Novel digestive-endoscope feeding apparatus

A feeding device and digestive endoscope technology, applied in endoscopy, medical science, surgery, etc., can solve the problems of easy jamming, unfavorable force detection of feeding device, unfavorable patient safety, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

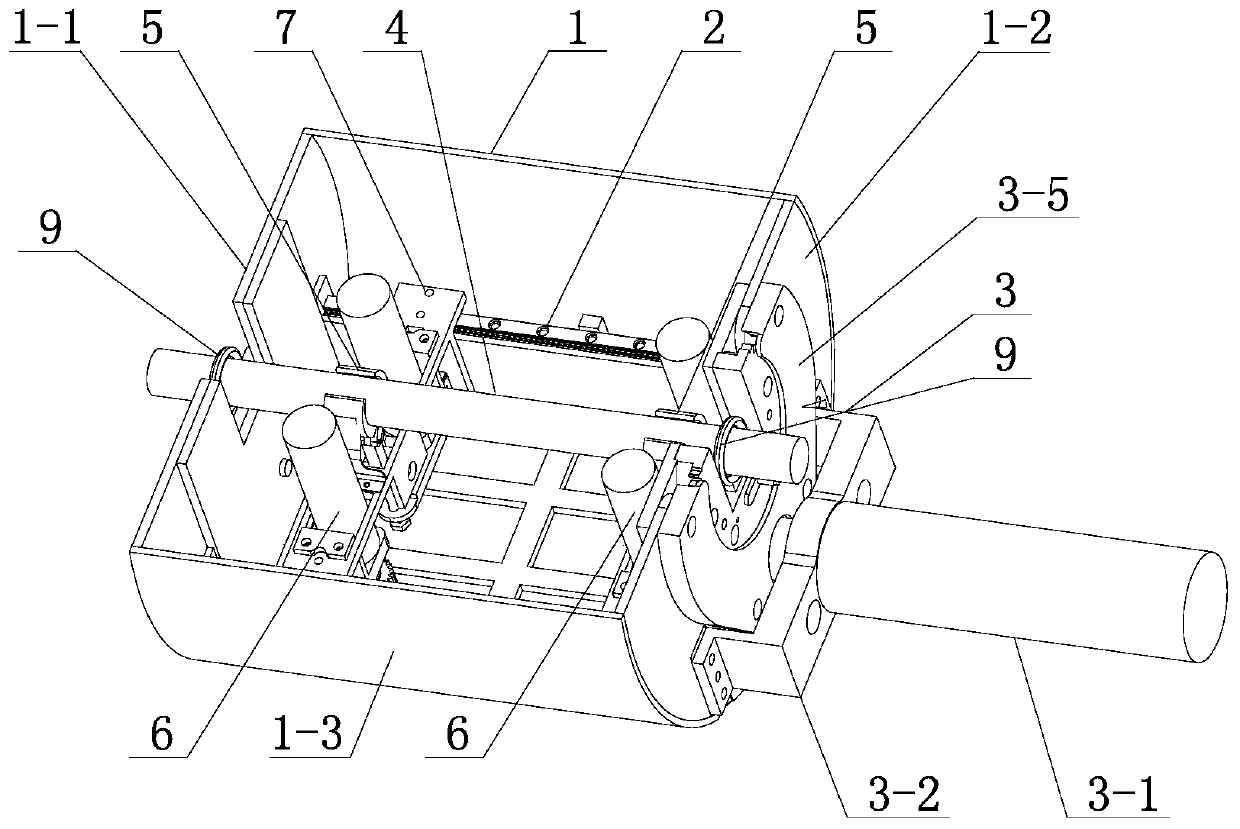

[0036] Specific implementation mode one: as figure 1 and figure 2 As shown, in this embodiment, the feeding device includes a fixed housing 1, a rotary mechanism, two clamping mechanisms 5, two feeding mechanisms 6, two upper slide plates 7 and four first sliders 8;

[0037] The fixed shell 1 includes a front fixed plate 1-1, a rear fixed plate 1-2 and an arc-shaped plate surface 1-3, the front fixed plate 1-1 and the rear fixed plate 1-2 are semicircular plates, and the front fixed plate 1-1 and the rear fixing plate 1-2 are matched with the arc openings on both sides of the arc-shaped plate surface 1-3, and the front fixing plate 1-1 and the rear fixing plate 1-2 are respectively fixed on the arc-shaped plate by screws In the arc-shaped mouth on both sides of surface 1-3;

