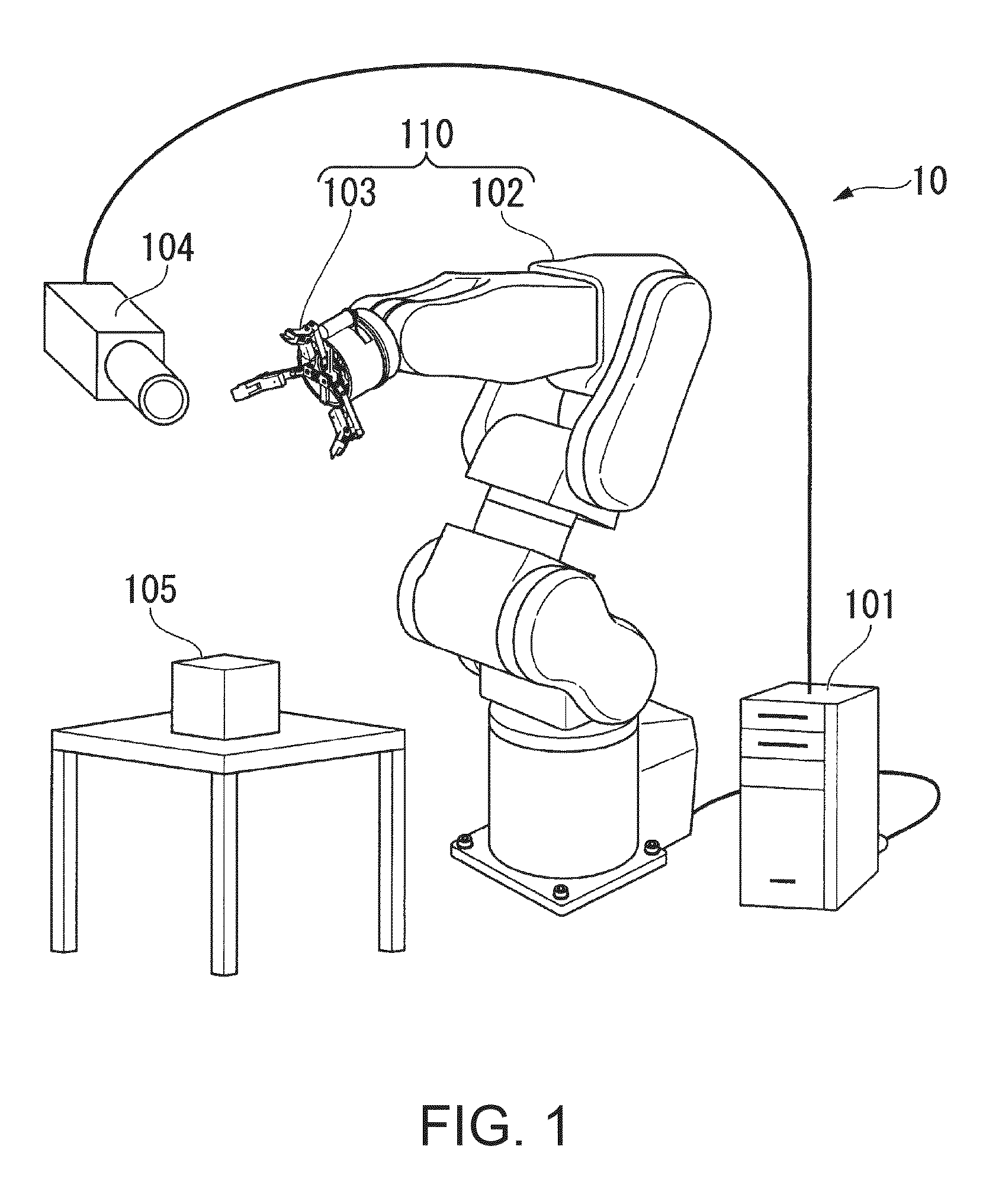

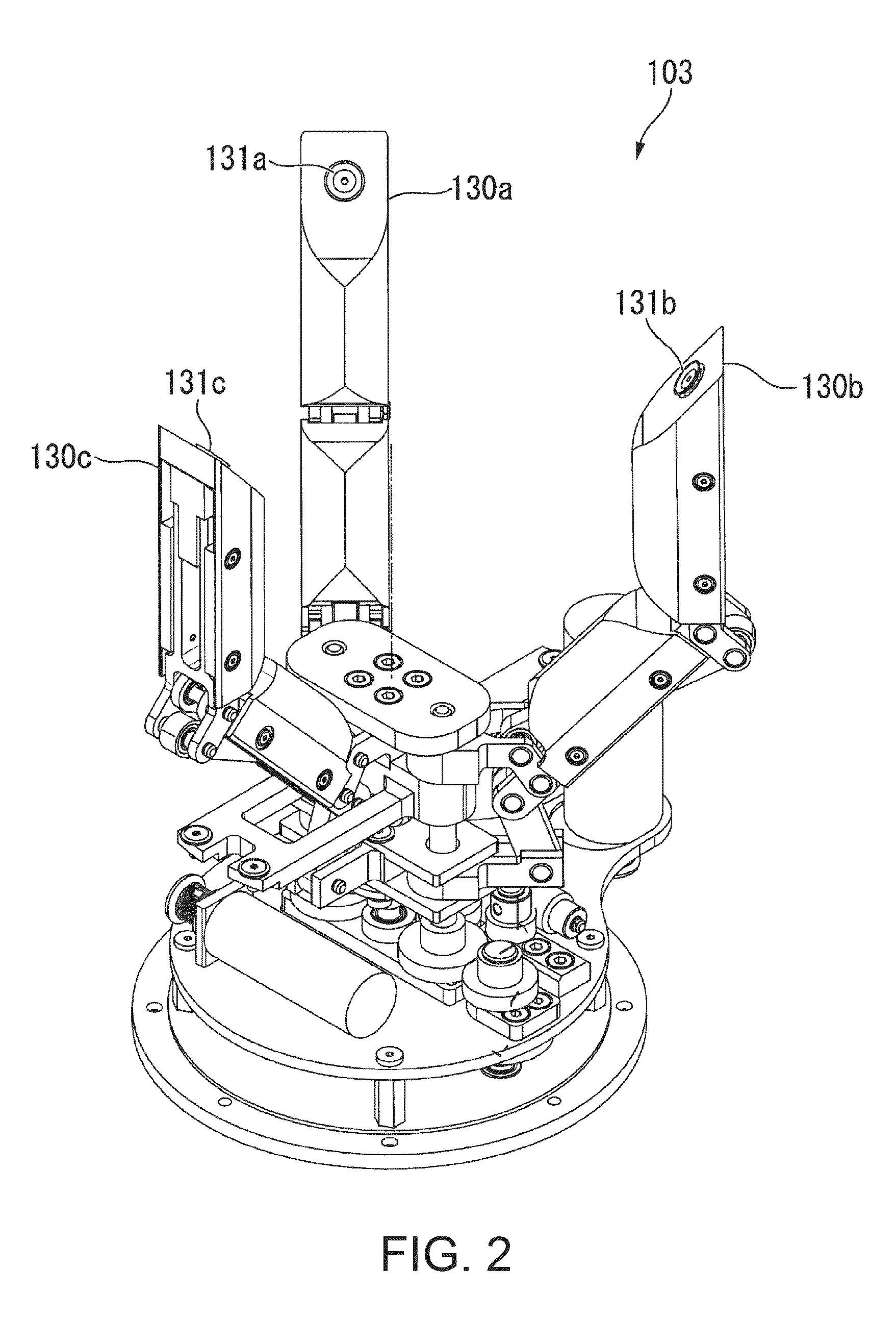

Robot control method, robot control device, robot, and robot system

ActiveUS20140214202A1Weight increaseProgramme controlProgramme-controlled manipulatorRobotic systemsSuction force

A robot control method includes a first step of selecting a holding form in which a robot holds an object and a second step of determining whether the object can continue to be stably held when a predetermined external force is applied to the object in the selected holding form. In the second step, it is determined that the object can continue to be stably held when a force which should be generated by a contact portion to generate resistance to the predetermined external force is included in a friction cone of a force generated by driving the contact portion and enlarged by a suction force from the suction mechanism.

Owner:SEIKO EPSON CORP

Curtain lockset

InactiveCN101606817AWill not affect the normal service lifeReduce tensionCurtain rodsRolling resistanceGear wheel

The invention discloses a curtain lockset which comprises a lockset casing with a cavity. A free gear and a rotating part are arranged in the lockset casing; the central axis direction of the free gear is basically parallel with the rotating axis direction of the rotating part; a tooth surface for causing the free gear to longitudinally roll is arranged on the inner surface of the side wall of the lockset casing; teeth of the tooth surface is matched with the teeth of the free gear; when the free gear is in a clamped condition, the free gear is clamped between the rotating part and the tooth surface; and when the free gear is in a loosened condition, the free gear is separated from the rotating part or the tooth surface, and two ends of the rotating part are respectively connected with the lockset casing through a bearing. The rolling friction force overcome by the rotating part is less when the rotating part is rotated, a guy rope can be conveniently operated with less effort, and the heat quantity released by the friction of the rotating part is less when the rotating part is rotated, the normal service life of the lockset casing can not be affected, and the less friction force during the rotation of the rotating part causes low rotation noise, therefore, the peripheral environment is prevented from being affected.

Owner:徐丽琴

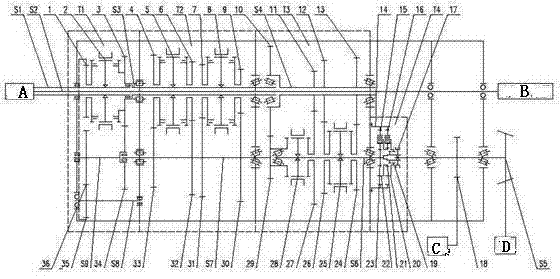

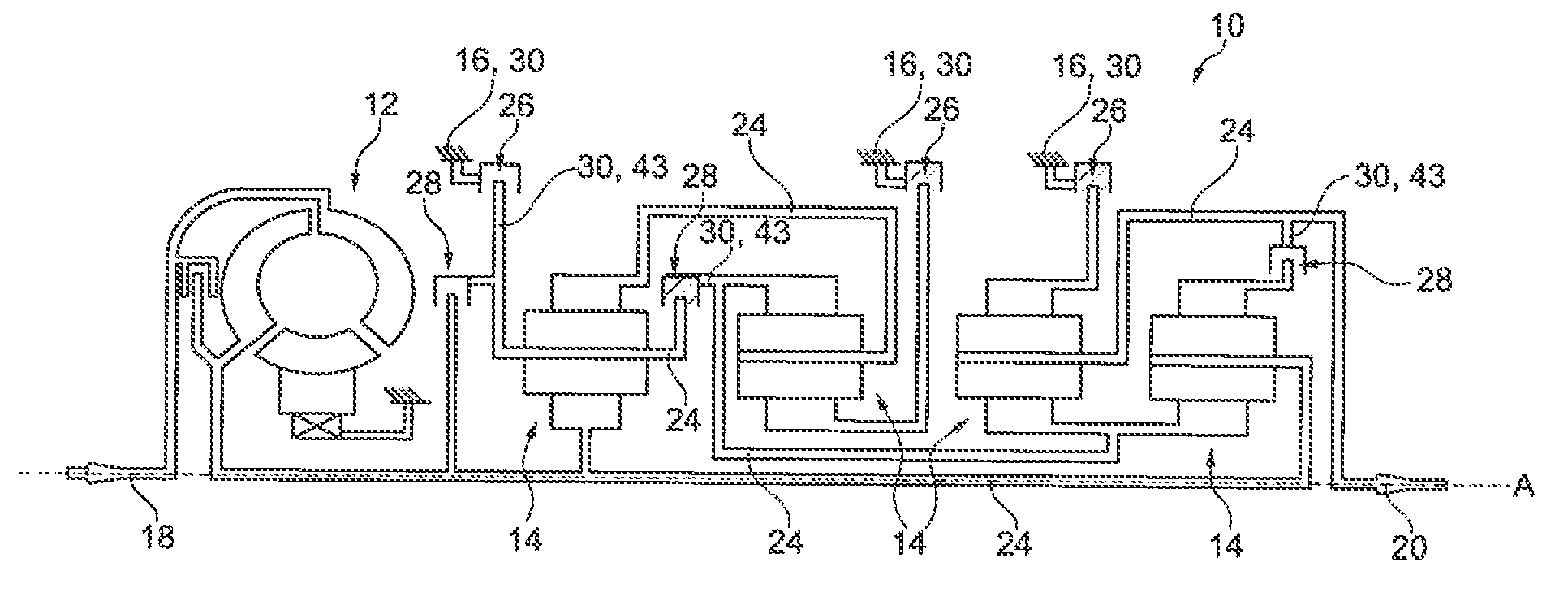

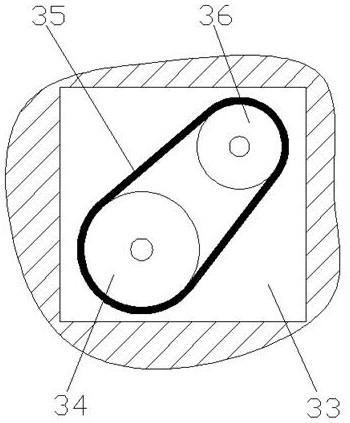

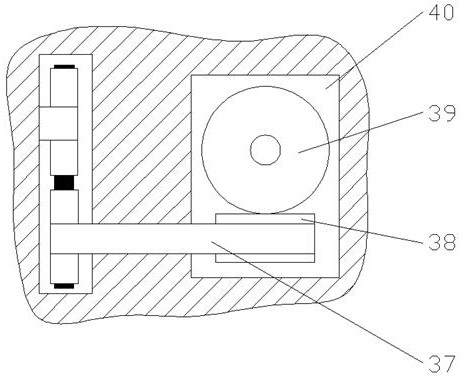

Synchronous reversing belt crawling-gear gearbox of tractor

The invention discloses a synchronous reversing belt crawling-gear gearbox of a tractor. The synchronous reversing belt crawling-gear gearbox comprises a synchronizer reversing device, a main speed variator, an auxiliary speed variator and a crawling gear device which are sequentially arranged. One end of the synchronizer reversing device is connected with an engine, and one end of the crawling gear device is connected with a bevel pinion. The synchronizer reversing device and the main speed variator are double-friction-cone synchronizers. By combining the synchronizer reversing device, the main speed variator, the auxiliary speed variator and the crawling gear device, 32 forward gears and 32 reverse gears can be realized, the more the reverse gears are, the better the operation needs can be met. The synchronizer reversing device is disposed at the front end of the main speed variator, gear reversing and engaging of the double-friction-cone synchronizers are realized, parking for gear engagement is omitted when at low speed, gear shift impact and force are low, gear shift time is short, and operation efficiency is high.

Owner:FIRST TRACTOR

Reduced-friction joint with electromagnetically separable bearing surfaces

ActiveUS9956080B1Reduce wear particle productionReduce frictionAnkle jointsJoint implantsRelative motionEngineering

The disclosure provides a joint replacement coupling comprising joint members with opposing joint surfaces, wherein one of the members has a magnetic portion therein which comprises an array of magnets, and the other of the members has a conduction portion therein that comprises a conductive surface. The magnets are arranged to produce a magnetic field that contacts the conduction portion. The conduction portion is optionally positioned so that at least a portion of the conductive surface contacts the magnetic field so that relative motion between the opposing joint surfaces induces current loops in the conductive surface and produces a repulsive force against the magnetic portion, thereby reducing friction between the joint surfaces, optionally separating the joint surfaces.

