AMT/DCT transmission clutch torque self-adaptation calibration method

A calibration method, clutch technology, applied in belts/chains/gears, elements with teeth, climate sustainability, etc., can solve problems such as difficulty in modeling clutch torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] This embodiment discloses an AMT or DCT transmission clutch torque adaptive calibration method

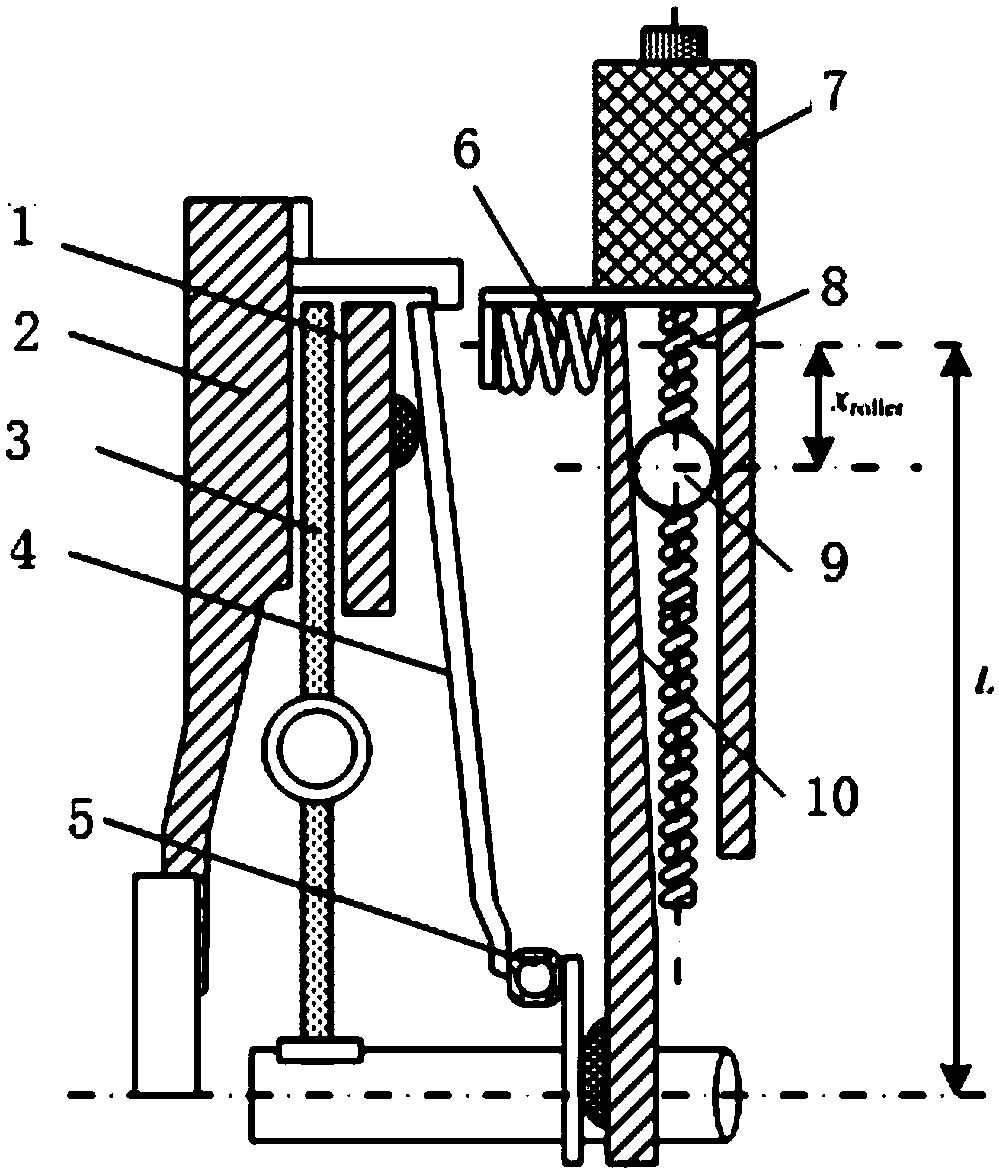

[0127] see figure 1 , including a schematic structural diagram of a DCT clutch actuator, which is characterized in that it includes a clutch pressure plate 1, an engine flywheel 2, a clutch friction plate 3, a lever spring 4, a release bearing 5, a pressure spring 6, an actuator motor 7, a screw rod 8, a roller Sub 9, combined leverage 10