[0038] The slewing mechanism includes a slewing frame body 2 and a drive assembly 3. The slewing frame body 2 is rotatably connected in the fixed shell 1, and the drive assembly 3 is fixed on the rear ...

specific Embodiment approach 2

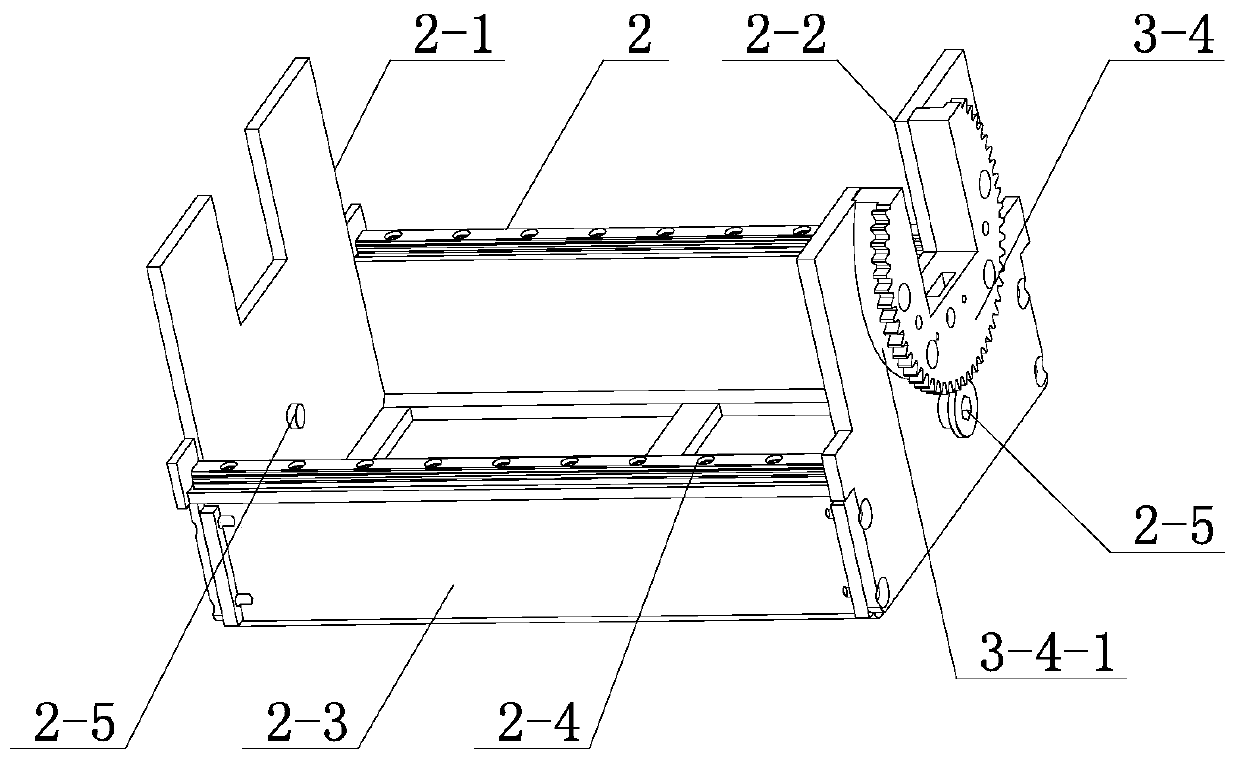

[0041] Specific implementation mode two: as image 3 As shown, in this embodiment, the slewing frame body 2 includes a front end plate 2-1, a rear end plate 2-2, two side vertical plates 2-3, two slide rails 2-4 and two sliding screws 2-5, two side vertical plates 2-3 are arranged vertically side by side, the front end plate 2-1 is fixed on the front ports of the two side vertical plates 2-3 by screws, and the rear end plate 2-2 is fixed on the front ports of the two side vertical plates 2-3 by screws. For the rear ports of the two side risers 2-3, a slide guide rail 2-4 is respectively fixed on the tops of the two side risers 2-3, at the positions opposite to the front end plate 2-1 and the rear end plate 2-2 Connect a slide screw 2-5 respectively;

