Clutch sleeve for a shift clutch and shift clutch

A technology for shifting clutches and engaging sleeves, applied in the field of engaging sleeves, can solve problems such as cold scratches, and achieve the effects of preventing shifting scratches, improving shifting quality, and increasing firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

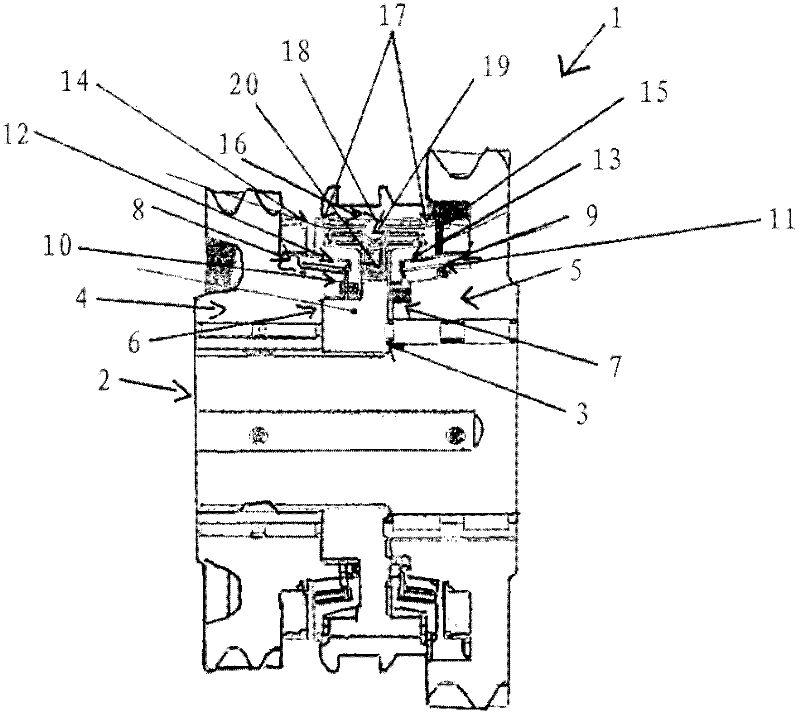

[0038] figure 1 A schematic perspective cross-sectional illustration of a transmission component 1 with a shifting clutch according to one embodiment is shown.

[0039] figure 1 A shaft 2 is shown, on which a guide sleeve 3 is fastened in a rotationally fixed and axially immovable manner by means of toothing. In addition to the guide sleeve 3 , on both sides of the shaft 2 are rotatably mounted gear wheels 4 , 5 , which have axial extensions 6 , 7 on the side facing the guide sleeve 3 , on the axial extensions 6 , 7 A clutch main body 8, 9 is installed respectively. The clutch bodies 8 , 9 engage the external toothings on the extensions 6 , 7 via the internal toothing, so that the clutch bodies are connected in a rotationally fixed manner to the gearwheels 4 , 5 assigned to them. The clutch bodies 8 , 9 also have conical surfaces 10 , 11 respectively, which constitute cooperating conical surfaces for the synchronizer rings 12 , 13 , respectively. The clutch bodies 8 , 9 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com