Twin-shaft six-speed mechanical speed changer

A mechanical and transmission technology, applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of low transmission efficiency, large shifting noise, large installation space, etc., and achieve a compact and reasonable space structure. Improved shifting performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

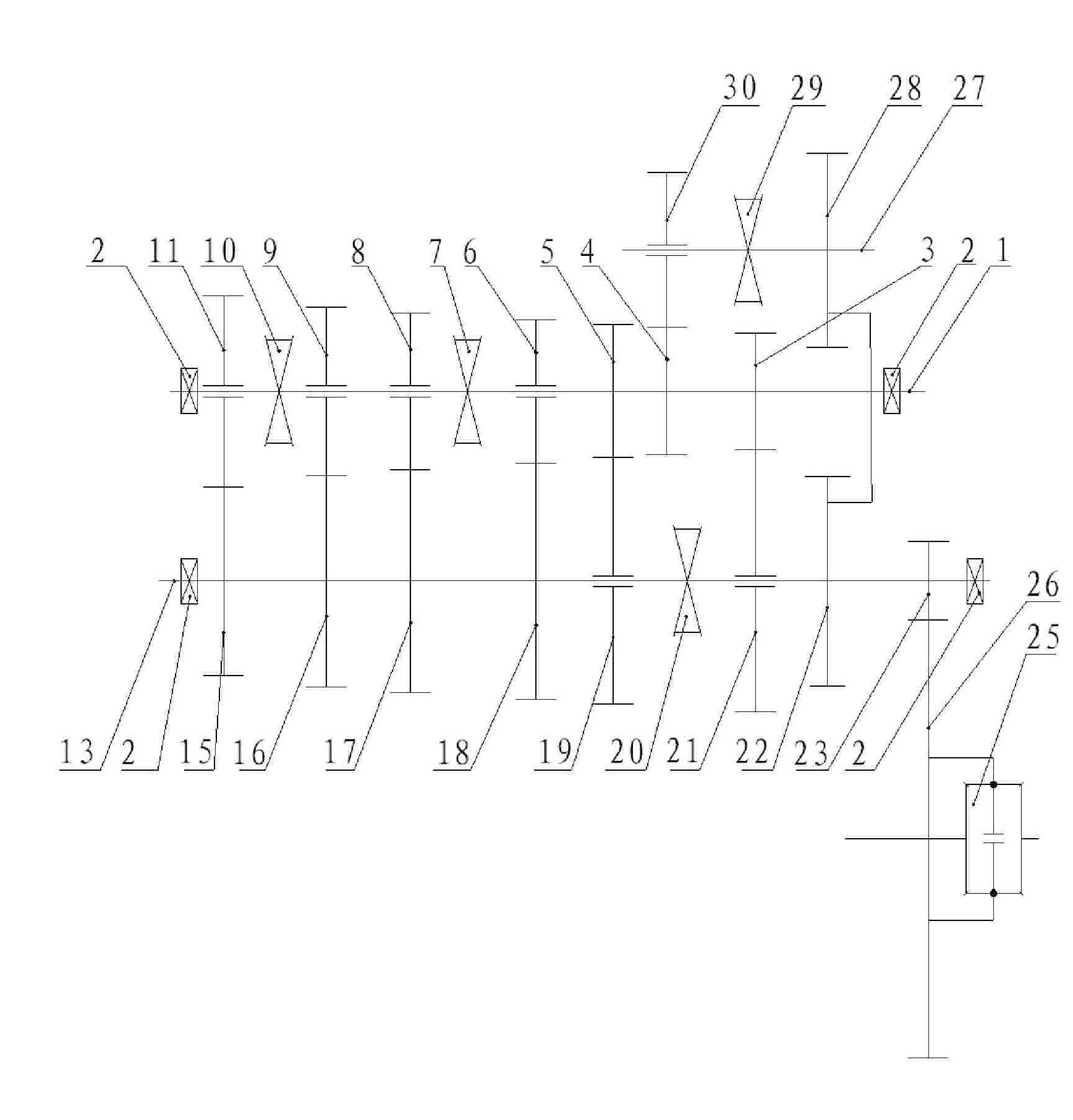

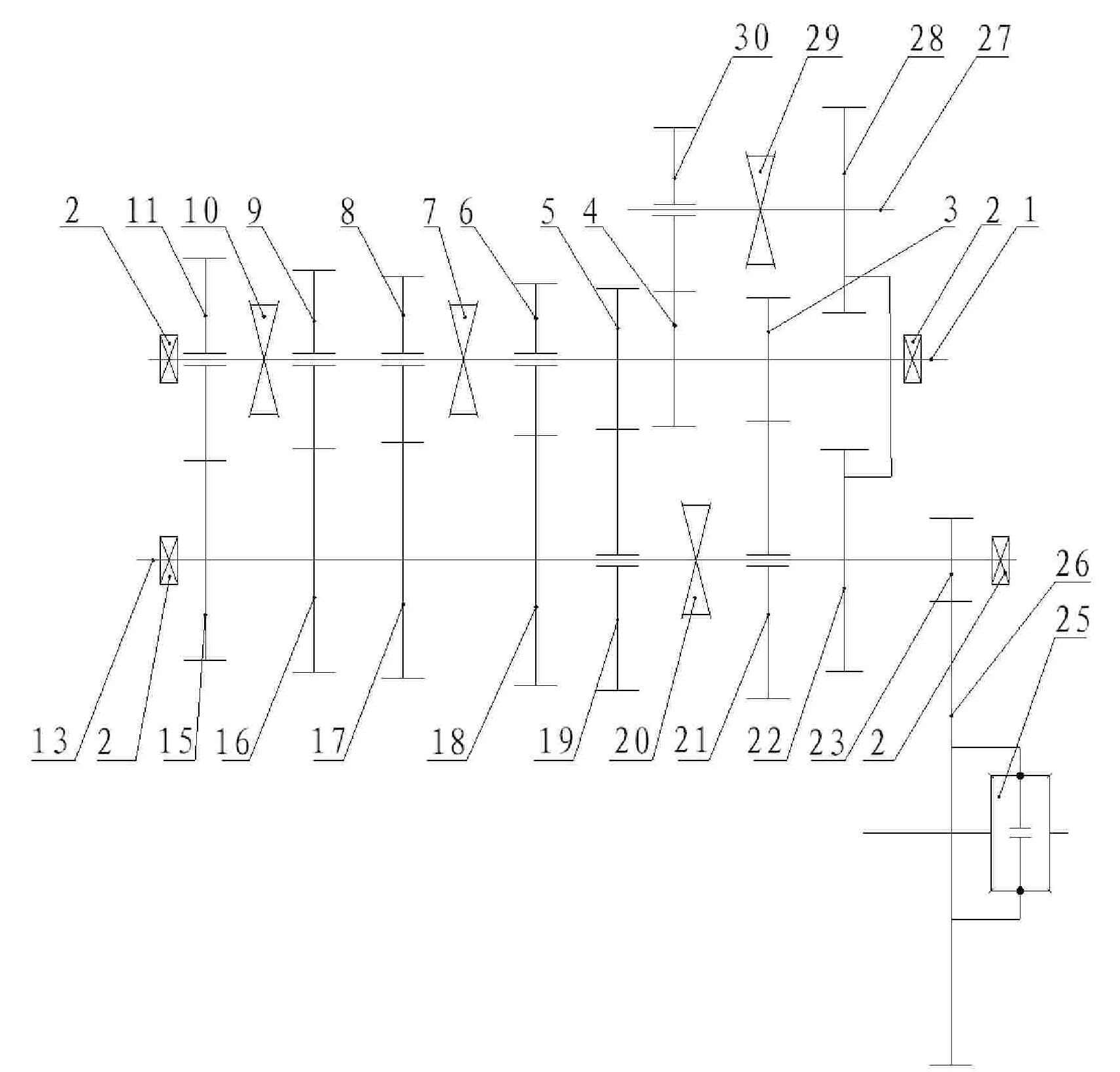

[0022] Such as figure 1 As shown, a two-shaft six-speed mechanical transmission includes an input shaft 1 connected to the engine and an output shaft 13 selectively meshed with the input shaft 1 through gears. On the output shaft 13, there are one, two, three, For four, five, and six gears, the output shaft 13 is meshed with the differential 25 through gears, and the input shaft 1 is meshed with the reverse shaft 27 through gears. The input shaft 1, the output shaft 13 and the reverse shaft 27 are horizontal directions parallel to each other. On the input shaft 1, there are ball bearings 2, first gear driving gear 3, reverse gear input driving gear 4, second gear driving gear 5, third gear driving gear 6, third and fourth gear synchronizers 7, fourth gear driving gear 8 , fifth gear driving gear 9, fifth and sixth gear synchronizers 10, sixth gear driving gear 11 and ball bearing 2; ball bearing 2, main reduction driving gear 23, reverse gear output driven gear 22 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com