Owner:HOWARD JASON

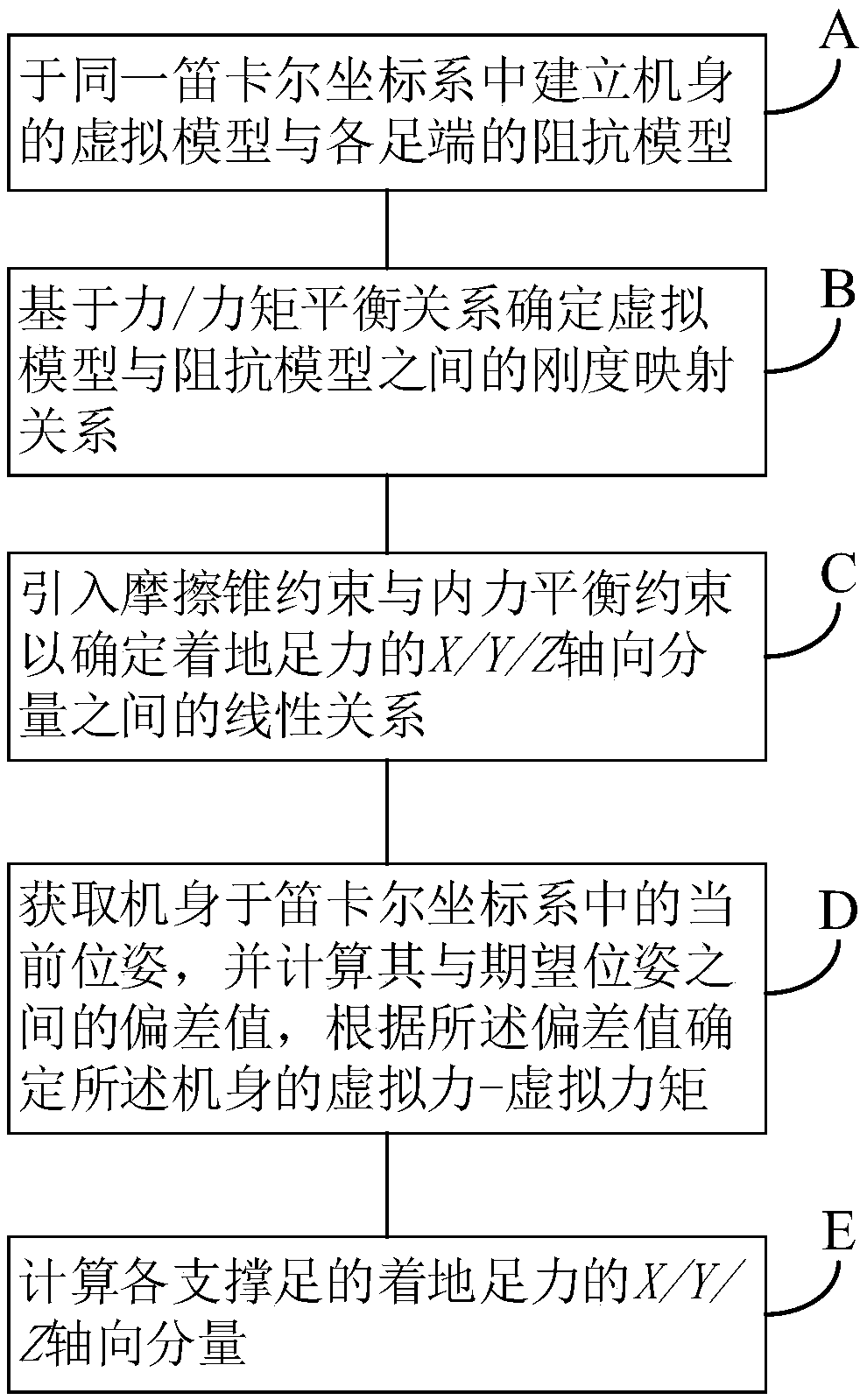

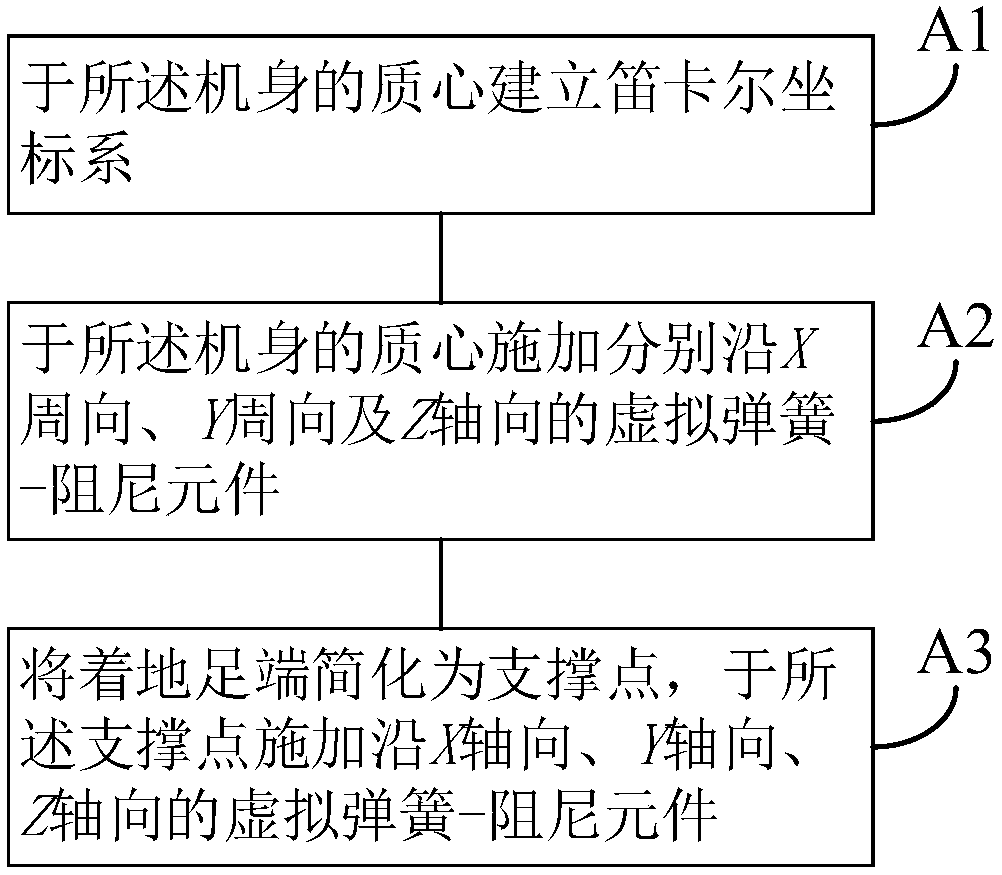

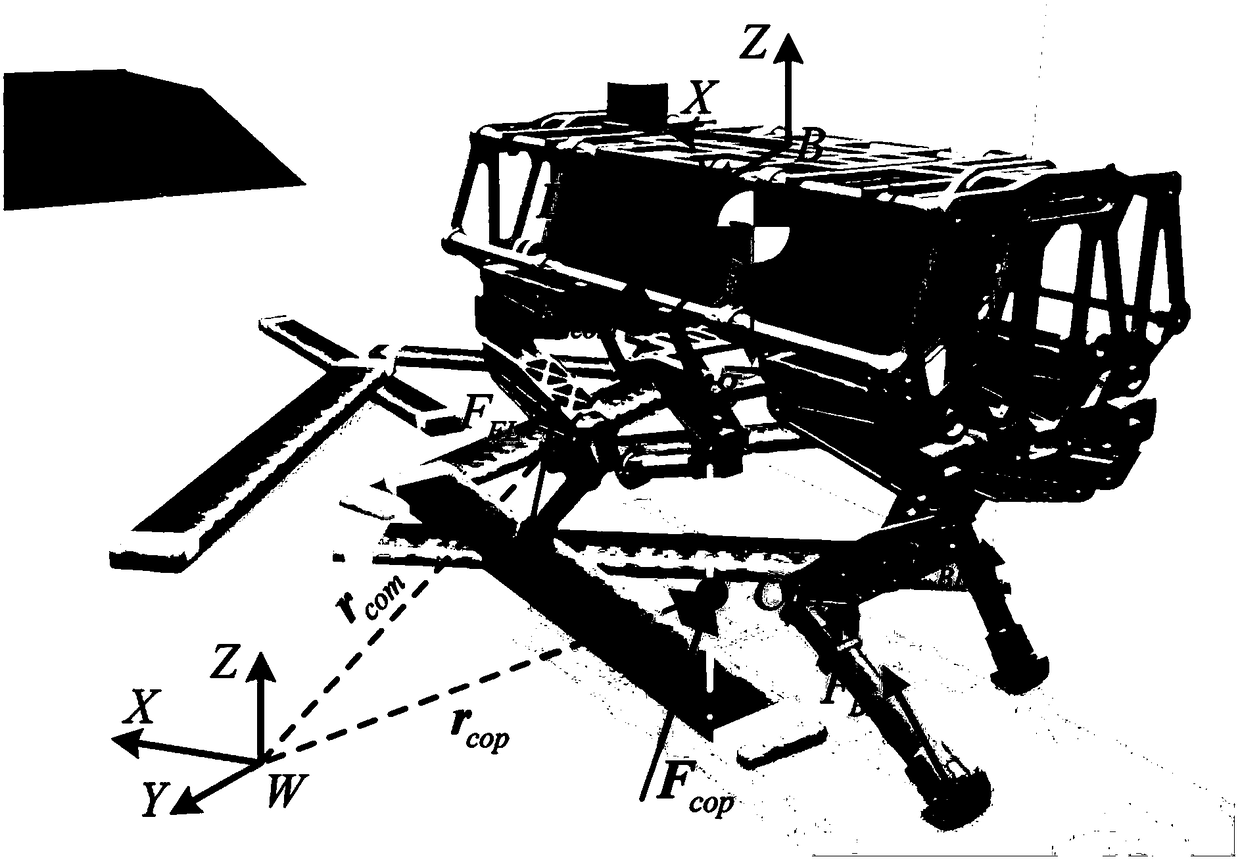

Quadruped robot landing foot force distribution method and device, terminal and computer readable storage medium

ActiveCN109500821AAdd linear constraintsAdd boundary conditionsProgramme-controlled manipulatorVehiclesDistribution methodSimulation

The invention discloses a quadruped robot landing foot force distribution method. The quadruped robot landing foot force distribution method comprises the steps that a virtual model of a machine bodyand an impedance model of each foot end are established in a same cartesian coordinate system; a stiffness mapping relationship between the virtual model and the impedance models is determined based on a force / torque balance relationship; a friction cone constraint and an internal force balance constraint are introduced to determine a linear relationship between X / Y / Z axial components of the landing foot force; fictitious force-fictitious torque of the machine body is determined according to a deviation value between a current pose and a desired pose in the cartesian coordinate system; and based on the Newton-euler equation, according to the stiffness mapping relationship, the linear relationship between the X / Y / Z axial components of the landing foot force and the virtual force-virtual torque of the machine body, the X / Y / Z axial components of the landing foot force of supporting foots are calculated. The quadruped robot landing foot force distribution method can realize the fast solution calculation of the analytical solution of the landing foot force, and has the advantages of high calculation efficiency and a low hardware cost.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

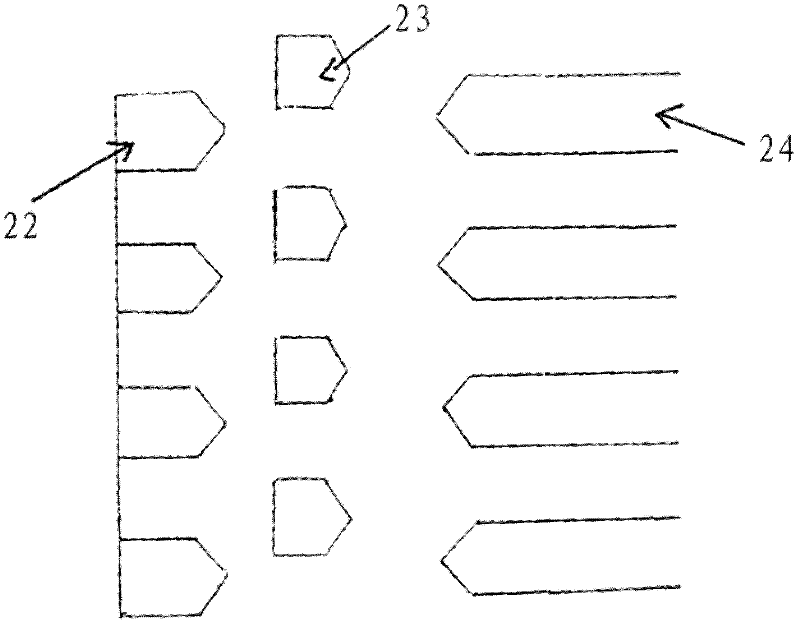

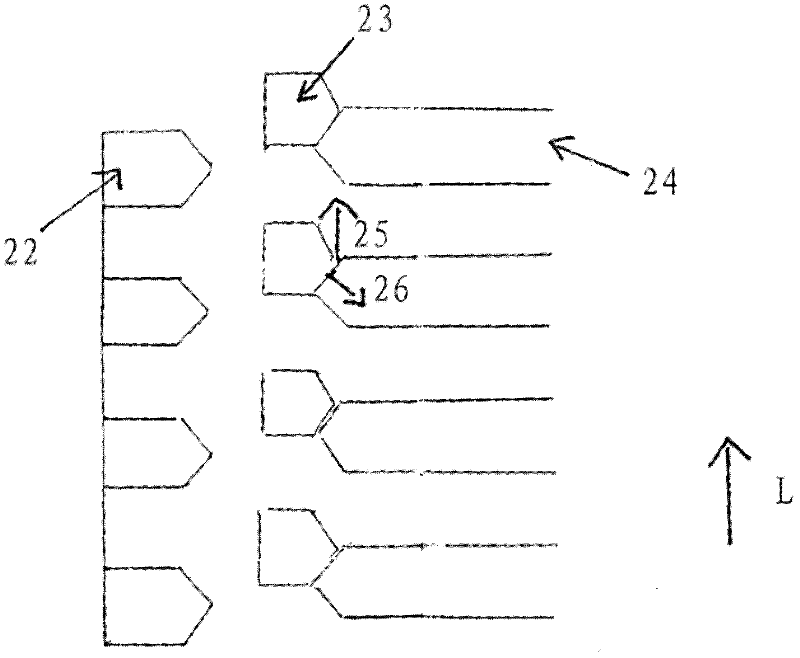

Large modulus gear and involute sawtooth wave clutch gearbox for lawn mower

InactiveCN102282974AMeet the installation requirementsAvoid undercutHarvestersPortable liftingPlastic injection moldingHigh volume manufacturing

There are a variety of solutions available on several models. In order to further reduce costs, plastic molding methods, especially injection molding, are recommended to mass-produce gears and gearboxes for lawn mowers. The ninth solution is to use less expensive non-machine Processing, especially the large modulus gears for injection-molded lawn mowers and the reduction boxes for involute saw-tooth wave clutches. A large number of injection molded parts are used. Let the injection molded gears be able to work with larger torques and clutch tasks, increase the modulus, reduce the number of teeth, and change the friction cone to an involute sawtooth wave clutch. It is characterized in that: the large modulus gear (88) with involute sawtooth wave clutch is provided with large modulus teeth (88a), connecting wall (88b), sawtooth (88c), involute sawtooth wave (88d), Main rear axle clearance slot (88e). The number of teeth of the pinion (89) is single teeth, or double teeth, or 3 teeth, or more, preferably 3 teeth.

