Brake actuating apparatus using an electric motor

A technology of brakes and brake pads, applied in the direction of brakes, brake types, brake transmissions, etc., can solve problems such as difficult manufacturing and assembly, complex structure, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

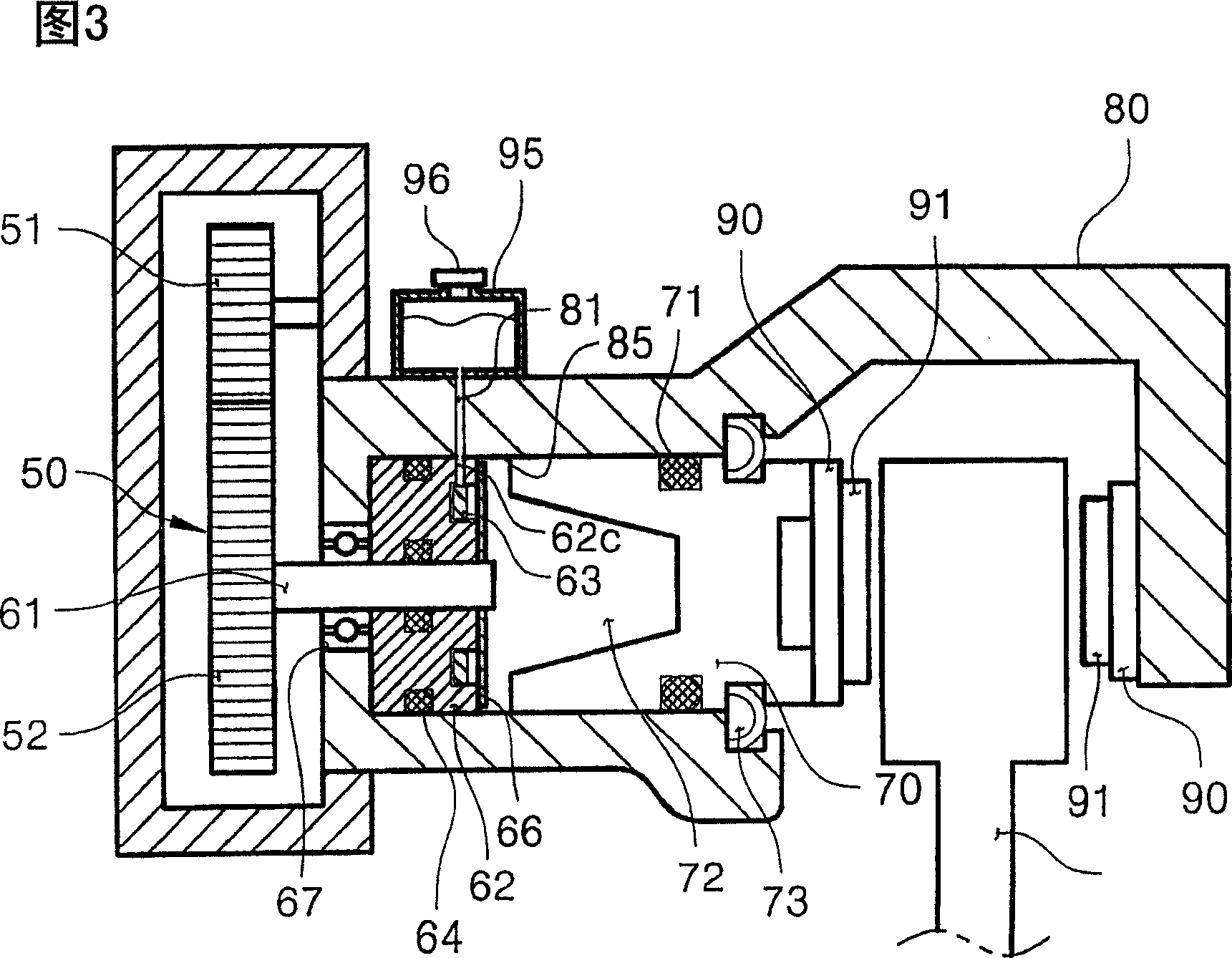

[0040] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

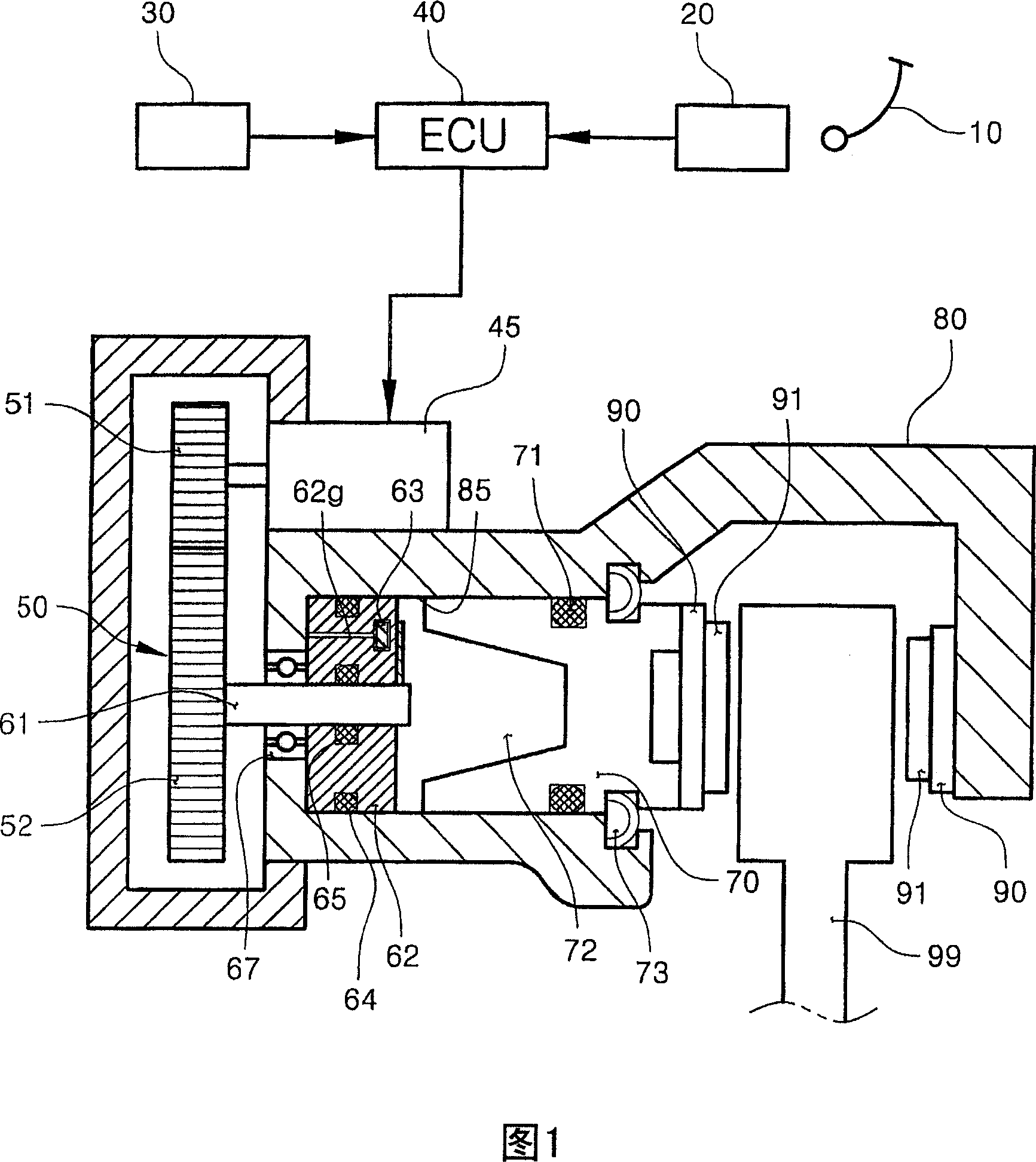

