Curtain lockset

A technology for locks and curtains, applied in the direction of curtain ropes, household appliances, window decorations, etc., can solve the problems of laborious pulling ropes, easy deformation, short service life of locks, etc., and achieve the effect of labor-saving and light operation and low rotation noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

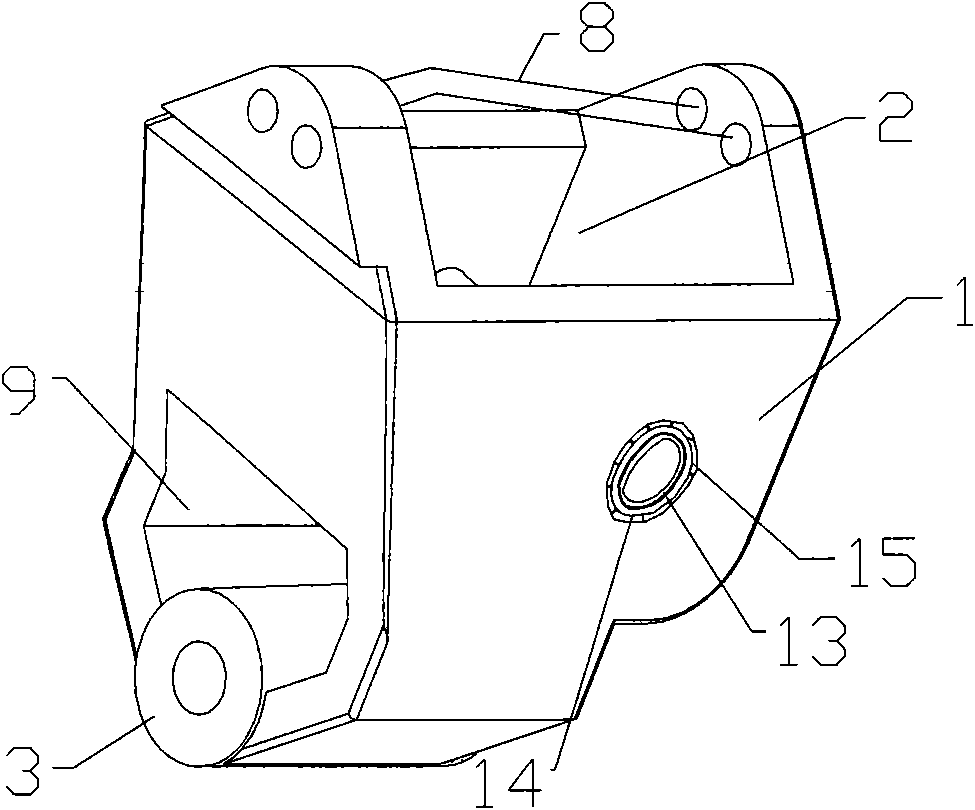

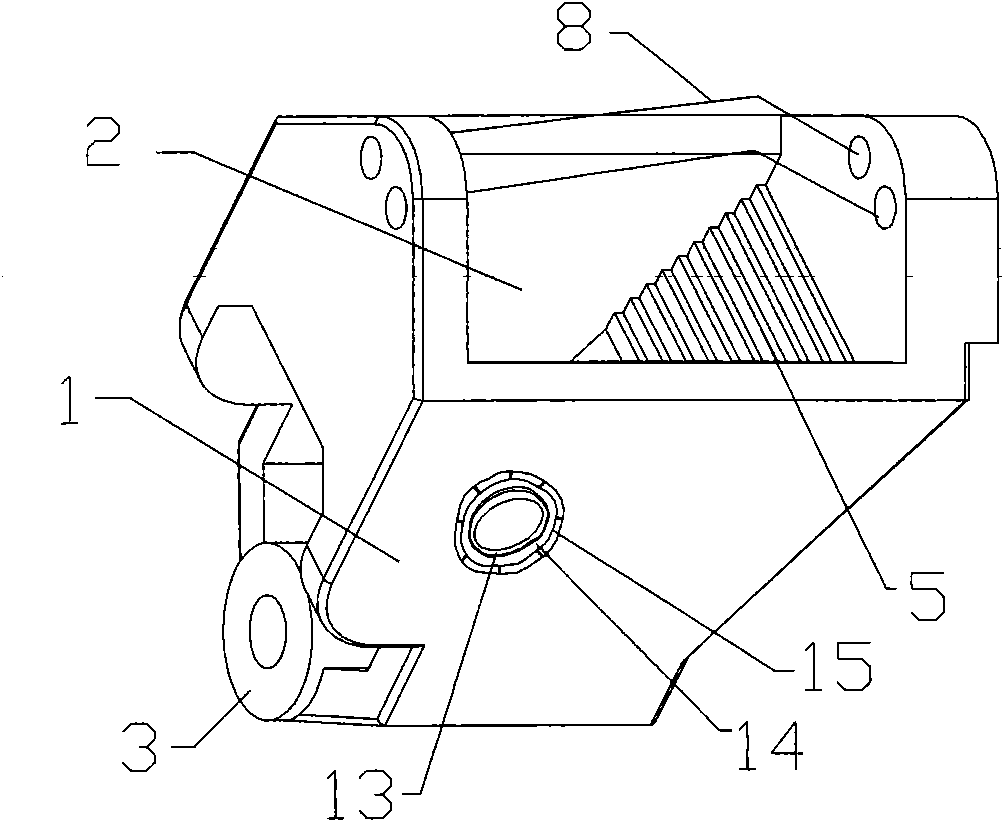

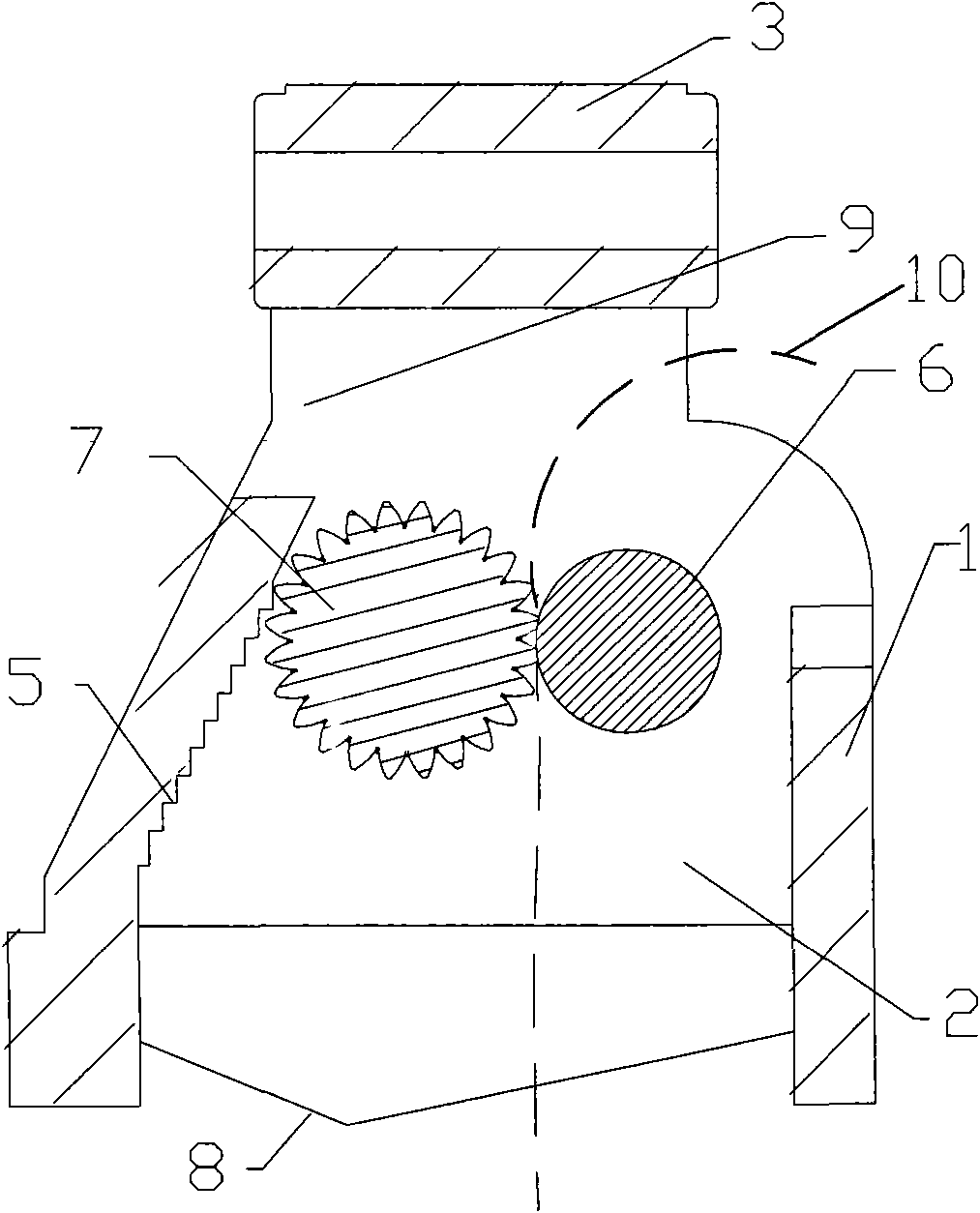

[0014] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] see Figure 1-4 Shown, a kind of curtain lock, its lock case 1 has inner cavity 2, and the top of lock case 1 has the connecting base 3 that is used for fixing and installing lock, and lock case 1 has four sidewalls around, and two sides that are arranged opposite The two ends of the rotating member 6 are connected to the side wall of the lock housing through the bearing 15, and the inner surface of one of the side walls is processed into a tooth surface 5 on the other two side walls. The teeth of 5 are arranged continuously along the up and down direction. In this embodiment, as figure 1 or figure 2 As shown, the end of the rotating part 6 is fixed in the inner ring 13 of the bearing, and the outer ring 14 of the bearing is fixed on the side wall of the lockset housing. The frictional force overcome when the rotating part 6 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com