Owner:NINGBO DAYE GARDEN EQUIP

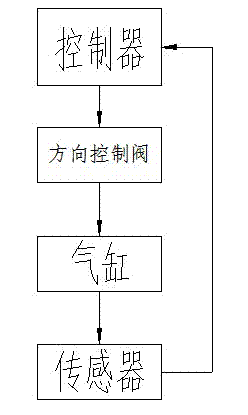

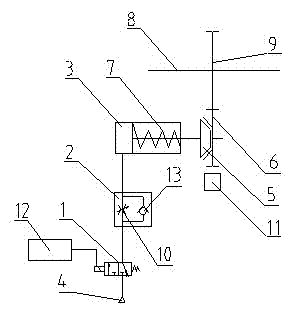

Pneumatic-type intermediate-shaft braking system and braking method

InactiveCN102352898ARealize the braking functionSteady braking forceAxially engaging brakesBrake actuating mechanismsAxial displacementVehicle frame

The invention relates to a pneumatic-type intermediate-shaft braking system and a braking method. The pneumatic-type intermediate-shaft braking system mainly comprises an air-pressure source, a cylinder, a return spring and a power take-off gear, and in addition, the pneumatic-type intermediate-shaft braking system also comprises a direction-controlling valve, a speed-regulating valve, a frictioncone, a braking gear, a sensor and a controller, wherein the air-pressure source, the direction-controlling valve, the speed-regulating valve and the cylinder are sequentially connected through air pipelines; the speed-regulating valve is installed on a vehicle frame; the braking gear is installed on a supporting shaft and is engaged with the power take-off gear which is installed on an intermediate shaft in a gearbox; the friction cone is installed at the end part of a cylinder rod; the return spring is installed in the cylinder; and the sensor, the direction-controlling valve and the controller are connected through line bundles. The sensor can be used for detecting the rotating speed of the power take-off gear or the braking gear or can be used for detecting the axial displacement quantity of the friction cone. Through the pneumatic-type intermediate-shaft braking system and the braking method, the defect that an original intermediate-shaft brake system has a short service life andcan not be used in the driving process of a vehicle is mainly overcome, and meanwhile, a technical scheme for improving the gear-shifting quality is also provided for an automatic gearbox without adopting a synchronizer.

Owner:一汽解放青岛汽车有限公司

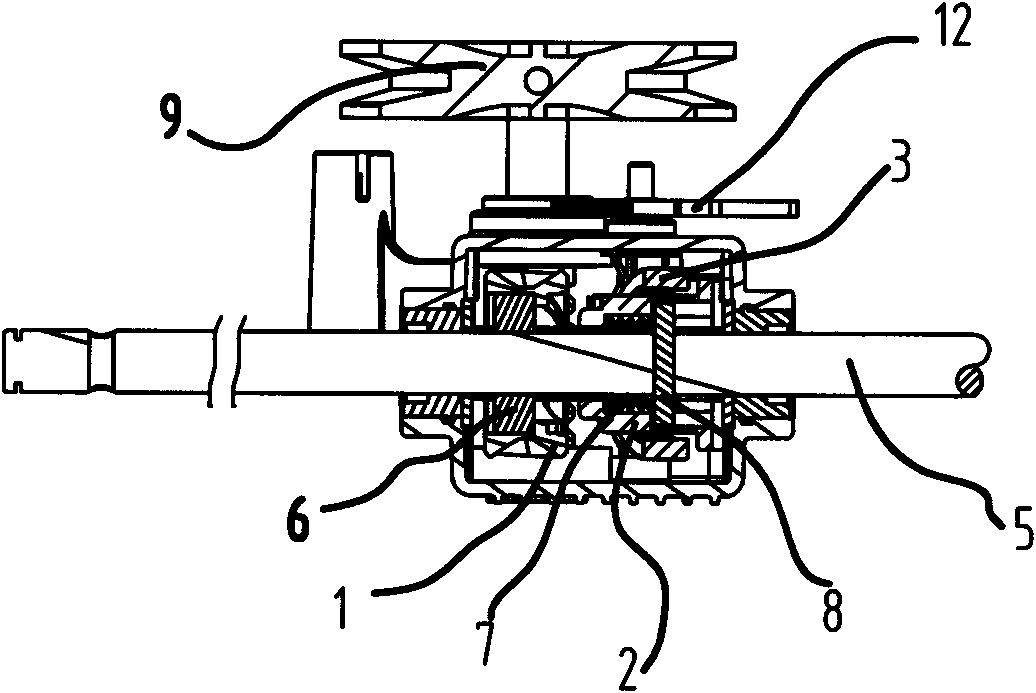

Linear damper

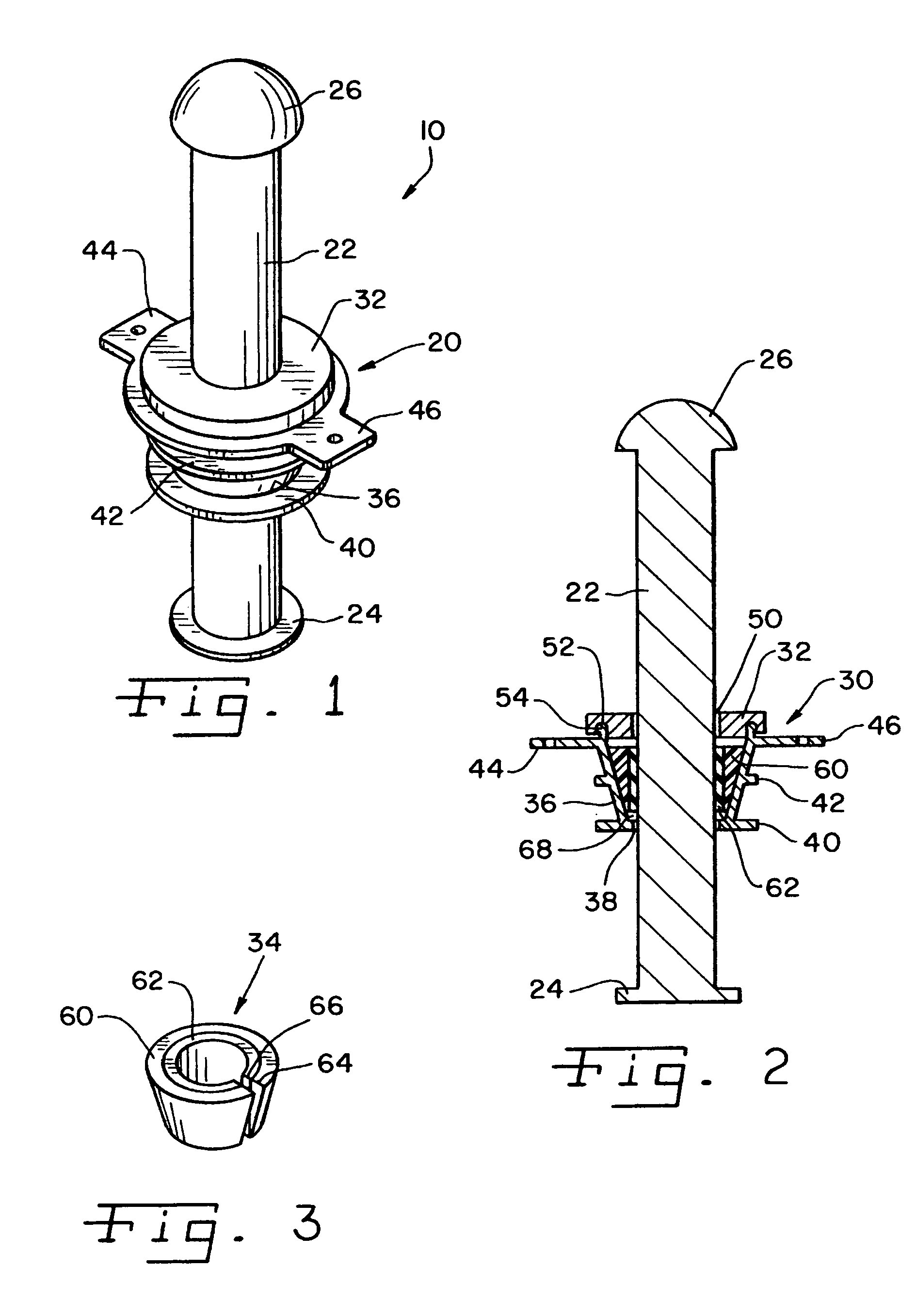

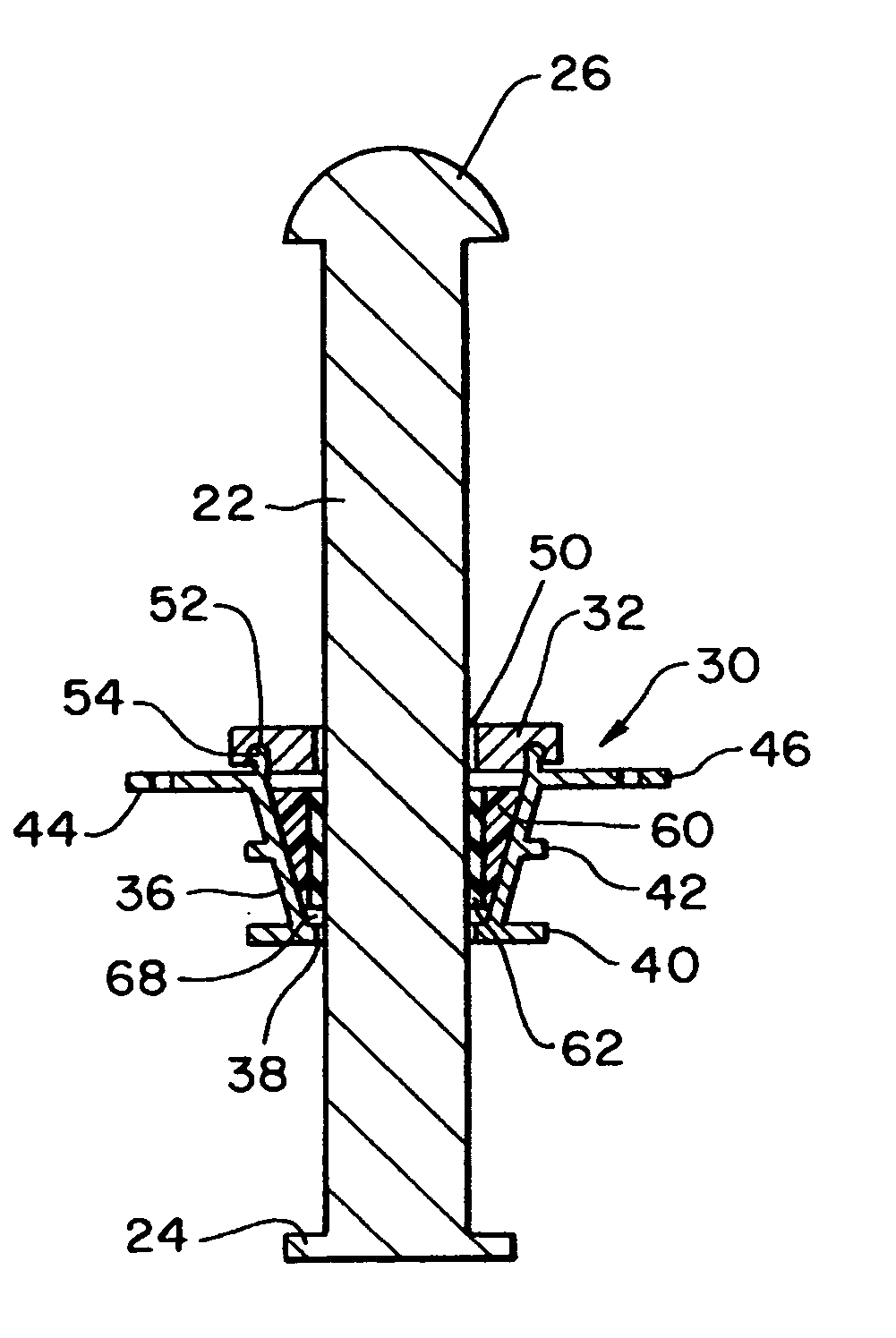

InactiveUS7717239B2Small operationSimple and inexpensive to manufacturePassenger spaceLeaf springsEngineeringFriction cone

A linear damper includes a conical housing with a friction cone in the housing and a rod extending therethrough and axially moveable relative thereto. The friction cone is axially moveable in the housing and radially expandable and contractible to provide clamping force against a rod when the rod is moved in one axial direction and to relieve clamping force from the rod when the rod is moved in the opposite axial direction.

