Powertrain system of hybrid electric vehicle

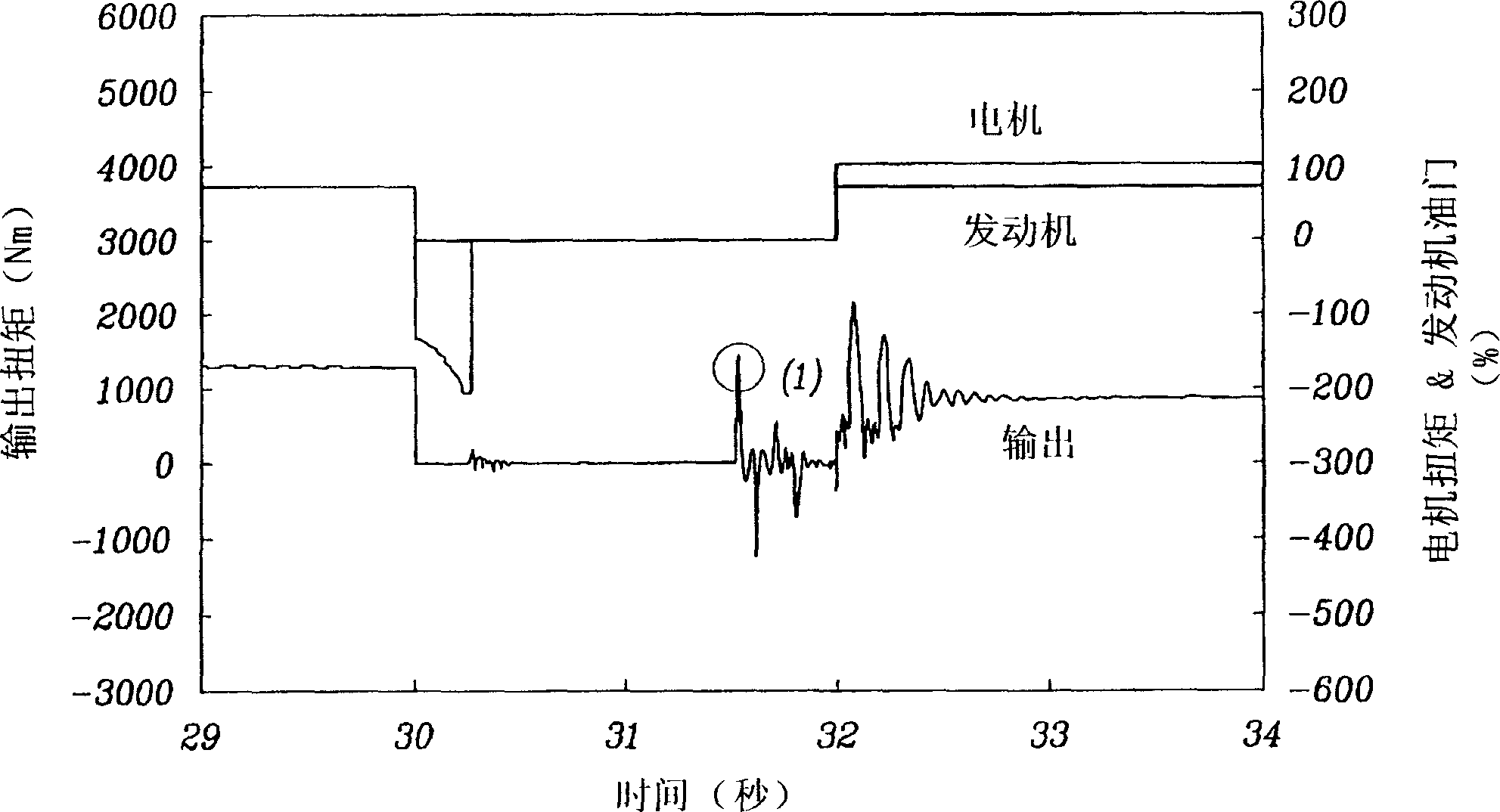

A technology of power system and clutch, applied in the field of power system, can solve problems such as instantaneous vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Detailed description of the preferred embodiment

