Patents

Literature

129results about How to "Improve shift performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

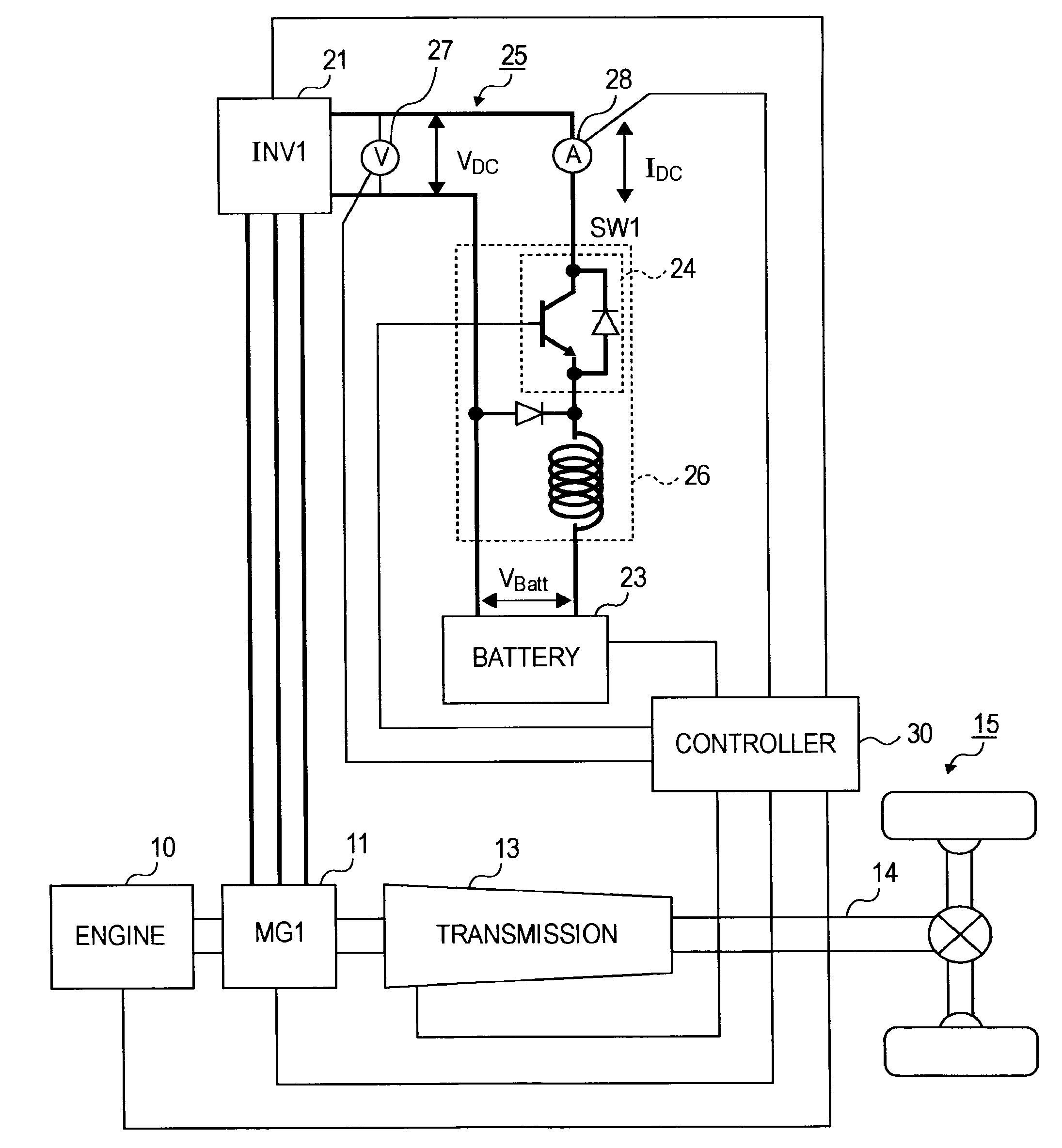

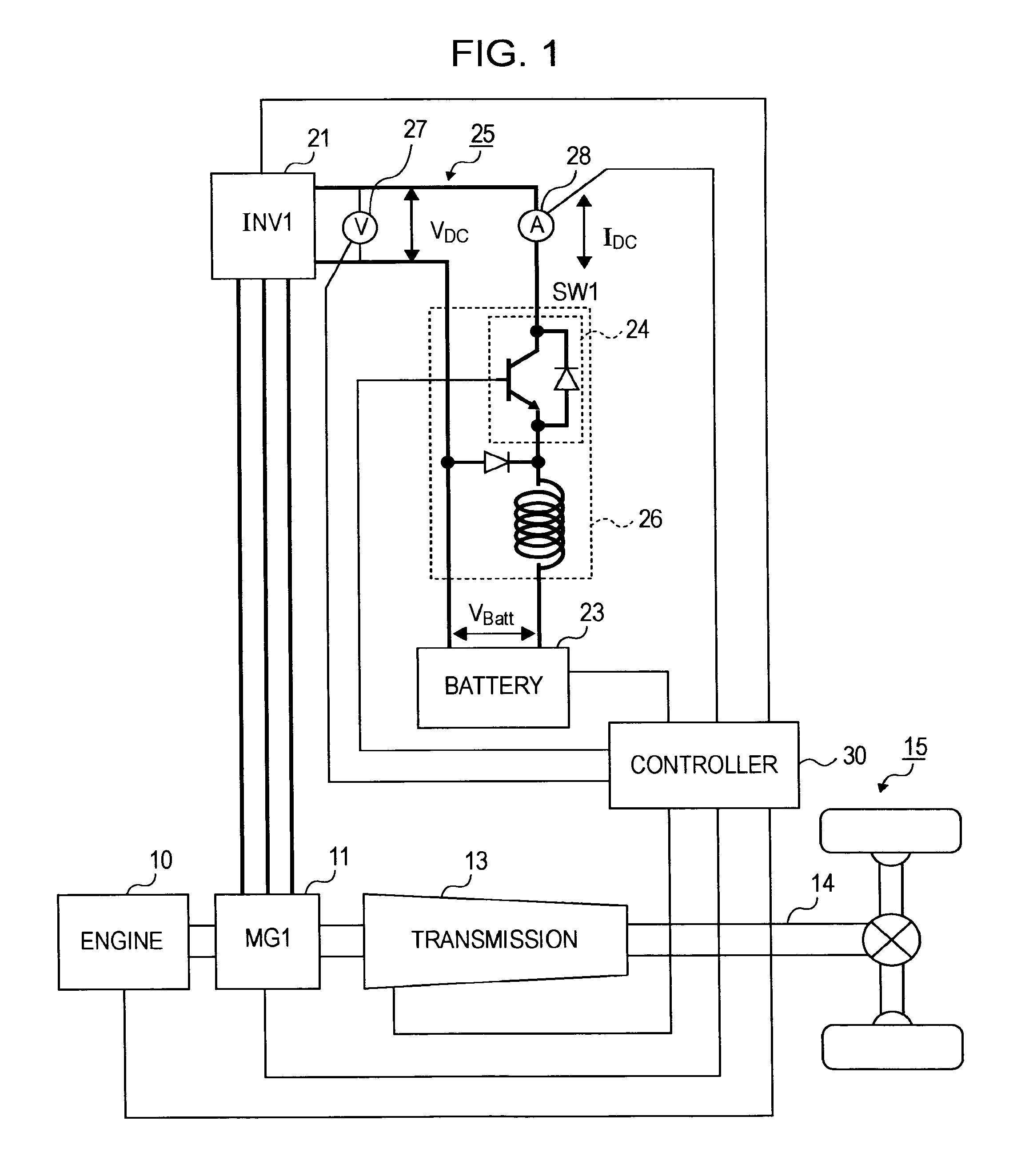

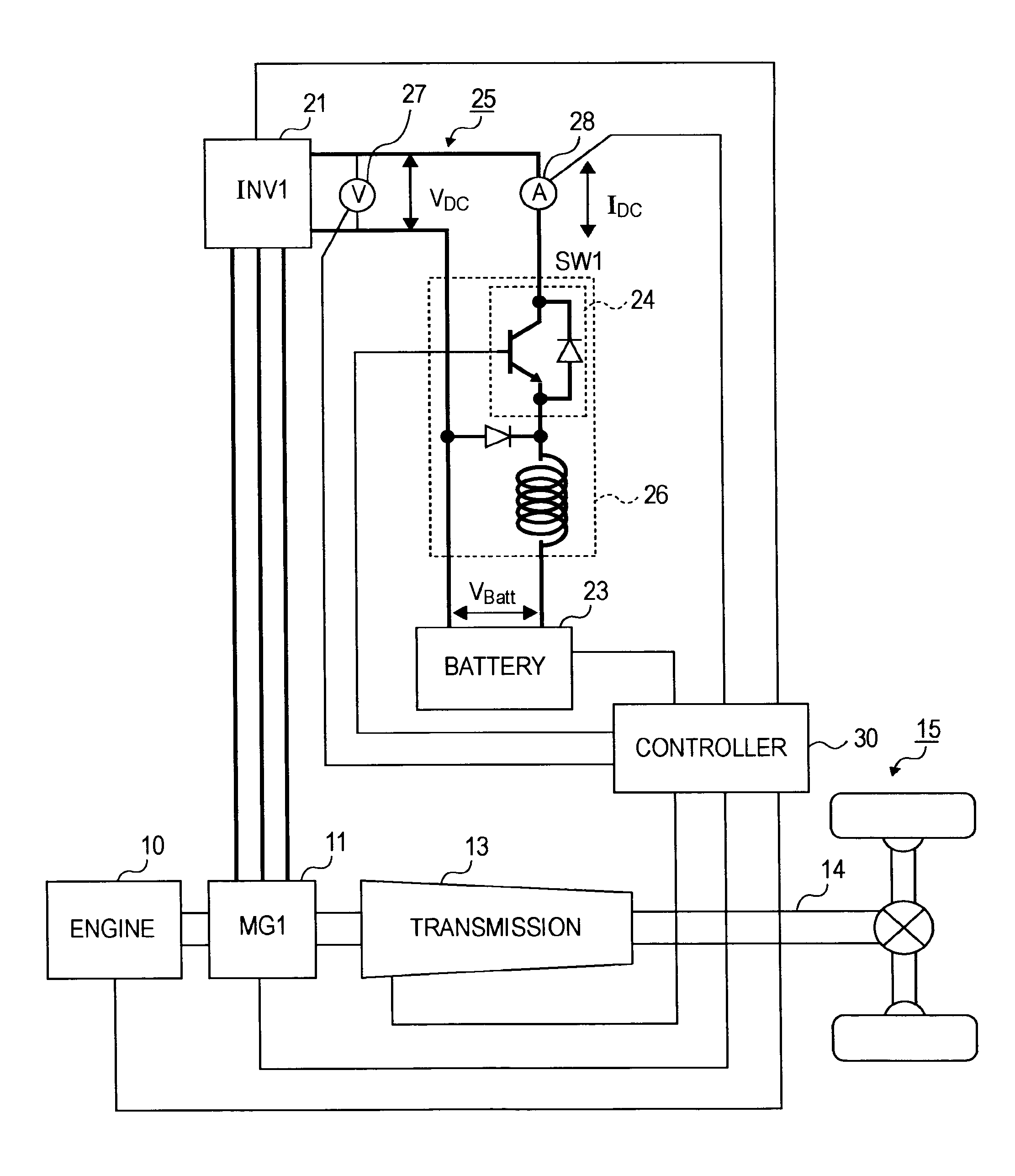

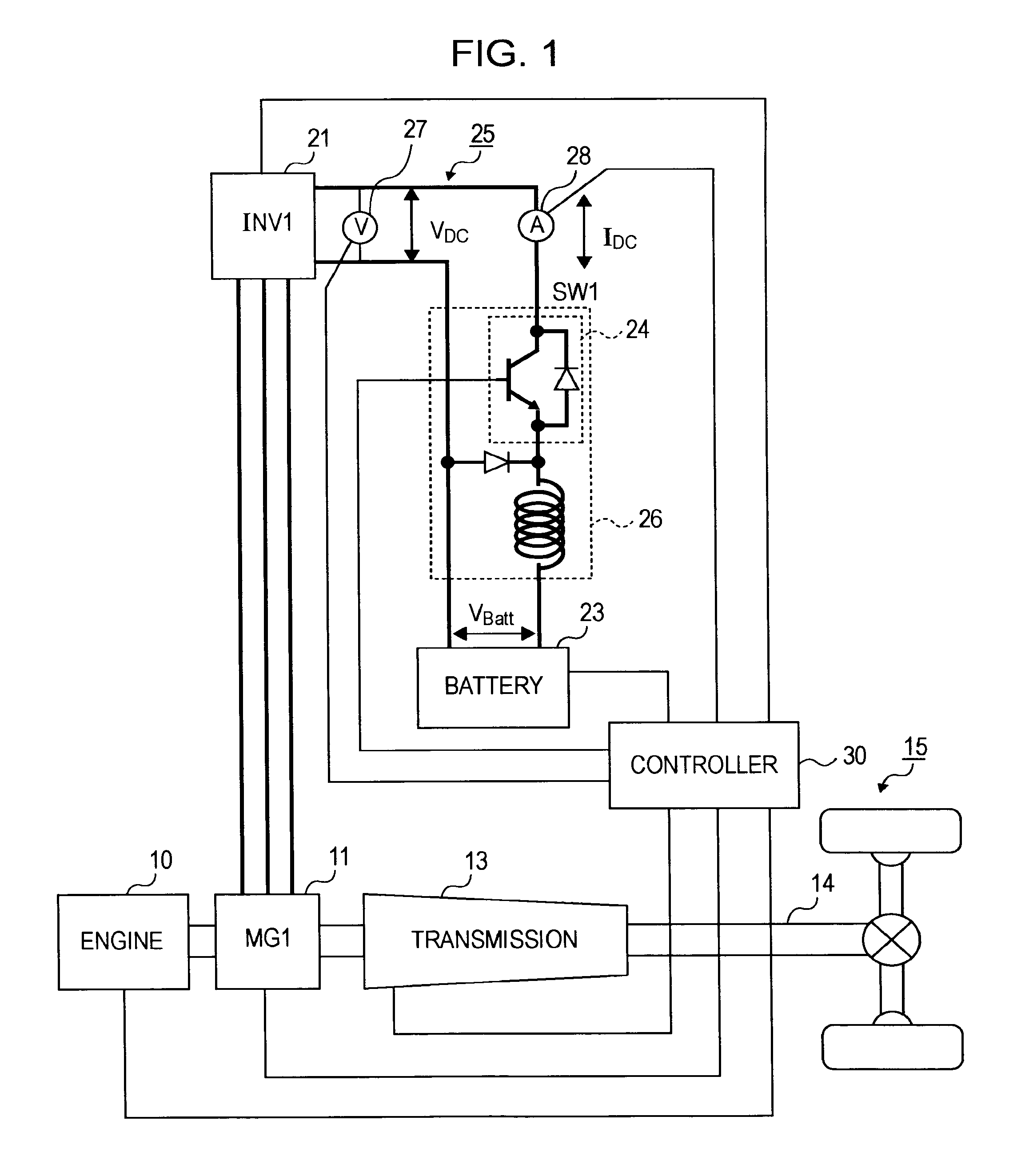

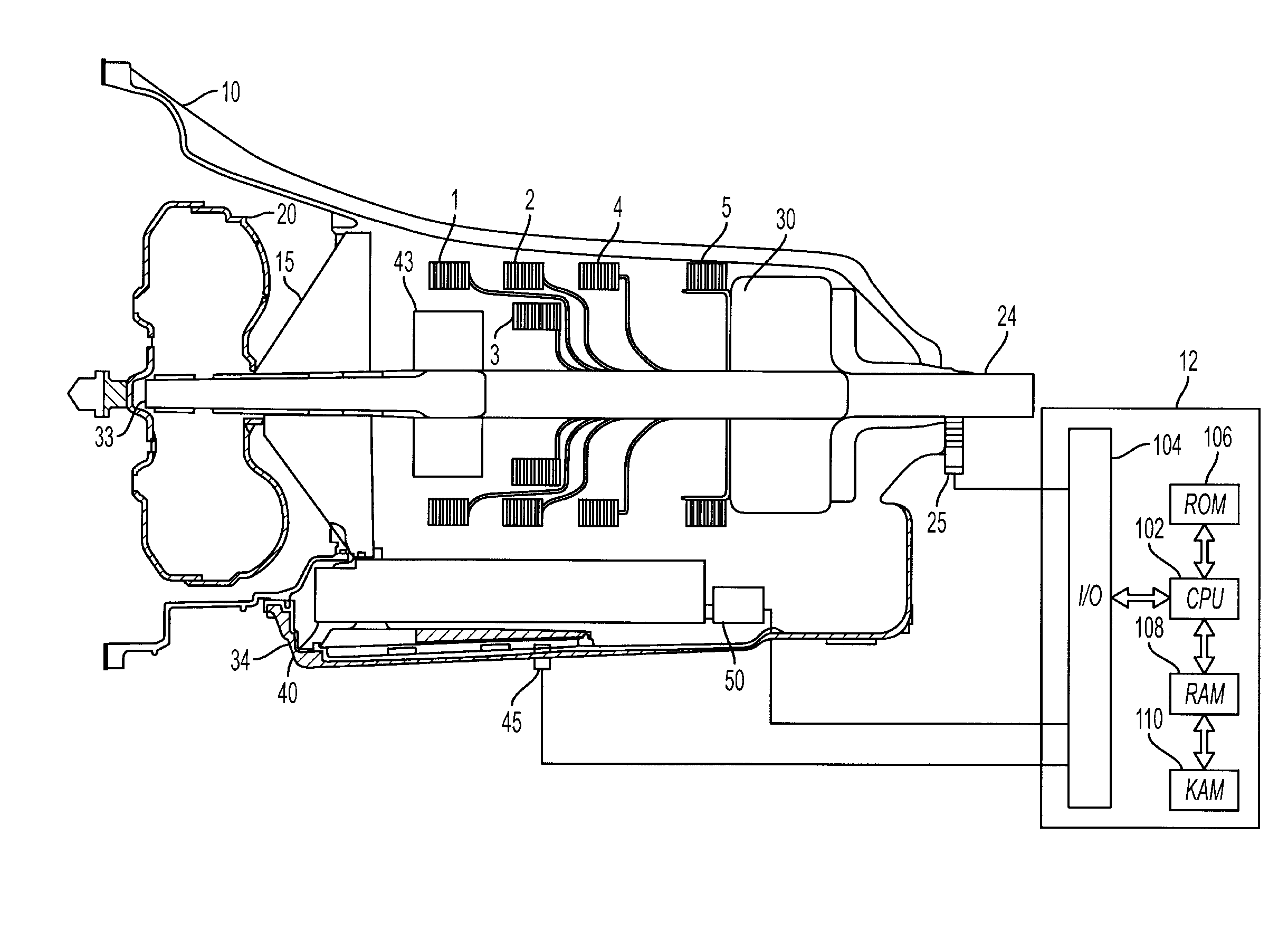

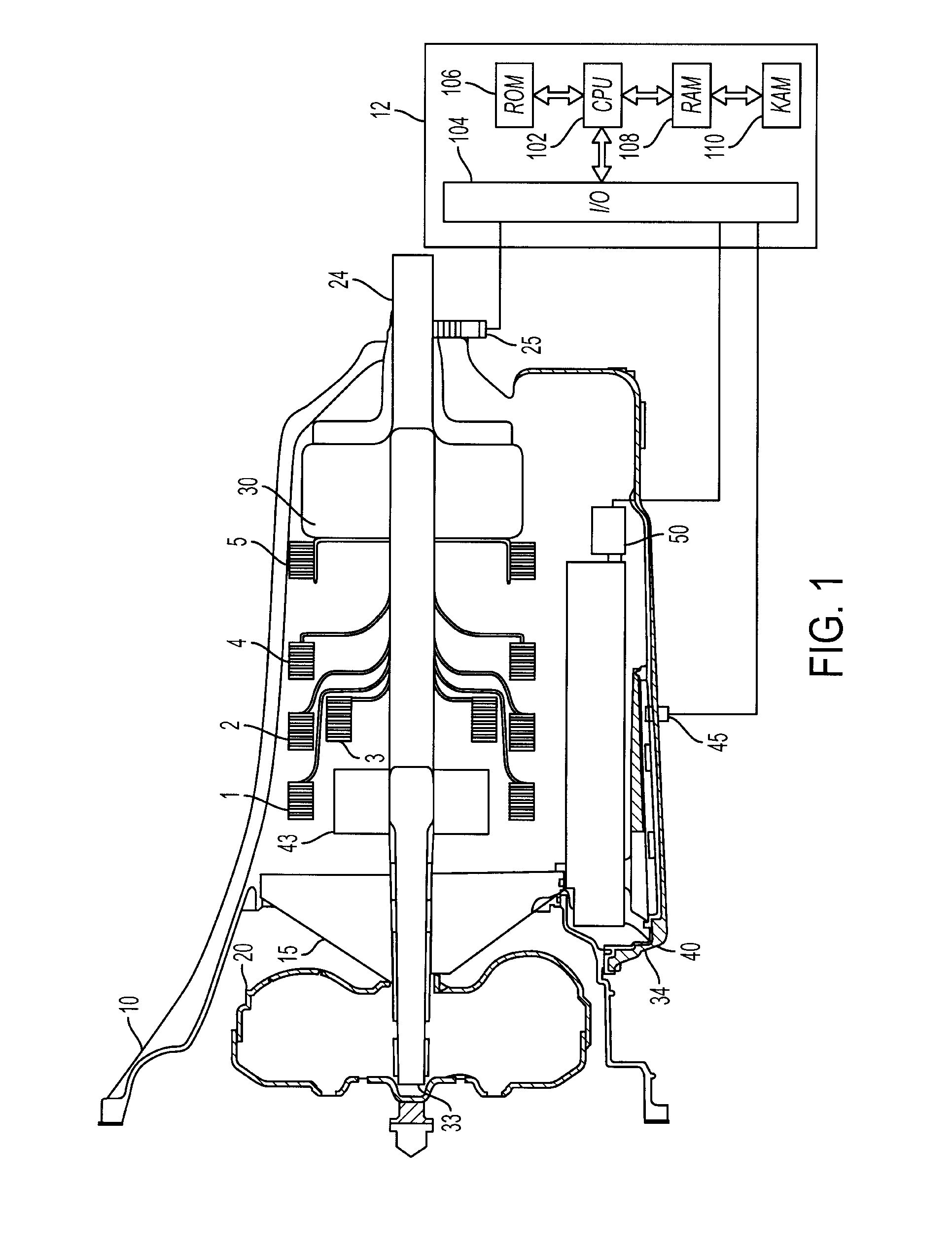

Driving System for Hybrid Vehicle

ActiveUS20080306643A1Improve responsivenessLow costDigital data processing detailsEmergency protective circuit arrangementsElectricityElectrical battery

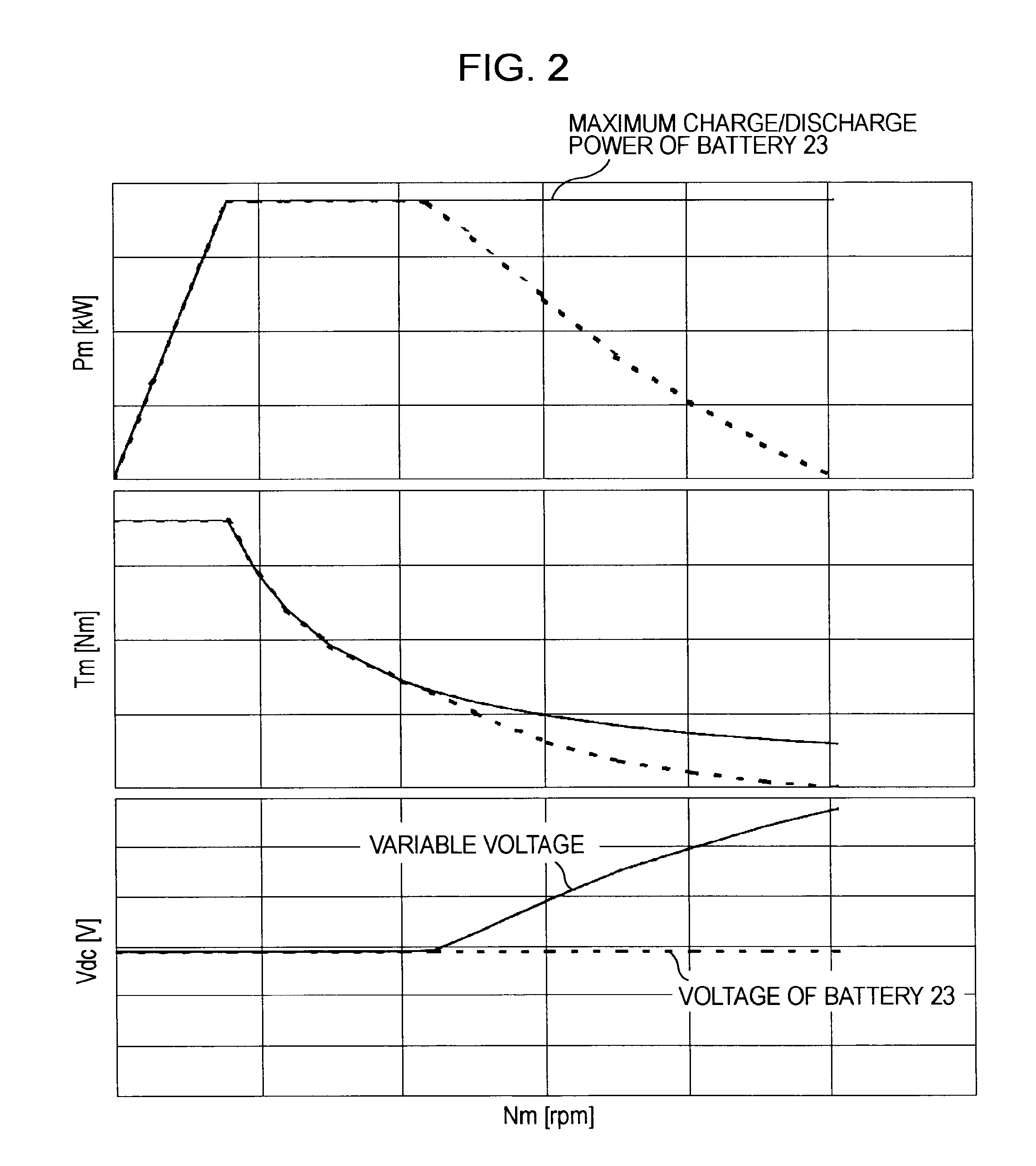

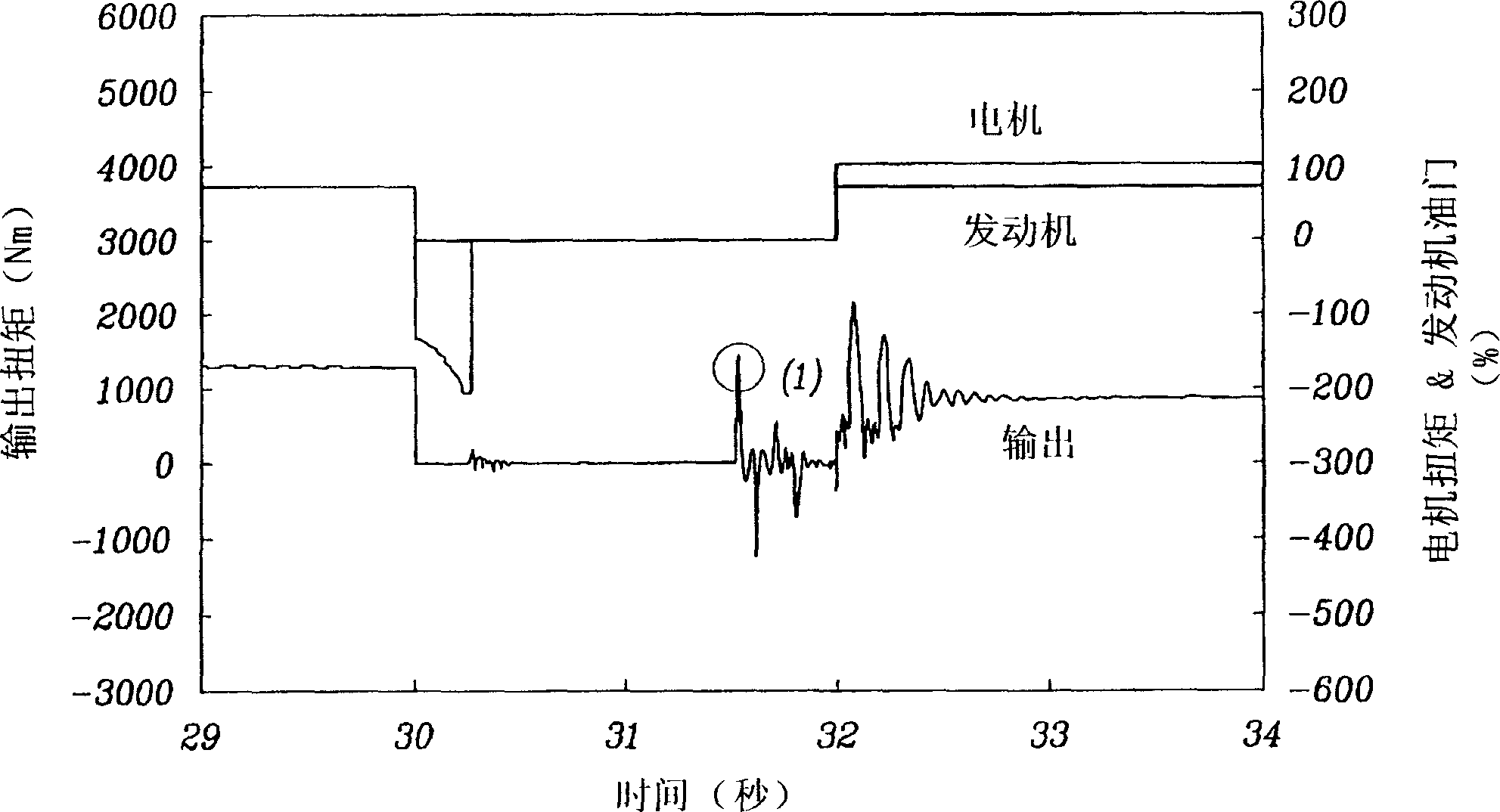

A hybrid-vehicle driving system includes an engine, a transmission, a first motor / generator provided between the engine and the transmission, and a battery that can charge and discharge the first motor / generator. When an estimated output voltage of the first motor / generator becomes higher than or equal to a predetermined voltage during a gear shift operation of the transmission, the battery is electrically disconnected from the driving system, and the voltage of a power line on the side of the first motor / generator is then decreased so as to charge the battery.