Owner:ILLINOIS TOOL WORKS INC

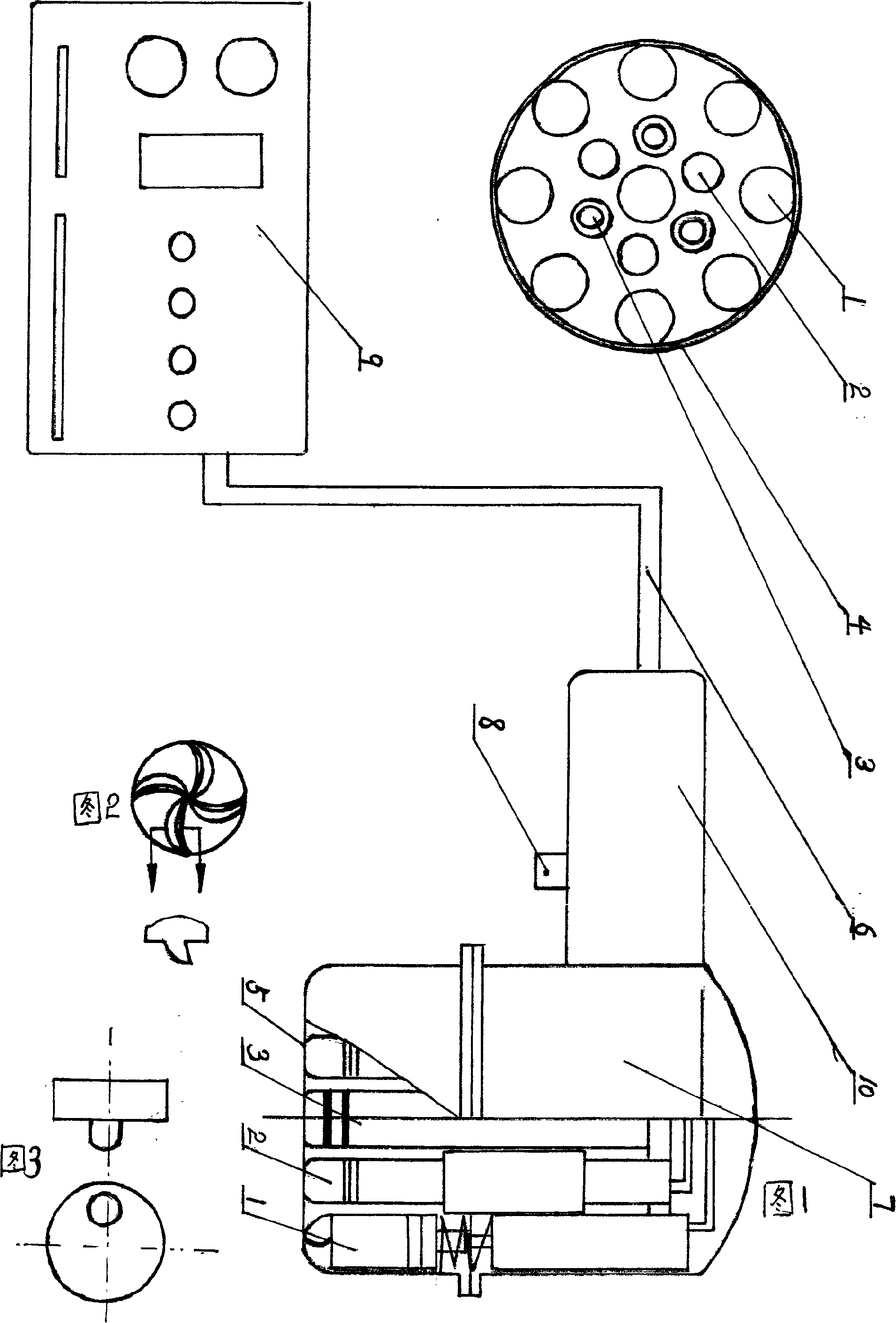

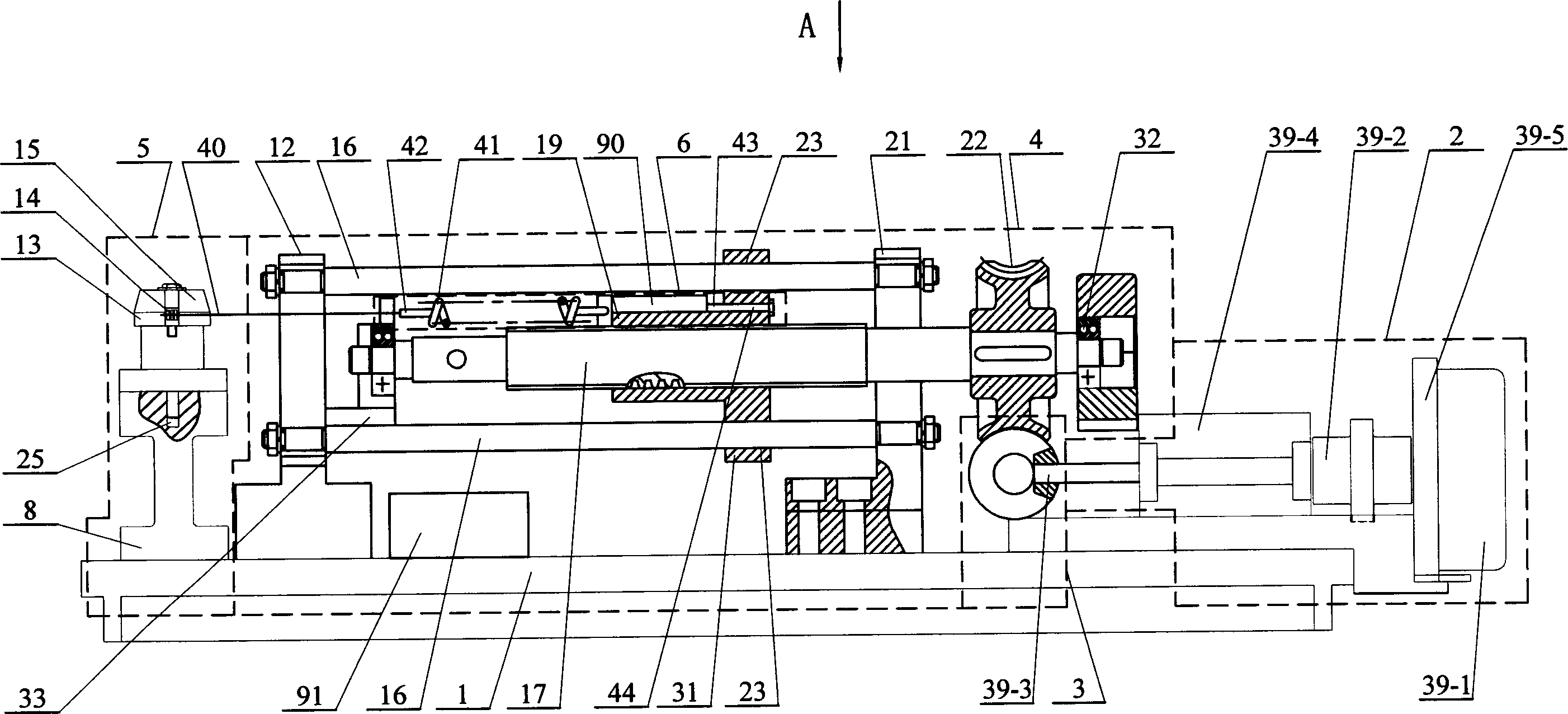

Simulator for friction force between denture groove and correction string

A simulator for the friction between the tooth deformity correcting bow wire and the supporting slot in order to test the friction force is composed of a base, a driver, a speed variator fixed on the base on the right of driver, a tester fixed in said driver, a tension sensor in the driver on the right of tester, and a signal amplifier with input connected to the output of tension sensor.

