Parallel-type hybrid-power multi-gear gearbox of commercial vehicle

A technology of hybrid power and gearbox, which is applied in the layout of multiple different prime movers and power devices of hybrid vehicles and general power plants, and can solve the problems of difficult realization of hybrid power functions, high torque performance requirements, and impact on vehicle power. Improve vehicle controllability at low speed, improve power performance, and improve compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

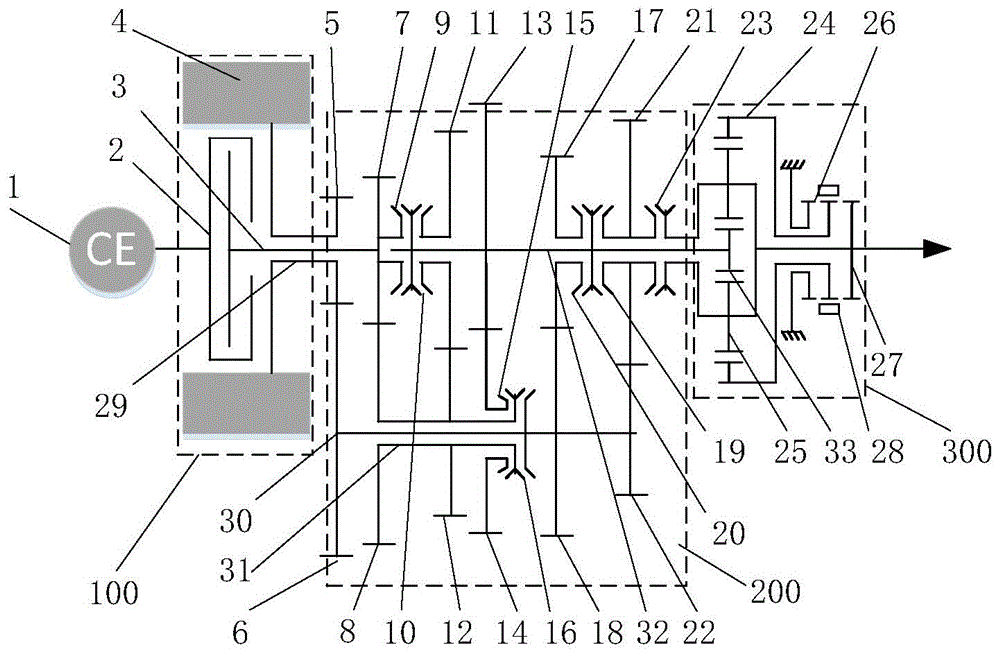

[0024] See attached figure 1 , a commercial vehicle parallel hybrid multi-speed gearbox, including: an engine 1, a clutch 2, a motor module 100, a gearbox main box module 200 and a gearbox auxiliary box module 300.

[0025] In the motor module 100 , the motor 4 is coaxially arranged with the engine input shaft 3 .

[0026] The gearbox main box module 200 adopts a four-shaft arrangement: the engine input shaft 3, the motor power input shaft 29 and the gearbox main box output shaft 32 are coaxially arranged, the first intermediate shaft 30, the second intermediate shaft 31 and the engine input shaft 3 Arranged in parallel; the engine input shaft 3 is connected to the third gear 7, the motor power input shaft 29 is connected to the first gear 5, the transmission main box output shaft 32 is connected to the variable speed planetary row sun gear 33, and the seventh gear 13; the second intermediate shaft 31 is sleeved on the first intermediate shaft 30 through the fourth synchroniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com