Owner:NISSAN MOTOR CO LTD

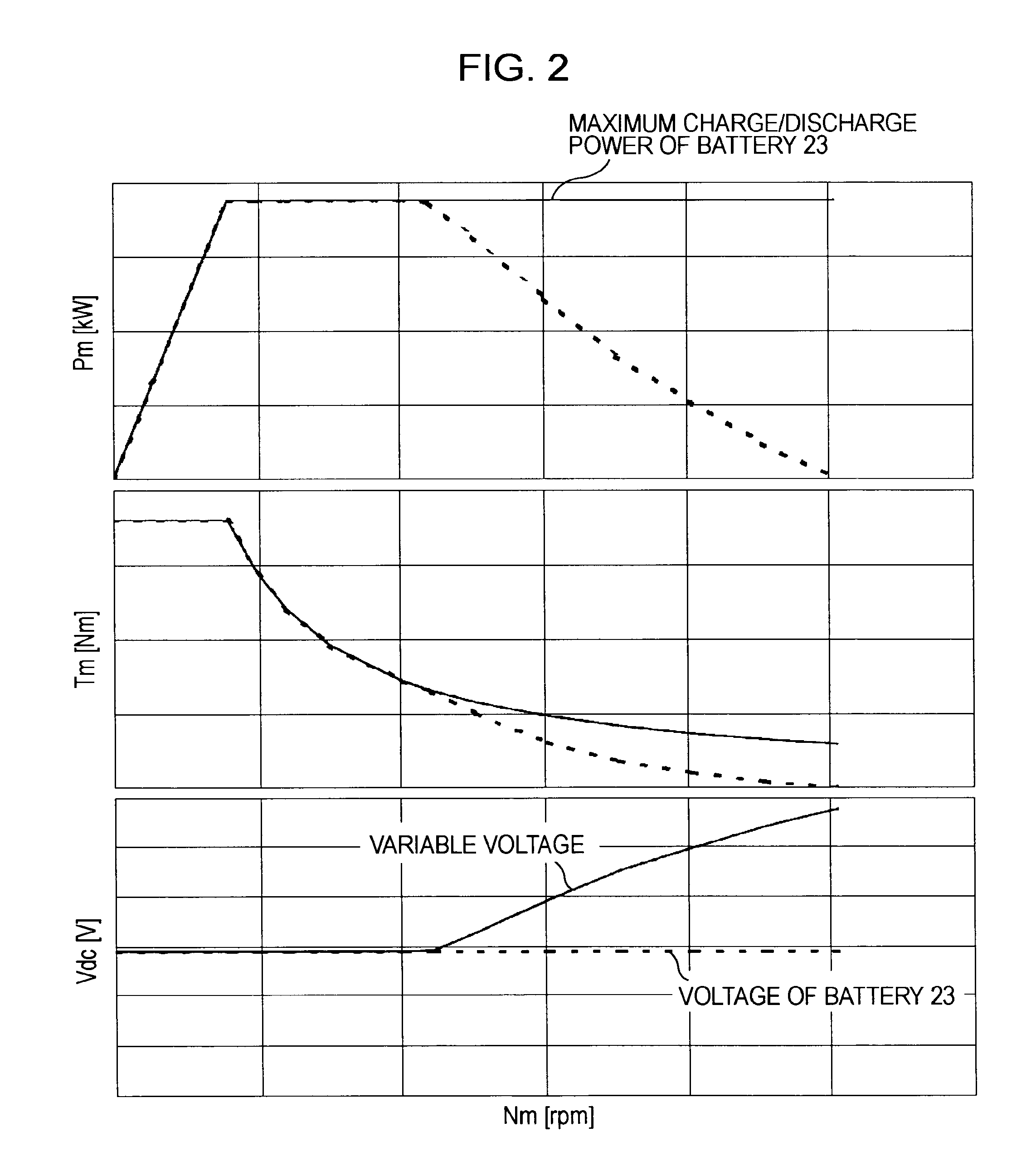

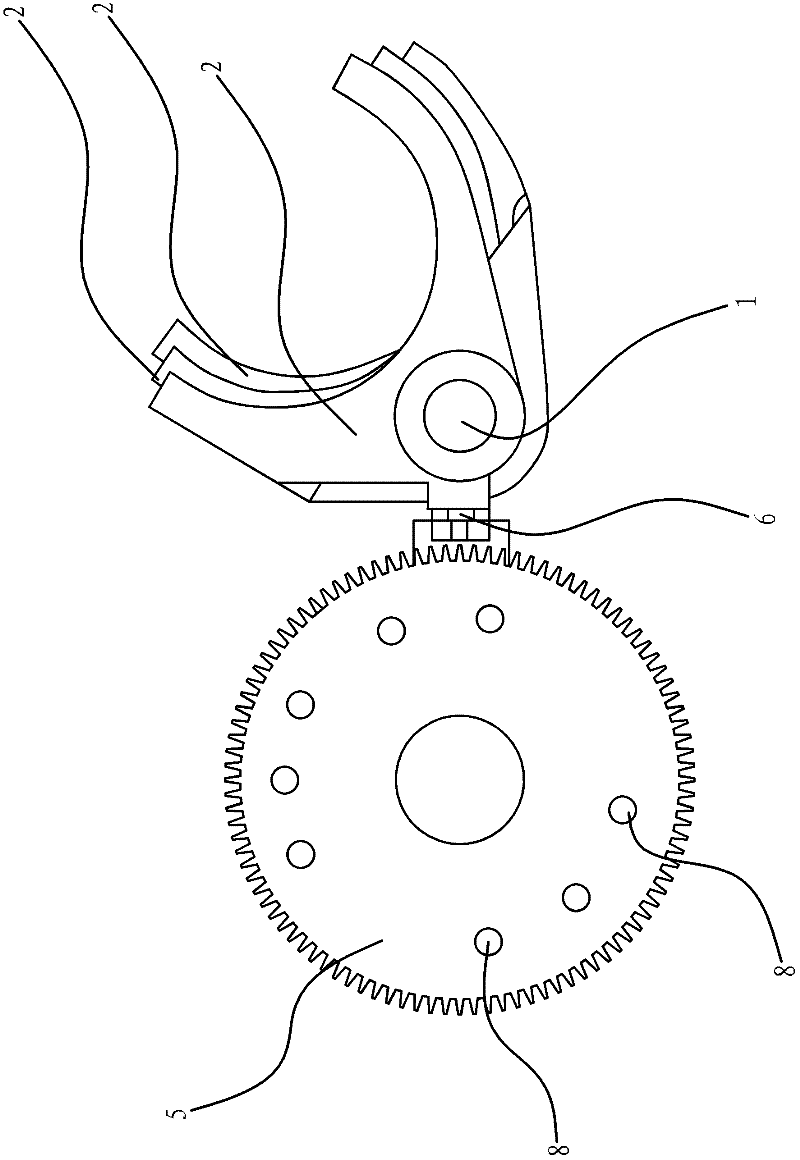

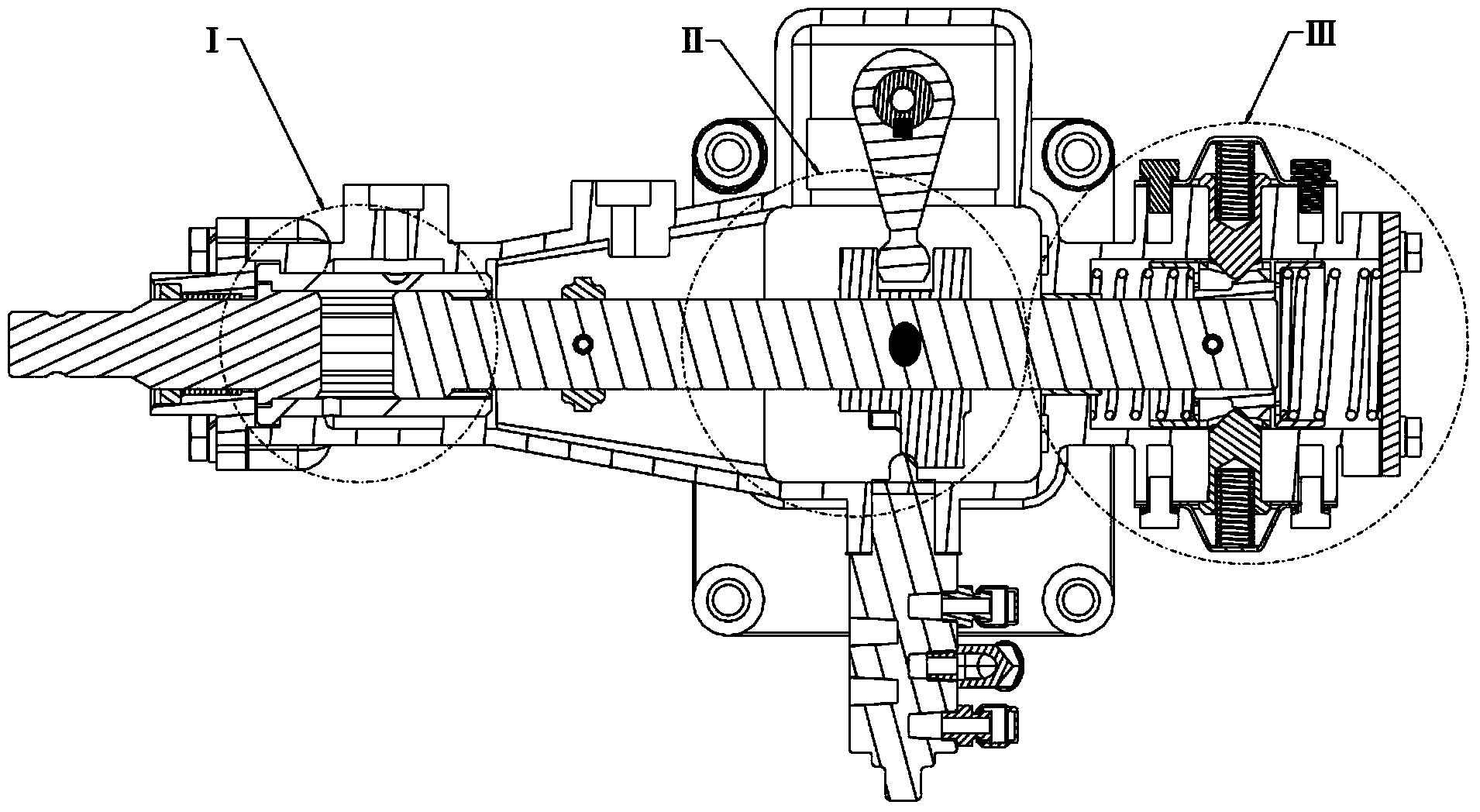

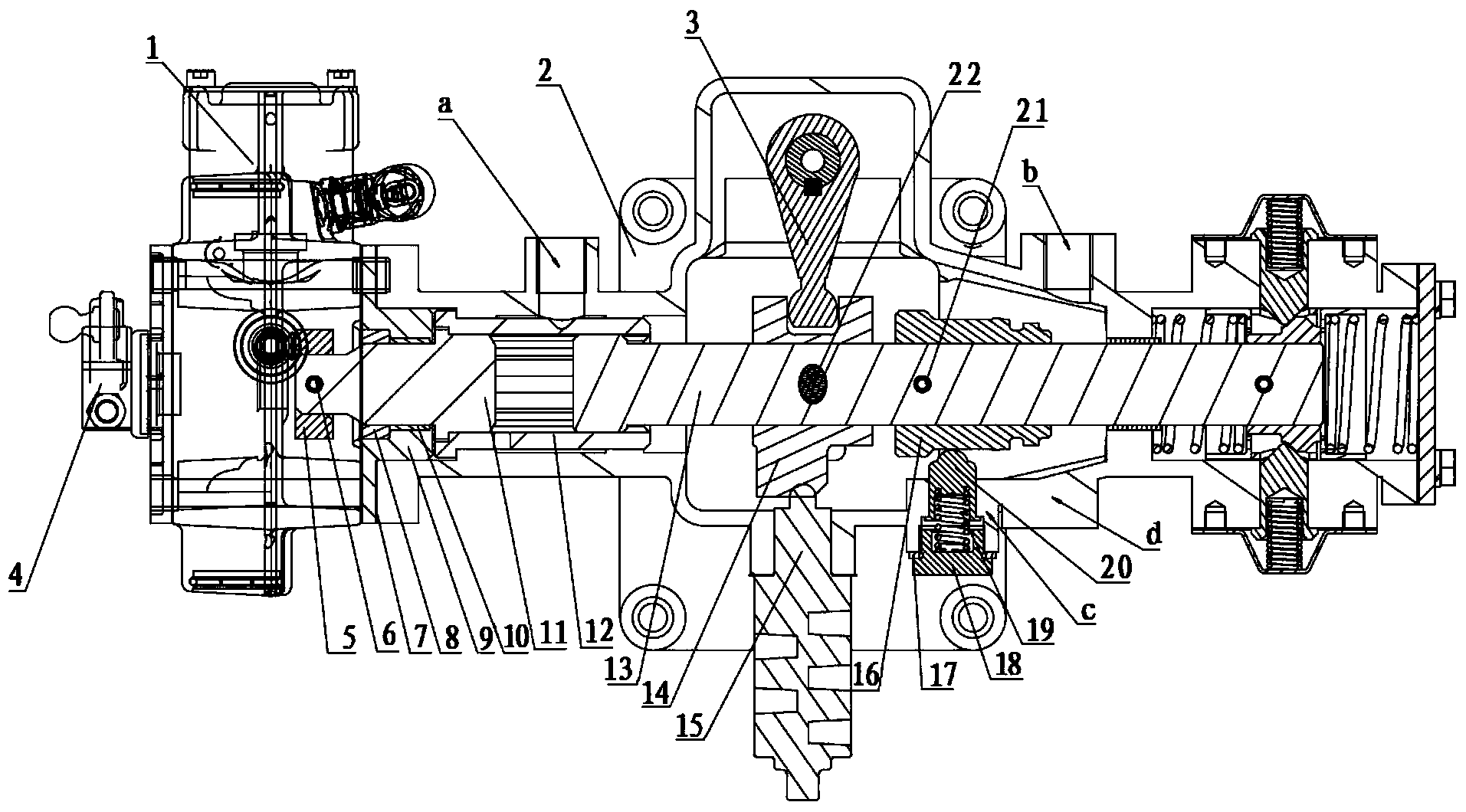

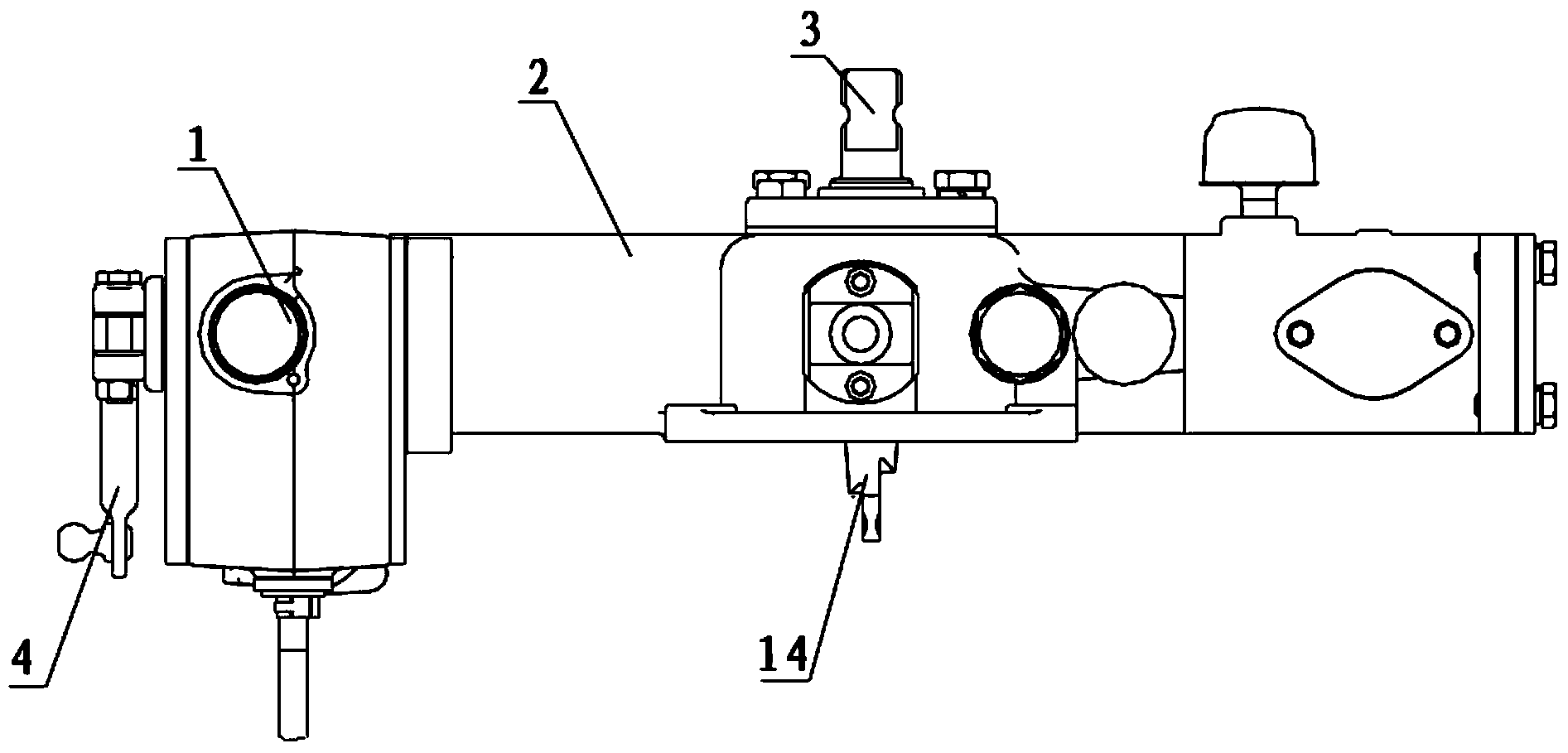

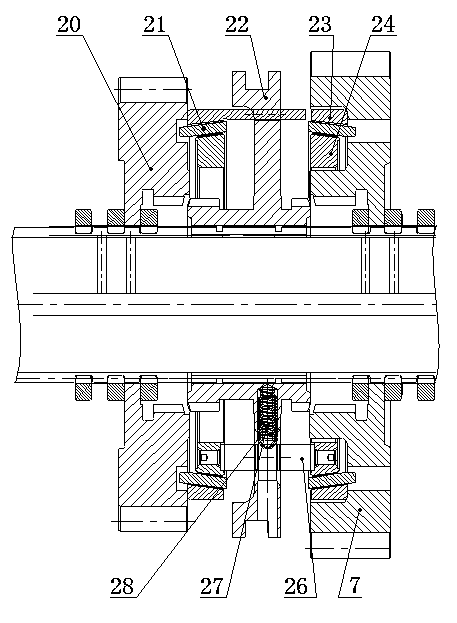

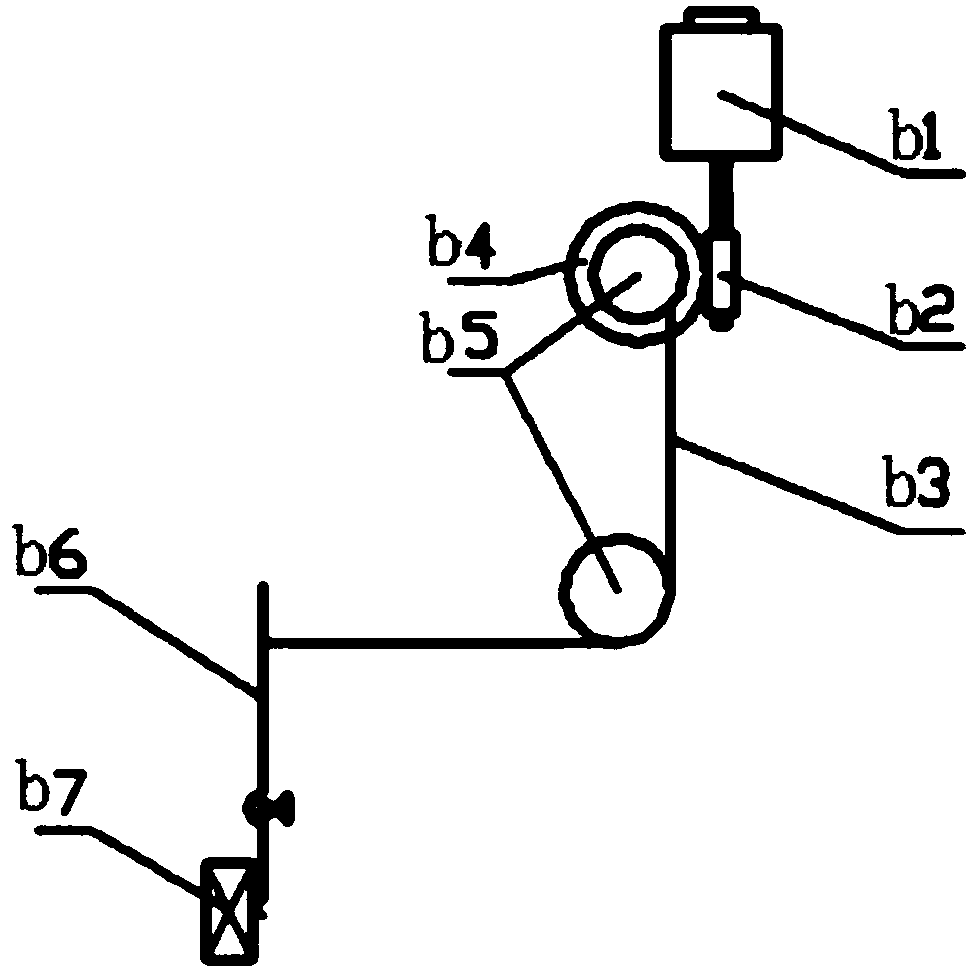

transmission shift mechanism

InactiveCN102287527ASave installation spaceImprove shift performanceControlled membersGearing controlElectrical and Electronics engineeringVariator

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Driving system for hybrid vehicle

ActiveUS8140205B2Short timeImprove shift performanceDigital data processing detailsEmergency protective circuit arrangementsElectricityElectrical battery

A hybrid-vehicle driving system includes an engine, a transmission, a first motor / generator provided between the engine and the transmission, and a battery that can charge and discharge the first motor / generator. When an estimated output voltage of the first motor / generator becomes higher than or equal to a predetermined voltage during a gear shift operation of the transmission, the battery is electrically disconnected from the driving system, and the voltage of a power line on the side of the first motor / generator is then decreased so as to charge the battery.

Owner:NISSAN MOTOR CO LTD

Oil mass measuring method, oil mass measuring device and oil pressure calibration method

InactiveCN102644736AExtended service lifeImproved shift qualityGear lubrication/coolingGearing controlAutomatic transmissionOil temperature

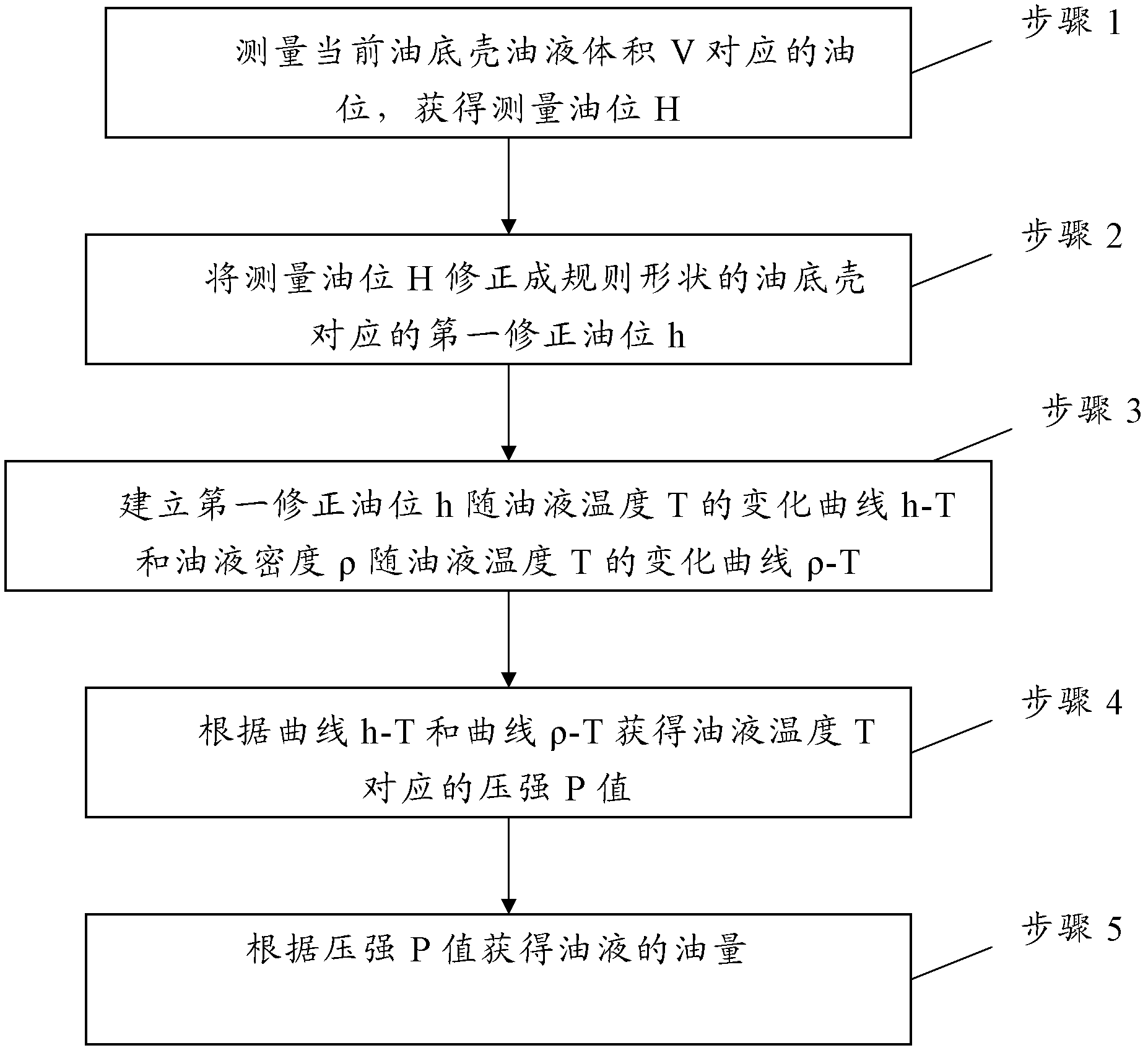

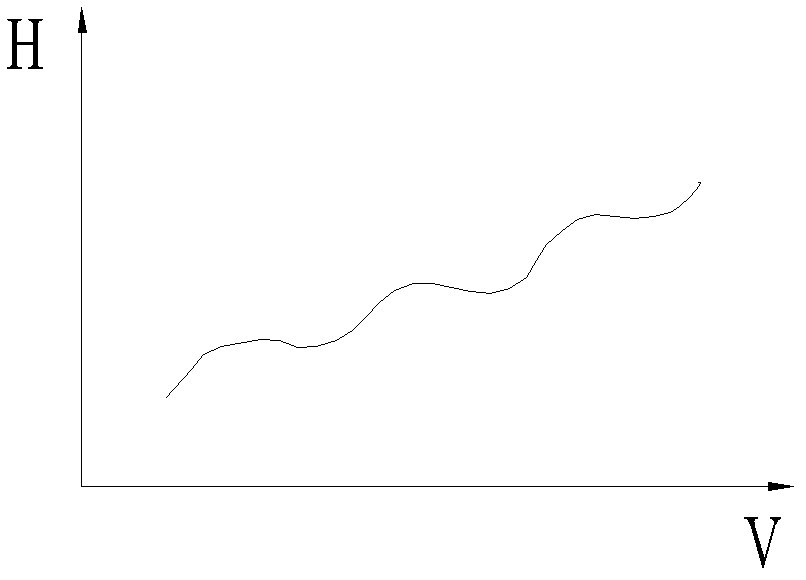

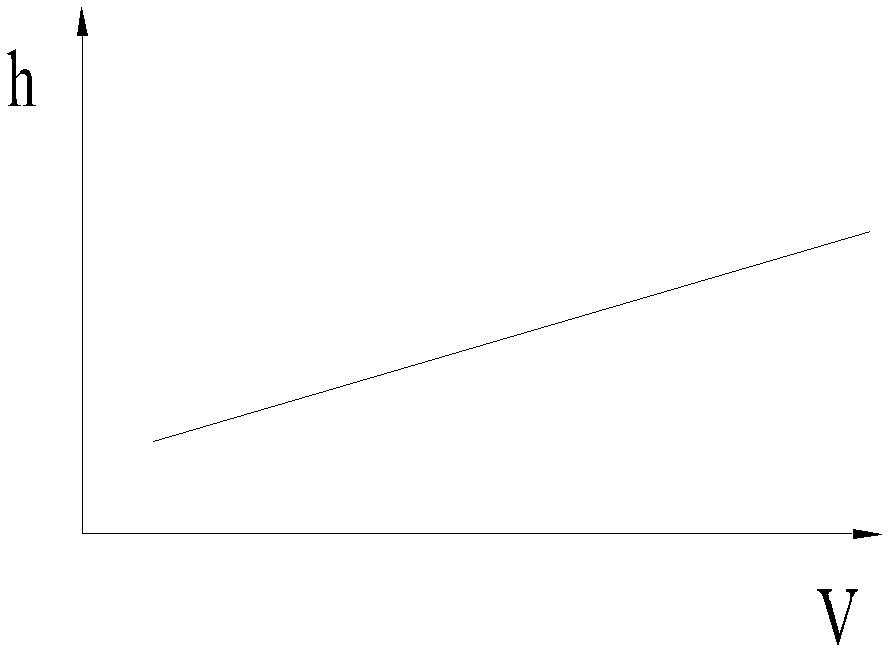

An embodiment of the invention discloses an oil mass measuring method, an oil mass measuring device and an oil pressure calibration method, relates to the technical field of automatic transmissions, and aims at solving the technical problem that in the prior art, an oil level is greatly influenced by temperature and shape variation of an oil pan so that the real oil mass of transmission oil cannot be measured accurately. The oil mass measuring method comprises measuring an oil level corresponding to current volume V of oil pan oil, and obtaining a measurement oil level H; correcting the measurement oil level H to a first correction oil level h corresponding to the oil pan in a regular shape; establishing a changing curve h-T of the first correction oil level h along with the oil temperature T and a changing curve rho-T of the oil density rho along with the oil temperature T; obtaining a pressure P value corresponding to the oil temperature T according to the curve h-T and the curve rho-T; and obtaining the oil mass of oil according to the pressure P value. The oil mass measuring method, the oil mass measuring device and the oil pressure calibration method are used for measuring the oil mass of a gearbox of the automatic transmissions.

Owner:GREAT WALL MOTOR CO LTD

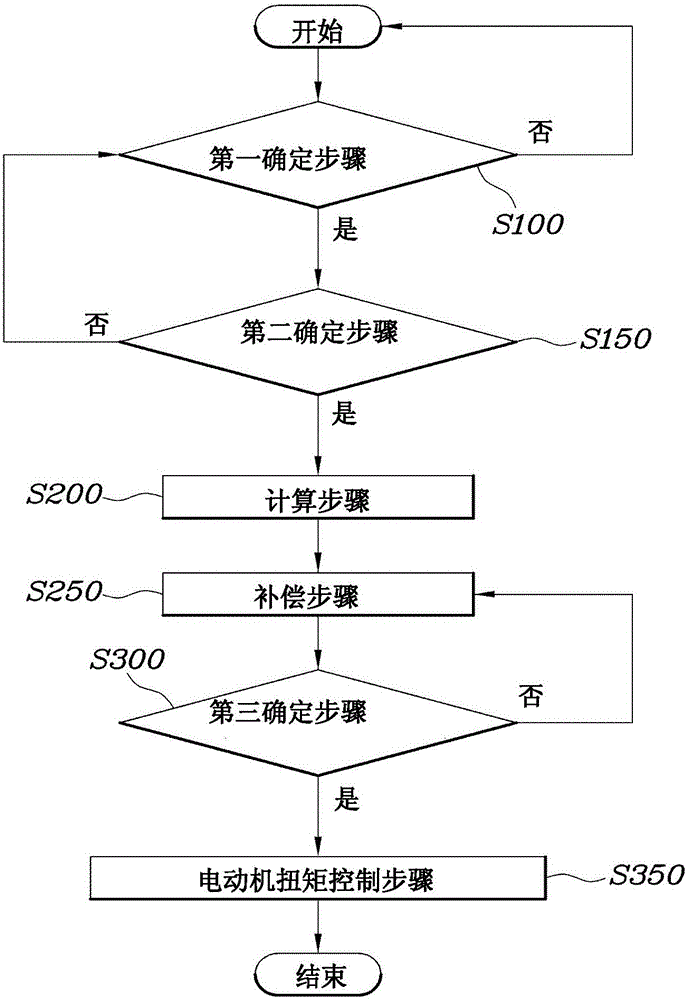

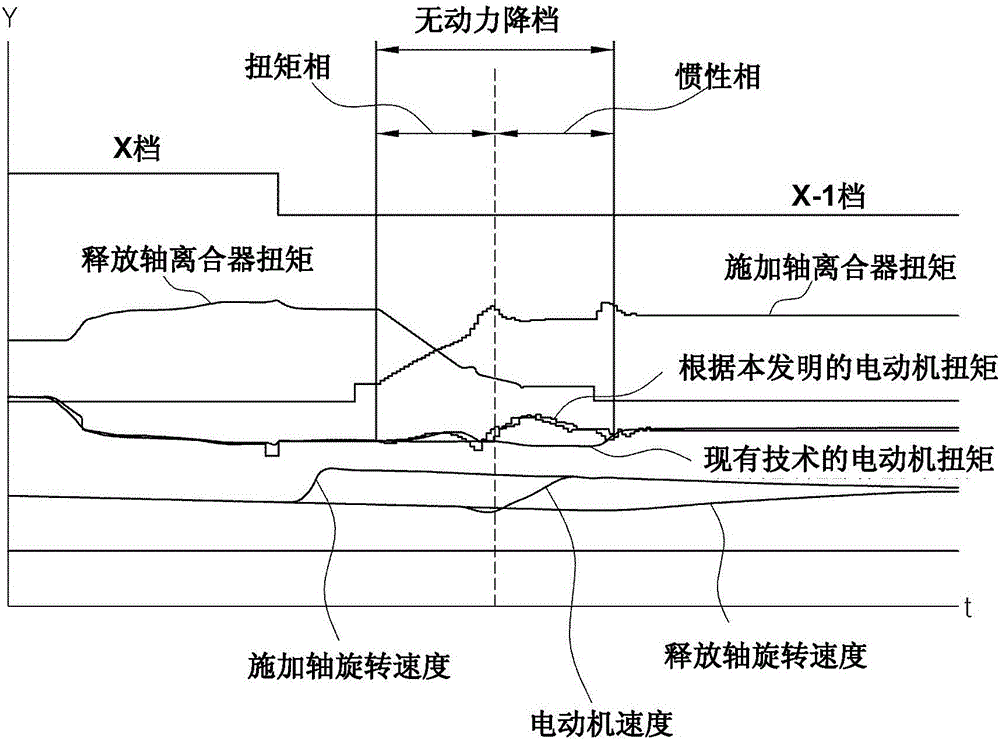

Control Method Of Dual Clutch Transmission For Hybrid Electric Vehicle And Control System For The Same

ActiveCN106560362APrevents brake linear dropQuick shift responseHybrid vehiclesSpeed controllerRegenerative brakeControl system

A control method of a dual clutch transmission for a hybrid electric vehicle includes: determining, by a transmission controller, whether a vehicle has entered a power-off down-shift state; determining, by the transmission controller, whether a transmission including a first input shaft, a second input shaft, and an output shaft has entered a torque phase, when the first determining step determines that the vehicle has entered the power-off down-shift state; calculating a compensatory torque for compensating for a change in a regenerative braking force according to a change of a gear ratio in accordance with a completion percentage of the torque phase, when it is determined that a transmission has entered the torque phase; and compensating for regenerative torque of a motor by applying the compensatory torque.

