Screw-nut gear-shifting mechanism for automatic two-gear transmission of electric car

A technology for automatic transmissions and lead screw nuts, which is applied to mechanical equipment, transmission devices, components with teeth, etc., can solve the problems of complex structure and large volume of the shift mechanism, and achieve enhanced shift reliability, small size, good reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

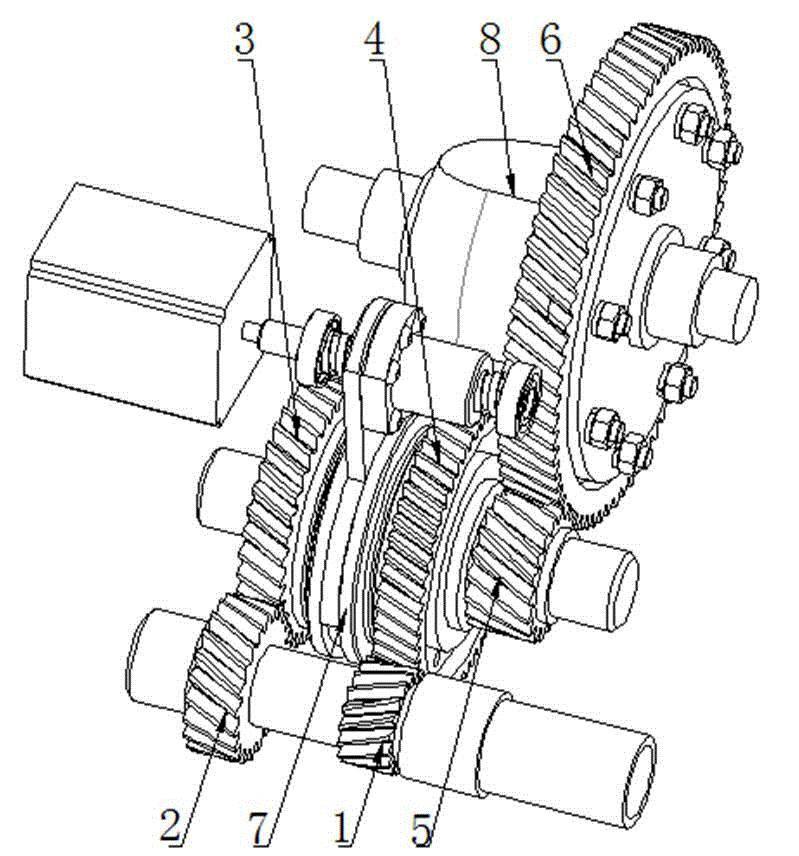

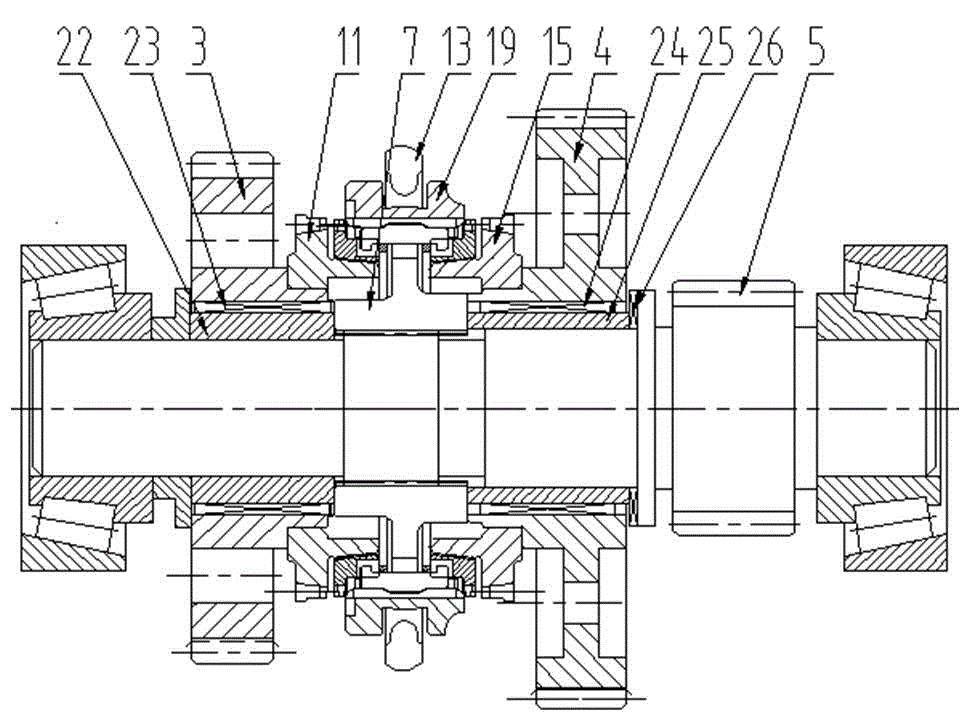

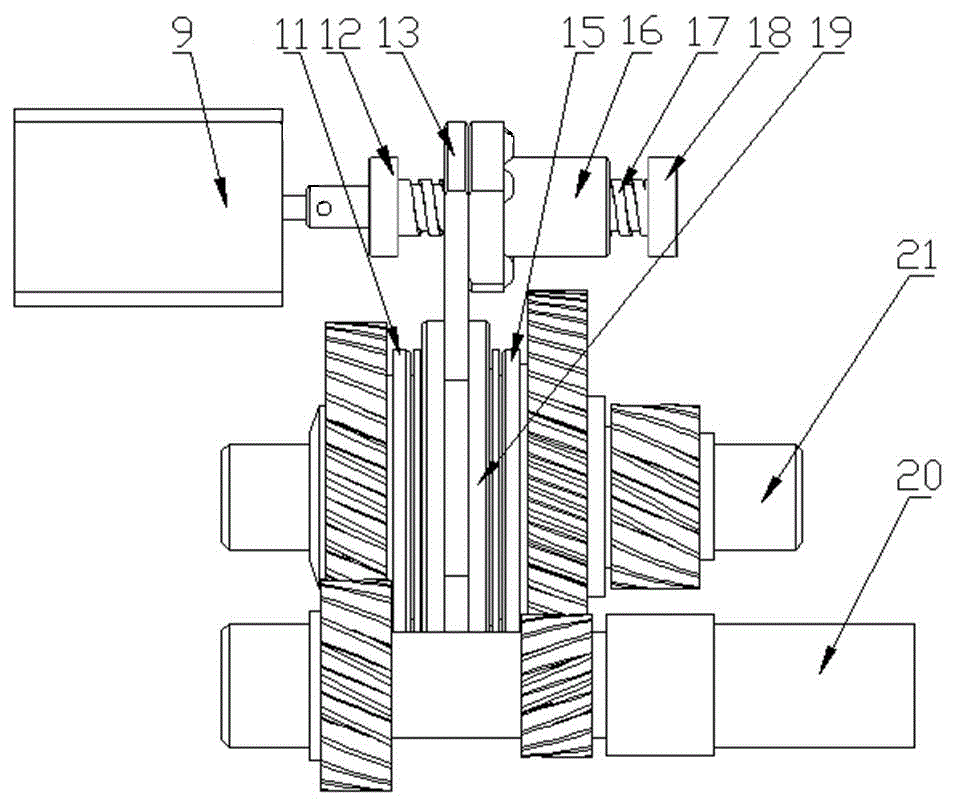

[0019] see figure 1 and figure 2 , the screw nut shifting mechanism used for the two-speed automatic transmission of electric vehicles includes two input shafts 20 and an intermediate shaft 21 parallel to each other. The first gear driving gear 1 and the second gear driving gear 2 are respectively fixedly installed on the input shaft 20 to form a gear shaft. see image 3 , the second-speed driven gear 3 and the first-speed driven gear 4 are installed on the intermediate shaft 21 respectively, wherein the second-speed driven gear 3 is idly sleeved on the intermediate shaft 21 through the first sleeve 22 and the first needle bearing 23 Above, the first gear driven gear 4 is idly sleeved on the intermediate shaft 21 through the second sleeve 24 and the second needle bearing 25 . The intermediate shaft 21 on the outside of the first gear driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com