Inverted siphon inlet water level intelligent adjusting system and adjusting method thereof

A technology of intelligent adjustment and inverted siphon, which is applied in the fields of farmland irrigation and long-distance water diversion, which can solve the problems of gas being brought into the pipe, offsetting height difference, and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

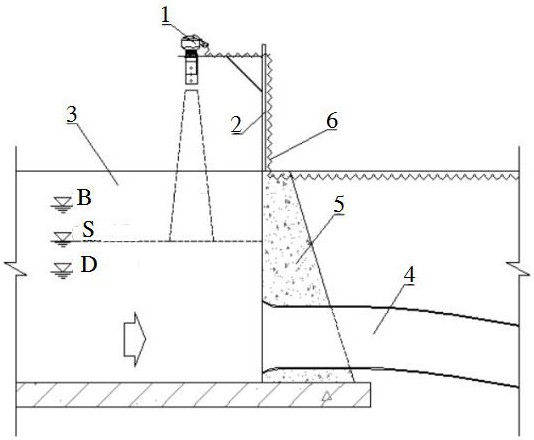

[0026] refer to figure 1 and figure 2 , the embodiment of the present invention provides an intelligent adjustment system for the inlet water level of an inverted siphon, comprising: an inlet pool 3, an inverted siphon 4, a controller 12, an outlet pool 8 and a downstream open channel 9; an ultrasonic wave is arranged above the inlet pool 3 Liquid level gauge 1; one end of the inverted siphon 4 communicates with the water inlet pool 3, and the inverted siphon 4 is connected with an electric flow regulating valve 10; the controller 12 communicates with the ultrasonic wave through the optical fiber signal input line 6 The liquid level gauge 1 is signal connected, and the controller 12 is connected with the electric flow regulating valve 10 through the control signal output line 18; the outlet pool 8 is connected with the outlet of the inverted siphon 4; the downstream open channel 9 It communicates with the outlet pool 8 .

[0027] The water inlet pool 3 and the water outlet ...

Embodiment 2

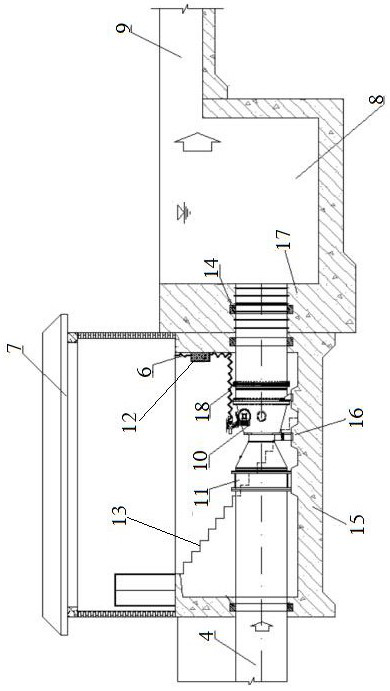

[0029] refer to figure 2 , on the basis of Embodiment 1, it also includes a sunken valve chamber 7, the sunken valve chamber 7 is a semi-basement structure, and the pipe section connected to the electric flow control valve 10 on the inverted siphon pipe 4 passes through the The sunken valve chamber 7 is described.

[0030] The lower half of the sunken valve chamber 7 is located below the ground, and the pipe section connected to the electric flow regulating valve 10 on the inverted siphon 4 is accommodated, so that the electric flow regulating valve 10 is isolated from the underground soil to keep it dry and convenient. The inverted siphon 4 and the electric regulating valve 10 are maintained and overhauled at any time, and the inverted siphon 4 with the electric regulating valve 10 does not need to be excavated and buried during the overhaul and maintenance.

Embodiment 3

[0032] refer to figure 2 , On the basis of Embodiment 2, a through-wall thrust ring 14 is provided between the inverted siphon 4 and the wall of the sunken valve chamber 7 .

[0033] The wall thrust ring 14 fixes the wall of the sunken valve chamber 7 and the inverted siphon 4 in the axial direction, so as to avoid the wall of the sunken valve chamber 7 caused by the axial displacement and gap of the inverted siphon 4 relative to the wall. Water seepage occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com