Owner:HYUNDAI MOTOR CO LTD +1

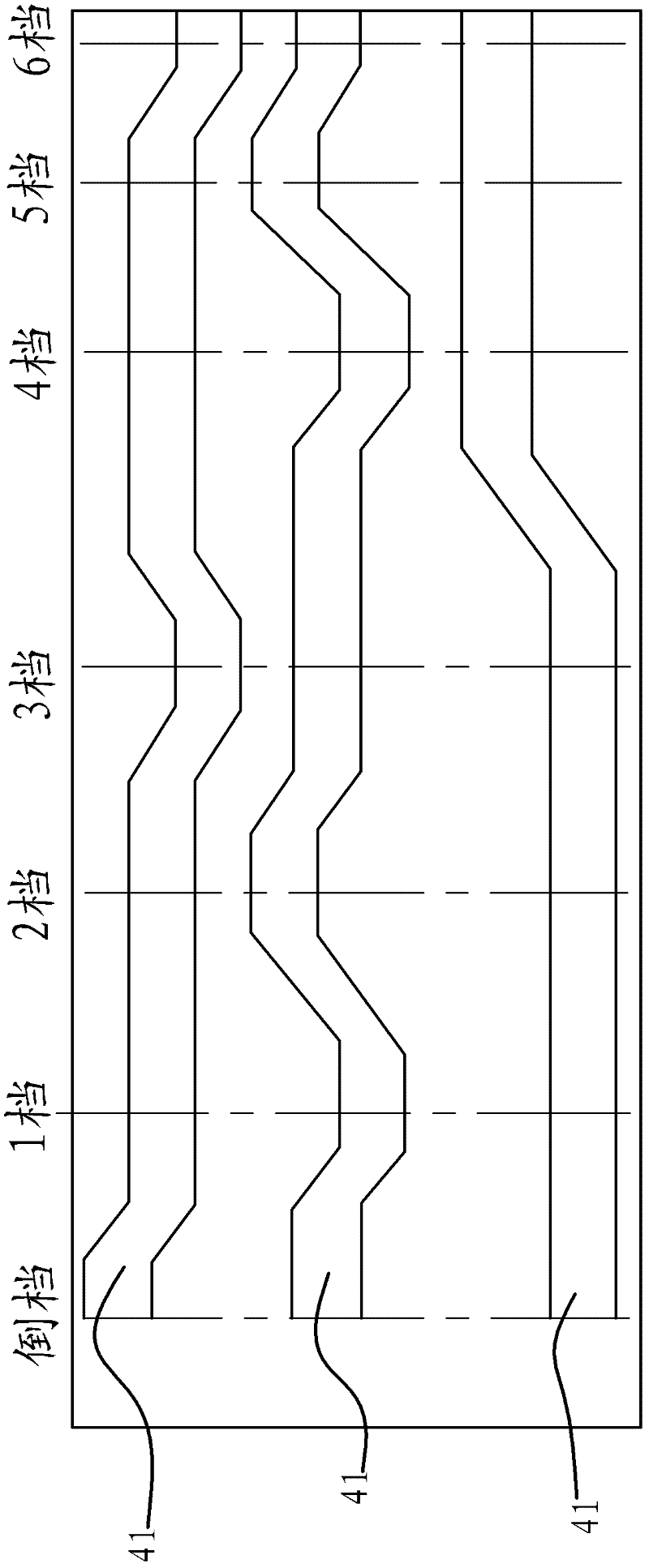

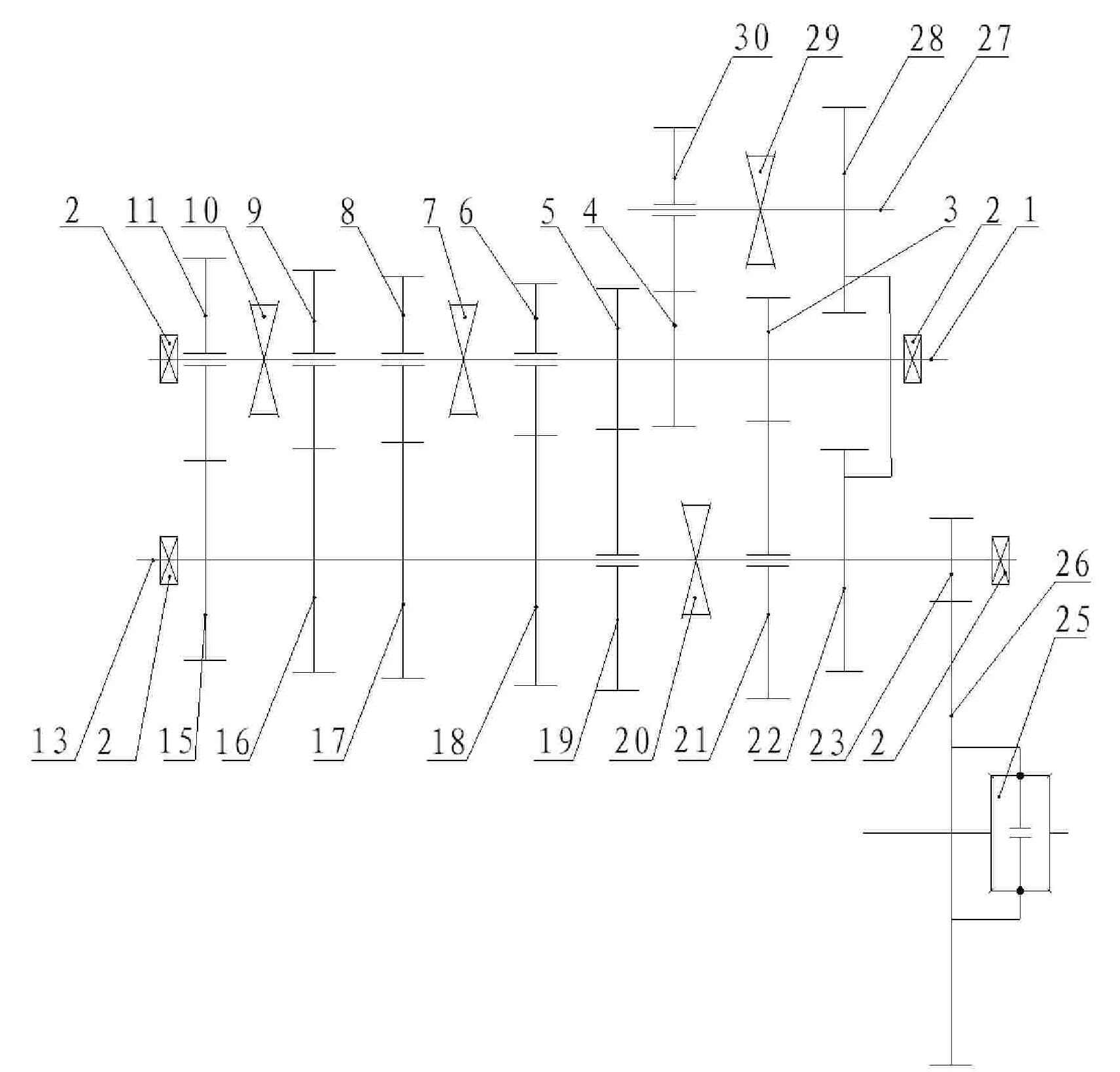

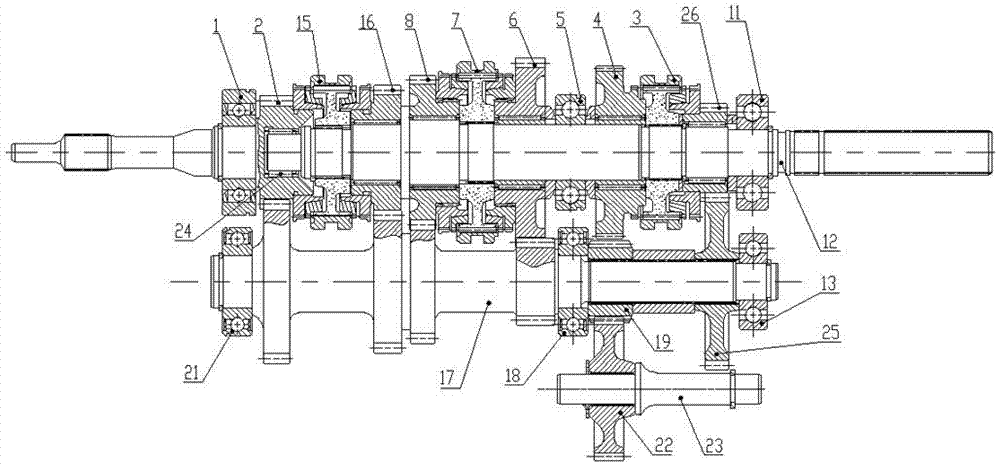

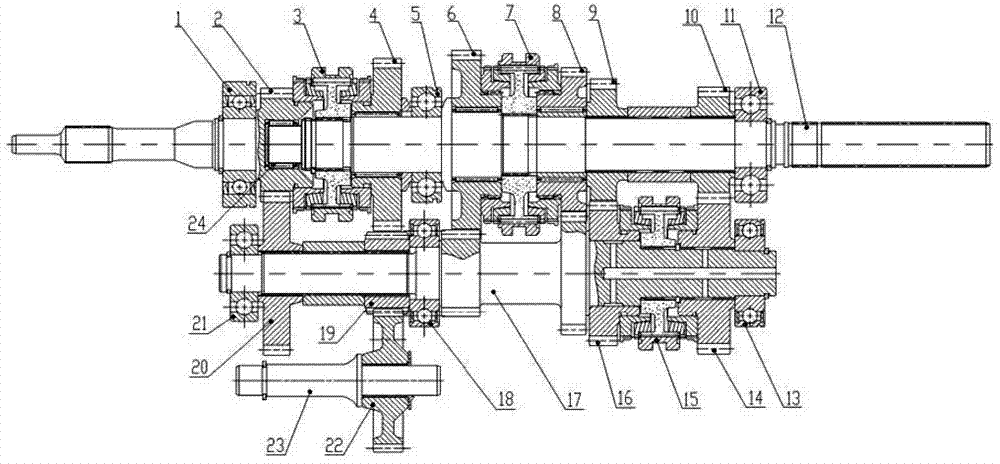

Twin-shaft six-speed mechanical speed changer

InactiveCN101915287AReduce radial sizeCompact and reasonable space structureToothed gearingsGear wheelControl theory

The invention discloses a twin-shaft six-speed mechanical speed changer, and provides the twin-shaft six-speed mechanical speed changer which has the advantages of multiple gears, high transmission efficiency, compact installation space, light weight, low cost, low gear shift noise and good handfeel, and is particularly suitable for medium and small torsion. The twin-shaft six-speed mechanical speed changer solves the technical problems of low transmission efficiency, large required installation space, heavy weight, high cost, high gear shift noise, poor handfeel and the like of the speed changer in the prior art, and comprises an input shaft connected with an engine and an output shaft and a differential mechanism which are engaged with the input shaft selectively, wherein the output shaft and a reverse gear shaft are parallel to the input shaft; a driving gear for realizing a first gear, a second gear, a third gear, a fourth gear, a fifth gear and a sixth gear is arranged on the input shaft; a driven gear corresponding to the driving gear on the input shaft is arranged on the output shaft; and a synchronizer is arranged on the input shaft, the output shaft and the reverse gear shaft.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

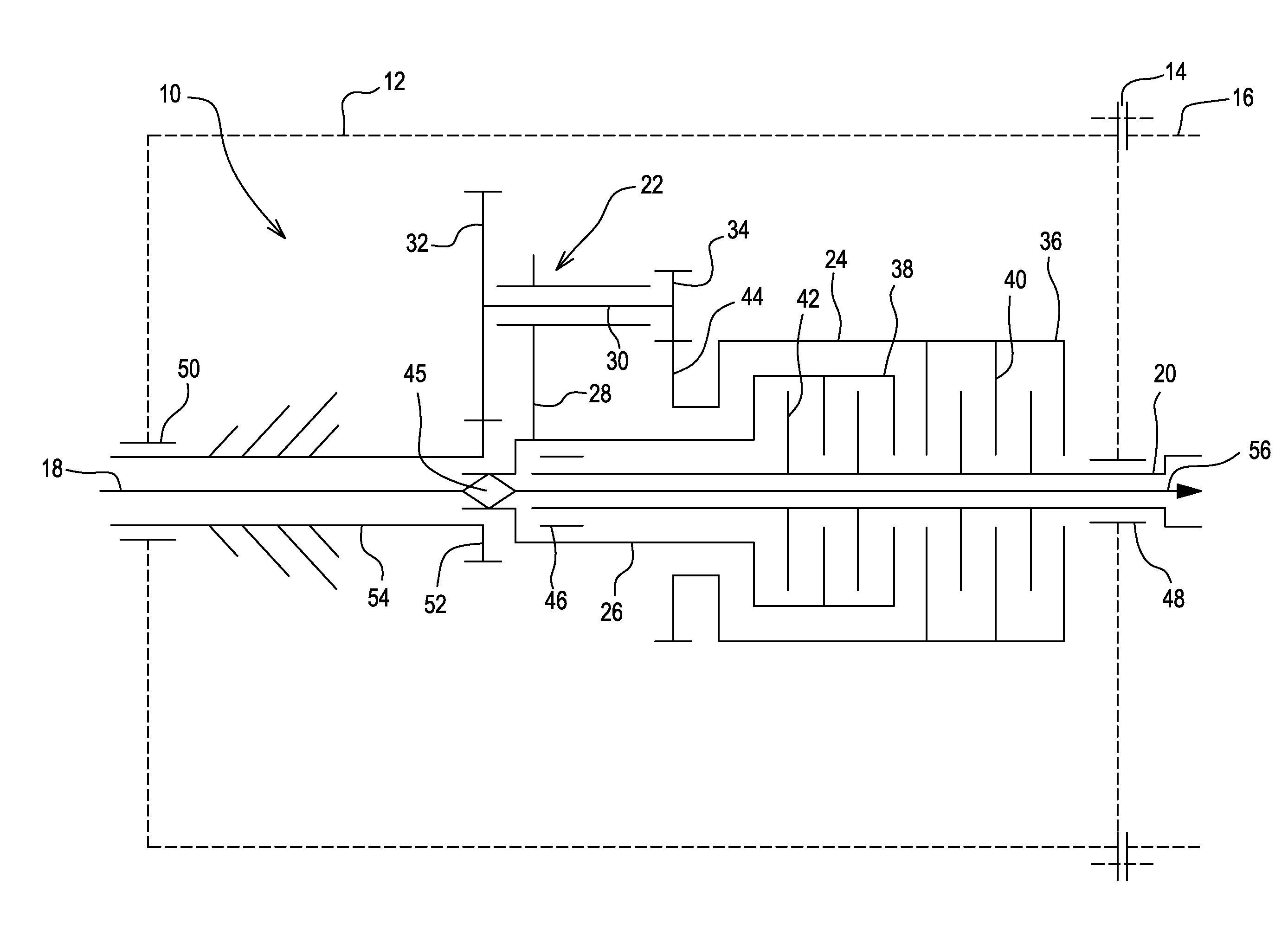

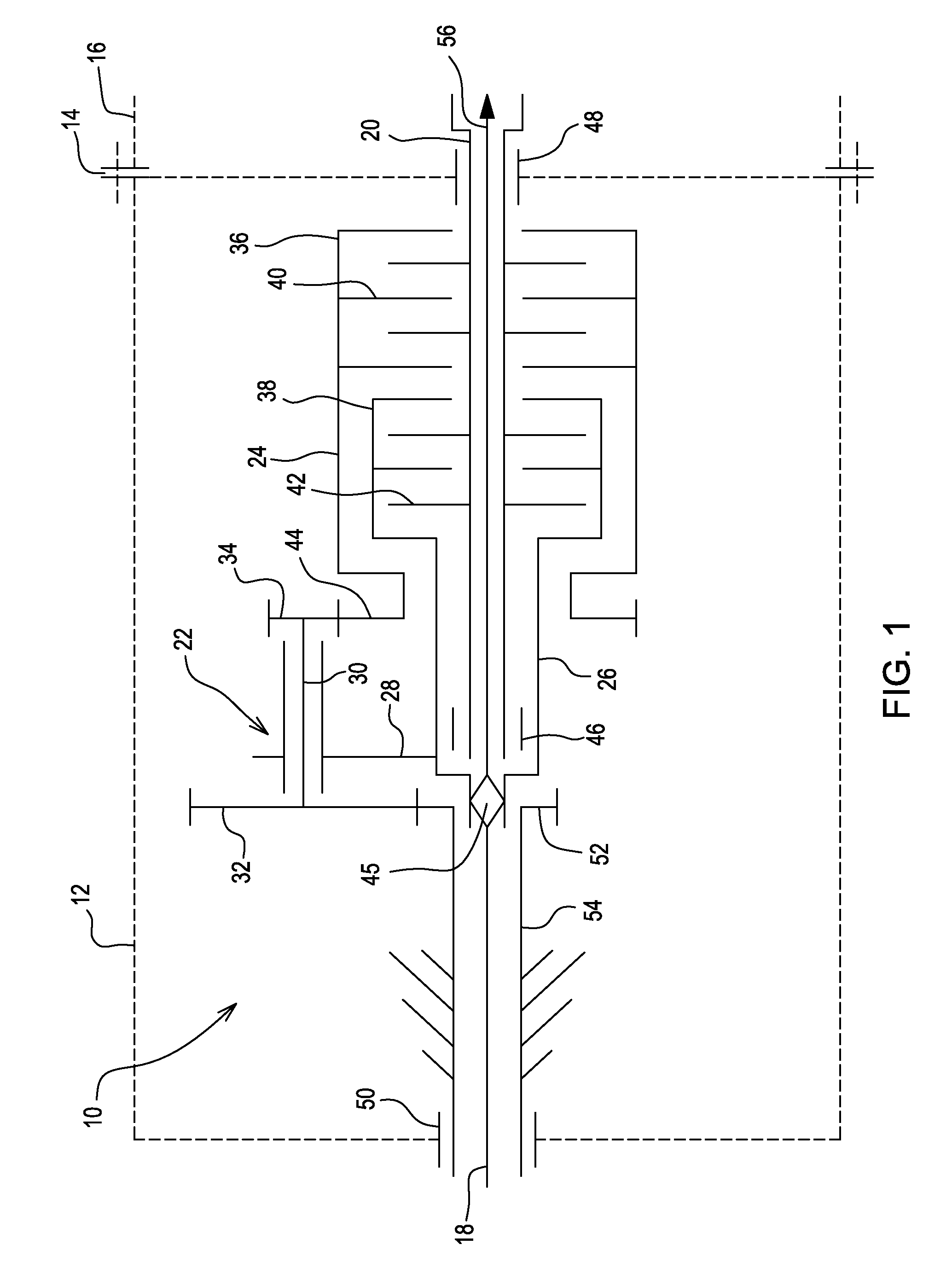

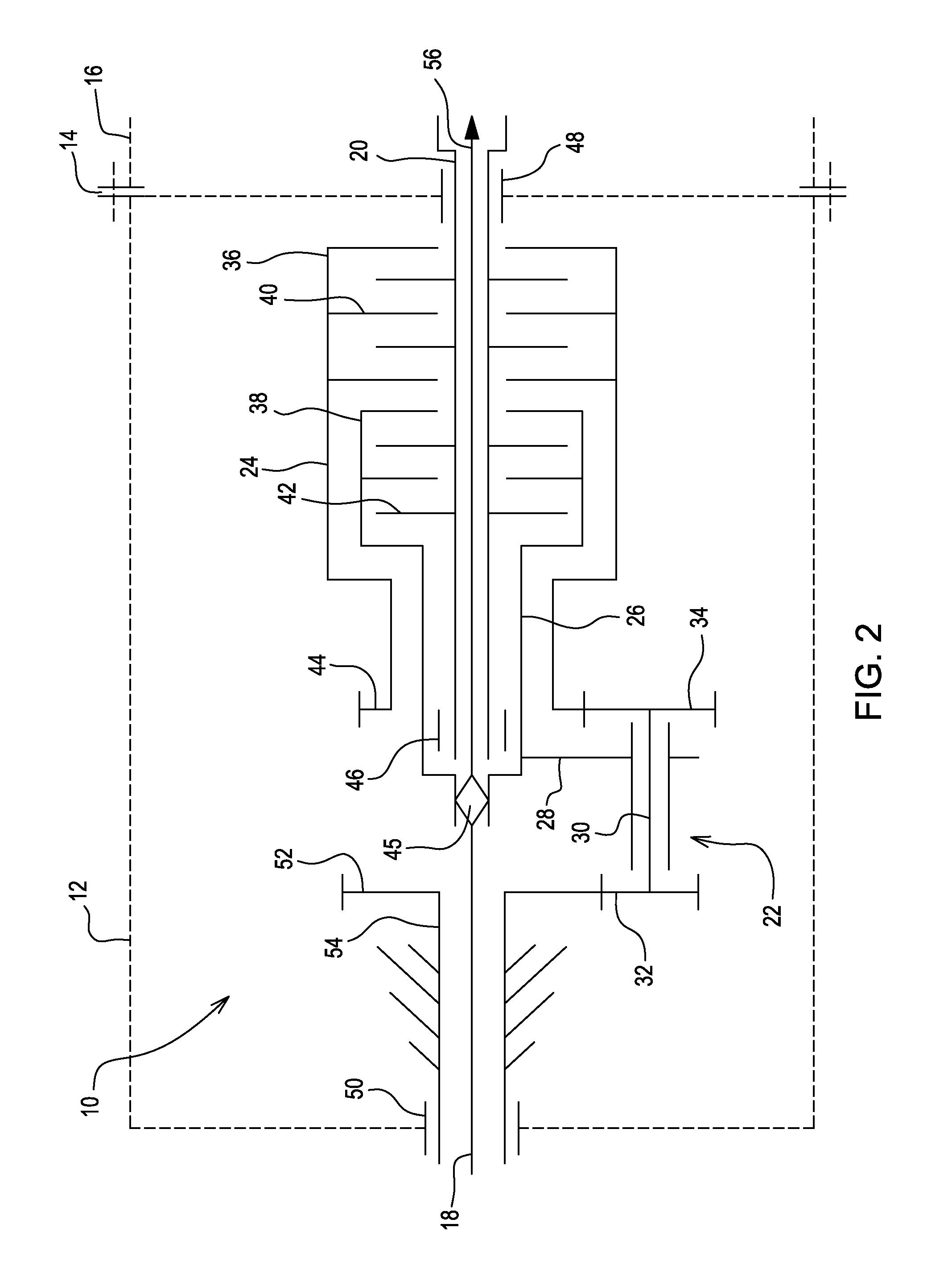

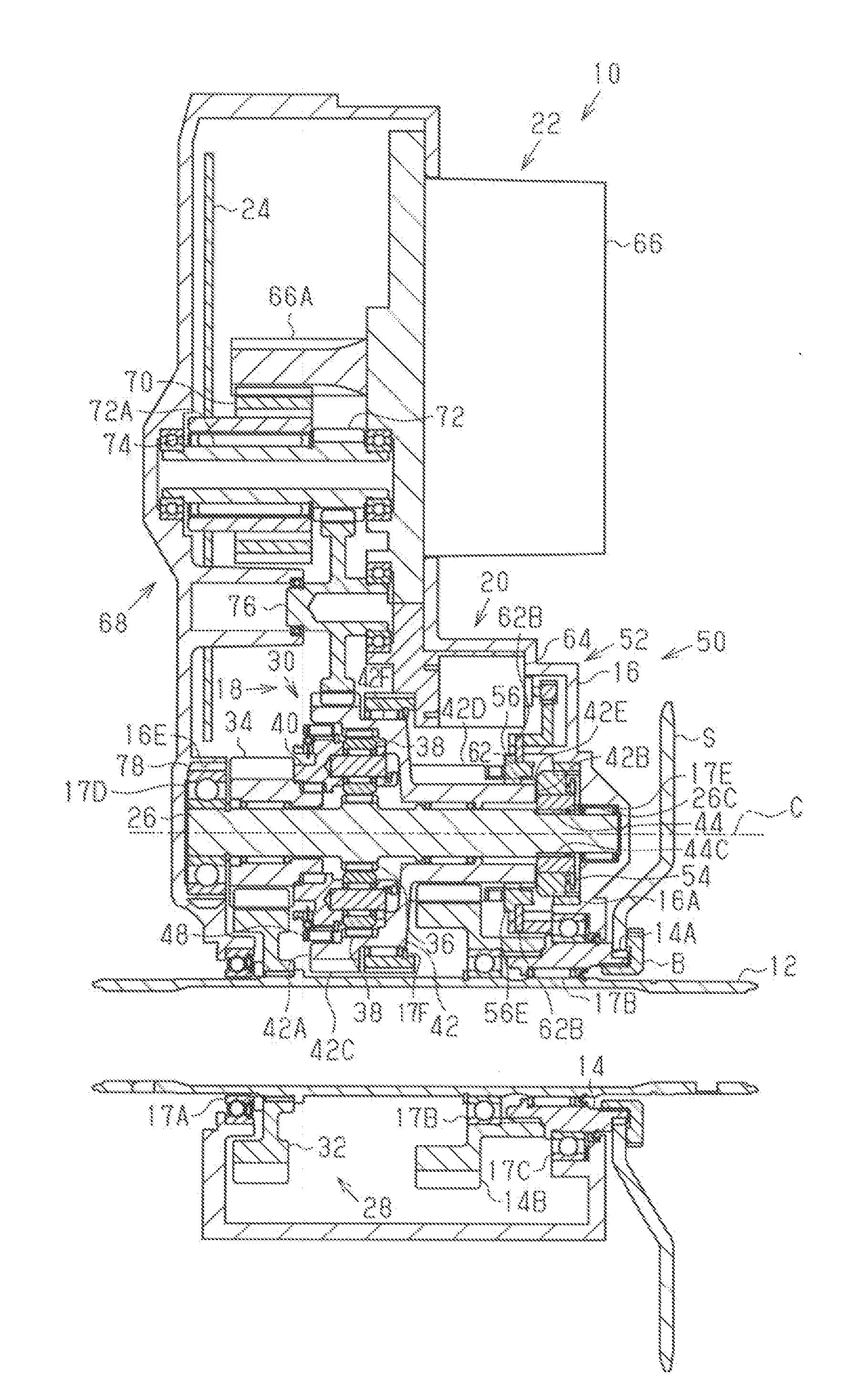

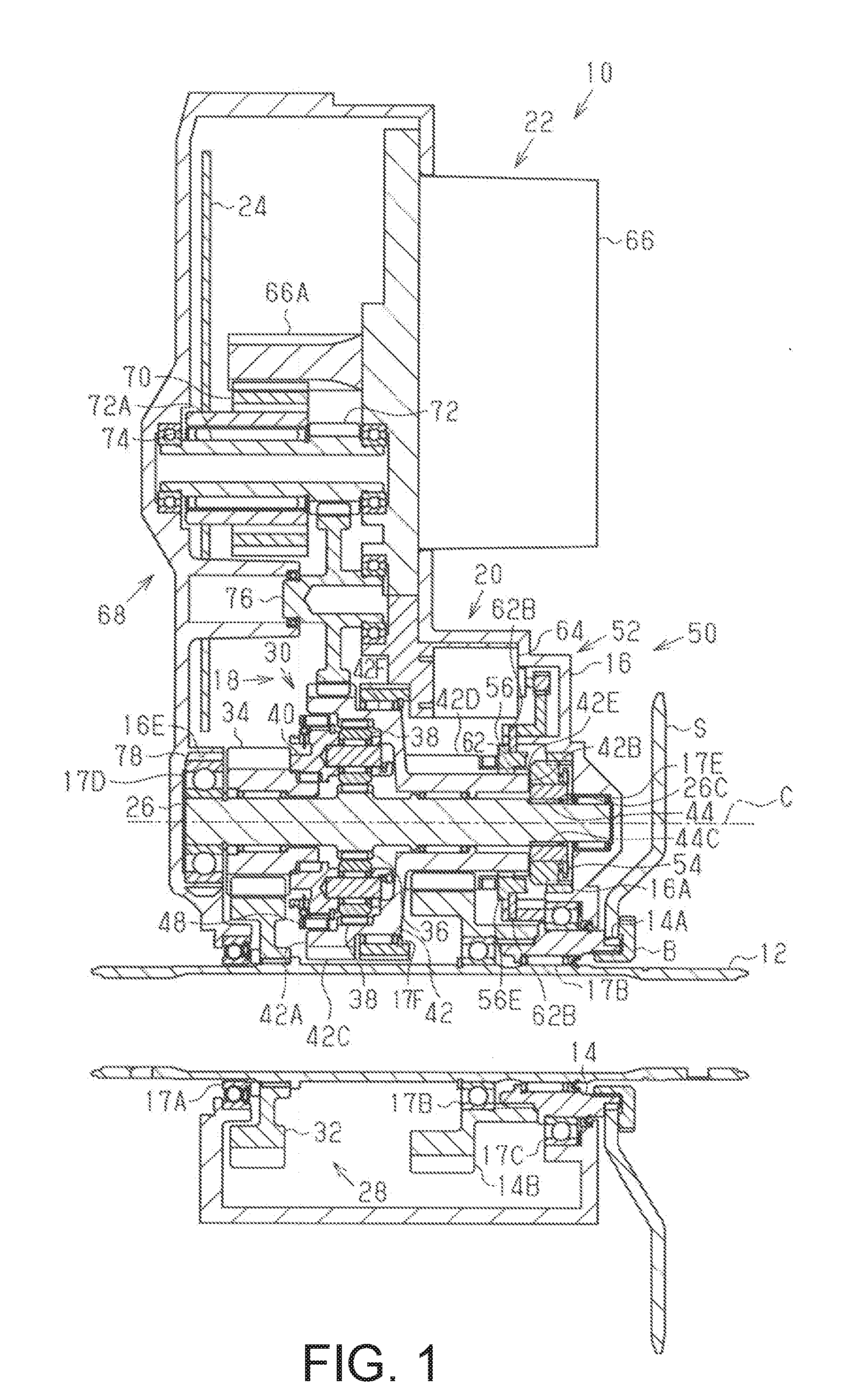

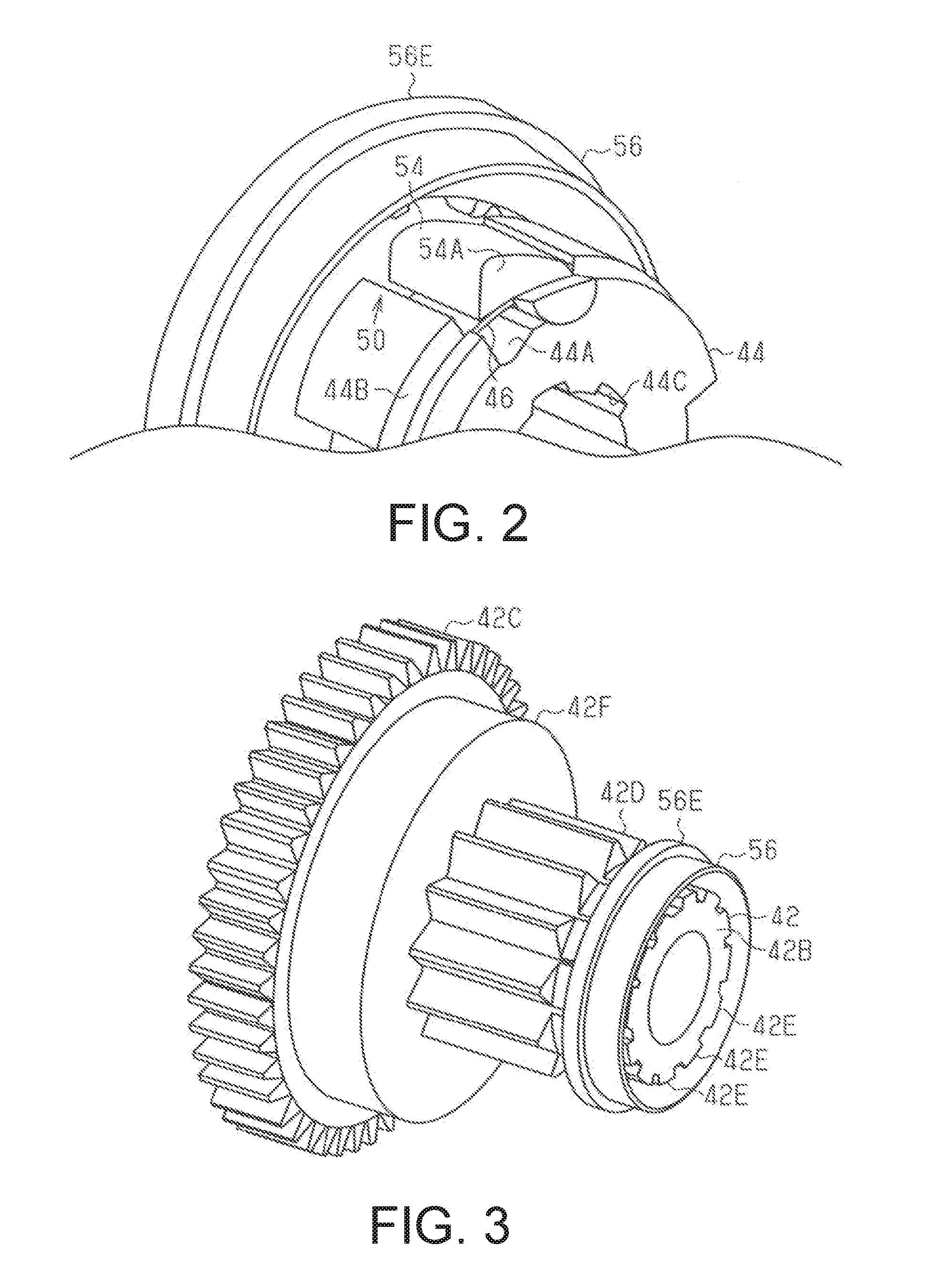

Power shift transmission

ActiveUS20150031491A1Closely arrangedSimple designToothed gearingsTransmission elementsDual stageEngineering

The invention relates to a power shift transmission (10). The power shift transmission comprises an input shaft (18), a first output shaft (20) arranged coaxially to the input shaft (18), a planetary transmission (22) having a planet gear carrier (28), which is connected to the input shaft (18), and at least one dual-stage planetary gear set (30), the dual-stage planetary gear set (30) engaging on the input side with an input-side sun gear (52) and on the output side with an output-side sun gear (44) in each case, and at least two shift elements (24, 26). To produce a variable power shift transmission for several pairings of various operation modes, the first output shaft (20) can be connected to the output-side sun gear (44) of the dual-stage planetary gear set (30) by means of a first shift element (24) and the first output shaft (20) can be directly connected to the input shaft (18) by means of a second shift element (26), the input-side sun gear (52) of the dual-stage planetary gear set (30) being non-non-rotatably connected to a housing (12) of the power shift transmission (10).