Owner:HARBIN INST OF TECH

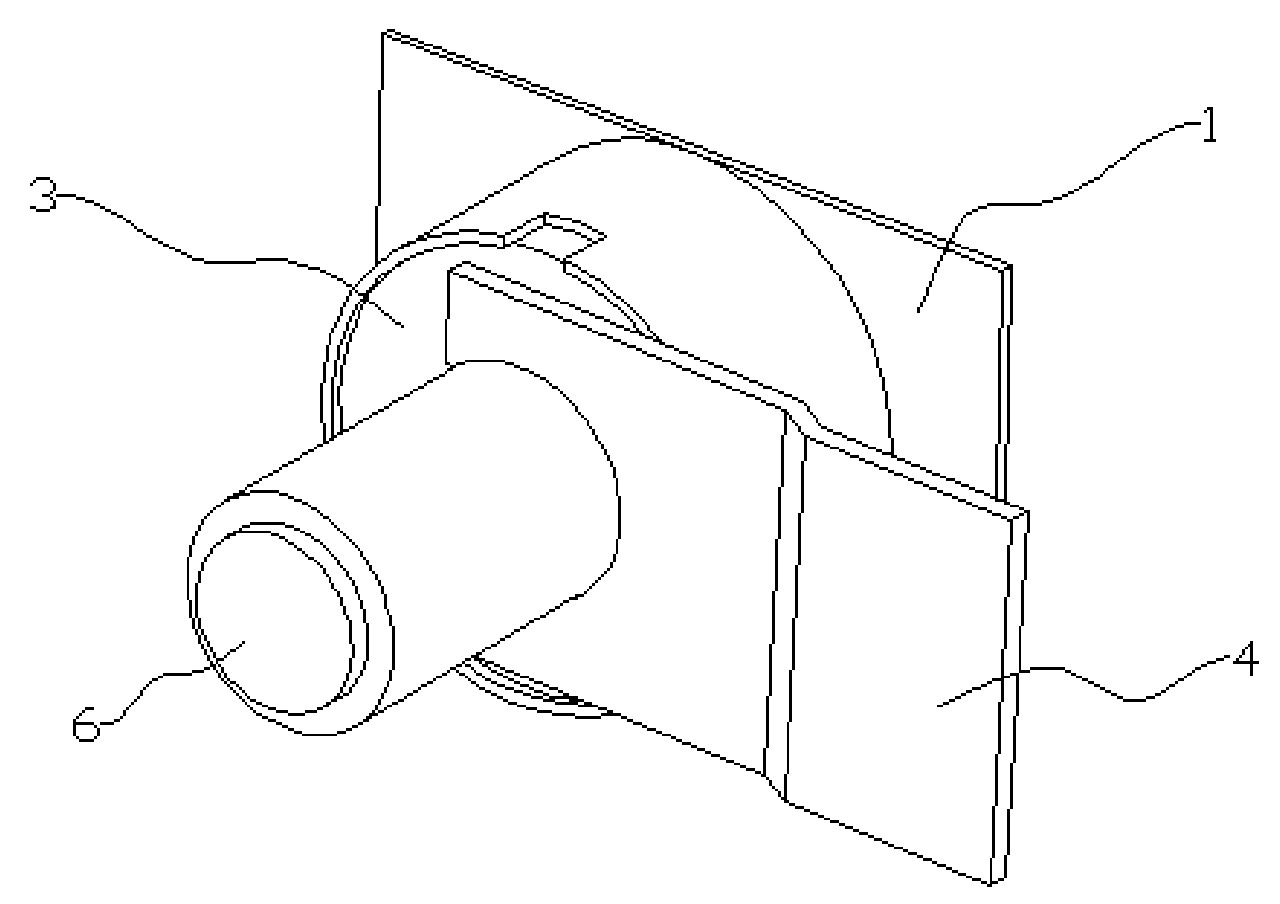

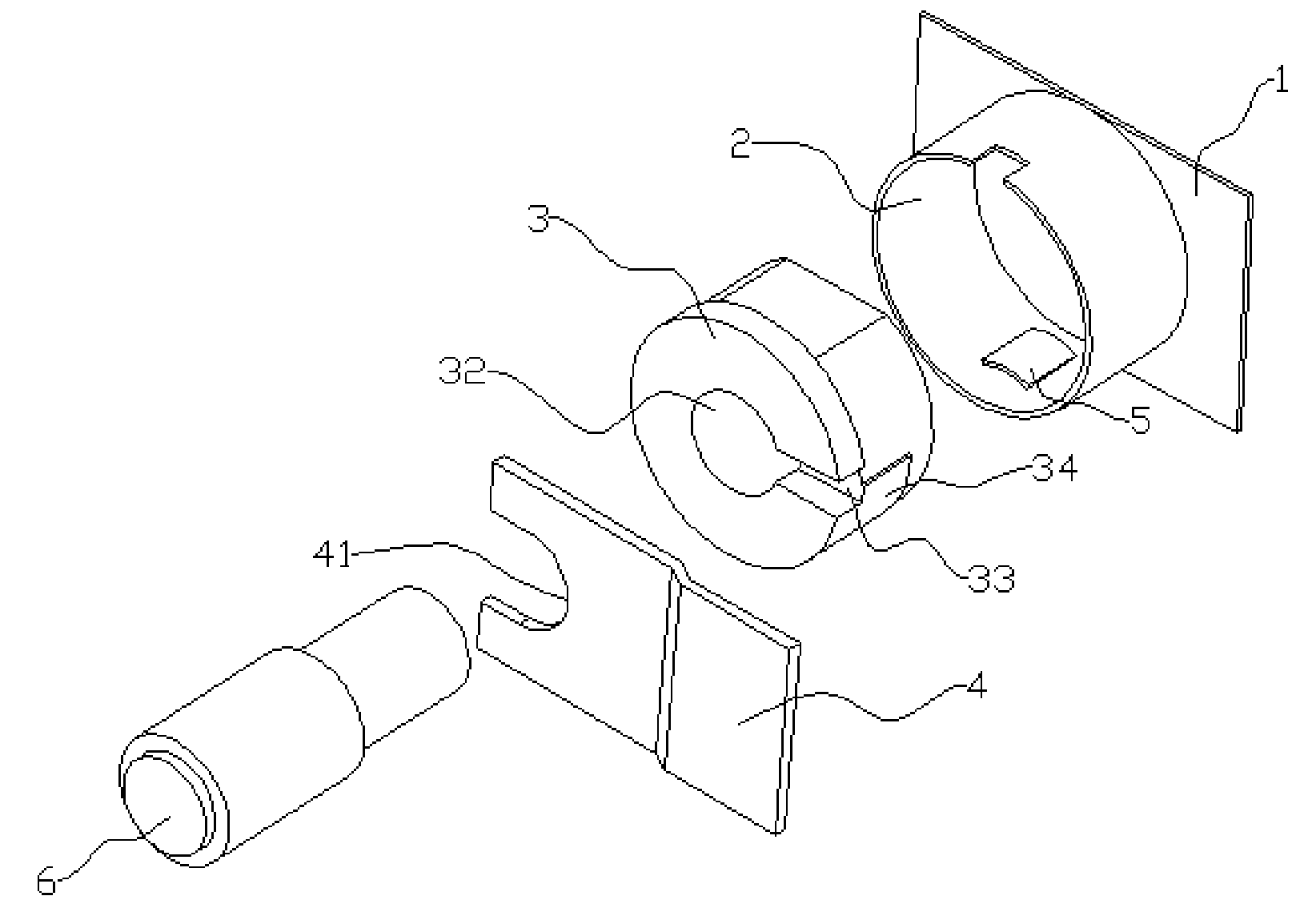

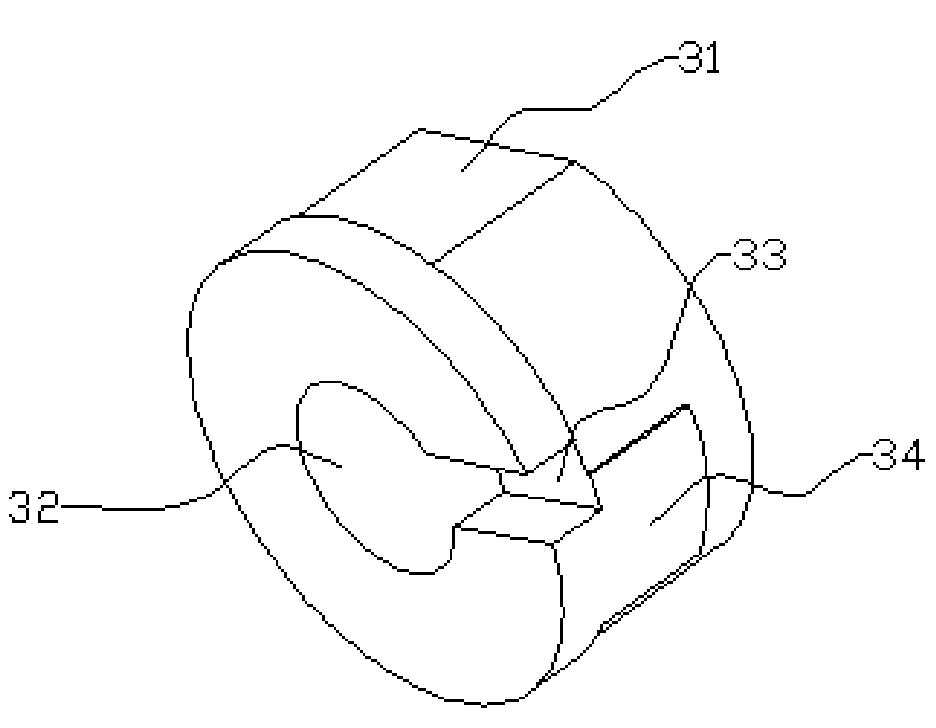

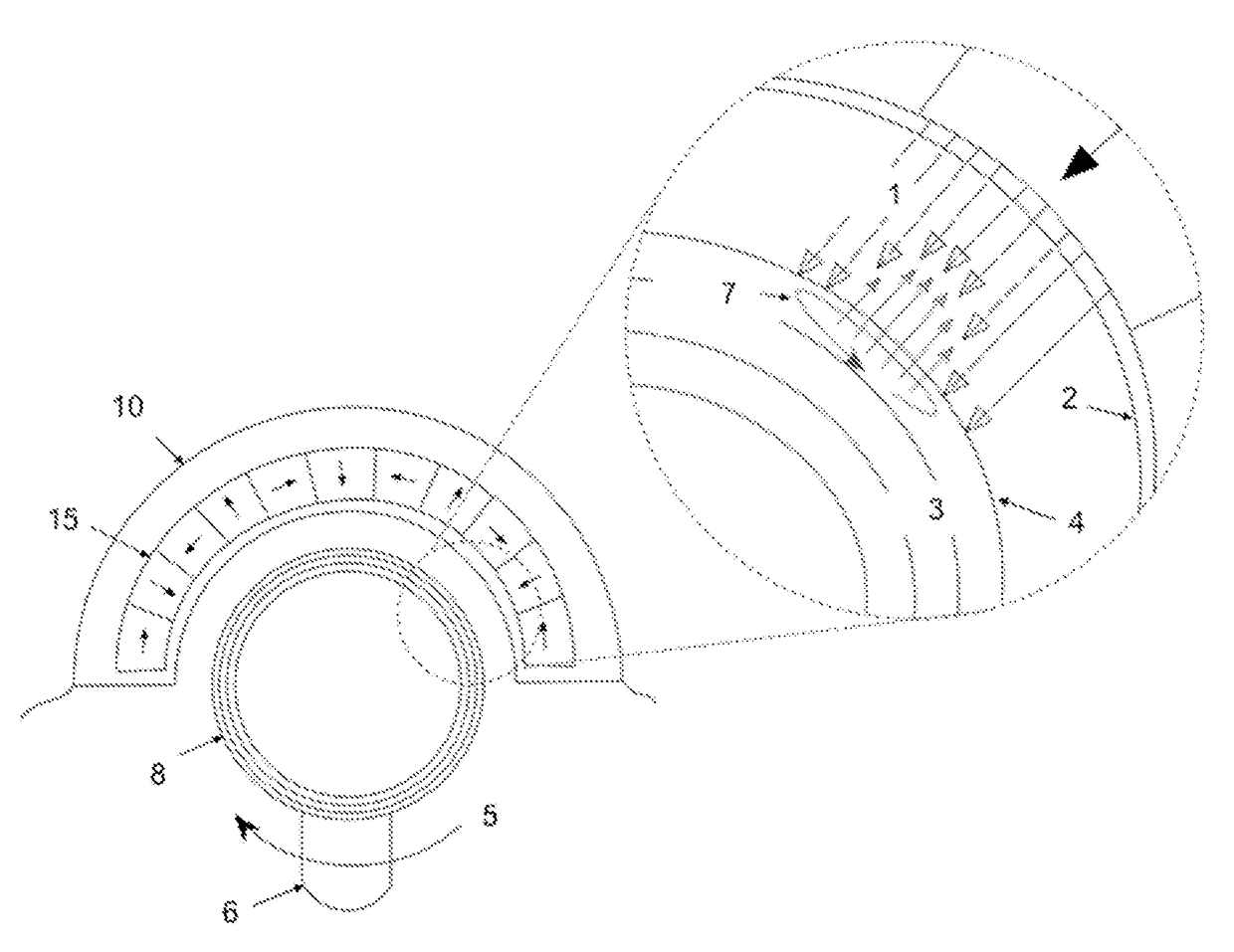

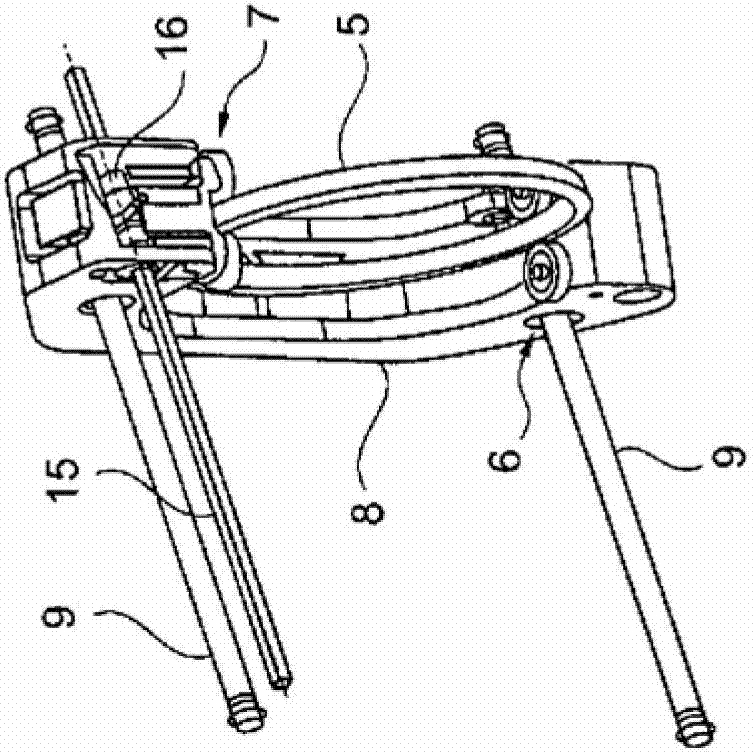

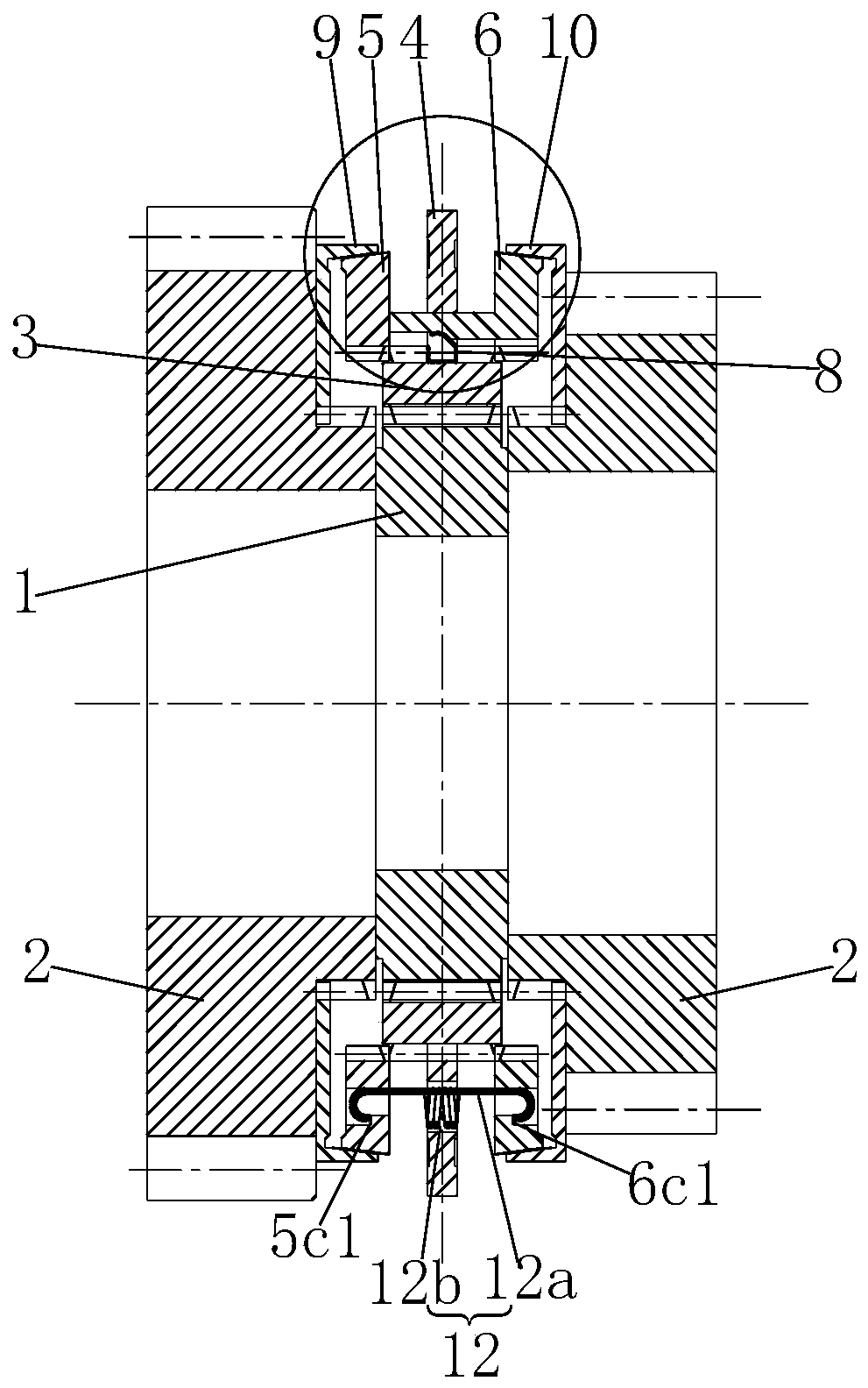

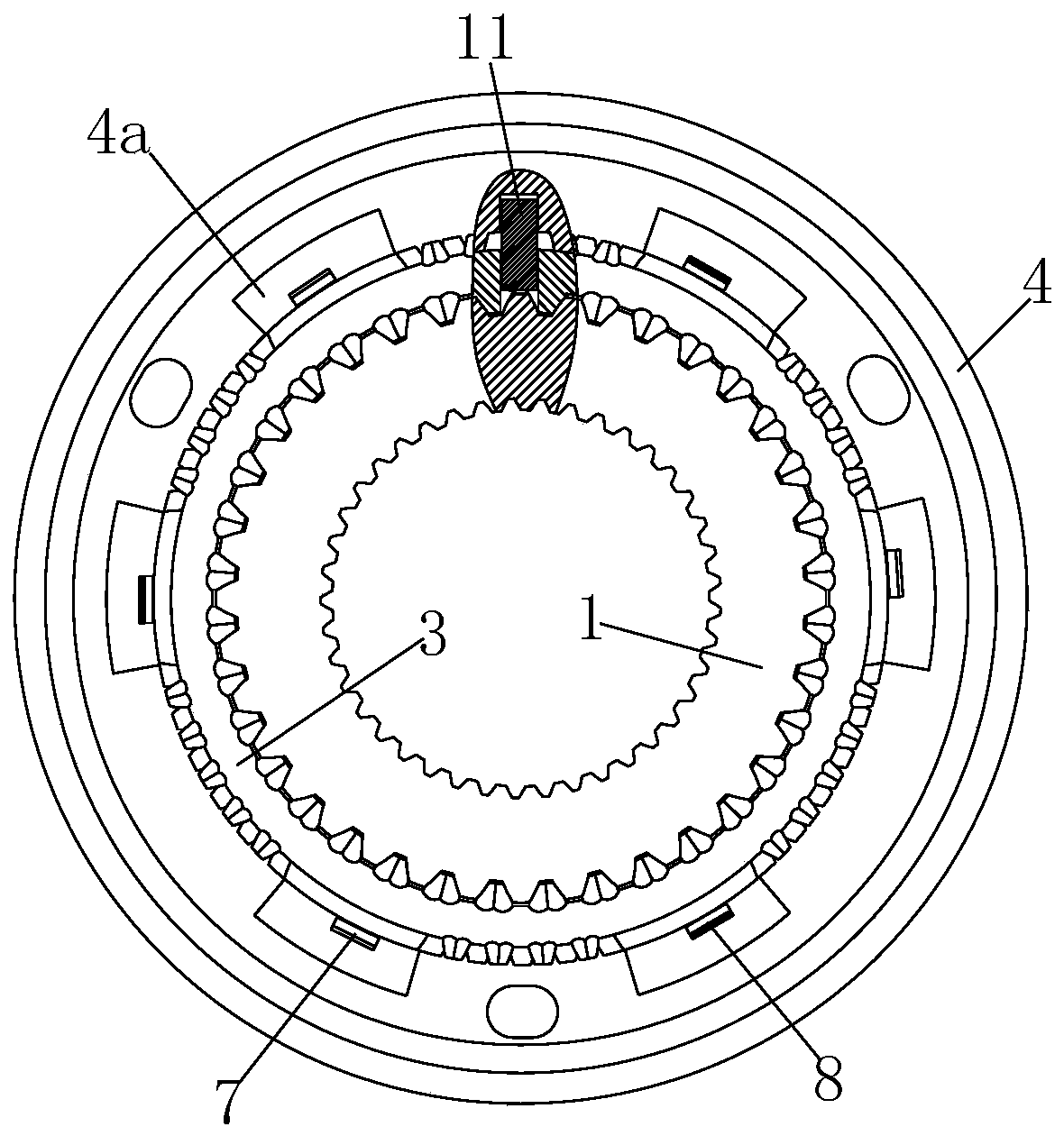

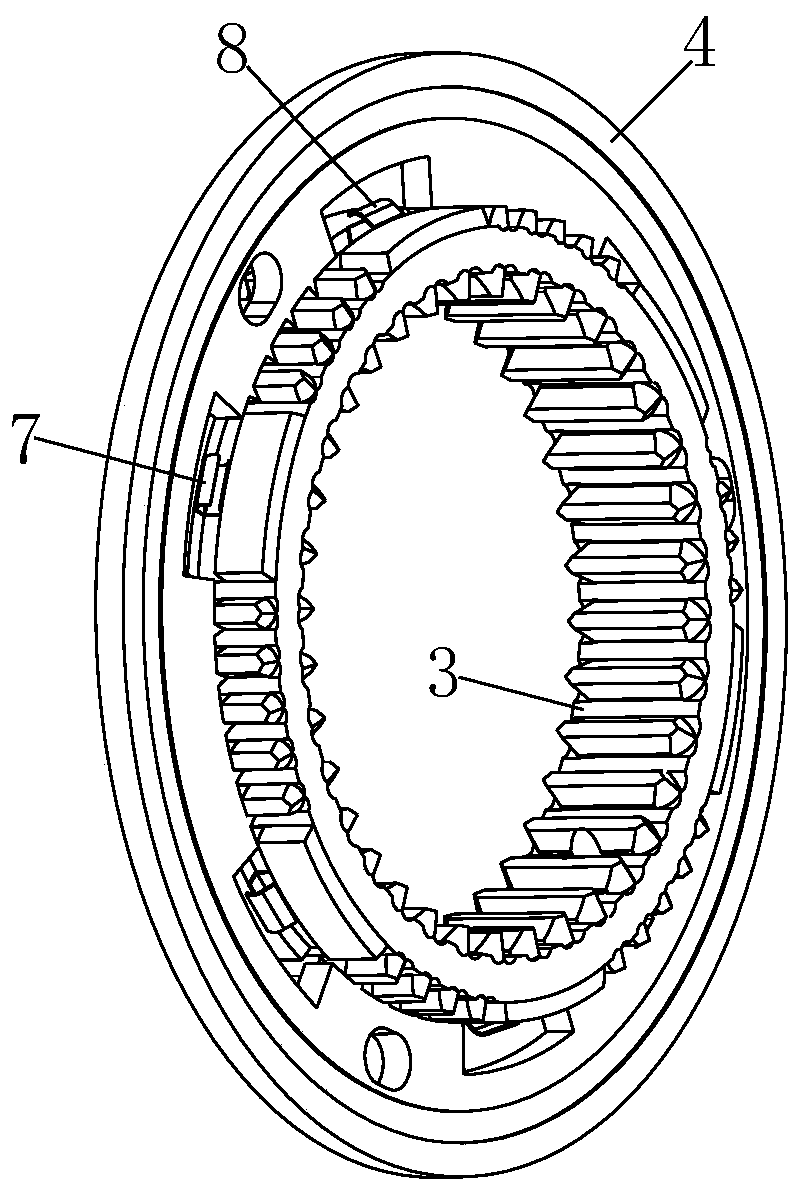

Conical friction ring gear

InactiveCN102959278APrecise positioningImprove operational reliabilityFriction gearingsFriction coneOperational reliability

In order to provide a conical friction ring gear having two friction cones which are spaced apart from each other by a gap and have a friction ring which revolves around one of the two friction cones through the gap and is arranged so as to be shiftable along the gap via an adjustment bridge, which can be freely shifted along an adjustment bridge path, wherein the adjustment bridge is mounted via an axial guide device and has a device for adjusting a friction ring angle, which conical friction ring gear has a high degree of operational reliability and reliably operates in particular in the event of failure of the means of activating the tilting movement of the guide device, the adjustment device is activated by means of a sliding rail which can be positioned in parallel.