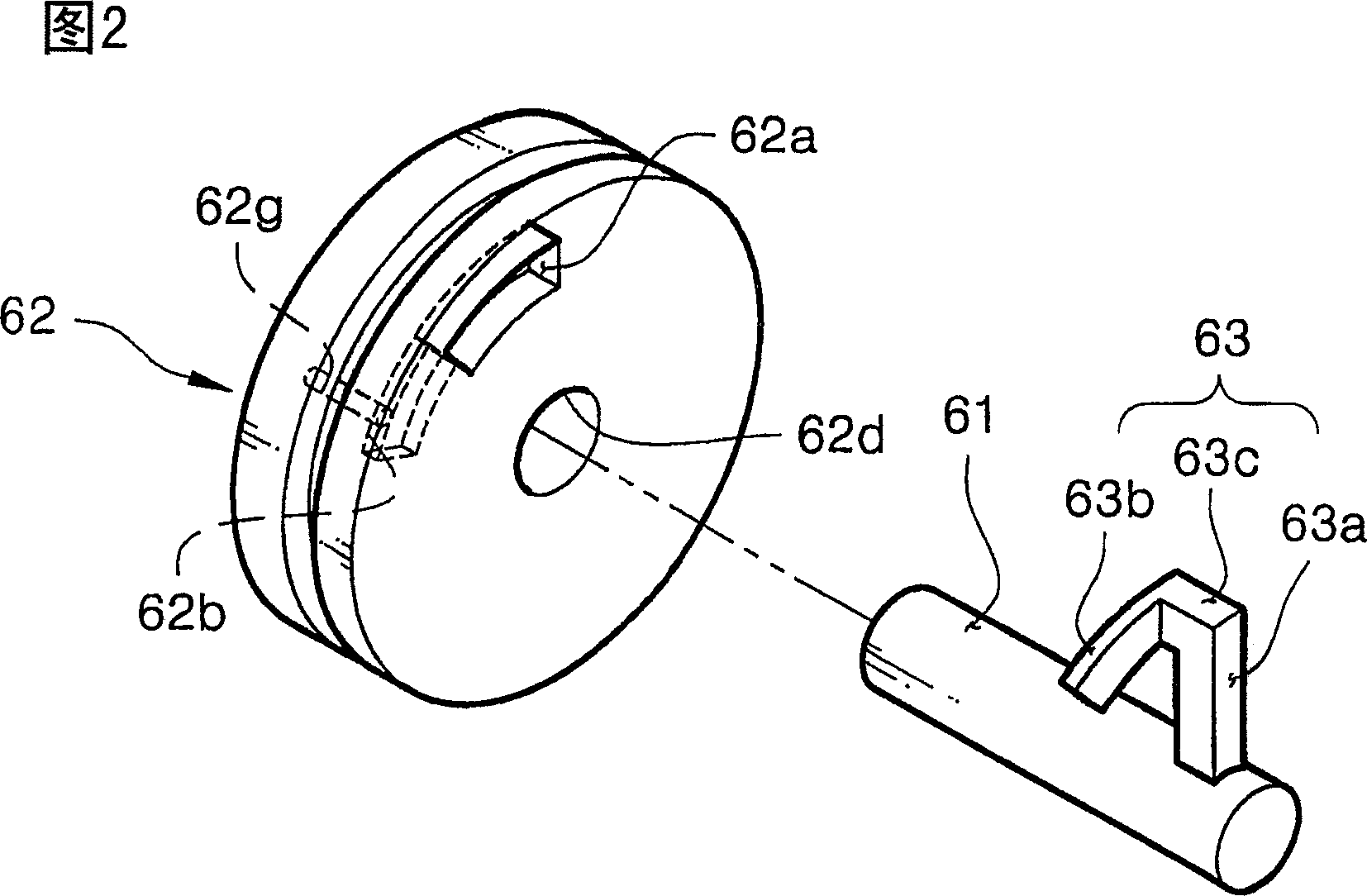

[0041] FIG. 1 is a schematic diagram of a brake device according to an embodiment of the present invention, and FIG. 2 is a perspective view of an embodiment of a housing and a fluid pressurizing component of the brake device shown in FIG. 1, the housing and fluid components Separated from each other.

[0042] As shown in FIG. 1, the brake device of this embodiment includes: a caliper body 80 with a cylinder 85; a motor 45 fixed to the caliper body 80; a pressure piston 70 installed in the cylinder 85; and a housing 62, which is separated from the pressure piston 70 by a predetermined distance in the back, and is fixedly installed on the cylinder 85 to maintain airtightness with the inner circumference of the cylinder 85; the rotating shaft 61 installed in the center of the housing 62 is received by The rotating force transmitted by the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com