Owner:DEERE & CO

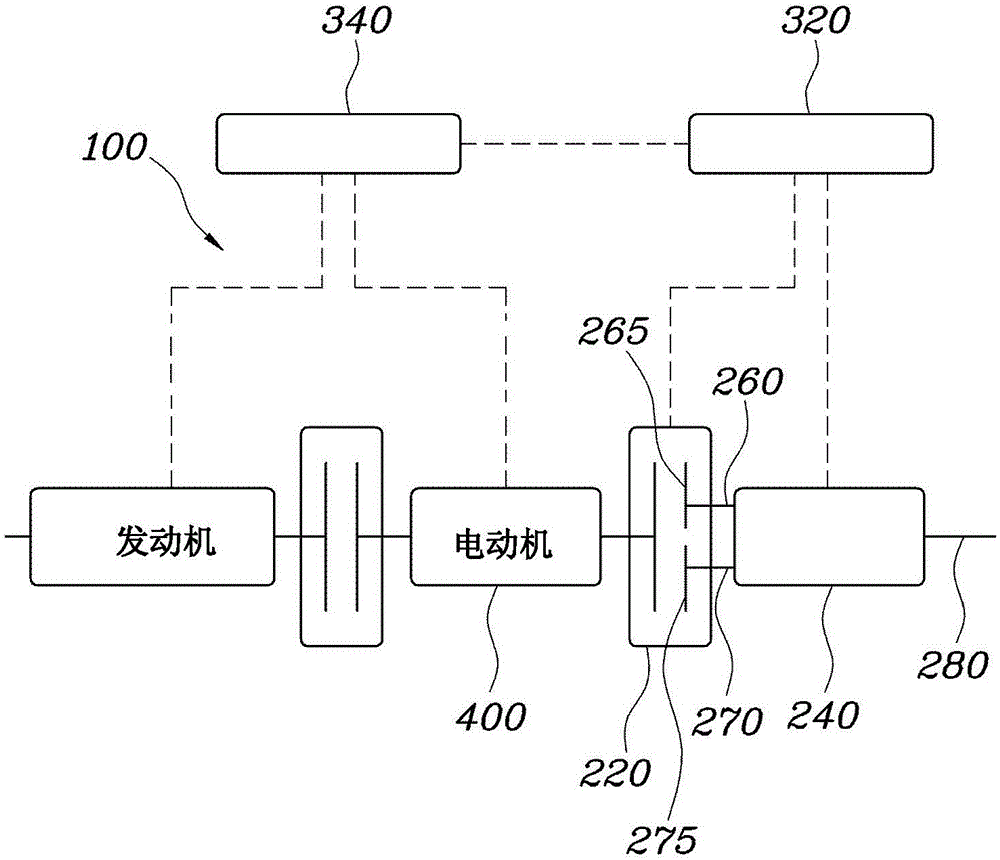

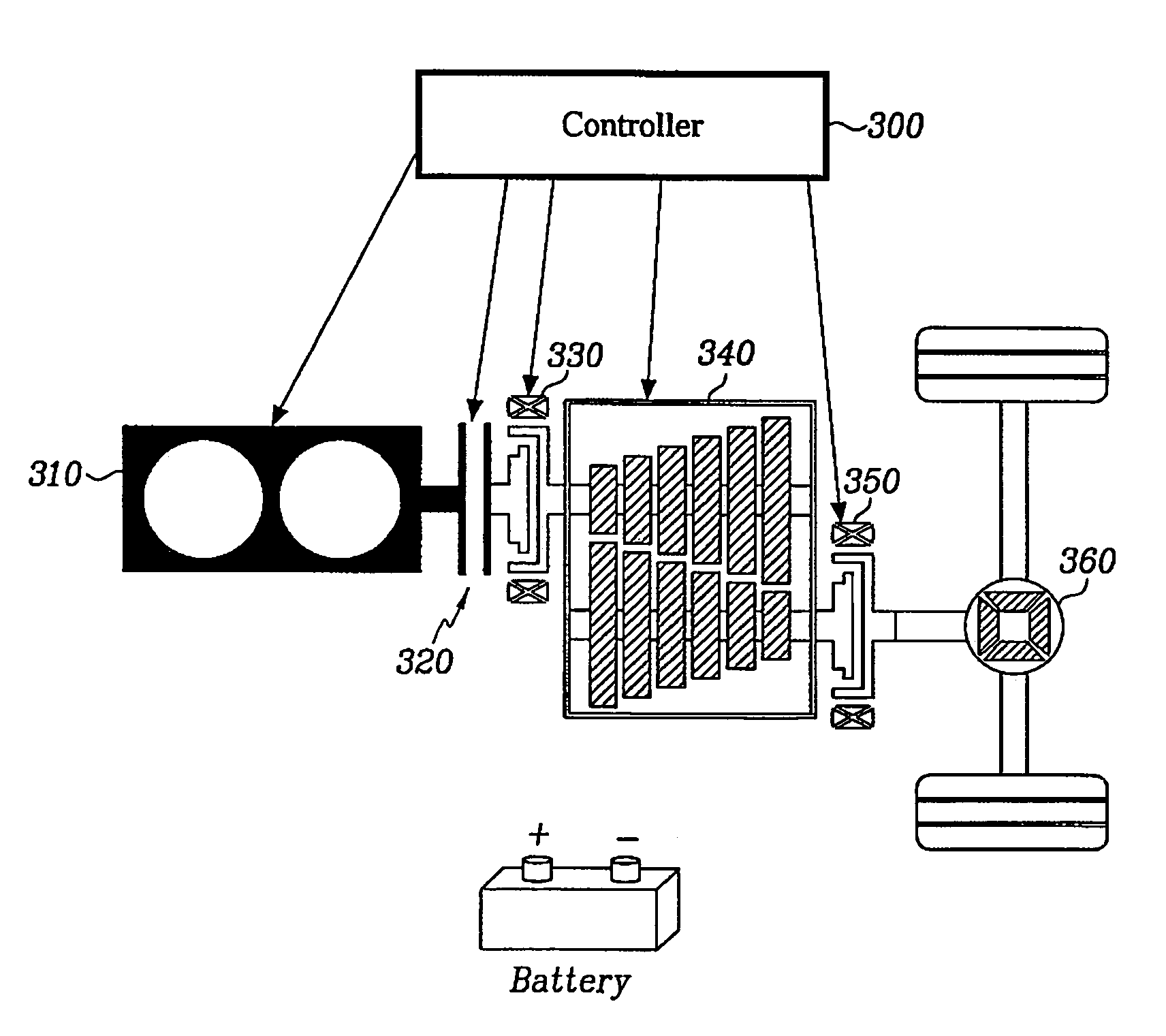

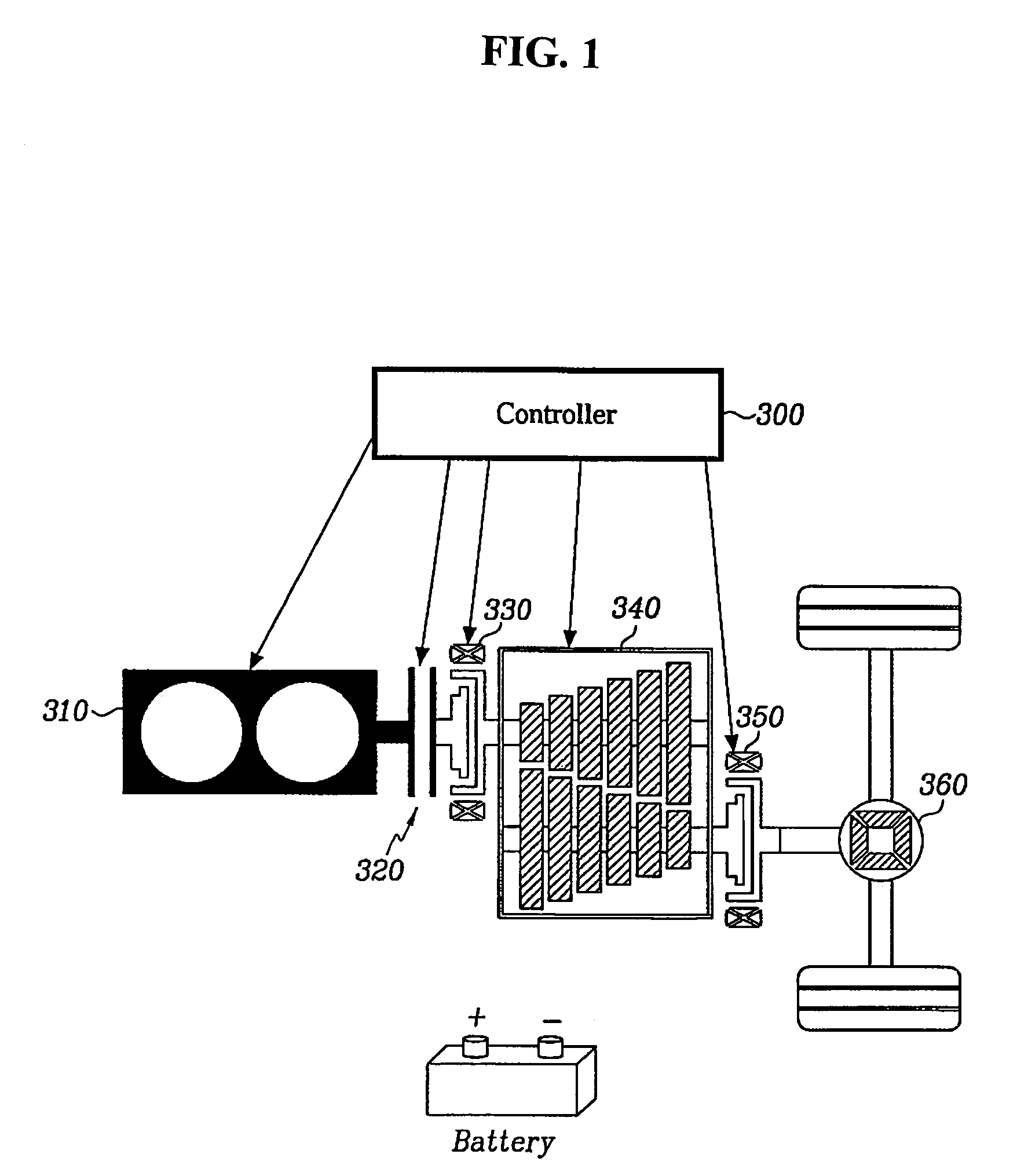

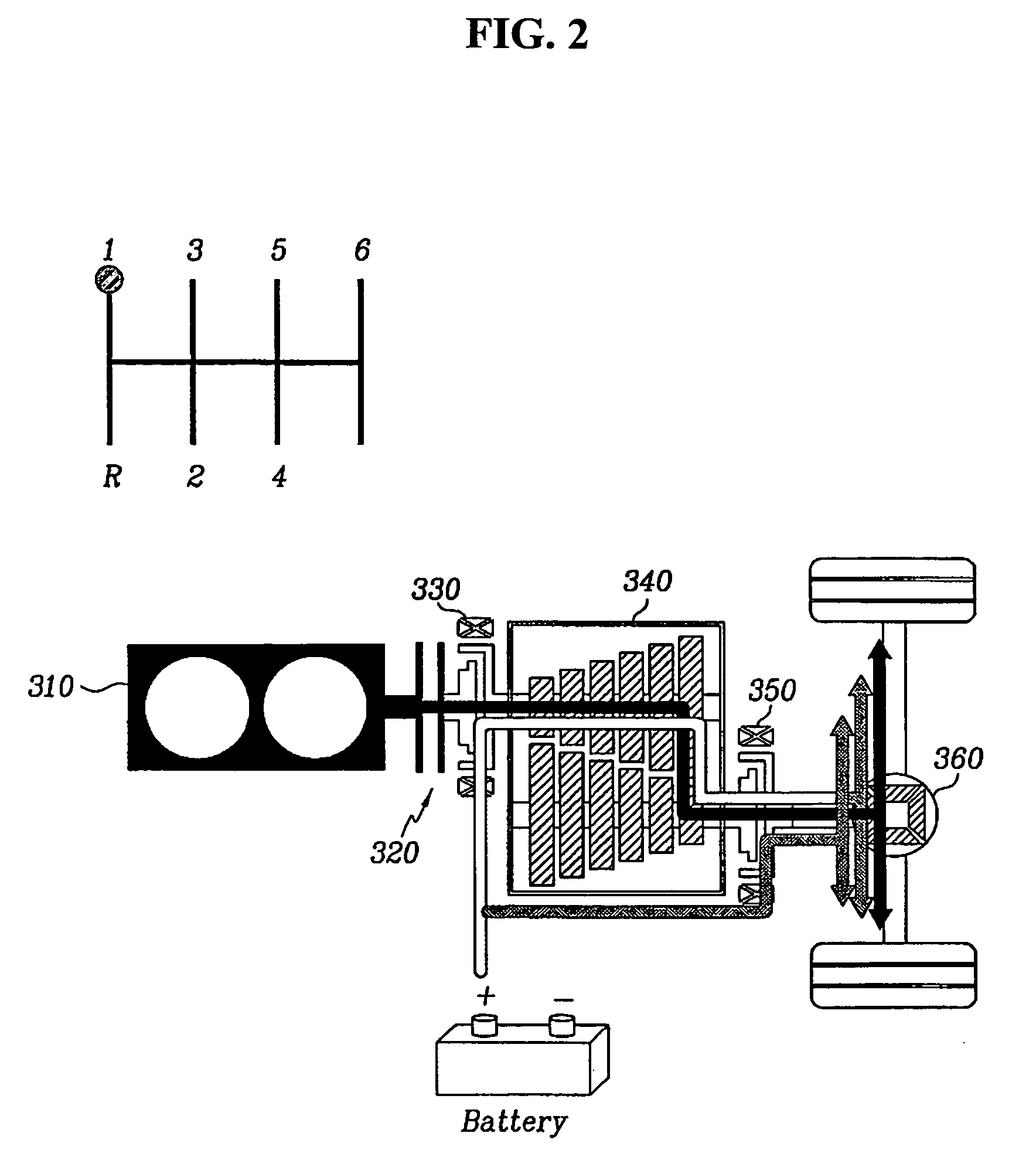

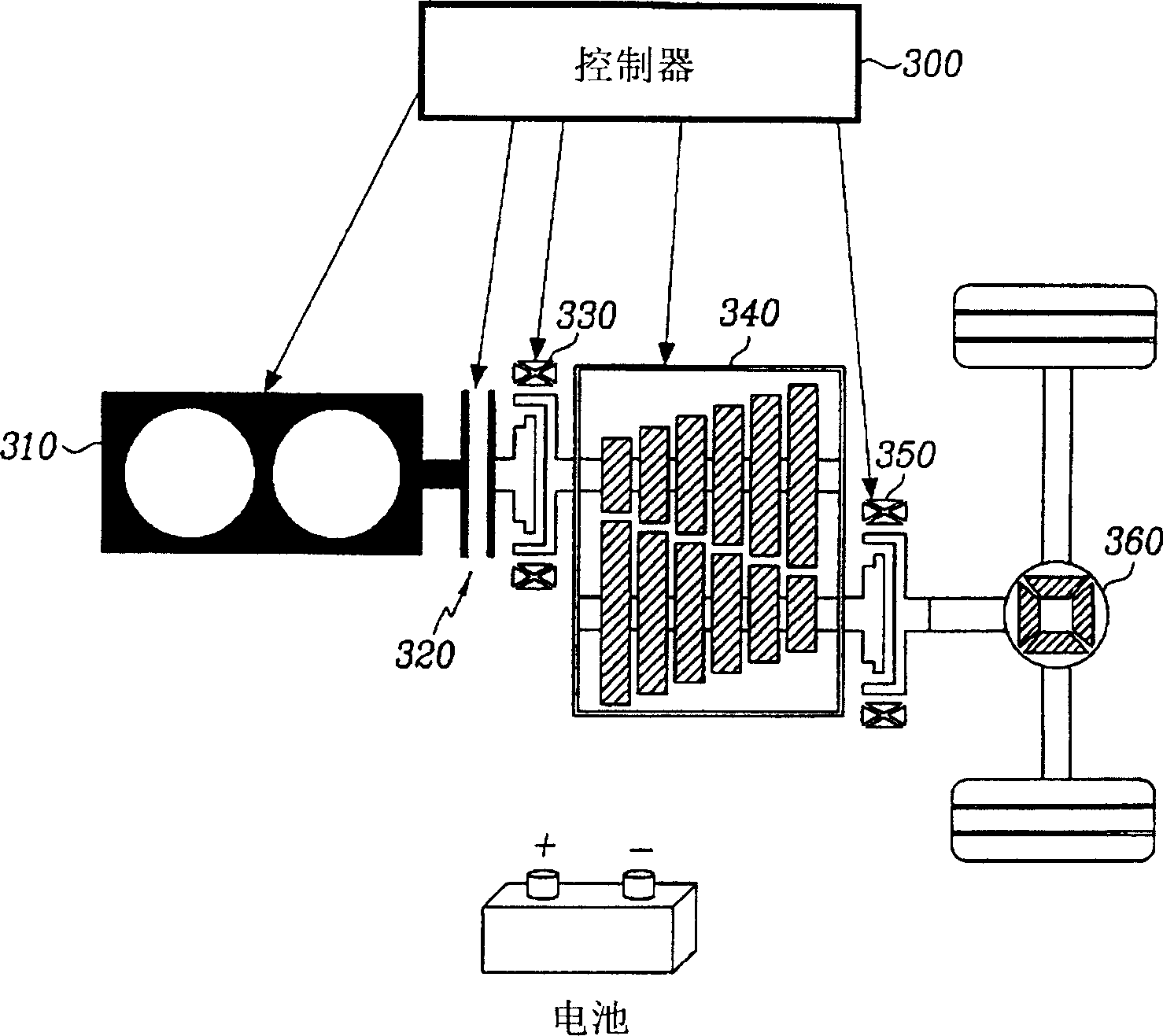

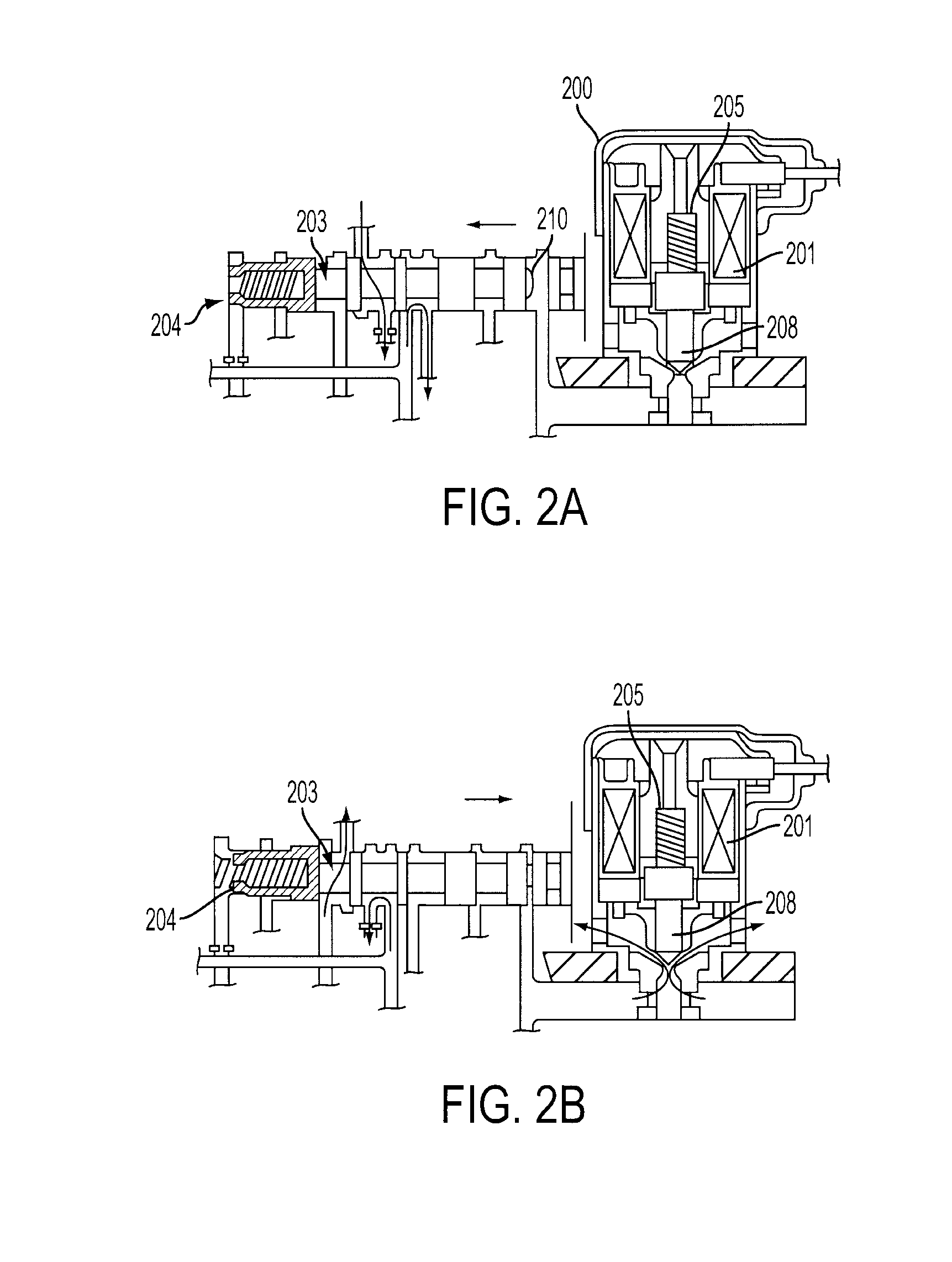

Powertrain system of hybrid electric vehicle

InactiveUS7004884B2Improve shift performanceHybrid vehiclesElectric propulsion mountingDrivetrainElectric vehicle

Shift performance of a powertrain system of a hybrid electric vehicle is enhanced by a powertrain system including a clutch, a primary motor, an automated shift gearbox (ASG) connected to the engine interposing the clutch, a secondary motor; and a differential gearbox, wherein the primary motor is disposed between an output shaft of the clutch and an input shaft of the ASG, and the secondary motor is disposed between an output shaft of the ASG and an input shaft of the differential gearbox.

Owner:HYUNDAI MOTOR CO LTD

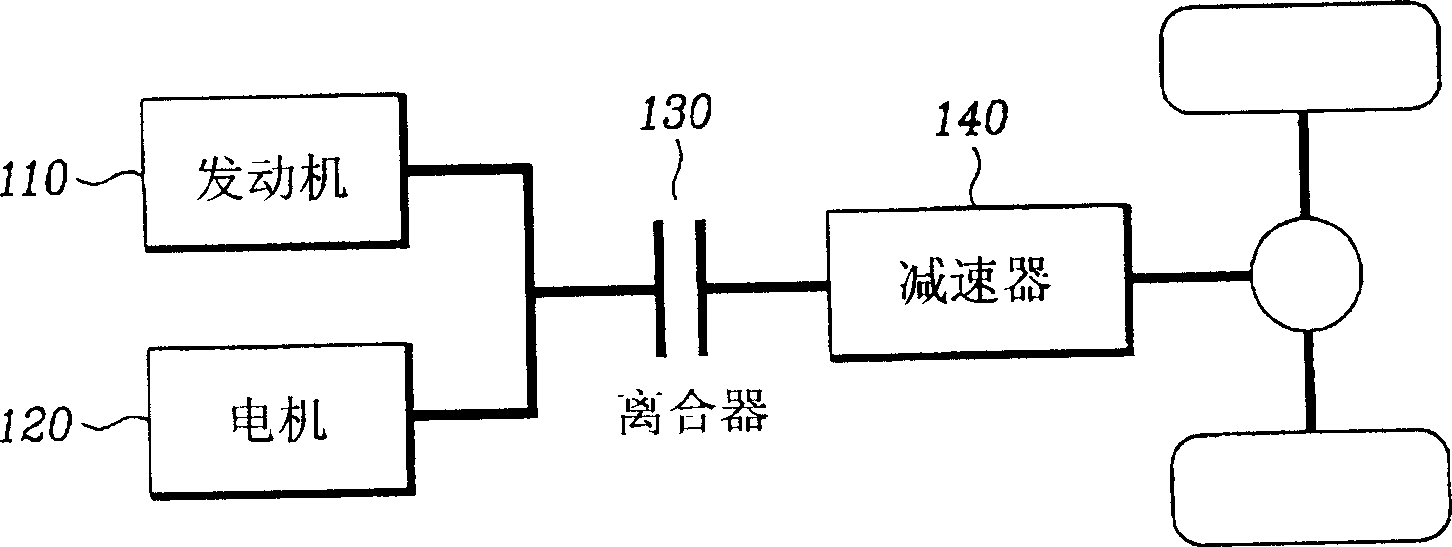

Powertrain system of hybrid electric vehicle

InactiveCN1576079AImprove shift performanceHybrid vehiclesToothed gearingsElectric machineElectric vehicle

A power transmission system of a hybrid electric vehicle comprises an engine, a clutch, a primary motor, an ASG(Automated Shift Gear), a secondary motor, and a differential gear. The primary motor is combined between an output shaft of the clutch and an input shaft of the ASG. The secondary motor is combined between an output shaft of the ASG and an input shaft of the differential gear.

Owner:HYUNDAI MOTOR CO LTD

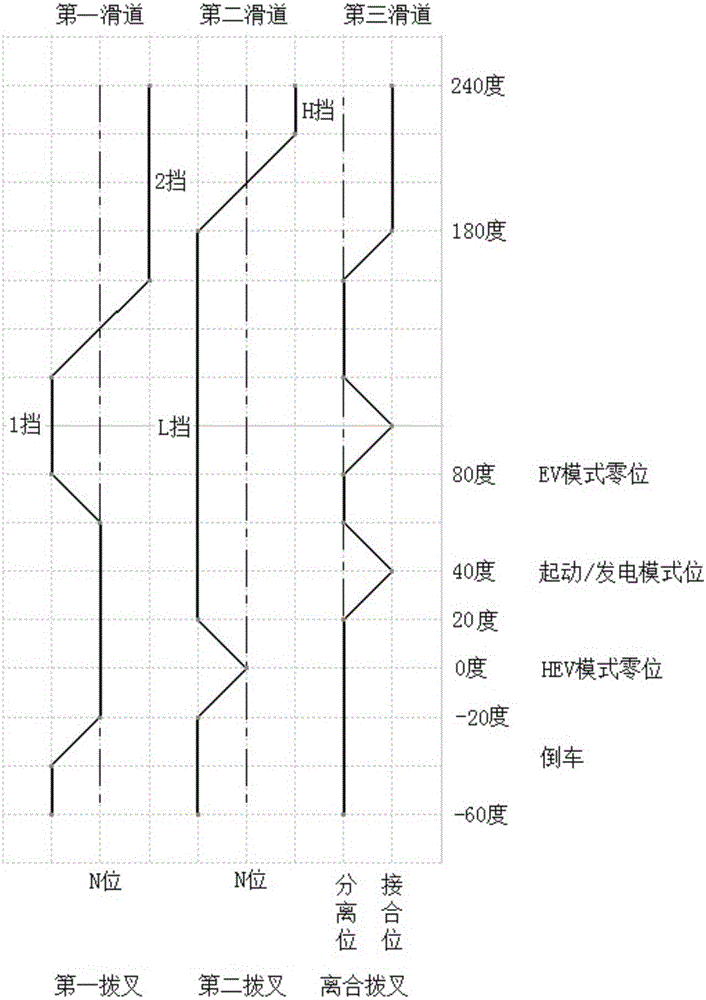

Transmission dual-H control mechanism

ActiveCN103968067AHigh strengthImprove operating experienceGearing controlH controlElectrical and Electronics engineering

Owner:SHAANXI FAST GEAR CO

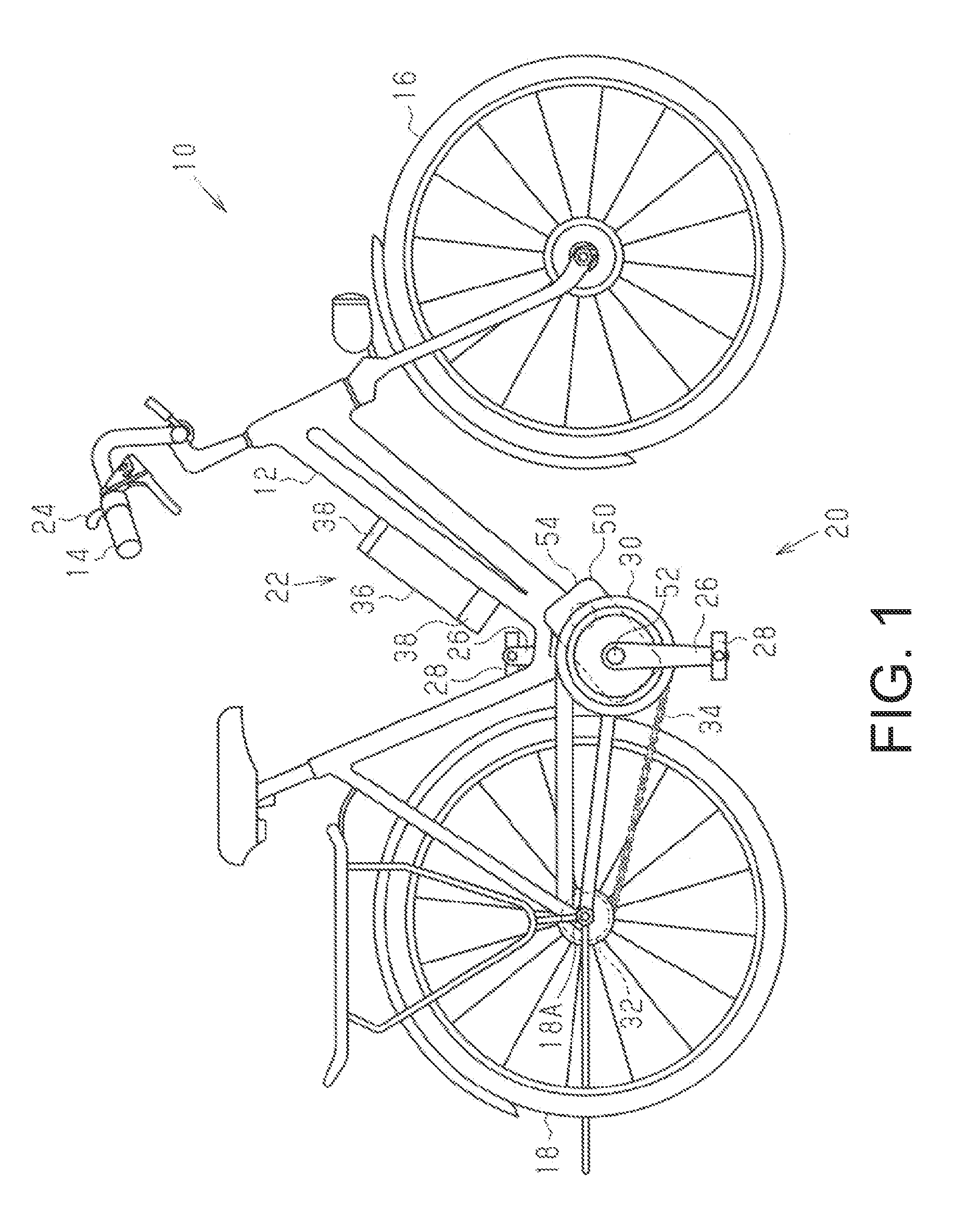

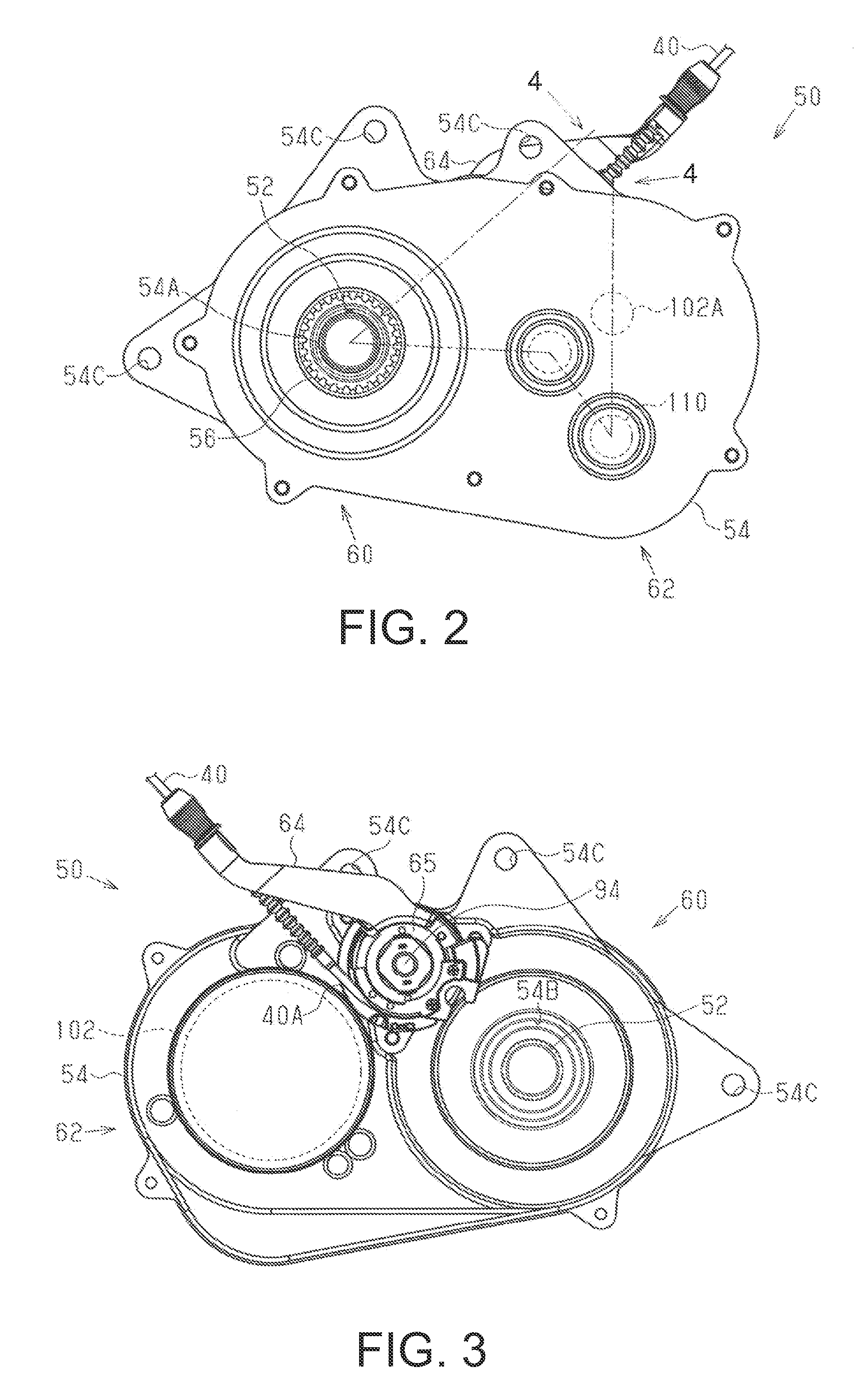

Bicycle drive unt

ActiveUS20160280328A1Improve transmission performanceImprove shift performanceWheel based transmissionRider propulsionControl theoryPower transmission

A bicycle drive unit is basically provided with an input rotational shaft, an output part, a transmission mechanism, an assist motor and a switching mechanism. The transmission mechanism has at least two shift stages, and is configured to change a speed of a rotational input that is input from the input rotational shaft and output this rotational input to the output part. The assist motor is coupled to a power transmission path from the input rotational shaft to the output part, and is driven according to a manual drive force. The switching mechanism is configured to switch a gear changing state of the transmission mechanism by using a rotational force of the assist motor.