Owner:乌尔里克·罗斯

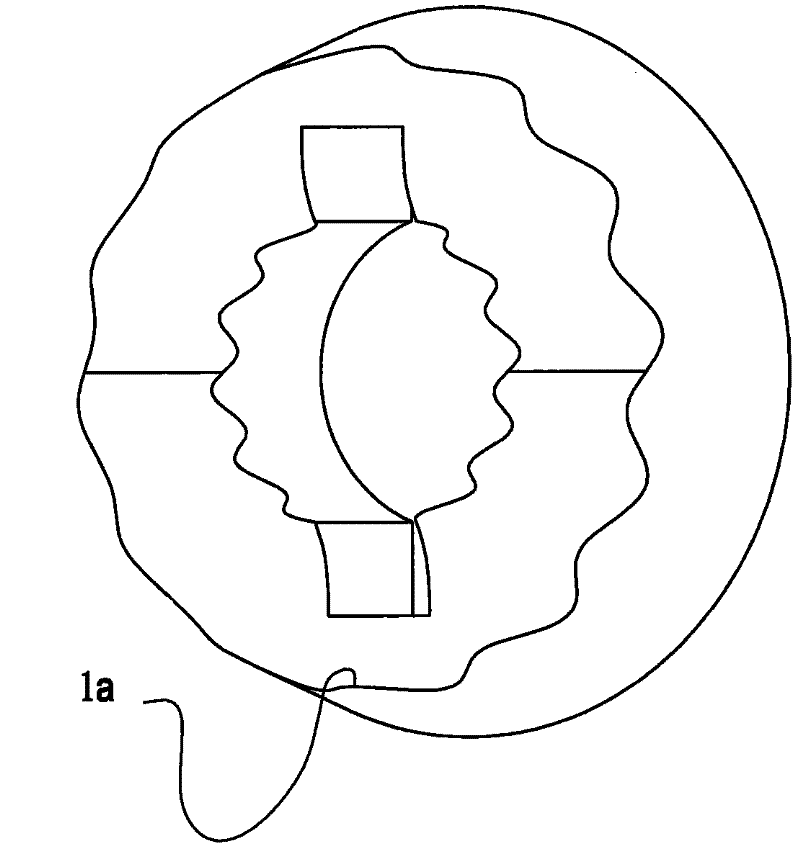

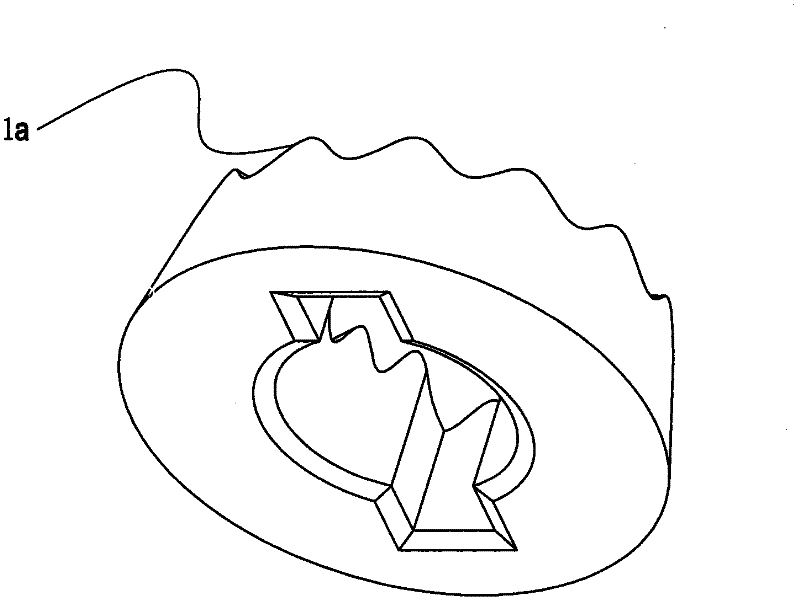

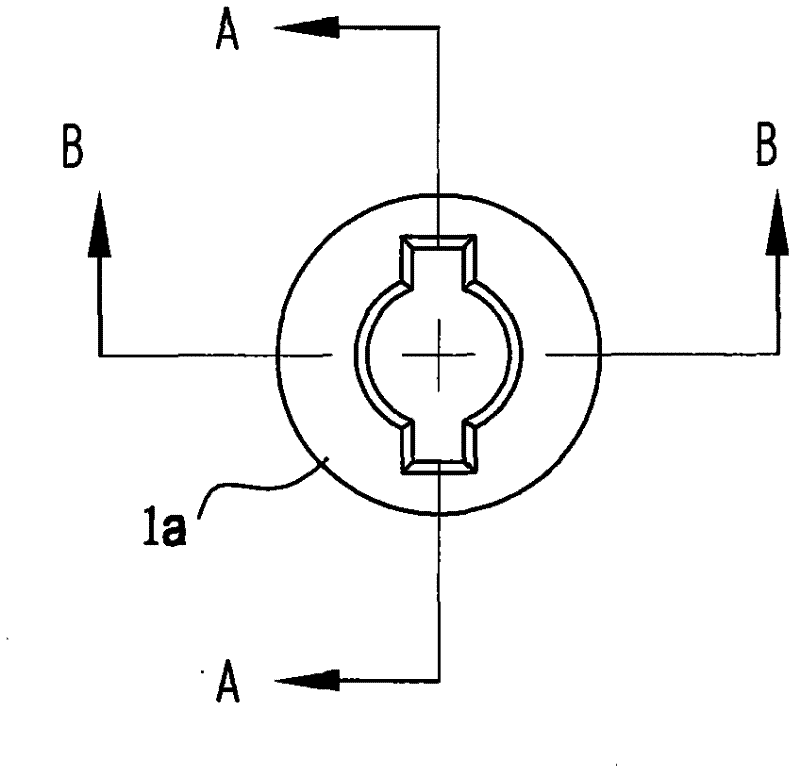

Short-stroke synchronizer ring

InactiveCN101788049AIncrease pressureIncrease speedMechanical actuated clutchesGearing detailsWorking pressureEngineering

The invention belongs to a 20-ton grade wheeled car synchronizer part, in particular to a short-stroke synchronizer ring which can improve the rotation speed and pressure value of operation by providing a rectangular groove on a friction cone, thus reducing the size of the synchronizer ring and effectively shortening the axial size of a speed changer so as to lessen the volume and weight of the speed changer. By adopting the method that an isobathic rectangular groove is arranged on the friction cone of the synchronizer ring, the synchronizer ring can bear higher relative rotation speed in an out-of-service condition; in the combination process of the synchronizer, the rotation of a mating member of the friction cone of the synchronizer enables oil around the isobathic rectangular groove and the isobathic rectangular groove to do relative movement; and the oil film is damaged effectively due to the step effect of the isobathic rectangular groove, thus improving working pressure and relative rotation speed of the friction cone of the synchronizer ring. The two effects are superposed, which can improve the work performance of the short stroke synchronizer ring and prolong the service life thereof greatly.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