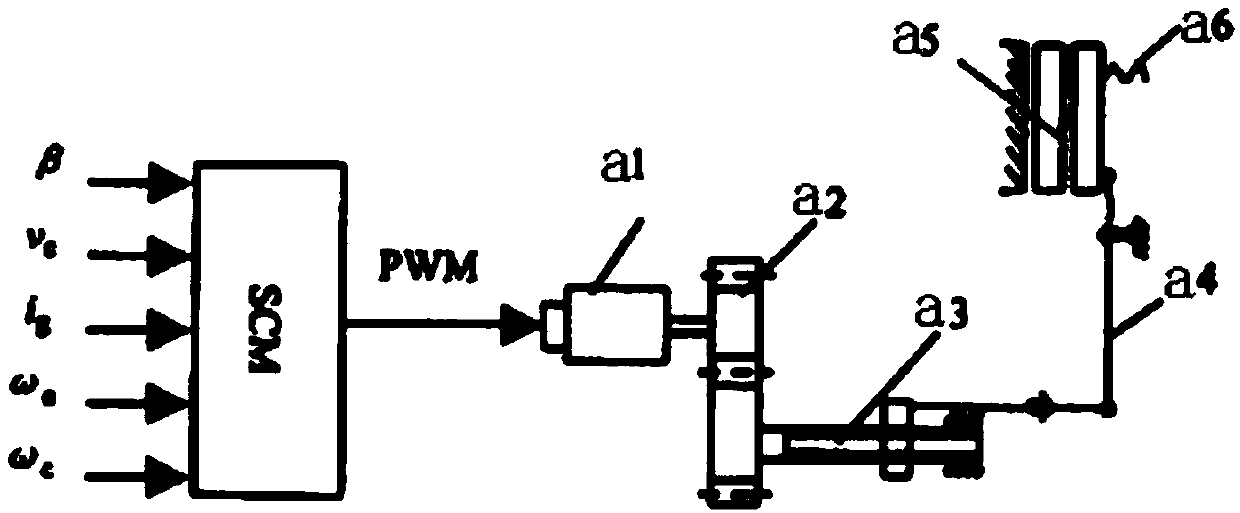

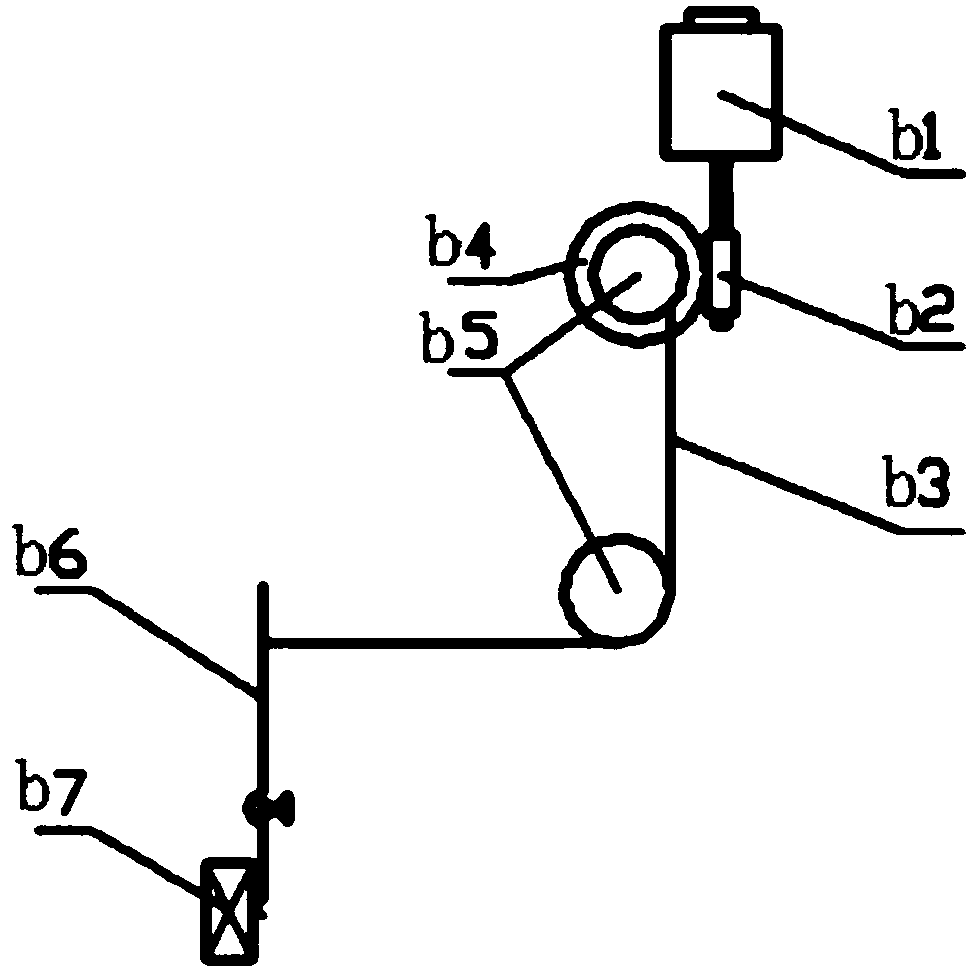

[0128] It is known that the torque adaptive calibration method includes clutch torque control modeling and clutch torque adaptive calibration model; the clutch torque control modeling includes mechanical analysis of the actuator, parameter analysis and establishment of the clutch torque control model; The mechanical analysis and parameter analysis of the actuator are in figure 1 Based on the structure shown, the relationship between the release bearing pressure and the displacement of the roller mechanism, as well as the clutch torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com