Owner:SHIMANO INC

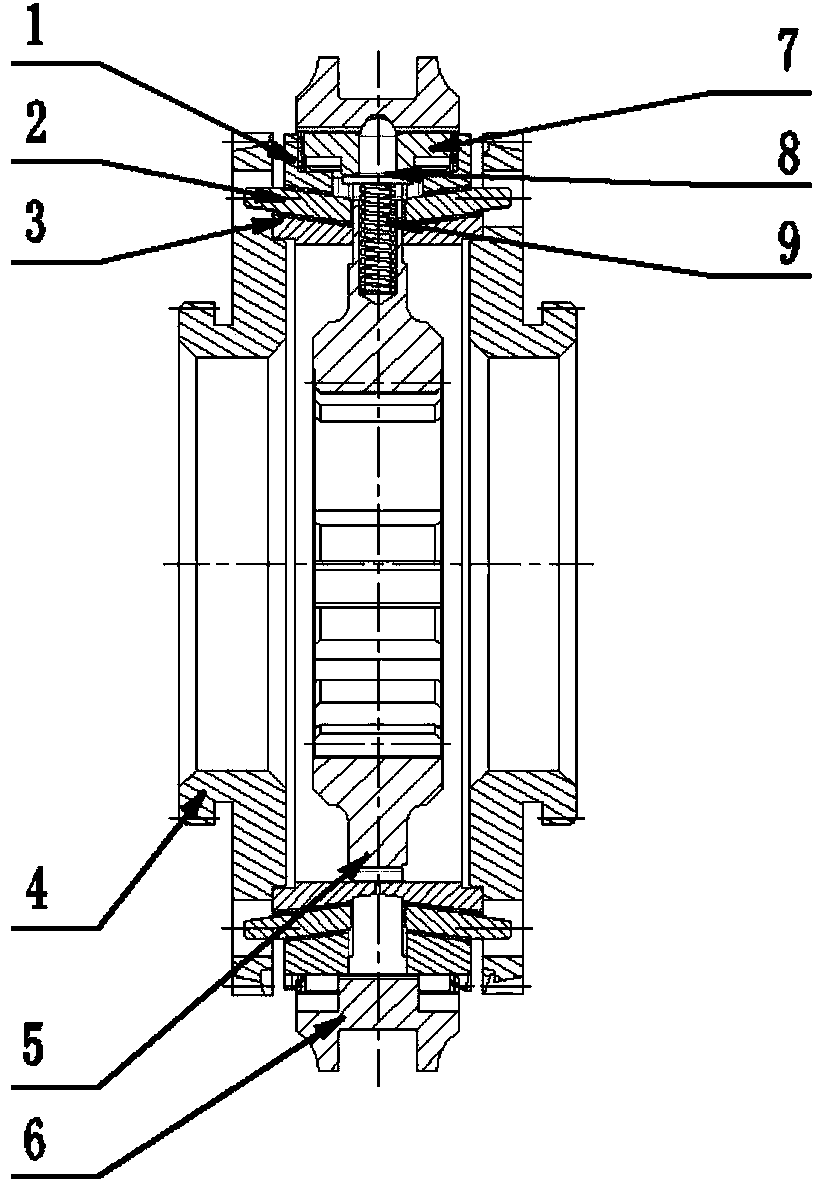

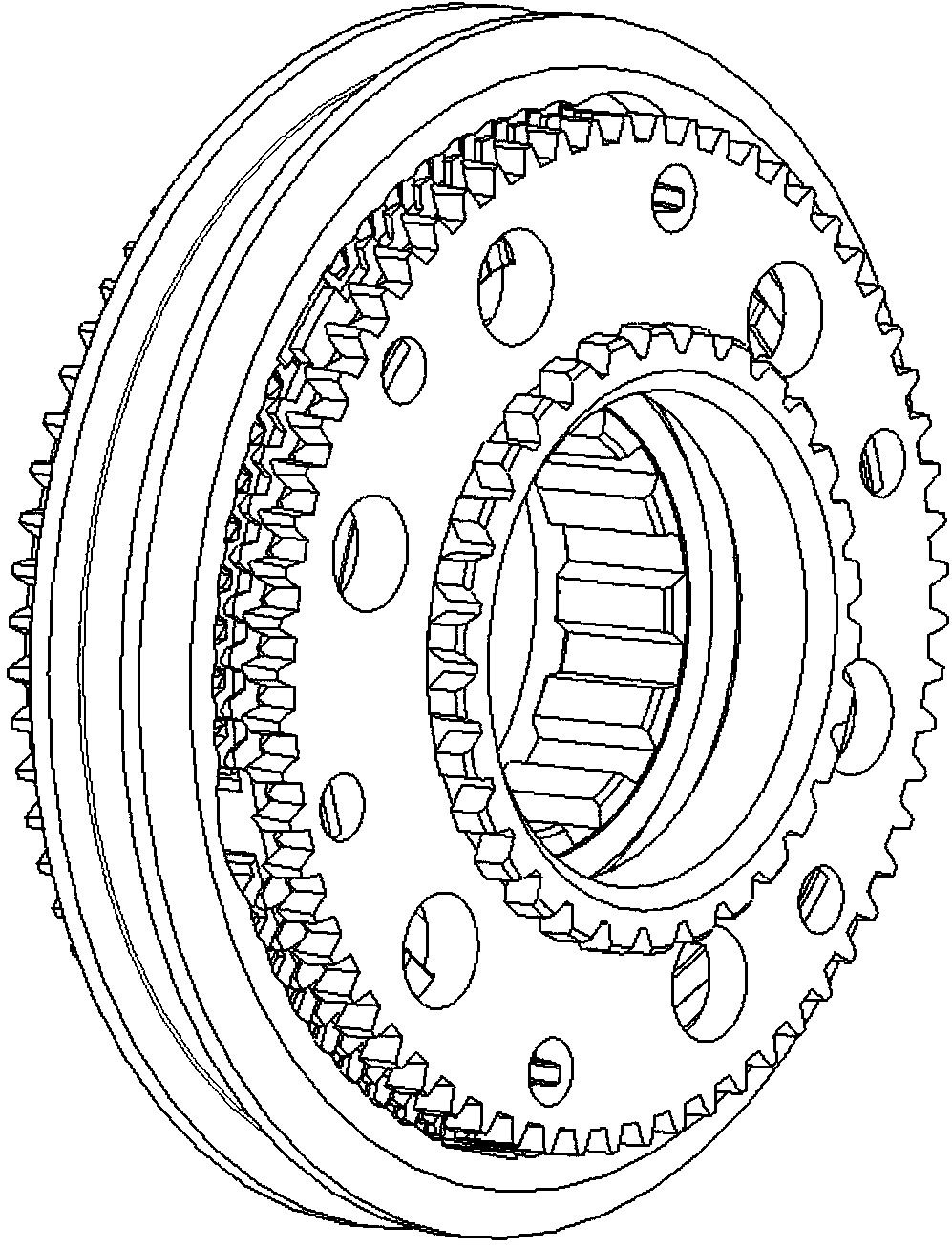

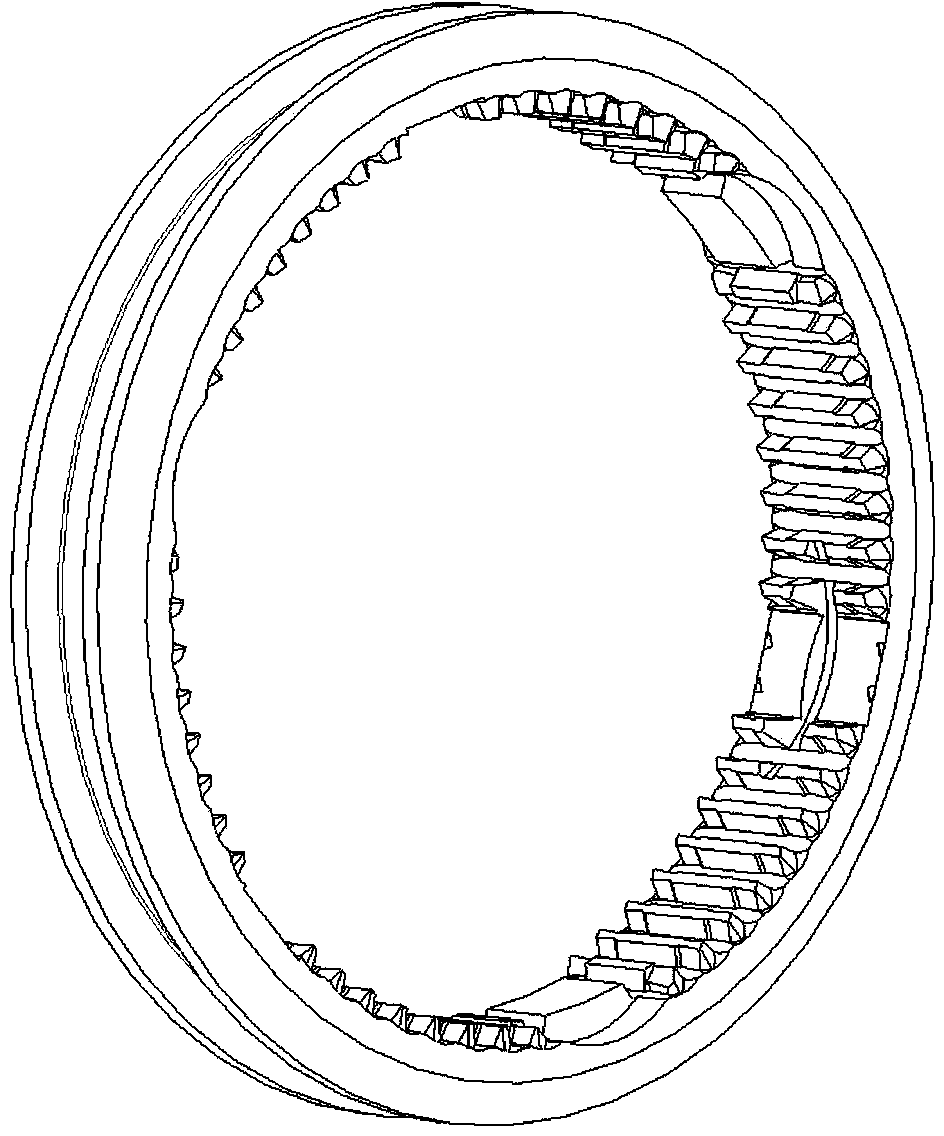

Locking ring type synchronizer with dissymmetric spline meshing teeth

InactiveCN104033506AExtended gliding distanceReduce shift speed differenceMechanical actuated clutchesEngineeringMechanical engineering

The invention discloses a locking ring type synchronizer with dissymmetric spline meshing teeth. The locking ring type synchronizer comprises a gear hub sleeving a transmission spindle, a slide bushing sleeves the gear hub, and combination tooth rings are arranged on two sides of the slide bushings respectively; a synchronization ring is arranged between each combination tooth ring and the slide bushing; the spline meshing teeth on the slide bushing, the combination tooth rings and the synchronization rings are all in dissymmetric structures. Since the spline meshing teeth on the slide bushing, the combination tooth rings and the synchronization rings are designed in the dissymmetric structures, the synchronizer is better in locking reliability, locking faces of the slide bushing and the synchronization rings are long in meshing time and large in combination area, and a favorable locking structure foundation is provided for a synchronization process; owing to the spline meshing teeth in the dissymmetric structures, sliding distance of the slide bushing on locking faces of the synchronization rings is increased, shifting speed difference caused by idle stroke generated when the slide bushing moves close to the combination tooth rings is reduced, large shifting speed difference results in impact of shifting, and accordingly secondary shifting impact after synchronization is alleviated.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Bicycle assist unit

ActiveUS20160107721A1Reduce rotationImprove shift performanceSpeed controllerPropulsion by humans/animalsGear wheelSprocket

A bicycle assist unit is basically provided with a transmission and an assist motor. The transmission is configured to receive rotation of a crankshaft. The transmission includes a planetary gear mechanism. The planetary gear mechanism includes an output unit, a plurality of ring gears and a rotation restricting mechanism that selectively restricts rotation of the ring gears. The assist motor is configured to output a second drive force that is added to a first drive force that is outputted from the transmission on a power transmission path between the output unit and a front sprocket that is attached to the crankshaft.

Owner:SHIMANO INC

Shaft system structure of five-gear rear drive transmission

ActiveCN104214282AIncrease spacingShorten the lengthToothed gearingsGearing controlLow speedEngineering

The invention discloses a shaft system structure of a five-gear rear drive transmission with small gear-shifting synchronous inertia. A spindle reverse gear assembly (4) is mounted on the left side of a spindle front bearing (5), a spindle first-gear gear assembly (6), a low-speed synchronizer component (7), a spindle second-gear gear assembly (8), a spindle third-gear gear (9) and a spindle fourth-gear gear (10) are sequentially mounted on a spindle (12) from left to right and positioned between the spindle front bearing and a spindle rear bearing (11), the low-speed synchronizer component, the spindle third-gear gear and the spindle fourth-gear gear are fixedly connected with the spindle, the spindle first-gear gear assembly and the spindle second-gear gear assembly rotatably sleeves the spindle, and a middle shaft fourth-gear gear assembly (14), a third-gear and fourth-gear synchronizer component (15) and a third-gear gear assembly (16) are sequentially mounted on a middle shaft (17) from right to left and positioned on the left side of a middle shaft rear bearing (13).

Owner:CHONGQING TSINGSHAN IND

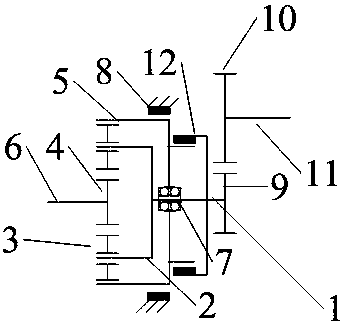

Automatic two-gear transmission with brake gear ring

InactiveCN108167405AFew control elementsSimple controlToothed gearingsGearing controlGear transmissionEngineering

The invention provides an automatic two-gear transmission with a brake gear ring and relates to an automobile power transmission device. The automatic two-gear transmission comprises a planet carrierconnecting shaft 1, a planet carrier 2, a planet gear 3, a sun gear 4, the gear ring 5, a sun gear connecting shaft 6, a one-way clutch 7, a brake 8, a reduction gear A9, a reduction gear B10, a reduction gear connecting shaft 11 and a clutch 12. By the adoption of the automatic two-gear transmission, continuous power during gear shifting can be achieved, the phenomenon of sliding on a slop duringthe uphill can be prevented, the wear to the clutch is reduced, and the reliability is improved.

Owner:LIUZHOU HUILIN TECH

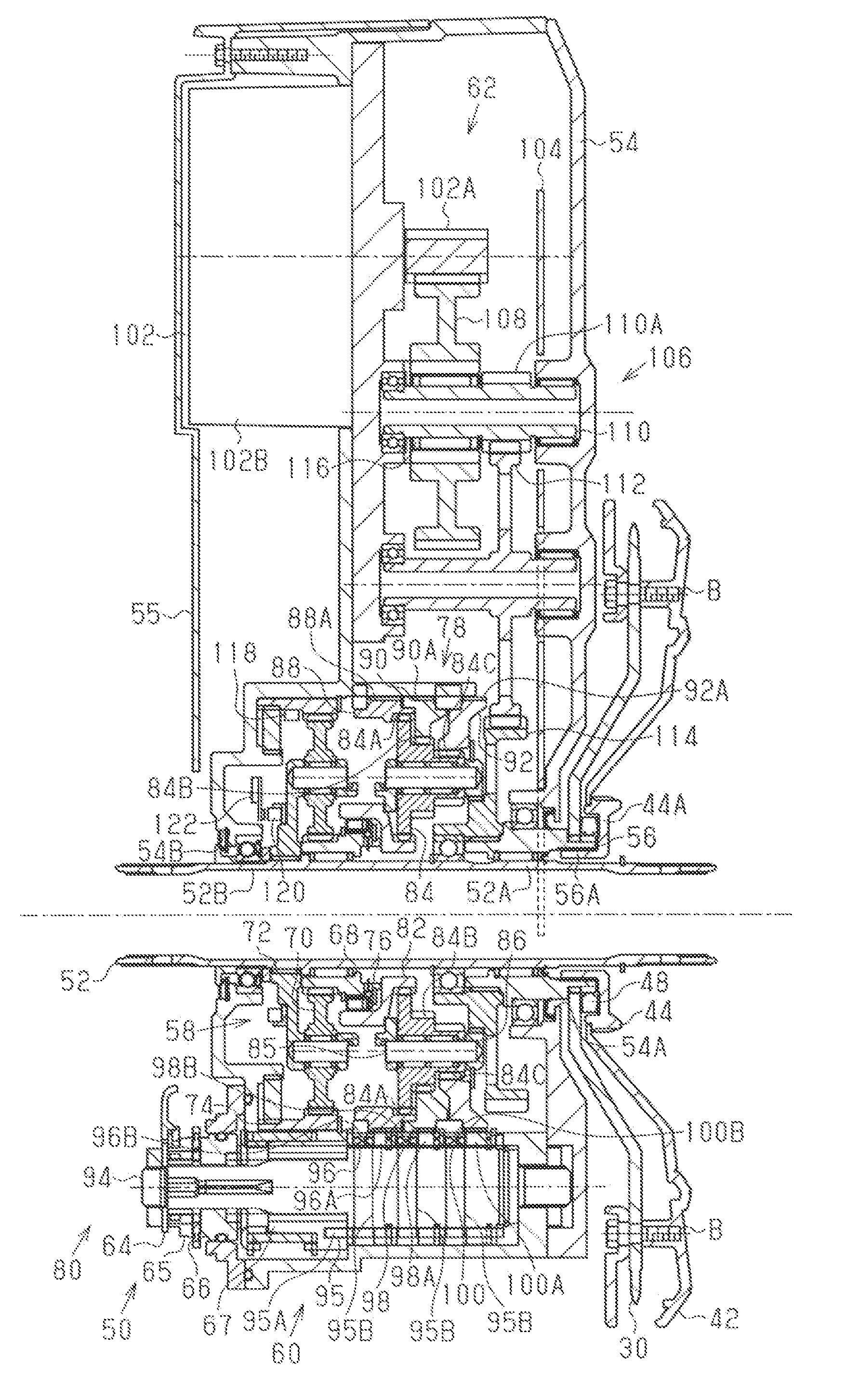

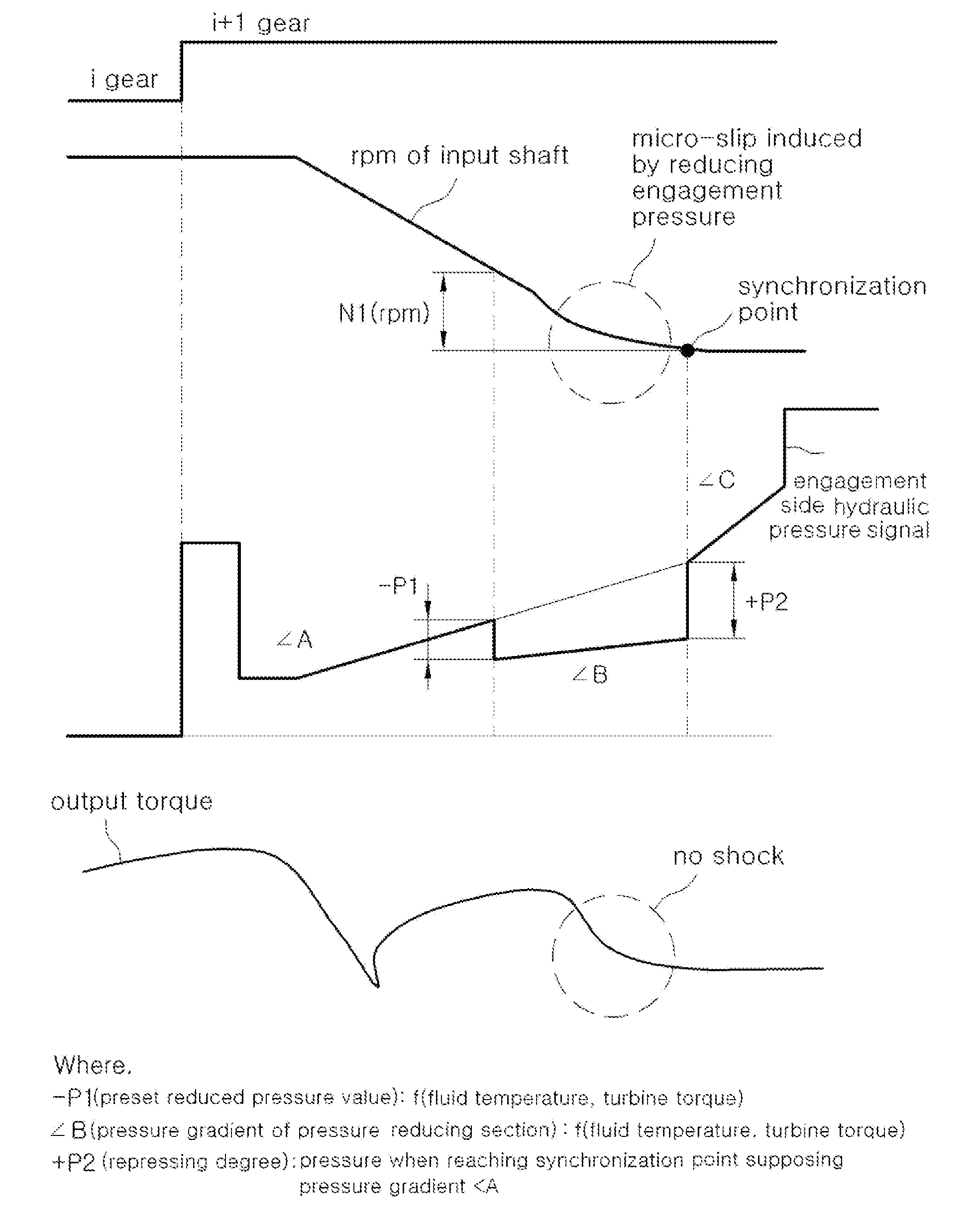

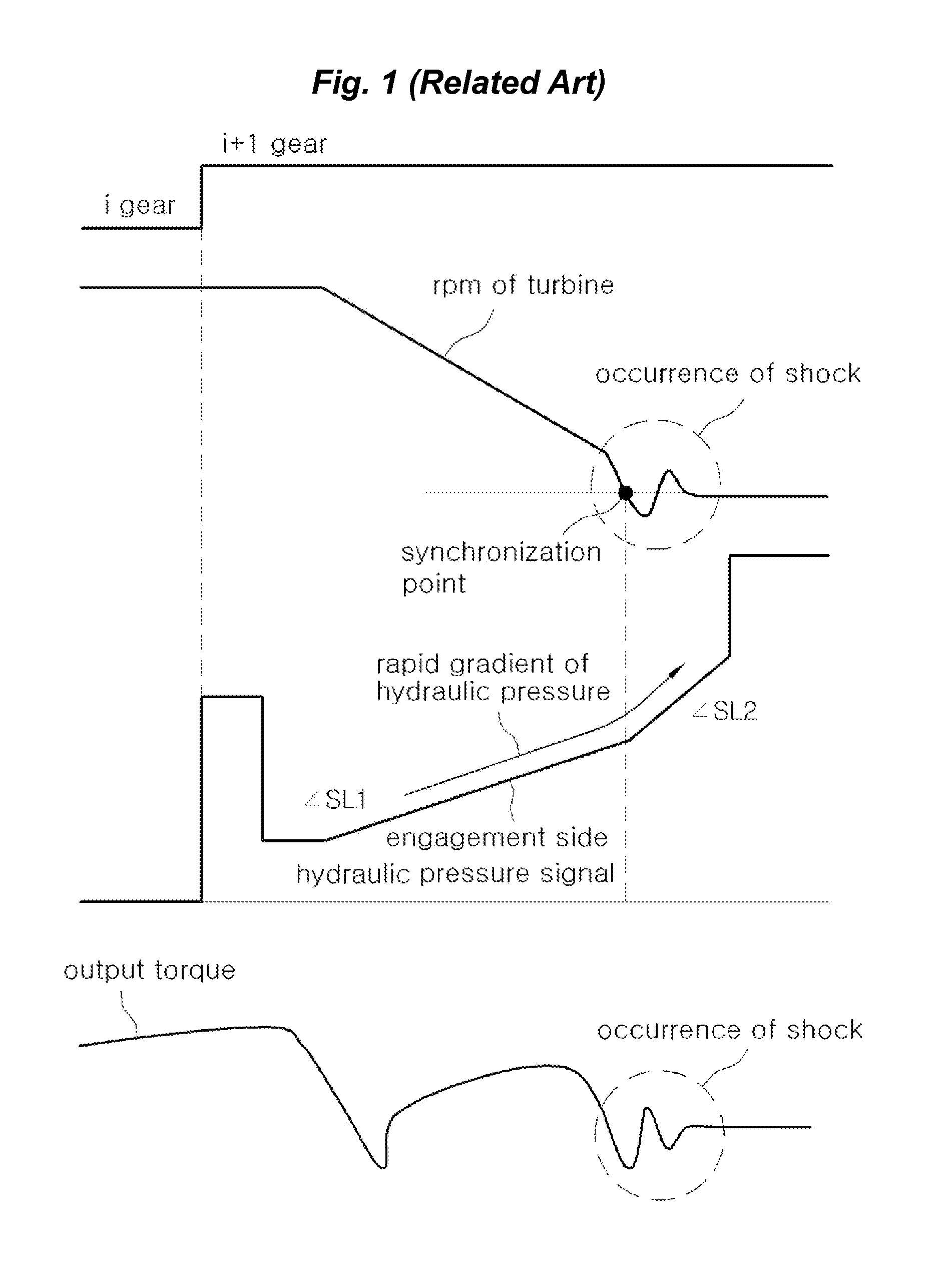

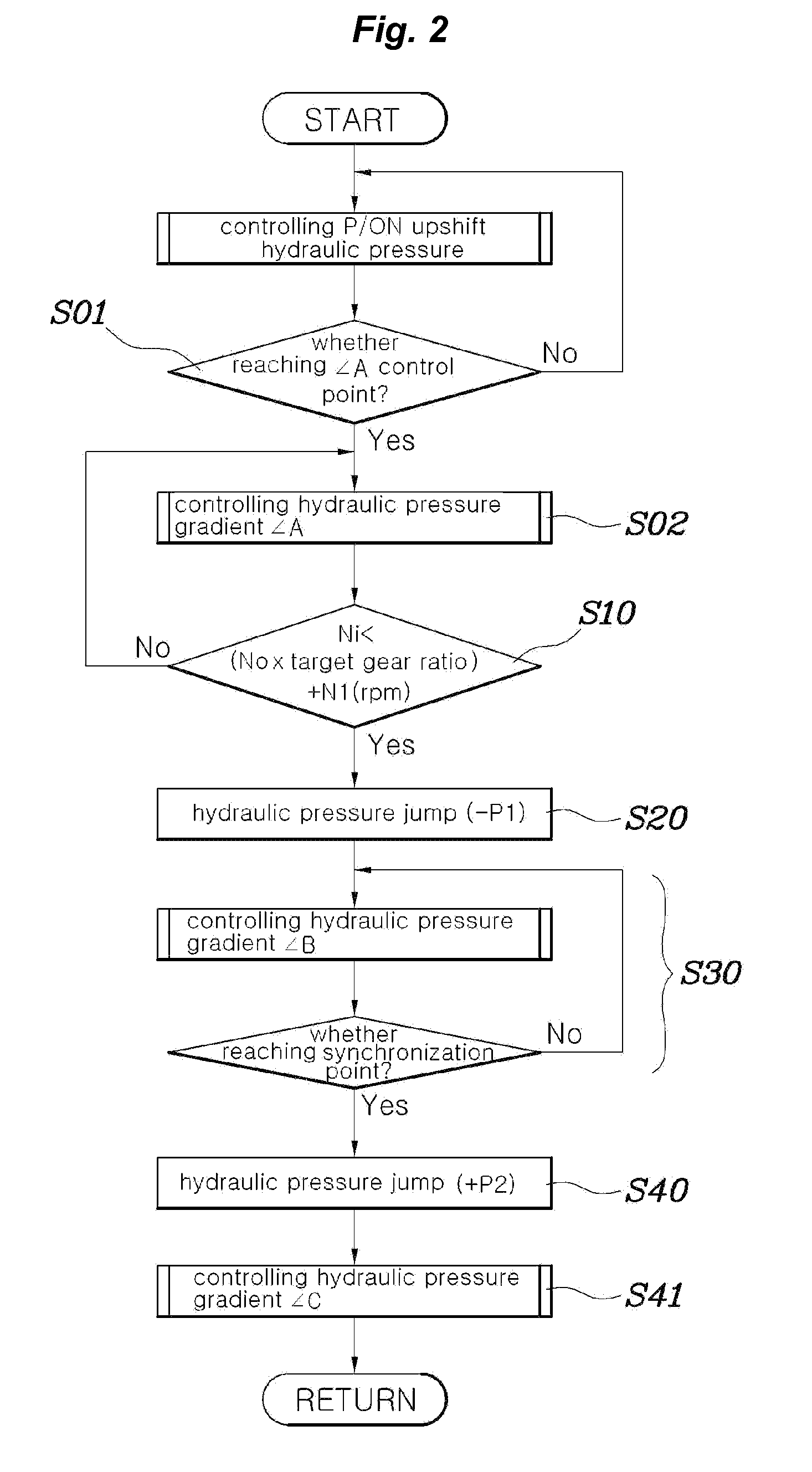

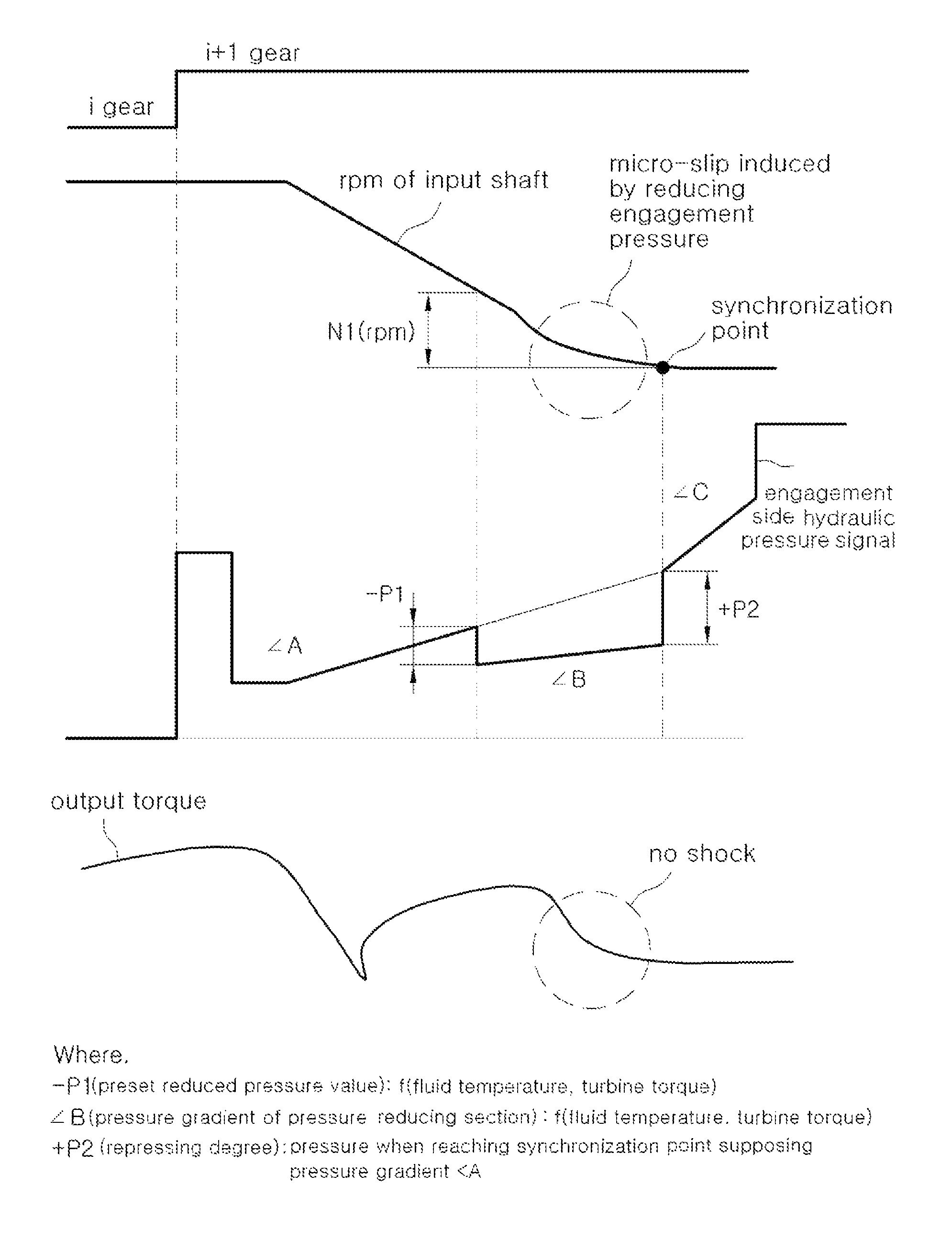

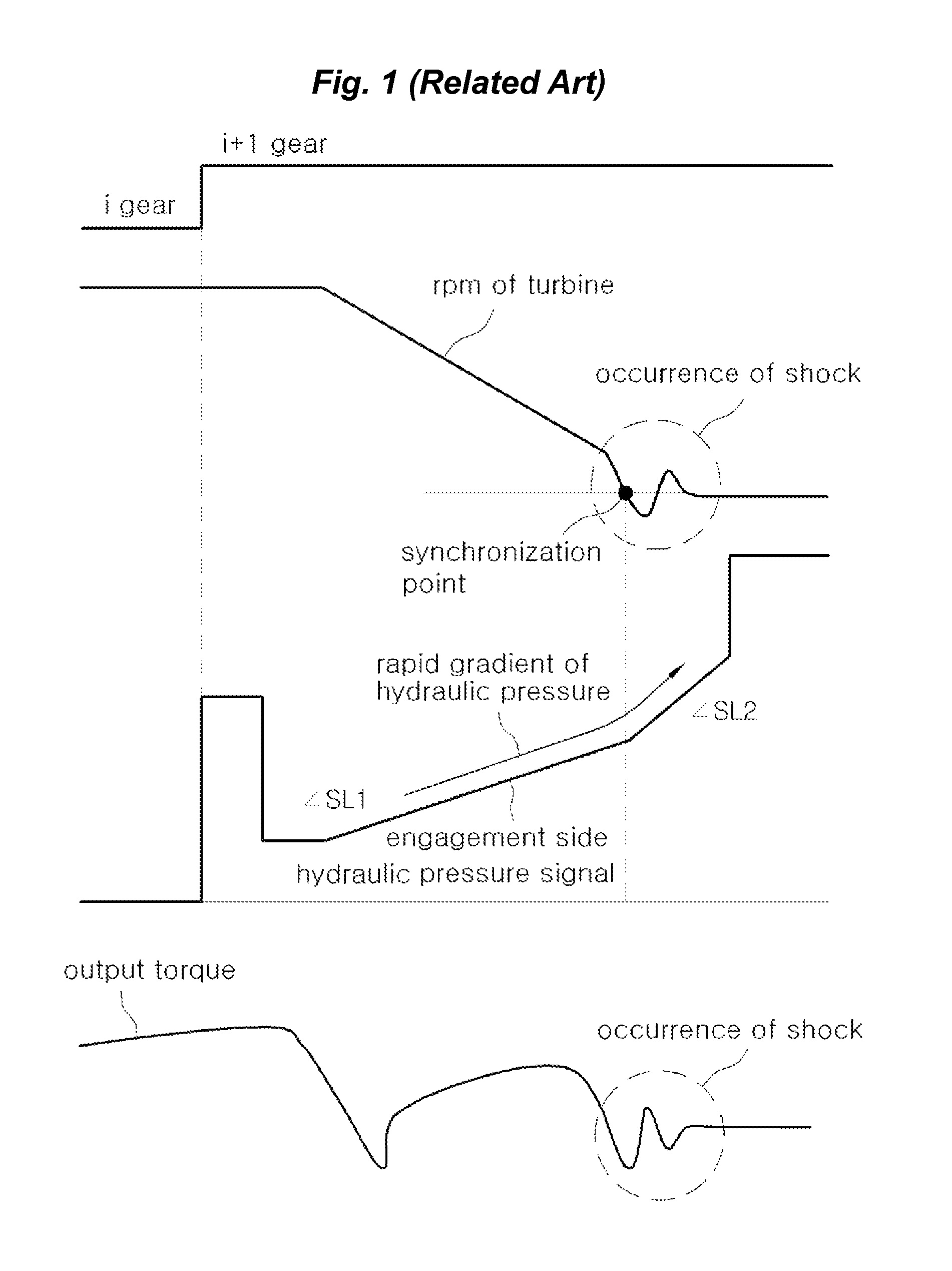

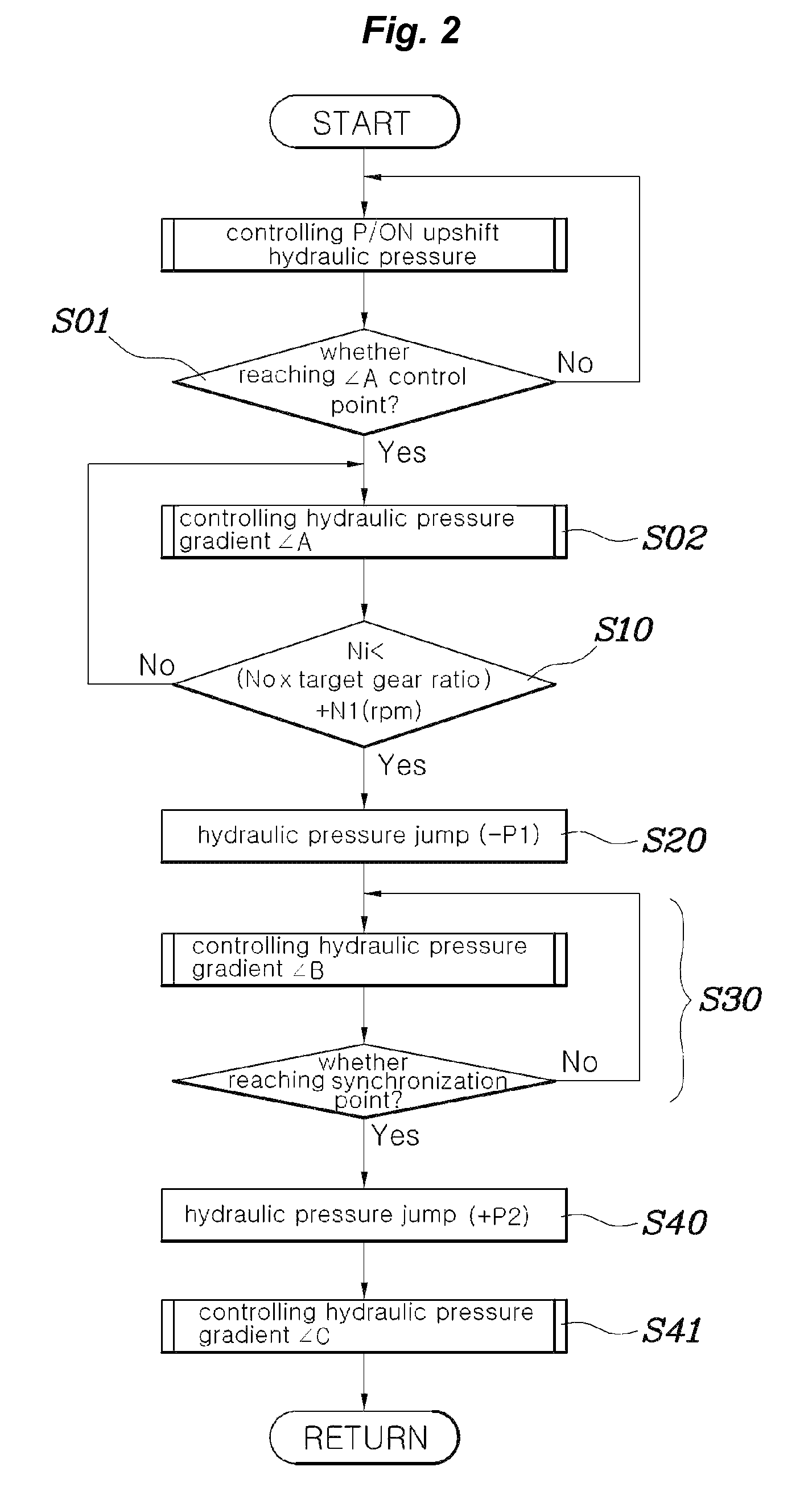

Shift control method of automatic transmission

ActiveUS20120318626A1Improve shift performanceImprove marketabilityGearing controlCoupling-brake combinationAutomatic transmissionControl theory