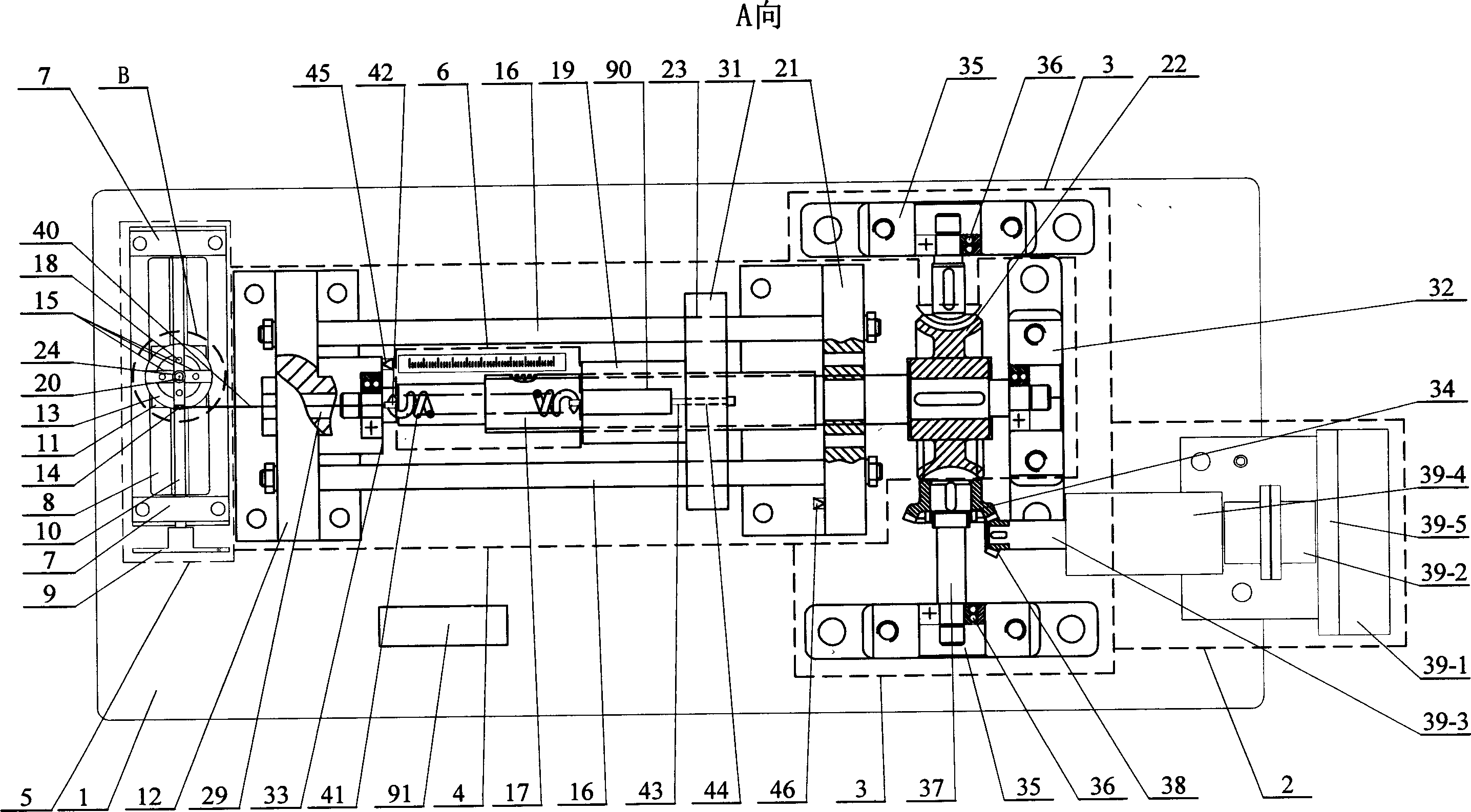

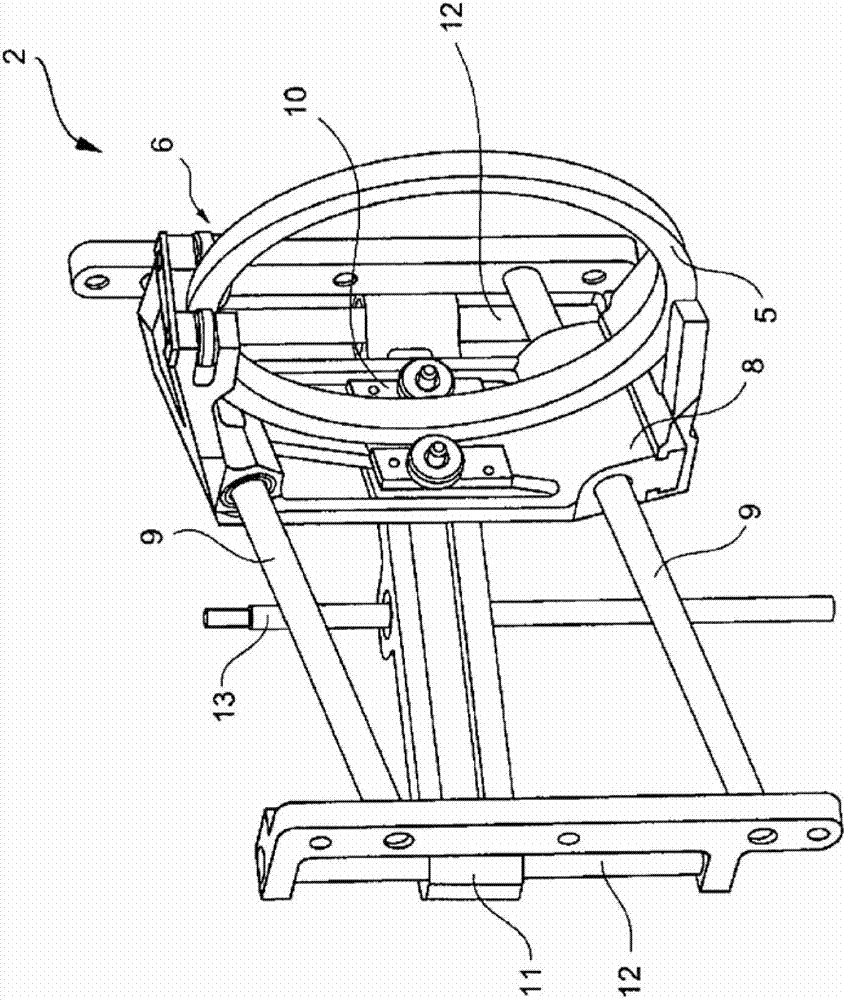

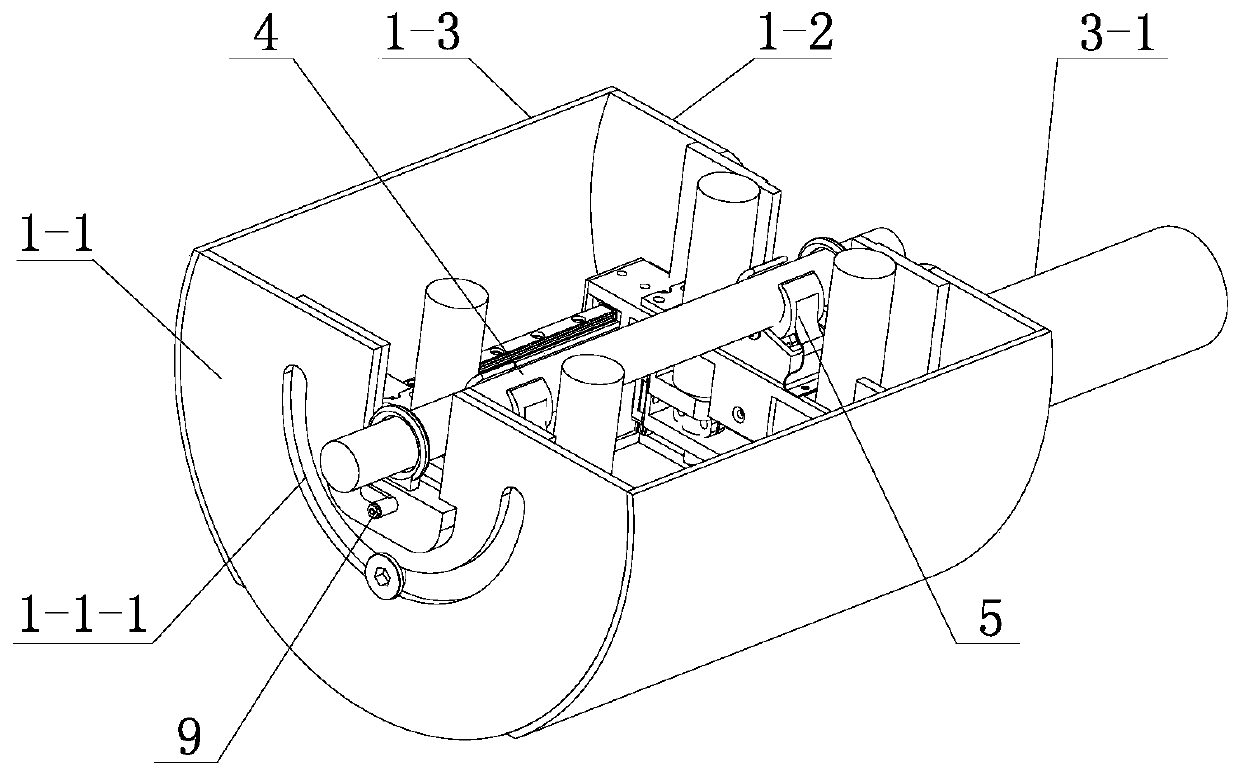

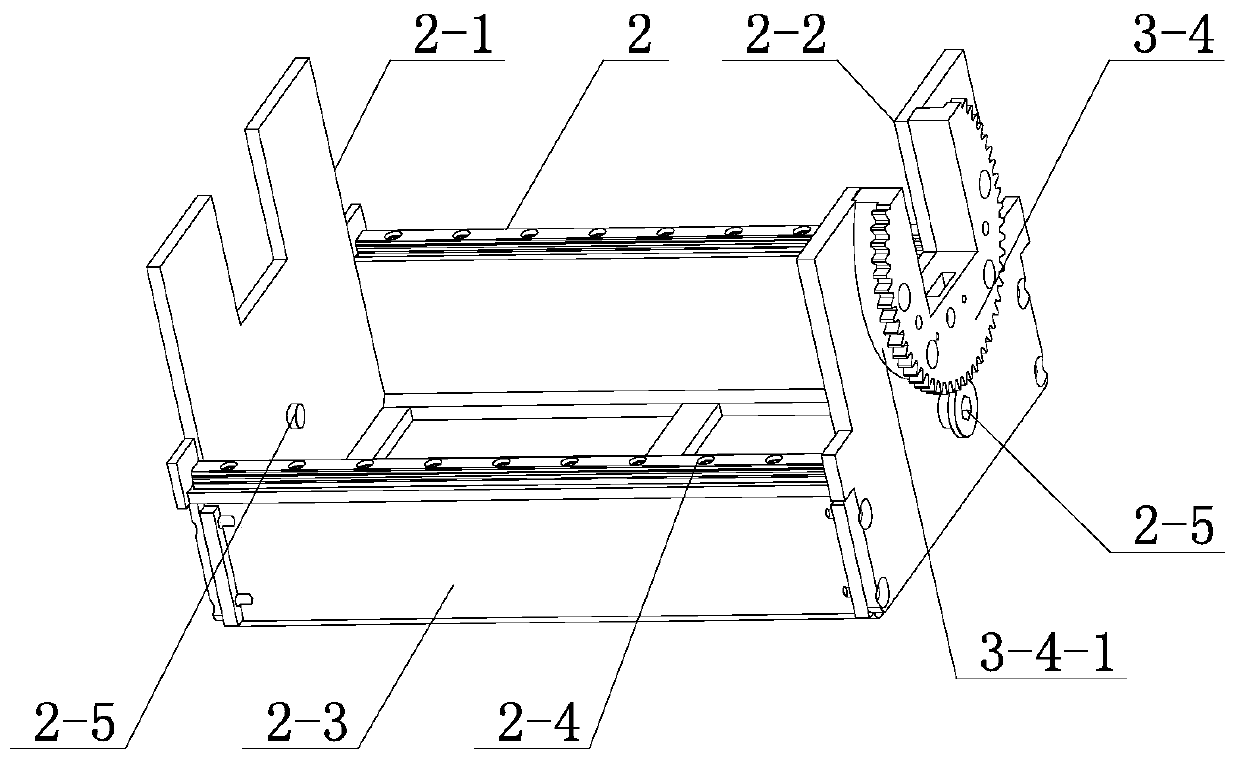

Novel digestive-endoscope feeding apparatus

The invention discloses a novel digestive-endoscope feeding apparatus and belongs to the field of medicine instruments, aiming to solve problems that an existing digestive-endoscope feeding apparatusadopts a friction wheel to realize the feeding function, the rotation of the friction wheel causes friction force which is not conducive to the detection of force, and easy getting stuck by accident is not conductive to the safety of patients. The novel digestive-endoscope feeding apparatus comprises a fixed housing, a swing mechanism, two clamping mechanisms, two feeding mechanisms, two upper sliding plates and four first sliders; the swing mechanism includes a rotary frame and a drive assembly, the rotary frame is arranged in the fixed housing, the drive assembly is arranged outside the fixed housing, and the rotary frame performs rotary motion through the drive assembly; each of lower ends of two ends of each upper sliding plate is provided with a first slider fixedly, the upper slidingplates are respectively and sliably connected onto the upper end face of the rotary frame side by side through the first sliders at two ends of the upper sliding plate, and each upper sliding plate is provided with one clamping mechanism and one feeding mechanism. The novel digestive-endoscope feeding apparatus is used for feeding and outputting of the digestive endoscopy.

Owner:HARBIN INST OF TECH

Robot control method, robot control device, robot and robot system

InactiveCN103963057AImprove gripProgramme controlProgramme-controlled manipulatorRobotic systemsSuction force

Owner:SEIKO EPSON CORP

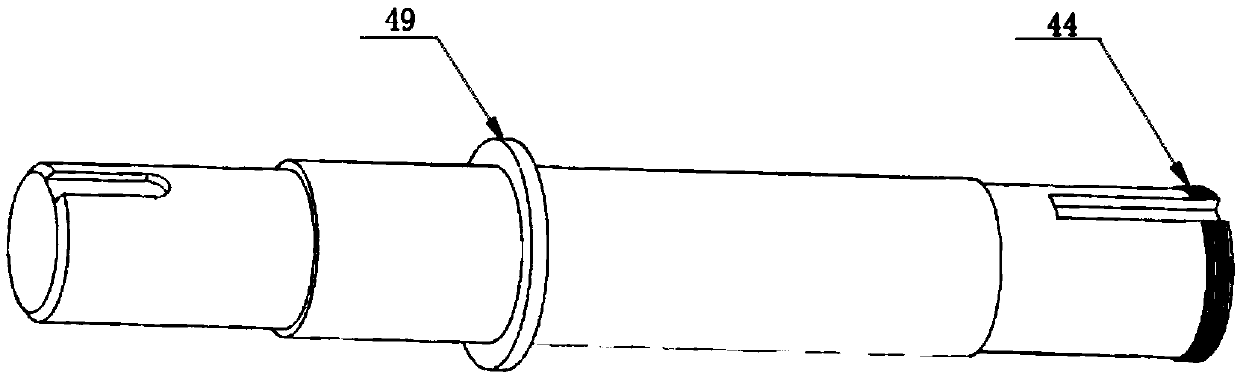

Automobile transmission synchronizer

PendingCN109737150AIncrease widthLarge synchronization capacityMechanical actuated clutchesAutomotive transmissionFriction cone

The invention discloses an automobile transmission synchronizer. The automobile transmission synchronizer comprises a gear hub. Modified gears are arranged on two sides of the gear hub respectively. Asliding sleeve is arranged outside the gear hub in a sliding and sleeving mode. The two ends of each outer spline of the sliding sleeve are each provided with a sliding sleeve locking surface. The outer surface of the sliding sleeve is fixedly provided with a sliding disc in a sleeved mode. An even number of sliding disc notches are formed in the inner surface of the sliding disc. The positions,corresponding to the two sides of the sliding disc, of the outer surface of the sliding sleeve are each sleeved with a synchronization ring in a sliding mode. The inner end surface of each synchronization ring is provided with limiting bosses inserted in the sliding disc notches at intervals. The inner surface of each synchronization ring is provided with inner splines, the inner splines and the sliding disc notches are arranged in a staggered mode, the inner end of each inner spline of each synchronization ring is provided with a synchronization ring locking surface, and the outer surface ofeach synchronization ring is a frication cone surface. The outer surface of the sliding sleeve is provided with elastic pieces capable of driving the synchronization rings to slide. Each modified gearis fixedly provided with a friction cone disc. The inner surfaces of the friction cone discs are friction cone surfaces matched with the frication cone surfaces of the synchronization rings. The automobile transmission synchronizer is suitable for a transmission.

Owner:武汉精密同创机械有限公司

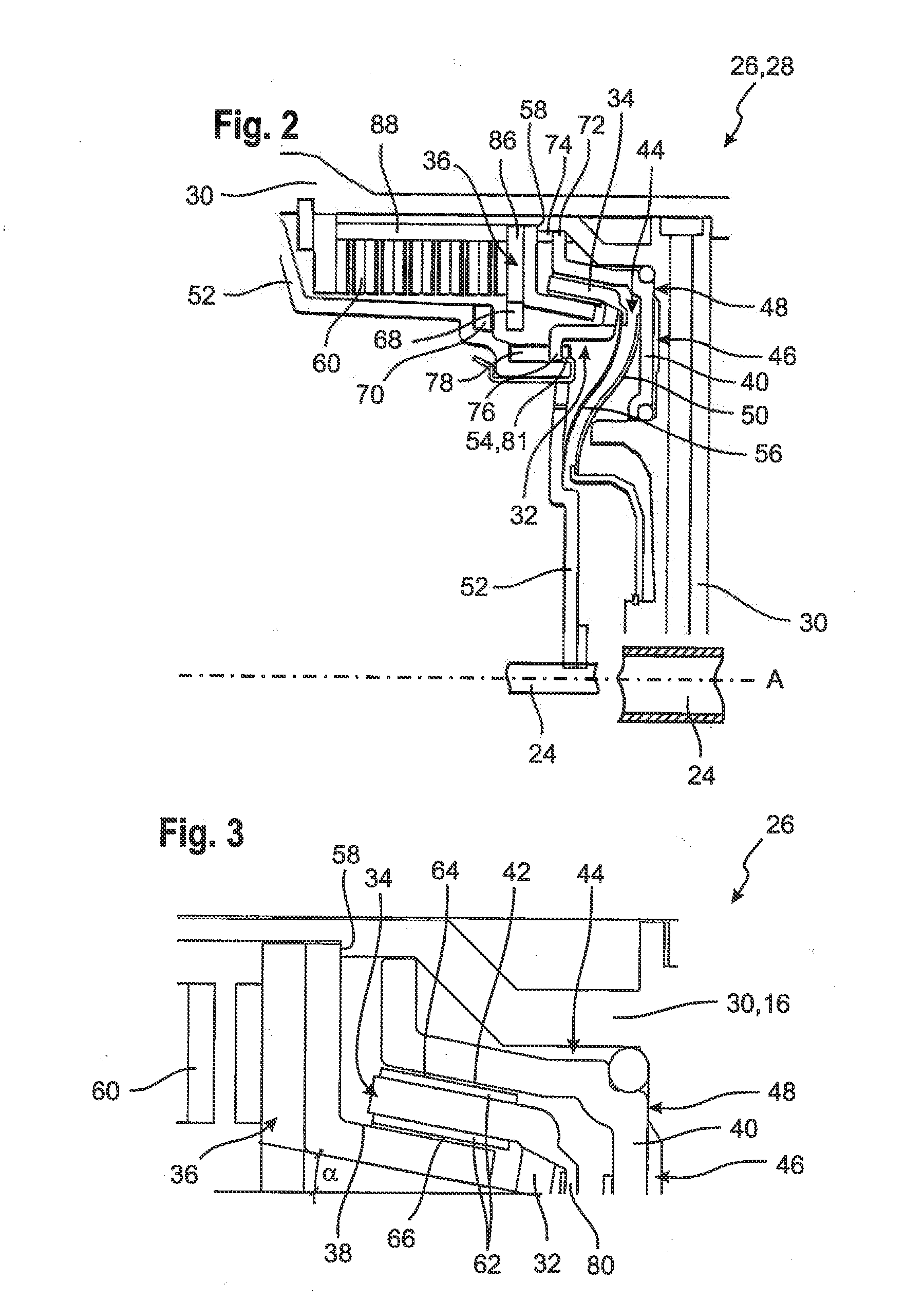

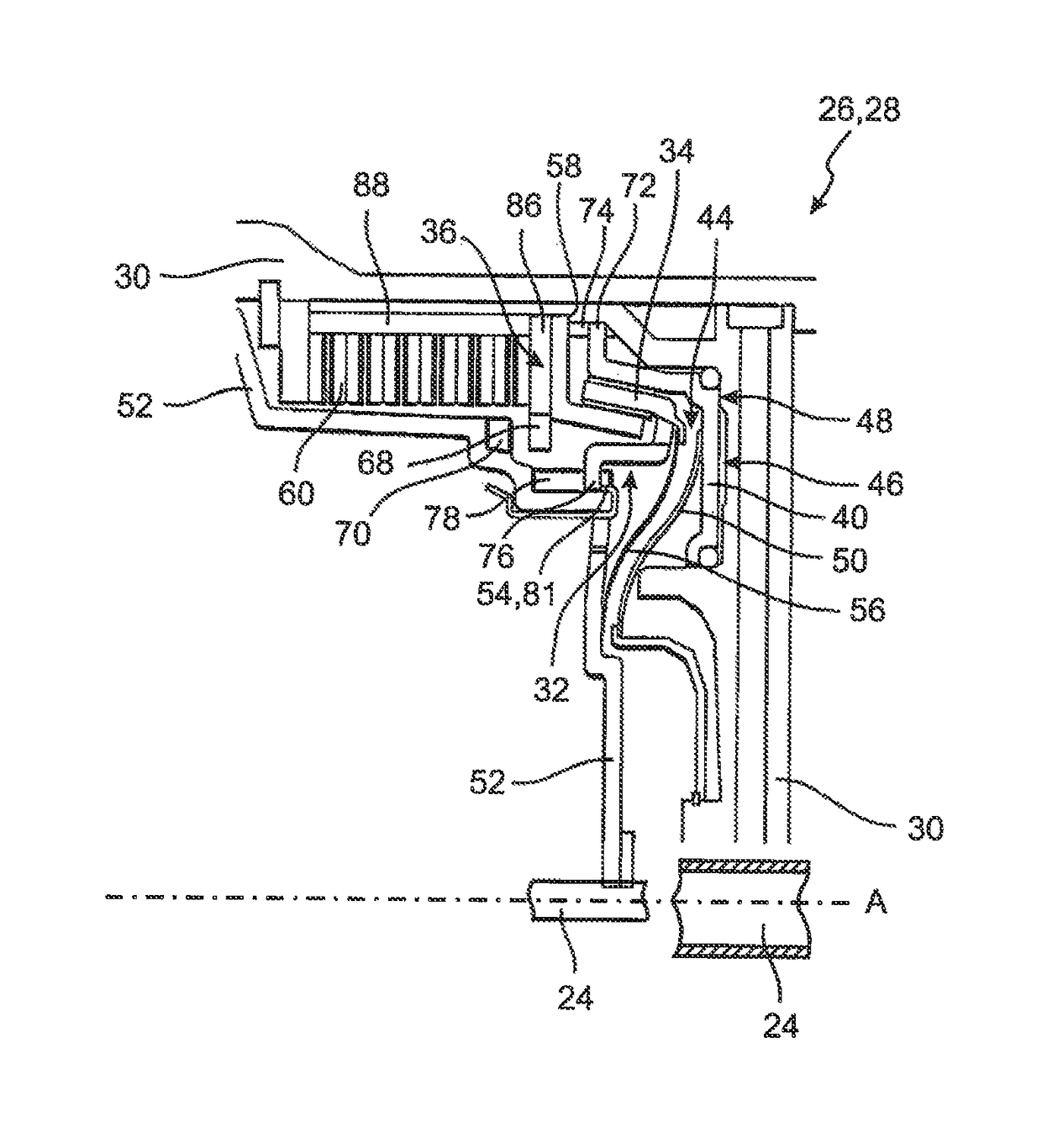

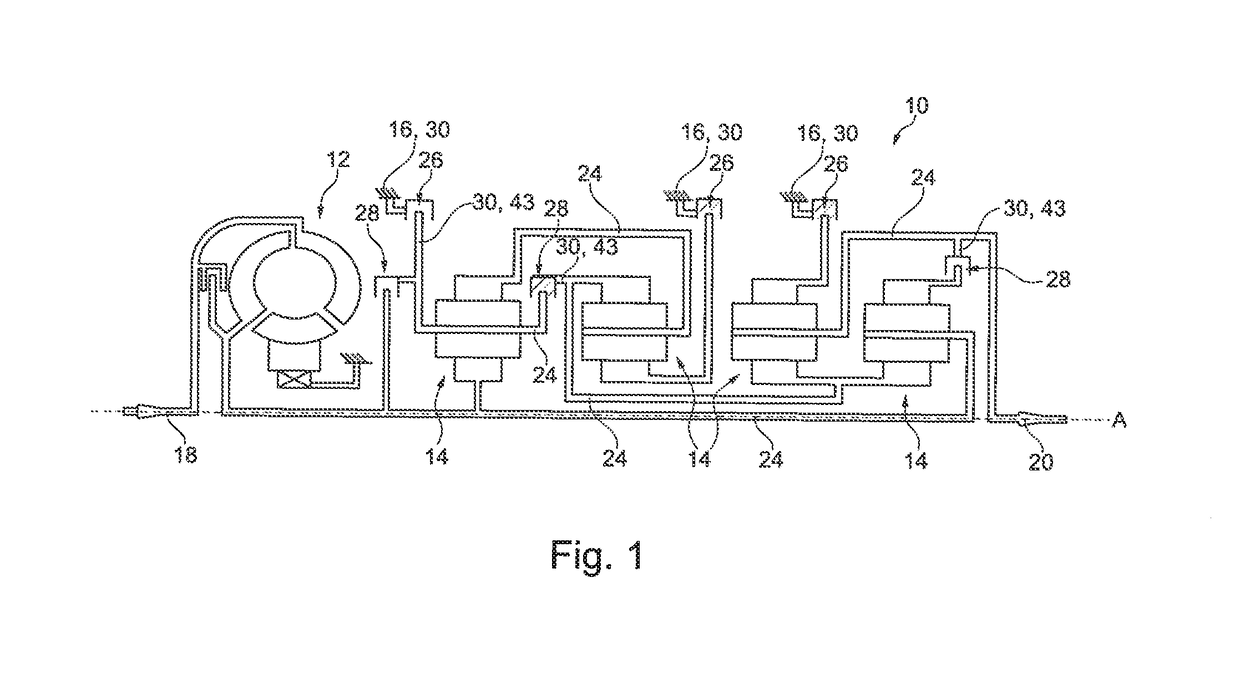

Switching device for a motor vehicle transmission and method for actuating a motor vehicle transmission

