Pneumatic-type intermediate-shaft braking system and braking method

A technology of braking system and intermediate shaft, which is applied in the direction of axial brake, brake type, brake actuator, etc., can solve the problems of long shifting time, unusable, difficult shifting, etc., and achieves high braking torque, The effect of large effective area and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

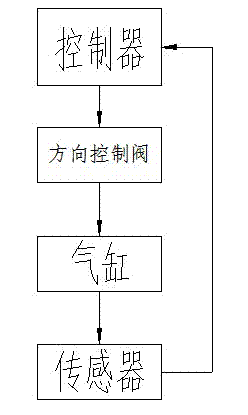

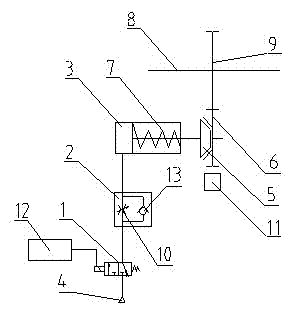

[0044] refer to figure 1 , figure 2 , to describe the embodiment of the present invention. The pneumatic intermediate shaft brake system described in this embodiment includes an air pressure source 4, a directional control valve 1, a cylinder 3, a return spring 7 and a power take-off gear 9, and also includes a speed regulating valve 2 and a friction cone 5 , brake gear 6, sensor 11 and controller 12, wherein air pressure source 4, directional control valve 1, cylinder 3 and speed regulating valve 2 are connected by air pipeline; brake gear 6 is meshed with power take-off gear 9; The sensor 11 is connected with the controller 12 by a wiring harness.

[0045] The sensor 11 is installed on the tooth top of the braking gear 6 , detects the rotation speed of the braking gear 6 , and transmits the rotation speed to the controller 12 . The controller 12 can calculate the working condition of the intermediate shaft brake system according to this information, and obtain the brakin...

Embodiment 2

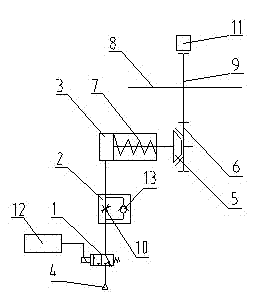

[0053] refer to figure 1 , image 3 , to describe the embodiment of the present invention. The pneumatic intermediate shaft braking system and braking method described in this embodiment are basically the same as those in Embodiment 1, and the similarities with Embodiment 1 will not be repeated, and only the differences from Embodiment 1 will be described here. .

[0054] The difference is that the sensor 11 is installed at the tooth top of the power take-off gear 9 to detect the rotation speed of the power take-off gear 9 and transmit the rotation speed to the controller 12 . The controller 12 can calculate the working condition of the intermediate shaft brake system according to this information, and obtain the braking condition at this time.

[0055]

Embodiment 3

[0057] refer to figure 1 , Figure 4 , to describe the embodiment of the present invention. The pneumatic intermediate shaft braking system and braking method described in this embodiment are basically the same as those in Embodiment 1, and the similarities with Embodiment 1 will not be repeated, and only the differences from Embodiment 1 will be described here. .

[0058] The difference is that the sensor 11 is connected to the piston rod on the cylinder 3, and the axial displacement of the friction cone 5 can be detected by detecting the movement position of the piston rod. The controller 12 can calculate the working condition of the intermediate shaft brake system according to this information, and obtain the braking condition at this time.

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com