A shift control method of an automatic transmission may include detecting an end point of an inertia section during upshifting, momentarily reducing a hydraulic pressure applied to engagement side frictional elements at the detected end point of the inertia section, increasing the reduced hydraulic pressure with a predetermined gradient until reaching a synchronization point, and momentarily increasing the hydraulic pressure when the synchronization point may be reached.

Owner:HYUNDAI MOTOR CO LTD +1

Hybrid power device and operation method thereof

ActiveCN106585356AReduce the required powerLow costHybrid vehiclesGas pressure propulsion mountingMotor driveReduction drive

The invention relates to a hybrid power device. The hybrid power device comprises an engine, a main clutch, a first motor, a second motor, a first speed change mechanism, a second speed change mechanism, a first main speed reducer driving gear, a second main speed reducer driving gear and a main speed reducer driven gear, wherein the engine drives the first main speed reducer driving gear and the main speed reducer driven gear through the main clutch and the first speed change mechanism; the first motor drives the first main speed reducer driving gear and the main speed reducer driven gear through the first speed change mechanism; and the second motor drives the second main speed reducer driving gear and the main speed reducer driven gear through the second speed change mechanism. According to the hybrid power device, on a pure electric driving mode, the two motors can drive a vehicle jointly after the main clutch is separated, so that the power and cost of the second motor are reduced; and in the hybrid power driving mode, the two speed change mechanisms can be shifted one after another, power interruption is avoided, and thus the gear-shifting performance is improved.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

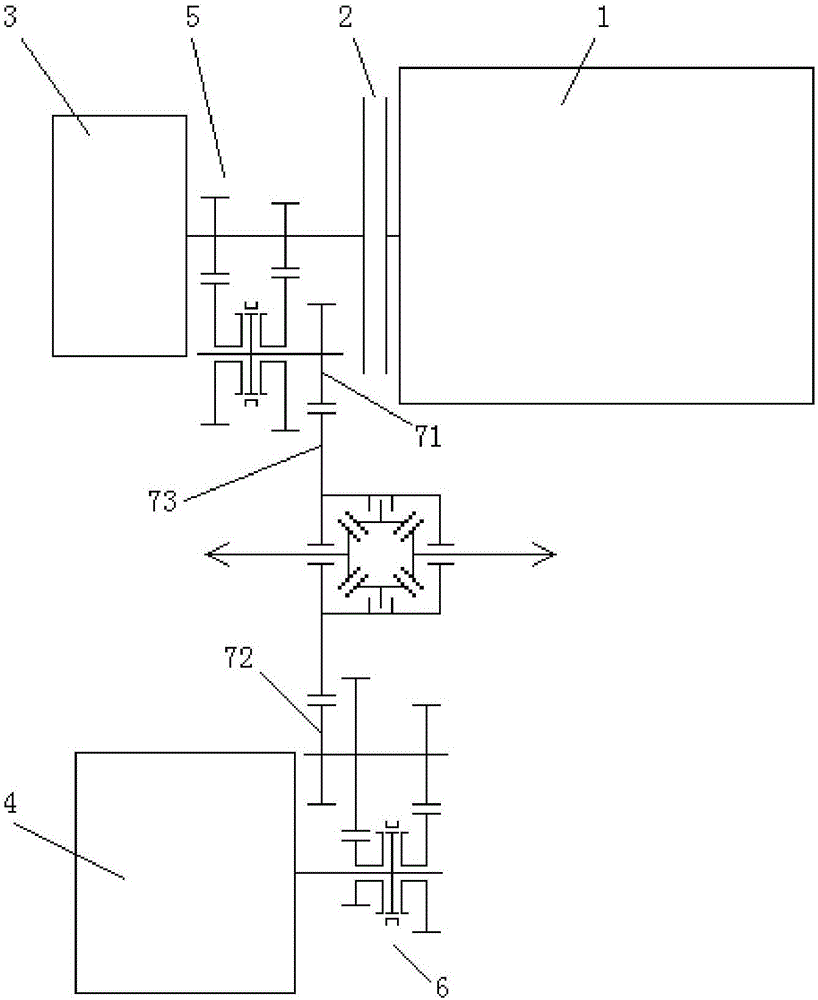

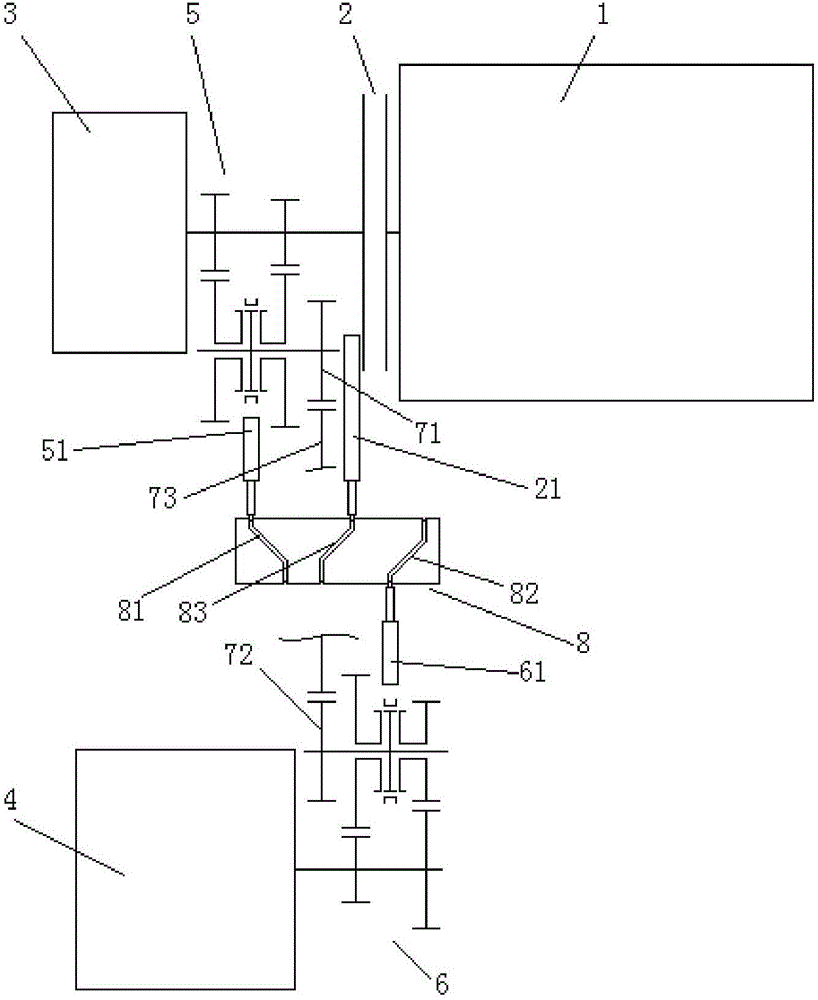

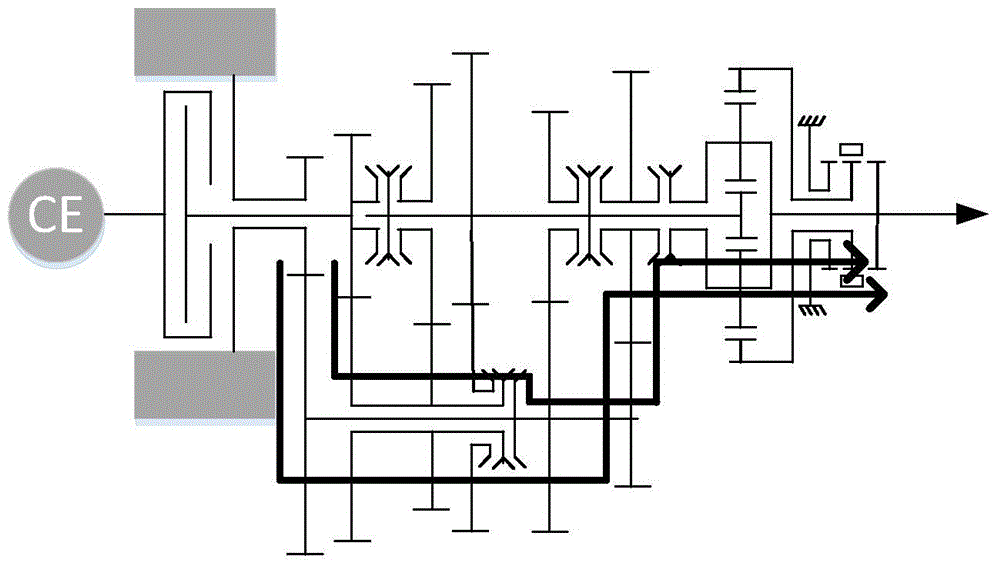

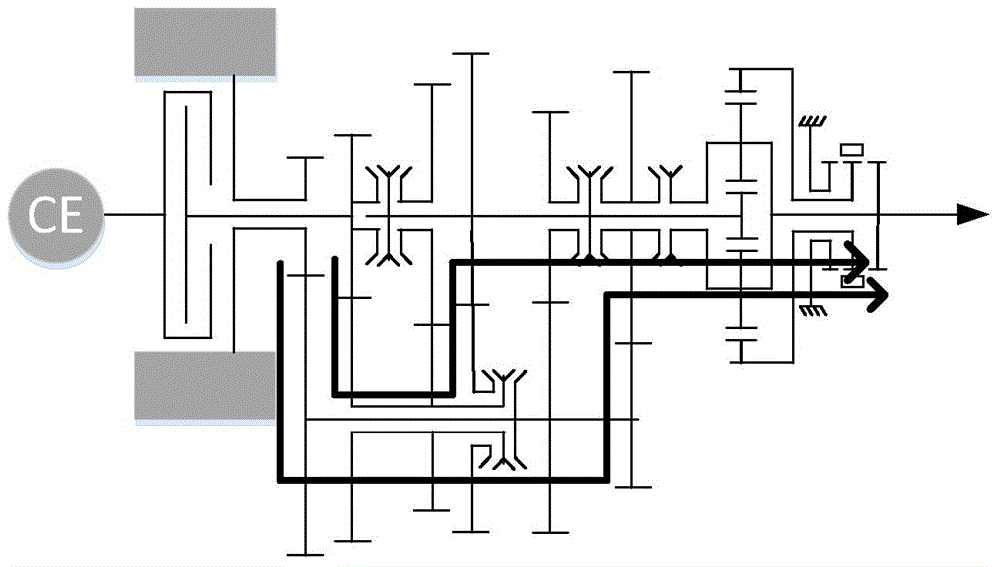

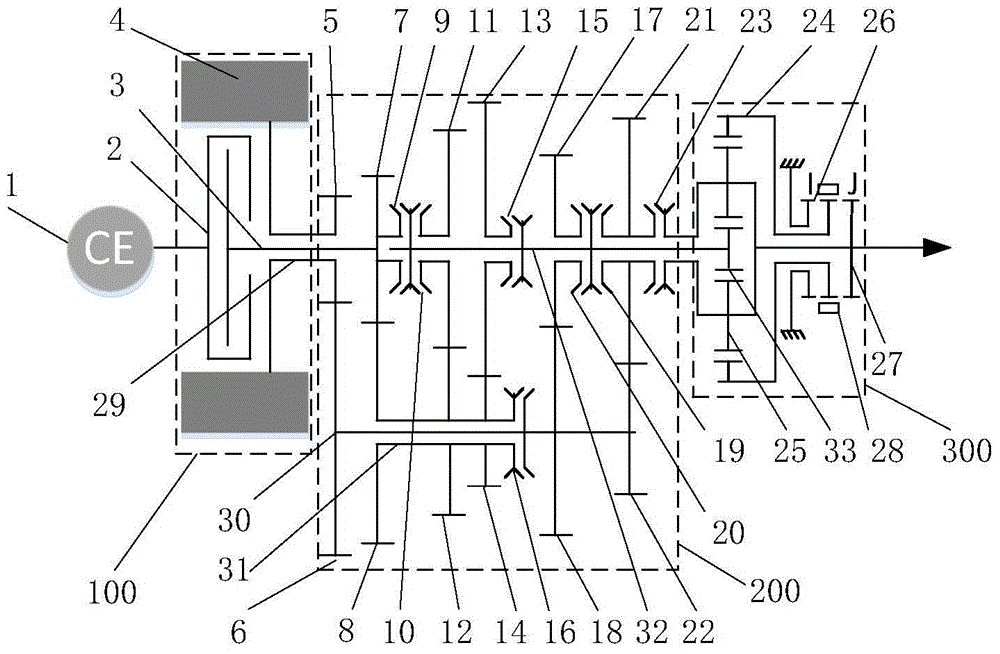

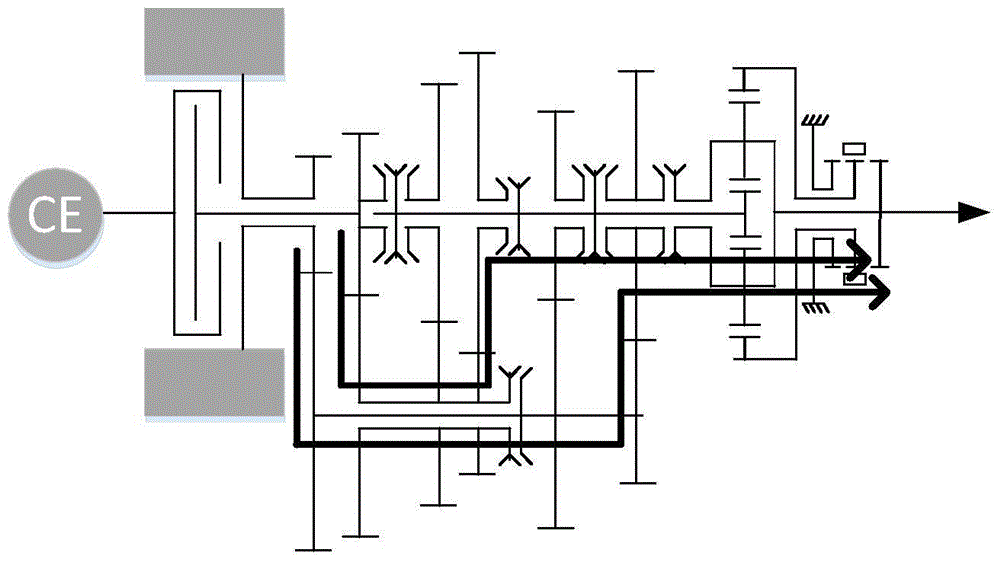

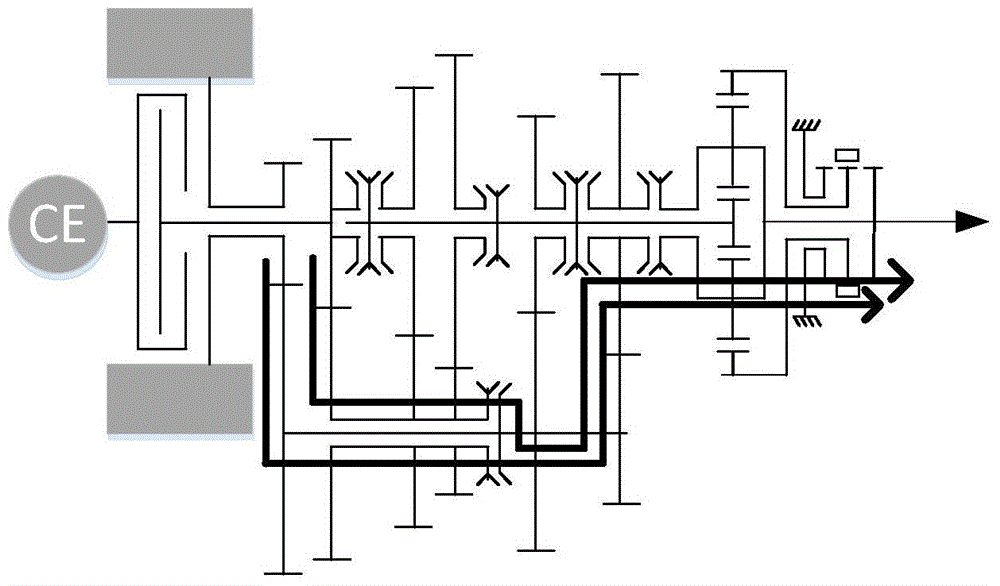

Parallel-type hybrid-power multi-gear gearbox of commercial vehicle

ActiveCN105196857AImprove power performanceImprove shift comfortHybrid vehiclesGas pressure propulsion mountingClutchCommercial vehicle

The invention belongs to the technical field of hybrid-power commercial vehicles, and particularly relates to a multi-gear gearbox. According to the technical scheme of a parallel-type hybrid-power multi-gear gearbox of a commercial vehicle, the power of an engine is input to an engine input shaft after passing through a clutch; a motor module comprises a motor and a drive gear, and the power of the motor is output through the drive gear and a motor input shaft; a gearbox primary box module consists of a multi-degree-of-freedom stationary-shaft gear mechanism, can be used for coupling the power of the engine and the motor, and can be used for realizing the gears of five matched engines and the gears of two matched motors; a gearbox auxiliary box module can be used for realizing two gears of a high gear and a lower gear, and can be used for realizing the gears of ten matched engines and the gears of four matched motors when jointly working with the gearbox primary box input module; the parallel-type hybrid-power multi-gear gearbox of the commercial vehicle is characterized in that the power of the motor and the engine is coupled by adopting the multi-degree-of-freedom gear mechanism, and the functions of hybrid power and power gear shifting are realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

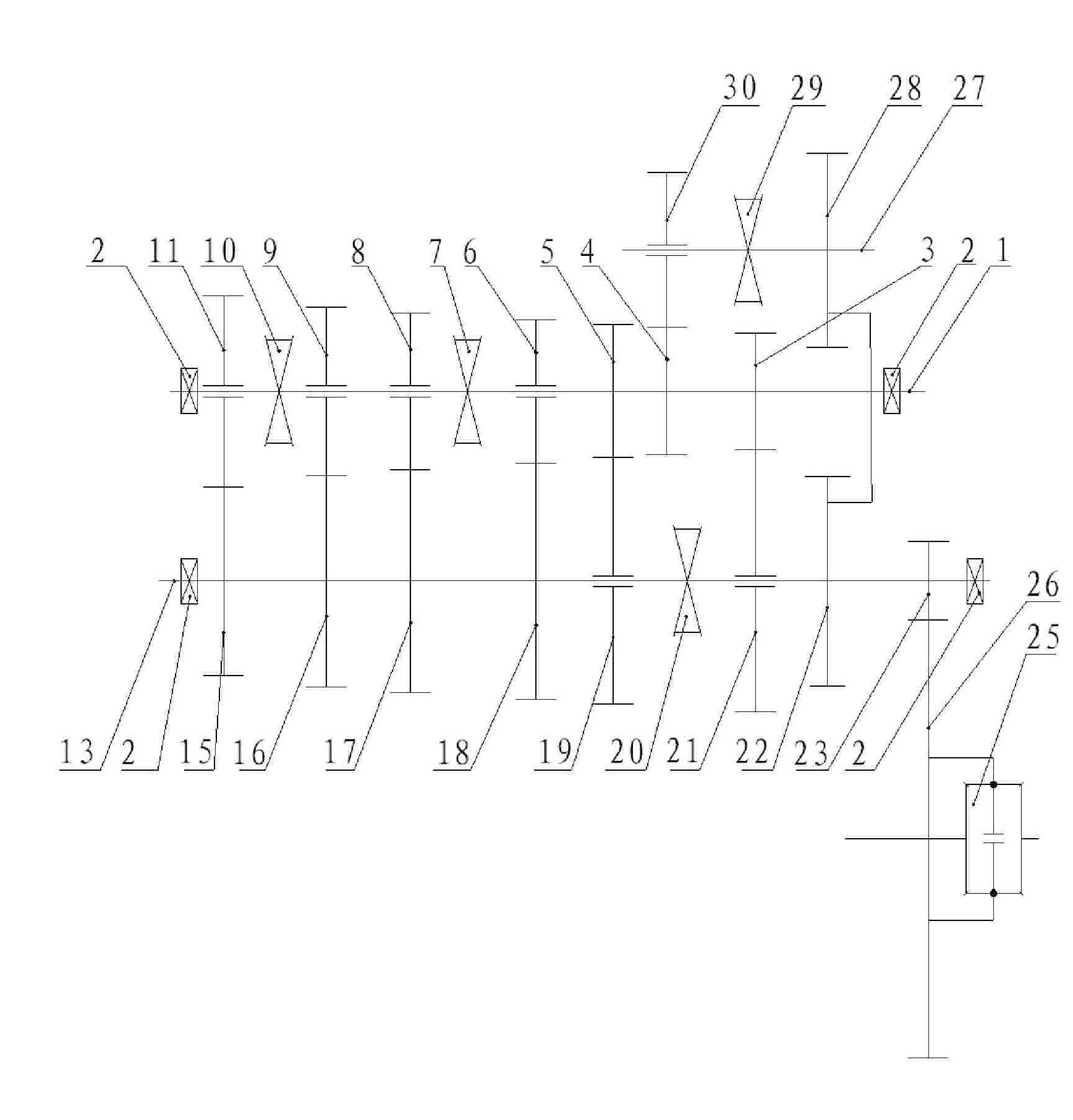

9-gear twin-countershaft helical gear lock pin synchronizer transmission

ActiveCN103388658AExtended service lifeHigh working reliabilityMechanical actuated clutchesToothed gearingsLow noiseGear wheel

The invention discloses a 9-gear twin-countershaft helical gear lock pin synchronizer transmission. Double countershafts and a large center distance are adopted by a main transmission part; all first, second, third and fourth speed gears, a climbing gear and a reverse gear take the shape of a helical gear; the front and rear ends of a main shaft are provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism respectively; a double cone lock pin synchronizer is arranged between the first and second speed gears; a single cone lock ring synchronizer is arranged between the third and fourth speed gears; the reverse gear and the climbing gear are connected with a sliding gear sleeve; a secondary transmission part is provided with a planetary gear train and a widened double cone lock ring synchronizer; and the main shaft is connected with a sun gear in the secondary transmission part through a spline transition sleeve. According to the 9-gear twin countershaft helical gear lock pin synchronizer transmission, full synchronizer gear shift is realized from the first to fourth speed gears, and meanwhile, the widths of the reverse gear, the climbing gear and the first gear are correspondingly increased, so that the service life at a low-gear zone during heavy load is prolonged, the gear shift performance of a high-gear zone is improved, and the working reliability of the transmission is also improved; and the 9-gear twin countershaft helical gear lock pin synchronizer transmission has the advantages of labor saving in operation, stable gear shift transmission, low noise and long service life.