ActiveUS20160146268A1Reliable torque transmissionMinimum expenditure of energyToothed gearingsFriction clutchesDrive shaftCoupling

A switching device for a motor vehicle transmission includes a coupling component, several transmission shafts which each are rotatable about a transmission axis, a frictional contact ring including a friction cone and being substantially non-rotatably and axially shiftably connected with a transmission shaft, a form-fit ring including a cone surface and being substantially non-rotatably and axially shiftably connected with the coupling component, as well as an actuating body including a cone surface and being substantially non-rotatably and axially shiftably connected with the coupling component. The friction cone of the frictional contact ring extends between the cone surface of the form-fit ring and the cone surface of the actuating body. The transmission shaft and the coupling component are decoupled in direction of rotation in an axial starting position of the actuating body, frictionally coupled in direction of rotation in an axial frictional contact position of the actuating body and positively coupled in direction of rotation in an axial form-fit position of the actuating body. The form-fit ring in a form-fit position is positively connected with the transmission shaft and in a release position is not positively connected with the transmission shaft. The form-fit ring is axially movable between its form-fit position and its release position and is urged into the release position. In addition, a method for actuating a motor vehicle transmission is provided.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

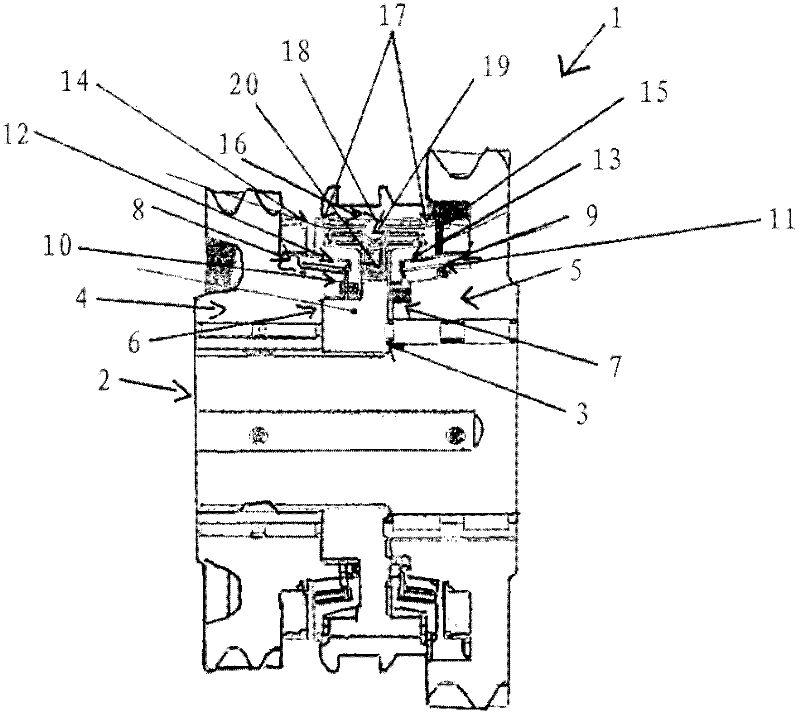

Clutch sleeve for a shift clutch and shift clutch

InactiveCN102444676AFunction increaseImprove shift performanceMechanical actuated clutchesGear wheelEngineering

A clutch sleeve is provided for a shift clutch having a synchronizing device, which includes, but is not limited to a clutch body (8,9), which is connected in a rotationally-fixed manner to gear wheels (4,5) mounted so it is rotatable on a shaft (2) and has coupling teeth (30) and a friction cone as well as synchronizing rings (12,13) having a counter cone and blocking teeth (28), and which has shift teeth (31,32), the clutch sleeve (16) having shift teeth (31,32), which are designed in such a manner that a first group of the shift teeth (27) cooperates with the blocking teeth (28) until a synchronized speed is reached and a second group of the shift teeth (29) engages in the coupling teeth (30) after the synchronized speed is reached.

Owner:GM GLOBAL TECH OPERATIONS LLC

Locking pin type double-cone synchronizer

The invention belongs to an automobile speed changer and particularly relates to a locking pin type double-cone synchronizer which is characterized by comprising an outer cone, an intermediate ring, an inner cone, a locking pin, a toothed sleeve and a gear, wherein the locking pin passes through a positioning pin hole on the toothed sleeve, thus the toothed sleeve can freely slide on the locking pin; the inner cone is riveted and fixed with the locking pin; the intermediate ring is in floating connection with the gear through a lug; the outer cone is directly hung on the intermediate ring; and the outer cone is connected with the inner cone through an end surface claw. When the gear of the speed changer provided by the invention is shifted, a relative angular speed difference is generated between the two shafts and gear of the speed changer; meantime, the toothed sleeve of the synchronizer pushes the locking pin, the locking pin pushes the inner cone, and the intermediate ring and the outer cone are sequentially pushed; and the synchronous friction torque of the axial thrust applied to the toothed sleeve of the synchronizer, which is generated on a friction cone surface, is equal to the sum of the friction torque between two pairs of cone surfaces, thereby reducing the gear shifting force of the synchronizer.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Switching device for a motor vehicle transmission and method for actuating a motor vehicle transmission

ActiveUS9939027B2Increased torque transfer capabilityMore energy efficientMechanical actuated clutchesToothed gearingsMobile vehicleDrive shaft

A switching device for a motor vehicle transmission includes a coupling component, several transmission shafts which each are rotatable about a transmission axis, a frictional contact ring including a friction cone and being substantially non-rotatably and axially shiftably connected with a transmission shaft, a form-fit ring including a cone surface and being substantially non-rotatably and axially shiftably connected with the coupling component, as well as an actuating body including a cone surface and being substantially non-rotatably and axially shiftably connected with the coupling component. The friction cone of the frictional contact ring extends between the cone surface of the form-fit ring and the cone surface of the actuating body. The transmission shaft and the coupling component are decoupled in direction of rotation in an axial starting position of the actuating body, frictionally coupled in direction of rotation in an axial frictional contact position of the actuating body and positively coupled in direction of rotation in an axial form-fit position of the actuating body. The form-fit ring in a form-fit position is positively connected with the transmission shaft and in a release position is not positively connected with the transmission shaft. The form-fit ring is axially movable between its form-fit position and its release position and is urged into the release position. In addition, a method for actuating a motor vehicle transmission is provided.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

End face tooth engaged and separated structure for speed reducer of mowing machine

The invention relates to an end face tooth engaged and separated structure for a speed reducer of a mowing machine. The engaged and separated structure comprises a worm wheel, a power input worm rod externally engaged with the worm wheel, a power output shaft arranged in the worm wheel and a pull and control operation component arranged at one side of the worm rod; one end face of the worm wheel is internally provided with an end face tooth and a shaft sliding sleeve sleeved outside the power output shaft; one end face of the shaft sliding sleeve is externally provided with an end face tooth correspondingly engaged with the end face tooth arranged in one end face of the worm wheel; the other end face of the shaft sliding sleeve is provided with a locating pin tightly fixed with the power output shaft; a compression spring is arranged between the inner wall of the end face tooth of the shaft sliding sleeve and the locating pin; and the outer peripheral wall of the shaft sliding sleeve is provided with a shift fork which enables the shaft sliding sleeve to axially slide. In the engaged and separated structure, bevel friction is replaced by end face gear engaging force, so that the dynamics and the speed of jointing or separation are improved to make operation convenient and control flexible and prevent the damage of bevel friction; the service life of the end face tooth engaged structure is doubled compared with that of a friction cone structure; and the climbing speed and the mowing efficiency are obviously improved under the same condition.

Owner:YUYAO SOBO GARDEN MACHINERY

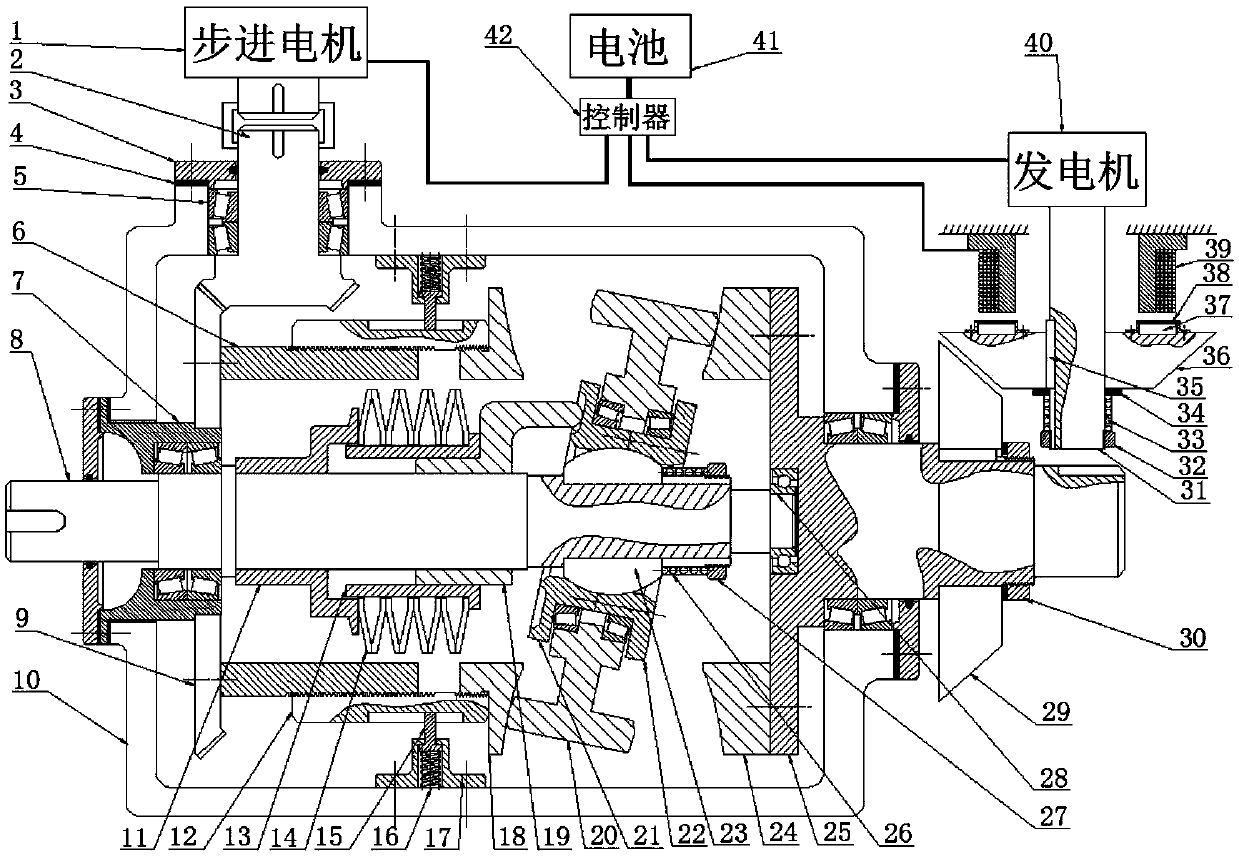

Nutation disc infinitely variable speed transmission

InactiveCN109630633ASolve complexitySolve efficiency problemsGearing controlGearing detailsElectricityNutation

The invention belongs to a speed reducer, and in particular, relates to a nutation disc infinitely variable speed transmission. The nutation disc infinitely variable speed transmission is characterized by consisting of an input shaft, a nutation disc, a spherical surface key, a pressing disc, a speed adjusting bevel gear, an output shaft, a friction cone, a generator, a battery and a stepper motor; the nutation disc is inserted in the input shaft, and can slide and rotate relative to the input shaft; the stepper motor drives the speed adjusting bevel gear mounted on a bearing sleeve cup, and drives a friction surface to axially move to achieve a speed change purpose; and the friction cone intermittently works through an electromagnetic axial clutch, and drives the generator to generate electricity only when the electric quantity of the battery is insufficient. Through a mode of changing a deflected angle of a deflected shaft section, the infinite speed change of the transmission is realized; and the transmission is reasonable in design, novel and unique, and solves the defects of low efficiency, speed change impact and no overload protection in similar infinitely variable speed transmissions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Three-dimensional automatic scanning device with adjustable rotation angle

InactiveCN112082505AReduce labor intensityImprove scanning efficiencyUsing optical meansRatchetEngineering

The invention relates to the field of three-dimensional manufacturing, and discloses a three-dimensional automatic scanning device with an adjustable rotation angle. The three-dimensional automatic scanning device comprises a main box body, wherein a workbench with an upward opening and a rightward opening is arranged in the main box body, a lifting block cavity is formed in the left side of the workbench, a scanner sliding cavity is formed between the right end wall of the lifting block cavity and the left end wall of the workbench in a communicating mode, a ratchet wheel cavity is formed inthe upper side of the lifting block cavity, a pawl sliding block cavity is formed in the left side of the ratchet wheel cavity, a three-dimensional automatic scanning unit is arranged to enable an object to rotate by a certain angle to be scanned once, and three-dimensional feature scanning of the whole object is finally completed. The three-dimensional automatic scanning device effectively reduces the labor intensity of operators, enhances the scanning efficiency, and controls the rotation angle of the object to be scanned in each scanning process by manually adjusting an abutting position ofa friction wheel and a friction cone wheel, so that three-dimensional scanning of objects with different feature complexity degrees can be achieved, and the scanning result is more accurate.

Owner:XIAMEN QIALE STATIONERY CO LTD

Linear damper

InactiveUS20070108004A1Operates in small spaceSimple and inexpensive to manufacturePassenger spaceLeaf springsEngineeringFriction cone

A linear damper includes a conical housing with a friction cone in the housing and a rod extending therethrough and axially moveable relative thereto. The friction cone is axially moveable in the housing and radially expandable and contractible to provide clamping force against a rod when the rod is moved in one axial direction and to relieve clamping force from the rod when the rod is moved in the opposite axial direction.

Owner:ILLINOIS TOOL WORKS INC

Robot control method, robot control device, robot, and robot system

InactiveUS9102059B2Weight increaseProgramme controlProgramme-controlled manipulatorRobotic systemsSuction force

A robot control method includes a first step of selecting a holding form in which a robot holds an object and a second step of determining whether the object can continue to be stably held when a predetermined external force is applied to the object in the selected holding form. In the second step, it is determined that the object can continue to be stably held when a force which should be generated by a contact portion to generate resistance to the predetermined external force is included in a friction cone of a force generated by driving the contact portion and enlarged by a suction force from the suction mechanism.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com