transmission shift mechanism

A technology of shifting mechanism and transmission, which is applied to instruments, controlled components, mechanical equipment, etc., can solve the problems of large space occupation, complex structure, unsuitable for light mini cars, etc., and achieves less installation space and better shifting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

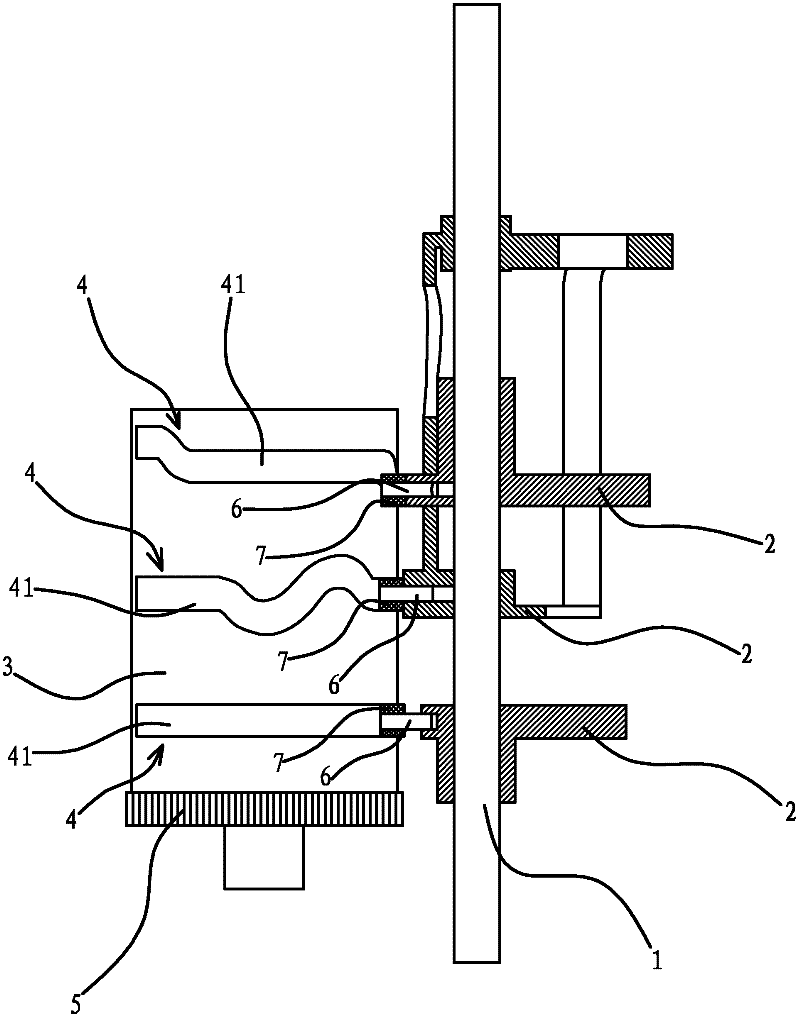

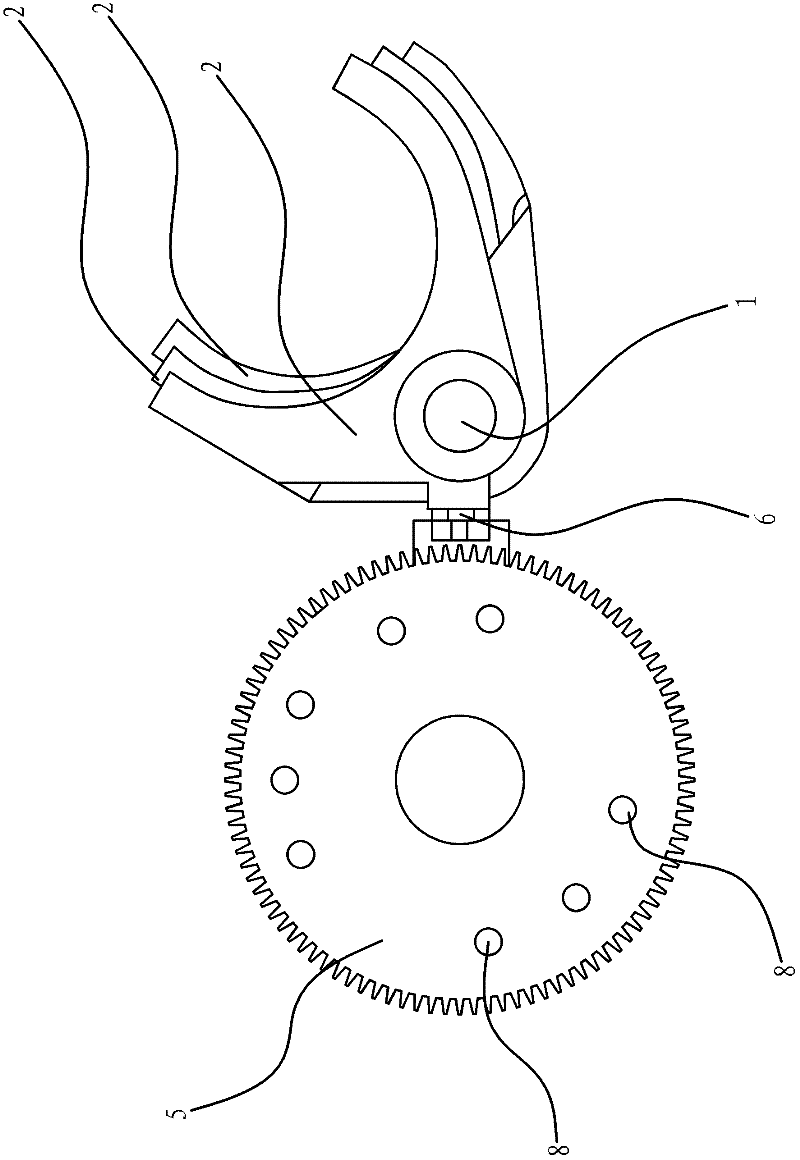

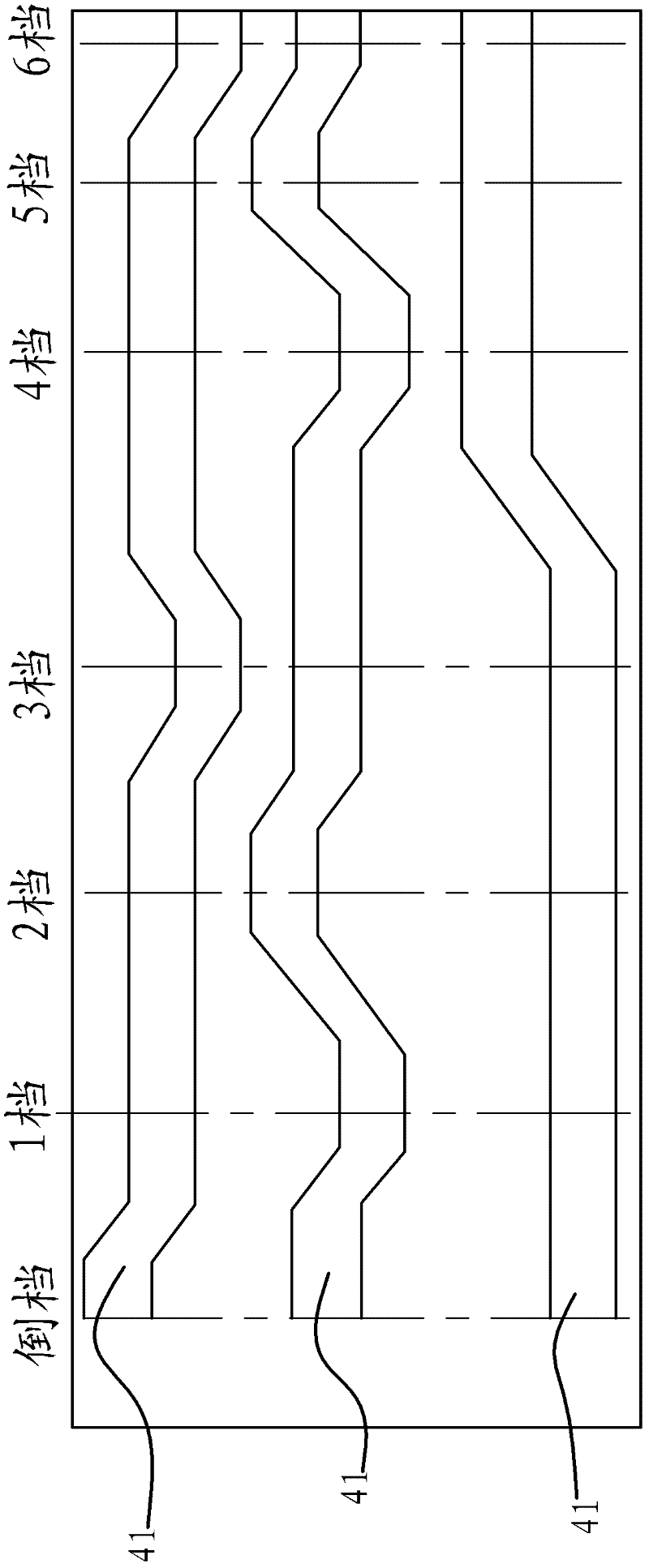

[0025] Such as Figures 1 to 3 As shown, a transmission shift mechanism includes a shift shaft 1 fixedly connected to the transmission case and three shift forks 2 that are vacantly sleeved on the shift shaft 1. There is also a cylindrical fork 2 in the transmission case. The wheel hub 3 is fixedly connected with a driven gear 5 at the lower end of the wheel hub 3, and the driven gear 5 is coaxially arranged with the wheel hub 3. There are three curved guide rails 4 on the outer side of the hub 3 respectively corresponding to the fork positions. The guide rails 4 are three grooves 41 located on the outer side of the hub 3 . The floating size of the guide rails 4 is equal to the shift stroke. A connecting pin 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com