Owner:SINO TRUK JINAN POWER

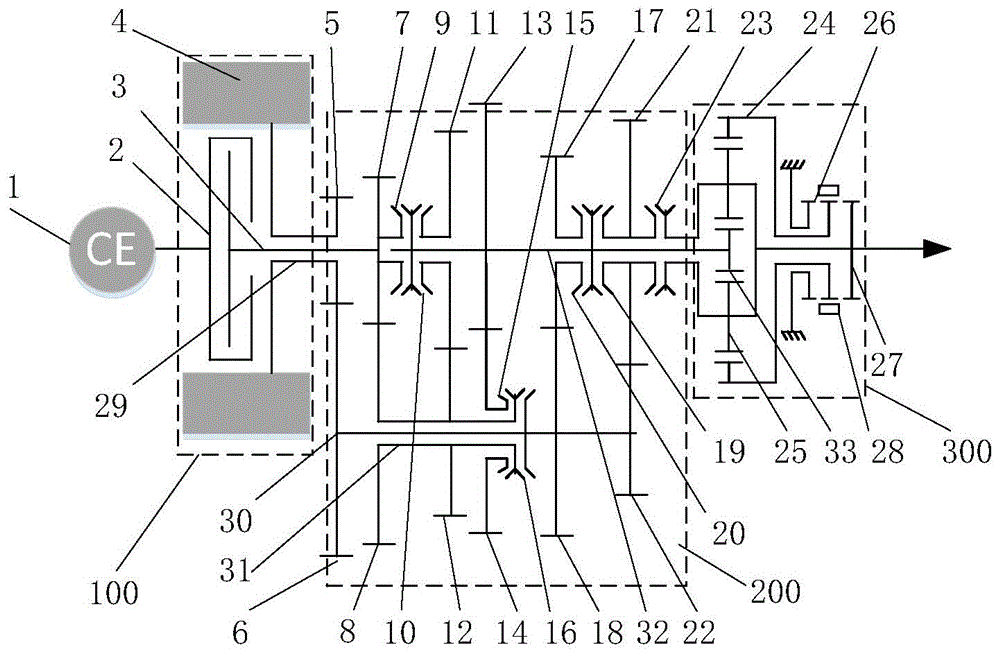

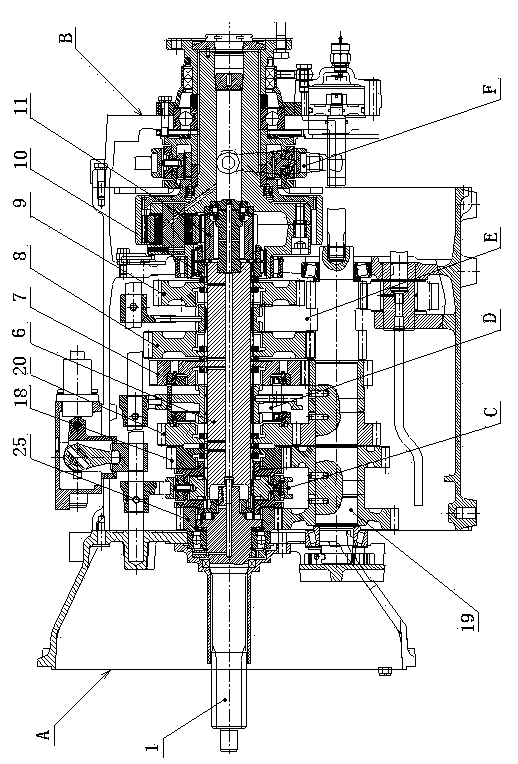

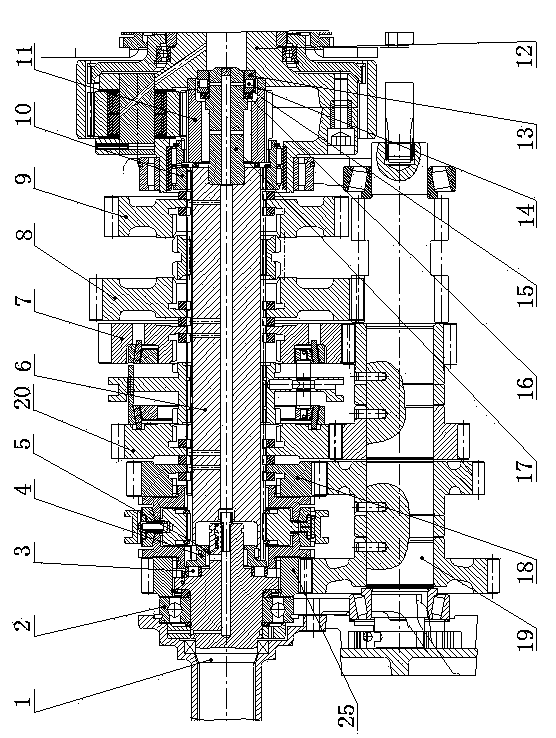

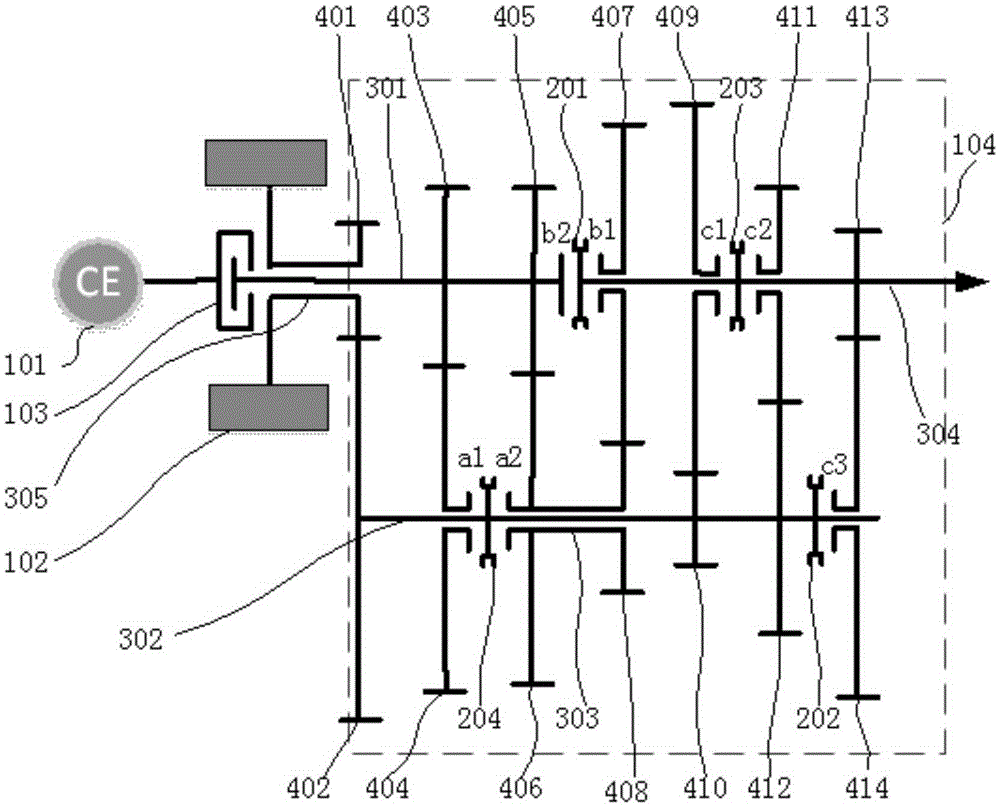

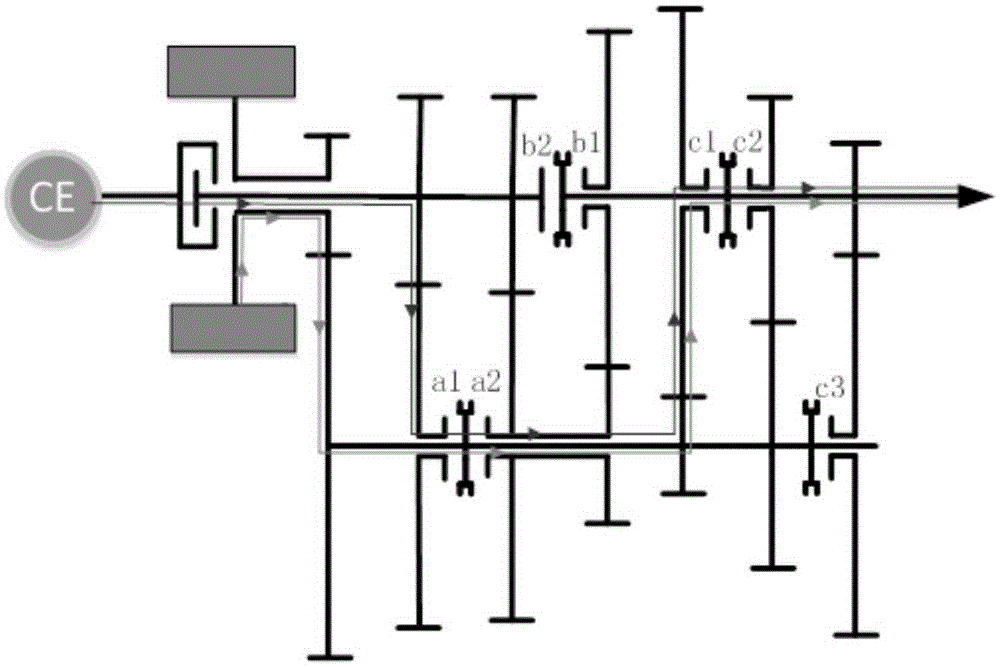

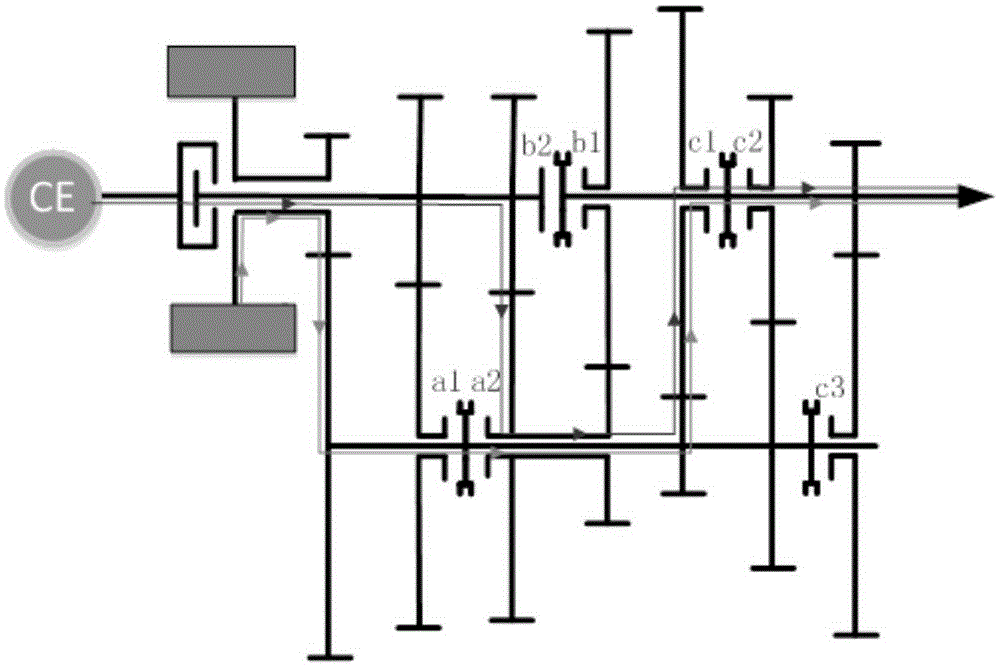

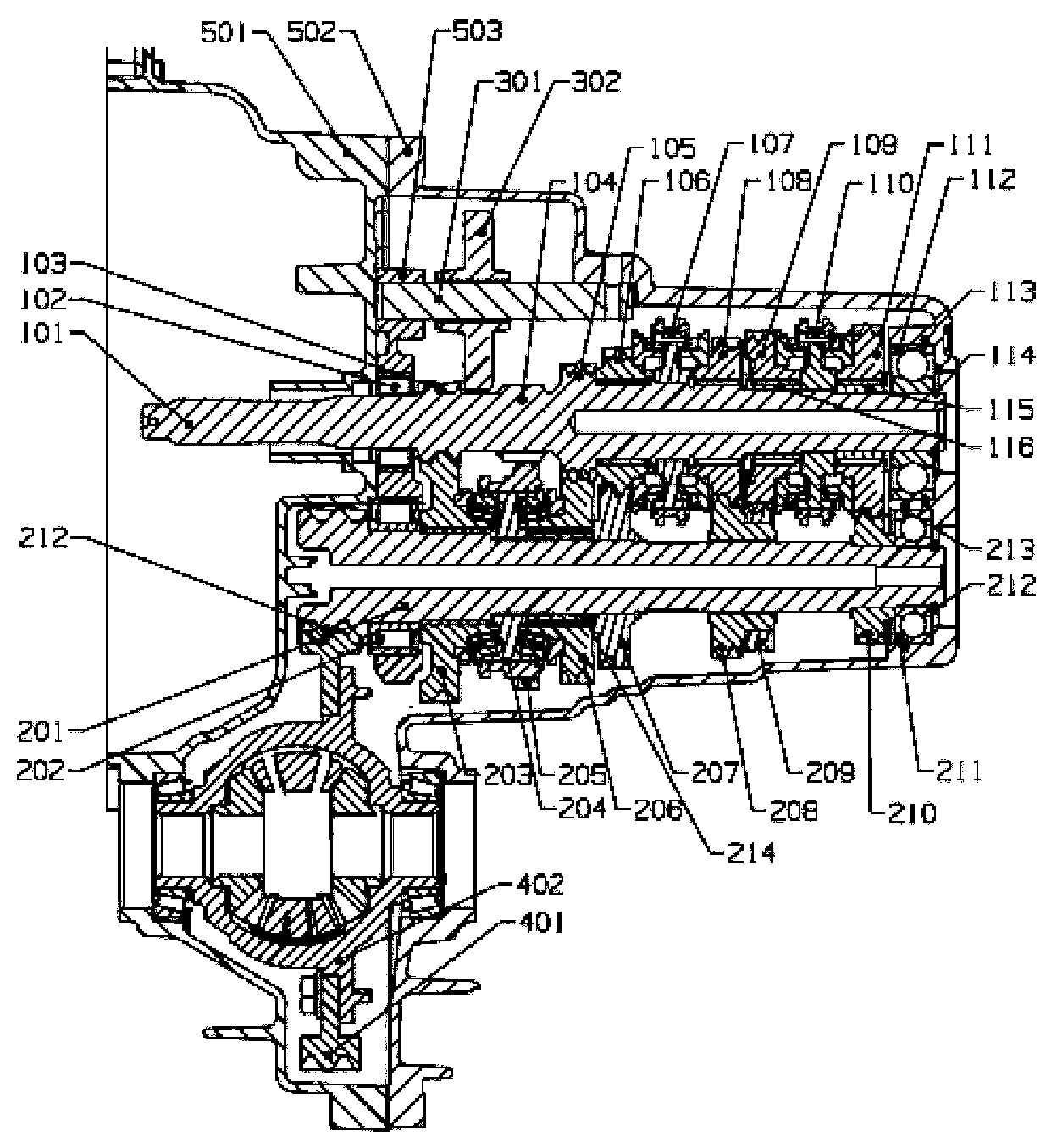

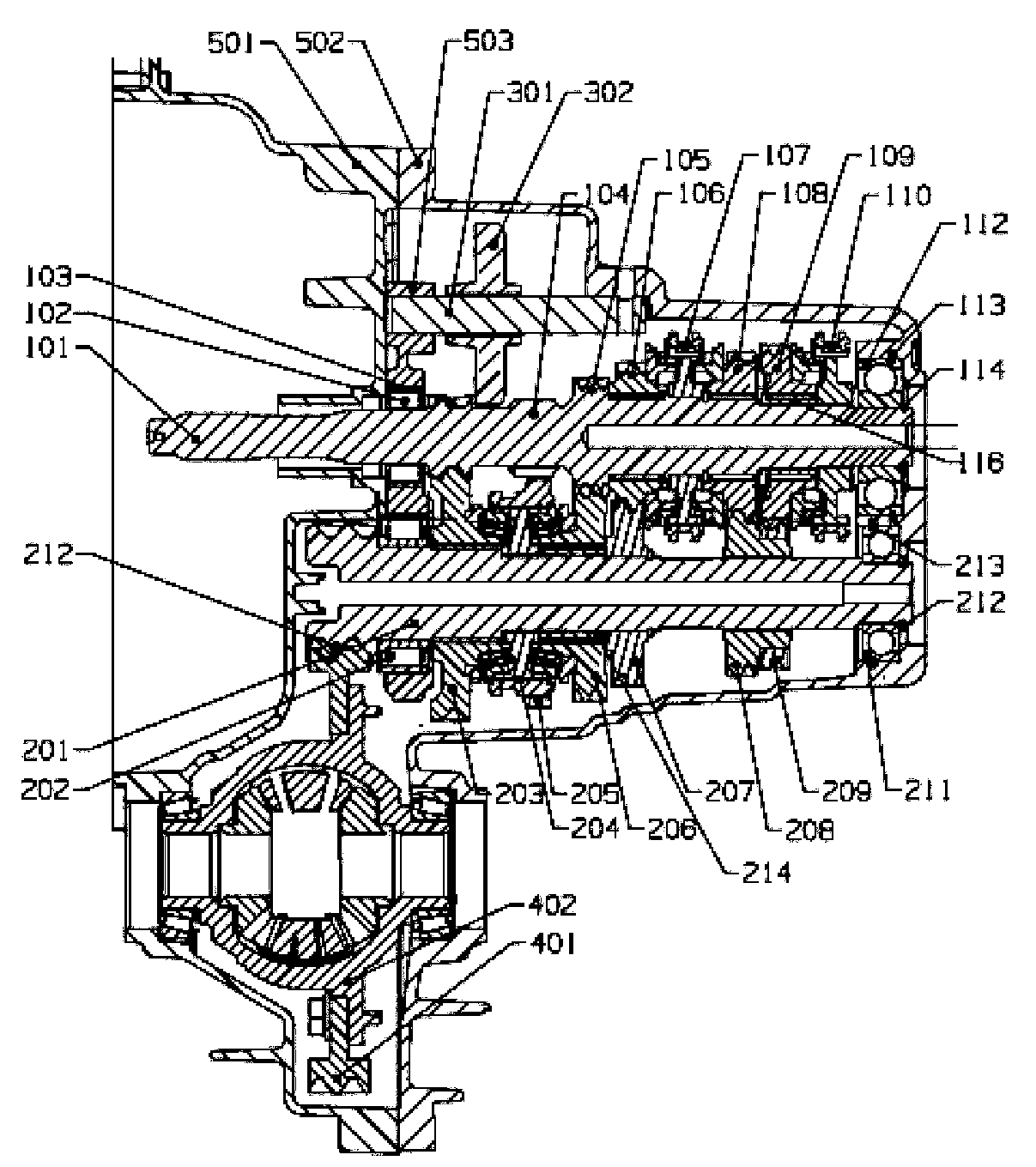

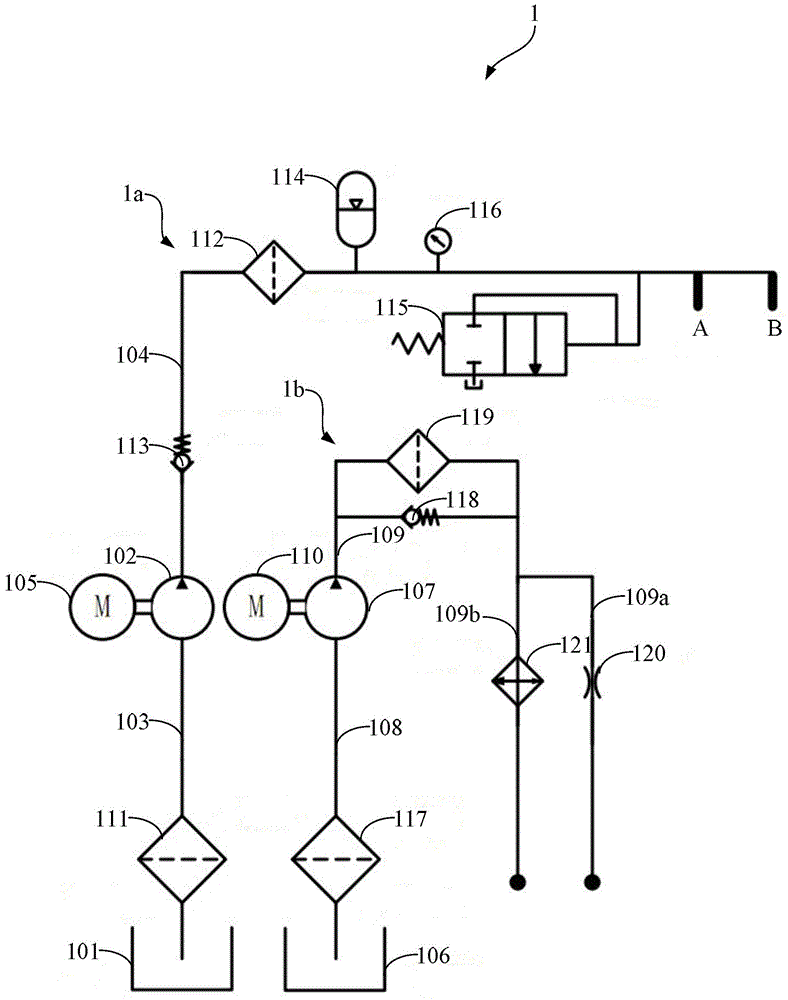

Power gear-shifting hybrid gearbox for commercial vehicle

ActiveCN105398323AOptimize space layoutImplement power shiftGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machine

The invention specifically relates to a hybrid multi-gear gearbox, which belongs to the technical field of vehicle transmission. A power gear-shifting hybrid gearbox for a commercial vehicle comprises an engine (101), a clutch (103), a motor (102) and a gearbox (104). The technical scheme of the power gear-shifting hybrid gearbox for the commercial vehicle is that the power of the engine (101) is input into an engine output shaft (301) after passing through the clutch (103); and the power of the motor (102) is input into a motor input shaft (305). The gearbox (104) comprises a plurality of free fixed-axle gear mechanisms, which can couple powers of the engine (101) and the motor (102) and can realize 8 gears matched with the engine, and 3 gears matched with the motor. According to the invention, power gear shifting and hybrid power working condition can be realized; vehicle power performance can be improved; gear shifting quality can be improved; clutch abrasion can be reduced; and fuel efficiency can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

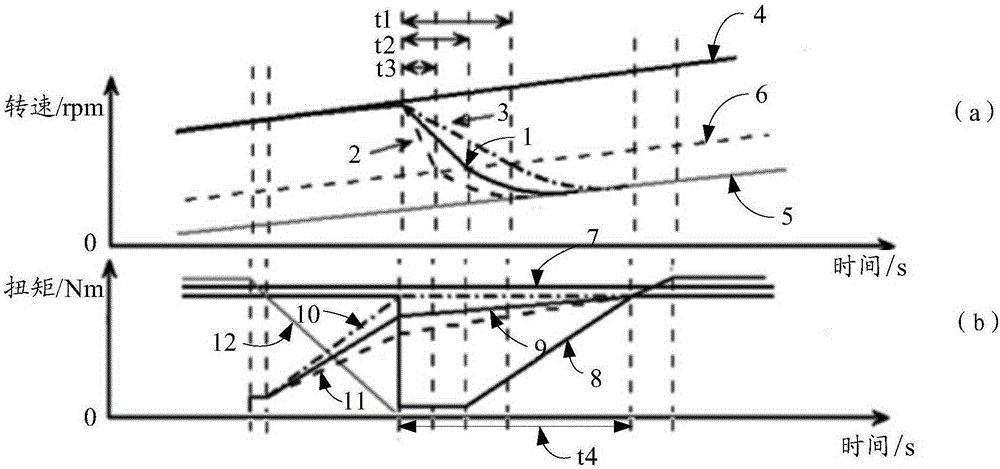

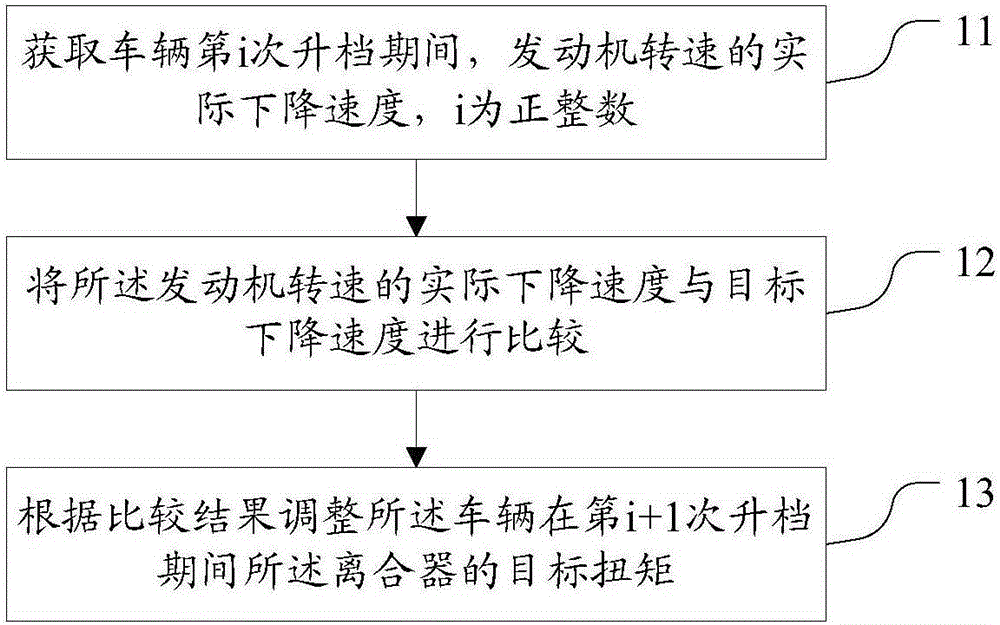

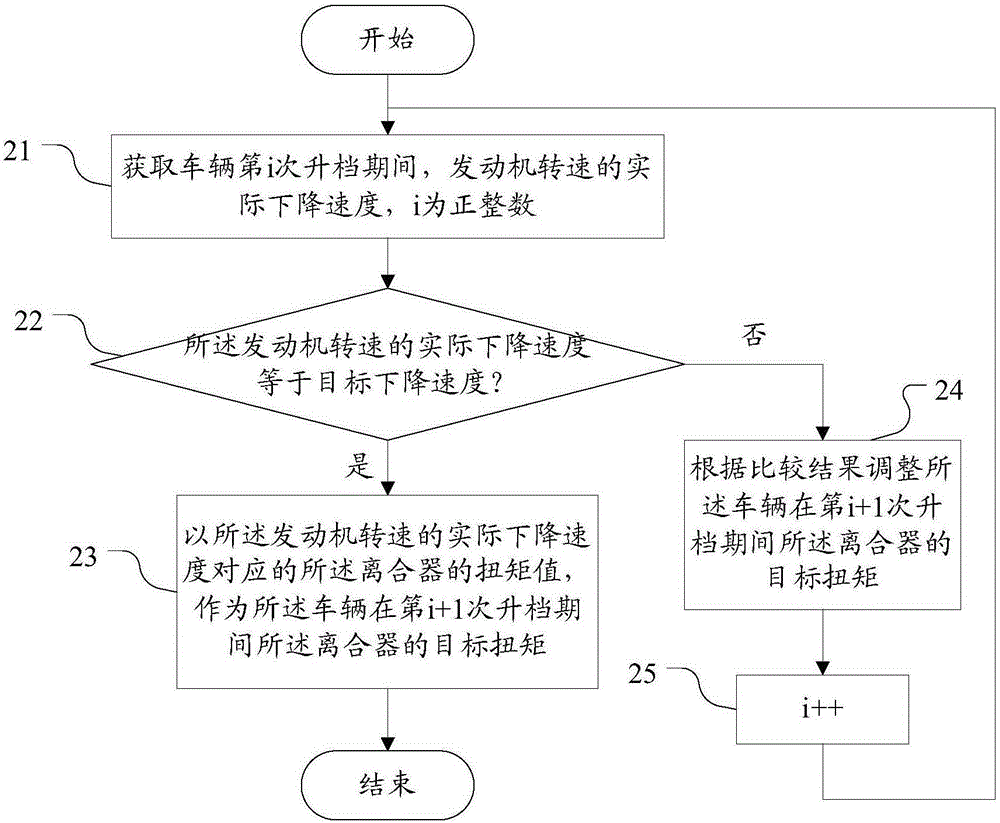

Control method and device for clutch

Provided is a control method and device for a clutch. The method comprises the steps that an actual descending speed of the engine rotating speed during the i-th upshift of a vehicle is acquired, wherein i is a positive integer; the actual descending speed of the engine rotating speed is compared with the target descending speed; and when the actual descending speed of the engine rotating speed is not equal to the target descending speed, the target torque of the clutch during the i+1th upshift of the vehicle is adjusted according to the comparison result till the actual descending speed of the engine rotating speed reaches the target descending speed during the i-th upshift of the vehicle. By the adoption of the method, the gear shift performance of the vehicle can be improved.

Owner:SAIC MOTOR

Shift control method of automatic transmission

ActiveUS8868307B2Improve marketabilityImprove shift performanceHybrid vehiclesDigital data processing detailsAutomatic transmissionControl theory

A shift control method of an automatic transmission may include detecting an end point of an inertia section during upshifting, momentarily reducing a hydraulic pressure applied to engagement side frictional elements at the detected end point of the inertia section, increasing the reduced hydraulic pressure with a predetermined gradient until reaching a synchronization point, and momentarily increasing the hydraulic pressure when the synchronization point may be reached.

Owner:HYUNDAI MOTOR CO LTD +1

Parallel type hybrid power multi-gear transmission case for power gear-shifting of commercial vehicle

ActiveCN105172569AAchieve hybridRealize functionHybrid vehiclesGas pressure propulsion mountingElectric machineMulti degree of freedom

The invention belongs to the technical field of commercial hybrid power vehicles and relates to a multi-gear transmission case, in particular to a parallel type hybrid power multi-gear transmission case for power gear-shifting of a commercial vehicle. According to the technical scheme, the power of an engine is input to an engine input shaft after passing through a clutch; a motor module comprises an electromotor and a transmission gear, and the motor power is output through the transmission gear and an electromotor input shaft; a main box module of the transmission case is composed of a multi-degree of freedom fixed-axle gear mechanism, can be coupled with the power of the engine and a motor, and can realize the gears of five matched engines and the gears of two matched motors; an auxiliary box module of the transmission case can realize a high gear and a low gear; the auxiliary box module of the transmission case collaborates with the main box input module of the transmission case, so that the gears of ten matched engines and the gears of four matched motors can be realized. The parallel type hybrid power multi-gear transmission case has the characteristics that the multi-degree of freedom gear mechanism is adopted to couple the power of the engine and the motor and realizes the hybrid power and power gear-shifting functions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Gearbox and vehicle

InactiveCN104132103AImprove shift performanceCompact layoutToothed gearingsTransmission elementsGear driveNoise level

The invention relates to a manual gearbox and a vehicle including the same. The manual gearbox comprises an input shaft connected with an engine, an output shaft selectively engaged to the input shaft through a blockage gear, and a reverse gear shaft parallel to the input shaft, wherein the input shaft is connected with a forward gear driving gear and a reverse gear driving gear; the output shaft is connected with a forward gear driven gear; synchronizers are arranged between every two forward gear pairs; a low-gear synchronizer gear sleeve is connected with a reverse gear driven gear; and a reverse gear idle wheel is arranged on the reverse gear shaft, and can forwards and backwards slide to be joined with the reverse gear driving gear and the reverse gear driven gear. The manual gearbox has the advantages of compact arrangement, low cost, light weight and high strength, satisfies the customer needs in gear shifting quality and noise level, and guarantees the maximal compatibility with an existing production process.

Owner:SAIC GENERAL MOTORS +1

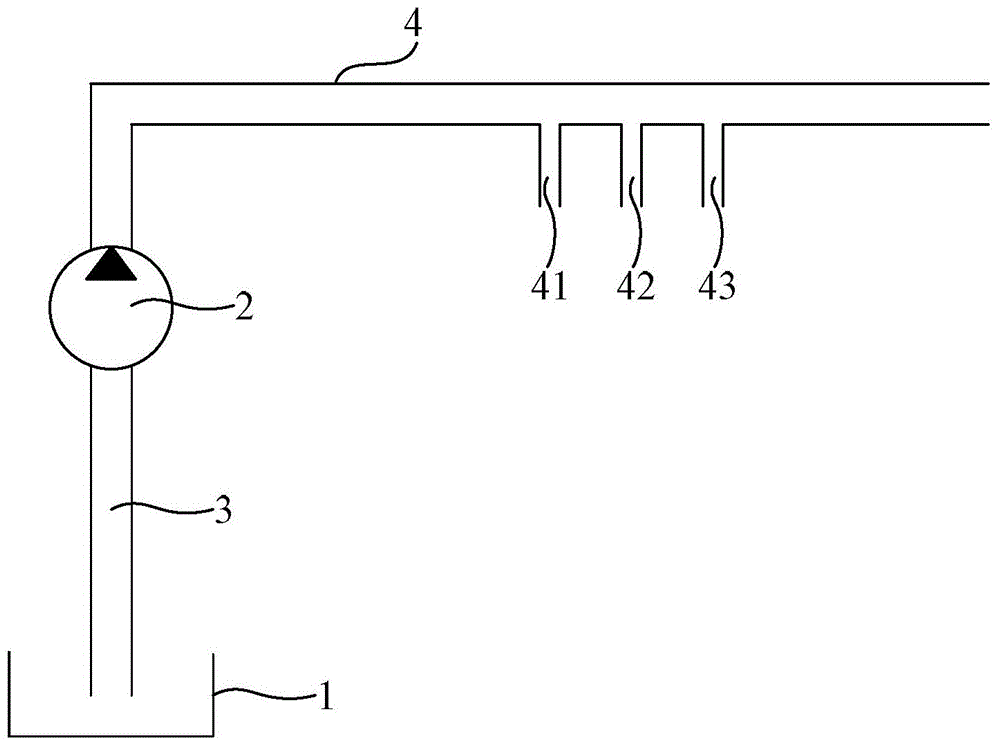

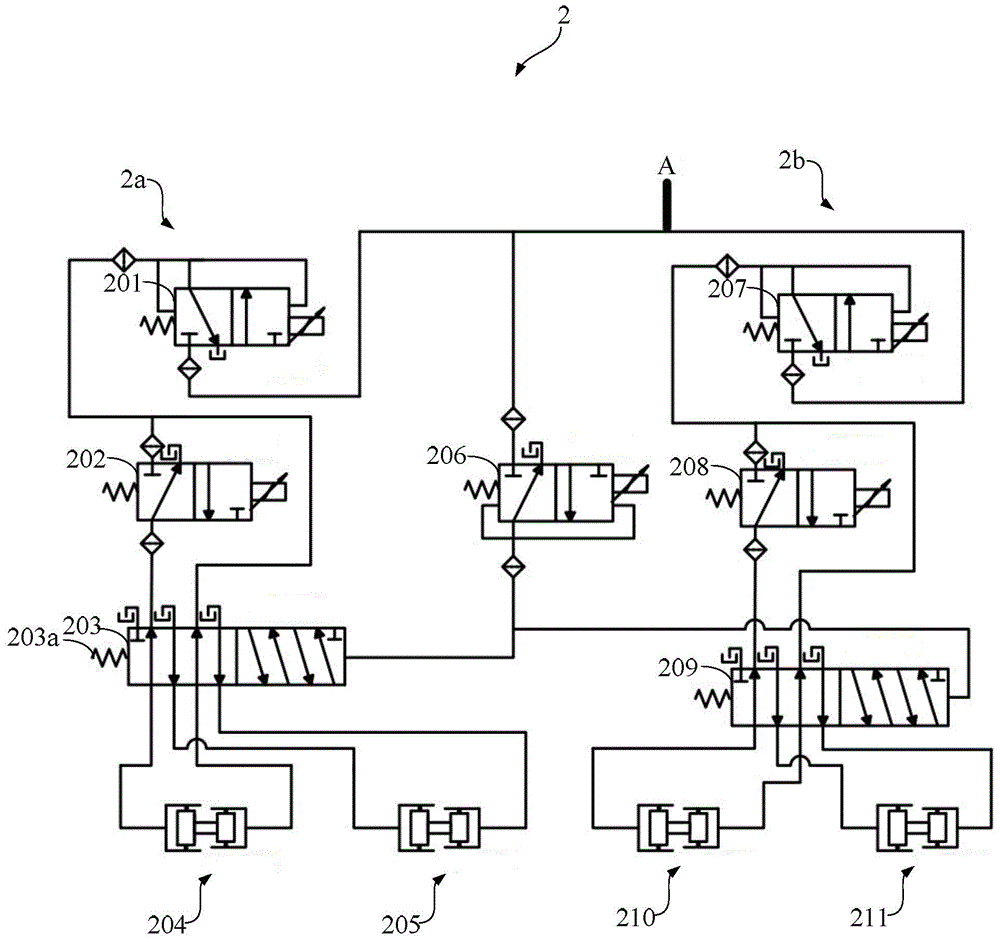

Dual-clutch transmission and hydraulic control system thereof

ActiveCN105465355AImprove cleanlinessRelieve pressureGearing controlFluid gearingsControl systemEngineering

The invention discloses a dual-clutch transmission and a hydraulic control system thereof. The hydraulic control system comprises a gear shifting oil circuit control device, a clutch oil circuit control device and an oil supply device, wherein the oil supply device is communicated with the gear shifting oil circuit control device and the clutch oil circuit control device so as to supply oil to the gear shifting oil circuit control device and the clutch oil circuit control device. The gear shifting oil circuit control device comprises at least one gear shifting control unit. Each gear shifting control unit comprises a gear shifting oil cylinder assembly communicated with the oil supply device. Each gear shifting oil cylinder assembly comprises a first oil cylinder, a first piston which is movably located in the first oil cylinder, a second oil cylinder, and a second piston which is movably located in the second oil cylinder; the first oil cylinder and the second oil cylinder are arranged in a spaced mode in the moving direction of the first piston and the second piston; a push rod stretching out of the first oil cylinder and the second oil cylinder is connected between the first piston and the second piston; the area of the end face, backing on to the push rod, of the first piston is not equal to the area of the end face, backing on to the push rod, of the second piston. By means of the technical scheme, the problems that an existing gear shifting oil cylinder assembly is poor in gear shifting performance and complex in structure are solved.

Owner:SAIC MOTOR

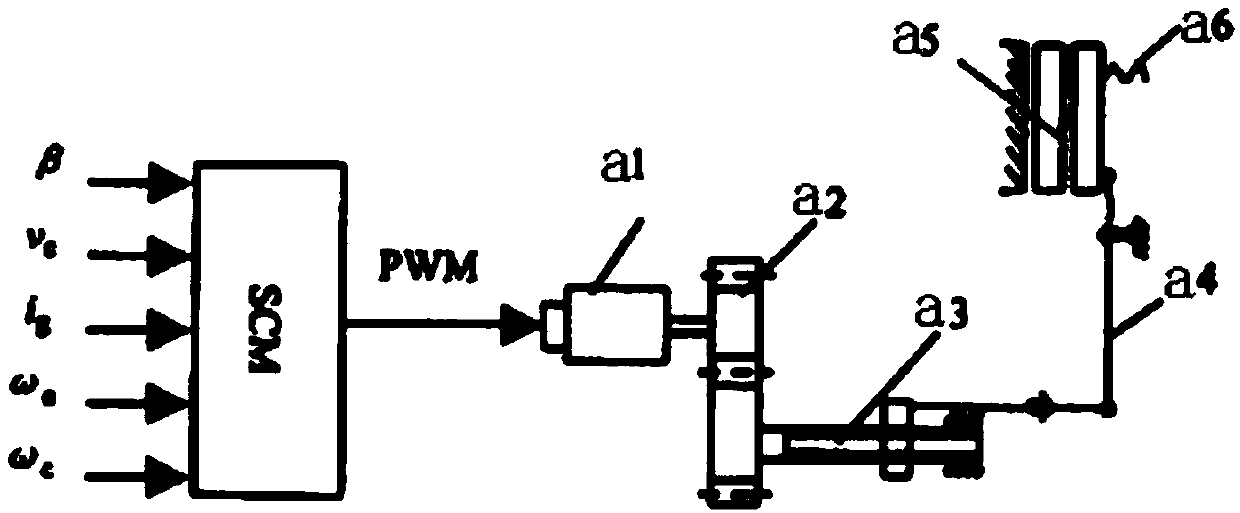

AMT/DCT transmission clutch torque self-adaptation calibration method

InactiveCN107559412AEasy to controlImprove shift performanceRoad transportGearing controlTime changesSelf adaptive

The invention provides an AMT / DCT transmission clutch torque self-adaptation calibration method. A clutch torque theoretical control model and a clutch torque calibration model are built, and the relation between the clutch torque and the position of an execution mechanism is finally built. The difficult clutch torque modeling caused by time change, nonlinearity and the like can be solved, precisecontrol over clutch torque can be achieved, and starting and gear shifting of an AMT / DCT carried vehicle are improved.