[0029] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

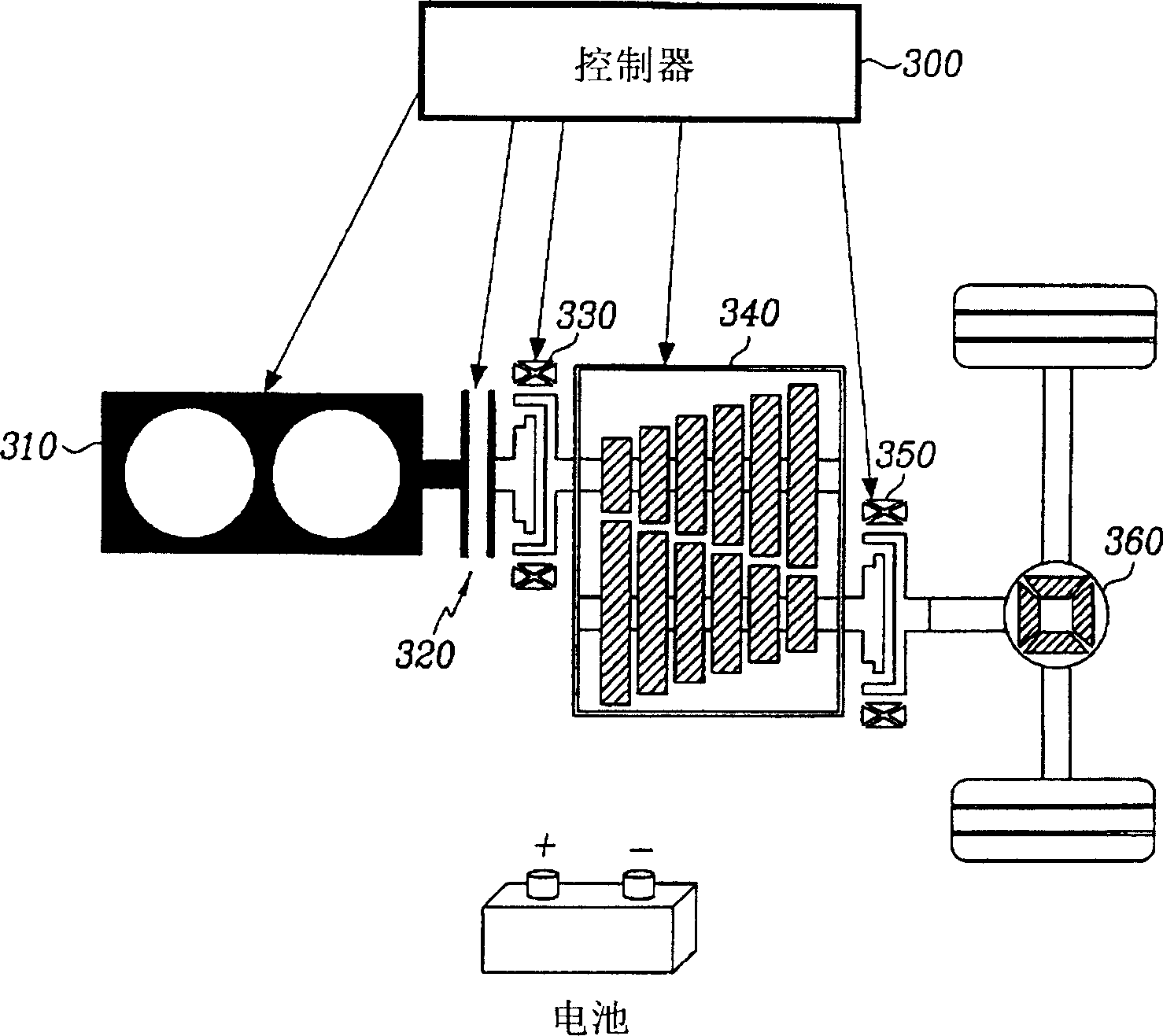

[0030] image 3 is a schematic diagram of a hybrid electric vehicle power system according to an embodiment of the present invention;

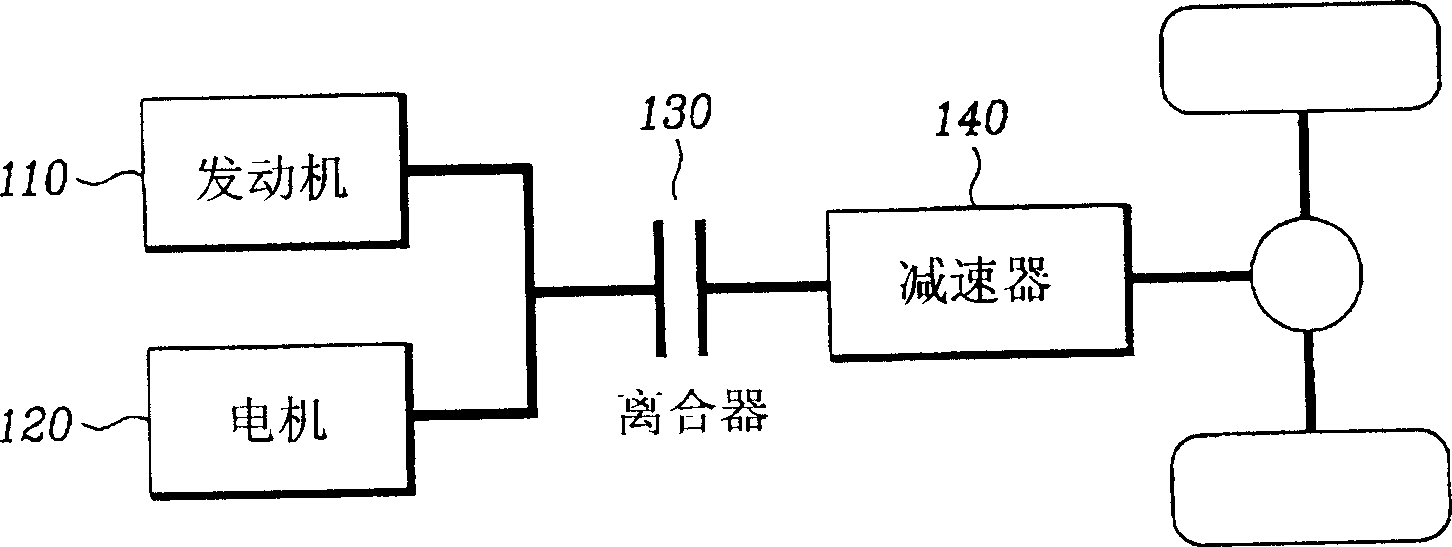

[0031] Such as image 3 As shown, a power system of a hybrid electric vehicle according to an embodiment of the present invention includes an engine 310 , a clutch 320 , primary and secondary motors 330 and 350 , an automatic shift gear (ASG) 340 and a differential gearbox 360 .

[0032] In addition, the power system of the hybrid electric vehicle of the embodiment of the present invention further includes a controller 300 controlling a shift operation by controlling an engine 310 , a clutch 320 , main and auxiliary motors 330 and 350 , and an ASG 340 .

[0033] Controller 300 may be controlled by one or more processors driven by a predetermined progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com