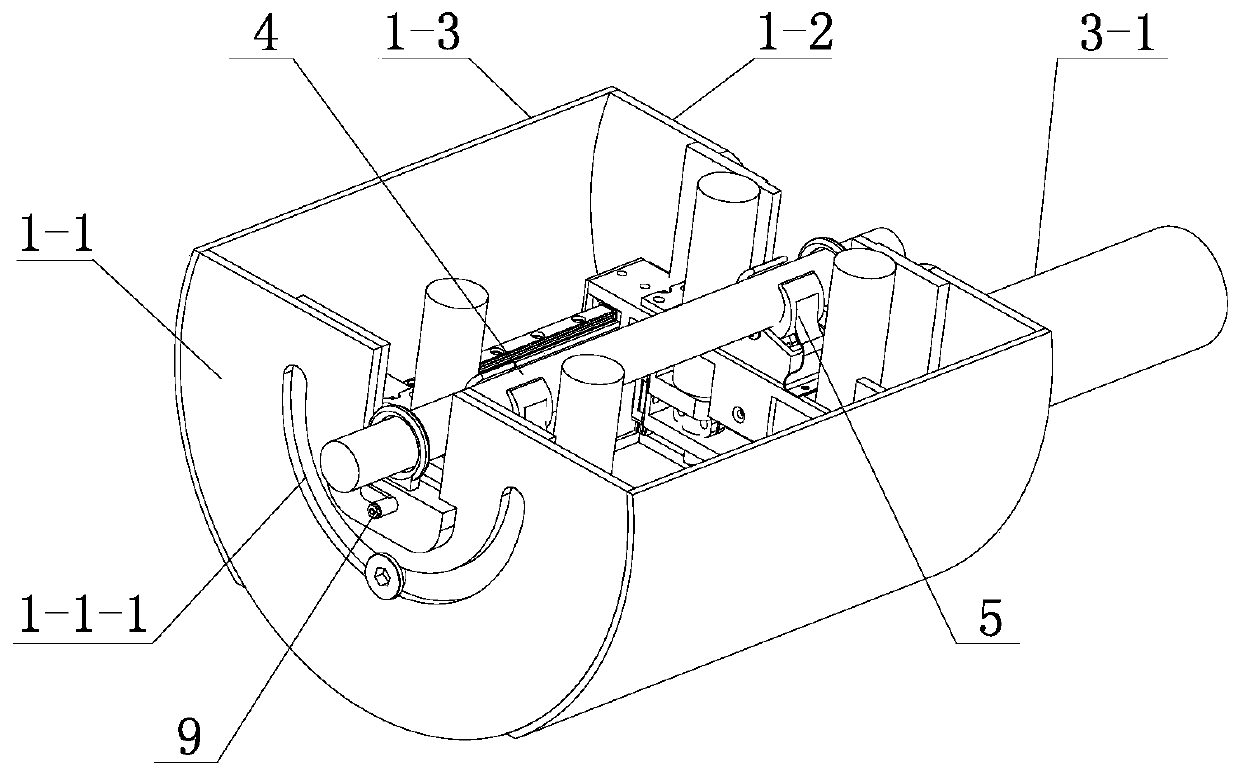

[0042] Such as figure 2 As shown, the front fixed plate 1-1 has a first arc-shaped chute 1-1-1, and the rear fixed plate 1-2 has an arc-shaped gap and a second arc-shaped chute, and the second arc The arc-shaped chute is dire...

specific Embodiment approach 3

[0045] Specific implementation mode three: as figure 1 , image 3 and Figure 4 As shown, in this embodiment, the drive assembly 3 includes a first drive motor 3-1, a first drive motor fixing frame 3-2, an output gear 3-3 and a rotary gear 3-4, wherein the output gear 3- The outer diameter of 3 is smaller than that of the rotary gear 3-4. In order to ensure that the rotary speed of the rotary mechanism is within a safe range, the reduction ratio can be changed by replacing the output gear 3-3 and the rotary gear 3-4. ;

[0046] Such as image 3 As shown, one side of the rotary gear 3-4 is provided with a connecting block 3-4-1, and the rotary gear 3-4 is integrally made with the connecting block 3-4-1 on it, and the connecting block on the rotary gear 3-4 3-4-1 passes through the arc-shaped gap on the rear fixed plate 1-2 and is fixedly connected to the rear end plate 2-2 of the revolving frame body 2 through cylindrical pins;

[0047] Such as Figure 4 As shown, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com