Owner:CHONGQING UNIV

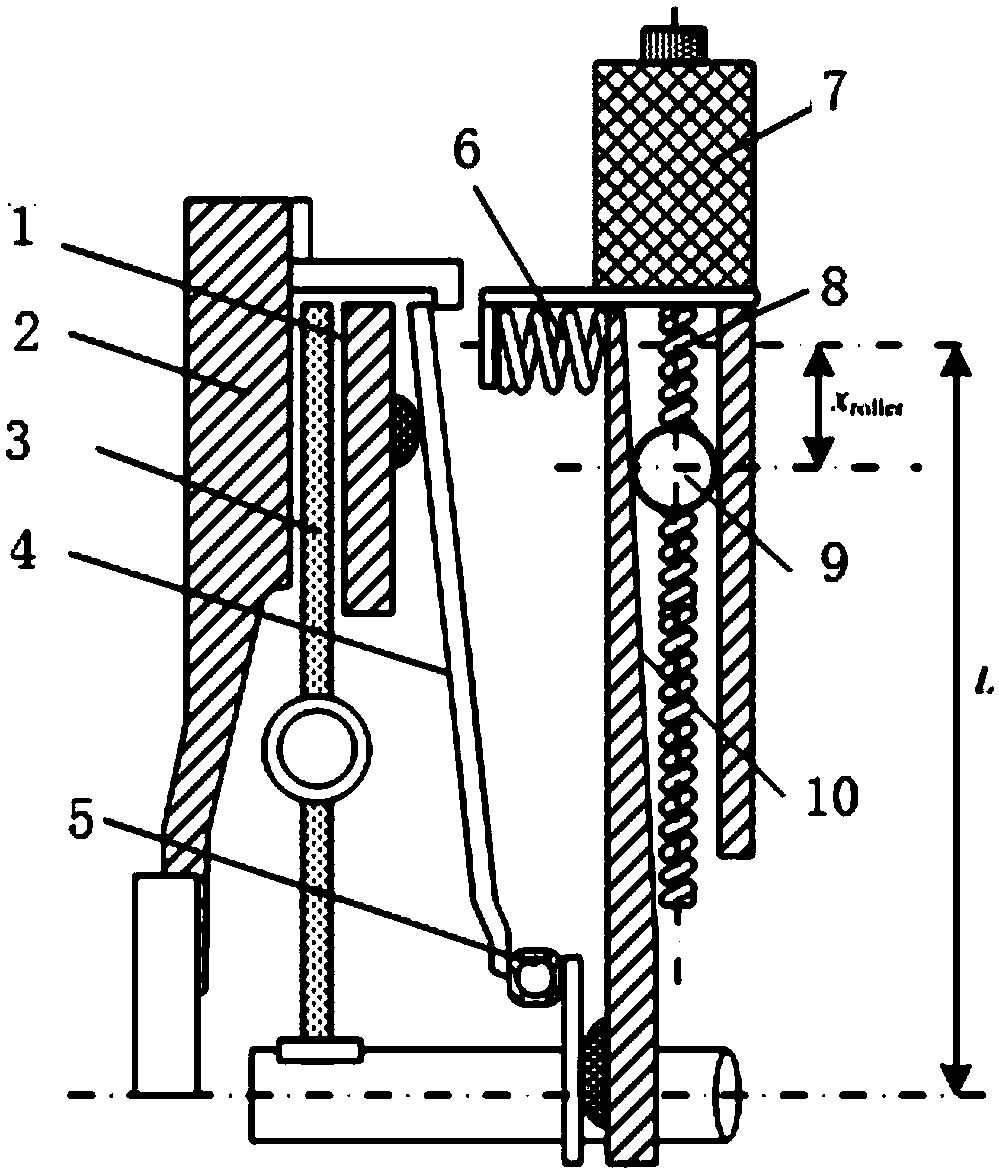

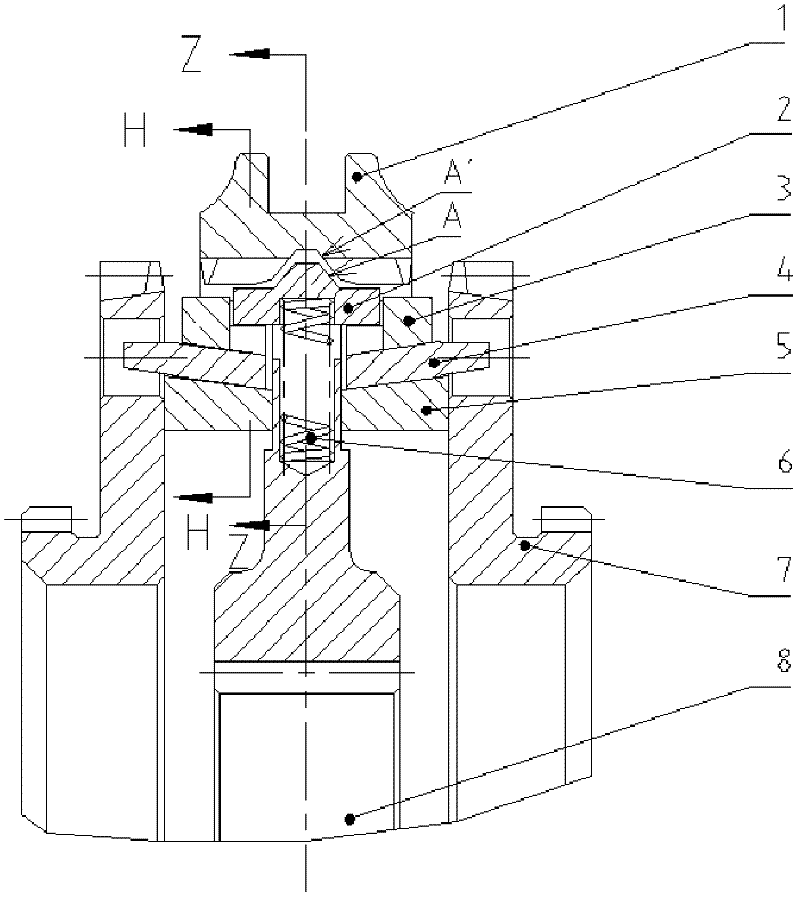

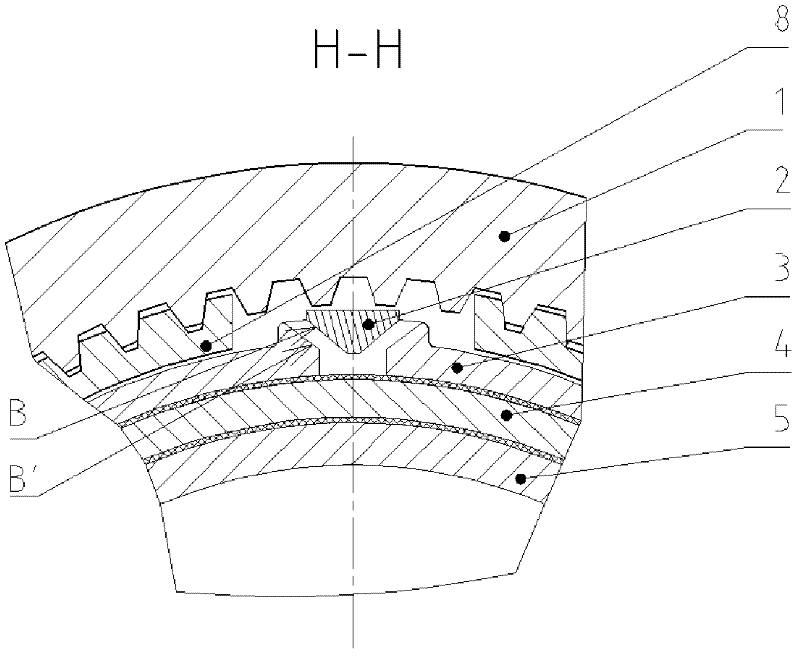

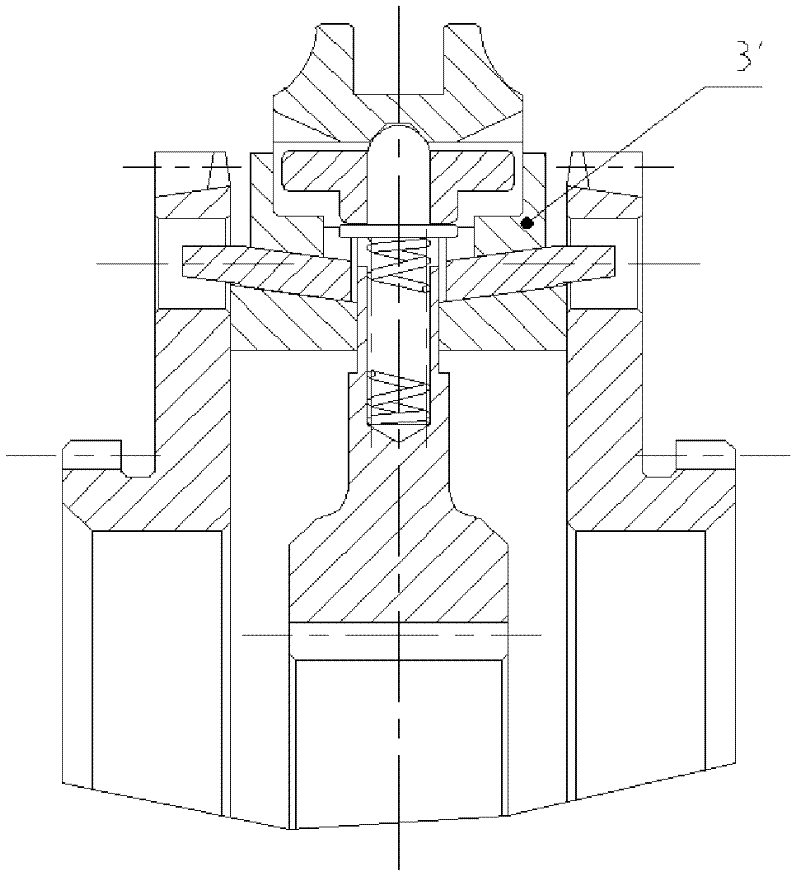

Lock ring type synchronization device and its synchronization method

The invention provides a lock ring type synchronization device and its synchronization method. The synchronization device comprises a slide sleeve, a first friction ring, a second friction ring, a combination toothed ring and a gear hub. On the gear hub are inlaid plural stoppers capable of moving axially; the slide sleeve is arranged at the periphery of the gear hub; plural locking grooves fitted with the stoppers are distributed on the circumferential direction of the slide sleeve; the first friction ring rotates along with the gear hub; the second friction ring and the combination toothed ring rotate together; the first friction ring is arranged at the periphery of the second friction ring and the opposite faces of the first and second friction rings are a pair of matching oblique planes; the first friction ring is provided with a groove having a first oblique plane, and the side wing of the stopper is provided with a second oblique plane matching with the first oblique plane; the locking groove of the slide sleeve has a third oblique plane and a fourth oblique plane matching with the third oblique plane is arranged at two sides of the top of the stopper; and the first friction ring is provided with a locking tooth. According to the invention, process precision requirements and costs are lowered, gear shift noise is low and reliability is high.

Owner:SHAANXI FAST GEAR CO

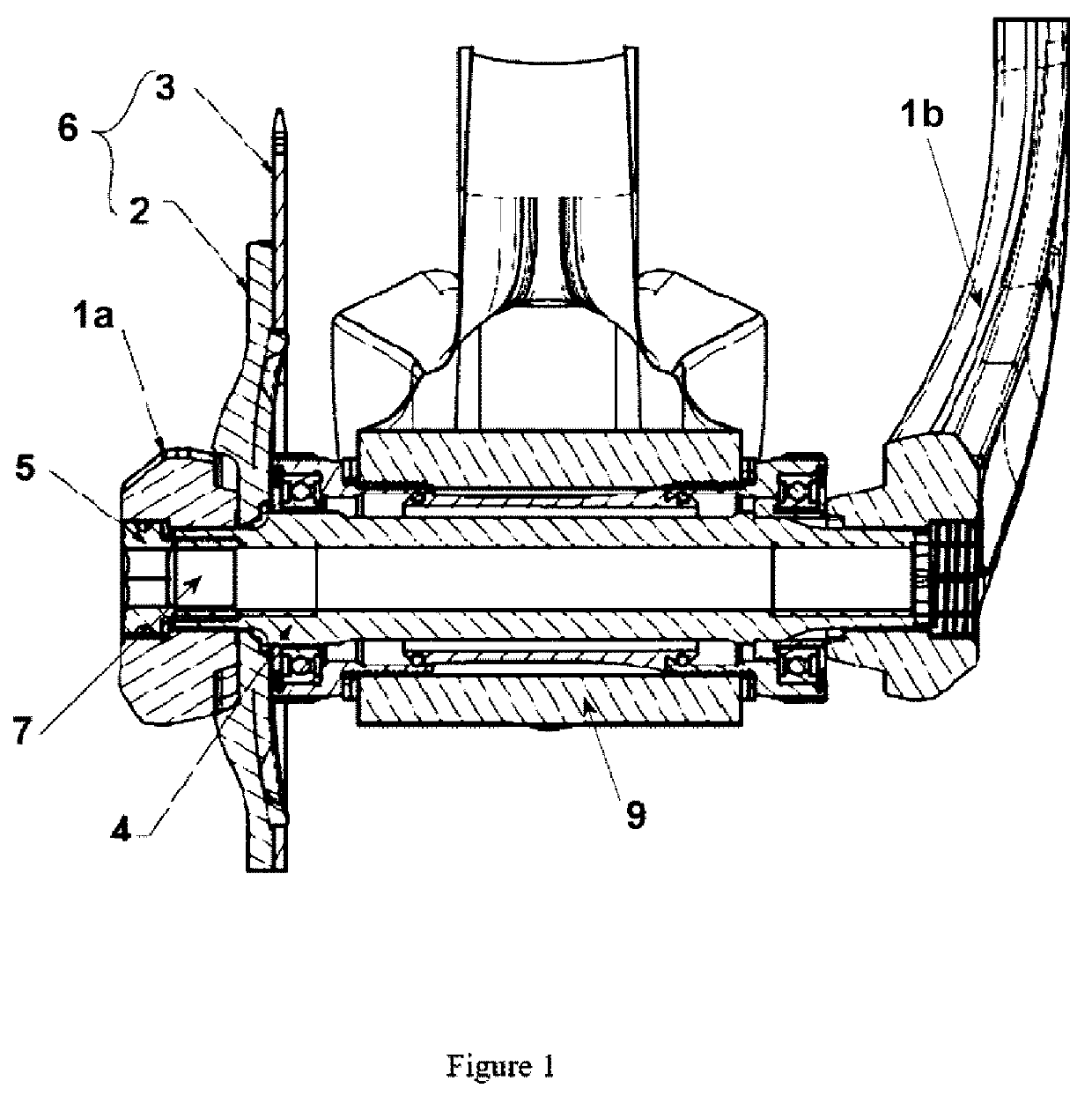

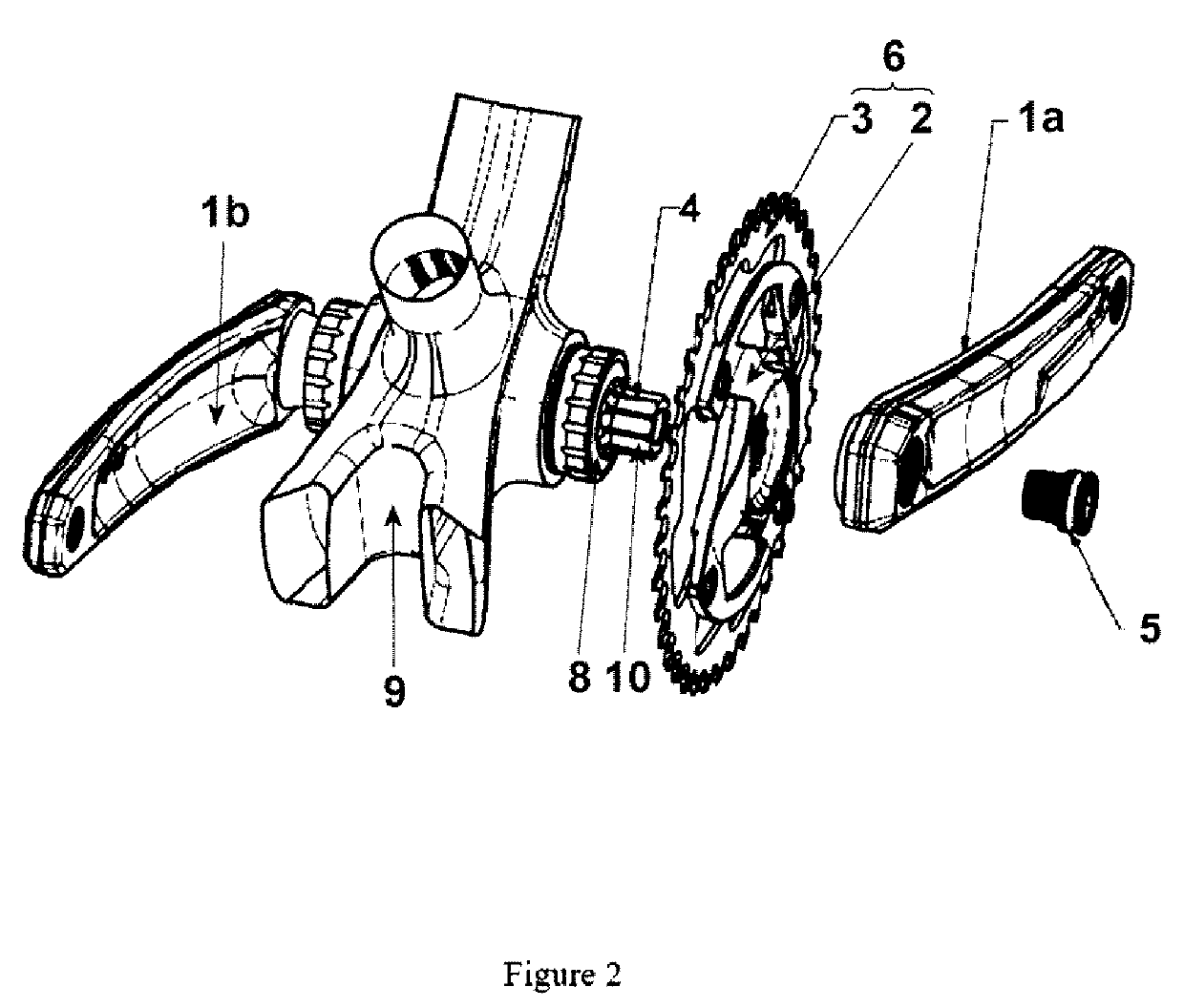

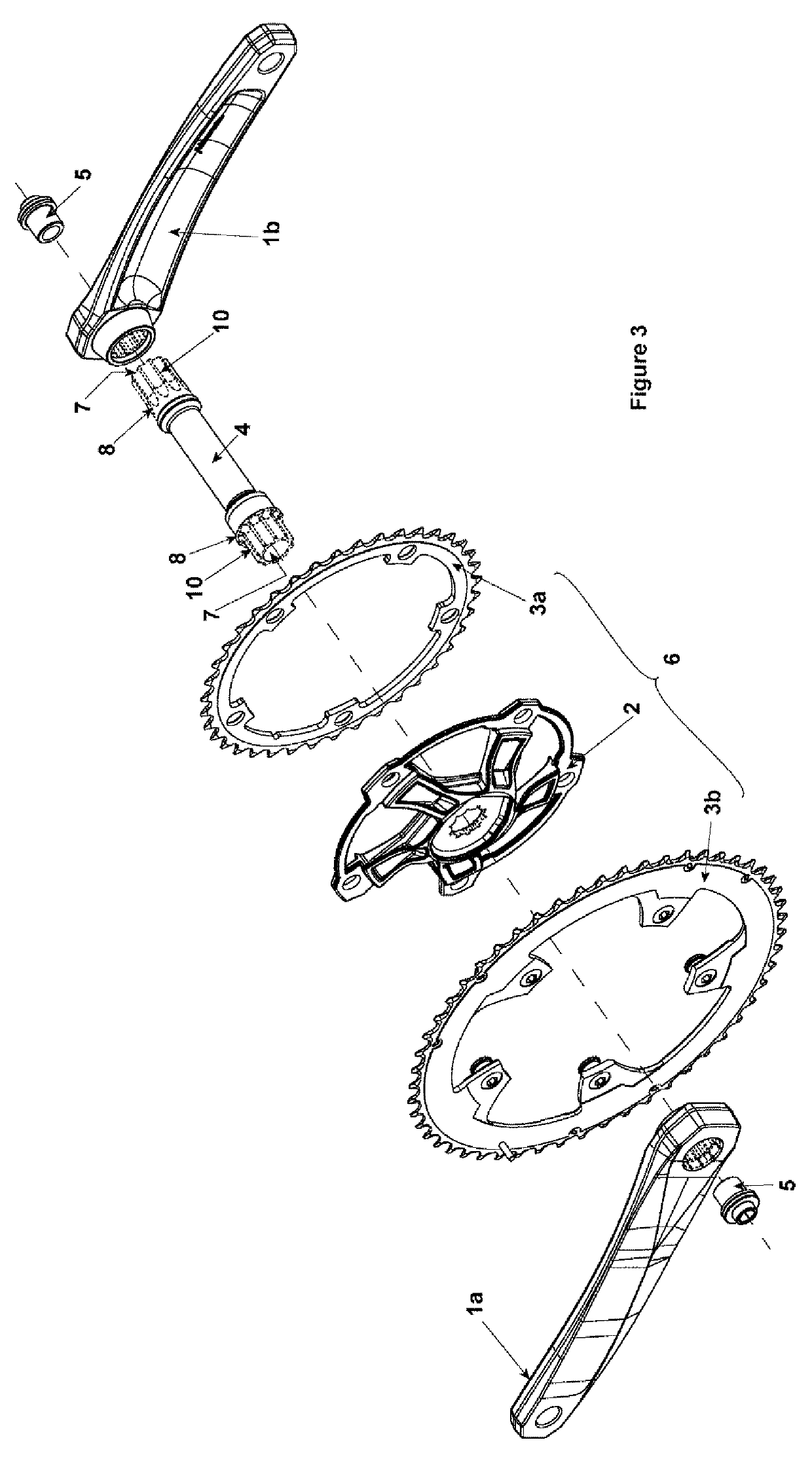

Modular crankset for bicycles

ActiveUS20190241233A1Easy to assembleEliminate lateral playVehicle cranksCouplings for rigid shaftsModularityEngineering

The present patent application describes a modular crankset for bicycles. The described modular crankset is useful for users, since it solves issues related to the speed of replacement of elements, the easiness of the replacement procedures and lowers the weight of the set without compromising the consistency and rigidity of the set. The current technology is applicable to any bicycle available in the market, including electrical bicycles, and it is especially interesting for competition bicycles, wherein the replacement of the constituent elements of the crankset should be made as quickly as possible.

Owner:MIRANDA & IRMAO LDA

Operation of electrically controlled transmissions at lower temperatures

InactiveUS20080132380A1Improve transmission performanceReduce torque disturbanceGearing controlEngine controllersEngineeringElectrical and Electronics engineering

A system and method for controlling electromechanical valves operating in a transmission is presented. According to the method, transmission operation can be improved by heating the valves, at least during some conditions.

Owner:FORD GLOBAL TECH LLC

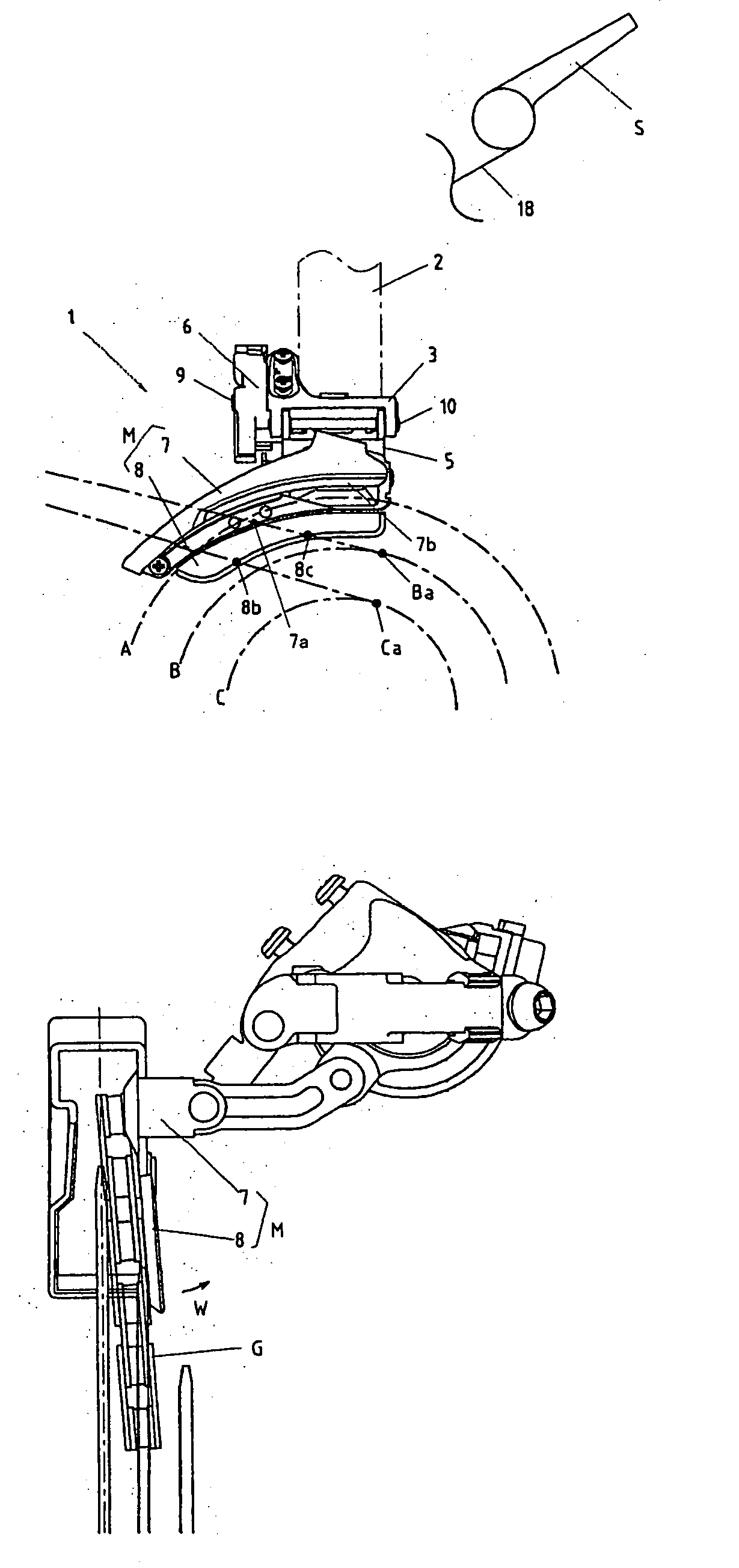

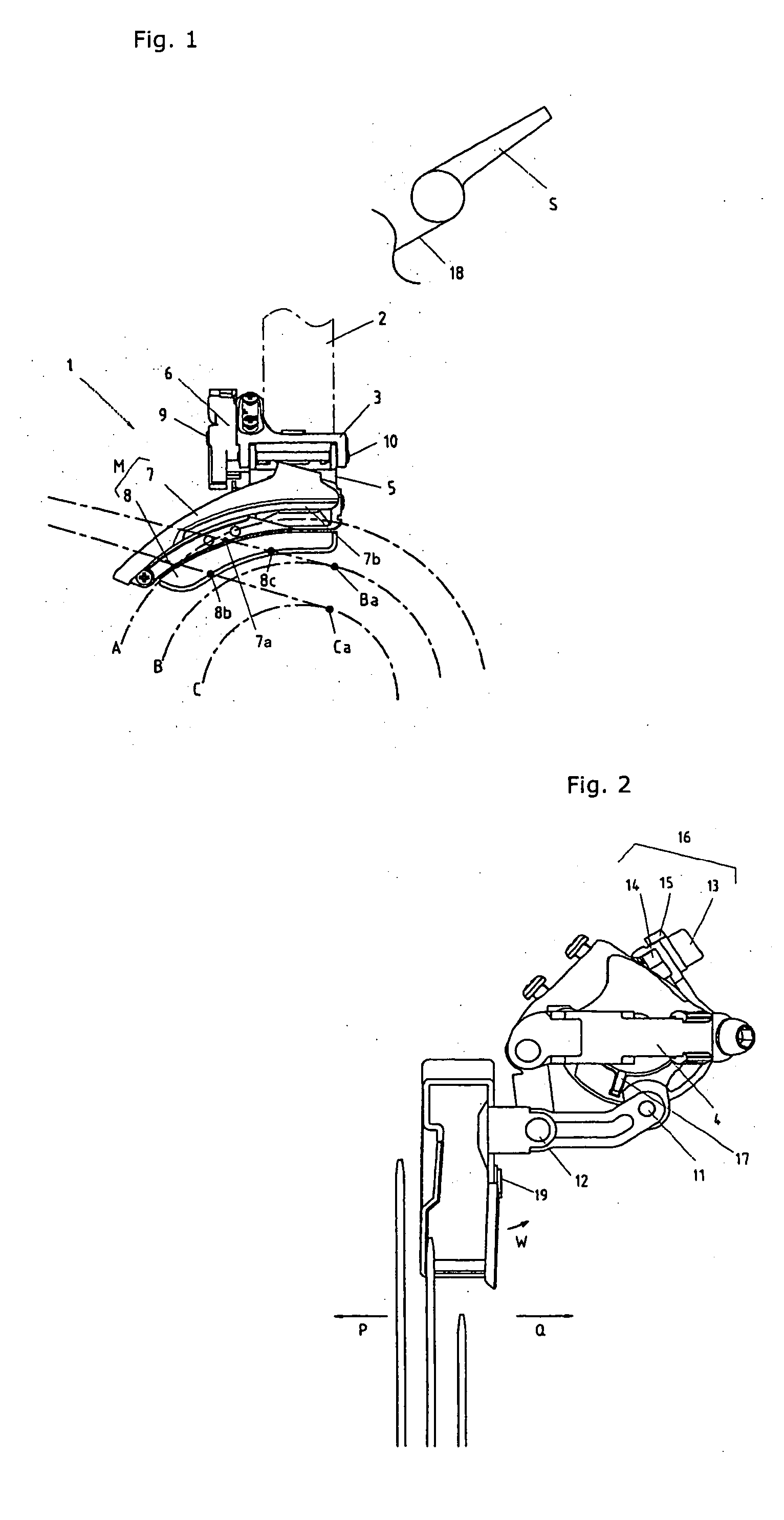

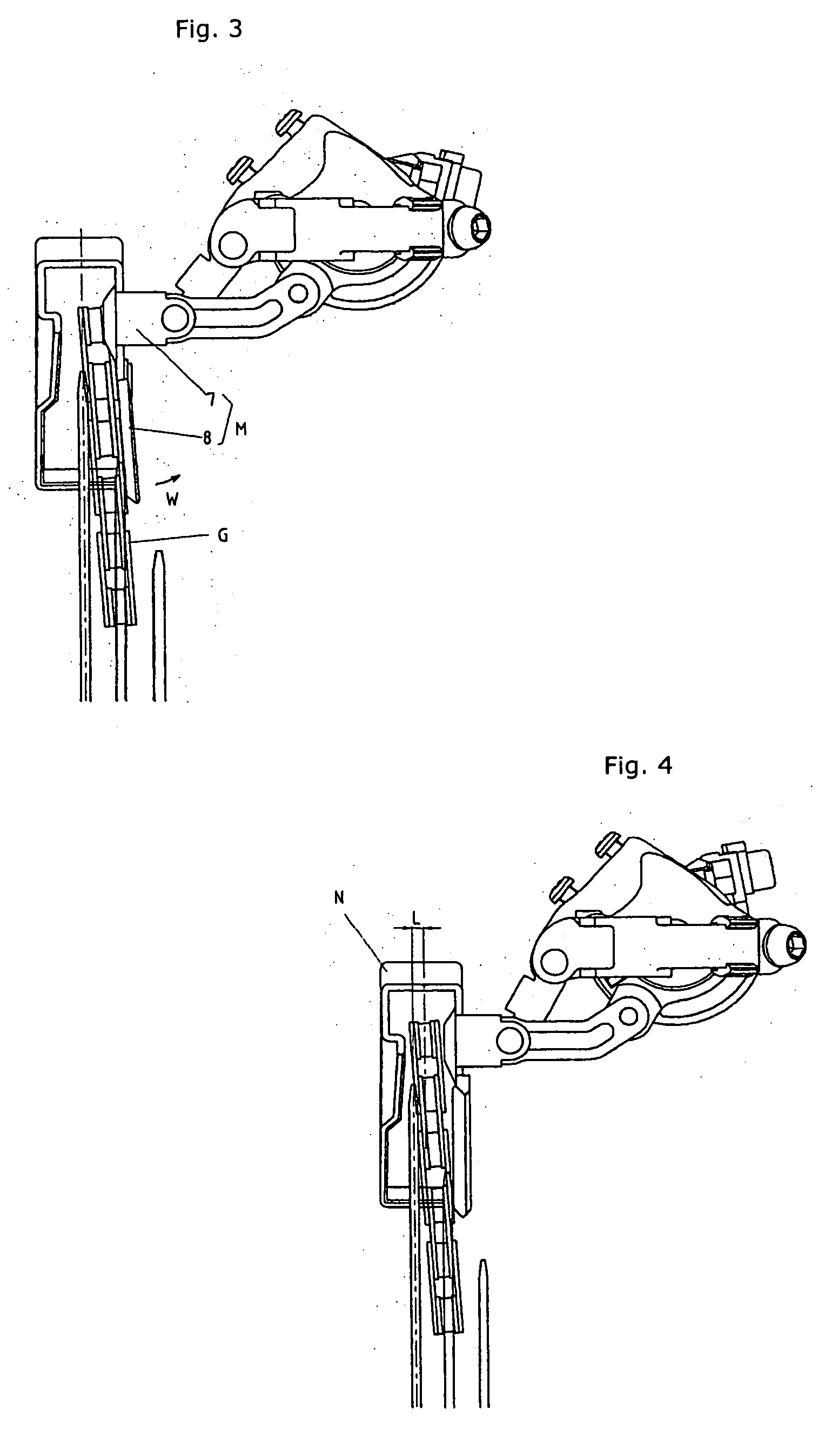

Transmission for bicycle

InactiveUS20060148602A1Improve shift performanceSmooth shiftingChain/belt transmissionGearingSprocketEngineering

A transmission for a bicycle for re-installing a chain in the lateral direction of the bicycle in a front chain wheel having two or more sheets of gear plates, comprising two sheets of guards, i.e., a main guard for re-installing the chain from a middle diameter gear to a large diameter gear and an auxiliary guard for re-installing the chain from a small diameter gear to the middle diameter gear, wherein the main guard is pivotally supported on a link mechanism for moving the guard in the lateral direction of the bicycle and the auxiliary guard is installed on the main guard so as to be elastically displaced.

Owner:SAKAE ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com