Lock ring type synchronization device and its synchronization method

A technology of synchronous devices and lock rings, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of high manufacturing cost and low yield, and achieve low cost, low cost, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

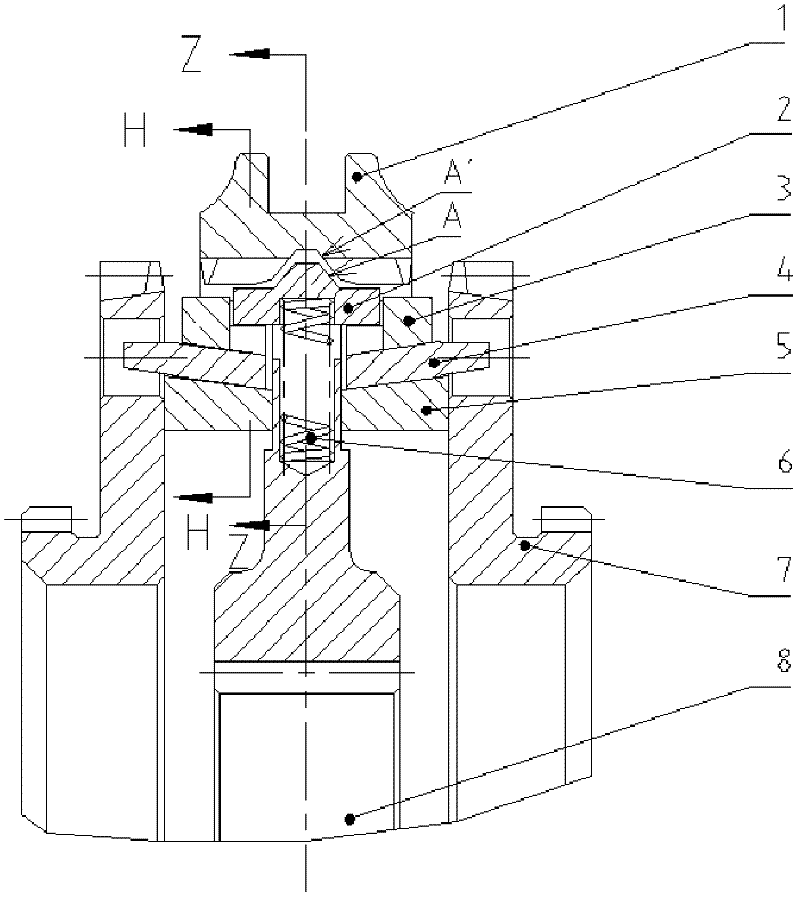

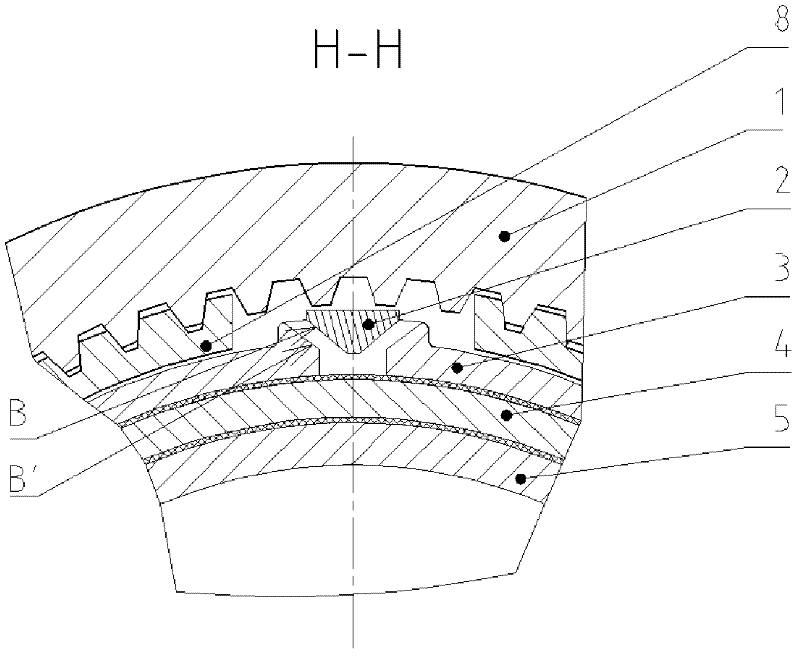

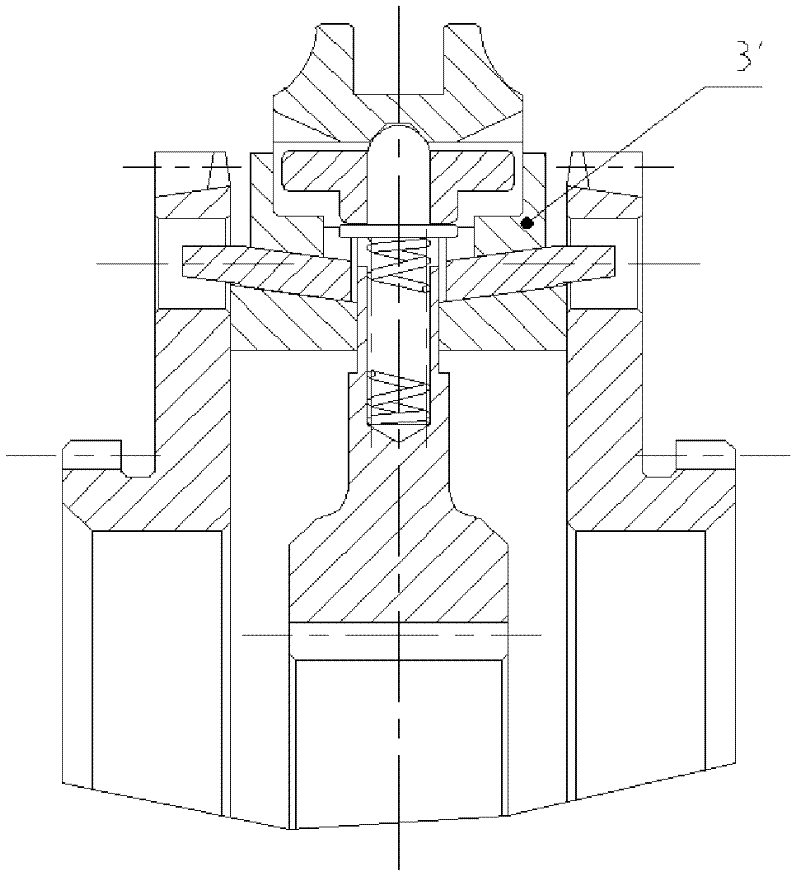

[0029] figure 1 A typical embodiment of the invention is presented. The synchronization device includes a sliding sleeve 1 , a stop block 2 , a friction ring 3 , an intermediate ring 4 , an inner friction ring 5 , a spring 6 , a combined ring gear 7 and a gear hub 8 .

[0030] The sliding sleeve 1 of the present invention has several locking grooves distributed in the circumferential direction, and the locking grooves are matched with the stop block 2. At the same time, the stop block 2 is embedded in several grooves on the gear hub 8. The shape of the groove and The dimensions ensure that the stop block 2 can move axially. The locking groove of the sliding sleeve 1 has a slope A', and the two sides of the top of the stop block 2 are provided with slopes A matched with the slope A'. There is also another group of inclined surfaces B on the stop block 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com